CANON LBP 3260 S-82 Service Manual

SERVICE

MANUAL

REVISION 0

COPYRIGHT 1999 CANON INC. CANON SORTER S-82 REV.0 JAN. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

RY8-1393-000

JAN. 1999

SORTER

COPYRIGHT © 1999 CANON INC

Printed in Japan

Imprimé au Japon

Use of this manual should be

strictly supervised to avoid

disclosure of confidential

information.

Prepared by

PERIPHERAL PRODUCTS QUALITY PLANNING DIV.

PERIPHERAL PRODUCTS TECHNICAL DOCUMENTATION DEPT.

CANON INC.

5-1, Hakusan 7-chome, Toride-City, Ibaraki-Pref. 302-8501, Japan

PREFACE

This Service Manual contains basic information required for after-sales service of the SORTER

S-82.

This information is vital to the service technician in maintaining the high print quality and performance of the SORTER S-82.

This manual consists of following chapters:

Chapter 1: Product information

Features, specifications, parts of the sorter, and installation

Chapter 2: Operation and Timing

A description of the operating principles and timing sequences of the electrical and

mechanical systems.

Chapter 3: The Mechanical System

Explanation of mechanical operation, disassembly, reassembly, and adjustment

procedures

Chapter 4: Troubleshooting

Maintenance and servicing, reference values and adjustments, troubleshooting procedures, lubricants, and solvents

Appendix: General circuit diagram, list of signals

Information in this manual is subject to change as the product is improved or redesigned.

All relevant information in such cases will be supplied in Service Information Bulletins.

A thorough understanding of this printer, based on information in this Manual and Service

Information Bulletins, is required for maintaining its performance and for locating and repairing the causes of malfunctions.

DTP system

This manual was produced on an Apple PowerMacintosh 9500/200 personal computer and output by an

Apple LaserWriter 16/600 PS laser beam printer; final pages were printed on AGFA Selectset avantra 25.

All graphics were produced with Macromedia FreeHand (E), and all documents and page layouts were

created with QuarkXPress (E).

The video images were captured with SONY degital video camcorder and Radius Photo DV capture

board, and modified with Adobe Photoshop (J).

CONTENTS

CHAPTER 1 PRODUCT INFORMATION

I. FEATURES ............................. 1-1

II. SPECIFICATIONS.................... 1-2

III. PARTS OF THE SORTER ........ 1-3

A. External Views .................. 1-3

B. Cross Sectional View ......... 1-4

IV. INSTALLATION ....................... 1-5

A. Cautions for Installation ... 1-5

B. Installation Space.............. 1-5

C. Unpacking and Installation

Procedure.......................... 1-6

D. Paper Jams........................ 1-12

CHAPTER 2 OPERATION AND TIMING

CHAPTER 3 THE MECHANICAL SYSTEM

I. BASIC OPERATION................. 2-1

A. Outline.............................. 2-1

B. Outline of Electric Circuit . 2-2

C. Inputs/Outputs of the

Sorter Driver ..................... 2-3

II. FEED/DRIVE SYSTEM............ 2-7

A. Outline.............................. 2-7

B. Face-up Feed/Delivery ...... 2-10

C. Face-down Feed/Delivery .. 2-11

D. Detecting Paper Jam ......... 2-19

III. POWER SUPPLY...................... 2-21

A. Outline.............................. 2-21

B. Protective Function........... 2-21

I. PREFACE ............................... 3-1

II. EXTERNALS ........................... 3-2

A. Location............................ 3-2

B. External Covers................. 3-2

III. MAIN UNITS........................... 3-6

A. Drive Unit ......................... 3-6

B. Reversing Unit .................. 3-7

IV. SENSORS/SWITCHES............. 3-8

A. Location............................ 3-8

B. Entrance Sensor................ 3-9

C. Reversing Sensor............... 3-9

D. Vertical Path Sensor.......... 3-10

E. Deflector Solenoid Sensor . 3-10

F. Full-load Sensor 1 to 7/

Joint Sensor...................... 3-11

G. Paper Sensor 1 to 7 ........... 3-11

H. Face-up Delivery Paper Sensor/

Face-up Full-load Sensor ... 3-11

I. Top Cover Open/Close Detection

Switch and Right Cover

Open/Close Detection Switch

(Cover Open/Close Detection

Switch Unit) ...................... 3-11

V. SOLENOIDS/MOTOR .............. 3-12

A. Location............................ 3-12

B. Reversing Solenoid............ 3-13

C. Face-up Deflector Solenoid 3-13

D. Deflector Solenoid Unit ..... 3-14

E. Feed Motor........................ 3-14

VI. PCBS...................................... 3-15

A. Location............................ 3-15

B. Sorter Driver PCB.............. 3-16

C. Paper Sensor PCB.............. 3-16

D. Full-load Sensor PCB ......... 3-17

E. Face-up Sensor PCB .......... 3-17

F. LED PCB............................ 3-18

G. Power Supply PCB ............. 3-18

CHAPTER 4 TROUBLESHOOTING

I. PREFACE ............................... 4-1

A. Malfunction Diagnosis

Flowchart .......................... 4-1

B. Initial Check ..................... 4-3

II. SERVICE MODE ..................... 4-4

A. Outline.............................. 4-4

B. Service Mode..................... 4-5

III. PAPER JAM............................ 4-9

IV. PAPER TRANSPORT

TROUBLESHOOTING .............. 4-13

V. MALFUNCTION

TROUBLESHOOTING .............. 4-14

VI. MALFUNCTION STATUS

TROUBLESHOOTING .............. 4-15

VII. MEASUREMENT AND

ADJUSTMENT ........................ 4-17

A. Mechanical Adjustment ..... 4-17

B. Electrical Adjustment........ 4-17

C. LEDs, Test Pins, Jumpers

and Switches on PCBs ....... 4-17

VIII.MAINTENANCE AND

SERVICING............................. 4-19

A. Periodic Replacement Parts 4-19

B. Expected Service Life of

Consumable Parts.............. 4-19

C. Periodic Service ................ 4-19

D. Standard Tools .................. 4-19

E. Special Tools ..................... 4-19

F. List of Lubricants and

Cleaners ............................ 4-19

IX. LOCATION OF CONNECTORS . 4-20

APPENDIX

I. GENERAL CIRCUIT DIAGRAM A-1 II. LIST OF SIGNALS................... A-3

A. Input/output signals to

sorter driver PCB............... A-3

CHAPTER 1

PRODUCT INFORMATION

I. FEATURES ............................. 1-1

II. SPECIFICATIONS.................... 1-2

III. PARTS OF THE SORTER ........ 1-3

IV. INSTALLATION ....................... 1-5

I. FEATURES

This sorter is operated in the following 4 modes in response to the command sent from the printer.

1. Mail Box

The 7 face-down bins are respectively allocated to each user.

2. Job Separation

Face-down bins can be changed so that the printed paper can be sorted according to jobs.

3. Stacker

Printed paper is loaded into bins in succession from the lowest one.

4. Sorting

When a document comprising multiple sheets is printed multiple times, the face-down bins are

changed over for each document.

1 - 1

CHAPTER 1

II. SPECIFICATIONS

1) Paper delivery method

Face-up with 1 bin fixed (removable, printer tray is used)

Face-down with 7 bins fixed

2) Loading method

Face-down Mail box, job separation, stacker, sorting

Face-up Simple loading

3) Printing paper types

Face-down Plain paper, colored paper, and thick paper

Face-up Plain paper, colored paper, thick paper, label paper, OHP film, and

envelope

4) Paper size

Face-down A3, B4, A4, Ledger, Legal, and Letter sized plain paper (60g/m2to

105g/m2recommended paper).

Face-up A3, B4, A4, A4-R, Ledger, Legal, Letter, Letter-R, B5-R, A5-R, exec-

utive sized plain paper (60g/m2to 199g/m2recommended paper),

98.4mm (W) x 190.5mm(L) (min.) to 304.8mm(W) x 469.9mm(L)

(max.) sized plain paper (60g/m2to 199g/m2recommended paper),

Monarch, COM-10, DL, B5, C5, Western standard No.4 and

98.4mm x 190.5mm (min.) to 176mm x 250mm (max.) sized

envelopes.

5) Capacity Face-up bin: Approx. 100 sheets of 75g paper can be loaded.

Face-down bin: Approx. 120 sheets of 75g paper can be loaded.

6) Max. power About 28W or below

consumption (at room temperature of 20C, rated power voltage input)

7) Dimensions (Note) 520(W) x 470(D) x 530(H) mm

8) Weight About 14kg

9) Line voltage 100-127V (50/60Hz)

200-240V (50/60Hz)

Note: Base unit width (excluding the tray) is 290mm.

Specifications are subject to change with product modification.

1 - 2

CHAPTER 1

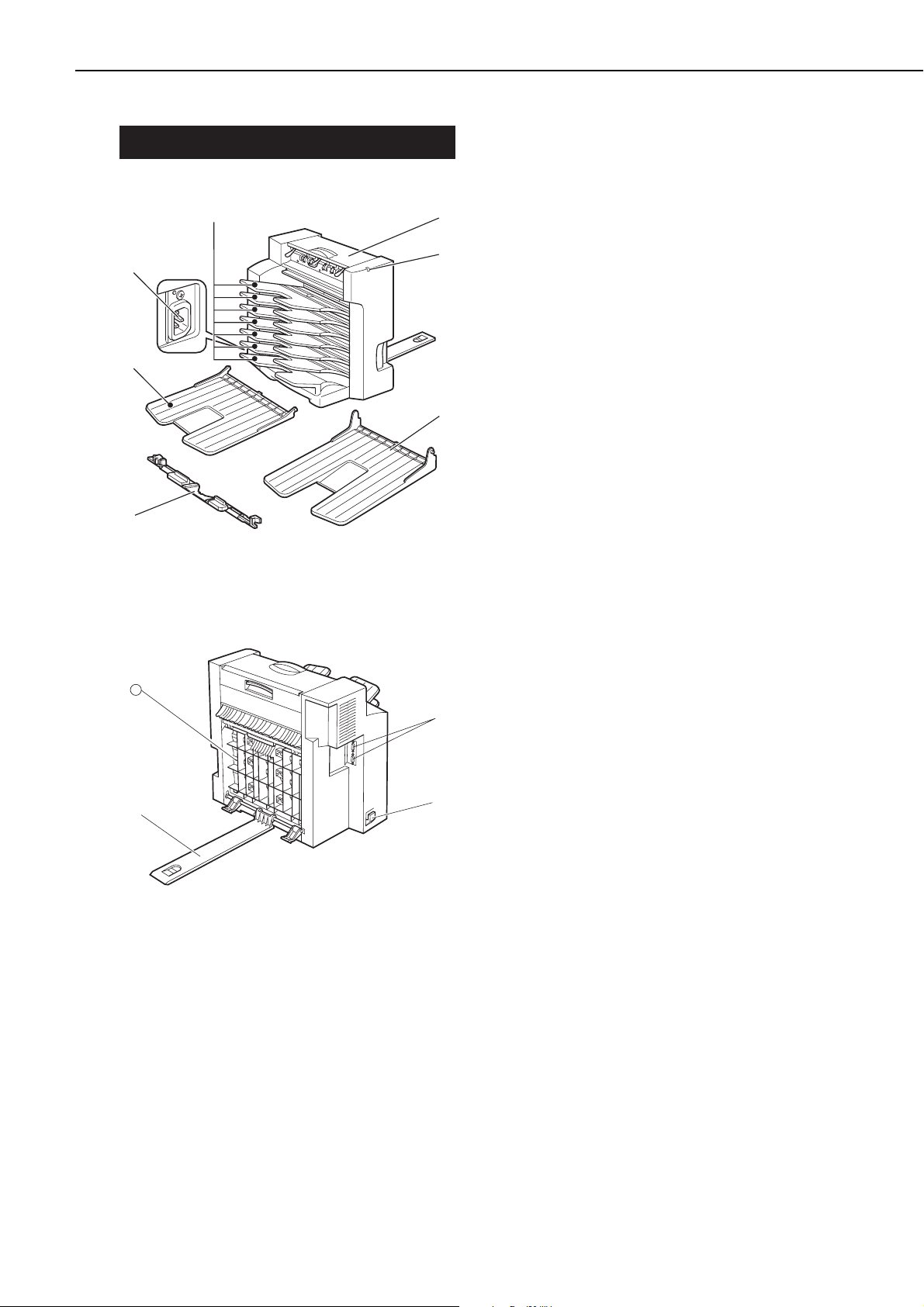

III. PARTS OF THE SORTER

A. External Views

Figure 1-3-1

Figure 1-3-2

1: Top cover unit

2: Status LED

3: Face-up tray (printer FU tray)

4: Sorter adapter plate

5: Reversing tray

6: Power receptacle

7: Face-down bin

8: Interface connector

9: Cable holder

10: Guide rail

11: Right cover

1 - 3

CHAPTER 1

➆

➅

➄

➃

11

➀

➁

➂

➇

➉

➈

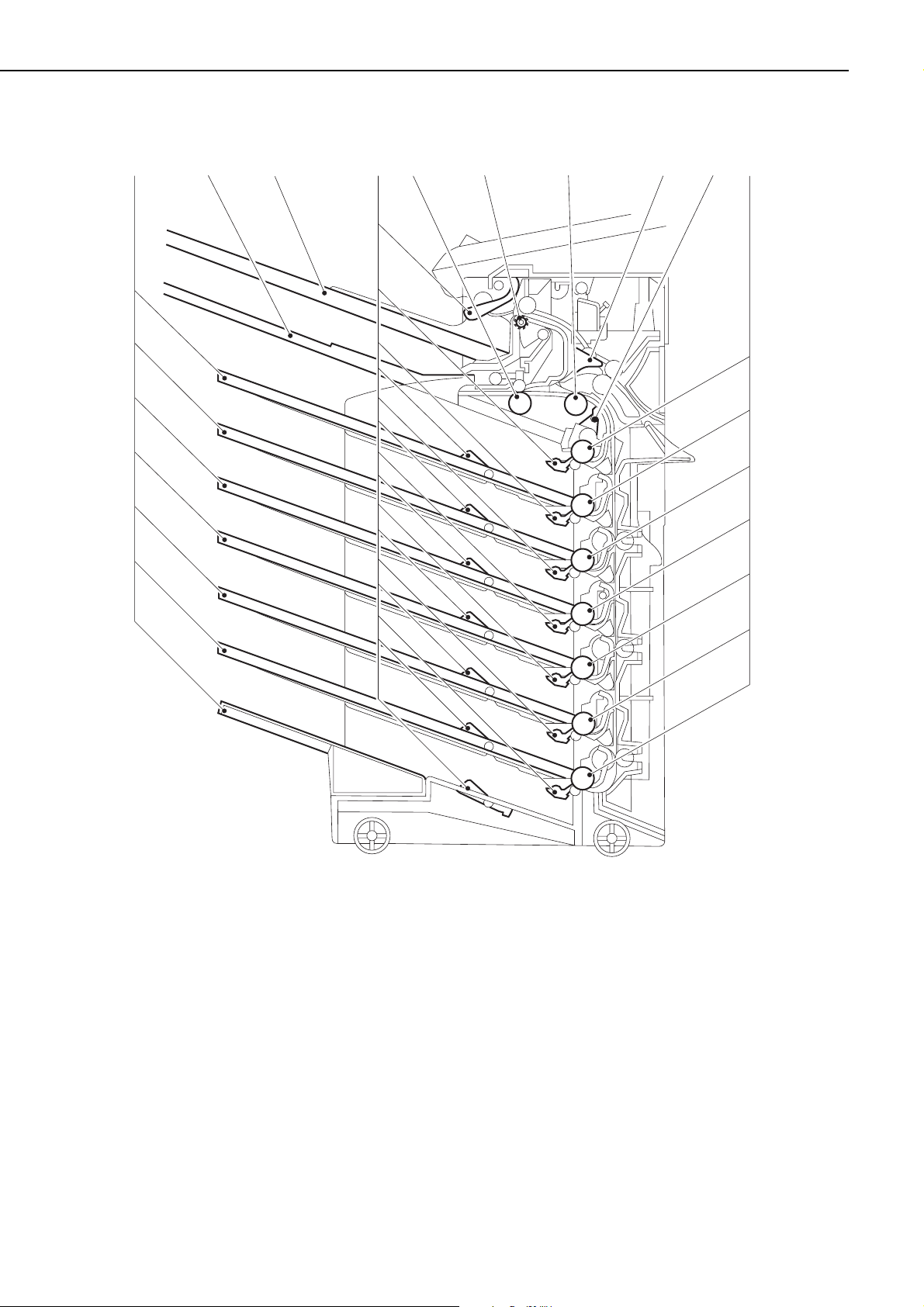

B. Cross Sectional View

Figure 1-3-3

1: Face-down bin

2: Reversing tray

3: Face-up tray (printer FU tray)

4: Sensor lever

5: Reversing roller

6: Face-up delivery roller

7: Feed roller

8: Face-up deflector

9: Face-down delivery roller

1 - 4

CHAPTER 1

➀➁➂ ➃➄➅ ➆ ➇ ➈➃

IV. INSTALLATION

A. Cautions for Installation

Use the power source which meets the following requirements:

AC: Rated voltage -10% to +6%

Power frequency: 50/60Hz ±2Hz

B. Installation Space

Refer to the Service Manual of the printer.

1 - 5

CHAPTER 1

C. Unpacking and Installation Procedure

Condensation will form on surfaces when brought into a warm room from the cold.

Condensation on the surfaces of the sorter can cause feeding failures. Therefore, when moving

the sorter to a warm environment, leave it packed in its box for at least an hour to acclimatize

to room temperature.

1. Unpacking the Sorter

1) Open the sorter packaging.

2) Take out the accessories. Confirm that the power cord, reversing tray, sorter adapter plate

and interface cable are included.

3) Remove the sorter from the box and stand it upright near the printer. Check that none of

the covers were scratched or deformed during shipment.

4) Remove the plastic bag from the sorter.

5) Peel off the packing tape, remove the guide rail packing materials, and then lower the guide

rail gently.

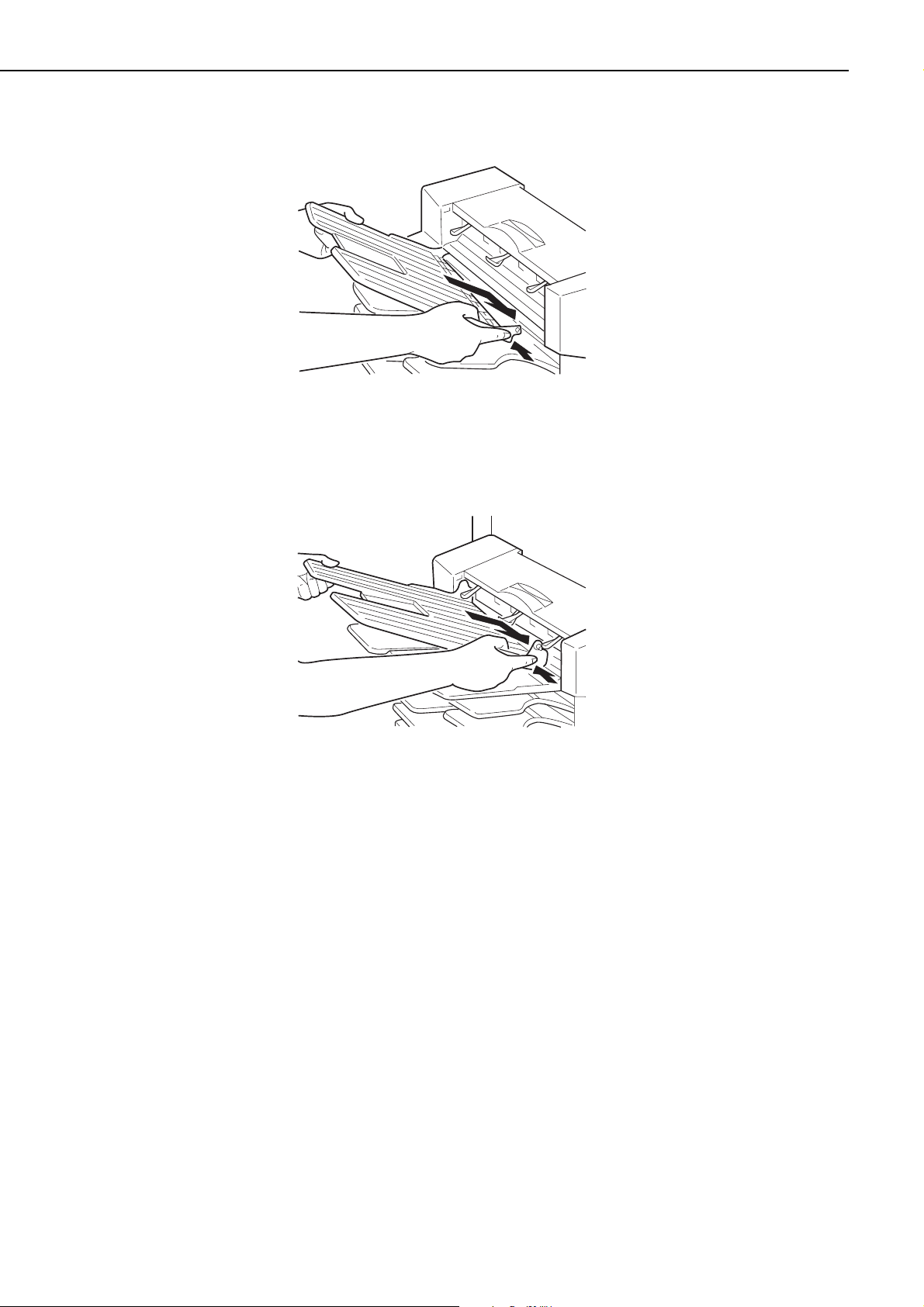

Figure 1-4-1

Note: 1. The guide rail will fall over once the packing tape is peeled off. Be sure to support

the guide rail when removing the packing tape.

2. Save the packing materials in case you have to move or transport the sorter in the

future, as they are needed for the movement or transportation.

1 - 6

CHAPTER 1

Packing materials

Guide rail

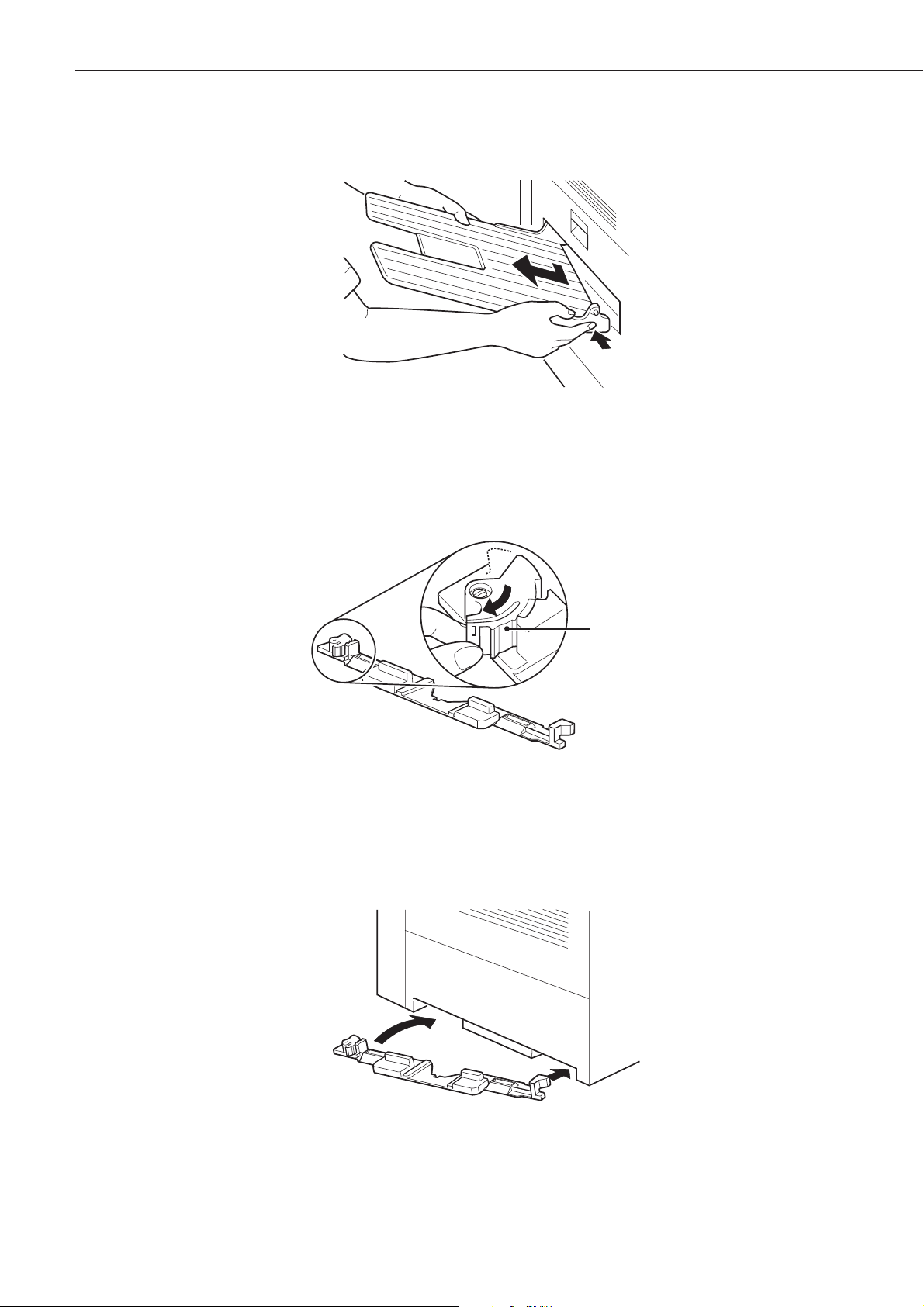

2. Attaching the sorter to Your Printer

1) Remove the face-up tray attached to the side of the printer.

Figure 1-4-2

2) Grasp the lock lever of the dial lock of the sorter adapter plate and squeeze it gently in the

direction of the arrow to release the lock.

Figure 1-4-3

3) Slide the edge 1 and then 2 of the sorter adapter plate into the recess at the bottom of the

printer so the plate is fitted to the printer.

Figure 1-4-4

1 - 7

CHAPTER 1

Lock lever

➁

➀

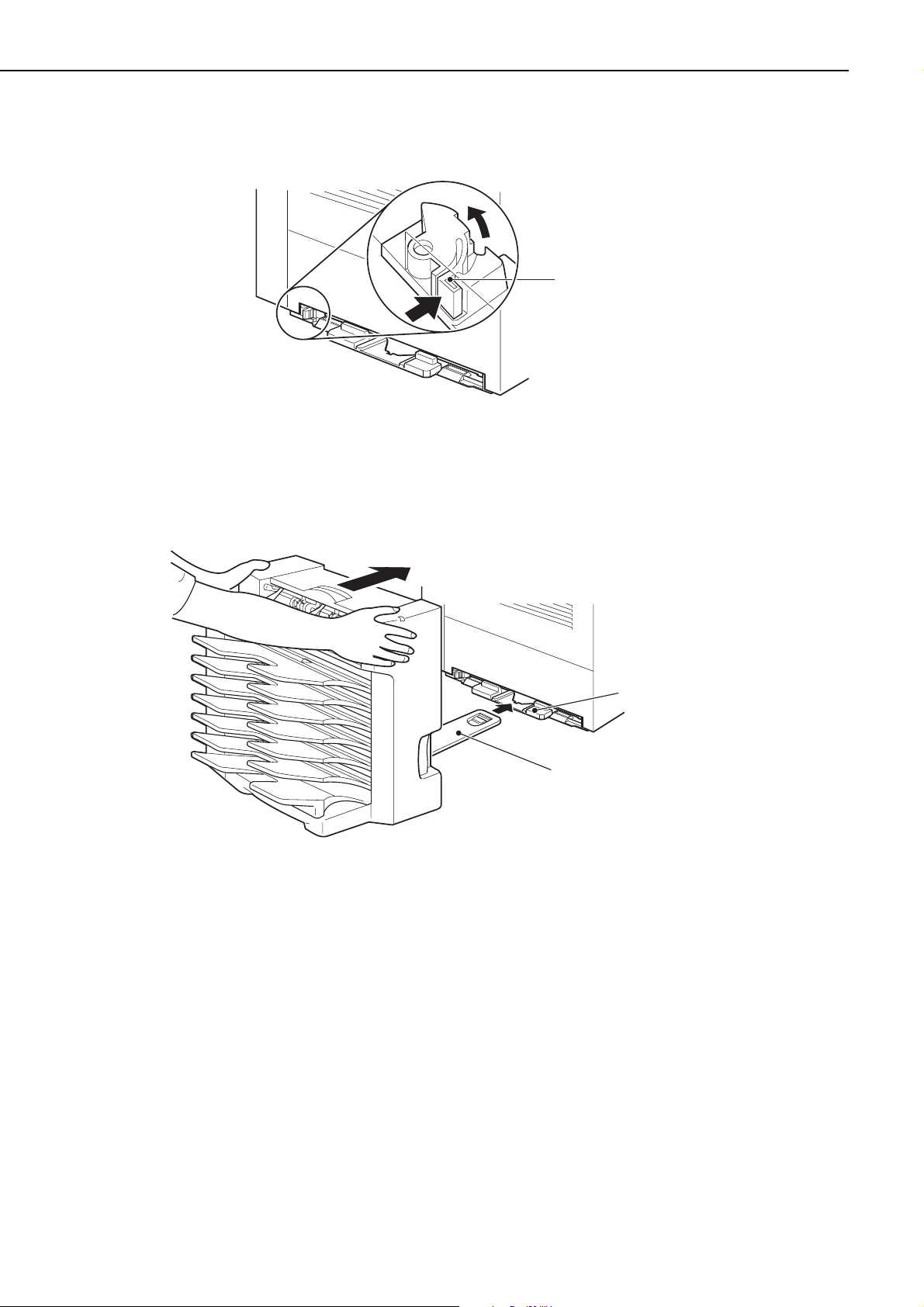

4) Grasp the lock lever of the dial lock and squeeze it gently in the direction of the arrow until

it is locked in position.

Figure 1-4-5

5) Align the guide rail with the guide rail slot in the sorter adapter plate. Gently push the sorter

towards the printer until it clicked into place.

Figure 1-4-6

1 - 8

CHAPTER 1

Lock lever

Guide rail slot

Guide rail

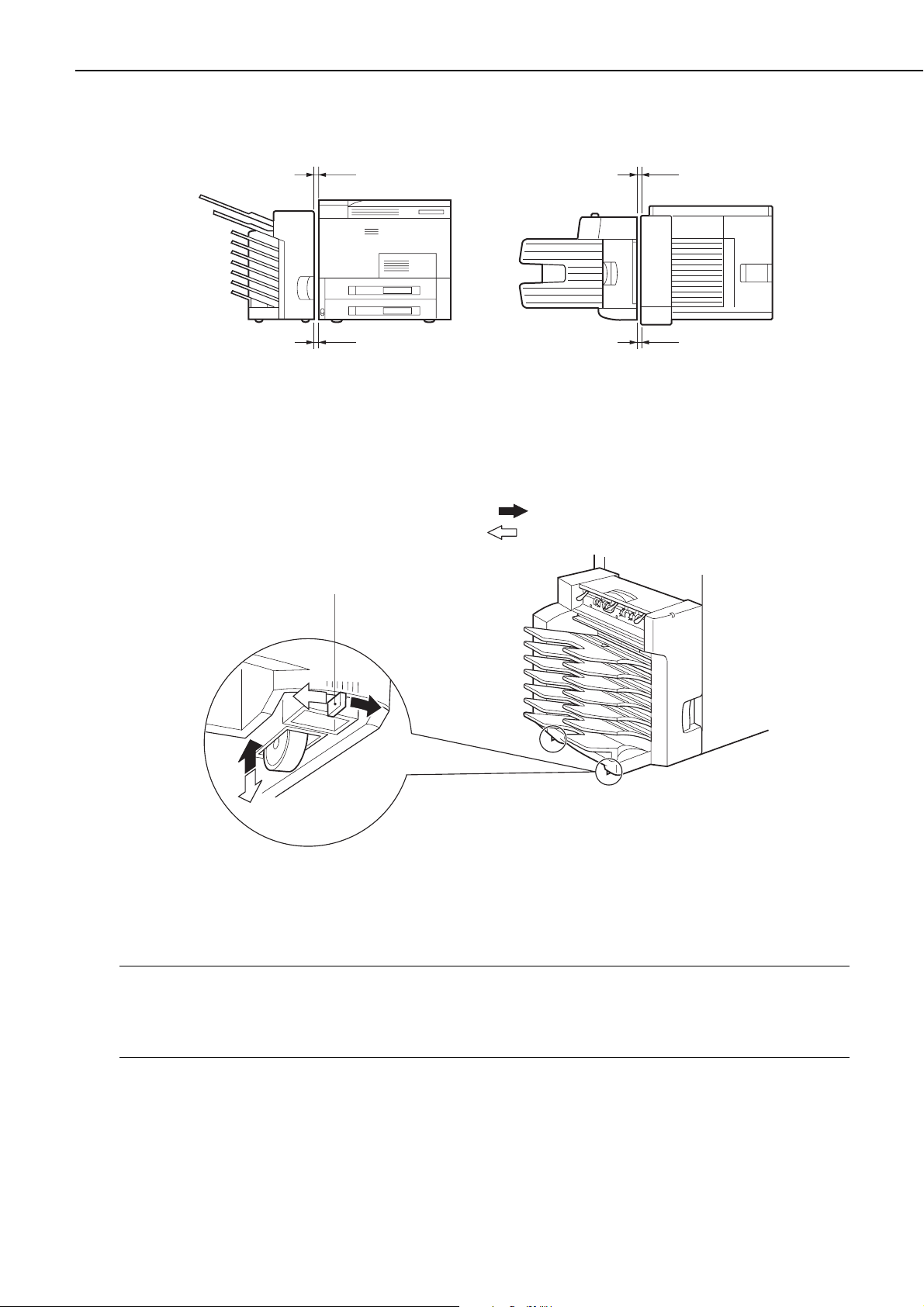

6) Check whether the sorter attached to the printer is parallel to the printer.

Figure 1-4-7

If not, adjust with the height adjusting lever under the sorter.

Pushing the height adjusting lever rightward ( direction) raises the tray side of the sorter.

Pushing the height adjusting lever leftward ( direction) lowers the tray side of the sorter.

Figure 1-4-8

Note: 1. Lift the sorter slightly to make space between the casters and the floor when moving

the height adjusting lever.

2. If the printer and the sorter do not become parallel to each other by the above adjust-

ment, move the printer and the sorter to a level place.

1 - 9

CHAPTER 1

x

1

y

1

x

x

2

1=x2

x

x

1

1=y1

Height adjusting lever

7) Insert the left and then the right side of the reversing tray into the slot on the sorter.

Figure 1-4-9

8) Insert the left and then the right side of the printer face-up tray into the slot on the sorter.

Figure 1-4-10

1 - 10

CHAPTER 1

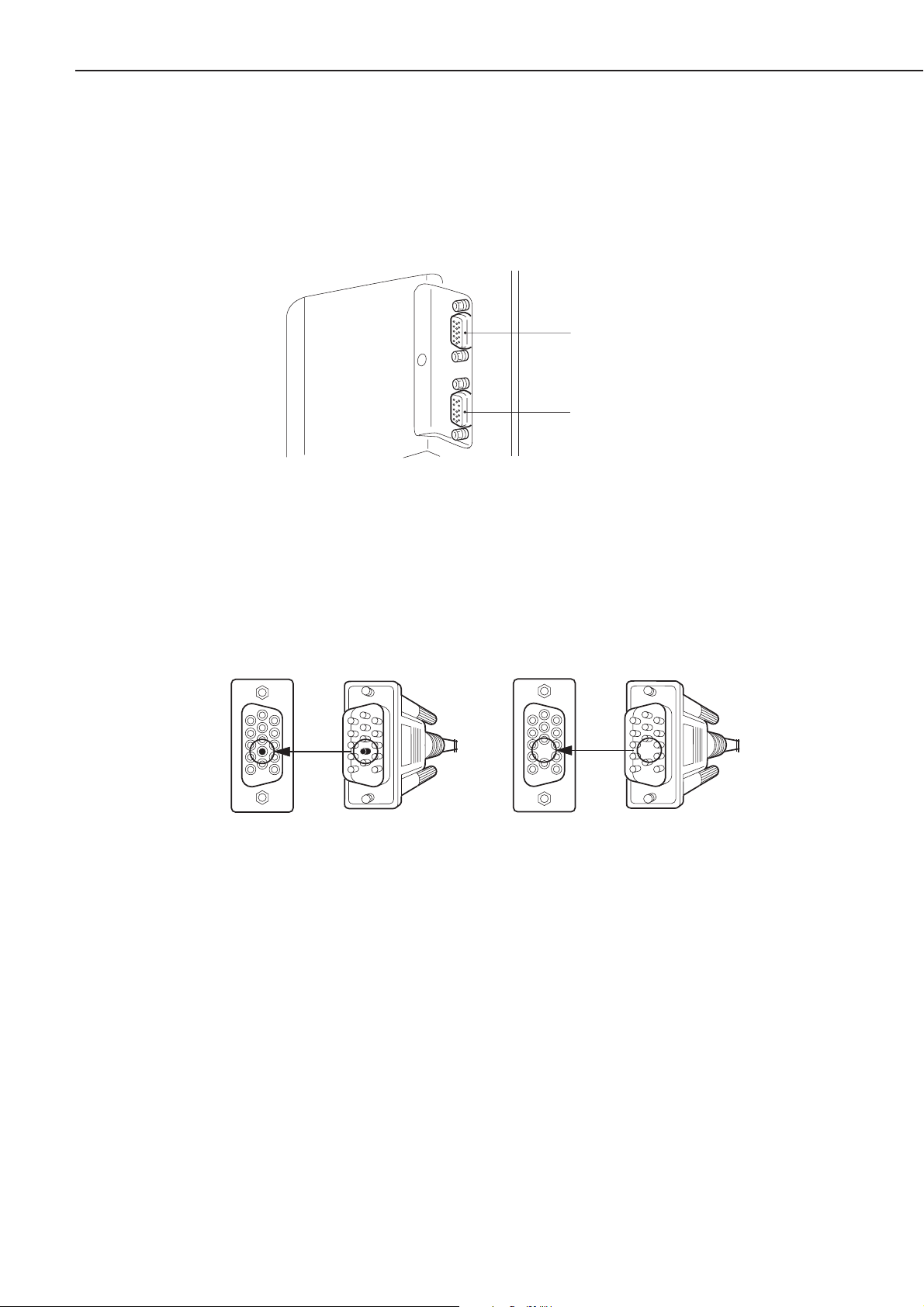

3. Connecting the Interface Cables

Always turn the printer and sorter OFF and remove the plug from the AC outlet before connecting or disconnecting the interface cable.

1) The sorter has two interface connectors. Use the upper connector (IN) to connect the sorter

to the printer, and the lower connector (OUT) to connect the sorter to other optional devices.

Figure 1-4-11

2) The connectors at each end of the interface cable that connects the sorter to the printer are

different from each other as illustrated below. The connector on the sorter side has 15 pins

and the one on the printer side has 14 pins.

Figure 1-4-12

3) Plug the connector with 15 pins on the interface cable into the upper connector (IN) on the

sorter and secure with the fixing screws.

4) Connect the connector with 14 pins on the other end of the interface cable to the option controller in the printer.

1 - 11

CHAPTER 1

Connector (IN)

Connector (OUT)

15 pins 14 pins

D. Paper Jams

When paper jams occur, follow the procedures below to remove the paper jammed inside the

unit.

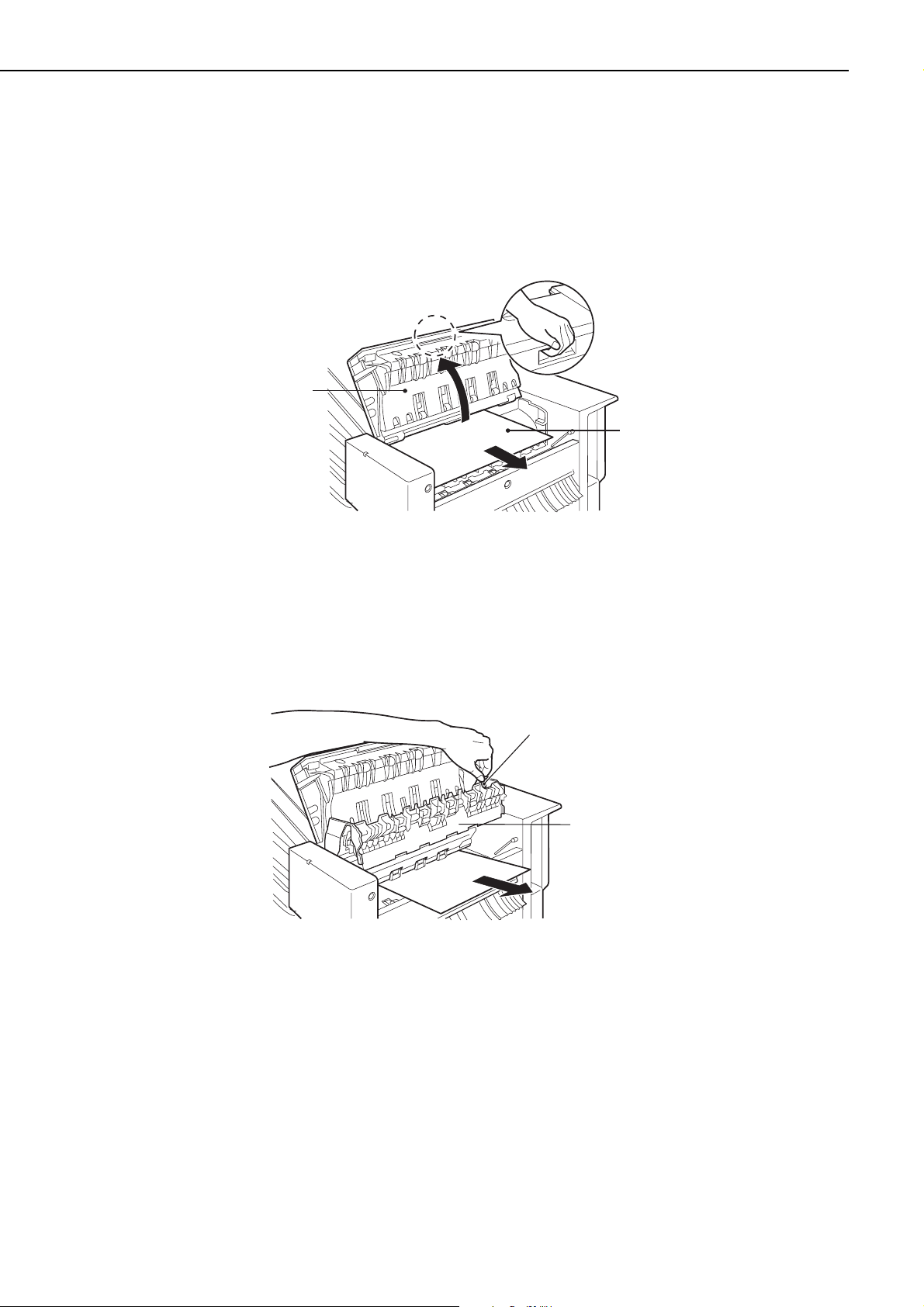

1. Paper James in the Face-up Area

1) Separate the sorter from the printer.

2) Open the top cover unit at the top of the sorter, then pull out the jammed paper.

Figure 1-4-13

2. Paper Jams in the Reversing Tray Guide Area

1) Open the top cover unit.

2) Grasp the holder at the end of the guide and lift the guide as shown in the figure below, then

pull out the jammed paper.

Figure 1-4-14

1 - 12

CHAPTER 1

Top cover unit

Paper

Holder

Guide

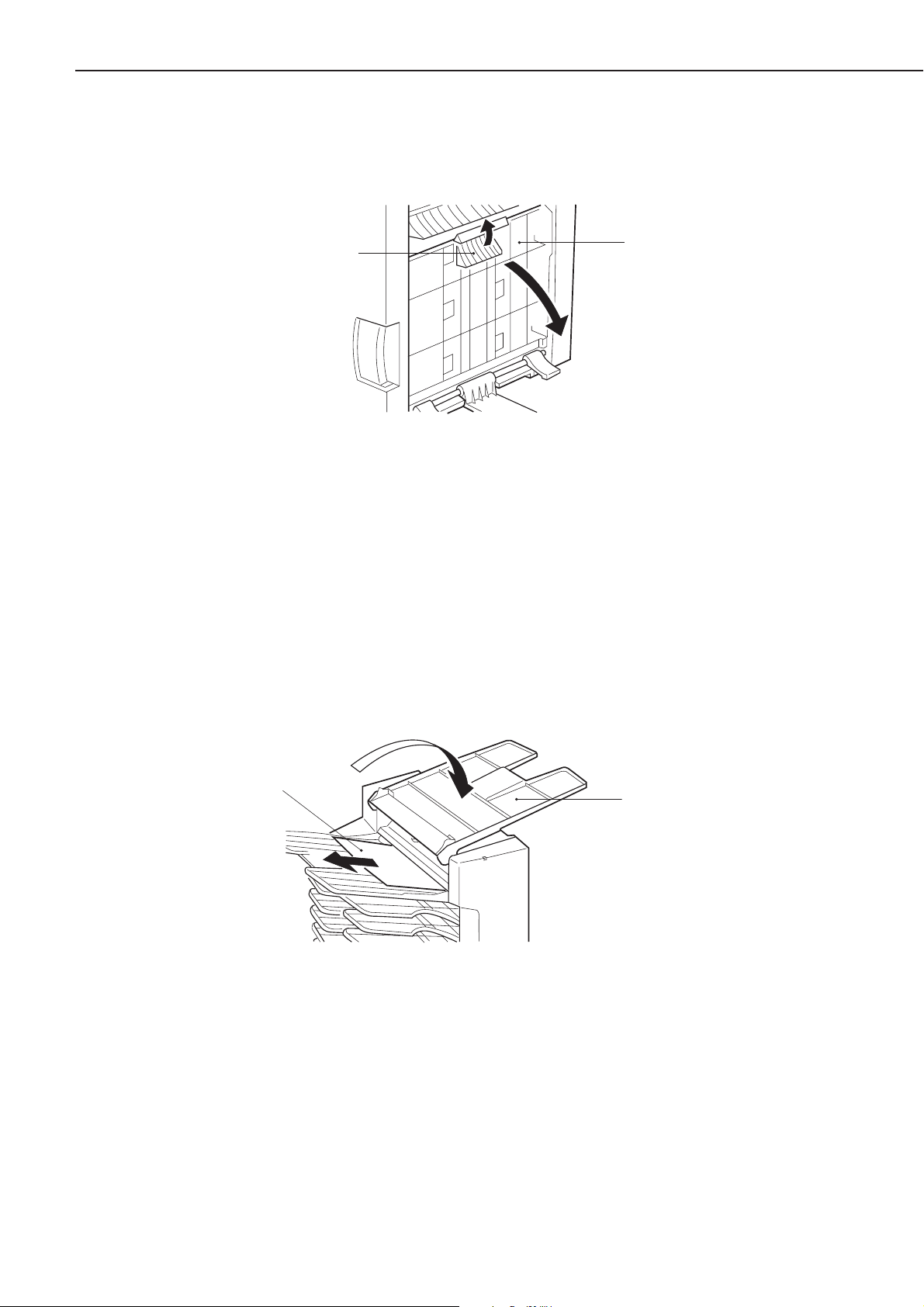

3. Paper Jams in the Transfer Area

1) If the paper is jammed at the right cover of the sorter, lift up the release lever and open the

right cover in the direction of the arrow.

Figure 1-4-15

2) Gently release the edge of paper by pulling the paper downwards, then remove the jammed

paper from the transfer area.

4. Paper Jams in the Face-down Bin Area

1) If the paper is jammed in one of the face-down bins, grasp the paper and gently pull it out

of the sorter.

5. Paper Jams in the Reversing Tray Area

1) If the paper is jammed in the reversing tray of the sorter, fold the face-up tray backwards,

then gently pull out the jammed paper.

Figure 1-4-16

1 - 13

CHAPTER 1

Release lever

Right cover

Paper

Face-up tray

CHAPTER 2

OPERATION AND TIMING

1. This chapter describes the printer functions, the relationships between mechanisms and circuits, and the timing of operations. Mechanical linkages are indicated by black and white

lines ( ), the flow of control signals by solid arrows ( ), and the flow of groups

of signals by outline arrows ( ).

2. An active-high signal is indicated by "H" or by a signal name without a slash in front of it,

such as "PSNS." An active-low signal is indicated by "L" or by a signal name with a slash in

front of, such as "/SCNON."

A signal that is "H" or has a name without a slash is active at the supply voltage level

(indicating that the signal is being output), and inactive at ground level (indicating that the

signal is not being output).

A signal that is "L" or has a slash in front of its name is active at ground level, and inac-

tive at the supply voltage level.

There is a microcomputer in this printer. But as the internal operation of the microcomputer cannot be checked, an explanation of the operation of the microcomputer has been left

out.

As it is assumed that no repair will be made to customer circuit boards, the explanation

of board circuits is limited to an outline using block diagrams. So there are two types of circuit explanations; (1) everything from the sensor to the input sections of the major circuit

boards, (2) everything from the output sections of the major circuit boards to the loads.

These are explained with block diagrams according to the function.

I. BASIC OPERATION................. 2-1

II. FEED/DRIVE SYSTEM............ 2-7

III. POWER SUPPLY...................... 2-21

I. BASIC OPERATION

A. Outline

The sorter delivers the paper fed from the printer face-down or face-up. In case of face-down

delivery, the job separation, sorting, etc. can be operated.

These operations are controlled by the various commands sent from the printer through the

option controller.

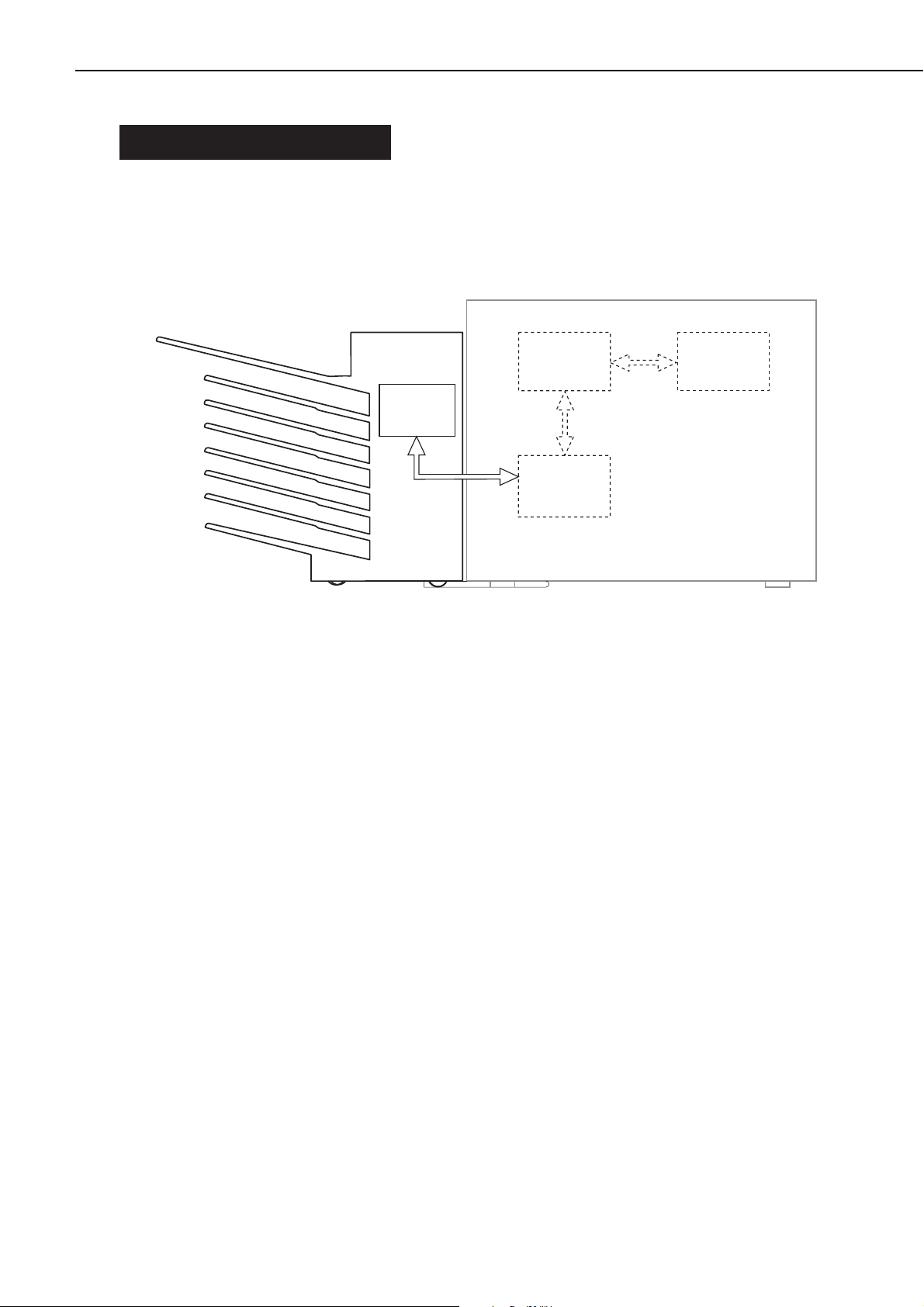

Figure 2-1-1

2 - 1

CHAPTER 2

Sorter

Sorter driver

PCB

Video controller

PCB

Option

controller

PCB

DC controller

PCB

Printer

B. Outline of Electric Circuit

The operation sequence of the sorter is controlled by the sorter driver PCB. The sorter driver

PCB employs an 8-bit microcomputer (CPU) and performs the sequence control and serial communication with the option controller PCB.

The sorter driver PCB drives the solenoids, motor, etc. in response to various commands sent

from the option controller. The sorter driver sends information on sensors and switches to the

option controller.

The ICs mounted on the sorter driver are as follows.

• IC6 (CPU)

Sequence control

Backup of initial data values

• IC7 (motor driver)

Motor drive control

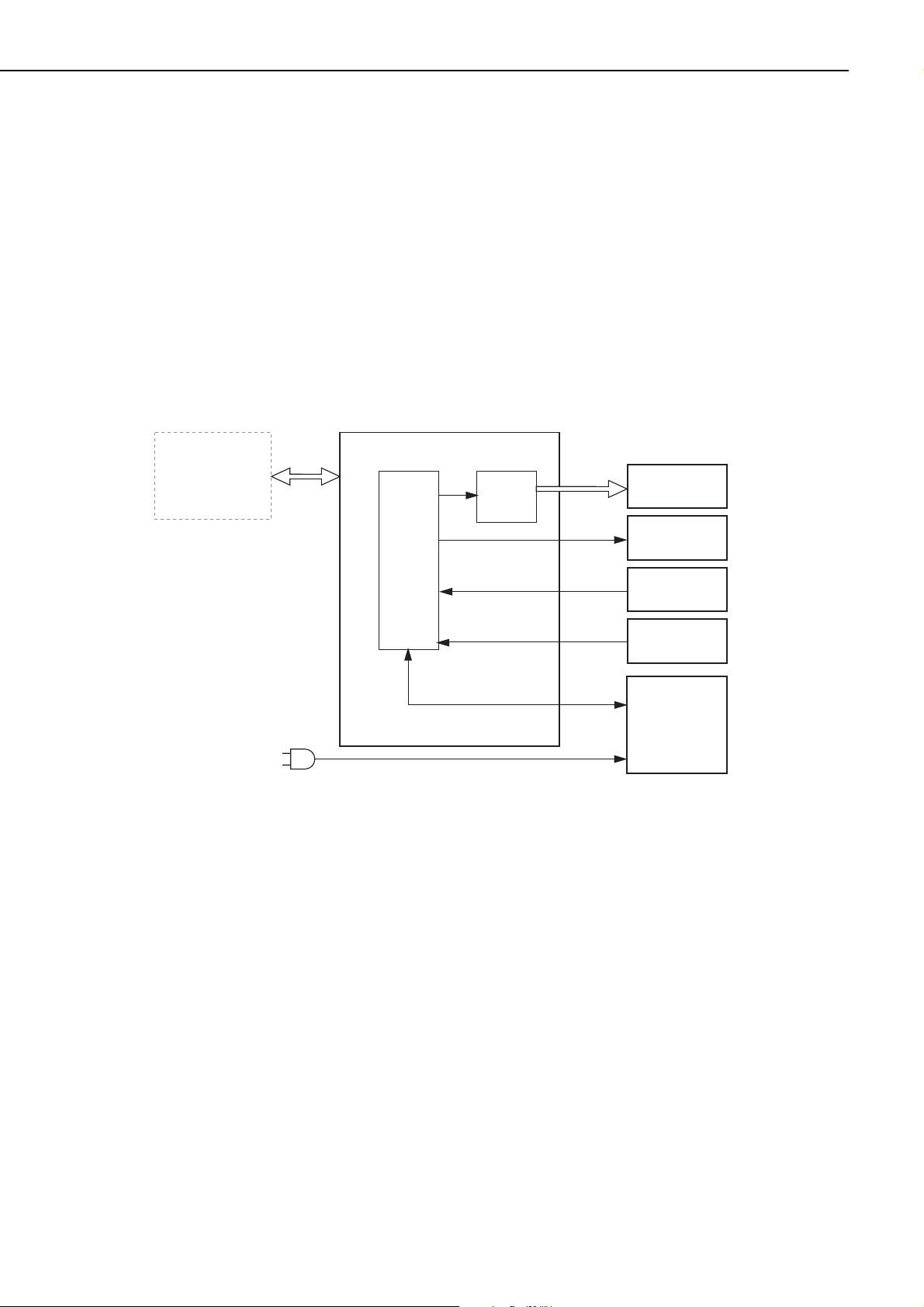

Flow of signals between the sorter and option controller is shown in the figure below.

Figure 2-1-2

2 - 2

CHAPTER 2

Sorter driver PCB

Option controller

PCB

IC6

CPU

IC7

Motor

driver

Motor

Solenoids

Switches

Sensors

Power supply

unit

C. Inputs/Outputs of the Sorter Driver

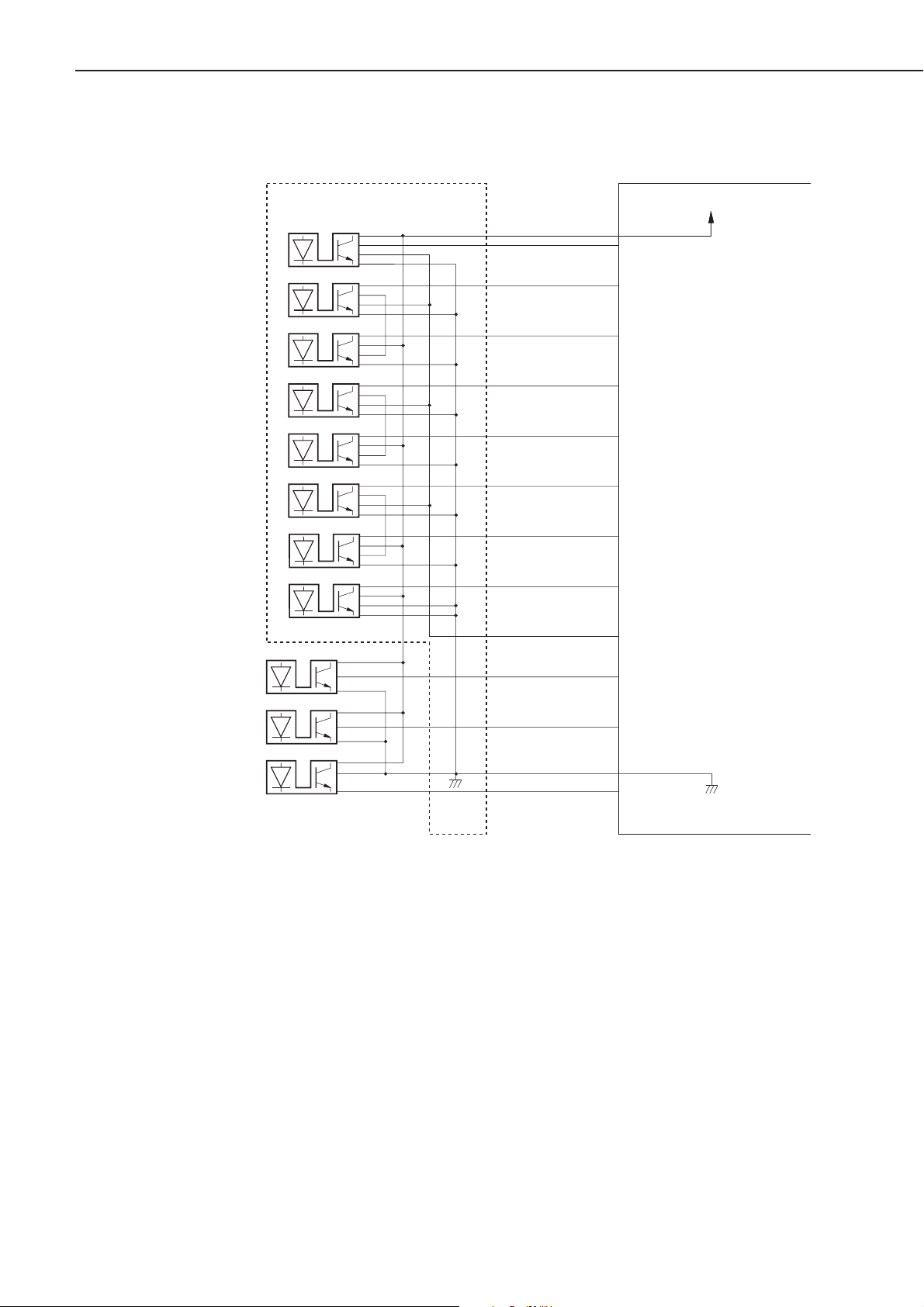

Figure 2-1-3

2 - 3

CHAPTER 2

PI 1

Full-load sensor 1

PI 2

Full-load sensor 2

PI 3

Full-load sensor 3

PI 4

Full-load sensor 4

PI 5

Full-load sensor 5

PI 6

Full-load sensor 6

PI 7

Full-load sensor 7

PI 8

Joint sensor

J301-11

J301-8

J301-7

J301-6

J301-5

J301-4

J301-3

J301-2

J301-1

J8-11

J8-8

J8-7

J8-6

J8-5

J8-4

J8-3

J8-2

J8-1

Sorter driver PCBFull-load sensor PCB

1BIN-FUL

2BIN-FUL

3BIN-FUL

4BIN-FUL

5BIN-FUL

6BIN-FUL

7BIN-FUL

J-S

+5V

"H" when sensor

detects paper.

"H" when sensor

detects paper.

"H" when sensor

detects paper.

"H" when sensor

detects paper.

"H" when sensor

detects paper.

"H" when sensor

detects paper.

"H" when sensor

detects paper.

"H" when connected

with printer.

Reversing sensor

Vertical path

sensor

Deflector solenoid

sensor

PI 10

PI 11

PI 4

J302-1

J303-1

J301-3

J301-10

-2

-3

-2

-3

-2

-1

J301-14

J301-13

J301- 9

J301-12

J8-10

J8-14

J8-13

J8-9

J8-12

SEL-FULL

TURN-S

PAS1-S

F-SOL-S

When "H", turn OFF

PI1 to PI8.

"H" when sensor

detects paper.

"H" when sensor

detects paper.

"H" when face-down

deflector is open.

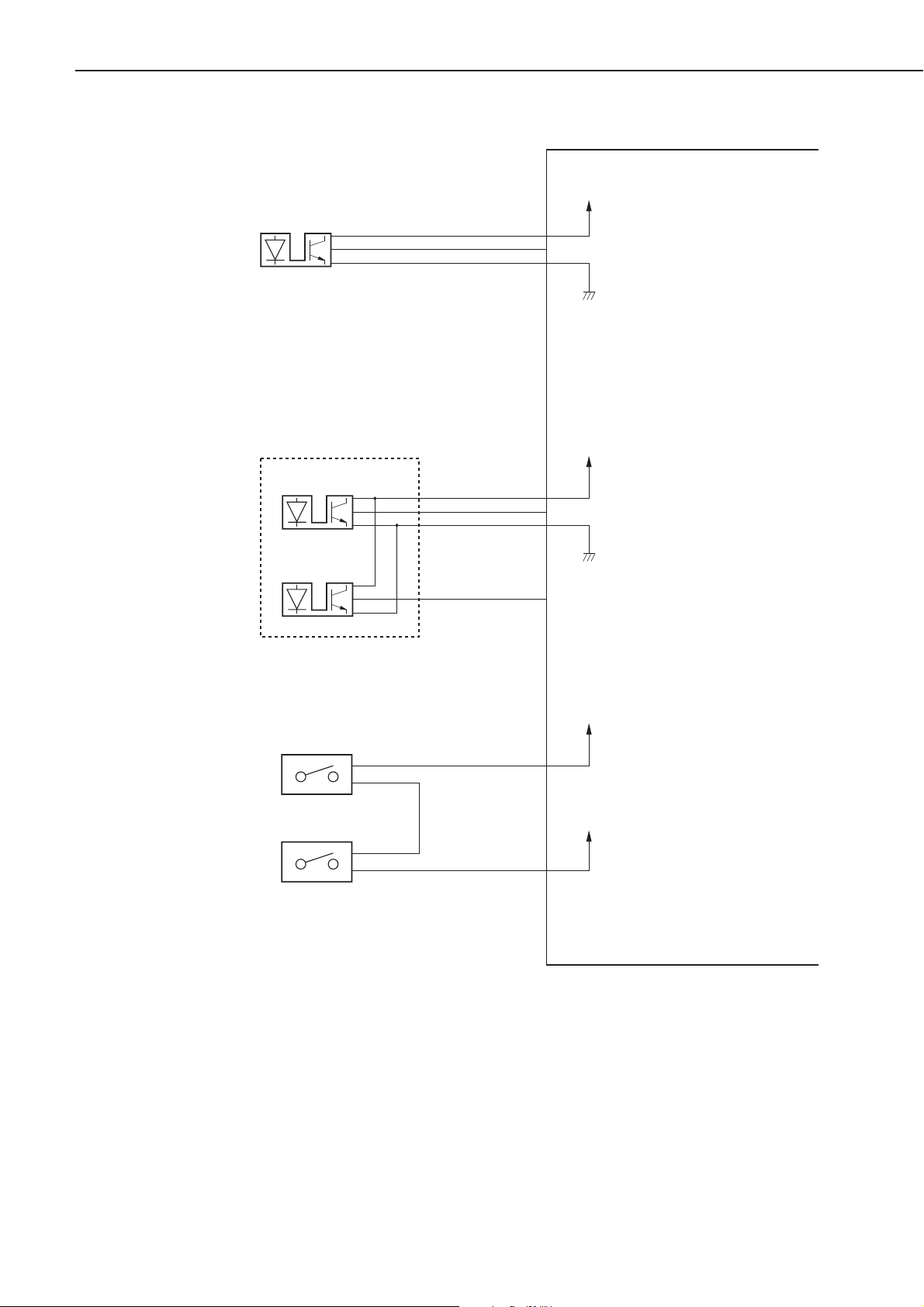

Figure 2-1-4

2 - 4

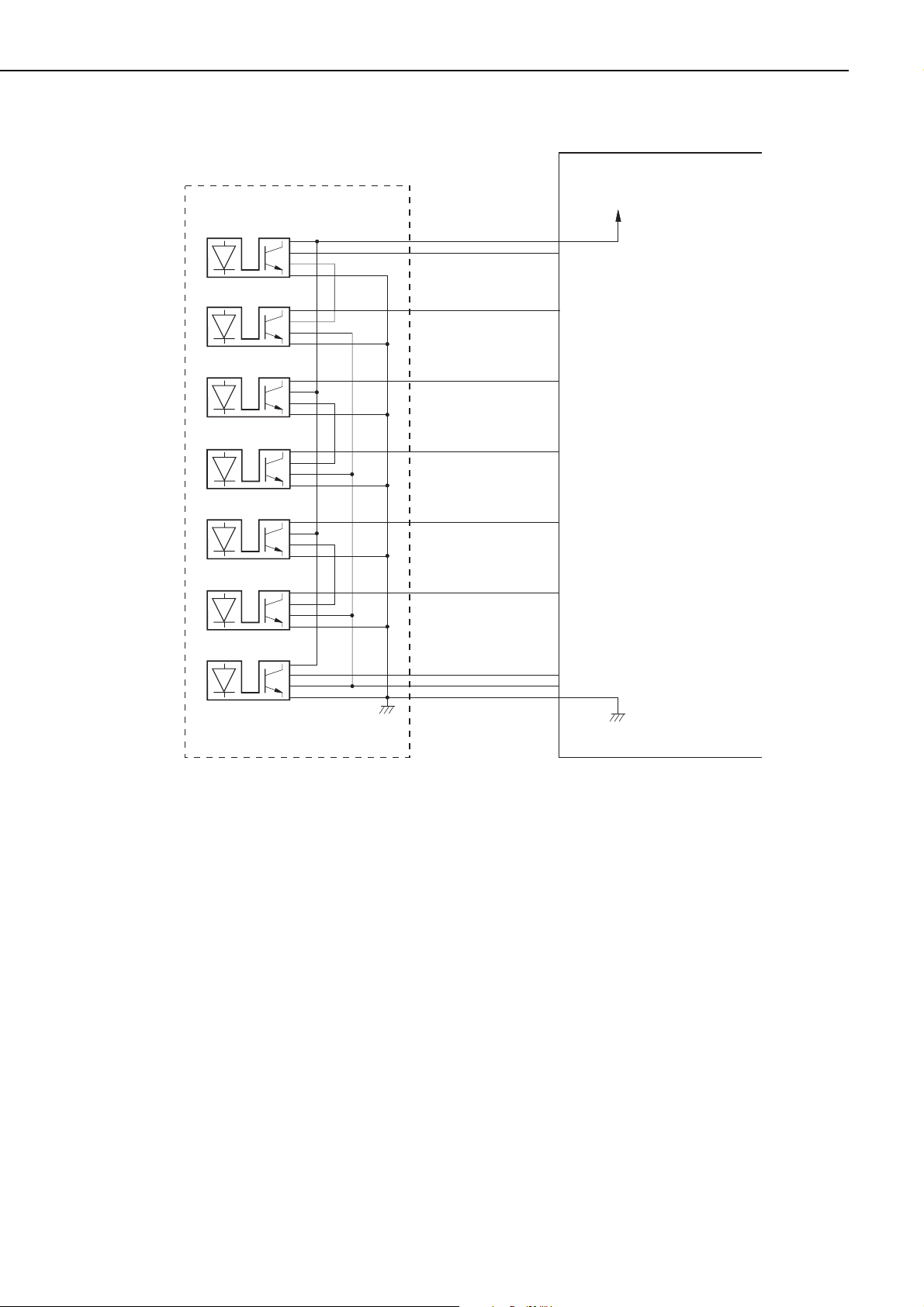

CHAPTER 2

Sorter driver PCB

Paper sensor 1

Paper sensor 2

Paper sensor 3

Paper sensor 4

Paper sensor 5

Paper sensor 6

Paper sensor PCB

PI 1

PI 2

PI 3

PI 4

PI 5

PI 6

J305-1

J305-9

J305-8 J7-8

J305-7 J7-7

J305-6 J7-6

J305-5 J7-5

J305-4 J7-4

J7-1

J7-9

+5V

1BIN-EMP

2BIN-EMP

3BIN-EMP

4BIN-EMP

5BIN-EMP

6BIN-EMP

"H" when sensor

detects paper.

"H" when sensor

detects paper.

"H" when sensor

detects paper.

"H" when sensor

detects paper.

"H" when sensor

detects paper.

"H" when sensor

detects paper.

Paper sensor 7

PI 7

J305-3

J305-2

J305-10

J7-3

J7-2

J7-10

7BIN-EMP

SEL-EMP

"H" when sensor

detects paper.

When "H", turn OFF

PI1 to PI7.

Figure 2-1-5

2 - 5

CHAPTER 2

+5V

Sorter driver PCB

Entrance sensor

Face-up delivery

paper sensor

Face-up paper

full sensor

PI9

J401-3

J401-1

J401-2

Face-up sensor PCB

PI1

PI2

J9-1

J9-3

J9-2

J306-3

J306-2

J306-4

J306-1 J9-7

J9-5

J9-6

J9-4

IN-S

+5V

FU-S

FU-FULL-S

"H" when sensor detects paper.

"H" when sensor detects paper.

"H" when sensor detects paper.

Top cover

open/close

detection switch

Right cover

open/close

detection switch

MS1

MS2

J601-1 J11-1

J602-2 J11-2

+24V

+24V

(Supplied from DC power source.)

Figure 2-1-6

2 - 6

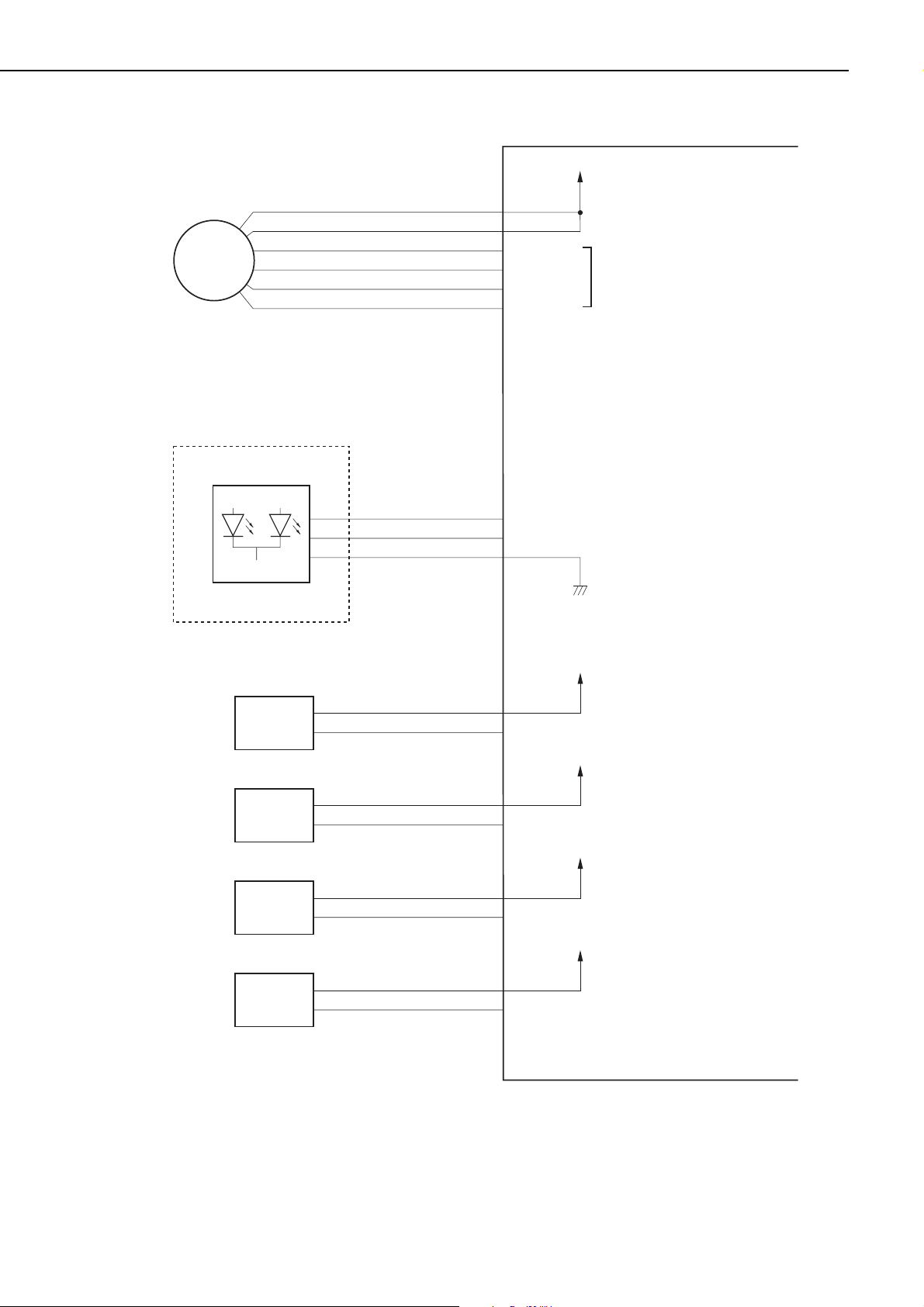

CHAPTER 2

Sorter driver PCB

+24V

Feed motor

Status LED

M1

J501-6

J501-5

J501-4

J501-3

J501-2

J501-1

LED PCB

J307-3

J307-2

J307-1

J1-1

J1-2

J1-3

J1-4

J1-5

J1-6

J9-8

J9-9

J9-10

HMOTA

/HMOTA

HMOT B

/HMOT B

LED GR

LED OR

Feed motor rotation control signals

"H" when sorter and printer

communicates normally.

"H" in failure or other troubles.

Reversing solenoid

Face-up deflector

solenoid

Face-down deflector

solenoid 1

Face-down deflector

solenoid 2

SL1

SL2

SL3

SL4

J602-1

J602-2

J603-2

J603-1

J604-4

J604-3

J604-2

J604-1

J3-1

J3-2

J2-1

J2-2

J4-1

J4-2

J4-3

J4-4

T SOL

G SOL

F SOL1

F SOL2

+24V

"L" to rotate cam.

+24V

"H" to switch face-up deflector

to face-up paper delivery.

+24V

"H" to shift face-down deflector

1, 3, and 5.

+24V

"H" to shift face-down deflector

2, 4, and 6.

Loading...

Loading...