Page 1

Type 8611

eCONTROL

Process controller and Ratio controller

Prozessregler und Verhältnisregler

Régulateur de process et commande proportionnelle

Quickstart

(Valid from software version B01 / Gültig ab Softwareversion B01

À compter de la version logicielle B01)

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© 2010 – 2012 Bürkert SAS

Operating Instructions 1209/2_EU-ML_00805838 / Original DE

Page 3

Contents

Type 8611

eCONTROL 8611: Process controller and Ratio controller

1. QUICKSTART .....................................................................................................5

1.1. Symbols ......................................................................................................5

2. AUTHORIZED USE .........................................................................................6

2.1. Restrictions ...............................................................................................6

2.2. Predictable Misuse ................................................................................6

3. BASIC SAFETY INSTRUCTIONS .............................................................7

4. GENERAL INFORMATION ...........................................................................8

4.1. Contact addresses ................................................................................8

5. SYSTEM DESCRIPTION ...............................................................................8

5.1. General Description ..............................................................................8

5.2. Interfaces of the process controller Type 8611 ...................8

5.3. Functions ....................................................................................................9

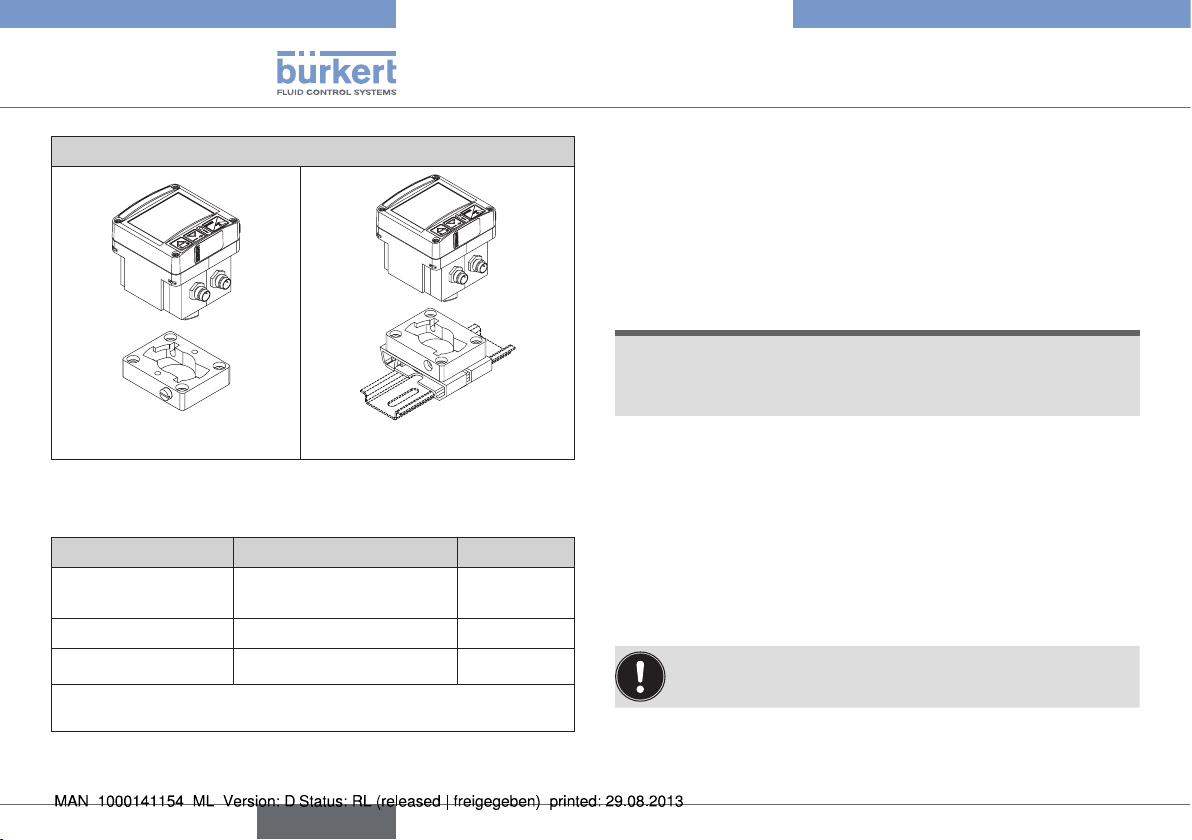

5.4. The various mounting and installation models ......................9

5.5. Software ...................................................................................................10

6. TECHNICAL DATA ........................................................................................10

6.1. Operating Conditions ........................................................................10

6.2. Conformity with the following standards ...............................10

6.3. General Technical Data .................................................................... 10

6.4. Rating plate description ..................................................................11

6.5. Electrical Data ....................................................................................... 12

7. ASSEMBLY .......................................................................................................13

7.1. Assembly models ...............................................................................13

7.2. Attachment to a proportional valve ...........................................14

7.3. Assembly of the control cabinet model .................................. 15

8. ELECTRICAL INSTALLATION ..................................................................17

8.1. Electrical installation for fitting assembly,

wall assembly, valve assembly or

rail assembly models ........................................................................ 17

8.2. Electrical installation of the control cabinet model .......... 22

9. OPERATION AND FUNCTION ................................................................25

9.1. Control and display elements ......................................................25

9.2. Operating levels and operating states ....................................26

9.3. Funktion of the keys ..........................................................................27

english

3

Page 4

10. FUNCTIONS, PROCESS OPERATING LEVEL ............................. 28

10.1. Operating state AUTOMATIC ......................................................28

10.2. Operating state MANUAL ............................................................. 30

10.3. Specific menu options of process and ratio control .....30

10.4. Menu options in the MANUAL operating state ................. 30

10.5. Operating structure of the process operating level

in MANUAL operating state ......................................................... 31

11. CONFIGURATION LEVEL .......................................................................33

11.1. Operating structure of the configuration level .................33

12. OVERVIEW SETTING PARAMETERS ............................................... 45

13. PACKAGING AND TRANSPORT......................................................... 47

14. STORAGE ....................................................................................................... 47

15. DISPOSAL .....................................................................................................47

Type 8611

4

english

Page 5

Type 8611

Quickstart

1. QUICKSTART

The operating instructions describe the entire life cycle of the device.

Keep these instructions in a location which is easily accessible to

every user and make these instructions available to every new owner

of the device.

Important Safety Information!

Read Quickstart carefully and thoroughly. Study in particular the

chapters entitled Basic Safety Instructions and Intended Use.

• Quickstart must be read and understood.

The Quickstart explains, for example, how to install and start-up the

device.

A detailed description of the device can be found in the operating

instructions for positioner Type 8611 eCONTROL.

The operating instructions can be found on the enclosed CD

and on the Internet at:

www.burkert.com

1.1. Symbols

The following symbols are used in these instructions.

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or serious

injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or

death.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a medium or minor

injury.

NOTE!

Warns of damage to property!

indicates important additional information, tips and

recommendations.

refers to information in these operating instructions or in

other documentation.

→ designates a procedure that must be carried out.

english

5

Page 6

Type 8611

Authorized use

2. AUTHORIZED USE

Non-authorized use of the process controller Type 8611

may be a hazard to people, nearby equipment and the

environment.

• The process controller is intended for controlling the process

variables for pressure, temperature or flow-rate in conjunction

with a proportional or process valve and a sensor.

• Do not use the device outdoors.

• Use according to the authorized data, operating conditions and

conditions of use specified in the contract documents and operating instructions. These are described in the chapter entitled

“Technical Data”.

• The device may be used only in conjunction with third-party

devices and components recommended and authorized by

Bürkert.

• Correct transportation, correct storage and installation and

careful use and maintenance are essential for reliable and faultless operation.

• Use the device only as intended.

2.1. Restrictions

If exporting the system/device, observe any existing restrictions.

2.2. Predictable Misuse

• The Type 8611 is not to be used in areas where there is a risk of

explosion.

• Do not physically stress the housing (e.g. by placing objects on it

or standing on it).

6

english

Page 7

Type 8611

Basic Safety Instructions

3. BASIC SAFETY

INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the installation,

operation and maintenance of the devices.

• local safety regulations – the operator is responsible for observing

these regulations, also with reference to the installation personnel.

General Hazardous Situations.

To prevent injury, ensure that:

• any installation work may be carried out by authorized technicians and with the appropriate tools only.

• after an interruption in the power supply or pneumatic supply,

ensure that the process is restarted in a defined or controlled

manner.

• the device may be operated only when in perfect condition and

in consideration of the operating instructions.

• the general rules of technology apply to application planning

and operation of the device.

NOTE!

Electrostatic sensitive components / modules!

The device contains electronic components which react sensitively

to electrostatic discharge (ESD). Contact with electrostatically

charged persons or objects is hazardous to these components. In

the worst case scenario, they will be destroyed immediately or will

fail after start-up.

• Observe the requirements in accordance with EN 61340-5-1

and 5-2 to minimise or avoid the possibility of damage caused

by sudden electrostatic discharge!

• Also ensure that you do not touch electronic components when

the power supply voltage is present!

The process controller Type 8611 was developed with due

consideration given to the accepted safety rules and is stateof-the-art. Nevertheless, dangerous situations may occur.

Failure to observe this operating manual and its operating

instructions as well as unauthorized tampering with the device

release us from any liability and also invalidate the warranty

covering the devices and accessories!

english

7

Page 8

Type 8611

General Information

4. GENERAL INFORMATION

4.1. Contact addresses

Germany

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of these printed

operating instructions.

And also on the internet at:

www.burkert.com

5. SYSTEM DESCRIPTION

5.1. General Description

The process controller Type 8611 is designed for integration in a

closed control circuit and can be used for numerous control tasks

in fluid technology. The figure below illustrates the integration of the

controller in a closed control circuit.

Controller

Set-point w

(set-point

value)

Fig. 1: Block diagram of a closed control circuit

8611

+

Manipulated

variable y

_

X

Feedback process actual value

5.2. Interfaces of the process

controller Type 8611

Depending on the controlled system and process, different controller

structures and different inputs/outputs are available for measuring

Controlled system

Actuating

element

Sensor Process

Controlled

variable

8

english

Page 9

Type 8611

System Description

the process actual value and for controlling the actuating elements.

The diagram below shows the available interfaces of the process

controller.

Supply

24 V DC

24 / 5 V DC

electrical power

supply for

sensors

Ext. set-point

value default

or ratio

4 - 20 mA /

0 - 10 V

Sensor inputs

4 - 20 mA /

0 - 10 V,

frequency, Pt 100

Binary input

0-30 V DC

Process

Supply

controller

eCONTROL

Typ 8611

Inputs

Analog output

4 - 20 mA /

0 - 10 V

Transistor

outputs

PWM, 2P – T,

3P – T

Process value

output

Outputs

4 - 20 mA /

0 - 10 V

Binary output

0 / 24 V

(NC / NO)

RS485

option, for

control cabinet

model only

Interfaces

Operation

5.3. Functions

The following control tasks can be executed with the process controller Type 8611 eCONTROL.

• Fixed command control (single-loop control circuit)

• Sequential control (external set-point value)

• Ratio control

• Cascade control

Standard signals (current / voltage) and frequency-analog signals

can optionally be applied or resistance thermometers (Pt 100) can be

connected to the scalable controller inputs.

Outputs for continuous standard signals (current / voltage) or transistor outputs can be used as controller outputs. Valves or other

switching actuators can be operated via the transistor outputs. One

binary output and up to 2 binary outputs for auxiliary functions are

additionally provided.

5.4. The various mounting and

installation models

The process controller Type 8611 is available in the following

models (see also chapter “7.1. Assembly models”):

• For installation in a pipeline system

• For attachment to a proportional valve

• For wall assembly or for assembly on a rail

• For installation in a control cabinet

Fig. 2: Interfaces of the process controller Type 8611

english

9

Page 10

Type 8611

Technical Data

Particularities of the control cabinet model:

Unlike the remaining assembly models, the cabinet model of

type 8611 has not one but two binary outputs.

5.5. Software

In the following description of the menu options and their operating

structures, the entire software of the eCONTROL Type 8611 is

explained. This complete software scope is only available for the control

cabinet model of the eCONTROL Type 8611.

The menu structure may vary depending on the device model (wall,

valve, rail or fitting assembly). In accordance with the device model, only

menu options that are logically purposeful for the application area can

be selected. This pre-selection is made upon delivery of the controller

in accordance with the chosen order part number.

6. TECHNICAL DATA

6.1. Operating Conditions

Permitted ambient temperature:

(operation and storage) 0 ... +70 °C

Protection class: IP65 to EN 60529

6.2. Conformity with the following

standards

CE mark conforms to

EMC Directive: EN61326

6.3. General Technical Data

Materials

Housing, cover: PC, + 20 % glass fiber

Front plate foil: Polyester

Screws: Stainless steel

Multipin: CuZn, nickel-plated

Wall assembly bracket: PVC

10

english

Page 11

Type 8611

Technical Data

Assembly

Installation position: Any position

Assembly models: Attachment to a pipeline with

Bürkert flow-rate fitting Type

S030

wall assembly, rail assembly,

valve assembly, control cabinet

assembly

Display: 2-line,

(see “Fig. 10: Display

elements”)

Operating voltage: Multipin: 3-pin or / and 4-pin

M8, 8-pin M12

2

Power cable: 0.5 mm

max. 100 m long, screened

max. cross section,

6.4. Rating plate description

The rating plate contains important technical data for the specific

device. The structure of the rating plate is described below by way

of example.

6.4.1. Rating plate of the controllers for

wall, rail, valve or fitting assembly

Example:

Controller

type

8611 Wall 24VDC

IN:Norm OUT:Norm

SET: Norm ACT: PWM

S/N xxxxxx

00177462

Serial number

Sensor input signal

(Norm, Pt 100 or Freq (NPN))

Assembly model

- Wall (wall assembly)

- Rail (rail assembly)

- Valve (assembly directly on valve)

- Fitting (assembly directly on flow-rate fitting)

Power supply voltage

Analog output

W16LU

(Norm or None)

Controller output signal

(PWM or Norm)

Set-point value input signal

Manufacturer's code

Order part number

Fig. 3: Example: Rating plate of the controllers for wall, rail, valve

or fitting assembly

english

11

Page 12

Type 8611

Technical Data

6.4.2. Rating plate of the control cabinet

model

Example:

Controller type

Assembly model

- Panel (control cabinet

8611 Panel 24VDC

Prozessregler

Power supply voltage

Controller design

S/N xxxxxx

00210206

Serial number

Fig. 4: Example: Rating plate of the control cabinet model

W16LU

Manufacturer's code

Order part number

6.5. Electrical Data

Operating voltage: 24 V DC ±10 %,

filtered and controlled

Power consumption without load: approx. 2 W

with load: maximum 48 W

100 % ED: 36 W

Controller sampling rate: 300 Hz

6.5.1. Inputs

Set-point value

Standard 4 - 20 mA Input impedance: 70 Ω

Resolution: 5.5 µA

Standard 0 - 10 V Input impedance: 11.5 kΩ

Resolution: 2,5 mV

Sensors

Standard 4 - 20 mA Input impedance: 70 Ω

Resolution: 5.5 µA

Frequecy

Input 1 External sensor

Frequency range: min. 0.25 Hz / max. 1 kHz

Input resistance: > 1 kΩ

Signal types: Sine, rectangle, triangle

(> 3000 mVss, max. 30 Vss)

Input 2 Internal Hall sensor

Frequency range: min. 0.25 Hz / max. 1 kHz

(only in conjunction with Bürkert

flow-rate fitting Type S030)

Pt 100

(2-wire) Measuring range: 0 °C ... 200 °C

Measured current: 1 mA

Measuring error: < 0.5 °C

12

english

Page 13

Type 8611

Assembly

Binary input Input impedance: 10 kΩ

Response threshold: 3 ... 30 V

Max. frequency: 1 kHz

6.5.2. Outputs

Continuous signal Standard signal 4 - 20 mA

Max. loop resistance: 680 Ω

Precision: 0,5 %

Standard signal 0 - 10 V

Maximum current: 20 mA

Precision: 0,5 %

Discontinuous signal 2 transistor outputs for PWM or

PTM control

Control frequency: 1.2 kHz ... 20 Hz

Max. resolution: 16 bit (depending on

frequency)

Max. current per

unit area: 1.5 A

Switching voltage: 24 V DC

Binary output Transistor output (PNP) configurable

Max. current per

unit area: 1.5 A

Switching voltage: 24 V DC

Sensor supply: 24 V DC

Total load for all outputs: 1,5 A

7. ASSEMBLY

7.1. Assembly models

Attachment to a Bürkert

flow-rate fitting

Bürkert

flow-rate

fitting Type

SO30

Installation in a control cabinet

Attachment to a proportional

valve

The description of the installation in a control cabinet and the

device dimensions can be found

in the following chapter “7.3.

Assembly of the control cabinet

model”

english

13

Page 14

Type 8611

Assembly

Wall assembly or rail assembly

Adapter for wall assembly Adapter for rail assembly

Tab. 1: Assembly models

7.1.1. Assembly accessories

Model Accessories Order no.

Installation in pipeline Flow-rate fitting, Type

S030

Rail assembly Adapter for rail assembly 655980

Wall assembly

The adapters for the wall and rail assembly are included in the

scope of supply of the assembly model.

Tab. 2: Assembly accessories

Adapter for wall assembly

See data

sheet S030

427098

7.2. Attachment to a proportional

valve

Attach the process controller Type 8611 to a proportional valve as

described below.

→ Loosen the 4 screws at the front of the process controller.

NOTE!

Be careful when opening the process controller so as not to

damage the internal cabling.

• Remove the cover carefully from the housing without jerks.

→ Remove the cover carefully from the housing.

→ Place the supplied flat seal over the contact tabs.

→ Attach the housing of the process controller on the contact tabs

and fasten with the valve screw.

→ Check the correct position of the profile gasket at the housing of

the process controller.

→ Place cover on the housing of the process controller and fasten

with 4 screws.

If necessary, the cover can also be mounted in a position

rotated by 90 ° to the left or the right.

14

english

Page 15

Type 8611

Assembly

Proportional valve

7.3. Assembly of the control cabinet

model

Housing of the process controller

Cover of

the process

controller

Contact tabs

Profile gasket

Valve screw

4 screws for fastening the cover

Fig. 5: Attachment of the process controller to a proportional

valve

Flat seal

54.2

66

44.5

Control panel recess for

the installation

Fig. 6: Device dimensions and control panel recess

76

R 3

45

29

english

15

Page 16

Type 8611

Assembly

7.3.1. Installation in a control cabinet

• Prepare control panel recess with the dimensions 45mm x 45mm

(corner radius 3mm).

• Place the supplied seal on the housing.

• Insert the controller from the front into the control panel recess.

• From the rear, snap the 4 supplied fastening elements into place

and fasten using a screwdriver.

4 Fastening elements

Seal

Fig. 7: Installation elements Fig. 8: Installed controller

Recommended line cross sections for the control cabinet

model:

Cross

section

min.

Cross section for

flexible lines

Cross section for

flexible lines with

cable end sleeve

without plastic

sleeve

Cross section for

flexible lines with

cable end sleeve

with plastic sleeve

Tab. 3: Recommended line cross sections

0.2 mm² 1.5 mm² 10 mm

0.25 mm² 1.5 mm² 10 mm

0.25 mm² 0.75 mm² 10 mm

Cross

section

max.

Minimum

length

(stripping)

16

english

Page 17

Type 8611

Electrical Installation

8. ELECTRICAL INSTALLATION

8.1. Electrical installation for fitting

assembly, wall assembly, valve

assembly or rail assembly

models

8.1.1. Connection versions

Connector

Circular

plug-in

connector

M12,

8-pole

Circular

plug-in

connector

M8, 3-pole

Connector

view

5

6

7

1

8

Configuration

Power supply voltage,

set-point input 4 - 20 mA / 0 - 10 V,

process actual value or position setpoint output 4 - 20 mA / 0 - 10 V,

4

binary input,

3

binary output

2

Note!

A straight plug (female) is recommended for the connecting cable, as

the alignment of the plug can vary.

Connection sensor

4

(4 - 20 mA / 0 - 10 V, Pt 100 or

31

frequency)

and sensor supply 24 V DC

Connector

Circular

plug-in

connector

M8, 4-pole

Connector

view

2

1

Configuration

Connection actuating element

4

• Proportional valve (1 x PWM)

• Process valve (1 x PTM)

• Manipulated variable 4 - 20 mA /

3

0 - 10 V and sensor supply 24 V DC

(only ID 182383)

DIN-EN

175301

Tab. 4: Connection versions for assembly on flow-rate fitting, wall

assembly, rail assembly or valve assembly

Connection for direct assembly on

proportional valve (1 x PWM) or

open/closed valve (1 x PTM)

12

english

17

Page 18

5

4

Type 8611

Electrical Installation

8.1.2. Pin assignment

Circular plug-in connector M12, 8-pole

A straight connector (female) is recommended for the connecting cable as the orientation of the connector may vary.

Connector

diagram

6

7

1

8

Tab. 5: Configuration of circular plug-in connector M12, 8-pole

Pin Color Configuration

4

3

2

1

2 (DIN2)

3

white 24 V DC power supply

brown Binary input (B_IN)

green GND – Power supply,

binary input, binary output

4 (AOUT)

yellow 4 - 20 mA or 0 - 10 V analog

output

(process value or manipulated

variable for valve)

5 (AIN2)

grey 4 - 20 mA or 0 - 10 V analog

input (set-point value / ratio)

6

7

pink GND – Analog output

blue GND – Analog input

(set-point value / ratio)

8 (BO1)

red (+) Binary output (B_O1)

Wire colors when using standard cables (e.g. from

Lumberg, Escha)

8.1.3. Sensor connection

Circular plug-in connector M8, 3-pole

31

Input

signal

4 - 20 mA

2-wire

supply of

Type 8611

(AIN1)

4 - 20 mA

/ 0 - 10 V

3-wire

supply of

Type 8611

(AIN1)

Pin Color

1 brown

3 blue

4 black

1 brown

3 blue GND

4 black

Configuration

+ 24 V

sensor

supply

not

connected

Signal input

(source)

+ 24 V

sensor

supply

Signal input

(source)

External circuit

4

3

4

1

1

I

24 V DC

4 - 20 mA

24 V DC

GND

4 - 20 mA /

0 - 10 V

Transmitter

Transmitter

18

english

Page 19

Type 8611

Electrical Installation

Input

signal

4 - 20 mA

/ 0- 10 V

4-wire

external

supply

(AIN1)

Frequency

3-wire

supply of

Type 8611

(DIN1)

Frequency

4-wire

external

supply

(DIN1)

Pin Color

1 brown

3 blue GND

4 black

1 brown

3 blue GND

4 black

1 brown

3 blue GND

4 black

Configuration

not

connected

Signal input

(source)

+ 24 V

sensor

supply

Frequency

input (NPN)

not

connected

Frequency

input (NPN)

External circuit

Trans-

GND

3

4

4 - 20 mA /

1

3

4

GND

3

4

Clock (DIN1)

mitter

0 - 10 V

24 V DC

GND

Clock (DIN1)

Trans-

mitter

Transmitter

GND

Supply

GND

Supply

Input

signal

Pt 100

(2-wire)

(AIN3)

Tab. 6: Sensor connection: Configuration of circular plug-in

Pin Color

1 brown

3 blue

4 black

connector M8, 3-pole

Configuration

not

connected

GND Pt

100

(+) Pt 100

(power

supply)

External circuit

Pt 100

3

4

english

19

Page 20

2

4

Type 8611

Electrical Installation

8.1.4. Valves connection

Circular plug-in connector M8, 4-pole

1

Output

signal:

PWM

(MODE =

SCV)

3-point

(MODE =

PCV)

3

Pin Color Configuration External circuit

1 brown not connected

2 white not connected

3 blue

4

(BO4)

1

(BO3)

black

brown

2 white

3 blue

4

(BO4)

black

(–) PWM

(valve2)

(+) PWM

(valve2)

(+) Aeration

(valve 1)

(–) Aeration

(valve 1)

(–) Deaeration

(valve 2)

(+) Deaeration

(valve 2)

Output

signal:

1)

4 - 20 mA

or

0 - 10 V

(MODE =

4 – 20 /

Proportional

0 – 10)

valve

3

4

1

NC valve

2

3-point

(MODE =

3P – T)

NO valve

3

Pin Color Configuration External circuit

1

(BO3)

brown

2 white

3 blue GND supply

+ 24 V DC

supply

GND

(4 - 20 mA or

0 - 10 V)

1

Supply of

8611

2

3

+ 4 - 20 mA

4

(AOUT)

black

or

0 - 10 V

manipulated

4

variable

1

(BO3)

2

3

4

(BO4)

brown

(+) Valve 1

white (–) Valve 1

blue (–) Valve 2

black (+) Valve 2

NC / NO valve

1

2

NC / NO valve

3

4

M

4

20

english

Page 21

5

Type 8611

Electrical Installation

Output

signal:

Pin Color Configuration External circuit

+ 24 V DC

1)

4 - 20 mA

or

0 - 10 V

(MODE =

4 – 20 /

0 – 10)

External

supply

1 brown

2 white

3 blue GND supply

4

(AOUT)

black

supply (max.

1A)

GND (4 - 20

mA or 0 - 10

V)

+ 4 - 20 mA

or

0 - 10 V

manipulated

External

supply

2

4

M

+ 24 V

DC

GND

variable

NC / NO valve

1

2

2-point

1

(BO3)

brown (+) Valve 1

2 white (–) Valve 1

(MODE =

2P – T)

3 blue not connected

4 black not connected

1) Only available for identification number 182383

Tab. 7: Configuration of circular plug-in connector M8, 4-pole

Circular plug-in connector M12, 8-pole

8

4

3

2

Pin Color

Configuration

External circuit

6

7

1

Output

signal:

4 - 20 mA

2)

4 - 20 mA

or

0 - 10 V

(MODE =

4 – 20 /

0 – 10)

4

(AOUT)

yellow

6 pink

or

0 - 10 V

manipulated

variable

GND –

Analog

+ 24 V

4

DC

M

6

GND

(24 V)

output

2) Available for all models except for identification number

182383

Tab. 8: Configuration of circular plug-in connector M12, 8-pole

english

21

Page 22

Type 8611

Electrical Installation

8.2. Electrical installation of the

control cabinet model

WARNING!

Risk of injury from incorrect installation!

Incorrect installation can damage or destroy the Type 8611

eCONTROL.

• The electrical installation may be performed by authorized electricians only!

Terminal block 1

1 2 3 4 5 6 7 8

Terminal block 2

91011 12 13 14 15 16 17 18

Terminal block 3

2019 21 22 23

24 25

26 27

Jumper 1

Jumper 2

8.2.1. Terminal assignment

Terminal block 1

Terminal

1

2

3

(BO2)

4

(BO1)

Configuration

GND –

Electrical

power supply

24 V DC

power supply

Binary output

2 (B_O2)

Binary output

1 (B_O1)

External circuit

1

2

(1, 6, 8, 11, or 23

(1, 6, 8, 11, or 23

GND

24 V DC

24 V DC ±10 %

max. residual ripple 10 %

3

24 V / 0 V

(max. 1 A)

NC / NO

GND)

4

24 V / 0 V

(max. 1 A)

NC / NO

GND)

Fig. 9: Control cabinet model; connection PCB with spring ter-

minals and jumpers

22

english

Page 23

Type 8611

Electrical Installation

Terminal

5

(BO3)

6

7

(BO4)

8

Tab. 9: Configuration of terminal block 1

Configuration

(+) Aeration

valve (PCV)

or valve 1

(2P – T or

3P – T)

(–) Aeration

valve (PCV)

or valve 1

(2P – T or

3P – T)

(+)

Proportional

valve (SCV),

bleed valve

(PCV) or

valve 2

(3P – T)

(–)

Proportional

valve (SCV),

bleed valve

(PCV) or

valve 2

(3P – T)

External circuit

MODE = 2P – T

or 3P – T

5

6

NC / NO

valve max. 1 A

MODE = 3P – T

7

8

NC / NO

valve max. 1 A

MODE = PCV

7

8

NO

valvel max. 1 A

MODE = PCV

5

6

NC

valve max. 1 A

MODE = SCV

7

8

NC

valve max. 1,5 A

Terminal block 2

Terminal Configuration External circuit

9

10

(AOUT)

11

12

13 not used not used

14

(AIN2)

15

16 RS485_COM 16

17 RS485_A (+) 17

18 RS485_B (–) 18

Tab. 10: Configuration of terminal block 2

GND –

Analog output

(+) Analog output

(process value

or manipulated

variable for valve

GND – Sensor,

actuating element

24 V DC sensor

supply or actuating

element

(+) External default

of set-point value

/ ratio

4 - 20 mA / 0 - 10 V

(+) 5 V DC sensor

supply (max. 20 mA)

9

10

11

12

14

(21

15

(1, 11 or 23

GND

4 - 20 mA /

0 - 10 V

GND

24 V DC

4 - 20 mA /

0 - 10 V

(source)

A-GND)

5 V DC

GND)

RS485_COM

RS485_A

RS485_B

english

23

Page 24

Type 8611

Electrical Installation

Terminal block 3

Terminal Configuration External circuit

19

20

(AIN3)

21

22

(AIN1)

GND – Pt 100,

RTD

(+) Pt 100,

RTD (power

supply)

GND – Analog

input

(+) Process

value input

4 - 20 mA /

0 - 10 V

21

22

21

19

20

GND – Sensor,

23

actuating

23

element

24 V DC

24

sensor supply

or actuating

24

23

element

Pt 100

(0 ... 200 °C)

A-GND

4 - 20 mA / 0 - 10 V

(source)

A-GND

GND

24 V DC - Out (max. 1 A)

GND

Terminal Configuration External circuit

25

Supply

of Type

8611

(DIN3)

25

External

supply

(DIN3)

Frequency

input 2

(NPN or PNP)

Q

for ratio

2

control (MODE

= RATI)

Frequency

input 2

(NPN or PNP)

for ratio

Q

2

control

(MODE =

Jumper 2

12 or

NPN

11 or

PNP

Jumper 2

NPN

11 or

PNP

RATI)

26

(+) Binary input

26

(DIN2)

1, 11 or 23

24

23

25

23

25

Supply of 8611

24 V DC

GND

Trans-

mitter

Clock

External supply

Supply

GND

Trans-

mitter

Clock

0 ... 2,7 V

(log. 0)

3 ... 30 V

(log. 1)

GND

GND

max.

1 kHz

24

english

Page 25

Type 8611

Operation and Function

Terminal Configuration External circuit

27

Supply

of Type

8611

(DIN1)

27

External

supply

(DIN1)

Tab. 11: Configuration of terminal block 3

Frequency

input 1

(NPN or PNP)

Actual value

flow-rate /

Q

for ratio

1

control

(MODE =

RATI)

Frequency

input 1

(NPN or PNP)

Actual value

flow-rate /

for ratio

Q

1

control (MODE

= RATI)

Jumper 1

NPN

PNP

Jumper 1

NPN

PNP

12 or

24

11 or

23

27

11 or

23

27

Supply of 8611

24 V DC

GND

GND

Trans-

mitter

Clock

External supply

Suply

Trans-

mitter

Clock

GND

9. OPERATION AND FUNCTION

9.1. Control and display elements

The control and display element of the eCONTROL Type 8611 is

equipped with 3 buttons and an LCD-Matrix display.

9.1.1. Display elements

4-character display

7-character matrix for

numerical values

4-character display

14-character matrix for

measuring units and

parameter designations

10-segment bar graph

for display of the manipulated variable in % (One

Is displayed for

external set-point

value default

Is displayed when the

control is activated

Indicates the operating

state Manual

Segment indicates 10 %

of manipulated variable)

Red LED is lit in case of

an alarm

Fig. 10: Display elements

english

25

Page 26

Type 8611

Operation and Function

9.1.2. Control elements

Arrow keys

• Change the display at the process operating level in AUTOMATIC operating state

left right

ENTER button

The detailed description of the function can be found in chapter

“9.3. Funktion of the keys”.

• Change the menu options in MANUAL

operating mode and at the

configuration level

• Entering of numerical values

• Switches between the operating states

AUTOMATIC and MANUAL

• Switches between operating and configuration level

• Selection of menu option

• Take over settings

9.2. Operating levels and operating

states

2 operating levels and 2 operating states AUTOMATIC and MANUAL

are available for the operation and setting of the eCONTROL Type

8611.

Level 1: Process operating level

At level 1, the user can switch between 2 operating

states AUTOMATIC and MANUAL.

Operating state: AUTOMATIC: The normal control

mode is executed and monitored.

MANUAL: Quick access to important

functions and test functions.

The operating state

MANUAL is indicated on the

display by a hand symbol.

Level 2: Configuration level

At level 2, the user can change the basic settings of the

controller.

After switching on the operating voltage, the controller is at the

process operating level and in the AUTOMATIC operating state.

When the operating voltage is applied, the software version will light

up on the display for approx. 2 seconds.

If the ENTER key is pressed during these 2 seconds, the subversion is displayed. After this, the controller is once again at the

process operating level.

26

english

Page 27

Type 8611

Operation and Function

9.2.1. Switching between the operating

levels and operating states

The ENTER key is pressed to change the operating level and operating state (see Fig. 11).

Any changes made within the configuration level are only

stored after returning to the process operating level.

Changes in the Manual operating state can be made while

the controller is running.

Process operating level

Operating state

AUTOMATIK

eCONTROL

Press button

8611

> 5 s (long)

025.5

L/M

ENTER

O

u

0.....9

t

Fig. 11: Changing the operating level and operating state

< 1 s (short)

Operating

SET

PARA

VALV

TEST

BACK

state

HAND

Configuration

level

8611

eCONTROL

MODE

ENTER

O

u

0.....9

t

MODE

UNIT.

END

.

.

.

9.3. Funktion of the keys

The device is operated using two arrow keys and one ENTER key.

The function of these in respect of the operating level and the operating state is shown in the table below.

Operating

level

Level 1:

Process

operating

level

Operating

state

AUTOMATIC

MANUAL

Switch display

between actual

value, set-point value

and manipulated

variable

Switches

to the

last

menu

option

Switches

to the

next

menu

option

Entering of values

Change

Increase

value

by one

position

to the left

• Press key briefly

(< 1 s):

Switches to

operating state

MANUAL

• Press and hold

key (> 5 s):

Switches to

configuration

level

• Selection of

menu option

• Take over

settings

• Switches to

operating state

AUTOMATIC

(for display

BACK)

english

27

Page 28

Type 8611

Functions, Process Operating Level

Operating

level

Level 2:

Configuration level

Tab. 12: Function of the keys

Operating

state

Switches

to the

last

menu

option

Entering of values

Increase

value

Switches

to the

next

menu

option

Change

by one

position

to the left

• Selection of

menu option

• Take over

settings

• Switches to

process operating level and

to operating

state AUTOMATIC (for

display END)

10. FUNCTIONS, PROCESS

OPERATING LEVEL

10.1. Operating state AUTOMATIC

After switching on the operating voltage, the controller is at the process

operating level and in the AUTOMATIC operating state. The normal

control mode is executed and monitored.

10.1.1. Displays in the AUTOMATIC

operating state

Press the arrow keys to switch between 4 different displays for monitoring the control operation. Which of these displays should be shown

as start display after applying the operating voltage can be defined in the

DSPL menu (see Operating structure of the configuration level Fig. 26).

28

english

Page 29

Type 8611

Functions, Process Operating Level

8611

025.5

L/M

0.....9

eCONTR OL

O

u

t

025.5

L/M

ENTER

Display process actual value

The display of the unit depends on the selection made in the UNIT menu

(see Operating structure of the configuration level Fig. 16).

For MODE = T – F or T + F the display switches between temperature and flow-rate.

For MODE = RATI the display switches between flow-rate Q1 and Q2

030.0

SET

030.0

RFAC

Display set-point value

The display depends on the selection made in the MODE menu (see Operating structure of the

configuration level Fig. 15).

SET = Display for process control

RFAC = Display for ratio control

For MODE = T – F or T + F the display switches between flow-rate set-point (SP_Q) and

temperture set-point (SP_T).

For MODE = RATI the display switches between ratio factor (RFAC) and

flow-rate set-point (SPQ1).

025.5

030.0

065.0

PRZV

065.0

065.0

Display process actual value

Display set-point value

Display manipulated variable for valve

Display depends on the actuating element selected in the MODE menu (see Operating structure

of the configuration level Fig. 15).

mA

PRZV = Display pulse duty factor for solenoid valve

V

mA = Display manipulated variable in mA

V = Display manipulatec variable in V

Fig. 12: Displays in the AUTOMATIC operating state

english

29

Page 30

Type 8611

Functions, Process Operating Level

10.2. Operating state MANUAL

Briefly press (< 1 s) the ENTER key to go to the MANUAL operating

state.

The operating state is indicated on the display by a hand symbol.

10.3. Specific menu options of

process and ratio control

The display of some menu options differs for the process and the

ratio control. This is described in detail in the respective menu

descriptions.

The control type is specified by the control variable selected in the

MODE menu:

• Process control: is active if all control variables have

been selected in the MODE menu

except forRATI.

• Ratio control is active if the RATI control variable has

been selected in the MODE menu

10.4. Menu options in the MANUAL

operating state

SET

RFAC

BACK

TEST

PARA

VALV

Tab. 13: Menu options of the process operating level

Set-point value default for process control

• Menu option is displayed for process control.

• Is not available if external set-point value default is

selected.

Ratio factor default for ratio control

• Menu option is only displayed for ratio control

(MODE = RATI).

• Is not available if external set-point value default is

selected.

When BACK is displayed on the display, press the

ENTER key briefly to switch to AUTOMATIC operating state.

When an arrow key is pressed, the next or respectively the previous menu option is displayed.

Display of the analog inputs and outputs and

the digital inputs.

Adjusting the controller parameters (Code must

be entered if code protection is activated).

Manual opening and closing of the connected

valves.

30

english

Page 31

Type 8611

Functions, Process Operating Level

10.5. Operating structure of the process operating level in MANUAL operating

state

SET ***

RFAC ****)

BACK

TEST

PARA

< 1 s

Changes in the MANUAL operating state can be made while the controller is running.

)

Enter set-point value

Enter ratio factor

Back to AUTOMATIC operating state

AIN1

AIN2

AIN3

DIN1

DIN2

DIN3

AOUT

4-20 mA / 0-10 V process value

4-20 mA / 0-10 V set-point value

Pt 100 input

Frequency input 1

Binary input (0 V / 24 V)

Frequency input 2

4-20 mA / 0-10 V Output

BACK

Back to AUTOMATIC operating state

Fig. 13: Operating structure of the process operating level in MANUAL operating state – 1 of 2

***) The SET menu option is only

displayed for process control.

Consequently for all control

variables set in the MODE menu

except for RATI.

)

The RFAC menu option is only

****

displayed for ratio control.

Consequently only if the RATI

control variable is set in the

MODE menu.

english

31

Page 32

Type 8611

Functions, Process Operating Level

TEST

CODE **

PARA

**) Code query only when code protection is activated

)

KP1

)

KP2 *

)

TREG *

)

TN *

DEAD

)

KP T *

)

TN T *

)

DE T *

BACK

VALV *

)

150 L/H

Open

Close

055 PRZ *

)

SET (start of the menu sequence)

Back to AUTOMATIC operating state

Proportional coefficient K

Proportional coefficient K

P1

P2

Cycle time for controller [s]

Reset time [s]

Dead zone (absolutely to the process value)

Proportional coefficient K

[∆Q / ∆°K] (cascaded temperature control)

P1

Reset time in [s] for cascaded temperature control

Dead zone [°C] (cascaded temperature control)

*) The display depends on the control variable

set in the MODE menu (see Fig. 15)

Fig. 14: Operating structure of the process operating level in MANUAL operating state – 2 of 2

32

english

Page 33

Type 8611

Configuration Level

11. CONFIGURATION LEVEL

11.1. Operating structure of the configuration level

Configuration level

CODE

UNIT,

Enter access code if the code protection has been activated in the CODE menu.

MODE

CODE

„0001“

Selection of

control variable

RATI

F

P

Selection of sensor input

for Flow-rate uncontrolled

FREQ

NORM

Selection of

actuating element

SCV

PCV

T

T – F

T + F

L

X

2P – T

3P – T

4 – 20

0 – 10

Select control frequency (PWM)

Select control times

Select control times

Select control times

Selection of sensor

input

for process variable

controlled

FREQ *

PT *

NORM *

Fig. 15: Operating structure of the configuration level - 1 of 12

english

33

Page 34

MODE

UNIT *

Selection of the measuring unit for the display

Q1 **

Q2 **

)

)

*) The display depends on the control variable set in the MODE menu.

)

**

L/H

L / M

G / H

G / M

MODE = F

ML / M

MODE = RATI

M3 / H

= T

°C

°F

NU

MODE = T+F, T-F

MODE

BAR

MBAR

= P

MODE

PSI

Type 8611

Configuration Level

Q1 and Q2 are only displayed if ratio control = RATI has been set in the MODE

menu. See Fig. 15

Selecting the decimal places

1

0.1

0.01

NU = Display without measuring unit

UNIT, MODE = L, MODE = X

Fig. 16: Operating structure of the configuration level - 2 of 12

34

english

Page 35

MODE

UNIT *

Type 8611

Configuration Level

Selection of the measuring unit for the display

*) The display depends on the control variable set in the MODE menu.

MM

CM

M

MODE = L

Ft

In

NU

PH

µS/c

mS/c

MODE = T

S/c

Ωxc

ppm

See Fig. 15

Selecting the

decimal places

1

0.1

0.01

NU = Display without measuring unit

SETP / RFAC

Fig. 17: Operating structure of the configuration level - 3 of 12

english

35

Page 36

UNIT

Selection of set-point value default and scaling of external default

SETP **

RFAC ***

)

)

Selection and scaling of sensor input

S_IN ****

)

Selection and scaling of analog output

AOUT 4 – 20

EXT

INT

4 – 20

0 – 10

0 – 10

4 – 20

0 – 10

Enter scaling

FLOW *

TEMP *

PRES *

)

LEVL*

)

VAL *

)

POS *

)

Q1 *

)

Q2*

RFAC *

Type 8611

Configuration Level

**) The SETP menu option is only displayed for

Enter scaling

process control. Consequently for all control variables set in the MODE menu except for RATI.

)

The RFAC menu option is only displayed for ratio

***

control. Consequently only if the RATI control variable

is set in the MODE menu.

)

The S_IN menu option is only displayed if standard

****

signal (NORM) was selected as sensor input.

*) The display depends on the control variable set in

the MODE menu.

)

Output of flow-rate as standard signal (only for control variable MODE = F, T + F, T - F)

)

Output of temperature as standard signal (only for control variable MODE = T, T + F, T - F)

)

Output of pressure as standard signal (only for control variable MODE = P)

Output of filling level (only for control variable MODE = L)

Output of process value (only for control variable MODE = X or T and UNIT = NU)

Output of actuating element position (only for actuating element type MODE = SCV)

Output of flow-rate Q1 for ratio control (control variable MODE = RATI)

Output of flow-rate Q2 for ratio control (control variable MODE = RATI)

)

Output of ratio factor RFAC for ratio control (control variable MODE = RATI)

Enter scaling

CALI

Fig. 18: Operating structure of the configuration level - 4 of 12

36

english

Page 37

Type 8611

Configuration Level

KFAC *

FILT

CALI

Calibration of the analog inputs and outputs

The detailed description of the CALI function can be found in the Operating Instruction of Type 8611 eCONTROL

The operating instructions can be found on the enclosed CD and on the Internet at:

www.burkert.com

Selection of K-factor for ratio control

)

Q1 **

Q2 **

)

)

FREE

BACK

Selection of Bürkert flow-rate sensor

Documentation

)

The KFAC menu option is not indicated unless a sensor with frequency input was selected in the

*

Type

MODE menu.

**) Q1 and Q2 are only displayed if frequency input (FREQ) was selected for both flow-rate sensors in

ratio control.

0.01

0.1

Enter value

The display 0.01, 0.1, 1 is used for setting the

decimal place.

Use the display 10 for setting the multiplier 10 for the

1

K-factor.

10

Fig. 19: Operating structure of the configuration level - 5 of 12

english

37

Page 38

Type 8611

Configuration Level

KFAC *

FILT

)

BACK

*) The KFAC menu option is not

indicated unless a sensor with

Selection of Bürkert flow-rate sensor

8081

QN0.6

. . . . . .

Display value

frequency input was selected in the

MODE menu.

QN6.0

8071

50L

Display value

100L

500L

S070

DN15

Display value

DN100

8031

100L

Display value

250L

S030

8030

8012

8011

VA

PVDF

PP

PVC

MS

DN06

. .

DN15

. .

DN50

Display value

V2

OLD

1)

1)

Fitting S030 and the fitting of devices

8030, 8011 and 8012, DN15, exist in

2 versions. The „v2“ marking can be

found either on the bottom or on the

side of the fitting.

Fig. 20: Operating structure of the configuration level - 6 of 12

38

english

Page 39

Type 8611

Configuration Level

FILT

Selection of

controller parameters

PARA

B_IN

Enter filter factor ( 2 - 20)

*) The display depends on the control variable set in the MODE menu (see Fig. 15)

KP1

KP2 *

TREG *

TN *

DEAD

KP_T *

TN_T *

DE_T *

)

)

KP1, Pproportional coefficient 1

KP2, proportional coefficient 2

)

Cycle time for controller [s] (display only for MODE = PVC, 3P – T, 2P – T,)

Reset time [s] (display only for MODE = SCV, 0 – 10, 4 – 20, 2P – T, 3P – T,)

Dead zone absolute. Unit and display of decimal place analogous to UNIT.

)

Proportional coefficient for cascaded temperature control (display only for MODE = T + F)

)

Reset time in [s] for cascaded temperature control (display only for MODE = T + F)

)

Dead zone absolute for cascaded temperature control (display only for MODE = T + F).

Effective direction

INV

NO

YES

Not inverted or direct control

Inverted control

Zero point shut-off (if default < 2 % of the set-point value range). Display only for INV = NO

ZERO

STRT *

NO

YES

)

Definition of start value for manipulated variable

Zero point shut-off is deactivated

Zero point shut-off is activated

(display only for MODE = SCV, 0 – 10, 4 – 20, 1P – T, 3P – T)

BACK

Fig. 21: Operating structure of the configuration level - 7 of 12

english

39

Page 40

B_IN

B_O1

B_O2

Selection of binary input

NO

Inverting of the effective direction defined in the PARA menu.

INV

Manipulated variable remains in current position

HOLD

Setting of a safety position that is approached when binary input is active

SAFP

Valve movement is stopped (e.g. if the valve has reached the limit stop)

STOP **

)

Valve is being opened = OPEN, Valve is being closed = CLOS

OPEN **

CLOS **

)

)

HIGH

LOW

HIGH

LOW

HIGH

LOW

HIGH

LOW

HIGH

LOW

PRZV **

mA **

)

V **

OPEN **

CLOS **

OPEN

CLOS

Type 8611

Configuration Level

)

)

Enter value

**) The display depends on the actuating element set in the

MODE menu (see Fig. 15)

)

)

Fig. 22: Operating structure of the configuration level - 8 of 12

40

english

Page 41

Type 8611

Configuration Level

B _O1

B_O1 /

2_P

NO

Selecting binary output as pulse output

PULS

DM3 1

IGAL 0.1

UGAL 0.01

M3

Selecting binary output as limit switch

LIMT

REL

ABS

POS

Time lag

DLY XXX.X

Enter hysteresis relatively to the set-point value

FLOW *

PRES *

TEMP *

LEVL *

VAL *

Enter valve postion

Effective direction LED indication?Output signal.

INV NO LED NO

INV YES LED YES

Enter number of pulses [PU]

(HYHI, HYLO)

)

)

)

)

)

Enter process value limit

(absolute)

*) The display depends on the control variable set in the

MODE menu (see Fig. 15)

(PVHI, PVLO)

(POSL, POSH)

Error message

indication?

HIGH TEXT NO

LOW TEXT YES

Fig. 23: Operating structure of the configuration level - 9 of 12

english

41

Page 42

Type 8611

Configuration Level

B _O1

B _O2 **

VALV

NO

Selecting binary output as 2-state controller

2_P REL

SP

ABS

Enter hysteresis relatively to the set-point value

Enter limits for set-point value default

FLOW *

PRES *

TEMP *

LEVL *

VAL *

Time lag Effective direction Output signal.

DLY XXX.X

)

**) The operating structure is identical to B_O1

(HYHI, HYLO)

(SPLO, SPHI)

)

)

)

)

)

Enter process value limit

(absolute)

*) The display depends on the control variable set in the

MODE menu (see Fig. 15)

INV NO

INV YES

(PVHI, PVLO)

HIGH

LOW

Fig. 24: Operating structure of the configuration level - 10 of 12

42

english

Page 43

Configuration Level

Setting of the control range

VALV

MODE = SCV, 4 – 20, 0 – 10, 2P – T, 3P – T

Open **)

Close

MODE = PCV, 2P – T, 3P – T

Open **)

Close

Enter code protection

CODE

The following operator actions are blocked if code protection is activated:

• Changing the controller parameters in manual mode under the PARA menu

• Access to the configuration level

Type 8611

L / H *

)

PRZ *

L / H *

)

)

END

MIN

MAX

END

MIN

MAX

Back without store

Store as MIN value

Store as MAX value

Back without store

Enter MIN

Enter MAX

*) The display depends

on the control variable

set in the MODE

menu (see Fig. 15)

)

Press the up arrow

**

key to open the

actuating element,

and the down arrow

key to close the

actuating element.

Factory setting:

Upon delivery from the factory, the display in the CODE menu is set to 0000. This means that the code protection is not activated. Switching to the configuration level is done without query of the code.

DSPL

Fig. 25: Operating structure of the configuration level - 11 of 12

english

43

Page 44

Setting the

display

DSPL

YES

Reset to the factory settings

FACT

CODE NO

"0003"

NO

Type 8611

Configuration Level

Activation of the background lighting:

The background lighting remains switched on continuously

The background lighting switches on when the button is pressed and switches off automatically after 60

seconds

Define what value or what manipulated variable should be displayed after switching on the voltage

CMD

BOTH

PVAL

SETP

Display manipulated variable

Display set-point value and process actual value

Display process actual value

Display set-point value

YES

U_xx

B_xx

END

Display program version

Display software version

Switching to the process operating level – AUTOMATIC operating state

Fig. 26: Operating structure of the configuration level - 12 of 12

44

english

Page 45

Type 8611

Overview Setting parameters

12. OVERVIEW SETTING PARAMETERS

Continuous control Quasi-continuous control Discontinuous control

Actuating element Proportional

valve

Program MODE

Control frequency

Operating principle [-] [-] [-] [-] NC/NO NC/NO NC/NO NC/NO

(MODE)

Minimum control

time

Valve parameter

Control structure PI oder P (TN = 9999) P PI oder P (TN = 9999) P (KP1 = 9999)

Proportional gain KP1

Reset time TN [s] TN [s] TN [s] [-] TN [s] TN [s] [-] [-]

Cycle time [-] [-] [-] TREG [s] TREG [s] TREG [s] [-] [-]

Dead zone DEAD

Control direction

Zero point shut-off

Control parameter (PARA)

Startposition of

control

Tab. 14: Overview setting parameters

SCV 0-10 4-20 PCV 2P – T 3P – T 2P – T 3P – T

PWM

[-] [-] [-] TMN1/TMN2

[%/PV]

[∆ PV]

INV

(Yes/No)

ZERO

(Yes/No)

STRT

[0-100]

Linear actuating

element

[-] [-] [-] [-] [-] [-] [-]

KP1

[%/PV]

DEAD

[∆ PV]

INV

(Yes/No)

ZERO

(Yes/No)

STRT

[0-10]

DEAD

[∆ PV]

INV

(Yes/No)

ZERO

(Yes/No)

STRT

[4-20]

Process

valve

[ms]

KP1

[%/PV]

DEAD

[∆ PV]

INV

(Yes/No)

ZERO

(Yes/No)

[-] STRT

Open/closed

valve

TMN1

[ms]

KP1

[%/PV]

DEAD

[∆ PV]

INV

(Yes/No)

ZERO

(Yes/No)

[0-100]

Open/closed

rotary actuator

TMN1/TMN2

[ms]

KP1

[%/PV]

DEAD

[∆ PV]

INV

(Yes/No)

ZERO

(Yes/No)

STRT

[0-100]

Open/closed

valve

TMN1

[ms]

KP1

(=9999)

DEAD

[∆ PV]

INV

(Yes/No)

ZERO

(Yes/No)

[-] [-]

Open/closed

valve

TMN1/TMN2

[ms]

KP1 / KP2

(=9999)

DEAD

[∆ PV]

INV

(Yes/No)

ZERO

(Yes/No)

english

45

Page 46

Additional control parameters for setting a cascaded control loop (MODE = T + F)

Continuous control Quasi-continuous control Discontinuous control

Control structure PI oder

P (TN = 9999)

P PI oder

Type 8611

Overview Setting parameters

P (TN = 9999)

P

(KP1 = 9999)

Proportional gain KP_T

[%/°K]

Reset time TN_T

(PARA)

Dead zone DEAD

Reglerparameter

Tab. 15: Overview: additional control parameters for setting a cascaded control loop

46

[s]

[∆ °K]

english

KP_T

[%/°K]

TN_T

[s]

DEAD

[∆ °K]

KP_T

[%/°K]

TN_T

[s]

DEAD

[∆ °K]

KP_T

[%/°K]

TN_T

[s]

DEAD

[∆ °K]

KP_T

[%/°K]

TN_T

[s]

DEAD

[∆ °K]

KP_T

[%/°K]

TN_T

[s]

DEAD

[∆ °K]

KP_T

[%/°K]

TN_T

[s]

DEAD

[∆ °K]

KP_T

[%/°K]

TN_T

[s]

DEAD

[∆ °K]

Page 47

Type 8611

Packaging and Transport

13. PACKAGING AND TRANSPORT

NOTE!

Transport damages!

Inadequately protected equipment may be damaged during

transport.

• During transportation protect the device against moisture and

dirt in shock-resistant packaging.

• Do not allow the temperature to exceed or drop below the permitted storage temperature.

14. STORAGE

NOTE!

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature: 0 – +70 °C.

15. DISPOSAL

→

Dispose of the device and packaging in an environmentally friendly

manner.

NOTE!

Damage to the environment caused by device components

contaminated with media.

• Observe applicable disposal regulations and environmental

regulations.

Observe national waste disposal regulations.

english

47

Page 48

Type 8611

Packaging and Transport

48

english

Page 49

Inhalt:

Typ 8611

eCONTROL 8611: Prozessregler und Verhältnisregler

1. DER QUICKSTART ....................................................................................... 51

1.1. Darstellungsmittel ..............................................................................51

2. BESTIMMUNGSGEMÄSSE VERWENDUNG ...................................52

2.1. Beschränkungen .................................................................................52

2.2. Vorhersehbarer Fehlgebrauch .....................................................52

3. GRUNDLEGENDESICHERHEITSHINWEISE .................................. 53

4. ALLGEMEINE HINWEISE .......................................................................... 54

4.1. Kontaktadressen .................................................................................54

5. SYSTEMBESCHREIBUNG ....................................................................... 54

5.1. Allgemeine Beschreibung .............................................................. 54

5.2. Schnittstellen des Prozessreglers Typ 8611 ...................... 54

5.3. Funktionen .............................................................................................. 55

5.4. Die verschiedenen An- und Einbauvarianten ......................55

5.5. Software ...................................................................................................56

6. TECHNISCHE DATEN ................................................................................ 56

6.1. Betriebsbedingungen .......................................................................56

6.2. Konformität mit folgenden Normen ..........................................56

6.3. Allgemeine Technische Daten .....................................................56

6.4. Typschildbeschreibung .................................................................... 57

6.5. Elektrische Daten ................................................................................58

7. MONTAGE ........................................................................................................59

7.1. Montagevarianten ...............................................................................59

7.2. Anbau an ein Proportionalventil .................................................. 60

7.3. Montage der Schaltschrankvariante ......................................... 61

8. ELEKTRISCHE INSTALLATION ..............................................................63

8.1. Elektrische Installation für Montagevarianten

Fittingmontage, Wandmontage, Ventilmontage

oder Hutschienenmontage ............................................................63

8.2. Elektrische Installation der Schaltschrankvariante ..........68

9. BEDIENUNG UND FUNKTION .............................................................. 71

9.1. Bedien- und Anzeigeelemente ....................................................71

9.2. Bedienebenen und Betriebszustände .....................................72

9.3. Funktion der Tasten ...........................................................................73

deutsch

49

Page 50

10. FUNKTIONEN DER PROZESSBEDIENEBENE ........................... 74

10.1. Betriebszustand AUTOMATIK .................................................... 74

10.2. Betriebszustand HAND .................................................................76

10.3. Spezifische Menüpunkte der Prozess- und

Verhältnisregelung ........................................................................... 76

10.4. Menüpunkte im Betriebszustand HAND ..............................76

10.5. Bedienstruktur der Prozessbedienebene im

Betriebszustand HAND .................................................................77

11. KONFIGURATIONSEBENE ...................................................................79

11.1. Bedienstruktur der Konfigurationsebene ............................ 79

12. ÜBERSICHT EINSTELLPARAMETER ............................................... 91

13. VERPACKUNG, TRANSPORT .............................................................. 93

14. LAGERUNG ...................................................................................................93

15. ENTSORGUNG ............................................................................................93

Typ 8611

50

deutsch

Page 51

Typ 8611

Der Quickstart

1. DER QUICKSTART

Der Quickstart beschreibt den gesamten Lebenszyklus des Gerätes.

Bewahren Sie diese Anleitung so auf, dass sie für jeden Benutzer gut

zugänglich ist und jedem neuen Eigentümer des Gerätes wieder zur

Verfügung steht.

Wichtige Informationen zur Sicherheit!

Lesen Sie den Quickstart sorgfältig durch. Beachten Sie vor

allem die Kapitel Grundlegende Sicherheitshinweise und Bestim-

mungsgemäße Verwendung.

• Der Quickstart muss gelesen und verstanden werden.

Der Quickstart erläutert beispielhaft die Montage und Inbetriebnahme des Gerätes.

Die ausführliche Beschreibung des Gerätes finden Sie in der Bedienungsanleitung für den Typ 8611 eCONTROL.

Die Bedienungsanleitung finden Sie auf der beigelegten CD

oder im Internet unter:

www.buerkert.de

1.1. Darstellungsmittel

In dieser Anleitung werden folgende Darstellungsmittel verwendet.

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen die

Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung können schwere Verletzungen oder Tod die

Folge sein.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen

zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

Wichtige Tipps und Empfehlungen.

verweist auf Informationen in dieser Anleitung oder in

anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den Sie ausführen müssen.

deutsch

51

Page 52

Typ 8611

Bestimmungsgemäße Verwendung

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz des Prozessreglers

Typ 8611 können Gefahren für Personen, Anlagen in der

Umgebung und die Umwelt entstehen.

• Der Prozessregler ist dafür bestimmt, in Verbindung mit einem

Proportional- oder Prozessventil und einem Sensor die Prozessgröße für Druck, Temperatur oder Durchfluss zu regeln.

• Das Gerät nicht im Außenbereich einsetzen.

• Für den Einsatz die in den Vertragsdokumenten und der Bedienungsanleitung spezifizierten zulässigen Daten, Betriebs- und

Einsatzbedingungen beachten. Diese sind im Kapitel“ Technische Daten“ beschrieben.

• Das Gerät nur in Verbindung mit von Bürkert empfohlenen bzw.

zugelassenen Fremdgeräten und -komponenten einsetzen.

• Voraussetzungen für den sicheren und einwandfreien Betrieb

sind sachgemäßer Transport, sachgemäße Lagerung und Installation sowie sorgfältige Bedienung und Instandhaltung.

• Setzen Sie das Gerät nur bestimmungsgemäß ein.

2.1. Beschränkungen

Beachten Sie bei der Ausfuhr des Systems/Gerätes gegebenenfalls

bestehende Beschränkungen.

2.2. Vorhersehbarer Fehlgebrauch

• Den Typ 8611 dürfen Sie nicht in explosionsgefährdeten Bereichen

einsetzen.

• Belasten Sie das Gehäuse nicht mechanisch (z. B. durch Ablage

von Gegenständen oder als Trittstufe).

52

deutsch

Page 53

Typ 8611

Grundlegende Sicherheitshinweise

3. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und Wartung

der Geräte auftreten können.

• ortsbezogenen Sicherheitsbestimmungen, für deren Einhaltung, auch

in Bezug auf das Montagepersonal, der Betreiber verantwortlich

ist.

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• Installationsarbeiten dürfen nur von autorisiertem Fachpersonal

mit geeignetem Werkzeug ausgeführt werden.

• Nach einer Unterbrechung der elektrischen oder pneumatischen

Versorgung ist ein definierter oder kontrollierter Wiederanlauf

des Prozesses zu gewährleisten.

• Das Gerät darf nur in einwandfreiem Zustand und unter Beachtung der Bedienungsanleitung betrieben werden.

• Für die Einsatzplanung und den Betrieb des Gerätes müssen

die allgemeinen Regeln der Technik eingehalten werden.

HINWEIS!

Elektrostatisch gefährdete Bauelemente / Baugruppen!

Das Gerät enthält elektronische Bauelemente, die gegen elektrostatische Entladung (ESD) empfindlich reagieren. Berührung

mit elektrostatisch aufgeladenen Personen oder Gegenständen

gefährdet diese Bauelemente. Im schlimmsten Fall werden sie

sofort zerstört oder fallen nach der Inbetriebnahme aus.

• Beachten Sie die Anforderungen nach EN 61340-5-1 und 5-2,

um die Möglichkeit eines Schadens durch schlagartige elektrostatische Entladung zu minimieren bzw. zu vermeiden!

• Achten Sie ebenso darauf, dass Sie elektronische Bauelemente

nicht bei anliegender Versorgungsspannung berühren!

Die Prozessregler Typ 8611 wurde unter Einbeziehung der

anerkannten sicherheitstechnischen Regeln entwickelt und

entspricht dem Stand der Technik. Trotzdem können Gefahren

entstehen.

Bei Nichtbeachtung dieser Bedienungsanleitung und ihrer Hinweise

sowie bei unzulässigen Eingriffen in das Gerät entfällt jegliche Haftung unsererseits, ebenso erlischt die Gewährleistung auf Geräte

und Zubehörteile!

deutsch

53

Page 54

Typ 8611

Allgemeine Hinweise

4. ALLGEMEINE HINWEISE

4.1. Kontaktadressen

Deutschland

Bürkert Fluid Control Systems

Sales Center

Christian-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der

gedruckten Bedienungsanleitung.

Außerdem im Internet unter:

www.burkert.com

5. SYSTEMBESCHREIBUNG

5.1. Allgemeine Beschreibung

Der Prozessregler Typ 8611 ist für die Einbindung in einen geschlossenen Regelkreis vorgesehen und kann für vielfältige Regelaufgaben

in der Fluidtechnik verwendet werden. Das nachfolgende Bild zeigt die

Integration des Reglers in einen geschlossenen Regelkreis.

Führungsgröße w

(Sollwert)

Bild 1: Blockschaltbild eines geschlossenen Regelkreises

Regler

8611

+

_

X

Stellgröße y

Rückführung Prozess-Istwert

5.2. Schnittstellen des

Prozessreglers Typ 8611

Je nach Regelstrecke und Prozess stehen verschiedene Reglerstrukturen und verschiedene Ein-/Ausgänge für die Messung des

Regelstecke

Stell-

Sensor Prozess

glied

Regelgröße

54

deutsch

Page 55

Typ 8611

Systembeschreibung

Prozess-Istwertes und für die Ansteuerung der Stellglieder zur Verfügung. Die nachfolgende Übersicht zeigt die verfügbaren Schnittstellen des Prozessreglers.