Canon iPF6350 Service Manual

Service Manual

iPF6000 series

Mar 7 2011

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, insta llati on, ma intenance, and repair

of products. This manual covers all localities where the products are sold. For this reason, there may be information in this

manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When

changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need

arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition

of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Memo

Introduction

REF.

Indicates an item of reference assisting the understanding of the topic in question.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Introduction

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol , the arrow indicates the

direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit door, which results in

supplying the machine with power.

2. In the digital circuits, '1'is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the fi eld. Ther efore, the operations of the microprocessors

used in the machines are not discussed: they are explained in terms of fro m sensors to the input of the DC controller PCB and from the output of the

DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service Information bulletins and be

able to identify and isolate faults in the machine."

Contents

1.5.11 Carriage ...............................................................................................................................................................1- 44

1.5.12 Inside....................................................................................................................................................................1- 45

1.5.13 Inside....................................................................................................................................................................1- 46

1.6 Basic Operation........................................................................................................................................1- 47

1.6.1 Operation Panel.....................................................................................................................................................1- 47

1.6.2 Operation Panel.....................................................................................................................................................1- 49

1.6.3 Main Menu.............................................................................................................................................................1- 50

1.6.4 Display...................................................................................................................................................................1- 70

1.6.5 Main Menu.............................................................................................................................................................1- 71

1.6.6 Main Menu.............................................................................................................................................................1- 91

1.6.7 Menu....................................................................................................................................................................1- 111

1.6.8 Menu....................................................................................................................................................................1- 127

1.7 Safety and Precautions ..........................................................................................................................1- 144

1.7.1 Safety Precautions...............................................................................................................................................1- 144

1.7.1.1 Moving Parts........................................................................................................................................................................1- 144

1.7.1.2 Adhesion of Ink .................................................................................................................................................................... 1- 144

1.7.1.3 Electric Parts........................................................................................................................................................................ 1- 146

1.7.1.4 Electric Parts........................................................................................................................................................................ 1- 146

1.7.2 Other Precautions................................................................................................................................................1- 147

1.7.2.1 Printhead.............................................................................................................................................................................. 1- 147

1.7.2.2 Printhead.............................................................................................................................................................................. 1- 148

1.7.2.3 Ink Tank ............................................................................................................................................................................... 1- 149

1.7.2.4 Handling the Printer ............................................................................................................................................................. 1- 149

1.7.2.5 Handling the Printer ............................................................................................................................................................. 1- 152

1.7.3 Precautions When Servicing Printer....................................................................................................................1- 154

1.7.3.1 Notes on the Data Stored in the Printer...............................................................................................................................1- 154

1.7.3.2 Confirming the Firmware Version ........................................................................................................................................1- 154

1.7.3.3 Precautions against Static Electricity...................................................................................................................................1- 154

1.7.3.4 Precautions for Disassembly/Reassembly........................................................................................................................... 1- 154

1.7.3.5 Self-diagnostic Feature........................................................................................................................................................1- 154

1.7.3.6 Disposing of the Lithium Battery .......................................................................................................................................... 1- 154

Chapter 2 TECHNICAL REFERENCE

2.1 Basic Operation Outline .............................................................................................................................2- 1

2.1.1 Printer Diagram........................................................................................................................................................2- 1

2.1.2 Printer Diagram........................................................................................................................................................2- 2

2.1.3 Printer Diagram........................................................................................................................................................2- 3

2.1.4 Printer Diagram........................................................................................................................................................2- 4

2.1.5 Printer Diagram........................................................................................................................................................2- 5

2.1.6 Printer Diagram........................................................................................................................................................2- 6

2.1.7 Print Signal Sequence ....................................................................................................................... ... ...................2- 7

2.1.8 Print Signal Sequence ....................................................................................................................... ... ...................2- 8

2.1.9 Print Signal Sequence ....................................................................................................................... ... ...................2- 9

2.1.10 Print Driving..........................................................................................................................................................2- 10

2.1.11 Print Driving..........................................................................................................................................................2- 12

2.1.12 Print Driving..........................................................................................................................................................2- 14

2.2 Firmware ..................................................................................................................................................2- 16

2.2.1 Operation Sequence at Power-on..........................................................................................................................2- 16

2.2.2 Operation Sequence at Power-off..........................................................................................................................2- 17

2.2.3 Print Control...........................................................................................................................................................2- 18

2.2.4 Print Position Adjustment Function........................................................................................................................2- 24

2.2.5 Head Management ................................................................................................................................................2- 24

2.2.6 Printhead Overheating Protection Control .............................................................................................................2- 24

2.2.7 Pause between Pages...........................................................................................................................................2- 24

2.2.8 White Raster Skip..................................................................................................................................................2- 24

2.2.9 Sleep Mode............................................................................................................................................................2- 24

Contents

2.2.10 Hard Disk Drive............................................................................................ ... .....................................................2- 24

2.3 Printer Mechanical System..................................................................................... ... ... ... .... ... ..................2- 26

2.3.1 Outline...................................................................................................................................................................2- 26

2.3.1.1 Outline.................................................................................................................................................................................... 2- 26

2.3.2 Ink Passage...........................................................................................................................................................2- 27

2.3.2.1 Ink Passage ........................................................................................................................................................................... 2- 27

2.3.2.2 Ink Tank Unit............................................................................................... ...........................................................................2- 29

2.3.2.3 Carriage Unit..........................................................................................................................................................................2- 33

2.3.2.4 Printhead................................................................................................................................................................................ 2- 37

2.3.2.5 Purge Unit..............................................................................................................................................................................2- 38

2.3.2.6 Maintenance Cartridge........................................................................................................................................................... 2- 42

2.3.2.7 Air Flow..................................................................................................................................................................................2- 44

2.3.3 Paper Path.............................................................................................................................................................2- 45

2.3.3.1 Outline.................................................................................................................................................................................... 2- 45

2.3.3.2 Paper Path.............................................................................................................................................................................2- 46

2.3.3.3 Cutter Unit..............................................................................................................................................................................2- 56

2.4 Printer Electrical System........................ ... .... ... ... ... ... .... ... ....................................... ... ... ... .........................2- 58

2.4.1 Outline...................................................................................................................................................................2- 58

2.4.1.1 Overview................................................................................................................................................................................2- 58

2.4.1.2 Overview................................................................................................................................................................................2- 60

2.4.1.3 Overview................................................................................................................................................................................2- 62

2.4.1.4 Overview................................................................................................................................................................................2- 64

2.4.1.5 Overview................................................................................................................................................................................2- 66

2.4.2 Main Controller......................................................................................................................................................2- 68

2.4.2.1 Main controller PCB components .......................................................................................................................................... 2- 68

2.4.2.2 Main controller PCB components .......................................................................................................................................... 2- 69

2.4.2.3 Main controller PCB components .......................................................................................................................................... 2- 71

2.4.2.4 Main controller PCB components .......................................................................................................................................... 2- 72

2.4.2.5 Main controller PCB components .......................................................................................................................................... 2- 74

2.4.2.6 Main controller PCB components .......................................................................................................................................... 2- 75

2.4.2.7 HDD expansion PCB components................................................................................................................................ ......... 2- 77

2.4.3 Carriage Relay PCB..............................................................................................................................................2- 77

2.4.3.1 Carriage PCB components .................................................................................................................................................... 2- 77

2.4.4 Motor Driver...........................................................................................................................................................2- 78

2.4.4.1 Roll feed unit PCB components.............................................................................................................................................2- 78

2.4.5 Maintenance Cartridge Relay PCB........................................................................................................................2- 78

2.4.5.1 Maintenance cartridge relay PCB components...................................................................................................................... 2- 78

2.4.6 Power Supply .............................................................................................. .. ........................................................2- 79

2.4.6.1 Power supply block diagram..................................................................................................................................................2- 79

2.5 Detection Functions with Sensors ................... ... ... ... .... ... ... ... .... ... .......................................... ... ...............2- 80

2.5.1 Sensors for covers.................................................. ...............................................................................................2- 80

2.5.2 Ink passage system...............................................................................................................................................2- 81

2.5.3 Ink passage system...............................................................................................................................................2- 83

2.5.4 Ink passage system...............................................................................................................................................2- 85

2.5.5 Ink passage system...............................................................................................................................................2- 87

2.5.6 Carriage system ....................................................................................................................................................2- 89

2.5.7 Paper path system.................................................................................................................................................2- 91

2.5.8 Paper path system.................................................................................................................................................2- 93

2.5.9 Others....................................................................................................................................................................2- 95

Chapter 3 INSTALLATION

3.1 Installation ..................................................................................................................................................3- 1

3.1.1 Making Pre-Checks.................................................................................................................................................3- 1

3.1.1.1 Making Pre-Checks...................... ............................................................................................................................................ 3- 1

3.1.2 Unpacking and Installation ......................................................................................................................................3- 1

3.1.2.1 Unpacking and Installation.......................................................................................................................................................3- 1

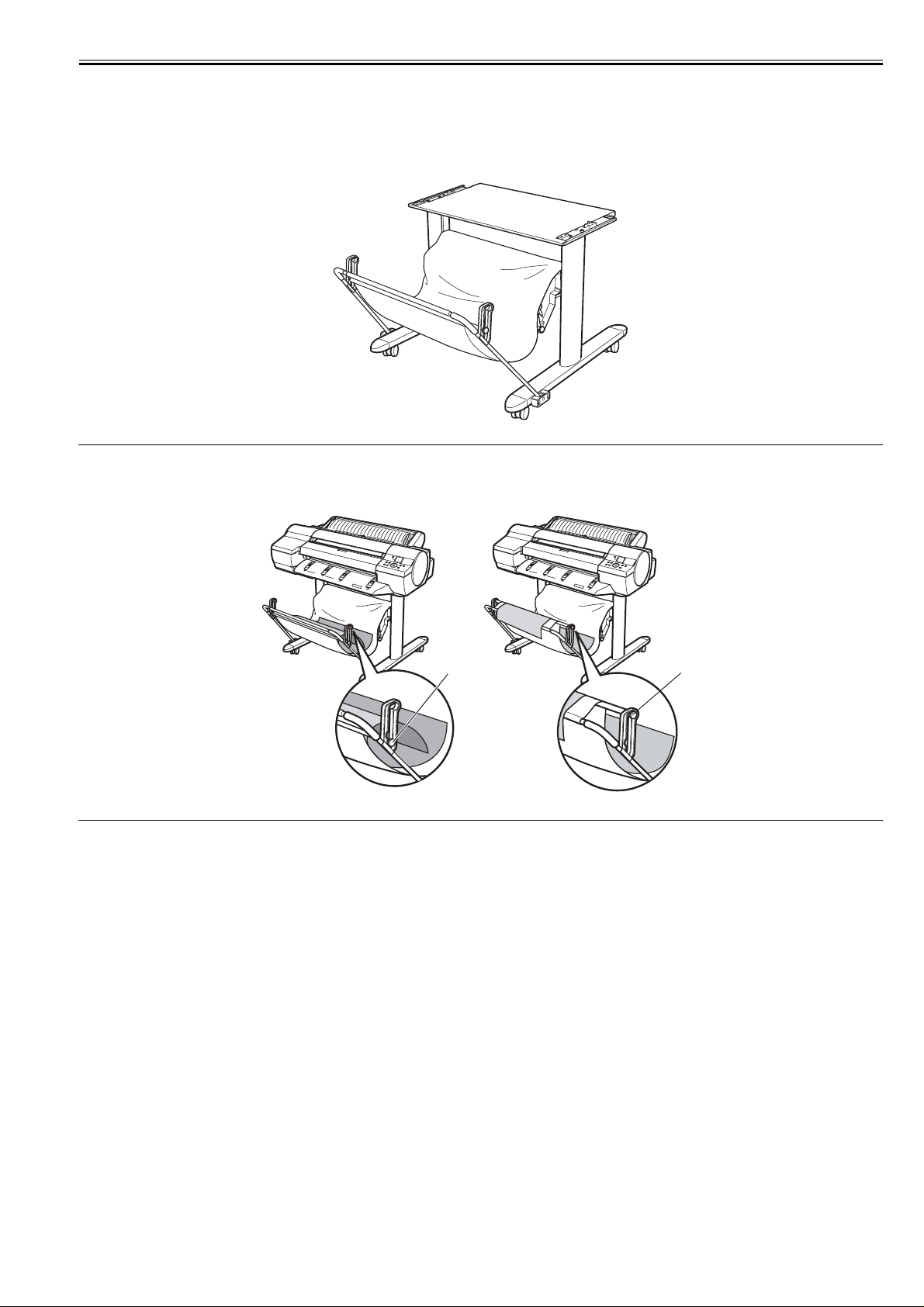

3.1.2.2 Installing the Stand ..................................................................................... ...........................................................................3- 10

3.1.3 Checking the Images/Operations ..........................................................................................................................3- 19

Contents

3.1.3.1 Checking the Image and Operation ....................................................................................................................................... 3- 19

3.2 Transporting the Printer............................................................................................................................3- 20

3.2.1 Transporting the Printer. ........................................................................................................................................3- 20

3.2.1.1 Transporting the Printer ......................................................................................................................................................... 3- 20

3.2.1.2 Transporting the Printer ......................................................................................................................................................... 3- 22

3.2.2 Reinstalling the Printer...........................................................................................................................................3- 24

3.2.2.1 Reinstalling the Printer........................................................................................................................................................... 3- 24

Chapter 4 DISASSEMBLY/REASSEMBLY

4.1 Service Parts..............................................................................................................................................4- 1

4.1.1 Service Parts............................... .................................................. .................................... ... ....................................4- 1

4.2 Disassembly/Reassembly ..........................................................................................................................4- 2

4.2.1 Disassembly/Reassembly........................................................................................................................................4- 2

4.3 Points to Note on Disassembly and Reassembly.......................................................................................4- 2

4.3.1 Note: Items that should never be disassembled......................................................................................................4- 2

4.3.2 Moving the carriage manually....... ...........................................................................................................................4- 2

4.3.3 Units requiring draining of ink ..................................................................................................................................4- 2

4.3.4 External Covers ..................................... ... .................................................. ... ....................................... ... ................4- 4

4.3.5 Driving Unit ............................................................................................................................................................4- 17

4.3.6 Cutter.....................................................................................................................................................................4- 18

4.3.7 Cutter.....................................................................................................................................................................4- 21

4.3.8 Carriage Unit....................................................................................................... ... ................................................4- 24

4.3.9 Carriage Unit....................................................................................................... ... ................................................4- 32

4.3.10 Feeder Unit .................................... ... .................................................. ... ..............................................................4- 40

4.3.11 Feeder Unit .................................... ... .................................................. ... ..............................................................4- 43

4.3.12 Roll Feed Unit ......................................................................................................................................................4- 46

4.3.13 Purge Unit............. .................................................. ... ..........................................................................................4- 49

4.3.14 Waste Ink Collection Unit.....................................................................................................................................4- 52

4.3.15 Ink Tank Unit........................................................................................................................................................4- 56

4.3.16 Ink Tank Unit........................................................................................................................................................4- 59

4.3.17 Head Management Sensor..................................................................................................................................4- 62

4.3.18 Multi Sensor.........................................................................................................................................................4- 62

4.3.19 Multi Sensor.........................................................................................................................................................4- 63

4.3.20 PCBs....................................................................................................................................................................4- 64

4.3.21 PCBs....................................................................................................................................................................4- 67

4.3.22 PCBs....................................................................................................................................................................4- 72

4.3.23 Opening the Cap/Moving the Wiper Unit..............................................................................................................4- 77

4.3.24 Opening the Cap/Moving the Wiper Unit..............................................................................................................4- 79

4.3.25 Opening/Closing the Ink Supply Valve.................................................................................................................4- 81

4.3.26 Draining the Ink............................................ ........................................................................................................4- 82

4.4 Applying the Grease.................................................................................................................................4- 83

4.4.1 Applying the Grease ..............................................................................................................................................4- 83

4.5 Adjustment and Setup Items ....................................................................................................................4- 87

4.5.1 Adjustment Item List .............................. ... .................................................. ... ........................................................4- 87

4.5.2 Adjustment Item List .............................. ... .................................................. ... ........................................................4- 87

4.5.3 Procedure after Replacing the Carriage Unit or Multi Sensor................................................................................4- 87

4.5.4 Procedure after Replacing the Carriage Unit or Multi Sensor................................................................................4- 90

4.5.5 Procedure after Replacing the Head Management Sensor ...................................................................................4- 93

Chapter 5 MAINTENANCE

5.1 Periodic Replacement Parts.................... ... ................................................................................................5- 1

5.1.1 Periodic Replacement Parts ....................................................................................................................................5- 1

5.2 Consumable Parts......................................................................................................................................5- 1

5.2.1 Consumable Parts ........................................................................................................................ .. .........................5- 1

Contents

5.2.2 Consumable Parts............................................................................................................................................ ... ....5- 2

5.2.3 Consumable Parts............................................................................................................................................ ... ....5- 3

5.2.4 Consumable Parts............................................................................................................................................ ... ....5- 4

5.3 Periodic Maintenance...................................................... ... ... .... .................................................................5- 5

5.3.1 Periodic Maintenance.......................................................................................................................................... ....5- 5

5.3.2 Periodic Maintenance.......................................................................................................................................... ....5- 8

5.3.3 Periodic Maintenance............................................................................................................................................5- 11

Chapter 6 TROUBLESHOOTING

6.1 Troubleshooting..........................................................................................................................................6- 1

6.1.1 Outline.....................................................................................................................................................................6- 1

6.1.1.1 Outline of Troubleshooting.......................................................................................................................................................6- 1

6.1.2 Troubleshooting When Warnings Occur..................................................................................................................6- 1

6.1.2.1 Ink Lvl: Chk XX (1000,1001,1002,1003,1004,1005,1006,1008,1009,100A,100B,100C)......................................................... 6- 1

6.1.2.2 MTCart Full Soon (1100) .........................................................................................................................................................6- 1

6.1.2.3 Mist Full Soon (1101)............................................................................................................................................................... 6- 1

6.1.2.4 GARO W12xx: xx stands for digits (1221,1222,1223,1225,1231,1232,1233,1234,1235) ....................................................... 6- 1

6.1.2.5 Feed Limit... (100F).................................................................................................................................................................. 6- 2

6.1.2.6 Check printed document.(1010)............................................................................................................................................... 6- 2

6.1.3 Troubleshooting When Errors Occur.......................................................................................................................6- 2

6.1.3.1 01800500-1012/01800500-1013 Defective printhead nozzle .................................................................................................. 6- 2

6.1.3.2 03010000-200C/03010000-2017/03010000-2018/03016000-2010 Multi sensor error............................................................ 6- 2

6.1.3.3 03010000-200D Cut sheet end cannot be detected ................................................................................................................ 6- 2

6.1.3.4 03010000-2820/03010000-2821/03010000-2822/03010000-2823/03130031-2F32/03010000-2F33 Adjustment error......... 6- 3

6.1.3.5 03010000-2E1F/03060000-2E14/03061000-2E15/03060000-2E16/03060200-2E03/03060200-2E0B/03060A00-2E00/

03060A00-2E01/03860002-2E0A Path mismatch error................................................................................................................. 6- 3

6.1.3.6 03010000-2E25/03010000-2E27 Paper feed/delivery jam error .............................................................................................6- 3

6.1.3.7 03030000-2E21 IEEE1394 error..............................................................................................................................................6- 4

6.1.3.8 03060A00-2E0E Roll media unit uninstallation........................................................................................................................6- 4

6.1.3.9 03060A00-2E1B Roll media end error.....................................................................................................................................6- 4

6.1.3.10 03130031-291B Lift home position error................................................................................................................................6- 4

6.1.3.11 03130031-291D Supr cam sensor error................................................................................................................................. 6- 5

6.1.3.12 03130031-2E23 Cutter unit breakdown ................................................................................................................................. 6- 5

6.1.3.13 03130031-2F13 A/D Converter external trigger output stopped ............................................................................................ 6- 5

6.1.3.14 03130031-2F14 ASIC Register cannot be written................................................................................................................. 6- 5

6.1.3.15 03130031-2F16 Mist fan error................................................................................................................................................ 6- 5

6.1.3.16 03130031-2F17 Suction fan error .......................................................................................................................................... 6- 6

6.1.3.17 03130031-2F20/03130031-2F28/03130031-2F22/03130031-2F23 Defective sensor in purge unit......................................6- 6

6.1.3.18 03130031-2F24 Cutter drive time-out error............................................................................................................................ 6- 6

6.1.3.19 03130031-2F25 Carriage home position error.......................................................................................................................6- 6

6.1.3.20 03130031-2F26/03130031-2F27 Carriage motor error.......................................................................................................... 6- 7

6.1.3.21 03130031-2F2A Feed roller home position error ................................................................................................................... 6- 7

6.1.3.22 03130031-2F2D The cassette cannot work. .......................................................................................................................... 6- 7

6.1.3.23 03130031-2F2E Roll drive time-out error...............................................................................................................................6- 7

6.1.3.24 03130031-2F3A Valve open/close error ................................................................................................................................ 6- 8

6.1.3.25 03180003-2E22 MIT error......................................................................................................................................................6- 8

6.1.3.26 03180101-2E17 Cassette uninstallation ................................................................................................................................6- 8

6.1.3.27 03800200-2802/03800400-2803/03800300-2801/03800201-280A/03800401-280B/03800301-2809/03800200-2804/

03800202-2807 Printhead error.....................................................................................................................................................6- 8

6.1.3.28 03810101-2501/03810102-2502/03810103-2503/03810104-2500/03810105-2508/03810106-2506/03810107-250A/

03810108-250C/03810109-250B/03810112-2504/03810113-2505/03810115-2509 No ink error.................................................6- 9

6.1.3.29 03830101-2521/03830104-2520/03830102-2522/03830103-2523/03830112-2524/03830113-2525/03830106-2526/

03830105-2528/03830115-2529/03830107-252A/03830109-252B/03830108-252C Ink tank is not installed.(This error occurs when

the ink tank is replaced.) ................................................................................................................................................................ 6- 9

6.1.3.30 03830201-2541/03800204-2540/03830202-2542/03830203-2543/03830212-2544/03830213-2545/03830206-2546/

03830205-2548/03830215-2549/03830207-254A/03830209-254B/03830208-254C Invalid ink tank ID.......................................6- 9

6.1.3.31 03830301-2561/03830304-2560/03830302-2562/03830303-2563/03830312-2564/03830313-2565/03830306-2566/

03830305-2568/03830305-2568/03830315-2569/03830307-256A/03830309-256B/03830308-256C Ink tank EEPROM error...6- 9

6.1.3.32 03841001-2819/03841201-2816/03841201-2817/03841101-2818/01841001-281B Maintenance cartridge error................ 6- 9

6.1.3.33 03861001-2405/03861001-2406 Borderless printing error .................................................................................................. 6- 10

Contents

6.1.3.34 03862000-2E09 Insufficient roll media error........................................................................................................................6- 10

6.1.3.35 03870001-2015 Cut error..................................................................................................................................................... 6- 10

6.1.4 Troubleshooting When Service Call Errors Occur.................................................................................................6- 10

6.1.4.1 Outline.................................................................................................................................................................................... 6- 10

6.1.4.2 E141-4046 Recovery system rotation count reached 50,000................................................................................................6- 11

6.1.4.3 E144-4047 Supply system's count error ................................................................................................................................ 6- 11

6.1.4.4 E146-4001 Borderless/idle ejection/mist collection count full ................................................................................................ 6- 11

6.1.4.5 E194-404A Non-discharge detection count error................................................................................................................... 6- 11

6.1.4.6 E196-4040/E196-4041/E196-4042/E196-4045/E196-4049 main controller PCB error .........................................................6- 11

6.1.4.7 E198-401C/E198-401D/E198-401E RTC error...................................................................................................................... 6- 11

6.2 Location of Connectors and Pin Arrangement .........................................................................................6- 12

6.2.1 Main controller PCB...............................................................................................................................................6- 12

6.2.2 Main controller PCB...............................................................................................................................................6- 24

6.2.3 Main controller PCB...............................................................................................................................................6- 35

6.2.4 Main controller PCB...............................................................................................................................................6- 46

6.2.5 Main controller PCB...............................................................................................................................................6- 57

6.2.6 Carriage PCB....................................................... ... .................................................. ... ..........................................6- 68

6.2.7 Power supply ...................................... .................................................. ... ..............................................................6- 77

6.2.8 Power supply ...................................... .................................................. ... ..............................................................6- 78

6.2.9 Roll feed unit PCB..................................................................................................................................................6- 79

6.3 Version Up..... ... ... .... ... ... ... ... ....................................... ... .... ... ... ... ..............................................................6- 80

6.3.1 Firmware Update Tool ...........................................................................................................................................6- 80

6.3.2 Firmware Update Tool ...........................................................................................................................................6- 81

6.4 Service Tools............................................................................................................................................6- 82

6.4.1 Tool List ................................... .................................................. ............................................................................6- 82

Chapter 7 SERVICE MODE

7.1 Service Mode .............................................................................................................................................7- 1

7.1.1 Service Mode Operation..........................................................................................................................................7- 1

7.1.2 Service Mode Operation..........................................................................................................................................7- 2

7.1.3 Map of the Service Mode................................................................................................................................. ... .....7- 3

7.1.4 Map of the Service Mode................................................................................................................................. ... .....7- 8

7.1.5 Map of the Service Mode.......................................................................................................................................7- 13

7.1.6 Map of the Service Mode.......................................................................................................................................7- 18

7.1.7 Map of the Service Mode.......................................................................................................................................7- 25

7.1.8 Details of Service Mode.................................................. ... ....................................................................................7- 32

7.1.9 Details of Service Mode.................................................. ... ....................................................................................7- 40

7.1.10 Details of Service Mode.............................................................. ... ... .................................... ...............................7- 48

7.1.11 Details of Service Mode.............................................................. ... ... .................................... ...............................7- 56

7.1.12 Details of Service Mode.............................................................. ... ... .................................... ...............................7- 71

7.1.13 Sample Printout....................................................................................................................................................7- 86

7.1.14 e-Maintenance/imageWARE Remote..................................................................................................................7- 90

7.1.15 Viewing PRINT INF............................................................................................................................................7- 100

7.1.16 Viewing PRINT INF............................................................................................................................................7- 114

7.2 Special Mode............................................................................................................................... ... ... ... ..7- 128

7.2.1 Special Modes for Servicing ................................................................................................................................7- 128

7.2.2 Special Modes for Servicing ................................................................................................................................7- 128

Chapter 8 ERROR CODE

8.1 Outline........................................................................................................................................................8- 1

8.1.1 Outline.................................................................................................................................................................... ..8- 1

8.1.2 Outline.................................................................................................................................................................... ..8- 2

8.2 Warning Table............................................................................................................................................8- 3

8.2.1 Warnings..................................................................................................................................................................8- 3

8.2.2 Warnings..................................................................................................................................................................8- 4

Contents

8.2.3 Warnings ................................................................................................................................... ..............................8- 5

8.3 Error Table..................................................................................................................................................8- 8

8.3.1 Error Code List ................................................................................................................................... ... ..................8- 8

8.3.2 Error Code List ......................................................................................................................................................8- 18

8.3.3 Errors.....................................................................................................................................................................8- 29

8.4 Sevice Call Table......................................................................................................................................8- 40

8.4.1 Service Call Errors....................................... ... .................................................. ... ..................................................8- 40

8.4.2 Service Call Errors....................................... ... .................................................. ... ..................................................8- 40

8.4.3 Service Call Errors....................................... ... .................................................. ... ..................................................8- 41

Chapter 1 PRODUCT DESCRIPTION

Contents

Contents

1.1 Product Overview ..........................................................................................................................................................1-1

1.1.1 Product Overview ........................................................................................................................................................................ 1-1

1.1.2 Product Overview ........................................................................................................................................................................ 1-2

1.1.3 Product Overview ........................................................................................................................................................................ 1-3

1.1.4 Product Overview ........................................................................................................................................................................ 1-4

1.1.5 Product Overview ........................................................................................................................................................................ 1-5

1.2 Features..........................................................................................................................................................................1-6

1.2.1 Features........................................................................................................................................................................................ 1-6

1.2.2 Features........................................................................................................................................................................................ 1-6

1.2.3 Features........................................................................................................................................................................................ 1-6

1.2.4 Features........................................................................................................................................................................................ 1-7

1.2.5 Features........................................................................................................................................................................................ 1-7

1.2.6 Features........................................................................................................................................................................................ 1-7

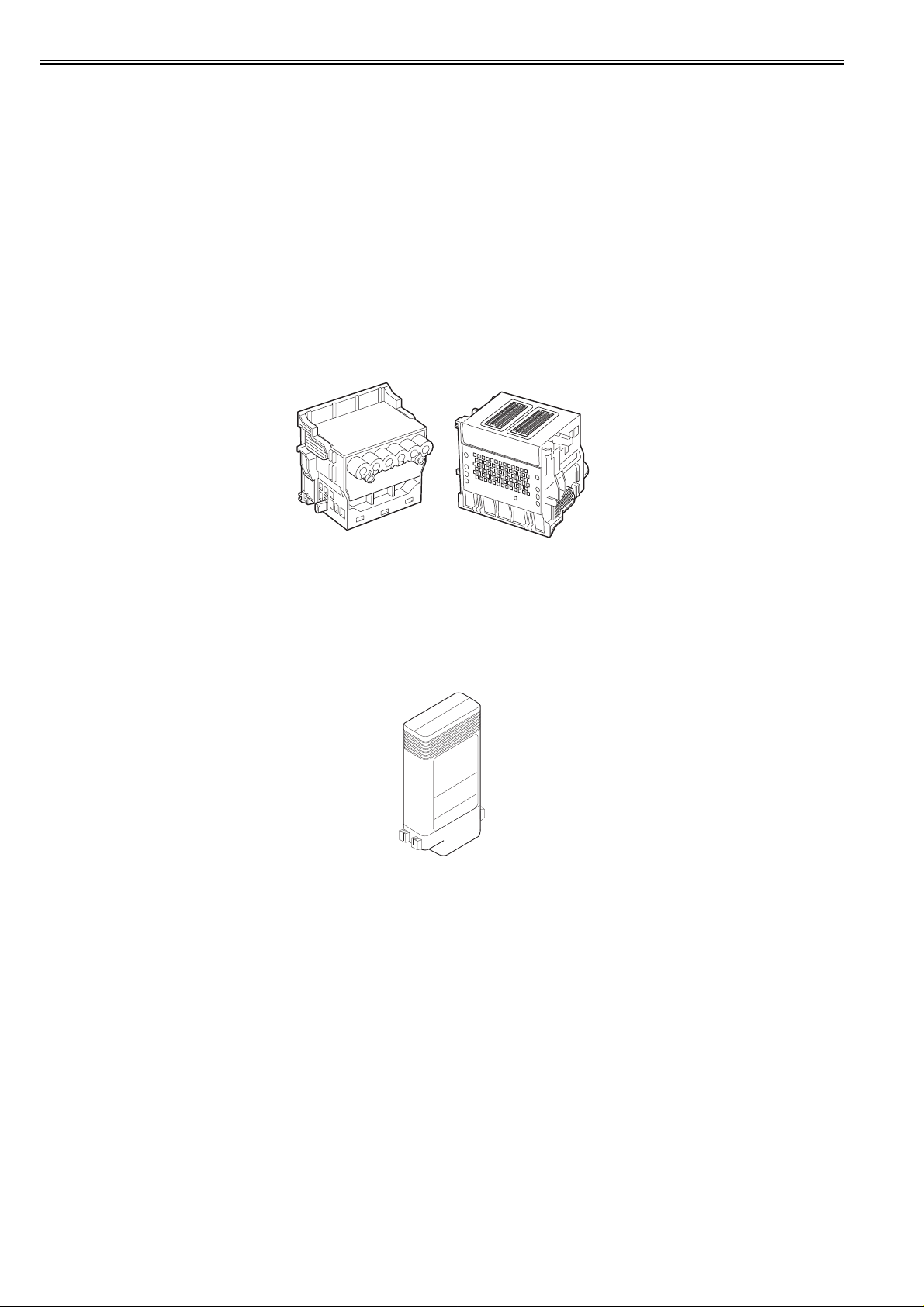

1.2.7 Printhead ...................................................................................................................................................................................... 1-8

1.2.8 Ink Tank....................................................................................................................................................................................... 1-8

1.2.9 Ink Tank....................................................................................................................................................................................... 1-9

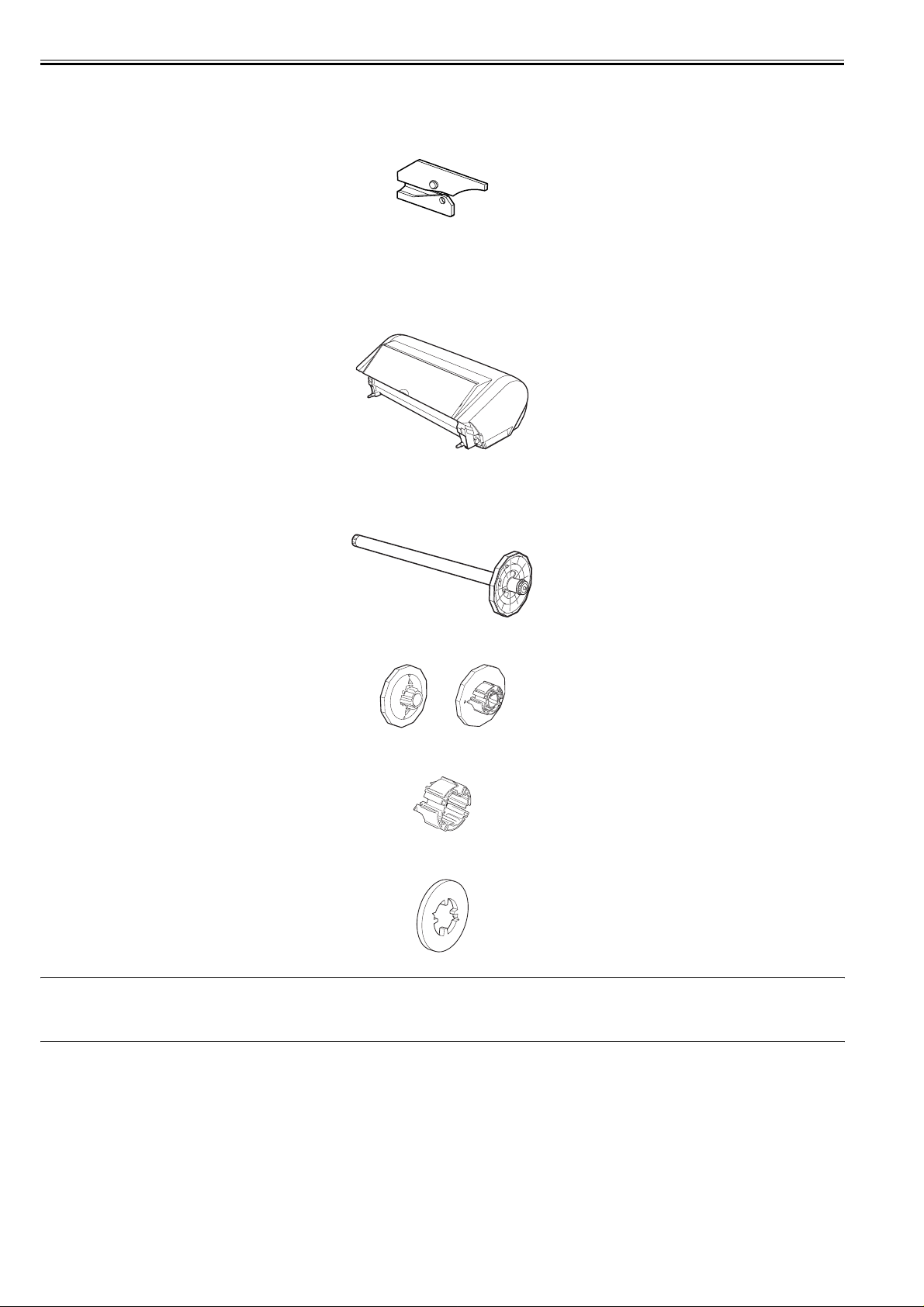

1.2.10 Cutter........................................................................................................................................................................................ 1-10

1.2.11 Roll Feed Unit.......................................................................................................................................................................... 1-10

1.2.12 Stand ........................................................................................................................................................................................ 1-11

1.2.13 Hard Disk Drive....................................................................................................................................................................... 1-11

1.2.14 Hard Disk Drive....................................................................................................................................................................... 1-11

1.2.15 IEEE1394 (FireWire) Board.............................................. ............................ .......................................................................... 1-12

1.2.16 Consumables............................................................................................................................................................................ 1-13

1.2.17 Consumables............................................................................................................................................................................ 1-14

1.2.18 Consumables............................................................................................................................................................................ 1-15

1.2.19 Consumables............................................................................................................................................................................ 1-16

1.3 Product Specifications..................................................................................................................................................1-17

1.3.1 Product Specifications ............................................................................................................................................................... 1-17

1.3.2 Product Specifications ............................................................................................................................................................... 1-18

1.3.3 Product Specifications ............................................................................................................................................................... 1-20

1.3.4 Product Specifications ............................................................................................................................................................... 1-22

1.3.5 Product Specifications ............................................................................................................................................................... 1-24

1.3.6 Product Specifications ............................................................................................................................................................... 1-26

1.4 Detailed Specifications ................................................................................................................................................1-28

1.4.1 Print Speed and Direction .......................................................................................................................................................... 1-28

1.4.2 Interface Specifications.............................................................................................................................................................. 1-34

1.4.3 Interface Specifications.............................................................................................................................................................. 1-35

1.4.4 Interface Specifications.............................................................................................................................................................. 1-36

1.5 Names and Functions of Components .........................................................................................................................1-37

1.5.1 Front........................................................................................................................................................................................... 1-37

1.5.2 Front........................................................................................................................................................................................... 1-38

1.5.3 Rear............................................................................................................................................................................................ 1-39

1.5.4 Rear............................................................................................................................................................................................ 1-39

1.5.5 Top Cover (Inside)..................................................................................................................................................................... 1-40

1.5.6 Top Cover (Inside)..................................................................................................................................................................... 1-40

1.5.7 Manual Loading Area ................................................................................................................................................................ 1-41

1.5.8 Manual Loading Area ................................................................................................................................................................ 1-42

1.5.9 Roll Feed Unit Cover (Inside).................................................................. .................................................................................. 1-43

1.5.10 Roll Feed Unit Cover (Inside).................................................................................................................................................. 1-43

1.5.11 Carriage.................................................................................................................................................................................... 1-44

Contents

1.5.12 Inside........................................................................................................................................................................................ 1-45

1.5.13 Inside........................................................................................................................................................................................ 1-46

1.6 Basic Operation...........................................................................................................................................................1-47

1.6.1 Operation Panel.......................................................................................................................................................................... 1-47

1.6.2 Operation Panel.......................................................................................................................................................................... 1-49

1.6.3 Main Menu................................................................................................................................................................................. 1-50

1.6.4 Display....................................................................................................................................................................................... 1-70

1.6.5 Main Menu................................................................................................................................................................................. 1-71

1.6.6 Main Menu................................................................................................................................................................................. 1-91

1.6.7 Menu ........................................................................................................................................................................................ 1-111

1.6.8 Menu ........................................................................................................................................................................................ 1-127

1.7 Safety and Precautions .............................................................................................................................................. 1-144

1.7.1 Safety Precautions.................................................................................................................................................................... 1-144

1.7.1.1 Moving Parts............................................................................................................................................................................................... 1-144

1.7.1.2 Adhesion of Ink .......................................................................................................................................................................................... 1-144

1.7.1.3 Electric Parts ............................................................................................................................................................................................... 1-146

1.7.1.4 Electric Parts ............................................................................................................................................................................................... 1-146

1.7.2 Other Precautions..................................................................................................................................................................... 1-147

1.7.2.1 Printhead ..................................................................................................................................................................................................... 1-147

1.7.2.2 Printhead ..................................................................................................................................................................................................... 1-148

1.7.2.3 Ink Tank......................................................................................................................................................................................................1-149

1.7.2.4 Handling the Printer.................................................................................................................................................................................... 1-149

1.7.2.5 Handling the Printer.................................................................................................................................................................................... 1-152

1.7.3 Precautions When Servicing Printer ........................................................................................................................................ 1-154

1.7.3.1 Notes on the Data Stored in the Printer ...................................................................................................................................................... 1-154

1.7.3.2 Confirming the Firmware Version.......................... ... ... ...................................... .... ... .................................................................................1-154

1.7.3.3 Precautions against Static Electricity..........................................................................................................................................................1-154

1.7.3.4 Precautions for Disassembly/Reassembly .................................................................................................................................................. 1-154

1.7.3.5 Self-diagnostic Feature ............................................................................................................................................................................... 1-154

1.7.3.6 Disposing of the Lithium Battery .................. ... ...................................... .................................................................................................... 1-154

1.1 Product Overview

Chapter 1

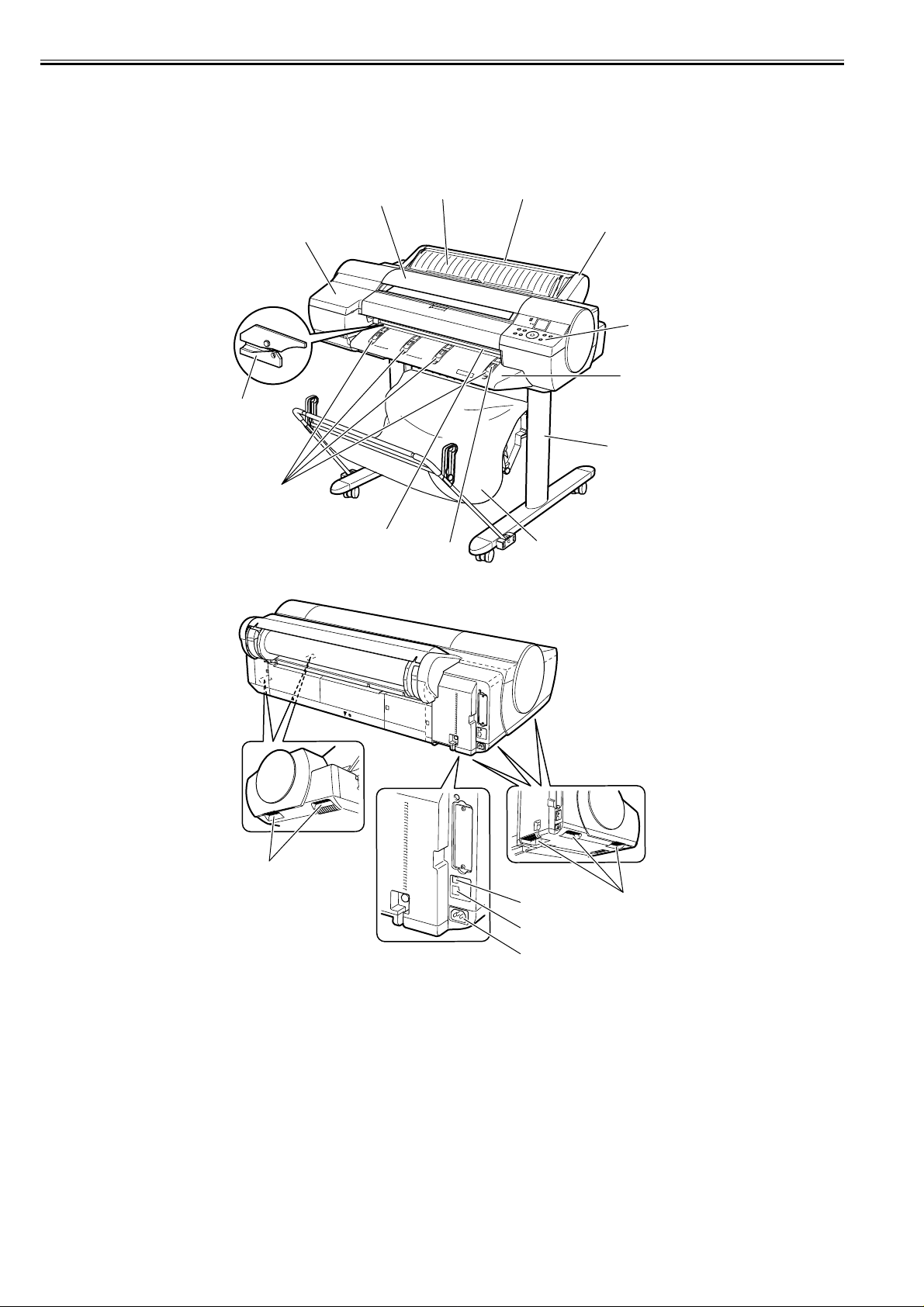

1.1.1 Product Overview

iPF6100

0016-8093

This printer is capable of printing on A4- to A1-size cut sheets and its maximum print width is 24 inches. This printer is a desktop large-format printer twelve-colors

(pigment-based colors) printer that can be used to print office documents as well as handy POP and posters. An auto roll feed unit is equipped for printing on roll

media.

[1]

[2]

[13] [12]

[11]

[10]

[9]

[3]

[8]

[4]

[5]

[6]

F-1-1

[7]

[18]

[17]

[16]

[15]

[14]

F-1-2

T-1-1

[1] Top Cover [10] Operation Panel

[2] Ink Tank Cover [11] Roll Feed Unit

[3] Cutter [12] Roll Feed Unit Cover

[4] Front Manual Feed Guide [13] Manual Feed Cover

[5] Peper Eject Slot [14] Power Connector

[6] Paper Alignment Line [15] Ethernet Connector

[7] Basket [16] USB Port

[8] Stand [17] Expansion Board Slot

[9]

Output Guide

[18]

Carrying Handle

[18]

1-1

Chapter 1

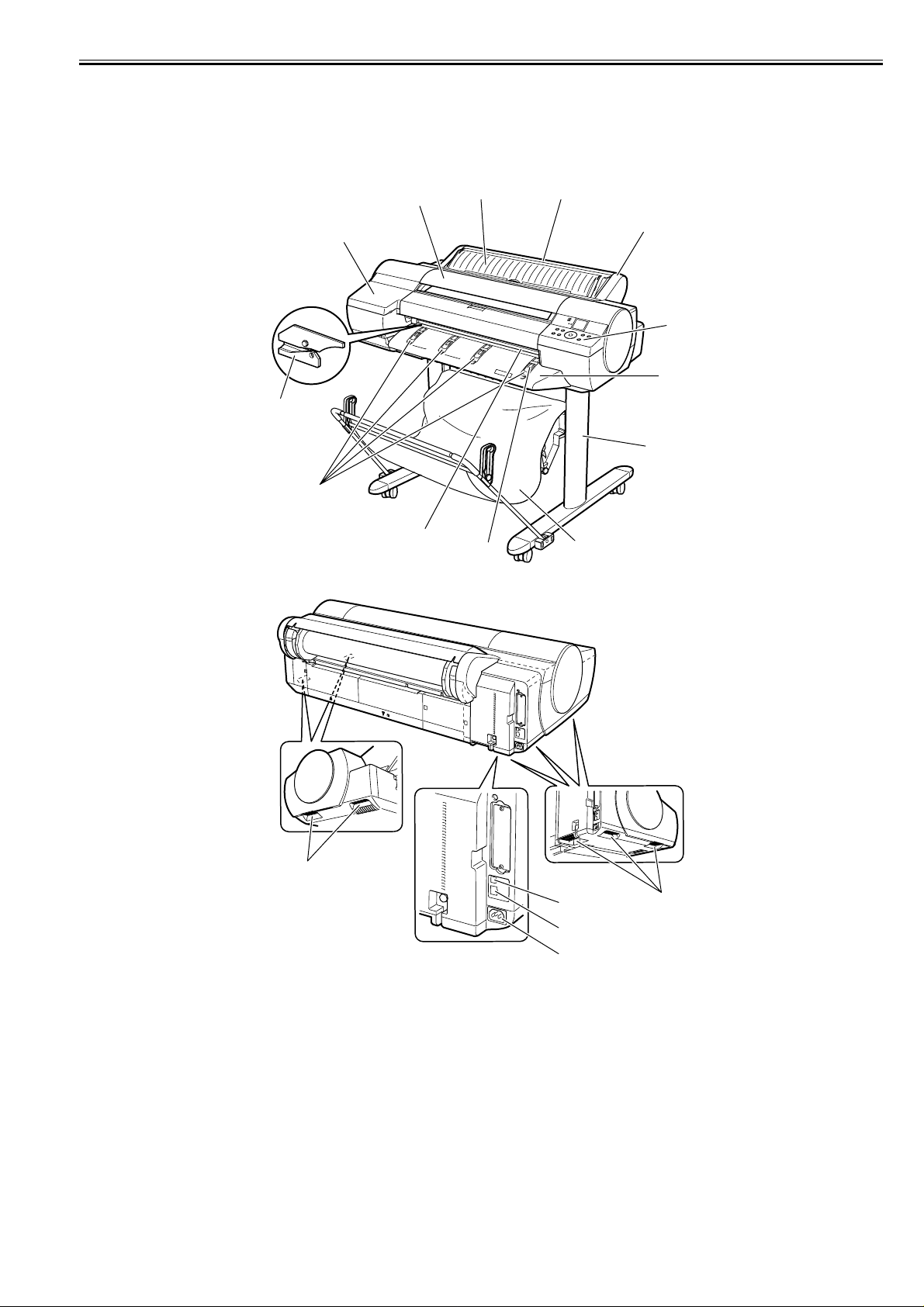

1.1.2 Product Overview

iPF6200

0020-1808

This printer is capable of printing on A4- to A1-size cut sheets and its maximum print width is 24 inches. This printer is a desktop large-format prin ter twelve-colors

(pigment-based colors) printer that can be used to print office documents as well as handy POP and posters. An auto roll feed unit is equipped for printing on roll

media.

[1]

[2]

[13] [12]

[11]

[10]

[9]

[3]

[8]

[4]

[5]

[6]

F-1-3

[7]

1-2

[17]

[16]

[15]

[14]

F-1-4

T-1-2

[1] Top Cover [10] Operation Panel

[2] Ink Tank Cover [11] Roll Feed Unit

[3] Cutter [12] Roll Feed Unit Cover

[4] Front Manual Feed Guide [13] Manual Feed Cover

[5] Peper Eject Slot [14] Power Connector

[6] Paper Alignment Line [15] Ethernet Connector

[7] Basket [16] USB Port

[8] Stand [17] Carrying Handle

Output Guide

[9]

[17]

Chapter 1

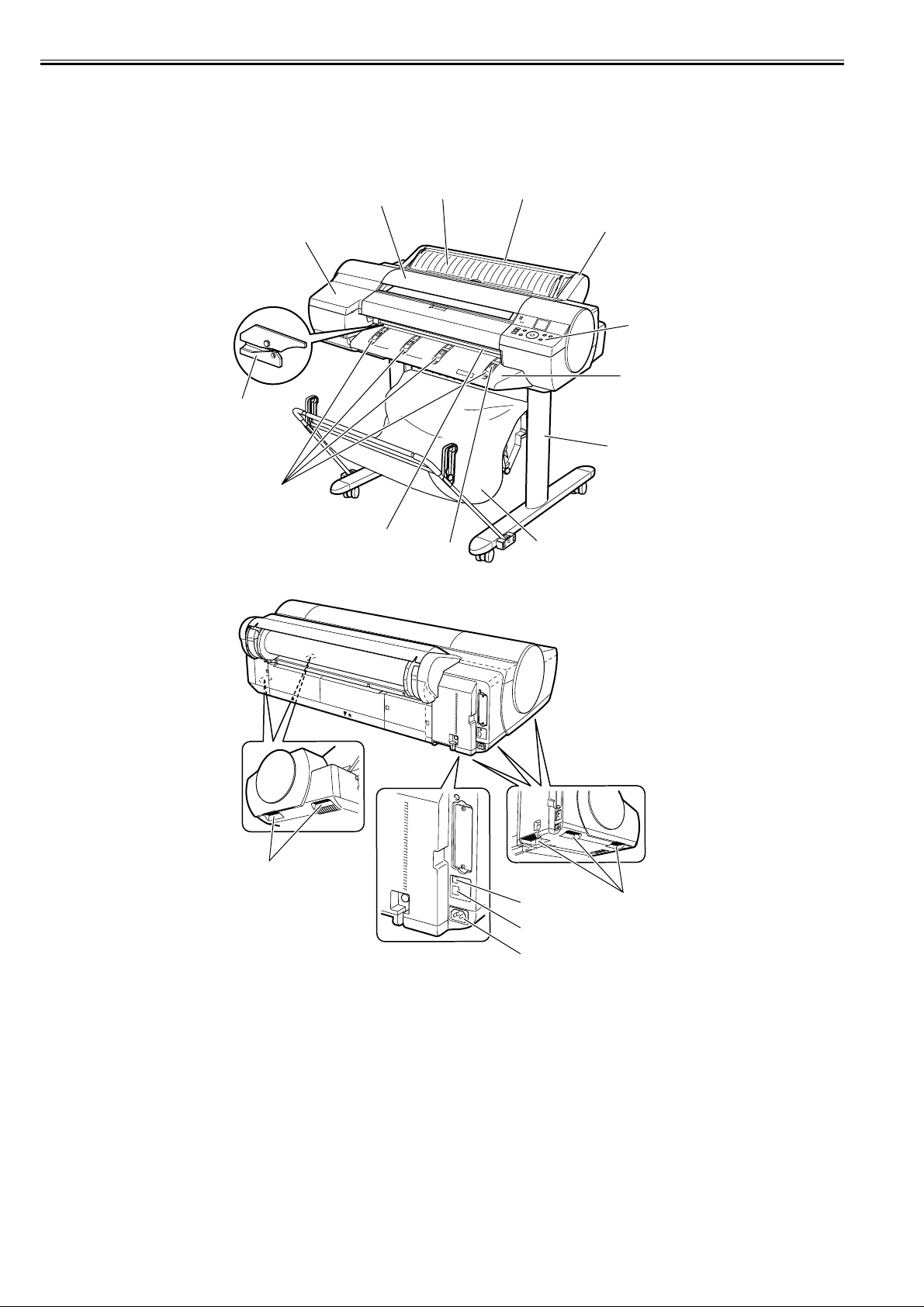

1.1.3 Product Overview

iPF6000S

0020-7368

This printer is capable of printing on A4- to A1-size cut sheets and its maximum print width is 24 inches. This printer is a desktop large-format printer eight-colors

(pigment-based colors) printer that can be used to print office documents as well as handy POP and posters. An auto roll feed unit is equipped for printing on roll

media.

[1]

[2]

[13] [12]

[11]

[10]

[9]

[3]

[8]

[4]

[5]

[6]

F-1-5

[7]

[17]

[16]

[15]

[14]

F-1-6

T-1-3

[1] Top Cover [10] Operation Panel

[2] Ink Tank Cover [11] Roll Feed Unit

[3] Cutter [12] Roll Feed Unit Cover

[4] Front Manual Feed Guide [13] Manual Feed Cover

[5] Peper Eject Slot [14] Power Connector

[6] Paper Alignment Line [15] Ethernet Connector

[7] Basket [16] USB Port

[8] Stand [17] Carrying Handle

Output Guide

[9]

[17]

1-3

Chapter 1

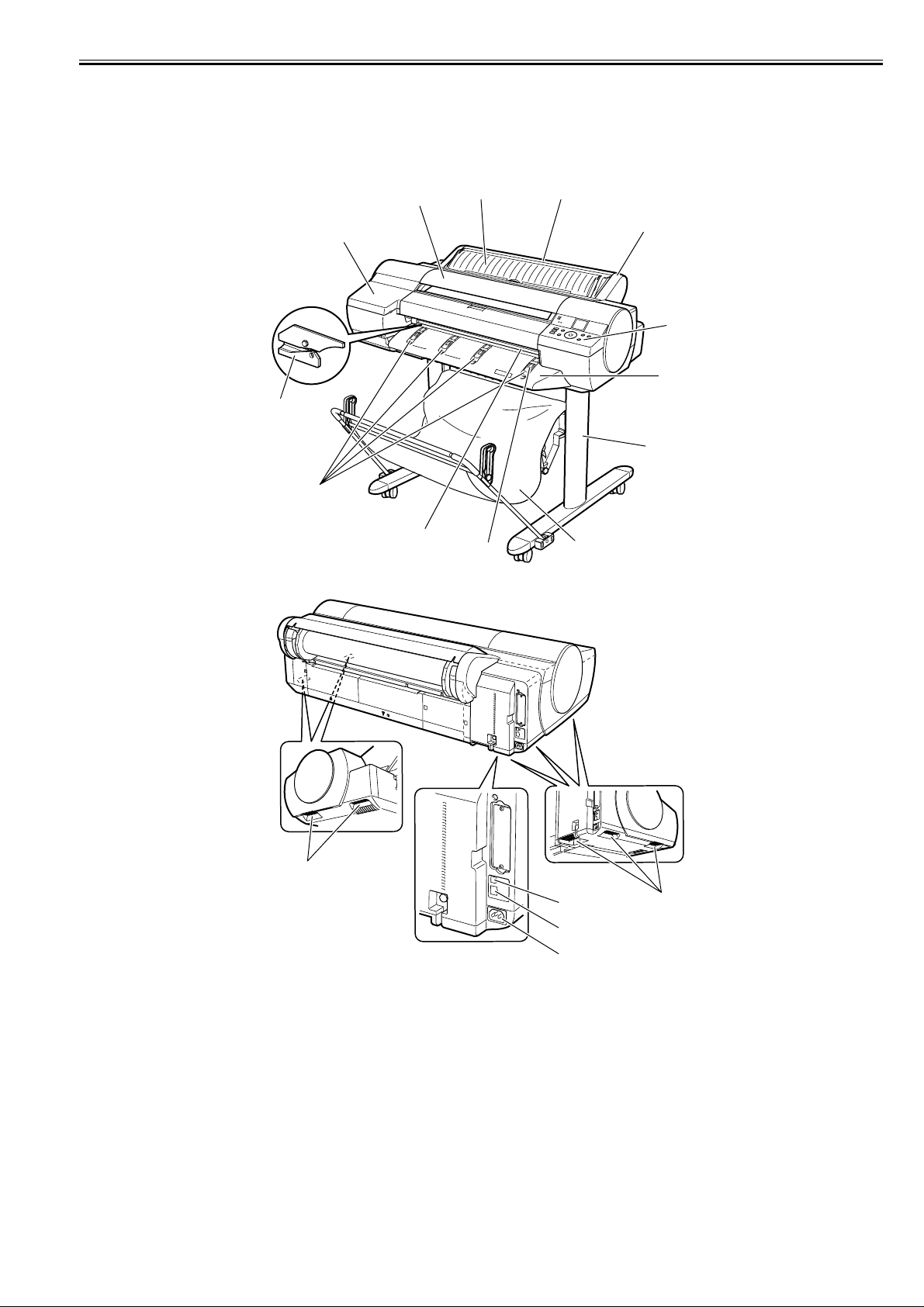

1.1.4 Product Overview

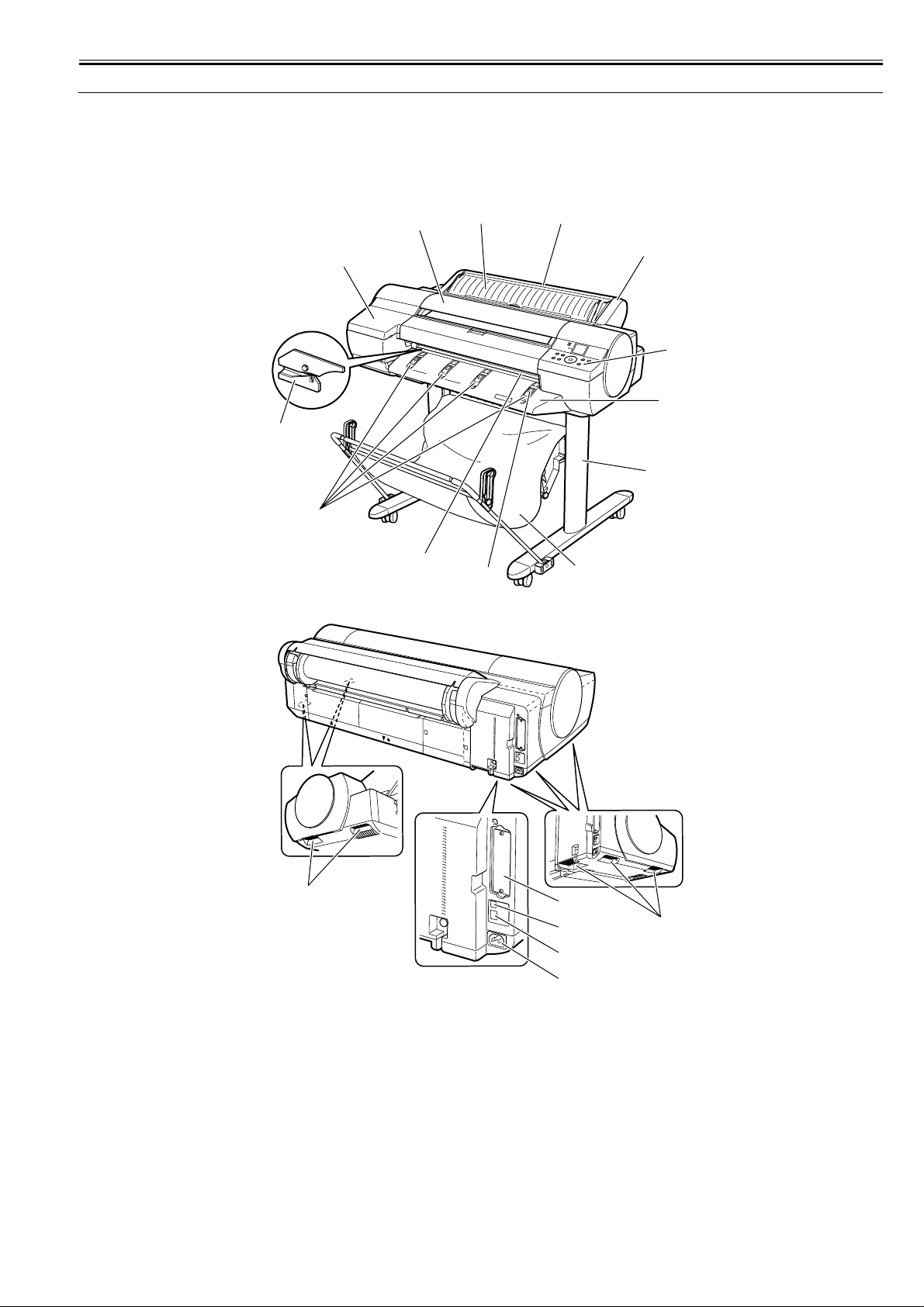

iPF6300 / iPF6350

0024-8326

This printer is capable of printing on A4- to A1-size cut sheets and its maximum print width is 24 inches. This printer is a desktop large-format prin ter twelve-colors

(pigment-based colors) printer that can be used to print office documents as well as handy POP and posters. An auto roll feed unit is equipped for printing on roll

media.

[1]

[2]

[13] [12]

[11]

[10]

[9]

[3]

[8]

[4]

[5]

[6]

F-1-7

[7]

1-4

[17]

[16]

[15]

[14]

F-1-8

T-1-4

[1] Top Cover [10] Operation Panel

[2] Ink Tank Cover [11] Roll Feed Unit

[3] Cutter [12] Roll Feed Unit Cover

[4] Front Manual Feed Guide [13] Manual Feed Cover

[5] Peper Eject Slot [14] Power Connector

[6] Paper Alignment Line [15] Ethernet Connector

[7] Basket [16] USB Port

[8] Stand [17] Carrying Handle

Output Guide

[9]

[17]

Chapter 1

1.1.5 Product Overview

iPF6300S

0026-6423

This printer is capable of printing on A4- to A1-size cut sheets and its maximum print width is 24 inches. This printer is a desktop large-format printer eight-colors

(pigment-based colors) printer that can be used to print office documents as well as handy POP and posters. An auto roll feed unit is equipped for printing on roll

media.

[1]

[2]

[13] [12]

[11]

[10]

[9]

[3]

[8]

[4]

[5]

[6]

F-1-9

[7]

[17]

[16]

[15]

[14]

F-1-10

T-1-5

[1] Top Cover [10] Operation Panel

[2] Ink Tank Cover [11] Roll Feed Unit

[3] Cutter [12] Roll Feed Unit Cover

[4] Front Manual Feed Guide [13] Manual Feed Cover

[5] Peper Eject Slot [14] Power Connector

[6] Paper Alignment Line [15] Ethernet Connector

[7] Basket [16] USB Port

[8] Stand [17] Carrying Handle

Output Guide

[9]

[17]

1-5

Chapter 1

1.2 Features

1.2.1 Features

iPF6100

- A new 12-color pigmented ink formulation featuring additional three types of special-color inks (red, green, blue) and two ty pes of gray ink var ying in grayscale,

"Lucia" prints on a variety of grades of paper, from glossy pap e r to art, mat and sign, with a high degree of coloring.

- Two types of black ink, vividly glossy "black ink" and "mat black ink" produce a higher quality, are loaded concurrently and are selected automatically to suit

paper types. There is no need to manually change inks.

- BK (black)/GY (gray)/PGY (photo gray) ink are mainly used to offer a drastically enhanced power of halftoning, achieving an equivalent of the high picture quality

of monochrome silver-salt films.

- One-inch wide printhead having 2,560 nozzles per color, which are twice as many as the those of the existing models. High-density printhead technology "FINE"

that can satisfy both of beautiful and fast printing requirements of a high order is employed for accurate ejection of ultrasmall 4-pl drops of ink to the target positions.

Prints with 2400 x 1200 dpi resolution can be made at a high speed.

- Imaging processor "L-COA" incorporated for high-speed image data processing. High-speed processing of 12-color, 2-bit large-size images and printer control

for high-accuracy operation of high-density double head can be performed with a single chip.

- Support for roll media, manual fe ed fro m front, a nd manu al fe ed fr om top (3-way p aper su pply). A maximu m of 1.5 mm th ick of paper (POP Board) can be manually fed from the front.

- Borderless printing on and auto cutting of roll media.

- Standard support for 10Base-T/100Base-TX. Standard support for USB 2.0 Hi-Speed. Optional support for IEEE1394.

- Data scanned using CanoScan can be easily printed on larg e-size paper just like a dedicated copier. Just pressing the Start button allows you to blow up an original

of up to A3 size in collaboration with Canon Image RUNNER.

0016-8104

- Support for remote notification utility which is used to send an E-mail when an alarm or error occurs.

Functional enhancements new to this model include:

- Higher image quality

Use of abrasion-resistant inks (MBK, BK, PGY, GY) offers enhanced image durability.

The color calibration feature adds to the faithfulness of color reproduction.

- Enhanced ease of operation

A 160-by-128-dot-large LCD, coupled with the new [Paper Load/Eject] button, offers drastically enhanced ease of operation.

The cassette feature has been removed in the interest of users who do not require a cassette capability, resulting in a downsized printer geometry and better roll

media accessibility.

1.2.2 Features

iPF6200

- A new 12-color pigmented ink formulation featuring additional three types of special-color inks (red, green, blue) and two ty pes of gray ink var ying in grayscale,

"Lucia" prints on a variety of grades of paper, from glossy pap e r to art, mat and sign, with a high degree of coloring.

- Two types of black ink, vividly glossy "black ink" and "mat black ink" produce a higher quality, are loaded concurrently and are selected automatically to suit

paper types. There is no need to manually change inks.

- BK (black)/GY (gray)/PGY (photo gray) ink are mainly used to offer a drastically enhanced power of halftoning, achieving an equivalent of the high picture quality

of monochrome silver-salt films.

- Use of abrasion-resistant inks (MBK, BK, PGY, GY) offers enhanced image durability.