Page 1

XRD9827REF

USER MANUAL

CANNON CIS 36-BIT COLOR

SINGLE LINE SCANNER

Page 2

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

EVALUATION KIT PART LIST

This kit contains the following:

• XRD9827REF CIS 36-Bit Color Single Line Scanner

• XRD9827REF User Manual

• SenseIt 1.0 Software Installation Diskettes (2)

• XRD9827 Data Sheet

• Scan Targets (Black, White, Color)

FEATURES

• One line scanning functionality of XRD9827 with CANON 600DPI CIS (Contact Image Sensor)

• Easy to use with most personal computers through Parallel Port Interface

• Simple way of loading the Serial Port of XRD9827 to adjust gain and offset

• Software SenseIt 1.0 to view single line scan

• Optimized PCB Layout with Four Layer

SYSTEM REQUIREMENTS

• Intel 486 compatible computer with Windows 95 operating system

• 8 MBytes system memory

• 25-pin D-shape parallel port receptacles

• 3 1/2” floppy disk drive

INTRODUCTION

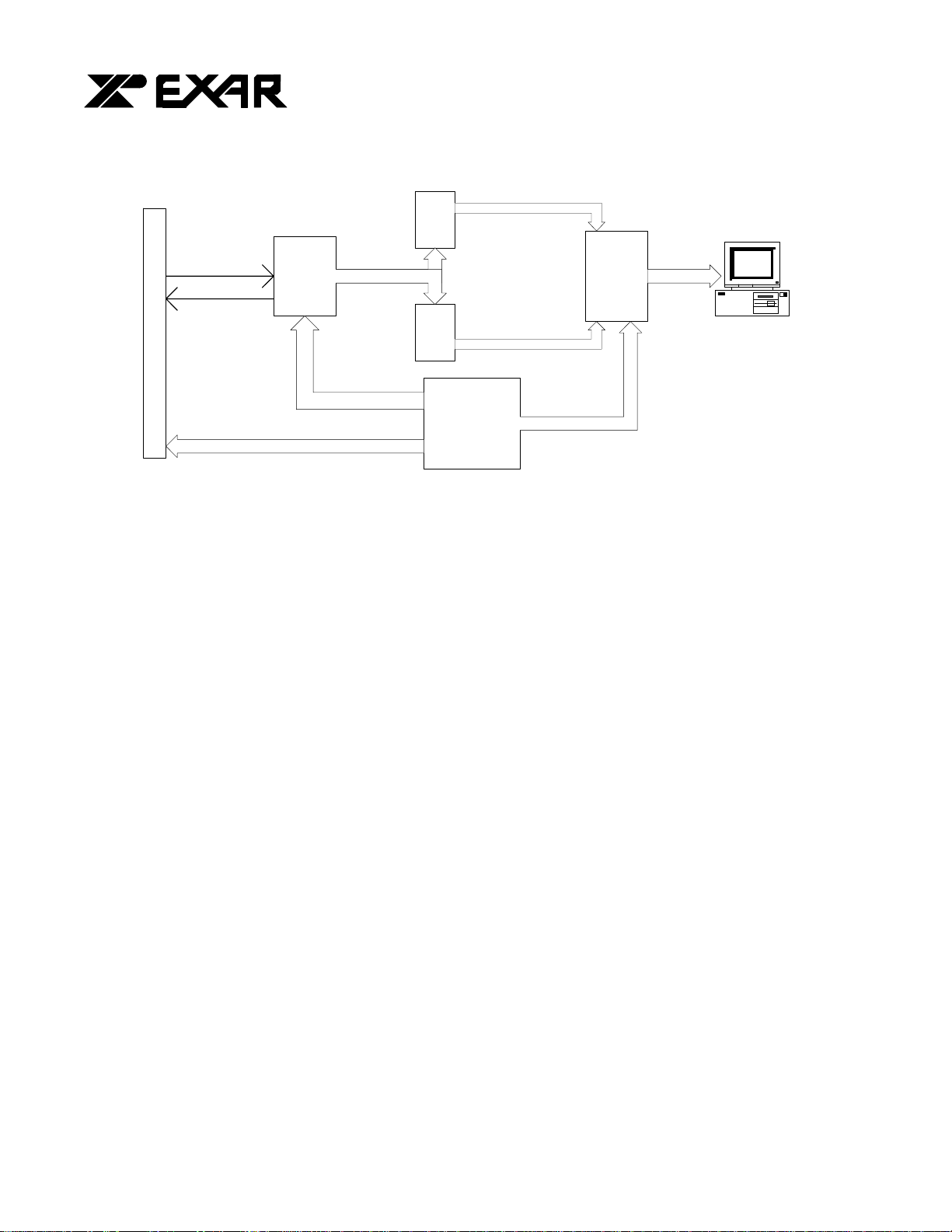

The XRD9827REF is a demo system which includes a PCB design with a CANON CVA-60216K 600DPI

Color Contact Image Sensor (CIS). It demonstrates how to interface a CIS with EXAR’s XRD9827, a 12bit Linear CIS/CCD Sensor Signal Processor to output a single line scan and display the amplitude of each

of the three colors. The XRD9827REF is designed to provide a signal path for the CIS output signals to be

processed, digitized by the XRD9827 and transmitted to a personal computer. There are no software

algorithms or hardware implementations, for example, gamma correction, to adjust for color response.

The XRD9827REF board is loaded with the XRD9827, a Vantis MACH435 CPLD, two FIFO SRAMs and

peripheral circuits for the CIS. The MACH435, which is a CMOS Programmable Logic Device (CPLD)

provides timing signals to the XRD9827, the SRAMs and the CIS. It also programs the XRD9827 to

operate in the correct mode and adjust for gain and offset values. The XRD9827 processes the analog

output from the CIS sensor, level-shifts and converts the signal into 12-bit digital codes. The SRAMs gate

the digitized data from the XRD9827 and stores the data temporarily. Controlled by the software, the

SRAMs send the data through a parallel port connection to the PC and histograms of raw data are

displayed in the monitor using the SenseIt software. A block diagram of the XRD9827REF is shown below

in Figure 1.

2

Page 3

a

... the analog plus comp

TM

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

PRELIMINARY

FIFO

SRAM

CANON CVA-60216K 600DPI COLOR CIS

CIS OUTPUT

CIS REFERENCE

VOLTAGE

XRD9827

XRD9827 CONTROL SIGNALS

CIS CONTROL SIGNALS

6-BIT BUS NIBBLE

FIFO

SRAM

MACH435 CPLD

Figure 1. Block Diagram of XRD9827REF

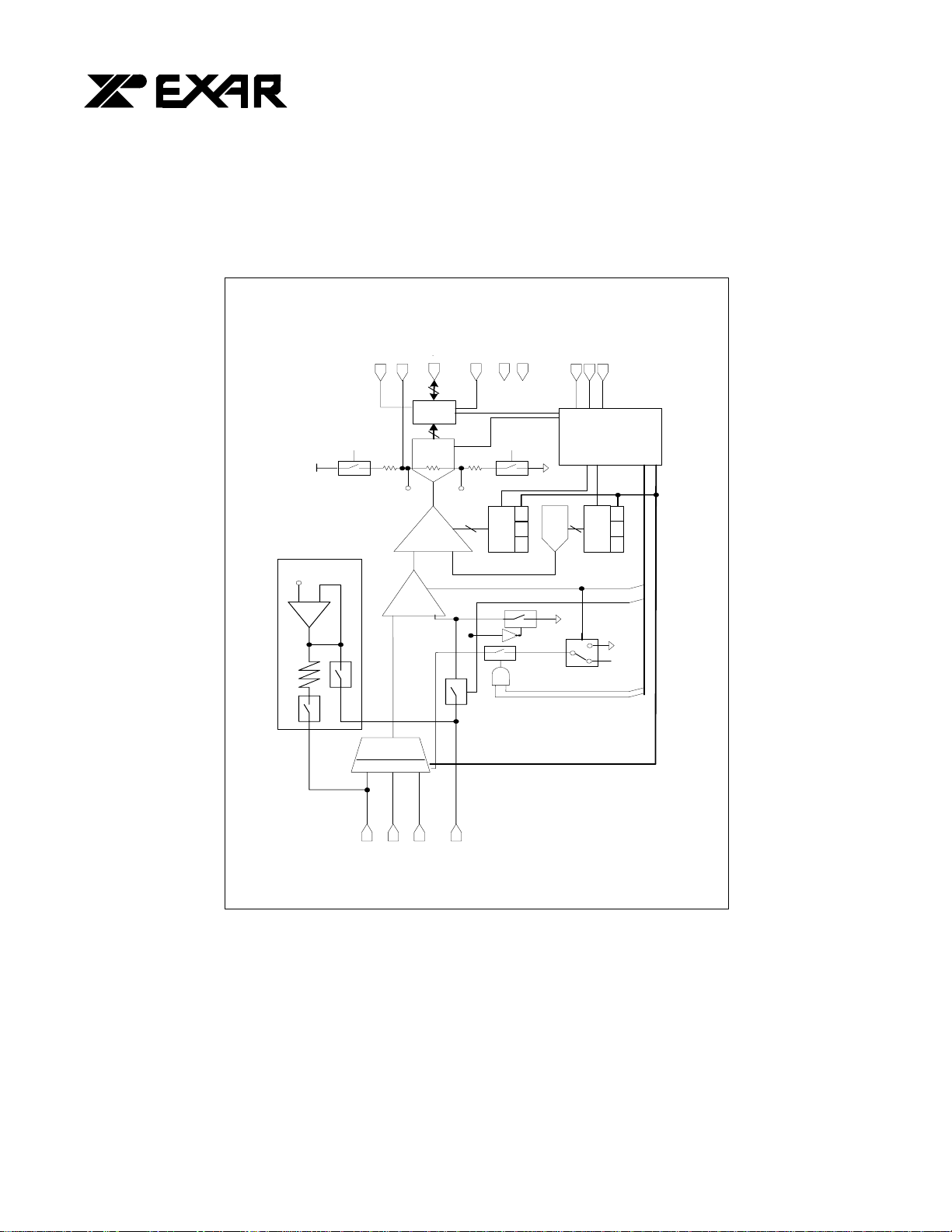

The XRD9827 is a complete linear CIS or CCD sensor signal processor on a single monolithic chip. The

XRD9827 includes a high speed 12-Bit ADC, a 6-Bit Programmable Gain Amplifier with gain adjustment

of 1 to 10 and an 8-Bit programmable input referred offset calibration range of 800 mV. The XRD9827

also provides the necessary biasing voltage for the CANON CIS, eliminating the use of external

components (two diodes and two resistors). See the XRD9827EVAL User Manual / PCB board for

evaluating the XRD9827 CIS / CCD signal processor chip. A simplified functional block diagram of

XRD9827 is shown below for your reference.

8-BIT DATA

8-BIT DATA

PARALLEL PORT CONTROL

PARALLEL

PORT DB25

CONNECTOR

DATA

INTEL 486 Compatible

3

Page 4

a

... the analog plus comp

TM

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

PRELIMINARY

DB7:0

VREF+

DVDD

8

I/O

DATA

PORT

Down

Power

AVDD

12

ADC

12-BIT

RL

VRT

VRB

G<5:0>

6

PGA

DGND

6-BIT GAIN

AVDD

Down

Power

REGISTERS

R G B

AGND

AGND

8-BIT DAC

CLAMP

SYNCH

O<7:0>

8

REGISTERS

8-BIT OFFSET

ADCCLK

TIMING &

CONTROL LOGIC

R G B

Biasing Circuit for CANON

CIS

VBG

BUFFER

_

S/H

RED

&

+

3-1

MUX

CLAMP

GRN

BLU

DCREF

DCREF

V

INT/EXT_V

CLP

DC/AC

CIS/CCD

AGND

CIS

VRT

CCD

VDCEXT

Figure 2. Simplified Functional Block Diagram of XRD9827

OPERATIONAL PROCEDURE

The routine listed below will first calibrate the photo response of the CIS using the XRD9827 by optimize

its offset and gain. After calibration, the XRD9827REF can be used to scan any color target to show CIS

non-color corrected response. (Color correction is typically done in the digital ASIC.)

4

Page 5

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

How to Run the XRD9827REF Demonstration

1. Make sure the computer is powered off and the AC power adapter is disconnected from a wall outlet

2. Connect the parallel port cable to the printer po rt of the computer

3. Connect the AC power adapter into a wall outlet

4. Turn on the computer and activate Windows 95

Loading EXAR Software

5. Load the diskette labeled SenseIt 1.0 Disk # 1 into the floppy drive

6. Select the Start menu in the program manager and choose RUN

7. Inside the small pop-up window, type: A:\setup

8. Follow the instructions to finish software installation

Parallel Port Configurations

9. Confirm the parallel port address as follows:

I. Select the Start Menu, choose Settings, then choose Control Panel

II. From the Control Panel window which pops up, double-click on System

III. In the System Properties window, select Device Manager

IV. From the Device Manager window, double-click on Ports (COM & LPT)

V. Double-click on Printer Port (LPT1). If you can not find it, please goto Step 10

VI. From the pop-up window, select Resources

VII. Verify the Input/Output Range is set to 0378 - 037F

VIII. If the range is not correct, clear the Use Automatic Settings check box by clicking it

IX. Choose correct address which is 0378 by default and click OK

X. Re-start the computer as advised

10. If you do not have a Printer Port configured on your computer, please follow the steps listed below:

I. From the Control Panel window which pops up, double-click on Add New Hardware

II. From the pop-up window, click the Next > button

III. Select ‘No’ when prompted for ‘Do you want Windows to search for your new

hardware?’, then click the Next > button

IV. Choose Ports (COM & LPT), then click the Next > button

V. Choose Printer Port, then click the Next > button

VI. Make a note of the Input/Output Range of Printer Port of your computer and click OK.

You will use these values later when configure the SenseIt software

VII. Re-start the computer as advised

Offset Adjustment With a Black Target

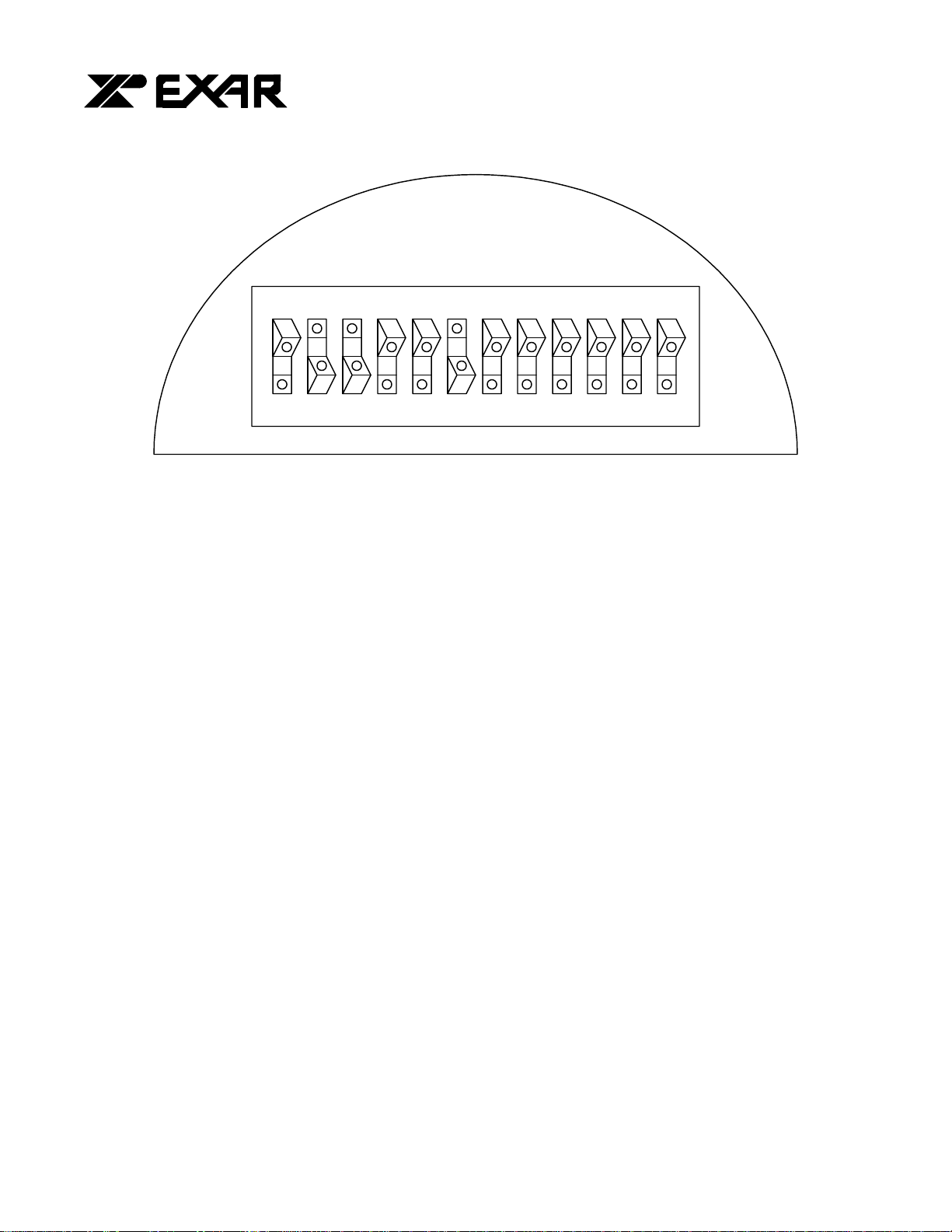

11. Set the dip switches located on the side panel of the scanner to [110 01000000] as shown in Figure 3

and push the Serial Port button which is located on the front panel of the demo system. This will reset the

XRD9827.

5

Page 6

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

S1S

S

2

D7D

0

6

D5D

4

D

3

D2D

1

D

0

1

0

Figure 3. Dip Switches Set to Value [110 01000000] to Reset XRD9827

12. Select the Start Menu, choose Programs, then choose SenseIt icon

13. A window will pop up as shown below. The upper window shows the plot of captured data and the

lower window shows the histogram of data. Figure 4 shows the pop-up window when SenseIt is first

started.

6

Page 7

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

Figure 4. SenseIt Software Window Before Scanning

14. Select SETUP from the pull-down menu and choose I/O ADDRESS. In the window that pops up, type

in the Input/Output Range of Printer Port of your computer. The default setting is 378H.

15. Pick the black target out from the kit and put it on a flat area. Place the XRD9827REF on top of the

black target with the CIS sensor facing downwards. From the CAPTURE menu select SNAP SHOT (or

simply press CTRL and B buttons simultaneously) for a single line scan of the black target with the dip

switches set to [000 00000000]. A typical result of a black target scan is shown below:

7

Page 8

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

Figure 5. Non-calibrated Black Target Scan

16. Set the dip switches to [110 00010000] to tie VDCREF and VDCEXT pin together internally. Push the

Serial Port button. The XRD9827 will subtract whatever voltage appears on VDCEXT (pin 16) from the

input and thus perform a global offset adjustment. A typical result of the global offset adjustment is shown

below. Please notice that the black code value has moved down.

8

Page 9

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

Figure 6. Black Target Scan After Global Offset Adjust Using the 9827 Internal

Bandgap Reference Voltage

17. Then, set the dip switches to [111 00010000] and push the Serial Port button again. By doing this, a

1.24V reference voltage provided by an internal bandgap is applied to the VDCEXT pin. VDCEXT is

connected to VREF pin (Pin 5) of the CANON CIS, this voltage is used by the CIS as a biasing voltage.

Moreover, a 12K built-in resistor of the XRD9827 serves as a pull-down for the output of the CIS. By

interfacing the XRD9827 with a CANON CIS, a designer can save two biasing diodes and two resistors

and thus reduce cost.

9

Page 10

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

C

I

S

2.2uF

PIN 19

(RED)

PIN 16

(VDCEXT)

XRD9827

1.24V

12K

BANDGAP

M

U

X

VDD

VRT

RL

VRB

Figure 7. Simplified Block Diagram Showing Global Offset Adjustment by XRD9827 Using

Internal Bandgap and CIS Using VDCEXT for Biasing

18. Set the dip switches to [001 01010000] to select the internal offset DAC for fine offset adjustment.

Push the Serial Port button. From the CAPTURE menu select SNAP SHOT. The offset should now move

the output of the CIS to almost zero scale. The other way to do a SNAP SHOT is by pressing CTRL and B

button at the same time. Please refer to data sheet for offset adjustment. A typical result of the fine offset

adjustment is shown below.

10

Page 11

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

Figure 8. Black Target Scan After Global and Fine Adjustment

11

Page 12

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

C

S

XRD9827

PIN 19

I

(RED)

M

U

X

8-BIT

OFFSET

DAC

VDD

VRT

RL

VRB

Figure 9. Simplified Block Diagram Showing Fine Offset Adjustment by XRD9827

19. Switch the black target to the enclosed white target. From the CAPTURE menu select SNAP SHOT

for a single line scan of the white target. A typical result of a white target is shown below.

12

Page 13

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

Figure 10. White Target Scan Without Gain Adjustment

20. Set the dip switches to [000 00001000] to select the desired gain. Push the Serial Port button. From

the CAPTURE menu select SNAP SHOT. The gain should move the output of the CIS to almost full scale.

Please refer to data sheet for further gain adjustment and optimal values of dip switches for your scanner.

A typical result of the white target with gain adjustment is shown below.

13

Page 14

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

Figure 11. White Target Scan After Gain Adjustment

14

Page 15

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

C

S

XRD9827

PIN 19

(RED)

I

M

U

X

PGA

6-BIT GAIN

REGISTER

VDD

VRT

RL

VRB

Figure 12. Simplified Block Diagram Showing Gain Adjustment by XRD9827

21. Once the XRD9827 has been fully calibrated, any target can be scanned. For example: Scan a gray

scale to demonstrate the stair step response or a color target for color responsitivity.

15

Page 16

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

Figure 13. Gray-scale Target Scan

22. To demonstrate the noise component is contributed from the CIS, we hooked up a DC reference to the

scanner and the results are shown below in Table 1.

REFERENCE DC (V) STANDARD DEVIATION SYSTEM SNR (dB) W/O CIS

NOISE COMPONENT

2.0 2.144328 62.6117

2.5 3.48261 58.3988

3.0 2.399188 61.6356

3.5 1.983461 63.28842

Table 1. Signal-to-Noise Ratio of the XRD9827REF with DC Source as Input (No CIS Noise

Component)

As we can see from Table 1, the SNR falls into the range of 58 dB to 63 dB when a DC reference is used

as input to the XRD9827REF. The system alone gives a 9 1/2 to 10 bit performance. The largest noise

source we saw in previous scans came from the CIS. A typical plot of the DC reference is shown in Figure

14.

16

Page 17

a

... the analog plus comp

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

TM

PRELIMINARY

Figure 14. Plot of 3.5V DC Source as Input to the XRD9827REF

Important:

1. If at any time an unexpected result is shown or the demo system seems to not working, please pull

the AC adapter out from the wall outlet to cycle power. Start the procedures again from Step 11.

2. Keep the scanner away from other electrical equipment, power cords, light dimmers, etc., as stray

electrical fields can end up in the digitized data.

3. Switch off all unnesscessary light sources and place the scanner flat on the image, this can prevent

stray light from entering the sensor and disrupt the scan.

17

Page 18

a

... the analog plus comp

TM

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

PRELIMINARY

C1

0.1uFC20.01uF

DGND

C5

0.1uFC60.01uF

AGND

CISOUT

AGND

VDCEXT

U1

15

VREF+

C4

C3

0.1uF

1uF

AGND

TP1

2

t1g

19

RED

18

GRN

17

BLU

16

VDCEXT

DB6/SDATA

DB5/SCLK

DVDD

DGND

AVDD

AGND

DB7/LD

DB4

DB3

DB2

DB1

DB0

ADCCLK

CLAMP

SYNCH

1

10

20

14

9

8

7

6

5

4

3

2

11

12

13

XRD9827

DVDD

AVDD

DB7/LD

DB6/SDATA

DB5/SCLK

DB4

DB3

DB2

DB1

DB0

ADCCLK

SYNC

U2

LM7805-5

IN1OUT

C8

0.22uF

J1

POWERJACK

L1

10uH

DGND

C32

OPEN

C10

0.22uF

AGND

2

IN1OUT

U3 LM7805-5

3

GND

2

DGND DGND

C11

GND

0.47uF

3

18

AVDD

C9

0.1uF

L2

OPEN

DVDD

POWER SUPPLY

CIRCUITS

DVDD

R3

1K

H:\PROJECT\ORCADWIN\9827\9827REFB.DSN

Title

XRD9827 REFERENCE BOARD

Size Document Number Rev

B

XRD9827REF

Date: Sheet

JP1

GO TO LED ON THE

1

CASE OF SCANNER

2

HEADER 2

13Thursday, July 23, 1998

of

B

Page 19

a

... the analog plus comp

TM

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

PRELIMINARY

S1

1

2

2324R8 2.2K

3

22

4

21

5

20

6

19

7

18

8

17

9

16

15

10

14

11

1312

C14

10uF

SW DIP-12

C15

0.1uF

C16

0.1uF

C17

0.01uF

DGND

DVDD

DGND

S2

S1

S0

D7

D6

D5

D4

D3

D2

D1

D0

C18

0.01uF

R9 2.2K

R10 2.2K

R11 2.2K

R12 2.2K

R13 2.2K

R14 2.2K

R15 2.2K

R16 2.2K

R17 2.2K

R18 2.2K

C19

0.01uF

DVDD

C20

0.01uF

JP2

1

2

3

HEADER 3

DVDD

DGND

SYNC

WCLK2

RCLK

ACK

RST

D7

WCLK1

D3

S1

D6

S0

ADCCLK

R4 33

R19 33

R20 33

R21 33

SP_PB

R23 33

82

IO63

81

IO62

80

IO61

79

IO60

78

IO59

77

IO58

76

IO57

75

IO56

73

IO55

72

IO54

71

IO53

70

IO52

69

IO51

68

IO50

67

IO49

66

IO48

65

CLK3

62

CLK2

61

IO47

60

IO46

59

IO45

58

IO44

57

IO43

56

IO42

55

IO41

54

IO40

52

IO39

51

IO38

50

IO37

49

IO36

48

IO35

47

IO34

46

IO33

45

IO32

41

I1

DVDD

42

44

63

84

DVDD4

DVDD5

DVDD6

MACH435

DGND5

DGND6

DGND7

DGND8

32

43

53

64

74

2

21

DVDD2

DVDD3

DGND3

DGND4

11

22

DGND

DVDD1

DGND1

DGND2

1

IO0

IO1

IO2

IO3

IO4

IO5

IO6

IO7

IO8

IO9

IO10

IO11

IO12

IO13

IO14

IO15

CLK0

CLK1

IO16

IO17

IO18

IO19

IO20

IO21

IO22

IO23

IO24

IO25

IO26

IO27

IO28

IO29

IO30

IO31

I2

U4

MACH435

83

R5 33

3

R6 33

4

R7 33

5

6

7

8

9

10

12

13

14

15

16

17

18

19

20

23

24

25

26

27

28

29

30

31

33

R22 33

34

35

36

37

38

39

40

DB5/SCLK

DB6/SDATA

DB7/LD

STROBE

S2

AUTOFD

D5

D1

DVDD

D4

D2

D0

SP

WEN

CISCLK

BLED

RLED

GLED

C12

1uF

H:\PROJECT\ORCADWIN\9827\9827REFB.DSN

Title

XRD9827 REFERENCE BOARD

Size Document Number Rev

B

XRD9827REF

Date: Sheet

Oscillator

U5

4

V+

3

OUT

C13

0.1uF

NC

GND

1

2

DGND

23Thursday, July 23, 1998

of

B

19

Page 20

a

... the analog plus comp

TM

EXAR Corporation 48720 Kato Road, Fremont, CA 94538 Phone (510)-668-7000, Fax (510)-668-7030

PRELIMINARY

AVDD

C25

C24

0.1uF

1uF

AGND

C23

10uF

C26

0.01uF

DB0

DB1

DB2

DB3

DB4

DB5/SCLK

DB6/SDATA

DB7/LD

C27

0.01uF

SP

CISCLK

RLED

GLED

BLED

DVDD

DGND

SP

CISCLK

RLED

GLED

BLED

C21

0.1uF

DGND

DGND

0.1uF

C22

0.1uF

C31

DVDD

3 4

5 6

9 8

11 10

14

13 12

7

DGND

30

31

32

1

2

3

4

5

6

7

8

10

11

12

13

14

15

30

31

32

1

2

3

4

5

6

7

8

10

11

12

13

14

15

U7B

74HC04

U7C

74HC04

U7D

74HC04

U7E

74HC04

U7F

74HC04

U6

D8

D7

D6

D5

D4

D3

D2

D1

D0

PAF*

PAE*

REN1*

RCLK

REN2*

OE*

EF*

FF*

U8

D8

D7

D6

D5

D4

D3

D2

D1

D0

PAF*

PAE*

REN1*

RCLK

REN2*

OE*

EF*

FF*

DVDD

WEN1*

WCLK

WEN2*

LSB

CY7C4261

DVDD

WEN1*

WCLK

WEN2*

MSB

CY7C4261

RS*

GND

RS*

GND

Q8

Q7

Q6

Q5

Q4

Q3

Q2

Q1

Q0

Q8

Q7

Q6

Q5

Q4

Q3

Q2

Q1

Q0

DVDD

25

29

DVDD

28

27

26

24

23

22

21

20

19

18

17

16

9

25

29

28

27

26

24

23

22

21

20

19

18

17

16

9

DGND

R24

SPN

300

R26

CISCLKN

300

R28

2

10K

R29

10K

R30

10K

2

O7

O6

O5

O4

O3

O2

O1

O0

O7

O6

O5

O4

O3

O2

O1

O0

1 3

BGND

Q1

NPN_TO18

GGND

Q2

NPN_TO18

1 3

2

DGND

WCLK2

RCLK

RST

WEN

WCLK1

O[7..0]

RGND

Q3

NPN_TO18

1 3

DGND

J2

STROBE AUTOFD

1

JP3

1

2

3

JUMPER

R27

2

3

4

5

6

7

8

9

10

11

12

13

DB25

C29

0.1uF

OPEN

14

15

INIT

16

17

18

19

20

21

22

23

24

25

DGND

AVDDDVDD

R25

OPEN

C30

47uF

AGND

O0

O1

O2

O3

O4

O5

O6

O7

R33 100

R32 100

R34 100

R31 100

C28

100uF

STROBE

AUTOFD

12

U7A

74HC04

ACK

CISOUT

VDCEXT

JP4

1

CISOUT

2

MODE

3

GND (ANALOG)

4

VCC

5

VREF

6

SP

7

CISCLK

8

LED ANODE

9

BLED

10

GLED

11

RLED

12

GND (FRAME)

C33

HEADER 12 TO CIS

47uF

H:\PROJECT\ORCADWIN\9827\9827REFB.DSN

Title

XRD9827 REFERENCE BOARD

Size Document Number Rev

B

XRD9827REF

Date: Sheet

DGND

AGND

B

33Thursday, July 23, 1998

of

20

Loading...

Loading...