Canon LBP-1260 Service Manual

LBP-1260

SERVICE

MANUAL

Canon

PREFACE

This Service Manual contains bask information required for after-sales service of the LBP- 1260

laser beam printer (hereinafter referred to as the “printer”). This information is vital to the

service technician in maintaining the high print quality and performance of the printer.

The cassette paper feeder and envelope feeder are prepared for the printer as optional

equipment, which contents are also described in this manual.

This manual is comprised of the following chapters:

Chapter 1:

Chapter 2:

Chapter 3:

Chapter 4:

Chapter 5:

Chapter 6:

Information in this manual is subject to change as the product is improved or redesigned.

All relevant information in such cases will be supplied in Service Information Bulletins.

A thorough understanding of this printer. based on information in this

Information Bulletins, is required for maintaining its performance and for locating and

repairing the causes of malfunctions.

General Description

Features. specifications, and operation

Operation and Timing

A description of the operating principles and timing sequences of the electrical and

mechanical systems.

The Mechanical System

Explanation of mechanical operation, disassembly, reassembly, and adjustment

procedures

Installation

Requirements for a suitable location, installation procedures, plus the storage and

handling of EP-E cartridges

Maintenance and Servicing

Parts replacement schedule, tools, lubricants, and solvents

Troubleshooting

Reference values and adjustments: troubleshooting procedures

General timing chart, general circuit diagram, PCB circuit diagrams, etc.

Manual and Service

CONTENTS

CHAPTER 1

I.

FEATURES

II.

SPECIFICATIONS

III.

ASAFETY

. . . . . . . . . . . . . . . . . , . . , . . , . . , . .

. . . . . . . . . . . . . . . . . . .

INFORMATION.....

CHAPTER 2

I.

II.

III. IMAGE FORMATION SYSTEM.

IV.

OPERATION . . . . . . . . . . . . . . . . .

BASIC

A.

FImctions..

B. Outline of the Electrical

System

C. DC Controller Input

SignsIs

D. DC Controller Input/

output

E. Basic Sequence of

operations

LASER/SCANNER SYSTEM

A.Outline..

B.

Scanning Exposure..

c.Laser Control circuit..

D.

Scanner

A.Outline..

B.

Printing

C. High-Voltage Power Supply

PICK-UP/FEED SYSTEM..

A.Outline

B.

Paper Size Detection

C.

Cassette

........................

..............................

..............................

SlgnaIs..................

.........................

............................

..........

.......

Drive..

..................

............................

................

Process

.......

..............................

.........

Feed..

..................

GENERAL DESCRIPTION

l-l

l-2

l-7

IV. PART3 OF

V.

OPERATION

OPERATION AND TIMING

2-l

2-l

2-2

2-3

2-4

2-0

2-7

.....

2-7

2-8

2-10

2-13

2-1s

2-1s

2-17

2-23

2-27

2-27

2-28

2-29

Fixing

D.

Paper Jam Detection

E.

V.

SYSTEM INTERFACE..

Outline..

A.

B. Operation

Video controller PCB

C.

Control panel

D.

Self-test..

E.

8tatus/Error Message..

F.

VI.

POWER SUPPLIES

OutlIne..

A.

Protective System

B.

VII.

ENVBLOPE FEEDER..

Outline of the Electrical

A.

System..

Pick-up/ Feed Gystem

B.

Paper Jam Detection..

C.

VIII. PAPER FEEDER.

A. Outline of the Electrical

System..

Pick-up/Feed

B.

Paper Jam Detection..

C.

TIIB PRINTER

...........................

and Delivery Unit

............................

..........................

...........................

............................

............................

.....................

............................

........

......

............

.........

....................

..................

.............

.............

........

system..

....

.:.

......

.......

......

.......

l-8

1-12

2-30

2-34

2-36

2-36

2-37

258

2-41

2-42

2-43

2-66

2-56

2-66

2-67

2-67

2-58

2-60

2-61

2-61

2-62

2-62

I.

EXTERNALS

A.Covers and Panels

B.

Bxkaust Fan..

C.

Control Panel Unit..

II.

DRIVE

A.

Drive

B.Main

SYSTEM..

Unit..........................

Motor

CHAPTER 3 THE MECHANICAL SYSTEM

...........................

.............

....................

...........

....................

........................

3-l

3-l

3-4

3-5

3-6

3-6

3-8

III. PAPER TRANSPORT SYSTEM. S-7

Iv. EXPOSURE SYSTEM..

Paper Pick-up Unit..

A.

B. Cassette pick-up Roller

MP Tray Pick-up Roller..

C.

Separation Pad..

D.

Paper Delivery Unit

E.

...........

......

................

...........

.............

....

3-7

3-9

3-9

S-10

3-10

3-11

A.

Laser/Scanner Unit

V.

ELECTROSTATIC IMAGING/ C.DC Controller PCB..

DEVELOPING/CLEANING

SYSTEM

A.

B. Transfer Charging Roller

FIXING SYSTEM..

VI.

A.

ELECTRONIC COMPONENTS.. 3-18

VII.

A.

.................................

EP-E Cartridge..

Firing

Unit..

Video Controller Unit..

........... 3-l

................. 3-12

....

...................

......................

.......

1 B.Video Controller PCB..

D. pick-up Motor

3-12 E. Sensor PCB

F.

Power

Supply..

3-13

3-14

3-14

S-18 X.OTHERR

G. High-voltage Power

Supply

PCB

VIII. ENVELOPE FEEDER...............

IX. PAPER FEEDER

...................................

CHAPTER 4 INSTALLATION

.......

3-19

...........

Driver

........................ 3-21

...................

........................

......................

PCB .

3-20

. 3-21

3-22

3-23

3-24

S-28

3-30

CHOOSING A LOCATION..

I.

II.

UNPACRING AND

INSTALLATION..

STORAGE AND HANDLING OF Cartridges

III.

CARTRIDGES

.....................

.........................

CHAPTER 5 MAINTENANCE

1.

PERIODIC REPLACEMENT . Standard Tools

PARTS

....................................

II.

EXPECTED LIVES OF

CONSUMABLES PARTS..

III.

PERIODIC SERVICING

SCHEDULE..

N.

LISTSOF TOOLS..

...........................

.......

.........S-

..................

4-1

4-2 B. Storage of Unsealed

4-4 C.Iiandling Suggestions

5-l B. Special Tools

1

5-

1

5-2 CUSTOMER..

. Storage of Sealed

Cartridges

AND

SERVICING

V.

LIST OF LUBRICANTS,

CLEANERS..

VI. SERVICE CHECKPOINTS

VII. MAINTENANCE BY

CHAPTER 6 TROUBLESHOOTING

INTRODUCTION..

I.

A.

Initial Check

B.

BasicProcedure..

C. How to use the

Troubleshoot

II.

EXPLANATION OF SPECIAL

TOOL

.....................................

. Printer Driver Tester..

MEASUREMENT AND

III.

ADJUSTMENT

A.Image Adjustment..

....................

.....................

...............

Tables

......

.......

........................

........... 6-S

6-

1

6-l

6-2

6-3

64

64

6-S

B. Mechanical Adjustment . . . . .

C. Electrical Adjustment . . . .

N.

IMAGE DEFECTS . . . . . . . . . . . . . . . . . . . .

A.

Examples

B. Troubleshooting Image

Defects

V.

TROUBLESHOOTlNG

MALFUNCTIONS . . . . . .

VI.

PAPER TRANSPORT

TROUBLESIiOOTING . . . . . . . . . . . . . .

A.

Print Paper Jams . . . . . . . . . . . . . . .

.........................

.........................

..................

.....................

...........................

..........................

of Image Defects 6-14

. . . . . . . ..I....................

. . . . . . . . . . . . . . .

........

........

..a.

4-4

4-4

4-5

5-2

5-3

5-4

5-5

5-7

6-S

6-10

6-14

6-15

6-28

6-42

6-42

B. Incomplete Paper Feed..

VII. LOCATION OF ELECTRICAL

PARTS/FUNCTION..

. Stitches..

B.

Sensors and Solenoids..

C.

Motors and Others..

D.

PC Boards..

E.

Connectors..

................

..........................

...........

........................

......................

....

.....

6-46

6-48

6-48

6-60

6-52

6-54

6-66

VIII. VARIABLE RESISTORS. LEDS.

TEST

PINS, JUMPBRS.

SWITCBBS ON pC BOARDS..... 6-68

A.

DC Controller PCB . . . . . . . . . . . . .

B.

Ii@-voltage

Supply PCB.... . . . .

C. Pick-up Motor Driver PCB.. 6-60

D. Paper Feeder Driver PCB.... 6-60

AND

Power

. . . . . . . . . . . . . . . .

6-68

6-59

I.

GENERALTIMING CHART..

II.

LIST OF SIGNAL6..

III. GENERAL CIRCUIT DIAGRAM. A-5

IV.

DC CONTROLLER..

.................

.................

....

A-l

A-3

A-6

V.

PICK-UP MOTOR DRIVER

VI.

SENSOR CIRCUIT

VII.

PAPER FEEDER DRIVER

VIII.

ENVELOPB

FEEDER

.......

...................

........

DRLVER

..

A-S

A-10

A-l 1

A-12

CHAPTER 1

.

GENEIUL

DESCRIPTION

I.

FEATURES.............................

II,

SPECIFICATIONS........ . . . . . . . . . . . .

III.

A

SAFETY INFORMATION..... I-7

l-1

l-2

IV. PARTS OF THE PRINTER........ l-8

V. OPERATION

. . . . . . . . . . . . . . ..f...........

l-L2

1. Non-impact page

This non-tmpact (low-noise) printer uses electrophotographic. electronic, and laser technology.

2.

High-speed printer

The same size as LBP-1260. it is a high-speed printer realizing a printing speed 1.5 times as

fast [about 12.9 pages of Letter size paper a minute].

3.

High print quality

Toner having a particle size half that of conventional Canon toner and higher resolution (600

dpi)

produce clearer images.

4. Easy

maintenance

The

photosensitive drum. toner, primary charging roller, and drum cleaning unit are

into one replaceable assembly called the “EP-E Cartridge”. By the use of the customer-

replaceable cartridge. high printing quality is maintained by replacing the cartridge and simple

cleaning in the printer.

5.

Roller charging/transfer system

Instead of the conventional corona system, a charging

charging and transfer processes. The charging roller system considerably reduces the ozone

produced by the charging system and the roller transfer system makes paper feeding more

stable.

6.

Space-saving front loading for paper feed

Front loading is used to make it easier to load paper. This, along with the

purpose tray, reduces the size of the printer and the space it takes up.

7.

Four paper feed methods with

Four-way paper feeding is made possible by installing the optional

(simply called the paper feeder below) and

tray and cassette. By combining the standard cassette

sheets of paper can

8.

Automatic interface change function

The printer has a parallel interface

the type (parallel or serial) of data from the computer, and automatically l changes the

interface. (Automatic interface function)

printer

through use

be loaded In both the upper and lower cassettes for

of fine toner and high resolution (600 dpi)

roller/transfer system is used for the

various

options

envelope feeder,

[Centronics)

with

the paper feeder,

and a serial interface (RS232C). It recognizes

cassette paper feeder

in addition to the multi-purpose

continuous

combined

bulk-in,

multi-

up to about 750

printing.

l-l

CHAPTER

1

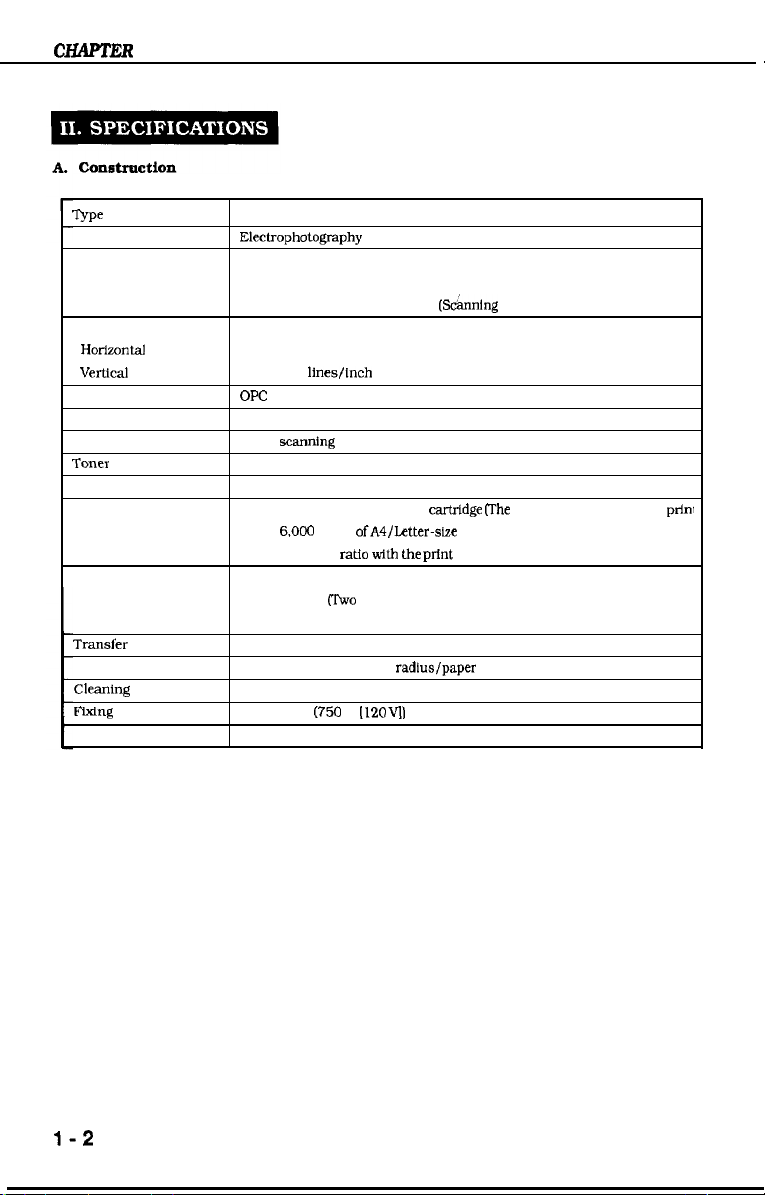

me

Printing method

laser scanning system

Laser

Scanning system Rotating six-faced prism mirror

Scanning pitch

H0ri20nti

Vertical

Photosensitive medium

Charging

Exposure

TOneI

Development

Toner supply

Paper feed

TransflX

Separation

Cleaning

F-w

Print delivery

Desktop page printer

Electrophotography

Semiconductor laser

600 dots/Inch

600 raster

OPC

Roller charging

Laser scanning

Single-component dry toner

Toner projection development

Included in replaceable EP-E

about 6.000 pages ofA4/Letter-size paper. The average print coverage is

a 4% image dot

Multi-purpose tray feed

Cassette feed

installed.)

Roller transfer

Curvature: (small drum radius/paper stiffness)

Blade

Heat roller

Face-down

lines/inch

ratio with the

Crwo

cassettes can be used when the paper feeder is

(750

W II20

VII

(S&mnlng

mirror)

cartrIdge mhhe

prfnt

cartridge can be used to

density setting in the middle.)

print

l-2

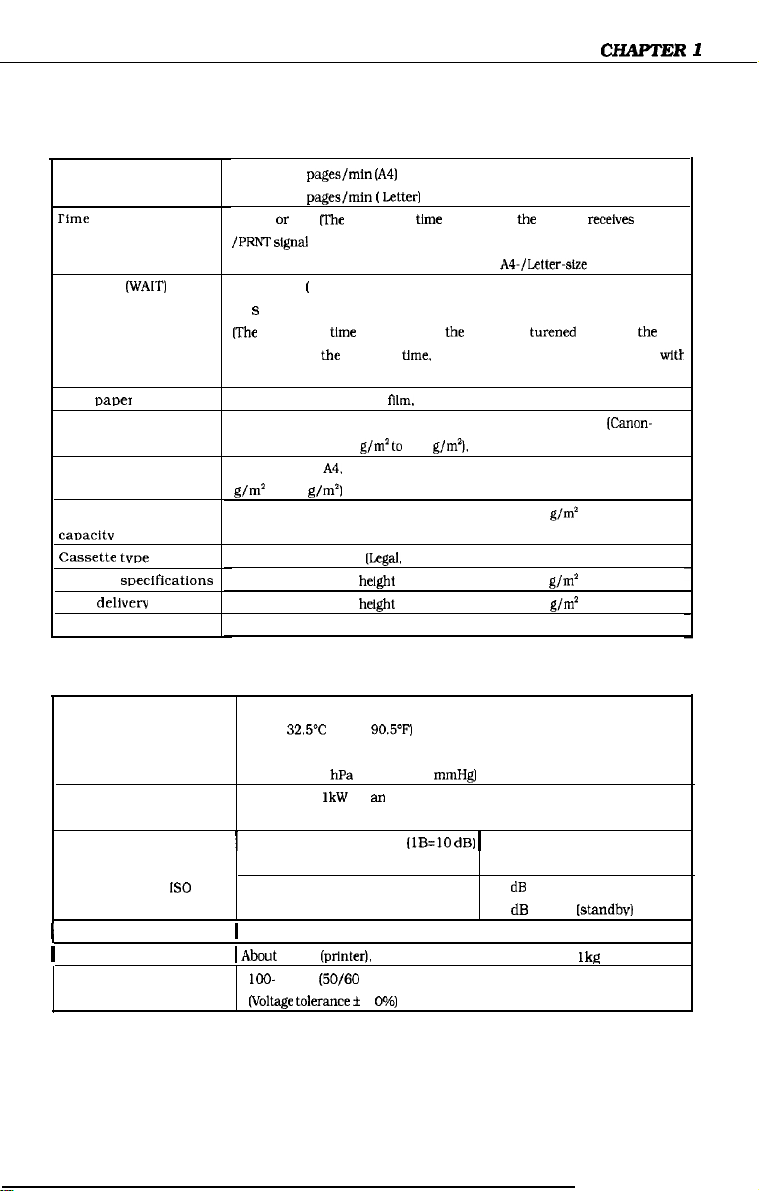

B. Performance

CHAPTER

1

Printing speed

rime for first print

Warm-up

Print

Paper size of multi

purpose tray

Paper size of cassette

Multi-purpose tray

caoacitv

DaDeI

(WAIT)

time

cassette twx

Cassette swxifications

Print delivev

Option

C. Others

Operating environment

Temperature

Humidity

Atmospheric pressure

Power consumption

Noise level (DECLARED1 SOUND POWER LEVEL (lB=lO

NOISE EMISSIONS in

accordance with IS0 9296) SOUND PRESSURE LEVEL

1

Dimensions

1

Weight

Line voltage requirements

About 12.2

About 12.9

18.9 s

/PRNT slgnal

temperature of 20°C until the deliver of an

60 s or less ( 120 v power source)

75 s or less (100 v power source)

IThe

completion of

a rated voltage input.)

Plain paper. labels, OHP

Plain paper from 182 mm X 257 mm to 216 mm X 356 mm

approved paper. 60

Plain paper of

g/m2

Up to 10 mm stack height (about 100 sheets of 80

A4. Letter, Universal

Up to 25 mm stack

Up to 25 mm stack

Envelope feeder and paper feeder

1

1 About

pages/min (A4)

pages/min

01’

less

from the video controller when it is ready at an ambient

amount of

to 90

g/m*)

10 to

32.5’C

20 to 80% RH

760 to 1013

Max. about

input)

(Bystander positions)

416 mm X 414 mm X 295 mm (width X depth X height)

17 kg

lOO-

120 V

(voltage tolerance i

(

Letter]

iThe

amount of

time

elapsed after

the

warn-up

film.

g/m’ lo

A4,

Legal. Letter. or Executive (Canon-approved paper. 60

(Legal,

height

(about 250 sheets of 80 g/m’ paper)

height

(about 250 sheets of 80 g/m’ paper)

(50 to

90.5”F)

hPa

(570 to 760

1kW

(at an ambient temperature of 20°C and rated voltage

(prlnterl.

About 1.5 kg (cartridge). About lkg (cassette)

(50/60

Hz)

1

G%)

time

from when

the

time.

at an ambient temperature of 20°C

envelopes

128

g/m’).

Letter, A4, Executive]

mmHg)

dB1 1

the

printer

receives

A4-/Letter-size

printer is

and above type mentioned above

6.5 B or less (printing)

4.4 B or less (standby)

51 dB or less (printing)

33 dB or less

turened

g/m*

paper.1

ON until

paper)

[standbv)

a

the

with

(Canon-

1-3

CHAPTER 1

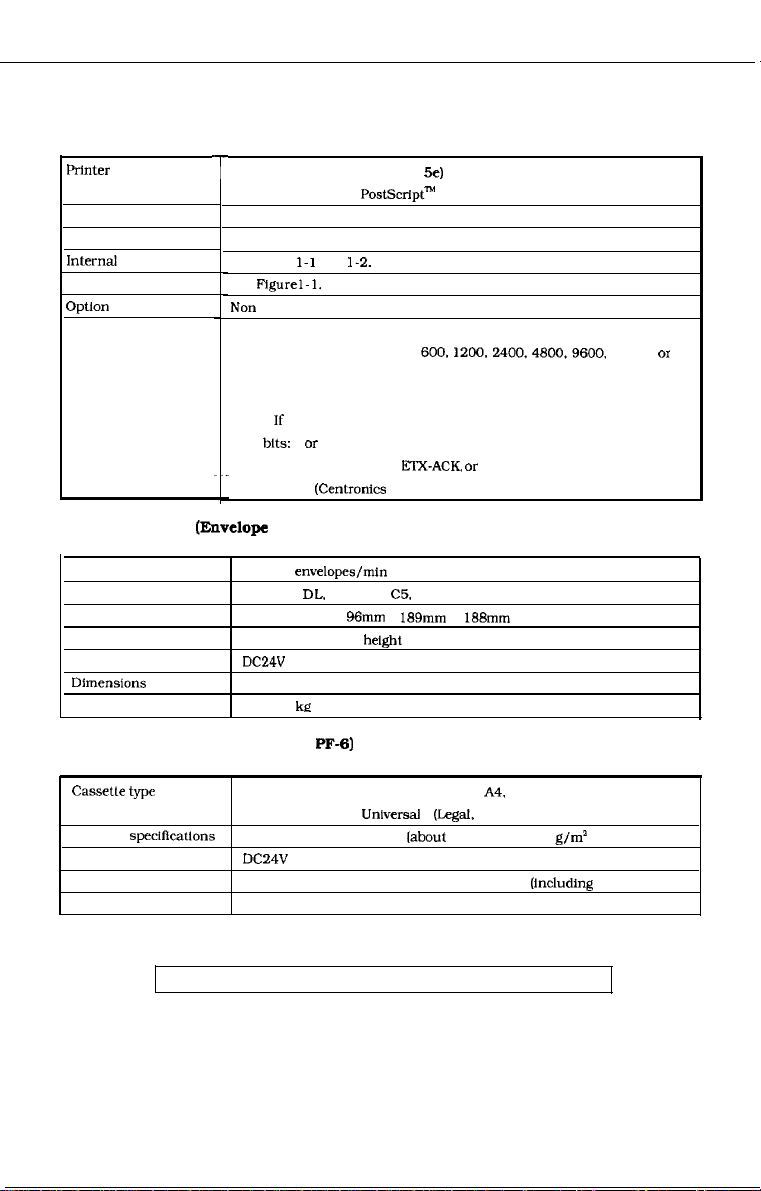

D. Video controller

Printer

control

language

Memory [RAM]

Memory (ROM)

internal

fonts

Effective printable area

Optlon

card slot

Standard Interfaces

Serial

Parallel

Standard: Enhanced PCL (PCL 5e)

T

Emulation: Optional

2MB (Expandable to 32 Megabytes in total with optional RAM SIMM)

2 or 4MB (Expandable to 32 Megabytes in total with optional ROM SIMM)

See Table

See

NOI?

RS-232C. asynchronous. 300. 600.

38400 baud

Data length: 7 or 8 bits

Parity: If desired

Stop bits: 1 or 2

Handshaking: XON-XOFF.

S-bit parallel

l-1

FigureI-1.

and I-2.

(Centronics

PostSctiptm

EZTX-ACK,

standard] interface

1200.2400.4800.9600.

or DTR

19200,

01

E. Envelope feeder

Pick-up speed

Envelope type

Envelope size

capacity

Power supply

DIIIlenSiOIlS

Weight

(~~~velope

Feeder EF-6)

About 9

envelopes/min

COM-10. DL, Monarch,

Envelopes from 96mm X

Up to 55 mm stack

DC24V

(Supplied by the printer)

297 X 293 X 91 mm (width X depth X height)

About 2

kcr

F. Paper feeder (Paper Feeder Unit

Cassette type

cassette

specifications

Power supply

Dimensions

weight

Specifications are subject to change with product improvement.

EP-E Cassette 500 Universal S (Letter. A4. Executive)

EP-E Cassette 500 Universal L (Legal, Letter. A4. Executive)

Up to 50 mm stack height labout 500 sheets of 80

DC24V

(Supplied by the printer)

416 X 470 X 134 mm (width X depth X height) Iincluding legal cover)

About 3.9 kg (paper

C5,

B5 (recommended envelope)

189mm

to

188mm

X 254mm

height

(about 75 envelopes)

PF-6)

feeder). about 2 kg (universal cassette]

g/m2

paper)

1-4 .

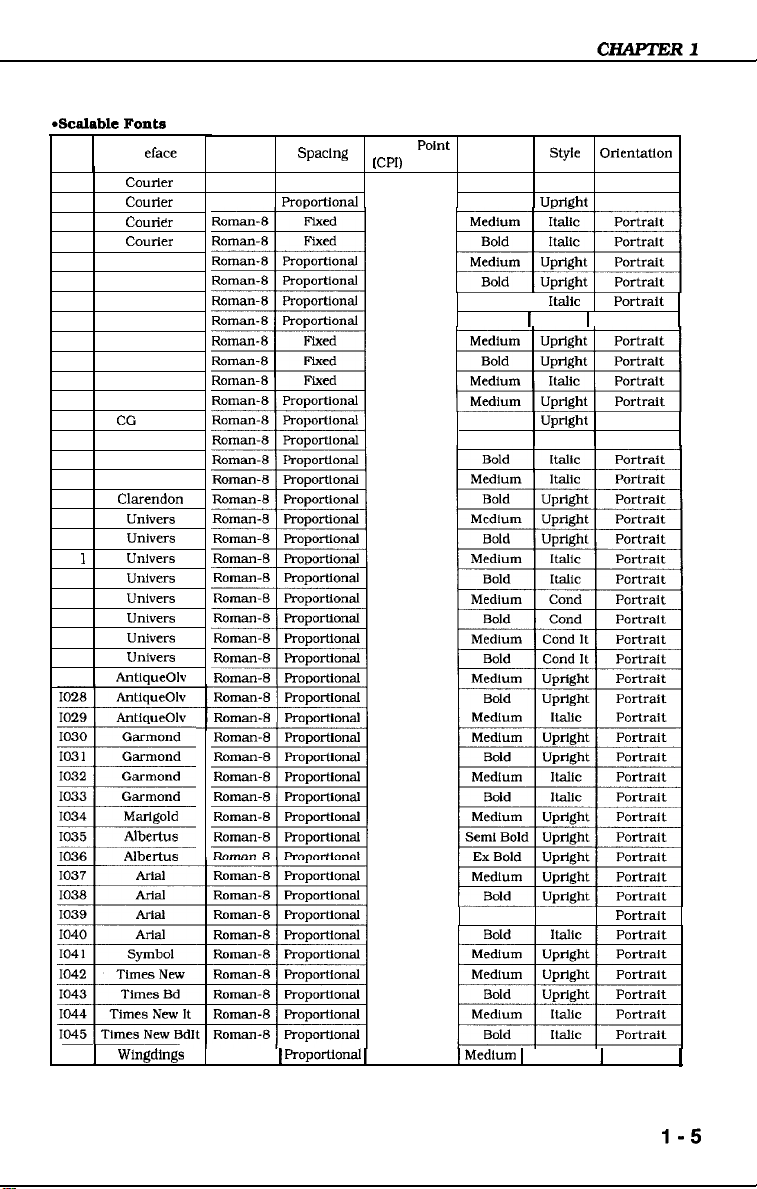

1000 C0Urll-Z

1003 COUl%X

1004 COUrier

1005

1006

1007

1008

1009

1010

1011

1012

1013

1014

1015

1016

1017

1018

1019

1020 UniVerS

102

1022 UniVel-S

1023

1024 UIllVeK?

1025

1026 UIIiVfXS

1027

Letter Gothic

Letter Gothic

Letter Gothic

CG Omega

CC Omega

CG Omega

CG Omega

1

Antiqueo1v

C0lltier

CG Times

CG Times

CG Times

CG Times

coronet

Clarendon

Univers

Univers

UIliK!rs

Uni%%L-s

Symbol

set

Roman-8

Roman-8 ProportIonal

spachlg

Fixed

Pitch Point Stroke

[CPI) Size Weight

Scalable

Medium Uptight Portrait

Bold

Medium

Bold 1 Italic 1 Portrait

Bold Uprtght Portrait

Medium 1Italic 1Portrait

style

OrleIltati0n

UmIaht

Italic Portrait

Portrait

1030

1031

1032

1033

1034

1035

r

1036

1046 1Wingdings

Gannond

Gannond

Gannond

Gannond

Marlgold

Albertus

Alberta

Roman-8 1 ProporttonaJ

Table l-l

Medium Italic

I

1 Medium I

Upright I Portrait

PortrAt

1

l-5

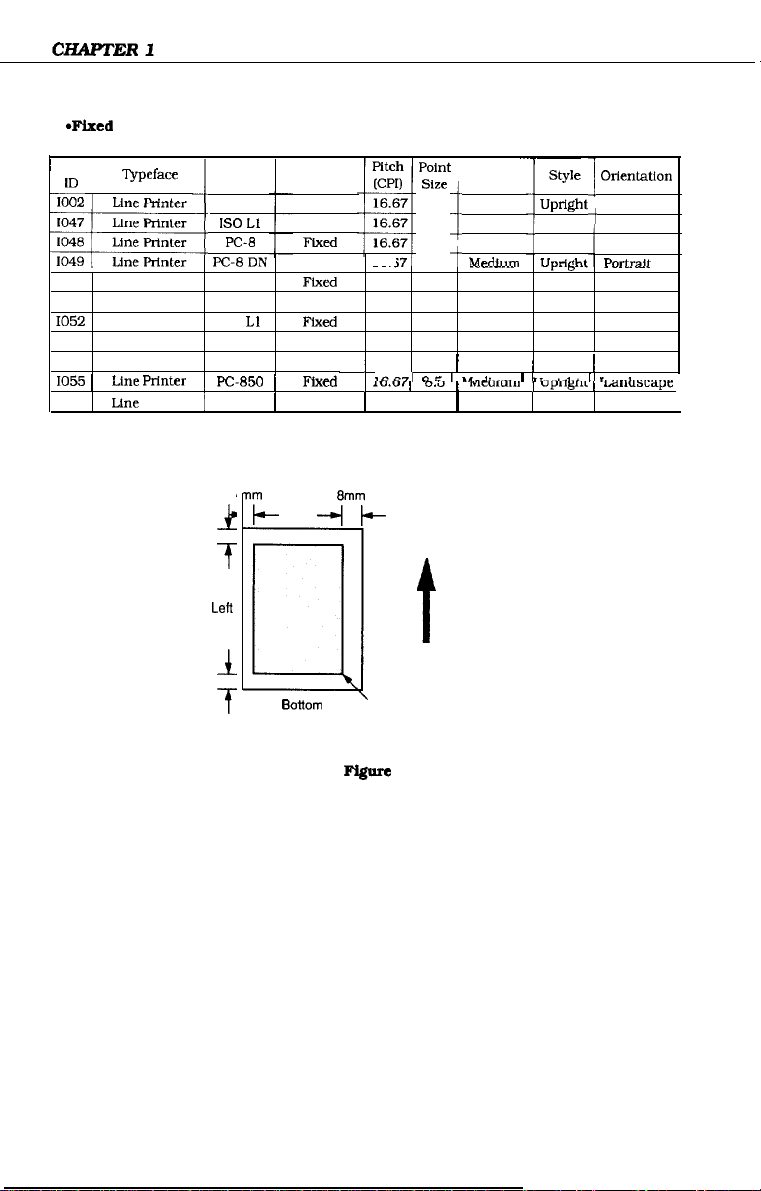

*Fixed

Fonts

~ Font

1050

105 1

1052

1053

1054

10551Line

1056

Qpeface

Line Printer

Line Printer LEGAL Fixed

Line Printer

Line Printer PC-8 Fixed

Line Printer PC-8 DN Fixed

Printer1PC-650

Printer/LEGAL

Line

Symbol

set

Roman-8 Fixed

IS0 Ll

PC-8 Fi?Xd

PC-6DN

PC-850 FLwd 16.67 8.5

IS0

i

5mm

f

spacing

Fixed

Fixed

Ll

fied

Fixed,Iu.vt ,

1

Fixed 1

1

“k

Top

-r”“mb

Len

I

5mm

II

-f-

r3onom

Point Stroke

Weight

Size

8.5 Medium

Medium

8.5

Medium

8.5

~~_

16.67 8.5 Medium

16.67 8.5 Medium

16.67 8.5 Medium

1

16.671

I 1cc7I CIC I ,“..-11_.- I ,,__a..l_L I r___l_____

16.671

Table l-2

Right

t

._-.-.._

a.5

Medium

1

Medium(Upright

8.5

,

,v,cu,uu,,u,,r,gu

0.0

1

8.5

Medium Upright

Upfight

Upright

Upright

1 lnrwlt

Updght Portrait

Upright Portrait

Upright Landscape

Upright Landscape

-r--e---

Olientat1on

1

Landscape

i

Portrait

Portrait

P”rtnll*

_ ___.-_

Landscape

1

uir,uscapr

,

Landscape

t

Feed-out direction

Effective printing area

(Image quality is guaranteed in this area.)

1-6

Figure l-1

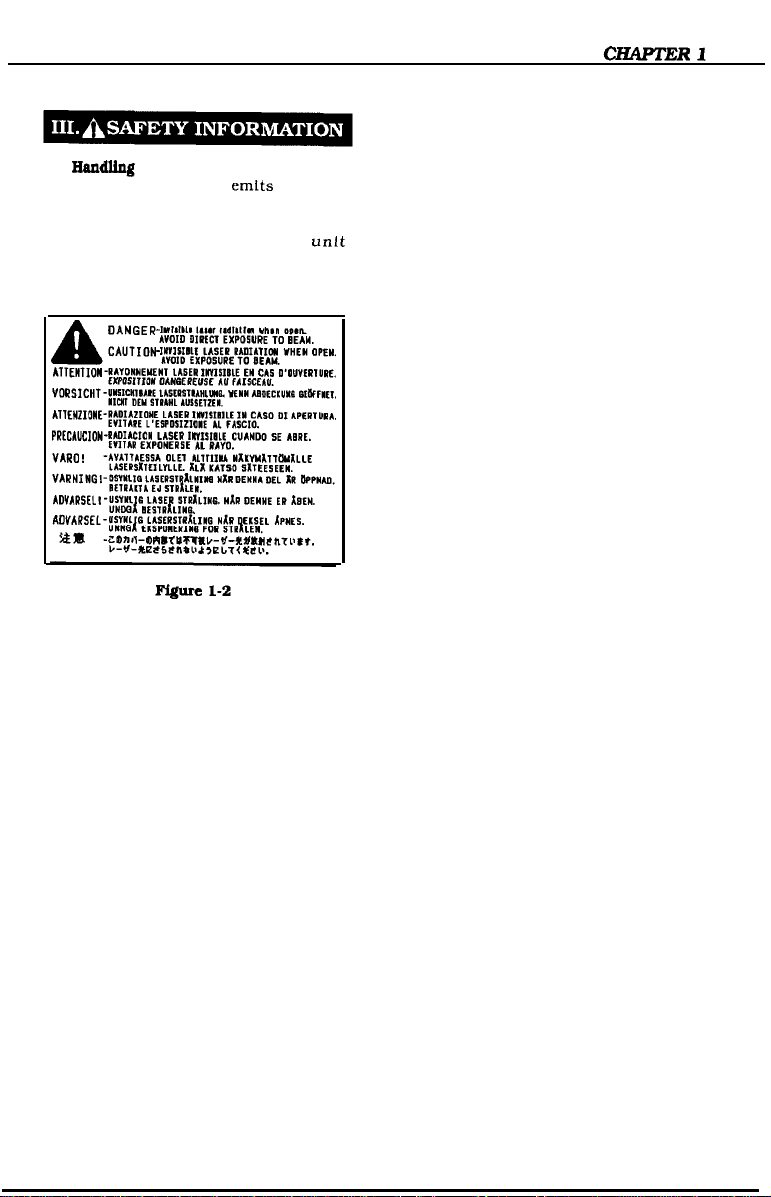

A.

Iiandllng

The laser/scanner unit

the

Laser/Scanner

emits

Unit

invisible

laser beam. Never disassemble the unit;

the reflected beam. although invisible, can

possibly damage your eyes. The

unit

cannot be adjusted in the field. The

following label is attached to the cover of

the unit:

1-7

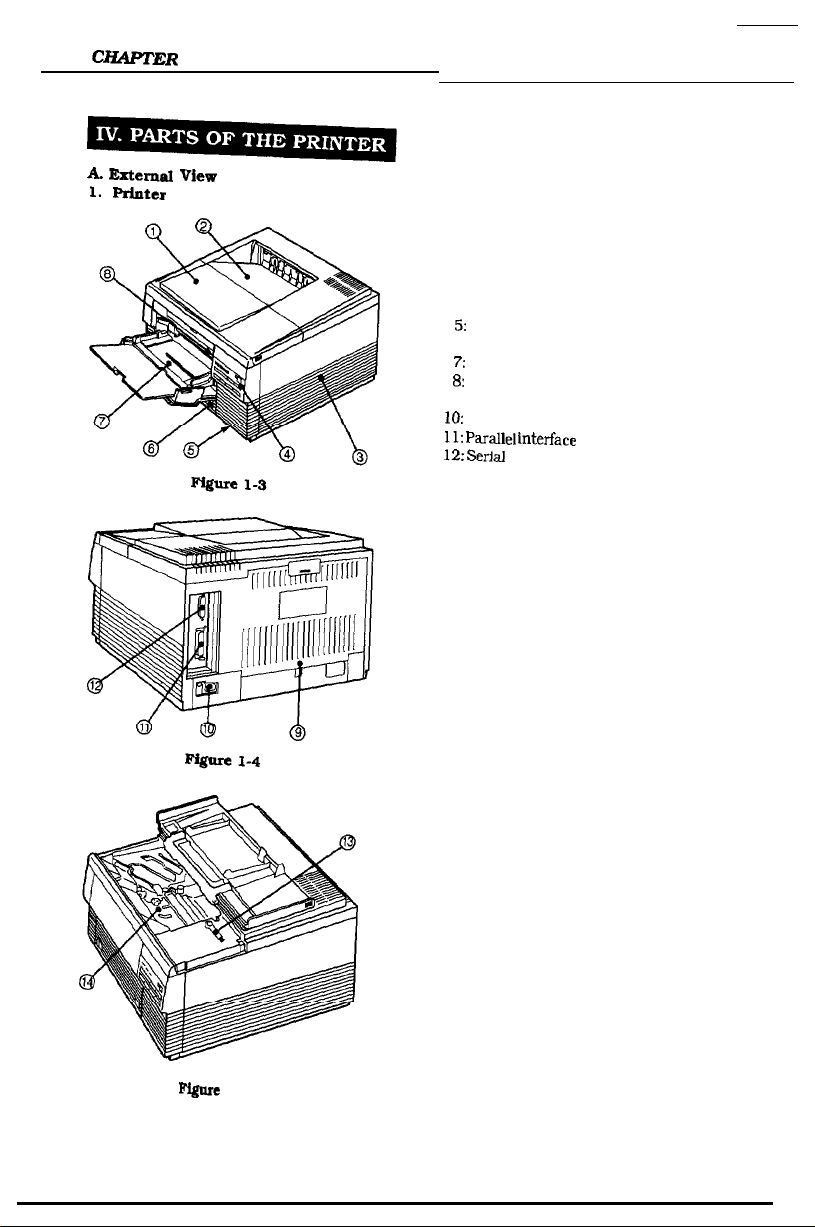

C-ER

A.

Erternpl

1.

Rlnter

1

View

1: upper cover

2: Face-down tray

3: Right cover

4: Control panel

5:

Power switch

6: Cassette

7:

Multi-purpose tray

6:

Test print switch

9: Delivery cover

IO:

Power receptacle

11: Parallel Lnterface

12: Serial

interface connector

13: Cleaning brush

14: Paper access door

connector

1-8

Figare

l-5

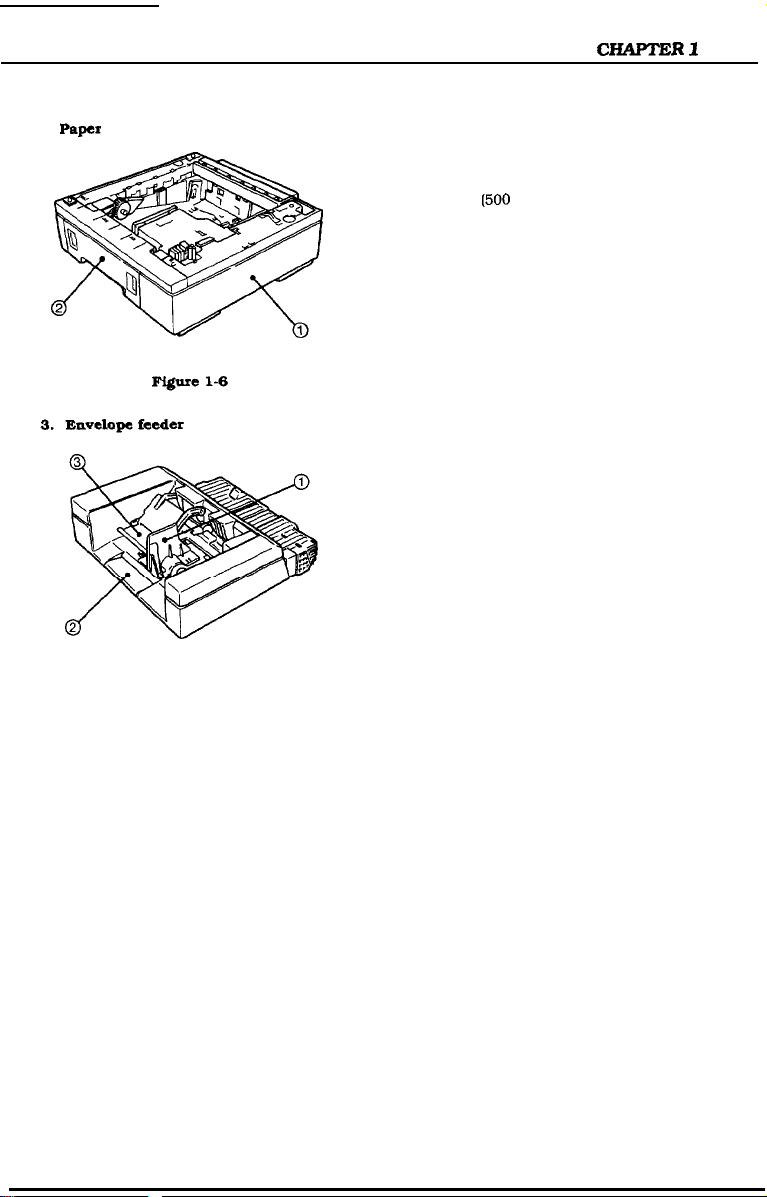

2.

Paper

feeder

1: Paper feeder

2: Cassette

1500

sheets can be stored)

1: Envelope side guide

2: Extension tray

3: weight

CHAPTER 1

Figure 1-7

1-9

CHAPTER1

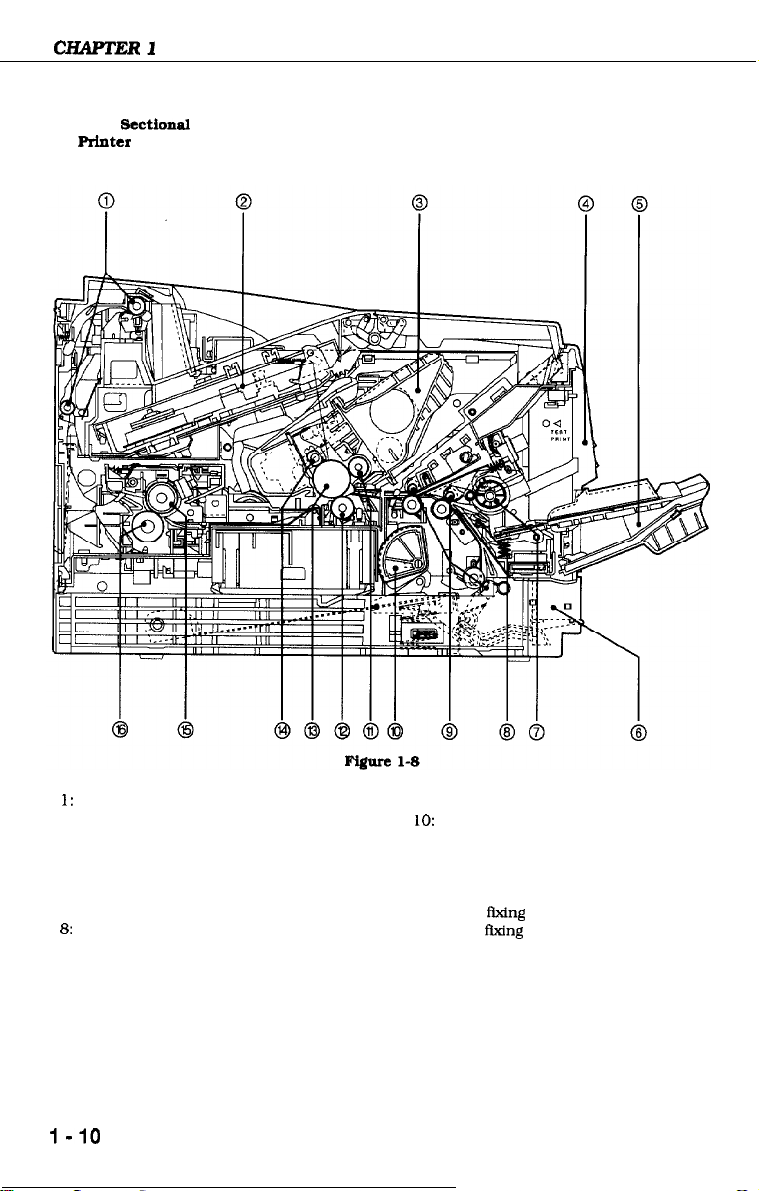

B. Cross Sectional View

1.

Printer

1:

Delivery rollers

2:

Laser/scanner unit

3:

EP-E cartridge

4:

Control panel

5:

Multi-purpose tray

6:

Cassette

7: Multi-purpose tray pick-up roller

8:

Separation pad

l-10

9:

Oblique rollers

10:

Cassette pick-up roller

11:

Developing cylinder

12: Transfer charging roller

13:

Photosensitive drum

14: Primary charging roller

15: Upper

16: Lower

fixing

fbdng

roller

roller

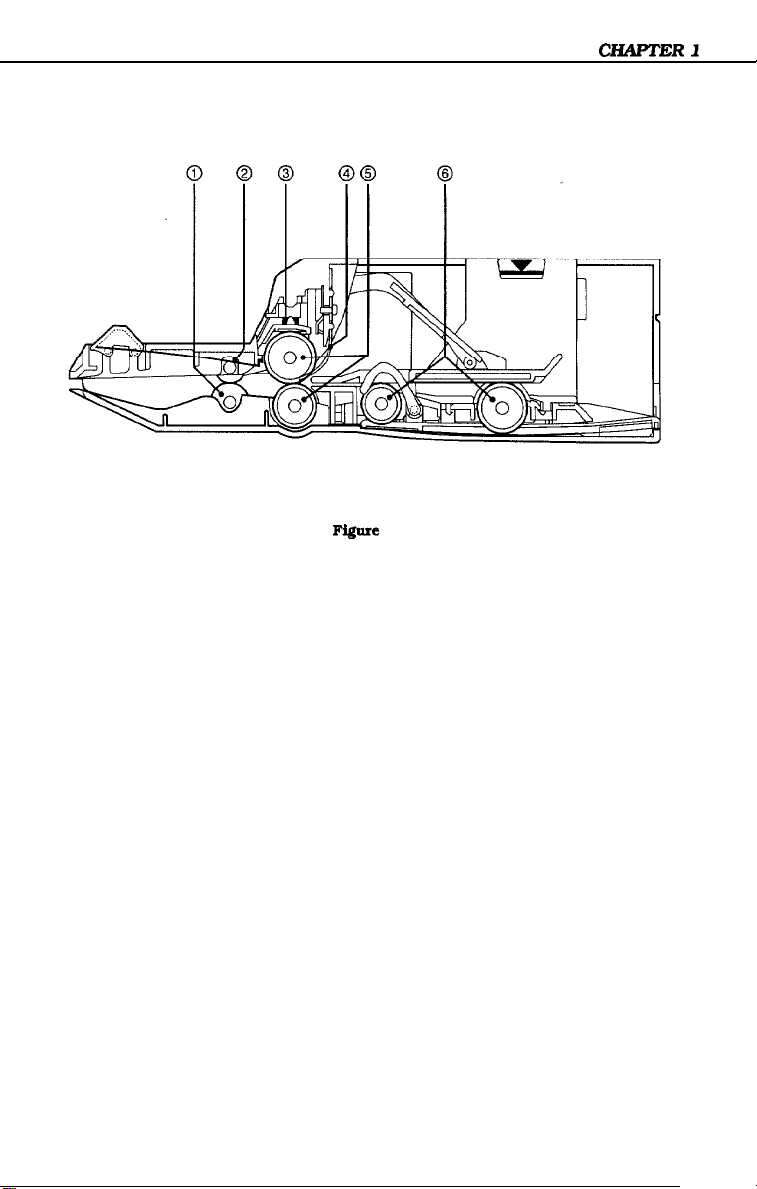

2. Envelope feeder

1:

Feed roller

2: Oblique roller

3: Separation roller pressure spring

4: Separation guide

5:

Separation rollers

6:

Pick-up rollers

Fignre

1-9

l-11

CHAPTER 1

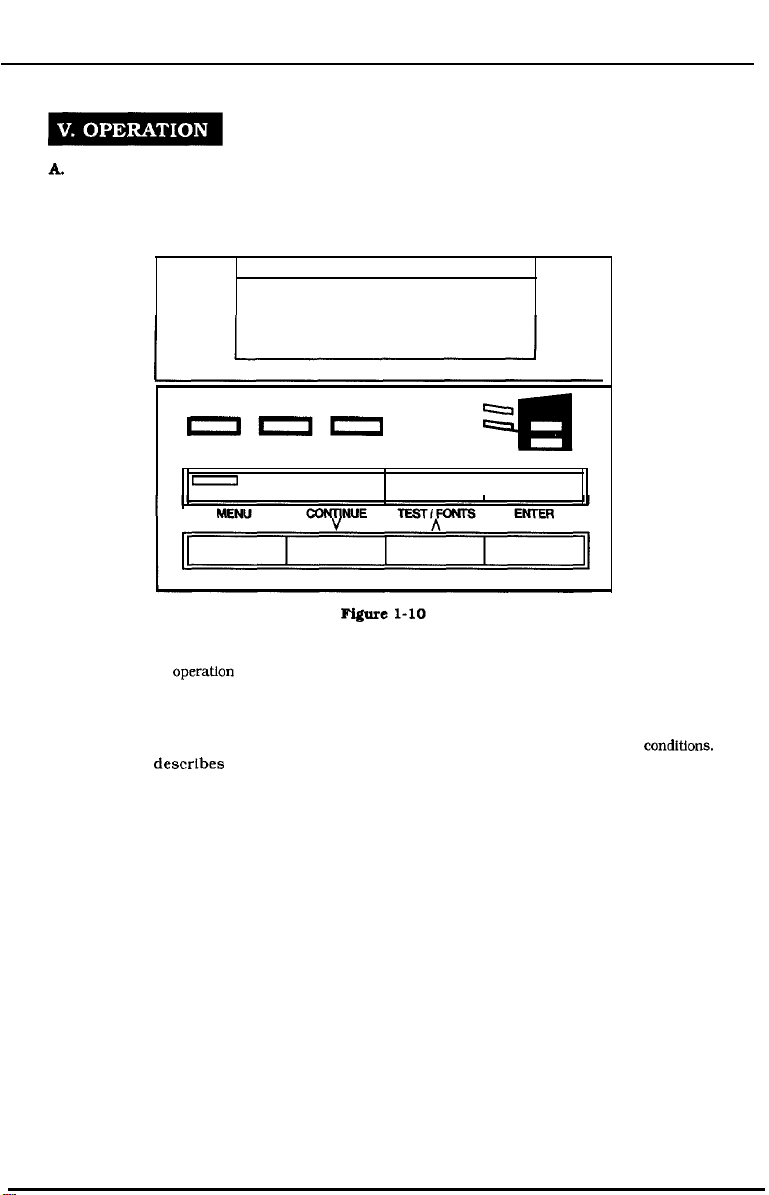

k

The Operator Panel

You use the operator panel to perform basic printer operations, make printer configuration

changes your software application cannot control, identify available typefaces, and check the

status of the printer.

I

READY

on0

I

ALARM

ONLINE

DATA

FORM FEED RESET

I

The operator panel consists of the message/menu display window, eight indicator lights, and

seven menu and

1. Message/Menu Display Window

The message/menu display window can display as many as 16 characters. It displays menu

items you can select, and messages that describe the status of the printer and error

This chapter

Troubleshooting, for information about the types of messages that may appear in the window.

operation

describes

keys.

condittons.

the menu items you can display in the window. See Chapter 6

1-12

CHAPTER1

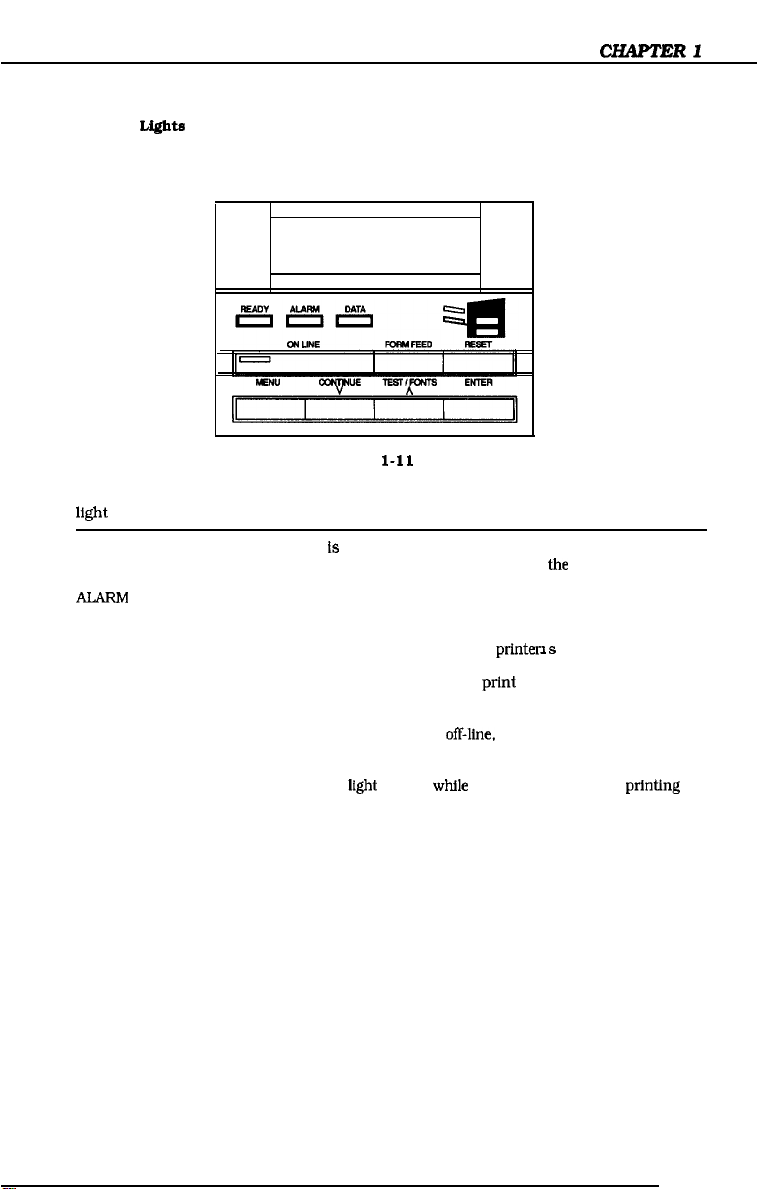

2. Indicator

The indicator lights provide status information about the

Lights

printer. The lights have different

meanings depending on whether they are on. off. or flashing.

Figure

l-11

Indicator

light

READY On

ALAF3vl

Mode Description

The printer is ready to print.

Off

Flashing

On

An error or attendance message appears in

The printer is receiving data.

An error has occurred and printing is disabled. An error or

attendance message appears in the display.

DATA

On

Off

ON LINE On

Off

No error has occurred.

Print data is currently stored in the

No buffered data is in the printer.

nd

The printer is ready to accept

print

printer1 s

(on-line status].

Off

The printer cannot accept print data from the computer [off-line

status). When the printer is

off-Hne.

you can use all keys on the

operator panel to operate the printer.

Flashing

You press ON LINE to set the printer off-line while a page is

printing. This

ltght

flashes

while

the printer completes

the page.

the

display.

buffer.

data from the computer

printing

1-13

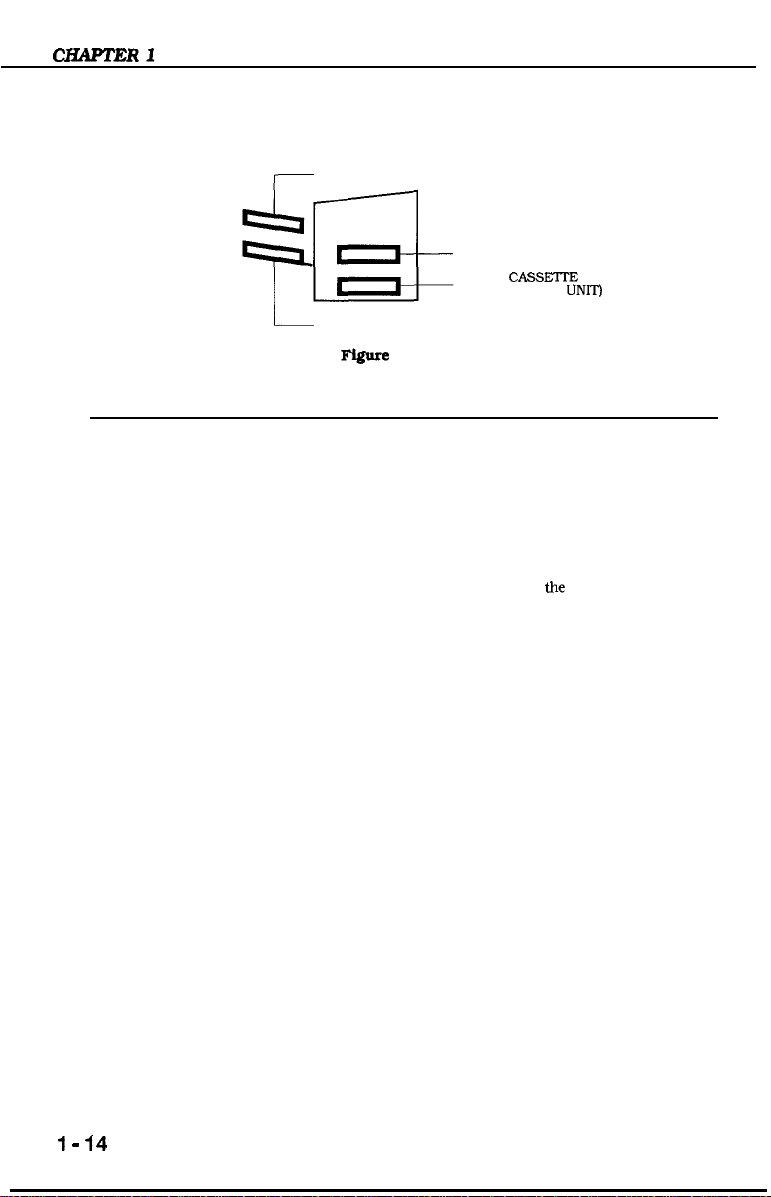

The paper input source indicators are:

ENVELOPE FEEDER

MULTI-PURPOSE TRAY

Flgun

1-12

STANDARD CASSETTE

LOWER

CASSEXTE

(PAPER FEEDER UNIT)

Indicator light

Envelope

Feeder

Multi-purpose

tray

Standard

cassette

Lower

cassette

Mode

On

Flashing

On

Flashing

On

Flashing

On

Flashing

Description

The optional Envelope Feeder is the input source.

The optional Envelope Feeder is selected, but does not

contain envelopes.

The multi-purpose tray is the input source.

The multi-purpose tray is selected, but does not contain

paper.

The paper cassette tray is the input source.

The paper cassette tray is selected, but does not contain

paper.

The optional Paper Feeder Unit is

the

input source.

The optional Paper Feeder Unit is selected, but does not

contain paper.

1 - 14

-Rl

3. Operation Keys

You use

the operation keys to control the basic functions of the printer.

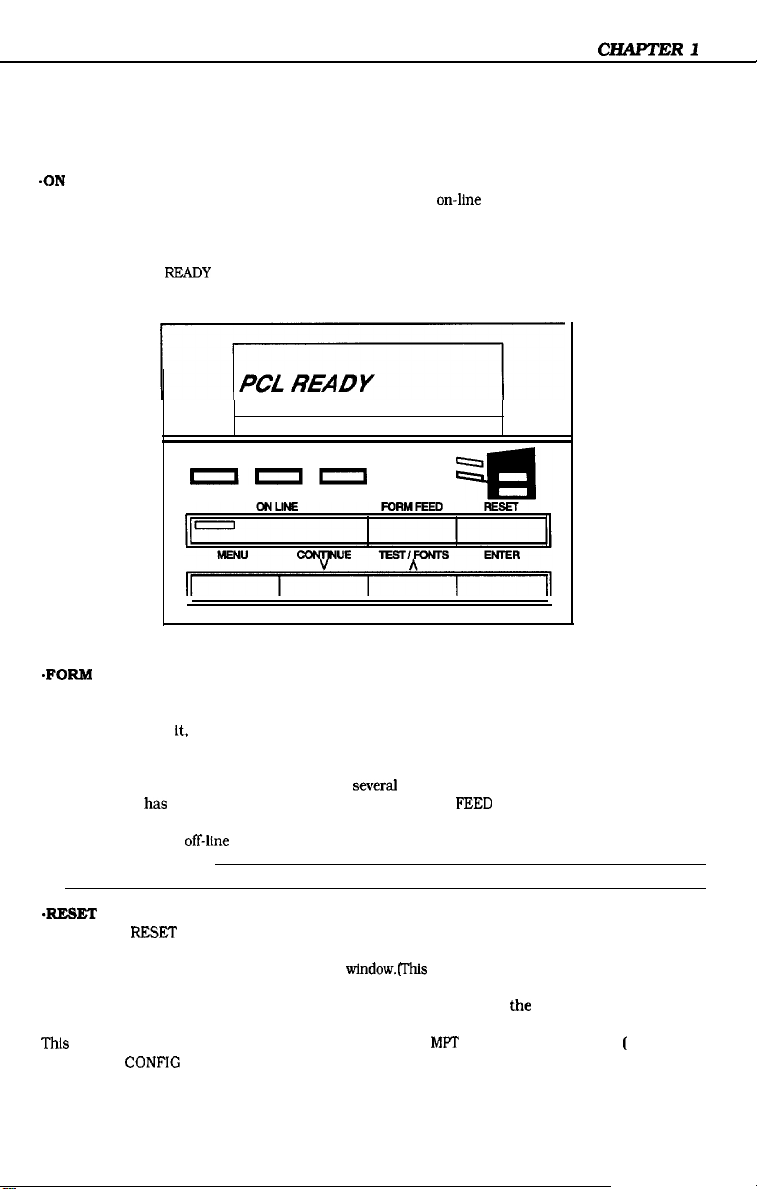

*ON

LINE key

You

use the ON LINE key to switch the printer between

be on-line to receive information from your computer. To use any of the other keys on the

operator panel, the printer must be off-line.

on-llne

and off-line. The printer must

The message PCL

READY

appears in the display window when the printer is on-line and ready

to receive data.

READY ALARM DATA

UIIII

Figure 1-13

*FORM

FEED key

You use

the FORM FEED key to print the data stored in the printer’s buffer. For example, if the

last page stored in the printer’s memory is a full page but your software does not send a

command to print

FEED to print the last page.

Keep in mind that complex pages may take

indicator light

The printer must be

It.

you can press ON LINE to set the printer off-line and then press FORM

several

has

stopped flashing before you press FORM

off-line

before you press FORM FEED.

minutes to process. Make sure the READY

FEED

to print the last page.

Note:

Pressing the FORM FEED key does not force a blank sheet through the printer.

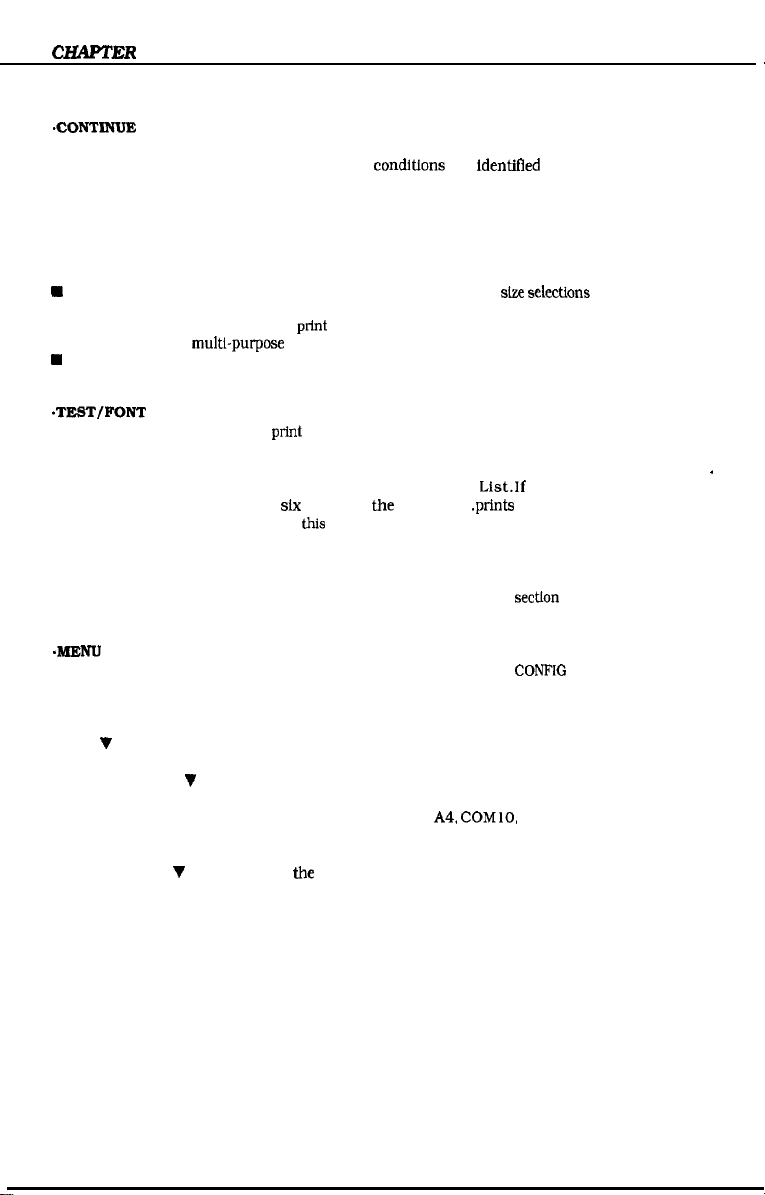

.RESET

key

You use the

RESKT

key to clear the printer’s buffer and remove all temporary typefaces and

macros from the printer’s memory. Press the RESET key for approximately three seconds until

the RESET message appears in the display

If you press and hold the RESET key for more than six seconds,

window.fIhis

prevents accidental loss of a print job)

the

MENU RESET message

appears in the display window. The printer resets all PCL parameters to their factory defaults.

This

includes all items in the PCL PRINT MENU except

in the PCL

CONFIG

MENU are not reset.) To reset all parameters to their factory defaults,

MPT

SIZE and ENVELOPE. ( The items

perform a cold reset by powering on the printer while holding the ON LINE key.

l-15

CIL4PTER

*CONTINUE key

You use the CONTINUE key to allow the pdnter to resume printing after it is placed off-line by

an operational condition. Most operational

PRINT OVERRUN. Before you continue printing. you need to press CONTINUE to clear the

message and set the printer back on-line.

The CONTINUE key sets the printer on-line just like the ON LINE key, but you can also use it

in the following ways:

K

K You can press CONTINUE to override a request to manually feeder paper or an envelope.

1

conditions

You can press CONTINUE to override the paper or envelope

media loaded In the multi-purpose tray, the optional Envelope Feeder, or a paper cassette.

This means you could use it to

is loaded in the

When you do this, the prlnter selects paper from the next available source.

multi-purpose

print

a letter-size page on legal-size paper if legal-size paper

tray

are

ldentlfled

by a message, such as

size selecttons

regardless of the

*TEST/FONT

You use

When the printer is off-line, you can press the TEST/FORT key once to start the Test Page

Press and hold the TEST/FONT key to print the Font

TEST/FONT key for more than

and Font List are described later in

4. Menu Keys

You use the menu keys to access the various menus and select the available menu items. This

section briefly describes each key. See the Operator Panel Menus

accessing and selecting menu items.

.MENu

The MENU key cycles through the PCL PRINT MENU and the PCL

The printer must be off-line when you press the MENU key.

A and V keys

You use the A and V keys to step through all available choices for a particular menu item. For

example, after you access the MPT SIZE option from the PCL PRINT MENU, you press A

repeatedly to display the LETTER, LEGAL, EXEC,

choices.

You can use the V key to dlsplay

key, the system scrolls rapidly through all choices for the menu optlon.

key

the TEST/FONT key to

key

print

the self tests Test Page or Font List.

ListIf

six

seconds,

this

the

the

chapter.

choices in reverse order. If you hold down either arrow

Test Page

A4. COMlO,

you press and hold the

.prints

continually. The Test Page

section

for Information about

CONFIG

MENU.

MONARC. B5. C5 and DL

.

l-16

-SELECT key

You use the

appears next to the selection in the menu display window indicating it is the current default

selection. This default selection

If you press SELECT when buffered or temporary data is present, the system only marks the

selectlons

displays the RESET TO SAVE message. At

8

8

SELECT key to save a selection in the printer’s permanent memory. An asterisk

remains In

with an asterisk. When you exit the menu by

Press RESET to clear

permanent default settings.

Press ON LINE or CONTINUE to place the printer on-line without performing a reset. The

selections you made in the menu are marked with an asterisk but do not become active

until the printer receives the next job or you reset the printer.

the

page buffers, remove temporary data, and return

effect even when you turn off orreset

pressing

this

point, you have two choices:

ON LINE or MENU,

the

printer.

the

all

items to their

(*)

system

When the printer is off-line. but not in the PCL PRINT MENU or PCL

SELECT prints a Printer Settings Page that lists

for details.

the

current menu settings. See page l-20-25

CONFlG

MENU, pressing

l-17

CHAPTER 1

B. Operator Panel Menus

You can

n PCL PRINT MENU

W

Depending on the options installed in your printer, other menus may display.

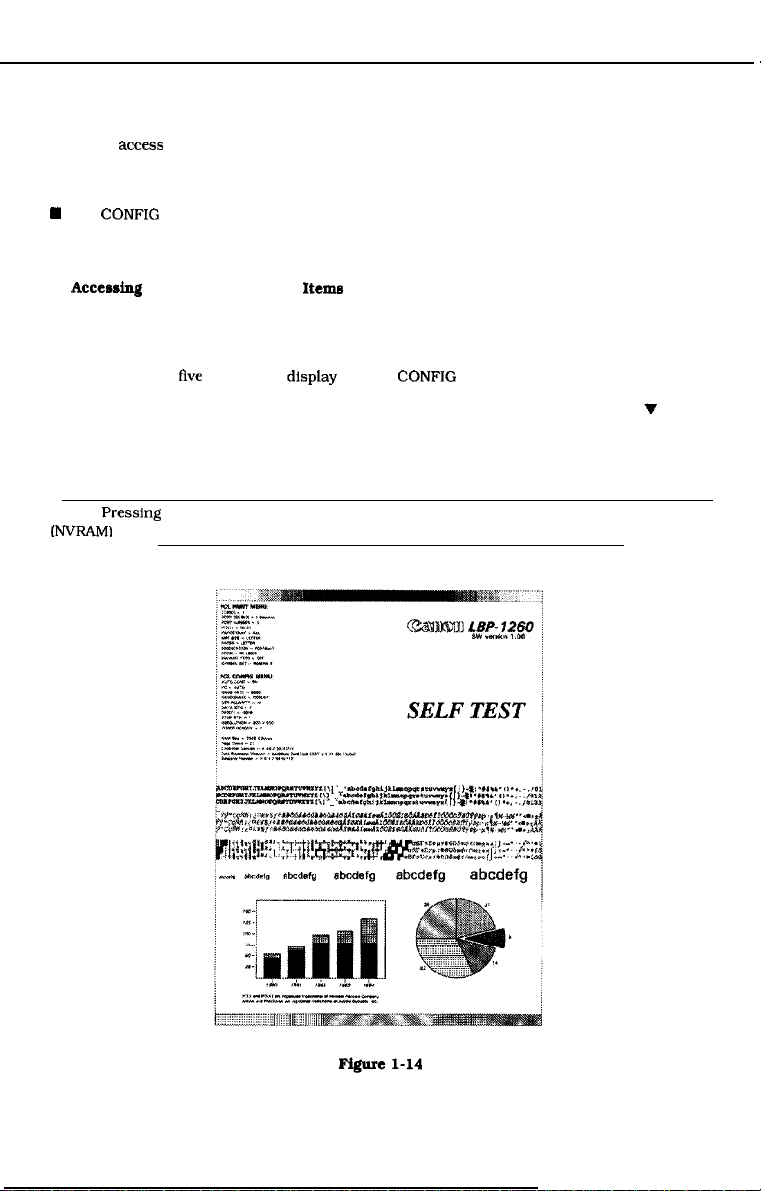

1.

Follow these steps to access the menus and make selections:

1.

2. Press MENU once to display the PCL PRINT MENU. Press and hold MENU [for

3.

4. When the item you want to change appears in the display window, press A or V to step

5.

6.

Note:

INvRAMl

accew

the following menus through the operator panel:

PCL CONFIG MENU

Accemsing

Press ON LINE to set the printer off-line.

approximately

Press MENU until you display the item you want to change.

through the available choices.

When the selection appears in the display window. press SELECT to save it as the default

setting. An asterisk appears next to your selection in the display window.

Press ON LINE to set the printer on-line.

and Selecting Menu

five

seconds) to display the PCL CONFIG MENU.

Pressing SELECT saves the value of the menu item to the printer’s nonvolatile memory

Iteme

1-18

CHAPTER

2. Confirming Your Menu Selections

There are two ways you can review the selections you made through the operator panel:

n

You can scroll through the menu items to check all selections marked

n

You can print a Printer Setting Page. The printed output lists all settings that are in effect.

See the Printing the Printer Setting Page section for more information.

3. Restorlng the Default Settings

There are several types of default settings:

Factory default settings are those set for each menu item at the factory. The printer uses

these settings until you change them.

Temporary default settings are those set by your application software for the current print

job.

Permanent default settings are those you set through the operator panel. These selections

remain in effect even when you

application.

You can restore the factory default settings by performing a cold reset. To perform a cold reset,

press and hold the ON LINE key while you turn on the

turn

off the

printer

or send a different request through your

printer.

tith an

asterisk.

1

The printer displays the message COLD

comes on-line, the factory default settings are restored.

RESET

followed by WARMING UP. When the printer

1-19

CHAPTER

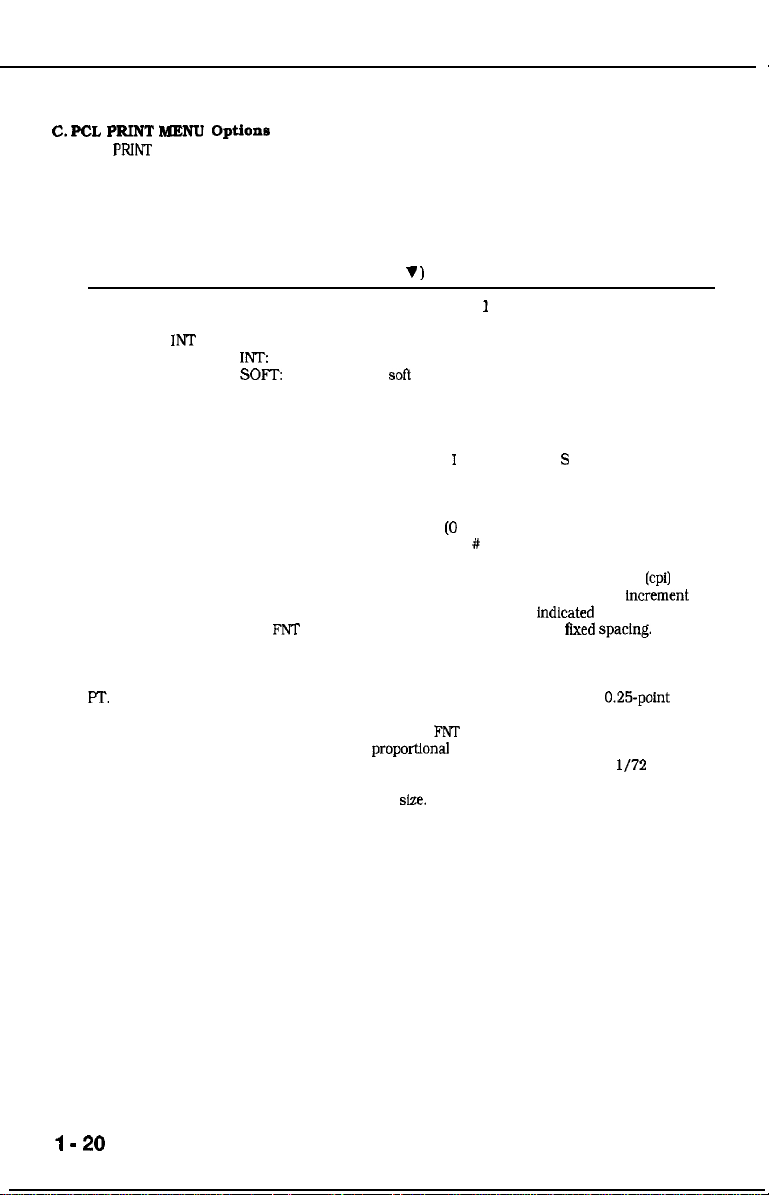

c.

PCL

The PCL

all options in thls menu through your software application. The changes you make through the

operator panel become the permanent default settings.

1

PRINT MENU

PRINT

Print

option

(Press Factory

MENU) default Description (Press A or V

COPIES 1

FNT INT

SOURCE

FNT

NUMBER

PITCH

PT.

SIZE

0

10.00

12.00

options

Selects the number of copies (from 1 to 99) you want to print.

Selects the font source. You can select:

INT:

SOFT

You see the SOFT option only if permanent soft fonts are

downloaded.

If you do not know the font source and font number, you can print a

Font List. The option you specify here must match the alpha portion

of the Font # on the Font List, I for internal or S for soft. For more

information about printing this list, see the Printing the Font List

section.

Identifies the Font Number (0 through 999) as listed on the Font

List. Make sure you use the Font # not the Font ID.

Selects pitch sizes from 0.44 to 99.99 characters per inch

scroll increments of 0.01. (Hold down the arrow key to

rapidly.) You can select a pitch if the font

and

LBP-1260 adjusts the height (point size) of the characters according

to the pitch you select.

Selects the point size from 4.00 to 999.75 points in

increments. The scroll increment is 0.25. You can select the point

size if the font indicated by

scalable font with

Point size is a measure of the height of a character in

inch. The LBP- 1260 adjusts the character’s horizontal spacing

according to the point

Internal fonts

Permanent

FNT

NUMBER is a scalable typeface with

soft

proportional

size.

MENU contains the most commonly used options. You can override or change

1

font

indicated

by FNT SOURCE

fIxed spacing.

FNT

SOURCE and FNT NUMBER is a

spacing.

[cpi)

increment

The

0.25-point

l/72

of an

in

1 - 20

Print

optlorl

(Press

MENU)

Factory

default

Description (Press A or V

)

TRAY ALL

MPTSIZE

PAPER

LETTER

LETTER

Selects how the printer will load paper:

ALL

MPT

FIRST

STD

LOWER

MPT

ENVELOPE

Selects the paper size loaded in the multi-purpose tray. You can

select:

LEXTER:

LEGAL:

EXEC:

A4:

COM 10:

MONARC:3.875

B5: 182 x 257 mm

c5:

DL:

Selects the Image size at which the printer formats the page unless

a software command overrides it. You can select:

LETIER:

LEGALz

EXEC:

A4:

COM 10:

MONARC:3.875 x

B5: 182 x 257 mm

c5:

DL:

Loads paper from any paper input source. The printer

loads from the standard cassette first: if this cassette

is empty, it loads from the lower cassette [if the Paper

Feeder Unit is installed) or the multi-purpose tray.

Loads from the mum-purpose tray first. If the tray is

empty, it loads from the standard cassette or the lower

cassette (if it is installed).

Loads from the standard paper cassette only. If this

cassette Is empty. you see a prompt to load paper.

Loads from the optional Paper Feeder Unit only;. If this

cassette is empty, you see a prompt to load paper. You

see this selection only if the optional Paper Feeder Unit

is installed.

Loads from the multi-purpose tray only. If this tray is

empty. you see a prompt to load paper.

Loads from the optional Envelope Feeder unit only: if

this feeder is empty, you see a prompt to load

envelopes. You see this selection only if the optional

Envelope Feeder unit is installed.

8.5 x 11 inches

8.5 x 14 inches

7.25 x 10.5 inches

21Ox297mm

4.125 x 9.5 inches

x 9.5 inches

l62x219mm

llOx220mm

8.5 x 11 inches

8.5 x 14 inches

7.5 x 10.5 inches

21Ox297mm

4.125 x 9.5 inches

9.5 inches

l62x219mm

llOx220mm

ENVELOPE COM

10

Selects the envelope size loaded in the Envelope Feeder. You see this

menu item only if the optional Envelope Feeder is installed. You can

select:

COM10:

9.5 x4.125 inches

MONARC:9.5

c5:

DL:

x 3.875 Inches

162 x 219 mm

llOx220mm

1-21

CHAPTER

Print

option

(Press

MENU)

ORIENTATI P

ON

1

Factory

default Description (Press A or

Selects the

p:

L:

You can print in reverse portrait or reverse landscape orientations

by making selections through your software application or using

printer commands. The LBP-1260 has a font rotation feature that

makes all fonts available in all orientations.

dlrection

Portrah prints text and graphics along the width of the

page

Landscape prints text and graphics along the length of the

page

V

)

of print on the page.

FORM 60

LINES

MANUAL OFF

FEED

SYMSET ROMAN

-8

Selects the number of lines to

well as the amount of space between lines. The FORM menu item

places the first line of text at the top margin, the last line of text at

the bottom margin, and spaces the remaining lines equally between

them. Make sure the text length setting In your software application

matches the value you use for this item. If it is set to a greater value

in your application, the first line of text may begin successively

lower on each page.

Turns the manual feed function ON or OFF. Manual feed is available

only through the multi-purpose tray. When MANUAL FEED=ON, the

printer goes

followed by FEED LETTER. Press ON LINE to manually feed the

media in the multi-purpose tray. Pressing CONTINUE when the

multi-purpose tray is empty override the manual feed request.

Selects the symbol set. The LBP-1260 provides 31 symbol sets you

can choose.A symbol set is a unique grouping of all the available

characters in a font. You can select these symbol sets from the

operator panel:

Roman-8

ISO-Ll

ISO-L2

ISO-L5

PC-8

PC-8 DN

PC-850

PC-852

PC-8 TK

WIN

WIN L2 MATH-8

WIN L5

LEGAL MS PUBL

ISOISOISO- 11

oif-line

when a print job is sent and displays MPT TRAY

ISO-

15

ISO-

17

ISOISOISOVNMATB

VNlNTL

VNUS

PS

Ll

MATB

PS

TEXT

PI FONT

WIN 3.0

DESKTOP

print

on each page (5 through 128) as

1

1 - 22

cHAPTEl?l

D. CONFIG

The PCL CONFIG MENU

the PCL CONFIG MENU options, press and hold the MENU key. To scroll through the options,

press the MENU key again.

The resolution and page protection options can be modified by PCL commands through the

print stream. However, you cannot override or change the other options in this menu through

your software application.

Note:

The I/O option allows you to set up the communication parameters for the serial

interface (if you are using it).

MENU

Options

controls certain

configuration settings for your LBP- 1260. To access

Config

option

(Press

MENU)

AUTO

FEED

I/O

Factory

default Description (Press A or V

ON

AUTO

Determines how the

can select:

ON:

OFF:

Selects the printer interface. You can select:

AUTO: Allows the printer to determine the interface port,

SERIAL:

PARALLEL:

printer

Any non-critical error message appears on the

display for about 10 seconds: then the PCL READY

message appears and printing resumes.

Any attendance or error message remains in the

display until you correct the problem, tell the

printer to continue, or both.

which can be either parallel

displays the communications options described in

the next section,

Selects the serial interface only. The printer

displays the communications options described in

the next section.

Selects the parallel interface only. The printer skips

1

reacts to data and printer errors. You

or serial.

The printer

to the RES menu option.

NETWORK:

Selects the optional network card. You see this

setting only if the Network option is installed.

RES

600 x 600 Selects 300 or 600 dots per

lnch(dpi1.

resolution. it takes effect for the next print job or when you reset

the printer through the operator panel. You can select:

300 x 300:

for graphics and fonts designed for 300 dpi.

600 x 600: for graphics and fonts designed for 600 dpi; use

when document contains a mix of 300 and 600 dpi

bitmaps.

When you change

1-23

conflg

option

[Press Factory

MENU]

PG

TONER 7

DENS

PROT

default

OFF or

LFXTER

Description (Press A or

Reserves additional memory for the page imaging process. This

allows the printer to create the complete page Image in memory

before paper starts through the printer, which ensures the entire

page is printed. The value you set for page protection takes effect

on the next print job

You see

this

take advantage of page protection. If you have only 2MB of

memory, the default is OFF. If you have 6MB of memory, the

default is

The complexity of a page may exceed the printer’s ability to

create the image and keep pace

page is too complex, the page may print in parts, or only part of

the page may print. If data loss occurs, the PRINT OVERRUN

message appears In the display window. If you often receive

message, you may need to Install additional memory and set a

value for page protection.

The memory required for page protection is dependent on the

resolution you select. A page at 600 dpi requires four times more

memory than a page at 300 dpi. If you use page protection, set it

for the paper

have

figures

You can

OFF:

LETIER:

LEGAL:

A4:

Print dens@ Is

the page. You can

best setting for your print job. To make print darker, use a higher

setting: to make print lighter, use a lower setting. The selections

are from 0 to 15.

Note that when you set the density to a higher level, the printer

uses more toner.

option only If

LETIER.

sufficient

shown here include 2MB of internal memory.

select:

V

)

youhave

enough memory installed to

with

the printing process. If a

this

size

you expect to use most often. Make sure you

memory Installed for the option you select. The

requires minimum installed memory of 2MB for

300 and 600 dpi.

requires 2MB for 300 dpi: 6MB for 600 dpi.

requires 3MB for 300 dpi; 6MB for 600 dpi.

requires 2MB for 300 dpi: 6MB for 600

a measure of the darkness of text and graphics on

experiment

with different settings to

dpl.

find

the

1 - 24

Loading...

Loading...