CANON LBP 3260 DU-82 Service Manual

SERVICE

MANUAL

REVISION 0

COPYRIGHT 1999 CANON INC. CANON DUPLEXING UNIT DU-82 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

RY8-1396-000

JAN. 1999

DUPLEXING UNIT

COPYRIGHT © 1999 CANON INC

Printed in Japan

Imprimé au Japon

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information.

Prepared by

PERIPHERAL PRODUCTS QUALITY PLANNING DIV.

PERIPHERAL PRODUCTS TECHNICAL DOCUMENTATION DEPT.

CANON INC.

5-1, Hakusan 7-chome, Toride-City, Ibaraki-Pref. 302-8501, Japan

PREFACE

This Service Manual contains basic information required for after-sales service of the

Duplexing unit DU-82. This information is vital to the service technician in maintaining the

high print quality and performance of the duplexing unit.

This manual consists of the following chapters:

Chapter 1: Product information

Features, specifications, parts of the duplexing unit, and installation

Chapter 2: Operation and Timing

A description of the operating principles and timing sequences of the electrical and

mechanical systems.

Chapter 3: The Mechanical System

Explanation of mechanical operation, disassembly, reassembly, and adjustment

procedures

Chapter 4: Troubleshooting

Maintenance and servicing, measurement and adjustments, troubleshooting

procedures, and location of electrical components

Appendix: General timing chart, general circuit diagram, and list of signals.

Information in this manual is subject to change as the product is improved or redesigned.

All relevant information in such cases will be supplied in Service Information Bulletins.

A thorough understanding of this unit, based on information in this Manual and Service

Information Bulletins is required for maintaining its performance and for locating and repairing

malfunctions.

DTP system

This manual was produced on an Apple PowerMacintosh 9500/200 personal computer and output by an

Apple LaserWriter 16/600 PS laser beam printer; final pages were printed on AGFA Selectset avantra 25.

All graphics were produced with Macromedia FreeHand (J), and all documents and page layouts were

created with QuarkXPress (E).

The video images were captured with SONY degital video camcorder and Radius PhotoDV capture

board system, and modified with Adobe Photoshop (J).

CONTENTS

CHAPTER 1 PRODUCT INFORMATION

I. FEATURES ............................. 1-1

II. SPECIFICATIONS.................... 1-2

III. PARTS OF THE DUPLEXING

UNIT ...................................... 1-3

A. External Views .................. 1-3

B. Cross Sectional Views........ 1-3

IV. INSTALLATION ....................... 1-4

CHAPTER 2 OPERATION AND TIMING

CHAPTER 3 THE MECHANICAL SYSTEM

CHAPTER 4 TROUBLESHOOTING

I. BASIC OPERATION................. 2-1

A. Outline of the Electrical

System .............................. 2-1

B. Duplexing Driver Input

Signals .............................. 2-2

C. Duplexing Driver Output

Signals .............................. 2-3

II. PAPER PICK-UP/FEED

SYSTEM ................................. 2-4

A. Operation .......................... 2-4

B. Paper Jam Detection ......... 2-10

I. PREFACE .............................. 3-1

II. EXTERNALS .......................... 3-2

A. Locations ......................... 3-2

B. External Covers ................ 3-3

III. SENSORS .............................. 3-5

A. Locations ......................... 3-5

B. Duplex Feed Roller 1

Home Position Sensor ...... 3-6

C. Duplexing Unit Paper

Sensor .............................. 3-6

D. Side Registration Guide

Home Position Sensor ...... 3-7

E. Reversing Sensor .............. 3-7

IV. CLUTCH/SOLENOIDS ............ 3-8

A. Locations ......................... 3-8

B. Reversing Roller Release

Solenoid ........................... 3-9

C. Duplex Deflector Solenoid 3-10

D. Duplex Feed Clutch .......... 3-11

V. MOTORS ............................... 3-12

A. Locations ......................... 3-12

B. Duplexing Unit Motor ....... 3-13

C. Side Registration Motor .... 3-13

VI. ELECTRICAL PARTS .............. 3-14

A. Locations ......................... 3-14

B. Duplexing Driver PCB ....... 3-15

I. PREFACE ............................... 4-1

A. Malfunction Diagnosis

Flowchart .......................... 4-1

B. Initial Checks.................... 4-3

II. IMAGE DEFECTS.................... 4-4

III. PAPER JAMS .......................... 4-5

IV. PAPER TRANSPORT

MALFUNCTION....................... 4-6

V. MALFUNCTION

TROUBLESHOOTING .............. 4-7

VI. MALFUNCTION STATUS

TROUBLESHOOTING .............. 4-9

VII. MEASUREMENT AND

ADJUSTMENT ........................ 4-11

A. Mechanical Adjustment ..... 4-11

B. Electrical Adjustment........ 4-11

C. Variable resistors, LEDs,

test pins, jumpers, and

switches on PCB ................ 4-11

VIII.MAINTENANCE AND

SERVICING............................. 4-12

A. Periodic Replacement

Parts ................................. 4-12

B. Expected Lives of Consumable

Parts ................................. 4-12

C. Regular Servicing

Schedule ........................... 4-12

D. Standard Tools .................. 4-12

E. Special Tools ..................... 4-12

F. List of Lubricants and

Cleaners ............................ 4-12

IX. LOCATION OF CONNECTORS.. 4-13

APPENDIX

I. GENERAL TIMING CHART ...... A-1

II. GENERAL CIRCUIT DIAGRAM. A-2

III. LIST OF SIGNALS ................... A-3

CHAPTER 1

PRODUCT INFORMATION

I. FEATURES ............................. 1-1

II. SPECIFICATIONS.................... 1-2

III. PARTS OF THE DUPLEXING

UNIT ...................................... 1-3

IV. INSTALLATION ....................... 1-4

1 - 1

CHAPTER 1

I. FEATURES

1. Optional built-in type duplexing unit

The duplexing unit is compact in size and can be installed inside the printer.

II. SPECIFICATIONS

1. Print paper A3, A4, B4, A5, B5, Ledger, Legal, Letter and Executive size plain

paper (64g/m2- 105g/m2recommended paper)

2. Power supply DC24V (supplied from printer)

3. Dimensions 379 (W) × 423 (D) × 82 (H) mm

4. Weight About 3.5kg

Specifications are subject to change with product modification.

1 - 2

CHAPTER 1

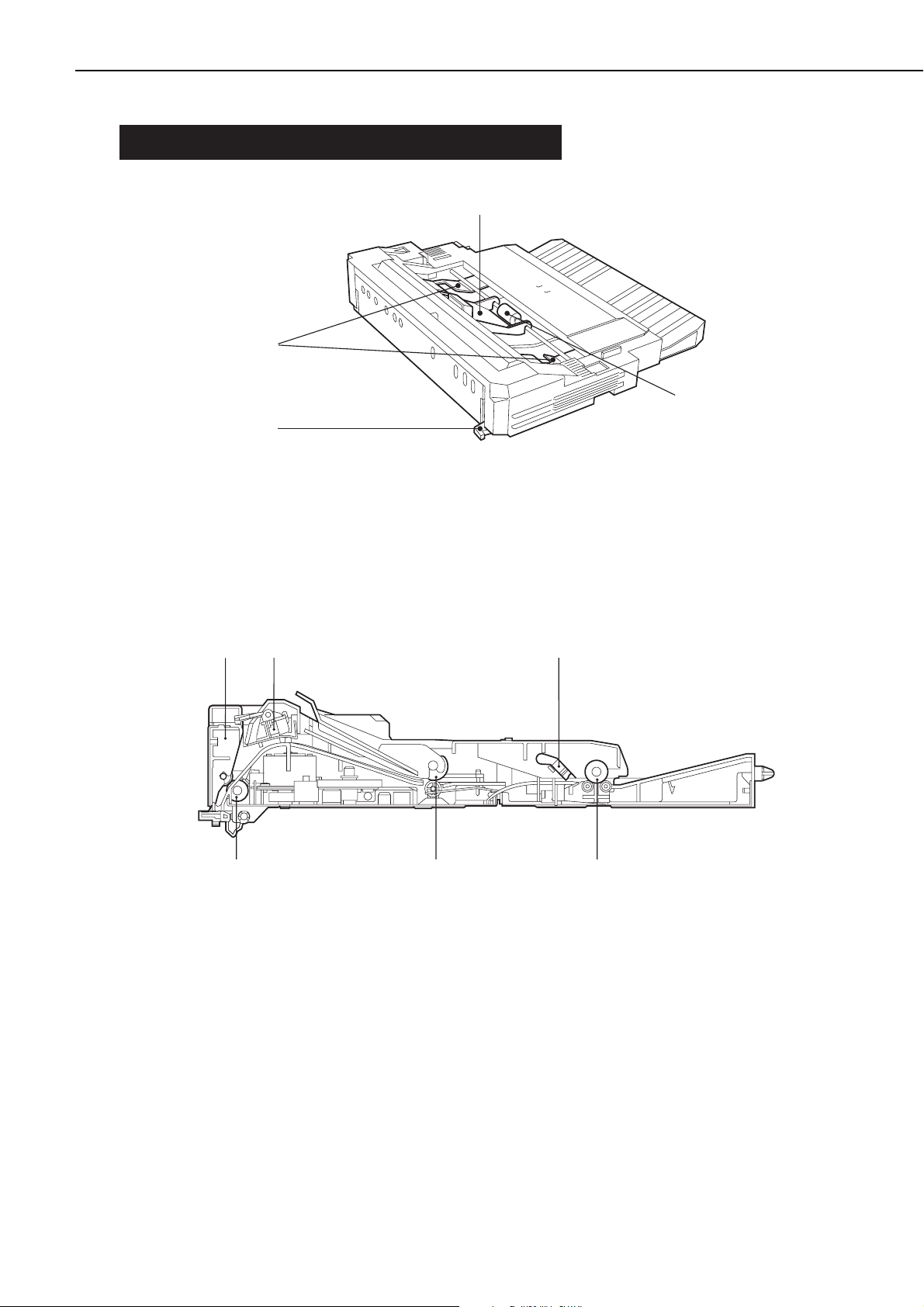

III. PARTS OF THE DUPLEXING UNIT

A. External Views

1: Side registration guide

2: Pick-up guide plate

3: Duplex feed roller 1

4: Duplexing unit removal lever

Figure 1-3-1

B. Cross Sectional Views

1: Reversing roller pressure release plate

2: Reversing sensor

3: Duplex pick-up sensor lever

4: Duplex feed roller 2

5: Duplex feed roller 1

6: Reversing roller

Figure 1-3-2

1 - 3

CHAPTER 1

➁

➀

➃

➂

➀➁

➂

➃➄➅

1 - 4

CHAPTER 1

IV. INSTALLATION

Condensation will form on metal surfaces when brought into a warm room from the cold.

Condensation in the duplexing unit can cause various troubles, such as paper feeding failure.

Therefore, when moving the duplexing unit to a warm environment, leave it packed in its box for

at least an hour to acclimatize to room temperature.

1) Open the duplexing unit packaging.

2) Take off the plastic bag and peel the tape off.

3) Remove the packing materials from the duplexing unit.

4) Open the delivery cover on the printer.

5) Holding the duplexing unit in both hands, install it into the printer.

CHAPTER 2

OPERATION AND TIMING

1. This chapter describes the duplexing unit functions, the relationships between mechanisms

and circuits, and the timing of operations. Mechanical linkages are indicated by black and

white lines ( ), the flow of control signals by solid arrows ( ), and the flow of

groups of signals by outline arrows ( ).

2. An active-high signal is indicated by "H" or by a signal name without a slash in front of it,

such as "PSNS." An active-low signal is indicated by "L" or by a signal name with a slash in

front of, such as "/SCNON."

A signal that is "H" or has a name without a slash is active at the supply voltage level

(indicating that the signal is being output), and inactive at ground level (indicating that the

signal is not being output).

A signal that is "L" or has a slash in front of its name is active at ground level, and inac-

tive at the supply voltage level.

There is a microcomputer in this printer. But as the internal operation of the microcomputer cannot be checked, an explanation of the operation of the microcomputer has been left

out.

As it is assumed that no repair will be made to customer circuit boards, the explanation

of board circuits is limited to an outline using block diagrams. So there are two types of circuit explanations; (1) everything from the sensor to the input sections of the major circuit

boards, (2) everything from the output sections of the major circuit boards to the loads.

These are explained with block diagrams according to the function.

I. BASIC OPERATION................. 2-1 II. PAPER PICK-UP/FEED

SYSTEM ................................. 2-4

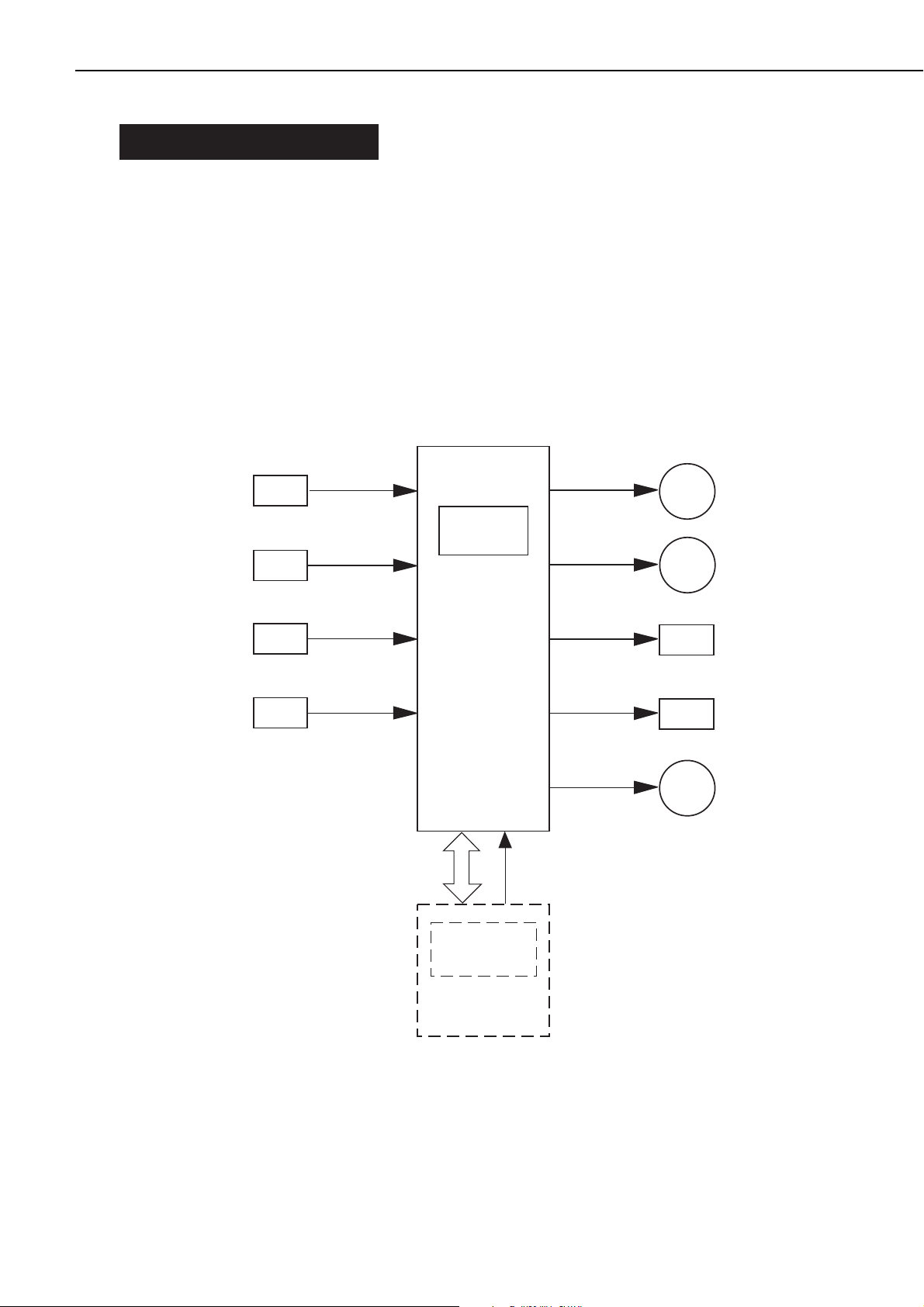

I. BASIC OPERATION

A. Outline of the Electrical System

The duplexing unit inverts the print paper and feeds it to the printer.

The duplexing unit is controlled with various commands sent from the DC controller PCB in

the printer.

The duplexing driver PCB controls the sequence of duplexing unit operations. The duplexing

driver PCB has a four-bit microcomputer (CPU, IC2002) which controls the sequence of duplexing unit operations and serially communicates with the DC controller PCB in the printer.

The CPU drives motors, solenoids, and a clutch according to the duplex unit specification

command and the duplex pick-up command sent from the DC controller PCB.

The printer provides +24 VDC to the duplexing unit. The duplexing driver PCB generates +5

V for ICs and sensors from +24 V.

The flow of signals between the duplexing unit and printer is shown below.

Figure 2-1-1

2 - 1

CHAPTER 2

Duplexing unit

paper sensor

Reversing sensor

Side registration

guide home

position sensor

Duplex feed roller

1 home position

sensor

PS24

PS26

PS25

PS23

Serial line

CPU

IC2002

Duplexing

driver PCB

+24VA

M8

M7

SL7

SL6

CL5

Duplexing unit

motor

Side registration

motor

Reversing roller

release solenoid

Duplex deflector

solenoid

Duplex feed cluch

DC controller

PCB

Printer

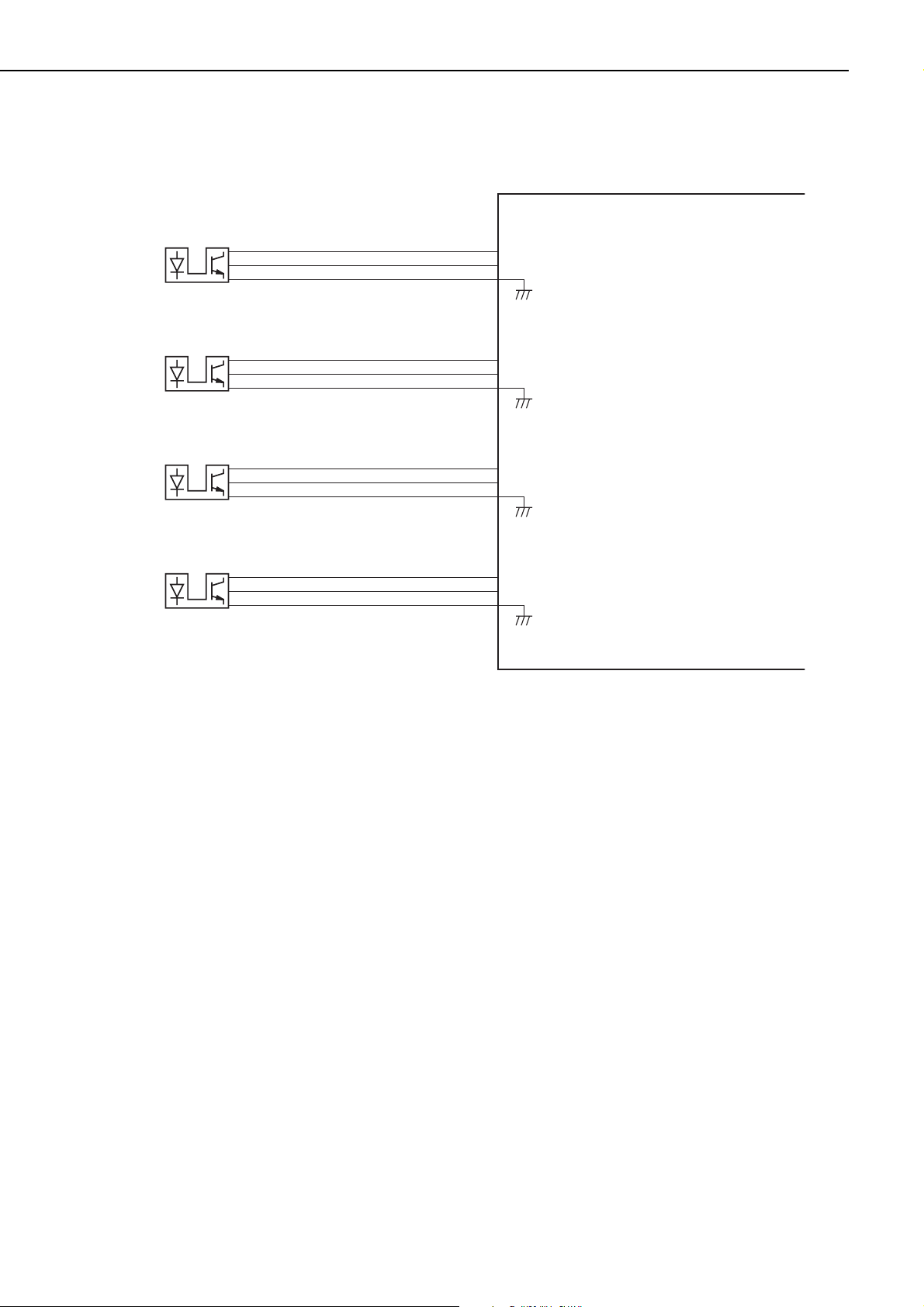

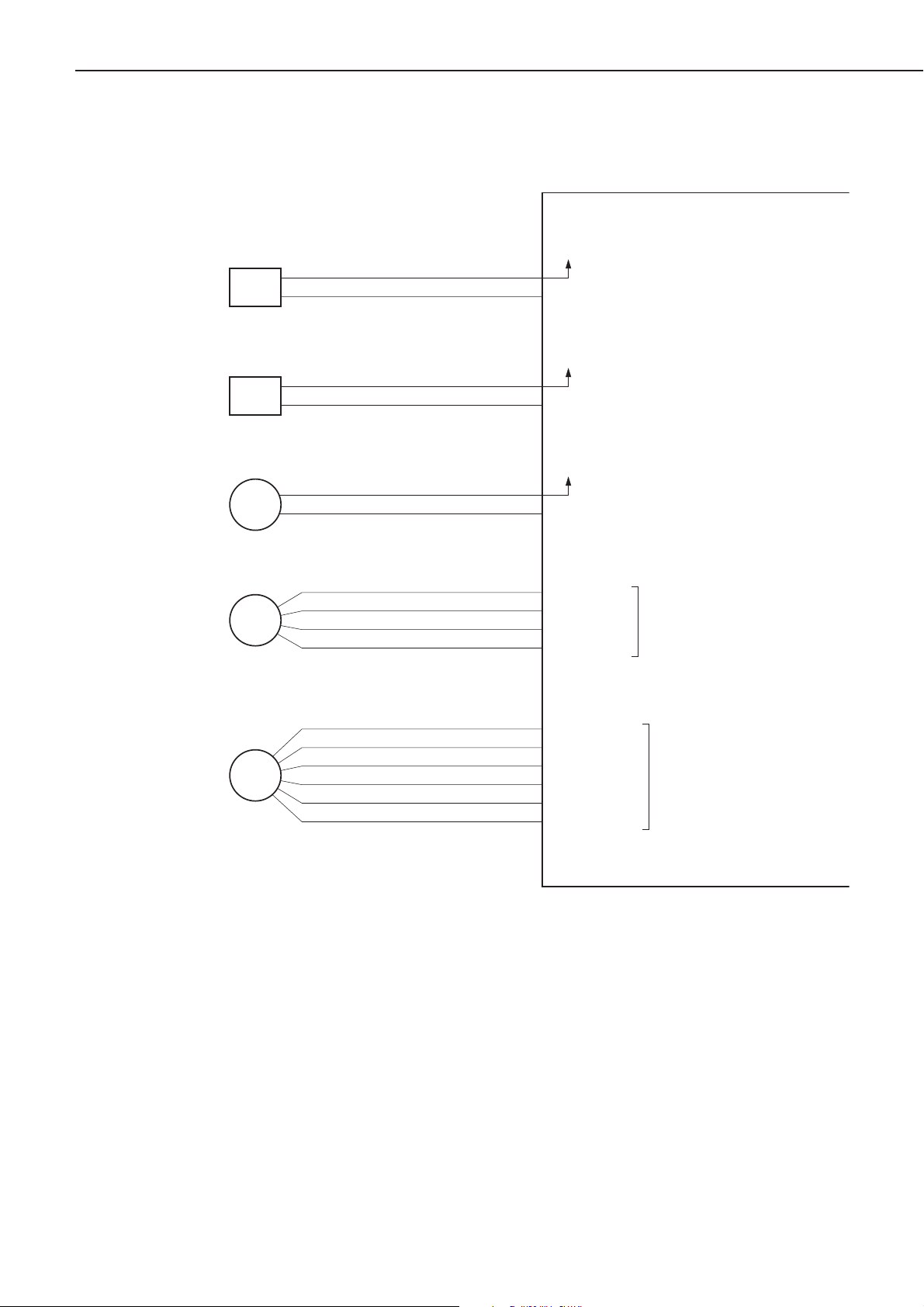

B. Duplexing Driver Input Signals

Figure 2-1-2

2 - 2

CHAPTER 2

PS24

Duplexing

unit paper

sensor

J20-3

-1

-2

J2008-1

-3

-2

+5V

/DUPPS

Duplexing driver PCB

"L" when the sensor detects paper.

Side registration guide

home position

sensor

Reversing

sensor

Duplex feed

roller 1 home

position

sensor

PS25

PS26

PS23

J21-3

-1

-2

J22-3

-1

-2

J23-3

-1

-2

J2006-1

-3

-2

J2007-1

-3

-2

J2007-4

-6

-5

+5V

HREGS

+5V

/SWBKS

+5V

DRPS

"H" when the sensor detects home

position of the side registration

guide.

"L" when the sensor detects paper.

"H" when the sensor detects home

position of the duplex feed roller 1.

C. Duplexing Driver Output Signals

Figure 2-1-3

2 - 3

CHAPTER 2

Reversing

roller release

solenoid

Duplex deflector

solenoid

Duplex feed

clutch

SL7

SL6

CL5

J2009-2

-1

J2002-2

-1

J2003-2

-1

+24VA

/PRRESLD

+24VA

/DUPSLD

+24VA

+24VA

/DUPCLD

Duplexing driver PCB

When "L", pressure is relased from

the reversing roller.

When "L", paper enters the

duplexing unit.

"L" to rotate the duplex feed roller.

Duplexing

unit motor

Side registration

motor

M8

M7

J2004-1

-2

-3

-4

J2005-1

-2

-3

-4

-5

-6

SWBAD

SWBAND

SWBBD

SWBBND

HRGCOMA

HRGCOMB

HRGAD

HRGAND

HRGBD

HRGBND

Duplexing unit motor control

signal

Side registration motor control

signal

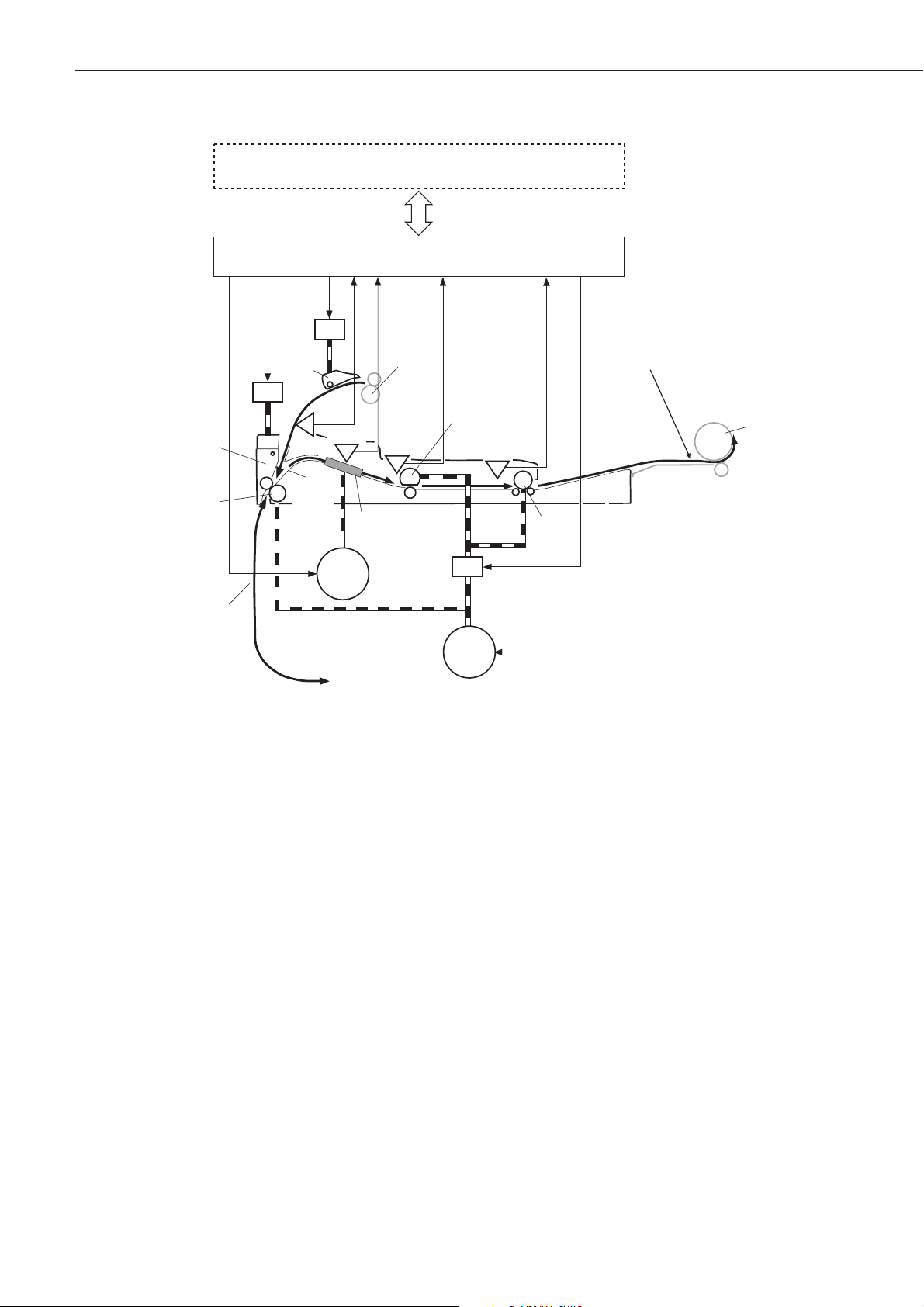

II. PAPER PICK-UP/FEED SYSTEM

A. Operation

1. Outline

The print paper is guided to the reversing unit in the printer through the duplexing unit with

the duplex deflector.

The paper fed to the reversing unit is transported to the duplexing unit by changing the feeding direction with the reversing roller. The side registration of the paper is adjusted by the side

registration guide in the duplexing unit (see page 2-8). The paper is then transported to the

printer with the duplex feed roller.

The reversing roller is rotated by the duplexing unit motor (M8). Duplex feed rollers 1 and 2

are turned by the duplexing unit motor (M8) through the duplex feed clutch.

The duplexing unit motor (M8) is a stepping motor that is run clockwise, counterclockwise,

at normal or high speed by the microcomputer (CPU) on the duplex driver PCB.

The side registration guide is driven by the side registration motor (M7) according to the print

paper size.

2 - 4

CHAPTER 2

Figure 2-2-1

2 - 5

CHAPTER 2

DC controller PCB

Serial line

Duplexing driver

➀➁ ➂➃➄ ➅ ➈➇➆

Reversing

roller pressure

release plate

Reversing

roller

Reversing unit

: SIDE REGISTRATION MOTOR DRIVE signal

➀

: REVERSING ROLLER RELEASE SOLENOID DRIVE signal (/PRRESLD)

➁

: DUPLEX DEFLECTOR SOLENOID DRIVE signal (/DUPSLD)

➂

: REVERSING PAPER DETECTION signal (/SWBKS)

➃

➄

: SIDE REGISTRATION GUIDE HOME POSITION DETECTION signal (HREGS)

➅

: DUPLEX FEED ROLLER 1 HOME POSITION DETECTION signal (DRPS)

➆

: DUPLEXING UNIT PAPER DETECTION signal (/DUPPS)

➇

: DUPLEX FEED CLUTCH DRIVE signal (/DUPCLD)

➈

: DUPLEXING UNIT MOTOR DRIVE signal

Duplex

deflector

SL7

SL6

PS26

Duplex

lower

guide

Fixing

delivery

roller

PS25

PS23

Side registration

guide

M7

Duplex feed

roller 1

PS24

CL5

M8

Second-pass pick-up wait position

Feed roller 2

Duplex

feed

roller 2

M7: Side registration motor

M8: Duplexing unit motor

SL6: Duplex deflector solenoid

SL7: Reversing roller release solenoid

CL5: Duplex feed clutch

PS23: Duplex feed roller 1 home position sensor

PS24: Duplexing unit paper sensor

PS25: Side registration guide home position sensor

PS26: Reversing sensor

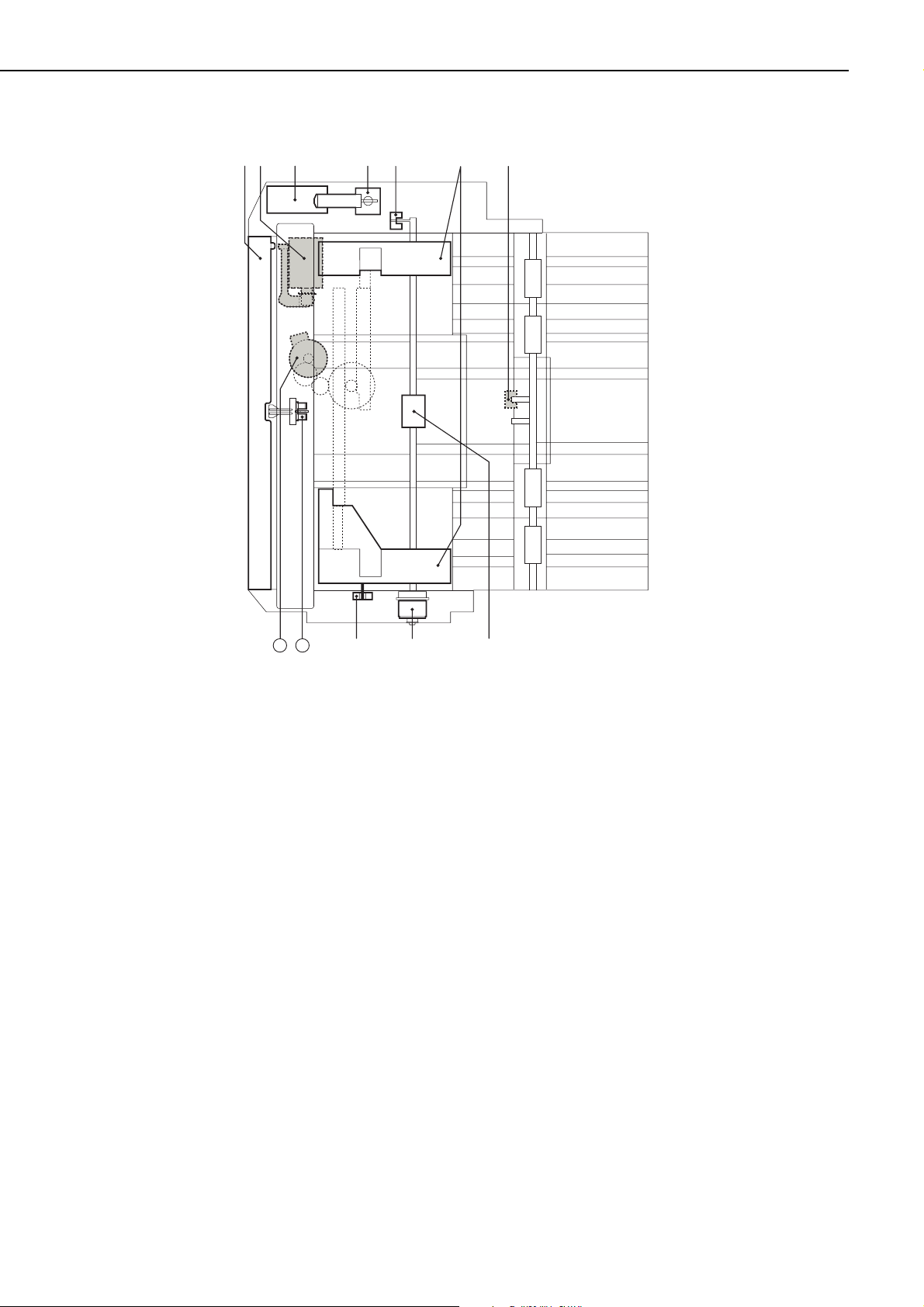

1: Reversing roller pressure release plate 2: Reversing roller release solenoid

3: Duplexing unit motor 4: Duplex deflector solenoid

5: Duplex feed roller 1 home position sensor 6: Side registration guide

7: Duplexing unit paper sensor 8: Duplex feed roller 1

9: Duplex feed clutch 10: Side registration guide home position sensor

11: Reversing sensor 12: Side registration motor

Figure 2-2-2

2 - 6

CHAPTER 2

➀➁ ➂ ➅➄➆➃

12

11

➈➇➉

Loading...

Loading...