Page 1

Type 8611

eCONTROL

Process controller and Ratio controller

Operating Instructions

(Valid from software version B01)

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modification technique.

© 2009 - 2012 Bürkert SAS

Operating Instructions 1209/4_EUen_00805625 / Original: DE

Page 3

Type 8611

eCONTROL 8611: Process Controller and Ratio Controller

Contents

1. OPERATING INSTRUCTIONS ........................................................................................................................................................6

1.1. Symbols....................................................................................................................................................................................6

2. AUTHORIZED USE .............................................................................................................................................................................7

2.1. Restrictions .............................................................................................................................................................................7

2.2. Predictable Misuse .............................................................................................................................................................7

3. BASIC SAFETY INSTRUCTIONS .................................................................................................................................................8

4. GENERAL INFORMATION ................................................................................................................................................................9

4.1. Contact Addresses .............................................................................................................................................................9

4.2. Warranty ...................................................................................................................................................................................9

4.3. Information on the Internet ............................................................................................................................................9

5. SYSTEM DESCRIPTION ................................................................................................................................................................10

5.1. General Description ........................................................................................................................................................10

5.2. Functions ..............................................................................................................................................................................11

5.3. The various mounting and installation models ................................................................................................11

5.4. Software ................................................................................................................................................................................11

6. TECHNICAL DATA .............................................................................................................................................................................12

6.1. Operating Conditions .....................................................................................................................................................12

6.2. Conformity with the following standards ............................................................................................................12

6.3. General Technical Data .................................................................................................................................................12

6.4. Rating plate description ................................................................................................................................................13

6.5. Electrical Data ....................................................................................................................................................................14

7. ASSEMBLY ...........................................................................................................................................................................................16

7.1. Assembly models .............................................................................................................................................................16

7.2. Attachment to a proportional valve ........................................................................................................................17

7.3. Assembly of the control cabinet model ...............................................................................................................18

english

3

Page 4

Type 8611

8. ELECTRICAL INSTALLATION ......................................................................................................................................................20

8.1. Electrical installation for fitting assembly, wall assembly, valve assembly or rail assembly

models ...................................................................................................................................................................................20

8.2. Electrical installation of the control cabinet model .......................................................................................24

9. OPERATION AND FUNCTION ....................................................................................................................................................27

9.1. Control and display elements ....................................................................................................................................27

9.2. Operating levels and operating states .................................................................................................................28

9.3. Function of the keys .......................................................................................................................................................29

10. OPERATING STRUCTURE ............................................................................................................................................................30

10.1. Operating structure of the process operating level in MANUAL operating state .........................30

10.2. Operating structure of the configuration level .................................................................................................31

11. FUNCTIONS OF THE PROCESS OPERATING LEVEL ...................................................................................................37

11.1. Operating state AUTOMATIC .....................................................................................................................................37

11.2. Operating state MANUAL .............................................................................................................................................38

11.3. Specific menu options of process and ratio control .....................................................................................38

11.4. Menu options in the MANUAL operating state .................................................................................................38

11.5. SET - Set-point value default for process control .........................................................................................39

11.6. RFAC - Ratio factor default for ratio control ......................................................................................................39

11.7. TEST – Display of the analog inputs and outputs and the digital inputs ..........................................40

11.8. PARA – Display and optimization of the controller parameters .............................................................41

11.9. VALV – Manual opening and closing of the connected actuating elements ....................................42

12. FUNCTIONS OF THE CONFIGURATION LEVEL ...............................................................................................................44

12.1. General Description ........................................................................................................................................................44

12.2. Menu options of the configuration level ..............................................................................................................45

12.3. MODE - Selection of control variable, actuating element and process value input ....................46

12.4. UNIT - Selection of measuring units and decimal places .........................................................................59

12.5. SETP / RFAC - Selection and scaling of set-point value default / entry of ratio factor ............62

4

12.6. S_IN - Scaling of sensor input signal

english

Page 5

Type 8611

(4 - 20 mA or 0 - 10 V) ......................................................................................................64

12.7. AOUT - Scaling of analog output

(4 - 20 mA or 0 - 10 V) ...................................................................................................65

12.8. CALI - Calibration of the analog inputs and outputs ....................................................................................67

12.9. Calibration of the assembly models:

Wall, rail, valve or fitting assembly ..........................................................................................................................68

12.10. Calibration of the control cabinet model .............................................................................................................69

12.11. KFAC - Entry of K-factor for flow-rate measurement ...................................................................................70

12.12. FILT - Filtering of the process actual value input ...........................................................................................72

12.13. PARA - Adjusting the controller parameters .....................................................................................................73

12.14. B_IN - Configuration of binary input ......................................................................................................................81

12.15. B_O1 - Configuration of the binary output .........................................................................................................82

12.16. B_O2 - Second binary output ....................................................................................................................................90

12.17. VALV - Test function and setting of the control range .................................................................................91

12.18. CODE - Code protection ..............................................................................................................................................93

12.19. DSPL - Setting the display ..........................................................................................................................................94

12.20. FACT - Reset to Factory Settings ............................................................................................................................95

12.21. U_xx, B_xx - Display of the program version and software version .....................................................95

12.22. END - Leaving the configuration level ..................................................................................................................96

13. OVERVIEW SETTING PARAMETERS ......................................................................................................................................97

14. MAINTENANCE, TROUBLESHOOTING .................................................................................................................................98

14.1. Malfunctions ........................................................................................................................................................................98

15. PACKAGING AND TRANSPORT ...............................................................................................................................................99

16. STORAGE ..............................................................................................................................................................................................99

17. DISPOSAL ............................................................................................................................................................................................99

english

5

Page 6

Type 8611

Operating Instructions

1. OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device. Keep these instructions in a location which is

easily accessible to every user, and make these instructions available to every new owner of the device.

WARNING!

The operating instructions contain important safety information!

Failure to observe these instructions may result in hazardous situations.

• The operating instructions must be read and understood.

1.1. Symbols

DANGER!

Warns of an immediate danger!

• Failure to observe the warning will result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a moderate or minor injury.

NOTE!

Warns of damage to property!

• Failure to observe the warning may result in damage to the device or the equipment.

Indicates important additional information, tips and recommendations.

refers to information in these operating instructions or in other documentation.

→ designates a procedure which you must carry out.

6

english

Page 7

Type 8611

Authorized use

2. AUTHORIZED USE

Non-authorized use of the process controller Type 8611 may be a hazard to people, nearby equipment

and the environment.

• The process controller is intended for controlling the process variables for pressure, temperature or flow-rate

in conjunction with a proportional or process valve and a sensor.

• Do not use the device outdoors.

• Use according to the authorized data, operating conditions and conditions of use specified in the contract

documents and operating instructions. These are described in the chapter entitled "Technical Data".

• The device may be used only in conjunction with third-party devices and components recommended and

authorized by Bürkert.

• Correct transportation, correct storage and installation and careful use and maintenance are essential for reliable and faultless operation.

• Use the device only as intended.

2.1. Restrictions

If exporting the system/device, observe any existing restrictions.

2.2. Predictable Misuse

• The Type 8611 is not to be used in areas where there is a risk of explosion.

• Do not physically stress the housing (e.g. by placing objects on it or standing on it).

english

7

Page 8

Type 8611

Basic Safety Instructions

3. BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the installation, operation and maintenance of the devices.

• local safety regulations – the operator is responsible for observing these regulations, also with reference to the

installation personnel.

General Hazardous Situations.

To prevent injury, ensure that:

• any installation work may be carried out by authorized technicians and with the appropriate tools only.

• after an interruption in the power supply or pneumatic supply, ensure that the process is restarted in a defined

or controlled manner.

• the device may be operated only when in perfect condition and in consideration of the operating instructions.

• the general rules of technology apply to application planning and operation of the device.

NOTE!

Electrostatic sensitive components / modules!

The device contains electronic components, which react sensitively to electrostatic discharge (ESD). Contact

with electrostatically charged persons or objects is hazardous to these components. In the worst case scenario,

they will be destroyed immediately or will fail after start-up.

• Observe the requirements in accordance with EN 61340-5-1 and 5-2 to minimize or avoid the possibility of

damage caused by sudden electrostatic discharge!

• Also, ensure that you do not touch electronic components when the power supply voltage is present!

The process controller Type 8611 was developed with due consideration given to the accepted safety rules

and is state-of-the-art. Nevertheless, dangerous situations may occur.

Failure to observe this operating manual and its operating instructions as well as unauthorized tampering

with the device release us from any liability and also invalidate the warranty covering the devices and

accessories!

8

english

Page 9

Type 8611

General Information

4. GENERAL INFORMATION

4.1. Contact Addresses

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed operating instructions.

And also on the Internet at:

www.burkert.com

4.2. Warranty

The warranty is only valid if the device is used as intended in accordance with the specified application

conditions.

4.3. Information on the Internet

The operating instructions and data sheets for Type 8611 can be found on the Internet at:

www.burkert.com

english

9

Page 10

Type 8611

System Description

5. SYSTEM DESCRIPTION

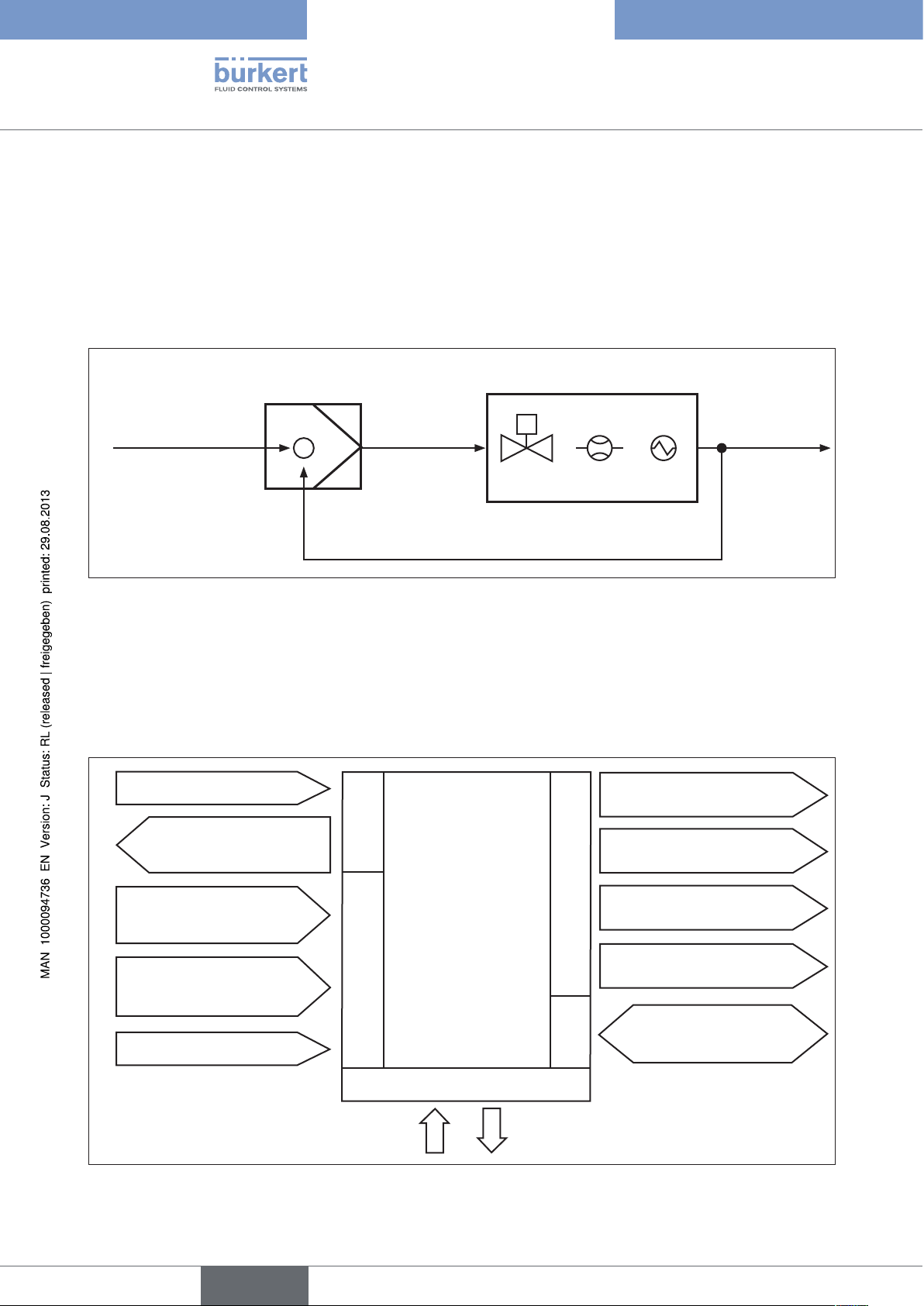

5.1. General Description

The process controller Type 8611 is designed for integration in a closed control circuit and can be used for

numerous control tasks in fluid technology. The figure below illustrates the integration of the controller in a closed

control circuit.

Controller 8611

Set-point SP

(set-point value)

Figure 1: Block diagram of a closed control circuit

+

_

X

Manipulated

variable MV

Feedback process actual value (PV)

Controlled system

Actuating

element

Sensor Process

Controlled

variable

5.1.1. Interfaces of the process controller Type 8611

Depending on the controlled system and process, different controller structures and different inputs/outputs are

available for measuring the process actual value and for controlling the actuating elements. The diagram below

shows the available interfaces of the process controller.

Supply 24 V DC

24 / 5 V DC

electrical power supply

for sensors

Ext. set-point value default

or ratio

4 - 20 mA / 0 - 10 V

Sensor inputs

4 - 20 mA / 0 - 10 V,

frequency, Pt 100

Binary input 0-30 V DC

Supply

Inputs

Process

controller

eCONTROL

Type 8611

Analog output

4 - 20 mA / 0 - 10 V

Transistor outputs

PWM, 2P – T, 3P – T

Process value output

Outputs

4 - 20 mA / 0 - 10 V

Binary output 0 / 24 V

(NC / NO)

RS485

Inter-

faces

option, for control

cabinet model only

10

Operation

Figure 2: Interfaces of the process controller Type 8611

english

Page 11

Type 8611

System Description

5.2. Functions

The following control tasks can be executed with the process controller Type 8611 eCONTROL.

• Fixed command control (single-loop control circuit)

• Sequential control (external set-point value)

• Ratio control

• Cascade control

Standard signals (current / voltage) and frequency-analog signals can optionally be applied or resistance thermometers (Pt 100) can be connected to the scalable controller inputs.

Outputs for continuous standard signals (current / voltage) or transistor outputs can be used as controller outputs.

Valves or other switching actuators can be operated via the transistor outputs. One binary output and up to 2 binary

outputs for auxiliary functions are additionally provided.

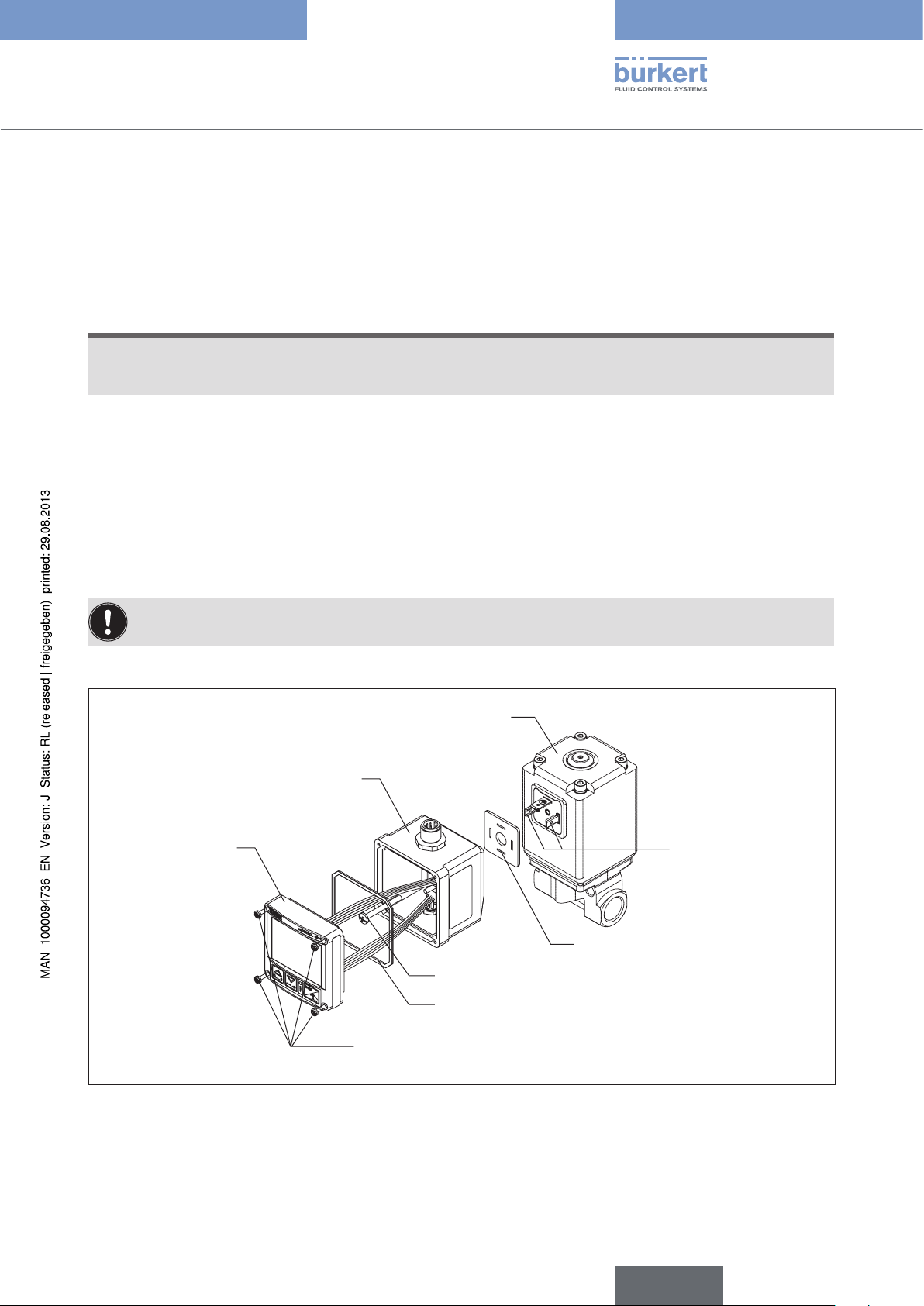

5.3. The various mounting and installation models

The process controller Type 8611 is available in the following models (see also chapter “7.1. Assembly models”):

• For installation in a pipeline system

• For attachment to a proportional valve

• For wall assembly or for assembly on a rail

• For installation in a control cabinet

Particularities of the control cabinet model:

Unlike the remaining assembly models, the cabinet model of type 8611 has not one but two binary

outputs.

5.4. Software

In the following description of the menu options and their operating structures, the entire software of the eCONTROL

Type 8611 is explained. This complete software scope is only available for the control cabinet model of the eCONTROL

Type 8611.

The menu structure may vary depending on the device model (wall, valve, rail or fitting assembly). In accordance

with the device model, only menu options that are logically purposeful for the application area can be selected. This

pre-selection is made upon delivery of the controller in accordance with the chosen order part number.

english

11

Page 12

Type 8611

Technical Data

6. TECHNICAL DATA

6.1. Operating Conditions

Permitted ambient temperature:

(operation and storage) 0 ... +70 °C

Max. permitted humidity: ≤ 80 %, non condensing

Protection class: IP65 to EN 60529

6.2. Conformity with the following standards

CE mark conforms to

EMC Directive: EN61326

6.3. General Technical Data

Materials

Housing, cover: PC, + 20 % glass fiber

Front plate foil: Polyester

Screws: Stainless steel

Multipin: CuZn, nickel-plated

Wall assembly bracket: PVC

Assembly

Installation position: Any position

Assembly models: Attachment to a pipeline with Bürkert flow-rate fitting Type S030

wall assembly, rail assembly, valve assembly, control cabinet assembly

Display: 2-line, (see “Figure 10: Display elements”)

Operating voltage: Multipin: 3-pin or / and 4-pin M8, 8-pin M12

Power cable: 0.5 mm

max. 100 m long, screened

2

max. cross section,

12

english

Page 13

Type 8611

Technical Data

6.4. Rating plate description

The rating plate contains important technical data for the specific device. The structure of the rating plate is

described below by way of example.

6.4.1. Rating plate of the controllers for wall, rail, valve or fitting

assembly

Controller type

Assembly model

Example:

8611 Wall 24VDC

IN:Norm OUT:Norm

SET: Norm ACT: PWM

S/N xxxxxx

00177462

- Wall (wall assembly)

- Rail (rail assembly)

- Valve (assembly directly on valve)

- Fitting (assembly directly on flow-rate fitting)

Power supply voltage

Sensor input signal (Norm, Pt 100 or Freq (NPN))

Analog output (Norm or None)

Controller output signal (PWM or NORM)

Set-point value input signal

W16LU

Manufacturer's code

Serial number

Figure 3: Example: Rating plate of the controllers for wall, rail, valve or fitting assembly

Order part number

6.4.2. Rating plate of the control cabinet model

Controller type

Assembly model

Example:

8611 Panel 24VDC

Prozessregler

- Panel (control cabinet)

Power supply voltage

Controller design

Serial number

S/N xxxxxx

00210206

W16LU

Manufacturer's code

Order part number

Figure 4: Example: Rating plate of the control cabinet model

13

english

Page 14

6.5. Electrical Data

Operating voltage: 24 V DC ±10 %, filtered and controlled

Power consumption without load: approx. 2 W

with load: maximum 48 W

100 % ED: 36 W

Controller sampling rate: 300 Hz

6.5.1. Inputs

Set-point value

Standard 4 - 20 mA Input impedance: 70 Ω

Resolution: 5.5 µA

Standard 0 - 10 V Input impedance: 11.5 kΩ

Resolution: 2,5 mV

Type 8611

Technical Data

Sensors

Standard 4 - 20 mA Input impedance: 70 Ω

Resolution: 5.5 µA

Frequency

Input 1 External sensor

Frequency range: min. 0.25 Hz / max. 1 kHz

Input resistance: > 1 kΩ

Signal types: Sine, rectangle, triangle (> 3000 mVss,

max. 30 Vss)

Input 2 Internal Hall sensor

Frequency range: min. 0.25 Hz / max. 1 kHz

(only in conjunction with Bürkert flow-rate fitting

Type S030)

Pt 100 (2-wire) Measuring range: 0 °C ... 200 °C

Measured current: 1 mA

Measuring error: < 0.5 °C

Binary input Input impedance: 10 kΩ

Response threshold: 3 ... 30 V

Max. frequency: 1 kHz

14

english

Page 15

Type 8611

Technical Data

6.5.2. Outputs

Continuous signal Standard signal 4 - 20 mA

Max. loop resistance: 680 Ω

Precision: 0,5 %

Standard signal 0 - 10 V

Maximum current: 20 mA

Precision: 0,5 %

Discontinuous signal 2 transistor outputs for PWM or PTM control

Control frequency: 1.2 kHz ... 20 Hz

Max. resolution: 16 bit (depending on frequency)

Max. current per unit area: 1.5 A

Switching voltage: 24 V DC

Binary output Transistor output (PNP) configurable

Max. current per unit area: 1.5 A

Switching voltage: 24 V DC

Sensor supply: 24 V DC

Total load for all outputs: 1,5 A

english

15

Page 16

Type 8611

Assembly

7. ASSEMBLY

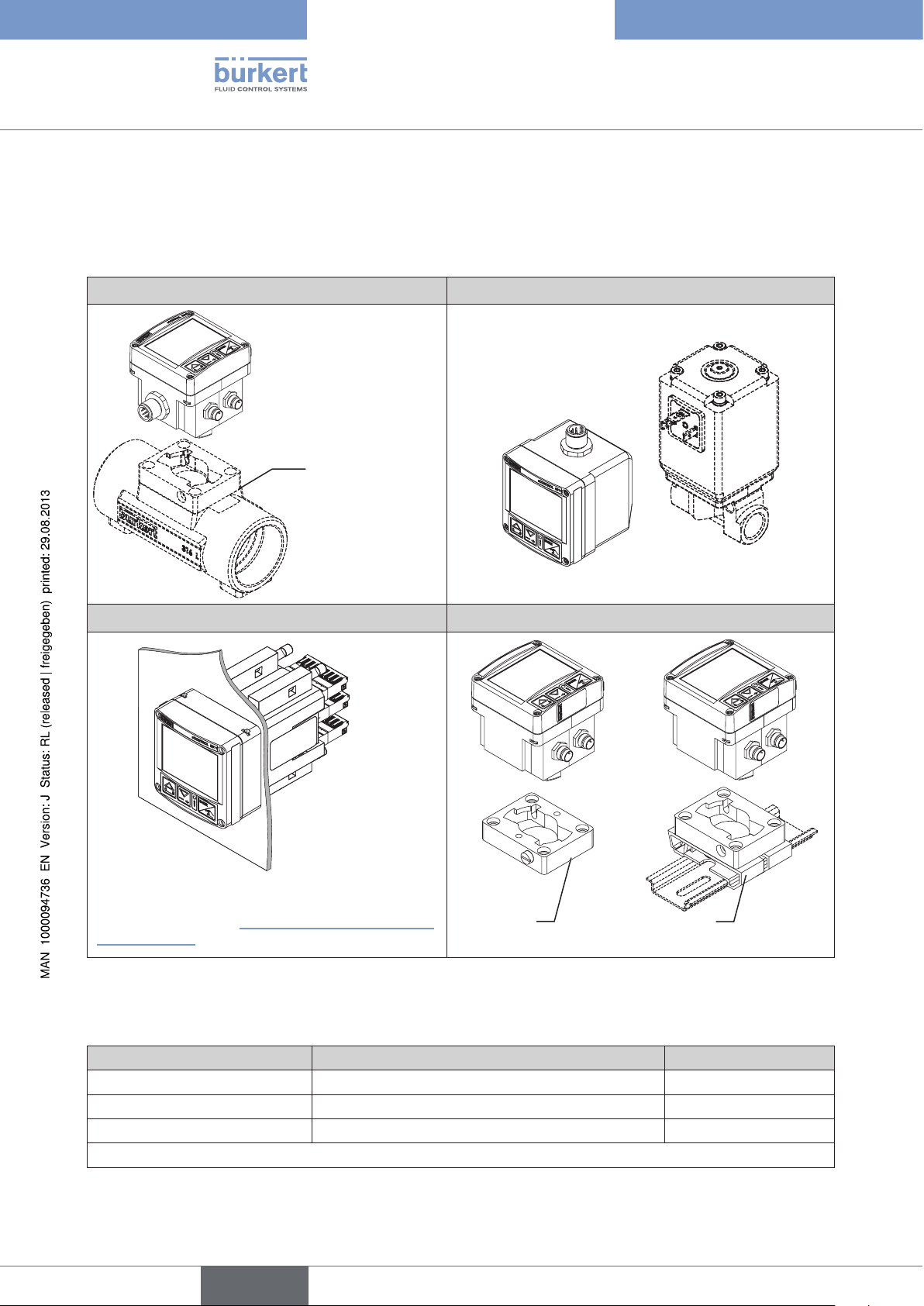

7.1. Assembly models

Attachment to a Bürkert flow-rate fitting Attachment to a proportional valve

Bürkert

flow-rate fitting

Type SO30

Installation in a control cabinet Wall assembly or rail assembly

The description of the installation in a control

cabinet and the device dimensions can be found in

the following chapter “7.3. Assembly of the control

cabinet model”.

Table 1: Assembly models

Adapter

for wall assembly

Adapter

for rail assembly

7.1.1. Assembly accessories

Model Accessories Order no.

Installation in pipeline Flow-rate fitting, Type S030 See data sheet S030

Rail assembly Adapter for rail assembly 655980

Wall assembly Adapter for wall assembly 427098

The adapters for the wall and rail assembly are included in the scope of supply of the assembly model.

16

Table 2: Assembly accessories

english

Page 17

Type 8611

Assembly

7.2. Attachment to a proportional valve

Attach the process controller Type 8611 to a proportional valve as described below.

→ Loosen the 4 screws at the front of the process controller.

NOTE!

Be careful when opening the process controller so as not to damage the internal cabling.

• Remove the cover carefully from the housing without jerks.

→ Remove the cover carefully from the housing.

→ Place the supplied flat seal over the contact tabs.

→ Attach the housing of the process controller on the contact tabs and fasten with the valve screw.

→ Check the correct position of the profile gasket at the housing of the process controller.

→ Place cover on the housing of the process controller and fasten with 4 screws.

If necessary, the cover can also be mounted in a position rotated by 90 ° to the left or the right.

Proportional valve

Housing of the process controller

Cover of the

process controller

Flat seal

Valve screw

Contact tabs

Profile gasket

4 screws for fastening the cover

Figure 5: Attachment of the process controller to a proportional valve

17

english

Page 18

Type 8611

Assembly

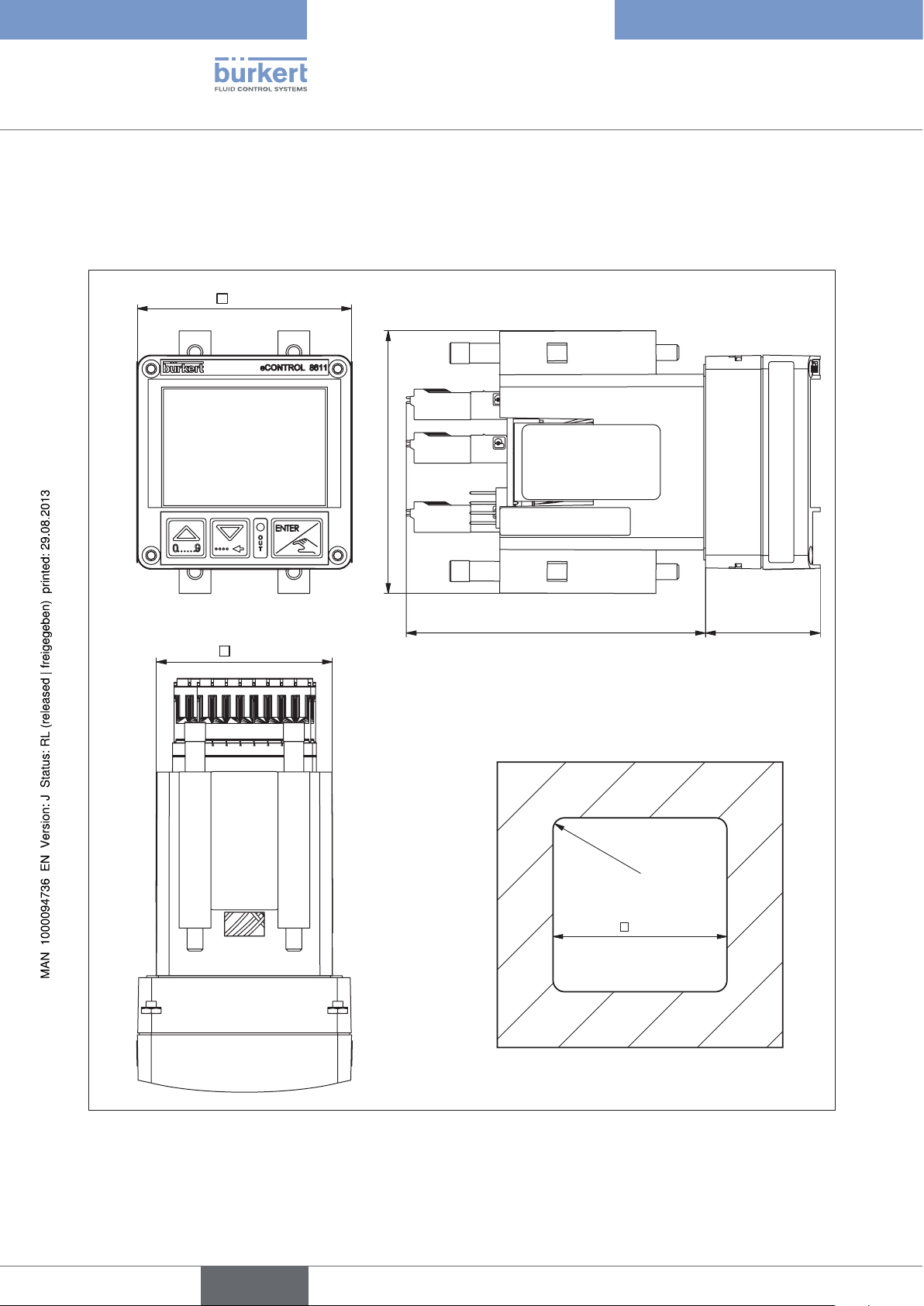

7.3. Assembly of the control cabinet model

7.3.1. Device dimensions and control panel cut-out

54.2

66

44.5

2976

Control panel cut-out for the installation

R 3

45

18

Figure 6: Device dimensions and control panel cut-out

english

Page 19

Type 8611

Assembly

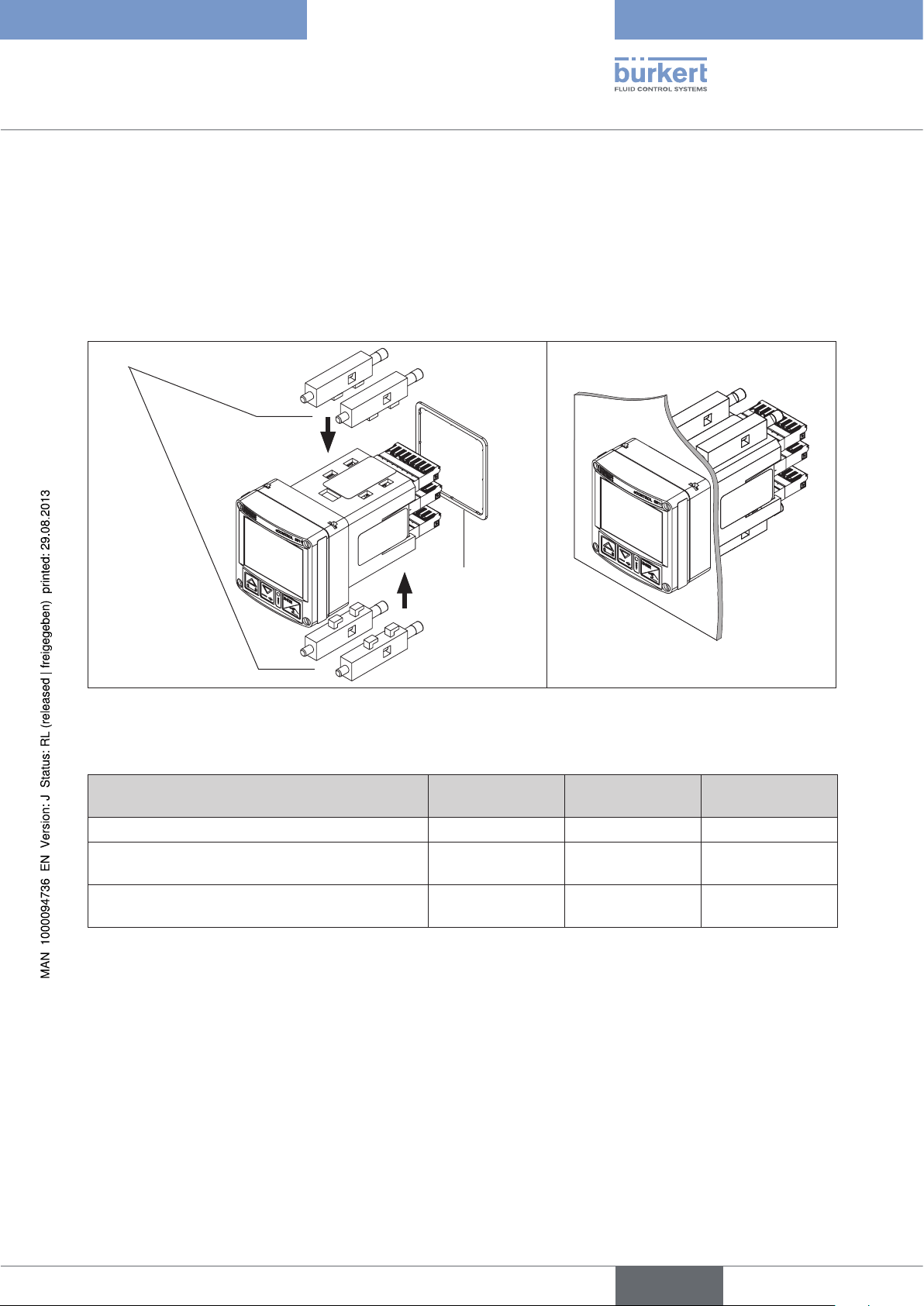

7.3.2. Installation in a control cabinet

• Prepare control panel cut-out with the dimensions 45mm x 45mm (corner radius 3mm).

• Place the supplied seal on the housing.

• Insert the controller from the front into the control panel cut-out.

• From the rear, snap the 4 supplied fastening elements into place and fasten using a screwdriver.

4 Fastening elements

Seal

Figure 7: Installation elements Figure 8: Installed controller

Recommended line cross sections for the control cabinet model:

Cross section

min.

Cross section

max.

Minimum length

Cross section for flexible lines 0.2 mm² 1.5 mm² 10 mm (stripping)

Cross section for flexible lines with cable end

sleeve without plastic sleeve

Cross section for flexible lines with cable end

sleeve with plastic sleeve

Table 3: Recommended line cross sections

0.25 mm²

0.25 mm²

1.5 mm² 10 mm

0.75 mm² 10 mm

english

19

Page 20

5

2

4

Type 8611

Electrical Installation

8. ELECTRICAL INSTALLATION

8.1. Electrical installation for fitting assembly, wall

assembly, valve assembly or rail assembly models

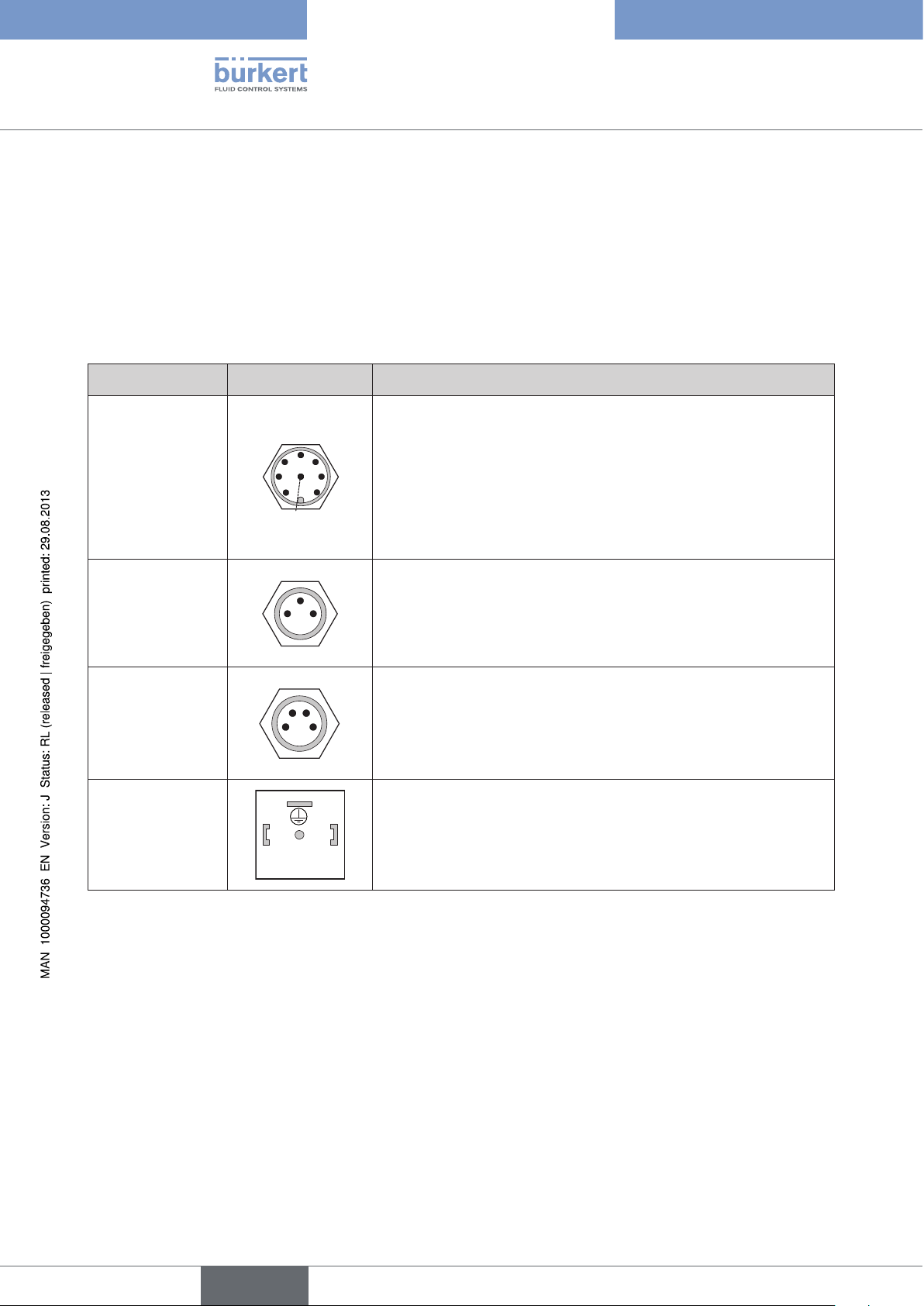

8.1.1. Connection versions

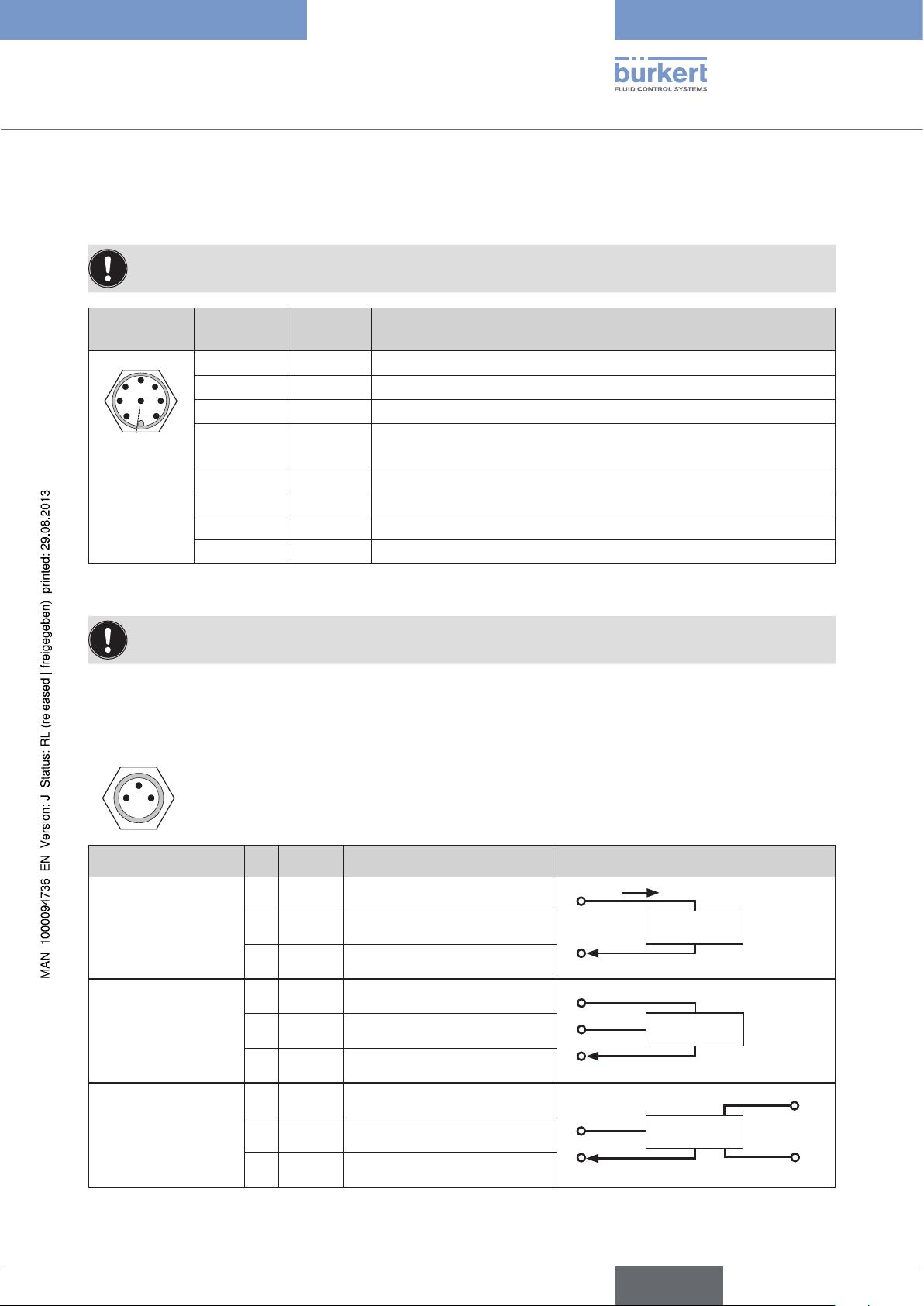

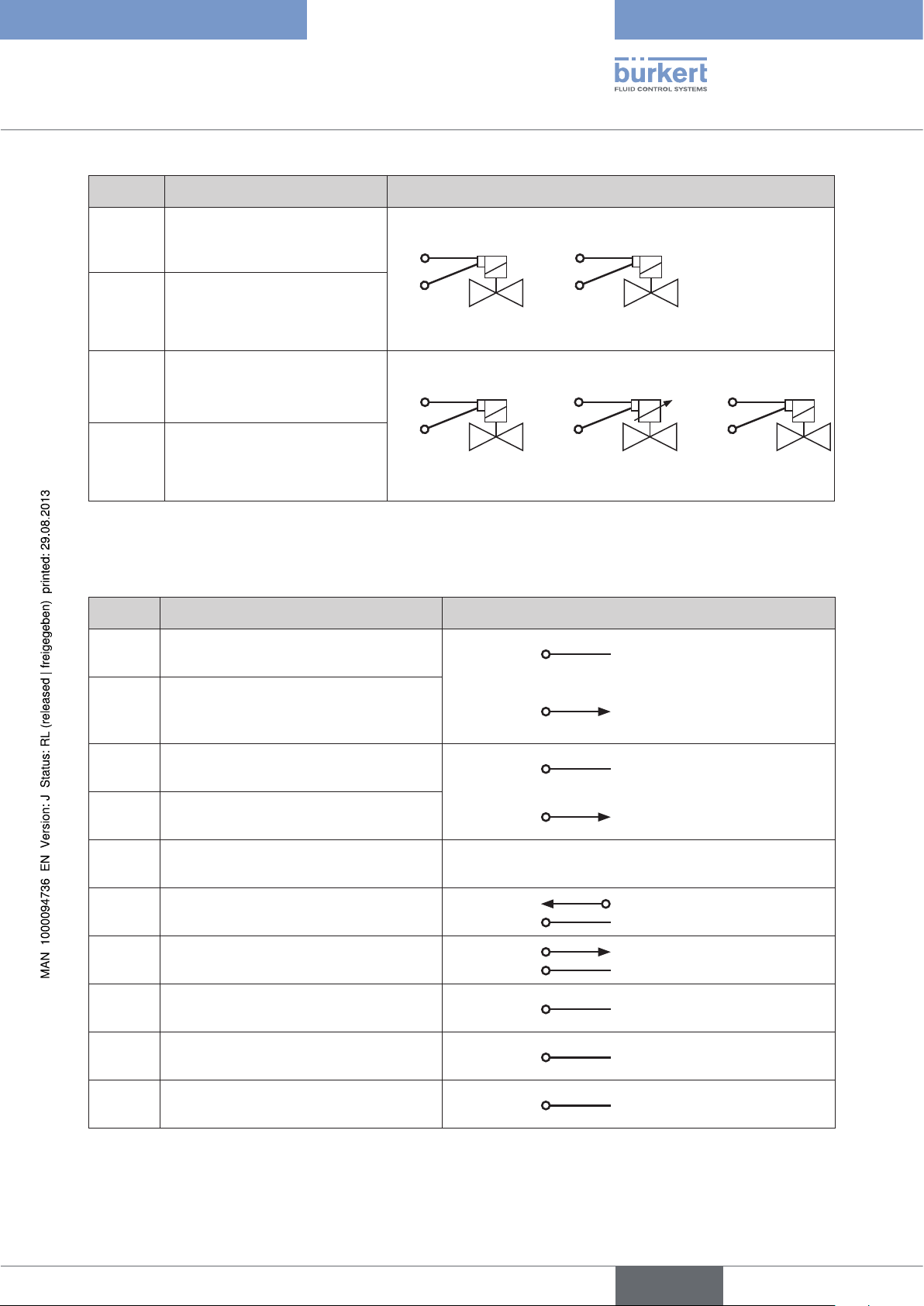

Connector Connector view Configuration

Circular plug-in

connector

M12, 8-pole

Circular plug-in

connector

M8, 3-pole

Circular plug-in

connector

M8, 4-pole

DIN-EN 175301

Power supply voltage,

set-point input 4 - 20 mA / 0 - 10 V,

6

7

1

1

4

2

8

4

3

12

process actual value or position set-point output 4 - 20 mA / 0 - 10 V,

binary input,

3

binary output

Note!

A straight plug (female) is recommended for the connecting cable,

as the alignment of the plug can vary.

Connection sensor

(4 - 20 mA / 0 - 10 V, Pt 100 or frequency)

and sensor supply 24 V DC

31

Connection actuating element

• Proportional valve (1 x PWM)

• Process valve (1 x PTM)

• Manipulated variable 4 - 20 mA / 0 - 10 V and

sensor supply 24 V DC (only ID 182383)

Connection for direct assembly on proportional valve (1 x PWM) or

open/closed valve (1 x PTM)

Table 4: Connection versions for assembly on flow-rate fitting, wall assembly, rail assembly or valve assembly

20

english

Page 21

5

Type 8611

Electrical Installation

8.1.2. Pin assignment

Circular plug-in connector M12, 8-pole

A straight connector (female) is recommended for the connecting cable as the orientation of the connector may vary.

Connector

diagram

6

7

1

8

Pin Color Configuration

1 white 24 V DC power supply

4

2 (DIN2) brown Binary input (B_IN)

3

3 green GND – Power supply, binary input, binary output

2

4 (AOUT) yellow 4 - 20 mA or 0 - 10 V analog output

(process value or manipulated variable for valve)

5 (AIN2) grey 4 - 20 mA or 0 - 10 V analog input (set-point value / ratio)

6 pink GND – Analog output

7 blue GND – Analog input (set-point value / ratio)

8 (BO1) red (+) Binary output (B_O1)

Table 5: Configuration of circular plug-in connector M12, 8-pole

Wire colors when using standard cables (e.g. from Lumberg, Escha)

8.1.3. Sensor connection

Circular plug-in connector M8, 3-pole

4

31

Input signal Pin Color Configuration External circuit

4 - 20 mA

1 brown + 24 V sensor supply

1

I

2-wire supply of Type

8611

(AIN1)

4 - 20 mA / 0 - 10 V

3-wire supply of Type

8611

(AIN1)

4 - 20 mA / 0- 10 V

4-wire external

supply

(AIN1)

3 blue not connected

4 black Signal input (source)

1 brown + 24 V sensor supply

3 blue GND

4 black Signal input (source)

1 brown not connected

3 blue GND

4 black Signal input (source)

4

1

3

4

3

4 - 20 mA

24 V DC

GND

4 - 20 mA / 0 - 10 V

GND

4

4 - 20 mA / 0 - 10 V

24 V DC

Transmitter

Transmitter

GND

Transmitter

Supply

21

english

Page 22

Type 8611

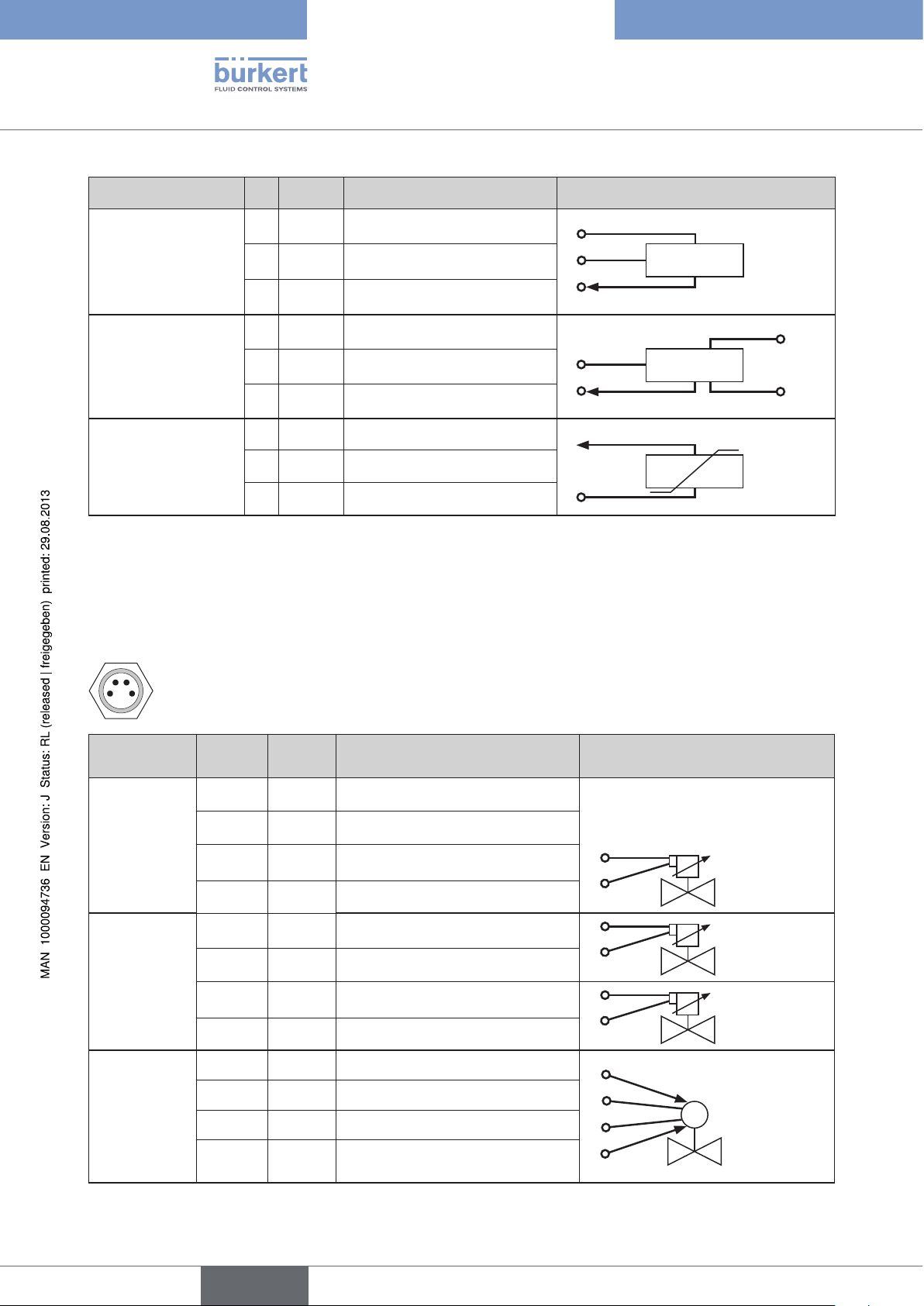

Electrical Installation

Input signal Pin Color Configuration External circuit

Frequency

3-wire supply of Type

8611

(DIN1)

Frequency

4-wire external

supply

(DIN1)

Pt 100

(2-wire)

(AIN3)

Table 6: Sensor connection: Configuration of circular plug-in connector M8, 3-pole

1 brown + 24 V sensor supply

3 blue GND

4 black Frequency input (NPN)

1 brown not connected

3 blue GND

4 black Frequency input (NPN)

1 brown not connected

3 blue GND Pt 100

4 black (+) Pt 100 (power supply)

1

3

4

3

4

3

4

GND

Clock (DIN1)

GND

Clock (DIN1)

8.1.4. Valves connection

Circular plug-in connector M8, 4-pole

2

4

24 V DC

Transmitter

GND

Transmitter

Supply

Pt 100

22

1

3

Output

signal:

PWM

(MODE =

SCV)

3-point

(MODE =

PCV)

1)

4 - 20 mA

or 0 - 10 V

(MODE =

4 – 20 /

0 – 10)

Pin Color Configuration External circuit

1 brown not connected

2 white not connected

3 blue (–) PWM (valve2)

3

4

4 (BO4) black (+) PWM (valve2)

1 (BO3) brown (+) Aeration (valve 1)

1

2

2 white (–) Aeration (valve 1)

3 blue (–) Deaeration (valve 2)

3

4

4 (BO4) black (+) Deaeration (valve 2)

1 (BO3) brown + 24 V DC supply

2 white GND (4 - 20 mA or 0 - 10 V)

3 blue GND supply

4 (AOUT) black

+ 4 - 20 mA or

0 - 10 V manipulated variable

1

2

3

4

Proportional

valve

NC valve

NO valve

Supply of 8611

M

english

Page 23

5

Type 8611

Electrical Installation

Output

signal:

3-point

(MODE =

3P – T)

1)

4 - 20 mA

or 0 - 10 V

(MODE =

4 – 20 /

0 – 10)

External

supply

2-point

(MODE =

2P – T)

Pin Color Configuration External circuit

1 (BO3) brown (+) Valve 1

1

2

2 white (–) Valve 1

3 blue (–) Valve 2

3

4

4 (BO4) black (+) Valve 2

1 brown + 24 V DC supply (max. 1A)

2 white GND (4 - 20 mA or 0 - 10 V)

External supply

2

3 blue GND supply

4

(AOUT)

black

1 (BO3) brown (+) Valve 1

+ 4 - 20 mA or

0 - 10 V manipulated variable

4

1

2

2 white (–) Valve 1

3 blue not connected

4 black not connected

M

NC / NO valve

NC / NO valve

+ 24 V DC

GND

NC / NO valve

1) Only available for identification number 182383

Table 7: Configuration of circular plug-in connector M8, 4-pole

Circular plug-in connector M12, 8-pole

6

7

1

Output

signal:

2)

or 0 - 10 V

4

3

2

8

4 - 20 mA

Pin Color Configuration External circuit

4

(AOUT)

yellow

4 - 20 mA or

0 - 10 V manipulated variable

(MODE =

4 – 20 /

6 pink GND – Analog output

0 – 10)

2) Available for all models except for identification number 182383

Table 8: Configuration of circular plug-in connector M12, 8-pole

4

M

+ 24 V DC

GND (24 V)

6

23

english

Page 24

Type 8611

Electrical Installation

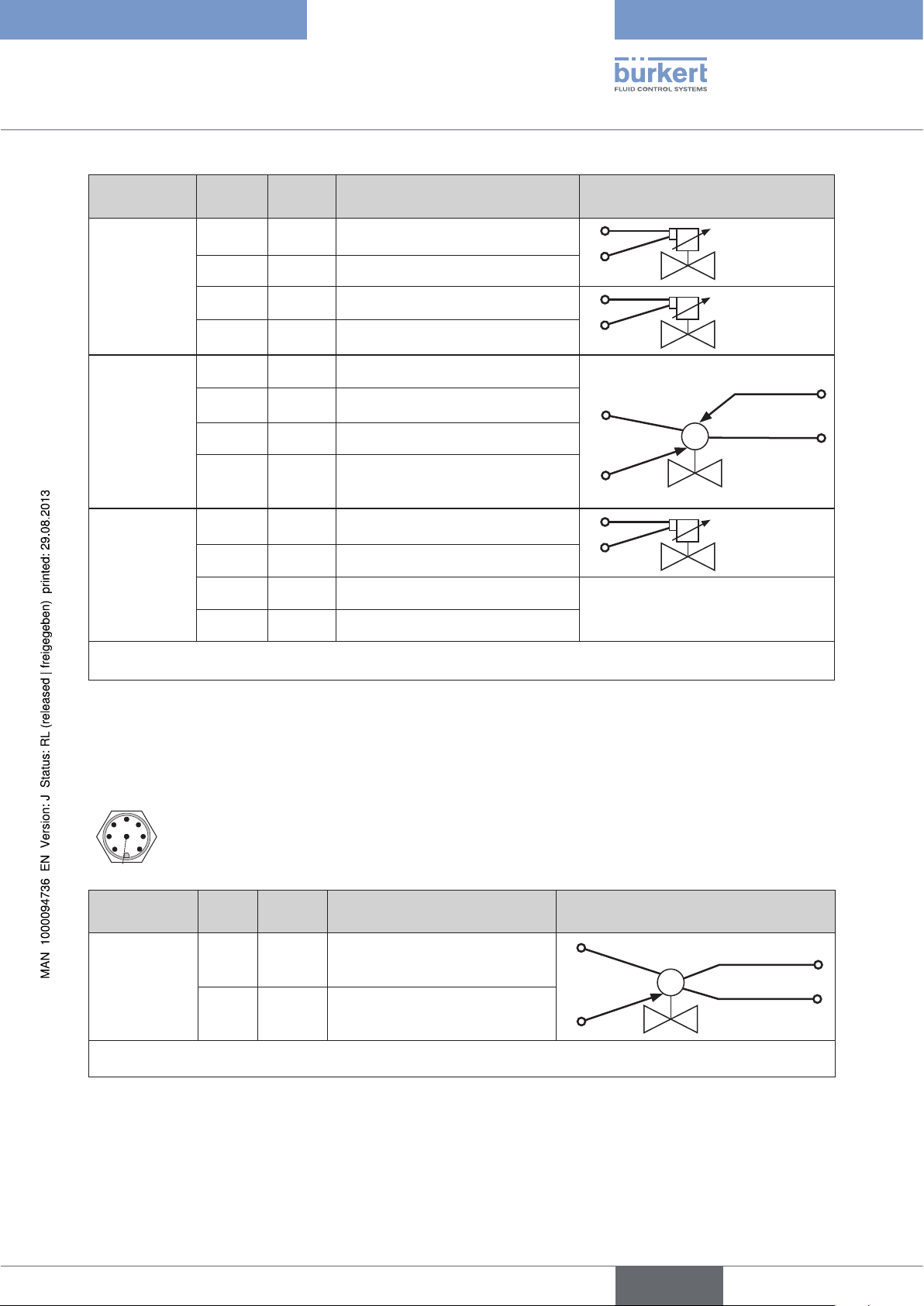

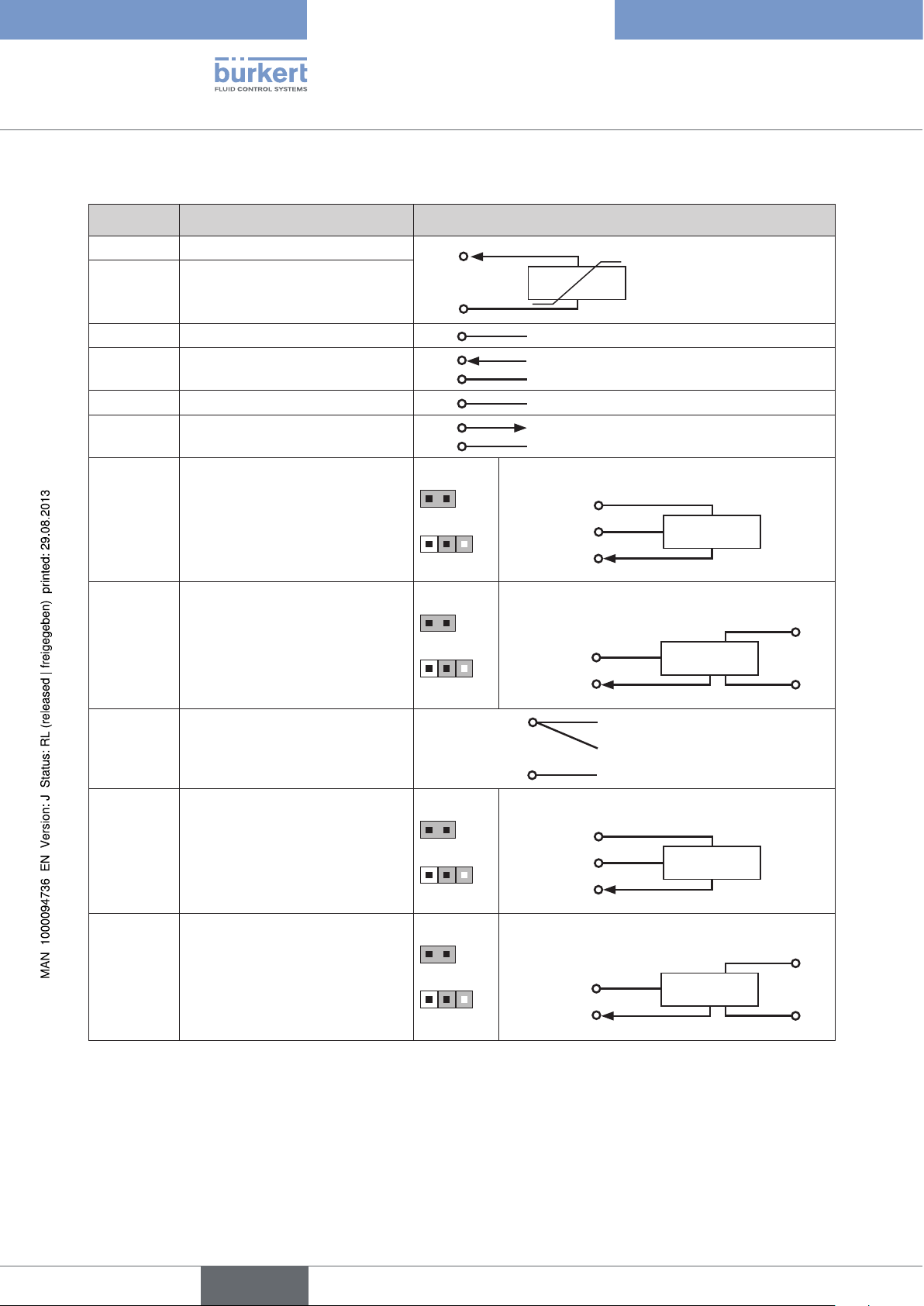

8.2. Electrical installation of the control cabinet model

WARNING!

Risk of injury from incorrect installation!

Incorrect installation can damage or destroy the Type 8611 eCONTROL.

• The electrical installation may be performed by authorized electricians only!

1 2 3 4 5 6 7 8

Terminal block 1

10

9

11 12 13 14 15 16 17 18

Terminal block 2

2019 21 22 23

Figure 9: Control cabinet model; connection PCB with spring terminals and jumpers

24 25

26 27

Terminal block 3

Jumper 1

Jumper 2

8.2.1. Terminal assignment

Terminal block 1

Terminal Configuration External circuit

1 GND – Electrical power supply

2 24 V DC power supply

1

2

GND

24 V DC

24 V DC ± 10 %

max. residual ripple 10 %

24

3

(BO2)

4

(BO1)

Binary output 2 (B_O2)

Binary output 1 (B_O1)

english

(1, 6, 8, 11, or 23

(1, 6, 8, 11, or 23

3

4

24 V / 0 V (max. 1 A) NC / NO

GND)

24 V / 0 V (max. 1 A) NC / NO

GND)

Page 25

Type 8611

Electrical Installation

Terminal Configuration External circuit

5

(BO3)

(+) Aeration valve (PCV) or

valve 1 (2P – T or 3P – T)

MODE = 2P – T

or 3P – T

5

6

6

7

(BO4)

(–) Aeration valve (PCV) or

valve 1 (2P – T or 3P – T)

(+) Proportional valve (SCV),

bleed valve (PCV) or valve 2

(3P – T)

NC / NO

valve max. 1 A

MODE = 3P – T

7

8

(–) Proportional valve (SCV),

8

bleed valve (PCV) or valve 2

(3P – T)

Table 9: Configuration of terminal block 1

NC / NO

valve max. 1 A

Terminal block 2

Terminal Configuration External circuit

9 GND – Analog output 9

MODE = PCV

5

6

valve max. 1 A

MODE = SCV

7

8

valve max. 1.5 A

GND

NC

NC

MODE = PCV

7

8

NO

valve max. 1 A

10

(AOUT)

11 GND – Sensor, actuating element 11

12

(+) Analog output (process value or

manipulated variable

for valve)

24 V DC sensor supply or actuating

element

10

12

4 - 20 mA / 0 - 10 V

GND

24 V DC

13 not used not used

14

(AIN2)

15 (+) 5 V DC sensor supply (max. 20 mA)

(+) External set-point value / ratio

4 - 20 mA / 0 - 10 V

14

(21

15

(1, 11, or 23

16 RS485_COM 16

17 RS485_A (+) 17

18 RS485_B (–) 18

4 - 20 mA / 0 - 10 V (Source)

A-GND)

5 V DC

GND)

RS485_COM

RS485_A

RS485_B

Table 10: Configuration of terminal block 2

25

english

Page 26

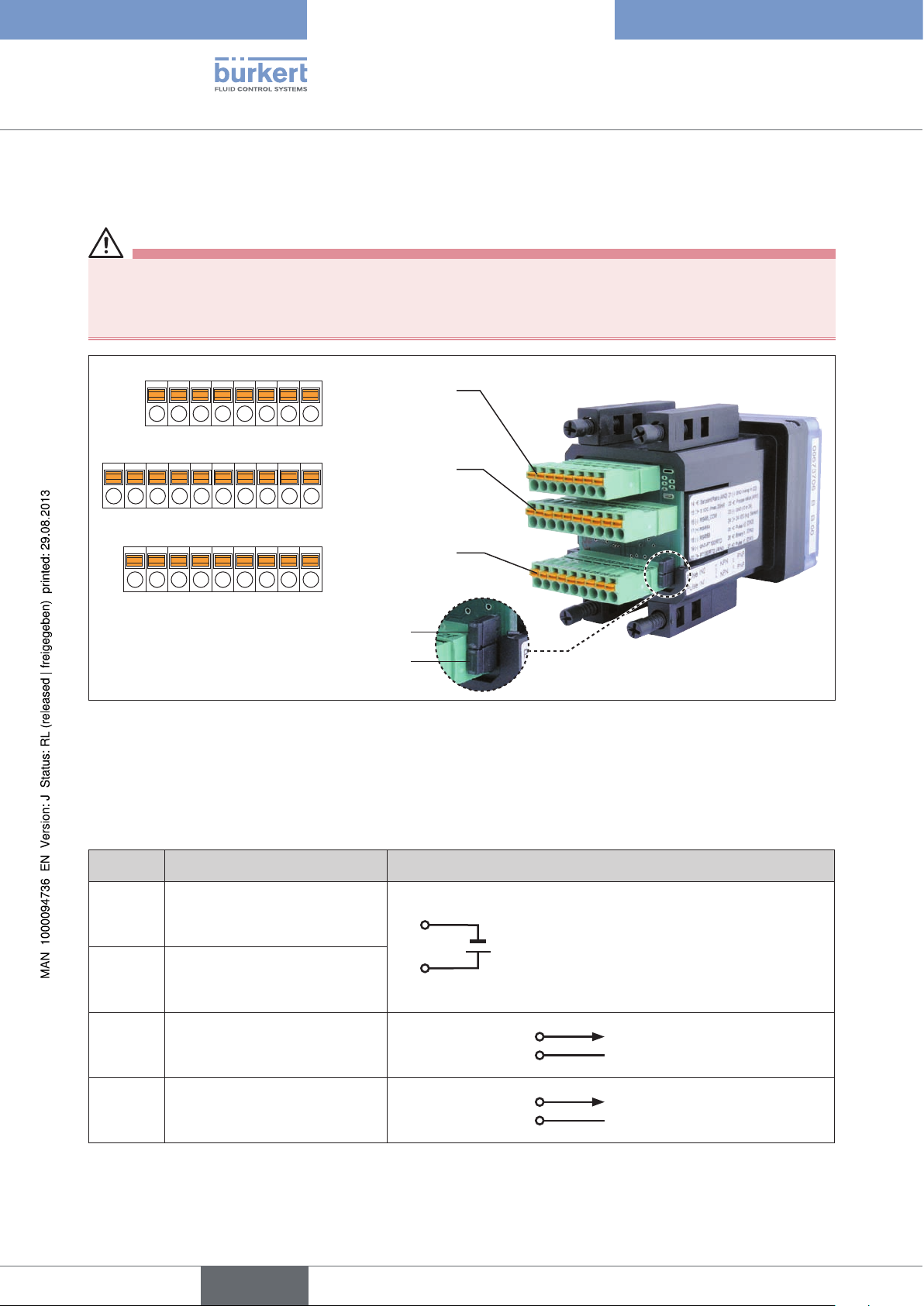

Terminal block 3

Terminal Configuration External circuit

Type 8611

Electrical Installation

19 GND – Pt 100, RTD

20

(AIN3)

(+) Pt 100, RTD (power supply)

19

20

21 GND – Analog input 21

22

(AIN1)

(+) Process value input

4 - 20 mA / 0 - 10 V

22

21

Pt 100

A-GND

4 - 20 mA / 0 - 10 V (source)

A-GND

23 GND – Sensor, actuating element 23 GND

24

25

Supply of

Type 8611

(DIN3)

25

External

supply

(DIN3)

24 V DC sensor supply or

actuating element

Frequency input 2

(NPN or PNP)

for ratio control

Q

2

(MODE = RATI)

Frequency input 2

(NPN or PNP)

for ratio control

Q

2

(MODE = RATI)

24

23

Jumper 2

NPN

PNP

Jumper 2

NPN

PNP

24 V DC - Out (max. 1 A)

GND

12 or 24

11 or 23

11 or 23

25

25

(0 ... 200 °C)

Supply of 8611

24 V DC

GND

Clock

GND

Clock

Transmitter

External supply

Supply

Transmitter

GND

26

(+) Binary input

(DIN2)

27

Supply of

Type 8611

(DIN1)

27

External

supply

(DIN1)

Table 11: Configuration of terminal block 3

Frequency input 1

(NPN or PNP)

Actual value flow-rate /

for ratio control

Q

1

(MODE = RATI)

Frequency input 1

(NPN or PNP)

Actual value flow-rate /

for ratio control

Q

1

(MODE = RATI)

1, 11, or 23

Jumper 1

NPN

PNP

Jumper 1

NPN

PNP

26

12 or 24

11 or 23

27

11 or 23

27

0 ... 2.7 V (log. 0)

3 ... 30 V (log. 1)

GND

Supply of 8611

24 V DC

GND

Transmitter

Clock

External supply

GND

Transmitter

Clock

max. 1 kHz

Supply

GND

26

english

Page 27

Type 8611

Operation and Function

9. OPERATION AND FUNCTION

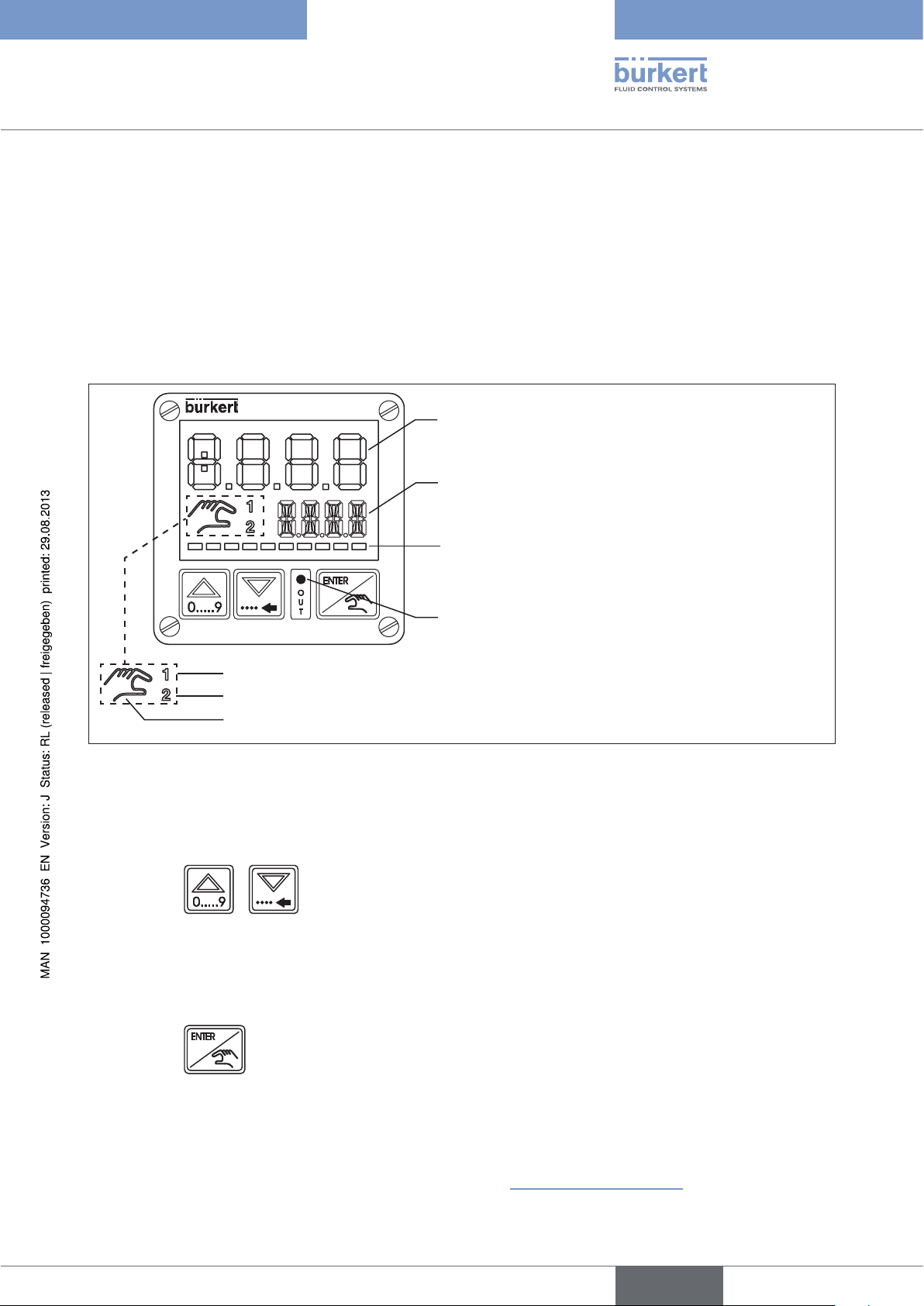

9.1. Control and display elements

The control and display element of the eCONTROL Type 8611 is equipped with 3 buttons and an LCD-Matrix

display.

9.1.1. Display elements

4-character display

7-character matrix for numerical values

4-character display

14-character matrix for measuring units and parameter

designations

10-segment bar graph for display of the manipulated

variable in % (One Segment indicates 10 % of

manipulated variable)

Is displayed for external set-point value default

Is displayed when the control is activated

Indicates the operating state MANUAL

Figure 10: Display elements

9.1.2. Control elements

Arrow keys

left right

ENTER

button

• Change the display at the process operating level in AUTOMATIC operating

state

• Change the menu options in MANUAL operating state and at the

configuration level

• Entering of numerical values

• Switches between the operating states AUTOMATIC and MANUAL

• Switches between operating and configuration level

Red LED is lit in case of an alarm

• Selection of menu option

• Take over settings

The detailed description of the function can be found in chapter “9.3. Function of the keys”.

english

27

Page 28

Type 8611

Operation and Function

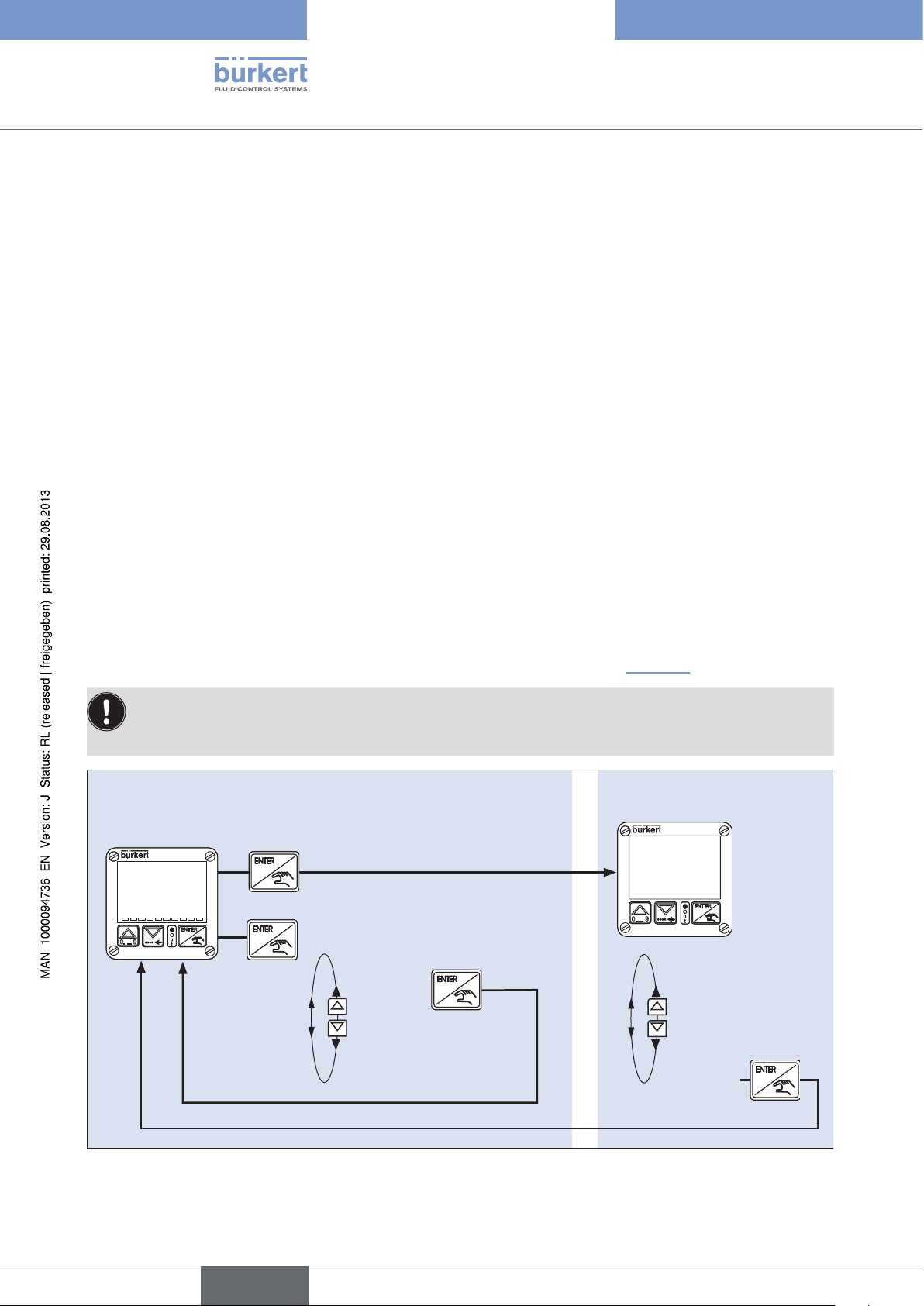

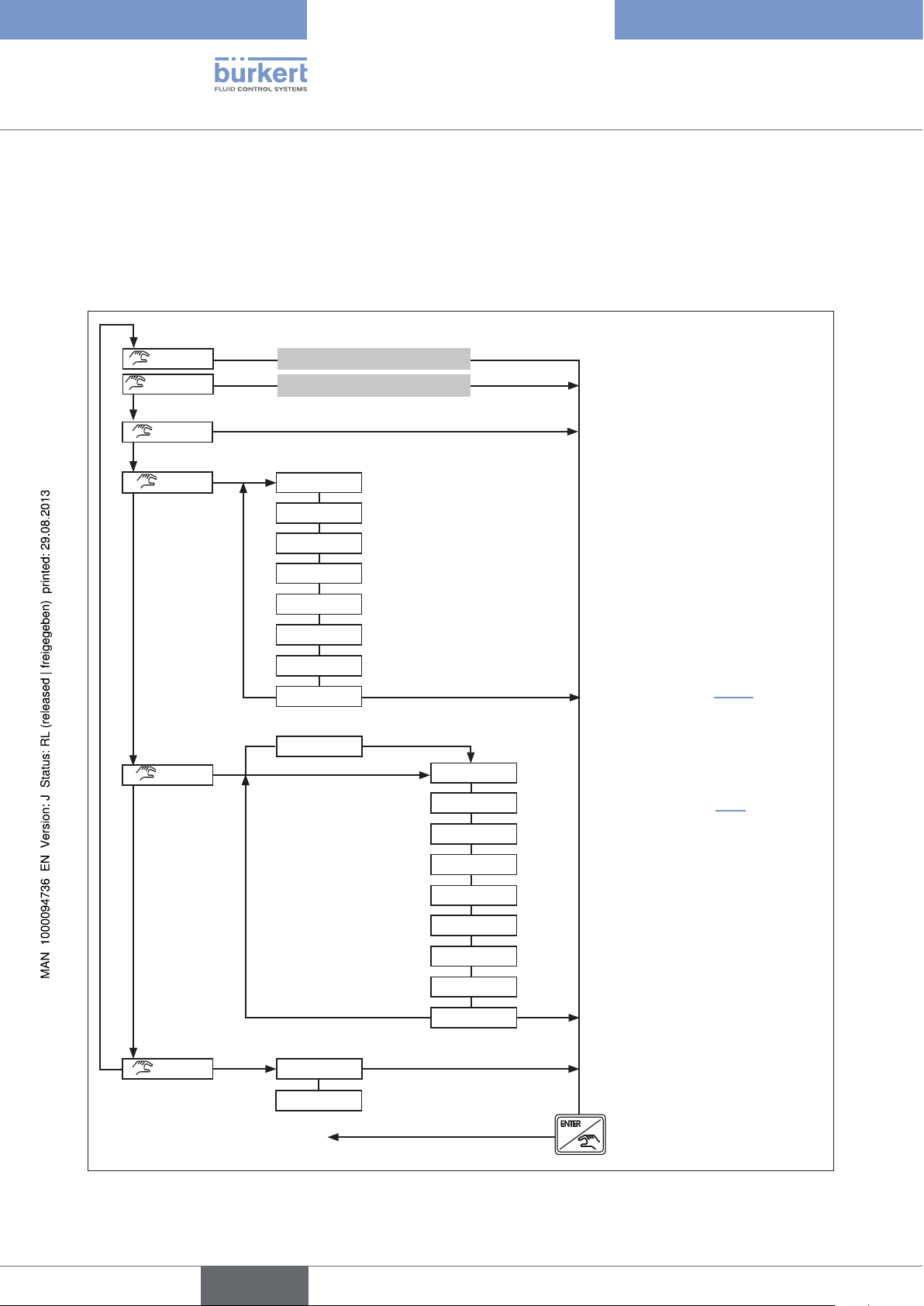

9.2. Operating levels and operating states

2 operating levels and 2 operating states AUTOMATIC and MANUAL are available for the operation and setting

of the eCONTROL Type 8611.

Level 1: Process operating level

At level 1, the user can switch between 2 operating states AUTOMATIC and MANUAL.

Operating state: AUTOMATIC: The normal control mode is executed and monitored.

MANUAL: Quick access to important functions and test functions.

The operating state MANUAL is indicated on the display by a hand

symbol.

Level 2: Configuration level

At level 2, the user can change the basic settings of the controller.

After switching on the operating voltage, the controller is at the process operating level and in the AUTOMATIC

operating state.

When the operating voltage is applied, the software version will light up on the display for approx. 2 seconds. If

the ENTER key is pressed during these 2 seconds, the sub-version is displayed. After this, the controller is once

again at the process operating level.

9.2.1. Switching between the operating levels and operating

states

The ENTER key is pressed to change the operating level and operating state (see Figure 11).

Any changes made within the configuration level are only stored after returning to the process operating

level.

Changes in the MANUAL operating state can be made while the controller is running.

Process operating level

Operating state

AUTOMATIC

8611

eCONTR OL

Press

button

025.5

L/M

ENTER

O

0..... 9

u

t

> 5 s (long)

< 1 s (short)

SET

PARA

VALV

TEST

BACK

Operating state

MANUAL

Configuration level

8611

eCONTR OL

MODE

ENTER

O

0..... 9

u

t

MODE

UNIT

END

.

.

.

.

28

Figure 11: Changing the operating level and operating state

english

Page 29

Type 8611

Operation and Function

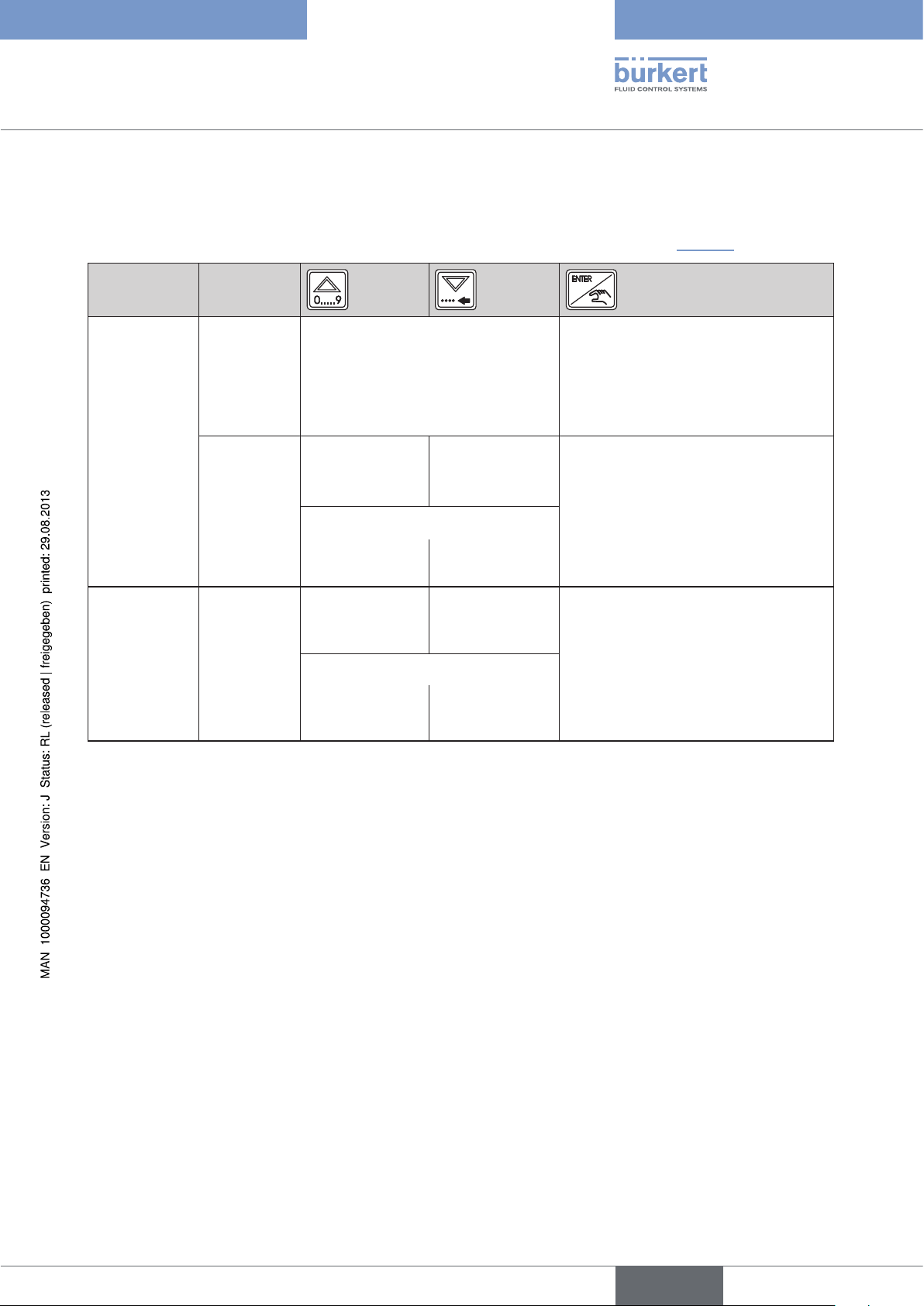

9.3. Function of the keys

The device is operated using two arrow keys and one ENTER key.

The function of these in respect of the operating level and the operating state is shown in Table 12 below.

Operating

level

Level 1:

Process

operating level

Level 2:

Configuration

level

Operating

state

AUTOMATIC

MANUAL

Switch display between actual value,

set-point value and manipulated

variable

Switches to the

last menu option

Entering of values

Increase value

Switches to the

last menu option

Entering of values

Increase value

Switches to the

next menu option

Change by one

position to the left

Switches to the

next menu option

Change by one

position to the left

• Press key briefly (< 1 s):

Switches to operating state MANUAL

• Press and hold key (> 5 s):

Switches to configuration level

• Selection of menu option

• Take over settings

• Switches to operating state AUTOMATIC (for display BACK)

• Selection of menu option

• Take over settings

• Switches to process operating level

and to operating state AUTOMATIC

(for display END)

Table 12: Function of the keys

29

english

Page 30

Type 8611

Operating Structure

10. OPERATING STRUCTURE

10.1. Operating structure of the process operating level in MANUAL operating state

SET ***

RFAC ****)

BACK

TEST

PARA

)

Enter set-point value

Enter ratio factor

***) The SET menu option is

only displayed for process

control.

Consequently for all control

variables set in the MODE

menu except for RATI.

AIN1

)

****

AIN2

The RFAC menu option

is only displayed for ratio

AIN3

DIN1

DIN2

DIN3

control.

Consequently only if the

RATI control variable is set in

the MODE menu.

**) Code query only when code

AOUT

BACK

CODE **

)

KP1

)

KP2 *

TN *

)

)

TREG *

protection is activated

(see chapter 12.18)

*) The display depends on the

control variable set in the

MODE menu

(see chapter 12.3)

30

DEAD

)

KP T *

)

TN T *

)

DE T *

BACK

VALV *

)

150 L/H

055 PRZ *

)

Back to

AUTOMATIC operating state

Figure 12: Operating structure of the process operating level in MANUAL operating state

english

Page 31

Type 8611

Operating Structure

10.2. Operating structure of the configuration level

Configuration level

CODE

MODE

UNIT *

Enter access code if the code protection has been activated in the CODE menu.

CODE

„0001“

Q1 **

Q2 **

RATI

F

P

T

T – F

T + F

L

X

)

*) The display depends on the control variable set in the MODE

menu.

)

)

Q1 and Q2 are only displayed if ratio control = RATI has

**

FREQ

NORM

SCV

PCV

2P – T

3P – T

4 – 20

0 – 10

Select

control frequency

(PWM)

Select

control times

Select

control times

Select

control times

been set in the MODE menu.

FREQ *

PT *

NORM *

See Chapter 12.3

L/H

L / M

0.01

MODE = T+F, T-F

MODE = F

MODE = RATI

= T

MODE

MODE = P

G / H

G / M

ML / M

M3 / H

°C

°F

NU

BAR

MBAR

PSI

UNIT, MODE = L, MODE = X

Figure 13: Operating structure of the configuration level - 1 of 6

1

0.1

31

english

Page 32

UNIT *

Type 8611

Operating Structure

)

*) The display depends on

MM

CM

M

1

0.1

0.01

the control variable set in

the MODE menu

(see chapter 12.3)

SETP **

RFAC ***

S_IN ****

)

)

)

4 – 20

0 – 10

AOUT 4 – 20

0 – 10

EXT

INT

MODE = L

MODE = X

4 – 20

0 – 10

Enter

scaling

FLOW *

TEMP *

PRES *

RFAC *

Ft

In

NU

PH

µS/c

mS/c

S/c

Ωxc

ppm

LEVL *

VAL *

POS *

Q1 *

Q2 *

Enter

scaling

**) The SETP menu option is

only displayed for

process control.

Consequently for all

control variables set in the

MODE menu except for

RATI.

)

***

The RFAC menu option

is only displayed for ratio

control.

)

Enter

scaling

)

)

)

)

)

)

)

)

Consequently only if the

RATI control variable is

set in the MODE menu.

)

****

The S_IN menu option is

only displayed if standard

signal (NORM) was

selected as sensor input.

32

CALI

Calibration of analog inputs and outputs

KFAC

Figure 14: Operating structure of the configuration level - 2 of 6

english

Page 33

KFAC *

Type 8611

Operating Structure

Select K-factor for ratio control

)

Q1 **

Q2 **

)

)

)

**

Q1 and Q2 are only displayed if frequency input (FREQ) was

selected for both flow-rate sensors in ratio control.

FREE

BACK

8081

8071

S070

0.01

0.1

1

10

QN0.6

QN1.5

QN2.5

QN3.5

QN6.0

50L

100L

500L

DN15

DN25

DN40

DN50

DN80

DN100

Enter value

The display 0.01, 0.1, 1 is used for setting the

decimal place.

Use the display 10 for setting the multiplier 10 for the

K-factor.

Display value

Display value

Display value

8031

S030

8030

8012

8011

100L

250L

VA

PVDF

PP

PVC

MS

*) The KFAC menu option is not

indicated unless a sensor with

frequency input was selected in the

MODE menu.

FILT

Figure 15: Operating structure of the configuration level - 3 of 6

Display value

DN06

DN08

DN15

DN20

DN25

DN32

DN40

DN50

Display value

V2

OLD

Fitting S030 and the fitting of

devices 8030, 8011 and 8012,

DN15, exist in 2 versions. The

„v2“ marking can be found

either on the bottom or on the

side of the fitting.

33

english

Page 34

Type 8611

Operating Structure

FILT

PARA

Enter filter factor ( 2 - 20)

KP1

)

KP2 *

)

TREG *

)

TN *

DEAD

)

KP_T *

)

TN_T *

)

DE_T *

INV

ZERO is only displayed

for entry INV / NO

ZERO

)

STRT *

BACK

*) The display depends on the

control variable set in the MODE

menu (see chapter 12.3)

NO

YES

NO

YES

34

B _IN

NO

INV

HOLD

SAFP

HIGH

LOW

HIGH

LOW

STOP **

)

HIGH OPEN

LOW CLOS

OPEN **

CLOS **

)

)

HIGH

LOW

B_O1 / B_O2

Figure 16: Operating structure of the configuration level - 4 of 6

PRZV **

mA **

)

V **

OPEN **

CLOS **

)

)

Enter value

**) The display depends on

)

)

the actuating element

set in the MODE menu

(see chapter 12.3)

english

Page 35

Type 8611

Operating Structure

B _O1

NO

Selecting binary output as pulse output

PULS

Selecting binary output as limit switch

LIMT

*) The display depends on

the control variable set

in the MODE menu:

(see chapter 12.3)

DM3 1

IGAL 0.1

UGAL 0.01

M3

REL

Enter

hyteresis

values

ABS

POS

Enter position

limit

DLY XXX.X

FLOW *

PRES *

TEMP *

LEVL *

)

VAL *

INV NO

Enter number

of pulses

)

Enter process

limit value

)

)

)

HIGH

B _O2 **

Selecting binary output as 2-state controller

2_P

DLY XXX.X INV NO LED NO

)

**) The operating structure is identical to B_O1

REL

SP

ABS

INV YES LED YES

INV YES

LOW

Enter

hysteresis

values

Enter set

point limit

value

FLOW *

PRES *

TEMP *

LEVL *

VAL *

)

)

)

)

)

Enter process

limit value

HIGH TEXT NO

LOW TEXT YES

VALV

Figure 17: Operating structure of the configuration level - 5 of 6

35

english

Page 36

VALV

Type 8611

Operating Structure

MODE = SCV, 4 - 20, 0 - 10: Continuous control

L/H *

PRZ

mA *

V *

)

)

*

)

)

END

MIN

MAX

*) The display depends on the

control variable set in the MODE

menu (see chapter 12.3)

MODE = PCV, 2P - T, 3P - T: Quasi-continuous control

L/H *

)

END

CODE

DSPL

FACT

NO

YES

NO

YES

CMD

BOTH

PVAL

SETP

MIN

MAX

Enter MIN

Enter MAX

36

U_xx

B_xx

END

Display program version

xxxxx

Display software version

Switching to the process operating level – AUTOMATIC operating state

Figure 18: Operating structure of the configuration level - 6 of 6

english

Page 37

Type 8611

Functions of the Process Operating Level

11. FUNCTIONS OF THE PROCESS OPERATING

LEVEL

11.1. Operating state AUTOMATIC

After switching on the operating voltage, the controller is at the process operating level and in the AUTOMATIC

operating state. The normal control mode is executed and monitored.

11.1.1. Displays in the AUTOMATIC operating state

Press the arrow keys to switch between 4 different displays for monitoring the control operation. Which of these

displays should be shown as start display after applying the operating voltage can be defined in the DSPL menu

(see “12.19. DSPL - Setting the display”).

025.5

L/M

0..... 9

eCONTR OL

O

u

t

ENTER

8611

025.5

L / M

Display process actual value

The display of the unit depends on the selection made in the

UNIT menu (see chapter 12.4).

For MODE = T – F or T + F the display switches between

temperature and flow-rate.

For MODE = RATI the display switches between flow-rate Q1

and Q2.

030.0

SET

030.0

RFAC

Display set-point value

The display depends on the selection made in the MODE menu

(see chapter 12.3).

SET = Display for process control

RFAC = Display for ratio control

For MODE = T – F or T + F the display switches between

flow-rate set-point (SP_Q) and temperture set-point (SP_T).

For MODE = RATI the display switches between ratio factor

(RFAC) and flow-rate set-point (SPQ1).

025.5

030.0

Display process actual value

Display set-point value

065.0

PRZV

065.0

mA

065.0

Display manipulated variable for valve

Display depends on the actuating element selected in the

MODE menu (see chapter 12.3).

PRZV = Display pulse duty factor for solenoid valve

V

mA = Display manipulated variable in mA

V = Display manipulatec variable in V

Figure 19: Displays in the AUTOMATIC operating state

37

english

Page 38

Type 8611

Functions of the Process Operating Level

11.2. Operating state MANUAL

Briefly press (< 1 s) the ENTER key to go to the MANUAL operating state. The operating state is indicated on the

display by a hand symbol.

11.3. Specific menu options of process and ratio control

The display of some menu options differs for the process and the ratio control. This is described in detail in the

respective menu descriptions.

The control type is specified by the control variable selected in the MODE menu:

• Process control: is active if all control variables have been selected in the MODE menu except forRATI.

• Ratio control is active if the RATI control variable has been selected in the MODE menu

(see chapter “12.3.1. RATI - Selection of external sensors for ratio control”).

11.4. Menu options in the MANUAL operating state

SET

RFAC

BACK

TEST

PARA

VALV

Table 13: Menu options of the process operating level

Set-point value default for process control

See chapter “11.5. SET - Set-point value default for process control”

• Menu option is displayed for process control.

• Is not available if external set-point value default is selected.

Ratio factor default for ratio control

See chapter “11.6. RFAC - Ratio factor default for ratio control”

• Menu option is only displayed for ratio control (MODE = RATI).

• Is not available if external set-point value default is selected.

When BACK is displayed on the display, press the ENTER key briefly to switch to AUTO-

MATIC operating state.

When an arrow key is pressed, the next or respectively the previous menu option is

displayed.

Display of the analog inputs and outputs and the digital inputs.

See chapter 11.7

Adjusting the controller parameters (Code must be entered if code protection is activated).

See chapter “11.8. PARA – Display and optimization of the controller parameters”

Manual opening and closing of the connected valves.

See chapter 11.9

38

english

Page 39

Type 8611

Functions of the Process Operating Level

11.5. SET - Set-point value default for process control

In the case of process control, the set-point value default can be entered in the MANUAL operating state using

the SET menu.

Process control is active if all control variables have been set in the MODE menu except for RATI.

Setting the set-point value default in the menu:

Process operating level

Enter a value between 0.00 and 9999

< 1 s

SET

030.0

SET *

(depends on the decimal places selected in the UNIT menu).

)

*) Menu option is only available if internal set-point

value default was selected (see chapter “12.5.

SETP / RFAC - Selection and scaling of setpoint value default / entry of ratio factor”).

BACK

Back to operating state

AUTOMATIC

Figure 20: SET; Set-point value default for process control

11.6. RFAC - Ratio factor default for ratio control

In the case of ratio control, the ratio factor can be entered in the MANUAL operating state using the RFAC menu.

The ratio control is active if the RATI control was set in the MODE menu.

Setting the ratio factor in the menu:

Process operating level

Enter a value between 0.000 and 9.999.

< 1 s

RFAC

0.000

RFAC *

)

BACK

Back to operating state

AUTOMATIC

Figure 21: RFAC; Ratio factor default for ratio control

*) Menu option is only available if internal set-point

value default was selected (see chapter “12.5.

SETP / RFAC - Selection and scaling of setpoint value default / entry of ratio factor”).

39

english

Page 40

Type 8611

Functions of the Process Operating Level

11.7. TEST – Display of the analog inputs and outputs

and the digital inputs

The analog inputs and outputs and the digital inputs are displayed while the controller is operating. No

changes can be made.

TEST

AIN1

AIN2

Analog input 1: 4 - 20 mA or 0 - 10 V

(process value Q1 or Q2 for ratio control)

Analog input 2: 4 - 20 mA or 0 - 10 V

(set-point value for process or ratio control)

AIN3

Analog input 3: Pt 100

(Process actual value temperature)

PARA

DIN1

Frequency input 1

(Process actual value flow-rate or Q

DIN2

DIN3

AOUT

Binary input: 0 / 1 corresponds to 0 V / 24 V input

Frequency input 2

for ratio control)

(Q

2

Analog output 4 - 20 mA or 0 - 10 V (process actual value

or manipulated variable for actuating element)

BACK

Back to operating state

AUTOMATIC

Figure 22: TEST; Display of the analog inputs and outputs and the digital inputs

for ratio control)

1

40

english

Page 41

Type 8611

Functions of the Process Operating Level

11.8. PARA – Display and optimization of the controller

parameters

In this menu of the process operating level, the controller parameters of the running process can be optimized.

The new controller parameters are taken over immediately after pressing the ENTER key.

The detailed description of the controller parameters depending on the selected process variable can be found in

chapter “11.8. PARA – Display and optimization of the controller parameters”.

Access to this menu can be protected by a user code (see chapter “12.18. CODE - Code protection”)

Enter code.

PARA

VALV

*) Display is shown only if

code protection was activated in the CODE menu

(see chapter 12.18)

0000

CODE *

**) The display depends on the control variable

set in the MODE menu (see chapter 12.3)

TN **

)

)

)

Enter value

)

)

)

)

)

0000

XXX

)

KP 1 **

KP 2 **

TREG **

DEAD **

KP T **

TN T **

DE T **

Back to operating state

AUTOMATIC

Figure 23: PARA; Display and optimization of the controller parameters

BACK

41

english

Page 42

Type 8611

Functions of the Process Operating Level

11.9. VALV – Manual opening and closing of the

connected actuating elements

If the VALV menu option is selected, the controller is stopped and the actuating element remains in the last

position. The manipulated variable can now by increased or lowered relatively to the last position by pressing

the key.

The display in the VALV menu option depends on the control variable set in the MODE menu:

• MODE = SCV, 0 - 10, 4 - 20, 2P - T, 3P - T (Reset time T

• MODE = PCV, 2P - T, 3P - T (Reset time T

deactivated, TN = 9999)

N

activated, TN > 0)

N

MODE = SCV, 0 - 10, 4 - 20, 2P - T, 3P - T (Reset time TN activated, TN > 0)

Display process value

VALV

150

L/H

In the case of cascaded control, the process value and

the flow-rate are displayed alternately

Actuating of Valve 1 (VLV1) (Increasing of the manipulated

variable, Bargraph length increases from left to right

SET

Actuating of Valve 1 (VLV1) (Decreasing of the manipulated

variable, Bargraph length decreases from right to left

055

PRZ

Display manipulated variable (4 – 20, 0 – 10 or PRZ)

When leaving the VALV menu option, the last selected

Back to operating state

manipulated variable is taken over.

AUTOMATIC

Figure 24: VALV; Manual opening and closing of the actuating element

3)

Changing the manipulated variable

Each time the key is pressed: MODE = SCV, 2P - T, 3P - T by 1%

MODE = 4 - 20 by 0.2 mA

MODE = 0 - 10 by 0.1 V

3) 4)

3) 4)

42

Continuous pressing of the key > 80 ms: Quick adjustment of the manipulated variable

4)

The manipulated variable can be changed between 0 and 100 %.

Only for MODE = 3p - T the manipulated variable can be changed between -100 % and +100 %.

-100 % = Valve 2 is controlled by 100 % pulse duty factor

+100 % = Valve 1 is controlled by 100 % pulse duty factor

english

Page 43

Type 8611

Functions of the Process Operating Level

MODE = PCV, 2P - T, 3P - T (Reset time TN deactivated, TN = 9999)

Display process value

VALV

150

L/H

In the case of cascaded control, the process value

and the flow-rate are displayed alternately

Actuating of valve 1 (VLV1)

5)

SET

Actuating of valve 2 (VLV2)

5)

Back to operating state

AUTOMATIC

Figure 25: VALV; Manual opening and closing of the actuating element

4)

Key functions

Each time the key is pressed: the actuating element is operated for 40 ms

Continuous pressing of the key > 80 ms: Continuous control of the actuating element

The detailed description of the VALV function can be found in chapter “12.17. VALV - Test function and

setting of the control range”

english

43

Page 44

Type 8611

Functions of the Configuration Level

12. FUNCTIONS OF THE CONFIGURATION

LEVEL

12.1. General Description

In the following description of the menu options and their operating structures, the entire software of the eCONTROL

Type 8611 is explained. This complete software scope is only available for the control cabinet model of the eCONTROL

Type 8611.

The menu structure may vary depending on the device model (wall, valve, rail or fitting assembly). In accordance

with the device model, only menu options that are logically purposeful for the application area can be selected. This

pre-selection is made upon delivery of the controller in accordance with the chosen order part number.

Any changes made within the configuration level are only stored after returning to the process operating

level.

Access to the configuration level can be protected by a code. Any unauthorized persons are thus denied

access and cannot change the parameters.

If the code protection is activated, a code must be entered before switching to the configuration level

(see chapter “12.18. CODE - Code protection”).

44

english

Page 45

Type 8611

Functions of the Configuration Level

12.2. Menu options of the configuration level

MODE

UNIT

SETP

RFAC

S_IN

AOUT

CALI

KFAC

FILT

PARA

B_IN

B_O1

B_O2

VALV

CODE

DSPL

FACT

U_XX

A_XX

END

Selection of control variable, actuating element and process value input.

See Chapter 12.3

Selection of measuring units and decimal places.

See chapter 12.4

Selection and scaling of set-point value default.

See chapter 12.5

Entry of ratio factor for ratio control (MODE = RATI).

See chapter 12.5

Scaling of sensor input signal ( 4 - 20 mA or 0 - 10 V).

See chapter 12.6

Scaling of analog output (4 - 20 mA or 0 - 10 V).

See chapter 12.7

Calibration of the analog inputs and outputs.

See chapter 12.8

Entry of K-factor for flow-rate measurement.

See chapter 12.11

Setting of the filtering factor.

See chapter 12.12

Setting of the controller parameters.

See chapter 12.13

Configuration of the binary input.

See chapter 12.14

Configuration of binary output 1.

See chapter 12.15

Configuration of binary output 2.

See chapter 12.16

Test function and setting of the control range.

See chapter 12.17

Code protection.

See chapter 12.18

Setting of the display.

See chapter 12.19

Resetting to factory settings.

See chapter 12.20

Display of program version.

See chapter 12.21

Display of software version.

See chapter 12.21

Leaving the configuration level See chapter 12.22

Table 14: Menu options of the configuration level

45

english

Page 46

Type 8611

Functions of the Configuration Level

12.3. MODE - Selection of control variable, actuating

element and process value input

The most important basic settings of the controller are made in this menu option.

The setting is done in 3 successive steps.

• Selection of control variable (e.g. flow-rate control, pressure control, etc.)

• Selection of actuating element (e.g. proportional valve, process valve, etc.)

• Selection of process value input (e.g. 4 - 20 mA, frequency, etc.)

The MODE menu option is at the configuration level. To go there, press and hold the ENTER key (> 5 s)

(see chapter “9.2. Operating levels and operating states”).

How the settings are made in the menu is explained below.

Configuration level

CODE

Enter access code if the code protection has been activated in the CODE menu.

If you have forgotten the code →see chapter “12.18.1. If you have forgotten the code”

MODE

0001

CODE

Selection of control

variable

RATI

T + F

T – F

F

P

T

Select

sensor input for Q

Select

sensor input for Q

Select

sensor input for Q

2

*

*

Flow-rate control

Pressure control

Temperature regulation

Ratio control

(see chapter 12.3.1

Temperature control with subor-

)

)

dinate flow control

Temperature control with

flow-rate display

)

*

The selection of the sensor

input is only available in the

control cabinet model

46

L

X

Filling level control

Other control variable

(pH, conductivity, process variables without unit)

Confirm selection

UNIT

Continue with

selection of actuating element

Figure 26: MODE; Selection of the control variable

english

Page 47

Type 8611

Functions of the Configuration Level

MODE

Selection of control variable

Selection of actuating element

SCV

PCV

3P – T

2P – T

0 – 10

4 – 20

Select

PWM frequency

Select

control times

Select

control times

operating principle

Select

control times

operating principle

Continuous control using proportional

valve and selection of PWM frequency

(see chapter 12.3.2)

Quasi-continuous control

using process valve

(see chapter 12.3.3)

Quasi-continuous 3-state control with

time-proportional control for opening

or closing

(see chapter 12.3.6)

Quasi-continuous 2-state control with

time-proportional control for opening

or closing

(see chapter 12.3.5)

Continuous control

using 0 - 10 V standard signal

(see chapter 12.3.4)

Continuous control

using 4 - 20 mA standard signal

(see chapter 12.3.4)

UNIT

Selection of process value input

FREQ

PT **

NORM

**

)

)

Frequency input

(can only be set for MODE = T+F, T-F, F, RATI, 2P-T, 3P-T) PT

PT100 sensor

(can only be set for MODE = T+F, T-F, T, 2P-T, 3P-T)

4 - 20 mA or 0 - 10 V standard signal

(can be set for all control variables)

**) The display depends on the control variable previously set in this

menu (see “Figure 26: MODE; Selection of the control variable”)

YES *

NO *

Confirm selection

)

*) The query YES/NO is only displayed

if the control variable or the selection

)

of the actuating element has been

changed.

Accept and save changes

After saving, all parameters are reset

to the default values.

Figure 27: MODE; Selection of the actuating element and of the process value input

47

english

Page 48

Type 8611

Functions of the Configuration Level

12.3.1. RATI - Selection of external sensors for ratio control

A ratio control can easily be implemented by combining the compact controller Type 8611 with flow-rate fitting

S030 and a second flow-rate sensor.

In a ratio control, the controlled flow-rate Q

is adapted to the uncontrolled flow-rate Q2 so that it corresponds to

1

a specified mixture ratio.

The flow-rate is measured for Q

using the Bürkert flow-rate fitting of Type S030

1

for Q2 using a second external flow-rate sensor.

The following relation exists between Q

= RFAC · Q2 Q1: controlled flow-rate

Q

1

and Q2:

1

Q2: uncontrolled flow-rate

RFAC: ratio factor

(for selection see chapter “11.6. RFAC - Ratio factor default for ratio

control”)

Example of a ratio control:

Selected ratio factor RFAC: 4, 00

Flow-rate Q

Control of Q

: 20 l/h

2

to: 20 l/h · 4 = 80 l/h

1

Schematic representation:

Manipulated variable 4 - 20 mA

Frequency (FREQ)

48

8611

Flow-rate fitting,

Type S030

Flow-rate Q

controlled

1

Q

2

Flow-rate Q

uncontrolled

2

Controller setting:

MODE = RATI, FREQ, 4 – 20, FREQ

Figure 28: Ratio control using process controller Type 8611 (assembly directly on flow-rate fitting Type S030).

Fluid mixture

english

Page 49

Type 8611

Functions of the Configuration Level

Settings in the menu:

MODE

0001

CODE

Selection of control variable

RATI

Continue with

Selection of actuating element

(see chapter 12.3.2 to

chapter 12.3.6)

Figure 29: RATI; Setting the ratio control

Select frequency input for sensor input Q

)

FREQ *

Select standard signal for sensor input Q

NORM **

)

2

2

*) FREQ: The sensor-specific K-factor is entered in the

KFAC menu.

)

NORM: The scaling of the standard signal is selected in

**

the S_IN menu

Particularity of the control cabinet model!

In the control cabinet model, the standard signal input is available for Q

However, for the inputs Q

and Q2, a standard signal (NORM) can only be assigned once.

1

in addition to the frequency input.

1

If the standard signal was selected for sensor input Q2 (MODE, RATI, NORM) only frequency is available

when selecting the process value input Q1.

Example:

Selection of sensor input Q

Selection option for process value input Q

2

1

FREQ (frequency) FREQ (frequency) or NORM (standard signal)

NORM (standard signal) FREQ (frequency)

Table 15: Select NORM/FREQ for sensor input and process value input

english

49

Page 50

Schematic representation:

Frequency input

(FREQ)

Control cabinet model

8611

Type 8611

Functions of the Configuration Level

4 - 20 mA