Canon H1, DADF-AG1 Service Manual

Color Image Reader Unit - H1

Product Outline

Technology

Periodic Servicing

Parts Replacement and Cleaning Procedure

Adjustment

Installation

Appendix

SERVICE MANUAL Rev0

654321

Application

This manual has been issued by Canon Inc. for qualied persons to learn technical theory,

installation, maintenance, and repair of products. This manual covers all localities where the

products are sold. For this reason, there may be information in this manual that does not

apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements

or changes in products. When changes occur in applicable products or in the contents of this

manual, Canon will release technical information as the need arises. In the event of major

changes in the contents of this manual over a long or short period, Canon will issue a new

edition of this manual.

The following paragraph does not apply to any countries where such provisions are

inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks

of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may

not be copied, reproduced or translated into another language, in whole or in part, without the

written consent of Canon Inc.

© CANON INC. 2013

Caution

Use of this manual should be strictly supervised to avoid disclosure of condential

information.

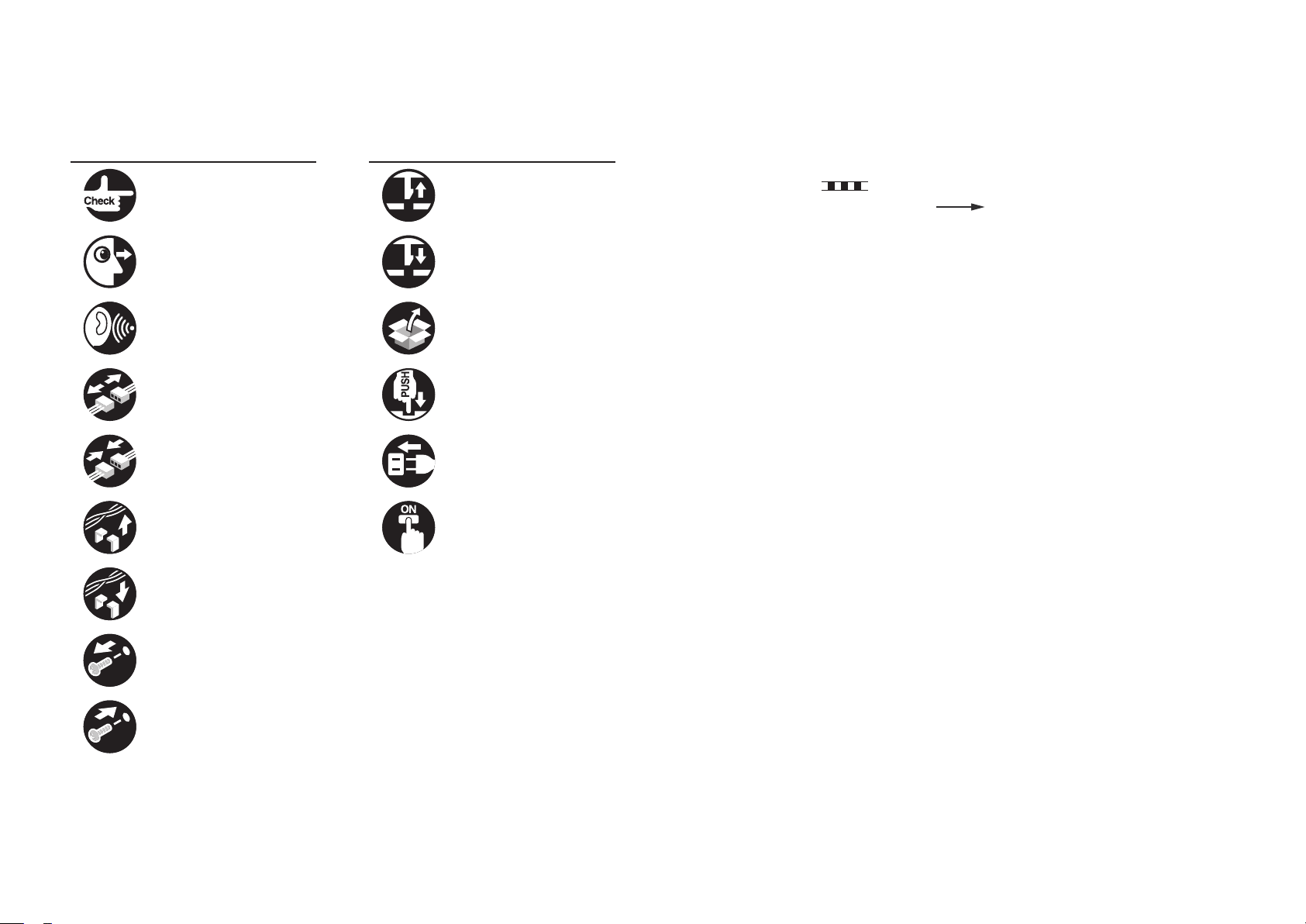

Explanation of Symbols

The following symbols are used throughout this Service Manual.

Symbols Explanation Symbols Explanation

Check. Remove the claw.

Check visually. Insert the claw.

The following rules apply throughout this Service Manual:

1. Each chapter contains sections explaining the purpose of specic functions and the

relationship between electrical and mechanical systems with reference to the timing of

operation.

In the diagrams, represents the path of mechanical drive; where a signal name

accompanies the symbol, the arrow indicates the direction of the electric

signal.

The expression "turn on the power" means ipping on the power switch, closing the

front door, and closing the delivery unit door, which results in supplying the machine with

power.

Check the noise. Use the bundled part.

Disconnect the connector. Push the part.

Connect the connector. Plug the power cable.

Remove the cable/wire

from the cable guide or wire

saddle.

Set the cable/wire to the

cable guide or wire saddle.

Remove the screw.

Tighten the screw.

Turn on the power.

2. In the digital circuits, '1' is used to indicate that the voltage level of a given signal is

"High", while '0' is used to indicate "Low". (The voltage value, however, differs from

circuit to circuit.) In addition, the asterisk (*) as in "DRMD*" indicates that the DRMD

signal goes on when '0'.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked

in the eld. Therefore, the operations of the microprocessors used in the machines

are not discussed: they are explained in terms of from sensors to the input of the DC

controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product

improvement or other purposes, and major changes will be communicated in the form of

Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service

Manual and all relevant Service Information bulletins and be able to identify and isolate faults

in the machine.

Contents

0

Safety Precautions

Notes Before it Works Serving ---------------------------------------------0-8

Points to Note at Cleaning --------------------------------------------------0-8

1

Product Outline

Original Exposure System (Reader) -------------------------------------1-2

Features (Reader) ----------------------------------------------------------------- 1-2

Specications (Reader) ------------------------------------------------------1-2

Specications -------------------------------------------------------------------------------- 1-2

Names of Parts (Reader) ---------------------------------------------------1-3

External View -------------------------------------------------------------------------------- 1-3

Cross Section -------------------------------------------------------------------------------- 1-3

Major Components ------------------------------------------------------------------------- 1-3

Reader Relay PCB ------------------------------------------------------------------------- 1-4

Features (DADF) --------------------------------------------------------------1-5

Specications (DADF) -------------------------------------------------------1-5

Names of Parts (DADF) -----------------------------------------------------1-5

External View ----------------------------------------------------------------------- 1-5

Cross Section ----------------------------------------------------------------------- 1-5

2

Technology

Controls (Reader) -------------------------------------------------------------2-2

Basic Sequence ----------------------------------------------------------------------------- 2-2

Controlling the Scanner Drive System ------------------------------------------------ 2-3

CCD Unit -------------------------------------------------------------------------------------- 2-4

Enlargement/Reduction ------------------------------------------------------------------- 2-6

Detecting the Size of Originals ---------------------------------------------------------- 2-6

Dirt Sensor Control ------------------------------------------------------------------------2-10

Image Processing ------------------------------------------------------------------------- 2-11

Color offset correction in sub scanning ----------------------------------------------2-13

Servicing (Reader)

------------------------------------------------------------------- 2-14

Periodically Replaced Parts -------------------------------------------------------------2-14

Consumable Parts -------------------------------------------------------------------------2-14

Periodical Servicing -----------------------------------------------------------------------2-14

Action to take when replacing parts ---------------------------------------------------2-14

Major Adjustments -------------------------------------------------------------------------2-14

Troubleshooting ----------------------------------------------------------------------------2-14

Basic Conguration (DADF) ---------------------------------------------- 2-15

Component Conguration ------------------------------------------------------2-15

Outline of Electric Circuits ---------------------------------------------------------------2-15

Drive Conguration --------------------------------------------------------------- 2-15

Sensor Layout ------------------------------------------------------------------------------2-16

Outline of Operation Modes ---------------------------------------------------- 2-16

Outline ---------------------------------------------------------------------------------------- 2-16

Forward Pickup/Delivery Operation ---------------------------------------------------2-16

Forward Pickup/Reverse Delivery Operation ---------------------------------------2-17

Controls (DADF) ------------------------------------------------------------- 2-19

Document Detection -------------------------------------------------------------2-19

Outline ---------------------------------------------------------------------------------------- 2-19

Initial Document Size Detection --------------------------------------------------------2-20

Document Pickup/Separation --------------------------------------------------2-21

Basic Pickup Operation ------------------------------------------------------------------2-21

Pickup Unit and Stopper -----------------------------------------------------------------2-22

Document Reversing -------------------------------------------------------------2-22

Basic Operation ----------------------------------------------------------------------------2-22

Document Feeding/Delivery ----------------------------------------------------2-23

Basic Operation ----------------------------------------------------------------------------2-23

Release Operation ------------------------------------------------------------------------2-24

Detecting Jams -------------------------------------------------------------------- 2-24

Jams ------------------------------------------------------------------------------------------2-24

Power Supply ----------------------------------------------------------------------2-25

Power Supply -------------------------------------------------------------------------------2-25

Stamp Operation ------------------------------------------------------------------ 2-25

Outline ---------------------------------------------------------------------------------------- 2-25

Fan -----------------------------------------------------------------------------------2-26

Fan Operation ------------------------------------------------------------------------------2-26

Work of service (DADF) --------------------------------------------------- 2-27

When replacing the parts -------------------------------------------------------2-27

0

1-5

Periodic Servicing -----------------------------------------------------------------2-27

3

Periodic Servicing

List of Work for Scheduled Servicing ------------------------------------3-2

4

Parts Replacement and Cleaning Procedure

List of Parts(Reader) ---------------------------------------------------------4-2

External Covers -------------------------------------------------------------------- 4-2

List of Electrical Components --------------------------------------------------- 4-2

External Covers(Reader) ----------------------------------------------------4-3

Removing the Reader Left Cover ---------------------------------------------- 4-3

Removing the Reader Front Cover -------------------------------------------- 4-3

Removing the Reader Right Cover -------------------------------------------- 4-3

Removing the Reader Rear Cover -------------------------------------------- 4-3

Original Exposure System (Reader) -------------------------------------4-4

Removing the Platen Glass ----------------------------------------------------- 4-4

Removing the ADF Scan Glass ------------------------------------------------ 4-5

Removing the CCD Unit ---------------------------------------------------------- 4-6

Cleaning in the CCD unit (Mirror No. 1 - 5) ---------------------------------4-10

Removing the Reader Controller PCB --------------------------------------- 4-11

Removing the Reader Assembly ----------------------------------------------4-12

List of Parts (DADF) -------------------------------------------------------- 4-15

External Covers -------------------------------------------------------------------4-15

Consumable Parts Requiring Periodic Replacement and Cleaning

Points --------------------------------------------------------------------------------4-15

List of Clutchs, Solenoids, Motors, Fans, PCBs --------------------------4-16

Others -------------------------------------------------------------------------------- 4-16

List of Sensors ---------------------------------------------------------------------4-17

External Covers (DADF) -------------------------------------------------- 4-18

Removing the Front Cover -----------------------------------------------------4-18

Removing the Rear Cover ------------------------------------------------------ 4-18

Removing the Feeder Cover --------------------------------------------------- 4-19

Main Units (DADF) ---------------------------------------------------------- 4-20

Removing the Feed Unit --------------------------------------------------------4-20

Consumable Parts Requiring Periodic Replacement and Cleaning

Points (DADF) --------------------------------------------------------------- 4-22

Removing the Pickup Roller Unit ---------------------------------------------4-22

Removing the Separation Pad -------------------------------------------------4-23

Replacing the Stamp -------------------------------------------------------------4-23

Exchanging the Feed Guide ---------------------------------------------------4-24

Clutch Solenoid Motor Fan PCB (DADF) ----------------------------- 4-25

Removing the ADF Motor(M1) -------------------------------------------------4-25

Removing the Release Motor(M2) --------------------------------------------4-25

Removing the Pressurization Solenoid(SL1) ------------------------------4-26

Pickup Clutch/Registration Clutch(CL1/CL2) ------------------------------4-26

Removing the ADF Driver PCB ------------------------------------------------4-27

Removing the LED PCB --------------------------------------------------------4-28

Removing the Fan ----------------------------------------------------------------4-28

Removing the Sensor(SR1,SR2,SR3) ---------------------------------------4-29

Removing the Timing Sensor(SR4) ------------------------------------------4-32

Removing the Document Set Sensor(SR5) --------------------------------4-32

Removing the Cover Open/Closed Sensor(SR6) ------------------------- 4-32

Removing the Document Length Sensor(SR7,SR10) -------------------4-33

Removing the A4R/LTRR Identication Sensor(SR8) -------------------4-33

Removing the Release Motor HP Sensor(SR11) -------------------------4-34

Removing the Document Width Volume(VR1) ----------------------------4-34

Removing the hinge -------------------------------------------------------------- 4-35

Removing the left hinge ------------------------------------------------------------------4-35

Removing the Right hinge ---------------------------------------------------------------4-35

Removing the Platen roller -----------------------------------------------------4-36

5

Adjustment

Overview (Reader) ------------------------------------------------------------5-2

When replacing parts (Reader) --------------------------------------------5-2

Platen Glass --------------------------------------------------------------------------------- 5-2

ADF Scan Glass ---------------------------------------------------------------------------- 5-3

CCD Unit -------------------------------------------------------------------------------------- 5-3

Overview (DADF) -------------------------------------------------------------5-6

Outline -------------------------------------------------------------------------------- 5-6

Adjustment Method (DADF) ------------------------------------------------5-7

Preparation or Creation of Test Chart ----------------------------------------- 5-7

Adjusting the Height of the hinge ---------------------------------------------- 5-7

0

1-5

0

1-6

Pre-check ------------------------------------------------------------------------------------- 5-7

Adjustment Procedure --------------------------------------------------------------------- 5-7

Check the height of the left hinge ------------------------------------------------------ 5-8

Check the height of the right hinge ----------------------------------------------------- 5-8

Adjust the height of the left hinge ------------------------------------------------------- 5-9

Adjust the height of the right hinge ----------------------------------------------------- 5-9

Adj of DADF Tray width ---------------------------------------------------------5-10

AB-Conguration Adjustment -----------------------------------------------------------5-10

Inch-Conguration Adjustment ---------------------------------------------------------5-10

Adjusting the Perpendicularity ------------------------------------------------- 5-10

Scan position auto adj in DADF mode --------------------------------------- 5-11

Adj img pstn in DADF mode:horz scan --------------------------------------5-12

Adj of DADF img lead edge margin: front -----------------------------------5-12

Fine adj of DADF image magnictn: front ----------------------------------5-13

White level adj ---------------------------------------------------------------------5-13

6

Installation

How to Utilize This Installation Procedure ------------------------------6-2

When using the parts included in the package ----------------------------- 6-2

Symbols in the Illustration ------------------------------------------------------- 6-2

Caution During Installation --------------------------------------------------6-2

Check Items when Turning OFF the Main Power ---------------------6-2

Checking the Contents ------------------------------------------------------6-3

Installation Procedure --------------------------------------------------------6-5

Installation Procedure ------------------------------------------------------------- 6-5

Signal Name List (DADF) ------------------------------------------------------v

Signal Name List ------------------------------------------------------------------------------- v

Appendix

Service Tools ----------------------------------------------------------------------ii

General Circuit Diagram(Reader) ------------------------------------------- iii

General Circuit Diagram (DADF) --------------------------------------------iv

0

Special Tools ------------------------------------------------------------------------------------ ii

Oils and Solvents ------------------------------------------------------------------------------ ii

General Circuit Diagram (1/1) -----------------------------------------------------iii

General Circuit Diagram (1/1) -----------------------------------------------------iv

1-6

Safety Precautions

Notes Before it Works Serving

■

Points to Note at Cleaning

■

0

Safety Precautions > Points to Note at Cleaning

Notes Before it Works Serving

CAUTION:

At servicing, be sure to turn off the power source according to the specied steps and

disconnect the power plug.

CAUTION:

Do not turn off the power switch when downloading is under way. Turning off the main

power switch while downloading is under way can disable the machine.

Points to Note at Cleaning

0-8

CAUTION:

When performing cleaning using organic solvent such as alcohol, be sure to check

that the component of solvent is vaporized completely before assembling.

Safety Precautions > Points to Note at Cleaning

0

0-8

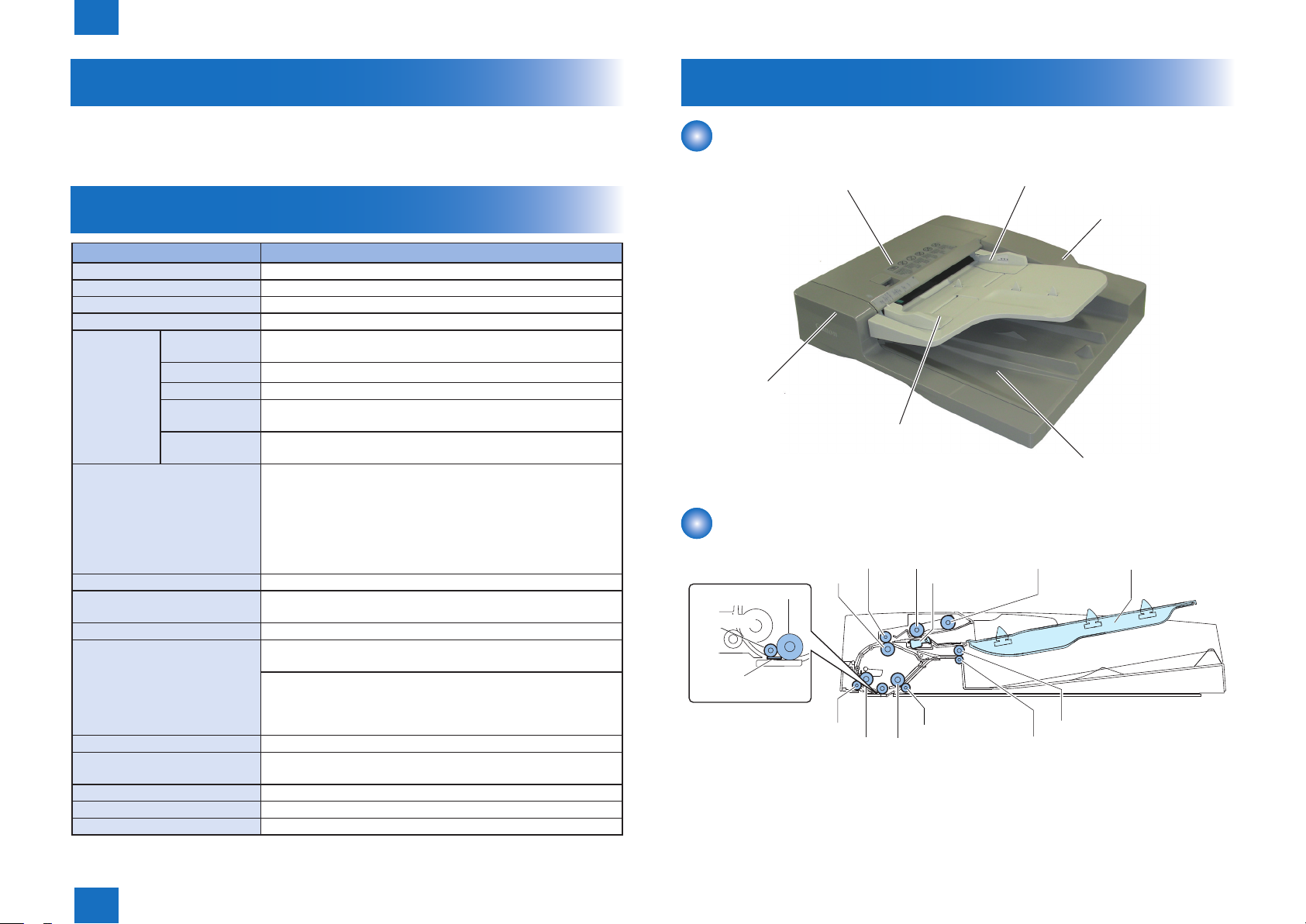

Product Outline

1

Original Exposure System

■

(Reader)

Specications (Reader)

■

Names of Parts (Reader)

■

Features (DADF)

■

Specications (DADF)

■

Names of Parts (DADF)

■

Product Outline

1

1

Product Outline > Specications (Reader)

1-2

Original Exposure System (Reader)

Features (Reader)

• Adapting new CCD unit, allows low power consumption.

• Improvement of the CCD unit disassembly

Specications (Reader)

■Specications

Item Specication/function

Original exposure

Original scan In book mode

In ADF mode

Read resolution

Gradation

Carriage position detection

Magnication

Main scanning

direction

Sub scanning

direction

Lens

CCD

CCD unit drive control

Original size

detection

In book mode

In ADF mode

Indirect exposure by LED (LED & photoconductive body)

Scan by movement of CCD

Stream reading with CCD xed

600 dpi (main scanning) x 600 dpi (sub scanning)

256 gradation

CCD HP sensor (S11)

25% to 400%

Image is processed on main controller PCB 2

In book mode: speed change by carriage travel, image

process on main controller PCB *1

In ADF mode: original feed speed change, image process on

main controller PCB *1

ST lens

Number of lines: 4 (R, G, B, B/W)

Number of pixels: 7500 x 3 color lines, 7500 x 1 B/W line

Maximum original read width: 317.5mm

By scanner motor (M14)

Main scanning direction: by CCD

Sub scanning direction: by reection sensor

Main scanning direction: by photo interrupter on DADF

Sub scanning direction: by photo interrupter on DADF

Product Outline > Specications (Reader)

1

T-1-1

*1 Controls differ depending on magnications. Refer to [Magnications] for more information.

1-2

1

Reader rear cover

CCD unit Platen glass

ADF scan glass

M14

Product Outline > Names of Parts (Reader)

1-3

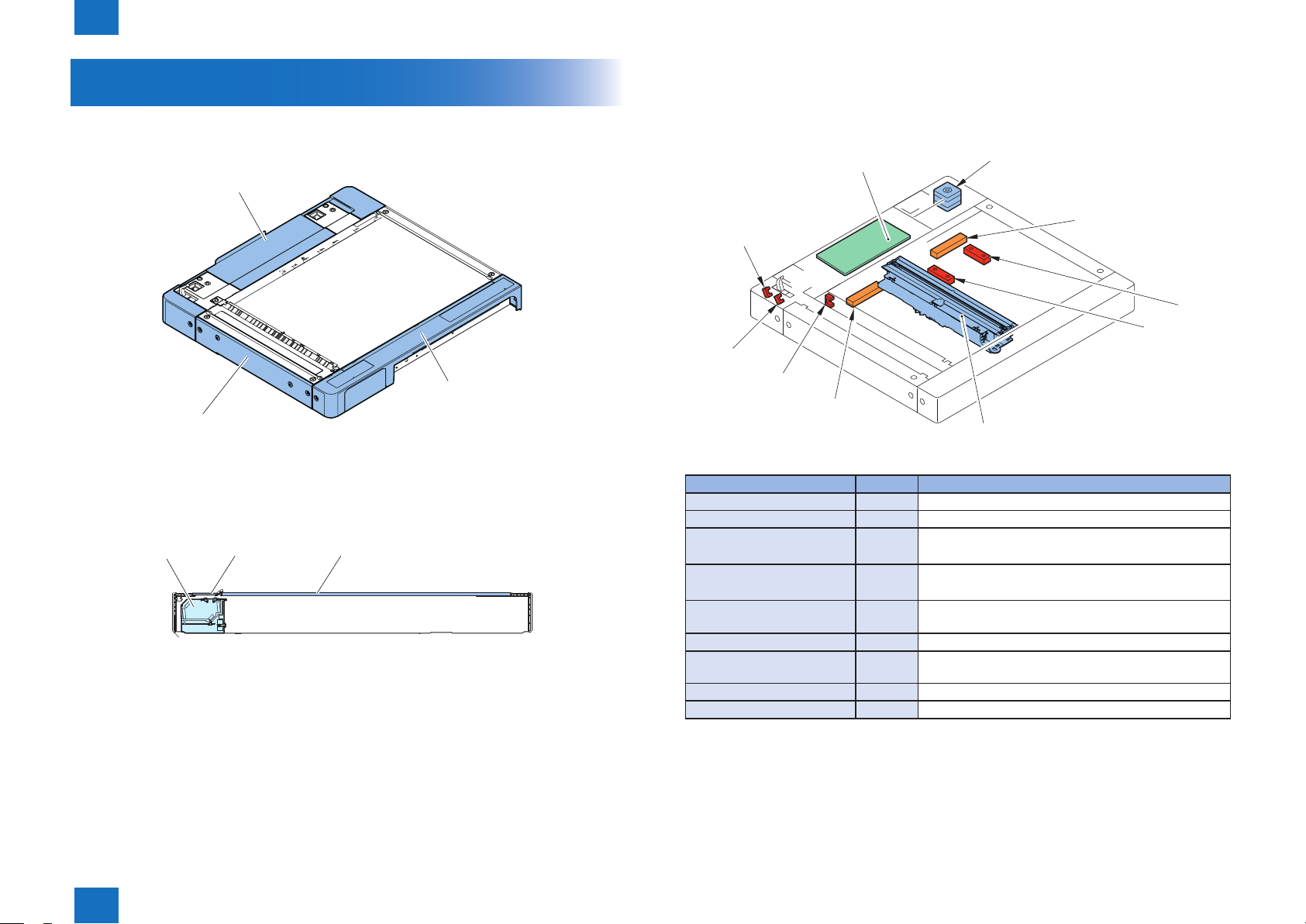

Names of Parts (Reader)

■External View

■Cross Section

Reader left cover

Reader front cover

F-1-1

F-1-2

■Major Components

Following shows major components of document exposure system.

UN4

S13

S12

S11

H6

CCD unit

Item Notation Specication/function

Scanner motor

CCD HP sensor

Copyboard Cover Open/

Closed Sensor (front)

Copyboard Cover Open/

Closed Sensor (rear)

Original Size Sensor 1

Original Size Sensor 2

CCD unit

Reader Heater (Option)

Reader controller PCB

M14 Pulse motor: controls the carriage drive

S11 Detects CCD home position

S12 Ends original size identication with the copy board

cover at 5 deg

S13 Detects the copyboard cover open/close. Starts original

size identication with the copy board cover at 30 deg.

S15 Helps identify original size(AB, INCH/AB/K, A)

S14 Helps identify original size(INCH/AB/K, INCH/A)

- Indirect exposure by LED (LED & photoconductive

body)

H6 Prevents condensation on the copyboard glass

UN4 Controls the reader unit drive and image process

H6

S14

S15

F-1-3

T-1-2

Product Outline > Names of Parts (Reader)

1

1-3

1

Product Outline > Names of Parts (Reader)

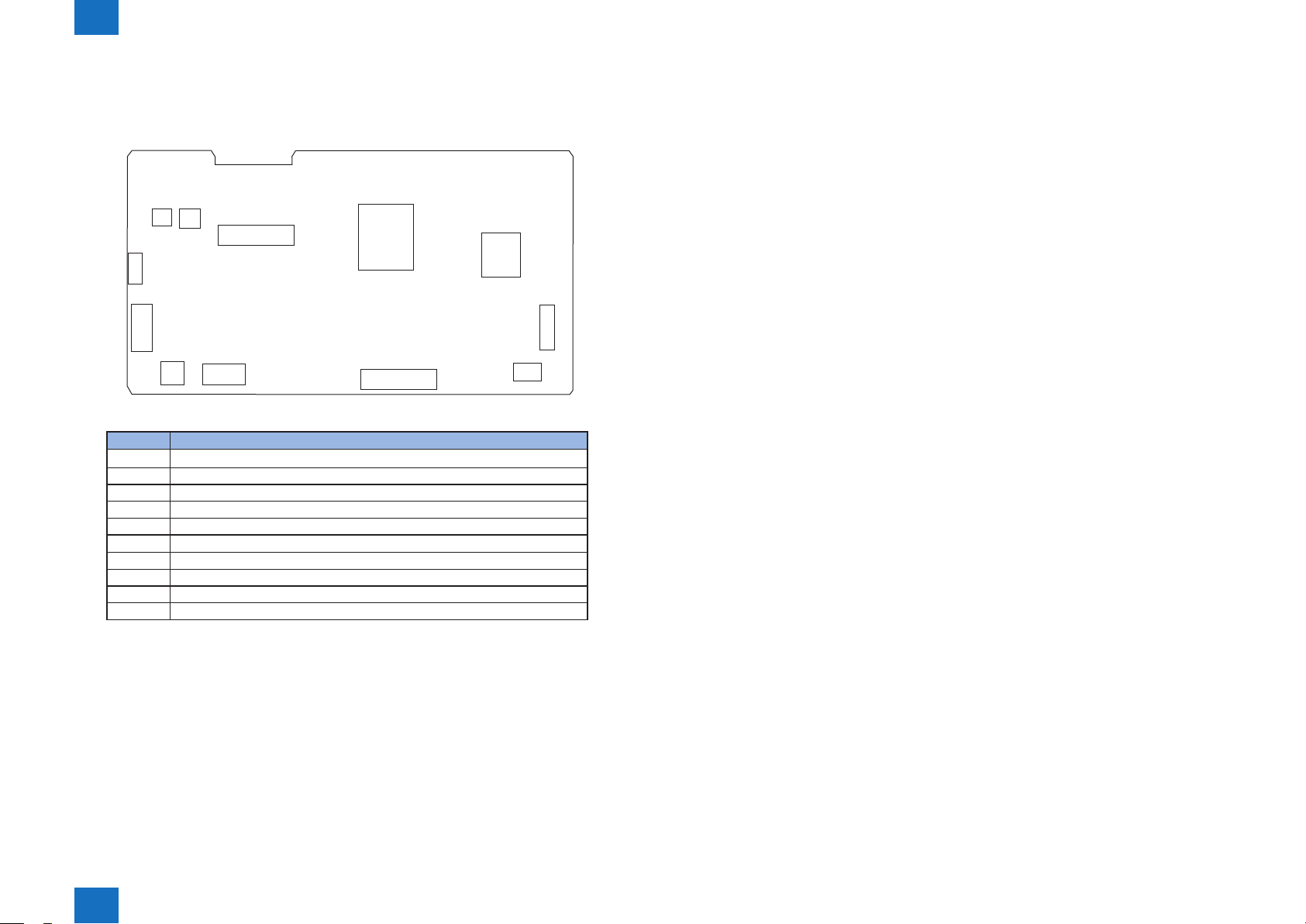

■Reader Relay PCB

The function conguration of reader controller PCB is described below.

J501

J508 J507

J503

1-4

J504

J505 J509

Jack No Description

J501 Communication with CCD

J502 Communication with main controller PCB

J503 Connection to Scanner motor

J504 Receives power from the machine (printer unit)

J505 Power supply to DADF

J506 Connection to copyboard cover open/close sensor and CCD HP sensor

J507 Connection to original size sensor 2

J508 Connection to original size sensor 1

J509 Communication with DADF

J510 Not used

J502

J506

J510

F-1-4

T-1-3

Product Outline > Names of Parts (Reader)

1

1-4

1

Product Outline > Names of Parts (DADF) > Cross Section

1-5

Features (DADF)

The mixed mode of the different width manuscript.

The detection of the different manuscript type (AB type / inch type).

Specications (DADF)

Item Specications

Document pickup method Automatic pickup and delivery

Document loading direction Face-up

Document loading position Aligned to center

Document separation method Upper separation

Document type Single -sided AB type: 42-128 g/m2

Inch type: 50-128 g/m2

Double-sided 50-128 g/m2

Color document 64-128 g/m2

Black and White/

Color Mixed

Document longer

than 432 mm

Document size AB type: B6/A5/B5/A4/B5R/A5R/A4R/B4/A3 (B6:Cross feed only)

Document tray capacity 100 sheets (80g/m2)

Document processing mode - Single-sided document processing

Document size recognition Available (Standard size)

Mixed document function Same types of paper can be mixed.

Book document Supported (The document thickness must be 50 mm or less.)

Interface with Install Connected

Equipment

Power supply Supplied from host machine

Dimensions 565 mm×510 mm×145 mm (W×D×H)

Weight Approx. 7.9 kg

50-128 g/m2 (Color:64-128 g/m2)

Single-sided one sheetFeed: 60- 90g/ m2

INCH type: STMT/LTR/LTRR/LGL/11"×17" (STMT:Cross feed

only)

Others:8K/16K

Document width: 148-297mm

Document length (longitudinal): 128-432mm (“630mm” is held by

the operator.)

- Double-sided document processing

Equivalent to that in continuous feed mode is assured.

Different types of paper can be mixed.

Different types original mixable combination:

A/B type: A3/B4R,A4/B5,B4/A4R,B5/A5,A4R/B5R,A5/B6

Inch type: LDR/LGL,LTR/LGL,LTR/STMT

Cereal Interface

Names of Parts (DADF)

External View

Feeder Cover

Front Cover

Document supply tray

Cross Section

Upper registration roller

Lower registration roller

Platen roller

Read roller

White sheet

Read roller 1 (upper)

Separation pad unit

Read roller 2 (lower)

Read roller 2 (upper)

Slide guide

Document delivery tray

Pickup roller Feed roller

Upper delivery reversal roller Read roller 1 (lower)

Lower delivery reversal roller

Rear Cover

F-1-5

Document supply tray

F-1-6

Product Outline > Names of Parts (DADF) > Cross Section

1

1-5

Technology

2

Controls (Reader)

■

Servicing (Reader)

■

Basic Conguration

■

(DADF)

Controls (DADF)

■

Work of service (DADF)

■

2

Technology

2

ON STBY

CCD adjustment

Dust detection

Technology > Controls (Reader)

2-2

Controls (Reader)

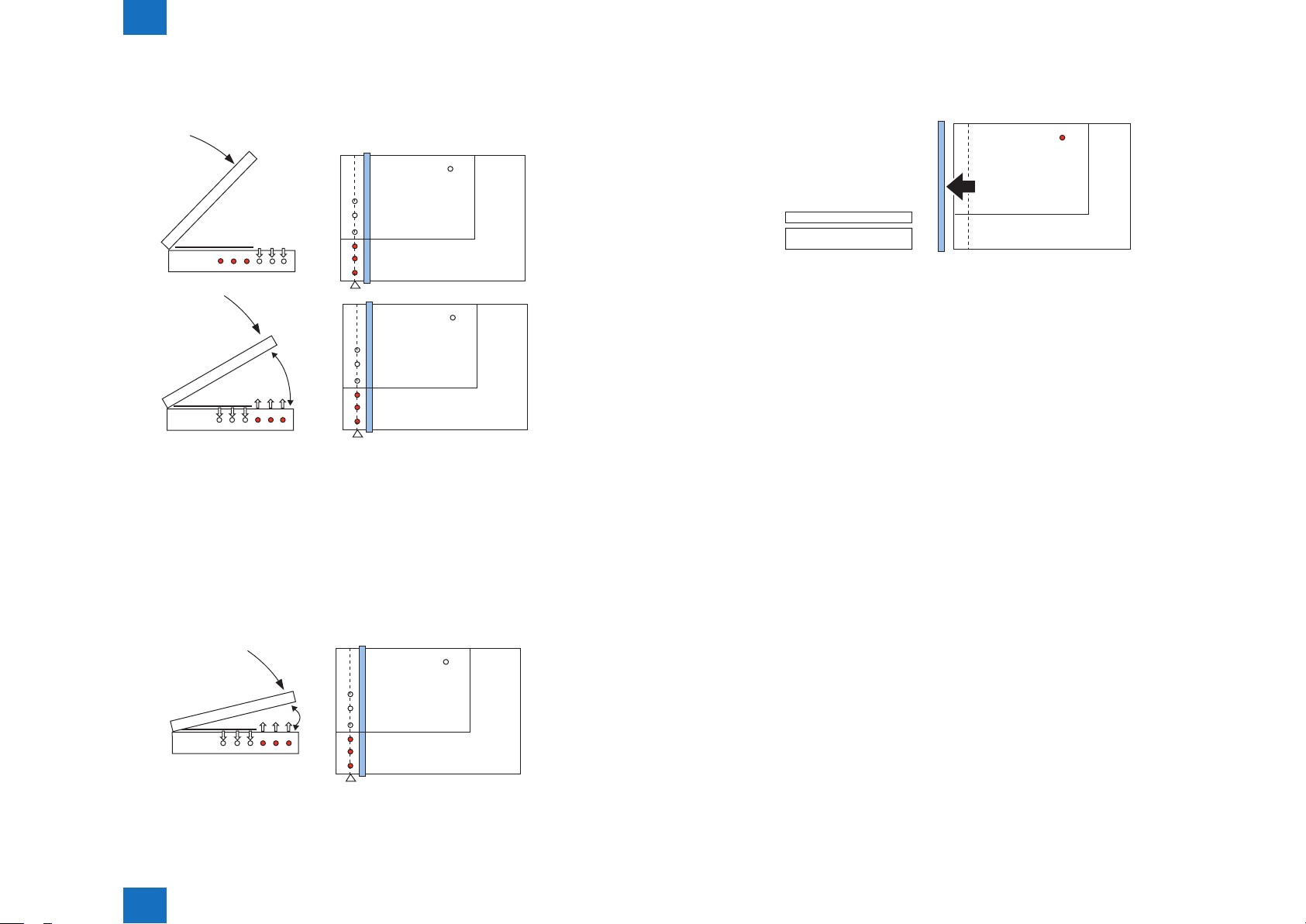

■Basic Sequence

●Basic Sequence at Power-On

(Scanner

motor)

(LED)

(CCD

HPsensor)

Footnote

• F: Scanner motor moves forward (toward right).

• B: Scanner motor moves backward (toward left).

• Light-ON: LED on CCD unit lights-on.

• ON: When CCD HP sensor (photo interrupter type) detects.

●Basic Sequence at Start Key ON (book mode/1 original)

B F

Light-ON

ON

F-2-1

●Basic Sequence at Start Key ON (ADF mode/1 original)

Copy start

(Scanner

motor)

(LED)

(CCD HP

sensor )

Dust detection control

This is activated when any of the following conditions is true.

• Dust has been detected in all 3 locations at previous 1 job.

• Dust detection could not be activated due to JAM etc at previous job.

Footnote

• F: Scanner motor moves forward (toward right).

• B: Scanner motor moves backward (toward left).

• Light-ON: LED on CCD unit lights-on.

• ON: When CCD HP sensor (photo interrupter type) detects.

control

B F F F B F

Light-ON

ON

In stream reading

Shading correction

F F F F

B B

Light-ON

End

F-2-3

Copy start

(Scanner

motor)

(LED)

(CCD HP

sensor )

Footnote

• F: Scanner motor moves forward (toward right).

• B: Scanner motor moves backward (toward left).

• Light-ON: LED on CCD unit lights-on.

• ON: When CCD HP sensor (photo interrupter type) detects.

Technology > Controls (Reader)

B

2

In reading

F

Light-ON

B

ON ON

Shading correction

End

F

F-2-2

2-2

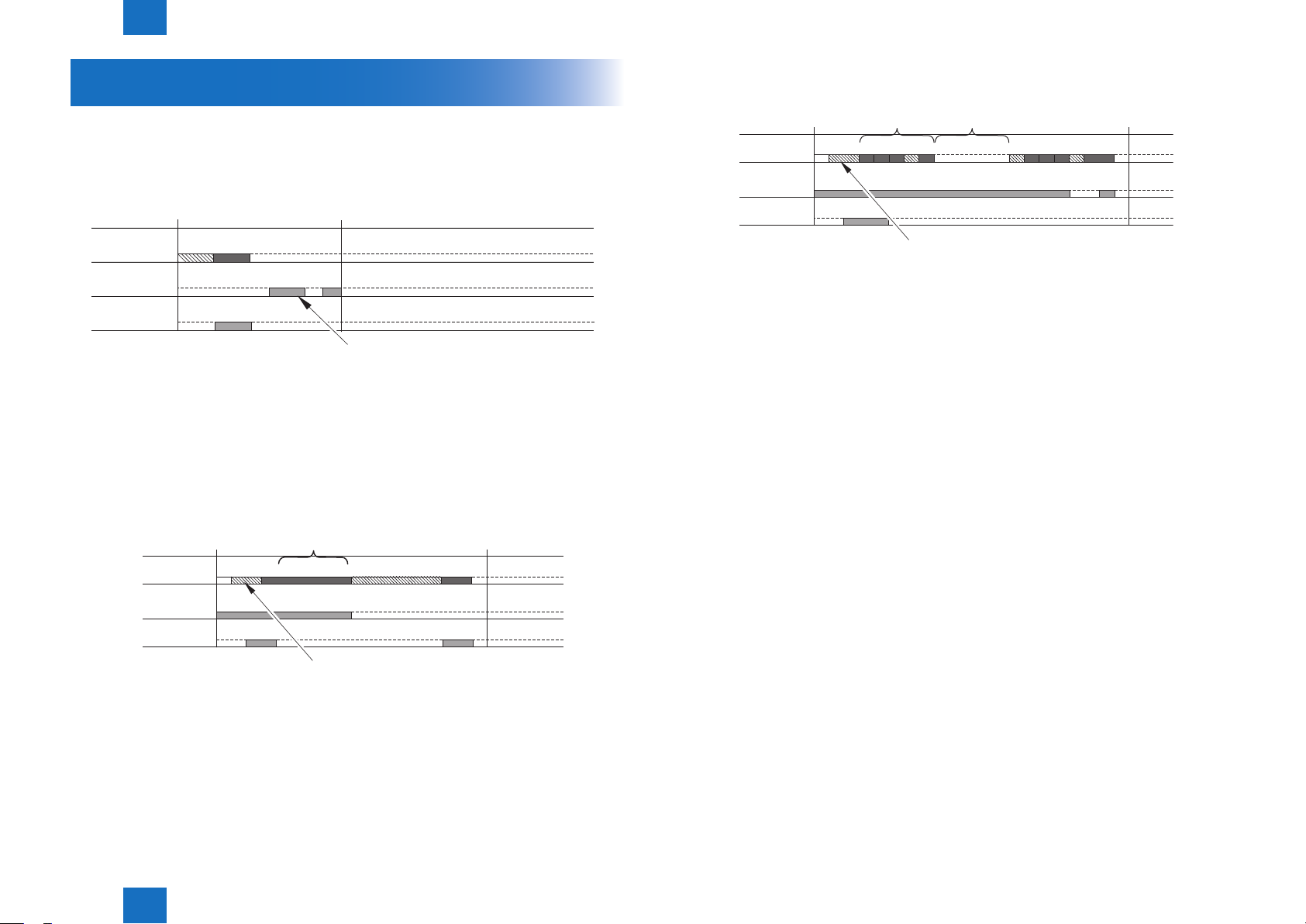

2

Scanner motor (M14)

Original

Acceleration area: Accelerates until a speed suited to the selected mode is reached

Deceleration area: Decelerates and stops promptly once the image end is reached.

Technology > Controls (Reader)

2-3

■Controlling the Scanner Drive System

●Conguration of drive system

Parts conguration of scanner drive is described below.

Reader controller PCB (UN4)

Copyboard cover

open/closed sensor (S13)

Copyboard cover

open/closed sensor (S12)

CCD HP sensor (S11)

• Scanner motor (M14) drive signal

Turns on/off the motor and controls its direction/speed of rotation.

• CCD HP sensor (S11) detection signal

Checks if CCD is at home position.

• Copyboard cover open/closed sensor (front: S12/rear: S13) detection signal

Detects the open/close status of the copyboard cover

Sensor light

block sheet

Backward

Guide shaft

Carriage drive belt

Forward

CCD unit

F-2-4

●Scanner Motor Control

1) Forward movement when scanning an image

CCD operation is controlled by the following sensors when scanning the image.

Start position

position

Acceleration

Shift

speed

[1] [2] [3] [4]

Shift distance

NOTE:

The scanning speed of this machine is as follows.

Black/white (600dpi x 600dpi):260 mm/sec

Color SEND(600dpi x 300dpi):140 mm/sec

2) Backward movement after scanning an image

After scanning an image, CCD moves backward to CCD shading position at a specic

speed (260 mm/sec).

Original

leading edge

Normal speed

[1]

[2]Run-up speed area: Run-up margin to ensure a stable speed.

[3]Image reading area: Reads an image at a specific speed.

[4]

trailing edge

Stop

Deceleration

F-2-5

Technology > Controls (Reader)

2

2-3

2

Technology > Controls (Reader)

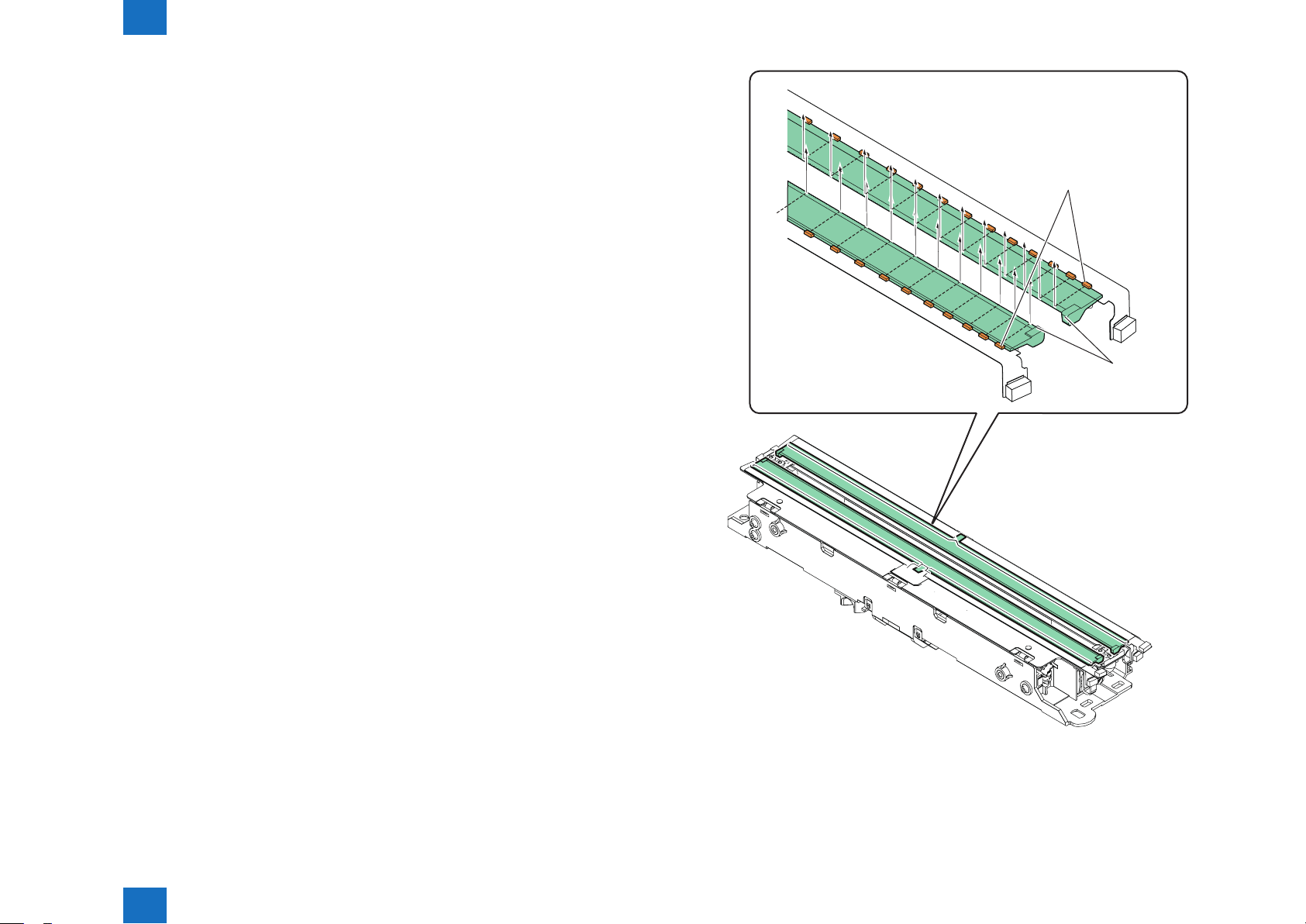

■CCD Unit

●Overview

The machine uses the CCD to expose and read an image and the image is read on a line-by-

line basis.

CCD features 4 lines (R, G, B, B/W) and B/W line is used in B/W copy and R, G, B lines are

used at color scan.

CCD overview

1. Integrated scanning conguration; CCD, lens, light source and mirror are integrated.

2. Light source: LED

3. Effective number of pixel: 7500 pix x 3 color lines, 7500 pix x 1 B/W line

4. Color lter: Colored lter (Red/Green/Blue)

[Optical path from LED]

The light generated from LED is reected by an original and by the 5 mirrors. And then it is

irradiated to the CCD through the lens.

2-4

LED (light source)

Photoconductive

body

Technology > Controls (Reader)

2

2-4

2

Technology > Controls (Reader)

Lens

mirror

No.4

mirror

No.2

LED (light source)

mirror No.3

Items Description

CCD

Lens

LED(light

source)

Mirror No. 1 - 5

Receives the reected light that has gone through the lens and converts it into

electric signal to output it.

Collects the light reected by an original.

Light source to expose an original to laser

Return the light

2-5

F-2-6

T-2-1

mirror

No.5

Lens

Technology > Controls (Reader)

2

mirror No.1

CCD

Red (R) line

Green (G) line

Blue (B) line

Black & White (B/W) line

F-2-7

2-5

2

Technology > Controls (Reader)

2-6

■Enlargement/Reduction

●Magnications in Main Scanning Direction

In book mode/ADF mode

An image is read at 100% in main scanning direction. Magnication variation and its data

process are controlled on main controller PCB 2.

●Magnication in Sub Scanning Direction

To vary the magnication of sub scanning direction, the machine operates as below

depending on the original reading methods and the magnications.

1) Magnications in book mode

To suite the selected rate of magnication, the machine changes the speed of original

reading and executes data processing on main controller PCB 2.

e.g.) Reduction to 25%: an original is read at 260mm/s, and the data is processed for 25%

reduction (skipping for 4/1) by the main controller PCB 2.

e.g.) at 100%: an original is read at 260mm/s.

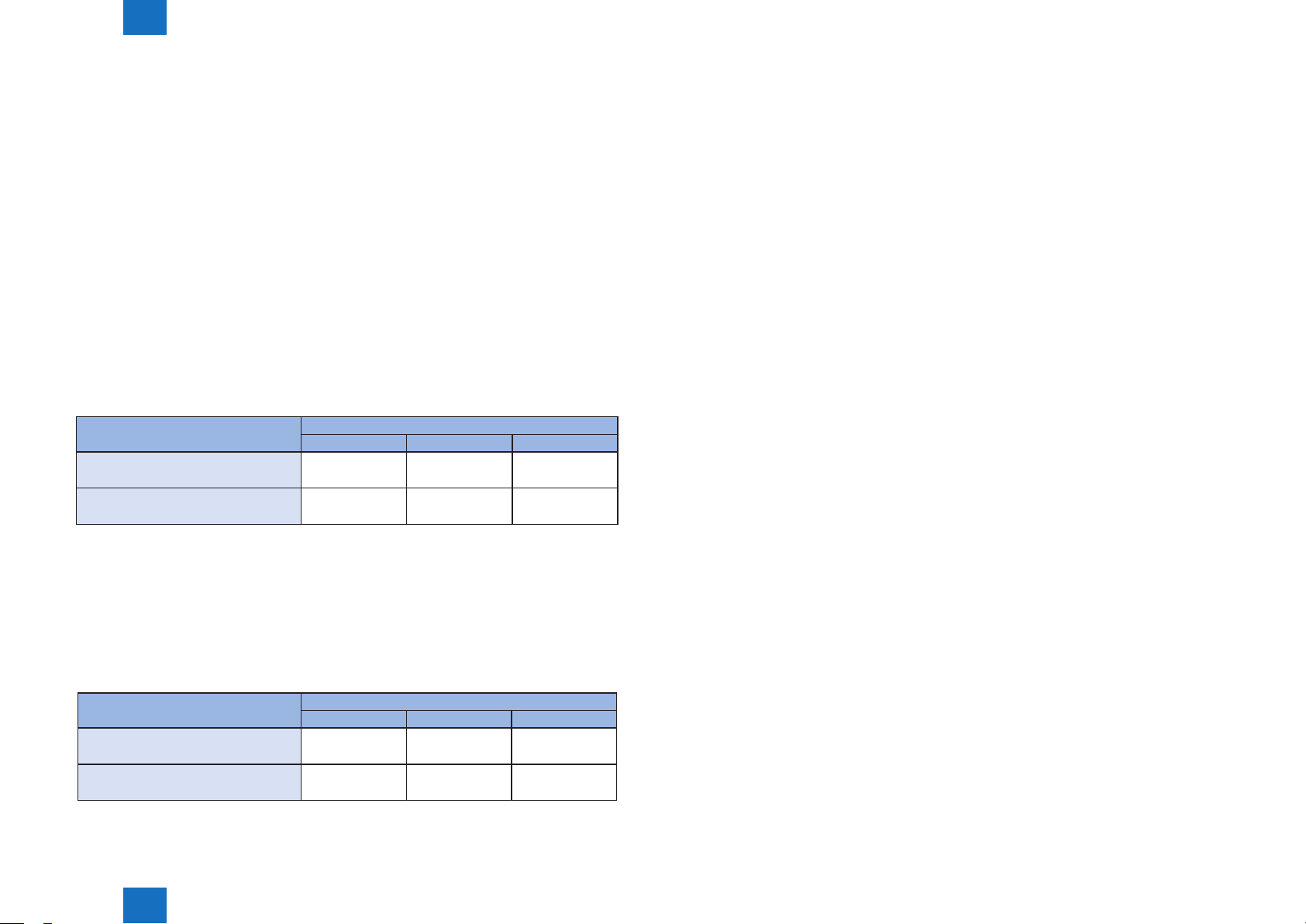

Operation Magnications

25% to 50% 50.1% to 199.9% 200% to 400%

Speed change of original reading

(mm/sec)

Digital magnication process (%) on

the main controller PCB 2

2) Magnications in ADF mode

To suite the selected rate of magnication, the machine changes the speed of original

reading and executes data processing on main controller PCB 2.

e.g.) Reduction to 25%: an original is read at 260mm/s and the data is processed for 25%

reduction (skipping 4/1) by the main controller PCB.

e.g.) Enlargement to 200%: an original is read at 130mm/s and the data is processed for

100% direct reproduction by main controller PCB.

Operation Magnications

Speed change of original reading

(mm/sec)

Digital magnication process (%) on

the main controller PCB 2

260 260 130

25 to 50 50.1 to 199.9 100 to 200

T-2-2

25% to 50% 50.1% to 199.9% 200% to 400%

260 260 130

25 to 50 50.1 to 199.9 100 to 200

T-2-3

■Detecting the Size of Originals

●Overview

The machine identies the original size by the combination of measurement result of reection

light from the reection sensor and specic points of CCD. Also to identify it accurately even

though an original moves when ADF is closed, the machine measures 2 points for each size.

• Main scanning direction: CCD (AB type: 12 points measurement, inch type: 6 points

measurement)

• Sub scanning direction: Reection type photo sensor (AB type: 1 point, inch type: 1 point,

AB/inch type: 2 point)

The followings are the procedures of original size identication.

1) External light search (main scanning direction only)

According to the LED status, the machine identies the CCD level of each detection

position in main scanning direction.

2) Output level detection of each sensor

The machine turns on the LED on CCD unit and measures the CCD level of each detection

position in main scanning direction.

Also, turns on the LED on reection type photo sensor in sub scanning direction and

measures the sensor output.

The original size is identied by the combination of these output result.

●Control Details

For main scanning direction, the machine moves the CCD unit to the following CCD original

detection positions according to the location of original to measure the CCD level of each

detection position. For sub scanning direction, the machine uses the original sensor 1, 2 to

identify sizes.

Technology > Controls (Reader)

2

2-6

AB type

detection point 1

1B=conventional

2

Technology > Controls (Reader)

Original detection

position 1

Original detection

position 2

Original detection

position 3

Original detection

position 4

Original detection position 5

Original detection position 6

A5

B5

A5R

K16

A4

Original sensor 1

B5R

A4R

B4

K8

A3

2-7

1. 2 points original detection at each detection position

For each point of measurement in main scanning direction, the machine checks the

presence/absence of an original with reference to the CCD output at 2 points near the point

of measurement.

* The machine checks if the signal is changed or not from ADF (pressure plate) open to close

at both points of 1A and 1B.

Change in the signal: Yes

Change in the signal: No

Judgment is done by the measurement results of 1A and 1B, and it indicates the presence

of original if either point shows No (absence). It indicates absence of original if both signals

show Yes (presence).

CCD original detection position

Inch type

Original detection

position 1

Original detection

position 2

Original detection

position 3

CCD original detection position

STMTR

STMT

LTR

LTRR

Original sensor 2

LGL

279.4×431.8mm

(11"×17")

F-2-8

Borderline of

original size

Borderline of

original size

1A 1B

Yes Yes

No Yes

Yes No

No No

approx 13mm

approx 4mm

1A=additional

detection point 2

Change Result of detection

Original absence

Original presence

Original presence

Original presence

F-2-9

T-2-4

Technology > Controls (Reader)

2

2-7

2

Rear

Technology > Controls (Reader)

2-8

2. Priority on the front sensor

When checking the measurements for main scanning direction, if the absence of an original

is indicated at the rear while the presence of an original is indicated at the front, the machine

will give priority to the indication at the front.

side

Original sensor 1

Position of

detection 1

Position of

detection 2

Position of

detection 3

Front

side

CCD original

detection position

Position of

detection 4

Position of detection 5

Position of detection 6

B5

F-2-10

●Detection Operation Overview

1) Standby state (The following is in case that the AB type, A4R size is set.)

CCD unit: shading position

LED: OFF

Original sensor: OFF

CCD unit

Copyboard glass

Original sensor

Position of detection 1

Position of detection 2

ADF

Reader unit

CCD original detection position

2) ADF opened

CCD unit: moves to original detection position

LED: OFF

Original sensor: OFF

Position of detection 3

Position of detection 4

Position of detection 5

Position of detection 6

F-2-11

In case of B5 size original

Position of detection Result of detection Result of identication

1 Yes Yes

2 No Yes

3 Yes Yes

4 Yes Yes

5 No No

6 No No

Technology > Controls (Reader)

2

(External

light)

F-2-12

3) ADF closed

T-2-5

CCD unit: in original detection position

LED: OFF to ON

Original sensor: in original detection operation

• With the ADF angle at 25 deg or less, the external light is blocked at the original width

area. Then, the machine determines that the original is absent at the points that the

external light is detected (external light search operation). When the original mount

sensor (rear) detects [close], original size detection is started. In this case, B5/B4/A4/

A3 size is eliminated at this point.

• After external light search, LED is turned ON at main scanning side and the CCD

2-8

2

Technology > Controls (Reader)

2-9

checks the reection light (4 points). For sub scanning direction, original sensor

detects the size.

(External

light)

F-2-13

25 deg

F-2-14

4) ADF fully closed (5 deg or less)

CCD unit: in original detection position

LED: ON

Original sensor: in original detection operation

• For 2 sec from the original mount sensor (front) detected [close], this monitors the

changes of output level of each sensor. The machine determines that the original is

present in the position where the level is not changed.

The machine identies the original size by the combination of level changes at 5 points

(in case of AB type size).

Original sensor: OFF

F-2-16

5) Standby status (waiting for start key)

CCD unit: in original detection position

LED: OFF

Technology > Controls (Reader)

2

5 deg

F-2-15

2-9

2

Main power

Technology > Controls (Reader)

2-10

■Dirt Sensor Control

●Overview

The machine changes the original read point or executes image correction depending on

the presence/absence of dust on the stream reading glass or the platen roller of the ADF to

prevent the dust from showing up in the output. These operations are carried out only when

the ADF is in use and, in addition, is closed.

[Control timing]

• At the end of a job

• Between sheets (for each reading of a sheet)

• At the start of a job (only when any of the following conditions is true.)

Dust detected at all points of detection at the end of the previous job

Dust detection failed to end normally at the end of the previous job (e.g., ADF opened)

switch ON

WMUP

Start key

STBY

ON

Dust detection

control

1st

SCAN

Dust detection

control

2nd

SCAN

Dust detection

control

F-2-17

[Particulars of control]

• At the end of a job (dust detection)

CCD checks the light reected by the surface of the platen roller of the ADF at the read

point to detect the presence/absence of dust. Presence of dust is detected at points A, B,

and C in this order. The point where least dust is detected will be used as the read position

for the next job. The point selected here will be used as the read position for the next job.

• At the start of a job (dust bypass)

Presence of dust is detected at points A, B, and C in this order in the same manner as at

the end of the job. Read will take place at the point where least dust is detected.

B C

A

F-2-18

2-10

Technology > Controls (Reader)

2

2

CCD PCB

Technology > Controls (Reader)

2-11

• Between sheets

The machine does not move CCD.

It reads the original using the position determined at the end or start of a job; however,

if the presence of dust is still detected at the position, the machine will execute image

correction.

Platen roller

0.5mm0.5mm

A B C

Stream

reading glass

F-2-19

■Image Processing

●Overview

The functions of image processing system’s PCB are described below.

• Main controller PCB Shading correction (executed per each job),

• CCD PCB CCD drive, analog image process, A/D conversion, A/D

conversion

The machine uses the main controller PCB to process images for every single image line.

Specic functions are as follows.

a. Main controller PCB

• Shading correction

• Color offset correction in sub scanning

b. CCD PCB (inside CCD unit)

• CCD drive

• CCD output gain correction, offset correction

CCD (4lines)

Reader controller PCB

Analog image

signal

Analog image

process

- gain correction

- offset correction

EEP-ROM

CCD drive

control

A/D

conversion

ASIC

Shading

correction

Color offset

correction

in sub scanning

Gain

correction

data

Digital

image

signal

SRAM

CPU

Service Mode

(Lv1) COPIER > OPTION > IMG-RDR > DFDST-L1

(used to adjust the dust detection level between sheets)

(Lv1) COPIER > OPTION > IMG-RDR > DFDST-L2

(used to adjust the dust detection level at the end of a job)

Technology > Controls (Reader)

2

CCD/AP PCB

F-2-20

2-11

2

Technology > Controls (Reader)

2-12

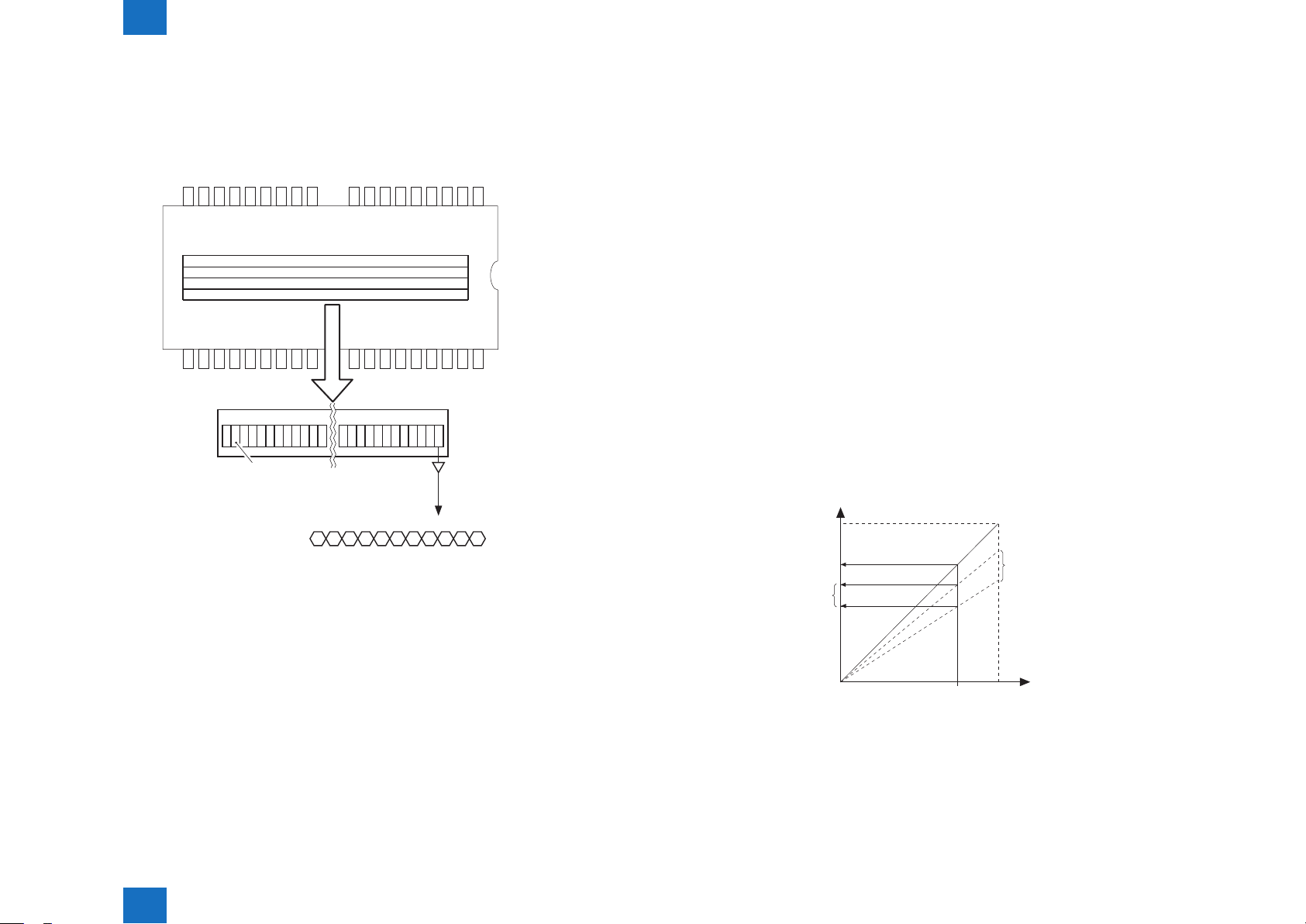

●CCD Drive

The machine's CCD sensor is a 4-line linear image sensor consisting of 7500 pixels. After

completion of photoelectric conversion in the light-receiving block, the signals are output to

the analog front end PCB unit on CCD PCB in parallel for each channel (Color scan: R, G, B

B/W scan: B/W) of the CCD array.

Red(R)line

Green(G)line

Blue(B)line

Black & white(B/W)line

Expanse

Light-receiving block

Output

HL L HH L HL H H L

………

F-2-21

●Gain Correction and Offset Correction of CCD Output

The analog video signal generated by the CCD is corrected so that it will have a specic level

(gain correction); moreover, the output voltage occurring in the absence of incident light is

also corrected so that it will have a specic level (offset correction).

●A/D Conversion of CCD Output

The corrected analog video signal is converted into a digital signal that is suited to the voltage

level of individual pixels by the A/D converter.

●Shading Correction (Overview)

The output of the CCD is not necessarily even for the following factors even when the density

of the original is uniform:

1) Variation in the sensitivity of the CCD among pixels

2) Variation in the intensity of the rod lens array

3) Variation in the intensity of light that goes through the center and surroundings of lens

4) Variation in the intensity of light at the center and surroundings of LED

5) LED deterioration

The machine executes shading correction to even out the output of the CCD.

Shading correction may be the shading correction executed for each job.

●Shading Correction

The machine executes the shading correction for every scan made.

In this correction, the analog image process unit on CCD PCB digitalizes the LED light

reected by the standard white board. After the reected light is digitalized, it is held in the

shading correction circuit on main controller PCB as a shading coefcient.

Shading correction circuit compares the stored target value with the shading coefcient. The

difference between the two will be held as the shading correction value for use in correcting

variation among CCD pixels when scanning the original, thus evening out the density levels

of the image.

CCD output

Target value

Measurement

value

Standard white plate

Features after correction

Features before correction

White

Original density

F-2-22

Technology > Controls (Reader)

2

2-12

2

Technology > Controls (Reader)

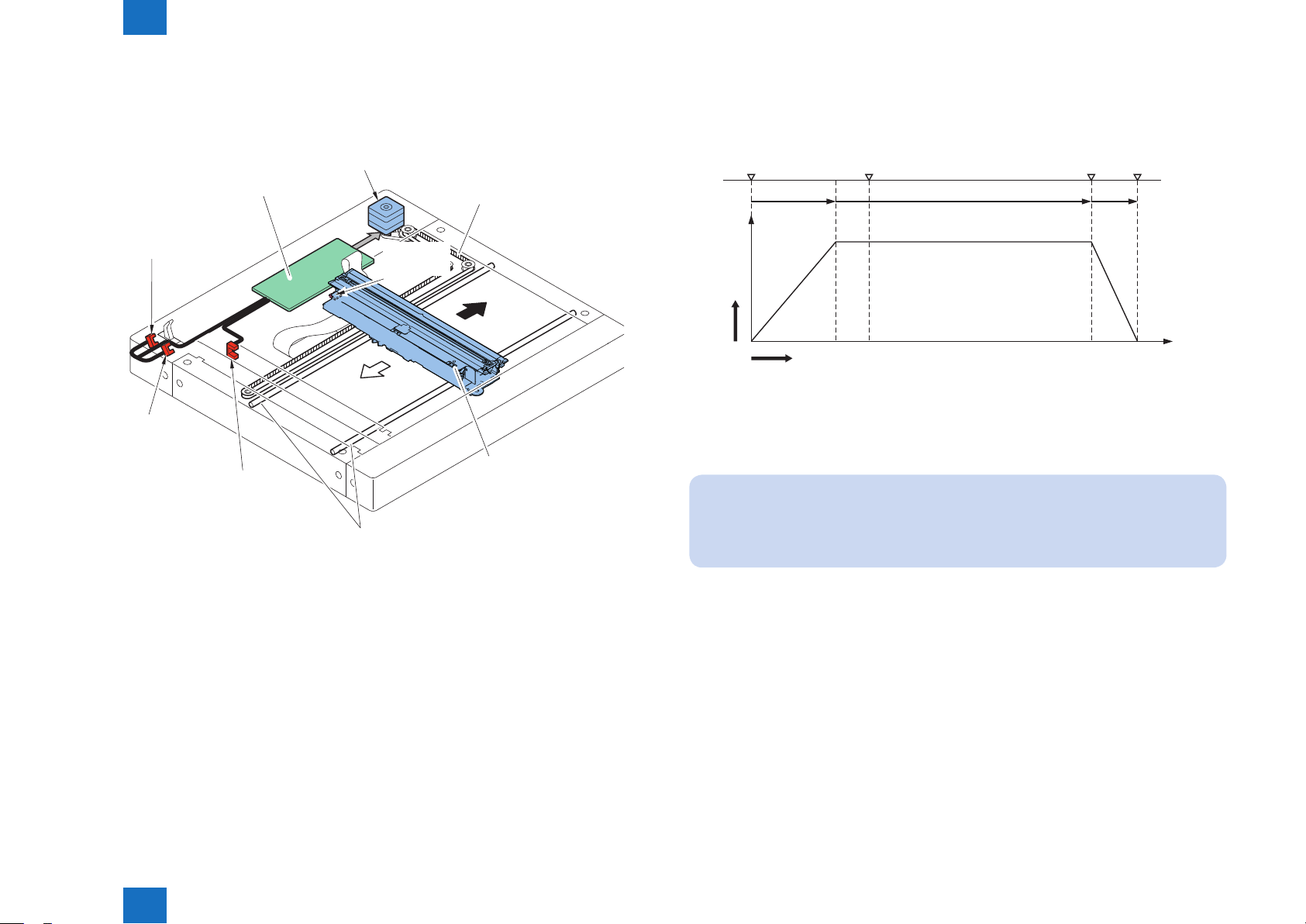

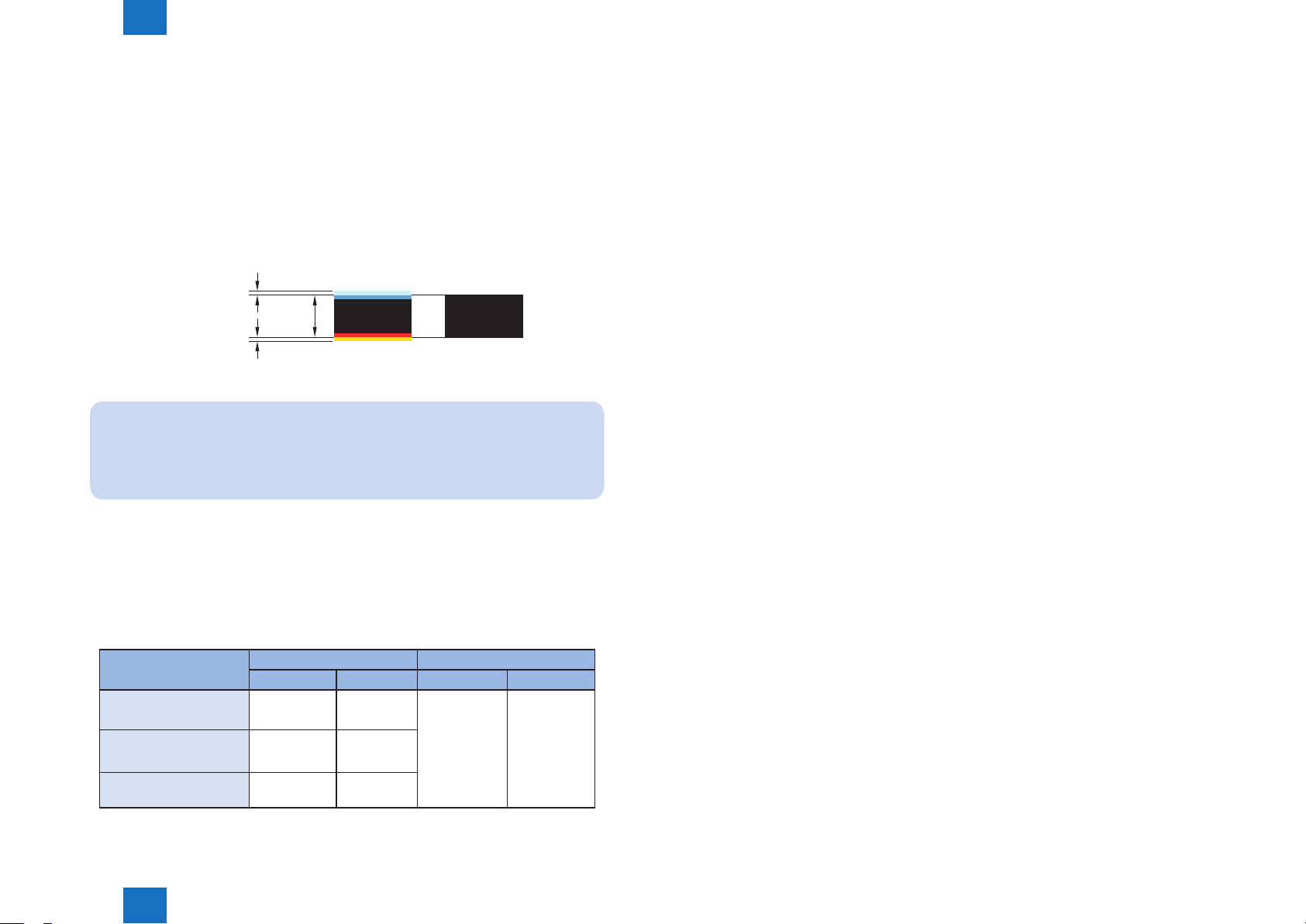

■Color offset correction in sub scanning

When R, G and B are not accurately synchronized in sub scanning, the color offset correction

will be made so that RED and BLUE synchronize with GREEN by shifting RED and BLUE

image within single pixel in the sub scanning direction.

Example)

For GREEN, RED offsets upward and BLUE offsets downward in the scan for black line

image.

Color offset in

sub scanning

R-G

Color offset in

sub scanning

G-B

MEMO:

Outstanding point of this CCD unit:

• Corrective values are different by the position in the main scanning.

1 line

Before correction

After correction

F-2-23

2-13

There are 12 corrective values in the book scan and 4 values in the ADF scan for the color

offset correction. The color offset corrections have been made at the factory and all the

corrective values have been stored in the service mode. (In COPIER > ADJUST > CCD)

At the beginning of job, color offset correction is performed based on the stored corrective

values.

Book scan ADFADF scan

100% 50% 100% 50%

Main scanning position 0

(rear)

Main scanning position 1

(center)

Main scanning position 2

(front)

Technology > Controls (Reader)

100-RG

100-GB

100-RG-2

100-GB-2

100-RG-3

100-RG-3

50-RG

50-GB

50-RG-2

50-GB-2

50-RG-3

50-GB-3

100DF-RG

100DF-GB

50DF-RG

50DF-GB

T-2-6

2

2-13

2

Technology > Controls (Reader) > Servicing (Reader) > Troubleshooting

2-14

Servicing (Reader)

■Periodically Replaced Parts

None

■Consumable Parts

None

■Periodical Servicing

None

■Action to take when replacing parts

Part name Action

CCD unit

Copyboard glass

Stream reading glass

• Platen board cover white level automatic adjustment

• ADF white level adjustment (This action is applicable only

when the DADF is installed in the host machine.)

• The values input of the label included to the new CCD unit

• White plate data adjustment

• Platen board cover white level automatic adjustment

• ADF white level adjustment (This action is applicable only

when the DADF is installed in the host machine.)

• Platen board cover white level automatic adjustment

• ADF white level adjustment

■Major Adjustments

T-2-7

None

■Troubleshooting

None

Technology > Controls (Reader) > Servicing (Reader) > Troubleshooting

2

2-14

2

Technology > Basic Conguration (DADF) > Drive Conguration

2-15

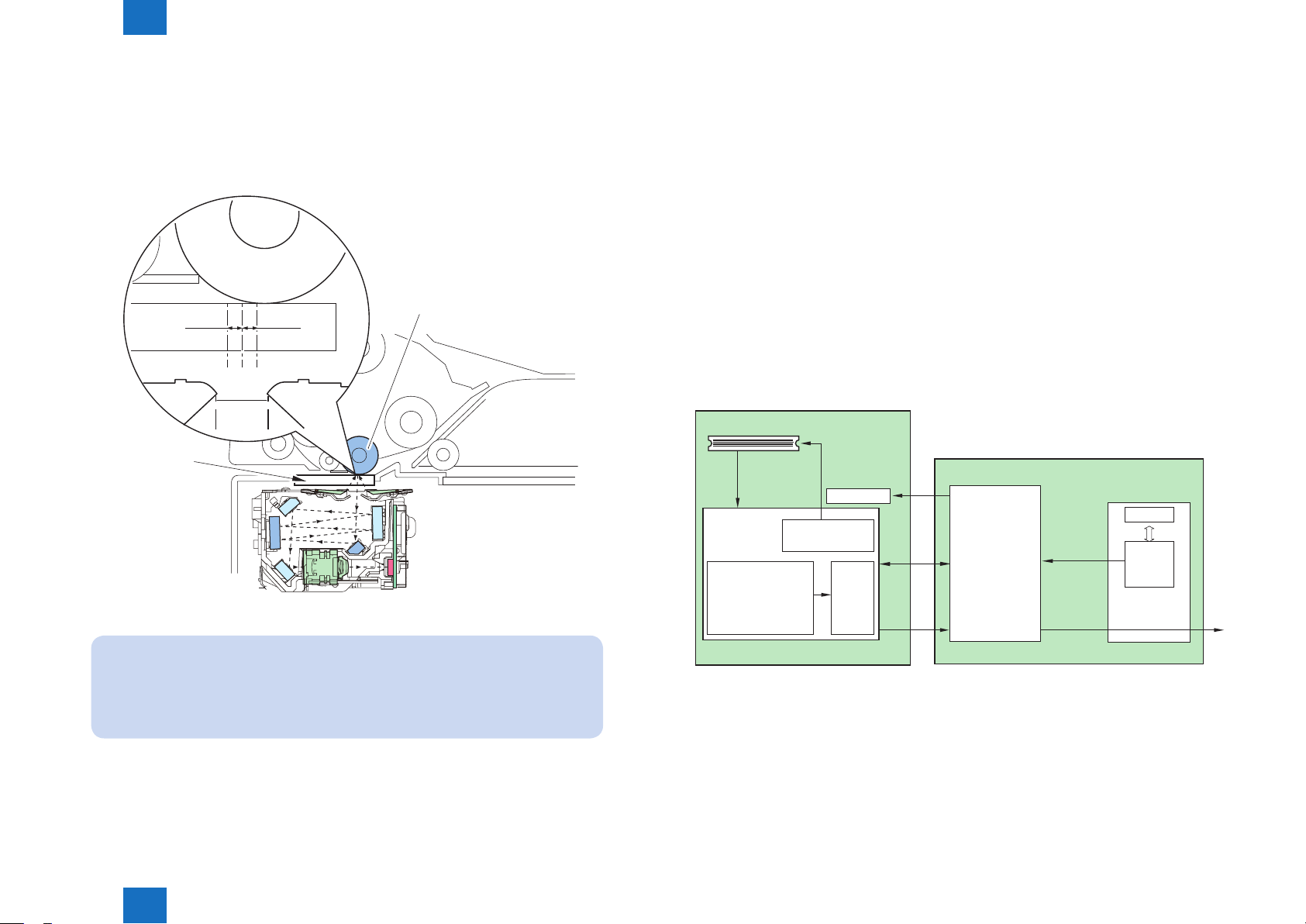

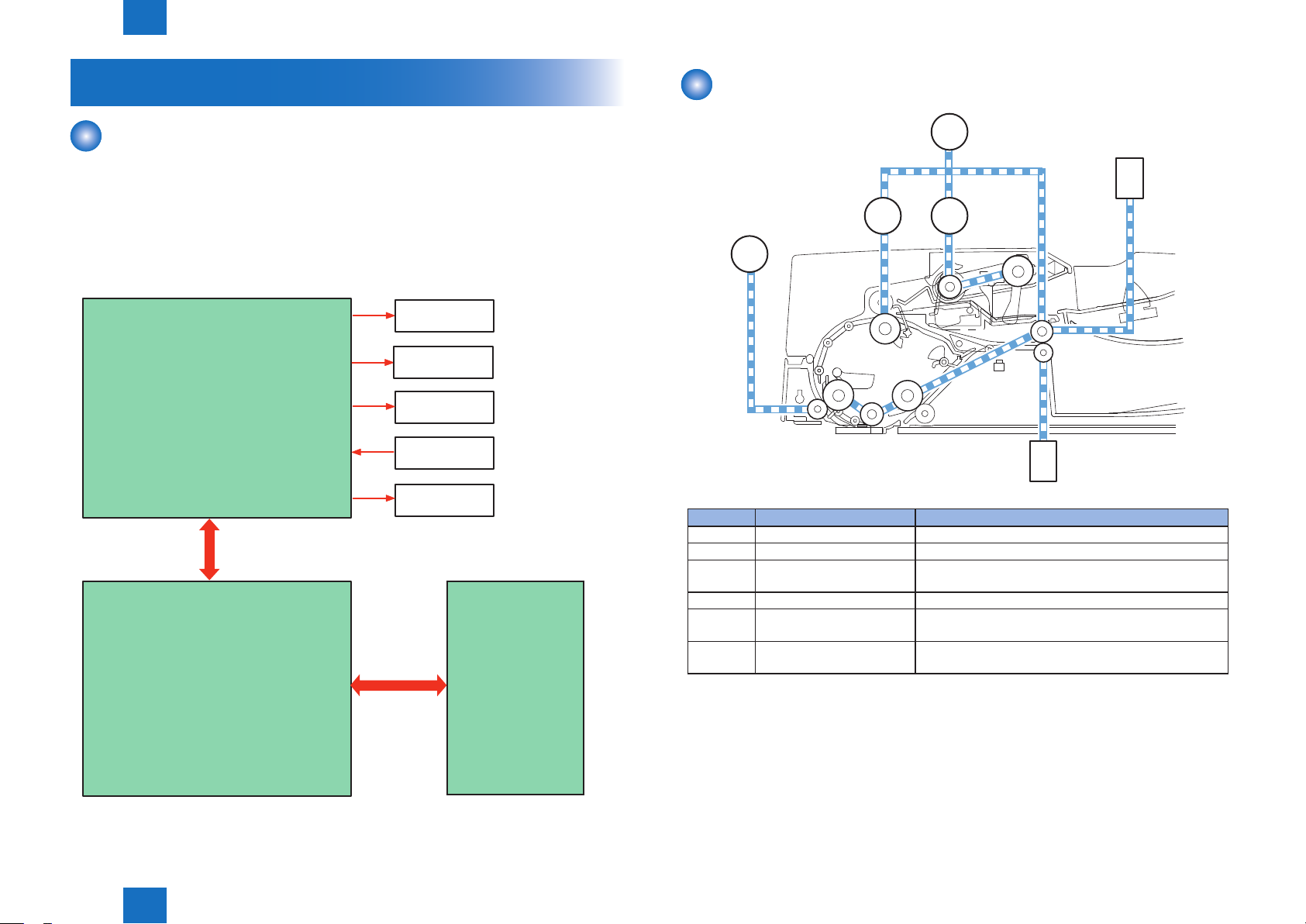

Basic Conguration (DADF)

Component Conguration

■Outline of Electric Circuits

Electric circuits of this machine are controlled by the main controller PCB2. The main

controller PCB2 detect the input signals from sensors to output the signals that

drive DC loads such as motors, solenoids, clutches, and fans at the predetermined timings.

The ADF driver PCB does not have a memory area; data such as the data used in the service

mode is stored in CCD unit (CCD PCB).

Clutch

Fan

ADF driver PCB

Reader controller PCB

Motor

Sensor

Solenoid

Main controller

PCB2

Drive Conguration

M1

SL1

CL2 CL1

M2

SL2

F-2-25

No Part name Content

M1 ADF motor Feeds documents.

M2 Release motor Prevents a document from swaying.

SL1 Pressurization solenoid Shifts the delivery lower roller after reversal of the

dualsided document, etc.

SL2 Stamp solenoid Drives the stamp mechanism.

CL1 Pickup clutch Drives the pickup clutch to transmit the power of the

pickup/feed motor to the pickup roller unit.

CL2 Registration clutch Drives the registration clutch to transmit the power of

the pickup/feed motor to the registration roller.

T-2-8

Technology > Basic Conguration (DADF) > Drive Conguration

2

F-2-24

2-15

2

Technology > Basic Conguration (DADF) > Outline of Operation Modes > Forward Pickup/Delivery Operation

2-16

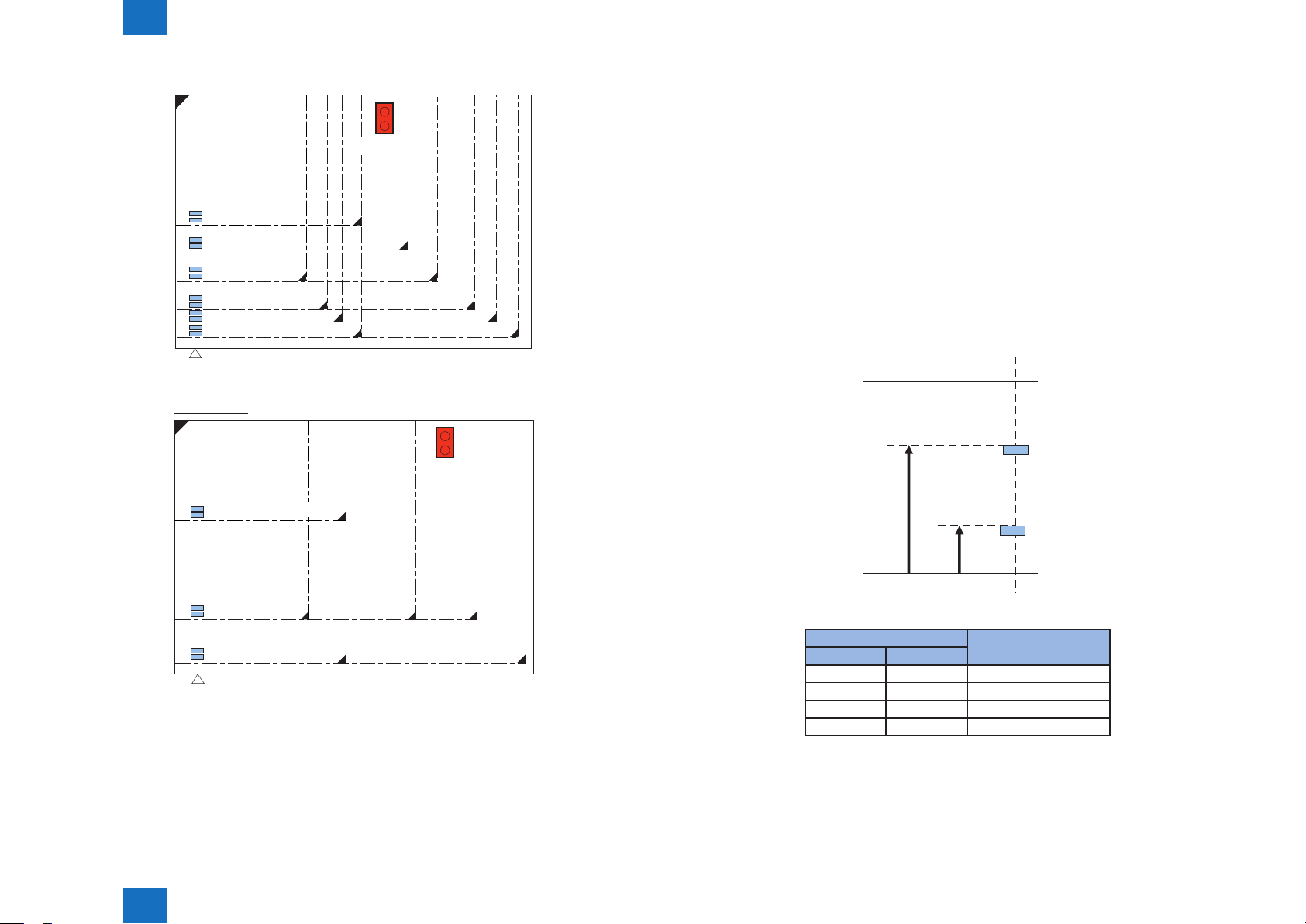

■Sensor Layout

SR11

SR4

SR2 SR1

SR5 SR7 PS1/PS2 SR8 SR9

SR3

No Sensor name

SR1 Registration sensor

SR2 Read sensor

SR3 Delivery reversal sensor

SR4 Timing sensor

SR5 Document set sensor

SR7 Document length sensor 1

SR8 A4R/LTRR identication signal

SR10 Document length sensor 2

SR11 Release motor HP sensor

VR1 Document wide volumel

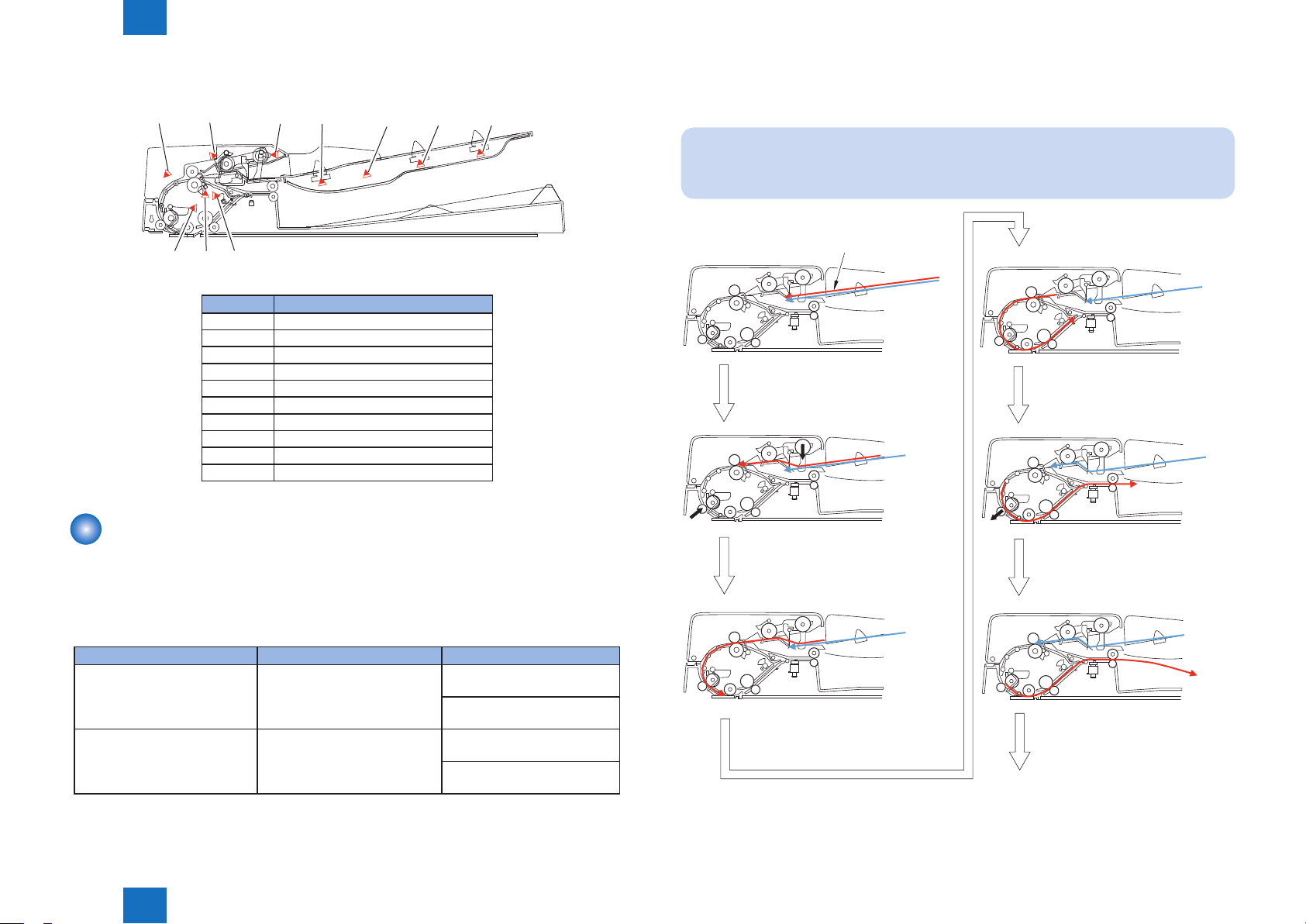

Outline of Operation Modes

■Outline

T-2-9

F-2-26

■Forward Pickup/Delivery Operation

• Simplex read operation (when two document sheets are placed)

NOTE:

This operation is performed for all single-sided documents irrespective of whether

document widths are the same or different.

Document

Reading of first document

sheet

Pickup of first document sheet/

Formation of loop

Pickup of second document

sheet

This machine has two operation modes. This machine operates in the operation mode

specied by the host machine to perform printing. Operation mode names,

brief outline of operations, ad associated print modes are given in the following table.

Operation mode name Outline of operation Associated print mode

Forward pickup/delivery Picks up, reads, and then

delivers a document.

Forward feed/reverse delivery Picks up, reads, reverses, and

delivers a document.

Technology > Basic Conguration (DADF) > Outline of Operation Modes > Forward Pickup/Delivery Operation

Single-sided document ->

Simplex printing

Single-sided document ->

Duplex printing

Double-sided document ->

Duplex printing

Double-sided document ->

Simplex printing

2

T-2-10

Waiting for reading of the

first document sheet

Formation of second document

To next

F-2-27

2-16

2

Technology > Basic Conguration (DADF) > Outline of Operation Modes > Forward Pickup/Reverse Delivery Operation

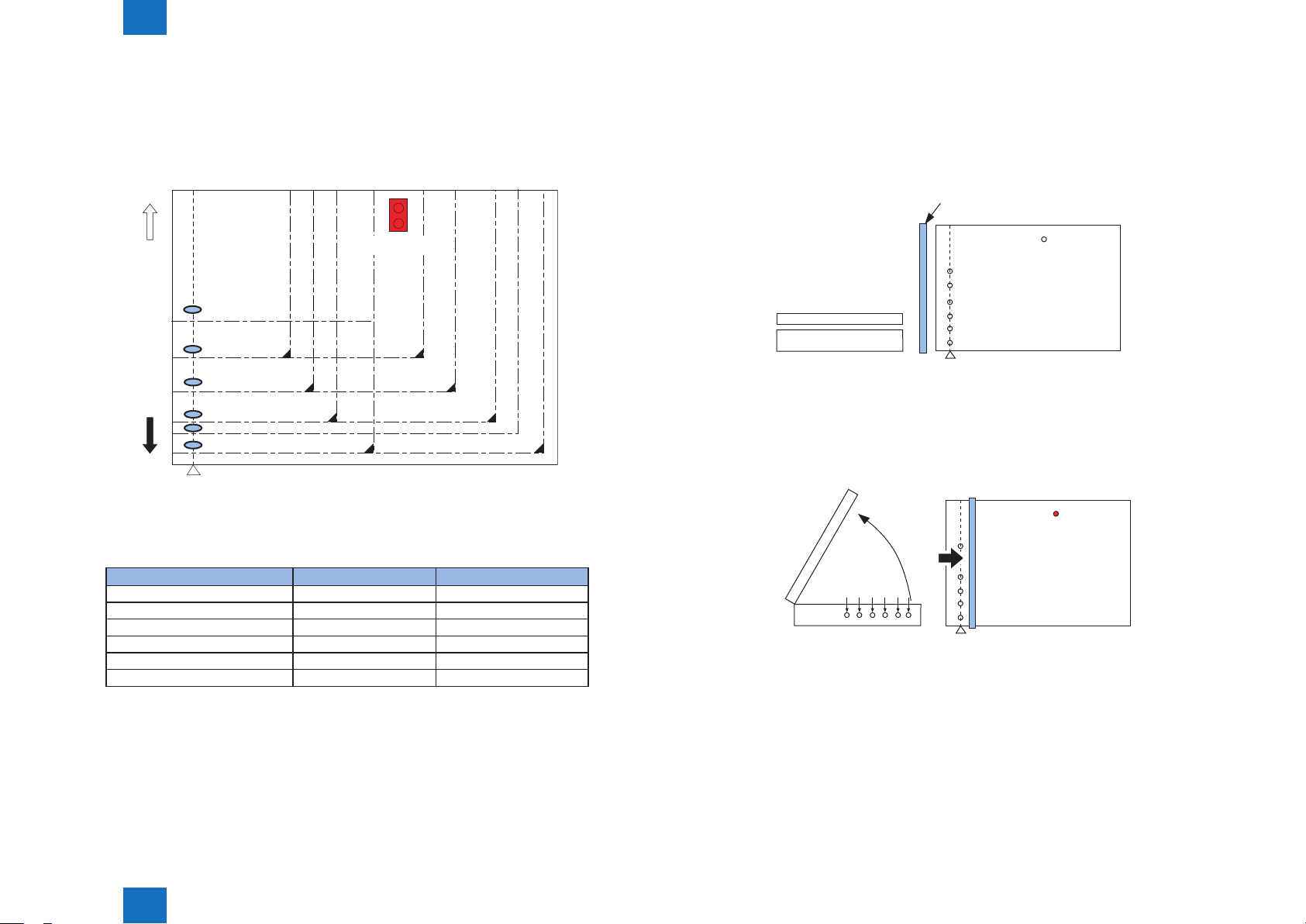

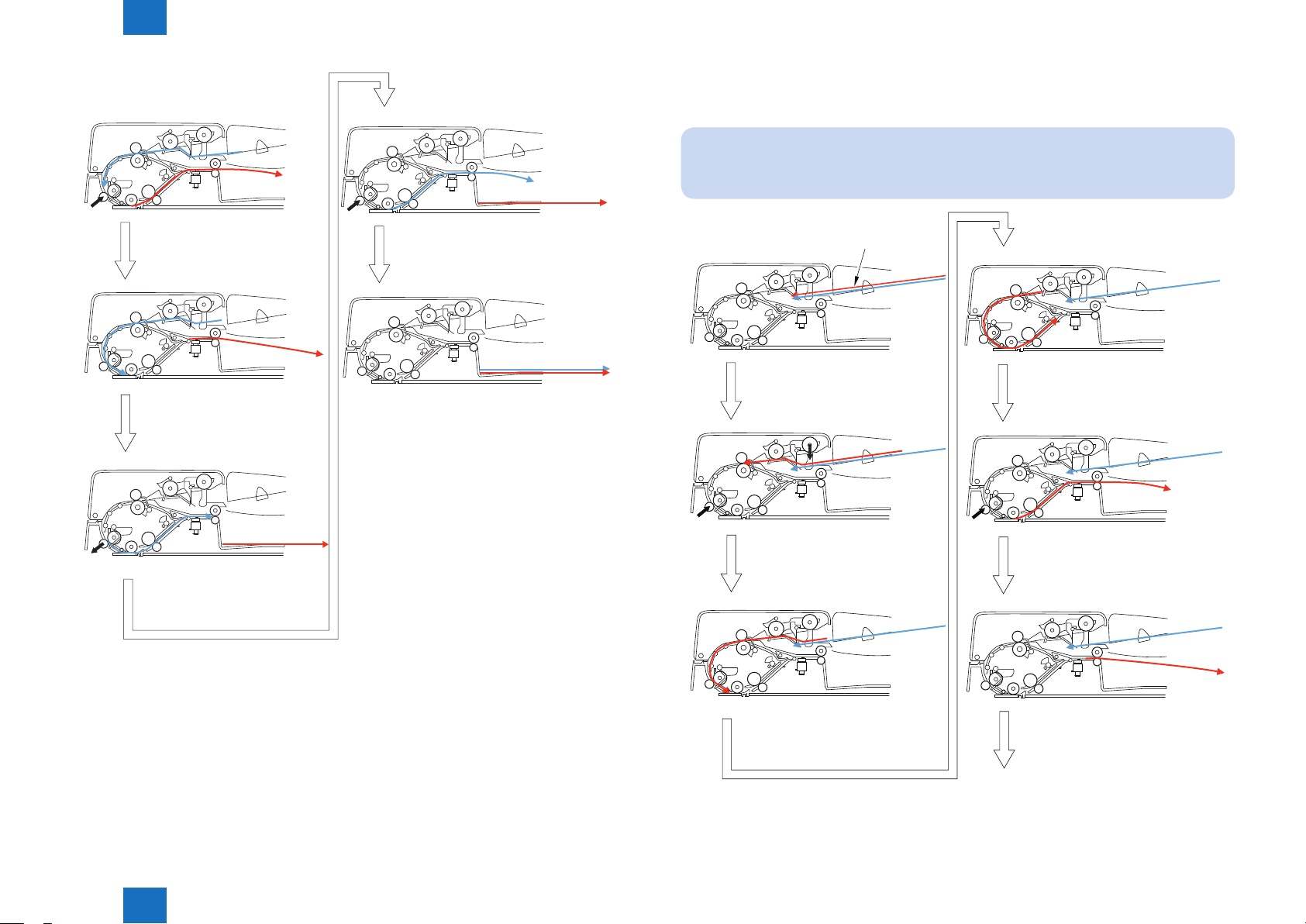

■Forward Pickup/Reverse Delivery Operation

Duplex read operation (when two document sheets are placed)

NOTE:

This operation is performed for all double-sided documents irrespective of whether

document widths are the same or different.

2-17

Completion of reading of

first document sheet

Start of reading of

second document sheet

Completion of delivery of

first document sheet

Completion of reading of

second document sheet

Completion of delivery of

second document sheet

End ob job

F-2-28

Document

Pickup and formation of loop

of first document sheet

Start of reading of front side

of first document sheet

End of reading of

first document sheet

Technology > Basic Conguration (DADF) > Outline of Operation Modes > Forward Pickup/Reverse Delivery Operation

2

Waiting for reading of

the first document

Stop after feeing the first

document sheet to reversal

position

To next

F-2-29

2-17

Loading...

Loading...