Page 1

Type 8695

Control Head

Steuerkopf

Tête de commande

Operating Instructions

Bedienungsanleitung

Manuel d‘ utilisation

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2008 - 2013 Bürkert Werke GmbH

Operating Instructions 1312/05_EU-ML_00805569 / Original DE

Page 3

Type 8695

Control head Type 8695

Table of ConTenTs

1 OPERATING INSTRUCTIONS ........................................................................................................................................................7

1.1 Symbols ......................................................................................................................................................................................7

1.2 Definition of term / abbreviation ...................................................................................................................................7

2 AUTHORIZED USE .............................................................................................................................................................................8

2.1 Restrictions ...............................................................................................................................................................................8

3 BASIC SAFETY INSTRUCTIONS .................................................................................................................................................9

4 GENERAL INFORMATION .............................................................................................................................................................10

4.1 Contact address ..................................................................................................................................................................10

4.2 Warranty ...................................................................................................................................................................................10

4.3 Trademarks ............................................................................................................................................................................10

4.4 Information on the internet ............................................................................................................................................10

5 SYSTEM DESCRIPTION ................................................................................................................................................................11

5.1 Structure and function .....................................................................................................................................................11

5.1.1 Control head for integrated installation on 21xx series (Element) ..........................................11

5.1.2 Model for control of process valves belonging to the 20xx series (Classic) ........................12

6 TECHNICAL DATA .............................................................................................................................................................................13

6.1 Conformity ..............................................................................................................................................................................13

6.2 Standards ................................................................................................................................................................................13

6.3 Operating conditions ........................................................................................................................................................13

6.4 Mechanical data ...................................................................................................................................................................13

6.5 Type label ...............................................................................................................................................................................14

6.6 Pneumatic data ....................................................................................................................................................................14

6.7 Electrical data .......................................................................................................................................................................15

6.7.1 Electrical data without bus control 24 V DC ...............................................................................15

6.7.2 Electrical data with AS-Interface bus control ..............................................................................15

6.7.3 Electrical data with DeviceNet bus control ..................................................................................15

english

3

Page 4

Type 8695

Inhaltsverzeichnis

7 INSTALLATION ...................................................................................................................................................................................16

7.1 Safety instructions .............................................................................................................................................................16

7.2 Installation of the control head Type 8695 on process valves of series 21xx (Element) ............16

7.3 Installation of the control head Type 8695 on process valves of series 20xx (Classic) ..............21

7.4 Rotating the actuator module on process valves of series 2100, 2101, 2000 and 2012 .............25

7.5 Rotating the control head for process valves belonging to series 20xx ..............................................27

8 PNEUMATIC INSTALLATION .......................................................................................................................................................28

9 ELECTRICAL INSTALLATION 24 V DC ...................................................................................................................................30

9.1 Safety instructions .............................................................................................................................................................30

9.2 Electrical installation .........................................................................................................................................................31

9.3 Teach function (calibrating the end position) ......................................................................................................32

9.4 Display and control elements 24 V DC ...................................................................................................................34

9.4.1 Status LED yellow ..............................................................................................................................34

9.4.2 Valve LED yellow ................................................................................................................................34

9.4.3 End position LED green and yellow ...............................................................................................35

9.4.4 Jumper function ...................................................................................................................................35

9.4.5 Change assignment of the end position LEDs ............................................................................35

10 AS-INTERFACE INSTALLATION ................................................................................................................................................37

10.1 AS-Interface connection .................................................................................................................................................37

10.2 Technical data for AS-Interface PCBs .....................................................................................................................37

10.3 Programming data ..............................................................................................................................................................37

10.4 Electrical installation AS-Interface ............................................................................................................................38

10.4.1 Safety instructions ..............................................................................................................................38

10.4.2 Connection with circular plug-in connector M12 x 1, 4-pole, male .......................................38

10.4.3 Connection with multi-pole cable and ribbon cable terminal ...................................................39

10.5 Teach function (calibrating the end position) ......................................................................................................40

10.6 Display and control elements AS-Interface ..........................................................................................................42

10.6.1 Status LED yellow ..............................................................................................................................43

10.6.2 Valve LED yellow ................................................................................................................................43

10.6.3 Bus LED red and green ....................................................................................................................43

4

english

Page 5

Type 8695

10.6.4 End position LEDs..............................................................................................................................44

10.6.5 Jumper function ...................................................................................................................................44

10.6.6 Change assignment of the end position LEDs ............................................................................45

11 DEVICENET INSTALLATION ........................................................................................................................................................46

11.1 Definition .................................................................................................................................................................................46

11.2 Technical data .......................................................................................................................................................................46

11.3 Maximum line lengths ......................................................................................................................................................46

11.3.1 Total line length according to DeviceNet specification .............................................................46

11.3.2 Drop line length...................................................................................................................................47

11.4 Safety setting if the bus fails ........................................................................................................................................47

11.5 Interfaces ................................................................................................................................................................................47

11.6 Electrical connection DeviceNet .................................................................................................................................47

11.6.1 Safety instructions ..............................................................................................................................47

11.6.2 Display and control elements DeviceNet ...................................................................................... 48

11.6.3 Bus connection (circular connector M12 x 1, 5-pole, male) ....................................................48

11.7 Terminating circuit for DeviceNet systems ...........................................................................................................48

11.8 Network topology of a DeviceNet system .............................................................................................................49

11.9 Configuring the control head .......................................................................................................................................49

11.9.1 DIP switches ........................................................................................................................................49

11.10 Configuration of the process data .............................................................................................................................51

11.11 Configuration of the safety position of pilot valves for bus error .............................................................52

11.12 Teach function (calibrating the end position) ......................................................................................................52

11.12.1 Starting the teach function ...............................................................................................................55

11.13 Display elements DeviceNet .........................................................................................................................................56

11.13.1 Device status LED and bus LED ....................................................................................................57

11.13.2 End position LEDs..............................................................................................................................58

11.13.3 Status LED yellow ..............................................................................................................................58

11.13.4 Valve LED yellow ................................................................................................................................58

12 SAFETY POSITIONS .......................................................................................................................................................................59

13 MAINTENANCE ..................................................................................................................................................................................59

14 ACCESSORIES ..................................................................................................................................................................................59

english

5

Page 6

Type 8695

15 DISASSEMBLY ...................................................................................................................................................................................60

15.1 Safety instructions .............................................................................................................................................................60

15.2 Disassembly the control head .....................................................................................................................................60

16 PACKAGING AND TRANSPORT ...............................................................................................................................................62

17 STORAGE ..............................................................................................................................................................................................62

18 DISPOSAL ............................................................................................................................................................................................62

6

english

Page 7

Type 8695

Operating instructions

1 OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device. Keep these instructions in a location which is

easily accessible to every user, and make these instructions available to every new owner of the device.

Important safety information.

Failure to observe these instructions may result in hazardous situations.

▶ The operating instructions must be read and understood.

1.1 Symbols

DANGER!

Warns of an immediate danger.

▶ Failure to observe the warning will result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation.

▶ Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger.

▶ Failure to observe this warning may result in a moderate or minor injury.

NOTE!

Warns of damage to property.

• Failure to observe the warning may result in damage to the device or the equipment.

Indicates important additional information, tips and recommendations.

refers to information in these operating instructions or in other documentation.

▶ Designates an instruction to prevent risks.

→ Designates a procedure which you must carry out.

1.2 Definition of term / abbreviation

The term “device” used in these instructions always stands for the control head Type 8695.

In these instructions, the abbreviation “Ex” always refers to “potentially explosive”.

english

7

Page 8

Type 8695

Authorized use

2 AUTHORIZED USE

Non-authorized use of the control head Type 8695 may be a hazard to people, nearby equipment and

the environment.

▶ The device is designed to be mounted on pneumatic actuators of process valves for the control of media.

▶ Do not expose the device to direct sunlight.

▶ Use according to the authorized data, operating conditions and conditions of use specified in the contract

documents and operating instructions. These are described in the chapter entitled “6 Technical data”.

▶ The device may be used only in conjunction with third-party devices and components recommended and

authorized by Bürkert.

▶ In view of the large number of options for use, before installation, it is essential to study and if necessary to

test whether the control head is suitable for the actual use planned.

▶ Correct transportation, correct storage and installation and careful use and maintenance are essential for reli-

able and faultless operation.

▶ Use the control head Type 8695 only as intended.

2.1 Restrictions

If exporting the system/device, observe any existing restrictions.

8

english

Page 9

Type 8695

Basic safety instructions

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the installation, operation and maintenance of the devices.

• local safety regulations – the operator is responsible for observing these regulations, also with reference to the

installation personnel.

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure and deaerate/drain lines.

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment..

General hazardous situations.

To prevent injury, ensure:

▶ In the potentially explosion-risk area the control head Type 8695 may be used only according to the specification

on the separate approval sticker. For use observe the additional instructions enclosed with the device together

with safety instructions for the explosion-risk area.

▶ Devices without a separate approval sticker may not be used in a potentially explosive area.

▶ That the system cannot be activated unintentionally.

▶ Installation and repair work may be carried out by authorized technicians only and with the appropriate tools.

▶ After an interruption in the power supply or pneumatic supply, ensure that the process is restarted in a defined

or controlled manner.

▶ The device may be operated only when in perfect condition and in consideration of the operating instructions.

▶ The general rules of technology apply to application planning and operation of the device.

To prevent damage to property on the device, ensure:

▶ Do not feed any aggressive or flammable media into the pilot air port.

▶ Do not feed any liquids into the pilot air port.

▶ When unscrewing and screwing in the body casing or the transparent cap, do not hold the actuator of the pro-

cess valve but the connection housing of Type 8695.

▶ Do not put any loads on the body (e.g. by placing objects on it or standing on it).

▶ Do not make any external modifications to the device bodies. Do not paint the body parts or screws.

english

9

Page 10

Type 8695

General information

4 GENERAL INFORMATION

4.1 Contact address

Germany

Bürkert Fluid Control System

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed operating instructions.

And also on the Internet at:

www.burkert.com

4.2 Warranty

The warranty is only valid if the control head Type 8695 is used as intended in accordance with the specified application conditions.

4.3 Trademarks

Brands and trademarks listed below are trademarks of the corresponding companies / associations / organizations

Loctite Henkel Loctite Deutschland GmbH

4.4 Information on the internet

The operating instructions and data sheets for Type 8695 can be found on the Internet at:

www.burkert.com

10

english

Page 11

Type 8695

System description

5 SYSTEM DESCRIPTION

5.1 Structure and function

The control head Type 8695 can control single or double-acting process valves.

The control head Type 8695 has been optimized for the integrated modular fitting of series 21xx process valves

(Element) with actuator size ∅ 50. Various expansion stages are possible thanks to the modular design.

For installation on the 20xx series (Classic) there is a special model which is described in chapter “5.1.2”.

The valve position is recorded via a contactless, analog sensor element which automatically detects and saves the

valve end positions by means of the teach function during start-up.

Option: Communication possible via AS-Interface and DeviceNet.

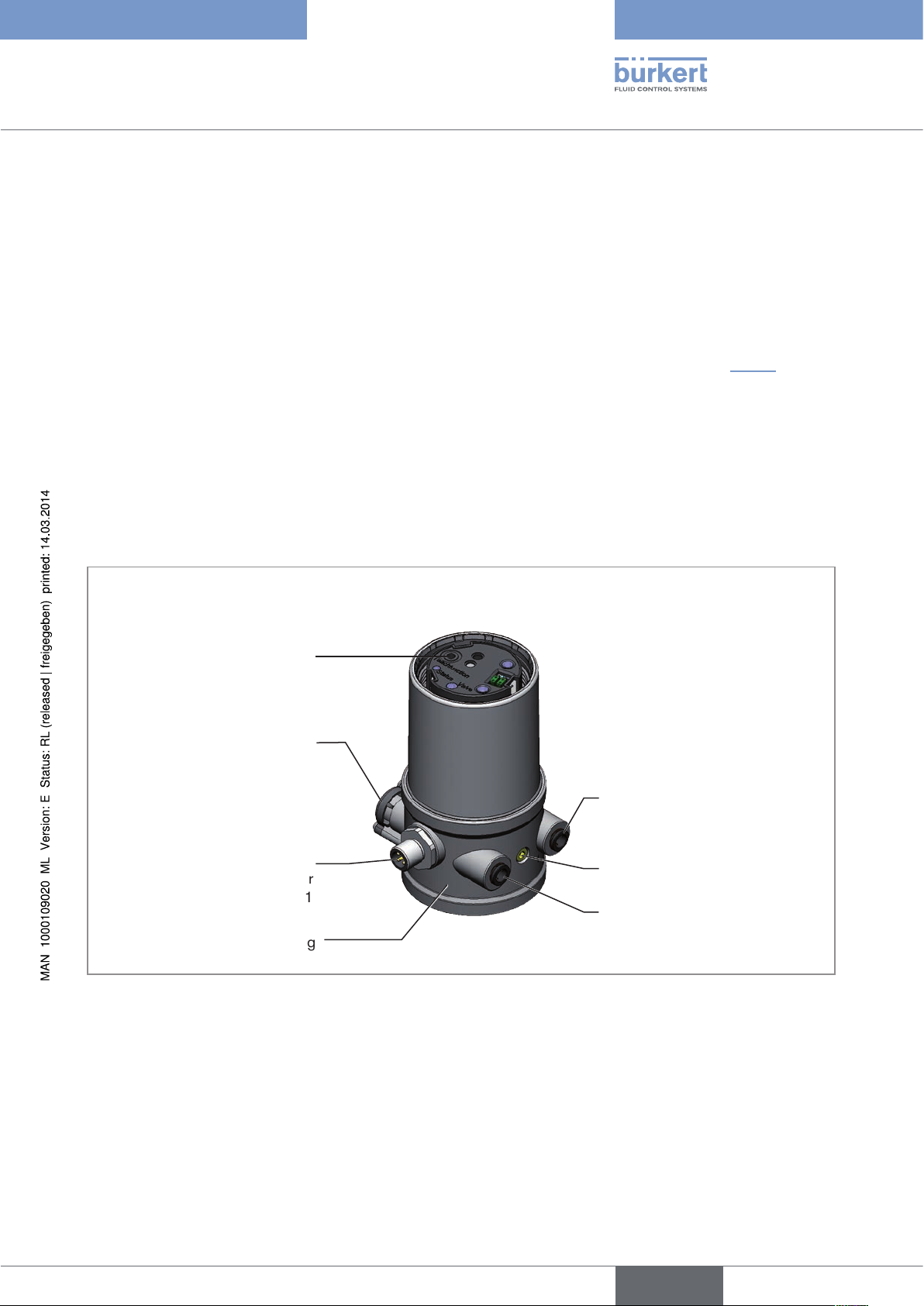

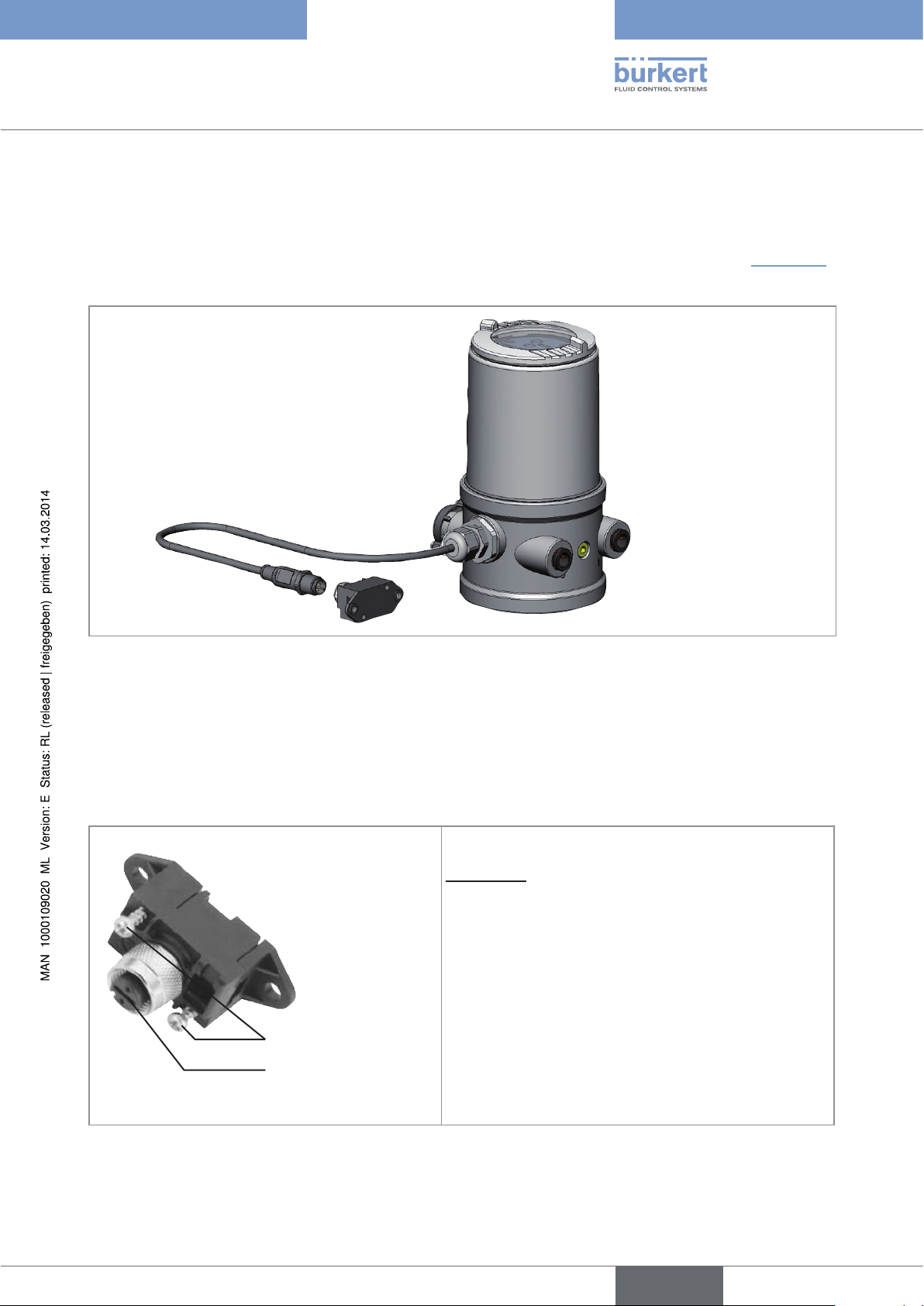

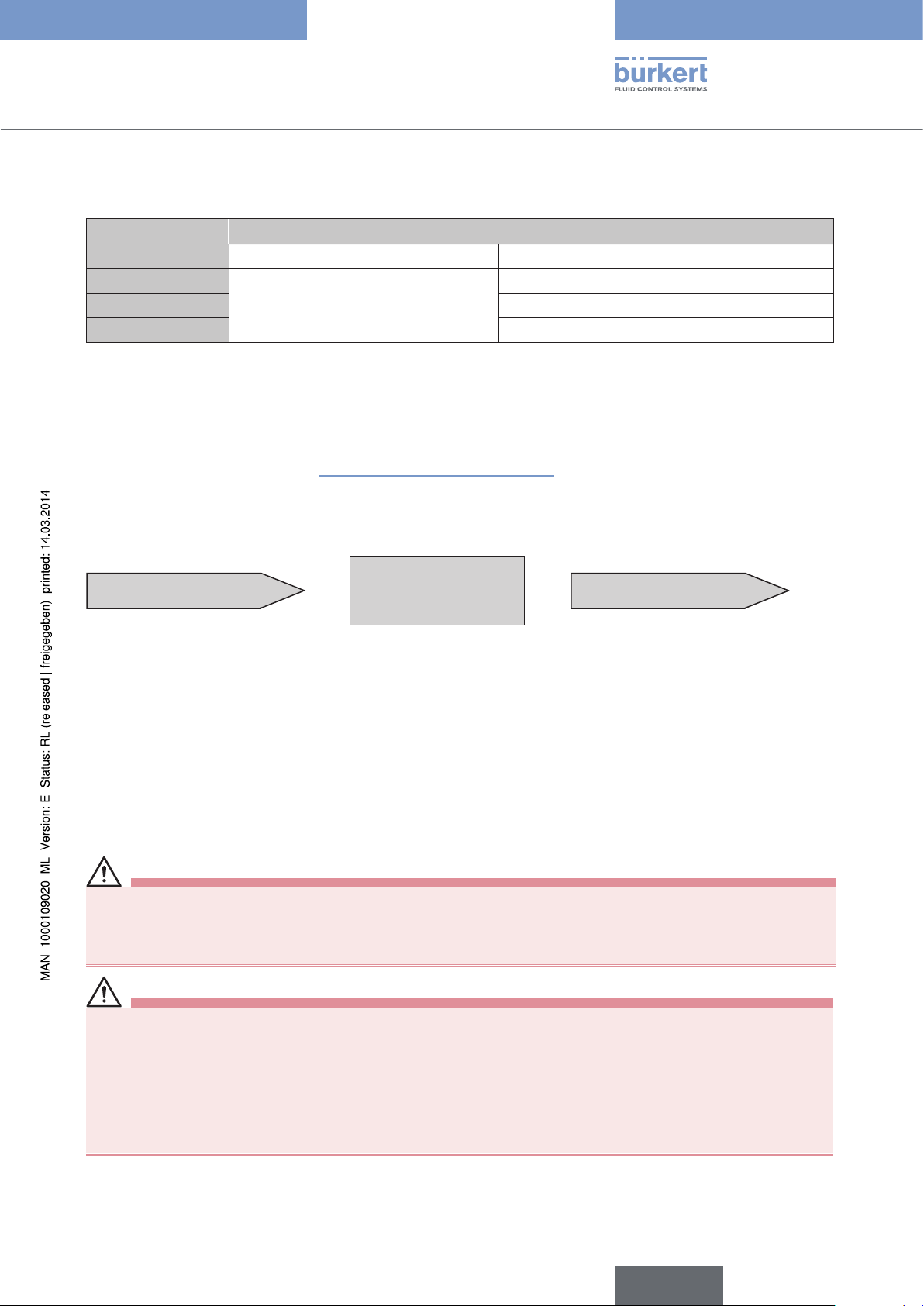

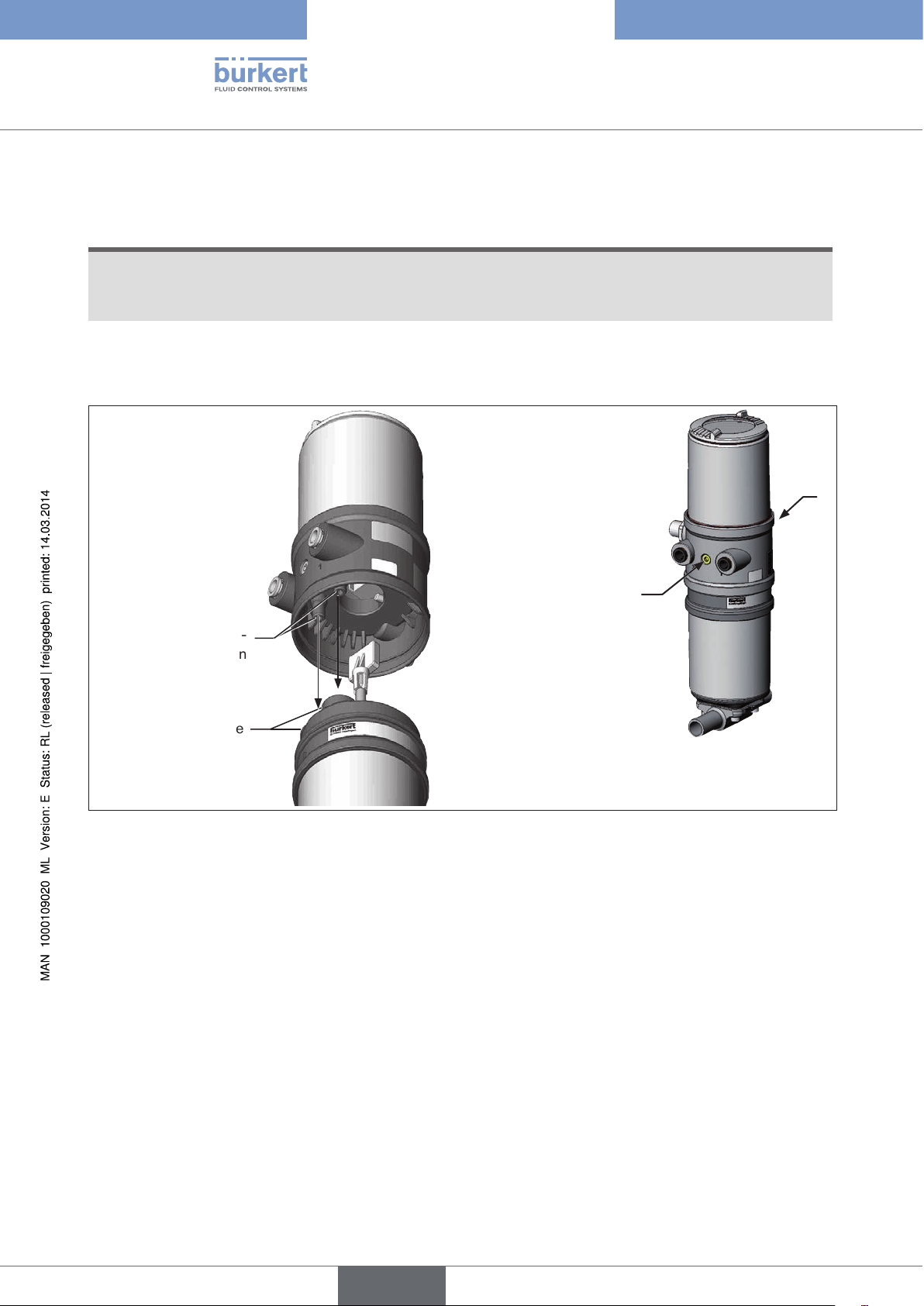

5.1.1 Control head for integrated installation on 21xx series

(Element)

View without transparent cap:

Teach function

Pressure limiting valve

(for protection against

too high internal pressure

in case of error)

Electrical connection

Circular plug-in connector

M12 x 1

Connection housing

Figure 1: Structure and function

Pilot air port

(label: 1)

Fastening screws (2 x)

Air exhaust port

(label: 3)

english

11

Page 12

Type 8695

System description

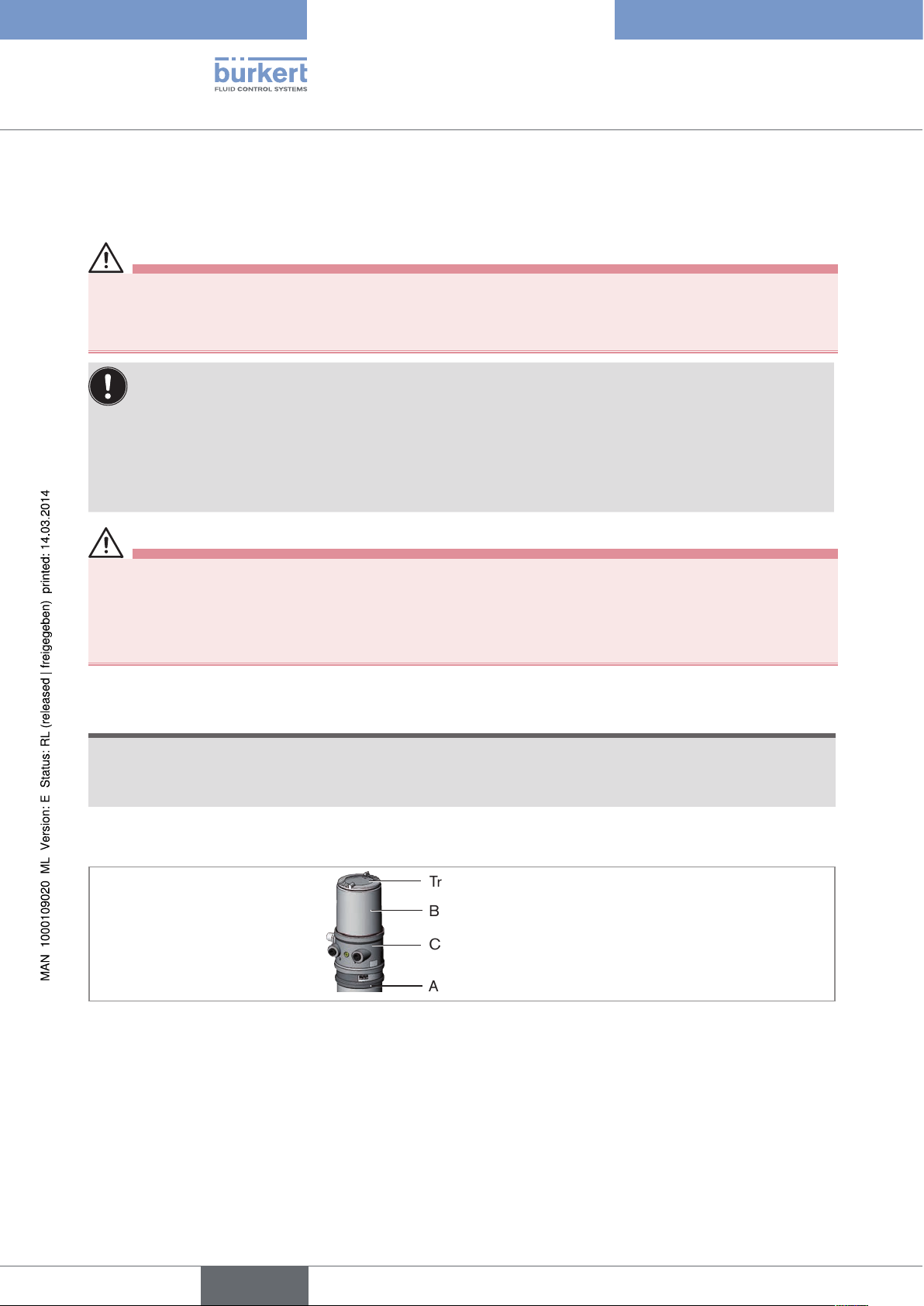

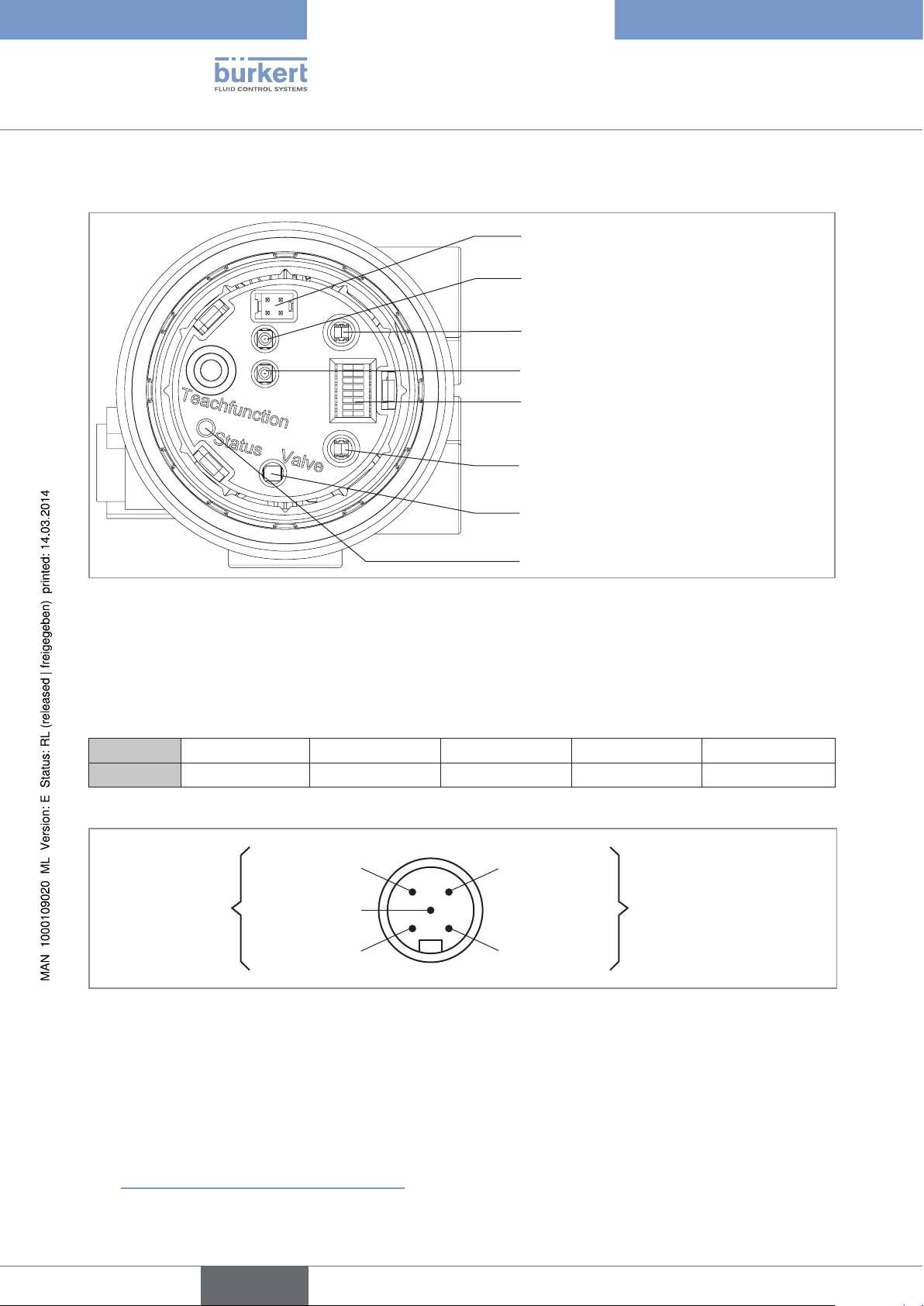

5.1.2 Model for control of process valves belonging to the 20xx

series (Classic)

A special model enables the control head Type 8695 to be attached to process valves belonging to the 20xx

series.

This model has a different pneumatic connection module so that the pilot air ports can be connected to the

outside of the actuator (see “Figure 2”).

Figure 2: Model for control of process valves, 20xx series

Pilot air outlet 2

Pilot air outlet 2

1

2

12

english

Page 13

Type 8695

Technical data

6 TECHNICAL DATA

6.1 Conformity

In accordance with the EC Declaration of conformity, the control head Type 8695 is compliant with the EC

Directives.

6.2 Standards

The applied standards on the basis of which compliance with the EC Directives is confirmed are listed in the EC

type examination certificate and/or the EC Declaration of Conformity.

6.3 Operating conditions

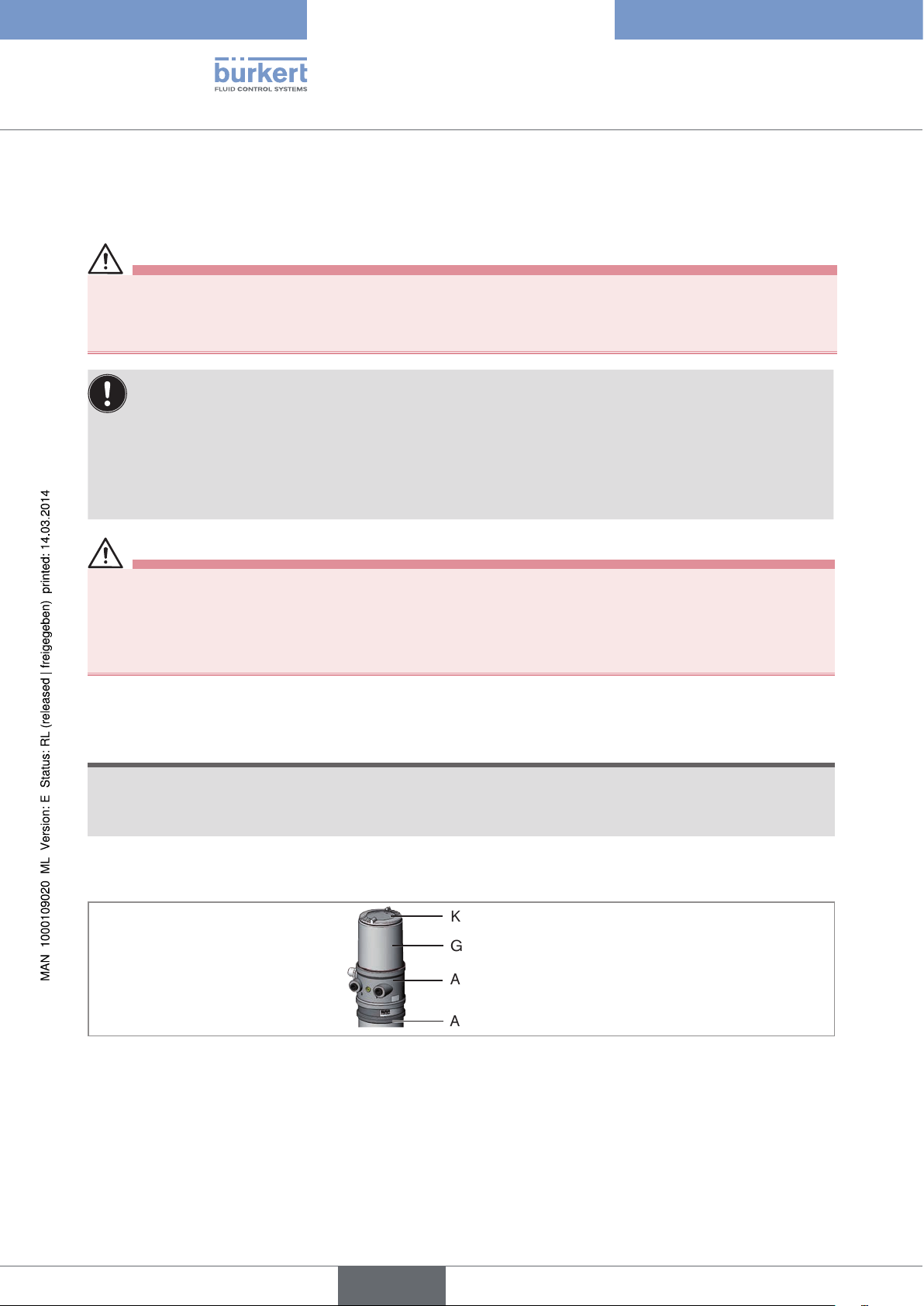

WARNING!

Solar radiation and temperature fluctuations may cause malfunctions or leaks.

▶ If the device is used outdoors, do not expose it unprotected to the weather conditions.

▶ Ensure that the permitted ambient temperature does not exceed the maximum value or drop below the mini-

mum value.

Ambient temperature see type label

Degree of protection IP65 / IP67 according to EN 60529

(only if cables, plugs and sockets have been connected correctly

and in compliance with the exhaust air concept in chapter “Procedure:”)

6.4 Mechanical data

Dimensions See data sheet

Body material exterior PPS, PC, VA

interior PA6; ABS

Sealing material exterior EPDM / FKM

Stroke range of valve spindle 21xx series (Element)

and 20xx series (Classic) AS-Interface 2 – 25 mm

24 V DC 2 – 35 mm

DeviceNet 2 – 35 mm

Third-party devices

(modified guide element

required) AS-Interface 2 – 34 mm

24 V DC 2 – 44 mm

DeviceNet 2 – 44 mm

13

english

Page 14

6.5 Type label

Example:

Type 8695

Technical data

Supply voltage / Control

Identification number

Figure 3: Type label (example)

Type

8695 24 V/DC

single act Pilot 0,6

Pmax 7 bar

Tamb 0°C - +55°C

S/N 001000

00185114

D-74653 Ingelfingen

W14UN

CE

Control function - Pilot valve

Max. operating pressure

Max. ambient temperature

Serial number - CE mark

Bar-code

6.6 Pneumatic data

Control medium neutral gases, air

Quality classes in accordance with DIN ISO 8573-1

Dust content Class 5 max. particle size 40 µm, max. particle density 10 mg/m³

Water content Class 3 max. pressure dew point

- 20 °C or min. 10 °C below the lowest operating temperature

Oil content Class 5 max. 25 mg/m³

Temperature range -10 – +50 °C

Pressure range 3 – 7 bar

Air output of pilot valve 7 l

/ min (for aeration and deaeration)

N

(QNn - value according to definition for pressure drop from 7 to 6 bar absolute)

Connections 21xx (Element) Plug-in hose connector ∅ 6 mm / 1/4“

Socket connection G 1/8

20xx (Classic) Socket connection G 1/8

with M5 connection for connecting to the actuator

14

english

Page 15

Type 8695

Technical data

6.7 Electrical data

6.7.1 Electrical data without bus control 24 V DC

Connections Circular plug-in connector (M12 x 1, 8-pole)

Pilot valve

Operating voltage 24 V DC ± 10% - max. residual ripple 10 %

Power input max. 1 W

Output max. 100 mA per output

Display max. 20 mA per illustrated illuminated display (LED)

6.7.2 Electrical data with AS-Interface bus control

Connections Circular plug-in connector (M12 x 1, 4-pole)

Profile S-B.A.E. (A/B slave, max. 62 slaves/master)

Operating voltage 29.5 V – 31.6 V DC (according to specification)

Outputs

Max. switching capacity 1 W via AS-Interface

Watchdog function integrated

Max. power consumption 120 mA

Power consumption input during

normal operation

(after current reduction;

valve + 1 end position reached) 90 mA

6.7.3 Electrical data with DeviceNet bus control

Connections Circular plug-in connector (M12 x 1, 5-pole)

Operating voltage 11 V – 25 V

Max. power consumption < 80 mA

Output Pull-in current current ≤ 50 mA

Holding current ≤ 30 mA

english

15

Page 16

Type 8695

Installation

7 INSTALLATION

7.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure and deaerate/drain lines.

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only and with the appropriate tools.

Risk of injury from unintentional activation of the system and an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following assembly, ensure a controlled restart.

7.2 Installation of the control head Type 8695

on process valves of series 21xx (Element)

Procedure:

1. Install switch spindle

Transparent cap

Pilot air ports

(plug-in hose connectors with collets or

threaded bushings)

16

Actuator

Figure 4: Installation of switch spindle (1), series 21xx

→ Unscrew the transparent cap on the actuator and unscrew the position display (yellow cap) on the spindle

extension (if present).

→ For version with plug-in hose connector, remove the collets (white nozzles) from both pilot air ports (if

present).

english

Page 17

Type 8695

Installation

Puck

Switch spindle

Guide element

Groove ring

max. 1 Nm

max. 5 Nm

Actuator cover

O-ring

Spindle extension

Figure 5: Installation of the switch spindle (2), series 21xx

NOTE!

Improper installation may damage the groove ring in the guide element.

The groove ring is already be pre-assembled in the guide element and must be “locked into position” in the

undercut.

▶ When installing the switch spindle, do not damage the groove ring.

→ Push the switch spindle through the guide element.

NOTE!

Screw locking paint may contaminate the groove ring.

▶ Do not apply any screw locking paint to the switch spindle.

→ To secure the switch spindle, apply some screw locking paint (Loctite 290) in the tapped bore of the spindle

extension in the actuator.

→ Check that the O-ring is correctly positioned.

→ Screw the guide element to the actuator cover (maximum torque: 5 Nm).

→ Screw switch spindle onto the spindle extension. To do this, there is a slot on the upper side

(maximum torque: 1 Nm).

→ Push puck onto the switch spindle and lock into position.

english

17

Page 18

Type 8695

Installation

2. Install sealing rings

→ Pull the form seal onto the actuator cover (smaller diameter points upwards).

→ Check that the O-rings are correctly positioned in the pilot air ports.

When the control head is being installed, the collets of the pilot air ports must not be fitted to the actuator.

Pilot air ports

Caution:

Collets must not be

fitted !

Figure 6: Installation of the sealing rings

Form seal

Installation of the form

seal

18

english

Page 19

Type 8695

Installation

3. Install control head

NOTE!

Damaged printed circuit board or malfunction.

▶ Ensure that the puck is situated flat on the guide rail.

→ Align the puck and the control head until

1. the puck can be inserted into the guide rail of the control head

and

2. the connection pieces of the control head can be inserted into the pilot air ports of the actuator.

Connection

pieces

Guide rail

Puck

Guide rail

Puck

Connection

pieces

Figure 7: Aligning the puck and the connection pieces

Pilot air ports

(actuator)

19

english

Page 20

Type 8695

Installation

→ Push the control head, without turning it, onto the actuator until no gap is visible on the form seal.

NOTE!

Too high torque when screwing in the fastening screw does not ensure degree of protection IP65 /

IP67.

▶ The fastening screws may be tightened to a maximum torque of 0.5 Nm only.

→ Attach the control head to the actuator using the two side fastening screws. In doing so, tighten the screws

only hand-tight (maximum torque: 0.5 Nm).

Connection

pieces

Pilot air ports

(actuator)

Figure 8: Installation of control head

Fastening screws

max. 0.5 Nm

20

english

Page 21

Type 8695

Installation

7.3 Installation of the control head Type 8695 on

process valves of series 20xx (Classic)

Procedure:

1. Install switch spindle

Transparent cap

Position indicator

Actuator

Figure 9: Installation of the switch spindle (1), series 20xx

→ Unscrew the transparent cap on the actuator.

→ Using a hexagon socket key, unscrew the orange/yellow position indicator from the inside of the actuator.

Puck

Switch spindle

Guide element

O-ring

Plastic part

(of the switch spindle)

Spindle (actuator)

Figure 10: Installation of the switch spindle (2), series 20xx

→ Press the O-ring downwards into the cover of the actuator.

→ Manually screw the switch spindle (and the plugged-on guide element) together with the plastic part onto the

spindle of the actuator, but do not tighten spindle yet.

→ Tighten the guide element with a face wrench

1)

into the actuator cover (maximum torque: 8.0 Nm).

→ Tighten the switch spindle on the spindle of the actuator. To do this, there is a slot on the upper side

(maximum torque: 1.0 Nm).

→ Push the puck onto the switch spindle until it engages.

1) journal Ø: 3 mm; journal gap: 23.5 mm

english

21

Page 22

2. Install control head

Type 8695

Installation

Guide rail

Puck

Guide rail

Puck

Figure 11: Aligning the puck, series 20xx

NOTE!

Damaged printed circuit board or malfunction.

▶ Ensure that the puck is situated flat on the guide rail.

→ Push the control head onto the actuator. The puck must be aligned in such a way that it is inserted into the

guide rail of the control head.

→ Press the control head all the way down as far as the actuator and turn it into the required position.

Ensure that the pneumatic connections of the control head and those of the valve actuator are situated

preferably vertically one above the other (see “Figure 12: Installing the control head, series 20xx”).

If they are positioned differently, longer hoses may be required other than those supplied in the accessory

kit.

22

english

Page 23

Type 8695

Installation

Fastening screws

maximum 0.5 Nm

Figure 12: Installing the control head, series 20xx

NOTE!

Too high torque when screwing in the fastening screw does not ensure degree of protection IP65 /

IP67.

▶ The fastening screws may be tightened to a maximum torque of 0.5 Nm only.

→ Attach the control head to the actuator using the two side fastening screws. In doing so, tighten the fastening

screws hand-tight only (maximum torque: 0.5 Nm).

english

23

Page 24

3. Install pneumatic connection between control head and actuator

Type 8695

Installation

Pilot air outlet 2

Pilot air outlet 2

1

2

Upper pilot air port

Lower pilot air port

Figure 13: Installing the pneumatic connection between control head and actuator, series 20xx

→ Screw the plug-in hose connectors onto the control head and the actuator.

→ Using the hoses supplied in the accessory kit, make the pneumatic connection between the control head and

actuator with the following “Table 1: Pneumatic connection to actuator CFA and CFB” or “Table 2: Pneumatic

connection to actuator CFI”.

NOTE!

Damage or malfunction due to ingress of dirt and moisture.

▶ To comply with degree of protection IP65 / IP67, connect the pilot air outlet (only for CFA or CFB) which is

not required to the free pilot air port of the actuator or seal with a plug.

24

“In rest position” means that the pilot valves of the control head Type 8695 are isolated or not actuated.

Control function A (CFA)

Process valve closed in rest position (by spring force)

Control head Pilot air outlet

Actuator

Upper pilot air port

222

1

or

Lower pilot air port

Control function B (CFB)

Process valve open in rest position (by spring force)

Control head Pilot air outlet

Actuator

Upper pilot air port

222

1

or

Lower pilot air port

Table 1: Pneumatic connection to actuator CFA and CFB

222

222

1

1

english

Page 25

Type 8695

Installation

Control function I (CFI)

Process valve closed in rest position

Control head Pilot air outlet

222

1

Actuator

Upper pilot air port

Lower pilot air port

Process valve open in rest position

Control head Pilot air outlet

Actuator

Upper pilot air port

222

1

Lower pilot air port

Table 2: Pneumatic connection to actuator CFI

If the ambient air is humid, a hose can be connected between pilot air outlet 22 of the control head and

the unconnected pilot air port of the actuator for control function A or control function B. As a result, the

spring chamber of the actuator is supplied with dry air from the vent duct of the control head.

7.4 Rotating the actuator module

on process valves of series 2100, 2101, 2000 and

2012

The actuator module (control head and actuator) can be rotated for globe valves and angle-seat valves

belonging to series 2100, 2101, 2000 and 2012 only.

The process valve must be in the open position for alignment of the actuator module.

The position of the ports can be aligned steplessly by rotating the actuator module (control head and actuator)

through 360°.

Series 2100 and 2101:

Only the entire actuator module can be rotated. The control head cannot be rotated contrary to the actuator.

25

english

Page 26

Type 8695

Installation

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure and deaerate/drain lines.

Procedure:

→ Clamp valve body in a holding device (only required if the process valve has not yet been installed).

→ Control function A: Open process valve.

Actuator module

Hexagon

Hexagon

Nipple

Series 2100 and 2101

Figure 14: Rotating the actuator module

Series 2000 and 2012

Nipple

→ Using a suitable open-end wrench, counter the wrench flat on the pipe.

→ Place suitable open-end wrench on the hexagon of the actuator.

WARNING!

Risk of injury from discharge of medium and pressure.

If the direction of rotation is wrong, the body interface may become detached.

▶ Rotate the actuator module counter-clockwise only (see “Figure 15”).

→ Rotate counter-clockwise (as seen from below) to bring the actuator module into the required position.

Open-end wrench

26

Figure 15: Rotating with open-end wrench

english

Page 27

Type 8695

Installation

7.5 Rotating the control head for process valves

belonging to series 20xx

If the connecting cables or hoses cannot be fitted properly following installation of the process valve, the control

head can be rotated contrary to the actuator.

Fastening screw (2x)

Control head

Pneumatic connection

Actuator

Figure 16: Rotating the control head, series 20xx

Procedure

→ Loosen the pneumatic connection between the control head and the actuator.

→ Loosen the fastening screws countersunk in the side of the body (hexagon socket wrench size 2.5).

→ Rotate the control head into the required position.

NOTE!

Too high torque when screwing in the fastening screw does not ensure degree of protection IP65 /

IP67.

▶ The fastening screws may be tightened to a maximum torque of 0.5 Nm only.

→ Tighten the fastening screws hand-tight only (maximum torque: 0.5 Nm).

→ Re-attach the pneumatic connections between the control head and the actuator. If required, use longer

hoses.

english

27

Page 28

Type 8695

Pneumatic installation

8 PNEUMATIC INSTALLATION

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure and deaerate/drain lines.

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only and with the appropriate tools.

Risk of injury from unintentional activation of the system and an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

Procedure:

→ Connect the control medium to the pilot air port (1)

(3 – 7 bar; instrument air, free of oil, water and dust).

→ Attach the exhaust airline or a silencer to the exhaust air port (3).

Important information for the problem-free functioning of the device:

▶ The installation must not cause back pressure to build up.

▶ Select a hose for the connection with an adequate cross-section.

▶ The exhaust air line must be designed in such a way that no water or other liquid can get into the device

through the exhaust air port.

28

english

Page 29

Type 8695

Pneumatic installation

Pilot air port

(label: 1)

Exhaust air port

(label: 3)

Figure 17: Pneumatic connection

Caution:(Air exhaust concept):

In compliance with degree of protection IP67, an air exhaust line must be installed in the dry area.

Keep the adjacent supply pressure always at least 0.5 – 1 bar above the pressure which is required to

move the actuator to its end position.

english

29

Page 30

Type 8695

Electrical installation 24 V DC

9 ELECTRICAL INSTALLATION 24 V DC

The kind of connection is used for the electrical bonding of the control head:

• Multi-pole

with circular plug-in connector M12 x 1, 8-pole

9.1 Safety instructions

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only and with the appropriate tools.

Risk of injury from unintentional activation of the system and an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

30

english

Page 31

Type 8695

Electrical installation 24 V DC

9.2 Electrical installation

Configuration circular plug (M12 x 1, 8-pole):

6

5

4

Figure 18: Circular plug M12 x 1, 8-pole

Pin

1

2

3

4

5

6

Wire color

white limit switch top IN 1 (=Top)

brown limit switch bottom IN 2 (=Bot)

green Supply voltage GND

yellow Supply voltage + 24 V DC

grey Valve control unit + Valve +

pink Valve control unit - Valve -

2)

Designation

7

3

8

2

1

Configuration

External circuit / signal level

+ 24 V

1

2

100K

GND

3

4

5

6

{

GND

24 V

24 V

GND

IN 1

IN 2

7

8

Table 3: Connection with circular plug-in connector

- not used

- not used

→ Connect the control head according to the table.

When the supply voltage is applied, the control head is operating.

→ To read in the end positions of the valve, start the teach function (see “9.3 Teach function (calibrating the end

position)”).

2) The indicated colors refer to the connecting cable available as an accessory (919061).

31

english

Page 32

Type 8695

Electrical installation 24 V DC

9.3 Teach function (calibrating the end position)

The teach function can be used to automatically determine and read in the end positions of the valve.

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

Necessary requirements:

Before you can actuate the teach function, you must

• mount the control head on the actuator,

• connect the supply voltage and

• connect the compressed-air supply.

DANGER!

Danger due to the valve position changing when the teach function is running.

When the teach function is running under operating pressure, there is an acute risk of injury.

▶ Never run the teach function while a process is running.

▶ Secure system from unintentional activation.

Procedure:

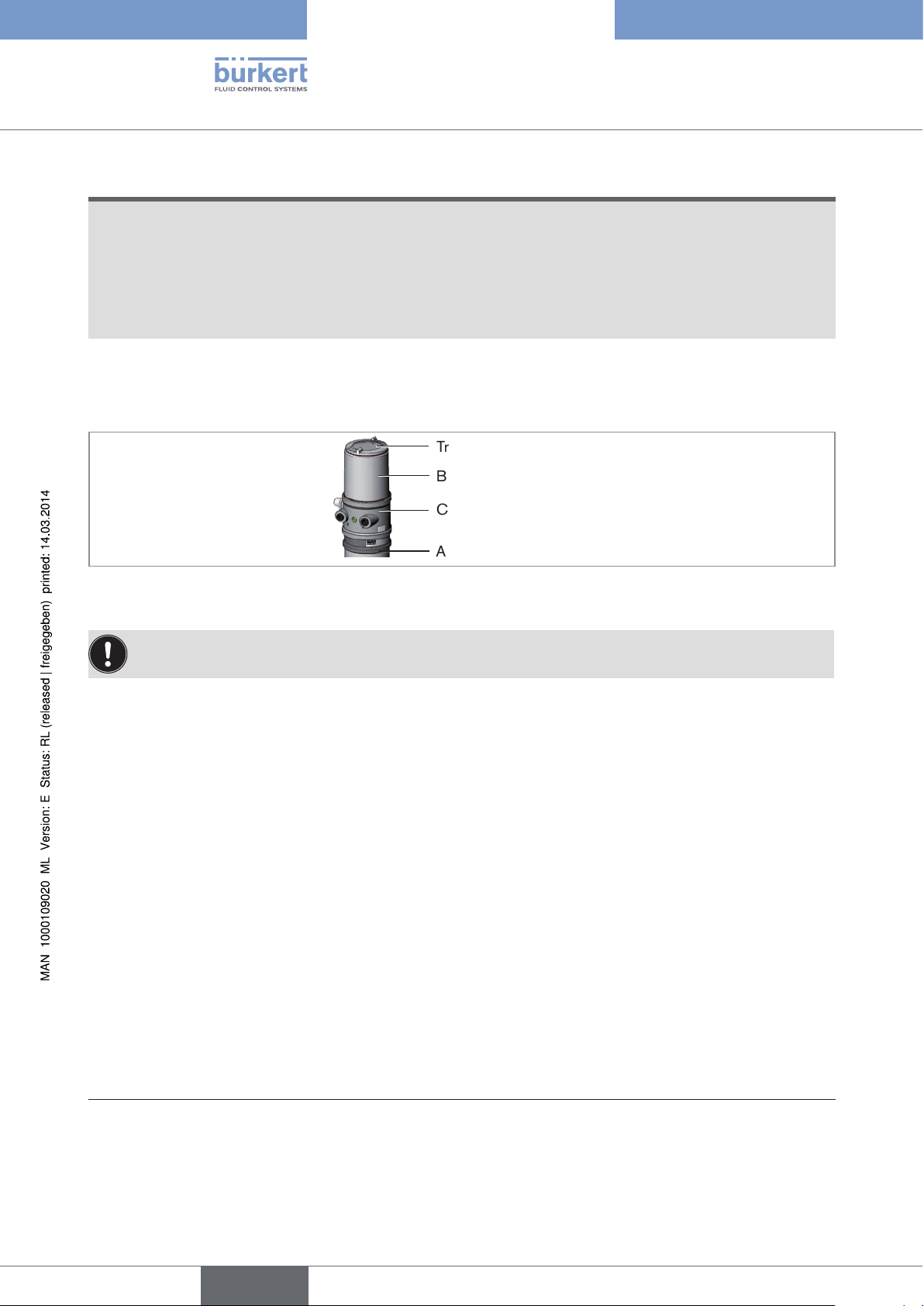

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not hold the actuator of the process valve but the

connection housing.

→ Open the control head: turning the transparent cap anti-clockwise.

Transparent cap

Body casing

Connection housing

Actuator

32

Figure 19: Open control head

english

Page 33

Type 8695

Electrical installation 24 V DC

→ The key in recess for actuating the Teach function keep pressed for approximately 5 seconds.

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not hold the actuator of the process valve but the

connection housing.

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the transparent cap in all the way.

→ Close the device (assembly tool: 674078

Key in recess for

actuating the teach

function (keep

pressed for approximately 5 seconds)

Figure 20: Teach function

3)

).

Chronological description of the teach function:

• the bottom position is read in internally

• the pilot valve switches

• the actuator moves automatically to the top

position

• the top position is read in internally

• the pilot valve is turned off

• the actuator moves back to the home position

3) The assembly tool (674078) is available from your Bürkert sales office.

33

english

Page 34

Type 8695

Electrical installation 24 V DC

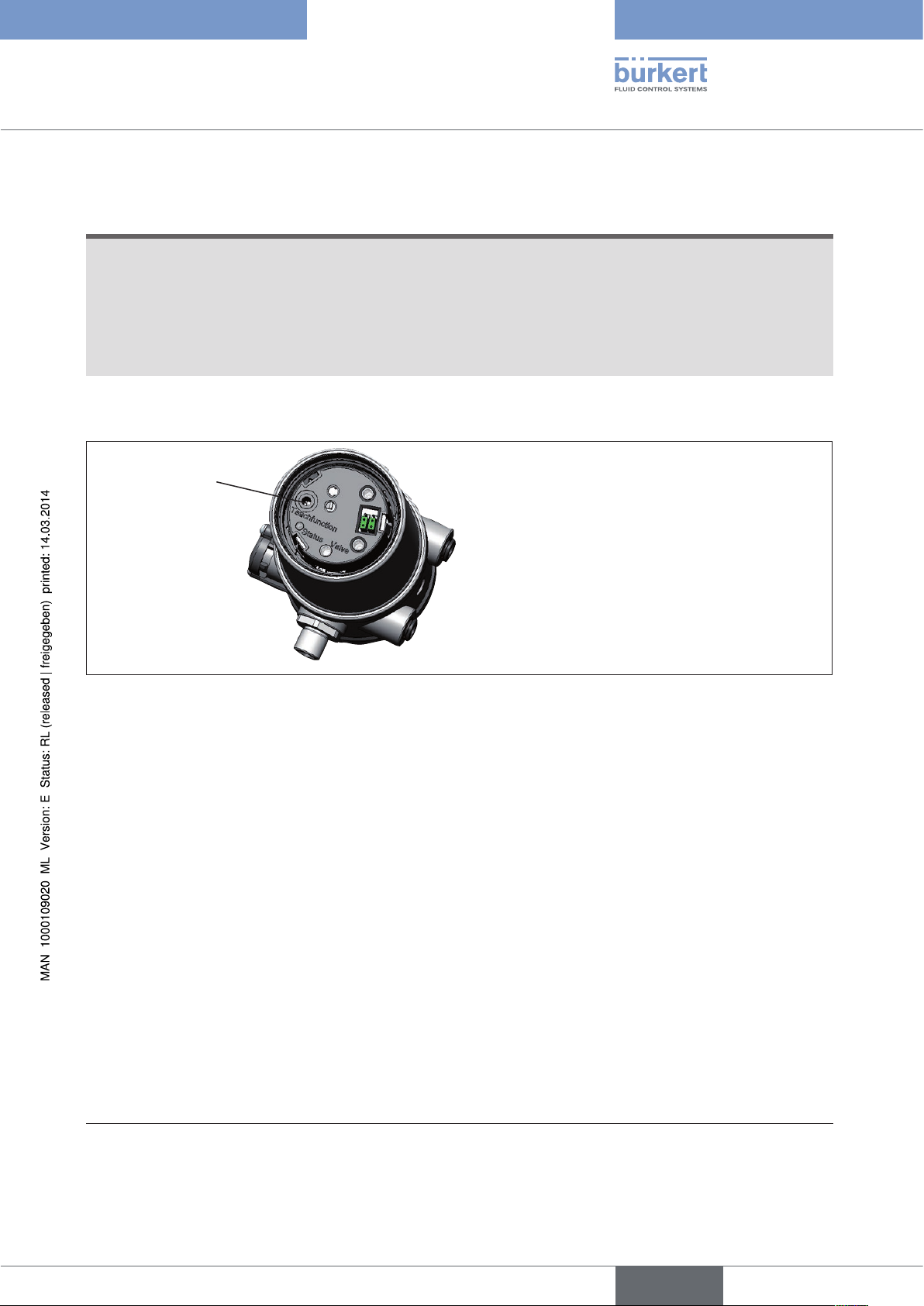

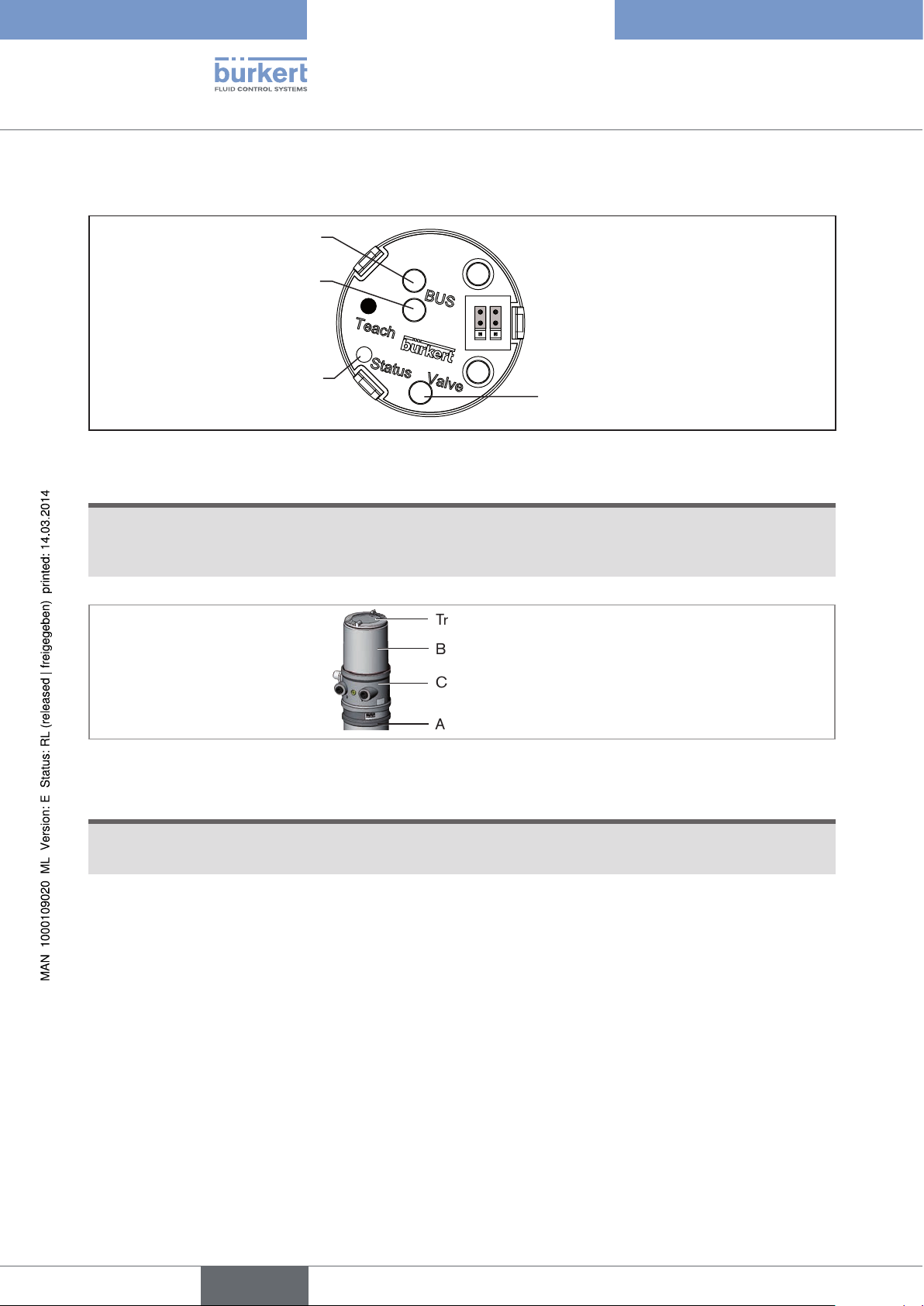

9.4 Display and control elements 24 V DC

End position LED green

Jumper for

assignment of

end position LEDs

End position LED yellow

Status LED yellow

ye

gn

Top

Bot

Top

Bot

gn

ye

Valve LED yellow (pilot valve)

Figure 21: Description LED and Jumpers - 24 V DC

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not hold the actuator of the process valve but the

connection housing.

Transparent cap

Body casing

Connection housing

Actuator

Figure 22: Open control head

34

NOTE!

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the transparent cap in all the way.

9.4.1 Status LED yellow

LED yellow

flashing Teach function is running

Puck not available

flickers

→ Insert puck

Table 4: Status LED yellow - 24 V DC

9.4.2 Valve LED yellow

The yellow LED (valve) indicates whether the pilot valve is actuated (LED is lit yellow).

english

Page 35

Type 8695

Electrical installation 24 V DC

9.4.3 End position LED green and yellow

Factory setting:

Color

green LED on End position bottom

yellow LED off End position top

Table 5: Assignment of end position LEDs - 24 V DC

Device status

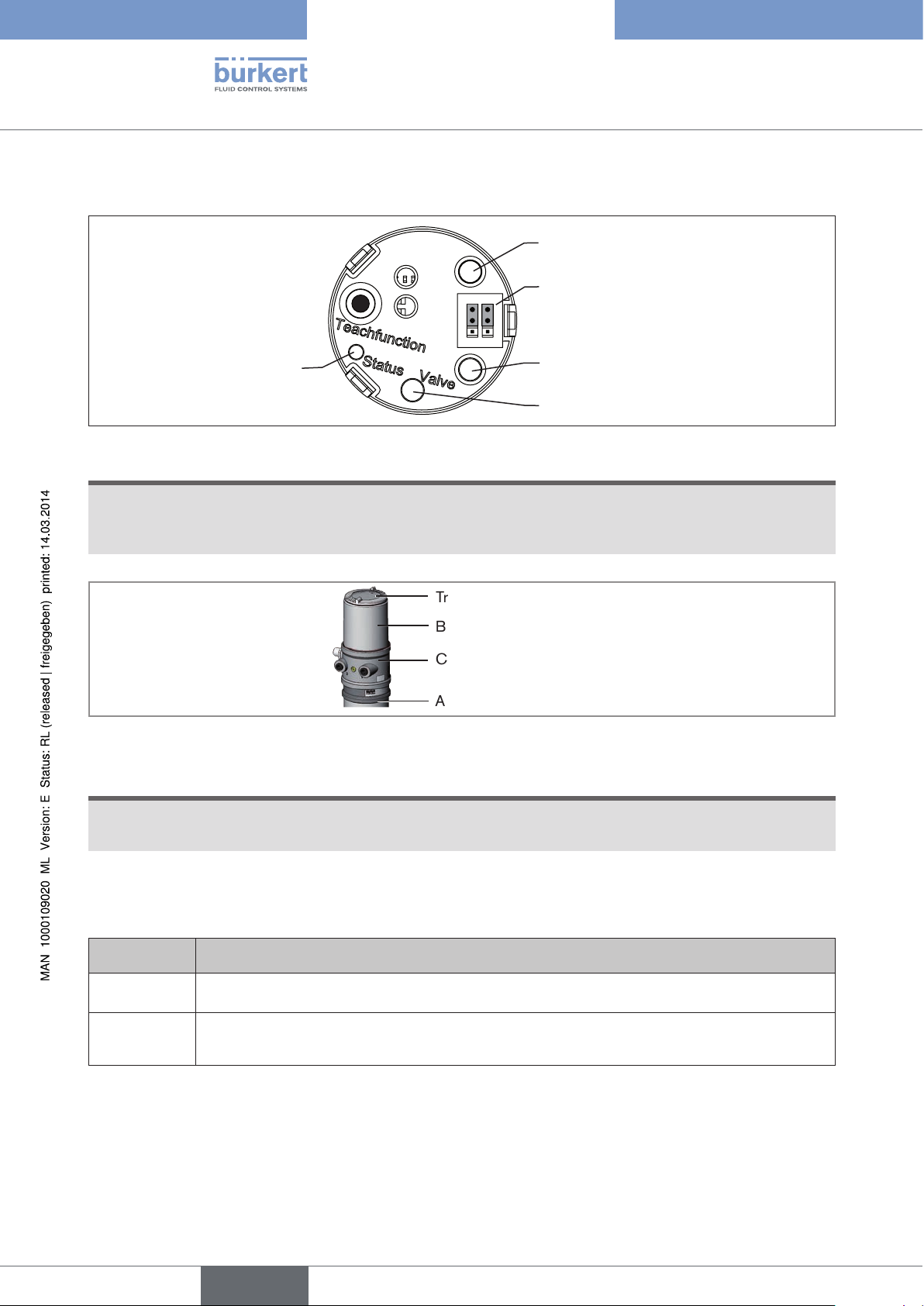

9.4.4 Jumper function

You can set the color assignment of the end positions with the jumpers. You can indicate for each color whether it

applies to the Top (end position top) or Bot (end position bottom).

9.4.5 Change assignment of the end position LEDs

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

Procedure:

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not hold the actuator of the process valve but the

connection housing.

→ Open control head: turn the transparent cap anti-clockwise.

Transparent cap

Body casing

Connection housing

Actuator

Figure 23: Open control head

english

35

Page 36

→ Using the jumpers, assign the required color to the end position LEDs.

Bot

Top

Bot

Top

Type 8695

Electrical installation 24 V DC

Jumper setting 1:

End position LED green

ye

gn

Top

ye

gn

Top

Bot

Top

Bot

gn

ye

Jumper for

assignment of end

position LEDs

Bot

ye

End position LED yellow

gn

Bot

Top

In the end position top (Top),

ye

the yellow LED is lit; in the

gn

end position bottom (Bot),

the green LED is lit.

Jumper setting 2:

In the end position top (Top),

ye

the green LED is lit; in the

gn

end position bottom (Bot),

the yellow LED is lit.

Figure 24: Description end position LEDs and Jumper - 24 V DC

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not hold the actuator of the process valve but the

connection housing.

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the transparent cap in all the way.

→ Close the device (assembly tool: 674078

Figure 25: Close control head

4)

).

Transparent cap

Body casing

Connection housing

Actuator

36

4) The assembly tool (674078) is available from your Bürkert sales office.

english

Page 37

Type 8695

AS-Interface installation

10 AS-INTERFACE INSTALLATION

10.1 AS-Interface connection

AS-Interface (Actuator Sensor Interface) is a field bus system which is used primarily for networking binary sensors

and actuators (slaves) with a higher-level control (master).

Bus line

Unshielded two-wire line (AS-Interface line as AS-Interface cable harness) along which both information (data) and

energy (supply voltage for the actuators and sensors) are transmitted.

Network topology

Freely selectable within wide limits, i.e. star, tree and line networks are possible. Further details are described in the

AS-Interface specification (A/B slave model conforms to the version 3.0 specification).

10.2 Technical data for AS-Interface PCBs

Supply: via AS-Interface (24 V + 20 % / -10 %)

Outputs: 1 Valve Y1, max. 1 W, Power reduction after approx. 100 ms

with integrated Watch-Dog function

Certification: Certificate no. 87301 after version 3.0

10.3 Programming data

I/O configuration B hex

ID code A hex (see below for bit configuration)

Extended ID code 1 7 hex

Extended ID code 2 E hex

Profile S-B.A.E

Table 6: Programming data

Bit configuration

Data bit D3 D2 D1 D0

Input

0 Top not reached

1 Top reached

Output – – not used

0 Bot not reached

– –

1 Bot reached

0 Pilot valve OFF

1 Pilot valve ON

Parameter bit P3 P2 P1 P0

Output not used not used not used

Table 7: Bit configuration

english

“0“ START Teach function

“1“ STOP Teach function

37

Page 38

Type 8695

AS-Interface installation

10.4 Electrical installation AS-Interface

10.4.1 Safety instructions

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only and with the appropriate tools.

Risk of injury from unintentional activation of the system and an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

10.4.2 Connection with circular plug-in connector M12 x 1, 4-pole,

male

Connect the control head according to the table.

→

Bus connection (circular plug M12 x 1, 4-pole, male)

4

NC

Bus +

1

Figure 26: Circular plug M12 x1, 4-pole

3

Bus -

NC

2

38

Pin Designation Configuration

1

2

3

4

Table 8: Pin assignment of circular plug-in connector for AS-Interface

Bus + AS-Interface bus line +

NC not used

Bus – AS-Interface bus line NC not used

english

Page 39

Type 8695

AS-Interface installation

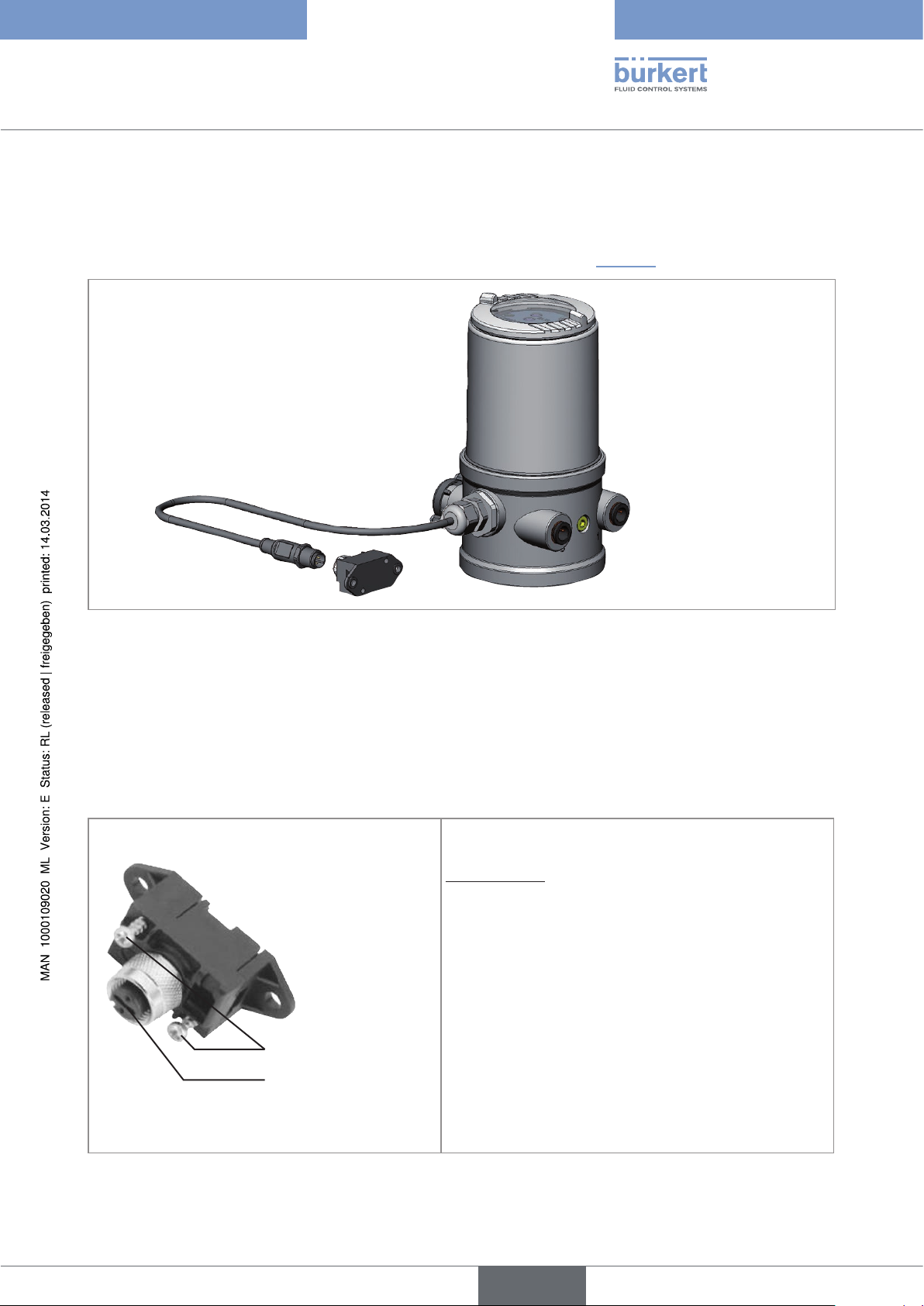

10.4.3 Connection with multi-pole cable and ribbon cable terminal

As an alternative to the bus connection model with 4-pole circular plug, there is the control head with multi-pole cable

(M12 circular plug) and ribbon cable terminal. The wiring diagram of the circular plug corresponds to the bus connection of the M12 4-pole circular plug and can easily be connected to the ribbon cable terminal (see “Figure 28”).

Figure 27: Control head 8695 with multi-pole cable and ribbon cable terminal

Handling the ribbon cable terminal

The multi-pole cable features a ribbon cable terminal - with M12 plug-in connector branch circuit - for AS-Interface

cable harness. The ribbon cable terminal contacts the AS-Interface cable harness by means of penetration technology

which allows installation by “clipping in” the AS-Interface cable harness without cutting and without removing insulation.

Work steps:

→ Open the ribbon cable terminal

(loosen screws and remove cover)

→ Insert cable harness conclusively

→ Close ribbon cable terminal again

→ Tighten screws

Screws

M12 plug-in connector branch circuit

Slightly undo thread-forming screws

(approx. 3/4 turn to the left) and position them on the

existing tapped bore and screw in.

Figure 28: Ribbon cable terminal

39

english

Page 40

Type 8695

AS-Interface installation

10.5 Teach function (calibrating the end position)

The teach function can be used to automatically determine and read in the end positions of the valve.

For the bus variant AS-Interface, the teach function can also be started via the bus protocol.

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

Necessary requirements:

Before you can actuate the teach function, you must

• mount the control head on the actuator,

• connect the supply voltage and

• connect the compressed-air supply.

DANGER!

Danger due to the valve position changing when the teach function is running.

When the teach function is running under operating pressure, there is an acute risk of injury.

▶ Never run the teach function while a process is running.

▶ Secure system from unintentional activation.

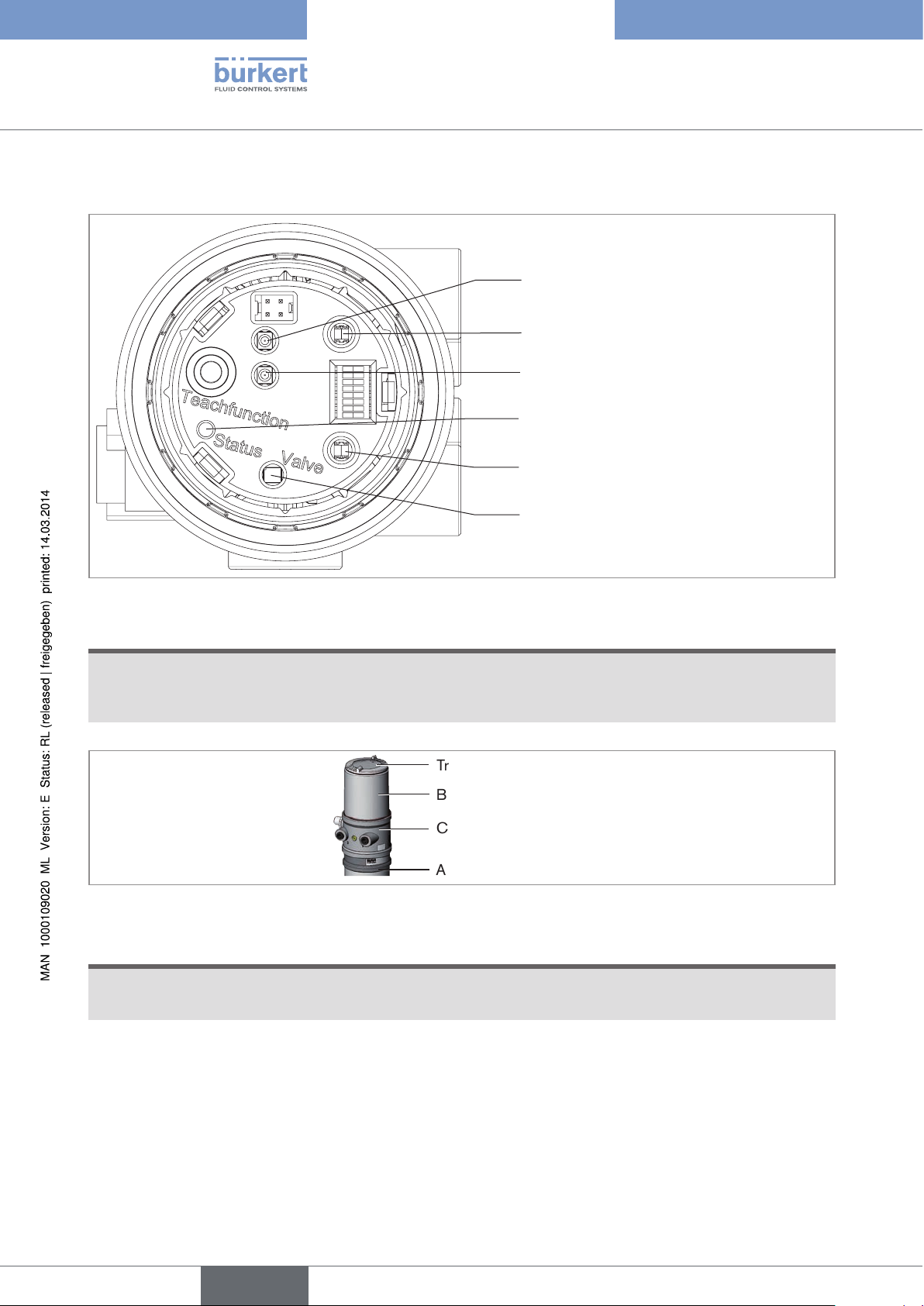

Procedure:

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not hold the actuator of the process valve but the

connection housing.

→ Open the control head: turning the transparent cap anti-clockwise.

Transparent cap

40

Body casing

Connection housing

Actuator

Figure 29: Open control head

english

Page 41

Type 8695

AS-Interface installation

→ The key in recess for actuating the teach function keep pressed for approximately 5 seconds.

Chronological description of the teach function:

Key in recess for

• the bottom position is read in internally

actuating the teach

function (keep

pressed for approximately 5 seconds)

• the pilot valve switches

• the actuator moves automatically to the top

position

• the top position is read in internally

• the pilot valve is turned off

• the actuator moves back to the home position

Figure 30: Teach function

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not hold the actuator of the process valve but the

connection housing.

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the transparent cap in all the way.

→ Close the device (assembly tool: 674078

5)

).

Important:

When the teach function is activated the actuator cannot be actuated via the AS-Interface communication.

5) The assembly tool (674078) is available from your Bürkert sales office.

english

41

Page 42

Type 8695

AS-Interface installation

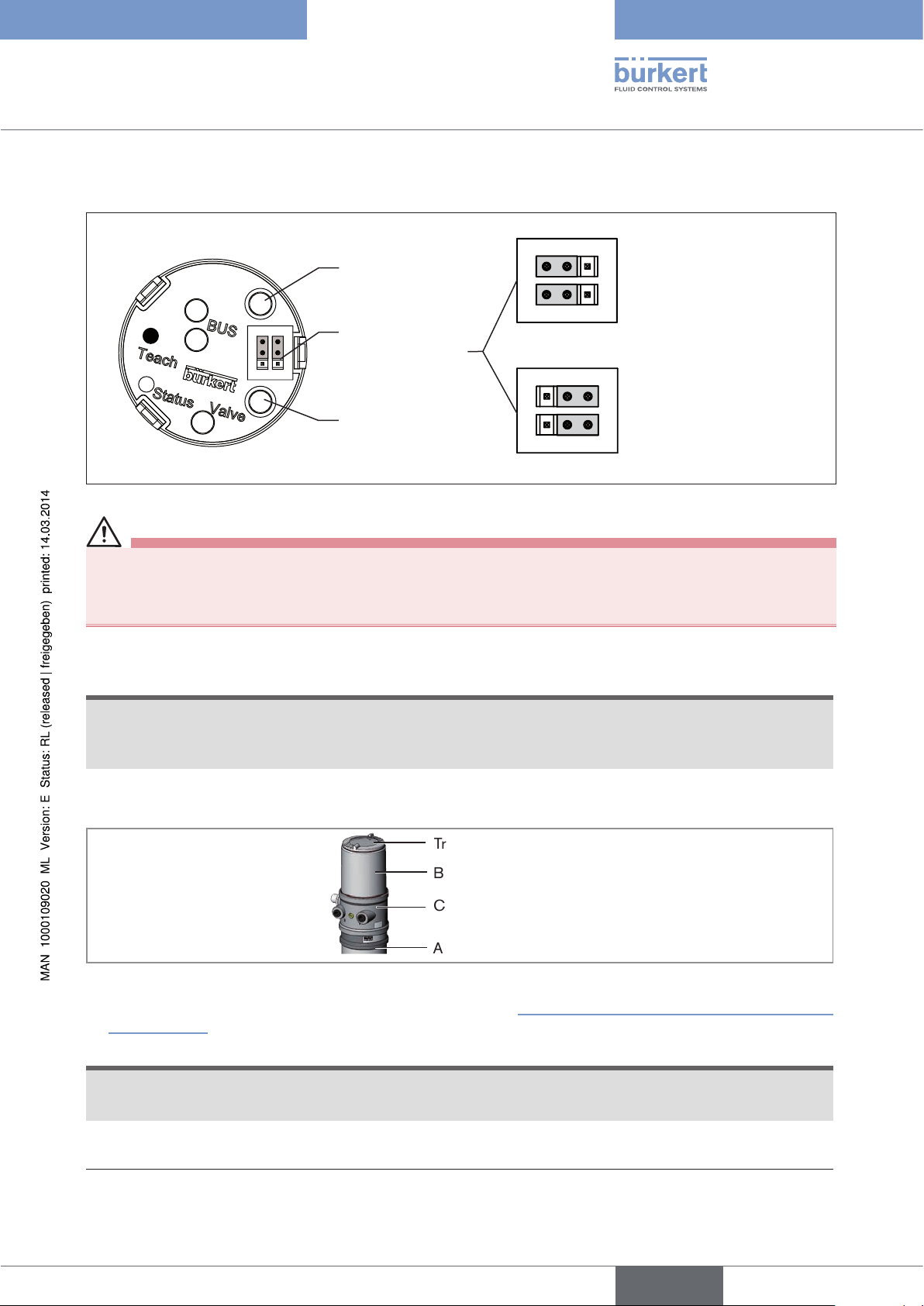

10.6 Display and control elements AS-Interface

Bus LED red

Bus LED green

ye

gn

Top

Bot

Top

Bot

gn

ye

Status LED yellow

Valve LED yellow (pilot valve)

Figure 31: Description LED and Jumper - AS-Interface

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not hold the actuator of the process valve but the

connection housing.

Transparent cap

Body casing

Connection housing

Actuator

42

Figure 32: Open control head

NOTE!

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the transparent cap in all the way.

english

Page 43

Type 8695

AS-Interface installation

10.6.1 Status LED yellow

LED yellow

flashing Teach function is running

flickers

Puck PCB or puck not available

→ Insert puck PCB or puck.

Table 9: Status LED yellow - AS-Interface

10.6.2 Valve LED yellow

The yellow LED (valve) indicates whether the pilot valve is actuated (LED is lit yellow).

10.6.3 Bus LED red and green

The red and green LEDs (bus) indicate the bus status:

LED green LED red

off off POWER OFF

off on No data traffic (expired Watch Dog at slave address does not equal 0)

on off OK

flashing on Slave address equals 0

off flashing Sensor supply overloaded or external reset

Table 10: LED bus status - AS-Interface

43

english

Page 44

10.6.4 End position LEDs

The end position is displayed optically by colored LEDs.

End position LED green

ye

gn

Top

Bot

Top

Bot

gn

ye

Figure 33: Description end position LEDs and Jumpers - AS-Interface

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

Jumper

for assignment of end position LEDs

End position LED yellow

Type 8695

AS-Interface installation

▶ When unscrewing and screwing in the transparent cap, do not hold the actuator of the process valve but the

connection housing.

Transparent cap

Body casing

Connection housing

Actuator

Figure 34: Open control head

NOTE!

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the transparent cap in all the way.

Factory setting:

Color

green LED on End position bottom

Device status

44

yellow LED off End position top

Table 11: Assignment of LEDs - AS-Interface

10.6.5 Jumper function

You can set the color assignment of the end positions with the jumpers.

You can indicate for each color whether it applies to the Top (end position top) or Bot (end position bottom).

english

Page 45

Bot

Top

Bot

Top

Type 8695

AS-Interface installation

10.6.6 Change assignment of the end position LEDs

Jumper setting 1:

End position

LED green

ye

gn

Top

Bot

Top

Bot

gn

ye

Jumper for

assignment of

end position LEDs

ye

gn

Bot

ye

End position

LED yellow

gn

Bot

ye

gn

Top

ye

gn

Top

In the end position top

(Top), the yellow LED

is lit; in the end position

bottom (Bot), the green

LED is lit.

Jumper setting 2:

In the end position top

(Top), the green LED is lit;

in the end position bottom

(Bot), the yellow LED is lit.

Figure 35: Assignment of the end position LED - AS-Interface

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

Procedure:

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not hold the actuator of the process valve but the

connection housing.

→ Open the control head: turning the transparent cap anti-clockwise.

Transparent cap

Body casing

Connection housing

Actuator

Figure 36: Open control head

→ Using the jumpers, assign the required color to the LEDs (see “Figure 35: Assignment of the end position LED

- AS-Interface”).

NOTE!

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the transparent cap in all the way.

→ Close the device (assembly tool: 674078

6) The assembly tool (674078) is available from your Bürkert sales office.

6)

).

45

english

Page 46

Type 8695

DeviceNet installation

11 DEVICENET INSTALLATION

11.1 Definition

• The DeviceNet is a field bus system which is based on the CAN protocol (Controller Area Network). It enables

actuators and sensors (slaves) to be networked with higher-level controllers (master).

• The control head in the DeviceNet is a slave device according to the Predefined Master/Slave Connection Set

stipulated in the DeviceNet specification. Polled I/O, Bit Strobed I/O and Change of State (COS) are supported

as an I/O connection variant.

• With DeviceNet it is necessary to differentiate between cyclical or event-driven high-priority process messages

(I/O Messages) and acyclical low-priority management messages (Explicit Messages).

• The protocol process conforms to the DeviceNet specification Release 2.0.

11.2 Technical data

EDS file BUE8695.EDS

Icons BUE8695.ICO

Baudrate 125 kbit/s, 250 kbit/s, 500 kbit/s (via DIP switches);

Factory setting: 125 kbit/s

Address 0 – 63 (via DIP switches);

Factory setting: 63

Process data 1 static input assembly (input: from the control head 8695 to the DeviceNet Master/Scanner)

1 static output assembly

11.3 Maximum line lengths

The maximum total line length (sum of trunk lines and drop lines) of a network depends on the baudrate.

11.3.1 Total line length according to DeviceNet specification

46

Baudrate

125 kbaud

250 kbaud

500 kbaud

Table 12: Total line length

7) According to DeviceNet specification.

If a different cable type is used, lower maximum values apply.

Maximum total line length

Thick cable Thin cable

500 m

250 m

100 m

english

7)

100 m for all baudrates

Page 47

Type 8695

DeviceNet installation

11.3.2 Drop line length

Baudrate

125 kbaud

250 kbaud

500 kbaud

Table 13: Drop line length

Length of the drop lines

Maximum length Maximum total length in the network

156 m

6 m for all baudrates

78 m

39 m

11.4 Safety setting if the bus fails

If the bus fails, the pilot valve is switched to a programmable safety setting (default: pilot valve isolated). For configuration data see chapter entitled “11.9 Configuring the control head”.

11.5 Interfaces

Bus + supply Bus

Control head 8695

DeviceNet

11.6 Electrical connection DeviceNet

The bus line is a 4-core cable with additional shielding which must conform to the DeviceNet specification.

The cable transmits both information (data) and energy (supply voltage for low-power actuators and sensors).

11.6.1 Safety instructions

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only and with the appropriate tools.

Risk of injury from unintentional activation of the system and an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

english

47

Page 48

11.6.2 Display and control elements DeviceNet

RS232

End position LED green

Device status LED (two-colored: red/green)

End position LED yellow

DIP switches for

bus address and baudrate

Bus LED (two-colored: red/green)

Type 8695

DeviceNet installation

Valve LED yellow (pilot valve)

Status LED yellow

Figure 37: Display and control elements - DeviceNet

11.6.3 Bus connection (circular connector M12 x 1, 5-pole, male)

The control head features a 5-pole micro-style circular connector.

The following configuration conforms to the DeviceNet specification.

Pin

Signal

Table 14: Pin assignment circular plug-in connector DeviceNet

1 2 3 4 5

Shielding V + V – CAN_H CAN_L

Data lines

Pin 4: CAN_H

white

Pin 5: CAN_L

blue

Pin 1: Drain

(Shield)

Pin 3: V–

black

Pin 2: V+

red

Supply voltage

11 ... 25 V DC

max. power 3 W,

if valve is switched

48

Figure 38: View of plug from the front onto the pins, the soldered connections are behind

11.7 Terminating circuit for DeviceNet systems

When installing a DeviceNet system, ensure that the terminating circuit of the data lines is correct.

The circuit prevents the occurrence of interference caused by signals reflected onto the data lines.

The trunk line must be terminated at both ends with resistors of 120 Ω each and 1/4 W power loss

(see “Figure 39: Network topology - DeviceNet”).

english

Page 49

Type 8695

DeviceNet installation

11.8 Network topology of a DeviceNet system

Line with a trunk line and several drop lines.

Trunk lines and drop lines consist of identical material (see “Figure 39”).

Trunk line

V +

V –

CAN_H

CAN_L

DeviceNet cable

Terminating

resistor

120 Ω

¼ W

T01 Tn

Subscriber 1 (node 1) Subscriber n (node n)

Figure 39: Network topology - DeviceNet

Drop lines

DeviceNet cable,

max. 6 m long

11.9 Configuring the control head

11.9.1 DIP switches

1 2 3 4 5 6 7 8

OFF

Terminating

resistor

120 Ω

¼ W

DIP switches for

bus address and baudrate

Figure 40: DIP switches - DeviceNet

8 DIP switches are available for configuration:

• DIP switches 1 to 6 for the DeviceNet address

• DIP switches 7 to 8 for the baudrate

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

english

49

Page 50

Type 8695

DeviceNet installation

Procedure:

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not hold the actuator of the process valve but the

connection housing.

→ Open the control head: turning the transparent cap anti-clockwise.

Transparent cap

Body casing

Connection housing

Actuator

Figure 41: Open control head

→ Set the DIP switches according to the following tables.

NOTE!

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the transparent cap in all the way.

→ Close the device (assembly tool: 674078

Settings of the DeviceNet address

MAC ID - Medium Access Control Identifier:

[DIP 1=off=0 / DIP 1=on=1 / MAC ID=DIP 1*2

DIP 1

[20=1]

off off off off off off 0

on off off off off off 1

off on off off off off 2

... ... ... ... ... ... ...

off on on on on on 62

on on on on on on 63

DIP 2

[21=2]

DIP 3

[22=4]

8)

).

0

+DIP 2*21+...+DIP 6*25]

DIP 4

[23=8]

DIP 5

[24=16]

DIP 6

[25=32]

MAC ID

50

Table 15: Settings of the DeviceNet address

8) The assembly tool (674078) is available from your Bürkert sales office.

english

Page 51

Type 8695

DeviceNet installation

Setting the baudrate

Adjusting the control head to the baudrate of the network.

DIP 7 DIP 8 Baudrate

off off 125 kbaud

on off 250 kbaud

off on 500 kbaud

on on not permitted

Table 16: Setting the baudrate

Please note: If the settings are changed by actuating the DIP switches, this change will not take

effect until the device is restarted.

For a restart

• briefly disconnect the control head from the power supply and reconnect or

• switch the power supply off/on or

• transmit an appropriate reset message.

11.10 Configuration of the process data

To transmit process data via an I/O connection, 1 static input and 1 static output assembly can be selected. These

assemblies contain selected attributes combined into one object so that process data can be transmitted collectively

via an I/O connection.

Process data can be accessed

• cyclically in the connection variants “Polled I/O” and “Bitstrobed I/O”, with “Change of state”, if input values

change, or

• acyclically via Explicit Messages.

The access path for acyclical access is: class 4

instance 1

attribute 3

With the Get_Attribute_Single service the input data can be accessed acyclically for reading.

With the Set_Attribute_Single service the output data can be accessed acyclically for writing.

1 data byte for inputs:

(sensors or initiators)

1 data byte for outputs:

(actuators or valves)

Bit Sensor Value assignment Bit Solenoid valve Value assignment

Bit 0 End position

Bit 1 End position

Bit 2... not used 0 always

Bit 7

Table 17: data byte for inputs Table 18: data byte for outputs

0 Bot not reached

1 Bot reached

0 Top not reached

1 Top reached

Bit 0

Bit 1... not used 0 always

Bit 7

Y1 0 Pilot valve OFF

1 Pilot valve ON

english

51

Page 52

Type 8695

DeviceNet installation

11.11 Configuration of the safety position of pilot valves

for bus error

If a bus fault occurs, the bus LED may assume the “Green flashing”, “Red flashing” or “Red” status.

(For a description see “Status of the bus LED”, page 57)

The valve safety position and safety module attributes can be used to configure the pilot valve in the event of a bus fault.

If a bus fault occurs, the configuration data of the pilot valves can be accessed acyclically via Explicit Messages.

• The Get_Attribute_Single service stands for a read access of the configuration data.

• The Set_Attribute_Single service stands for a write access of the configuration data.

1 data byte for safety mode:

(Attribute address: class 150, instance 1, attributes 7)

Bit Mode Value assignment Bit Solenoid valve Value assignment

Character-

Bit 0

Bit

1...7

Table 19: data byte for safety mode Table 20: data byte for valve safety position

istics in event

of bus fault

not used 0 always Bit 7

0 Output safety position

1 Retain last valve

position

1 data byte for valve safety position:

(Attribute address: class 150, instance 1, attributes 6)

Bit 0

Bit 1... not used 0 always

Y1

(Pilot valve 1)

0 Pilot valve 1 OFF

1 Pilot valve 1 ON

11.12 Teach function (calibrating the end position)

The teach function can be used to automatically determine and read in the end positions of the actuator.

For the bus variant DeviceNet, the teach function can also be started via the bus protocol (see “11.12.1

Starting the teach function”).

DANGER!

Risk of electric shock.

52

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

Necessary requirements:

Before you can actuate the each function, you must

• mount the control head on the actuator,

• connect the supply voltage and

• connect the compressed-air supply.

english

Page 53

Type 8695

DeviceNet installation

Key in recess for actuating the teach function (keep

pressed for approximately 5 seconds

Chronological description of the teach function:

• the bottom position is read in internally

• the pilot valve switches

• the actuator moves automatically to the top position

• the top position is read in internally

• the pilot valve is turned off

• the actuator moves back to the home position

Status LED:

flashes yellow when teach function is running

Figure 42: Teach function

DANGER!

Danger due to the valve position changing when the teach function is running.

When the teach function is running under operating pressure, there is an acute risk of injury.

▶ Never run the teach function while a process is running.

▶ Secure system from unintentional activation.

Procedure:

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the transparent cap, do not hold the actuator of the process valve but the

connection housing.

→ Open the control head: turning the transparent cap anti-clockwise.

Transparent cap

Body casing

Connection housing

Actuator

Figure 43: Open control head

→ The key in recess for actuating the teach function keep pressed for approximately 5 seconds.

english

53

Page 54

Type 8695

DeviceNet installation

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.