Canon LBP-2460 User Manual

WXTECH

Technical Instructions Printers OEM Info Tools 1

CORPORATE

LOS ANGELES, USA

U

S 1 800 394.9900

Int’l +1 818 837.8100

FAX 1 800 394.9910

Int’l +1 818 838.7047

ATLANTA, USA

U

S 1 877 676.4223

t’l +1 770 516.9488

In

FAX 1 877 337.7976

Int’l +1 770 516.7794

DALLAS, USA

US 1 877 499.4989

Int’l +1 972 840.4989

FAX 1 877 774.1750

Int’l +1 972 840.1750

MIAMI, USA

US 1 800 595.429

Int’l +1 305 594.3396

FAX 1 800 522.8640

Int’l +1 305 594.3309

NEW YORK, USA

US 1 800 431.7884

Int’l +1 631 345.0121

FAX 1 800 431.8812

Int’l +1 631345.0690

SANFORD,USA

US 1 800 786.9049

Int’l +1 919 775.4584

FAX 1 800 786.9049

Int’l +1 919 775.4584

TORONTO, CAN

CAN 1 877 848.0818

Int’l +1 905 712.9501

FAX 1 877 772.6773

Int’l +1 905 712.9502

BUENOS AIRES, ARG

ARG 0810 444.2656

Int’l +011 4583.5900

FAX +011 4584.3100

MELBOURNE, AUS

AUS 1 800 003. 100

Int’l +62 03 9561.8102

X 1 800 004.302

A

F

Int’l +62 03 9561-7751

SYDNEY, AUS

US 1 800 003.100

A

Int’l +62 02 9648.2630

FAX 1800 004.302

Int’l +62 02 9548.2635

MONTEVIDEO,URY

URY 02 902.7206

Int’l +5982 900.8358

FAX +5982 908.3816

JOHANNESBURG, S.A.

S.A. +27 11 974.6155

FAX +27 11 974.3593

Canon LBP-2460

Data Products DD524

P 5Si, 5Si MX, 5Si Mopier

H

IBM Network Printer 24

Lexmark Optra N Model 240

QMS 2425-2425 EX

Troy 524

Photo 1

Photo 2a

Photo 2b

Part Number: C3909A

Gram Load: 840 grams

Yield @ 5%: 15,000 pgs

Pages/Min.: 24ppm

Resolution: 600 dpi

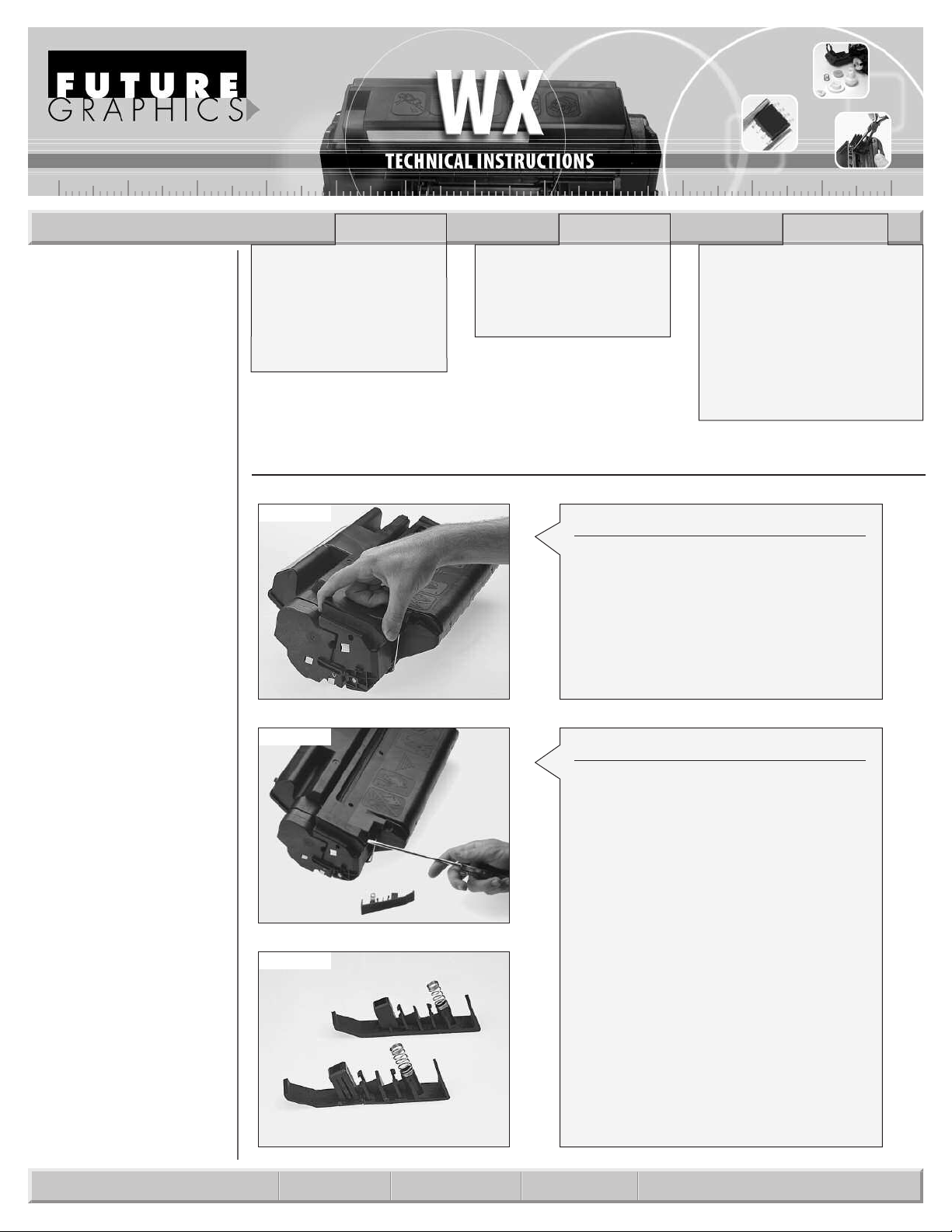

Step 1

Locate and remove the cartridge clips on

both sides of the cartridge using your finger. Gently pry up on the clip until it pops

up.

(See Photo 1)

ep 2

St

Using a flat blade screwdriver, pry up on

the other clip and remove it.

(See Photo 2a)

NOTE: I

eak while the

br

these break, replace with aftermarket

part. You may need to use the springs

om the OEM clip

fr

(See Photo 2b)

Needle Nose Pliers

mall Flat Blade Screwdriver

S

#2 Phillips Head Screwdriver

Small Hammer

Soft Lint-Free Cloth/ Damp Cloth

5/32” Drift Punch

Anhydrous Isopropyl Alcohol

800gms 5Si Toner

Nu-Finish (optional)

Damp Cloth

t is very likely that these clips will

eing removed. If

e b

y ar

.

E-mail: info@futuregraphicsllc.com Website: www.futuregraphicsllc.com

2 WX Technical Instructions

Notes

Photo 3

Photo 4

Photo 5

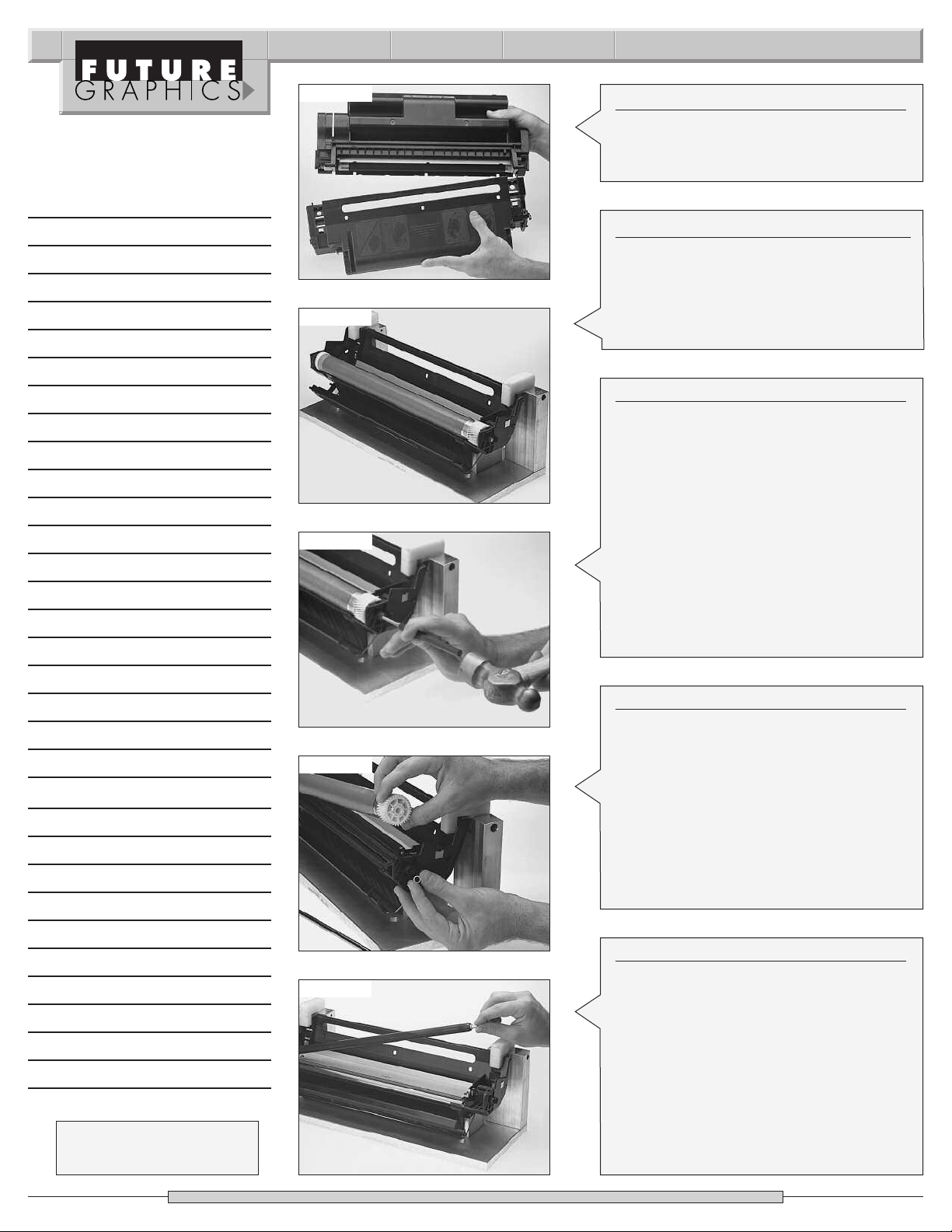

Step 3

Just like the HP4 cartridge, the two halves

of the cartridge can now be separated.

(See Photo 3)

Step 4

Set the hopper aside. If you have a waste

hopper fixture, set the waste hopper in the

fixture. If not, place the waste hopper on

the table.

(See Photo 4)

Step 5

The drum axle is a metal rod that goes

through the center of the drum end to

end. On the large gear end of the axle is a

small white plastic retaining ring. Using a

drift punch and a hammer, tap directly on

the shaft (large gear side) and drive it out

the other end. (See Photo 5)

NOTE: Make sure you don’t lose the retaining ring. The ring fits into a groove on the

drum shaft to hold the shaft in position.

Repeated removal will wear this ring and

the ring will no longer snap into position.

If the ring does not snap, replace it.

Need trust-worthy, detailed Technical

Instructions for another engine?

Visit: www.futuregraphicsllc.com

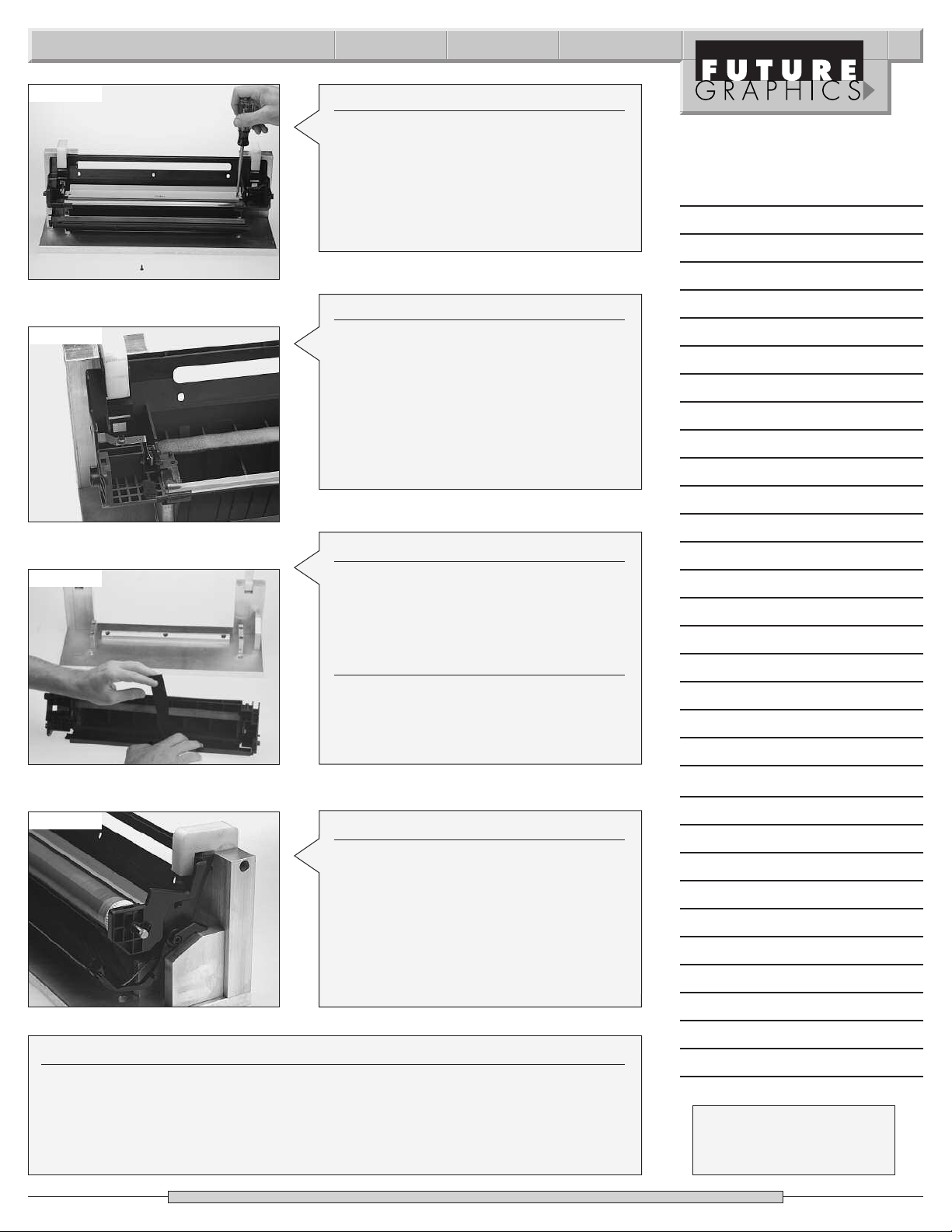

o 6

hot

P

Photo 7

ep 6

St

Remove the drum, blow off excess toner

with compressed air and clean with isopropyl alcohol. Wrap the drum in a protective paper or cloth and set it aside in a dark,

ted place. (S

ec

ot

pr

ee P

o 6)

hot

NOTE: We were able to use the OEM drum

ter the Oem cycle with no loss in

e af

onc

density, however, you may choose to

recoat or replace the drum after the first

recharge.

Step 7

Remove the primary charge roller from its

lean clips with isopr

clips.

C

and a cotton swab. Inspect the primary

charge roller for damage. Clean the pri-

y charge roller with a mild soap and

mar

water and set it aside.

ee Photo 7)

(S

NOTE: We have had no problems using the

OEM primary charge roller three cycles in

mild weather climates.

opyl alcohol

WX Technical Instructions 3

Photo 8

Photo 9

S

tep 8

Remove the two Phillips head screws holding the wiper blade and remove the blade.

Be careful not to break the plastic positioning posts.

(See Photo 8)

Step 9

Empty out the waste toner and clean felts

and foam with a vacuum or compressed

air.

(See Photo 9)

NOTE: Be careful not to damage felts,

foam or the mylar recovery blade, as this

can cause leaks. If the felts or foam are

damaged or worn, replace.

Notes

Photo 10

hoto 12

P

Step 10

Apply OPC protector felt to the drum

shutter door. You will need to remove the

cartridge from the fixture.

(See Photo10)

Step 11

Apply padding powder on wiper blade

and reinstall.

NOTE: If you are going to use a new aftermarket drum, always replace wiper blade.

Step 12

Apply padding powder to the OPC drum

and install. The big helical gear will go on

the right side of the waste hopper. Install

the drum axle only far enough to hold the

drum against the wiper blade. Rotate

drum so the wiper blade wipes the

padding powder off the drum.

(See Photo12)

Step 13

Once again, remove the drum axle and the drum. Reinstall the primary charge roller

then reinstall the drum and drum axle.

NOTE: When reinstalling the drum axle, the axle slides through the drum from the

left side. Make sure you install the axle in the right way. The notched end of the axle

goes on the large gear end.

N

eed help with a particular remanu-

facturing problem?

Call the Technical Resource Center from

8am - 5pm PST: 800 394.9900

Loading...

Loading...