Page 1

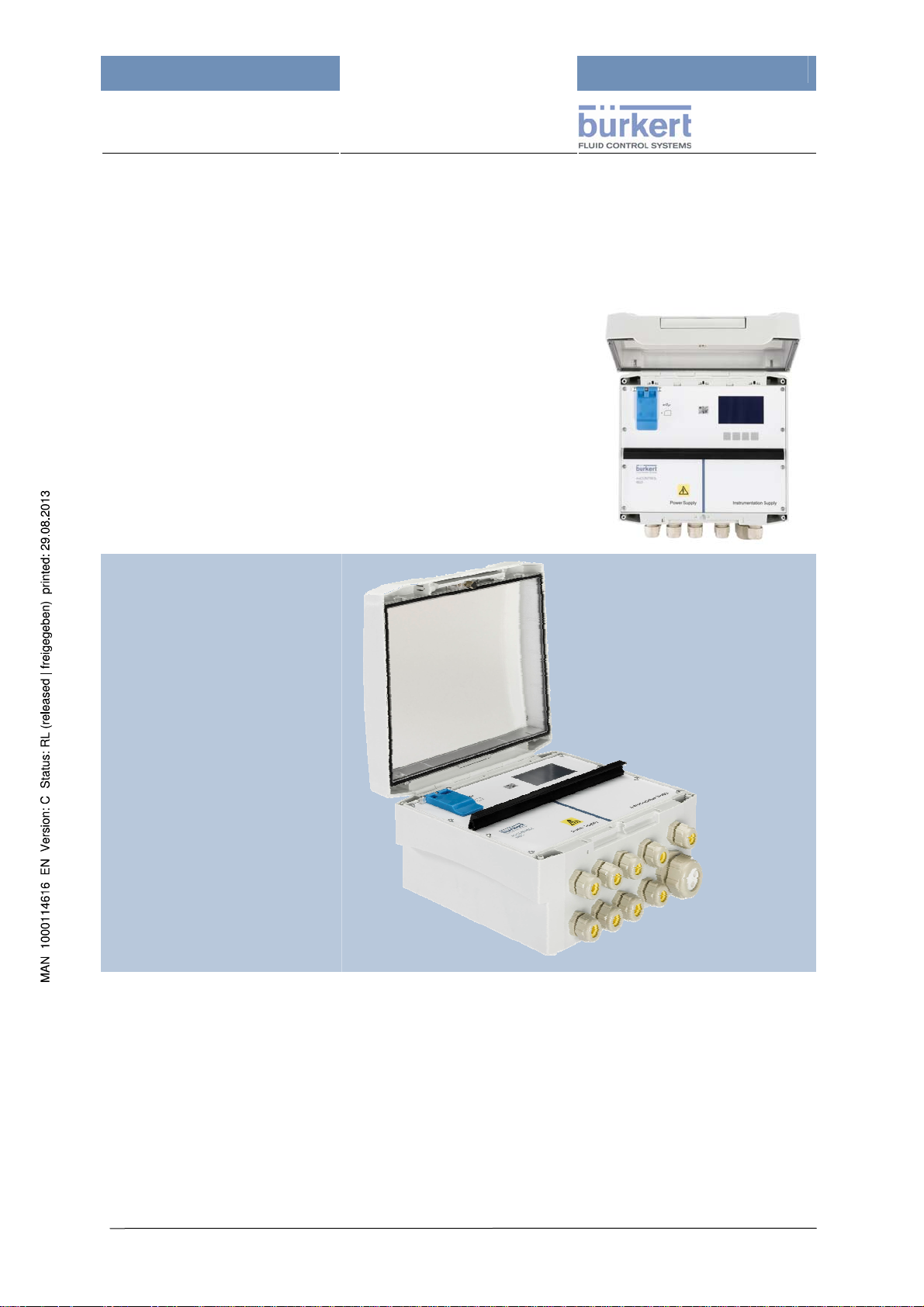

mxCONTROL Type 8620

Type 8620

mxCONTROL

Multifunction

Water Treatment

Controller

Operating Instructions

Page 1

Page 2

mxCONTROL Type 8620

We reserve the right to make changes without notice!

© 2009 - 2010 Bürkert Werke GmbH & Co. KG

Operating instructions 1007/03_EU_EN_00805853

Page 2

Page 3

mxCONTROL Type 8620

Contents

CONTENTS 3

1 THE OPERATING INSTRUCTIONS 6

2 INTENDED USE 7

2.1 Restrictions 7

2.2 Anticipated misuse 7

3 GENERAL SAFETY INSTRUCTIONS 8

4 GENERAL INFORMATION 10

4.1 Scope of Delivery 10

4.2 Warranty Regulations 10

4.3 Certifications 10

4.4 Information in the Internet 10

5 ABBREVIATIONS 11

5.1 Abbreviations in Software and Documentation 11

5.2 Display of the units 15

6 TECHNICAL DATA 17

6.1 Technical Specifications 17

6.2 Type Plate – Example 20

6.3 Hardware Structure 21

6.4 Module Overview 22

7 INSTALLATION 23

7.1 Safety Notes 23

7.2 Quick Start Guide 23

7.3 Mechanical Installation 24

7.4 Electrical Connections 24

7.5 Terminal Strip Pin Assignment 26

7.5.1 Power Supply (PS) 26

7.5.2 Instrumentation Supply (IS) 27

7.6 Download of a Configuration and Parameter File 27

8 DESCRIPTION OF HUMAN-MACHINE INTERFACE 28

8.1 Safety Notes 28

8.2 Operating and Display Elements 28

8.3 Operation Mode 29

8.3.1 Automatic & Manual Mode Key 29

8.3.2 Automatic Mode (LED on) 29

8.3.3 Manual Mode (LED off) 29

8.4 Layout of Menu Screens 30

9 MENU STRUCTURE 31

9.1 Principle of Menu Tree Structure 31

9.2 Setting Numeric Values 33

10 PASSWORD PROTECTION 34

11 GENERAL SOFTWARE CONCEPT AND FUNCTIONS 36

11.1 Functional Overview 36

11.2 Up- and Downloading of Configuration/Parameter Files 37

11.2.1 Download 37

11.2.2 Upload 38

11.3 Data Logging 39

11.3.1 Selection of SD card size for Data Logging purposes 42

11.3.2 Start of Data Logging (enabling) 43

11.3.3 Stop of Data Logging (disabling) 44

Page 3

Page 4

mxCONTROL Type 8620

11.4 Configuration and Parameterization 45

11.4.1 Preface about Configuration/Parameterisation 45

11.4.2 Operating Language 45

11.4.3 Factory Setting of Parameters and Factory Reset 45

11.5 Communication 46

11.5.1 USB 46

11.5.2 Ethernet (only devices with Ethernet option) 46

11.5.3 (Remote) Device access via PC-Tool 52

12 INPUTS 55

12.1 Digital Inputs 55

12.1.1 Binary Inputs 56

12.1.2 Frequency Inputs 57

12.1.3 Pulse Counter Inputs 62

12.2 Analog Inputs 62

12.2.1 4…20 mA Inputs 62

12.2.2 Pt100 Inputs 69

13 OUTPUTS 72

13.1 Relay Outputs 72

13.1.1 Relay as Binary Output (On/Off) 73

13.1.2 Relay as PFM Output 73

13.1.3 Relay as PWM Output 74

13.1.4 Configuration (CodeLevel: Specialist) 74

13.2 Analog 4...20 mA Outputs (Option) 75

13.3 Transistor Outputs (Option) 77

13.3.1 Transistor output as On/Off-Output 77

13.3.2 Transistor output as PFM Output 77

13.3.3 Transistor output as PWM Output 77

13.3.4 Transistor output as fast PWM Output 78

13.3.5 Configuration (Code Level: Specialist) 79

14 CONTROLLER MODULES 80

14.1 Common Settings 80

14.1.1 Automatic and Manual Mode 80

14.1.2 Definitions for “Inversion” and “All Timers” 80

14.1.3 System Switch override function (Specialist level) 81

14.1.4 Flow Switch override function (Specialist level) 82

14.1.5 Maximum Output Timer (MOT) 84

14.2 General PID controller (COMMON_PID) 85

14.3 Conductivity Control Modules 94

14.3.1 On-/Off-Control (COND_CONTROL) 95

14.3.2 PI-Control (COND_PI) 99

14.3.3 On-/Off-Ratio Control (COND_CONTROL_RATIO) 103

14.3.4 PI-Ratio Control (COND_PI_RATIO) 106

14.4 Corrosion Display (CORROSION-DISPLAY) 109

14.5 pH Controller Modules (PH_ACID_CAUS) and (PH_ACID_OR_CAUS) 110

14.5.1 pH-Control (PH_ACID_CAUS) 110

14.5.2 pH Control (PH_ ACID_OR_CAUS) 115

14.6 Dosing of oxygen absorption media 119

14.6.1 Flow and temperature-based dosing (O2_SCAV_CTRL_RATIO) 119

14.6.2 Process-value-proportional dosing (OPEN_PROP) 123

14.7 Chlorine / Redox Control (CL_ORP) 125

14.8 Batch Dosing (BATCH) 128

14.9 Time scheduled Biocide Dosing (BIOCIDE_DOSING) 131

14.10 Monitoring Process Values (MONITOR_PV) 137

14.11 Dual Channel Totalizer (TOTALIZER) 139

Page 4

Page 5

mxCONTROL Type 8620

15 ALARM AND ERROR MESSAGES 142

15.1 Alarm function 142

15.2 Displaying (Input-) Alarms and different (Output-) States 144

15.3 Error Messages and Warnings 145

16 MAINTENANCE AND TROUBLESHO OTING 153

16.1 Safety Notes 153

16.2 Maintenance work 153

16.3 Malfunctions 153

17 SPARE PARTS 154

18 PACKING AND TRANSPORT 154

19 STORAGE 154

20 DISPOSAL 154

21 APPENDICES 155

21.1 Project (for example "BW 06") 155

21.1.1 Input/Output Assignment – project "BW 06" 155

21.1.2 Wiring Diagram Example for Project "BW 06" 155

21.2 Power Supply of Actuators/Sensors 156

21.2.1 Power Supply out of the mxCONTROL 156

21.2.2 Separate Power Supply 156

21.3 Hardware Version 1 157

21.3.1 PIN Assignment for Power Supply Level (Power Supply) 157

21.3.2 PIN Assignment for Low Voltage Level (Instrumentation Supply) 158

21.3.3 Connection Examples for Inputs and Outputs 159

21.4 Hardware version 2 162

21.4.1 PIN assignment for power supply level (power supply) 162

21.4.2 PIN Assignment for Low Voltage Level (Instrumentation Supply) 163

21.4.3 Connection Examples for Inputs and Outputs 164

21.5 Main Menu Structure – Menu Tree (Example for Project "BW 06T") 168

21.5.1 Processdata – Inputs – Outputs 168

21.5.2 Processdata – Cond Control 169

21.5.3 Configuration of Inputs 170

21.5.4 Configuration of the Codes 171

21.5.5 System Settings 172

21.5.6 Up-/Download - Download 173

21.5.7 Up-/Download – Upload 174

21.5.8 Data Logging / Calibration / Clock 175

21.6 Data Logging File – Example 176

Page 5

Page 6

mxCONTROL Type 8620

1 The operating instructions

WARNING!

The operating instructions must be read and understood.

Read the operating instructions carefully.

Note the chapters Intended Use and General Safety Instructions!

Presentation elements

DANGER!

Mains voltage! Immediate danger!

Death or serious injuries are the result of non-compliance with the safety instructions.

DANGER!

Immediate danger!

Death or serious injuries are the result of non-compliance with the safety instructions.

WARNING!

Potentially dangerous situation!

Serious injuries or death may result from non-compliance with the safety instructions.

CAUTION!

Potentially dangerous situation!

Medium or light injuries may result from non-compliance with the safety instructions.

CAUTION!

Potentially dangerous situation!

Likely property damages in case of non-compliance.

Designates important additional information, tips and recommendations important for your

safety and the flawless function of the device.

Refers to information in these operating instructions or other documentation.

→ Marks a section you have to carry out.

Page 6

Page 7

mxCONTROL Type 8620

2 Intended Use

WARNING!

Hazards to persons, equipment in the vicinity and the environment may result when not using

the „Type 8620 mxCONTROL“ as intended.

The „Type 8620 mxCONTROL“ may not be used in explosion-hazard rooms.

The „Type 8620 mxCONTROL“ may only be used at temperatures from 0 °C.

The permissible data and operating conditions specified in the operating instructions as well

as the application areas described in chapter 6.1 must be followed. The customer is responsible for choosing the device suitable for his application.

Proper transport, proper storage and installation as well as careful operation and service are

the prerequisites for safe and flawless operation.

Use the „Type 8620 mxCONTROL“ only as intended.

The „Type 8620 mxCONTROL“ is a multifunction controller. This multifunction controller was

developed to automate the control and process variables in a water treatment system (e.g.

boiler, cooling tower or Reverse Osmosis system).

Sophisticated electronics and state of the art control algorithms ensure that optimum process control is

maintained at all times, with minimal operator intervention.

Depending on the hardware version, the „Type 8620 mxCONTROL“ is capable of processing several

analog and digital inputs as well as several relay, transistor and analog outputs at the same time.

Combined with an easy to read display in three languages: English, German and French (other

languages on request), the device offers nearly unlimited options for process automation systems.

The „Type 8620 mxCONTROL“ functions are highly software-based. All configuration and

parameter files can be created in a quick and unsophisticated manner with the help of a PC Tool

and downloaded in the „Type 8620 mxCONTROL“ via SD card or USB. Alternatively, the optional

Ethernet interface can be used to configure and parameterize the device. The operator can then enter

and display all important variables and parameters using five soft-touch keys.

The „Type 8620 mxCONTROL“ is supplied with an SD card containing not only the configuration and

parameter files but also the operating instructions.

Three authorization levels (code level) allow for the safe operation of the „Type 8620 mxCONTROL“:

Open access, access only for instructed operators, access for specialists.

2.1 Restrictions

Note possibly existing restrictions when exporting the device.

2.2 Anticipated misuse

• The „Type 8620 mxCONTROL“ may not be used in explosion-hazard areas!

• Do not put mechanical stress on the unit (e.g. by storing heavy objects on it or using it as a

step).

Page 7

Page 8

mxCONTROL Type 8620

3 General Safety Instructions

These safety instructions do not take any

• Incidents and occurrences into account which may occur during assembly, operation and

maintenance of the devices.

• Local safety regulations where the operating party is responsible for its compliance, also in

Danger from electrical voltage

Reaching into the system presents an acute risk of injury.

Always switch off the power before beginning with the work activities and secure it against being

switched back on inadvertently! Obey the applicable accident prevention and safety regulations for

electrical devices!

Inadvertent operation or impermissible restrictions may cause general danger situations

through the downstream actuators, including physical injuries.

regard to the installation staff.

DANGER!

WARNING!

Take proper precautions to prevent accidental actuation or inadmissible impeding.

Dangerous situations may develop during installation and repair activities. This type of work may only

be carried out by authorized technical personnel and with suitable tools!

After an interruption of the electric supply, ensure a defined and controlled restart of the processes!

WARNING!

Personal injuries and damage to the system may occur following a system interruption or after

manual operation through unwanted operation of output devices.

Before changing the mode of operation (Manual or Automatic), appropriate measures must be

taken to prevent harm to personnel and the system due to unwanted actuation of an output device

(e.g. biocide pump).

CAUTION!

The general engineering rules apply to the deployment planning and operation of the device!

Disregarding these rules may result in injuries and/or damages to the device and possibly its

environment.

Follow the general rules of engineering!

CAUTION!

Electrostatically endangered components/modules

The device contains electronic components which may react sensitively against electrostatic

discharges (ESD). Touching electrostatically charged persons or objects puts these components at

risk. In the worst case, they will be destroyed or fail after startup.

Follow the requirements according to DIN EN 61340-5 to minimize or prevent the possibility of

damage due to sudden electrostatic discharge!

Make also sure not to touch the electronic components if supply voltage is supplied!

Page 8

Page 9

mxCONTROL Type 8620

CAUTION!

Hardware and Software modifications and changes

For safety reasons unauthorised modifications and changes of hardware and software are not allowed.

Make sure to comply with the notes, thresholds, operating modes and safety instructions given in this

manual.

Non-compliance with this manual and operating sequence will void any liability claims.

CAUTION!

Temporary protection against overload and short circuit

Instrumentation Supply part (24 V DC): the device is protected against destruction by overload and

short circuit. No safe function is ensured for the duration of such disturbance. After such a disturbance,

the „Type 8620 mxCONTROL“ automatically continues its normal operation.

The plant must be dimensioned so that the sum of extracted current of all actuators/sen¬sors

connected at the Instrumentation Supply side never exceeds the value of 1.04 A.

The „Type 8620 mxCONTROL“ was developed on the basis of recognized technical safety

rules and corresponds to the state of technology. Hazards may nonetheless develop.

Operate the „Type 8620 mxCONTROL“ only in flawless condition and in compliance with the

operating instructions. Also make sure to comply with the conditions of use according to

the specifications in chapter 6.1 „Technical Specifications“ and on the type plate of the

device.

Non-compliance with these instructions and unauthorized tampering with „Type 8620

mxCONTROL“ voids any liability by us; the warranty for the device and accessories also

becomes void!

Page 9

Page 10

mxCONTROL Type 8620

4 General Information

4.1 Scope of Delivery

Verify immediately after receiving the shipment that the contents are not damaged and agrees with the

specified scope of delivery as stated on the enclosed "Delivery instructions"; also make sure that the

details on the type plate match the conditions of use.

Please contact our sales centre immediately in case of disagreements:

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Germany

or your Bürkert distribution centre.

Phone: +49 (0)7940 - 10 111

Fax: +49 (0)7940 - 10 448

Email: info@de.buerkert.com

4.2 Warranty Regulations

This document contains no promise of guarantee. Please refer to our terms of sales and delivery. The

warranty is only valid if the device is used as authorized in accordance with the specified application

conditions.

The warranty extends only to defects of the „Type 8620 mxCONTROL“ and its components.

We accept no liability for any kind of collateral damage which can occur due to failure or

malfunction of the device.

4.3 Certifications

The certification designation on the Bürkert type plates refers to the Bürkert products.

More information on the certifications can be found in the chapter

6.1 “Technical Specifications“.

4.4 Information in the Internet

You can find operating instructions and data sheets on type 8620 in the Internet at:

www.buerkert.de → Technical Data → Operating instructions → Data sheets → Type 8620.

The complete documentation is supplied on the SD card.

Page 10

Page 11

mxCONTROL Type 8620

5 Abbreviations

5.1 Abbreviations in Software and Documentation

Further abbreviations (Error messages) can be found in chapter 15.3.

Abbreviation Explanation

+Tm Maximum output time

+TmPB Maximum pre-bleed duration

AH Higher Alarm Process Value

AL Lower Alarm Process Value

Alarm- Lower alarm limit

Alarm+ Upper alarm limit

AlarmHys Alarm hysteresis in % of process value range

Alarm H Upper Process Value Alarm

Alarm L Lower Process Value Alarm

AnalogIn 1 to 4 Analog input 1 … 4

ASL Acid (pump) stop limit (Acid Stop Limit)

ASL PumpStop Pump Stop due to the ASL alarm

Au Automatic Mode

BATCH (or Batch Dosing) Batch Module (dosing by batches)

Binary Binary input (digital: 0 / 24 VDC)

BIOCIDE_DOSING Biocide dosing module

BioDos Biocide dosing module (abbrev.)

Cd Conductivity module (On/Off control) - abbrev.

Cd-PI

Cd-PIr

Cd r

CL Chlorine

CL/ORP Chlorine/Oxidising Redox Potential PI-Control Module - abbrev.

CL_ORP Chlorine/Oxidising Redox Potential-PI-Control Module

CM Calibration mode: 4-20mA input or output is currently calibrated

CMD Module output (command) to actuator (%) - proportional/integral

CMD A Module output (Acid) - acid pump

CMD C Module output (Caustic) - caustic pump

CMD on Output value at module output e.g. during dosing

CMDsafe

CMD 1, CMD 2 Module output for channel 1, module output for channel 2 (at BIOCIDE_DOSING)

Cond Conductivity

COND_CONTROL Conductivity module (On/Off control)

COND_CONTROL_RATIO

COND_PI

COND_PI_RATIO

Cor Corrosion

CorroD Corrosion Display Module (short name)

Conductivity module (PI control) - abbrev.

(in part with 3-point step output)

Conductivity module (PI-Ratio-Control) - abbrev., set point depending on MakeUp-Channel ratio

Conductivity module (On/Off Ratio-Control) - abbrev., set point depending on

Make-Up-Channel ratio

Safety output value, it is active if

- on the 4…20 mA input less than 3.5 mA or more than 20.5 mA are applied,

- on the Pt100 input, a temperature outside of the measuring range is applied

Conductivity module (On/Off Ratio-Control), set point depending on Make-UpChannel ratio

Conductivity module (PI control)

(in part with 3-point step output)

Conductivity module (PI-Ratio-Control), set point depending on Make-Up-Channel

ratio

Page 11

Page 12

Abbreviation Explanation

CORROSION_DISPLAY Corrosion Display Module

Cut- Lower CutOff threshold (Module "COMMON_PID")

Cut+ Upper CutOff threshold (Module "COMMON_PID")

D- Max. negative set point change per minute, falling (Delta-)

D+ Max. positive set point change per minute, rising (Delta+)

Dbnd Deadband - to prevent vibration of the actuator

DigIn 1 … 4 Digital input 1 … 4

Dos1 … Dos8 Biocide timer settings (8 per day per channel)

FA AD-Fault

Fc Calibration Data Fault

FC Configuration Fault

fF Flow switch: “No Flow”

FI Input Fault

Filter Filter stage (for Low Pass Filter)

Fmax Maximum actuator output pulse rate per minute or per hour

fo forced by other modules

Freq- Lower frequency value of a frequency range

Freq+ Upper frequency value of a frequency range

Fr Friday

fS System switch: “Stand-by”

FS Sensor Fault; Full scale (in connection with Technical Specification)

FSOR Flow switch override

Hyst Switching hysteresis set in engineering units

HO Process Value state, Value Hold during User Calibration of 4-20mA inputs

Inv Inversion of the sense of action of a module/signal

IS Instrumentation Supply

Kp Gain/amplification factor (in [% control output/PV unit])

Kx Ratio factor for internal set point calculation

Lim- Lower output limit in %

Lim+ Upper output limit in %

Ma Manual (operation) mode

Mo Monday

MONITOR_PV Module - monitoring only a Process Value PV (data logging)

Mon PV Module - monitoring only a Process Value (data logging) - short name

MOT Maximum Output Timer

MPY Mils Per Year

MTPB Maximum pre-bleed timer

µMPY Micro Mils Per Year

nA Input not active

O2_SCAV_CTRL_RATIO Dosing of O2-absorption media based on flow and temperature

O2SCR Dosing of O2-absorption media based on flow and temperature - abbrev.

OF Output fault of the 4…20 mA outputs

OPEN_PROP Dosing proportionally to process value

OpProp Dosing proportionally to process value - abbrev.

ORP Oxidising Redox Potential (Redox)

PB

PB ratio

PFM Pulse Frequency Modulation

pH-AC

pH-A/C

Page 12

Pre-Bleed Limit of biocide dosing module in connection with the

COND_CONTROL and COND_PI modules

Pre-Bleed Ratio Limit of biocide dosing module - only in connection with the

modules COND_CONTROL_RATIO and COND_PI_RATIO

pH PI Module with selection of acid and caustic pump (abbrev.)

pH PI Module with selection of acid or caustic pump (abbrev.)

mxCONTROL Type 8620

Page 13

mxCONTROL Type 8620

Abbreviation Explanation

PH_ACID_CAUS

PH_ACID_OR_CAUS

pH PI Module with selection of acid and caustic pump

pH PI Module with selection of acid or caustic pump

ptf.binary Binary input (digital, potential-free)

PS Power Supply

Psd Process switching difference

PumpStop Pump stopped because corrosion limit exceeded

PV Process value

PV BSi Process value of Batch size

PV cal Conductivity value (for TDS-calibration)

PWM Pulse Width Modulation

r read (access via configuration menu or via XML-configuration or parameter file)

Ref.Date Week1 Reference Date for week 1

rw read and write (access via configuration menu or via XML-config. / parameter file)

Sa Saturday

Scal- Minimum value of sensor range (in engineering units)

Scal+ Maximum value of sensor range (in engineering units)

SP Set point

SP BSi Set point of Batch size

SpecFunc Special input function for 4…20 mA inputs

SPLim Set point minimum (internal calculation for conductivity)

SPLim- Lower set point limit for pH measurement

SPLim+ Upper set point limit for pH measurement

SP Limit Set point Limiter

SP Ramp Set point ramp

SSOR System switch override

State Current state of dosing process in batch module

Su Sunday

Tco cl Time for complete closing: 100% Æ 0%)

Tco op Time for complete opening: 0% Æ 100%)

Tdose (Total) Biocide dosing time; Batch dosing time

TDS Total Dissolved Solids

TDS cal TDS-value (Total Dissolved Solids value)

Th Thursday

+Tm Maximum output time

+TmPB Maximum pre-bleed duration

Tm1 Interval between main biocide dosing & post dosing

Tm2 Delay after post-dosing before conductivity control resumes

Tn Reset time in seconds

Tperiod period duration

Tpuls Pulse duration of the actuator output in milliseconds or seconds

Tsample Sample time of the respective control loop; sample time with data logging

Tu Tuesday

Tv Rate time

w write (access via configuration menu or via XML-configuration or parameter file)

Warn- Lower warning limit

Warn+ Upper warning limit

WarnHys Warning hysteresis in % of process value range (AwHyst)

WH Upper warning process value

We Wednesday

WL Lower warning process value

YA Abbreviation in the alarm display for ASL-pump-stop

Page 13

Page 14

Abbreviation Explanation

YF Out fails (MOT is expired)

YS Safety output value is active (due to input/sensor fault)

mxCONTROL Type 8620

Page 14

Page 15

mxCONTROL Type 8620

5.2 Display of the units

Because of the limited display, there is not always sufficient room available for the detailed display of

the unit. Depending on the available positions, 3 or 6 positions are shown in the display; the

equivalents as well as the output during data logging are listed in the following table, arranged by

groups.

Display

max. 3 characters

Volume units

L L L Litre

hL hL hL Hectolitre

m3 m3 m3 Cubic metre

Gal Gal US Gal US U.S. liq. Gallon

bbl bbl US bbl US U.S. Barrel

gal gal Im gal Imp Imperial Gallon

ft3 ft3 ft3 Cubic Foot

yd3 yd3 yd3 Cubic Yard

Flow units

L/s L/s L/s Litre per second

L/m L/min L/min Litres per minute

L/h L/h L/h Litre per hour

m3M m3/min m3/min Cubic metre per minute

m3H m3/h m3/h Cubic metres per hour

G/s Gal/s Gal/s US U.S. liq. Gallons per second

G/m Gal/m Gal/m US U.S. liq. Gallons per minute

G/h Gal/h Gal/h US U.S. liq. Gallons per hour

g/s gal/s gal/s Imp Imperial gallons per second

g/m gal/m gal/m Imp Imperial gallons per minute

g/h gal/h gal/h Imp Imperial gallons per hour

bbS bbl/s bbl/s US U.S. Barrel per second

bbM bbl/m bbl/m US U.S. Barrel per minute

bbH bbl/h bbl/h US U.S. Barrel per hour

f3S ft3/s ft3/s Cubic Feet per second

f3M ft3 /m ft3 /min Cubic Feet per minute

f3H ft3/h ft3/h Cubic Feet per hour

P/s Pul/s Pul/s Pulses per second

P/m Pul/m Pul/m Pulses per minute

Units for chemical analysis

µS µS/cm µS/cm Microsiemens per centimetre

mS mS/cm mS/cm Millisiemens per centimetre

MPY MPY MPY Mils per year

µMY µMPY µMPY Micromils per year

mV mV mV Millivolt

mgL mg/L mg/L Milligrams per litre

%Sa %Sat %Sat Percent of saturation

pH pH pH pH

Temperature units

°C °C °C Degree Centigrade

°F °F °F Degree Fahrenheit

°Ra °Rank °Rank Degree Rankine

K K K Kelvin

Display

max. 6

characters

Display of the unit

selection as well as

data logging

Page 15

unit

Page 16

Display

max. 3 characters

Display

max. 6

characters

Display of the unit

selection as well as

data logging

mxCONTROL Type 8620

unit

Pressure units

bar bar bar Bar

mba mbar mbar Millibar

psi psi psi psi

Various units

ppm ppm ppm Parts per million

V V V Volt

mA mA mA Milliamps

Pul Pulse Pulse Pulse

Hz Hz Hz Hertz

% % % Percent

Other parameter units

ms ms ms Milliseconds

s s s Seconds

min min min Minutes

h h h Hours

/m /min /min Per minute

/h /h /h Per hour

Page 16

Page 17

mxCONTROL Type 8620

6 Technical Data

6.1 Technical Specifications

These operating instructions are valid from Firmware revision: C.00.00.00

General Details of the Device

Enclosure with sealed keypad and display

Enclosure outer dimensions L x W x H 230 x 204 x 119 mm (without cable glands)

Enclosure material PC (UL94) with transparent door and key

Weight 1.8 kg

Degree of protection

Graphic display, large and backlighted 128 x 64 dots, two colored (blue and white)

Keypads for manual operation 5 keys for user inputs

Operating temperature 0 … +50 °C

Storage temperature -20 … +60 °C

Electrical Details

Mains voltage (power supply) 100 … 240 V AC, 50/60 Hz, no adjustment necessary

Power consumption (of mxCONTROL device) max. 35 W (incl. sensor supply at Instrumentation Supply part)

Total power consumption

(using the internal power distribution)

Total input current I

Total output current I

(using internal power distr.) max. 10 A

in

out

(using the internal power distribution)

Instrumentation supply for sensors / transistor

outputs

Fuse for device protection

(Instrumentation)

Fuse for Relays outputs

Inrush current (typ.) Cold start: 30 A / 230 V AC

Electrical Connections

Electrical connection Power Supply Hardware version 1: Screw terminals, grid 5.08 mm,

Electrical connection Instrumentation Supply Hardware version 1: Screw terminals, grid 3.81 mm,

Cable glands and cables

IP 65 and NEMA/UL 50, Type No. 4X, with door closed and

properly sealed cable glands,

additional cover of USB port and SD card slot

max. 2400 W (at 240 V AC) or max. 1100 W (at 110 V AC)

incl. connected actuators at Power Supply part

<10 A (incl. device power consumption of 35 W)

24 V DC (±5 %), max. 1.04 A (25 W),

short circuit and overload protected

internal: electronic fuse, recovers automatically after fault

condition is removed

Relay outputs to be fused in external installation according to

actuators

for wire gauges 0.14 … 1.5/2.5 mm

Hardware version 2: Spring type terminal, grid 5.0 mm,

for wire gauges 0.2 … 2.5/4.0 mm

for wire gauges 0.14 … 1.0/1.5 mm

Hardware version 2: Spring type terminal, grid 3.5 mm,

for wire gauges 0.2 … 1.5 mm

2

(AWG 26…14)

2

(AWG 24…12)

2

(AWG 26…16)

2

(AWG 24…16)

Hardware version 1:

9 x M16 (PG9) 5 ... 6.5 mm cable

1 x M32 (PG21) 5 mm cable (5x)

Hardware version 2:

4 x M16 (PG9) 5 ... 6.5 mm cable

2 x M16 (PG9) 6 ... 9.5 mm cable

3 x M20 (PG13) 9 ... 13.5 mm cable

1 x M32 (PG21) 5 mm cable (5x)

(cable = outer diameter of cable)

Not used cable glands have to be sealed with appropriate

sealing bolts to guarantee the Degree of protection IP65.

Thermal stability (cable material):

105 °C for cables at Power Supply part

80 °C for cables at Instrumentation Supply part

Page 17

Page 18

mxCONTROL Type 8620

Internal Equipment – Inputs

Inputs Hardware version 1:

4 Analog inputs (4 … 20 mA or Pt100; software-

configurable) +

4 digital (On/Off or Freq) inputs

Hardware version 2:

4 Analog inputs 4 … 20 mA +

2 Pt100 +

4 Digital (On/Off or Freq) inputs +

4 digital (On/Off) inputs

Analog inputs – Characteristics

Input resistance of 4…20 mA inputs

max. 300 Ω

Measuring error of 4…20 mA inputs < 0.2 % FS

Range of Pt100 inputs -20 … +150 °C

Measuring error Pt100 inputs

max. ±0.25 K

3 wire connection; software compensated wire resistance

required

Digital Inputs - Characteristics

Logical values binary inputs 1 or HIGH: 13 ... 35 V; 0 or LOW: 0 … 4.5 V

Input resistance of binary inputs

≥ 20 kΩ

Max. frequency 2 kHz

Duty factor frequency 1 : 1

Measuring error frequency max. 0.2 % FS

Input accepts signals from

open collector; open emitter; push-pull output; hall effect; reed

switch; micro switch

Internal Equipment - Outputs

Outputs Hardware version 1:

5 Relay outputs +

4 Analog outputs 4 … 20 mA (optional) +

4 Transistor outputs (optional)

Hardware version 2:

5 Relay outputs +

2 Analog outputs 4 … 20 mA +

2 Transistor outputs

4…20 mA Analog outputs - Characteristics

Relay outputs - Characteristics

max. 500 Ohmic load, output resolution 10 bit (effective >9 bit)

max. 250 V AC/DC, max. 10 A, potential-free, two-way

contacts,

max. 2500 VA (AC), max. 40 W Ohmic load (DC),

3 million switching cycles at 1 A, 10 million switching cycles at

0 A

Transistor outputs - Characteristics

24 V DC, switching capacity each max. 16 W, pnp, max. 2200

Hz

Further internal Equipment

Micro-controller core 32 bit with integrated flash memory

Slot for SD card (memory card)

Can be used for data logging, up- and download of

configuration and parameter files

Clock real-time clock with calendar

Battery back-up for real-time clock

Lithium battery CR2032, exchangeable, approx. 10 years

service life

Continuation next page

Page 18

Page 19

mxCONTROL Type 8620

Communication

SD card

SD card capacity: minimum 64 MB, maximum 2 GB,

formatted with FAT16 file system

Up-/download of configuration data

via USB or SD card

and parameters

Data-logging on SD card

Firmware update via USB

USB slave interface standard USB interface for PC communication

Ethernet interface

optional: Ethernet interface for easy diagnosis including Web

Server and email option

Extension bus interface

CAN-based bus for connection of extension units

(e.g. I/O extensions)

Controller structure

Number of control loops max. 8 active control loops

Controller outputs/Module outputs 1) On/Off

2) Pulse frequency modulated (PFM)

3) Pulse width modulated (PWM)

4) Analog

Sample period

approx. 50 ms (with 1…4 active control loops);

approx. 100 ms (with more than 4 active control loops)

User configuration

Cascade control possible; inputs, outputs and control function

designations can be changed via configuration file

Characteristics of modules

General PID control

PID process controller for fixed value, subsequent value or

cascade control

Conductivity control

On/Off or PI control - continuous dosing through PFM, PWM or

4…20 mA analog output,

automatic or manual drain

Corrosion display

No controller function, only display of measuring values;

impact on general alarm output

pH control

PI control - continuous dosing through PFM, PWM or 4…20

mA analog output

Module for dosing of oxygen scavenger media

Proportional dosing for flow and oxygen content depending on

flow with or without temperature input

Chlorine / Redox Control

PI control - continuous dosing through PFM, PWM or 4…20

mA analog output

Batch-Dosing

Allows batching of a chemical based on volume of water

added

Biocide dosing

14-day program, 8 dosing events per channel/per day; Prebleed function to optimize biocide kill time

Monitor module Display of process values

Totalizer function

Single or dual channel flow totalizer (each having two

manually resetable totalizers)

Further functionalities

Password protection, filter; selection of engineering units,

alarm; inverse function

Norms and standards

Environment standards IEC/ DIN IEC 60068

EMC standards EN 61000, EN 55011

Continuation next page

Page 19

Page 20

CE mark applicable tests resulting in CE mark

UL/CSA (for UL/CSA approved versions)

conform to Std. UL61010-1 Second Edition “Process Control

Equipment” and to the appropriate

CSA standard C22.2 No. 61010-1 Second Edition

mxCONTROL Type 8620

Table 1: Technical Specifications

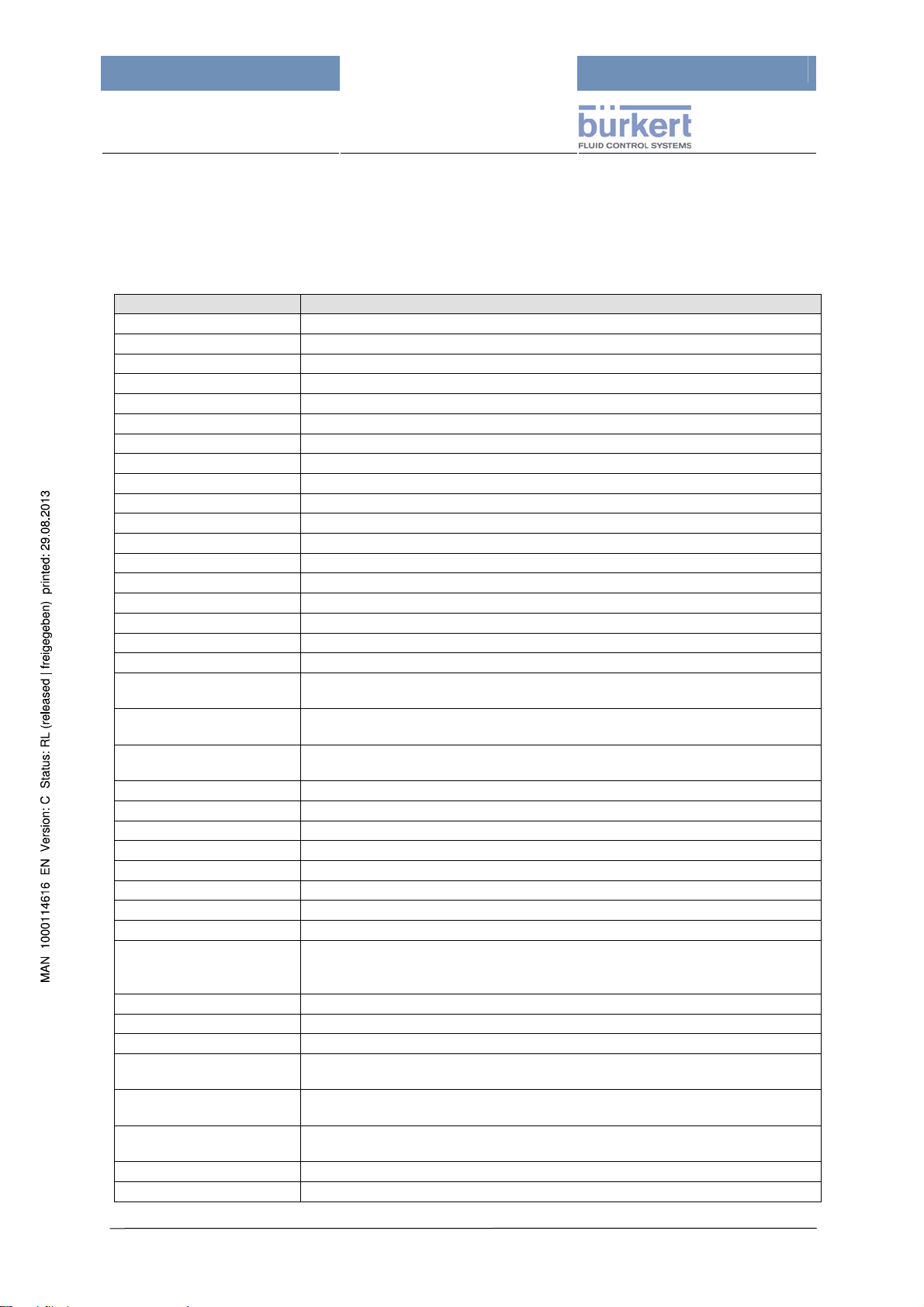

6.2 Type Plate – Example

Device designation (multi function controller)

Type

Specifical Configuration of the device

Voltage and Frequency range, admissible Current

Serial Number and

Order Number and Production Code

The UL Mark is necessary for marketing at the US and

Canadian market.

Attention! Consider the manual!

This UL Mark certifies that the appropriate safety

requirements are observed (for UL approved versions

only.)

Page 20

Page 21

mxCONTROL Type 8620

6.3 Hardware Structure

This simplified block diagram shows the main hardware components of „Type 8620 mxCONTROL“.

Figure 1: Block diagram - Hardware structure

The number of the in- and outputs of the several hardware versions is listed in the following

Table 2:

Inputs

Outputs

Analog 4 … 20 mA - 4

Analog Pt100 - 2

Analog 4 … 20 mA or Pt100 4 -

Digital (Binary) - 4

Digital (Binary or Frequency) 4 4

Analog 4 … 20 mA 4 (optional) 2

Relay 5 5

Transistor 4 (optional) 2

Table 2: Number of inputs and outputs of the hardware versions

Hardware version 1 Hardware version 2

Page 21

Page 22

mxCONTROL Type 8620

6.4 Module Overview

This table shows the available standard modules which can be combined specifically for the

application. They can function either as process or control or merely as display module.

The module names as used in the configuration files and the short designations for the menu are

listed as well as a short explanation of the module type.

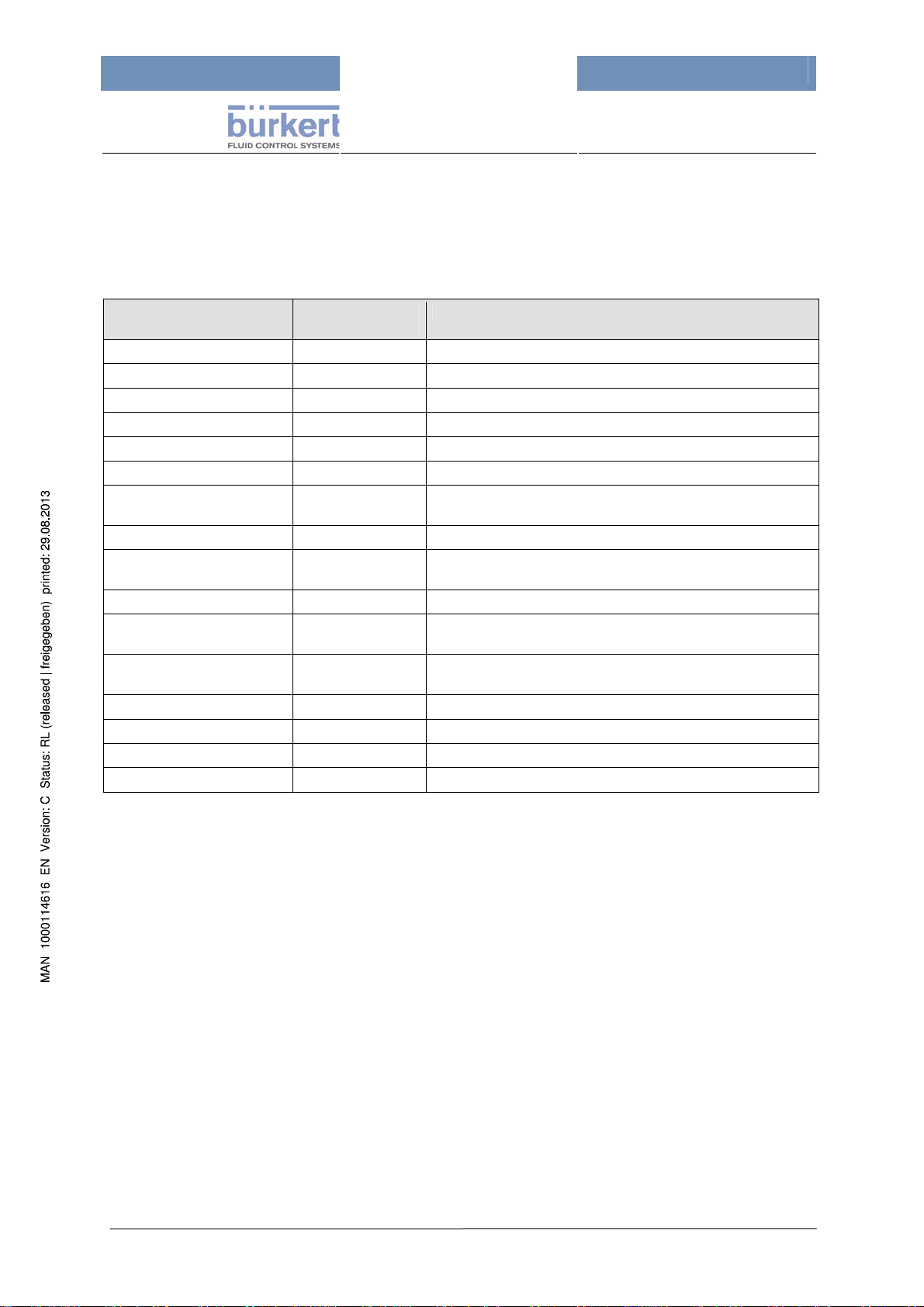

Module-name for XMLconfiguration-file

NONE -- --

BATCH Batch Batch-Dosing

BIOCIDE_DOSING BioDos Biocide-Dosing

CL_ORP CL/ORP Chlorine/Redox-PI-Control

COMMON_PID PID General PID controller

COND_CONTROL Cd Conductivity On/Off control

COND_CONTROL_RATIO Cd r

COND_PI Cd-PI Conductivity PI-Control

COND_PI_RATIO Cd-PIr

CORROSION_DISPLAY CorroD Corrosion-Display

MONITOR_PV Mon PV

O2_SCAV_CTRL_RATIO O2SCR

OPEN_PROP OpProp Dosing (proportionally to process value)

PH_ACID_CAUS pH-AC pH PI-Control with outputs for acid and caustic pumps

PH_ ACID_OR_CAUS pH-A/C pH PI-Control with output for acid (or caustic) pump

TOTALIZER Total 2-channel totalizer

Short name in

menu

Module type

Conductivity On/Off control, set point via ratio from Make-Up

Channel

Conductivity PI-Control,

set point via ratio from Make-Up-Channel

Monitoring only up to two process values (data logging) and

optionally output

Dosing of oxygen absorption media based on flow rate and

temperature of the feed water

Table 3: Module designations and types

Page 22

Page 23

mxCONTROL Type 8620

7 Installation

7.1 Safety Notes

DANGER!

Danger from electrical voltage!

Reaching into the system presents an acute risk of injury.

Always switch off the power before beginning with the work activities and secure it against being

switched back on inadvertently!

Obey the applicable accident prevention and safety regulations for electrical devices! Please, compare

the DANGER and UL indications in chapter 7.4 “Electrical Connections”!

WARNING!

Danger from improper installation!

Improper installations may result in injuries as well as damages on the device and its environment.

This type of work may only be carried out by authorized technical personnel and with suitable tools!

Danger from unintentional operation!

Dangerous situations may develop from unintentional operation of the plant.

Prevent the possibility of unintentional operation of the plant through suitable measures.

7.2 Quick Start Guide

Install the „Type 8620 mxCONTROL“ in a plant or

mounted on a backboard as shown in figure 2

Figure 2:

→ Install the required sensors and other equipment, according to the separate operating

instructions.

→ Make the wiring connections according to the specifications in chapter

→

Switch on the operating voltage.

→ Load the configuration file and the parameter file from an SD card (see chapter

→ Chec

→ Set

k/edit parameters and values in the operating menu according to the menu description

(see Chapter

9) and module description (chapter 14).

the date and time in the corresponding menu (refer to chapter

„Type 8620 mxCONTROL“ - Installation example

7.4.

11.2).

21.5.8).

Page 23

Page 24

mxCONTROL Type 8620

7.3 Mechanical Installation

Direct sunlight will reduce the viewing contrast at the display – although it is harmless to the

display. Therefore find a suitable, protected location for the installation.

The „Type 8620 mxCONTROL“ is not designed for ambient temperatures below.0 °C.

If this cannot be avoided, the „Type 8620 mxCONTROL“ must be installed in a

thermostatically controlled cabinet to maintain a normal ambient temperature.

In North America, the device must not be installed directly at building walls! In this case use

always appropriate backboards or switchboards/switching cabinets for mounting the device.

→ Open the cover (unlock it if a key is supplied) by pressing the snap lock with both thums.

For closing the cover press it down until a “click” is to be heard (and lock it with the key).

→ The „Type 8620 mxCONTROL“ is designed for wall mounting (exception: North America – see

information frame above).

Figure 2 shows the preferred mountin

g position.

Drill 4 holes (according to

the used screws) according

to the dimension shown.

Mount the device with 4 appropriate screws

(recommended screws:

M4.5 or M5,

screw head: ≤ 9.5 mm).

Figure 3: Dimensions for mounting

4 Mounting holes

→ Wall mounting with screws is made possible by 4 openings located in each corner of the

enclosure (see

Figure 3). Access to these openings is obtained by opening the cover.

7.4 Electrical Connections

DANGER!

Danger from electrical voltage

Reaching into the system presents an acute risk of injury.

Make sure that no supply voltage is present on the device when working on it! Obey the applicable

accident prevention and ensure that all electrical connections comply with local and plant regulations!

Pay attention to correct design of the fuse and/or the line safety switch in the power supply

line.

For dimensioning and installation of disconnecting switch, fuses etc. necessarily refer to further

information below!

In North America, devices with UL certification have to be used for these purposes.

Page 24

Page 25

mxCONTROL Type 8620

Dimensioning of fuses, line safety switches, overcurrent protection devices

Pay attention to correct design of the fuse and/or the line safety switch in the power supply line.

The L- and N-conductors have to be protected with overcurrent protection devices (max. 10 A) as e.g.

fuses, line safety switch etc.

Also install an equipment for the disconnection of L- and N-conductors from the power supply

near the „Type 8620 mxCONTROL“. Therefor e.g. the above-mentioned overcurrent protection

device or an appropriate disconnecting switch (110/240 V and with at least the size of current of the

overcurrent protection device) can be used.

If the sum of extracted current of all connected actuators at the Power Supply part exceeds the

value of 10 A, the actuators can be connected with a separate voltage supply for those actuators -

please refer to the schemata in appendix

21.2 „Power Supply of Actuators/Sensors“.

Electrical Connections

The preferred mounting position for the „Type 8620 mxCONTROL“ is with the cable glands facing

downward, i.e. all cable glands are located at the bottom of the device.

→ The electrical connections can be accessed by loosening the screws that hold the lower cover

plate in place. You can then lift the cover plate by the black handle.

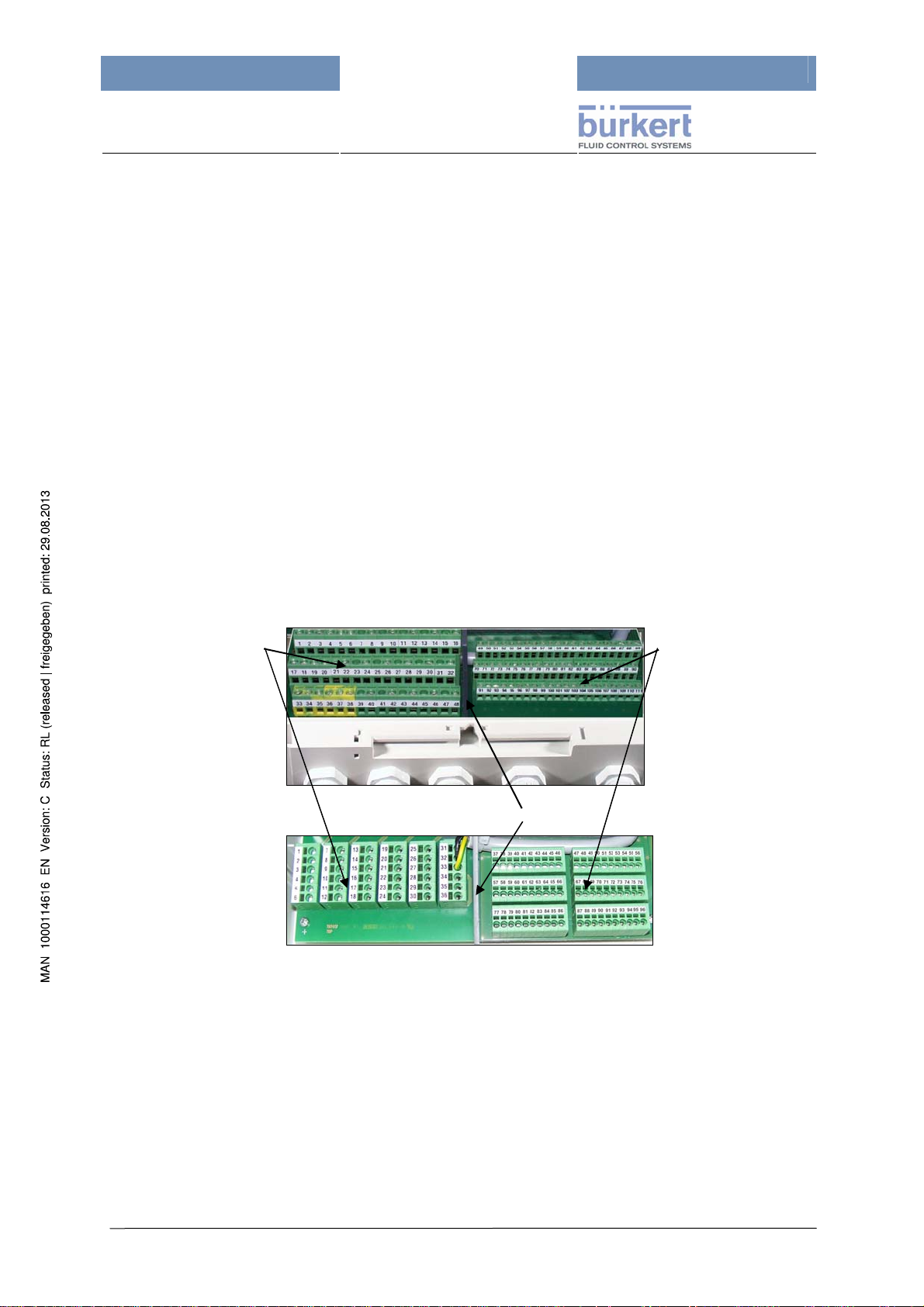

→ The terminal strips for the mains voltage level (power supply) and the low-voltage level

(instrumentation supply) are separated by an isolating plate (see

Mains voltage level

(Power supply PS)

(Hardware version 1)

Figure 4).

Low-voltage level

(Instrumentation

supply IS)

Isolating plate

(Hardware version 2)

Figure 4: Viewing the inside of the terminal strip compartment (with the cover plate removed) of the

„Type 8620 mxCONTROL“:

top: Hardware version 1: Screw terminals

bottom: Hardware version 2: Spring type terminals

→ Use suitable cables (for wire gauges/cross sections see chapter 7.5) for the passage through the

cable glands (for outside cable diameters and thermal stability of cable material refer to chapter

6.1, paragraph “Electrical connections”).

→

Unscrew the nut of cable gland and remove the seal.

→ First push the cable through the nut of the cable gland and the seal insert and then prepare each

wire of the cable with a cable end sleeve (see

(cable for Power Supply: sleeve length: 7 mm,

Figure 5) of the recommended length:

cable for Instrumentation Supply: sleeve length: 5 mm).

Page 25

Page 26

mxCONTROL Type 8620

Figure 5:

Cable with cable end sleeves

→ Then guide the prepared cable through the cable gland opening into the device and attach the

wires to the terminal strip.

→ Now screw the cable gland nut tight until the cable is securely attached

(tightening torque for cable gland M16: max. 6 Nm

(tightening torque for M20 cable gland: max. 8 Nm

(tightening torque for M20 cable gland: max. 10 Nm)

→ After clamping all required connections re-attach the plate and tighten the screws.

Important! Seal unused cable glands with sealing bolts – protection class IP65 is otherwise

not guaranteed.

7.5 Terminal Strip Pin Assignment

7.5.1 Power Supply (PS)

Connect the cables as shown in the PIN tables in the appendix (21.3.1 and 21.4.1).

The respective terminal assignment plans are created with the PC Tool according to the “project”.

They serve as basis for wiring diagrams and the input/output assignment as shown in the example in

the appendix

Hardware version 1

Figure 6: Terminal strips for the mains voltage level, with PIN numbers

21.1

Hardware version 2

Hardware version 1 Hardware version 2

PIN numbering 1 to 48 1 to 36

Terminal strips Screw terminals Spring type terminals

Terminal grid 5.08 mm, AWG 26 … 14 5.0 mm, AWG 24 … 12

Wire gauges - rigid wires 0.14 … 2.5 mm² 0.2 … 4.0 mm²

Wire gauges - flexible wires 0.14 … 1.5 mm² 0.2 … 2.5 mm²

Tightening torque for screws 0.5 … 0.6 Nm (4.5 … 5.3 lb in) --

PIN table Table in appendix 21.3.1 Table in appendix 21.4.1

Page 26

Page 27

mxCONTROL Type 8620

7.5.2 Instrumentation Supply (IS)

Connect the cables as shown in the PIN tables in the appendix (21.3.2 and 21.4.2).

The respective terminal assignment plans are created with the PC Tool according to the “project”.

They serve as basis for wiring diagrams and the input/output assignment as shown in the example in

the appendix

Hardware version 1

Figure 7: Terminal strips for the low voltage level, with PIN numbers

21.1

For sensor inputs and analog 4…20 mA outputs shielded cables are recommended for best

EMC. Connect the cable shields with the respective Pin “GND” for EMC.

Hardware version 2

Hardware version 1 Hardware version 2

PIN numbering 49 to 111 37 to 96

Terminal strips Screw terminals Spring type terminals

Terminal grid 3.81 mm, AWG 26 … 16 3.5 mm, AWG 24 … 16

Wire gauges - rigid wires 0.14 … 1.5 mm² 0.2 … 1.5 mm²

Wire gauges - flexible wires 0.14 … 1.0 mm² 0.2 … 1.5 mm²

Tightening torque for screws 0.22 … 0.25 Nm (2 … 2.2 lb in) --

PIN table Table in appendix 21.3.2 Table in appendix 21.4.2

7.6 Download of a Configuration and Parameter File

A configuration file must be downloaded to the „Type 8620 mxCONTROL“ before it can be effectively

used in an automation system. Downloading of configuration files is for the Specialist Level only!

After successful download of the configuration file the parameters will be set back to the default

values. With the download of the corresponding parameter file the default values will be overwritten

with these values.

Read chapter

8 and especially chapter 11.2 before.

Page 27

Page 28

mxCONTROL Type 8620

8 Description of Human-Machine Interface

8.1 Safety Notes

WARNING!

Danger from improper operation!

Improper operation may result in injuries as well as damages on the device and its environment.

The device may only be operated by authorized technical personnel!

The persons operating the device must be familiar with the content of the operating instructions and

have understood the same. The safety instructions and intended use require special consideration.

8.2 Operating and Display Elements

Hinged lid protection for

the USB-Interface and

SD card-slot

(SD card will be ejected

by pressing it)

A/M-Key - switches

between automatic and

manual mode, with

flashing alarm-LED

Display

4 soft keys.

(the functions change as

shown in the lowest line

of the respective

display)

handle for lifting the

cover plate

Figure 8: View on the panel of „Type 8620 mxCONTROL“

The „Type 8620 mxCONTROL“ is operated with 4 soft keys below the display (with alternating

functions) and an A/M key to switch between automatic and manual mode.

The brightness of the display can be changed. The brightness can be adjusted in 10 brightness

levels under the main menu item "System settings"; refer to

The default setting is brig

htness level 5 to ensure a long service life of the display.

Table 4 in chapter 9.1.

Page 28

Page 29

mxCONTROL Type 8620

8.3 Operation Mode

8.3.1 Automatic & Manual Mode Key

A/M key with

yellow LED

In case of alarm, follow the descriptions in chapter 15 “Alarm and Error Messages”.

8.3.2 Automatic Mode (LED on)

The „Type 8620 mxCONTROL“ starts in automatic mode after powering up. The LED is on; a "running

bar" in the top line of the display also indicates the Automatic Mode.

The A/M key switches between the Automatic and Manual Mode;

the A/M key includes a yellow LED:

LED on Æ Automatic Mode

LED off Æ Manual Mode

LED flashing Æ ALARM (at least one alarm) both in

automatic and manual mode

8.3.3 Manual Mode (LED off)

The operating mode for all modules can be changed directly by pressing the separate A/M-Key.

Attention: All dosing processes of the Batch- and Biocide-Dosing-Modules are cancelled

in Manual Mode!

(The next dosing process will start at its programmed time when returning to Automatic Mode.)

In manual operation, the control of the process values is transferred from the device to the user. The

user now controls the process values manually with the soft keys of the „Type 8620 mxCONTROL“

whereby the connected actuators are operated. For this purpose, the values in the main menu

"Process data" need to be changed under the corresponding module.

Switching from Automatic to Manual Mode is “changeless”, except for the "Biocide-Dosing" and

"Batch" modules. “Changeless switching” means that the last output value in Automatic Mode is the

current output value in Manual Mode as long as the operator does not change the output value

manually.

If the system switch override function or the flow switch override function or the

safety output value is activated the manual output value will be reset to “0”!

Page 29

Page 30

mxCONTROL Type 8620

8.4 Layout of Menu Screens

Running bar directly below the upper horizontal screen border, running

from the left to the right – indicates the Automatic Mode

Cursor bar

Menu items

Current position inside

the whole menu tree

4 Soft keys

Menu title - indicates the (self selected) designation for the

BW 06

Processdata

Parameter

Configuration

System settings

1

ENTER

“project” (module combination)

(or "No Config. loaded", if no

configuration file is

downloaded)

Current cursor position within

the current menu (slide bar)

The soft keys at the device have no symbols. Their function is defined

in the bottom screen line, where the current function of each key is

displayed as a text string or as a symbol.

The keys have symbols to explain the possible actions, in the above

example:

no function, up-arrow, down-arrow, Enter

The current position inside the menu tree is shown in the middle of the

bottom screen line.

You can scroll through the menu with the "up-arrow" and "down-arrow"

soft keys.

The menu position/numbering is indicated by the main menu and max.

4 submenus, i.e. it is a max. 5-character alphanumeric combination and

is shown in the following format: "4-A-3-1-2".

(the numbering of the menu items within the menu goes from 1 to 9,

higher positions are continued with capital letters because of the limited

space in the display:

from "A" (=10), "B" (=11) to "Z" (=35).

The font size of the current position string depends on the number of

submenus to be displayed.

Cond Control

The trend of the process value PV from standard (4...20 mA) and

frequency signal inputs is shown as chart and regularly updated.

The example shows a trend chart of set point SP and process value PV -

EXIT HOLD

SP/PV

the inscription ("SP/PV") only names the trend chart without identifying

any soft key.

“HOLD“ freezes the display (“CONT” continues displaying the trend.)

Page 30

Page 31

mxCONTROL Type 8620

9 Menu Structure

9.1 Principle of Menu Tree Structure

A welcome message appears in the display after switching on the „Type

8620 mxCONTROL“. This display content is then shown with the current

software version number for approx. 4 seconds.

When starting the „Type 8620 mxCONTROL“ for the first time, the next

display text shows "No Config. loaded", i.e., no (configuration/parameter)

files have been downloaded yet. In this case, refer to chapter

downloading configuration and parameter files.

The menu of „Type 8620 mxCONTROL“ contains 8 main menu items; its

submenus are used to display and set variables and parameters.

The first number in the bottom line of display is the number of the active

main menu item (items 1 to 8).

Depending on the hardware version, the „Type 8620 mxCONTROL“ has digital and analog inputs

which can be configured according to the user requirements.

The configuration via the configuration file is needed for enabling and labelling the desired inputs and

outputs and for activation of special input functions. The scaling, filter and alarm settings can be done

with the configuration file, too, but also directly at the „Type 8620 mxCONTROL“ device.

11.2 about

The main menu and submenu items for a “project” (module combination) with freely selectable name

(in this case "BW 06") are listed in the appendix (

of the menu tree an

d illustrates the structure of the menu.

21.4.3 ff). The following figure shows exemplified part

Figure 9: Structure principle of the menu tree

Page 31

Page 32

mxCONTROL Type 8620

A similar structure is given for all “projects”.

The main menu items contain submenus as exemplary listed below:

Main Menu Submenus

1 Processdata

2 Parameter

(CodeLevel:

Operator)

3 Configuration

(CodeLevel:

Specialist)

4 System settings

5 Upload/Download

(CodeLevel:

Operator/Specialist)

6

Data logging

(CodeLevel: Operator)

7

Calibration

(CodeLevel:Specialist)

8

Clock

(CodeLevel: Operator)

(*) function – refer to chapter 11.1 „Functional Overview“

Display of the process values depending on the current configuration:

Inputs and outputs, module-specific process data displays:

1-1 Inputs

1-2 Outputs

1-3 Cond Control (module in function (*) 1)

1-4 O2 Scav Ctrl (module in function (*) 2)

…

1-A (module in function (*) 8)

Access to the parameters of the configured modules:

2-1 Cond Control

2-2 O2 Scav Ctrl

2-3 Batch-Dosing

…

Access to the configuration data of the configured inputs, outputs and modules. Also

access to Alarm Output, System Switch and Flow Switch configuration and to Codes:

3-1 Inputs

3-2 Outputs

3-3 Modules

3-3-1 Cond Control (module in function (*) 1)

3-3-2 O2 Scav Ctrl (module in function (*) 2)

…

3-3-8 (module in function (*) 8)

3-3-9 System Switch

3-3-A Flow Switch

3-3-B Alarm

3-4 Codes

Language selection, display inversion, factory reset (CodeLevel: Specialist), Device

information (with Firmware revision, Number of restarts, Restart function (CodeLevel:

Specialist)):

4-1 Language

4-1-1 German

4-1-2 English

4-1-3 French

4-2 Display

4-2-1 normal

4-2-2 inverse

4-2-3 brightness

4-3 Factory Reset (CodeLevel: Specialist)

4-4 Device info

4-5 Network info (CodeLevel: Operator, available only for devices with Ethernet

Option)

Upload / Download of

- Configuration file (Specialist level)

- Parameter file (Operator level)

from / into „Type 8620 mxCONTROL“ via SD card:

5-2 Download

5-3 Upload

Start / Stop of data logging on SD card, Setting of data logging sample time (Tsample),

log file options and event log settings (CodeLevel: Specialist).

User calibration of 4-20mA inputs and 4-20mA outputs

Setting time and date.

Table 4: Main menu and submenu items (in the example for "BW 06")

Page 32

Page 33

mxCONTROL Type 8620

9.2 Setting Numeric Values

Parameters, i.e. their numeric values can be changed within predefined ranges. They are described in

the following chapters. Not all numeric values allow to move the decimal point.

The operator has to select the variable or parameter he wants to change with the soft key “ENTER”.

Before the operator can change the value of a parameter, he has to enter the correct password. To

change values from the main menu items "Parameter" or "Configuration", the password needs to be

entered only once. For changing parameters from process data level, the operator has to enter the

correct password every time he wants to change a variable.

(Compare also chapter

→

If the password protection is passed, a special input screen is displayed. In this screen either the

decimal point (if available) or the lowest numeral or character will be automatically selected as

the first cursor position.

→ The current cursor position is always displayed in inverse colour. It can be changed step-by-

step by pressing the key “<-“.

→ If the decimal point is selected by the current cursor position, it can be moved step-by-step to the

left by pressing the soft key “+”.

→ Change the value of a selected numeral/character by pressing the key “+”.

→ Cancel the whole setting process by pressing the key “ESC” (Escape).

→ Confirm the whole setting process by pressing the key “ENTER”.

→ After leaving the setting process by pressing the key “ESC” or “ENTER” the original menu

screen is shown again.

10.)

Important!

The new parameter/configuration data will be saved only after returning to the main

menu – a short message thereby shows “Save in EEPROM”.

The password protection only becomes active again after returning to the main menu!

Return therefore to the main menu after completing the changes!

In the following example soft key 1 is “ESC”, key 2 is “+“, key 3 is “<-” and key 4 is “OK”.

Soft key 1:

Soft key 2:

Soft key 3:

Soft key 4:

ESC

+

Å

OK

Soft key 1 2 3 4

Page 33

Page 34

mxCONTROL Type 8620

10 Password Protection

Three authorization levels (CodeLevel) are provided for the operation of „Type 8620 mxCONTROL“:

General access, access for operators, access for specialists.

A password is a 4 digit number. The operator has to enter the password of the required protection

level in order to enter protected menus or menu items.

The specialist password also overrides the operator password.

A separate description on how to change the password is provided below.

Following user operations are password protected – see also table below:

• Editing parameters / configuration data

• Download/upload of parameter/configuration files

• User calibration of 4-20mA outputs

• Changing passwords

• Factory Reset

• Software Reset

• Data Logging

• Clock setting

Note! The "Master" password cannot be changed. The user of this password is granted

access to all protected code levels. This Master Password is available at Bürkert Service.

Protection

Level

0

1

2

Table 5: Password protection – different levels

User Notes

Generell/normal process level:

Current process and control outputs are displayed.

Following actions are allowed:

• Changing the operating mode of the „Type 8620 mxCONTROL“ between

General

access

Operator

(Factory

set:

Code: 0001)

Specialist

(Factory

set:

Code: 0002)

automatic and manual mode.

• Changing values in manual mode

• Acknowledgement of Alarms (e.g. Maximum Output Timer) and messages.

• Operating Language

• Display-Mode

In addition to protection level 0 the following actions are allowed:

• Parameter access

• Up- and Download of parameter files

• Data Logging

• Setting Up Real Time Clock

In addition to protection levels 0 and 1 the following actions are allowed:

• Configuration access

• Up- and Download of configuration files

• User calibration of 4-20mA outputs

• Changing Passwords

• Factory Reset

• Software Reset

Page 34

Page 35

mxCONTROL Type 8620

Changing Passwords

→ Choose the main menu item “Configuration”, enter with “ENTER”

→ Enter the specialist password (by possibly pressing the "+" key several times; you can also use

the "<-" for multi-digit numbers), then press "OK".

→ Scroll for Menu item “Codes” with the “Arrow”-keys, enter with “ENTER”

→ Choose the Operator or Specialist Level which shall be changed, then press key “INPUT”

→ Input the specialist code by pressing the key “+” the required number of times, then press “OK”

→ Set a new value for the code by pressing the key “+” (for multi-digit codes use also the key “<-“),

then press “OK”.

If the menu item was left by pressing key “ESC” the new value is not accepted!

→ Leave the Menu item “Codes” by pressing “EXIT”

Page 35

Page 36

mxCONTROL Type 8620

11 General Software Concept and Functions

11.1 Functional Overview

The „Type 8620 mxCONTROL“ is a configurable multifunction controller. Its principal of function can

be divided into three main process areas:

Input process, control process and output process (see

Figure 10).

Figure 10: Process diagram

Input Process:

• Reading of the enabled inputs and the processing of scaled process values from raw values.

• alarm functionality for each of the inputs - except binary and pulse counter inputs

Control Process:

• Simultaneous activity of up to 8 Control Functions (further on named Function)

• Available modules in the device (see chapter

s

everal times as function with its own configuration and parameter data – considering the

14 „Controller Modules“) can be used also

required resources. The very data-intensive module „BIOCIDE_DOSING" can be used only 1

times, for example

• Each function can be configured to work as one of the available modules (see chapter

the stru

cture of the function allows

• Each function can contain modules with few module inputs and outputs. But only spezial

functions can work as modules with many in- and outputs

• The in- and outputs of the functions will be linked by means of the PC Tool

14) – if

Page 36

Page 37

mxCONTROL Type 8620

Most modules have a spezial ”Output Override“-Function (override the original output value) in

order to react to situations as:

- Input or Sensor Faults,

- Activation of the System or Flow Switch or

- special states or alarms of other activ modules.

Output Prozess:

• Converting and transferring of the virtual module outputs to the configured real outputs (that

means the real outputs are controlled to output the configured form of output signal)

11.2 Up- and Downloading of Configuration/Parameter Files

11.2.1 Download

Before the „Type 8620 mxCONTROL“ can act in an automation system, a configuration file

must be downloaded to the device (e.g. from the SD card).

(The last downloaded configuration and parameter file defines the function of the „Type 8620

mxCONTROL“!)

This is for the Specialist Level only!

Up-/Download processes on SD-Card are only possible if Data Logging is disabled.

For the Download process proceed as stated below

(see also the sample menu tree in the appendix

→ Supply the „Type 8620 mxCONTROL“ with power

→ Insert an SD card (formatted with FAT16) into the interface (SD card slot)

21.5.6):

under the hinged lid

→ Scroll in the main menu to the menu item “Up-/Download” (via “arrow” keys),

press key “ENTER”.

→ Enter the correct password (via keys „+“ and „<-“)

(specialist password for configuration files,

operator or specialist password for parameter files).

→ Select “Download”, press key “ENTER”

→ Navigate via arrow keys to file folder containing the desired configuration or

parameter file.

Return to parent folder by scrolling to ".." or

open a folder by pressing the key "ENTER".

To furnish the „Type 8620 mxCONTROL“ with a new configuration, first

the configuration file must be downloaded to the device, followed by the

corresponding parameter file.

Page 37

Page 38

mxCONTROL Type 8620

→ Select the desired configuration file "XXX.cfg" for download into the „Type

8620 mxCONTROL“, press key "ENTER".

Download of the configuration file is running. If the download was successful, the

message "Successful" appears in the display.

→ Return to submenu by pressing key "EXIT".

→ Select associated parameter file “XXX.par”, press key "ENTER".

Download of the configuration file is running. If the download was successful, the

message "Successful" appears in the display.

→ Return to submenu by pressing key "EXIT".

→ Leave the submenu by pressing key “EXIT” (several times).

Remove the SD card by pressing against it.

11.2.2 Upload

For saving parameter/configuration files use the function “Upload”.

Comments in a downloaded xml-file will not be stored in „Type 8620 mxCONTROL“ – when

uploading a file no comments are included!

Up-/Download processes on SD-Card are only possible if Data Logging is disabled.

For the Upload process proceed as stated below

(see also the sample menu tree in the appendix

21.5.7)

→ Supply the „Type 8620 mxCONTROL“ with power

→ Insert an SD card (formatted with FAT16) into the interface (SD card slot)

under the hinged lid

→ Scroll in the main menu to the menu item “Up-/Download” (via “arrow” keys),

press key “ENTER”

→ Enter the correct password (via keys „+“ and „<-“)

(specialist password for configuration files,

operator or specialist password for parameter files)

→ Select “Upload”, press key “ENTER”

→ Select “Param-File” (operator or specialist level)

or „Config-File“ (for specialist level only) by pressing key “START”.

The device saves the file to the current folder (marked by a single dot ".") after

pressing the key "ENTER" or

scroll to another folder and press key "ENTER".

The device either uses the name of the last file loaded or creates a new internal

name for the file by extending with “vXX”. (XX is running from 01 to 99).

To overwrite an existing file with new data, select the desired existing file, press

key “ENTER”. It appears a request for overwriting:

→ Press “YES” for overwriting the selected file,

→ press “NO” for creation of a new file name (with extension vXX) or

→ press “EXIT” to stop/cancel the upload process

Page 38

Page 39

mxCONTROL Type 8620

Stopping/cancelling of the upload process – by pressing key „EXIT“ -

makes the uploaded file incomplete and it cannot be used for a download

process.

But only at next download process appears the error message!

And if upload process was successful the display shows the notification

“Successful”.

→ Leave the submenu by pressing key “EXIT” (several times). Remove the SD

card by pressing against it.

11.3 Data Logging

The "Data Logging" function

• stores all important process values for reading, checking and archiving

• has to be activated/enabled for that functionality

• logs the data cyclically according to the set data logging sampling time "Tsample"

• logs the data event-triggered (for details refer to “

Each time the internal (volatile) 512-Byte-memory is filled, its content will be attached at the end of the

datalog file on the SD card (formatted with FAT16) and will be saved then.

The Data Logging continues

Event Triggered Data Logging Function”)

• as long as the data logging function is activated

• as long as the SD card is filled - which causes an error message on the display

• as long data can be saved on the SD card - if the logged data cannot be written (anymore) to

the SD card, data logging will be stopped and a corresponding error message is shown on the

display.

The "Tsample" sample time has a factory setting of 3600 seconds.

If the selected sample time is too short, an excessive data volume will be produced and may

fill the memory capacity of the SD card very fast.

Therefore select a sample time that enables the SD card to be written with the data until the

next change of the SD card or use an SD card with higher capacity (described in next section).

A new set sample time gets active when returning to the main menu.

No Up-/Download processes on SD-Card are possible if Data Logging was active.

The data is stored into the current log file “8620-DEV_ID-DEV_SERIAL-INDEX.log”:

with: DEV_ID device ID number (8 digits with leading zeros)

DEV_SERIAL device serial number (7 digits with leading zeros)

INDEX log file index (00001...65535) (5 digits with leading zeros)

The current log file name is displayed in the menu “Data logging\Logfile\” under the item “Current”.

The log file index “INDEX” can be increased manually by the operator in the same menu with the item

“New logfile” (CodeLevel Operator) – in this case a new log file is started.

If data logging was disabled the log file index can be adjusted (CodeLevel: Specialist); e.g. in order to

restore manually the old log file index after a firmware update or a factory reset.

The data can be selected, indicated, edited with PC and also archived externally if necessary.

Page 39

Page 40

mxCONTROL Type 8620

Log files are stored in the root directory of the SD card. The root directory can contain

approximately max. 100 entries (files and folders; each file / folder name has max. 31

characters).

The layout of the data logging file, the abbreviations and the coding used in the header are shown

in an example in appendix

21.6.

Automatic log file size limitation (FSizeLimit = Yes)

A new log file is started automatically by increasing the log file index,

if data logging was active and the current log file size exceeded the maximum log file size FSizeMax.

Back up older log files in time from SD card on PC. If permitted, delete them afterwards on SD

card.

Event Triggered Data Logging Function

An integrated Event Triggered Data Logging Function logs a complete set of process data with

max. 10 s delay, after a specific event was triggered.

Such specific events are:

• Occurrence / Disappearance of an alarm.

• Occurrence of important error messages

- Battery Failed / RTC Failed / Check Clock!

- Eeprom Fault XXY

- Error ISR timing!

- Calibdata Fault 4-20mA In / Pt100 in / 4-20 mA Out

- 4-20mA Out X failed

• Changing operational mode (Automatic / Manual)

• Switching on/off of an output, which is configured as an On/Off output

• Communication events and errors (devices with Ethernet Option only)

- Start / end of incoming / outgoing connection

- Changes of net link status

- Important communication error messages

• Miscellaneous events

- Totalizer reset

- Start / end of user calibration of 4-20mA inputs / outputs

The event triggered data logging function can be enabled / disabled and configured by means of

configuration. For details refer to section “Configuration”.

Datalog failed alarm

If data logging failed (e.g. in case of writing error or full/missing SD Card), a special datalog alarm is

raised and the common alarm is actuated, too.

This special datalog alarm needs to be reset in the data logging menu by the operator.

Page 40

Page 41

mxCONTROL Type 8620

Parameter (CodeLevel: Operator)

Parameter

Access via

Datalogmenu

Access via

XMLParam.-File

Abbreviation

(menu)

Datalog Logging SD-Card rw -- -- enable/disable

Sample Time rw rw Tsample 10 ... 99999sec 3600sec (*)

Logfile

Current log file name r -- Current -- --

Increase log file index by

one (Creates new log file)

Automatic log file size

w --

New

Logfile

rw rw FSizeLimit Yes / No No

limitation

Max. log file size rw rw FSizeMax 0.1 … 100.0 MB 1.0 MB

(*) Default value also after successful download of Cfg-File

Range

Default values

(after factory reset or at

start of Param-FileDownload)

Disable (only after

factory reset)

-- --

Configuration (CodeLevel: Specialist)

Configuration

Access

via

Datalog-

Access

via XMLCfg.-File

Abbreviation

(menu)

menu

Log File

Log file index (**) rw -- LFI 1 … 65535

EventLog

Event Log function rw rw EventLog On, Off On

Log Events (*)

Alarms rw rw Alarms On, Off On

Important error messages rw rw ErrorMsg On, Off On

Switching Operational

rw rw OpMode On, Off On

Mode

Switching of On/Off

rw rw O/O outputs On, Off On

outputs

Communication events /

rw rw Comm On, Off On

errors

Miscellaneous rw rw Misc On, Off On

(*) Only displayed, if Event Log function was set to On.

(**) Only displayed, if Datalogging was disabled

Value range

Default values

(after factory reset or

at start of Cfg-FileDownload)

1 (only after factory

reset)

Page 41

Page 42

(

mxCONTROL Type 8620

11.3.1 Selection of SD card size for Data Logging purposes

The size required for one process data sample depends on the current configuration and the sample

time. Every Tsample seconds a new sample of process data is written into the internal volatile Data

Logging memory.

Required free memory

in [kByte]

with

()

LogsPerDay

Tsample

86400

s

NOE

+=

)

kByte1024HeaderDataNOCSampleDataDaysLogsPerDay +∗+∗∗=

NOE

“Number Of trigger Events per day” which forces a new

process data sample to be written.

Event

Days

SampleData

NOC

Tsample

For trigger events refer to above section “

ered Data Logging Function”.

Trigg

Data Logging Sample Time in seconds

Number of Days to be logged

See below

"Number Of Changes": Number of events requiring a

new "header" in the data log file

HeaderData

86400 s

See below

= 24 h = 1 day

Required free memory

in [MByte]

= Required free memory

in [kByte]

MByte 1

∗

kByte1024

It is:

SampleData - storage capacity required on the SD card to log 1 process data sample after Tsample

has run down and

HeaderData - storage capacity required on the SD card to log 1 header + 1 process data sample.

That means, a new header and a current process data sample is written each time, when:

• enabling the Data Logging

or if Data Logging already is enabled:

• returning to the Main Menu after configuration and/or parameter were changed

• the download is finished successfully / is cancelled / failed

SampleData in [kByte]

HeaderData in [kByte]

with

Page 42

= 0.05 kB * (2 + Number of modules)

= 0.4 kB

Number of modules:

(1.5 + Number of modules) + SampleData