Carrier 31MF Installation And Operating Instructions Manual

Installation and Operating Instructions

NOTE: Read the entire instruction before starting the installation.

SAFETY CONSIDERATIONS

Installation and service of heating and air conditioning equipment

can be hazardous due to system pressure and gas and electrical

components. Only trained and qualified personnel should install,

repair or service heating and air conditioning equipment.

Untrained personnel can perform basic maintenance functions

such as cleaning and replacingair filters. All other operations must

be performed by trained service personnel. When working on

heating and air conditioning equipment, observe precautions in the

literature, tags, and labels attached to or shipped with the unit and

other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work gloves.

Read these instructions thoroughly and follow all warnings or

cautions attached to the unit. Consult local building codes for

special installation requirements.

Recognize safety information. This is the safety-alert symbol

When you see this symbol on the unit or in instructions and

manuals, be alert to the potential for personal injury.

Understand the signal word—DANGER, WARNING, or CAUTION. These words are used with the safety-alert symbol. DANGER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards that could

result in personal injury or death. CAUTION is used to identify

unsafe practices, which would result in minor personal injury or

product and property damage.

INTRODUCTION

The Model 31MF High-Efficiency Mechanical Air Cleaner is

designed for installation in the return-air duct of any forced-air

heating and/or cooling system. It is designed for use in systems

with airflow up to 2000 cfm. For higher airflows, additional units

may be required.

The Model 31MF is a mechanical air cleaner incorporating 78 sq

ft of glass microfiber filter media to clean the air circulated

through it with a low pressure drop. (See Table 1.)

Table 1—Air Cleaner Resistance

RESISTANCE

(IN. WC)

.03 600

.05 800

.07 1000

.10 1200

.13 1400

.16 1600

.20 1800

.24 2000

AIRFLOW

(CFM)

31MF

Mechanical Air Cleaner

.

Fig. 1—Model 31MF Mechanical Air Cleaner

INSTALLATION

Step 1—Install Air Cleaner Cabinet in Return-air System

Turn OFF the electrical supply to the furnace before beginning installation.

1. Remove and discard existing furnace filter(s).

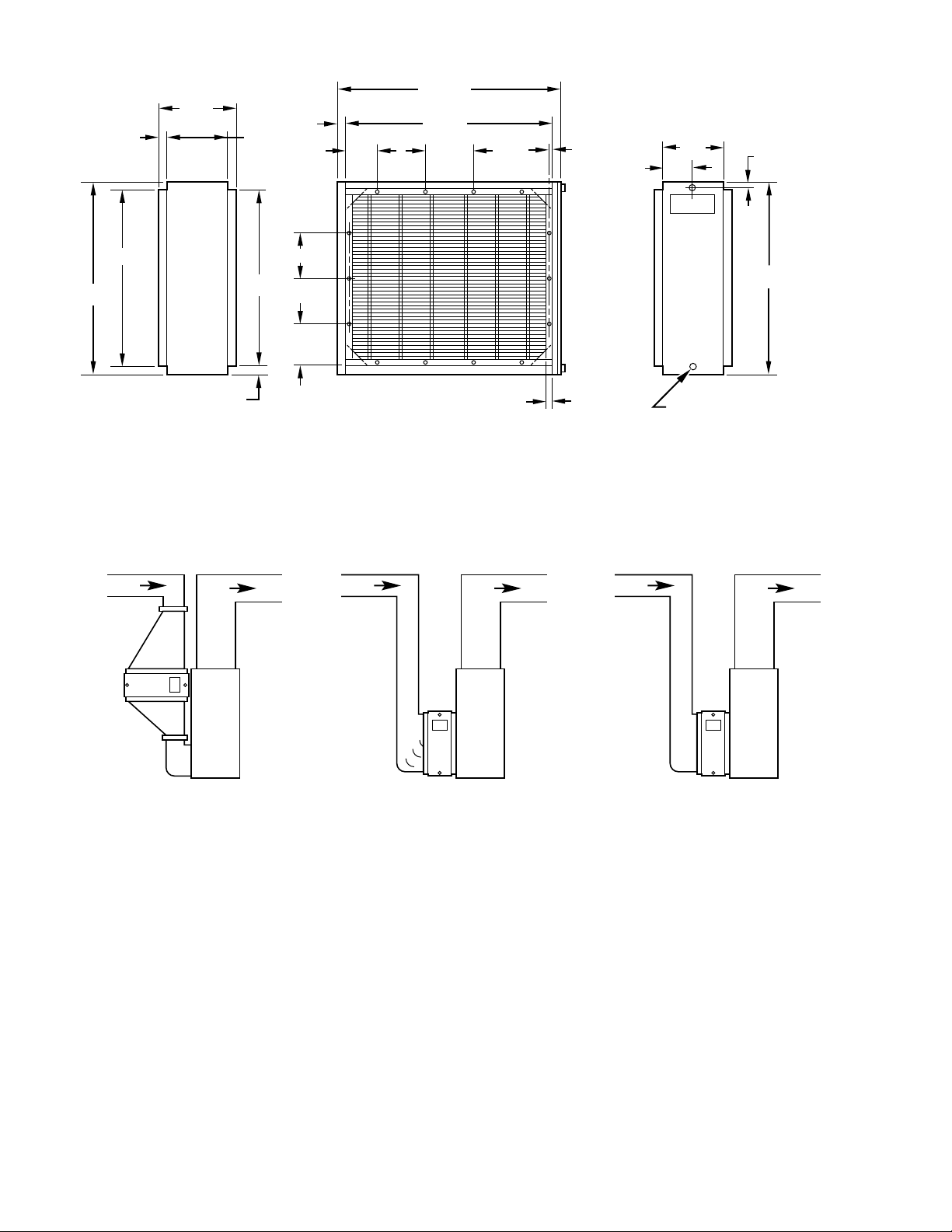

2. Referring to Fig. 2 and 3 for air cleaner dimensions and typical

installations, determine best installation location of air cleaner.

NOTE: A 26-in. clearance must be allowed for removal of the

media frame assembly from the air cleaner cabinet.

3. Using standard practices, remove a section of return-air duct

to allow installation of air cleaner cabinet.

4. Install air cleaner in duct opening, providing an airtight seal to

duct with necessary materials.

NOTE: For systems with a right side return-air duct, rotate the air

cleaner 180° for proper installation. Remove and reinstall the front

access panel in an upright position. (See Fig. 3 for typical

installations.)

A90321

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 7a 9a

PC 101 Catalog No. 533-132 Printed in U.S.A. Form 31MF-2SI Pg 1 12-91 Replaces: 31MF-1SI

11

25

⁄16″

1

9

⁄4″

13

⁄16″

7

1

1

⁄8″

3

⁄4″

3

3

⁄16″ 5 5⁄8″

23

5

⁄16″

5

⁄16″

7

7

⁄8″

15

3

⁄16″

1

⁄2″

13

19

7

21

⁄16″

AIR FLOW

⁄16″

6″

1

21

13

19

⁄16″

15

3

⁄16″

13

⁄16″

1

⁄2″

KNURLED THUMBSCREW

WITH .130 IN. DIA STARTER

POINT.

Fig. 2—Dimensional Drawing

AIR FLOW AIR FLOW

⁄2″

A90295

FURNACE WITH

TRANSITION

FURNACE WITH

TURNING VANES

Fig. 3—Typical Installations (Upflow Furnaces)

Step 2—Install Air Cleaner Filter Gage

Blower suction will create a slight vacuum so air will flow into the

bottom of the filter gage and through its chamber—lifting the ball

in the gage. As the filter media in the air cleaner becomes dirty, the

increase in vacuum and resulting airflow will lift the ball proportionally. When the ball reaches the top arrow, the air cleaner media

should be replaced.

The air cleaner filter gage should be installed in a convenient

location on a vertical duct surface between the air cleaner and the

furnace blower or in the furnace casing of the blower compartment.

1. Drill a 3/8-in. hole in duct work or casing. Place spring gage

holder in hole. (See Fig. 4.)

2. Insert gage mounting stud through hole in condition indicator

card and then in spring gage holder so stud projects into duct

or casing. (See Fig. 4.)

FURNACE NO

TRANSITION

A90294

3. Adjust airflow gage by rotating range adjustment plug until

ball hovers at tip of lower arrow. (See Fig. 4.)

When the air cleaner media begins to become clogged and dirty,

the ball will move up the gage. When the ball is in the red range

(shown on the condition indicator card), the air cleaner should be

serviced.

Step 3—Install Filter Media in Air Cleaner Cabinet

NOTE: These instructions should also be followed when the filter

gage indicates the filter media needs to be changed.

1. Loosen two thumb screws on front access panel and remove

panel. Slide filter media frame assembly from air cleaner

cabinet.

2. Remove filter media from carton. Ensure there are no holes or

tears in filter media.

2

Loading...

Loading...