Burkert 8619 multiCELL WM AC, 8619 multiCELL WM DC, 8619 multiCELL Operating Instructions Manual

Page 1

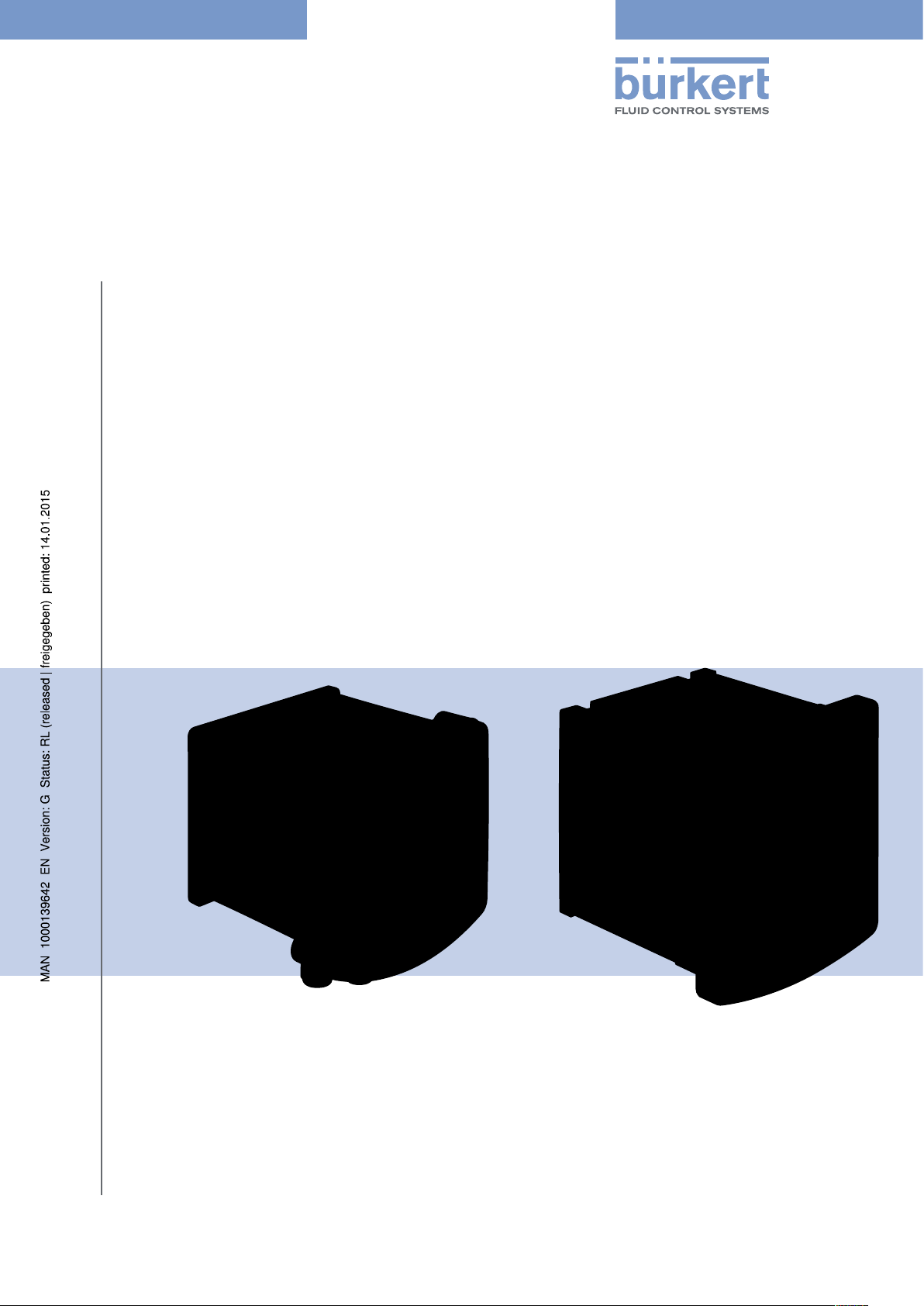

Type 8619

8619 multiCELL WM AC

8619 multiCELL WM DC

8619 multiCELL

Modular transmitter/controller

Operating Instructions

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert SAS, 2010-2014

Operating Instructions 1412/6_EU-ML 00561096 Original_FR

Page 3

Type 8619

1 GENERAL INFORMATION ................................................................................................................................................................3

1.1 About this operating instructions ..................................................................................................................................4

1.2 Intended use .............................................................................................................................................................................5

1.3 Basic safety information ....................................................................................................................................................6

1.4 General information ..............................................................................................................................................................7

2 PRODUCT DESCRIPTION ...............................................................................................................................................................9

2.1 Area of application .............................................................................................................................................................10

2.2 Construction of a 8619 multiCELL .............................................................................................................................10

2.3 Construction of a 8619 multiCELL WM DC ...........................................................................................................11

2.4 Construction of a 8619 multiCELL WM AC ............................................................................................................12

2.5 Functional diagram ............................................................................................................................................................13

2.6 Functional description ......................................................................................................................................................13

2.7 Description of the name plate .....................................................................................................................................15

3 TECHNICAL DATA .............................................................................................................................................................................17

3.1 Conditions of use of the 8619 multiCELL ..............................................................................................................18

3.2 Conditions of use of the 8619 multiCELL WM DC ............................................................................................18

3.3 Conditions of use of the 8619 multiCELL WM AC .............................................................................................19

3.4 Compliance to standards and directives ...............................................................................................................19

3.5 Mechanical data ...................................................................................................................................................................20

3.6 Specifications of the "M0" main board of the 8619 multiCELL ..................................................................21

3.7 Specifications of the "M0" main board of the 8619 multiCELL WM .........................................................22

3.8 Specifications of the power supply board of the 8619 multiCELL WM .................................................23

3.9 Specifications of the "POWER OUT" power distribution board for the 8619 multiCELL WM ....24

3.10 Specifications of the "Input" board ...........................................................................................................................24

3.11 Specifications of the memory card reader/recorder ....................................................................................25

3.12 Specifications of the outputs board "OUT" ...........................................................................................................25

3.13 Specifications of the "pH/redox" module ..............................................................................................................26

3.14 Specifications of the "COND" conductivity module .........................................................................................26

4 INSTALLATION AND WIRING ......................................................................................................................................................29

4.1 Safety instructions .............................................................................................................................................................30

English

1

Page 4

Type 8619

4.2 Installation procedure ......................................................................................................................................................31

4.3 Electrical wiring ....................................................................................................................................................................34

5 ADJUSTMENT AND COMMISSIONING .................................................................................................................................53

5.1 Safety instructions .............................................................................................................................................................56

5.2 Switching on the device for the first time .............................................................................................................56

5.3 Using the navigation button and the dynamic keys .........................................................................................57

5.4 Entering text .........................................................................................................................................................................59

5.5 Entering a numerical value ............................................................................................................................................60

5.6 Description of the icons ..................................................................................................................................................61

5.7 Operating levels ................................................................................................................................................................... 62

5.8 Process level .........................................................................................................................................................................63

5.9 Configuration level access ............................................................................................................................................64

5.10 "Parameters" menu ............................................................................................................................................................65

5.11 Calibration menu ..............................................................................................................................................................108

5.12 "Diagnostics" menu .........................................................................................................................................................126

5.13 Tests menu ..........................................................................................................................................................................132

5.14 Information menu ............................................................................................................................................................ 134

5.15 Structure of the configuration menus .................................................................................................................. 135

5.16 Process inputs or values ............................................................................................................................................. 150

6 REPAIR AND MAINTENANCE ..................................................................................................................................................153

6.1 Safety instructions .......................................................................................................................................................... 154

6.2 Maintenance of the 8619 ............................................................................................................................................. 154

6.3 If you encounter problems ......................................................................................................................................... 154

6.4 Spare parts and accessories .....................................................................................................................................162

6.5 Packaging and transport ..............................................................................................................................................162

6.6 Storage .................................................................................................................................................................................. 162

6.7 Disposal of the device ...................................................................................................................................................163

2

English

Page 5

Type 8619

Type 8619

General information

1 GENERAL INFORMATION

1.1 About the Operating Instructions ..................................................................................................................................4

1.1.1 Symbols used ........................................................................................................................................ 4

1.1.2 Definition of the word "device" .......................................................................................................... 4

1.2 Intended use .............................................................................................................................................................................5

1.3 Basic safety information ....................................................................................................................................................6

1.4 General information ..............................................................................................................................................................7

1.4.1 Manufacturer's address and international contacts ...................................................................... 7

1.4.2 Warranty conditions ............................................................................................................................. 7

1.4.3 Information on the internet ................................................................................................................. 7

English

3

Page 6

1.1 About the Operating Instructions

The Operating Instructions describe the entire life cycle of the device. Please keep this operating instructions in a

safe place, accessible to all users and any new owners.

This operating instructions contains important safety information.

Failure to comply with these instructions can lead to hazardous situations.

▶ When the symbol

▶ Whatever the version of the device, the Operating Instructions must be read and understood.

is marked inside or outside the device, carefully read the Operating Instructions.

1.1.1 Symbols used

DANGER

Warns against an imminent danger.

▶ Failure to observe this warning can result in death or in serious injury.

WARNiNG

Warns against a potentially dangerous situation.

▶ Failure to observe this warning can result in serious injury or even death.

CAUTiON

Warns against a possible risk.

▶ Failure to observe this warning can result in substantial or minor injuries.

NOTE:

Warns against material damage.

Important advice or recommendations.

Refers to information contained in the Operating Instructions or in other documents.

→ Indicates a procedure to be carried out.

1.1.2 Definition of the word "device"

The word "device" used in the Operating Instructions refers to the controller/transmitter type 8619 multiCELL,

8619 multiCELL WM AC or 8619 multiCELL WM DC.

English

4

Page 7

Type 8619

General information

1.2 Intended use

Use of this device that does not comply with the instructions could present risks to people, nearby

installations and the environment.

▶ The device is intended, depending on the modules fitted and the measurement sensors connected, for the

acquisition, processing, transmission and regulation of physical parameters such as pH, conductivity, tem-

perature or flow rate... .

▶ This device must be protected against electromagnetic interference, ultraviolet rays and, when installed out-

doors, the effects of climatic conditions.

▶ This device must be used in compliance with the characteristics and commissioning and use conditions

specified in the contractual documents and in the user operating instructions.

▶ Requirements for the safe and proper operation of the device are proper transport, storage and installation, as

well as careful operation and maintenance.

▶ Only use the device as intended.

▶ Observe any existing restraints when the device is exported.

English

5

Page 8

Type 8619

General information

1.3 Basic safety information

This safety information does not take into account:

• any contingencies or occurrences that may arise during assembly, use and maintenance of the device.

• the local safety regulations that the operator must ensure the staff in charge of installation and maintenance

observe.

Danger due to electrical voltage.

▶ If a 12-36 V DC version is installed either in a wet environment or outdoors, all the electrical voltages must be

of max. 35 V DC.

▶ Disconnect the electrical power for all the conductors and isolate it before carrying out work on the system.

▶ All equipment connected to the 8619 must be double insulated with respect to the mains according to the

standard IEC 61010-1:2010.

▶ Observe all applicable accident protection and safety regulations for electrical equipment.

Various dangerous situations.

To avoid injury take care:

▶ to prevent any unintentional power supply switch-on.

▶ to carry out the installation and maintenance work by qualified and skilled staff with the appropriate tools.

▶ to guarantee a set or controlled restarting of the process after a power supply interruption.

▶ to use the device only if in perfect working order and in compliance with the instructions provided in the user

operating instructions.

▶ to observe the general technical rules during the planning and use of the device.

▶ not to use this device in explosive atmospheres.

▶ not to use this device in an environment incompatible with the materials from which it is made.

▶ not to subject the device to any mechanical stresses (for example by placing objects on top of it or using it as

a step).

▶ not to make any external modifications to the device such as for instance painting or varnishing any part of the

device.

NOTE:

Elements/components sensitive to electrostatic discharges

▶ This device contains electronic components sensitive to electrostatic discharges. They may be damaged if

they are touched by an electrostatically charged person or object. In the worst case scenario, these compo-

nents are instantly destroyed or go out of order as soon as they are activated.

▶ To minimise or even avoid all damage due to an electrostatic discharge, take all the precautions described in

standard EN 61340-5-1.

▶ Also ensure that you do not touch any of the live electrical components.

6

English

Page 9

Type 8619

General information

1.4 General information

1.4.1 Manufacturer's address and international contacts

To contact the manufacturer of the device, use following address:

Burkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

You may also contact your local Burkert sales office.

The addresses of our international sales offices are available on the internet at: www.burkert.com

1.4.2 Warranty conditions

The condition governing the legal warranty is the conforming use of the device in observance of the operating conditions specified in this operating instructions.

1.4.3 Information on the internet

You can find the operating instructions and technical data sheets regarding the type 8619 at: www.burkert.com

English

7

Page 10

Type 8619

General information

8

English

Page 11

Type 8619

Product description

2 PRODUCT DESCRIPTION

2.1 Area of application .............................................................................................................................................................10

2.2 Construction of a 8619 multiCELL .............................................................................................................................10

2.3 Construction of a 8619 multiCELL WM DC ...........................................................................................................11

2.4 Construction of a 8619 multiCELL WM AC ............................................................................................................12

2.5 Functional diagram ............................................................................................................................................................13

2.6 Functional description ......................................................................................................................................................13

2.7 Description of the name plate .....................................................................................................................................15

English

9

Page 12

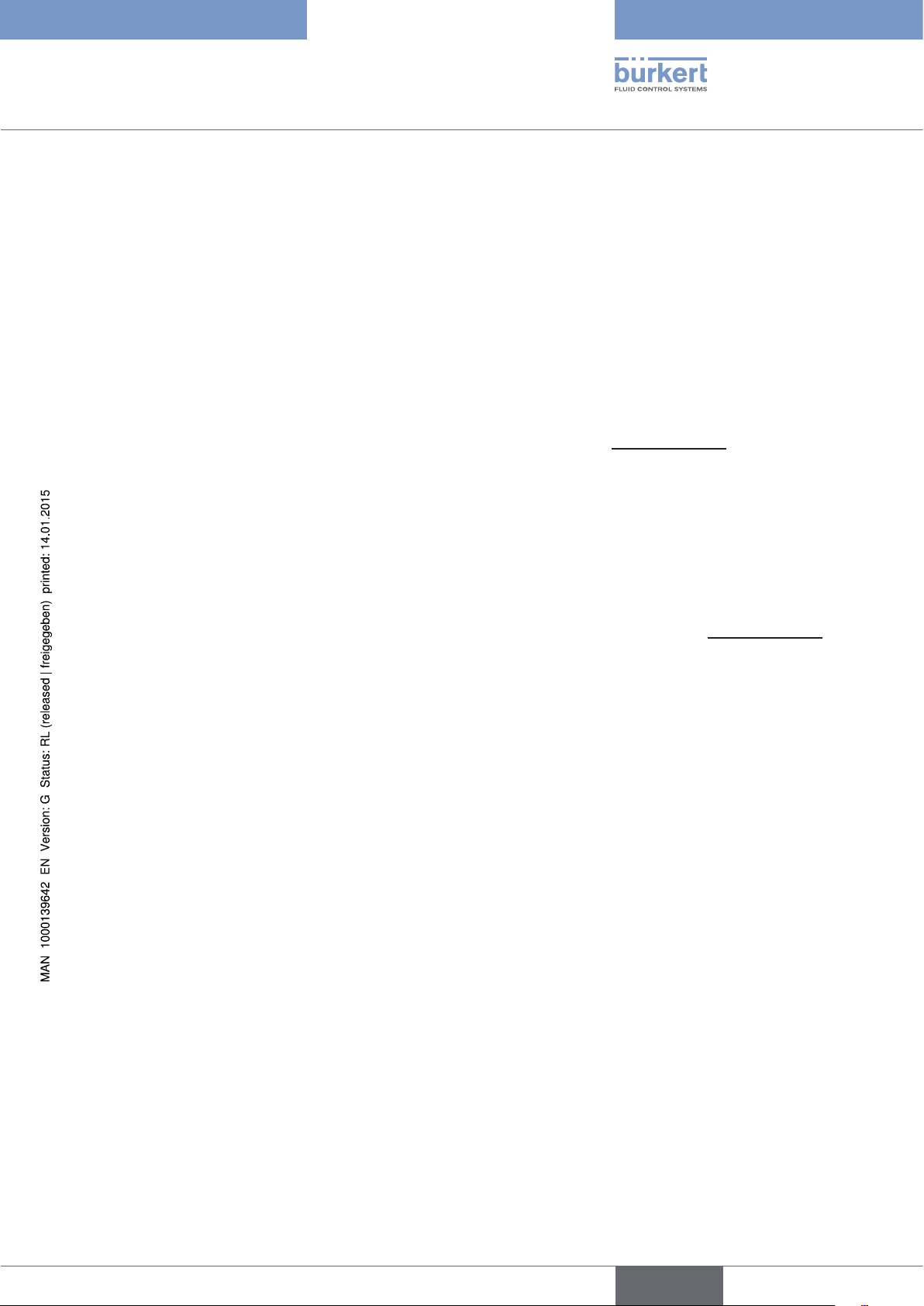

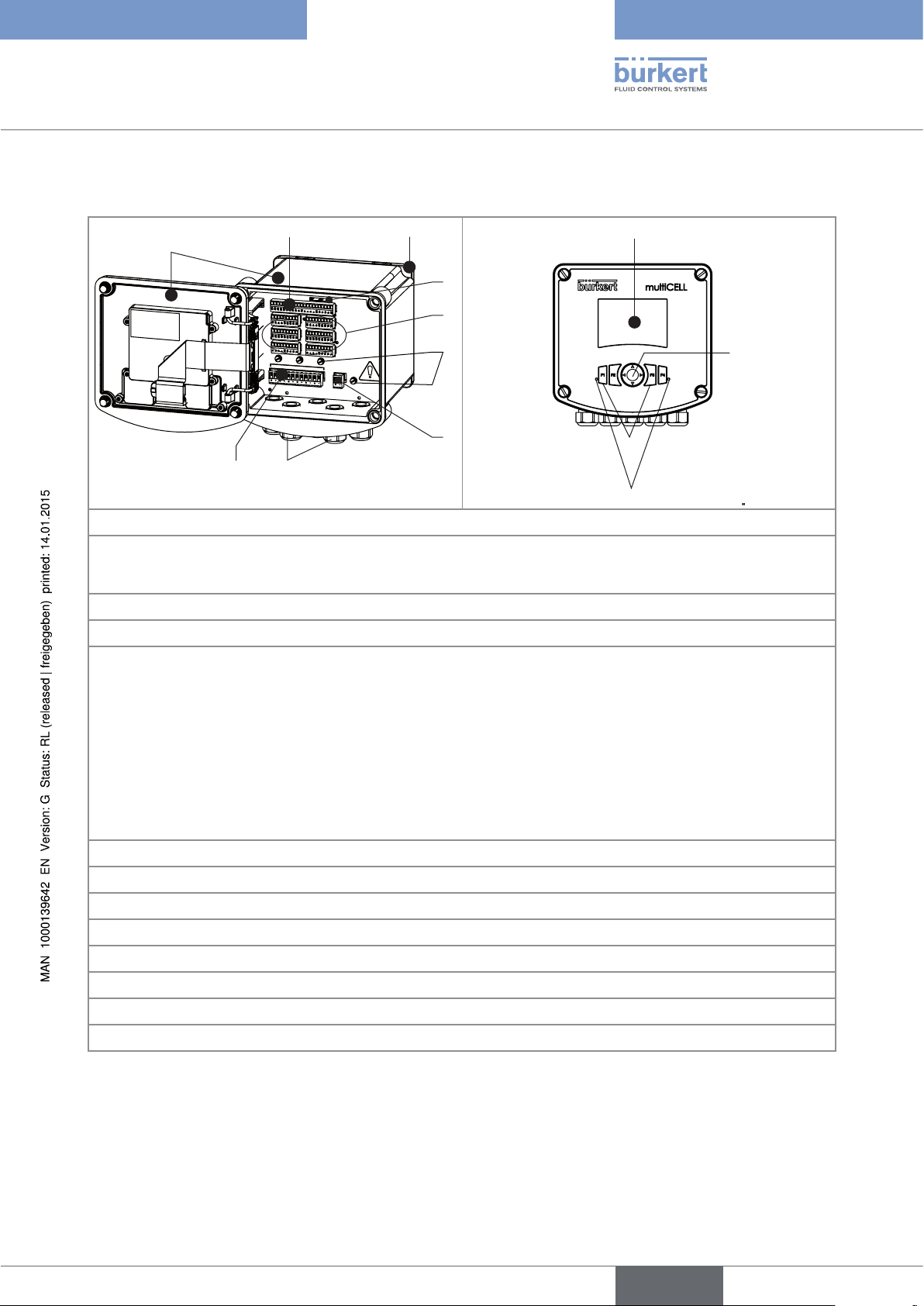

A

B

D

Type 8619

Product description

2.1 Area of application

The 8619 multiCELL is a multifunction device intended to display, transmit and regulate various physical parameters. It can be used, for example, to manage a water treatment system (a boiler, a cooling tower or a reverse

osmosis system).

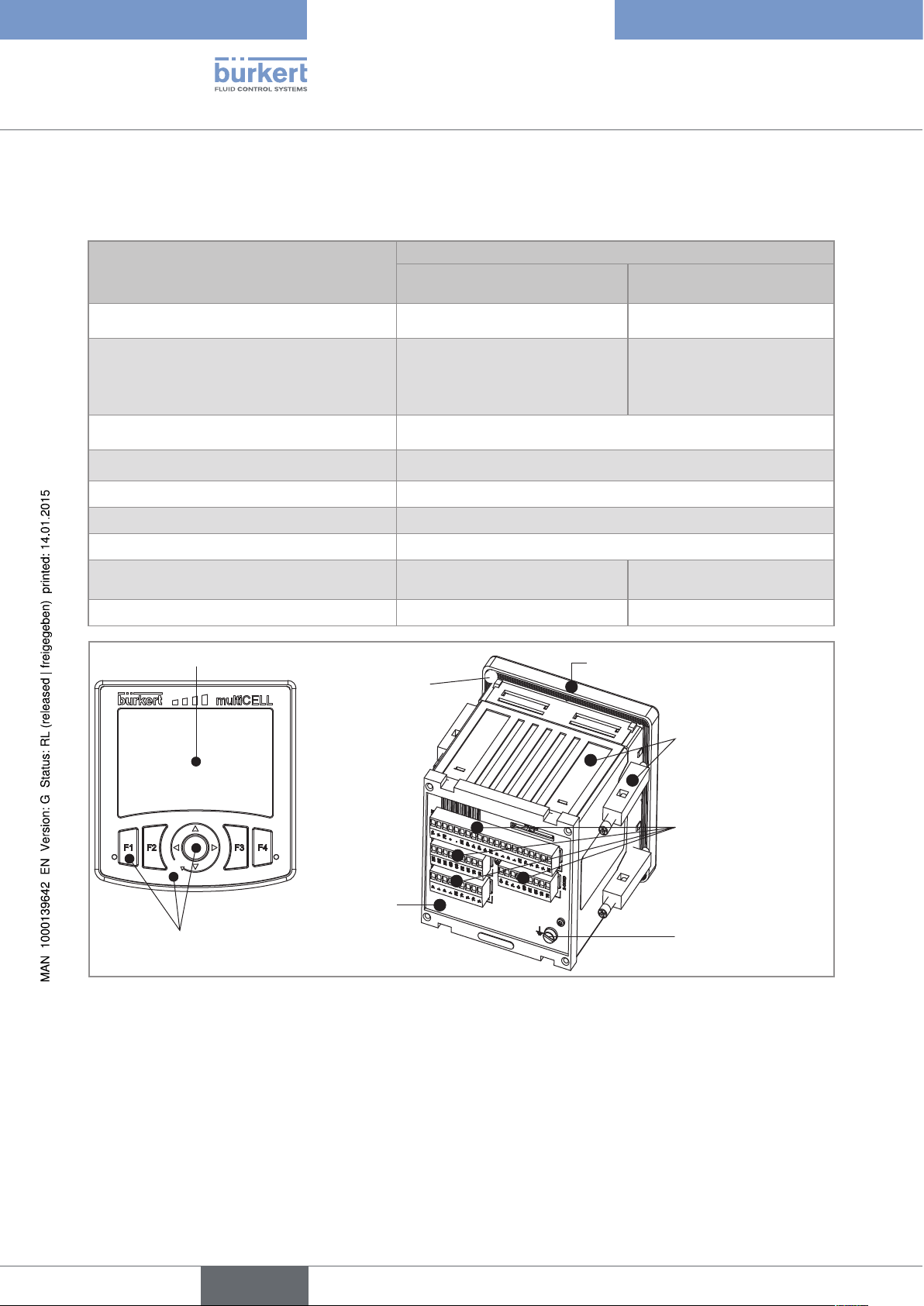

2.2 Construction of a 8619 multiCELL

F

G

E

C

H

J

A: standardised 1/4 DIN housing (92x92 mm) with seal, to be mounted in the door of the electrical enclosure or

cabinet and attached using 4 fasteners.

B: a main board (identified by "M0" on the rear plate):

• To connect the electrical power source of the multiCELL;

• to power another device, e.g. a flow-rate sensor;

• offering 2 digital inputs (identified by "DI", digital input), two 4-20 mA current outputs (identified by "AO",

analogue output) and 2 digital outputs (identified by "DO", digital output).

C: 1 to 6 slots for placing the following connection modules:

• module with light grey connector for connection of a pH sensor or oxidation reduction potential sensor and/or

a temperature sensor

• module with green connector for connection of a conductivity sensor and/or a temperature sensor

• module with black connector with two 4-20 mA current outputs and 2 digital outputs.

• module with orange connector with two analogue inputs and 2 digital inputs.

D: functional earth screw (connected internally to all "FE" terminals on the main board and additional modules).

E: memory card (SD type) reader/recorder

F: display with backlight.

G: navigation button (4 directions).

H: 4 dynamic keys

J: 2 LEDs

Fig. 1 : Construction of a 8619 multiCELL

10

English

Page 13

CB

HJ

G

K

L

N

KLK

L

Type 8619

Product description

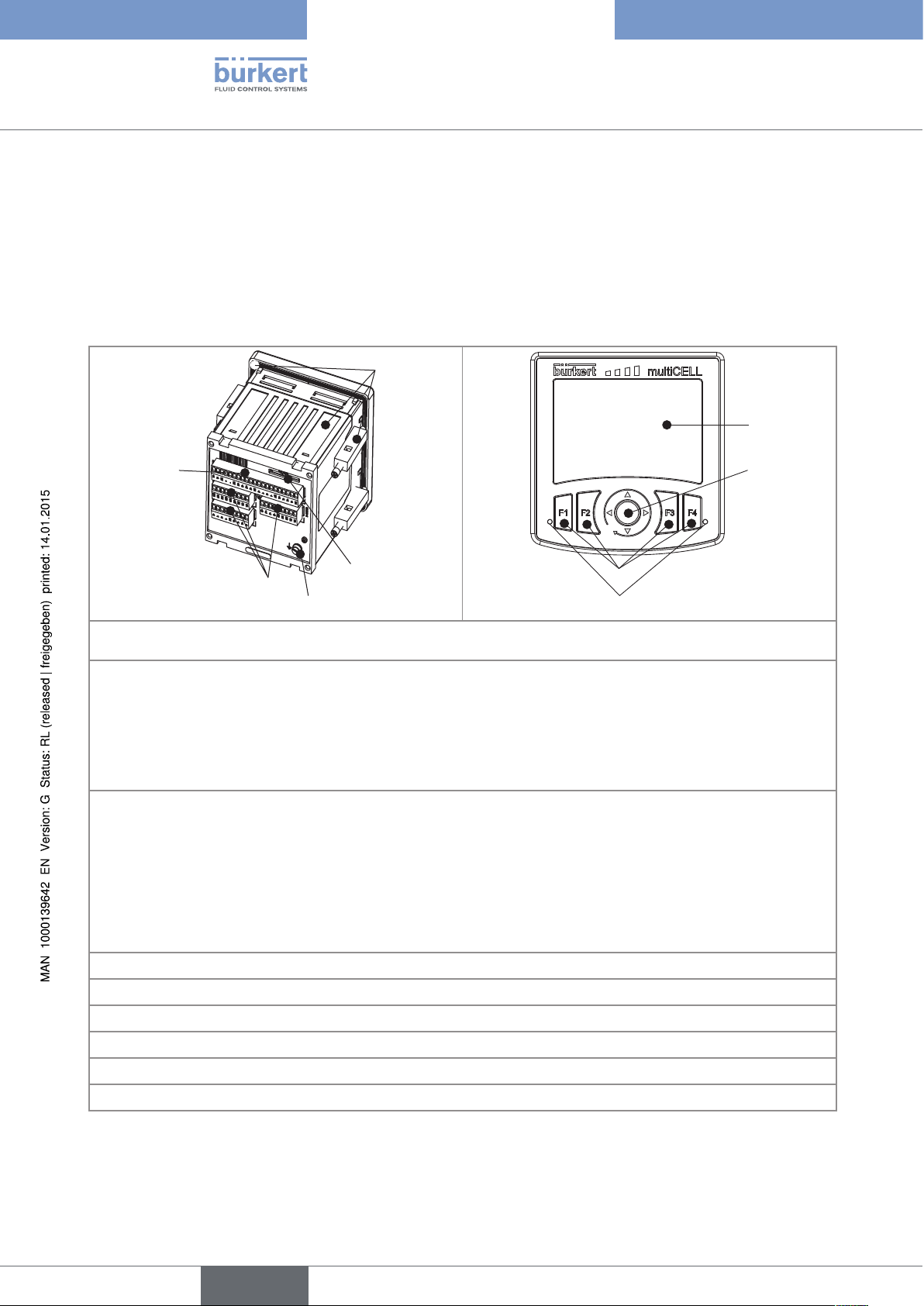

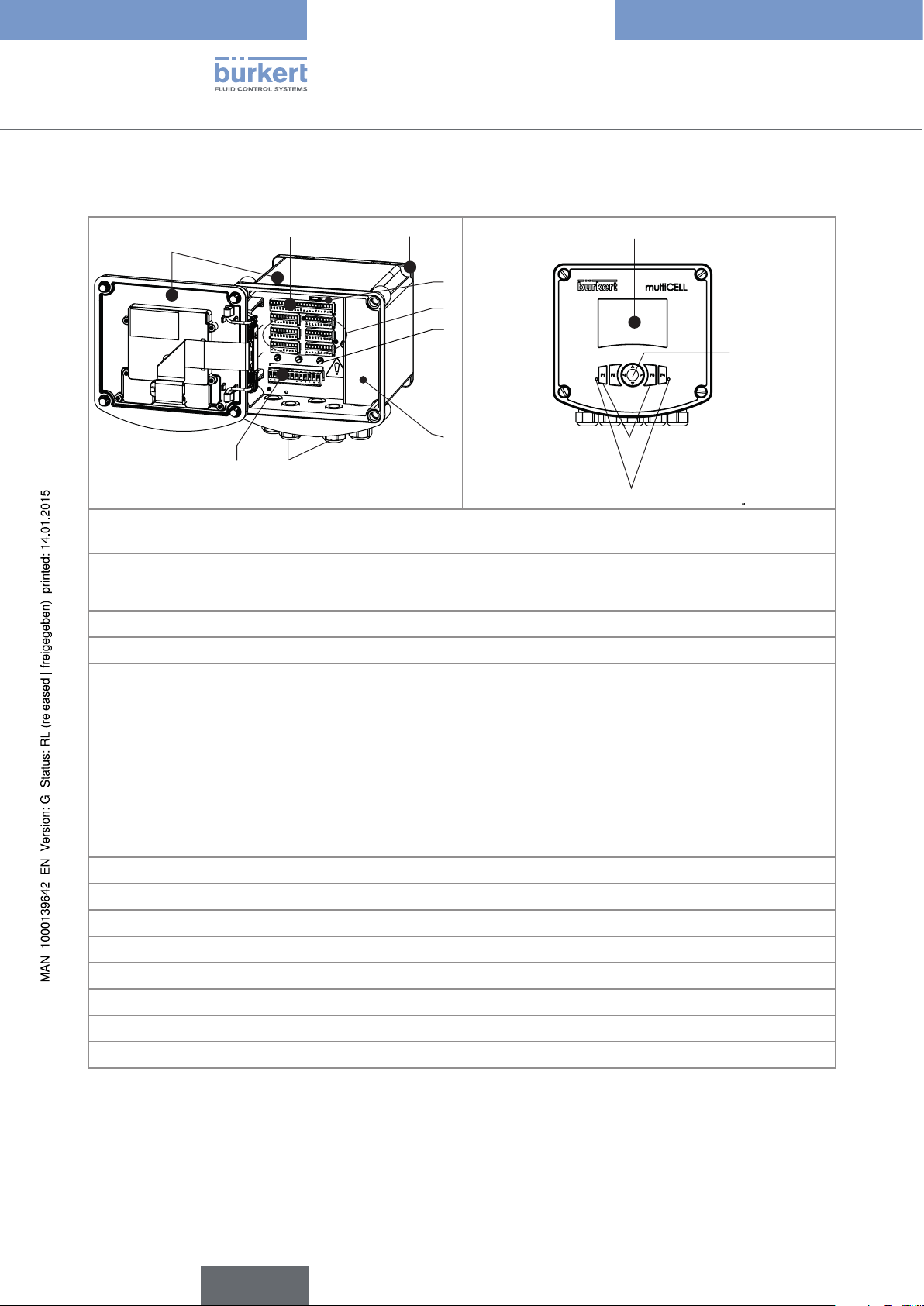

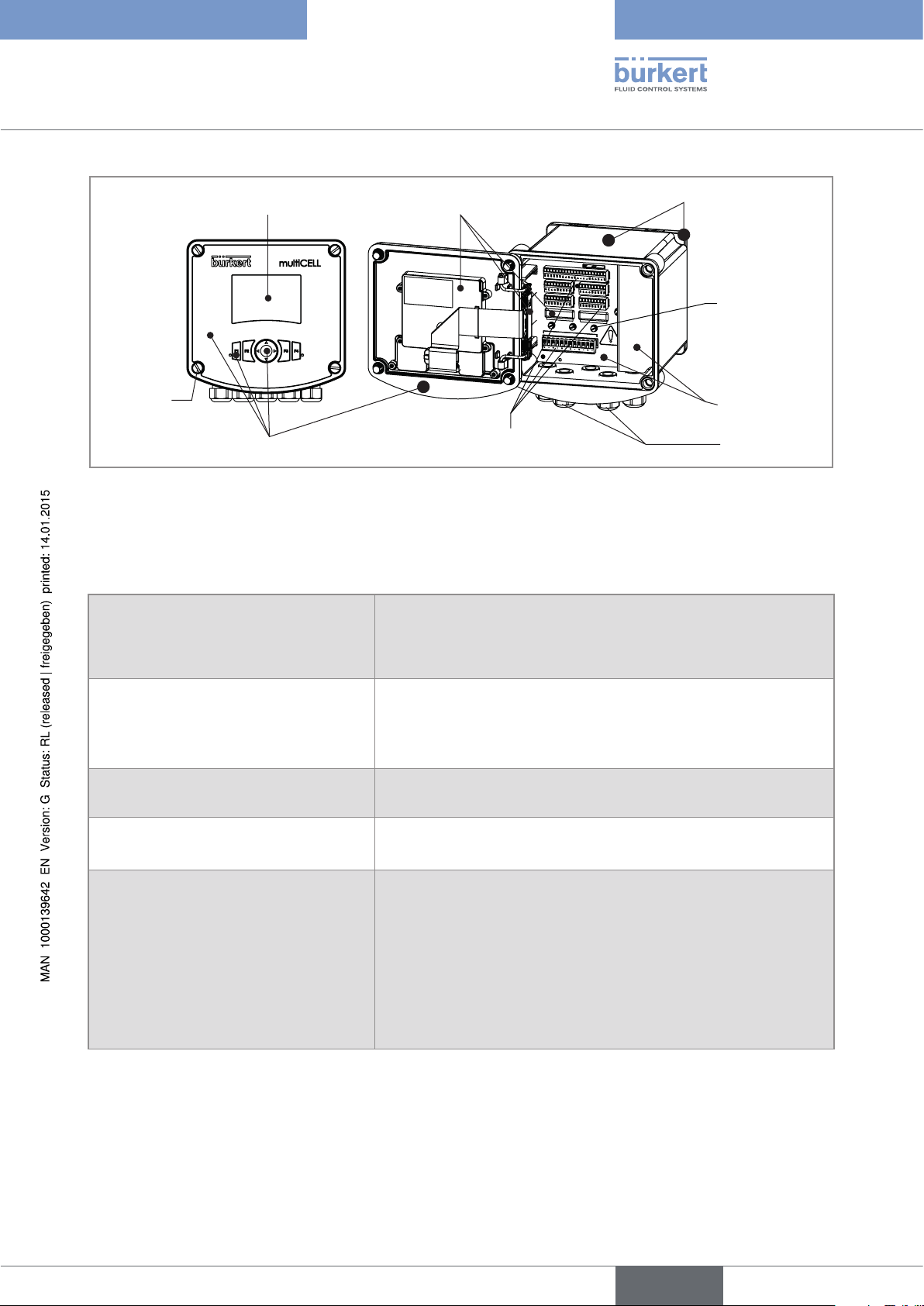

2.3 Construction of a 8619 multiCELL WM DC

A

MEMORY

CARD

M0

M1

M3

M5

FE

PWR OUT

M2

M4

M6

FE

FE

12-36 V

DC

FE

D

E

F

M

A: Wall-mounting housing; Cover with seal, closed by 4 screws; Display with navigation components and LEDs.

B: main board (identified by "M0" on the plate) with two digital inputs (identified by "DI", digital input), two

4-20 mA current outputs (identified by "AO", analogue output) and two digital outputs (identified by "DO", digital

output).

C: Wall-mounting plate, removable

D: memory card (SD type) reader/recorder

E: 6 slots for placing the following connection modules:

• module with light grey connector for connection of a pH sensor or oxidation reduction potential sensor and/or

a temperature sensor;

• module with green connector for connection of a conductivity sensor and/or a temperature sensor;

• module with black connector with two 4-20 mA current outputs and two digital outputs;

• module with orange connector with two analogue inputs and two digital inputs.

If a slot is unused, a cap blanks off the opening

F: functional earth screw (connected internally to all "FE" terminals on the main board and additional modules).

G: Connection terminal board for the 12-36 V DC power supply

H: 5 M20 x 1.5 cable glands

J: supply and distribution board

K: display with backlight.

L: navigation button (4 directions).

M: 4 dynamic keys

N: 2 LEDs

Fig. 2 : Construction of a 8619 multiCELL WM DC

11

English

Page 14

CB

HJ

G

K

L

N

KLK

L

Type 8619

Product description

2.4 Construction of a 8619 multiCELL WM AC

A

MEMORY

CARD

M0

M1

M3

M5

PWR OUT

M2

M4

M6

D

E

F

M

A: Wall-mounting housing; Cover with seal, closed by 4 screws; Display with navigation components and LEDs.

B: main board (identified by "M0" on the plate) with two digital inputs (identified by "DI", digital input), two 4-20

mA current outputs (identified by "AO", analogue output) and two digital outputs (identified by "DO", digital

output).

C: Wall-mounting fastening plate, removable

D: Memory card (SD type) reader/recorder

E: 6 slots for placing the following connection modules:

• module with light grey connector for connection of a pH sensor or oxidation reduction potential sensor and/or

a temperature sensor;

12

• module with green connector for connection of a conductivity sensor and/or a temperature sensor;

• module with black connector with two 4-20 mA current outputs and two digital outputs.

• module with orange connector with two analogue inputs and two digital inputs.

If a slot is unused, a cap blanks off the opening

F: functional earth screw (connected internally to all "FE" terminals on the main board and additional modules).

G: Protective cap for the 110-240 V AC power supply terminal board

H: 5 M20 x 1.5 cable glands

J: supply and distribution board

K: display with backlight.

L: navigation button (4 directions).

M: 4 dynamic keys

N: 2 LEDs

Fig. 3 : Construction of a 8619 multiCELL WM AC

English

Page 15

0 %

Type 8619

Product description

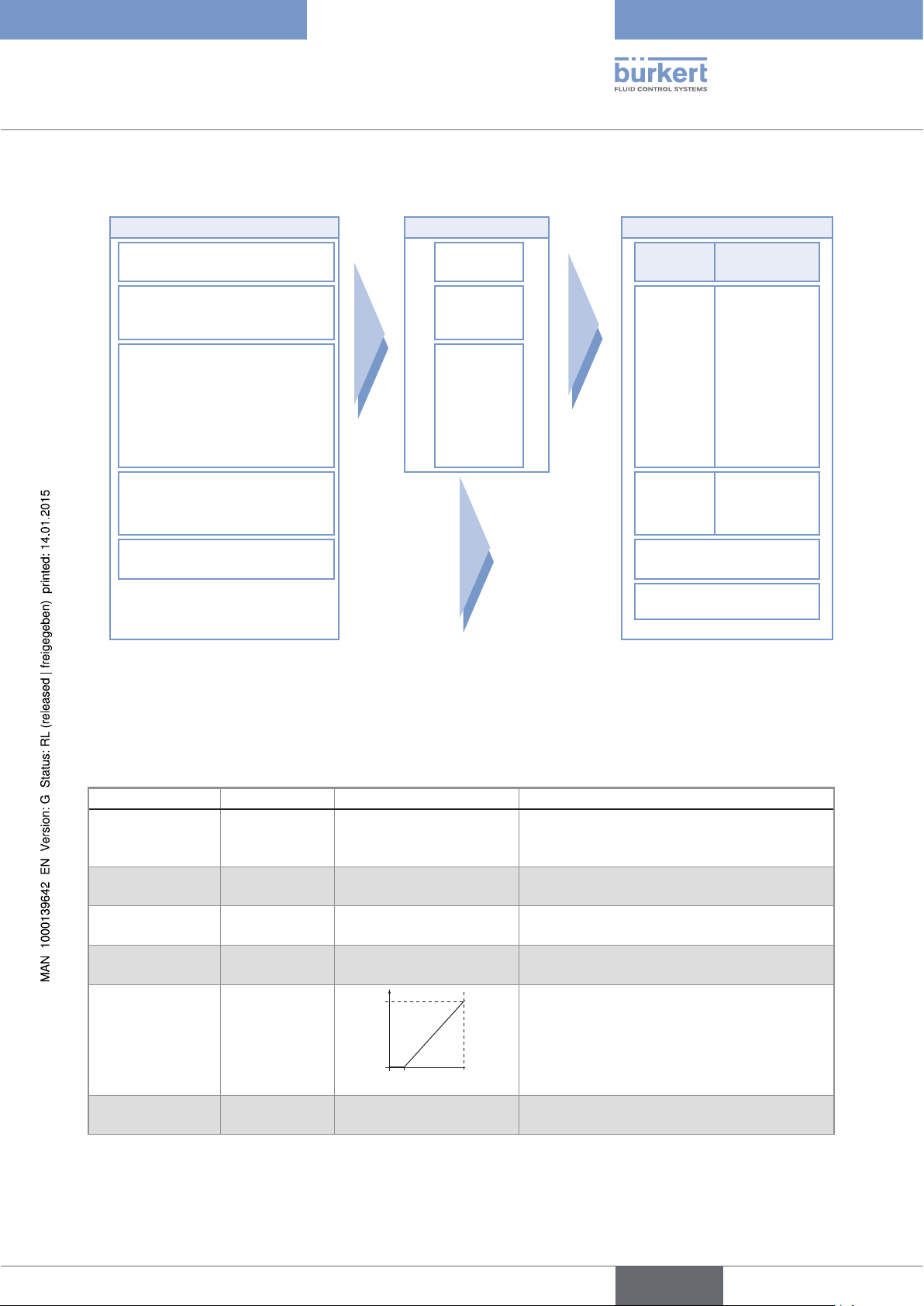

2.5 Functional diagram

INPUTS FUNCTIONS

Digital inputs or frequency

inputs

Analogue inputs, current or

voltage

Conductivity sensor (2 or 4

electrodes)

pH/Redox sensor

Temperature sensor

PT100/PT1000

1)

simultaneously active

1)

OUTPUTS

Function 1 OUTPUT SIGNAL

...

Transistor,

1 and 2

Function 6

4-20 mA,

PWM or on/

off or PFM or

pulse

4-20 mA

1 and 2

Display

Memory card

2.6 Functional description

The multiCELL assigns each input to a function (such as dosing, for example) which is entirely configurable by the

user. According to the model selected, the following are offered as basic or optional functions:

Function Availability Formula Use

Arithmetic Standard on all

models

PASS Standard on all

models

REJECT Standard on all

models

DEVIAT Standard on all

models

PROP

(proportional)

Standard on all

models

ON/OFF Standard on all

models

A+B, A-B, A/B Arithmetic operation between two values

having the same units. A or B may be the

result of another function.

A/B x 100% Calculation of the passage rate.

(1 - A/B) x 100 % Calculation of the rejection rate.

(A/B - 1) x 100 % Calculation of the deviation rate.

100 %

Calculation of an output proportional to a

bounded input.

process

scal- scal+

parameter

ON/OFF control For all input types.

13

English

Page 16

Function Availability Formula Use

Flow rate

measurement

• Standard

on models

Each digital input can be used to measure the

flow rate.

560205,

560213,

565984 à

565987

• Optional

(see section

5.10.4) on all

other models

PID

Time dosing

Optional (see

section 5.10.4)

Optional (see

section 5.10.4)

Continuous regulation For all input types; with internal or external

setpoint.

In a cooling tower, for example; used to dose

2 products at fixed intervals or for twice daily

dosing scheduled over one week.

Type 8619

Product description

Volume dosing

Concentration

Datalogger on

memory card

Optional (see

section 5.10.4)

Optional (see

section 5.10.4)

Optional (see

section 5.10.4)

The time dosing function can be combined

with an ON/OFF function on a conductivity

measurement only, in order to ensure prepurging of the system. The "ON/OFF" function

must be configured and activated before the

time dosing function.

dedicated to the cooling towers. Metering of

a specific volume of water and activation of an

actuator during a specific period in order to

add a product and, finally, reset of the water

volume to zero.

The concentration graphs for certain

compounds such as NaCl and H2SO4

are memorised for use over the entire

concentration range.

Option to memorise the variations in 1 to 16

values in a given time interval.

14

English

Page 17

Type 8619

Product description

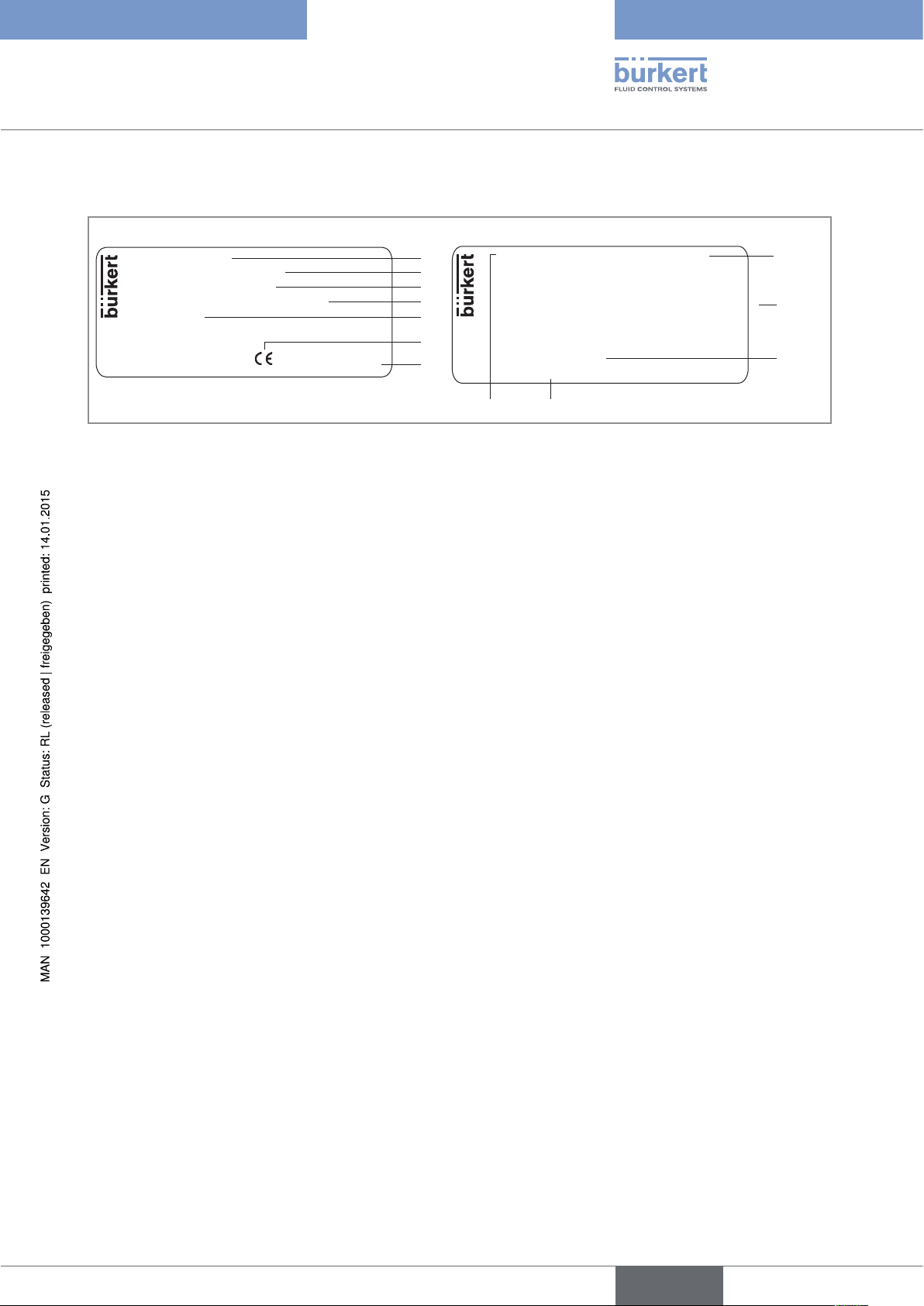

2.7 Description of the name plate

8619 multiCELL

Supply: 12-36V DC, 1.8 A

Temp: -10...+60 °C

IP65 PANEL (FRONT) IP20 (REAR)

Made in France

S-N:1110

00560204

W44ML

Fig. 4 : Example of a name plate

1. Type of device

2. Electrical power supply

3. Ambient temperature range

4. Protection rating

5. Serial number

6. Conformity logo

7. Construction code

8. Device fitted with a memory card reader

1

2

3

4

5

6

7

M0: 2xDI - 2xAO - 2xDO - SD CARD

M1: pH/ORP - PT100/1000

M2: RES COND 2/4 POLES PT100/1000

M3: 2xAO - 2xDO

Made in France

M4:

M5:

M6:

Softw.:

00560204 W44ML

12

11

8

9

}

10

9. Characteristics of the connection modules

10. Software options

11. Order code

12. Properties of the main "M0" board

English

15

Page 18

Type 8619

Product description

16

English

Page 19

Type 8619

Technical data

3 TECHNICAL DATA

3.1 Conditions of use of the 8619 multiCELL ..............................................................................................................18

3.2 Conditions of use of the 8619 multiCELL WM DC ............................................................................................18

3.3 Conditions of use of the 8619 multiCELL WM AC .............................................................................................19

3.4 Compliance to standards and directives ...............................................................................................................19

3.5 Mechanical data ...................................................................................................................................................................20

3.6 Specifications of the "M0" main board of the 8619 multiCELL ..................................................................21

3.7 Specifications of the "M0" main board of the 8619 multiCELL WM .........................................................22

3.8 Specifications of the power supply board of the 8619 multiCELL WM .................................................23

3.9 Specifications of the "POWER OUT" power distribution board for the 8619 multiCELL WM ....24

3.10 Specifications of the "Input" board ...........................................................................................................................24

3.11 Specifications of the memory card reader/recorder ....................................................................................25

3.12 Specifications of the outputs board "OUT" ...........................................................................................................25

3.13 Specifications of the "pH/redox" module ..............................................................................................................26

3.14 Specifications of the "COND" conductivity module .........................................................................................26

English

17

Page 20

Type 8619

Technical data

3.1 Conditions of use of the 8619 multiCELL

Ambient temperature

• without connection module

• with connection module

1)

1)

• -10 to +70 °C

• -10 to +60 °C

Air humidity < 85 %, not condensing

Height above sea level max. 2000 m

Protection rating • IP65, NEMA4X on front, once mounted, and elec-

trical enclosure closed

• IP20 for the parts inside the electrical enclosure

Pollution degree Degree 2 according to UL 61010-1

Category of installation Category 1 according to UL 61010-1

1)

with a memory card available as an accessory (order reference 564072). If a different memory card is used,

observe the operating temperatures given by the manufacturer of the memory card.

3.2 Conditions of use of the 8619 multiCELL WM DC

Ambient temperature

• without connection module

• with connection module

Air humidity < 85 %, not condensing

Height above sea level max. 2000 m

Protection rating IP65, IP67, if the following conditions are met:

1)

1)

• -10 to +75 °C

• -10 to +60 °C

18

• Body of the cable glands tightened with a torque of

5.5 Nm ± 20 % at the factory.

• Cable glands blanked off or wired.

• Screws of the cable glands tightened with a torque

of 4.5 Nm ± 20 %.

• Housing closed.

• The 4 screws for the cover are tightened crosswise

with a torque of 1.4 Nm ± 20 %.

Pollution degree Degree 2 according to UL 61010-1

Category of installation Category I according to UL 61010-1

1)

with a memory card available as an accessory (order reference 564072). If a different memory card is used,

observe the operating temperatures given by the manufacturer of the memory card.

English

Page 21

Type 8619

Technical data

3.3 Conditions of use of the 8619 multiCELL WM AC

Observe the maximum permissible load as a function of the ambient temperature. See the derating curves

Fig. 7, section 3.9.

Ambient temperature -10 to +70 °C

1)

Air humidity < 85 %, not condensing

Height above sea level max. 2000 m

Protection rating, panel-mounting version IP65, IP67, if the following conditions are met:

• Body of the cable glands tightened with a torque of

5.5 Nm ± 20 % at the factory.

• Cable glands blanked off or wired.

• Screws of the cable glands tightened with a torque

of 4.5 Nm ± 20 %.

• Housing closed.

• The 4 screws for the cover are tightened crosswise

with a torque of 1.4 Nm ± 20 %.

Pollution degree Degree 3 according to UL 61010-1 following the con-

ditions below:

• Housing closed.

• The 4 screws for the cover are tightened crosswise

with a torque of 1.4 Nm ± 20 %.

Category of installation Category II according to UL 61010-1

1)

with a memory card available as an accessory (order reference 564072). If a different memory card is used,

observe the operating temperatures given by the manufacturer of the memory card.

3.4 Compliance to standards and directives

The device conforms to the EC directives through the following standards:

• EMC: EN 61000-6-2, EN 61000-6-3

• Resistance to vibrations EN 60068-2-6

• Resistance to shocks: EN 60068-2-27

• For the 8619 multiCELL WM AC: Low voltage directive

The UL devices with command key PE72 (identified by the logo

key PU02 (identified by the logo ), for the United States and Canada, comply with the following

standards:

• UL 61010-1

• CRN/CSA-C22.2 n° 61010-1

) and the UL devices with command

19

English

Page 22

Type 8619

Technical data

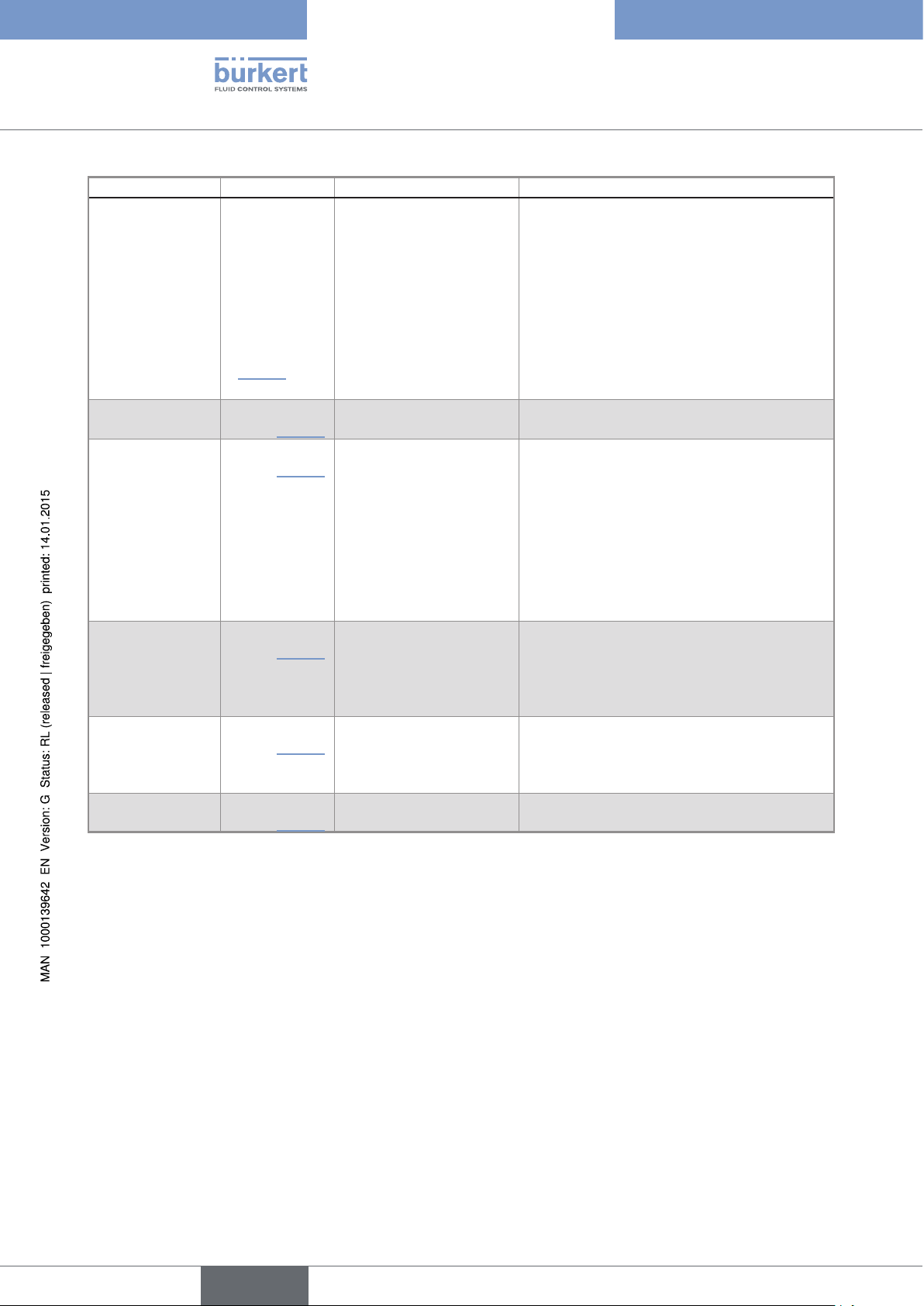

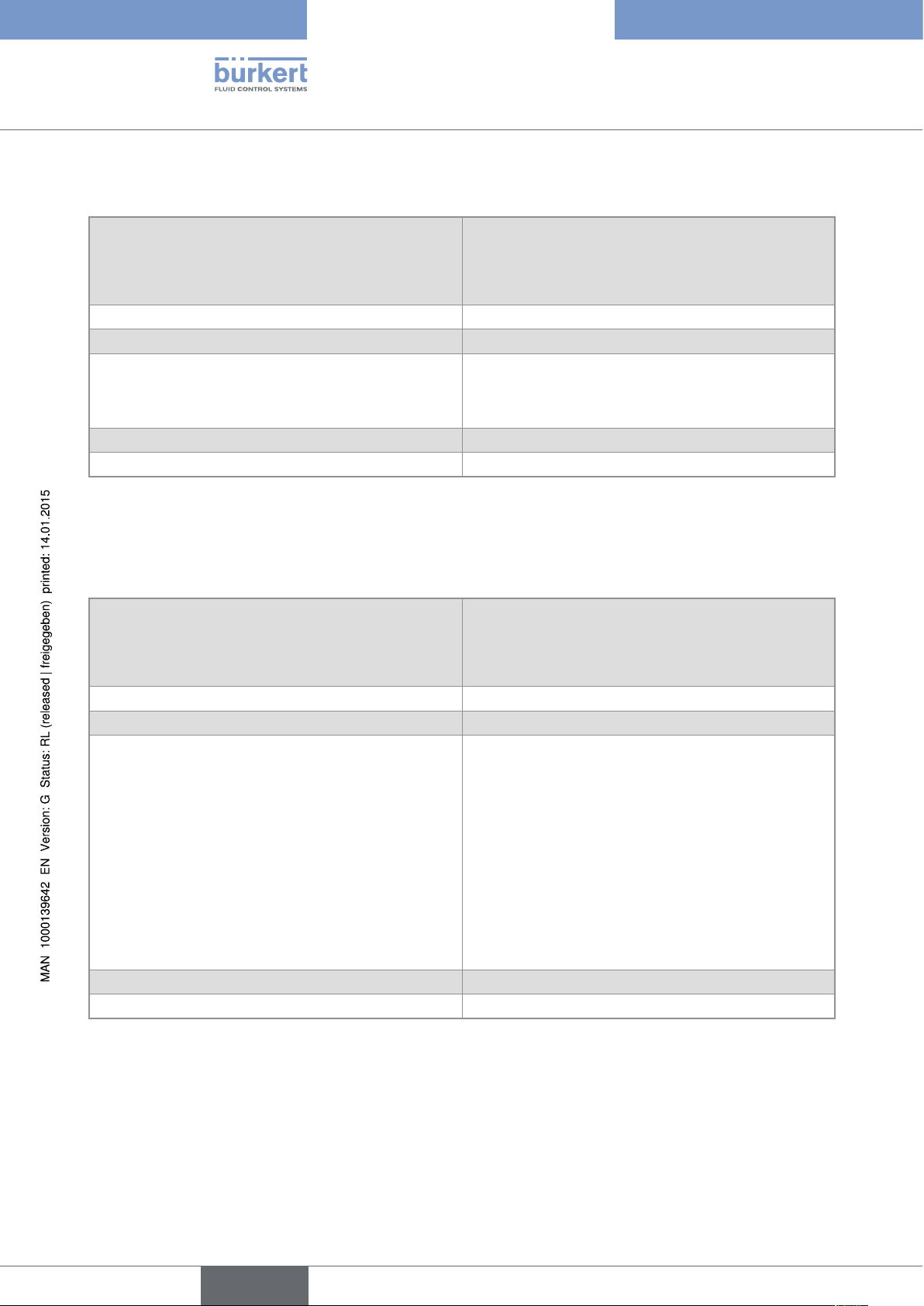

3.5 Mechanical data

Tab. 1 : Materials in contact with the ambient air

Material

Component

8619 multiCELL

Panel-mounting housing and fastener PPO -

Wall-mounting housing, wall-mounting

fastening plate, cable glands, protective cap

(for LCD display), protective blank (for a slot

- PA66

without connection terminal), hinge stiffener.

Seal Silicone

Front panel and keys PC/silicone

Terminal support plate Stainless steel 304

8619 multiCELL WM AC or

8619 multiCELL WM DC

Terminal blocks PBT, contacts in gold-plated copper alloy

Ground screw + spring washer Stainless steel 316 (A4)

Protective cap for the 110-240 V AC power

supply terminal board

- Stainless steel 304

4 cover screws - PVC

PC

Silicone

Stainless steel 304

Silicone

PC

PPO

PBT, contacts in gold-plated

copper alloy

Stainless steel 316 (A4)

20

Fig. 5 : Component materials of the 8619 multiCELL

English

Page 23

Type 8619

Technical data

PC

PVC

Silicone

PA66

PBT, contacts in gold-plated

copper alloy

MEMORY

CARD

M0

M1

M3

M5

1

2

3

45

6

7

PE

PWR OUT

M2

M4

M6

8

9

1

2

3

45

6

7

8

9

PE

PE

Stainless steel 316

(A4)

Stainless steel 304

PA66

Fig. 6 : Component materials of the 8619 multiCELL WM

3.6 Specifications of the "M0" main board of the 8619 multiCELL

Electrical supply 12-36 V DC • filtered and regulated

• SELV circuit, at a non-hazardous energy level

PA66

• Tolerance: ±10 %

Specifications of the 12-36 V DC power

source (not provided) of the UL devices,

• Limited power source (in accordance with section 9.3 of the UL

61010-1 standard)

with variable key PE72

• or class 2 type power source (according to the 1310/1585 and

60950-1 standards)

Own consumption (without connection

1.5 VA

module, outputs not connected)

Power distribution ("PWR OUT") • 12-36 V DC, 1.8 A max.

• Protected against polarity reversal

All digital inputs ("DI") • Switching threshold V

• Switching threshold V

on

off

• Input impedance: 3 kW

• Galvanically isolated

• Protected against polarity reversal and voltage spikes

• Frequency: 0.5 to 2500 Hz

: 5 to 32 V DC

: < 2 V DC

English

21

Page 24

All analogue outputs ("AO") • 4-20 mA current

• Any connection mode, in sink or source mode

• Galvanically isolated

• Protected against polarity reversal

• Max. loop impedance 1100W to 36 V DC, 610W to 24 V DC,

100W to 12 V DC

All digital outputs ("DO") • Transistor

• Any connection mode, in NPN or PNP mode

• Galvanically isolated

• Protected against short circuits

• Max. voltage: 36 V DC

Type 8619

Technical data

• Max. 700 mA per transistor; total of max. 1A if both transistors are

connected

• Max. frequency 2000 Hz

Flow rate measurement Refer to the user operating instructions for the flow sensor con-

nected to the 8619

3.7 Specifications of the "M0" main board of the 8619 multiCELL WM

All digital inputs ("DI") • Switching threshold Von: 5 to 32 V DC

• Switching threshold V

• Input impedance: 3 kW

• Galvanically isolated

• Protected against polarity reversal and voltage spikes

• Frequency: 0.5 to 2500 Hz

All analogue outputs ("AO") • 4-20 mA current

• Any connection mode, in sink or source mode

: < 2 V DC

off

22

• Galvanically isolated

• Protected against polarity reversal

• Max. loop impedance 1100W to 36 V DC, 610W to 24 V DC,

100W to 12 V DC

English

Page 25

Type 8619

Technical data

All digital outputs ("DO") • Transistor

• Any connection mode, in NPN or PNP mode

• Galvanically isolated

• Protected against short circuits

• Max. voltage: 36 V DC

• Max. 700 mA per transistor; total of max. 1A if both transistors are

connected

• Max. frequency 2000 Hz

Flow rate measurement (software option) Refer to the user operating instructions for the flow sensor con-

nected to the 8619

3.8 Specifications of the power supply board of the 8619 multiCELL WM

Electrical supply 12-36 V DC

Maximal consumption

Specifications of the 12-36 V DC power

source (not provided) of the UL devices,

with variable key PU02

Electrical supply 110-240 V AC

• Frequency

• Max. current

• integrated protection

Own consumption (without connection

module, outputs not connected)

• filtered and regulated

• SELV circuit, at a non-hazardous energy level

• Tolerance: ±10 %

• 1.8 A

• Limited power source (in accordance with section 9.3 of the UL

61010-1 standard)

• or class 2 type power source (according to the 1310/1585 and

60950-1 standards)

• 50-60 Hz

• 500 mA

• delayed 3.15 A fuse, 250 V AC, (breaking capacity = 1500 V AC

at 250 V AC)

2 VA

English

23

Page 26

[A]

[°C]

0.8

1.2

1.8

Type 8619

Technical data

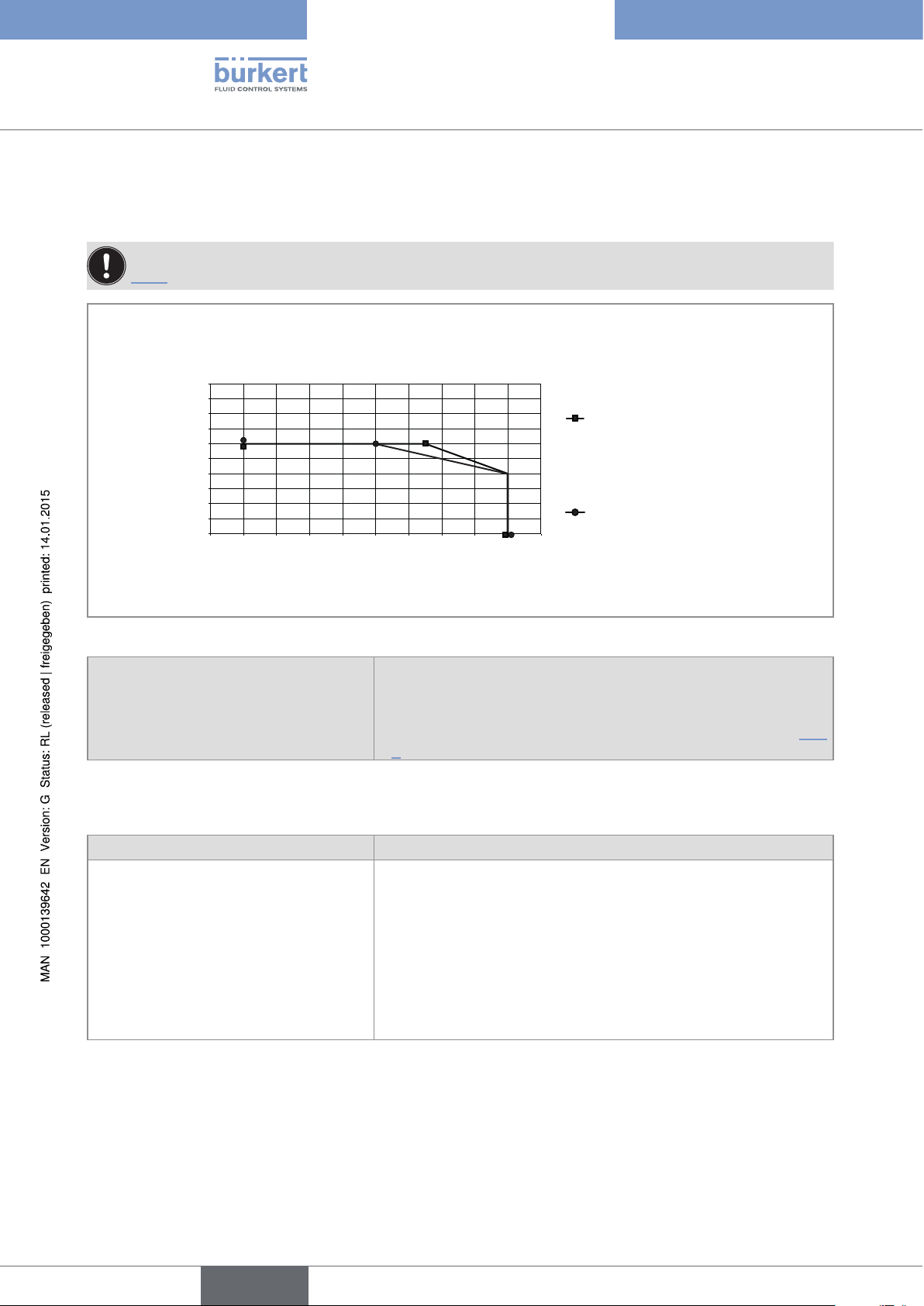

3.9 Specifications of the "POWER OUT" power distribution board for the 8619 multiCELL WM

Observe the maximum permissible load as a function of the ambient temperature. See the derating curves

Fig. 7.

Maximum current

of the load

8619 multiCELL WM AC, without

connection module

8619 multiCELL WM AC, with

0

-10 +100 +20 +30 +40 +50 +60 +70 +80

connection module

Ambient temperature

Fig. 7 : Derating curves of the maximum permissible current, depending on the ambient temperature

Power distribution

• 12-36 V DC version

• 110-240 V AC version

Protected against polarity reversal

• 12-36 V DC, 1.8 A max.

• 24 V DC, filtered and regulated, 1,2 A max.: see the curves in Fig.

7. SELV circuit, at a non-hazardous energy level

3.10 Specifications of the "Input" board

Power consumption 0.1 VA

Digital inputs ("DI") • Switching threshold V

• Switching threshold V

• Input impedance: 3 kW

• Galvanically isolated

• Protected against polarity reversal and voltage spikes

• Frequency: 0.5 to 2500 Hz

: 5 to 32 V DC

on

: < 2 V DC

off

24

English

Page 27

Type 8619

Technical data

Analogue inputs ("AI") • Any connection mode, in sink or source mode

• Galvanically isolated

• Precision ±0.25 %

• Current: 0 - 22 mA or 3.5 - 22 mA. Max. voltage: 36 V DC.

Impedance: 50 W. Resolution: 1.5 µA

• Voltage: 0 - 5 V DC or 0 - 10 V DC. Max. voltage: 36 V DC.

Impedance: 110 kW. Resolution: 1 mV

3.11 Specifications of the memory card reader/recorder

• Memory card type

• Capacity

• File system

• SD (Secure Digital) or SDHC (Secure Digital High Capacity)

• 8 GB max.

• FAT32

3.12 Specifications of the outputs board "OUT"

Power consumption 0.1VA

All digital outputs ("DOx") • Transistor

• Any connection mode, in NPN or PNP mode

• Galvanically isolated

• Protected against short circuits

• Max. voltage: 36 V DC

• Max. 700 mA per transistor; total of max. 1A if both transistors are

connected

• Max. frequency 2000 Hz

All analogue outputs ("AOx") • 4-20 mA current

• Any connection mode, in sink or source mode

• Galvanically isolated

• Protected against polarity reversal

• Max. loop impedance 1100W to 36 V DC, 610W to 24 V DC,

100W to 12 V DC

English

25

Page 28

Type 8619

Technical data

3.13 Specifications of the "pH/redox" module

pH measurement

• pH measurement range

• Resolution of pH measurement

• Systematic variation in the pH

measurement

• Potential difference measurement range

• Resolution of the potential difference

measurement

• Systematic variation in the potential difference measurement

• pH probe type

Power consumption 0.1VA

Measurement of the oxidation reduction

potential

• Oxidation reduction potential measurement

range

• Resolution of the potential difference

measurement

• Systematic variation in the potential difference measurement

• -2.00...+16.00 pH

• 0.01pH

• ±0.02 pH + pH probe error

• -600...+600 mV

• 0.1 mV

• ±1 mV + pH probe error

• Electrochemical

• -2000 ... +2000 mV

• 0.1 mV

• ±1 mV + ORP probe error

26

• Oxidation reduction potential probe type

Temperature measurement

• Measurement range

• Measurement resolution

• Systematic variation in the measurement

• Temperature sensor type

• Electrochemical

• -25 °C ... +130 °C

• 0.1 °C

• ±1 °C + temperature probe error

• Pt100 or Pt1000, with 2 or 3 wires

3.14 Specifications of the "COND" conductivity module

Resistance measurement (without

conductivity sensor connected)

Power consumption 0.25VA

Conductivity cell type With 2 or 4 electrodes; the specifications of Bürkert cells are

5 W ... 1 MW

described in the related operating instructions.

English

Page 29

Type 8619

Technical data

Conductivity measurement (with

connected conductivity sensor)

• Measurement range

• Measurement resolution

• Systematic variation in the measurement

Resistivity measurement (with connected

conductivity sensor)

• Measurement range

• Measurement resolution

• Systematic variation in the measurement

(without sensor)

Temperature measurement

• Measurement range

• Measurement resolution

• Systematic variation in the measurement

• Temperature sensor type

• 0.000 µS/cm ... 2 S/cm (depends on the conductivity sensor)

-9

• 10

S/cm

• ±0.5% of the measured value + conductivity sensor error

• 0.500 W.cm ... 100 MW.cm (depends on the conductivity

sensor)

-1

• 10

W.cm

• ±0.5% of the measured value + conductivity sensor error

• -40 °C ... ±200 °C

• ±0.1 °C

• ±1 °C + temperature probe error

• Pt100 or Pt1000, with 2 or 3 wires

English

27

Page 30

Type 8619

Technical data

28

English

Page 31

Type 8619

Installation and wiring

4 INSTALLATION AND WIRING

4.1 Safety instructions .............................................................................................................................................................30

4.2 Installation procedure ......................................................................................................................................................31

4.2.1 Installing a 8619 multiCELL on an enclosure or electrical cabinet ........................................31

4.2.2 Installing a 8619 multiCELL WM on a support ...........................................................................32

4.3 Electrical wiring ....................................................................................................................................................................34

4.3.1 Recommendations for wiring a 8619 multiCELL WM ...............................................................34

4.3.2 Specifications of the connection cables .......................................................................................34

4.3.3 Wiring the 12-36 V DC electrical supply for a 8619 multiCELL ............................................35

4.3.4 Wiring the 12-36 V DC electrical supply for a 8619 multiCELL WM DC ...........................36

4.3.5 Wiring the 110-240 V AC electrical supply for a 8619 multiCELL WM AC ......................36

4.3.6 Supplying an external instrument via a 8619 multiCELL .......................................................... 37

4.3.7 Supplying an external instrument via a 8619 multiCELL WM .................................................38

4.3.8 Wire the inputs and outputs on the main board "M0" ...............................................................38

4.3.9 Examples of the connection of flowmeters to a 8619 multiCELL ...........................................40

4.3.10 Examples of the connection of a solenoid valve to a 8619 multiCELL WM ........................41

4.3.11 Identifying the pins on the connection modules ..........................................................................41

4.3.12 Wiring the input module "INPUT" ...................................................................................................42

4.3.13 An example of the connection of a type 8232 chlorine sensor (order code

566051 or 566052) to the input module "INPUT". ...................................................................44

4.3.14 An example of the connection of a type 8232 chlorine sensor (order code

565164) to the input module "INPUT". .........................................................................................44

4.3.15 Wiring the output module "OUT"....................................................................................................46

4.3.16 Wiring the "pH/ORP" module .........................................................................................................47

4.3.17 Examples of connection to be "pH/ORP" module ......................................................................48

4.3.18 Wiring the "COND" conductivity module .....................................................................................49

4.3.19 Examples of connection to the "COND" conductivity module .................................................50

English

29

Page 32

Type 8619

Installation and wiring

4.1 Safety instructions

DANGER

Risk of injury due to electrical voltage.

▶ If a 12-36 V DC version is installed either in a wet environment or outdoors, all the electrical voltages must be

of max. 35 V DC.

▶ Disconnect the electrical power for all the conductors and isolate it before carrying out work on the system.

▶ All equipment connected to the 8619 shall be double insulated with respect to the mains according to the

standard IEC 61010-1:2010.

▶ Observe all applicable accident protection and safety regulations for electrical equipment.

WARNiNG

Risk of injury due to nonconforming installation.

▶ Electrical installation can only be carried out by qualified and authorised personnel with the appropriate tools.

▶ Fit a circuit breaker or switch to the electrical installation of the building in which the device is installed.

▶ Install the circuit breaker or switch in an easily accessible place.

▶ Identify the circuit breaker or switch as the disconnecting component for the electrical power supply to the

device.

▶ Install appropriate safety devices (correctly rated fuse and/or circuit-breaker).

▶ For a version powered by 110-240 V AC, insert an overload device between the live and the neutral.

▶ Do not power the 24 V DC version of the device with an AC voltage or with a DC voltage higher than

36V DC.

▶ Do not power the 100-240 V AC version with a DC voltage or with an AC voltage higher than 240 V AC.

▶ Observe standard NF C 15-100 / IEC 60634.

▶ The use of probes/sensors sold by Bürkert is preferable.

▶ Follow the instructions for installation and wiring of remote sensors connected to the 8619.

▶ On a 8619 multiCELL WM, only authorized personnel may insert in or remove the memory card from the

reader/recorder.

Risk of injury due to unintentional switch on of power supply or uncontrolled restarting of the

installation.

▶ Avoid unintentional activation of the installation.

▶ Guarantee a set or controlled restart of the process subsequent to the installation of the device.

30

Protect this device against electromagnetic interference, ultraviolet rays and, when installed outdoors, the effects of the climatic conditions.

Make sure the installation inputs are transformed-coupled for galvanic isolation.

English

Page 33

Type 8619

Installation and wiring

4.2 Installation procedure

1. To carry out mechanical installation: Depending on the version, follow the instructions in section 4.2.1 or 4.2.2.

2. To wire the device: Depending on the version, follow the instructions in section 4.3.

4.2.1 Installing a 8619 multiCELL on an enclosure or electrical cabinet

Follow the instructions below to mount the 8619, delivered fully assembled, onto an enclosure or cabinet.

→

92 +0,5/-0

5

5,55,5

92 +0,5/-0

10

This diagram is not to scale. The dimensions are given

in mm.

Body

x4

Screw

Step 1:

→ Check that the thickness of the door of the enclosure

or cabinet is no more than 4 mm.

→ Ensure there will be sufficient space around the cut

out hole and on the inside of the cabinet to easily

accommodate the 4 fasteners.

→ Cut a hole in the door of the enclosure or electrical

cabinet according to standard CEI 61554:1999 (DIN

43700).

Step 2:

Prepare the 4 fasteners:

→ Insert a screw into each device.

→ Tighten the screw until the end of the shaft of the

screw is flush with the device.

Step 3:

→ Slide the housing into the cut-out with the connectors

to the back, until it can go no further.

Step 4:

→ Insert (1) the hooks on the first fastener into the slots

on the housing.

1

→ Pull the fastener (2).

2

31

English

Page 34

Risk of material damage the cable glands are loosened. The body of the cable glands are screwed into

the housing at the factory with a torque of 5.5 Nm

Type 8619

Installation and wiring

Step 5:

→ Place the fastener flush against the 8619 by hand,

so that the hooks remain in place.

Step 6:

→ Fully tighten the screws using an appropriate

screwdriver.

→ Repeat steps 4 to 6 to fit the remaining 3 fasteners.

Fig. 8 : Panel mounting of the 8619 on an enclosure or cabinet

4.2.2 Installing a 8619 multiCELL WM on a support

NOTE

▶Before installing the wall-mounting housing on its support, check that the bodies of the cable glands are tight-

ened. If the bodies of the cable glands are loose, tighten them with a torque of 5.5 Nm ± 20 %.

The 8619 multiCELL WM is installed on a support using the wall-mounting fastening plate.

→ Choose a location such that:

• The surface is plane.

• The surface temperature of the support remains below 100 °C.

• The display is at eye level.

• There is sufficient space to open the housing by 180°.

32

English

Page 35

135

90

Type 8619

Installation and wiring

3

2

Step 1: Removing the wall-mounting fastening plate

from the device.

1. Press the tab to unlock the device.

2. Lift the device.

3. Separate the device from the wall-mounting fastening plate.

1

Step 2: Installing the wall-mounting fastening plate on

the support.

The screws and washers are not provided.

→ Drill holes in the support according to the dimensions

indicated on the diagram to the left.

→ Use 4 screws of 6 mm diameter, which will support the

weight of the device and are suitable for the support.

→ Insert a washer for each screw.

→ Insert the 4 screws in the wall-mounting fastening

plate and in the holes drilled in the support.

This diagram is not to scale. The dimensions are given

in mm.

runners

slides

1

2

→ Tighten the 4 screws in a crosswise manner, with a

maximum torque of 5.3 Nm.

Step 3: Installing the device on the fastening plate.

→ Align the base of the slides with the height of the

runners.

→ Insert the 4 slides into the 4 runners until you hear

a click.

Fig. 9 : Installation of a 8619 multiCELL WM on a support

33

English

Page 36

Type 8619

Installation and wiring

4.3 Electrical wiring

DANGER

Risk of injury due to electrical voltage.

▶ If a 12-36 V DC version is installed either in a wet environment or outdoors, all the electrical voltages must be

of max. 35 V DC.

▶ Disconnect the electrical power for all the conductors and isolate it before carrying out work on the system.

▶ All equipment connected to the 8619 shall be double insulated with respect to the mains according to the

standard IEC 61010-1:2010.

▶ Observe all applicable accident protection and safety regulations for electrical equipment.

4.3.1 Recommendations for wiring a 8619 multiCELL WM

NOTE

On a 8619 multiCELL WM, the ribbon cable which connects the display to the electronic board can be

damaged.

▶ Open and close the cover of the housing with care.

▶ Do not pinch the ribbon cable.

▶ Do not pull the ribbon cable.

▶ Manipulate the ribbon cable with care.

▶ If the ribbon cable is disconnected, reconnect it with care.

NOTE

A 8619 multiCELL WM may be damaged if the device is not tight.

▶ Make sure the nuts of the unused cable glands are tightened (at the factory, a stopper gasket has been

inserted in each cable gland).

▶ When the mechanical installation and wiring are completed, tighten the cable gland screws with a torque of

4.5 Nm ± 20 %.

▶ When the mechanical installation and wiring are completed, tighten the 4 screws of the cover in a crosswise

manner with a torque of 1.4 Nm ± 20 %.

→ Before wiring the device, install it according to the instructions in section 4.2.1 or section 4.2.2.

4.3.2 Specifications of the connection cables

The electrical connections are carried out via terminal blocks:

34

• Directly, on a 8619 multiCELL.

• Via the cable glands, on a 8619 multiCELL WM.

→ Use shielded cables (not provided) with a maximum operating temperature greater than 80 °C.

→ Use cables and electric wires with dimensions that adhere to the specifications described in Tab. 2.

English

Page 37

Type 8619

Installation and wiring

Tab. 2 : Specifications of the cables and conductors

External diameter of the cable (8619 multiCELL WM) 6 to 12 mm (4 mm if using multiply drilled seals)

Cross-section of the local earth connection conductor

0.75 ... 1.5 mm

2

(12-36 V DC versions)

Rigid conductor cross-section H05(07) V-U 0.2 ... 1.5 mm2, stripped over 7 mm

2

Flexible conductor cross-section H05(07) V-K 0.2 ... 1.5 mm

Cross-section of a conductor with a non-insulated lug 0.2 ... 1.5 mm

Cross-section of a conductor with an insulated lug 0.2 ... 0.75 mm

, stripped over 7 mm

2

, stripped over 7 mm

2

, stripped over 7 mm

4.3.3 Wiring the 12-36 V DC electrical supply for a 8619 multiCELL

Use a filtered and regulated 12-36 V DC electrical power supply.

→

→ Wire the 12-36 V DC power supply on the "M0" terminal board of a 8619 multiCELL.

→ Connect the functional earth of the installation to the earth screw of the device (see section 2.2, Fig. 1) using

a lug with an eyelet, suitable for the M4 earth screw and earth conductor. Tighten with a torque of 1 Nm ±

20 %.

→ Connect the shielding on each wire to an "FE" (functional earth) terminal to guarantee the equipotentiality of

the installation.

12-36 VDC

+

Electrical power supply

-

+

V-

FE

V+

SUPPLY PWR OUT DI1 FEDI2 DO2DO1AO1 AO2 FE FE

FE

D+D-D+

Removable screw terminals, 21-positions, orange

Fig. 10 : Wiring the 12-36 V DC electrical supply for a 8619 multiCELL

D-

FE

I+I-I+

I-

FE

T+T-T+

T-

FE

English

35

Page 38

Type 8619

Installation and wiring

4.3.4 Wiring the 12-36 V DC electrical supply for a 8619 multiCELL WM DC

Use a filtered and regulated 12-36 V DC electrical power supply.

→

→ Use the rightmost cable gland for the electrical power supply cable.

→ Wire the 12-36 V DC power supply for a 8619 multiCELL WM on a terminal block marked 12-36 V DC.

→ Connect the functional earth of the installation to the earth screw of the device (see section2.3, Fig. 2)

using a lug with an eyelet, suitable for the M4 earth screw and earth conductor. Tighten with a torque of

1 Nm ± 20 %.

→ Connect the shielding on each wire to an "FE" (functional earth) terminal to guarantee the equipotentiality of

the installation.

Removable screw

terminals, 2-positions,

green

12-36 V

MEMORY

CARD

M0

M1

M3

M5

FE

FE

PWR OUT

M2

M4

M6

FE

12-36 V

DC

FE

DC

+

-

FE

12-36 VDC

-

Electrical power supply

+

Fig. 11 : Wiring the 12-36 V DC electrical supply for a 8619 multiCELL WM

4.3.5 Wiring the 110-240 V AC electrical supply for a

8619 multiCELL WM AC

→ Unscrew and remove the

MEMORY

CARD

M0

M1

M3

M5

PE

PWR OUT

M2

M4

M6

PE

PE

protective cover of the power

supply connection terminal

block.

36

Protective cover

English

Page 39

L

Type 8619

Installation and wiring

Removable screw

terminals, 2-positions,

green

110-240 V~

50/60 Hz

L

N

PE

N

PE

Fig. 12 : Wiring the 110-240 V AC electrical supply for a 8619 multiCELL WM AC

PE

110-240 V~

50/60 Hz

LN

→ Use the rightmost cable

gland for the electrical power

supply cable.

→ Wire the 110-240 V AC

power supply for a

8619 multiCELL WM AC

on a terminal block marked

110-240 V AC.

→ Connect the protective earth

of the installation to the earth

screw of the device (see

section2.4, Fig. 3) using a

lug with an eyelet, suitable for

the M4 earth screw and earth

conductor. Tighten with a

torque of 1 Nm ± 20 %.

L: Live conductor

N: Neutral conductor

→ Put in place and screw on the

protective cover.

4.3.6 Supplying an external instrument via a 8619 multiCELL

The device can be used to supply an external instrument, for example a flow sensor, with a voltage identical to the

supply voltage of the 8619

The power supply is available on the "M0" terminal block of a 8619 multiCELL.

12-36 VDC

+

Electrical power supply

V-

FE

V+

SUPPLY PWR OUT DI1 FEDI2 DO2DO1AO1 AO2 FE FE

Removable screw terminals, 21-positions, orange

Fig. 13 : Supplying an external instrument via a 8619 multiCELL

Power supply available for an

external instrument

{

-

+

FE

D+D-D+

D-

FE

I+I-I+

I-

FE

T+T-T+

T-

FE

37

English

Page 40

POWER OUT

Type 8619

Installation and wiring

4.3.7 Supplying an external instrument via a 8619 multiCELL WM

The device can be used to supply power to several external instruments, such as flow sensors or conductivity

sensors for example.

→ To supply power to an external instrument, connect it to a positive and negative terminal on the POWER OUT

terminal block.

The voltage available on the POWER OUT terminal block of a 8619 multiCELL WM:

• is equal to the supply voltage of the 8619 multiCELL WM DC which is supplied with a voltage of 12-36 V DC.

• is equal to a voltage of 24 V DC on a 8619 multiCELL WM AC which is supplied with a voltage of

110-240 V AC.

+ -+- + - + -+- + -

Removable screw terminals,

12-positions, green

Fig. 14 : Supplying external instruments via a 8619 multiCELL WM

4.3.8 Wire the inputs and outputs on the main board "M0"

The M0 board has:

• 2 digital inputs (marked DI1 and DI2), for connecting a flow sensor for example

• Two 4-20 mA analogue outputs (marked AO1 and AO2)

• 2 digital outputs (marked DO1 and DO2)

The inputs and outputs are galvanically insulated and therefore floating.

38

English

Page 41

5-36 VDC

Type 8619

Installation and wiring

1st 4-20 mA input (at

external instrument)

+-

0 VDC

1st digital output (at exter-

nal instrument)

Removable screw ter-

minals, 21-positions,

2nd digital output (at

external instrument)

orange

-

+

0 VDC

5-36 VDC

0 VDC

D-

D+D-D+

DI1 FEDI2 DO2DO1AO1 AO2 FE FE

FE

digital inputs digital

12-36 VDC

12-36 VDC

I+I-I+

analogue

outputs

0 VDC

I-

FE

12-36 VDC

T+T-T+

outputs

+-

2nd 4-20 mA input (at

external instrument)

Load 1

+

-

0 VDC

12-36 VDC

+

-

0 VDC

Load 2

T-

FE

DI1, DI2, AO1, AO2, DO1 and DO2: designation in the configuration menus of the M0 main board.

FE = functional earth

Fig. 15 : Wiring the inputs and outputs on the main board "M0"

39

English

Page 42

Type 8619

Installation and wiring

4.3.9 Examples of the connection of flowmeters to a

8619 multiCELL

PNP

1

1

V+

12-36 VDC

3

+

Electrical power

supply

Removable screw

terminals, 21-posi-

tions, orange

V-

V+

SUPPLY PWR OUT DI1 FEDI2 DO2DO1AO1 AO2 FE FE

Fig. 16 : Wiring the 2 type 8030 flow sensors

8071

FE

-

+

FE

X

0V

D+D-D+

2

D-

NPN

FE

I+I-I+

V+

I-

3

FE

T+T-T+

0V

2

FE = functional earth

T-

FE

8041

4...20V+V-PEPls+Pls-

40

VDC

Red

Black

White

12-36 VDC

+

Electrical power

supply

Removable screw

terminals, 21-posi-

V-

tions, orange

Fig. 17 : Wiring a type 8071 flow sensor and a type 8041 flow sensor

V+

SUPPLY PWR OUT DI1 FEDI2 DO2DO1AO1 AO2 FE FE

FE

-

+

FE

D+D-D+

D-

FE

I+I-I+

I-

FE

T+T-T+

1 2 3 4 5 6

FE = functional earth

T-

FE

English

Page 43

12-36 VDC

Type 8619

Installation and wiring

4.3.10 Examples of the connection of a solenoid valve to a 8619 multiCELL WM

The solenoid valve can be connected to the device via board "M0" or via the outputs module, "OUT".

→ If a solenoid valve is connected to the device, connect a flyback diode in parallel to the solenoid valve. If the

solenoid valve is connected via a type 2508 connector, this connector is available with an integrated flyback

diode.

Solenoid valve

+

-

Removable screw terminals, 21-positions, orange

0 VDC

D+D-D+

DI1 FEDI2 DO2DO1AO1 AO2 FE FE

Fig. 18 : Wiring a solenoid valve to the "M0" board of the 8619

D-

FE

I+I-I+

I-

FE

T+T-T+

T-

FE

4.3.11 Identifying the pins on the connection modules

If you use terminal blocks other than those supplied with the device, these terminal blocks will not be marked.

Fig. 19 enables labelling of the terminals.

MEMORY CARD

M0

NC DI1 DI2 FE AO1 AO2 FE DO1 DO2 FE

M1

M2

M3

M5

Fig. 19 : Identifying the pins on the connection modules

M4

M6

Terminal No. 9Terminal No. 1

41

English

Page 44

4.3.12 Wiring the input module "INPUT"

The "INPUT" inputs module has:

• Two analogue inputs;

• Two digital inputs.

The inputs are galvanically insulated, and therefore floating.

1st 0/4-20 mA output (at

+-

external instrument)

0 VDC

2nd 0/4-20 mA output (at external instrument)

Type 8619

Installation and wiring

Removable screw termi-

nals, 9-positions, orange

+-

12-36 VDC

12-36 VDC

A+A-A+

1

2 3 4 5 6 7 8 9

(AI1) (AI2) (DI1) (DI2)

0 VDC

A-

FE

5-36 VDC

0 VDC

D+D-D+

5-36 VDC

1st digital output (at

external instrument)

+

-

0 VDC

D-

2nd digital output (at

external instrument)

(designation in the configuration menus of the Mx

additional output module)

42

digital inputsanalogue

inputs

FE = functional earth

Fig. 20 : Connecting the analogue inputs to a 2-wire current transmitter and connecting the digital inputs of the input

module

English

Page 45

Type 8619

Installation and wiring

1st 0/4-20 mA output

(at external instrument)

12-36 VDC

0 VDC

Removable screw termi-

nals, 9-positions, orange

+-

I

12-36 VDC

A+A-A+

1

2 3 4 5 6 7 8 9

A-

FE

(AI1) (AI2) (DI1) (DI2)

digital inputsanalogue

inputs

+-

0 VDC

12-36 VDC

D+D-D+

2nd 0/4-20 mA output

(at external instrument)

I

1st digital output (at

external instrument)

0 VDC

+

-

12-36 VDC

+

-

2nd digital output (at

external instrument)

0 VDC

D-

(designation in the configuration menus of the Mx

additional output module)

FE = functional earth

Fig. 21 : Connecting the AI1 analogue input in source mode and the analogue input AI2 in sinking mode to a 3-wire

current transmitter (for example type 8025 with relay outputs) and connecting the digital inputs of the input module

1st 0-5/10 V DC output

(external instrument)

+-

V

0 VDC

+

-

1st digital output (at

external instrument)

12-36 VDC

12-36 VDC

0 VDC

12-36 VDC

+

-

2nd digital output (at

external instrument)

0 VDC

Removable screw termi-

nals, 9-positions, orange

A+A-A+

1

2 3 4 5 6 7 8 9

(AI1) (AI2) (DI1) (DI2)

A-

FE

D+D-D+

D-

(designation in the configuration menus of the Mx

additional output module)

digital inputsanalogue

inputs

FE = functional earth

Fig. 22 : Connecting the analogue inputs to a voltage transmitter and connecting the digital inputs of the input module

English

43

Page 46

89

(AI1) (AI2) (DI1) (DI2)

89

(AI1) (AI2) (DI1) (DI2)

Type 8619

Installation and wiring

4.3.13 An example of the connection of a type 8232 chlorine

sensor (order code 566051 or 566052) to the input module

"INPUT".

Electrical supply to the

chlorine sensor

12-36 VDC

+-

+-

Removable screw

terminals, 9-positions,

orange

A+A-A+

1

2345 67

A-

FE

D+D-D+

D-

"INPUT" module of the 8619

Electrical supply to the

chlorine sensor

12-36 VDC

+-

+-

Removable screw

terminals, 9-positions,

orange

A+A-A+

1

2345 67

A-

FE

D+D-D+

D-

"INPUT" module of the 8619

FE = functional earth

Fig. 23 : Possible connections of a type 8232 chlorine sensor (order code 566051 or 566052) powered by an external

voltage source

44

4.3.14 An example of the connection of a type 8232 chlorine

sensor (order code 565164) to the input module "INPUT".

NOTE

The type 8232 chlorine sensor may be damaged by the electrical power supply.

▶ Power the chlorine sensor with a voltage between 22.5 and 26 V DC.

▶ If the chlorine sensor is powered via a type 8619, power the type 8619, 12-36 V DC version, with a power

supply between 22.5 and 26 V DC.

Colour of the conductor for chlorine sensor (order code 565164) Signal

Green Negative voltage signal

Yellow Positive voltage signal

White Positive supply

Brown Negative supply

English

Page 47

89

(AI1) (AI2) (DI1) (DI2)

Type 8619

Installation and wiring

22.5-26 VDC

Electrical power supply of the 8619

+

White

M0: Removable screw terminal,

21-positions, orange

-

+

V-

FE

V+

SUPPLY PWR OUT DI1 FEDI2 DO2DO1AO1 AO2 FE FE

FE

D+D-D+

D-

I+I-I+

FE

I-

FE

T+T-T+

T-

Brown

Green

Yellow

Removable screw

terminals, 9-positions,

orange

A+A-A+

1

2345 67

A-

FE

D+D-D+

FE

D-

"INPUT" module of the

8619

FE = functional earth

Fig. 24 : Connection of the type 8232 chlorine sensor (order code 565164), powered via the 8619 multiCELL

45

English

Page 48

4.3.15 Wiring the output module "OUT"

The "OUT" outputs module has:

• Two 4-20 mA analogue outputs;

• Two digital outputs.

The outputs are galvanically insulated, and therefore floating.

Type 8619

Installation and wiring

1st 4-20 mA

input (at external

instrument)

+-

0 VDC

12-36 VDC

Removable screw termi-

nals, 9-positions, orange

I+I-I+

1

(AO1) (AO2) (DO1) (DO2)

FE = functional earth

Fig. 25 : Wiring the "OUT" output module

12-36 VDC

12-36 VDC

0 VDC

I-

FE

T+T-T+

2 3 4 5 6 7 8 9

digital outputsanalogue outputs

2nd 4-20 mA input (at

+-

external instrument)

Load 1

+

0 VDC

12-36 VDC

0 VDC

-

+

-

Load 2

T-

(designation in the configuration menus of the Mx

output module)

46

English

Page 49

Type 8619

Installation and wiring

4.3.16 Wiring the "pH/ORP" module

• To avoid the influence of disturbances, wire the pH/redox sensor in symmetric mode. In this case, it is

compulsory to wire the equipotential electrode.

• When the pH/redox sensor is wired in asymmetrical mode, measurement of the pH or the oxidation

reduction potential may drift over time when the equipotential electrode is not wired.

Temperature sensor

Oxidation reduction potential

measurement electrode

Reference electrode

Strap (not delivered)

FE

RE

RE

ME

1 2 3 4 5 6 7 8 9

GD

CG

SE

TS

FE = functional earth

TS

Removable screw terminals,

9-positions, grey

Fig. 26 : Wiring an oxidation reduction potential sensor and a Pt100 or Pt1000 temperature sensor in a pH/ORP module

Oxidation reduction potential meas-

urement electrode

Temperature sensor

Reference electrode

pH measurement

electrode

FE

TS

RE

RE

ME

1 2 3 4 5 6 7 8 9

GD

CG

SE

TS

Removable screw terminals,

9-positions, grey

FE = functional earth

Fig. 27 : Wiring a pH sensor, an oxidation reduction potential sensor and a Pt100 or Pt1000 temperature sensor in a pH/

ORP module

English

47

Page 50

Black

Type 8619

Installation and wiring

(1)

(1)

Temperature sensor

Reference electrode

Translucent

Equipotential electrode

pH measurement electrode

Strap (not delivered)

FE

TS

RE

RE

ME

1 2 3 4 5 6 7 8 9

GD

CG

SE

TS

Removable screw terminals, 9-positions, grey

FE = functional earth

(1)

Colour of the wires in Bürkert connection cables with order codes 561904, 561905 or 561906.

Fig. 28 : Wiring a pH sensor and a Pt100 or Pt1000 temperature sensor in asymmetrical mode to a pH/ORP module

4.3.17 Examples of connection to be "pH/ORP" module

(1)

Black

Equipotential electrode

48

(1)

Temperature sensor

Reference electrode

CG

(2)

Brown

FE

(2)

White

SE

TS

(2)

Black

TS

pH measurement electrode

Translucent

(2)

Blue

RE

RE

ME

1 2 3 4 5 6 7 8 9

GD

Removable screw terminals, 9-positions, grey

FE = functional earth

(1)

Colour of the wires in Bürkert connection cables with order codes 561904, 561905 or 561906.

(2)

Colour of the wires of the Pt1000 sensor with order code 427023 and its Bürkert connection cable with order code

427113.

Fig. 29 : Wiring a Bürkert 8200 type sensor and a Pt1000 temperature sensor in symmetrical mode

English

Page 51

Type 8619

Installation and wiring

wire colour signal

translucent pH sensor

red (coax cable

reference electrode

shielding)

Black

translucent

(coax)

Red

Blue

Green/yellow

Grey

Green

White

strap (not

delivered)

blue rhodium electrode

green/yellow cable shielding

FE

TS

grey sensor body

RE

RE

ME

1 2 3 4 5 6 7 8 9

GD

CG

SE

TS

Green Pt1000

Removable screw terminals,

White Pt1000

9-positions, grey

FE = functional earth