Page 1

Type 8619

multiCELL

Modular transmitter/controller

Modularer Transmitter/Controller

Transmetteur/contrôleur modulaire

Quickstart

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2010 - 2013 Bürkert SAS

Operating Instructions 1303/3_EU-ML 00561095 Original_FR

Page 3

Type 8619

Contents

1. ABOUT THE QUICKSTART .............................................................................................................................................................3

1.1. Symbols used ..........................................................................................................................................................................3

1.2. Definition of the word "device" .......................................................................................................................................3

2. INTENDED USE ....................................................................................................................................................................................4

3. BASIC SAFETY INFORMATION ....................................................................................................................................................4

4. GENERAL INFORMATION ................................................................................................................................................................5

4.1. Manufacturer's address and international contacts ............................................................................................5

4.2. Warranty conditions ..............................................................................................................................................................5

4.3. Information on the Internet ...............................................................................................................................................5

5. DESCRIPTION .......................................................................................................................................................................................6

5.1. Area of application ................................................................................................................................................................6

5.2. Description of the device name plate .........................................................................................................................6

6. TECHNICAL DATA ................................................................................................................................................................................7

6.1. Conditions of use ...................................................................................................................................................................7

6.2. Compliance to standards and directives ..................................................................................................................7

6.3. General technical data ........................................................................................................................................................7

7. INSTALLATION AND WIRING ......................................................................................................................................................13

7.1. Safety instructions .............................................................................................................................................................13

7.2. Building the device into a housing or cabinet ....................................................................................................13

7.3. Electrical wiring ....................................................................................................................................................................15

8. ADJUSTMENT AND COMMISSIONING .................................................................................................................................24

8.1. Safety instructions .............................................................................................................................................................24

8.2. Switching on the device for the first time .............................................................................................................24

8.3. Description of the icons ..................................................................................................................................................25

8.4. Using the navigation button and the dynamic keys .........................................................................................26

8.5. Entering some text .............................................................................................................................................................27

8.6. Operating levels ...................................................................................................................................................................28

english

1

Page 4

Type 8619

8.7. Process level .........................................................................................................................................................................29

8.8. Configuration level access ............................................................................................................................................30

8.9. Calibrating the measuring sensors ...........................................................................................................................31

8.10. Process inputs or values ................................................................................................................................................33

9. MAINTENANCE AND TROUBLESHOOTING .......................................................................................................................35

9.1. Safety instructions .............................................................................................................................................................35

9.2. Maintenance of the multiCELL .....................................................................................................................................35

9.3. If you encounter problems ............................................................................................................................................35

10. SPARE PARTS AND ACCESSORIES ......................................................................................................................................36

11. PACKAGING, TRANSPORT ..........................................................................................................................................................36

12. STORAGE ..............................................................................................................................................................................................36

13. DISPOSAL OF THE DEVICE ........................................................................................................................................................36

2

english

Page 5

Type 8619

About the Quickstart

1. ABOUT THE QUICKSTART

The Quickstart describes the entire life cycle of the device. Please keep it in a safe place, accessible to all users

and any new owners.

Important safety information.

Failure to comply with the information mentioned especially at chapters Intended use and Basic safety instructions

can lead to hazardous situations.

• This Quickstart must be read and understood.

The Quickstart describes the main steps to be carried out when installing, commissioning and programming the

device.

Refer to the corresponding instruction manual to get a complete description of the device.

The instruction manual for type 8619 can be found on the CD provided with the device or on internet

under:

www.burkert.com

Type 8619

1.1. Symbols used

DANGER

Warns against an imminent danger.

• Failure to observe this warning can result in death or in serious injury.

WARNING

Warns against a potentially dangerous situation.

• Failure to observe this warning can result in serious injury or even death.

CAUTION

Warns against a possible risk.

• Failure to observe this warning can result in substantial or minor injuries.

NOTE

Warns against material damage.

• Failure to observe this warning may result in damage to the device or system.

Indicates additional information, advice or important recommendations.

Refers to information contained in this manual or in other documents.

→ Indicates a procedure to be carried out.

1.2. Definition of the word "device"

The word "device" used within this manual refers to the controller/transmitter type 8619.

english

3

Page 6

Type 8619

Intended use

2. INTENDED USE

Use of this device that does not comply with the instructions could present risks to people, nearby

installations and the environment.

• The device is intended, depending on the modules fitted and the measurement sensors connected, for the

acquisition, processing, transmission and regulation of physical parameters such as pH, conductivity, tem-

perature or flow rate... .

• This device must be protected against electromagnetic interference, ultraviolet rays and, when installed outdoors, the effects of climatic conditions.

• This device must be used in compliance with the characteristics and commissioning and use conditions

specified in the contractual documents and in the user manual.

• Requirements for the safe and proper operation of the device are proper transport, storage and installation, as

well as careful operation and maintenance.

• Only use the device as intended.

→ Observe any existing restraints when the device is exported.

3. BASIC SAFETY INFORMATION

This safety information does not take into account:

• any contingencies or occurrences that may arise during assembly, use and maintenance of the device.

• the local safety regulations that the operator must ensure the staff in charge of installation and maintenance

observe.

Danger due to electrical voltage.

• Shut down and isolate the electrical power source before carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

Various dangerous situations.

To avoid injury take care:

• to prevent any unintentional power supply switch-on.

• to carry out the installation and maintenance work by qualified and skilled staff with the appropriate tools.

• to guarantee a set or controlled restarting of the process after a power supply interruption.

• to use the device only if in perfect working order and in compliance with the instructions provided in the user

manual.

• to observe the general technical rules during the planning and use of the device.

• not to use this device in explosive atmospheres.

• not to use this device in an environment incompatible with the materials from which it is made.

• not to make any external modifications to the device such as for instance painting or varnishing any part of the

device.

• not to power the device with an AC voltage or a DC voltage higher than 36V DC.

4

english

Page 7

Type 8619

Intended use

NOTE

Elements / Components sensitive to electrostatic discharges

• This device contains electronic components sensitive to electrostatic discharges. They may be damaged if

they are touched by an electrostatically charged person or object. In the worst case scenario, these compo-

nents are instantly destroyed or go out of order as soon as they are activated.

• To minimise or even avoid all damage due to an electrostatic discharge, take all the precautions described in

the EN 100 015-1 norm.

• Also ensure that you do not touch any of the live electrical components.

This device was developed with due consideration given to accepted safety rules and is state-of-the-art.

However, risks may arise.

Failure to observe these instructions as well as any unauthorised work on the device excludes us from any liability and also

nullifies the warranty which covers the device and its accessories.

4. GENERAL INFORMATION

4.1. Manufacturer's address and international contacts

To contact the manufacturer of the device, use following address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Bürkert sales office.

The addresses of our international sales offices are available on the internet at: www.burkert.com

4.2. Warranty conditions

The condition governing the legal warranty is the conforming use of the multiCELL 8619 in observance of the

operating conditions specified in this manual.

4.3. Information on the Internet

You can find the Operating instructions and technical data sheets regarding the type 8619 at: www.burkert.com

english

5

Page 8

Type 8619

Description

5. DESCRIPTION

5.1. Area of application

The 8619 multiCELL is a multifunction device intended to display, transmit and regulate various physical parameters. It can be used, for example, to manage a water treatment system (a boiler, a cooling tower or a reverse

osmosis system).

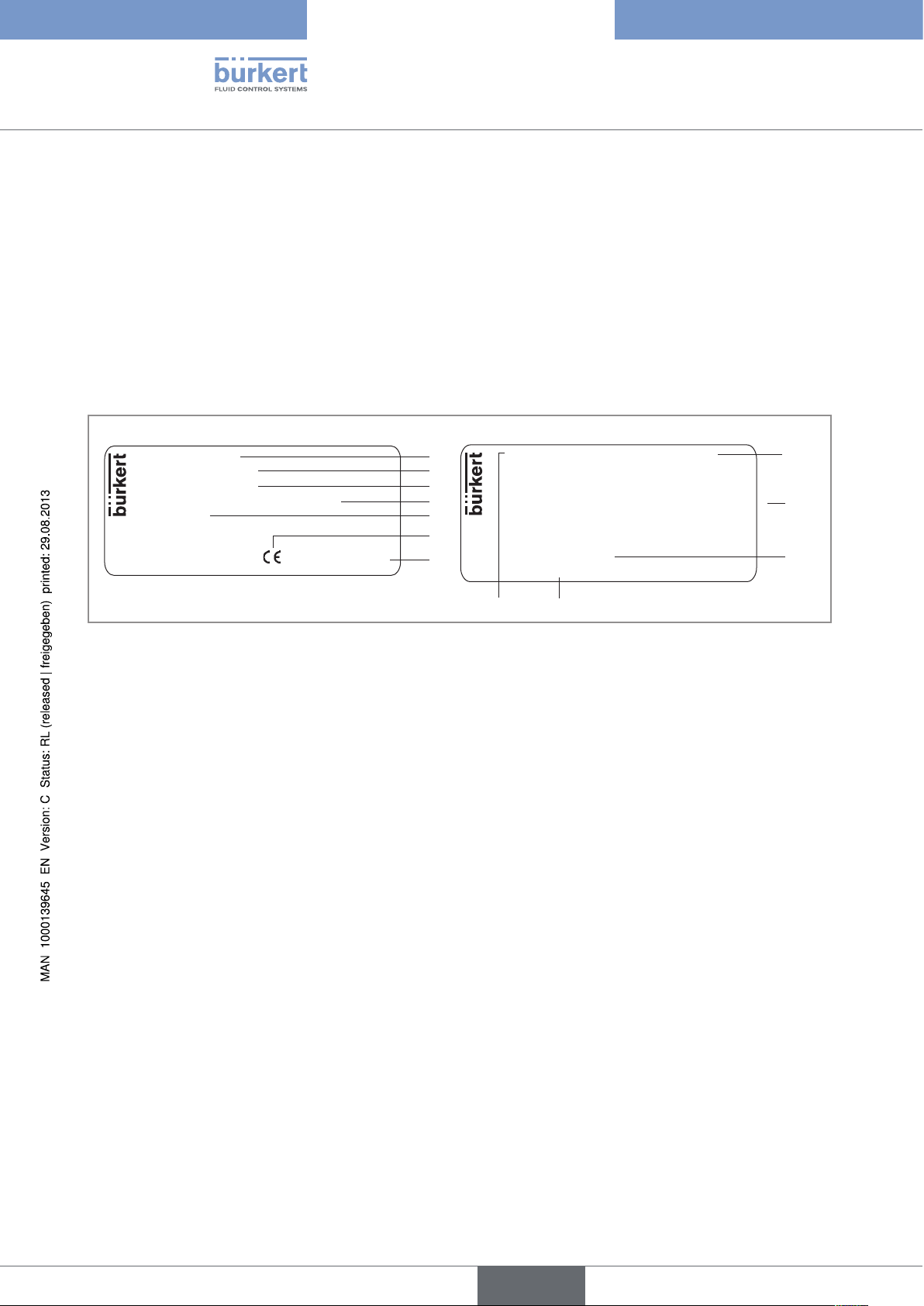

5.2. Description of the device name plate

8619 multiCELL

Supply: 12-36VDC

Temp: -10...+60 °C

IP65 PANEL (FRONT) IP20 (REAR)

Made in France

S-N:1110

00560204

W44ML

Figure 1 : Example of a name plate

1. Type of device

2. Electrical power supply

3. Ambient temperature range

4. Protection rating

5. Serial number

6. Conformity logo

7. Manufacturing code

8. Device fitted with a memory card reader

1

2

3

4

5

6

7

M0: 2xDI - 2xAO - 2xDO - SD CARD

M1: pH/ORP - PT100/1000

M2: RES COND 2/4 POLES PT100/1000

M3: 2xAO - 2xDO

Made in France

M4:

M5:

M6:

Softw.:

00560204 W44ML

12

11

8

9

}

10

9. Properties of the additional modules

10. Software options

11. Order code

12. Properties of the M0:MAIN board

6

english

Page 9

Type 8619

Technical data

6. TECHNICAL DATA

6.1. Conditions of use

Ambient temperature -10 to +70 °C (operating, without memory card), restricted to 0 ... +70°C if

a memory card is used

Air humidity < 85 %, non condensated

Height above sea level max. 2000 m

Protection rating • IP65 and NEMA4X (on front, once built in, housing closed)

• IP20 (non front parts inside the housing)

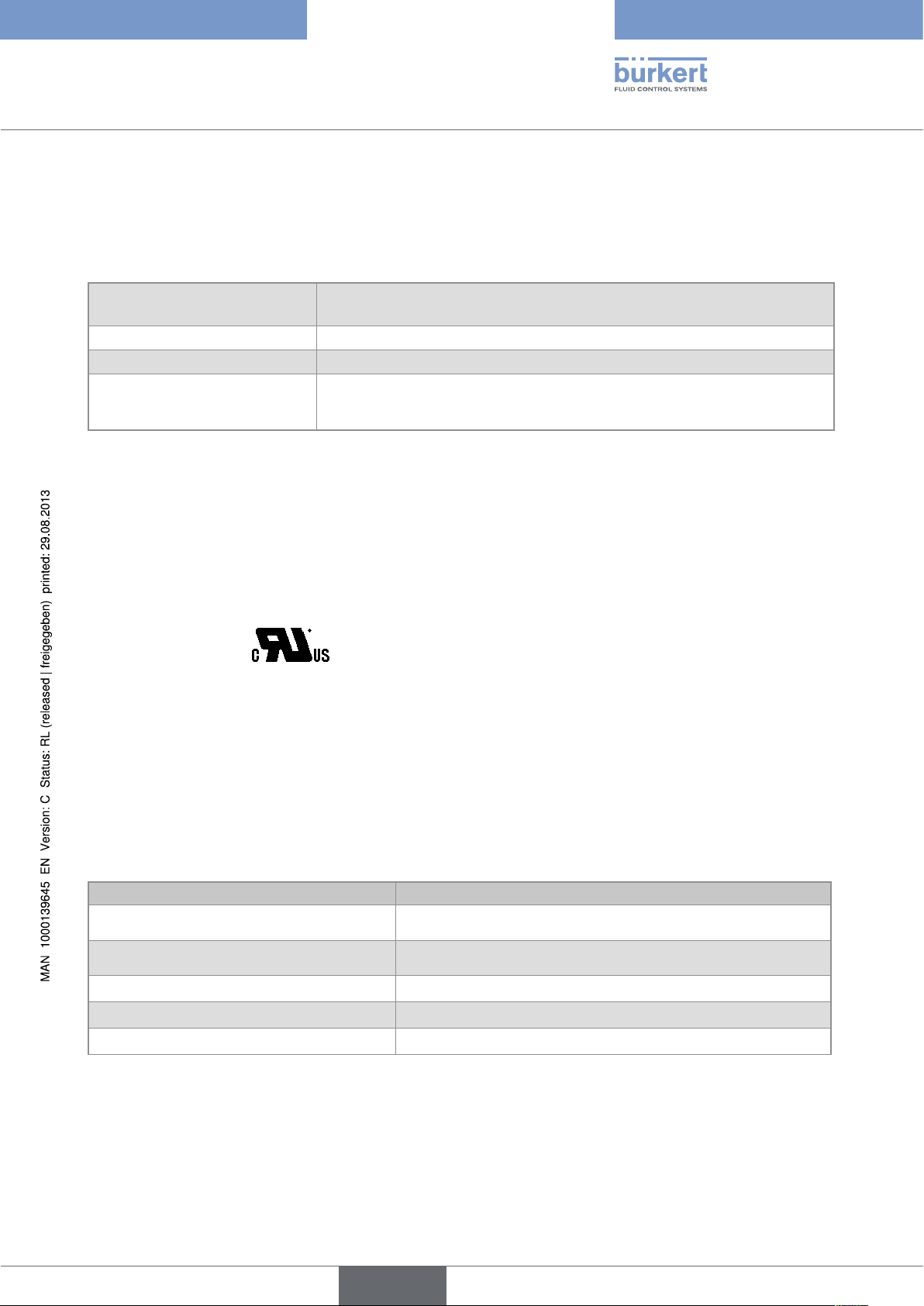

6.2. Compliance to standards and directives

The device conforms to the EC directives through the following standards:

• EMC: EN 61000-6-2, EN 61000-6-3

• Vibration: EN 60068-2-6

• Shock: EN 60068-2-27

UL recognised devices (

standards:

• UL 61010-1

• CAN/CSA-C22.2 n° 61010-1

) for the United States of America and Canada comply to the following

6.3. General technical data

6.3.1. Mechanical data

Mechanical data Material

Built in and locking system / seal PPO / silicone

Front cover, upper layer, and keys / front

cover, sublayer, and display

Rear plate Stainless steel 304

Silicone / PC

Terminal blocks PBT, contacts in gold-plated copper alloy

Ground screw + spring washer Stainless steel 316 (A4)

english

7

Page 10

Type 8619

Technical data

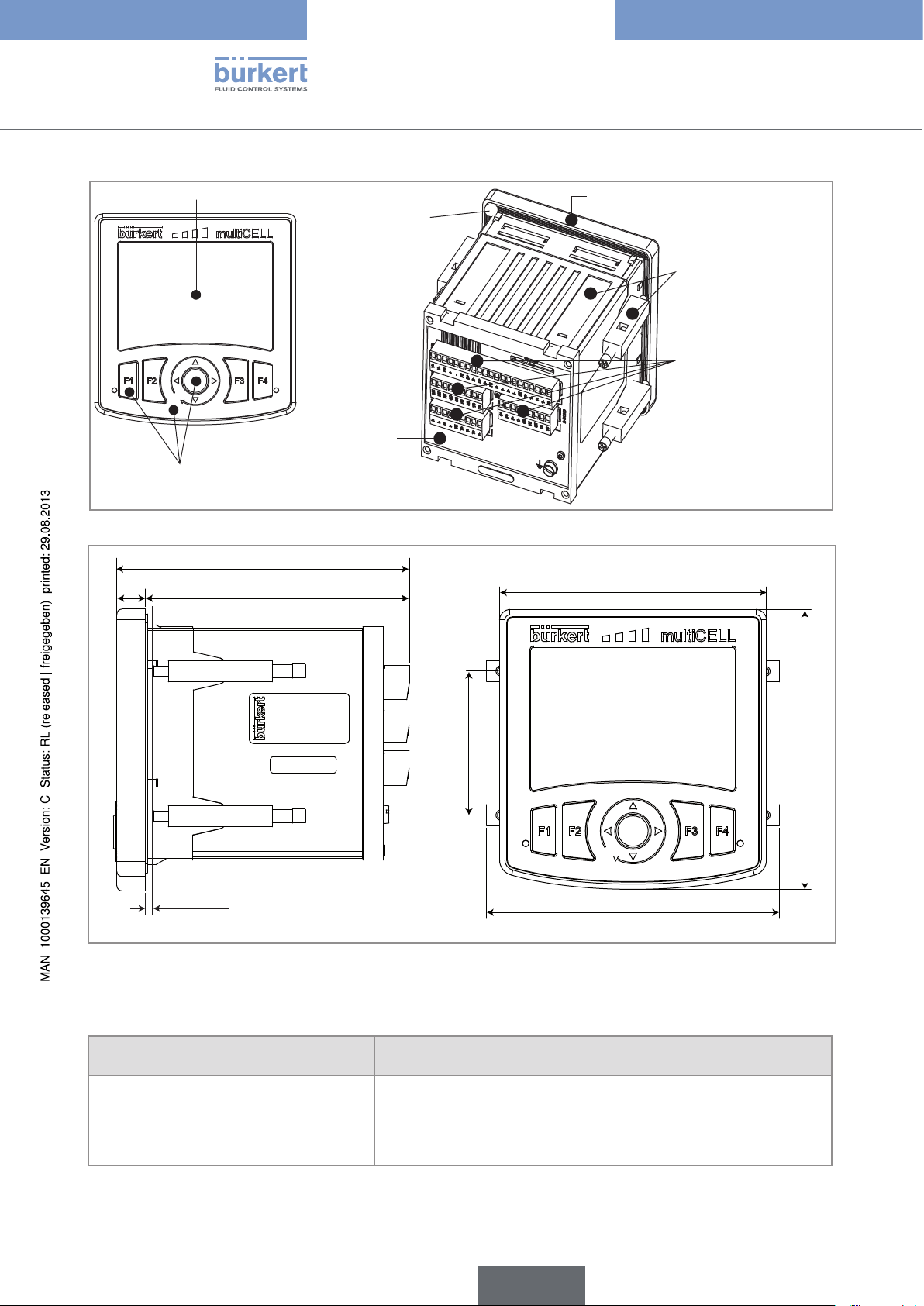

PC

Stainless steel 304

Silicone

Figure 2 : Materials used for the multiCELL

112

10111

PC

Silicone

PPO

PBT, contacts in gold-plated

copper alloy

Stainless steel 316 (A4)

102

max. 4 mm

55

112

107

(wall thickness)

Figure 3 : Dimensions of the multiCELL [mm]

6.3.2. Specifications of the "M0:MAIN" board

Power supply 12-36 V DC, filtered and regulated

Specifications of the power source (not

provided) of UL-recognised devices, with

variable key PE72

8

• Limited power source (in accordance with chap. 9.3 of the UL

61010-1 standard)

• or class 2 type power source (according to the 1310/1585 and

60950-1 standards)

english

Page 11

Type 8619

Technical data

Max. power consumption (without additional

1.5VA

module, outputs not connected)

Power distribution ("PWR OUT") 12-36 V DC, 1.8A max.

All digital inputs ("DI") • Switching threshold V

• Switching threshold V

• Input impedance: 3kW

• Galvanically insulated

• Protected against polarity reversal and voltage spikes

• Frequency: 0.5 to 2500Hz

All analogue outputs ("AO") • 4-20mA current

• Any connection mode, in sink or source mode

• Galvanically insulated

• Protected against polarity reversal

• Max. loop impedance: 1100W at 36V DC, 610W at 24V DC,

100W at 12V DC

All digital outputs ("DO") • Transistor

• Connection mode unimportant in NPN or PNP mode

: 5 à 36 V DC

on

: < 2 V DC

off

• Galvanically insulated

• Protected against short circuits

• Max. voltage: 36V DC

• max. 700mA if one transistor is connected but max. 1A for both

transistors connected

• Max. frequency: 2000Hz

Electrical connection

• Per detachable 21-point set-screw connector, orange

• Refer to chap. 6.3.8 for the specifications of the connection

cables

Flow rate measurement (software option) Refer to the user manual for the flow sensor connected to the 8619

6.3.3. Specifications of the input board "Input"

Power consumption 0.1 VA

Digital inputs ("DI") • Switching threshold V

• Switching threshold V

• Input impedance: 3 kW

• Galvanically insulated

: 5 à 36 V DC

on

: < 2 V DC

off

• Protected against polarity reversal and voltage spikes

• Frequency: 0.5 to 2500 Hz

english

9

Page 12

Type 8619

Technical data

Analogue inputs ("AI") • Any connection mode, in sink or source mode

• Galvanically insulated

• Accuracy: ±0,25%

• Current input: 0 - 22 mA or 3,5 - 22 mA. Max. voltage: 36 V DC.

Impedance: 50 W. Resolution : 1.5 µA

• Voltage input: 0 - 5 V DC or 0 - 10 V DC. Max. voltage: 36 V DC.

Impedance: 110 kW. Resolution: 1 mV

Electrical connection

• Per detachable 9-point set-screw connector, orange

• Refer to chap. 6.3.8 for the specifications of the connection

cables

6.3.4. Specifications of the additional outputs board "OUT"

Power consumption 0.1VA

All digital outputs ("DOx") • Transistor

• Any connection mode, in NPN or PNP mode

• Galvanically insulated

• Protected against short circuits

• Max. voltage: 36V DC

• max. 700mA per transistor but max. 1A if both transistors are

connected

• Max. frequency 2000Hz

All analogue outputs ("AOx") • 4-20mA current

• Any connection mode, in sink or source mode

• Galvanically insulated

• Protected against polarity reversal

• Max. loop impedance: 1100W at 36V DC, 610W at 24V DC,

100W at 12V DC

Electrical connection

• Per detachable 9-point set-screw connector, black

• Refer to chap. 6.3.8 for the specifications of the connection

cables

10

6.3.5. Specifications of the memory card reader/recorder

• Memory card type

• Capacity

• File system

• SD (Secure Digital)

• 2 Go max.

• FAT16

english

Page 13

Type 8619

Technical data

6.3.6. Specifications of the "pH/redox" module

pH measurement

• pH measurement range

• Resolution of pH measurement

• Accuracy of pH measurement

• Potential difference measurement range

• Resolution of potential difference

measurement

• Accuracy of potential difference

measurement

• pH probe type

Power consumption 0.1VA

Measurement of the oxidation reduction

potential

• Oxidation reduction potential measurement

range

• Resolution of the potential difference

measurement

• Accuracy of potential difference

measurement

• -2.00...+16.00

• 0.01pH

• 0.02pH

• -600...+600mV

• 0.1mV

• 1mV

• Electrochemical

• -2000 ... +2000mV

• 0.1mV

• 1mV

• Electrochemical

• Oxidation reduction potential probe type

Temperature measurement

• Measurement range

• Measurement resolution

• Measurement accuracy

• Temperature sensor type

Electrical connection

• -25°C ... +130°C

• 0.1°C

• 1°C

• Pt100 or Pt1000, with 2 or 3 wires

• Per detachable 9-point set-screw connector, grey

• Refer to chap. 6.3.8 for the specifications of connection

cables

6.3.7. Specifications of the "COND" conductivity module

Resistance measurement (without conductivity

sensor connected)

Power consumption 0.25VA

Conductivity cell type With 2 or 4 electrodes; the specifications of Bürkert cells are

5W ... 1MW

described in the related operating instructions.

english

11

Page 14

Type 8619

Technical data

Conductivity measurement (with

connected conductivity sensor)

• Measurement range

• Measurement resolution

• Measurement error

Resistivity measurement (with connected

conductivity sensor)

• Measurement range

• Measurement resolution

• Measurement error (without sensor)

Temperature measurement

• Measurement range

• Measurement resolution

• Measurement error

• Temperature sensor type

Electrical connection

• 0.000 µS/cm...2 S/cm (depends on the conductivity sensor)

-9

• 10

S/cm

• < 0.5% of measured value + sensor error

• 0.500W.cm...100MW.cm (depends on the conductivity sensor)

-1

• 10

W.cm

• < 0.5% of measured value

• -40°C ... 200°C

• 0.1°C

• ±1°C

• Pt100 or Pt1000, with 2 or 3 wires

• Per detachable 9-point set-screw connector, green

• Refer to chap. 6.3.8 for the specifications of the connection

cables

6.3.8. Specifications of the connection cables

• Use shielded cables for the electrical connection.

• Be sure to use cables in which the wires present the specifications described in the table below.

Wire specifications Dimensions of the max. clamping area

• Single core H05(07) V-U 0.2...1.5 mm

• Flexible wire H05(07) V-K 0.2...1.5 mm

• With non-insulated end connection 0.2...1.5 mm

• With insulated end connection 0.2...0.75 mm

Table 1: Specifications of the wires making up the connection cables

2

2

2

2

12

english

Page 15

Type 8619

Installation and wiring

7. INSTALLATION AND WIRING

7.1. Safety instructions

DANGER

Risk of injury due to electrical discharge.

• Shut down and isolate the electrical power source before carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

WARNING

Risk of injury due to non-conforming installation.

• Electrical installation can only be carried out by qualified and authorised personnel with the appropriate tools.

• Install appropriate safety devices (correctly rated fuse and/or circuit-breaker).

• The use of probes/sensors sold by Bürkert is preferable.

• Follow the instructions on installation and wiring of remote sensors connected to the multiCELL.

Risk of injury due to unintentional switch on of power supply or uncontrolled restarting of the

installation.

• Take appropriate measures to avoid unintentional activation of the installation.

• Guarantee a set or controlled restart of the process subsequent to the installation of the device.

Protect this device against electromagnetic interference, ultraviolet rays and, when installed outdoors, the effects of the climatic conditions.

7.2. Building the device into a housing or cabinet

→ Follow the instructions below to build the multiCELL delivered fully assembled, into a housing or cabinet.

92 +0,5/-0

5

5,55,5

92 +0,5/-0

10

Stage 1:

→ Check that the thickness of the door of the

housing or cabinet is 4 mm max.

→ Cut out the hole in the door of the electrical housing

or cabinet in accordance with the standard, IEC

61554:1999 (DIN 43700), allowing the space

required around the cut-out and inside the cabinet

to easily handle the 4 locking systems, delivered

with the multiCELL.

This diagram is not to scale. The dimensions are given in

mm.

english

13

Page 16

Type 8619

Installation and wiring

Screw

Body

x4

Stage 2:

Prepare the 4 locking systems:

→ Insert a screw into each device.

→ Tighten the screw until the end of the shaft of the

screw is flush with the device.

Stage 3:

→ Slide the housing into the cut-out with the con-

nectors to the back until it can go no further.

Stage 4:

→ Insert (1) the hooks on the first locking system

into the slots on the housing.

1

2

→ Pull the locking system (2) until you hear a click.

The click may be heared when tightening the

locking system at stage 6.

Stage 5:

→ Place the locking system flush against the mul-

tiCELL by hand, so that the hooks remain in place.

14

english

Page 17

Type 8619

Installation and wiring

Stage 6:

→ Fully tighten the screws using an appropriate

screwdriver.

→ Repeat stages 4 to 6 to fit the other 3 locking

systems.

Figure 4 : Insertion of the 8619 into a housing or cabinet

7.3. Electrical wiring

DANGER

Risk of injury due to electrical discharge.

• Shut down and isolate the electrical power source before carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

• Use a high quality electrical power supply (filtered and regulated).

• Connect the functional earth on the installation to the ground screw on the device.

• Connect the shielding on each wire to an "FE" (functional earth) terminal to guarantee the equipotentiality of the installation.

• Use shielded cables that respect the specifications described in "Table 1: Specifications of the wires

making up the connection cables".

7.3.1. Electrical connections

For all versions of the multiCELL, the electrical connection is made by set-screw connectors.

7.3.2. Wiring the M0:MAIN board

The M0:MAIN board is used to connect the multiCELL's electrical power source. It has:

• 2 digital inputs (marked DI1 and DI2), for connecting a flow sensor for example

• Two 4-20 mA analogue outputs (marked AO1 and AO2)

• 2 digital outputs (marked DO1 and DO2)

The inputs and outputs are galvanically insulated and therefore voltage free.

english

15

Page 18

Type 8619

Installation and wiring

1st digital output at

external instrument

5-36 VDC

12-36 VDC

-

+

Power supply

2nd digital

output at external

instrument

-

+

5-36 VDC

0 VDC

1st 4-20 mA input at

external instrument

+-

0 VDC

12-36 VDC

0 VDC

2nd 4-20 mA input at

12-36 VDC

0 VDC

external instrument

+-

Load 1

+

-

0 VDC

12-36 VDC

12-36 VDC

+

-

0 VDC

Load 2

SUPPLY PWR OUT DI1 FEDI2 DO2DO1AO1 AO2 FE FE

Electrical

power supply

V-

V+

Power

distribution

FE

-

+

FE

D+D-D+

Digital inputs Digital

D-

I+I-I+

FE

Analogue

outputs

I-

FE

T+T-T+

outputs

T-

FE

DI1, DI2, AO1, AO2, DO1 and DO2: designation in the configuration menus of the M0 main board.

FE = functional earth

Figure 5 : Wiring of the "M0:MAIN" board

16

english

Page 19

Type 8619

Installation and wiring

PNP

1

1

V+

NPN

V+

12-36 VDC

3

-

0V

2

+

Power supply

-

+

V-

FE

V+

SUPPLY PWR OUT DI1 FEDI2 DO2DO1AO1 AO2 FE FE

FE

D+D-D+

D-

FE

I+I-I+

FE = functional earth

Figure 6 : Connection example for the 8619 with two flow sensors, type 8030

8071

X

I-

3

FE

T+T-T+

0V

2

T-

FE

8041

4...20V+V-PEPls+Pls-

VDC

red

black

white

12-36 VDC

-

+

Power supply

-

+

V-

FE

V+

SUPPLY PWR OUT DI1 FEDI2 DO2DO1AO1 AO2 FE FE

FE

D+D-D+

D-

FE

I+I-I+

I-

FE

T+T-T+

FE = functional earth

Figure 7 : Connection example for the 8619 with 2 flow sensors, types 8071 and 8041

1 2 3 4 5 6

T-

FE

17

english

Page 20

7.3.3. Wiring the input module "INPUT"

The "INPUT" inputs module has:

• Two analogue inputs;

• Two digital inputs.

The inputs are galvanically insulated, and therefore voltage free.

1st 0/4-20 mA output (at

+-

external instrument)

0 VDC

2nd 0/4-20 mA output (at external instrument)

Type 8619

Installation and wiring

+-

12-36 VDC

12-36 VDC

A+A-A+

1

2 3 4 5 6 7 8 9

(AI1) (AI2) (DI1) (DI2)

0 VDC

A-

FE

5-36 VDC

0 VDC

D+D-D+

5-36 VDC

1st digital output (at

external instrument)

+

-

0 VDC

D-

2nd digital output (at

external instrument)

(designation in the configuration menus of the Mx

input module)

18

analogue

digital inputs

inputs

FE = functional earth

Figure 8 : Connecting the analogue inputs to a 2-wire current transmitter and connecting the digital inputs of the input

module

english

Page 21

Type 8619

Installation and wiring

1st 0/4-20 mA output

(at external instrument)

12-36 VDC

0 VDC

+-

I

12-36 VDC

A+A-A+

1

2 3 4 5 6 7 8 9

A-

FE

(AI1) (AI2) (DI1) (DI2)

digital inputsanalogue

inputs

+-

0 VDC

12-36 VDC

D+D-D+

2nd 0/4-20 mA output

(at external instrument)

I

1st digital output (at

external instrument)

0 VDC

+

-

12-36 VDC

+

-

2nd digital output (at

external instrument)

0 VDC

D-

(designation in the configuration menus of the Mx

input module)

FE = functional earth

Figure 9 : Connecting the AI1 analogue input in source mode and the analogue input AI2 in sinking mode to a 3-wire

current transmitter (for example type 8025 with relay outputs) and connecting the digital inputs of the input

module

1st 0-5/10 V DC output

(at external instrument)

+-

V

0 VDC

+

-

1st digital output (at

external instrument)

12-36 VDC

12-36 VDC

0 VDC

12-36 VDC

+

-

2nd digital output (at

external instrument)

0 VDC

A+A-A+

1

2 3 4 5 6 7 8 9

A-

FE

D+D-D+

(AI1) (AI2) (DI1) (DI2)

D-

(designation in the configuration menus of the Mx

input module)

digital inputsanalogue

inputs

FE = functional earth

Figure 10 : Connecting the analogue inputs to a voltage transmitter and connecting the digital inputs of the input module

english

19

Page 22

Type 8619

Installation and wiring

7.3.4. Wiring the output module "OUT"

The "OUT" outputs module has two 4-20 mA analogue outputs and two digital outputs. The outputs are galvanically insulated, and therefore voltage free.

1st 4-20 mA

input (at external

instrument)

+-

0 VDC

12-36 VDC

I+I-I+

1

2 3 4 5 6 7 8 9

(AO1) (AO2) (DO1) (DO2)

FE = functional earth

Figure 11 : Wiring the "OUT" output module

12-36 VDC

12-36 VDC

0 VDC

I-

FE

T+T-T+

2nd 4-20 mA input (at

+-

external instrument)

Load 1

+

0 VDC

12-36 VDC

0 VDC

-

+

-

Load 2

T-

(designation in the configuration menus of the Mx

additional output module)

digital outputsanalogue outputs

7.3.5. Wiring the "pH/ORP" module

• Wire a pH/redox sensor in symmetrical mode to obviate the influence of interference and, in this case,

wire the equipotential electrode (compulsory).

• When the pH/redox sensor is wired in asymmetrical mode, measurement of the pH or the oxidation

reduction potential may drift over time when the equipotential electrode is not wired.

20

english

Page 23

Type 8619

Installation and wiring

black

Equipotential electrode

(1)

Temperature

(2)

(2)

white

black

sensor

Reference

electrode

pH measurement

(1)

translucid

(2)

blue

(2)

brown

electrode

FE

TS

RE

RE

ME

1 2 3 4 5 6 7 8 9

GD

CG

SE

TS

FE = functional earth

(1)

Colour of the wires in the Bürkert connection cables with order codes 561904, 561905 or 561906.

(2)

Colour of the wires in the Pt1000 sensor with order code 427023 and its Bürkert connection cable with order code

427113.

Figure 12 : Wiring a Bürkert 8200 type sensor and a Pt1000 temperature sensor in symmetrical mode

(1)

black

Reference

(1)

Temperature

sensor

electrode

translucid

pH measurement electrode

(recommended)

Equipotential electrode

Strap (not delivered)

FE

TS

RE

RE

ME

1 2 3 4 5 6 7 8 9

GD

CG

SE

TS

FE = functional earth

(1)

Colour of the wires in Bürkert connection cables with order codes 561904, 561905 or 561906.

Figure 13 : Wiring a pH sensor and a Pt100 or Pt1000 temperature sensor in asymmetrical mode to a pH/ORP module

english

21

Page 24

Type 8619

Installation and wiring

Temperature

Oxidation reduction potential

sensor

measurement electrode

Reference electrode

Strap (not delivered)

FE

TS

RE

RE

ME

1 2 3 4 5 6 7 8 9

GD

CG

SE

TS

FE = functional earth

Figure 14 : Wiring an oxidation reduction potential sensor and a Pt100 or Pt1000 temperature sensor in a pH/ORP

module

Oxidation reduction potential

measurement electrode

Temperature

sensor

Reference

electrode

pH

measurement

electrode

FE

TS

RE

RE

ME

1 2 3 4 5 6 7 8 9

GD

CG

SE

TS

FE = functional earth

Figure 15 : Wiring a pH sensor, an oxidation reduction potential sensor and a Pt100 or Pt1000 temperature sensor in a

pH/ORP module

7.3.6. Wiring the "COND" conductivity module

Conductivity

sensor

Temperature

sensor

22

P-

C-

FE

TS

TS

P+

C+

1 2 3 4 5 6 7 8 9

GD

SE

FE = functional earth

Figure 16 : Wiring a resistive conductivity cell with 2 electrodes and a Pt100 or Pt1000 temperature sensor in a conduc-

tivity module

english

Page 25

Type 8619

Installation and wiring

Temperature

sensor

P-

C-

FE

TS

TS

P+

C+

1 2 3 4 5 6 7 8 9

Figure 17 : Wiring a resistive conductivity cell with 4 electrodes and a Pt100 or Pt1000 temperature sensor in a conduc-

tivity module

GD

SE

FE = functional earth

english

23

Page 26

Type 8619

Adjustment and commissioning

8. ADJUSTMENT AND COMMISSIONING

8.1. Safety instructions

WARNING

Risk of injury due to non-conforming adjustment.

Non conforming adjustment could lead to injuries and damage the device and its environment.

• The operators in charge of adjustment must have read and understood the contents of this manual.

• In particular, observe the safety recommendations and intended use.

• The device/installation must only be adjusted by suitably trained staff.

WARNING

Danger due to non-conforming commissioning.

Non-conforming commissioning could lead to injuries and damage the device and its surroundings.

• Before commissioning, make sure that the staff in charge have read and fully understood the contents of the

manual.

• In particular, observe the safety recommendations and intended use.

• The device/installation must only be commissioned by suitably trained staff.

Before commissioning, calibrate each measuring sensor connected to the device.

8.2. Switching on the device for the first time

When switching on the device for the first time, the display shows the first view in Process level:

M0:MAIN

MENU

OFF

OFF

DI1

DI2

2010/06/29

OFF

OFF

6.000

20.00

13:40

DO1

DO2

mA

AO1

mA

AO2

24

Figure 18 : Display when switching on for the first time

When switched on subsequently, the last active view in the Process leve is displayed. See chap. 8.7 to

browse in all views in Process level.

english

Page 27

H

T

Type 8619

Adjustment and commissioning

8.3. Description of the icons

Figure 19 : Position of the icons

Icon Meaning and alternatives

Default icon when process monitoring is not activated via the "Diagnostics" menu; if monitoring is

activated, this icon indicates that the parameters monitored are not out of range.

If at least one monitoring is activated, the alternative icons in this position are:

•

, combined with : go to the menu "Information -> System log" to read the associated warning

message.

, combined with X: go to the menu "Information -> System log" to read the associated error

•

message.

Device currently measuring.

M0:MAIN

X

MENU

OFF

OFF

DI1

DI2

2010/06/29

OFF

OFF

6.000

20.00

13:40

DO1

DO2

mA

AO1

mA

AO2

The alternative icons in this position are:

flashing: HOLD mode activated.

•

•

flashing: running check that an output is working and behaving correctly.

X

"Maintenance" event; Go to the menu "Information -> System log" to read the associated message.

"Warning" event; Go to the menu "Information -> System log" to read the associated message.

Error" event; Go to the menu "Information -> System log" to read the associated message.

Memory card inserted and datalogger activated.

X

The alternative to this position is the icon

System log", to read the associated error message.

indicating an error. Go to the menu "Information ->

25

english

Page 28

Type 8619

Adjustment and commissioning

8.4. Using the navigation button and the dynamic keys

The arrows displayed show

the directions in which you

can browse in this view.

26

To activate the dynamic

function to the far left,

press F1

LED A: shows the system

status. See chap. 9.

To activate the second

dynamic function, press F2

MENU ABORT SAVE OK

F1

F2

F3

F4

To activate the third

dynamic function, press F3

To activate the dynamic

function to the far right, press

F4

LED B: shows the sensor

status. See chap. 9.

The navigation button is used to move in 4 directions, symbolised throughout the

manual by

Figure 20 : Using the navigation button and the dynamic keys

and .

You want to... Press...

....access the Configuration level Dynamic function, "MENU", from any view in Process

level

...go back to Process level Dynamic function, "MEAS"

...access the menu displayed Dynamic function, "OK"

...access the highlighted function Dynamic function, "OK"

...confirm the enter Dynamic function, "OK"

...save modifications Dynamic function "SAVE"

...go back to the parent menu Dynamic function "BACK"

...cancel the current operation Dynamic function "ABORT"

...set a setpoint value Dynamic function "SETP"

...activate manual mode in a configured and activated

Dynamic function "MANU"

function

...manually set the percentage of the function Dynamic function "CMD"

...force the result of a function to 0% Dynamic function "0%"

...force the result of a function to 100% Dynamic function "100%"

...activate automatic mode in a configured and acti-

Dynamic function "AUTO"

vated function

...start teach-in Dynamic function "START"

...end teach-in Dynamic function "END"

...answer the question asked in the affirmative Dynamic function "YES"

...answer the question asked in the negative Dynamic function "NO"

...select the highlighted character or mode Dynamic function "SEL"

english

Page 29

Type 8619

Adjustment and commissioning

You want to... Press...

...browse in Process level

...browse in the Configuration level menus

next view

previous

view

next level

previous

level

...browse in the menu functions

...set the contrast or brightness percentage for the

display (after accessing the function in the "Parameters" menu)

...modify a numerical value or the units

...allocate the "+" or "-" sign to a numerical value

display the next

menu

highlight the next

function

increase the

percentage

increment the

figure selected or modify

the units

select the next

figure

to the extreme left of the numerical value then

display the pre-

vious menu

highlight the pre-

vious function

reduce the

percentage

decrement the

figure selected or modify

the units

select the pre-

vious figure

until the desired sign is displayed

...move the decimal point in a numerical value

to the extreme right of the numerical value

then

place

until the decimal point is in the desired

8.5. Entering some text

This chap. describes how to use the keyboard displayed to modify the name of a process variable (13 characters

max.), a function (12 characters max.) or the title of a view (12 characters max.).

english

27

Page 30

Type 8619

Adjustment and commissioning

Cursor of the data entering area

Selector

The arrows indicate that the selector

can be moved on the line or that the

3 available character pages can be

scrolled through.

Indicates the active page

among 3 pages

Edit name

ABORT SEL

_

f

_

a b c d e f g 7 8 9

h i j k l m n 4 5 6

o p q r s t u 1 2 3

v w x y z + - . 0

' ? ! : ; % * / < >

2/3

F3

SAVE

F4

→ To move the cursor in the data entering area using keys and , first move the selector into

the data entering area using the keys

→ To insert a character in place of the cursor, move the selector over this character and press key

and .

F3

(function "SEL").

→ To remove the character before the cursor, move the selector into the data entering area then press key

(function "backspace"):

F3

selector

Edit name

ABORT

_

f

_

a b c d e f g 7 8 9

h i j k l m n 4 5 6

o p q r s t u 1 2 3

v w x y z + - . 0

' ? ! : ; % * / < >

2/3

F3

The arrows indicate that the selector can be

moved on the name entering area.

SAVE

F4

To retrieve the original name of a variable, even after modification and saving:

→ move the selector into the customized name entering area.

28

→ delete all the characters.

→ save.

8.6. Operating levels

The device has 2 operating levels: the Process level and the Configuration level which is made of the following

5 menus : "Parameters", "Calibration", "Diagnostics", "Tests" and "Information".

english

Page 31

Type 8619

Adjustment and commissioning

8.7. Process level

M0:MAIN:

OFF

OFF

MENU

U1:PH_COND

2

2

3

3

M0:MAIN:

2010/06/29

DI1

DI2

6.000

20.00

2010/06/29

25

6.53

M6:Outputs

OFF

OFF

13:40

DO1

DO2

mA

AO1

mA

AO2

M1:pH

2010/06/29

0.500

30.00

1.000

33.00

M2:Conductivity

13:40

L/s

DI1

L

DI1

L/s

DI2

L

DI2

6.53

39.20

25.2

2010/06/29

13:40

25

pH

mV

25.2

°C

13:40

mS/cm

........

°C

MENU

Views of the modules connected to the device (cannot be modified):

• "M0:MAIN" view: displays the values of inputs and outputs on the main

board; the second "M0:" view is available if the software option, "FLOW", is

activated.

• "M1:" to "M6:" views display the data for modules 1 to 6.

13:40

mS/cm

pH

U4:PROCESS1

......

MENU

2010/06/29

1

3

0

1

6.53

25

25.2

205

13:40

pH

mS/cm

°C

l/min

User defined views (U1 to U4) are

each used to display 1, 2 or 4 data

or a graph. Only the effectively

defined views are shown.

2010/06/29

OFF

OFF

5.000

12.00

13:40

DO1

DO2

mA

AO1

mA

AO2

MENU

F1:A+B

MENU

µS/cm

PV

µS/cm

SP

%

CMD1

F3 Dos.St

13:40

F6:ONOFF

1

1

F2:PROP

1

PV

2010/06/29

250.2

0

CMD1

2010/06/29

0

0

0

148

57

205

MENU

13:40

13.00

L/min

L/min

l/min

FlowProcess1

13:40

........

µS/cm

%

MANU

0

0

SETPMENU

2010/06/29

250.0

500.0

0.00

Off

Views of active functions which

cannot be modified (F1: to F6:)

are used to display one function

each. Only the views of functions

declared "active" are shown.

29

english

Page 32

8.8. Configuration level access

On any view in

Process level,

press

MENU

F1

MEAS

This is

when the

device is being parame-

tered............

....................

Parameters

OK

F4

Code

incorrect

"Param-

eters" code

correct

1)

Type 8619

Adjustment and commissioning

This is

when the

device is being parame-

tered............

Parameters

....................

System

Display

Functions

Datalogger

M0:Outputs

Mx:pH/ORP

Mx:Conductivity

Mx:Outputs

Mx:Inputs

2)

MEAS

MEAS

Calibration

Diagnostics

Tests

OK

OK

F4

F4

Code

incorrect

Code

incorrect

Code

incorrect

"Cali-

bration" code

correct

1)

"Diag-

nostics"

code correct

1)

"Tests"

code

correct

1)

Calibration

System

M0:Outputs

M0:Inputs

Mx:pH/ORP

Mx:Conductivity

Mx:Outputs

Mx:Inputs

Diagnostics

System

Mx:pH/ORP

Mx:Conductivity

Mx:Inputs

Tests

System

Simulate PV

T

M0:Outputs

Mx:Outputs

30

MEAS

OK

F4

Information

MEAS

1)

The code is not requested if the default code "0000" is used.

2)

This menu is available as an option.

OK

F4

Information

Error

Warning

Maintenance

Smiley

System log

Versions

english

Page 33

Type 8619

Adjustment and commissioning

8.9. Calibrating the measuring sensors

8.9.1. Calibrating a flow sensor

Enter the K factor in pulse/liter unique to the fitting used. Refer to the user manual of the fitting used.

→

Calibration

Mx:Inputs

DI1/2:FlowM0:Inputs

K factor ENTERING

8.9.2. Calibrating a conductivity sensor

Choose the reference solution used in the menu "Parameters -> Mx:Conductivity -> Buffer".

→

→ Calibrate the conductivity sensor by automatically determining its specific C constant.

Calibration

Automatic calibMx:Conductivity

RESULT

8.9.3. Calibrating a pH sensor

• In order not to interrupt the process, activate the HOLD function in the menu "Calibration -> System ->

Hold". The Hold mode is automatically deactivated when the multiCELL restarts after a power interruption,

if the Hold mode was activated at the moment of the power cut-off.

• Before each calibration, correctly clean the electrode with a suitable product.

→ Choose the buffer solution used, in the menu "Parameters -> Mx:pH/ORP -> Buffer". The multiCELL auto-

matically recognizes the pH of the buffer used.

→ Automatically calibrate the pH sensor:

Calibration

Mx:pH/ORP

The calibration may fail:

• a possible "warning" message indicates either an error in the buffer solution or the ageing of the probe.

• a possible "error" message indicates that the probe must be replaced.

pH auto calib.

NON

1st point

2nd point?

YES

Rinse

2nd point

pH Cal.Result

31

english

Page 34

Type 8619

Adjustment and commissioning

8.9.4. Calibrating a redox sensor

• Modify the default calibration limits before calibrating your sensor in the menu "Parameters" -> "Mx:pH/

ORP" -> "Calibration limits" -> "Offset ORP".

• In order not to interrupt the process, activate the HOLD function in the menu "Calibration -> System ->

Hold". The Hold mode is automatically deactivated when the multiCELL restarts after a power interruption,

if the Hold mode was activated at the moment of the power cut-off.

• Before each calibration, correctly clean the electrode with a suitable product.

→ Calibrate the redox sensor using a 1-point procedure.

The calibration may fail:

• a possible "warning" message indicates either an error in the buffer solution or the ageing of the probe.

• a possible "error" message indicates that the probe must be replaced.

The 1-point calibration procedure is used for a quick calibration by adjusting the zero of the measurement graph

with a buffer solution with a known oxidation reduction potential.

Calibration ORP calibrationMx:pH/ORP 1st point

→ Immerse the clean probe in the redox solution:

the multiCELL displays the measured potential

difference of the solution

1st point

465.0 mV

475.0 mV

→ Enter the potential difference of the redox

solution (indicated on the bottle).

OK

F4

ORP Calibr. result

Offset:-55.60 mV

The multiCELL displays the calibration result.

1)

32

english

Page 35

Type 8619

Adjustment and commissioning

8.10. Process inputs or values

8.10.1. On the M0:MAIN board

M0:MAIN

1)

Available on the device if the software option

None

Warning

AO1

AO2

DO1

DO2

SysSwitch

DI1

DI2

DI1: Qv

DI2: Qv

DI1: TotA

DI1: TotB

DI2: TotA

DI2: TotB

DI1: Hz

DI2: Hz

Fx:

1)

"FLOW" is active

8.10.2. On the input module

Mx:Entrées

1)

Available on the device if the software option

"FLOW" is active

AI1

AI2

DI1

DI2

DI1: Qv

DI2: Qv

DI1: TotA

DI1: TotB

DI2: TotA

DI2: TotB

AI1Raw

AI2Raw

DI1:Hz

DI2:Hz

1)

"Warning" = event generated by the multiCELL

"AOx" = analogue output

"DOx" = digital output

"System switch" = when the corresponding event is

configured and activated

"DIx" = digital input

"DIx Qv" = flow rate on digital input DIx

"DIx TotA" = totalizer A on digital input DIx

"DIx TotB" = totalizer B on digital input DIx

"DIx Hz" = frequency on digital input DIx

"Fx:" = result of configured and activated functions

"AIx" = scaled process variable.

"DIx" = digital input

"DIx Qv" = flow rate on digital input DIx

"DIx TotA" = totalizer A on digital input DIx

"DIx TotB" = totalizer B on digital input DIx

"AIxRaw" = current or voltage standard signal on analogue input AIx

"DIx Hz" = frequency on digital input DIx

8.10.3. On the additional outputs module

Mx:Outputs

AO1

AO2

DO1

DO2

"AOx" = analogue output

"DOx" = digital output

english

33

Page 36

8.10.4. On the pH/redox module

Type 8619

Adjustment and commissioning

Mx:pH/ORP

pH

mV

ORP

°C

°F

RTD

"pH" = measured pH of the fluid

"mV" = measured pH of the fluid in mV

"ORP" = measured oxidation reduction potential of the fluid in mV

"°C" = measured temperature of the fluid in °C

"°F" = measured temperature of the fluid in °F

"RTD" = resistance of the temperature input in W

8.10.5. On the conductivity module

Mx:Conductivity

µS/cm

W.cm

°C

°F

RTD

TDS

%

USP

"µS/cm" = measured conductivity of the fluid

W.cm" = resistivity

"

"°C" = measured temperature of the fluid in °C

"°F" = measured temperature of the fluid in °F

"RTD" = input resistance of the temperature stage in W

"TDS" = quantity of dissolved solids in the fluid in ppm

"%" = mass concentration of the fluid (software option)

"USP" = state of the USP function

34

english

Page 37

Type 8619

Maintenance and troubleshooting

9. MAINTENANCE AND TROUBLESHOOTING

9.1. Safety instructions

DANGER

Risk of injury due to electrical discharge.

• Shut down and isolate the electrical power source before carrying out work on the system.

• Observe all applicable accident protection and safety regulations for electrical equipment.

WARNING

Risk of injury due to non-conforming maintenance.

• Maintenance must only be carried out by qualified and skilled staff with the appropriate tools.

• Guarantee a set or controlled restarting of the process, after a power supply interruption.

9.2. Maintenance of the multiCELL

The multiCELL can be cleaned with a duster slightly moistened with water with possible addition of a detergent

compatible with the materials it is made of.

Please feel free to contact your Bürkert supplier for any additional information.

9.3. If you encounter problems

The following table gives the association between the LEDs, the icons and the types of events generated by the

device.

The messages generated in the system log are detailled in the complete instruction manual.

LEDs Displayed icons

left right Smiley Error Warning Maintenance

green green

green red

red green

green orange

orange green

red green

any colour any colour any colour

X

X

Type of event and possible

cause

Normal operating and default

icon if no diagnostic function is

active on the device.

"Error" event linked to the

diagnostic.

"Error" event linked to the

device.

"Warning" event linked to the

diagnostic.

"Warning" event linked to the

device.

"Maintenance" event linked to

the calibration.

Problem linked to the

X

datalogger

english

35

Page 38

Type 8619

Spare parts and accessories

10. SPARE PARTS AND ACCESSORIES

CAUTION

Risk of injury and/or material damage caused by the use of unsuitable parts.

Incorrect accessories and unsuitable replacement parts may cause injuries and damage the device and the surrounding area.

• Use only original accessories and original replacement parts from Bürkert.

11. PACKAGING, TRANSPORT

ATTENTION

Damage due to transport

Transport may damage an insufficiently protected device.

• Transport the device in shock-resistant packaging and away from humidity and dirt.

• Do not expose the device to temperatures that may exceed the admissible storage temperature range.

12. STORAGE

CAUTION

Poor storage can damage the device.

• Store the device in a dry place away from dust.

• Storage temperature: -20 ... +70°C, restricted to 0 ... +70°C if a memory card is inserted

13. DISPOSAL OF THE DEVICE

→ Dispose of the device and its packaging in an environmentally-friendly way.

CAUTION

Damage to the environment caused by products contaminated by fluids.

• Keep to the existing provisions on the subject of waste disposal and environmental protection.

Note

36

Comply with the national and/or local regulations which concern the area of waste disposal.

english

Page 39

Page 40

www.burkert.com

Loading...

Loading...