Canon DADF-AV1 Service Manual

DADF-AV1

Service Manual

Revision 2.0

1x

1x

Introduction

Introduction

Important Notices

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair

of products.

This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does

not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products.

When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the

need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or

translated into another language, in whole or in part, without the consent of Canon Inc.

Copyright CANON INC. 2016

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

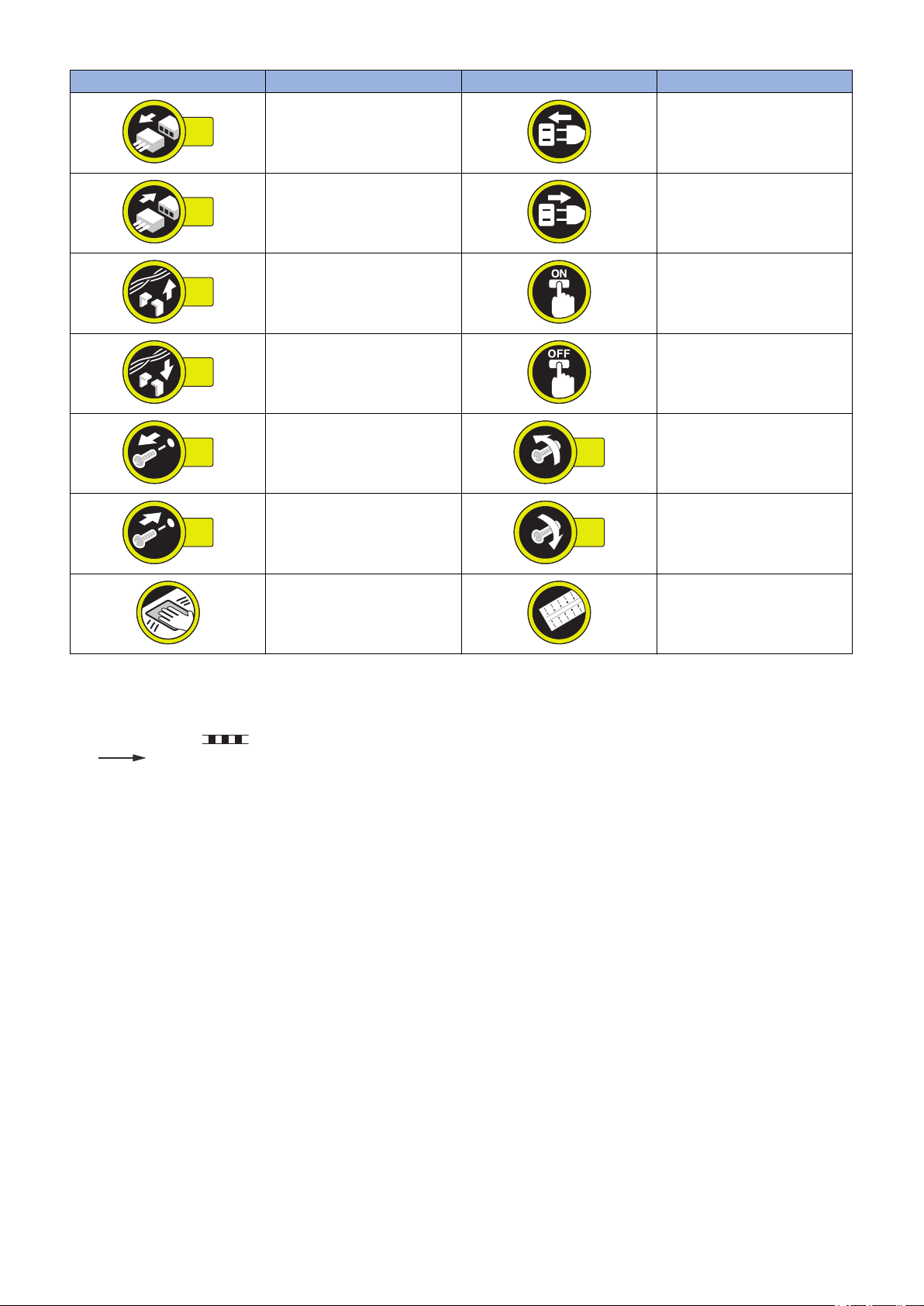

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Check.

Remove the claw.

Check visually.

Check a sound. Push the part.

Insert the claw.

1x

1x

1x

1x

1x

1x

1x

1x

Introduction

Symbols Explanation Symbols Explanation

Disconnect the connector. Connect the power cable.

Connect the connector. Disconnect the power cable.

Remove the cable/wire from the

cable guide or wire saddle.

Install the cable/wire to the cable

guide or wire saddle.

Remove the screw.

Install the screw.

Cleaning is needed. Measurement is needed.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and

mechanical systems with reference to the timing of operation.

In the diagrams, represents the path of mechanical drive; where a signal name accompanies the symbol, the arrow

indicates the direction of the electric signal.

The expression "turn on the power" means flipping on the power switch, closing the front door, and closing the delivery unit

door, which results in supplying the machine with power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is "High", while '0' is used to indicate "Low".

(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations

of the microprocessors used in the machines are not discussed: they are explained in terms of from sensors to the input of

the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and

major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service

Information bulletins and be able to identify and isolate faults in the machine.

Turn on the power.

Turn off the power.

Loosen the screw.

Tighten the screw.

Contents

Contents

Safety Precautions...............................................................................................1

Notes Before Servicing........................................................................................................................2

Points to Note at Cleaning...................................................................................................................2

Notes on Assembly/Disassembly........................................................................................................2

1. Product Overview.............................................................................................3

Features.............................................................................................................................................4

Specifications.................................................................................................................................5

Name of Parts..................................................................................................................................... 6

External View........................................................................................................................................6

Cross Section ................................................................................................................................... 6

2. Technical Explanation..................................................................................... 7

Basic Configuration............................................................................................................................. 8

Functional Configuration........................................................................................................................8

Electric Circuit Diagram....................................................................................................................... 10

Controls.............................................................................................................................................11

Controls..............................................................................................................................................11

Basic Operation.................................................................................................................................12

Outline............................................................................................................................................... 12

Forward Pickup/Delivery Operation...................................................................................................... 12

Forward Pickup/Reverse Delivery Operation......................................................................................... 13

Document Pickup/Feed.....................................................................................................................18

Basic Operation.................................................................................................................................. 18

Pickup Roller Assembly and Separation Roller......................................................................................19

Document Reversing.........................................................................................................................20

Basic Operation.................................................................................................................................. 20

Document Delivery............................................................................................................................22

Document Detection..........................................................................................................................23

Outline............................................................................................................................................... 23

Initial Document Size Detection............................................................................................................23

Mixed width document size detection....................................................................................................25

Detecting Jams..................................................................................................................................27

Power Supply.................................................................................................................................... 29

Stamp Operation (If equipped with the Stamp Unit)..........................................................................30

Original Output Indicator................................................................................................................... 31

Upgrading..........................................................................................................................................32

Outline............................................................................................................................................... 32

3. Periodical Service.......................................................................................... 33

List of Work for Servicing.................................................................................................................. 34

i

Contents

4. Parts Replacement and Cleaning................................................................. 35

List of Parts....................................................................................................................................... 36

External Cover....................................................................................................................................36

Main Unit............................................................................................................................................37

Consumable Parts Requiring Periodic Replacement and Cleaning Points............................................... 37

List of Clutch, Solenoid, Motor, PCB.....................................................................................................38

List of Sensor......................................................................................................................................39

Other..................................................................................................................................................40

Removing this Machine from the Host Machine................................................................................41

Procedure...........................................................................................................................................41

Actions after Reinstalling the ADF........................................................................................................ 43

External Cover...................................................................................................................................44

Removing the Front Cover...................................................................................................................44

Removing the Rear Cover....................................................................................................................45

Removing the Feeder Cover................................................................................................................ 46

Removing the Inner Cover................................................................................................................... 47

Main Unit........................................................................................................................................... 49

Removing the Feed Assembly..............................................................................................................49

Periodic Replacing Parts, Durable Parts, Cleaning Parts................................................................. 52

Removing the Pickup Roller Assembly..................................................................................................52

Removing the Separation Roller...........................................................................................................53

Replacing the Stamp........................................................................................................................... 53

Removing the Left Hinge..................................................................................................................... 54

Sensor...............................................................................................................................................56

Removing the Different Width Sensor PCB (PCB3)............................................................................... 56

Removing the Sensor (SR1,SR2,SR3)..................................................................................................56

Clutch, Motor, PCB, Other.................................................................................................................61

Removing the Pickup Motor (M1)......................................................................................................... 61

Removing the Read Motor (M2)........................................................................................................... 61

Removing the Pickup Clutch/Registration Clutch (CL1/CL2)...................................................................62

Removing the ADF Driver PCB (PCB1)................................................................................................ 63

Removing the Document Set LED PCB (PCB2).................................................................................... 63

Removing the Right Hinge................................................................................................................... 64

Removing the Platen Roller................................................................................................................. 65

5. Adjustment..................................................................................................... 68

Overview........................................................................................................................................... 69

Adjustment After Replacing the Parts................................................................................................... 69

Adjustment......................................................................................................................................... 69

Preparation or Creation of Test Chart................................................................................................... 69

Basic Adjustment...............................................................................................................................70

Overview of Adjustment.......................................................................................................................70

Adjusting the Height............................................................................................................................ 70

Adjusting the Perpendicularity..............................................................................................................74

Adjusting the Reading Position.............................................................................................................78

Adjusting the Magnification.................................................................................................................. 79

Adjusting the Image Position (Main Scanning Direction).........................................................................80

Adjusting the Image Position (Sub Scanning Direction)..........................................................................81

Adjusting the White Level.................................................................................................................... 82

ii

Contents

6. Installation...................................................................................................... 84

Checking Before Installation..............................................................................................................85

Check Items when Turning OFF the Main Power...................................................................................85

Points to Note on Installation................................................................................................................85

Product Name.....................................................................................................................................85

Unpacking......................................................................................................................................... 86

Unpacking Procedure..........................................................................................................................86

Checking the Contents......................................................................................................................87

Installation Procedure........................................................................................................................88

Installing the DADF............................................................................................................................. 88

Connecting the DADF Cable................................................................................................................91

Installing Hinge Covers........................................................................................................................94

Affixing the Labels (INCH/AB/K Type Only)...........................................................................................94

Cleaning the ADF Scan Glass..............................................................................................................95

Checking After Installation.................................................................................................................96

Disposal Parts.....................................................................................................................................96

Operation Check................................................................................................................................. 96

Adjustment........................................................................................................................................ 97

Overview of Adjustment.......................................................................................................................97

Preparation or Creation of Test Chart................................................................................................... 97

Adjusting the Height............................................................................................................................ 97

Adjusting the Perpendicularity............................................................................................................ 100

Adjusting the Reading Position...........................................................................................................102

Adjusting the Magnification................................................................................................................ 103

Adjusting the Image Position (Main Scanning Direction).......................................................................104

Adjusting the Image Position (Sub Scanning Direction)........................................................................105

Adjusting the White Level...................................................................................................................106

APPENDICES....................................................................................................107

Service Tools...................................................................................................................................108

Solvents and Oils.............................................................................................................................. 108

Special Tools.................................................................................................................................... 108

General Circuit Diagram..................................................................................................................109

General Circuit Diagram (1/1).............................................................................................................109

iii

Safety Precautions

Notes Before Servicing......................... 2

Points to Note at Cleaning.................... 2

Notes on Assembly/Disassembly..........2

Safety Precautions

Notes Before Servicing

CAUTION:

At servicing, be sure to turn off the power source of the host machine according to the specified steps and disconnect the

power plug.

CAUTION:

Do not turn off the power switch when downloading is under way. Turning off the main power switch while downloading is

under way can disable the machine.

Points to Note at Cleaning

CAUTION:

When performing cleaning using organic solvent such as alcohol, be sure to check that the component of solvent is

vaporized completely before assembling.

Notes on Assembly/Disassembly

Follow the items below to assemble/disassemble the device.

1. Disconnect the power plug to avoid any potential dangers during assembling/disassembling works.

2. If not specially instructed, reverse the order of disassembly to reinstall.

3. Ensure to use the right screw type (length, diameter, etc.) at the right position when assembling.

4. To keep electric conduction, binding screws with washers are used to attach the grounding wire and the varistor. Ensure to

use the right screw type when assembling.

5. Unless it is specially needed, do not operate the device with some parts removed.

6. Never remove the paint-locked screws when disassembling.

7. During disassembly, reassembly or transportation of the printer, remove the cartridge if required. When the cartridge is out

of the printer, put it in a protective bag even in a short period of time to prevent the adverse effect of light.

8. When you replace the part that the rating plate or the product code label is attached, be sure to remove the rating plate or

the product code label and put it to the new part.

2

1

Product Overview

Features.............................................. 4

Specifications.................................. 5

Name of Parts....................................... 6

Features

• Improvement of quick-engaging/disengaging the Pickup roller assembly and the Separation roller

• Improvement of paper curl detection by the modification the Document length sensor

• Installation of the Document delivery Lamp function

1. Product Overview

4

1. Product Overview

Specifications

Item Specifications

Document pickup method Automatic pickup and delivery

Document loading direction Face-up

Document loading position Aligned to center

Document separation method Upper separation

Document weight Single -sided

AB configuration: 42 to 128 g/m

(Single-sided one sheet feed: 38 to 128 g/m2)

Inch configuration: 50 to 128 g/m

Double-sided

Black and White mixed

width document

Color mixed width document

50-128 g/m

Same types of paper: 50 to 128 g/m

Different types of paper: 64 to 81 g/m

Same types of paper: 64 to 128 g/m

Different types of paper: 64 to 81 g/m

2

Black and White/Color

mixed

Document longer than

Single-sided one sheet feed: 60 to 90 g/m

432 mm

Document size AB configuration: B6, A5R, A5, B5R, B5, A4R, A4, B4, A3

Inch configuration: 11×17, LGL, LTR, LTRR, STMT, STMTR, 8K, 16K

Width: 140 to 297 mm

Length: 128 to 432 mm

(It is available when the operator holds long documents between 432mm and

630mm.)

Document supply tray capacity

100 sheets (80 g/m2)

Document feeding mode Single-sided/Double-sided

Document size detection Available (Standard size)

Mixed document function Same types mixed width

Yes

document

Different types mixed

Yes

width document

Book document Supported (The document thickness must be 50 mm or less.)

Power supply Supplied from the host machine

Dimensions 565 mm×525 mm×139 mm (W×D×H)

Weight Approx. 8kg

2

2

2

2

2

2

2

5

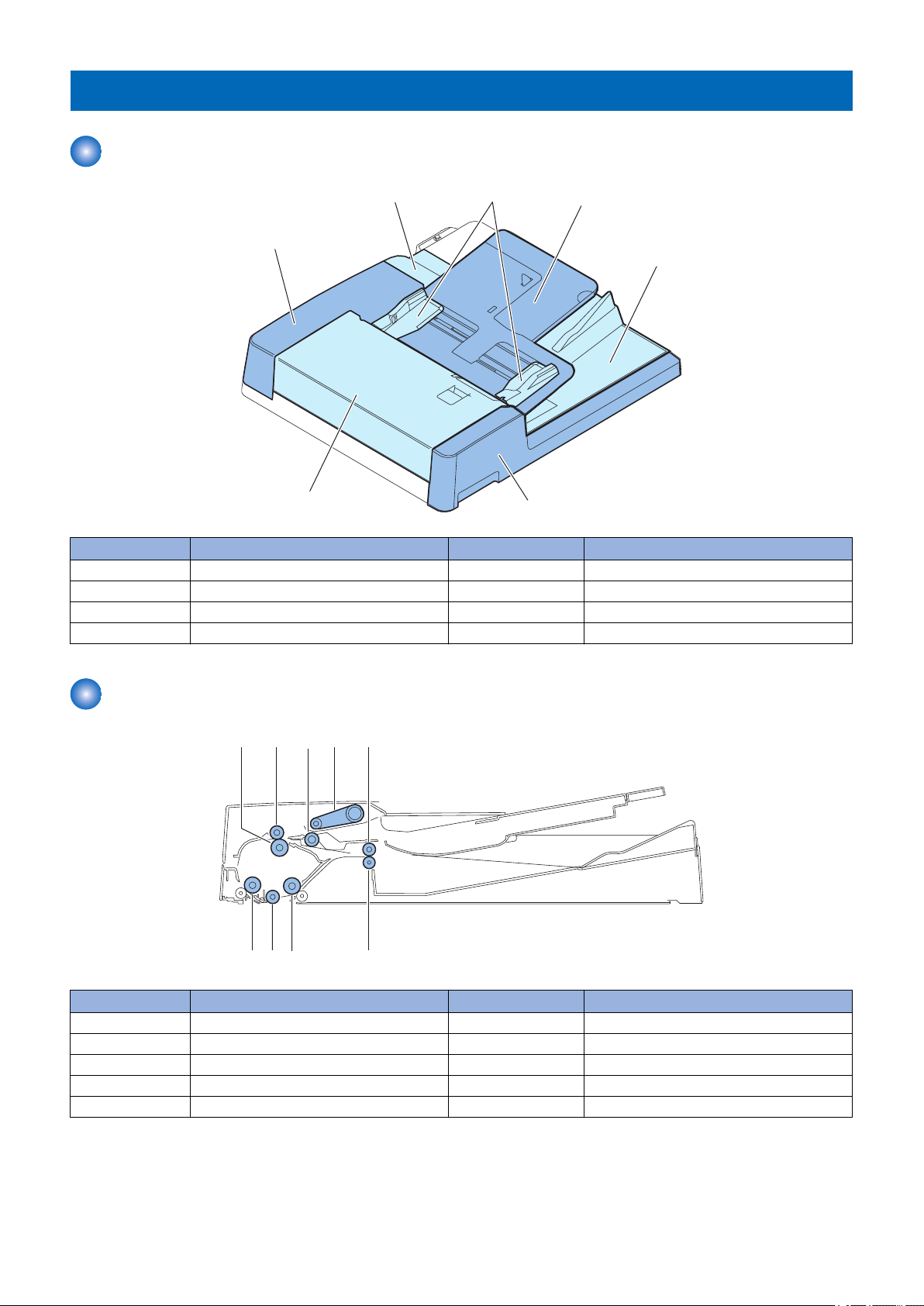

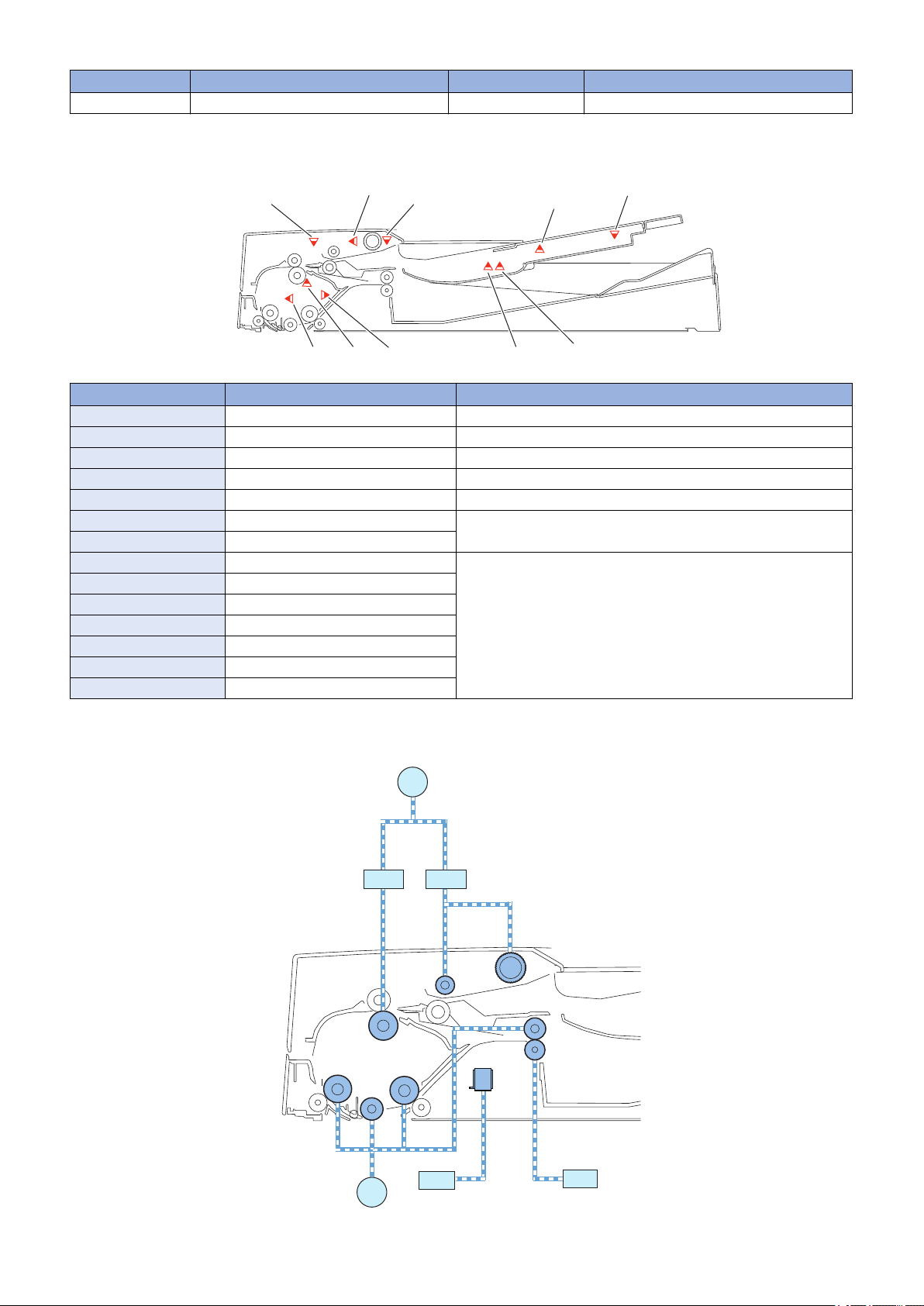

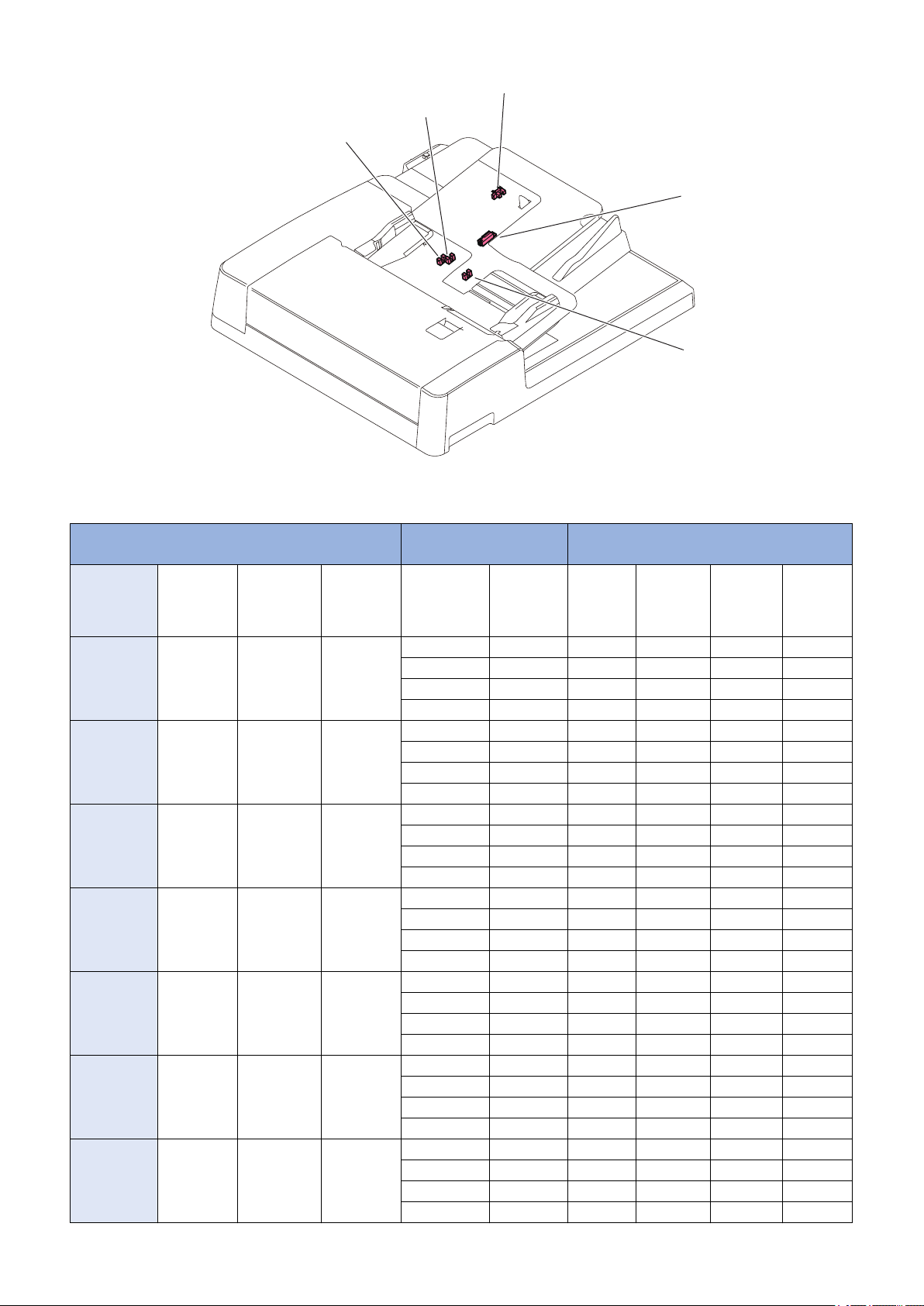

Name of Parts

[1]

[7]

[3] [4]

[2]

[5]

[6]

[3][4][1] [2]

[6][7][9]

[8]

[5]

External View

1. Product Overview

No. Name No. Name

[1] Feeder Cover [5] Document supply tray

[2] Front Cover [6] Document delivery assembly

[3] Rear Small Cover [7] Front Cover

[4] Slide guide - -

Cross Section

No. Name No. Name

[1] Lower registration roller [6] Lower delivery reversal roller

[2] Upper registration roller [7] Lead roller 2 (upper)

[3] Pickup roller assembly [8] Platen roller

[4] Separation roller [9] Lead roller 1 (upper)

[5] Upper delivery reversal roller - -

6

Technical

2

Explanation

Basic Configuration...............................8

Controls...............................................11

Basic Operation...................................12

Document Pickup/Feed.......................18

Document Reversing...........................20

Document Delivery..............................22

Document Detection............................23

Detecting Jams................................... 27

Power Supply......................................29

Stamp Operation (If equipped with the

Stamp Unit)......................................30

Original Output Indicator..................... 31

Upgrading............................................32

Basic Configuration

M1

SL1

SL2

PCB1

PCB4

PCB5

PCB2

PCB3

M2

CL1

CL2

[3] [5][4][1] [2]

[6][7][8][9]

[13]

[12]

[10]

[11]

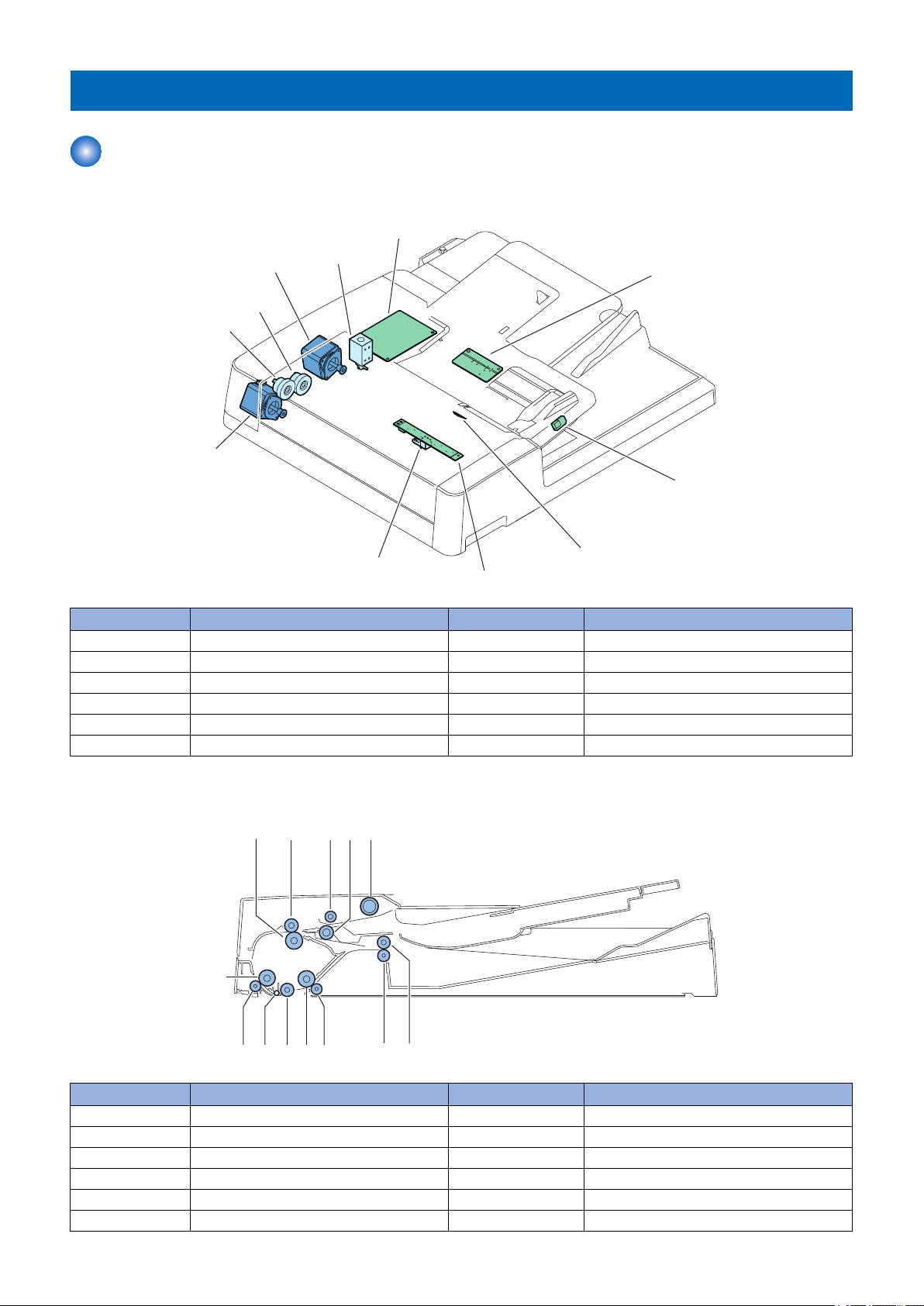

Functional Configuration

■ List of Major Electric Parts

2. Technical Explanation

Symbol Name Symbol Name

CL1 Pickup clutch PCB1 ADF driver PCB

CL2 Registration clutch PCB2 Document set LED PCB

SL1 Release solenoid PCB3 Different width sensor PCB

SL2 Stamp solenoid PCB4 Document width sensor PCB

M1 Pickup motor PCB5 Document delivery LED PCB

M2 Read motor - -

■ Roller Layout

No. Name No. Name

1 Lower registration roller 8 Lead roller 2 (lower)

2 Upper registration roller 9 Lead roller 2 (upper)

3 Feed roller 10 Platen roller

4 Separation roller 11 Lead roller

5 Pickup roller 12 Lead roller 1 (lower)

6 Upper delivery reversal roller 13 Lead roller 1 (upper)

8

No. Name No. Name

SR1SR2

SR3

SR5

SR6

SR7

SR8

SR9/SR10/SR11/SR12

SR13/SR14

SR15

CL1

M1

SL1

M2

CL2

SL2

7 Lower delivery reversal roller - -

■ Sensor Layout

Symbol Name Detection description

SR1 Registration sensor Registration arch creation timing

SR2 Lead sensor Image Leading start/completion timing

SR3 Delivery reversal sensor Delivery reversal timing

SR5 Document set sensor Document set detection

SR6 Cover open/closed sensor Open/close of Feeder Cover

SR7 Document length sensor 1 Document size detection (length)

SR8 Document length sensor 2

SR9 Different width sensor 1 Document size detection (width)

SR10 Different width sensor 2

SR11 Different width sensor 3

SR12 Different width sensor 4

SR13 Document width sensor 1

SR14 Document width sensor 2

SR15 Document width sensor 3

2. Technical Explanation

■ Drive Configuration

9

ADF driver

PCB

Sensor

Motor

Clutch

Solenoid

Main controller PCBReader controller PCB

2. Technical Explanation

Symbol Name Role

M1 Pickup motor Pickup documents.

M2 Read motor Feeds documents when Stream reading or Delivery.

SL1 Release solenoid Shifts the Lower delivery reversal roller after reversal of a document.

SL2 Stamp solenoid Stamps on a document.

CL1 Pickup clutch Transmit the Pickup motor drive to the Pickup roller and the Feed

roller.

CL2 Registration clutch Transmit the power of the Pickup motor to the Lower registration

roller.

Electric Circuit Diagram

Electric circuits of this machine are controlled by the host machine.

The Main Controller PCB of the host machine detects the input signals from sensors to output DC load drive signal such as

motors, solenoids, and clutches at the predetermined timing.

The ADF driver PCB (PCB1) does not have a memory space. The data, such as the service mode, is stored in the host machine.

10

2. Technical Explanation

Controls

Controls

Item Reference

Basic Operation “Basic Operation” on page 12

Document Pickup/Separation “Document Pickup/Feed” on page 18

Document Reversing “Document Reversing” on page 20

Document Delivery “Document Delivery” on page 22

Document Detection “Document Detection” on page 23

Detecting Jams “Detecting Jams” on page 27

Power Supply “Power Supply” on page 29

Stamp Operation “Stamp Operation (If equipped with the Stamp Unit)” on page 30

Original Output Indicator “Original Output Indicator” on page 31

Upgrading “Upgrading” on page 32

11

Document

Pickup of first document sheet/

Formation of loop

Start for reading of

the first document sheet

Reading of first document

sheet

Pickup of second document

sheet

Formation of loop

of second document

To next

2. Technical Explanation

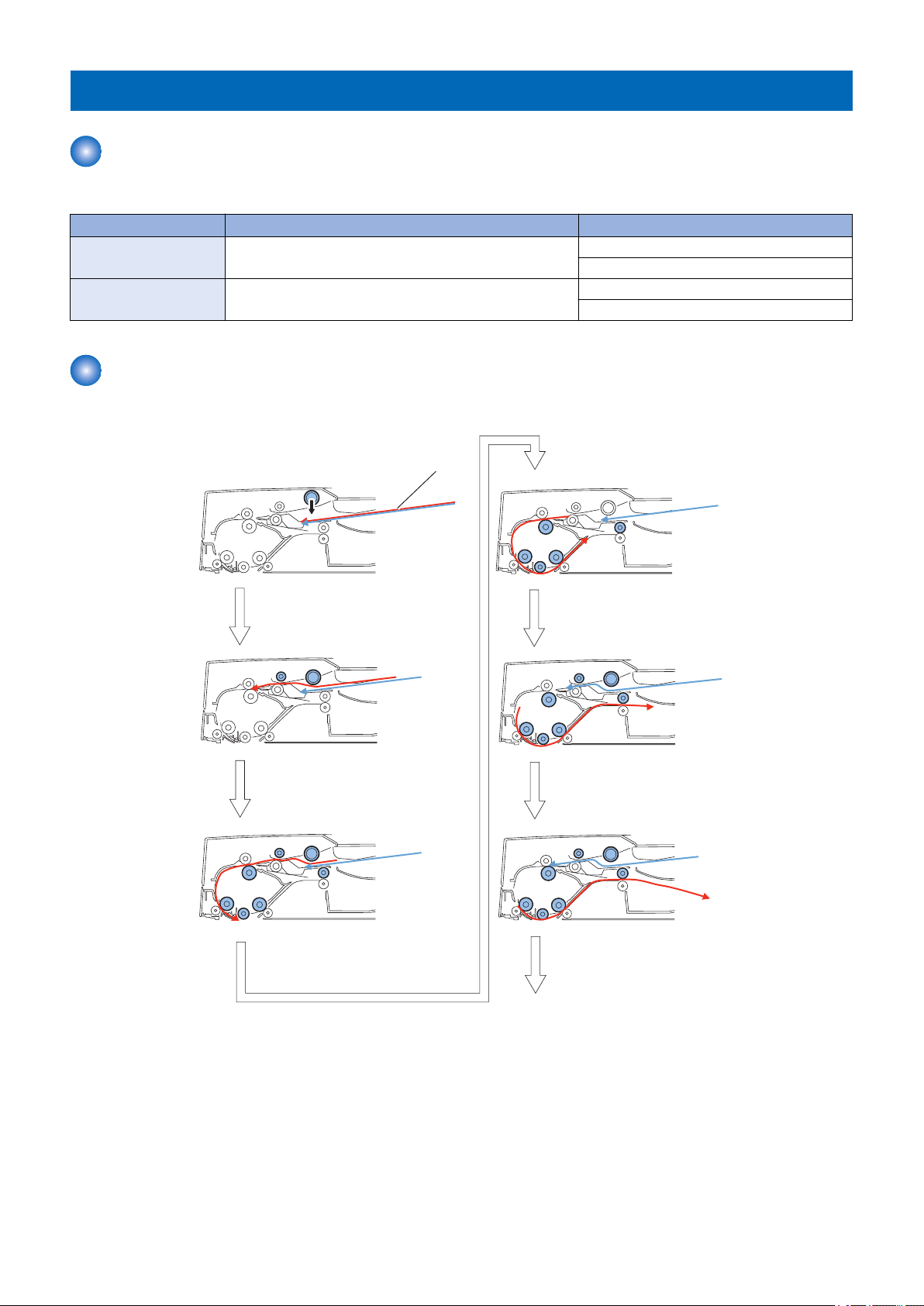

Basic Operation

Outline

The ADF has the following operation modes.

Operation mode name Outline of operation Associated print mode

Forward pickup/Delivery Picks up, reads, and then delivers a document. Single-sided document -> Simplex printing

Single-sided document -> Duplex printing

Forward feed/Reverse

delivery

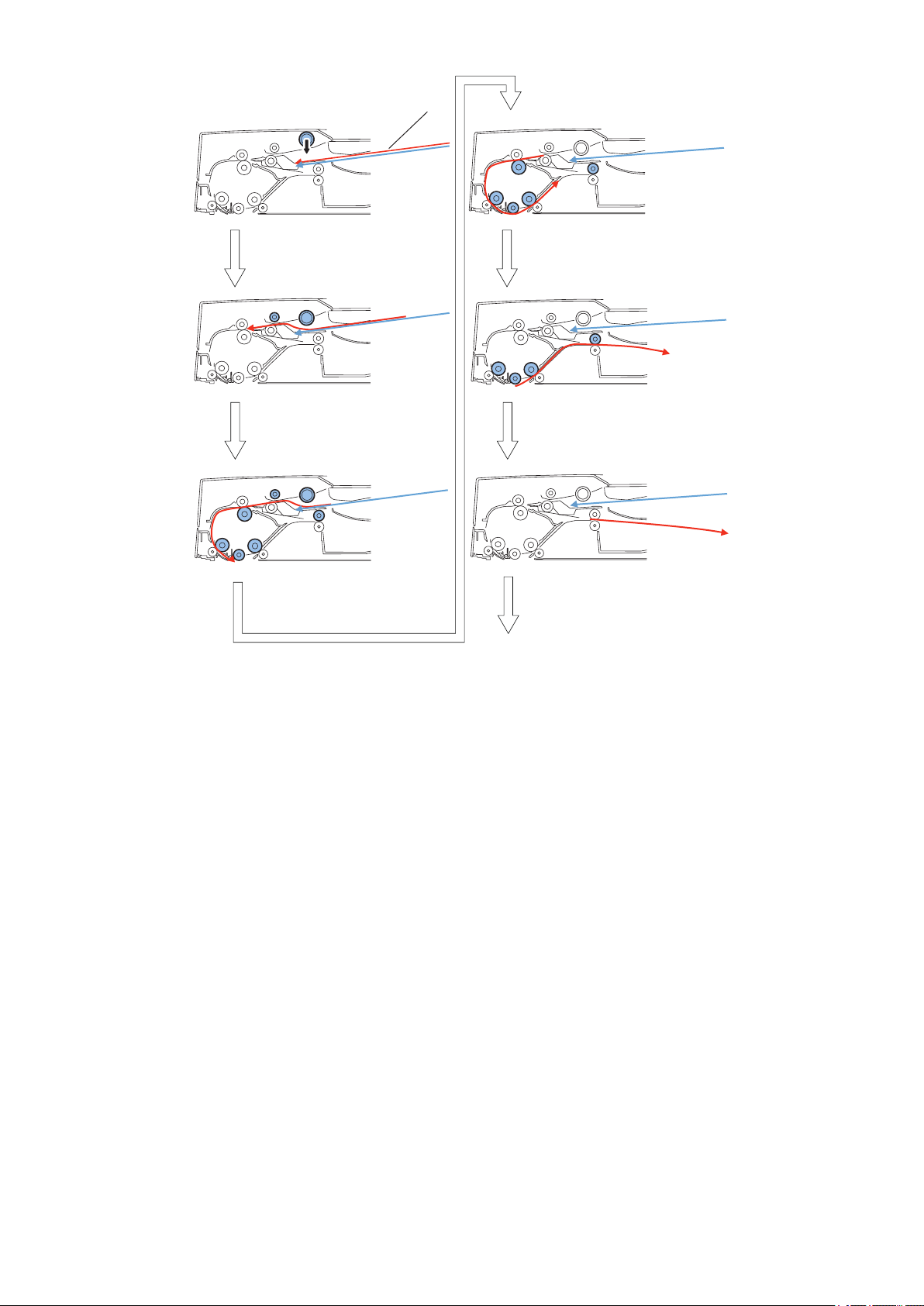

Forward Pickup/Delivery Operation

Simplex read operation (when two document sheets are placed)

Picks up, reads, reverses, and delivers a document. Double-sided document -> Duplex printing

Double-sided document -> Simplex printing

12

Completion of reading of

first document sheet

Completion of reading of

second document sheet

Completion of delivery of

first document sheet

Completion of delivery of

the second document sheet/

End of job

Start of reading of

second document sheet

2. Technical Explanation

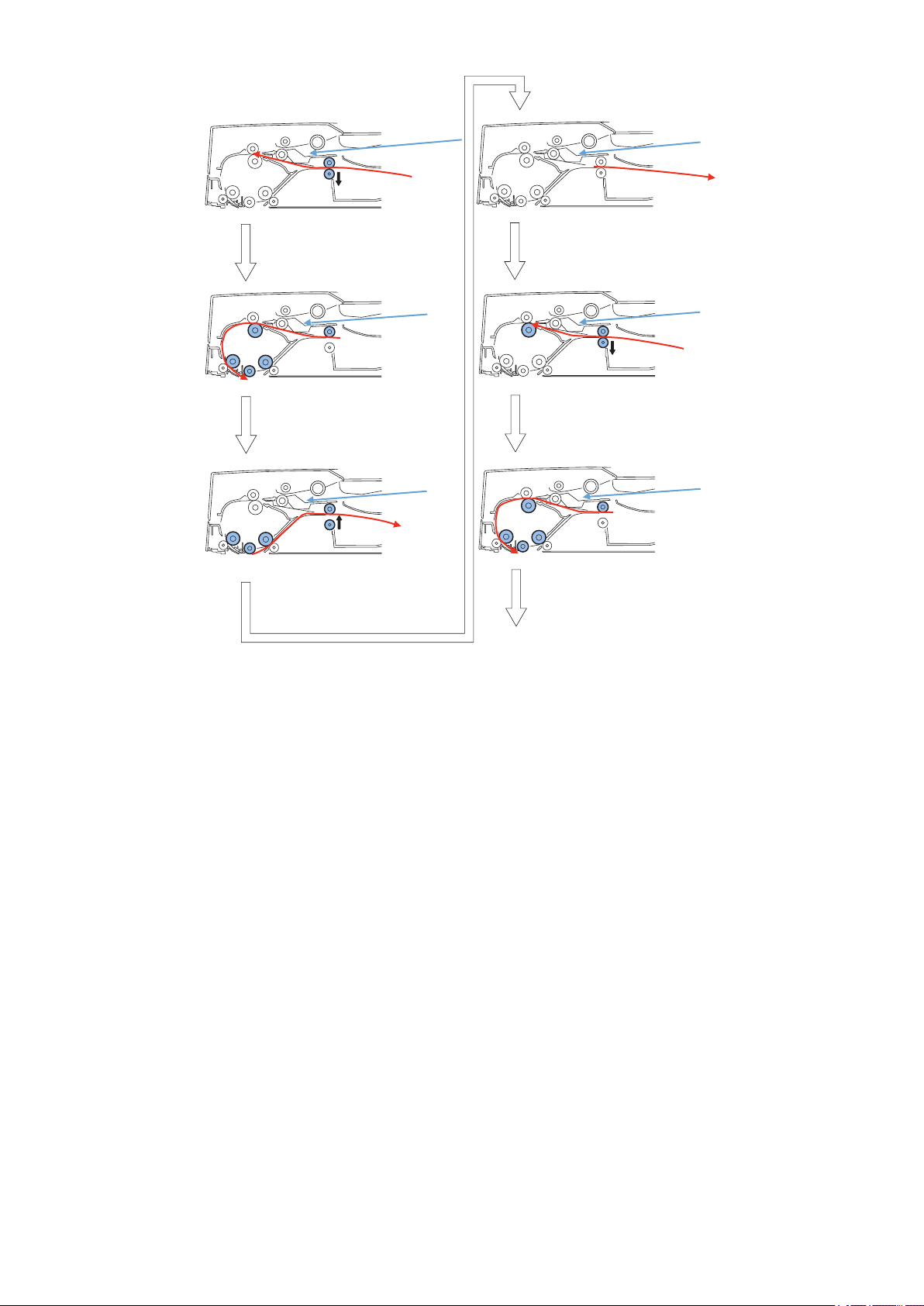

Forward Pickup/Reverse Delivery Operation

Duplex read operation (when two document sheets are placed)

13

Pickup and formation of loop

of first document sheet

Position to start of

reading of first document sheet

Start of reading of front side

of first document sheet

End of reading of

first document sheet

Stop after feeing the first

document sheet to reversal

position

To next

Document

2. Technical Explanation

14

Removal of registration loop of

reverse side of the first document

sheet/Re-pickup/

Release of

the Lower delivery reversal roller

Position to start reading of

reverse side at

the first document sheet

Stop after feeding the first

document sheet to reversal

position

Idle feed of first document

sheet

Removal of idle registration

loop at the first document sheet/

Re-pickup/Release of

the Lower delivery reversal roller

To next

Completion of reading of

reverse side at the first document

sheet/Pressurization of

the Lower delivery reversal roller

2. Technical Explanation

15

Start of separation at

the seconddocument sheet/

Pressurization of

the Lower delivery reversal roller

Start of reading of top side of

second document sheet

End of reading of front side of

second document sheet

Stop after feeding

the second document sheet

to reversal position

Delivery of first document sheet

Removal of registration loop of

reverse side at the second document

sheet/Re-pickup/Release of

the Lower delivery reversal roller

To next

2. Technical Explanation

16

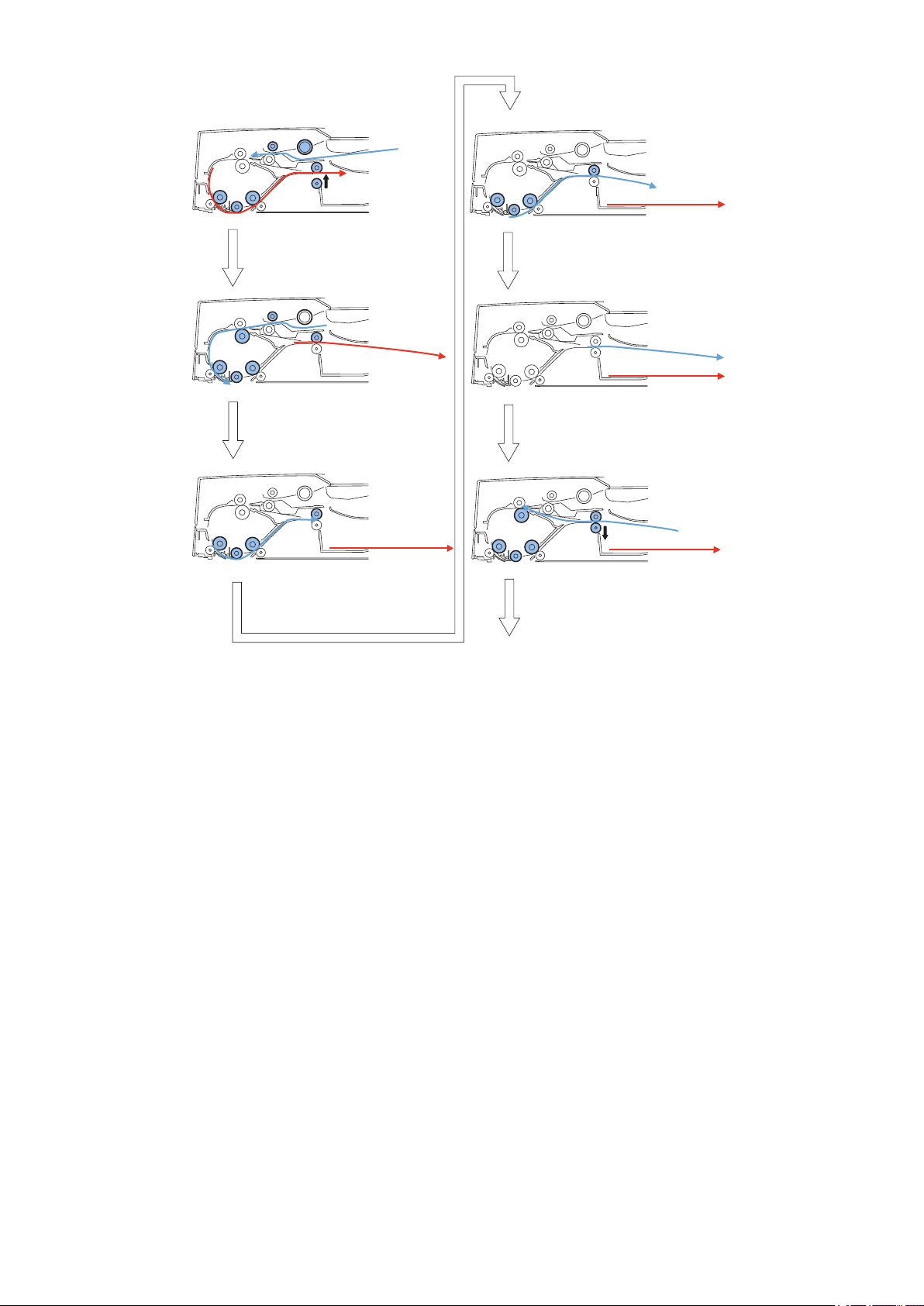

Start of reading of reverse

side of second document sheet

End of reading of reverse

side of second document sheet

Stop after feeding the second

document sheet to reversal position

Removal of idle registration

loop at the second document sheet/

Re-pickup/Release of

the Lower delivery reversal roller

Delivery of second document sheet/

Pressurization at

the Lower delivery reversal roller

Completion of delivery of

second document sheet/end of job

2. Technical Explanation

17

M1

Document

Pickup roller

ศ㞳࣮࣮ࣟࣛ

Stopper

CL1CL1

Pickup roller

ศ㞳࣮࣮ࣟࣛ

Separation roller

M1

Upper/Lower registration roller

Loop

Lower registration roller

Read roller 1

(Upper)

Reading start point

CL2

M1

M2

2. Technical Explanation

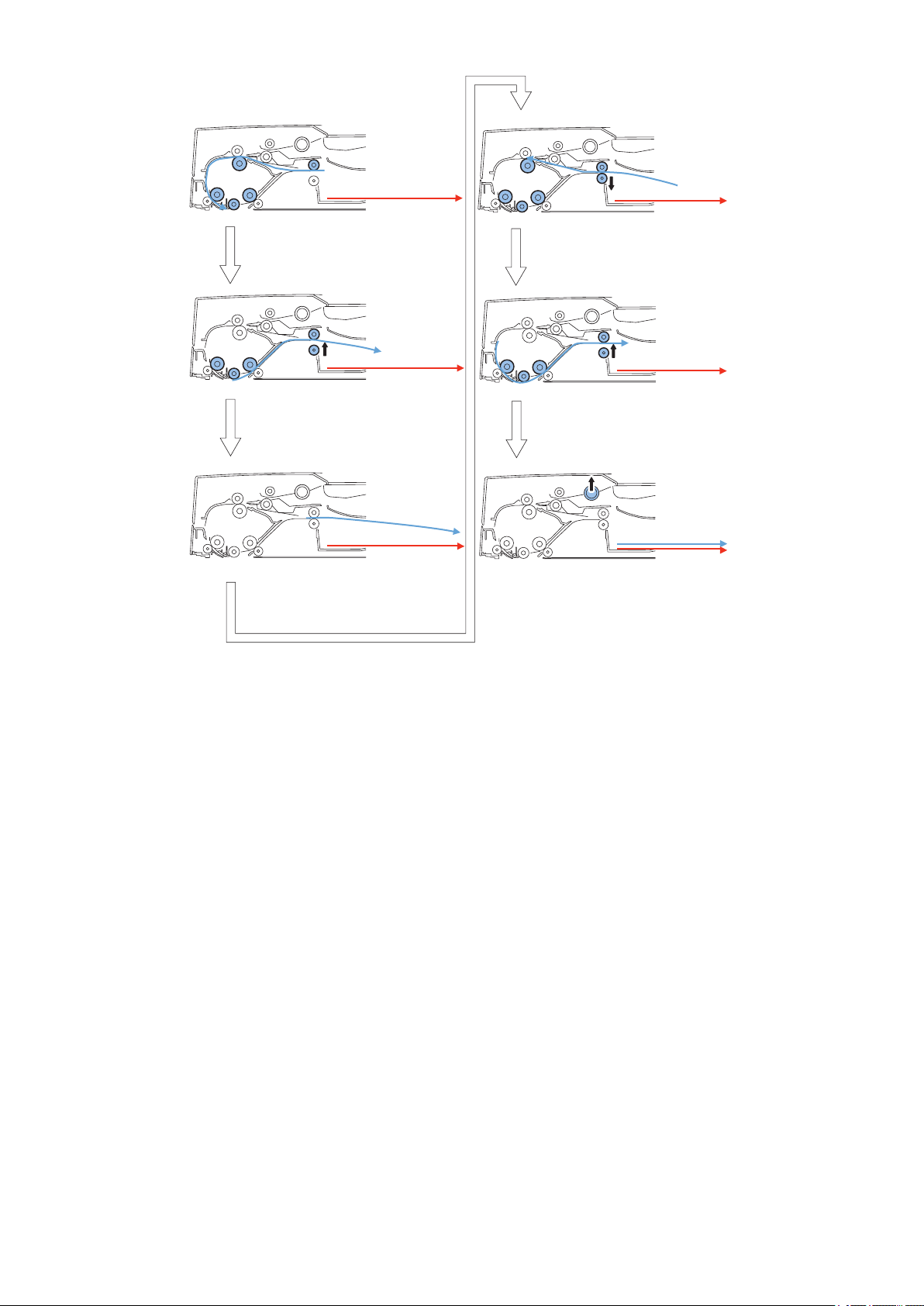

Document Pickup/Feed

Basic Operation

After pressing the start key with a document placed on the Document supply tray, a document is picked up in the following

procedure.

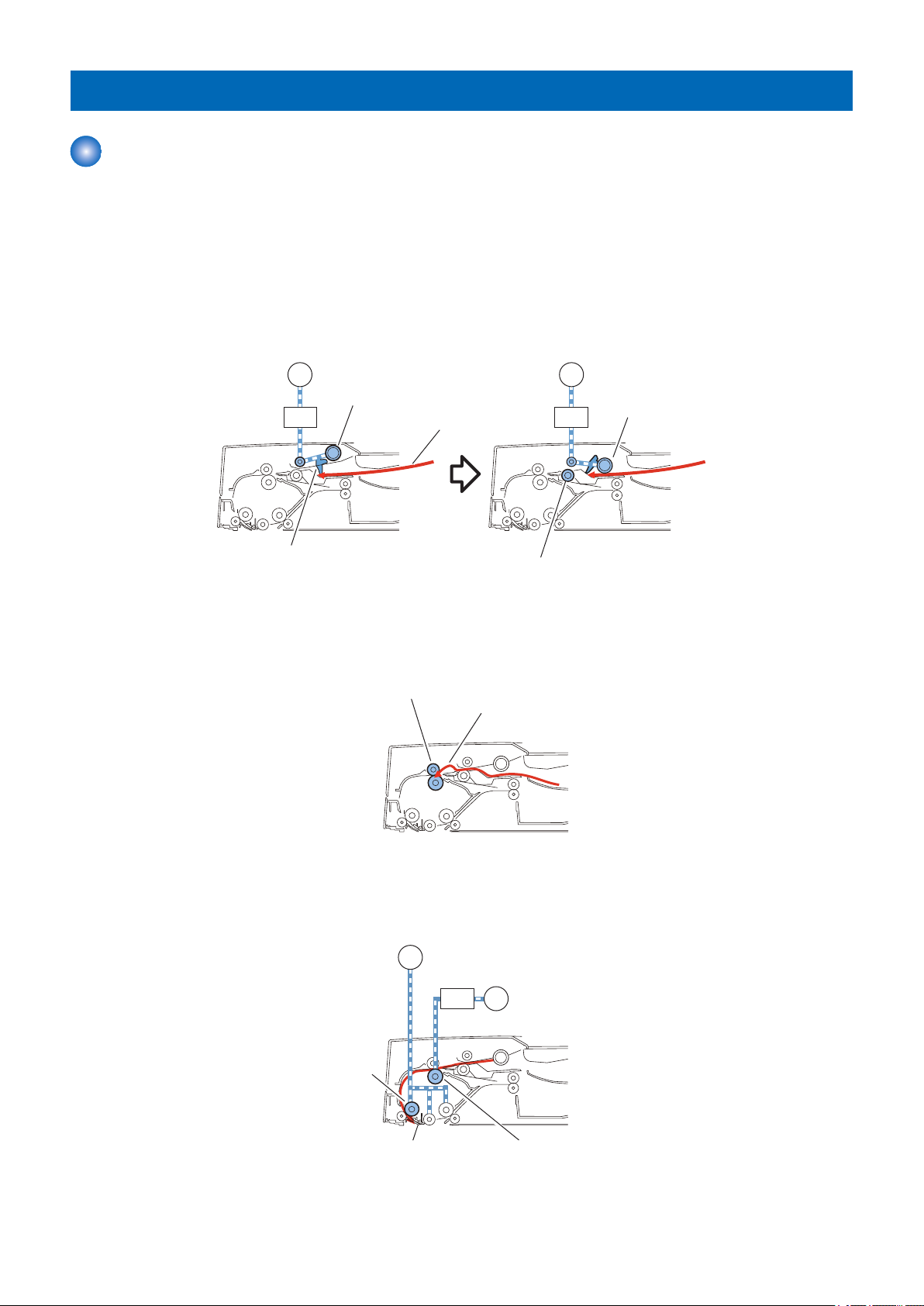

■ Pickup Operation

The Pickup motor (M1) drives to lower the Pickup roller assembly through the Pickup clutch (CL1) and then the Pickup roller

rotates to feed a document.

The lock of the stopper is released by linking the Pickup roller assembly. The Separation roller is used to improve the separation

performance while feeding a document.

■ Formation of loop

During Pickup Operation, the Lower registration roller is stopped rotating while moving a document against the Upper/Lower

registration rollers and then form a loop. Thus it prevents a document from skewing.

■ Feed

The Pickup motor (M1) drives the Lower registration roller through the Registration clutch (CL2). Thus a document is fed.

A document is fed to the read wait point when the Read motor (M2) drives the Lead roller 1 (upper).

18

Document glass

Scanner

Platen roller

M2

Pickup clutch(CL1)

Pickup motor(M1)

Stopper

Stopper

Document

Pickup roller

Separation roller

Feed roller

2. Technical Explanation

■ Stream reading

The stream reading starts when the leading edge of a document reaches the reading point and the read start signal is received

from the host machine.

"Stream reading" is a scan function which a document is scanned while feeding along the Document glass. The Scanner which

is fixed under the Document glass reads the image.

A document is fed by the Lead roller 1 (upper) and the Platen roller driven by the Read motor (M2). The read image is stored in

the memory of the host machine.

Pickup Roller Assembly and Separation Roller

The Pickup roller assembly consists of the Pickup roller and the Feed roller.

When the start key is pressed or a document pickup signal is input, the Pickup motor (M1) drives to lower the Pickup roller

assembly through the Pickup clutch (CL1) and then the Pickup roller and the Feed roller rotates to feed a document to the

Registration roller.

The Pickup roller assembly is equipped with stoppers to prevent that a document is inserted deeper than appropriate position.

The Separation roller is used to improve the separation performance while picking up a document.

19

Upper delivery reversal roller

Platen roller

Read roller 2(Upper)

Read roller 1

(Upper)

M2

M2

Delivery reversal sensor(SR3)

SL1

M2

SL1

M2

2. Technical Explanation

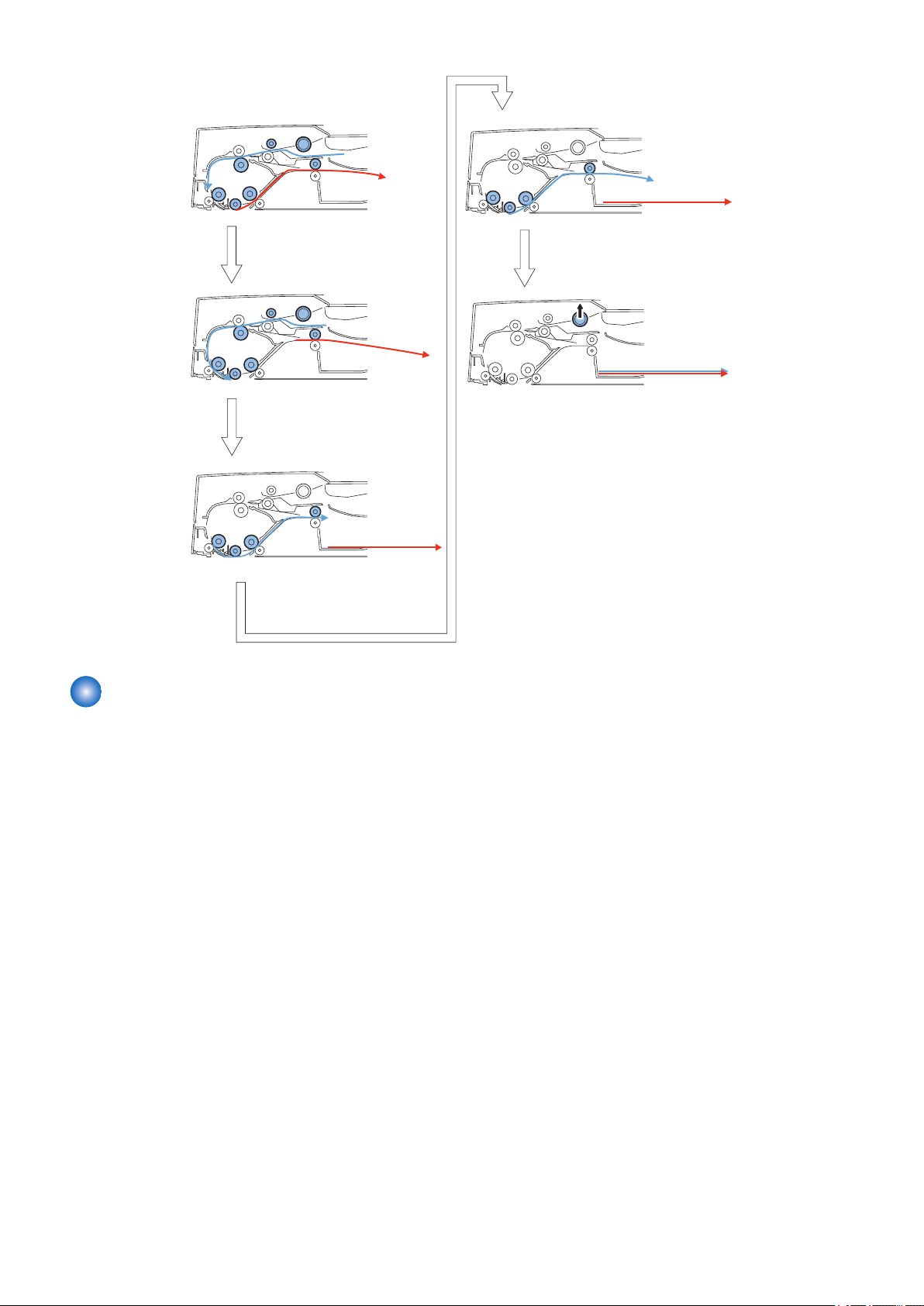

Document Reversing

Basic Operation

There are two types of document reversal operation: one that is performed from the top to the reverse side of the document and

the other that is performed from the reverse side to the top of the document.

Since the basic operation methods are identical, only the reversal operation performed from the reverse side to the top is discussed

below.

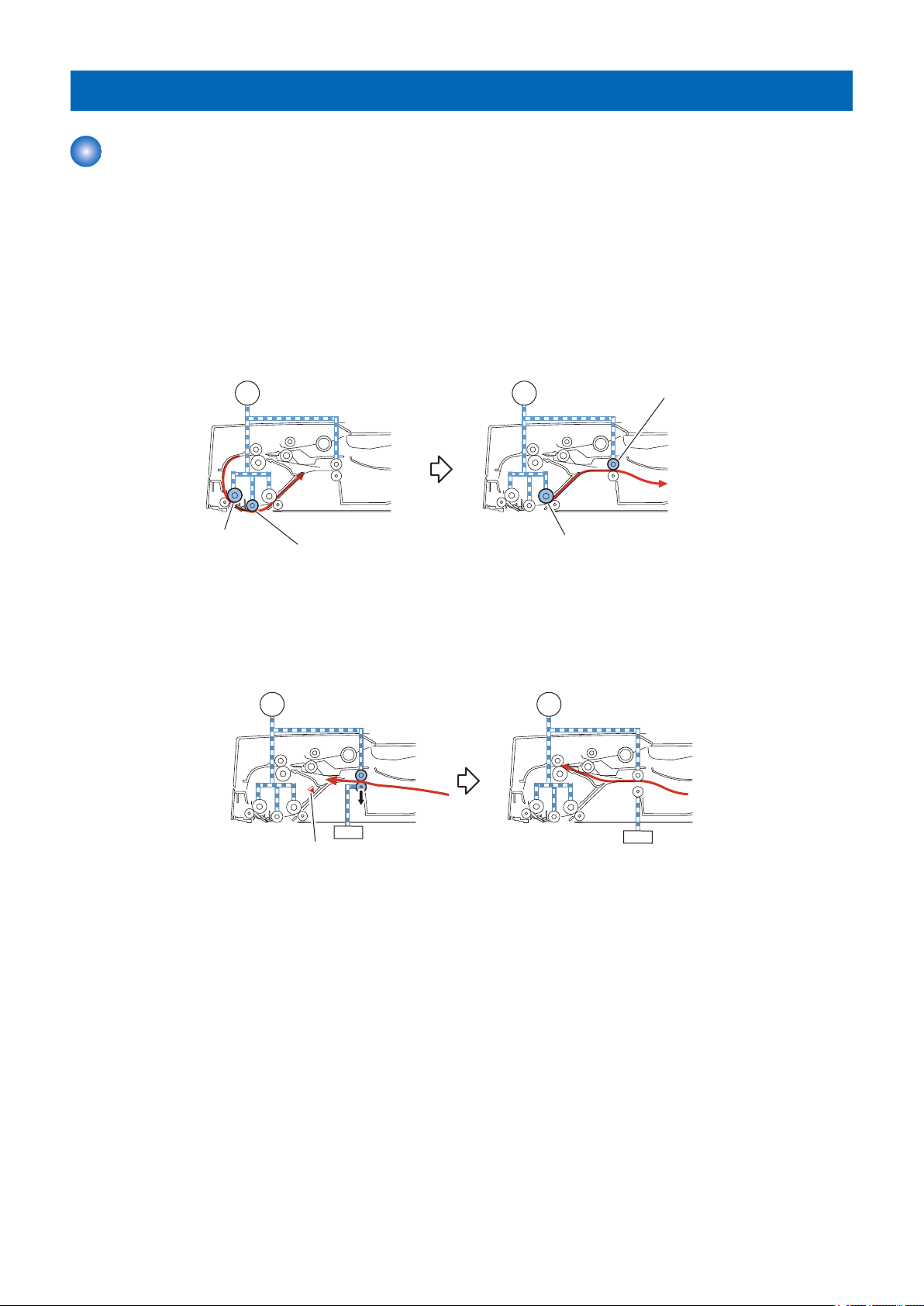

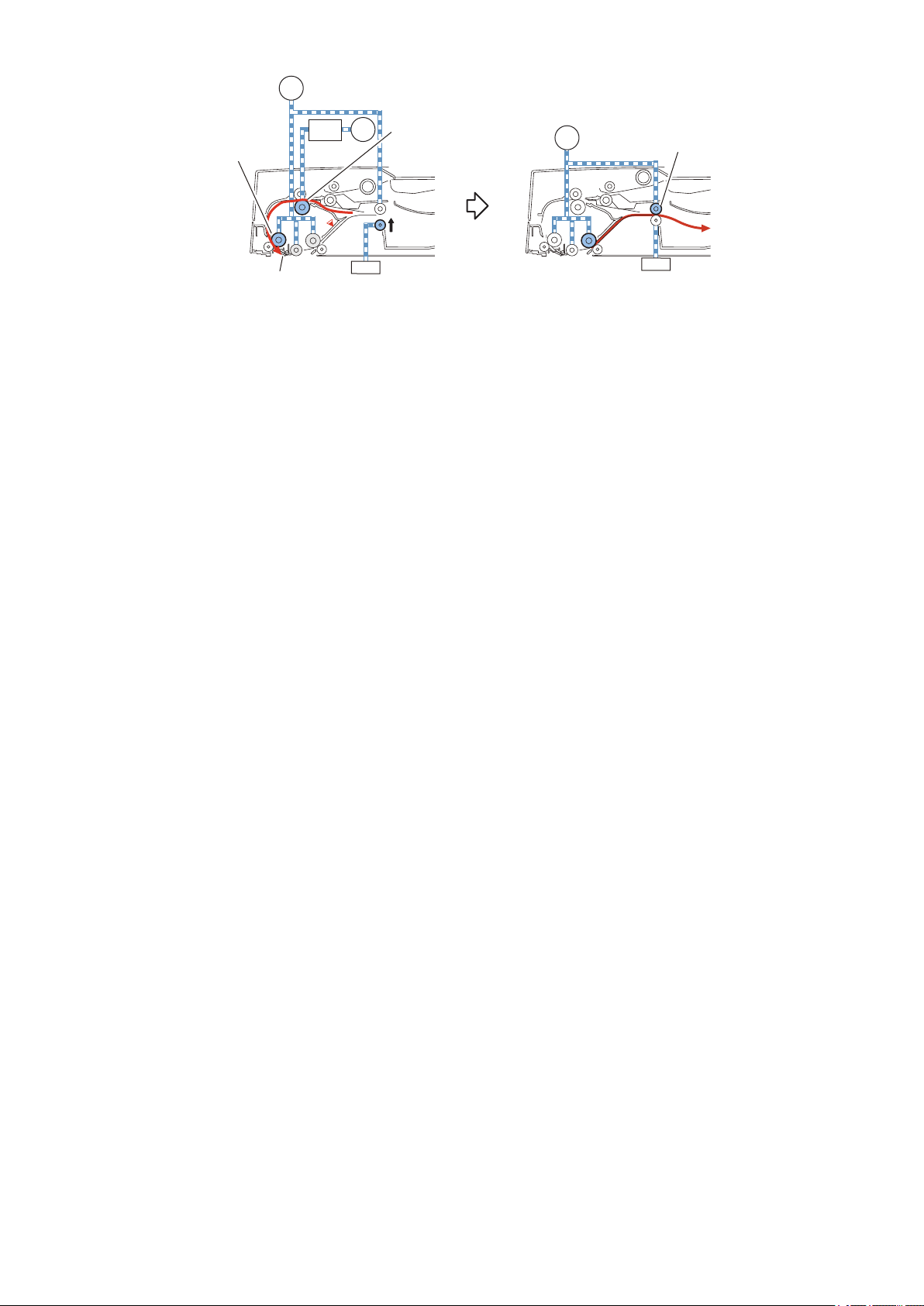

■ Top side pickup

The Read motor (M2) drives the Lead roller 1 (upper) and the Platen roller to scan the surface of a document on stream reading.

After completion of scanning, Read motor (M2) drives the Lead roller 2 (upper) and the Upper delivery reversal roller to feed a

document to the reverse point.

■ Reversal/Feed 1

After the trailing edge of a fed document passes the Delivery reversal sensor (SR3), the Read motor (M2) stops.

Thus a document stops at the reverse point. The Read motor (M2) drives in reverse direction to feed a document to the Registration

roller and then it stops. After that, the Release solenoid (SL1) turns on to release the Lower delivery reversal roller.

■ Reversal/Feed 2

The Pickup motor (M1) drives the Lower registration roller through the Registration clutch (CL2) to feed a document to the Read

wait point.

Thus, the document is reversed. After a document is picked up again, turn OFF the Release solenoid (SL1) to pressurize at the

same time that reverse side reading is complete. After that, each operation is performed such as re-reverse, feeding and

delivering.

20

Read roller 1

(Upper)

Upper delivery

reversal roller

SL1

CL2

Reading start point

Lower registration roller

M2

M1

SL1

M2

2. Technical Explanation

21

SL1

Upper delivery reversal roller

SL1

M2

Read roller 2 (Upper)

M2

2. Technical Explanation

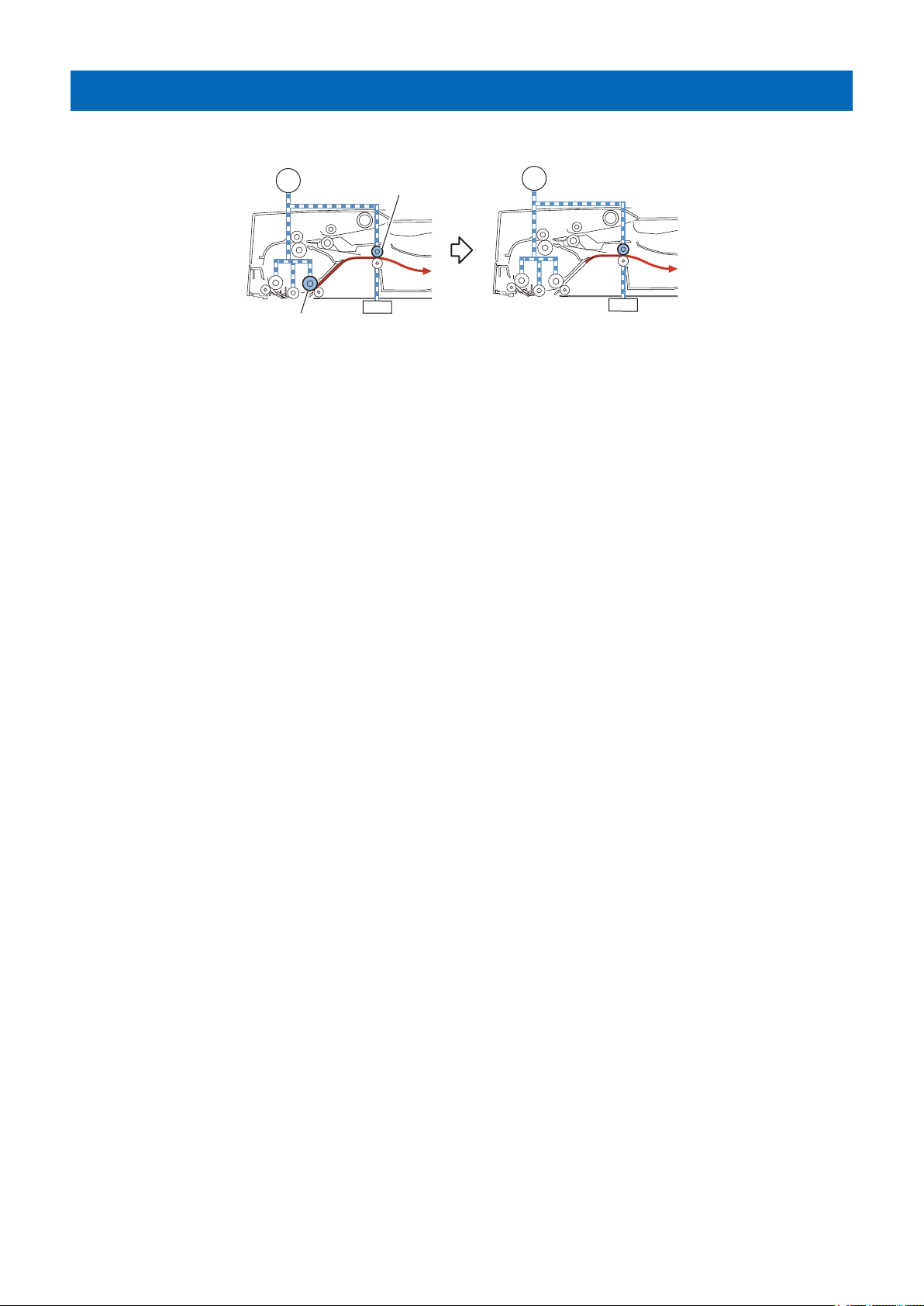

Document Delivery

A document is delivered by the Lead roller 2 (upper) and the Upper delivery reversal roller driven by the Read motor (M2).

22

Document Detection

Outline

This machine detects a document using either of the two methods depending on the print mode.

• Normal print mode (other than mixed size print mode and banner paper mode)

• Mixed size print mode and banner paper mode

Normal print mode

Function Description Symbol

Document presence/absence detection Detects document existence on the Document sup-

ply tray.

Initial document size absence

detection

Mixed size print mode and banner paper mode

Length Detects document length on the Document supply

tray.

Width Detects the document width on the Document sup-

ply tray.

2. Technical Explanation

Document set sensor(SR5)

Document length sensor 1/2

(SR7/SR8)

Document width sensor1/2/3

(SR13/SR14/SR15)

Function Description Symbol

Document presence/absence detection Detects document existence on the Document sup-

ply tray.

Mixed width document size detection

Length Document length is detected while feeding. Registration sensor (SR1)

Width Detects the maximum document width on the

Document supply tray.

Document width is detected while feeding. Different width sensor 1/2/3/4

Document set sensor (SR5)

Read sensor (SR2)

Document width sensor1/2/3

(SR13/SR14/SR15)

(SR9/SR10/SR11/SR12)

Initial Document Size Detection

Initial document size is detected when a document is placed on the Document supply tray. The Document length sensor 1/2 (SR7/

SR8) and the Document width sensor 1/2/3 (SR13/SR14/SR15) are used for the detection.

The light shading detects document length whose sensor is the Document length sensor 1/2 (SR7/SR8).

Document width is detected by the Document width sensor 1/2/3 (SR13/SR14/SR15) which performs by light prevention plate

connected with the Slide guide adjustment.

Document sizes are determined by combination of ON/OFF states of these sensors.

The Document length sensor 1 (SR7) is a Reflection Sensor which is available to detect the length of a document in case that

the curled paper is placed on the document pickup tray.

23

SR8

SR7

SR13

SR15

SR14

2. Technical Explanation

The following table shows the relationship among length detection sensor signals, document widths, and initial document sizes.

Document width detection Document length detec-

Detected size

tion

Width (mm) Document

width sensor

1 (SR13)

143.9 or less OFF OFF OFF ON ON - - STMTR A5R

More than

143.9 and

165.0 or less

More than

165.0 and

196.0 or less

More than

196.0 and

213.9 or less

More than

213.9 and

236.5 or less

More than

236.5 and

263.5 or less

More than

263.5 and

288.2 or less

OFF ON ON ON ON - - A5R A5R

OFF OFF ON ON ON - - B5R B5R

ON OFF ON ON ON - - A4R A4R

ON ON ON ON ON - LGL LGL A4R

ON OFF OFF ON ON B4 - B4 B4

ON ON OFF ON ON - 11 × 17 11 × 17 K8

Document

width sensor

2 Document

(SR14)

Document

width sensor

3 (SR15)

Document

length sensor

1 (SR7)

OFF ON - - STMTR A5R

ON OFF - - STMTR A5R

OFF OFF - STMTR STMTR A5R

OFF ON - - A5R A5R

ON OFF - - A5R A5R

OFF OFF A5R - A5R A5R

OFF ON - - B5R B5R

ON OFF B5R - B5R B5R

OFF OFF B6 - B6 B6

OFF ON - - A4R A4R

ON OFF A4R - A4R A4R

OFF OFF A5 - A5 A5

OFF ON - - LGL A4R

ON OFF - LTRR LTRR A4R

OFF OFF - STMT STMT A5

OFF ON - - B4 B4

ON OFF - - B4 B4

OFF OFF B5 - B5 B5

OFF ON - 11 × 17 11 × 17 K8

ON OFF - 11 × 17 11 × 17 K8

OFF OFF - LTR LTR K16

Document

length sensor 2 (SR8)

AB INCH AB/INCH AB/K

24

Loading...

Loading...