Page 1

iP2000

SIMPLIFIED SERVICE MANUAL

1. PRODUCT LIST

2. PRODUCT SPECIFICATIONS

3. ERROR DISPLAY

4. ADJUSTMENT / SETTINGS

5. EXTERNAL VIEW / PARTS LIST

6. TROUBLESHOOTING FLOWCHART

7. SPECIAL NOTES ON SERVICING IN ASIA

8. PRODUCT TECHNICAL INFORMATION

APPENDIX 1: SERVICE TEST PRINT 1 PRINT SAMPLE

APPENDIX 2: iP2000 EEPROM INFORMATION PRINT SAMPLE

QY8-13A1-000

Rev. 00 EUR

August 6, 2004

Canon Inc.

1

Page 2

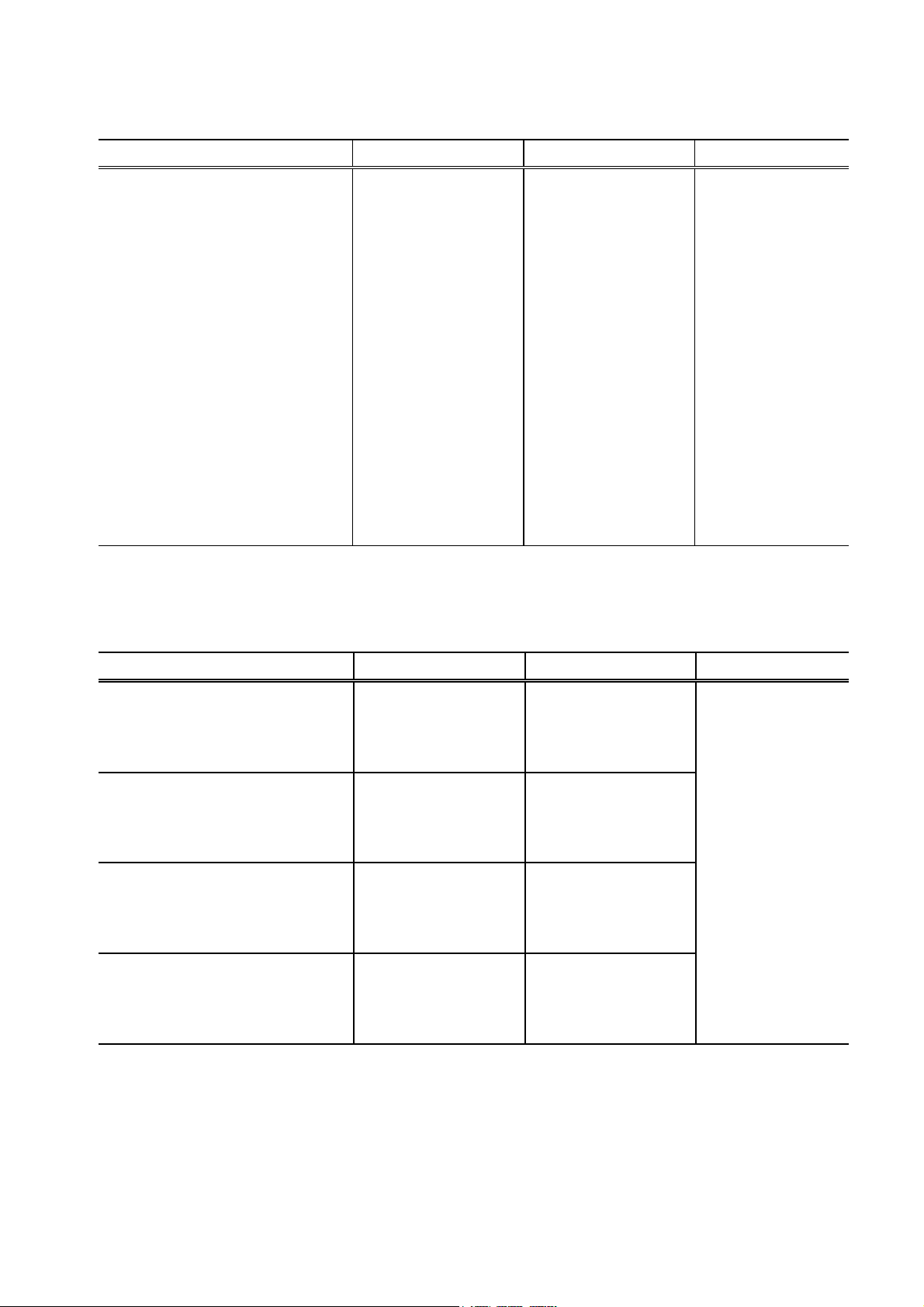

1. PRODUCT LIST

1-1. Main Units

Product name Product code Sales territory Remarks

Canon Bubble Jet Printer

iP2000

1-2. Options

None

1-3. Consumables

9318A001AA US

9318A002AA CA

9318A003AA LAM LVT

9318A004AA LAM HVT

9318A005AA EMB

9318A005AB EMB

9318A008AA ASA HVT

9318A009AA AU

9318A010AA KR

9318A011AA GB

9318A012AA JP

9318A013AA TW

9318A014AA HK

9318A015AA CN

9318A017AA EUM

Product name Product code Sales territory Remarks

Canon Ink Tank

BCI-24 Black

Canon Ink Tank

BCI-24 Color

Canon Ink Tank

BCI-24 Black Twin Pack

Canon Ink Tank

BCI-24 Color Twin Pack

6881A001AA

6881A002AA

6881A003AA

6881A004AA

6882A001AA

6882A002AA

6882A003AA

6882A004AA

6881A008AA

6881A009AA

6881A010AA

6881A011AA

6882A008AA

6882A009AA

6882A010AA

6882A011AA

JPN

EUR

USA/CAN

ASIA/AUST

JPN

EUR

USA/CAN

ASIA/AUST

JPN

EUR

USA/CAN

ASIA/AUST

JPN

EUR

USA/CAN

ASIA/AUST

In common with the

S200, S200x,

S300, S330, i320,

i350, i355, i250,

i255, iP1000, and

iP1500.

2

Page 3

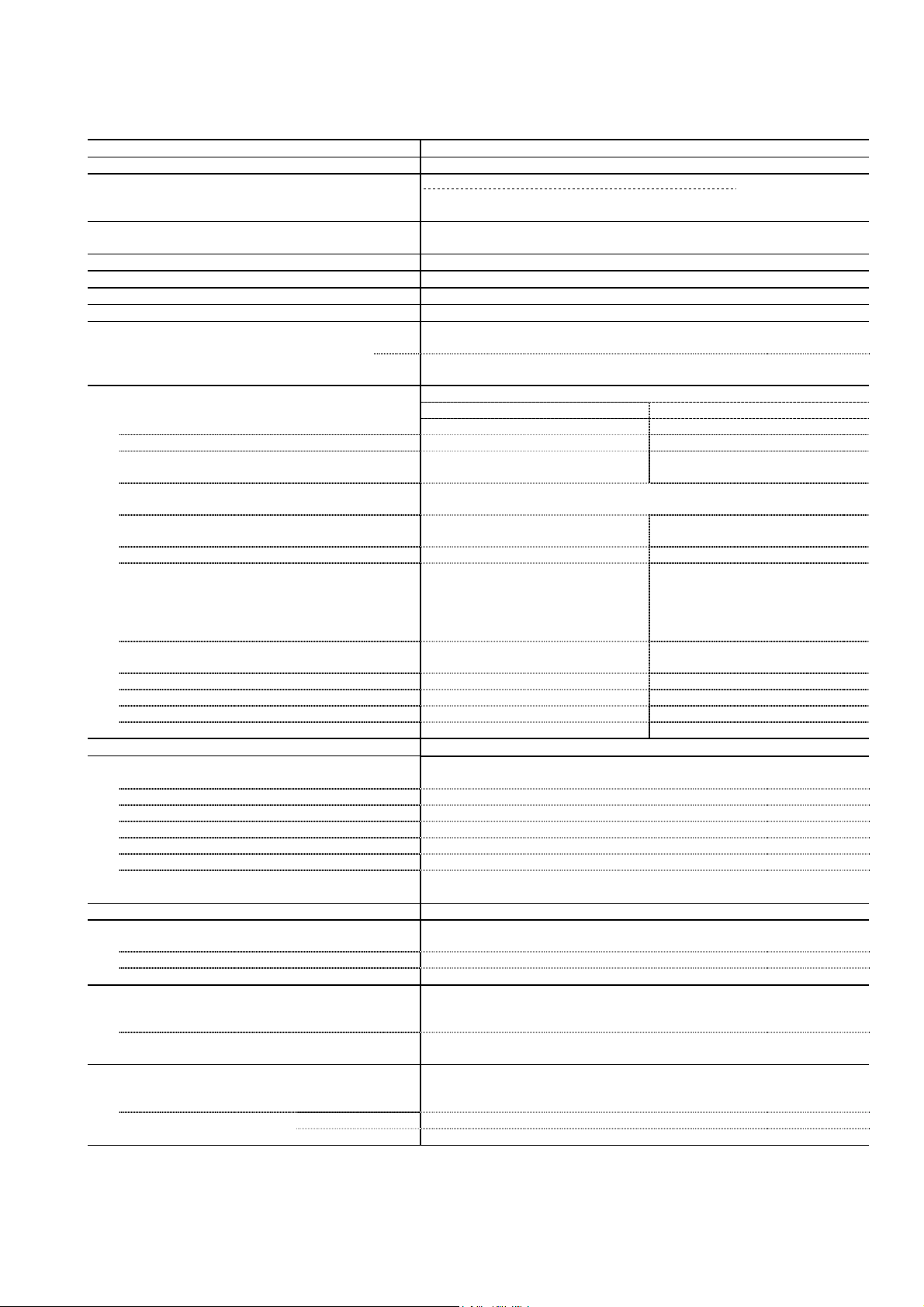

2. PRODUCT SPECIFICATIONS

2-1. Printer Main Unit Specifications

Paper feeding method ASF and front sheet feeder

Resolution 4,800 x 1,200 dpi (max.)

Printing speed (ASF) Draft Standard

BK (FINE_BK) 20 ppm 14.4 ppm

CL (FINE_CL) 14 ppm 7.3 ppm

Printing direction Bi-directional / Uni-directional (automatically switched according to print

data and print mode)

Draft mode print duty 50% duty

Print width 203.2 mm (8 inches), 216.0 mm (8.5 inches) in borderless printing

Interface USB (2.0) Full Speed only

Supported print head Service part: QY6-0054-000

Number of pages that can be printed

CL Approx. 170 pages (SCID No.5 pattern, default print mode)

BK Approx. 520 pages (SCID No.5 pattern, default print mode)

Approx. 300 pages (1,500-character pattern, default print mode)

Stacking capacity (ASF, front sheet feeder) Max. 13 mm (Approx. 150 pages of 64 g/m

Plain paper

High Resolution Paper (HR-101)

Glossy Photo Paper (GP-401)

Photo Paper Pro (PR-101)

Photo Paper Plus Glossy (PP-101)

Matte Photo Paper (MP-101)

Photo Paper Plus Double Sided (PP-101D)

Manual duplex printing is supported.

Photo Paper Plus Semi-gloss (SG-101)

Transparency (CF-102)

T-shirt Transfer (TR-301)

Envelope

Photo Stickers (PS-101)

13 mm or less (64 to 105 g/m

13 mm (approx. 80 sheets) or less 13 mm (approx. 80 sheets) or less

A4, LTR: 10 sheets or less

4x6, Credit Card: 20 sheets or less

A4, LTR, 5x7: 10 sheets or less

4x6: 20 sheets or less

A4, LTR, 5x7: 10 sheets or less

4x6: 20 sheets or less

A4, LTR: 10 sheets or less A4, LTR: 10 sheets or less

A4, 5x7: 1 sheet A4, LTR: 10 sheets or less

A4, LTR, 5x7: 10 sheets or less

4x6: 20 sheets or less

1 sheet 1 sheet

1 sheet 1 sheet

COM#10, DL: 10 sheets or less Not feedable.

1 sheet Not feedable.

ASF Front sheet feeder

2

) 13 mm or less (64 to 105 g/m2)

2

)

A4, LTR: 10 sheets or less

A4, LTR: 10 sheets or less

A4, LTR: 10 sheets or less

(Printing on the front side of paper

in duplex printing can be

performed from the front sheet

feeder.)

A4, LTR: 10 sheets or less

Borderless printing Up to A4, LTR

Detection function

Cover open Available

Presence of print head Available

Presence of ink tank Not available

Presence of paper Available

Paper width Not available

Waste ink absorber full Available

Remaining ink amount Available (Detected by dot counting. Reset by user operation. Enabled

at default.)

Print head alignment Available (11 types)

Acoustic noise level

Fine (Photo Paper Pro / Fine mode) Approx. 43 dB (Sound pressure level ISO9296)

HQ Approx. 44 dB

HS Approx. 53 dB

Environmental requirements

During operation Temperature: 5C to 35C (41F to 95F)

Humidity: 10% to 90%RH (no condensation)

Non-operation Temperature: 0C to 40C (32F to 104F)

Humidity: 5% to 95%RH (no condensation)

Power supply

Input voltage / Frequency AC 100 to 127 V, 50/60Hz (LV)

AC 220 to 240 V, 50/60Hz (HV)

Power consumption:

During printing Approx. 11 W

Stand-by status Approx. 2 W

3

Page 4

(2-1. Printer Main Unit Specifications cont’d)

External dimensions

With the paper support and front sheet feeder

extended

With the paper support and front sheet feeder

retracted

Approx. 418 (W) x 510 (D) x 315 (H) mm

Approx. 418 (W) x 260 (D) x 169 (H) mm

Weight Approx. 4.4 kg (excluding the print head and ink tanks)

Related standards

Electromagnetic radiance VCCI, FCC, IC, CE Mark, Taiwan EMC, C-Tick, CCC (EMC), Korea

MIC, Gost-R

Electrical safety DENAN, UL, C-UL, CB Report, CE Mark, GS, Gost-R, FT, SASO, CCC,

SPRING, Korea EK, IRAM

Environmental regulations RoHS (EU), WEEE (EU), Korea Package Recycle Law, Green Point

(Germany), Energy Star, Eco Mark, Law on Promoting Green

Purchasing

Note: Not Blue Angel compliant.

2-2. Product Life

Specified print volume or the years of use, whichever comes first.

- 3 years of use

- Print volume: 4,000 pages

- Black: 2,000 pages (A4, standard mode, 1,500-character pattern)

- Color: 1,200 pages (A4, 7.5% duty per color pattern)

120 pages (A4, photo, borderless printing)

80 pages (4 x 6, photo, borderless printing)

600 pages (Postcard, photo, borderless printing)

Note: The above print volume breakdown is estimated using average user consumption

patterns.

2-3. Print Head Specifications

Type 4-color integrated type (ink tank separate type)

Print head BK: 320 nozzles in 2 vertical lines

C/M/Y: 128 nozzles in 2 vertical lines per color

Ink droplet: BK 30 pl, CL 5 pl / 2 pl

Ink color BK (pigment-based ink)

CL: Y, M, C (high brilliance)

Ink tank BCI-24 Black, BCI-24 Color

Weight Approx. 58g (excluding ink tanks)

Supply method Service part (excluding ink tanks)

Part number: QY6-0054-000

Print head life 4,000 pages (Same as the printer main unit)

Note: - The print head is in common with the iP1500.

- Although the print head can be physically installed in the i350, i355, i250, i255, S300, S330,

and iP1000 series printers, it is incompatible with and cannot be used in those models.

4

Page 5

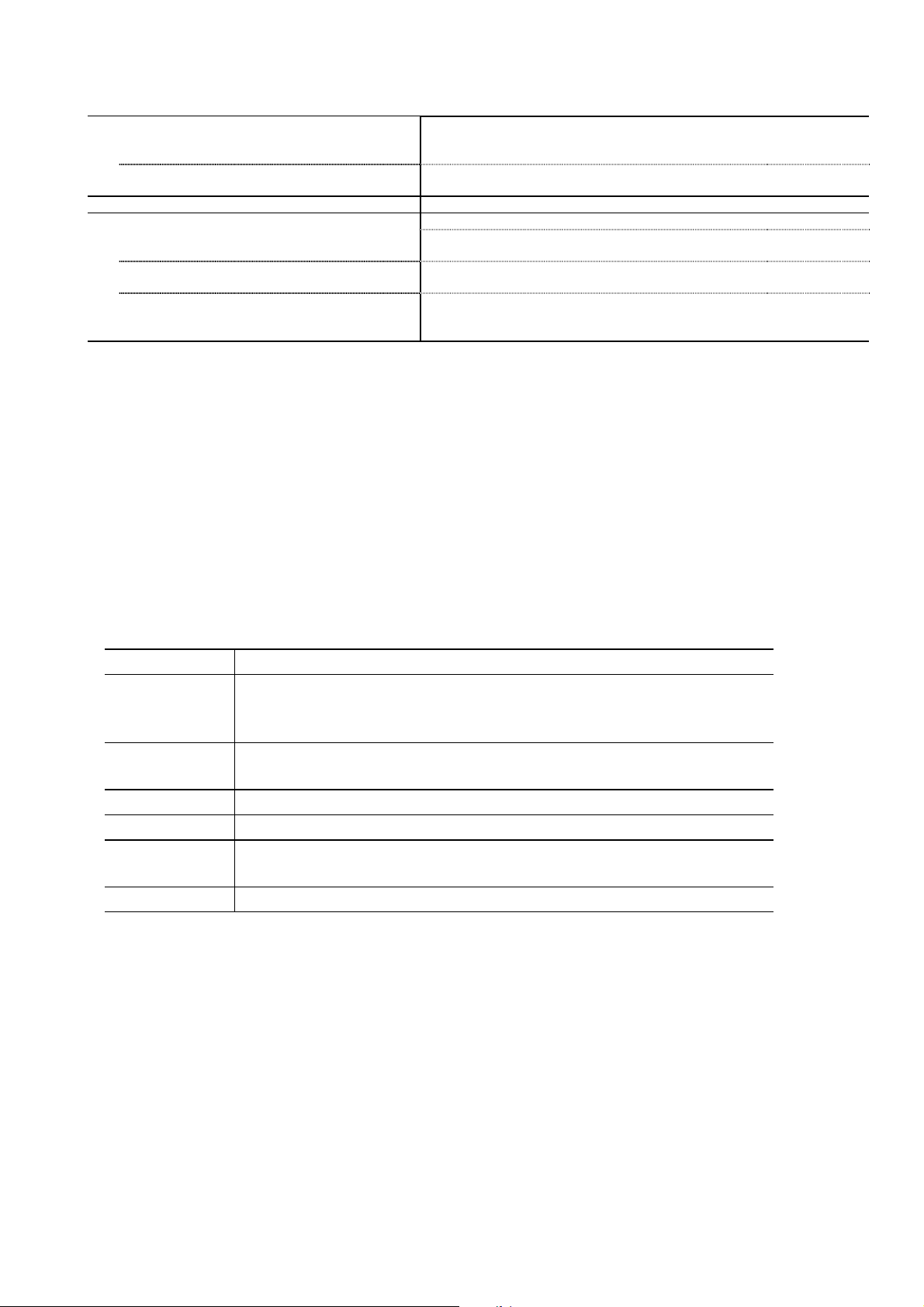

3. ERROR DISPLAY

Errors are displayed by the LEDs, and ink low warnings are displayed by the Status Monitor.

3-1. Operator Call Error (LED Blinking in Orange)

LED

blinking

2 times Paper out Set paper, and press the Resume/Cancel button

3 times Paper jam Remove the jammed paper, and press the

4 times Ink tank not installed Re-install the ink tanks, and close the front cover.

5 times Print head not installed or failure has

occurred in the print head.

(Non-supported print head (see page 4) is

installed or print head EEPROM data is

abnormal.)

8 times Waste ink absorber full or platen waste ink

absorber full warning (approx. 95% of the

maximum capacity)

9 times Non-supported digital camera or digital

video camera is connected.

Error Corrective action

to feed the paper.

Resume/Cancel button.

After confirming that the print head is for the

iP2000 (QY6-0054), re-install the print head, and

close the front cover.

If not recovered, with the print head installed,

power the printer off and on.

Pressing the Resume/Cancel button will exit the

error, and enable printing.

After removing the cable between the printer and

the camera, press the Resume/Cancel button, and

re-connect the cable. If the error is not resolved,

the connected camera may not be supported for

Camera Direct Printing. Check that a supported

camera is connected.

3-2. Service Call Error (LED Blinking in Orange and Green Alternately)

LED

blinking

2 times Carriage error Turn the printer off and on again. If the error is not resolved,

3 times LF error Turn the printer off and on again. If the error is not resolved,

4 times Purge unit error Turn the printer off and on again. If the error is not resolved,

5 times ASF cam sensor error Turn the printer off and on again. If the error is not resolved,

6 times Internal temperature error Turn the printer off and on again. If the error is not resolved,

7 times Waste ink absorber full or

platen waste ink absorber

full

8 times Print head temperature

rise error

9 times EEPROM error Turn the printer off and on again. If the error is not resolved,

13 times PF position error Turn the printer off and on again. If the error is not resolved,

14 times PF cam sensor error Turn the printer off and on again. If the error is not resolved,

17 times Motor driver error Turn the printer off and on again. If the error is not resolved,

Error Corrective Action

replace the printer.

replace the printer.

replace the printer.

replace the printer.

replace the printer.

Replace the printer. (In waste ink absorber replacement, perform

the EEPROM information print to identify if the main and/or platen

waste ink absorber should be replaced. After replacement, reset

the applicable waste ink counter(s).)

Turn the printer off and on again. If the error is not resolved,

replace the printer.

replace the printer.

replace the printer.

replace the printer.

replace the printer.

5

Page 6

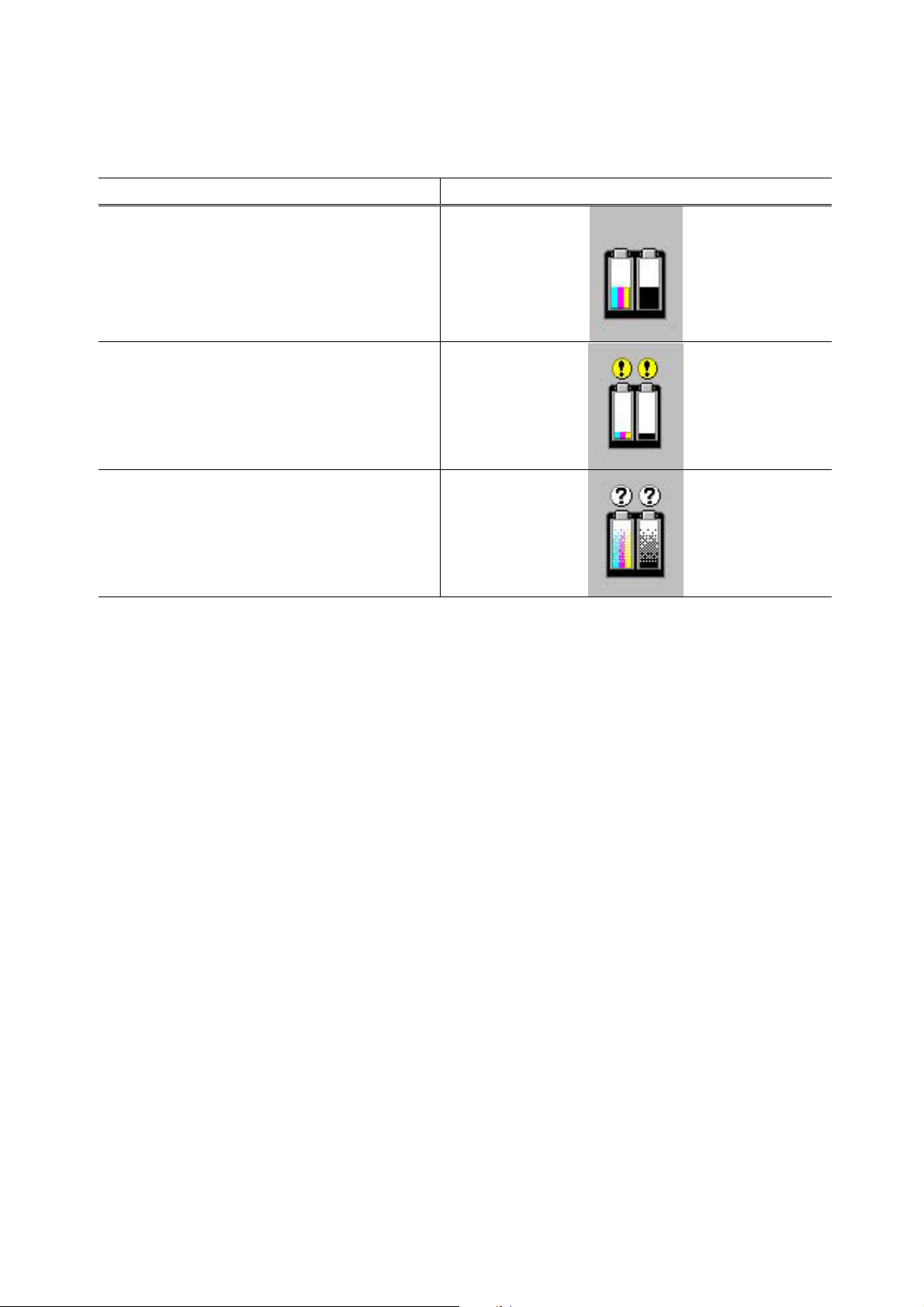

3-3. Ink Low Warning (Ink low warnings are displayed by the Status Monitor only when the

remaining ink level detection is enabled, and no Status Monitor display when disabled.)

Note: The Status Monitor display in the table below is for Windows.

Warning Display by Status Monitor

Ink low warning 1 (approx. half level)

Ink low warning 2 (low remaining ink)

Ink low warning 3 (ink level unknown)

6

Page 7

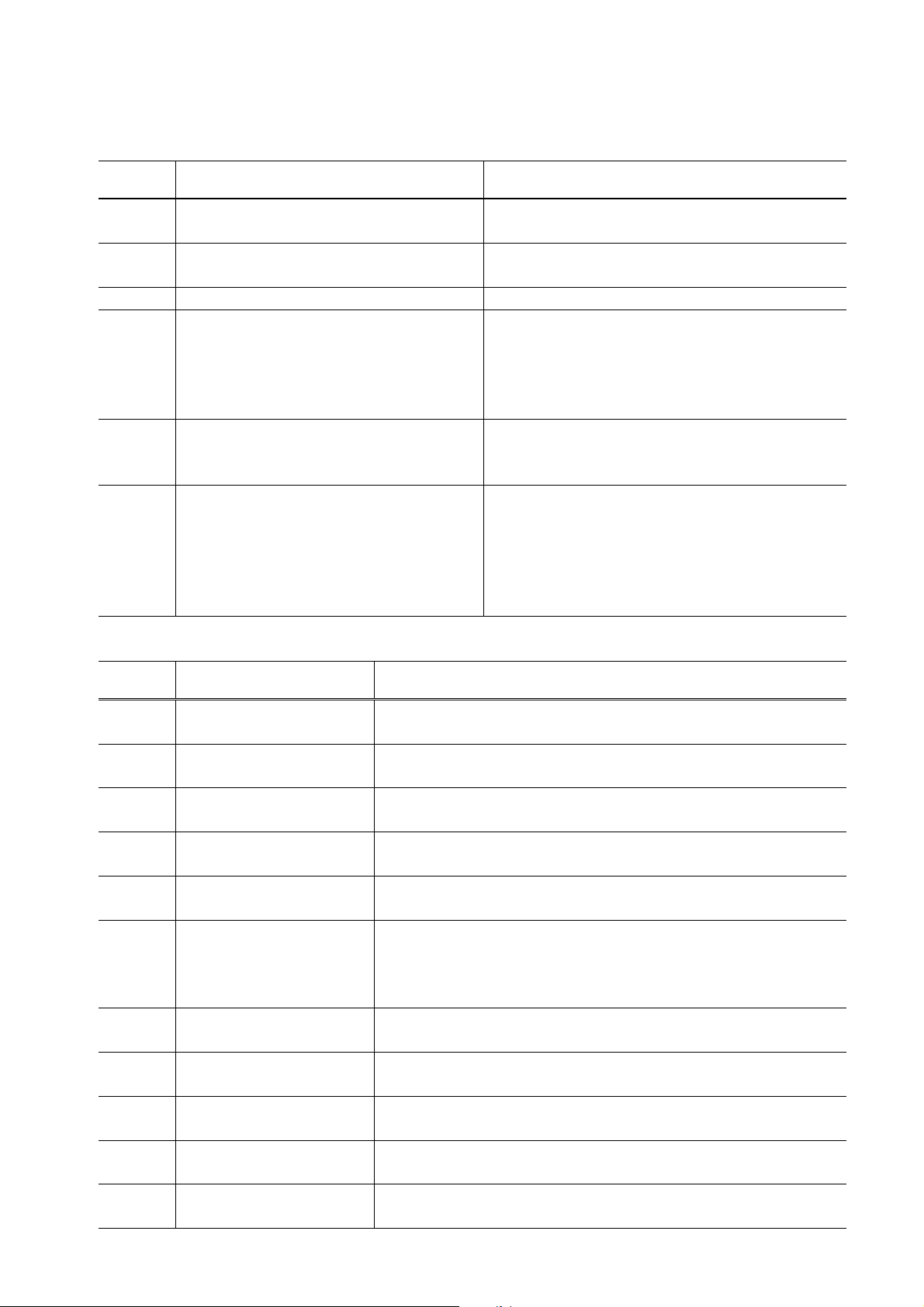

4. ADJUSTMENT / SETTINGS

4-1. User Mode

Function Procedures Remarks

Print head manual

cleaning

Print head deep

cleaning

Paper feed roller

cleaning

Bottom plate cleaning

(cleaning of ink mist

on the platen ribs)

Nozzle check pattern

printing

Print head alignment 1) Perform from the printer driver’s

- Cleaning both black and color:

See “Standalone printer operation” below.

- Cleaning black or color separately, or

both black and color:

Perform from the printer driver’s

Maintenance tab.

- Cleaning black or color separately, or

both black and color:

Perform from the printer driver’s

Maintenance tab.

1) Using the Paper Feed switch, select the

sheet feeder unit to perform paper feed

roller cleaning.

2) Remove all paper from the selected sheet

feeder unit.

3) Perform paper feed roller cleaning,

following the “Standalone printer

operation” procedures below.

1) Fold a sheet of plain paper (A4 or letter)

in half crosswise, then unfold and set it in

the ASF with the folded ridge facing

down.

2) Perform bottom plate cleaning, following

the “Standalone printer operation”

procedures below.

3) When the folded ridge of the ejected

paper is NOT soiled, cleaning is

completed. If it is soiled, repeat the steps

1) and 2).

See “Standalone printer operation” below. Also available from the printer

Maintenance tab.

2) According to the printout, set the optimum

values.

If the paper feed roller cleaning is

not effective, manually clean the

rollers with a cloth slightly

dampened with water.

If soiling on the paper persists

after the bottom plate cleaning is

performed 3 times, manually

clean the platen ribs with a cotton

swab.

driver’s Maintenance tab.

<Standalone printer operation>

1) Turn on the printer.

2) Press and hold the Resume/Cancel button until the LED blinks the specified number of times

listed in the table below, and release it. The operation starts.

LED blinking Operation Remarks

1 time Print head manual cleaning

2 times Nozzle check pattern printing

3 times Paper feed roller cleaning

4 times Unspecified

5 times Bottom plate cleaning

6 times Unspecified

7

Page 8

4-2. Service Mode

Function Procedures Remarks

EEPROM information print

- Destination

- ROM version

- Waste ink amount

- Total number of sheets fed

EEPROM initialization See “Service mode operation

Waste ink counter reset See “Service mode operation

Destination settings See “Service mode operation

Print head deep cleaning See “Service mode operation

See “Service mode operation

procedures” below.

procedures” below.

procedures” below.

procedures” below.

procedures” below.

Set a sheet of A4-, letter-, or larger-sized

paper.

For print sample, see APPENDIX 2, iP2000

EEPROM INFORMATION PRINT SAMPLE.

The following items are NOT initialized:

- Destination settings

- Waste ink counters

The following 3 methods are available:

- Resetting the main waste ink counter (0%)

- Re-setting the main waste ink counter

value to 50%

- Resetting the platen waste ink counter

(0%)

<Service mode operation procedures>

1) With the front cover closed, and the printer power turned off, while pressing the Resume/Cancel

button, press and hold the Power button. (DO NOT release the buttons. The LED lights in green

to indicate that a function is selectable.)

2) While holding the Power button, release the Resume/Cancel button. (DO NOT release the

Power button.)

3) While holding the Power button, press the Resume/Cancel button 2 times, and then release

both the Power and Resume/Cancel buttons. (Each time the Resume/Cancel button is pressed,

the LED lights alternately in orange and green, starting with orange.) During initial operations,

the LED blinks in green.

4) When the LED light sin green, press the Resume/Cancel button the specified number of time(s)

according to the function listed in the table below. (Each time the Resume/Cancel button is

pressed, the LED lights alternately in orange and green, starting with orange.)

Time(s) LED Function Remarks

0 times Green Power off When the print head is not installed, the

carriage returns and locks in the home

position.

1 time Orange Service test print

2 times Green EEPROM information print

3 times Orange EEPROM initialization

4 times Green Waste ink counter resetting Proceed to the step 5), and follow the

Waste ink counter reset procedures.

5 times Orange Destination settings Proceed to the step 5), and following the

Destination settings procedures.

6 times Green Print head deep cleaning

7 to 9 times Orange Not used in servicing

10 times Green Return to the menu selection

5) After the function (menu) is selected, press the Power button. The LED lights in green, and the

selected function is performed. (When the operation completes, the printer returns to the menu

selection mode automatically.)

8

Page 9

<Waste ink counter reset procedures>

In the waste ink counter resetting mode, press the Resume/Cancel button the specified number of

time(s) according to the ink counter reset value listed in the table below, and press the Power button.

Time(s) LED Waste ink counter value

0 times Green Reset the main waste ink counter (0%).

1 time Orange Reset the platen waste ink counter (0%)

2 times Green Re-set the main waste ink counter value to 50%.

<Destination settings procedures>

In the destination settings mode, press the Resume/Cancel button the specified number of time(s)

according to the destination listed in the table below, and press the Power button.

Time(s) LED Destination

0 times Green No change

1 time Orange Japan

2 times Green Other than Japan (A4)

3 times Orange Other than Japan (LTR)

9

Page 10

10

Page 11

5. PARTS LIST

Key Part Number Rank Q'ty Description Remark

QY6-0054-000 K 1 PRINT HEAD *

Common

parts

note: In common with the iP1500

*

11

Page 12

6. TROUBLESHOOTING FLOWCHART

S

p

S

6-1. Printer Main Unit Troubleshooting Flowchart (how to confirm printer operation at refurbishment)

Service mode

Service Call

Error?

No

Open front cover,

and install print head

Service Call

Error?

No

Service test print

Correct?

Yes

ee 4-2. Service Mode for

details.

Yes

Yes

ee 4-2. Service Mode for

printing method.

No

Replace print head and

erform service test print

Correct?

<Service test print check items>

(See APPENDIX 1, SERVICE TEST PRINT 1 PRINT

SAMPLE.)

1. Non-ejection of ink: Yes NG

2. Top of form: Off the paper NG

3. Vertical lines: Not connected NG

4. Gray area: White lines / uneven density NG

No

Yes

Main waste ink counter

less than 7%?

Yes

EEPROM initialization

Power off

No

Visually check the platen waste ink

absorber, and replace it if it is

soiled.

Normal Defective

<Note for normal printer refurbishment>

At end of refurbishment, set the printer to the default shipment conditions (with the paper lifting plate

in the raised position, and the carriage locked in the print head replacement position), following the

steps below.

1. Install the print head, and while pressing and holding the Power button, connect the AC plug.

After the LED lights in green, with the Power button still pressed, press the Resume/Cancel

button 2 times, and release both the Power and Resume/Cancel buttons. (Each time the

Resume/Cancel button is pressed, the LED lights alternately in orange and green, starting with

orange.)

2. Press the Resume/Cancel button 4 times, and then press the Paper Feed switch 2 times. The

shipment inspection pattern is printed, and the EEPROM is initialized.

3. After removing the print head, press the Paper Feed switch 2 times to turn off the printer. (The

paper lifting plate is raised, and the carriage moves to the print head replacement position.)

DO NOT print after this point.

12

Page 13

6-2. Print Head Troubleshooting Flowchart (print head operation confirmation)

Connect to computer

Nozzle check pattern printing

Correct?

No

Print head cleaning

Nozzle check pattern printing

Correct?

No

Print head deep cleaning

Nozzle check pattern printing

Correct?

No

Yes

Yes

Yes

Print head deep cleaning

Nozzle check pattern printing

Correct?

No

Replace ink tanks

Nozzle check pattern printing

Correct?

No

Yes

Yes

Defective

Normal

13

Page 14

7. SPECIAL NOTES ON SERVICING IN ASIA

A

7-1. Resetting the Main and Platen Waste Ink Counters

The iP2000 has separate waste ink counters for the main waste ink absorber and the platen waste

ink absorber, respectively. At waste ink absorber replacement, in the service mode, reset the

applicable waste ink counter according to the replaced waste ink absorber. (When both the main and

platen waste ink absorbers are replaced, reset both the main and platen waste ink counters.)

For the main waste ink absorber, a new design has been adopted so that a half portion of the main

waste ink absorber can be replaced just by removing the printer housing.

When compared with replacement of the entire main waste ink absorber, replacement of the half

portion is extremely simple and easy, as it does not require removal of other components such as

the chassis and ASF.

The printable number of pages after replacement of the half portion of the main waste ink absorber

is 2,000 pages.

According to the above, 2 methods are available for replacement of the main waste ink absorber,

and the main waste ink counter should be reset according to the replacement method.

- Replacement of the half of the main waste ink absorber:

Easy, and the printable number of pages after the replacement is approx. 2,000.

- Replacement of the entire main waste ink absorber:

Difficult, and the printable number of pages after the replacement is approx. 4,000.

After replacement, the main or platen waste ink counter should be reset according to the replaced

absorber portion.

<Waste ink counter value to be re-set to after waste ink absorber replacement>

Replaced waste ink absorber Waste ink counter value

Entire main waste ink absorber Reset the main waste ink counter (0%).

Half of the main waste ink absorber* Re-set the main waste ink counter value to 50%.

Entire platen waste ink absorber Reset the platen waste ink counter (0%).

* How to replace half of the main waste ink absorber:

1. Remove the upper cover unit.

2. Replace the 4 ink absorbers (2 types, equivalent to half of the main waste ink absorber),

shown in the figure below.

<Waste ink absorber replacement procedures>

1. Error check

Perform EEPROM information printing, and check the following values:

- D: Main waste ink counter

- PD: Platen waste ink counter

2. Replace the applicable waste ink absorber(s).

3. Reset the waste ink counter.

For waste ink counter resetting procedures, see 4. ADJUSTMENT / SETTINGS, 4-2. Service Mode.

Replaceable half portion (4 ink absorbers)

fter the half portion is replaced, re-set the

waste ink counter to 50%.

14

Page 15

8. PRODUCT TECHNICAL INFORMATION

8-1. FAQ (Problems specific to the iP2000 and corrective actions)

No. * Function Phenomenon Possible Call / Claim Corrective action Cause

1 A Carriage error (LED blinks

2 A

3 B No paper feeding (due to

4 B Multi-feeding - Multiple pages of paper are fed

5 B Envelope not feeding - Paper out error

6 B Credit Card size paper jam at

7 C

Installation

Paper

feeding

alternately in orange and green

2 times).

Ink tank installation error

(LED blinks in orange 4 times.)

incorrect Paper Feed switch

setting)

feeding

Paper jam - Paper jam error

- LED blinks alternately in orange and

green, 2 times (carriage error).

- LED blinks in orange 4 times (ink

tank installation error). (As this

occurs at printer installation, the user

cannot recognize the error.)

- Paper out error

- Paper cannot be fed

- Cannot print

simultaneously.

-Blank paper is ejected.

- Paper cannot be fed

- Cannot print

- Paper jam error

- Paper cannot be fed

- Cannot print

- Paper cannot be fed

- Cannot print

Remove the packing material fixing the

carriage.

Open the access cover, and install the ink

tanks properly.

1. Perform roller cleaning from the printer

driver.

2. Change the paper feed method by the

Paper Feed switch.

3. Clean the paper feed roller with

moistened cloth.

1. Fan the paper and set them.

2. In case of PR-101, set the paper sheet

by sheet.

1. Perform roller cleaning from the printer

driver.

2. Clean the paper feed roller with

moistened cloth.

3. Reduce the number of envelopes

loaded in the ASF.

4. Flatten the envelope (with a pen).

Set a sheet of Credit Card size paper in

the ASF with the longer edge in vertical

orientation, and press the

Resume/Cancel button.

When using the ASF, remove the jammed

paper from the paper pick-up side.

When using the front sheet feeder, open

the rear cover, and remove the jammed

paper.

The user may not have removed the

packing material at unpacking and

installation.

Although a caution sheet is packaged

together with the printer, the user may not

have noticed it.

Note: Even if the packing material

remains, no parts are damaged.

Since the user did not seat the ink tanks

completely at unpacking, installation, or

ink tank replacement, the ink tank

contacts the main case.

The paper feed roller slips on the paper at

paper feeding, or the Paper Feed switch

setting is not correct.

Note: Camera Direct Printing is available

only when paper feeds from the

ASF.

In the high temperature and high humidity

environment, the frictional force between

the front and back sides of paper

becomes high, and sheets stick to each

other, contributing to multi-feeding.

The paper feed roller slips on the paper at

paper feeding.

Note: Depending on the paper lots. This

phenomenon may occur in DL

envelope.

When Credit Card size paper is set with

the shorter edge in vertical orientation,

the paper does not reach the LF roller,

and the paper is not fed.

As the LF roller slips on the paper, the

paper is not fed, causing the jam error at

paper ejecting.

15

Page 16

(8-1. FAQ (Problems specific to the iP1000 and corrective actions) cont’d)

No. * Function Phenomenon Possible Call / Claim Corrective action Cause

8 B Smearing on printed side. - Smear on the printed side of paper

9 B Smearing on the backside, or

10 C Horizontal lines or uneven print

11 C

*Occurrence level:

A: The phenomenon is likely to occur frequently. (Caution required).

B: The phenomenon may occur under certain conditions, but likeliness is assumed very low in practical usage.

C: The phenomenon is unlikely to be recognized by the user, and no practical issues are assumed.

Image

quality

address side of postcards

density at the trailing edge of

paper

Horizontal lines or uneven print

density due to LF roller feeding

at small pitch

- Cannot print properly

- Paper edge crease

<Photo Paper Plus Double Sided>

- Smears on the already printed side

when printing the other side

<When printing the address side of

postcards>

- Smears on the address side

<When printing the message side of

postcards>

- Smears on the backside

- Cannot print to the bottom edge of

paper

- Lines or uneven print density appear

in the trailing edge of paper

- Cannot print properly

- Lines or uneven print density (on

skin tones and background)

- Cannot print properly

1. Correct the paper curl.

2. Change the paper thickness lever

setting.

3. Recommend the user to conduct

printing in the print quality assurance

area.

1. Perform bottom plate cleaning from

the printer driver.

2. Clean the ribs on the platen with

cotton swabs/buds.

1. Recommend printing in the print

quality assurance area.

2. Change the print quality from standard

to high mode.

3. Try other paper (PP-101)

Change the print quality from standard to

high mode.

The edge of paper rises due when paper

is curled, causing the print head to rub

against the printed surface of paper,

resulting in smearing.

When borderless printing is conducted

continuously, ink mist attaches to the ribs

on the platen, and is transferred to the

backside of the following paper.

When the paper end comes off the pinch

roller, printing is performed without the

paper being held, preventing the ink

drops from being ejected in the correct

positions, resulting in unevenness.

Note: The problem is less noticeable

than that of the i320.

As the print media slightly slips while

being fed by the LF roller, printed areas

overlap, causing the problem.

16

Page 17

8-2. Major Functions

(1) Borderless printing (up to A4 and LTR sizes)

<Possible problems with this function>

- Smearing on the address side of postcards in continuous borderless printing on the message side.

-> Perform bottom plate cleaning, and clean the ribs on the platen.

- Smearing on the backside of paper in continuous borderless printing.

-> Perform bottom plate cleaning, and clean the ribs on the platen.

- Ink mist on the platen.

-> Perform bottom plate cleaning, and clean the ribs on the platen.

(2) 2 types of paper path feeding (paper feeding from the ASF and front sheet feeder)

The printer has 2 paper feeding methods, from the ASF and from the front sheet feeder.

Paper feeding from the front sheet feeder does not support,

- paper size smaller than A5,

- Camera Direct Printing, and

- printing on the back side of paper in duplex printing.

<Possible problems with this function>

- “No paper” error due to incorrect Paper Feed switch setting (such as when the Resume/Cancel

button is pressed after Paper Feed switch setting).

Printer driver default setting: Paper Source is set to Paper Feed Switch.

Printer’s Paper Feed switch default setting: ASF

Paper feed setting priority: Printer driver setting over printer’s Paper Feed switch setting

- Paper feed problem due to incorrect paper size setting (the front sheet feeder supports only A5- or

larger-sized paper).

(3) Remaining ink level detection function

The printer has a function to detect the remaining ink level. (Default setting: ON)

Detection method: Dot counting (Counted for each BK/CL ink tank)

CL tank: The remaining ink level is detected by total counted dot values of 3

colors of ink.

Display method: Displayed on the Status Monitor (at 3 levels listed below for each BK/CL ink tank)

Level 1: Half level of remaining ink level (Approx. 40% of ink remaining)

Level 2: Indication of “!” mark (Approx. 10% of ink remaining)

Level 3: Indication of “?” mark (Remaining ink level is unknown, ink may be

used up anytime)

Note: Remaining ink detection function displays the status only, and does not

cause errors.

Accuracy: The margin of error of detection accuracy is +/-10% in normal printing.

The margin of error is likely to be large in the following specific print patterns:

When printing continuously using any one of the CMY colors of ink

-> As the remaining ink level is calculated by total counted dot values of 3

colors of ink, if any of the C/M/Y inks is heavily consumed, the margin of

error for remaining ink increases.

When performing continuous BK solid printing

-> With continuous printing, ink flow from the tank to the ink chamber can be

interrupted, after which ink remains unused in the tank.

Reset procedure: Perform the following operations from the printer driver’s Maintenance tab:

1. In Low Ink Warning Setting, enable Display low ink warning.

2. In Ink Counter Reset, reset the applicable ink counter(s).

Note: Be sure to reset the ink counter from the printer driver’s Maintenance tab

after replacing ink tanks.

17

Page 18

<Possible problems with this function>

- Due to user error, the actual remaining ink level does not match the indicated remaining ink level,

resulting in “ink out”, etc.

User error: Forgetting to reset the ink counter / ink counter reset other than when replacing ink

tanks.

- Due to the specific print pattern, the actual remaining ink level does not match the indicated

remaining ink level, resulting in “ink out”.

Specific print pattern: Continuous printing using any one of the CMY colors of ink / continuous

BK solid printing, etc.

(4) Print head deep cleaning

The printer has a print head deep cleaning (refreshing) function.

Print head deep cleaning (refreshing):

This is a deep cleaning function in order to resolve print failure due to ink clogging

the print head. (The black ink is pigment-based, and clogs easier than other

dye-based ink.)

Perform from the printer driver’s Maintenance tab.

<Possible problems with this function>

- Excessive ink consumption when conducting print head deep cleaning repeatedly. (The amount of

ink used is approx. 10 to 15 times the normal manual cleaning amount.)

<Reference> Cleaning types, amount of ink used, and time required

BK and CL ink drawing is simultaneously performed.

Cleaning type Amount of ink used Time required

Manual cleaning

Dot count cleaning

Cleaning on arrival at user

Print head replacement

Timer cleaning (24 hours to 3 months)

Cleaning when the print head is not capped at printer power on

Ink tank replacement BK: Approx. 0.57 g

Print head deep cleaning

Timer cleaning (3 months or more)

(5) Print head alignment

The printer has a print head alignment function (print head position adjustment function). As it is not

necessary to perform print head alignment at setup or installation of the printer, the function is only briefly

introduced at installation.

Print head alignment: This is a function to correct displacements between the nozzle lines of the

print head, and incorrect print position at bi-directional printing.

The adjustment is conducted using the printed head position adjustment

pattern.

A: Print head alignment between black even and odd nozzles

B: Print head alignment between cyan even and odd large nozzles

C: Print head alignment between magenta even and odd large nozzles

D: Print head alignment between cyan even and odd small nozzles

E: Print head alignment between magenta even and odd small nozzles

F: Print head alignment in bi-directional black printing

G: Print head alignment of large nozzles in color bi-directional printing

H: Print head alignment between black and photo black nozzles

BK: Approx. 0.12 g

CL: Approx. 0.14 g

BK: Approx. 0.42 g

CL: Approx. 0.52 g

CL: Approx. 0.62 g

BK: Approx. 1.50 g

CL: Approx. 2.35 g

Approx. 40 sec.

Approx. 60 sec.

Approx. 60 sec.

Approx. 70 sec.

18

Page 19

I: Print head alignment of small nozzles in color bi-directional printing

J: Print head alignment between cyan large and small nozzles

K: Print head alignment between magenta large and small nozzles

Perform from the printer driver’s Maintenance tab.

(At initial set-up by the user, notice to perform the print head alignment is

displayed in the Status Monitor.)

<Possible problems with this function>

- The line is not straight.

-> Perform print head alignment from the printer driver.

- Printout is granulated.

-> Perform print head alignment from the printer driver.

19

Page 20

APPENDIX 1: SERVICE TEST PRINT 1 PRINT SAMPLE

Check item 1 (Non-ejection of ink): Total area of the sample below

EEPROM information print

-> See below for details.

BK nozzle check pattern

C nozzle check pattern (5 pl)

C nozzle check pattern (2 pl)

M nozzle check pattern (5 pl) Y nozzle check pattern (5 pl)

M nozzle check pattern (2 pl) Y nozzle check pattern (2 pl)

Check item 3 (Gray area)

Check item 2 (Top of form)

Check item 4 (Vertical lines)

<EEPROM information print>

Model name

ROM version

USB No.

IP_2000 V X.XX USB(XXXXX) FA=XX XX XX D=XXX.X

Paper size: A4

Line inspection information

Main waste ink absorber ink amount (%)

20

Page 21

APPENDIX 2: iP2000 EEPROM INFORMATION PRINT SAMPLE

Print sample:

iPXXXX V1.03 IF(USB=1) D=004.5 PD=000.0 ST=2001/09/27-18:30

ER(ER0=1000 ER1=5100 ER2=0000 ER3=0000) LPT=2001/09/09-09:09

PC(M=002 R=00 T=0001 D=009 C=000)

CLT(BK=2001/09/27-18:30 CL=2001/09/27-18:30)

CH=00002 DC(BK1=040 CL=000)

IC(BK1=00001 C=00001 M=00001 Y=00001)

P_ON(S=00009 h=00005) REG=1

UR(A(BKoe)=+01 B(Coe)=-01 C(Moe)=+01 D(SCoe)=-01 E(SMoe)=+01 F(BKbi)=+01

G(CLbi)=+01 H(BK-PCBK)=+01 I(SCLbi)=+01 J(C-SC)=+01 K(M-SM)=+01)

WP=00024 CDIN(LG=000 PB=000) MSD(015)

PAGE(All=00083 PP=00035 HR+MP=00003 PR+SP+SG=00000 GP=00000 PC=00000 EVN=00000)

UCPAGE(All=00083 PP=00035 HR+MP=00003 PR+SP+SG=00000 GP=00000)

CDPAGE(All=000) EDGE=00083 L=00000 2L=00000

Head TempBK=18.5 Head TempC=17.5 Env Temp=30.0 FF(3F 3F 3F)

HDEEPROM

V0001

SN=0000-0EA5

LN(00000 00000 00001 00003 00013 00017 00015)

ID=03

IL=(BK=000 C=+01 M=000 Y=+01 C2=+01 M2=+01 Y2=+01)

Printed items:

1. Model name 2. ROM version 3. Connected I/F (USB1) 4. Waste ink amount/Platen waste ink amount 5.

Installation date

6. Operator call/service call error record 7. Last printing time

8. Purging count (manual/deep cleaning/timer/dot count/ink tank or print head replacement)

9. Cleaning time (BK/CL)

10. Print head replacement count 11. Number of times the dot count values are reset (pigment BK1/CL)

12. Total ink consumption (pigment BK/C/M/Y)

13. Power-on count (soft/hard) 14. Print head alignment by user

15. User print head alignment values (Bkoe/Coe/Moe/SCoe/SMoe/BKbi/CLbi/BK-PCBK/SCLbi/C-SC/M-SM)

16. Wiping count 17. Camera Direct Print-supported device connection count (PictBridge/legacy) 18. Longest period

where printing stops

19. ASF feed pages (total, plain paper, High Resolution Paper & Matte Photo Paper, Photo Paper Pro & Photo Paper

Plus Glossy & Photo Paper Plus Semi-gloss, Glossy Photo Paper, postcard, envelope)

20. U-turn cassette feed pages (total, plain paper, High Resolution Paper & Matte Photo Paper, Photo Paper Pro & Photo

Paper Plus Glossy & Photo Paper Plus Semi-gloss, Glossy Photo Paper)

21. Camera Direct print pages (total) 22. Borderless print pages (total) 23. L-size & 4x6 print pages 24. 2L-size &

5x7 print pages 25. Print head temperature (BK/CL) 26. Inside temperature 27. Line inspection information

HDEEPROM

28. Version

29. Serial number

30. Lot number

31. Print head ID

32. Ink ejection level (BK/C/M/Y/C2/M2/Y2)

21

Loading...

Loading...