Page 1

Operating Instructions

Type 8605

Digital Control Electronics for Proportional Valves

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert Werke GmbH & Co. KG, 2007 - 2018

Operating Instructions 1804/05_EN-EN_00805613 / Original DE

Page 3

english

Type 8605

Digital Control Electronics Type 8605

Contents

1. OPERATING INSTRUCTIONS ........................................................................................................................................................5

1.1. Symbols

Definition of Term “Device” ...............................................................................................................................................5

1.2.

INTENDED USE ....................................................................................................................................................................................6

2.

BASIC SAFETY INSTRUCTIONS .................................................................................................................................................7

3.

GENERAL INFORMATION ................................................................................................................................................................8

4.

Contact address .....................................................................................................................................................................8

4.1.

4.2. Warranty

Information on the Internet ...............................................................................................................................................8

4.3.

PRODUCT DESCRIPTION ...............................................................................................................................................................9

5.

Field of Application ...............................................................................................................................................................9

5.1.

General Description ..............................................................................................................................................................9

5.2.

Form of the Device ................................................................................................................................................................9

5.3.

5.3.1. Type 8605 Cable plug version ............................................................................................................... 9

......................................................................................................................................................................................5

......................................................................................................................................................................................8

5.3.2. Type 8605 DIN rail version ....................................................................................................................10

TECHNICAL DATA .............................................................................................................................................................................11

6.

Operating Conditions ........................................................................................................................................................11

6.1.

CONFIGURATION AND FUNCTION ........................................................................................................................................12

7.

Operating and Display Elements ................................................................................................................................ 12

7.1.

7.1.1. Operating unit ..........................................................................................................................................12

7.1.2. LED’s during operation without operating unit .................................................................................13

Basic function .......................................................................................................................................................................13

7.2.

Adjustment to the Valve and Application Data ...................................................................................................14

7.3.

8. INSTALLATION

Safety instructions .............................................................................................................................................................16

8.1.

Electrical connections ......................................................................................................................................................16

8.2.

...................................................................................................................................................................................16

3

Page 4

english

Type 8605

8.2.1. Cable plug version ..................................................................................................................................16

8.2.2. DIN rail version .........................................................................................................................................18

9. CONFIGURATION

Operating modes ................................................................................................................................................................20

9.1.

Basic settings .......................................................................................................................................................................20

9.2.

Menu of the configuration mode ................................................................................................................................21

9.3.

9.3.1. InP (Input) - Selection of the input signal ..........................................................................................22

9.3.2. Out (Output) - Valve settings ............................................................................................................... 22

9.3.3. VAdJ (Valve adjust) - Fine tuning of the valve frequency ...............................................................25

9.3.4. AdJ (Adjust) - Adaptation of the coil current .................................................................................... 26

9.3.5. dELY (Delay) - Ramp function ..............................................................................................................27

9.3.6. Cut (Cut off) - Zero point cut off .........................................................................................................28

9.3.7. PArA (Parameter) - Controller setting ................................................................................................ 29

9.3.8. Addr (Address) - Interfaces ..................................................................................................................29

9.3.9. SPOS (Safe position) - Setting of the safety position ...................................................................30

9.3.10. dAtA (Data) - Upload and Download of parameters between the operating unit and the

basic device ..............................................................................................................................................30

9.3.11. END

.............................................................................................................................................................................20

............................................................................................................................................................................31

Factory Settings of the Control Electronics .........................................................................................................31

9.4.

10. MAINTENANCE

Safety Instructions .............................................................................................................................................................32

10.1.

10.2. Service

SPARE PARTS ....................................................................................................................................................................................33

11.

Ordering charts: Device variants ................................................................................................................................33

11.1.

11.2. Accessories

PACKAGING, TRANSPORT ..........................................................................................................................................................35

12.

13. STORAGE

13.1. Decommissioning

13.2. Restarting

14. DISPOSAL

..................................................................................................................................................................................32

......................................................................................................................................................................................32

............................................................................................................................................................................34

..............................................................................................................................................................................................35

...............................................................................................................................................................35

................................................................................................................................................................................35

............................................................................................................................................................................................36

4

Page 5

english

Type 8605

Operating Instructions

1. OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device. Keep these instructions in a location which is

easily accessible to every user and make these instructions available to every new owner of the device.

WARNING!

The operating instructions contain important safety information!

Failure to observe these instructions may result in hazardous situations.

• The operating instructions must be read and understood.

1.1. Symbols

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger!

• Failure to observe the warning may result in moderately serious or minor injuries.

NOTE!

Warns of damage to property!

• Failure to observe the warning may result in damage to the device or the equipment.

Designates additional significant information, tips and recommendations.

Refers to information in these operating instructions or in other documentation.

→ designates a procedure which you must carry out.

1.2. Definition of Term “Device”

The term “device” used in these instructions always stands for the electromagnetic positioner type 8604.

5

Page 6

english

Type 8605

Intended Use

2. INTENDED USE

Non-intended use of the Type 8605 may be a hazard to people, nearby equipment and the environment.

• The device is designed for controlling Bürkert proportional valves.

• The device must not be exposed to direct sunlight.

• Do not use the device outdoors.

• To ensure that the device functions perfectly, set the PWM frequency which is suitable for the valve. A table

of set values can be found on the Bürkert homepage www.burkert.com → Type 8605.

• Use according to the authorized data, operating conditions and conditions of use specified in the contract

documents and operating instructions. These are described in the chapter entitled “6. Technical Data”.

• The device may be used only in conjunction with third-party devices and components recommended and

authorized by Bürkert.

• Correct transportation, correct storage and installation and careful use and maintenance are essential for reliable and faultless operation.

• Use the device only as intended.

6

Page 7

english

Type 8605

Basic Safety Instructions

3. BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any:

• Contingencies and events which may arise during the installation, operation and maintenance of the devices.

• Local safety regulations – the operator is responsible for observing these regulations, also with reference to the

installation personnel.

Danger – high pressure!

• Before loosening the lines and valves, turn off the pressure and vent the lines.

Risk of electric shock!

• Before reaching into the device or the equipment, switch off the power supply and secure to prevent

reactivation!

• Observe applicable accident prevention and safety regulations for electrical equipment!

There is a risk of injury when the pressure drops in the system!

• Avoid pressure drops!

• Design the pressure supply system with as large a volume as possible, even with upline devices such as e. g.

pressure regulators, air conditioners, shut-off valves.

General hazardous situations.

To prevent injury, ensure that:

• That the system cannot be activated unintentionally.

• Installation and repair work may be carried out by authorised technicians only and with the appropriate tools.

• After an interruption in the power supply or pneumatic supply, ensure that the process is restarted in a defined

or controlled manner.

• The device may be operated only when in perfect condition and in consideration of the operating instructions.

• The general rules of technology apply to application planning and operation of the device.

NOTE!

Electrostatic sensitive components / modules!

The device contains electronic components which react sensitively to electrostatic discharge (ESD). Contact with

electrostatically charged persons or objects is hazardous to these components. In the worst case scenario, they

will be destroyed immediately or will fail after start-up.

• Observe the requirements in accordance with EN 61340-5-1 and 5-2 to minimise or avoid the possibility of

damage caused by sudden electrostatic discharge!

• Do not touch live electronic components!

The Type 8605 was developed with due consideration given to the accepted safety rules and are state-ofthe-art. Nevertheless, dangerous situations may occur.

Failure to observe this operating manual and its operating instructions as well as unauthorized tampering

with the device release us from any liability and also invalidate the warranty covering the devices and

accessories!

7

Page 8

english

Type 8605

General Information

4. GENERAL INFORMATION

4.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the printed operating instructions.

And also on the Internet at:

www.burkert.com

4.2. Warranty

The warranty is only valid if the device is used as authorized in accordance with the specified application conditions.

4.3. Information on the Internet

Operating instructions and data sheet for Type 8605 can be found on the Internet at:

www.burkert.com

8

Page 9

english

Type 8605

Product description

5. PRODUCT DESCRIPTION

5.1. Field of Application

The Control Electronics, Type 8605, is designed for continuous operation in industrial environments, in particular in

the fields of open-loop and closed-loop control engineering.

5.2. General Description

The Digital Control Electronics for Proportional Valves, Type 8605 (hereinafter referred to as Control Electronics,

Type 8605) controls all Bürkert proportional valves with a max. current in the range from 40 to 2000 mA.

It transforms an external standard signal into a pulse-width modulated voltage signal (PWM) that is supplied to the

solenoid coil of the proportional valve.

A given value of the average coil current is thereby assigned to each value of the input signal. The proportional

opening of the valve can be set via the coil current.

5.3. Form of the Device

The Control Electronics is available in two forms.

5.3.1. Type 8605 Cable plug version

Figure 1: Type 8605 Cable plug version

9

Page 10

english

Type 8605

Product description

Plug-in version on valves with connector pattern A:

e. g. types 2832, 2833, 2834, 2835, 2836,

2853,

2863, 2865,

2873, 2875

6022, 6023, 6024,

6223.

The operating unit can be removed after the setting process. During operation of the Control Electronics 8605 in

cable plug version without operating unit, the operating status is indicated by two LED’s.

Device variants:

• Variant 1 for valves with a max. current from 200 to 1000 mA

• Variant 2 for valves with a max. current from 500 to 2000 mA

5.3.2. Type 8605 DIN rail version

10

Figure 2: Type 8605 DIN rail version

Separate electronics in housing for DIN rail mounting to DIN EN 50022. This form is suitable for all proportional

valves in the indicated current range. The operating unit cannot be removed.

Device variants:

• Variant 1 for valves with a max. current from 40 to 220 mA

• Variant 2 for valves with a max. current from 200 to 1000 mA

• Variant 3 for valves with a max. current from 500 to 2000 mA

Page 11

english

Type 8605

Technical Data

6. TECHNICAL DATA

6.1. Operating Conditions

WARNING!

The Type 8605 is not designed for use outdoors!

• Do not use the Type 8605 outdoors and avoid heat sources which may result in the permitted temperature

range to be exceeded.

Power supply 12...24V DC ± 10%

Residual ripple 5 %

Power consumption ca. 1 W

Output current (on the valve) max. 2 A

Operating temperature -10 ... 60º C / 14 ...140ºF

Interference resistance to EN50082-2

Emission to EN50081-2

Current range, depending

on the version for valves 40 ... 220 mA,

200 ... 1000 mA,

500 ... 2000 mA

Standard signal input

Voltage (0 ... 5, 0 ... 10 V) input impedance > 20 kW

Current (0 ...20, 4 ... 20 mA) input impedance <200 W

Housing: DIN rail version

Degree of protection IP40 (DIN EN 60529)

Materials Polyamide / PBT

Dimensions LxBxH: 97x27x57 mm

Housing: Cable plug version

Degree of protection IP65 (DIN EN 60529)

Materials Polyamide / PC

Dimensions LxBxH: 70x32x42.5 mm

11

Page 12

english

Type 8605

Configuration and Function

7. CONFIGURATION AND FUNCTION

7.1. Operating and Display Elements

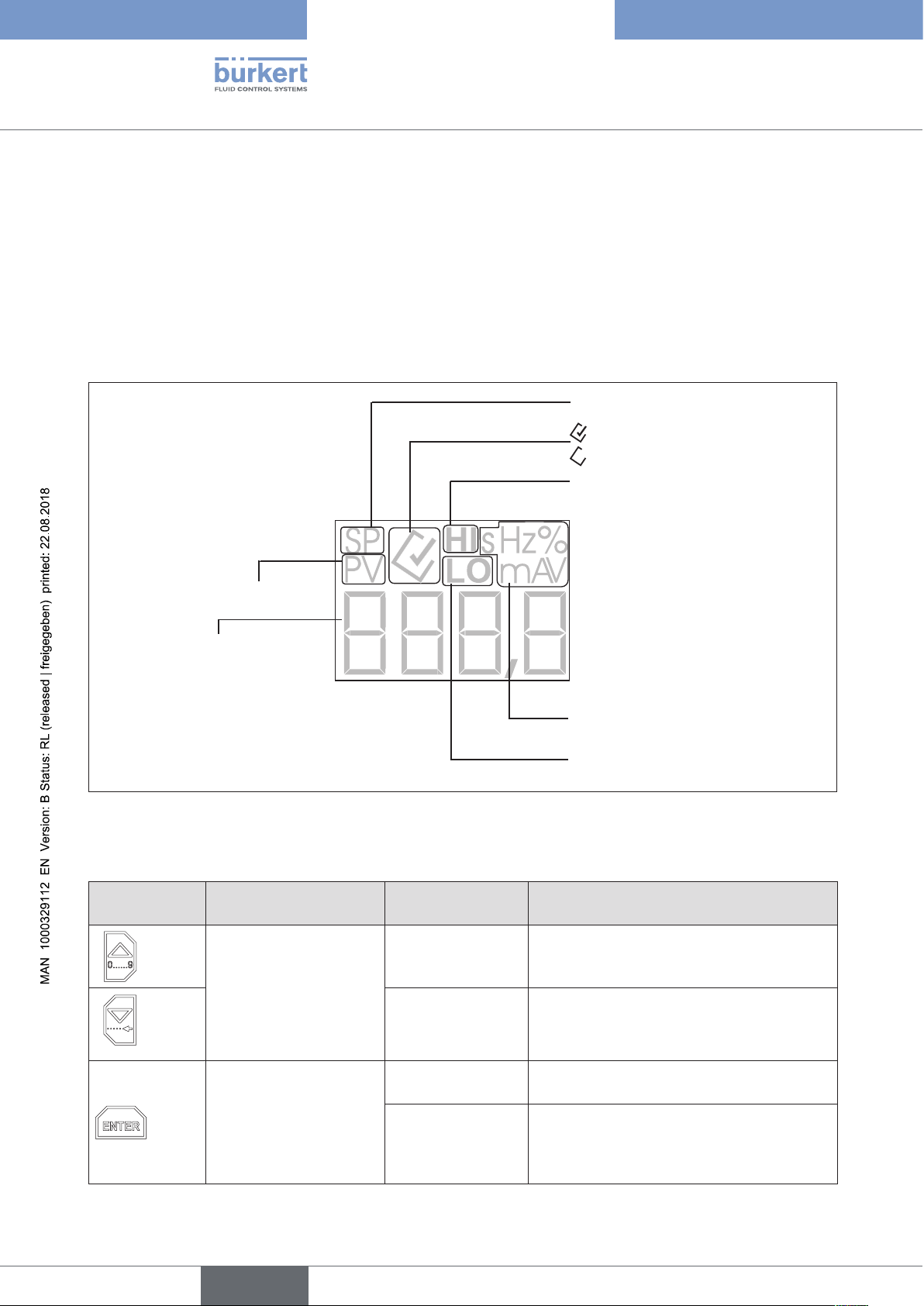

7.1.1. Operating unit

The operating unit consists of a LCD and keys. It is used for displays and settings of the Control Electronics, Type

8605.

Setpoint = Setpoint

(of the coil current)

= active

= not active

Upper limit

Process value = Actual value

(of the coil current)

LCD

Figure 3: Operating unit

Key assignment:

Key Display mode Configuration

Switch over the display

value

PV [mA] process value

PV [%] process value

SP [%] setpoint

TV [%] duty cycle

Scroll up

(selection)

Scroll down

(selection)

Unit of the displayed value

(s, Hz, %, mA, V)

Lower limit

Selected and confirmed menu item

mode

Increment (increase)

numerical values

Decrement (decrease)

numerical values

12

3 sec

Enter configuration mode

Confirm the

selected menu item

Switch between

main-menu and

sub-menu items

e. g.: Out-VALV

Select and deselect the individual menu

items

Confirm set values

Page 13

english

Type 8605

Configuration and Function

7.1.2. LED’s during operation without operating unit

During operation of the Control Electronics 8605 without operating unit, the operating status is indicated by two LED’s.

LED green: Device in operation

LED yellow: Current through valve

Figure 4: LED’s on version without operating unit

7.2. Basic function

The Control Electronics, Type 8605, is suitable for the control of all Bürkert proportional valves with a max. current

in the range from 40 to 2000 mA. It transforms an external standard signal into a pulse-width modulated voltage

signal (PWM) that is supplied to the solenoid coil of the proportional valve (see “Figure 5: Basic function of the

Control Electronics, Type 8605”). A given value of the average coil current is thereby assigned to each value of the

input signal. The proportional opening of the valve can be set via the coil current.

0 ... 5/10 V

0/4 ... 20 mA

Standard

1

Loadp

Figure 5: Basic function of the Control Electronics, Type 8605

0 to 5 V, 0 to 10 V, 0 to 20 mA or 4 to 20 mA can be set as standard signals.

13

Page 14

t

U

english

Type 8605

Configuration and Function

Due to the inductivity of the coil, the rectangular time curve of the PWM voltage signals is not transformed into a

corresponding current curve; instead the coil current has a sawtooth like „rounded“ time curve (see “Figure 6: Time

response of PWM voltage signal and coil current”). The mean (effective) coil current over time depends on the pulse

duty factor τ of the voltage signal.

τ = t

/(ton+ t

on

)

off

The curve of the coil current in the cycle of the PWM frequency generates a proportional change in the magnetic

force acting on the armature and hence, with an appropriate choice of this frequency (see chapter “7.3. Adjustment

to the Valve and Application Data”), a steady slight movement of the armature about its momentary equilibrium

position (dither movement). This avoids static friction effects at the bearing points.

t

off

I

Figure 6: Time response of PWM voltage signal and coil current

t

on

Due to the intrinsic heating of the coil and the associated large changes in resistance of the winding, the coil current

and hence the opening of the valve with a fixed pulse duty factor do not remain constant. An internal current control

system serves to compensate these thermal effects by corresponding tracking of the pulse duty factor.

7.3. Adjustment to the Valve and Application Data

The working range of a valve in a particular application depends greatly on its nominal size and the prevailing pressure

conditions.

In order to adapt the working range optimally to the range of the control signal, the key values for the effective coil

current are set via the operating unit in such a way that:

• the opening of the valve starts at a current value slightly above the lower key value (I1) and

• the full flow rate is achieved at a current value slightly below the upper key value (I2).

The lower key value is the current controlled at the lowest value of the standard signal (0 V, 0 mA or 4 mA).

The upper key value is obtained at the maximum value of the standard signal (5 V, 10 V or 20 mA).

Between the two key values, the effective coil current has a linear relationship to the input signal (see “Figure 7:

Current over standard signal”)

14

Page 15

2 % 100 %

t

english

Type 8605

Configuration and Function

I

I

2

I

1

Standard signal

Figure 7: Current over standard signal

The working range can also be scaled using the key values I1 and I2 in such a way that only a part of the full opening

of the valve is covered over the full range of the standard signal. In particular the flow rate range can be limited to a

smaller value than the valve would permit under the given pressure conditions.

The zero point cut-off guarantees the leak-tight closing of the valve at input signals below a given threshold of the

input signal (e.g. < 2 % of the limit value). In this case at values below this threshold, the coil current is set - in

deviation from the line shown in “Figure 7: Current over standard signal” - to zero so that the full force of the return

spring of the valve acts as a closing force.

The zero point cut-off can be optionally activated or deactivated.

ramp function serves to attenuate sudden changes in the input signal and to transform them into an adjustable ramp

A

(time constant 0 to 10 s) (see “Figure 8: Ramp function”). This is expedient for applications in which sudden changes

in the fluidic controlled variable are undesirable. The ramps can be set separately for positive and negative jumps.

The frequency of the PWM signal must be adapted to the valve used.

Standard signal

Current

Figure 8: Ramp function

The digital communication with superordinate controllers (PC’s, etc.) is possible via RS232 or RS485 interfaces

using auxiliary modules (see “11.1. Ordering charts: Device variants”).

15

Page 16

english

Type 8605

Installation

8. INSTALLATION

8.1. Safety instructions

DANGER!

Risk of injury from high pressure in the equipment!

• Before loosening the lines and valves, turn off the pressure and vent the lines.

Risk of injury due to electrical shock!

• Before reaching into the device or the equipment, switch off the power supply and secure to prevent

reactivation!

• Observe applicable accident prevention and safety regulations for electrical equipment!

WARNING!

Risk of injury from improper installation!

• Installation may be carried out by authorised technicians only and with the appropriate tools!

Risk of injury from unintentional activation of the system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following assembly, ensure a controlled restart.

8.2. Electrical connections

DANGER!

Risk of injury due to electrical shock!

• Before reaching into the device or the equipment, switch off the power supply and secure to prevent

reactivation!

• Observe applicable accident prevention and safety regulations for electrical equipment!

8.2.1. Cable plug version

16

The electrical connection of the Controller Type 8605 in cable plug version is made via a 4-pin terminal strip inside

the device.

Cable:

• Diameter 6 ... 8 mm

• Cross-section max. 0.75 mm²

• Cable connections Cable gland or plug connector M12

4-pin

Page 17

english

Type 8605

Installation

Figure 9: Terminal strip connection

Standard signal (+)

12 . 24 V DC

Standard signal (-)

GND

12 . 24 V DC

GND

Figure 10: Plug connector connection

Standard signal (+)

Standard signal (-)

NOTE!

Ensure proper seating of the valve when screwing onto the valve (cable plug version)

Do not tighten the screw M3 too tightly (max. 0.3 Nm), as otherwise the housing will be deformed and proper

operation of the keys will no longer be possible.

17

Page 18

english

Type 8605

Installation

Tighten screw M3 to max. 0.3 Nm

Figure 11: Installation of the cable plug version on the valve

8.2.2. DIN rail version

The electrical connection of the Controller Type 8605 in DIN rail version is made via terminal strips.

Terminal strip Cable cross-section

2-pin for valve max. 1.5 mm²

3-pin for RS232- and RS485-interface max. 0.5 mm²

4-pin for voltage supply and standard signal max. 1.5 mm²

18

Page 19

english

Type 8605

Installation

1

2

3

4

Figure 12: Terminal strip connection

Legend:

1. 12 ... 24V DC

2. GND

3. Standard signal (-)

4. Standard signal (+)

5. Valve

5

6

7

8

9

6. Valve

7. RS485-B7T x D

8. RS485-A/R x D

9. GND

19

Page 20

9. CONFIGURATION

english

Type 8605

WARNING!

Danger may result from improper use!

Improper use can result in personal injury or damage to the device.

• The Control Electronics, Type 8605 may only be operated by qualified personnel.

NOTE!

Carry out the fluidic and electrical installation before starting the configuration.

9.1. Operating modes

Configuration

The Control Electronics can be operated in two modes:

• Display mode

• Configuration mode

After switching on the operating voltage, the Control Electronics, Type 8605 is in display mode.

Display mode

Configuration mode

3s

InP

Out

dELY

…

dAtA

End

20

Figure 13: Switching between display and configuration mode

9.2. Basic settings

Switch to the configuration mode to make the basic settings.

→ Hold the Enter key depressed for 3 seconds.

InP, the first menu item of the configuration menu, appears on the display.

→ Press the Enter key to make settings in the menu item InP.

Page 21

3 sec

english

Type 8605

Configuration

A sub-menu appears on the display.

You can switch between the sub-menu items by pressing the arrow keys and make the desired settings.

→ Confirm the desired setting by pressing the Enter key.

9.3. Menu of the configuration mode

Display mode

Input

Selection of the

input signal

Output

Valve settings

Delay

Ramp function

Cut off

Zero point cut off

Parameter

Settings Current

control

Address

Interface address

Figure 14: Menu of the configuration mode

Safe position

Safety setting

Data

Upload and Download

(only

Cable plug version)

End

Back to Display

mode

21

Page 22

english

Type 8605

Configuration

9.3.1. InP (Input) - Selection of the input signal

Enter the type of standard signal used in this menu item. You can select between the following standard signals:

• 0 ... 5 V,

• 0 ... 10 V,

• 0 ... 20 mA,

• 4 ... 20 mA.

Figure 15: InP (Input) - Selection of the input signal

9.3.2. Out (Output) - Valve settings

In this menu the electronics are adjusted to

• the valve used and

• the fluidic conditions in the application.

Absolutely vital are

• the setting of the valve type in the sub-menu VALV and

• the setting of the working range of the coil current in the sub-menu AdJ.

To ensure that the device functions perfectly, set the PWM frequency which is suitable for the valve.

• In the case of types 2871, 2873 and 2875 the PWM control frequencies must be adjusted in the VAdJ

submenu.

• In the case of special applications the PWM control frequency must be individually set in the VAdJ submenu.

If you have any queries, please contact your sales office or the Bürkert Technical Center. 24 h service

number: +49 (0) 7940 / 10 91 110

22

Set values for PWM frequencies:

A table of PWM frequencies which are suitable for controlling the valve type can be found on the Bürkert

homepage: www.burkert.com → Type 8605.

Page 23

english

Type 8605

Configuration

Figure 16: Out (output) - Valve setting

VALV (VALVE) - SETTING OF THE VALVE TYPE

CAUTION!

Danger from the selection of the wrong valve type!

The valve can be damaged if the wrong valve type is selected.

• Pay attention to the choice of the right valve type.

The Control Electronics, Type 8605, can be used for the whole range of Bürkert proportional valves. Depending on

the nominal sizes and fluidic performance data, the individual valve types contain solenoid coils with very different

sizes, winding data and dynamic properties (defined by the inductivity and Ohmic resistance).

The ability to react to a PWM voltage signal with a small dither movement and hence to give the valve a particularly

good response depends to a very great extent on the dynamic characteristic of the coil.

As a general rule of thumb it can be said that small coils with low magnetic force still react well even to higher

frequencies. At low frequencies, they even generate excessively large movement amplitudes and an unnecessarily

high noise level. Large coils with high magnetic force still generate dither movements only at low frequencies and

thus ensure sliding friction states.

The reaction of a valve to a PWM signal is dependent not only on its frequency but also on the current pulse duty

τ and the working point.

factor

The valve reacts more sensitively when the working point with average pulse duty factors [τ] and more slowly when

the opening corresponds to a pulse duty factor in the limit areas close to 0 % or close to 100 %. In order to compensate this dependence, control is effected with a PWM frequency that is dependent on the pulse duty factor

whose curve follows a triangular function (see “Figure 17: PWM frequency / pulse duty factor”). Here the frequency

is lowest at the limit points (0 %, 100 %), and highest at τ = 60 %.

23

Page 24

english

Type 8605

Configuration

f

f

HI

f

LO

0 %

60 %

100 %

τ

Figure 17: PWM frequency / pulse duty factor

The two limit frequencies of the PWM control (HI and LO) are set with the selection of the valve type. The frequency

output actually varies within this range, depending on the working point.

The following values (see “Figure 17: PWM frequency / pulse duty factor”) were determined empirically from the

behavior of a large number of individual devices of the corresponding type.

Type

24

Figure 18: Limit frequencies for Bürkert valve types

Set values for PWM frequencies:

A table of PWM frequencies which are suitable for controlling the valve type can be found on the Bürkert

homepage

www.burkert.com → Type 8605.

Page 25

english

Type 8605

Configuration

CAUTION!

Danger from wrong setting of the valve type.

If the selected valve type differs from the valve actually used whose coil has very different characteristics, the

function of the valve can be severely impaired. When using the flat spring valve, Type 2822, the input of a

wrong valve type can lead to irreparable device damage!

• Always set the valve type correctly. For this parameter, the value „----“ (no valve) is set as default value in the

delivery condition. If no valve is selected, the coil remains de-energised.

• In the case of types 2871, 2873 and 2875 the PWM frequency must be adjusted in addition to selecting the

type. A table of PWM frequencies which are suitable for controlling the valve type can be found on the Bürkert homepage: www.burkert.com → Type 8605.

The choice of valves depends on the device type being used

Due to the scatter of the valve types with respect to friction characteristics and the relationship between

sensitive control behavior and low hysteresis or low noise development and larger hysteresis, it can be

advisable to deviate from the recommended PWM frequencies (see also chapter “9.3.3. VAdJ (Valve

adjust) - Fine tuning of the valve frequency”).

9.3.3. VAdJ (Valve adjust) - Fine tuning of the valve frequency

In the menu VAdJ, the two frequencies defined with the selection of the valve type can be varied within certain limits.

A reduction of the values is generally associated with:

• a reduction in the hysteresis of the valve characteristic,

• improved response sensitivity and

• an increased noise level.

If the frequencies are increased, the hysteresis increases and the response sensitivity becomes poorer. The control

becomes slower and the noise level decreases.

Figure 19: VAdJ (Valve adjust) - Fine tuning of the valve frequency

25

Page 26

english

Type 8605

Configuration

• The following rule applies for the input of the frequency pairs: HI value > LO value

• In the menu item VALV, the HI and LO values are limited to an expedient range in relation to the valve

type. No normal control behaviour can be expected outside this range.

9.3.4. AdJ (Adjust) - Adaptation of the coil current

The working range of a proportional valve is defined by the coil current.

• Lower current limit - LO [mA]

Current value at which the valve just starts to open. This value corresponds to the nominal and actual value of

0 %. The setting range depends on the device version being used.

• Upper current limit - HI [mA]

Current value at which the valve just reaches the maximum flow rate. An increase in the coil current above the

upper value does not result in any noticeable increase in the flow rate. This value corresponds to the nominal

and actual value of 100 %. The setting range depends on the device version being used.

Current values outside the working range are irrelevant for a control. The range of the input standard signal (e. g.

0 to 10 V) is therefore set to the working range of the coil current (see chapter “7. Configuration and Function”).

• For a given valve type (coil version), the working range depends on the nominal size of the valve and on the

pressure ratios (inlet and return pressure) in the system. The setting has to be made under typical operating

conditions.

Figure 20: AdJ (Adjust) - Adaptation of the coil current

• A flow indicator is necessary for the setting of the working range. Determine the start and the achievement

of the maximum flow rate with this indicator.

26

• The absolute precision of the flow indicator is not crucial!

SETTING THE MINIMUM AND MAXIMUM COIL CURRENT

Start of flow

→ Set the minimum coil current I

(AdJ = LO mA) via the arrow keys so that the valve just starts to open.

1

Page 27

english

Type 8605

Configuration

→ Start with a current value at which the valve is still reliably closed and increase the coil current with the arrow

key until the flow indicator detects a flow for the first time.

→ Reduce the coil current by a few mA with the key until the valve is reliably closed again.

→ Confirm the minimum coil current I

with the -key.

1

Maximum flow rate

→ Set the maximum coil current I

(AdJ = HI mA) via the arrow keys so that the maximum flow rate is just

2

achieved.

→ Increase the coil current with the arrow key until the maximum flow rate is reached and a further increase in

the current does not result in a further increase in flow rate.

→ Reduce the coil current with the arrow key until the flow rate starts to drop noticeably again and confirm this

value with the -key as the maximum coil current I2 (AdJ = HI mA).

Indicative current values, depending on the valve type

For the current values of the start of opening and the maximum flow rate there are default values for each valve type

stored in the menu. These values are only indicated values depending on the nominal size of the valve and pressure

ratio.

In the menu item ADJ the valve must be set to the nominal size of the valve and the current pressure.

For all direct-acting proportional valves (i. e. all types with the exception of Type 6223), the current value I

start of opening drops with increasing inlet pressure; with an increasing pressure drop through the valve, the value

I2 at which the maximum flow rate is achieved also decreases.

For the pilot-controlled valve, Type 6223, the current value for the start of opening increase with increasing inlet

pressure; with an increasing pressure drop through the valve, the value I

also increases.

2

for the

1

9.3.5. dELY (Delay) - Ramp function

The ramp time for attenuating sudden changes in the input signal can be entered separately for changes upwards

and downwards.

• HI [s] - Ramp for a positive signal jump

The time indicated in seconds (0.1 to 10.0 s) relates to a change in set point from 0 % to 100 %.

• LO [s] - Ramp for a negative signal jump

The time indicated in seconds (0.1 to 10.0 s) relates to a change in set point from 100 % to 0 %.

With smaller changes in the input signal, the delay time corresponds to the set value multiplied by the size of the

change in percent. For example, with a sudden change from 20 % to 70 %, it corresponds to exactly half the

value set under HI in seconds. With a setting value of 0.0 s, the respective ramp function is deactivated.

27

Page 28

Figure 21: dELY (Delay) - Ramp function

english

Type 8605

Configuration

9.3.6. Cut (Cut off) - Zero point cut off

In order to guarantee leak-tight closing of the valve, the valve is completely de-energised with input signals below

the set limit (0.1 to 5.0 % of the set standard signal) when the zero point shutdown is active.

In addition to its control function, the valve can also take on the function of a cut-off valve.

Figure 22: Cut (Cut off) - Zero point cut off

• With a set value of 0.0 %, the zero point cut-off is deactivated. Even at an input signal of 0 %, the valve

no longer reliably shuts off the flow.

• The valve flow control restarts with a hysteresis of 0.5 %.

• The reactivation of the current controls starts as soon as the input signal is set to a value 0.5 % above

the defined threshold value; i. e. there is a hysteresis of 0.5 % for the activation and deactivation of the

cut off function

28

• The range of the input signal lying below the set threshold is no longer available for the current control

and fluidic flow control

Page 29

english

Type 8605

Configuration

9.3.7. PArA (Parameter) - Controller setting

The controlled coil current cannot follow changes in the input signal at any random speed.

Different sets of control parameters are stored for the internal current control. The controller dynamics can

therefore be set in three discrete steps between:

• very fast control with the probably occurrence of overswing behavior and

• slow control with a guaranteed elimination of overswing.

Set 1: slow

......

Set 3: fast

Figure 23: PArA (Parameter) - Controller setting

9.3.8. Addr (Address) - Interfaces

Setting of the bus address when using the serial interface (0 to 31).

Figure 24: Addr (Address) - Interfaces

29

Page 30

english

Type 8605

Configuration

9.3.9. SPOS (Safe position) - Setting of the safety position

Input of the safety position (0.0 to 100.0 %) that is controlled with a selected standard signal input of 4 to 20 mA

and a drop below the 4 mA input signal.

Figure 25: SPOS (Safe position) - Setting of the safety position

The standard signal 4 to 20 mA is the only one that permits a fault to be detected when the input value

drops below 4 mA. In this case it is possible to define which current value is to be controlled (e. g. 50 %)

9.3.10. dAtA (Data) - Upload and Download of parameters between the operating unit and the basic device

This function is used for data transfer from one operating unit to several basic devices. After connecting the operating

unit, the stored parameters can be transmitted to the basic device.

This function is only available for the cable plug version.

Figure 26: dAtA (Data)

uPLd (upload)

30

When upload is selected the parameters of the basic device are transferred to the operating unit. That means, that

first the memory of the operating unit is cleared and then filled with all relevant data of the basic device. After that

the operating unit displays „rdY“ (ready). If the data transfer failed „Err“ (error) is displayed.

Page 31

SP

%Hz

,

HI

s

english

Type 8605

Configuration

dnLd (download)

When download is selected the parameters stored in the operating unit are transferred to the basic device.

This is only possible, if the version of the data is the same as in the basic device (e. g. data transfer between a

200 - 1000 mA version and a 500 - 2000 mA version is not possible).

After that the operating unit displays “rdY”. If the data transfer failed “Err” is displayed.

9.3.11. END

To quit the respective menu level, select the menu item END with the arrow keys.

The settings made are saved on leaving the configuration menu.

PV

Figure 27: End

LO

mA

V

9.4. Factory Settings of the Control Electronics

Menu item Factory setting Comment

InP 0 ...10 V Input signal 0 ...10 V selected

Out / VALV - - - - No valve selected

Out / VAdJ OFF Manual fine tuning of the valve fre-

quency inactive

Out / AdJ LO: 2 mA

HI: 200 mA

deLY LO: 0.0 s

HI: 0.0 s

Cut LO: 2.0 % Zero point cut-off active at 2 %

These values are changed by a

valve selection

Ramp function inactive

PArA SEt2 Controller parameter set 2 selected

Addr 0 Address 0 for the serial communi-

cation selected

SPOS 0.0 % Safety setting 0 % at an input

signal below 4 mA (with selection

of the 4 ... 20 mA input signal)

selected

31

Page 32

english

Type 8605

Maintenance

10. MAINTENANCE

10.1. Safety Instructions

WARNING!

Danger due to improper maintenance work!

Improper maintenance may result in injuries as well as damage to the device and the surrounding area.

• Maintenance work may be carried out by authorised technicians only and with the appropriate tools!

Danger due to unintentional activation of the equipment!

Unintentional activation of the equipment during maintenance and repair work may result in injuries and / or

damage.

• Take appropriate measures to prevent the equipment from being unintentionally activated.

10.2. Service

When used in accordance with the instructions given in this operating manual, the Control Electronics Type 8605

is maintenance-free.

32

Page 33

english

Type 8605

Spare Parts

11. SPARE PARTS

CAUTION!

Danger due to incorrect accessories and replacement parts!

Incorrect accessories or unsuitable spare parts can result in injuries and in damage to the device and its

surroundings.

• Use only original accessories and original spare parts from Bürkert GmbH & Co. KG!

11.1. Ordering charts: Device variants

Design

Max.

coil current

range [mA]

Order no.:

2822 24V DC

2822 12V DC

2824 24V DC

2824 12V DC

2833 24V DC

2833 12V DC

2835 24V DC

2836 24V DC

2861 24V DC

2861 12V DC

2863 24V DC

2863 12V DC

2865 24V DC

2871 24V DC

2871 12V DC

2873 24V DC

2873 12V DC

2875 24V DC

6024 24V DC

6024 12V DC

6223 24V DC

6223 12V DC

Cable plug with PG

screw connection

Cable plug with

PG screw connection

without control unit

Cable plug with

M12 connection

Cable plug with

M12 connection

without control unit

Cable plug with PG

screw connection

Cable plug with

PG screw connection

without control unit

Cable plug with

M12 connection

Cable plug with

M12 connection

without control unit

DIN-rail

200 -

1000

178 354 178 358 178 355 178 359 178 356 178 360 178 357 178 361 178 362 178 363 178 364

X X X X X

X X X X X X X X X X

X X X X X X X X X X

X X X X X

X X X X X X X X X X

X X X X X X X X X X

X X X X X

X X X X X X X X X X

X X X X X X X X X X

X X X X X X X X X X

X X X X X

200 -

1000

200 -

1000

200 -

1000

500 -

2000

X X X X X

X X X X X

X X X X X

500 -

2000

500 -

2000

500 -

2000

40 -

220

X

X

X X

X X

X X

DIN-rail

200 -

1000

X

X

X

DIN-rail

500 -

2000

33

Page 34

english

Type 8605

Spare Parts

If two current ranges of the control electronics are possible choose the lower one

11.2. Accessories

Accessories / Individual parts Identification

Number

Operating unit for Type 8605 Cable plug 667 839

RS232 module for Type 8605 Cable plug 667 840

RS485 module for Type 8605 Cable plug 667 841

RS232 module for Type 8605 DIN Rail 667 842

RS485 module for Type 8605 DIN Rail 667 843

Angle-entry plug M12, 4pin 784 301

Connecting lead M12, 4-pin, 5 metres long 918 038

Connecting lead M8 for serial communication RS232 or RS485 918 718

Cap set (for operating without control unit) 670 549

34

Page 35

english

Type 8605

Packaging, Transport

12. PACKAGING, TRANSPORT

NOTE!

Transport damages!

Inadequately protected equipment may be damaged during transport.

• During transportation protect the device against wet and dirt in shock-resistant packaging.

• Avoid exceeding or dropping below the allowable storage temperature.

13. STORAGE

NOTE!

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature. -40 °C … +55 °C.

13.1. Decommissioning

Switch off the Control Electronics Type 8605 as follows:

→ Depressurize the system.

→ Switch off the power supply.

→ Remove the Control Electronics.

→ Keep the control electronics in the original packaging or in some other suitable packaging.

13.2. Restarting

Switch on the Control Electronics Type 8605 again as follows:

→ Unpack the Control Electronics and allow it to reach room temperature before switching on again.

→ Then proceed as described in chapter “8. Installation”.

35

Page 36

english

Type 8605

Packaging, Transport

14. DISPOSAL

→ Dispose of the device and packaging in an environmentally friendly manner.

NOTE!

Damage to the environment caused by device components contaminated with media.

• Observe applicable regulations on disposal and the environment.

Note:

Observe national waste disposal regulations.

36

Page 37

www.burkert.com

Loading...

Loading...