Page 1

Operation Manual

Mini Spray Dryer B-290

093001 en

Page 2

Page 3

Table of contents

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1 User qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Safety warnings and safety signs used in this manual . . . . . . . . . . . . . . . . . . 8

2.5 Product safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.1 General hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.2 Warning labels on housing and assemblies . . . . . . . . . . . . . . . . . . . . . . 14

2.5.3 Personal protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5.4 Safety elements and measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.6 General safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Scope of application and delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1.1 Standard instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1.2 Standard accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1.3 Standard accessories with the B-290 Advanced . . . . . . . . . . . . . . . . . . . 18

3.1.4 Standard accessories with the B-290 Acid resistant. . . . . . . . . . . . . . . . . . 18

3.1.5 Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Technical data overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 Materials used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 Description of function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1 Functional principle of the drying gas . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.2 Functional principle of the sample feed and dispersion . . . . . . . . . . . . . . . . 22

4.3 Outlet filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4 Inert Loop B-295 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.5 Dehumidifier B-296 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.6 Spray chilling accessory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.7 Connected accessories to the Mini Spray Dryer B-290 . . . . . . . . . . . . . . . . 25

4.7.1 Feed switch valve and remote control panel. . . . . . . . . . . . . . . . . . . . . . 26

4.7.2 Printer or PC for data output via RS-232 serial port . . . . . . . . . . . . . . . . . . 26

5 Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.1 Installation site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.3 Installing the compressed air maintenance unit and compressor (optional) . . . . . . 28

5.4 Installing the glass assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.5 Installing the spraying nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.6 Installing the filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.6.1 Inlet filter installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.6.2 Outlet filter installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.6.3 PTFE filter membrane installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.6.4 Cleaning filter installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.7 Adjusting the peristaltic pump bed and choosing the feeding tube . . . . . . . . . . 35

5.8 Tubing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.9 Installing the compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.10 Quick hose couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table of contents

3 B-290 Operation Manual, Version I

Page 4

5.11 Installing the Inert Loop B-295 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.12 Dehumidifier B-296 and Inert Loop B-295 combination . . . . . . . . . . . . . . . . 42

5.13 Installing the Dehumidifier B-296 . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.14 Installing the Spray Chilling Accessory. . . . . . . . . . . . . . . . . . . . . . . . . 44

5.15 Installation check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

5.16 Additional cleaning measures for food, pharma and cosmetic applications . . . . . . 46

5.16.1 Primary cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.1 Layout of the operating and display elements . . . . . . . . . . . . . . . . . . . . . 48

6.2 Conversion tables for the parameters . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.2.1 Flow meter spraying air (rotameter) . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.2.2 Peristaltic pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.2.3 Aspirator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.3 Spray process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.4 Optimizing parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.5 End of spray process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.6 Recovering particles of the outlet filter . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.7 Operation with the Inert Loop B-295 . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.7.1 Status messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.8 Operation with the Spray Chilling Accessory. . . . . . . . . . . . . . . . . . . . . . 55

6.9 Mini Spray Dryer B-290 acid resistant . . . . . . . . . . . . . . . . . . . . . . . . . 56

7 Maintenance and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.1 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.2 Glass assembly, tubes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.3 Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.4 Aspirator cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.5 Inert Loop B-295 and Dehumidifier B-296. . . . . . . . . . . . . . . . . . . . . . . 59

7.6 Outlet filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.7 Calibrating the oxygen sensor of the Inert Loop B-295 . . . . . . . . . . . . . . . . 60

7.8 Replacing the oxygen sensor of the Inert Loop B-295 . . . . . . . . . . . . . . . . . 61

7.9 Spray chilling accessory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.10 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.1 Error messages and their remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

8.2 Malfunctions and their remedy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9 Shutdown, storage, transport and disposal . . . . . . . . . . . . . . . . . . . . . . . . 65

9.1 Storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.2 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.1 Spray nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.2 Glass parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.3 Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.4 Tubings and connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.5 Trolley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.6 Measurement pipe for gas flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.7 Feed switch valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.8 Remote control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.9 Inert Loop B-295 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.10 Cylinder insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.11 Spray chilling accessory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Table of contents

4 B-290 Operation Manual, Version I

Page 5

10.12 Decontamination Glass-Set and sterile filter . . . . . . . . . . . . . . . . . . . . . . 77

10.13 Acid resistant accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

11 Declarations and requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

11.1 FCC requirements (for USA and Canada) . . . . . . . . . . . . . . . . . . . . . . . 79

11.2 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

11.3 Safety certificate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

11.4 Health and safety clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Table of contents

5 B-290 Operation Manual, Version I

Page 6

1 About this manual

This manual describes the Mini Spray Dryer B-290 and its optional accessories and provides all information required for its safe operation and to maintain it in good working order.

It is addressed to laboratory personnel and operators in particular.

Read this manual carefully before installing and running your system and note the safety precautions

in chapter 2 in particular. Store the manual in the immediate vicinity of the instrument, so that it can be

consulted at any time.

No technical modifications may be made to the instrument without the prior written agreement of

BUCHI. Unauthorized modifications may affect the system safety or result in accidents. Technical data

are subject to change without notice.

NOTE

The symbols pertaining to safety are explained in chapter 2.

This manual is copyright. Information from it may not be reproduced, distributed or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of

this manual without prior written agreement is also prohibited.

1 About this manual

The English manual is the original language version and serves as basis for all translations into other

languages. If you need another language version of this manual, you can download other versions at

www.buchi.com or reorder manuals from a BUCHI representative.

Abbreviations

EPDM: Ethylene Propylene Dimonomer

FFKM: Perfluoroelastomers

FPM: Fluoroelastomer

PEEK: Polyetheretherketone

PTFE: Polytetrafluoroethylene

POM: Polyoxymethylene

PFA: Perfluoroalkoxy

6 B-290 Operation Manual, Version I

Page 7

2 Safety

This chapter highlights out the safety concept of the instrument and contains general rules of behavior

and warnings from direct and indirect hazards concerning the use of the product.

For the users safety, all safety instructions and safety messages in the individual sections shall

be strictly observed and followed. Therefore, the manual must always be available to all persons

performing any tasks described herein.

2.1 User qualification

The instrument is designed and built in accordance with state-of-the-art technology. Nevertheless, risks

to users, property, and the environment can arise when the instrument is used carelessly or improperly.

The manufacturer has determined residual dangers emanating from the instrument

• if the instrument is operated by insufficiently trained personnel without supervision.

• if the instrument is not operated according to its proper use.

Appropriate warnings in this manual serve to make the user alert to these residual hazards.

Personnel without this training or persons who are currently being trained require careful instruction.

The present Operation Manual serves as the basis for this.

2 Safety

2.2 Proper use

The Mini Spray Dryer B-290 has been designed and built as laboratory instrument and for batch

production. It serves to spray-dry aqueous solutions or suspensions in one operating process.

In combination with the Inert Loop B-295, it is possible to work with organic solvents in “closed

mode”. Processing in “closed mode” requires N2 or CO2 as an inert gas.

The output particle size of the Mini Spray Dryer B-290 is between 2–25 µm. Thus, the instrument is

suited to generate particles in the inhalable size range from a solution of suspension.

• If the instrument is used with potentially toxic or hazardous substances in ‘open mode’, it has

to be installed inside a closed fume hood or glove box. In such cases, the complete processing

and system handling has to be performed within the ventilated box to avoid toxication and other

hazardous situations to the user and the environment.

• Spray drying of corrosive samples require handling in a closed fume hood. An acid proof system in

open loop is a variant of the Mini Spray Dryer B-290.

• In any case, all exhausts leaving the exhaust gas tubing have to be lead away instantly by a ventilation system, to remove possibly hazardous substances and fumes from the working area. The

ventilation system has to be equipped with safety measures such as outlet filters to avoid contamination of the environmen.

• Operation and handling can require additional personal protective equipment. Operate the instrument with respect to standard laboratory safety rules (i.e. as stated in the latest version of the WHO

“Laboratory biosafety manual”) at all times.

• If the Mini Spray Dryer B-290 is used in combination with other instruments (e.g. Chiller) all related

manuals are to be fully observed.

• Electrostatic charges are to be arrested from both the product collection vessel and the cyclone via

the standard grounding cable if the cyclone is equipped with a grounding socket.

• If the instrument is used for food, pharma and cosmetic products additional cleaning measures

(primary cleaning and in place disinfection) are required (see chapter 5.7).

7 B-290 Operation Manual, Version I

Page 8

2.3 Improper use

Applications not mentioned in section 2.2 are considered to be improper. Also, applications which do

not comply with the technical data (see section 3 of this manual) are considered to be improper. The

operator bears the sole risk for any damages or hazards caused by such improper use.

The following uses are expressly forbidden:

• Use of gases with unknown chemical composition.

• Spray drying of biohazardous materials such as viruses or bacteria.

• Spray drying of organic solvents without safety lamella curtain, Inert Loop B-295 and in open mode.

• Use of the instrument in rooms which require ex-protected instruments.

• Spray drying of substances which might explode or ignite due to the processing and the selected

parameters of the Mini Spray Dryer B-290 or installed sub systems.

• Spray drying of toxic substances.

• Use of samples which might produce oxygen during the processing.

• Unattended use.

2.4 Safety warnings and safety signs used in this manual

2 Safety

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying levels of

hazards and risks related to personal injury and property damage. All signal words, which are related

to personal injury are accompanied by the general safety sign.

For your safety it is important to read and fully understand the table below with the different signal

words and their definitions!

Sign Signal word Definition Risk level

DANGER

WARNING

CAUTION

NOTICE

no

Supplementary safety information symbols may be placed in a rectangular panel on the left to the

signal word and the supplementary text (see example below).

Space for

supplementary

safety

information

symbols.

!

Supplementary text, describing the kind and level of hazard/risk seriousness.

• List of measures to avoid the herein described, hazard or hazardous situation.

• ...

• ...

Indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation which, if not avoided, may

result in minor or moderate injury.

Indicates possible property damage, but no practices

related to personal injury.

SIGNAL WORD

★★★★

★★★☆

★★☆☆

★☆☆☆

(property damage only)

8 B-290 Operation Manual, Version I

Page 9

2 Safety

Table of supplementary safety information symbols

The reference list below incorporates all safety information symbols used in this manual and their

meaning.

Symbol Meaning

General warning

Electrical hazard

Heavy weight, avoid over exertion

Explosive gases, explosive environment

Harmful to life-forms

Hot item, hot surface

Device damage

Inhalation of substances

Chemical burns by corrosives

Fragile components

Wear laboratory coat

9 B-290 Operation Manual, Version I

Page 10

2 Safety

Wear protective goggles

Wear protective mask

Wear protective gloves

Additional user information

Paragraphs starting with NOTE transport helpful information for working with the device/software or its

supplementaries. NOTEs are not related to any kind of hazard or damage (see following example).

NOTE

Useful tips for the easy operation of the instrument/software.

2.5 Product safety

Safety warnings in this manual (as described in section 2.4) serve to make the user alert and to avoid

hazardous situations emanating from residual dangers by giving appropriate counter measures.

However, risks to users, property and the environment can arise when the instrument is damaged,

used carelessly or improperly.

2.5.1 General hazards

The following safety messages show hazards of general kind which may occur when handling the

instrument. The user shall observe all listed counter measures in order to achieve and maintain the

lowest possible level of hazard.

Additional warning messages can be found whenever actions and situations described in this manual

are related to situational hazards.

!

DANGER

Death by suffocation or serious poisoning by inhalation of inert gases.

• Do not inhale inert gases

• Directly withdraw released gases and gaeous substances by sufficient ventilation

• Only operate the instrument in ventilated environments

• Before opertation, check all parts, connections and sealings involved in the gasflow for proper

sealing

• Exchange worn out or defective parts immediately

10 B-290 Operation Manual, Version I

Page 11

2 Safety

!

DANGER

Death or serious poisoning by gases or particles due to O2- sensonr or filter malfunction

• Exchange defective O2-sensor immediately

• Exchange O2-sensor regularly within the specified maintenance intervals

• Exchange clogged filters immediately

• Exchange filters regularly within the specified maintenance intervals

• Dispose of filter immediately

!

DANGER

Death or serious poisoning by inhalation or incorporation of dried particles during spray process.

• Wear safety goggles

• Wear safety gloves

• Wear a suitable protective mask

• Wear a laboratory coat

• Check for proper sealing before use

• Do not inhale dried particles

• Stop drying gas flow before opening the drying circuit

11 B-290 Operation Manual, Version I

Page 12

!

DANGER

Death or serious posioning by inhalation or incorporation of dried particles at recovery.

• Wear safety goggles

• Wear safety gloves

• Wear a suitable protective mask

• Wear a laboratory coat

• Do not inhale dried particles

• Stop drying gas flow before opening the drying circuit

• Only recover particles in sufficiently ventilated flue or glove-box

• Do not disperse the dried particles

• Do not clean dusty parts with compressed air

2 Safety

!

WARNING

Death or serious injuries by use in explosive environments.

• Do not operate the instrument in explosive environments

• Do not operate the instrument with explosive gas mixtures

• Before operation, check all gas connections for correct installation

• Directly withdraw released gases and gaseous substances by sufficient ventilation

12 B-290 Operation Manual, Version I

Page 13

!

WARNING

Death or serious poisoning by contact or incorporation of harmful substances at use.

• Before operation, check the instrument for correct assembling

• Before operation, inspect sealings and tubes for good condition

• Exchange worn out or defective parts immediately

• Exchange clogged filters immediately

• Only operate the instrument in ventilated environments

• Directly withdraw released gases and gaseous substances by sufficient ventilation

• Perform a dry-run without sample material and check for gas leakages

!

CAUTION

Risk of minor poisoning by inhalation of ozone.

• Directly withdraw released gases and gaseous substances by sufficient ventilation

2 Safety

!

CAUTION

Risk of minor or moderate burnings when handling hot parts.

• Do not touch hot parts

• Let the system cool down for some minutes after use

!

NOTICE

Risk of instrument short-circuits and damage by liquids.

• Do not spill liquids over the instrument or its component parts

• Wipe off any liquids instantly

• Place the sample vessel onto the designated reservoir-plate on top of the instrument

• Ensure a safe positioning of the sample vessel

• Do not move the instrument when it is loaded with liquid

• Keep external vibrations away from the instrument

!

NOTICE

Risk of instrument damage by internal overpressure.

• External supply pressure must meet the system specifications

• Exchange clogged filters immediately

• Dispose of filter immediately

13 B-290 Operation Manual, Version I

Page 14

!

NOTICE

Risk of instrument damage by wrong mains supply.

• External mains supply must meet the voltage given on the type plate

• Check for sufficient grounding

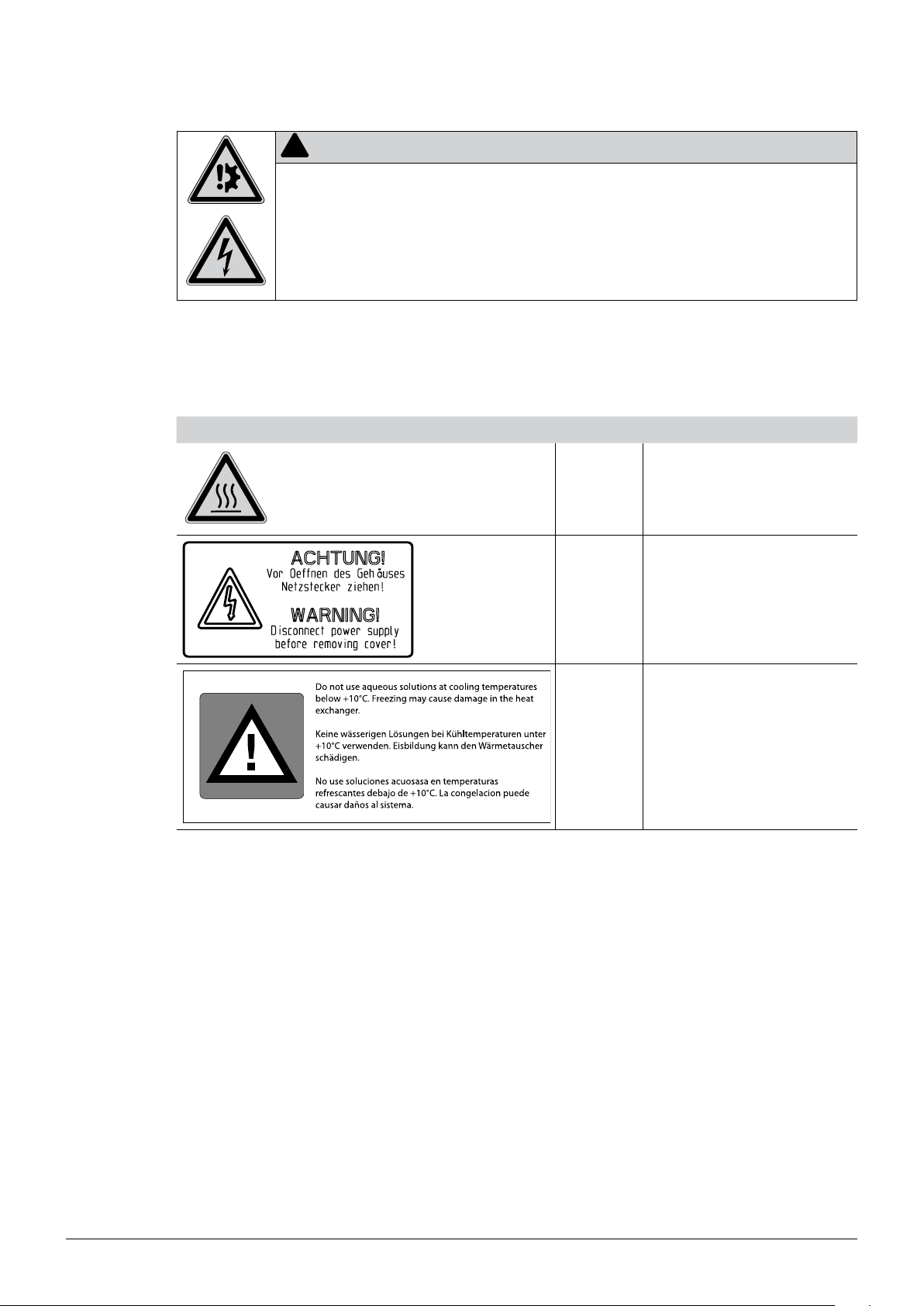

2.5.2 Warning labels on housing and assemblies

The following warning sticker(s) can be found on the housing or assemblies of the Mini Spray Dryer

B-290 and Inert Loop B-295:

Symbol Meaning Location

2 Safety

2.5.3 Personal protective equipment

Always wear personal protective equipment such as protective eye goggles, protective clothing and

gloves. Wear protective mask to protect from inhalation of fine particles. The personal protective

equipment must meet all requirements of all data sheets for the chemicals used. These instructions

are an important part of the instrument and must be made available at all times to the operating

personnel at the place where the equipment is deployed. Additional protective measures can

be necessary according to the applications! The user is fully responsible for choosing adequate

measures!

Do not touch

hot item, hot

surface!

See text Sticker at the rear side, B-290

See text Sticker/label, located on the B-295

Label, located at the spray cylinder,

B-290

14 B-290 Operation Manual, Version I

Page 15

!

WARNING

Serious chemical burns by corrosives.

• Observe all data sheets of the used chemicals

• Handle corrosives in well ventilated environments only

• Always wear protective goggles

• Always wear protective gloves

• Always wear protective clothes

• Do not use damaged glassware

• Wear protective mask when working with inhalable particles

2.5.4 Safety elements and measures

2 Safety

To arrest electrostatic charges from the instrument, it is internally grounded. Electrostatic charges are

to be arrested from both the product collection vessel via the external (yellow) grounding cable for all

cyclones with grounding socket.

Heating

• Excess temperature protection against uncontrolled overheating.

• Automatic temperature control of the heater and inlet temperature.

• Heater can not be started before the closed loop is inert

Spraying (Pump)

• Pump can not be started before the closed loop is inert

Air/Gas

The system can be used in suction mode (standard) or in pressure mode. The suction procedure used

in the Mini Spray Dryer B-290 produces a light negative pressure in the instrument and thus rules out,

together with the inlet filter and outlet filter, a contamination of the environment through leaking from

the instrumen.

Automatic processing interruption when system pressure is too low in closed mode

• Outlet filter to protect the environment contamination of fine dust particles via exhaust gas tubing

N2 inert gas

The Mini Spray Dryer B-290 Advanced can be used to work with organic solvent in combination with

the Inert Loop B-295.

• Inertization against explosive gas mixtures

• oxygen concentration measurement (inside the Inert Loop B-295)

• pressure measurement (inside the Inert Loop B-295)

The heater and the pump stop if the oxygen level is > 6 vol.% or if the pressure level is < 10 mbar.

15 B-290 Operation Manual, Version I

Page 16

Glass

• Use of inert 3.3 borosilicate glass.

• Grounded coating of the inner surface of the cyclone to prevent any electrostatic charge of the

power.

• Screw couplings between glass connections to prevent glass breakage.

Optional system configuration with Inert Loop B-295

• Overpressure leakage detection.

• Safe gas condition (< 6 % O2 content) is detected and enables the regulation of the drying gas

mixture via a communication cable.

2.6 General safety rules

Responsibility of the operator

The head of the laboratory is responsible for training his/her personne.

The operator shall inform the manufacturer without delay of any safety-related incidents which might

occur during operation of the instrument or its accessories. Legal regulations, such as local, state and

federal laws applying to the instrument or its accessories must be strictly followed.

2 Safety

Duty of maintenance and care

The operator is responsible for the proper condition of instrument. This includes maintenance, service

and repair jobs that are performed and on schedule by authorized personnel only.

Spare parts to be used

Use only genuine consumables and spare parts for maintenance to assure good system performance,

reliability and safety. Any modifications of spare parts or assemblies are only allowed with the prior

written permission of the manufacturer.

Modifications

Modifications to the instrument are only permitted after prior consultation and with the written approval

of the manufacturer. Modifications and upgrades shall only be carried out by an authorized BUCHI

technical engineer. The manufacturer will decline any claim resulting from unauthorized modifications.

16 B-290 Operation Manual, Version I

Page 17

3 Technical data

This chapter introduces the reader to the instrument specifications. It contains the scope of delivery,

technical data, requirements and performance data.

3.1 Scope of application and delivery

The Mini Spray Dryer B-290 is available in three different set-ups:

Mini Spray Dryer B-290 Basic

• For aqueous applications with air in ‘open mode’

Mini Spray Dryer B-290 Acid resistant

• For acidic applications with air in ‘open mode’

Mini Spray Dryer B-290 Advanced

• For solvent applications in combination with Inert Loop B-295

• Optional use with Dehumidifier B-296

• Accessories are solvent resistant

3 Technical data

The scope of delivery can only be checked according to the individual delivery note and the listed

order numbers.

NOTE

For additional information on the listed products, see www.buchi.com or contact your local dealer.

3.1.1 Standard instrument

Table 3-1: Standard instrument

Product Order number

Mini Spray Dryer B-290 200 V 44781

Mini Spray Dryer B-290 230 V 44780

Mini Spray Dryer B-290 Advanced 200 V 44700

Mini Spray Dryer B-290 Advanced 230 V 44699

Mini Spray Dryer B-290

Acid resistant 200 V

Mini Spray Dryer B-290

Acid resistant 230 V

11056420

11056421

17 B-290 Operation Manual, Version I

Page 18

3.1.2 Standard accessories

3 Technical data

Table 3-2: Standard accessories

Product Order number

Operation Manual:

German 093000

English 093001

French 093002

Italian 093003

Spanish 093004

Glass assembly complete 044680

Compressed gas tube, 5 m with quick

coupling, complete

046356

Silicone tube for nozzle cooling, 4 m 004139

Silicone tube (per m) 004138

Cleaning brush for nozzle 044782

Polypress tube for gas stream, 3 m 046341

Hose clamps 004236

Spray Dryer Application Support and

910040

Training (1 day training and application

tests)

3.1.3 Standard accessories with the B-290 Advanced

3.1.4 Standard accessories with the B-290 Acid resistant

Table 3-3: Standard accessories with the B-290

Advanced

Product Order number

Lamella safety curtain 044783

Feed switch valve 044725

Spray cylinder, vertical outlet 044697

Nozzle cap, 1.4 mm 044649

Tygon tube MH 2075 transparent (per m) 046314

Tygon tube F 4040 A yellow (per m) 046315

Table 3-4: Standard accessories with the B-290

Acid resistant

Product Order number

Two-fluid nozzle acid resistant 11056320

Glass assembly acid resistant complete 11056386

Spray cylinder holder PFA coated 11056324

Cyclone metall cover PFA coated 11056327

Knurled screws PFA coated 11056325

Flange coupling PFA coated 11056326

Temperature sensor acid resistant 11056329

18 B-290 Operation Manual, Version I

Page 19

3.1.5 Optional accessories

3 Technical data

Table 3-4: Standard accessories with the B-290

Acid resistant (cont.)

Temperature sensor support adapter 11056318

Clamp ring ID 8 mm 11056387

O-ring FPM 8×1 mm 004221

Connecting nipple PFA coated 11056328

Connecting piece PFA coated 11056334

Needle 0.7 mm titanium 11056415

Nozzle tip 0.7 mm titanium 11056317

Table 3-5: Optional accessories

Product Order number

Inert Loop B-295 50 Hz, 200 V 044779

Inert Loop B-295 50 Hz, 230 V 044701

Inert Loop B-295 60 Hz, 200 V 046345

Inert Loop B-295 60 Hz, 230 V 046344

Dehumidifier B-296 50/60 Hz, 230 V 040188

Dehumidifier B-296 50/60 Hz, 200 V 040181

Spray chilling accessory 50/60 Hz, 230 V 040351

Spray chilling accessory 50/60 Hz, 200 V 040352

Brown glass assembly 044758

Two-fluid nozzle, complete 044698

Three-fluid nozzle, complete 046555

Three-fluid nozzle conversion kit 046556

Three-fluid nozzle acid resistant 11056971

Cylinder Insulation 040058

Remote control panel B-290 044702

Outlet filter acid resistant complete 11056333

Outlet filter, complete 044754

Inlet filter 011235

Compressed air maintenance unit 004366

Oil-free compressor, 230 V/50 Hz 027907

Oil-free compressor, 230 V/60 Hz 11055737

IQ/OQ Documentation B-290 11057023

OQ Documentation B-290 11057024

19 B-290 Operation Manual, Version I

Page 20

3.2 Technical data overview

Table 3-6: Technical data Mini Spray Dryer B-290

Power consumption max. 2900 W

Connection voltage 200–230 V ± 10 %

Frequency 50/60 Hz

Environmental conditions

Temperature

Altitude

Humidity

Evaporating capacity 1.0 l/h H2O, higher for organic solvents

Airflow max. of 35 m3/h

Motor control Frequency converter

Max. temperature input 220 °C

Heating capacity 2300 W

Heating control PT-100, fuzzy logic, control accuracy ± 2 °C

Interface Serial port RS-232 for all parameters

Spray gas Compressed air or nitrogen/200–800 l/h, 5–8 bar

Nozzle tip diameter 0.7 mm standard, other sizes 1.4 and 2.0 mm available

Possible particle diameter range 1–25 µm

Mean residence time 1.0–1.5 sec.

Pollution degree 2

Installation category II

Dimensions (W×H×D) 65×110×70 cm

Weight 46 kg

3 Technical data

for indoor use only

5–40 °C

up to 2000 m

maximum relative humidity 80 % for temperatures up to

31 °C decreasing linearly to 50 % relative humidity at 40 °C

Table 3-7: Technical data Spray Chilling accessory

Power consumption max. 400 W

Connection voltage 200–230 V ± 10 %

Frequency 50/60 Hz

Heating control (from B-290) PT-100, fuzzy logic, control accuracy ± 2 °C

Interface Serial port RS-232 for all parameters

Spray gas Compressed air or nitrogen/200–800 l/h, 5–8 bar

Nozzle tip diameter 0.7 mm standard, other sizes 1.4 and 2.0 mm available

Possible particle diameter range 20–200 µm

Mean residence time 1.0–1.5 sec.

Pollution degree 2

Installation category II

Dimensions (W×H×D) 20×20×30 cm

Weight 2.4 kg

Product vessel 87 mm height, 71 mm inner ∅

Batch volume 0.3 liter

20 B-290 Operation Manual, Version I

Page 21

3 Technical data

Table 3-7: Technical data Spray Chilling accessory (cont.)

Heating liquid water or a thermal oil (polyethylene glycol PEG 400 with

low viscosity)

Heating liquid volume 1.4 liter

Max. melting point of sample 70 °C

Table 3-8: Technical data Inert Loop B-295

Power consumption max. 1400 W

Connection voltage 200-230 V ± 10 %

Frequency 50/60 Hz

Min. outlet temperature down to –25 °C

Rate of cooling 800 W at –10 °C

Dimensions (W×H×D) 60×70×84.5 cm

Weight 88 kg

Table 3-9: Technical data Dehumidifier B-296

Power consumption 700 W

Connection voltage 200/230 V ± 10 %

Frequency 50/60 Hz

Min. outlet temperature + 2 °C

Rate of cooling 600 W at 0 °C

Dimensions (W×H×D) 35×40×60 cm

Weight 36 kg

3.3 Materials used

Table 3-10: Materials used

Component Material designation Material code

Glass assembly 3.3 borosilicate glass

Nozzle/heater/connection piece Stainless steel 1.4301/1.4305

Seal of product collection vessel FPM (FFKM)

Seal cyclone/cylinder Silicone

Preheat exchanger Inert Loop B-295 Stainless steel 1.4301

Polypress tube EPDM

Product feed tube Silicone and tygon

Molecular sieve bag of adsorption unit PEEK

Acid resistant coated metal PFA (perfluoroalkoxy polymer)

Acid resistant metal titanium, Alloy 600

Metal parts Mini Spray Dryer B-290 acid

resistant

PFA-coated

21 B-290 Operation Manual, Version I

Page 22

4 Description of function

This chapter explains the basic working principle of the Mini Spray Dryer B-290 Basic (open mode

only) and the Mini Spray Dryer B-290 Advanced (for closed mode operation). It also shows how the

instruments are structured and provides a general functional description of the assemblies.

4.1 Functional principle of the drying gas

The Mini Spray Dryer B-290 operates according to a co-current drying gas (e.g. air in open mode)

and product stream. This means that sprayed product and hot gas have the same flow direction from

downward.

2

1

3

4

5

7

4 Description of function

a Gas inlet (optional with attached inlet filter)

b Electric heater

8

c Concentric inlet of the hot gas around the

spray nozzle

d Spray cylinder

e Cyclone to separate particles from gas

stream

f Product collection vessel

g Outlet filter

h Aspirator to pump gas through system

6

Fig. 4.1: Functional principle of the drying air

4.2 Functional principle of the sample feed and dispersion

The Mini Spray Dryer has a integrated two-fluid nozzle: Compressed gas (normally air or N2) is used to

disperse the liquid body into fine droplets which are subsequently dried in the cylinder.

a Feed solution

4

5

Fig. 4.2: Functional principle of the sample feed and dispersion

6

3

2

1

b Peristaltic pump

c Two fluid nozzle

d Connection for cooling water

e Connection for compressed spray gas

f Automatic nozzle cleaning system

Spraying nozzle

The nozzle consists of the nozzle tip with a 0.7 mm dia meter hole and the nozzle cap

(1.4 or 1.5 mm in diameter). This geometry results in a mixing of fluid body and gas.

22 B-290 Operation Manual, Version I

Page 23

The nozzle cap has an inserted ruby stone with a precise opening and sharp edges to guaran tee a

N

precise and reproducible spray cone.

The smaller nozzle cap of 1.4 mm diameter leads to a lower consumption of spray gas, as the

concentric ring around the nozzle is smaller. This nozzle is recommended when nitrogen is used to

minimize operating costs. The larger nozzle cap opening of 1.5 mm is typically used when air serves

as spraying gas, as this design is more robust regarding concentric alignment to form a vertical and

uniform spray cone.

Optional nozzle sets with 1.4 mm or 2.0 mm nozzle tip diameter are available to increase the droplet

size and/or to spray more viscous samples or dispersions.

4.3 Outlet filter

The outlet filter, consisting of a polyester textile, prevents environmental pollution and the possible

corrosion of the aspirator by very fine particles which cannot be separated in the cyclone. It can be

washed by hand or machine. All needed connections are included.

The second filter included is made of a PTFE membrane. By counter-pulsing the filter with pressurised

air, some of the collected particles can be reco vered resulting in a higher yield (see chapter 6.6.

The manometer indicates the system pressure in front of the filter. With a clean filter, the corresponding

pressure drop is marked.

4 Description of function

4.4 Inert Loop B-295

Mini Spray Dryer B-290

Advanced

2

1

a Feed

b Product

c Exhaust gas

d Solvent

Fig. 4.3: Combined system of the Mini Spray Dryer B-290 and Inert Loop B-295

Inert Loop B-295

5

6

7

2

3

4

e Preheat exchanger

f Condensation

g Cooling unit

The Inert Loop B-295 is an accessory to enable the safe use of organic solvent in a closed loo.

The inert gas is loaded with solvent from the spray drying process. After precooling in a preheat

exchanger, the solvent is condensed in a refrigerator and collected in a closed bottle. The cleaned

gas stream is preheated in the preheat exchanger and flows back to the Mini Spray Dryer B-290

Advanced.

23 B-290 Operation Manual, Version I

Page 24

4.5 Dehumidifier B-296

4 Description of function

Dehumidifier B-296

Mini Spray Dryer B-290

8

7

1

2

3

4

a Ambient air

b Condensation

c Cooling unit

d Condensed water

Fig. 4.4: Open loop Mini Spray Dryer B-290 with Dehumidifier B-296 for inlet air conditioning

5

e Product

f Exhaust gas

g Compressed air as spray gas

h Feed

6

Use as inlet air conditioning

The Dehumidifier B-296 is an accessory to enable a drying under constant and reproducible humidity

conditions cooling to a dew point of 3–5 °C.

The drying air is passing the refrigerator of the Dehumidifier B-296. The humidity in the ambient air

condenses in the refrigerator and is collected in a closed bottle.

The dry air is then heated up by the heater of the Mini Spray Dryer B-29.

Use in the closed mode

The Dehumidifier B-296 is an accessory to enable the safe use of a water-organic solvent mixture in a

closed loop with up to 50 % organic solvents content.

The inert gas is loaded with water-solvent mixture from the spray drying process in an external preheat

exchanger.

The solvent condenses in the Dehumidifier B-296 and is collected in a receiving vessel.

24 B-290 Operation Manual, Version I

Page 25

4.6 Spray chilling accessory

During spray chilling a hot melt is dispersed into a cold gas stream. The droplets are solidified into

particles and are separated. The matrix substance and the active ingredients are heated above the

melting point. Highest melting point is 70 °C. The nozzle is also heated to prevent any blocking. No

additional thermostat is required, as the existing heating control and peristaltic pump in the instrument

are used. If the sample has a low melting point, then the inlet air is cooled to increase the temperature

gradient. If lower temperatures than 10 °C (provided by the B-296) are used, e.g. for hard fats, the

inlet air can be cooled to –5 °C by using a specially developed refrigeration unit (please contact your

local distributor.

1

4

4 Description of function

a Temperature sensor

b Circulating heating liquid to bath – nozzle –

peristaltic pump – bath

c Cold gas

d Heated feed sample

e Droplets spray

2

3

5

Fig. 4.5: Functional principle of the sample feed and dispersion

4.7 Connected accessories to the Mini Spray Dryer B-290

a Serial port RS-232 for data output to a PC

b Connection for the remote control panel

c Connection for Inert Loop B-295

1

Fig. 4.6: Rear connections of the Mini Spray Dryer B-290

2

3 4

d Connection for feed switch valve

25 B-290 Operation Manual, Version I

Page 26

4.7.1 Feed switch valve and remote control panel

Fig. 4.7: Feed switch valve and remote control panel

The remote control panel enables an easy operation even within a closed fume hood. The flow meter

for the spraying gas is the only parameter which cannot be adjusted via the remote control panel.

The feed switch valve is a useful tool together with the remote control panel. During the start and end

of the spray process, the feeding tube has to be moved from pure solvent to product solution and

vice versa. This can be automated by means of the feed switch valve. A Y-piece is inserted between

peristaltic pump and feed switch valve.

4 Description of function

4.7.2 Printer or PC for data output via RS-232 serial port

The Mini Spray Dryer B-290 is supplied with a standard protocol for data readout. This is of special

importance if the system is qualified and underlies special regulations.

The connection starts as soon as the heater is switched on.

The transmission rate is 2400 Baud/s, Parity: No.

The parameters are sent out every 30 seconds as an ASCII-Code, separated by a TAB (ASCII 09)

and ended with a RETURN (ASCII 0D). They can be read out e.g. via the program “HyperTerminal”

included in the Microsoft package.

The source is defined as follows:

No. Information Type Unit

1 Time since mains on integer s

2 Current temperature inlet integer °C

3 Current temperature outlet integer °C

4 Heater on/off 0/1

5 Set temperature inlet integer °C

6 Aspirator on/off 0/1

7 Aspirator rotation speed integer %

8 Pump on/off 0/1

9 Pump rotation speed integer %

10 Feed switch valve 1/2

11 Connection Inert Loop B-295 no/yes 0/1

12 Oxygen high 0/1

13 Pressure low 0/1

14 Error message integer

26 B-290 Operation Manual, Version I

Page 27

5 Putting into operation

This chapter describes how the instrument is installed and gives instructions on initial startup.

NOTE

Inspect the instrument for damages during unpacking. If necessary, prepare a status report immediately to inform the postal company, railway company or transportation company.

Keep the original packaging for future transportation.

5.1 Installation site

Put the instrument on a stable, horizontal surface. Consider the maximum product dimensions and

weight and the operation height of 1.30 meters for spray chilling applications. Make sure that you can

comfortably reach the instrument.

Installation on a mobile trolley is also possible. Obtain the environmental conditions as described in

section 3.2, technical data.

5 Putting into operation

Put the instrument on a stable, horizontal base.

!

Death or serious injuries by use in explosive environments.

• Do not operate the instrument in explosive environments

• Do not operate the instrument with explosive gas mixtures without inertization

• Before operation, check all gas connections for correct installation

• Directly withdraw released gases and gaseous substances by sufficient ventilation

!

Risk of minor or moderate injury by heavy weight of the instrument.

• Consult a second person to transport the instrument

• Do not tilt or drop the instrument

• Place the instrument on a stable, even and vibration-free surface

• Keep limbs out of crushing zone

• Lift the device at the right and left bottom reaching areas for the hands

5.2 Electrical connections

The Mini Spray Dryer B-290 is aimed to be installed mobile and is and is shipped with a flexible power

cord. After the installation, an electrical safety test is recommended to verify a safe system condition

such as sufficient grounding.

Warning

Caution

Risk of instrument damage by wrong mains supply.

• External mains supply must meet the voltage given on the type plate

• Check for sufficient grounding

27 B-290 Operation Manual, Version I

NOTICE

Page 28

5 Putting into operation

NOTE

To cut the power in case of an emergency by unplugging, the instruments or any other items

must not block the mains plug! External connections and extension lines must be provided with a

grounded conductor lead (3-pole couplings, cord or plug equipment). All used power cords must

meet the input power requirements.

Demands on the mains circuit

The mains circuit must

• provide the voltage that is given on the type plate of the instrument.

• be able to handle the load of the connected instrument(s).

• be equipped with adequat fusage and electrical safety measures, in particular proper grounding.

NOTE

Additional electrical safety measures such as residual current breakers may be necessary to meet

local laws and regulation!

External power switches (e.g. emergency stop switches) must meet IEC 60947-1 and IEC 60947-3

requirements. Such devices must be clearly labeled and accessible at any tim.

5.3 Installing the compressed air maintenance unit and compressor (optional)

To ensure the Mini Spray Dryer B-290 achieves an optimal atomization performance, the supply of

compressed air with a pressure of 5–8 bar is necessary. The compressed air must be dried and free of

impurities (contamination of the product through impure air). If this is not guaranteed, we recommend

the use of a WILKERSON maintenance unit.

Risk of instrument damage by internal overpressure.

• External supply pressure must meet the system specifications

• Exchange clogged or defective filters immediately

• Dispose of clogged or defective filter immediately

1

Notice

2

a Activated charcoal filter

b Filter

c Water separator

3

Fig. 5.1: Compressed air maintenance unit

If there is no compressed air plant available, the compressed air can be taken from an oil-free air

compressor with an output of 5– 8 bar as require.

28 B-290 Operation Manual, Version I

Page 29

5.4 Installing the glass assembly

!

CAUTION

Risk of minor or moderate cuts by sharp edges.

• Do not touch defective or broken glassware with bare hands

• Do not touch thin metal edges

To install the spray cylinder, proceed as follows:

5 Putting into operation

1

2

3

8

7

6

5

4

9

10

11

6

4

• Screw the seal holder b on the instrument

using the three knurled screws.

• Connect the separation flask d to the spray

cylinder c by closing the screw connection

(SVL 42) tightly.

• Screw the connection piece f on the cylinder

outlet flange with the left flange screw joint g.

The connection is sealed with a Viton o-ring.

• To mount the cylinder on the instrument,

hold the glass in the upper flange around the

nozzle and insert the connection piece into

the support element h.

• Open the fixation e.

• Press the glass flange on the above seal.

• Push the lever a carefully on the left side, so

that the flange of the cylinder is held firmly.

• Close the fixation e.

• Attach the cyclone k together with the

product collection vessel n to the connection

piece f with a second flange screw joint j.

• Screw the glass elbow i onto the top of the

cyclone.

• Connect the grounding cable l to the cover

of the product collection vessel m and to the

housing to minimize the electrostatic charge

of the powder.

12

13

14

29 B-290 Operation Manual, Version I

Page 30

5 Putting into operation

• Connect the outlet temperature sensor o to

the plug in the housing.

• Insert the outlet temperature sensor into the

connection piece f and screw it in. A metallic

ring and O-ring is inserted to seal the probe.

• Close all connections tightly.

15

6

Fig. 5.2: Installing the glass assembly

5.5 Installing the spraying nozzle

4

3

2

Fig. 5.3: Installing the spraying nozzle

3

5

• Insert the nozzle into the heater element at

the top of the instrument.

• The two fluid spraying nozzle has a connec-

tion for the feeding tube a, a connection for

the pressurized air or nitrogen b and two

connections c for an optional cooling/heating

1

with an external thermostat. The top connection d is for the implemented pneumatic

nozzle cleaning: a needle pushes through the

nozzle and prevents clogging.

The three fluid nozzle has a second feed supply

3

e instead of the nozzle cleaning.

The three fluid nozzle has two connections for

two feeding tubes. An external peristaltic pump

has to be mounted for the second feed supply.

12

Fig. 5.4: Installing the spraying nozzle

30 B-290 Operation Manual, Version I

Page 31

5.6 Installing the filters

5 Putting into operation

5.6.1 Inlet filter installation

Use

Pre-filtering of environmental air to keep most impurities and particles away from the spray drying

process.

Risk of instrument damage by internal overpressure.

• External supply pressure must meet the system specifications

• Exchange clogged or defective filters immediately

• Dispose of clogged or defective filters immediately

Notice

Fig. 5.5: Installing the inlet filter

To install the inlet filter directly connect it to the air inlet of the heater.

5.6.2 Outlet filter installation

Fig. 5.6: Installing the outlet filter

• Screw the support angle to the bottom side of the panel.

• Mount the filter directly.

• Install the connecting tubing between cyclone and filter with an SVL 42.

31 B-290 Operation Manual, Version I

Page 32

5 Putting into operation

• Unscrew all screw caps of the tubing at the filter head a and unhook the complete filter from the

holder.

• Unscrew the screw cap b and pull off the filter housing glass. Remove the sealing ring.

a

b

c

d

filter housing glass

Fig. 5.7: Outlet filter installation

• Unscrew the hose clamp c and pull off the filter cartridge.

• Remove the hose clamp d from the filter cartridge.

➡ Wash the polyester filter manually or in a laboratory washing machine. Use standard soap deter-

gents for cleaning.

For installation proceed in reverse order. Mind the correct mounting direction of the sealing ring (order

no. 040471) at the filter housing glass!

NOTE

The flange screw coupling made of aluminum (order no. 048539) is recommended for the use of

outlet temperatures higher than 80 °C for better sealing performance compared to the polymer

(POM) flange (order no. 034139).

filter cartridge

32 B-290 Operation Manual, Version I

Page 33

5.6.3 PTFE filter membrane installation

b

c

a

filter tube

5 Putting into operation

Fig. 5.8: Outlet fi lter membrane (PTFE) installation

• Pull out the end-cap a of the filter membrane.

• Unscrew the hose clamp b and pull off the filter membrane.

• Remove the hose clamp c from the filter tube.

➡ Gently flush the PTFE filter membrane manually only. Use standard soap detergents for cleaning.

It is recommended to exchange the filter membrane regularly.

For installation proceed in reverse order.

Wrap the end of the filter tube into the filter carrier and push in the end-cap (see Fig. 5.7).

33 B-290 Operation Manual, Version I

Page 34

5 Putting into operation

NOTE

Make sure the end-cap properly seals the filter carrier and the filter membrane! This is essential for

effective filtering.

Fig. 5.9: Installing the end-cap to seal the filter tube

Mind the correct mounting direction of the sealing ring (order no. 040471) at the filter housing glass!

NOTE

The flange screw coupling made of aluminum (order no. 048539) is recommended for the use of

outlet temperatures higher than 80 °C for better sealing performance compared to the polymer

(POM) flange (order no. 034139).

5.6.4 Cleaning filter installation

Use

• When connected to the air inlet at the heater the filter works as an inlet cleaning filter to remove

even finest particles from the drying air.

• When connected to the process air outlet tube the filter works as a safety element to hold back

finest product residues from the environmental air.

Fig. 5.10: Housing with filter cartridge

Installation as inlet cleaning filter

Install the filter between the heater air inlet and the inlet filter. The filter cascade will ensure maximal

particle free air in standard environment.

34 B-290 Operation Manual, Version I

Page 35

5 Putting into operation

Installation as safety outlet filter

Install the filter between the outlet filter and the Aspirator. This will hold back finest particles from the

Aspirator and the environment e.g. the laboratory air.

Fig. 5.11: Cleaning filter installed with stop cock

5.7 Adjusting the peristaltic pump bed and choosing the feeding tube

The pump bed of the peristaltic pump is adjusted ex works to the standard silicone tube.

If different tubes, e.g. the tygon tubes for organic solvents, are used, adjust the pump bed with an

allen key. Connect an adapter piece as a tube stopper between two feeding tubes to prevent slipping

in the peristaltic pump.

Adjusting the peristaltic pump bed

Risk of instrument short-circuits and damage by liquids.

• Do not spill liquids over the instrument or its component parts

• Wipe off any liquids instantly

• Place the sample vessel onto the designated reservoir-plate on top of the instrument

• Ensure a safe positioning of the sample vessel

• Do not move the instrument when it is loaded with liquid

• Keep external vibrations away from the instrument

Notice

35 B-290 Operation Manual, Version I

Page 36

5 Putting into operation

a Tube to spraying nozzle

b Handle, pump bed

c Distilled water

d Flow meter valve

e Adjusting screw, pump bed

Fig. 5.12: Pump bed adjustment

1. Remove spraying nozzle from the Mini Sprayer B-290 and hold spraying nozzle into a suitable

container.

2. Insert tube a in to the pump bed.

3. Put tube on the suction side into distilled water c.

4. Close pump bed with handle b.

5. Unscrew adjusting screw e 1 turn.

6. Open the flow meter valve d to 40 mm.

NOTE

Distilled water c is now flowing through the tubing without the feeding pump running.

7. Turn the adjusting screw e in until the water flow stops.

8. Turn adjusting screw ¼ further in.

9. Close flow meter valve to 0 mm.

10. Install spraying nozzle back into the Mini Sprayer B-290.

Choose the feeding tube according to the following table. For short processes, even unsuitable tubes

can be used, as swelling takes some time.

Table 5-1: Choosing the feeding tube

Solvent Silicone tube Tygon MH 2075 Tygon F 4040 A

Methanol suitable suitable suitable

Ethanol suitable suitable suitable

Acetone unsuitable suitable unsuitable

Toluoene unsuitable unsuitable unsuitable

Isopropanol suitable suitable suitable

Chloroform unsuitable unsuitable unsuitable

Dichloro methane unsuitable unsuitable unsuitable

THF unsuitable unsuitable unsuitable

Ethylacetate unsuitable suitable unsuitable

Hexane unsuitable unsuitable suitable

36 B-290 Operation Manual, Version I

Page 37

5.8 Tubing installation

The Mini Spray Dryer B-290 needs compressed gas for the two-fluid nozzle and the nozzle cleaner

between 5 and 8 bar. Therefore, the air or nitrogen is connected on the rear of the instrument via a

quick coupling.

Fig. 5.13: Quick coupling rear side

The Mini Spray Dryer B-290 can be used in an open or closed mode. The open mode is set in the

suction mode as a standard. However, if the exhaust gas is aggressive and could lead to a cor ro sion

of the aspirator, the instrument can also be run in a pressure mode. This mode leads to a higher noise

emission.

5 Putting into operation

NOTE

Risk of instrument malfunction when the instrument is operated with bent hoses.

• Always inspect the instrument for bends or kinks in hoses and eliminate them prior to operation.

• Exchange hoses with signs of mechanical stress such as small cracks and blind spots at the

surface immediately.

1

2

a Tubing between cyclone respectively filter and

aspirator

b Exhaust tube

Fig. 5.14: Open mode set-up in suction mode

37 B-290 Operation Manual, Version I

Page 38

5 Putting into operation

a Exhaust tube of cyclone or filter, respectively

b Tubing between aspirator and heater

2

1

Fig. 5.15: Open mode set-up in pressure mode

5.9 Installing the compressor

Use

For the spray process compressed air or gas is necessary. If no compressed air supply is available in

the laboratory the compressor can be installed instead.

Installation

• Place it in a dry, dust free and well tempered room with appropriate ventilation.

• Follow the compressors manual to install the device.

• Connect the outlet of the compressor to the compressed air inlet of the Mini Spry Dryer B-290.

Fig. 5.16: Oil- and dust-free air compressor

NOTE

Set the compressor to 6 bar output pressure to achieve recommended standard spray conditions.

38 B-290 Operation Manual, Version I

Page 39

5.10 Quick hose couplings

Use

For fast and reliable connecting/disconnecting of polypress tubes e.g. the tubing of Inert Loop B-295

and Dehumidifier B-296.

Installation

• Cut the polypress tube with a sharp knife or a special tube cutter into two halfs with a clean cut.

The tube ends must be straight!

• Slip one hose clamp over each tube end.

• Use one male and one female coupling adapter and install them at the tube ends.

• Secure the coupling adapters with the hose clamps.

• Test all tubes and connectors for tightness prior use!

Male coupling

5 Putting into operation

Female coupling (including a flat seal)

Fig. 5.17: Quick hose couplings

5.11 Installing the Inert Loop B-295

!

Danger

Death or serious poisoning by gases or particles due to O2– sensor or filter malfunction

• Exchange defective O2– sensor immediately

• Exchange O2– sensor regularly within the specified maintenance intervals

• Exchange clogged filters immediately

• Exchange filters regularly within the specified maintenance intervals

• Dispose of clogged or defective filters immediately

39 B-290 Operation Manual, Version I

Page 40

5 Putting into operation

!

Warning

Death or serious poisoning by contact or incorporation of harmful substances at use.

• Before operation, check the instrument for correct assembling

• Before operation, inspect sealings and tubes for good condition

• Exchange worn out or defective parts immediately

• Exchange clogged filters immediately

• Only operate the instrument in ventilated environments

• Directly withdraw released gases and gaseous substances by sufficient ventilatio.

• Perform a dry-run without sample material and check for gas leakages

The Inert Loop B-295 has wheels and can be placed

next to the Mini Spray Dryer B-290. Moreover it can be

used as a trolley if the instrument has been purchased in

2011 or later.

Connect the system to the mains supply with the power

cord.

Connect the two instruments with the communication cable to ensure their safe operation. The tubing is

described below.

Fig. 5.18: Inert Loop B-295

Fig. 5.19: Mini Spray Dryer B-290 Advanced with Inert Loop B-295 as trolley

40 B-290 Operation Manual, Version I

Page 41

5 Putting into operation

The Inert Loop B-295 has a sideward hose connection

for the exhaust gas. Due to the constant feeding with

nitrogen, a certain amount of it is permanently leaving

the system through this outlet tube. If air is sucked in

through the tube, this is an indication that the closed

loop is not tight.

a Tubing between outlet filter and aspirator inlet

b Nitrogen inlet

c Tubing between heater inlet and B-295 outlet

d Tubing between aspirator outlet and B-295 inlet

e Exhaust gas (nitrogen) outlet tube

1

3

Fig. 5.20: Tubing installation for closed mode operation with Mini Spray Dryer B-290 Advanced and Inert Loop B-295

5

41 B-290 Operation Manual, Version I

Page 42

5.12 Dehumidifier B-296 and Inert Loop B-295 combination

a Mini Spray Dryer B-290 outlet tube

b Dehumidifier B-296 outlet tube

c Inert Loop B-295 outlet tube

5 Putting into operation

Fig. 5.21: Tube connections B-290, B-296 and B-295

• Connect the Mini Spray Dryer B-290 outlet tube a with the inlet of the Dehumidifier B-296

• Connect the Dehumidifier B-296 outlet tube b to the Inert Loop B-295 inlet.

• Connect the outlet c of the Inert Loop B-295 to the Mini Spray Dryer B-290.

5.13 Installing the Dehumidifier B-296

NOTE

Disconnect the display from the front side and insert a LR 44 battery in the display.

Fig. 5.22: Installation of the display

42 B-290 Operation Manual, Version I

Page 43

5 Putting into operation

Used as inlet air conditioning system

Installation steps:

1. Place the Dehumidifier B-296 next to the Mini Spray Dryer B-290.

2. Connect the tubing a from the outlet (labelled on the enclosure) of the Dehumidifier B-296 to the

gas inlet of the Mini Spray Dryer B-290 heater.

3. Use hose clamps to fix the tubing.

4. Connect the power cord to the mains. The device can now be switched on.

a Dehumidifier B-296 outlet tube

Fig. 5.23: Tubing between the Mini Spray Dryer B-290 and the Dehumidifier B-296

Used in the closed mode

When mixtures of organic solvents and water (with less than 50 % solvents) are being processed in

‘closed loop’ configuration, the use of the Dehumidifier B-296 is highly recommended. The cooling

temperature is fixed to 0 °C.

a Inlet tubing B-296

b Outlet tubing B-296

Fig. 5.24: Tubing between the preheat exchanger and the Mini Spray Dryer B-290

Installation steps:

1. Place the Dehumidifier B-296 next to the Mini Spray Dryer B-290.

2. Connect the tubing b from the outlet (labelled on the enclosure) of the Dehumidifier B-296 to the

gas inlet of the Mini Spray Dryer B-290.

3. Connect the tubing a from the Mini Spray Dryer B-290 outlet to the inlet of the Dehumidifier

B-296 (labelled on the enclosure).

4. Use hose clamps to fix all Polypress tubings.

5. Connect the power cord to the mains. The device can now be switched on.

43 B-290 Operation Manual, Version I

Page 44

NOTE

See section 7.6 for information about the cleaning procedure of the Dehumidifier B-296.

5.14 Installing the Spray Chilling Accessory

2

1

6

a Product feed vessel

b Heating bath

c Heater

Fig. 5.25: Spray Chilling Accessory

3

4

5

5 Putting into operation

• Mount the complete bath b on the top of the

Mini Spray Dryer B-290.

• Use the knurled screws to fix the spray chilling

accessory on the Mini Spray Dryer B-290

cover panel. Plug in the heater c of the spray

chilling accessory instead of the standard

heater of the Mini Spray Dryer B-290.

• Connect the long temperature sensor d

instead of the standard outlet temperature

sensor to the electrical plug and put the

temperature sensor into the holder on top of

the heating bath.

d Temperature sensor

e Capillary inlet

f Capillary outlet

NOTE

The nozzle tip 1.4 mm with nozzle cap 2.0 mm are recommended to increase the droplet size and if

clogging occurs with the standard 0.7 mm nozzle. The resulting particle size is typically in the order

of the droplet size.

Open suction mode installation with the Dehumidifier B-296 to pre-cool the inlet air is recommended.

A slight negative pressure in the spray chamber forces the melted sample feed to enter the nozzle

after opening the feed valve.

1

3

4

7

2

5

4

4

7

8

5

4

10

9

4

4

11

44 B-290 Operation Manual, Version I

Page 45

5 Putting into operation

1

2

5

3

4

4

• Apply the tubes b to h according to the

above figures. For the tubes d and e, apply

cable binders to fixate them at their connection.

• Install the spray gas tube to the capillary inlet

connector on top of the heating bath.

• Connect the gas flow tube from the capillary

outlet to the nozzle inlet (gas).

• The feeding tube is connectable in two ways

1

6

depending on whether the nozzle cleaning

option is required or not.

• The heating liquid tubes are connected from

7

the bath to the nozzle port (C in) and from

the nozzle port (C out) throught the pump

back to the bath.

• This way, the nozzle is also heated to prevent

any solidification and blocking.

• Adjust the peristaltic pump bed to the 6 mm

silicone tube.

a Needle valve for dosage

b Feeding tube with nozzle cleaning option: Needle

valve - nozzle (feed)

c Cleaning gas nozzle: Instrument - nozzle (top)

d Heating liquid tube: Bath - nozzle (C in) -

nozzle (C out) - peristaltic pump - bath

e Drain tube for heating liquid

Fig. 5.26: Installing the spray chilling tubing with (left) or without nozzle cleaning option (right)

f Gas flow tube: Instrument - capillary inlet

g Gas flow tube: Capillary outlet - nozzle (gas)

h Feeding tube without nozzle cleaning option

i Nozzle cleaning unit

j Screw connection for feeding tube

k Closed feed connection

5

4

4

5.15 Installation check

Carry out an installation check after a successful installation and prior to the first spray drying

process.

• Inspect the glass visually for possible damage.

• Check the electrical connections.

• Make sure that the cover of the product collection vessel is connected to the instrument by means

of the cable for arresting electrostatic charges.

• Make sure that the outlet temperature probe is inserted in the coupling.

45 B-290 Operation Manual, Version I

Page 46

5 Putting into operation

5.16 Additional cleaning measures for food, pharma and cosmetic applications

For food, pharma and cosmetic products additional measures are required during the whole spray

drying process to establish the necessary hygienic level. Any risk of infection, diseases or contagion

must be excluded!

To disinfect the Mini Spray Dryer B-290 in place the glass does not have to be sterilized separately.

The device must not be opened before the experiment after the SIP (Sterilization In Place)

process.

NOTE

It is highly recommended to use a new set of tubes and filters to further reduce the risk of contamination between two spray drying processes. The filters must either be decontaminated and sterile or

disinfected prior to use.

5.16.1 Primary cleaning

All glass parts can be manually rinsed with a disinfection medium (e.g. ethanol) under hygienic conditions. Primary cleaning can be done mechanically e.g. by means of a disinfected brush. However, the

primary cleaning must effectively remove all residua of previous operations!

Because of the bandwith of possible materials to be processed with the Mini Spray Dryer B-290 it

is not possible to recommend a general purpose detergent. Contact your local hygienic specialist or

BUCHI representative for a suitable detergent for your specific application! NOTE the material list in

section 3.3.

Clean all used hoses with isopropanol 70 % and keep them at 110 °C for 30 minutes.

Sealings in contact with the product can be cleaned and disinfected in an ultrasonic bath with a corresponding disinfection medium. At reinstallation, mind hygienic handling!

NOTE

Do not bring the seals in contact with lubricants or other harmful substances!

After cleaning, the system must be assembled to run the in place disinfection process.

46 B-290 Operation Manual, Version I

Page 47

6 Operation

This chapter gives examples of typical instrument applications and instructions on how to operate the

instrument properly and safely.

6 Operation

!

Danger

Death or serious poisoning by inhalation or incorporation of dried particles during spray process.

• Wear safety goggles

• Wear safety gloves

• Wear a suitable protective mask

• Wear a laboratory coat

• Check for proper sealing before use

• Do not inhale dried particles

• Stop drying gas flow before opening the drying circuit

!

Warning

Death or serious poisoning by contact or incorporation of harmful substances at use.

• Before operation, check the instrument for correct assembling

• Before operation, inspect sealings and tubes for good condition

• Exchange worn out or defective parts immediately

• Exchange clogged filters immediately

• Only operate the instrument in ventilated environments

• Directly withdraw released gases and gaseous substances by sufficient ventilation

• Perform a dry-run without sample material and check for gas leakages

47 B-290 Operation Manual, Version I

Page 48

6.1 Layout of the operating and display elements

a Main switch

b Flow meter for spraying gas volume

c Needle valve for gas flow adjustment

1

2

3

Fig. 6.1: Switch, flow meter and valve

6 Operation

1

a LED display current value inlet air temperature

b LED display current value outlet air temperature

c LED display set value inlet air temperature

d LED display aspirator output in % of max. aspirator rate

e LED display pump output in % of max. pump rate

f LED display for nozzle cleaning

g Feed switch valve button

Fig. 6.2: Operating and display elements

2

3

4

5

6

14

15

12

13

h Nozzle cleaner interval adjustment

i Manual operation pneumatic nozzle cleaner

j Regulating push-button pump

k Main switch pump

l Regulating push-button aspirator

m Main switch aspirator

n Regulating push-button heating

o Main switch heating

10

11

8

7

9

48 B-290 Operation Manual, Version I

Page 49

6.2 Conversion tables for the parameters

6.2.1 Flow meter spraying air (rotameter)

The rotameter is an indicator for the spray gas flow. The table gives a correlation between indicated

height and volume throughput. The nozzle has a certain pressure drop which increases with higher

gas flow. As the gas volume strongly corresponds to the actual pressure, the table also contains a row

for the effective volume flow, determined in a spray process with air.

Height (mm) Liters/hour Pressure drop (bar) Actual volume flow (at standard

5 84

10 138

15 192

20 246 0.15 283

25 301 0.18 355

30 357 0.23 439

35 414 0.3 538

40 473 0.41 667

45 536 0.55 831

50 601 0.75 1052

55 670 1.05 1374

60 742 1.35 1744

65 819 1.8 2293

6 Operation

temperature and pressure)

in liters/hour

6.2.2 Peristaltic pump

Fig. 6.3: Pump settings versus throughput

The peristaltic pump can be adjusted to different tubes according to the inner and outer

diameters. With different tube diameters, the

absolute flow is varying. The diagram shows

the correlation for the standard silicone tube

(2 mm ID, 4 mm OD) for water.

49 B-290 Operation Manual, Version I

Page 50

6.2.3 Aspirator

Fig. 6.4: Aspirator settings versus throughput

6.3 Spray process

During the spray process some parts i.e. all glassparts can get hot according to the

temperature settings of the instrument!

6 Operation

The aspirator has a maximum gas flow rate

of approx. 35 m3/h. The flow depends on the

pressure drop of the overall system.

To determine the exact volume flow for steady

and re pro du cible operating conditions, a

measurement tube is supplied as an accessory. A handheld gas flow meter (hot-wire flow

meter) is required for the mea surement.

Caution

!

Risk of minor or moderate burnings when handling hot parts.