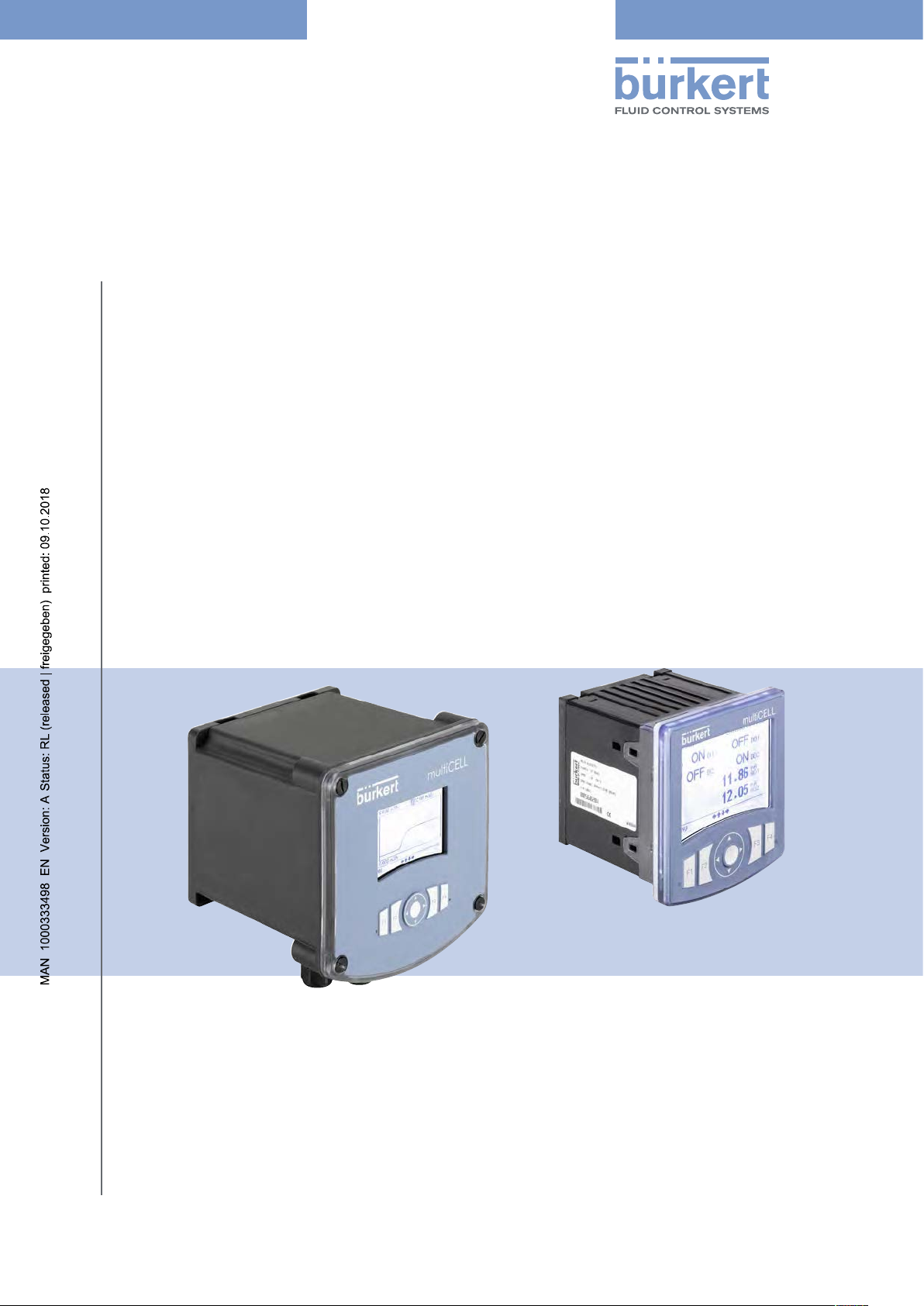

Burkert 8619 Series, 8619 multiCELL, 8619 multiCELL WM DC Quick Start Manual

Type 8619

8619 multiCELL WM AC

8619 multiCELL WM DC

8619 multiCELL

Modular transmitter/controller

Modularer Transmitter/Controller

Transmetteur/contrôleur modulaire

Quickstart

(from software version B.0101/ Gültig ab Softwareversion B.01.01/ À partir de la version logicielle B.01.01)

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert SAS, 2017-2018

Quickstart 1803/01_EU-ML 00569044 / Original_FR-EN

Type 8619

Table of Contents

1 ABOUT THE QUICKSTART ............................................................................................................................................................6

1.1 Symbols used .........................................................................................................................................................................6

1.2 Definition of the word "device" ......................................................................................................................................7

1.3 Definition of the word "Industrial Ethernet" .............................................................................................................7

1.4 Validity of the Quickstart ...................................................................................................................................................7

2 INTENDED USE ...................................................................................................................................................................................7

3 BASIC SAFETY INFORMATION ..................................................................................................................................................8

4 GENERAL INFORMATION ................................................................................................................................................................9

4.1 Manufacturer's address and international contacts ............................................................................................9

4.2 Warranty conditions .............................................................................................................................................................9

4.3 Information on the internet .............................................................................................................................................9

5 DESCRIPTION OF THE RATING PLATE ...............................................................................................................................10

5.1 Additional markings (only for an Ethernet version) ........................................................................................10

6 TECHNICAL DATA ...........................................................................................................................................................................11

6.1 Conditions of use of the 8619 multiCELL ............................................................................................................11

6.2 Conditions of use of the 8619 multiCELL WM DC ...........................................................................................11

6.3 Conditions of use of the 8619 multiCELL WM AC ...........................................................................................12

6.4 Compliance to standards and directives ..............................................................................................................12

6.5 Material data .........................................................................................................................................................................13

6.6 Dimensions ...........................................................................................................................................................................14

6.7 Electrical specifications of the 8619 multiCELL ...............................................................................................15

6.8 Electrical specifications of the 8619 multiCELL WM DC ..............................................................................16

6.9 Electrical specifications of the 8619 multiCELL WM AC ..............................................................................17

6.10 Specifications common to all the versions .........................................................................................................18

6.10.1 Specifications of the memory card reader/recorder .................................................................18

6.10.2 Flow rate measurement ...................................................................................................................18

6.10.3 Specifications of the "Input" module ............................................................................................19

6.10.4 Specifications of the output module "OUT" .................................................................................19

6.10.5 Specifications of the "pH/ORP" module .....................................................................................20

6.10.6 Specifications of the conductivity module "COND"...................................................................21

6.10.7 Specifications of the Ethernet module M1 ..................................................................................21

English

3

6.11 Specifications of the Industrial Ethernet protocols ........................................................................................22

6.11.1 Modbus TCP protocol ......................................................................................................................22

6.11.2 PROFINET protocol ..........................................................................................................................23

6.11.3 EtherNet/IP protocol .........................................................................................................................24

7 INSTALLATION AND WIRING ....................................................................................................................................................25

7.1 Safety instructions ............................................................................................................................................................25

7.2 Installation procedure .....................................................................................................................................................26

7.2.1 Installing a 8619 multiCELL on an enclosure or electrical cabinet ....................................... 26

7.2.2 Installing a 8619 multiCELL WM on a support .........................................................................27

7.3 Electrical wiring ..................................................................................................................................................................29

7.3.1 Recommendations for wiring a 8619 multiCELL WM .............................................................29

7.3.2 Specifications of the cables and conductors .............................................................................30

7.3.3 Wiring the 12...36 V DC electrical supply for a 8619 multiCELL ..........................................30

7.3.4 Wiring the 12...36 V DC electrical supply for a 8619 multiCELL WM DC ..........................31

7.3.5 Wiring the 110...240 V AC electrical supply for a 8619 multiCELL WM AC ....................32

7.3.6 Supplying an external instrument via a 8619 multiCELL .........................................................33

7.3.7 Supplying an external instrument via a 8619 multiCELL WM .................................................33

7.3.8 Wiring the inputs and outputs on the main board "M0" ............................................................34

7.3.9 Identifying the pins on the extension modules ............................................................................35

7.3.10 Wiring the Industrial Ethernet ..........................................................................................................36

7.4 Description of the LEDs for the connection to the network (Industrial Ethernet only) ...............36

7.4.1 Connection example of the Ethernet module .............................................................................37

7.4.2 Wiring the module "INPUT" ............................................................................................................. 38

7.4.3 Wiring the output module "OUT"....................................................................................................40

7.4.4 Wiring the "pH/ORP" module .........................................................................................................41

7.4.5 Wiring the conductivity module "COND" .....................................................................................42

8 COMMISSIONING, DISPLAY DESCRIPTION .....................................................................................................................44

8.1 Safety instructions .............................................................................................................................................................44

8.2 Operating levels ...................................................................................................................................................................44

8.3 Process level .........................................................................................................................................................................44

8.4 Configuration level access ...........................................................................................................................................46

8.5 Checking the IP address of an Ethernet module ..............................................................................................47

8.6 Calibrating the measuring sensors .........................................................................................................................47

8.6.1 Entering the K factor for the used fitting or determining it using teach-in ............................47

8.6.2 Calibrating a pH sensor ...................................................................................................................47

English

4

8.6.3 Calibrating a redox sensor ............................................................................................................... 48

8.6.4 Calibrating a conductivity sensor ..................................................................................................48

9 TROUBLESHOOTING AND MAINTENANCE .....................................................................................................................49

9.1 Safety instructions ............................................................................................................................................................49

9.2 If you encounter problems ...........................................................................................................................................49

10 SPARE PARTS AND ACCESSORIES ....................................................................................................................................50

11 PACKAGING AND TRANSPORT ............................................................................................................................................... 50

12 STORAGE ..............................................................................................................................................................................................50

13 DISPOSAL OF THE DEVICE ........................................................................................................................................................50

English

5

Type 8619

About the Quickstart

1 ABOUT THE QUICKSTART

The Quickstart describes the entire life cycle of the device. Please keep it in a safe place, accessible to all users

and any new owners.

This Quickstart contains important safety information.

Failure to comply with these instructions can lead to hazardous situations.

▶ When the symbol

▶ Whatever the version of the device, this Quickstart must be read and understood.

The Quickstart describes the main steps to be carried out when installing, commissioning and programming the

device.

Refer to the corresponding Operating Instructions to get a complete description of the device.

The Operating Instructions for type 8619 can be found on internet under: www.burkert.com Type 8619

is marked inside or outside the device, carefully read the Operating Instructions.

1.1 Symbols used

DANGER

Warns against an imminent danger.

▶ Failure to observe this warning can result in death or in serious injury.

WARNING

Warns against a potentially dangerous situation.

▶ Failure to observe this warning can result in serious injury or even death.

CAUTION

Warns against a possible risk.

▶ Failure to observe this warning can result in substantial or minor injuries.

NOTE:

Warns against material damage.

Important advice or recommendations.

Refers to information contained in the Quickstart or in other documents.

▶ Indicates an instruction to be carried out to avoid a danger, a warning or a possible risk.

→ Indicates a procedure to be carried out.

6

English

Type 8619

About the Quickstart

1.2 Definition of the word "device"

The word "device" used in the Quickstart refers to the controller/transmitter:

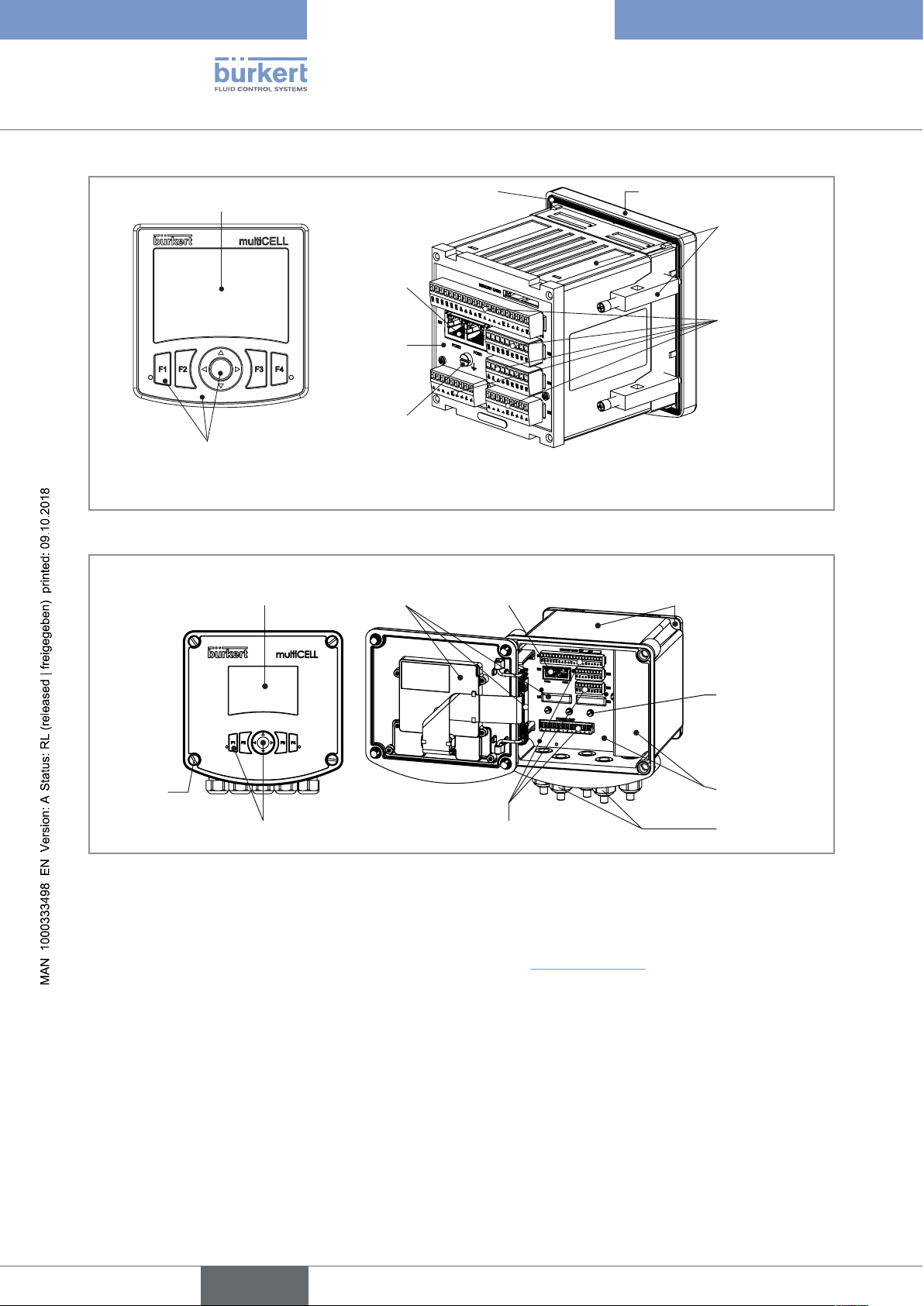

• type 8619 multiCELL, i.e. the panel-mounted versions,

• type 8619 multiCELL WM AC, i.e. the wall-mounted versions with an AC operating voltage,

• type 8619 multiCELL WM DC, i.e. the wall-mounted versions with a DC operating voltage,

1.3 Definition of the word "Industrial Ethernet"

The term “Industrial Ethernet” as used in the Quickstart, refers to the devices that communicate with the industrial

network protocols Modbus TCP, PROFINET or EtherNet/IP.

1.4 Validity of the Quickstart

The Quickstart is valid for the devices from software version B.01.01

→ On the device, check the software version in the menu "Information -> Versions -> M0: Main -> Firmware".

2 INTENDED USE

Use of this device that does not comply with the instructions could present risks to people, nearby

installations and the environment.

The device is intended, depending on the modules fitted and the measurement sensors connected, for the

acquisition, processing, transmission and regulation of physical parameters such as pH/ORP, conductivity, tem-

perature, flow rate... .

▶ Use the device only in combination foreign devices or foreign components recommended or approved by

Bürkert.

▶ Protect the device against electromagnetic interference, ultraviolet rays and, when installed outdoors, the

effects of climatic conditions.

▶ Use the device in compliance with the characteristics and commissioning and use conditions specified in the

contractual documents and in the Operating Instructions.

▶ Never use the device for security applications.

▶ Store, transport, install and operate the device properly.

▶ Only operate a device in perfect working order.

▶ Only use the device as intended.

7

English

Type 8619

Basic safety information

3 BASIC SAFETY INFORMATION

This safety information does not take into account any contingencies or occurrences that may arise during installation, use and maintenance of the device.

The operating company is responsible for the respect of the local safety regulations including for the staff safety.

Risk of injury due to electrical voltage.

▶ If a 12...36 V DC wall-mounted version is installed either in a wet environment or outdoors, all the electrical

voltages must be of max. 35 V DC.

▶ Before carrying out work on the system, disconnect the electrical power for all the conductors and isolate it.

▶ All equipment connected to the device must be double insulated with respect to the mains according to the

standard IEC 61010-1:2010.

▶ Observe all applicable accident protection and safety regulations for electrical equipment.

Various dangerous situations.

To avoid injury:

▶ Do not use the device in explosive atmospheres.

▶ Do not use the device in an environment incompatible with the materials it is made of.

▶ Do not subject the device to mechanical loads.

▶ Do not make any modifications to the device.

▶ Prevent any unintentional power supply switch-on.

▶ Only qualified and skilled staff can carry out the installation and maintenance work.

▶ Guarantee a defined or controlled restarting of the process, after a power supply interruption.

▶ Observe the general technical rules.

NOTE:

Elements/components sensitive to electrostatic discharges

This device contains electronic components sensitive to electrostatic discharges. They may be damaged if they

are touched by an electrostatically charged person or object. In the worst case scenario, these components are

instantly destroyed or go out of order as soon as they are activated.

▶ To minimise or even avoid all damage due to an electrostatic discharge, take all the precautions described in

standard EN 61340-5-1.

▶ Also ensure that you do not touch any of the live electrical components.

8

English

Type 8619

General information

4 GENERAL INFORMATION

4.1 Manufacturer's address and international contacts

To contact the manufacturer of the device, use following address:

Burkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Burkert sales office.

The addresses of our international sales offices are available on the internet at: www.burkert.com

4.2 Warranty conditions

The condition governing the legal warranty is the conforming use of the device in observance of the operating conditions specified in the Operating Instructions.

4.3 Information on the internet

You can find the Operating Instructions and technical data sheets regarding the type 8619 at: www.burkert.com

English

9

12

10

}

11

13

Type 8619

Description of the rating plate

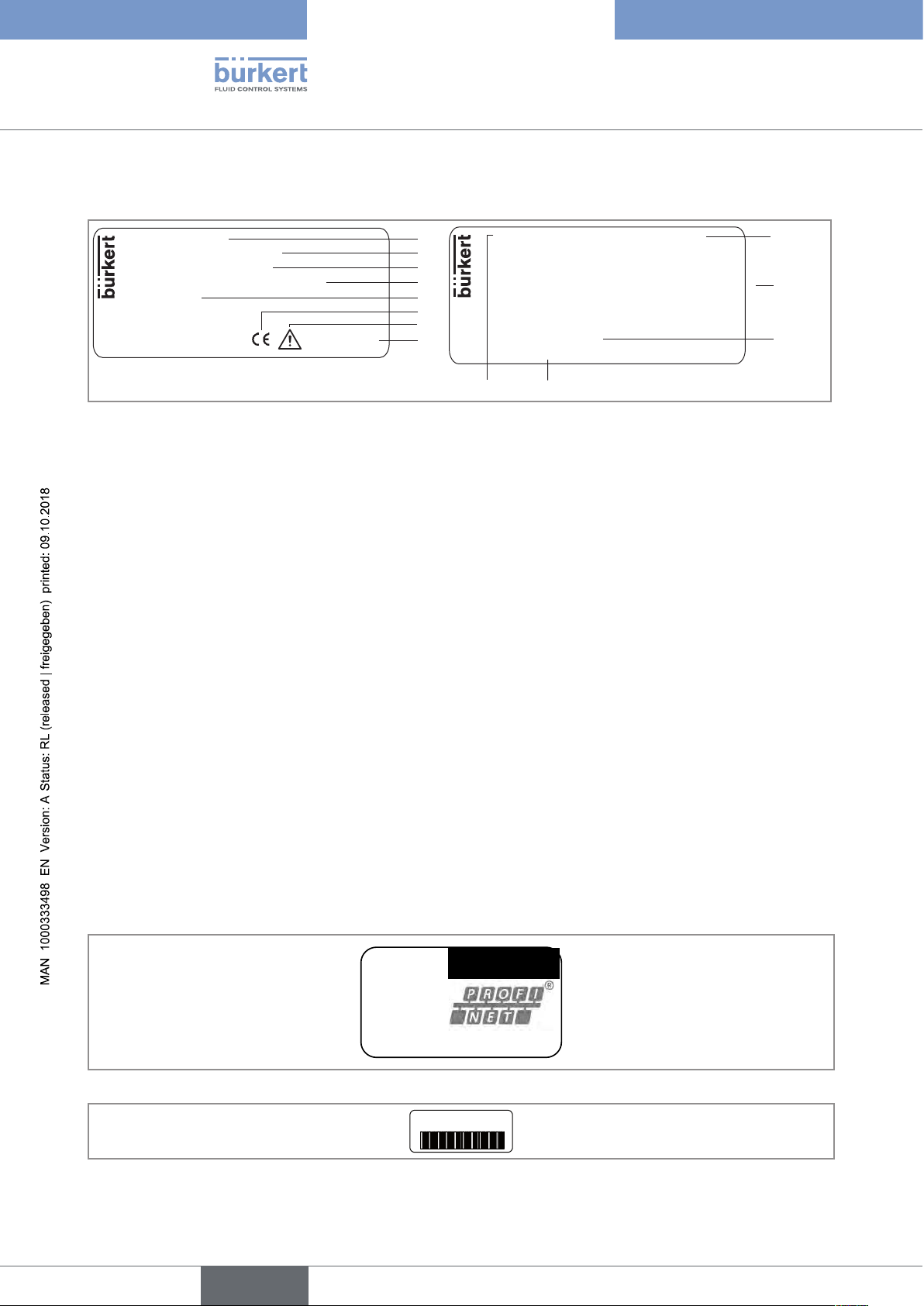

5 DESCRIPTION OF THE RATING PLATE

8619 multiCELL

Supply: 12...36 V DC, 2 A

Temp: -10...+60 °C

IP65 PANEL (FRONT) IP20 (REAR)

Made in France

S-N:1110

00560204

W44ML

Fig. 1: Description of a rating plate (example)

1

2

3

4

5

6

7

8

M0: 2xDI - 2xAO - 2xDO - SD CARD

M1: pH/ORP - PT100/1000

M2: RES COND 2/4 POLES PT100/1000

M3: 2xAO - 2xDO

Made in France

M4:

M5:

M6:

Softw.:

00560204 W44ML

1. Type of the device

2. Electrical power supply

3. Ambient temperature range

4. Protection rating

5. Serial number

6. Conformity marking

7. Warning: Before using the device, take into account the technical specifications given in the Operating

Instructions.

9

8. Construction code

9. Device fitted with a memory card reader

10. Characteristics of the extension modules

11. Software options

12. Order code

13. Properties of the main board “M0”

5.1 Additional markings (only for an Ethernet version)

Modbus TCP

Fig. 2: Marking with the protocols (example)

DC-B0-58-FF-FF-FF

10

Fig. 3: Marking with the MAC address of the device (example)

English

Type 8619

Technical data

6 TECHNICAL DATA

6.1 Conditions of use of the 8619 multiCELL

Ambient temperature

• without extension modules

• with extension modules

1)

1)

• –10...+70 °C

• –10...+60 °C

Air humidity < 85%, not condensing

Height above sea level max. 2000 m

Protection rating according to EN 60529 • IP65, NEMA4X on front, once mounted, and elec-

trical enclosure tightly closed

• IP20 for the parts inside the electrical enclosure

Pollution degree Degree 2 according to EN 61010-1

Category of installation Category I according to UL 61010-1

1)

with a memory card available as an accessory (order reference 564072). If a different memory card is used,

observe the operating temperatures given by the manufacturer of the memory card.

6.2 Conditions of use of the 8619 multiCELL WM DC

Ambient temperature

• without extension modules

• with extension modules

Air humidity < 85%, not condensing

Height above sea level max. 2000 m

Protection rating according to EN 60529 IP65, IP67, if the following conditions are met:

1)

1)

• –10...+75 °C

• –10...+60 °C

• Body of each cable gland tightened with a torque of

5.5 N·m ± 20% (4,06 lbf·ft ± 20%) at the factory.

• Cable glands blanked off or wired.

• Nut of each cable gland tightened with a torque of

4.5 N·m ± 20% (3,32 lbf·ft ± 20%).

• Housing tightly closed.

• The 4 screws for the cover are tightened crosswise

with a torque of 1.4 N·m ± 20% (1,03 lbf·ft ± 20%).

Pollution degree Degree 2 according to EN 61010-1

Category of installation Category I according to UL 61010-1

1)

with a memory card available as an accessory (order reference 564072). If a different memory card is used,

observe the operating temperatures given by the manufacturer of the memory card.

English

11

Type 8619

Technical data

6.3 Conditions of use of the 8619 multiCELL WM AC

Observe the maximum permissible load as a function of the ambient temperature.

See the derating curves in Fig. 6 chap. 6.9.

Ambient temperature 1) –10...+70 °C

2)

Air humidity < 85%, not condensing

Height above sea level max. 2000 m

Protection rating according to EN 60529 IP65, IP67, if the following conditions are met:

• Body of each cable gland tightened with a torque of

5.5 N·m ± 20% (4,06 lbf·ft ± 20%) at the factory.

• Cable glands blanked off or wired.

• Nut of each cable gland tightened with a torque of

4.5 N·m ± 20% (3,32 lbf·ft ± 20%).

• Housing tightly closed.

• The 4 screws for the cover are tightened crosswise

with a torque of 1.4 N·m ± 20% (1,03 lbf·ft ± 20%).

Pollution degree Degree 3 according to EN 61010-1 if the following

conditions are met:

• Housing tightly closed.

• The 4 screws of the cover are tightened crosswise

at a torque of 1.4 N·m ± 20% (1,03 lbf·ft ± 20%).

Category of installation Category II according to UL 61010-1

1)

with a memory card available as an accessory (order reference 564072). If a different memory card is used,

observe the operating temperatures given by the manufacturer of the memory card.

2)

Refer to the derating curves Fig. 6 chap. 6.9.

12

6.4 Compliance to standards and directives

The applied standards, which verify conformity with the EU Directives, can be found on the EU Type Examination

Certificate and/or the EU Declaration of Conformity (if applicable).

UL certification

Finished devices with variable key PU01 or PU02 are UL-certified devices and comply also with the following

standards:

• UL 61010-1

• CAN/CSA-C22.2 n°61010-1

English

Type 8619

Technical data

Identification on the device Certification Variable key

Measuring

®

Equipment

EXXXXXX

UL-listed PU02

UL-recognized PU01

For Ethernet versions, the device is certified by the following certification bodies:

• ODVA for EtherNet/IP protocol,

• PI for PROFINET protocol.

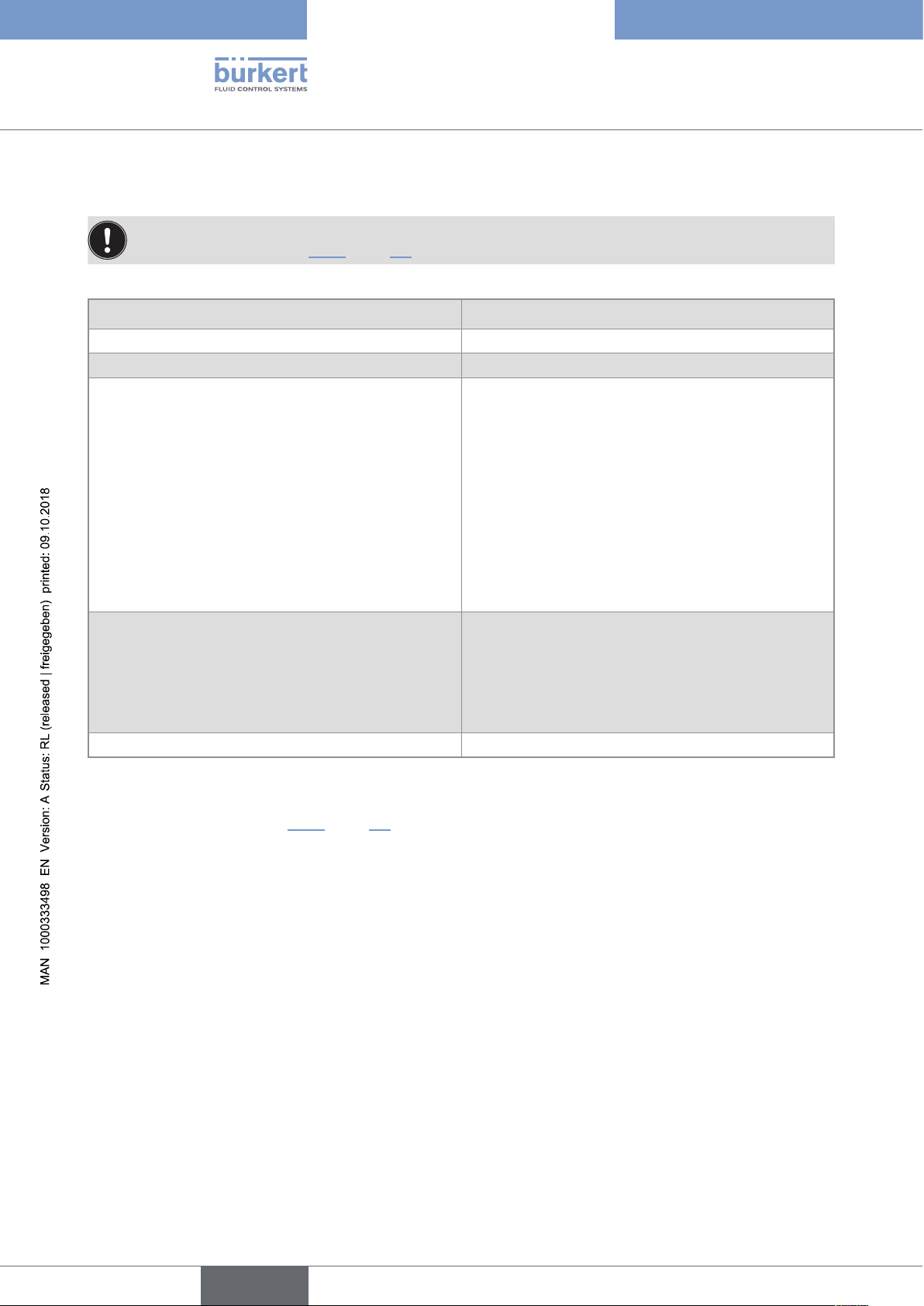

6.5 Material data

Table 1: Materials in contact with the ambient air

Material

Component

8619 multiCELL

Panel-mounting housing and fastener PPO -

Wall-mounting housing, wall-mounting

fastening plate, cable glands, protective cap

- PA66

(for LCD display), hinge stiffener.

Protective blank (for a slot without

connection terminal)

Seal Silicone

8619 multiCELL WM AC or

8619 multiCELL WM DC

PA66

Front panel and keys PC/silicone

Terminal support plate Stainless steel 304

Terminal blocks PBT, contacts in gold-plated copper alloy

Port for an RJ45 connector Housing: copper alloy and thermoplastic

Contacts: gold-plated

Ground screw + spring washer Stainless steel 316 (A4)

Protective cap for the 110...240 V AC power

supply terminal board

- Stainless steel 304

4 cover screws - PVC

13

English

Type 8619

Technical data

PC

copper alloy, ther-

moplastic, gold-

plated contacts

Stainless steel 304

Stainless steel 316 (A4)

Silicone

Fig. 4: Component materials of the 8619 multiCELL

PC

PA66

Silicone

copper alloy, thermoplastic,

gold-plated contacts

PC

PPO

PBT, contacts

in gold-plated

copper alloy

PA66

PVC

Silicone

PBT, contacts in gold-plated

copper alloy

Fig. 5: Component materials of the 8619 multiCELL WM

6.6 Dimensions

Please refer to the technical data sheets of the device, available at: www.burkert.com

Stainless steel 316

(A4)

Stainless steel 304

PA66

14

English

Type 8619

Technical data

6.7 Electrical specifications of the 8619 multiCELL

Electrical supply 12...36 V DC • filtered and regulated

• SELV circuit, at a non-hazardous energy level

• Tolerance: ±10%

• Maximal consumption: 2 A

Specifications of the 12...36 V DC power

source (not provided) of the UL devices,

with variable key PU02

Own consumption (without extension

• Limited power source according to §9.4 of EN 61010-1 standard

• or class 2 source according to UL 1310/1585 and EN 60950-1

standards

1.5 VA

modules, outputs not connected)

Power distribution ("PWR OUT") • 12...36 V DC, 1.8 A max.

• Protected against polarity reversal

All digital inputs ("DI") • Switching threshold V

• Switching threshold V

on

off

• Input impedance: 3 kW

• Galvanically isolated

• Protected against polarity reversal and voltage spikes

• Frequency: 0.5...2500 Hz

All analogue outputs ("AO") • 4...20 mA current

• Uncertainty: ±0.5 % of the measured value

• Any connection mode, in sink or source mode

• Galvanically isolated

• Protected against polarity reversal

• Max. loop impedance 860 W at 30 V DC, 610 W at 24 V DC,

100 W at 12 V DC

All digital outputs ("DO") • Transistor

• Any connection mode, in NPN or PNP mode

• Galvanically isolated

• Protected against short circuits

• Max. voltage: 36 V DC

• Max. frequency 2000 Hz

• Maximum current consumption allowed:

- Max. 700 mA if 1 DO per module is activated

- Max. 1 A if the 2 DO's per module are activated

- Max. 4 A for an Ethernet version if the device has 4 output

modules

: 5...36 V DC

: < 2 V DC

English

15

Type 8619

Technical data

6.8 Electrical specifications of the 8619 multiCELL WM DC

Electrical supply 12...36 V DC • filtered and regulated

• SELV circuit, at a non-hazardous energy level

• Tolerance: ±10%

• Maximal consumption: 2 A

Own consumption (without extension

2 VA

module, outputs not connected)

Power distribution

(POWER OUT module)

Specifications of the 12...36 V DC power

source (not provided) of the UL devices,

with variable key PU02

• Protected against polarity reversal

• 12...36 V DC, 1.8 A max.

• Limited power source according to §9.4 of EN 61010-1 standard

• or class 2 source according to UL 1310/1585 and EN 60950-1

standards

All digital inputs ("DI") • Switching threshold V

• Switching threshold V

• Input impedance: 3 kW

• Galvanically isolated

• Protected against polarity reversal and voltage spikes

• Frequency: 0.5...2500 Hz

All analogue outputs ("AO") • 4...20 mA current

• Uncertainty: ±0.5 % of the measured value

• Any connection mode, in sink or source mode

• Galvanically isolated

• Protected against polarity reversal

• Max. loop impedance 1100 W at 36 V DC, 610 W at 24 V DC,

100 W at 12 V DC

All digital outputs ("DO") • Transistor

• Any connection mode, in NPN or PNP mode

• Galvanically isolated

• Protected against short circuits

• Max. voltage: 36 V DC

• Max. frequency 2000 Hz

• Maximum current consumption allowed:

- Max. 700 mA if 1 DO per module is activated

- Max. 1 A if the 2 DO's per module are activated

- Max. 4 A for an Ethernet version if the device has 4 output

modules

: 5...36 V DC

on

: < 2 V DC

off

16

English

Loading...

Loading...