Page 1

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifications

techniques.

© 2008 – 2012 Bürkert Werke GmbH

Operating Instructions 1201/05_EU-ml_00805637/ Original DE

Type 8605

Digital Control Electronics for Proportional Valves

Digitale Ansteuerelektronik für Proportionalventile

Régulateur électronique numérique pour vannes

proportionnelles

Quickstart

English

Deutsch

Français

2

1. QUICKSTART

The operating instructions describe the entire life cycle of the

device. Keep these instructions in a location which is easily

accessible to every user and make these instructions available

to every new owner of the device.

Important Safety Information!

Read Quickstart carefully and thoroughly. Study in par-Quickstart carefully and thoroughly. Study in par- carefully and thoroughly. Study in particular the chapters entitled “4. Basic Safety Instructions”

and “3. Intended Use”.

• Quickstart must be read and understood.

Quickstart for Type 8605 explains, for example, how to install

and start-up the device.

A detailed description of the device can be found in the

operating instructions for Type 8605. These instructions also

include the warranty provisions and details about the correct

disposal of the device.

The operating instructions can be found on the

enclosed CD and on the Internet at:

www.burkert.com

Documentation Type 8605

1.1. Definition of Term “Device”

The term “device” used in these instructions always stands

for the electromagnetic positioner type 8791.

english

3

2. SYMBOLS

The following symbols are used in these instructions.

DANGER!

Warns of an immediate danger!

• Failure to observe the warning may result in a fatal or

serious injury.

WARNING!

Warns of a potentially dangerous situation!

• Failure to observe the warning may result in a serious or

fatal injury.

CAUTION!

Warns of a possible danger!

• Failure to observe this warning may result in a medium

or minor injury.

NOTE!

Warns of damage to property!

Important tips and recommendations.

→ designates a procedure which you must carry out.

english

Page 2

4

3. INTENDED USE

Non-intended use of the Type 8605 may be a hazard

to people, nearby equipment and the environment.

• The device is designed for controlling Bürkert proportional valves.

• The device must not be exposed to direct sunlight.

• Do not use the device outdoors.

• To ensure that the device functions perfectly, set the

PWM frequency which is suitable for the valve. A table

of set values can be found on the Bürkert homepage

www.burkert.com → Type 8605.

• Use according to the authorized data, operating conditions and conditions of use specified in the contract

documents and operating instructions. These are

described in the chapter entitled “7. Technical Data”.

• The device may be used only in conjunction with thirdparty devices and components recommended and

authorized by Bürkert.

• Correct transportation, correct storage and installation

and careful use and maintenance are essential for reliable and faultless operation.

• Use the device only as intended.

english

5

4. BASIC SAFETY

INSTRUCTIONS

These safety instructions do not make allowance for any:

• Contingencies and events which may arise during the instal-

lation, operation and maintenance of the devices.

• Local safety regulations – the operator is responsible for

observing these regulations, also with reference to the

installation personnel.

Danger – high pressure!

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

Risk of electric shock!

• Before reaching into the device or the equipment,

switch off the power supply and secure to prevent

reactivation!

• Observe applicable accident prevention and safety

regulations for electrical equipment!

english

6

There is a risk of injury when the pressure drops in the

system!

• Avoid pressure drops!

• Design the pressure supply system with as large a volume as possible, even with upline devices such as e. g.

pressure regulators, air conditioners, shut-off valves.

General hazardous situations.

To prevent injury, ensure that:

• That the system cannot be activated unintentionally.

• Installation and repair work may be carried out by

authorised technicians only and with the appropriate

tools.

• After an interruption in the power supply or pneumatic supply, ensure that the process is restarted in a

defined or controlled manner.

• The device may be operated only when in perfect

condition and in consideration of the operating

instructions.

• The general rules of technology apply to application

planning and operation of the device.

english

7

NOTE!

Electrostatic sensitive components / modules!

The device contains electronic components which react

sensitively to electrostatic discharge (ESD). Contact with

electrostatically charged persons or objects is hazardous

to these components. In the worst case scenario, they

will be destroyed immediately or will fail after start-up.

• Observe the requirements in accordance with

EN 61340-5-1 and 5-2 to minimise or avoid the

possibility of damage caused by sudden electrostatic

discharge!

• Do not touch live electronic components!

The Type 8605 was developed with due consideration given to the accepted safety rules and are

state-of-the-art. Nevertheless, dangerous situations

may occur.

Failure to observe this operating manual and its operating

instructions as well as unauthorized tampering with the

device release us from any liability and also invalidate the

warranty covering the devices and accessories!

english

Type 8605

Page 3

8

5. GENERAL INFORMATION

5.1. Contact address

Germany

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Contact addresses can be found on the final pages of the

printed operating instructions.

And also on the Internet at:

www.burkert.com

5.2. Warranty

The warranty is only valid if the device is used as authorized

in accordance with the specified application conditions.

5.3. Information on the Internet

Operating instructions and data sheet for Type 8605 can be

found on the Internet at:

www.burkert.com

english

9

6. PRODUCT DESCRIPTION

6.1. Field of Application

The Control Electronics, Type 8605, is designed for continuous operation in industrial environments, in particular in

the fields of open-loop and closed-loop control engineering.

6.2. General Description

The Digital Control Electronics for Proportional Valves, Type

8605 (hereinafter referred to as Control Electronics, Type

8605) Controls all Bürkert proportional valves with a max.

current in the range from 40 to 2000 mA.

It transforms an external standard signal into a pulse-width

modulated voltage signal (PWM) that is supplied to the

solenoid coil of the proportional valve.

A given value of the average coil current is thereby assigned

to each value of the input signal. The proportional opening

of the valve can be set via the coil current.

english

10

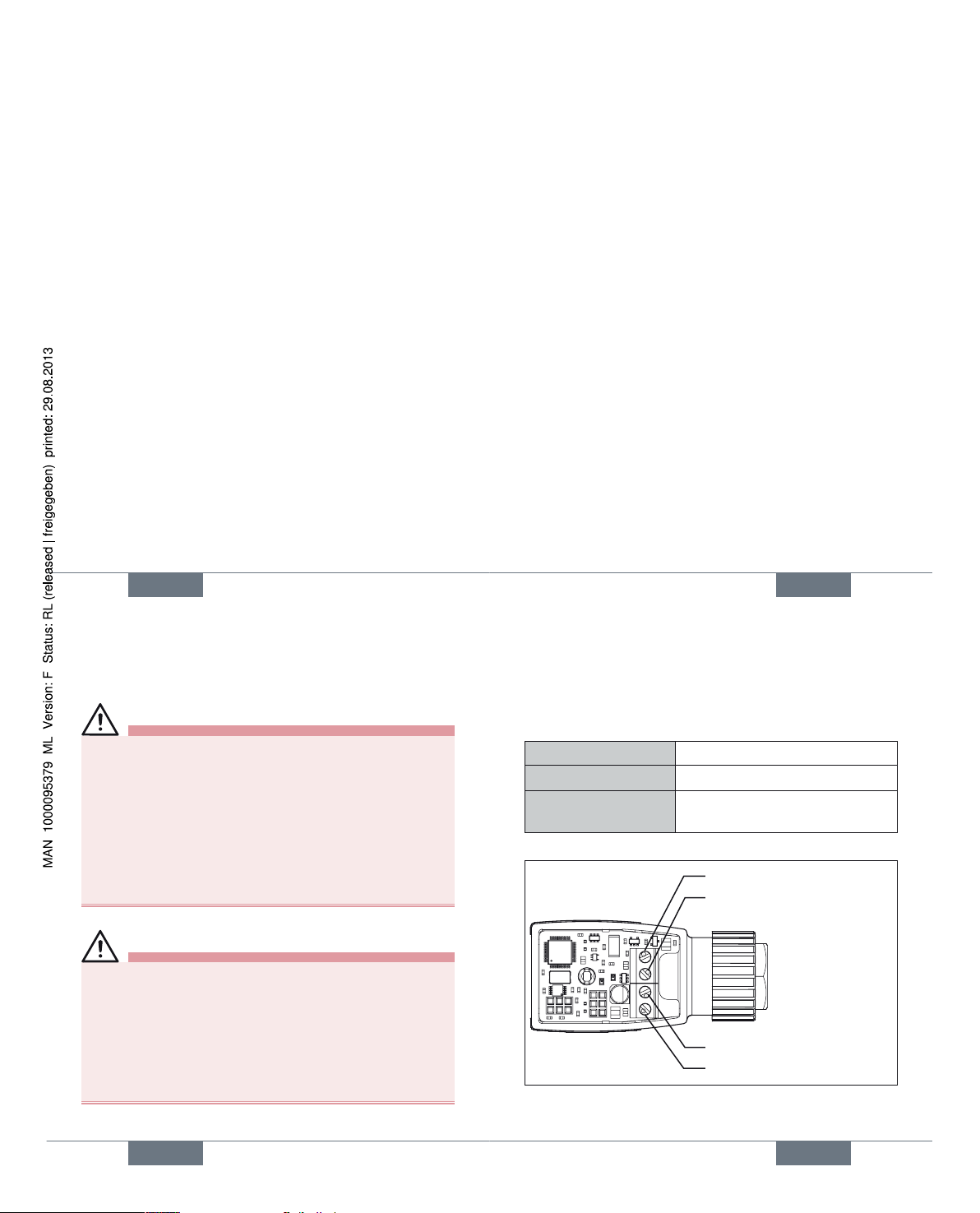

6.3. Forms of the device

6.3.1. Type 8605 Cable plug version

Fig. 1: Type 8605 Cable plug version

Plug-in version on valves with connector pattern A (e. g. types

2832, 2833, 2834, 2835, 2836, 2853, 2863, 2865, 2873,

2875, 6022, 6023, 6024, 6223).

The operating unit can be removed after the setting process.

During operation of the Control Electronics 8605 in cable

plug version without operating unit, the operating status is

indicated by two LEDs.

Device variants:

• Variant 1 for valves with a max. current from

200 to 1000 mA

• Variant 2 for valves with a max. current from

500 to 2000 mA

english

11

6.3.2. Type 8605 DIN rail version

Fig. 2: Type 8605 DIN rail version

Separate electronics in housing for DIN rail mounting to DIN

EN 50022. This form is suitable for all proportional valves in

the indicated current range. The operating unit cannot be

removed.

Device variants:

• Variant 1 for valves with a max. current from

40 to 220 mA

• Variant 2 for valves with a max. current from

200 to 1000 mA

• Variant 3 for valves with a max. current from

500 to 2000 mA

english

Type 8605

Page 4

12

7. TECHNICAL DATA

7.1. Operating Conditions

Power supply 12...24 V DC ± 10%

Residual ripple 5 %

Power consumption ca. 1 W

Output current

(on the valve) max. 2 A

Operating temperature -10 ... 60 ºC / 14 ...140 ºF

Interference resistance to EN50082-2

Emission to EN50081-2

Current range, depending

on the version for valves 40 ... 220 mA,

200 ... 1000 mA,

500 ... 2000 mA

Standard signal input

Voltage (0 ... 5, 0 ... 10 V) input impedance > 20 kW

Current (0 ...20, 4 ... 20 mA) input impedance <200 W

english

13

Housing: DIN rail version

Degree of protection IP40 (DIN EN 60529)

Materials Polyamide / PBT

Dimensions LxWxH: 97 x 27 x 57 mm

Housing: Cable plug version

Degree of protection IP65 (DIN EN 60529)

Materials Polyamide / PC

Dimensions LxWxH: 70 x 32 x 42.5 mm

english

14

8. INSTALLATION

8.1. Safety Instructions

DANGER!

Risk of injury from high pressure in the equipment!

• Before loosening the lines and valves, turn off the

pressure and vent the lines.

Risk of injury due to electrical shock!

• Before reaching into the device or the equipment,

switch off the power supply and secure to prevent

reactivation!

• Observe applicable accident prevention and safety

regulations for electrical equipment!

DANGER!

Risk of injury from improper installation!

• Installation may be carried out by authorised technicians only and with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following assembly, ensure a controlled restart.

english

15

8.2. Electrical connections

8.2.1. Type 8605 Cable plug version

Type 8605 with cable plug version is connected electrically

via a 4-pin terminal strip in the device.

Cable diameter 6 ... 8 mm

Cable cross-section max. 0.75 mm

2

Cable connections Cable gland or plug-in connector

M12, 4-pin

Standard signal (+)

Standard signal (-)

GND

12 ... 24 V DC

Fig. 3: Terminal strip connection

english

Type 8605

Page 5

16

Standard signal (+)

Standard signal (-)

12 ... 24 V DC

GND

Fig. 4: Plug connector connection

Tighten screw M3 to max. 0.3 Nm

Fig. 5: Assembly at the valve

english

17

NOTE!

Ensure proper seating of the valve when screwing onto

the valve (cable plug version).

Do not tighten the screw M3 too tightly (max. 0.3 Nm),

as otherwise the housing will be deformed and proper

operation of the keys will no longer be possible.

8.2.2. LEDs during operation without

operating unit

During operation of the control electronics Type 8605 cable

plug version without operating unit, the operating status is

indicated by two LEDs.

LED green: Device in operation

LED yellow: Current through valve

Fig. 6: LEDs for version without operating unit

english

18

8.2.3. Type 8605 DIN rail version

The electrical connection of Type 8605 DIN rail version is

made via terminal strips.

Terminal strip Cable

cross-section

2-pin For valve max. 1.5 mm

2

3-pin For RS232 or RS485 interface max. 0.5 mm

2

4-pin For voltage supply and

standard signal

max. 1.5 mm

2

1

2

5

6

3

4

7

8

9

Fig. 7: Terminal strip connection

Legend to figure:

1 12 ... 24 V DC 6 Valve

2 GND 7

RS485-B / TxD

3 Standard signal (-) 8 RS485-A / RxD

4 Standard signal (+) 9 GND

5 Valve

english

19

9. CLEANING

Use the normal cleaning agents to clean the Control Electronics, Type 8605. Use no alkaline cleansing agents, as these

have a damaging effect on the materials used.

10. PACKAGING, TRANSPORT,

STORAGE

NOTE!

Transport damages!

Inadequately protected equipment may be damaged

during transport.

• During transportation protect the device against wet

and dirt in shock-resistant packaging.

• Avoid exceeding or dropping below the allowable

storage temperature.

Incorrect storage may damage the device.

• Store the device in a dry and dust-free location!

• Storage temperature. -40 …+ 55 °C.

english

Type 8605

Page 6

20

10.1. Decommissioning

Switch off the Control Electronics Type 8605 as follows:

→ Depressurize the system.

→ Switch off the power supply.

→ Remove the Control Electronics.

→ Keep the control electronics in the original packaging

or in some other suitable packaging.

10.2. Restarting

Switch on the Control Electronics Type 8605 again as follows:

→ Unpack the Control Electronics and allow it to reach room

temperature before switching on again.

→ Then proceed as described in chapter “8. Installation”.

11. DISPOSAL

→ Dispose of the device and packaging in an environmen-

tally friendly manner.

NOTE!

Damage to the environment caused by device components contaminated with media.

• Observe applicable regulations on disposal and the

environment.

Observe national waste disposal regulations.

english

Type 8605

Page 7

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifications

techniques.

© 2008 – 2012 Bürkert Werke GmbH

Operating Instructions 1201/05_EU-ml_00805637/ Original DE

Typ 8605

Digitale Ansteuerelektronik für Proportionalventile

Quickstart

Deutsch

22

1. DER QUICKSTART

Der Quickstart beschreibt den gesamten Lebenszyklus des

Gerätes. Bewahren Sie diese Anleitung so auf, dass sie für

jeden Benutzer gut zugänglich ist und jedem neuen Eigentümer des Gerätes wieder zur Verfügung steht.

Wichtige Informationen zur Sicherheit!

Lesen Sie den Quickstart sorgfältig durch. Beachten Sie

vor allem die Kapitel „4. Grundlegende Sicherheitshinweise“ und „3. Bestimmungsgemäße Verwendung“.

• Der Quickstart muss gelesen und verstanden werden.

Der Quickstart erläutert beispielhaft die Montage und Inbetriebnahme des Gerätes.

Die ausführliche Beschreibung des Gerätes finden Sie in der

Bedienungsanleitung für den Typ 8605.

Die Bedienungsanleitung finden Sie auf der beigelegten CD oder im Internet unter:

www.buerkert.de

Dokumentation Typ 8605

1.1. Begriffsdefinition Gerät

Der in dieser Anleitung verwendeten Begriff „Gerät“ steht

immer für den elektromagnetischen Positioner Typ 8791.

deutsch

23

2. DARSTELLUNGSMITTEL

In dieser Anleitung werden folgende Darstellungsmittel

verwendet.

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichtbeachtung sind Tod oder schwere Verletzungen die Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen Situation!

• Bei Nichtbeachtung können schwere Verletzungen oder

Tod die Folge sein.

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

Wichtige Tipps und Empfehlungen.

→ markiert einen Arbeitsschritt den Sie ausführen müssen.

deutsch

Page 8

24

3. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz können

Gefahren für Personen, Anlagen in der Umgebung

und die Umwelt entstehen.

• Das Gerät ist für die Ansteuerung von Bürkert Proportionalventilen konzipiert.

• Das Gerät darf nicht der direkten Sonneneinstrahlung

ausgesetzt werden.

• Das Gerät nicht im Außenbereich einsetzen.

• Damit das Gerät einwandfrei funktioniert muss die zum

Ventil passende PWM-Frequenz eingestellt werden.

Die Tabelle mit den Einstellwerten finden Sie auf der

Bürkert Homepage www.buerkert.de → Typ 8605.

• Für den Einsatz die in den Vertragsdokumenten und der

Bedienungsanleitung spezifizierten zulässigen Daten,

Betriebs- und Einsatzbedingungen beachten. Diese

sind im Kapitel „7. Technische Daten“ beschrieben.

• Das Gerät nur in Verbindung mit von Bürkert empfohlenen bzw. zugelassenen Fremdgeräten und -komponenten einsetzen.

• Voraussetzungen für den sicheren und einwandfreien

Betrieb sind sachgemäßer Transport, sachgemäße

Lagerung und Installation sowie sorgfältige Bedienung

und Instandhaltung.

• Setzen Sie das Gerät nur bestimmungsgemäß ein.

deutsch

25

4. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine:

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und

Wartung der Geräte auftreten können.

• Ortsbezogenen Sicherheitsbestimmungen, für deren

Einhaltung, auch in Bezug auf das Montagepersonal, der

Betreiber verantwortlich ist.

Gefahr durch hohen Druck!

• Vor dem Lösen von Leitungen und Ventilen den Druck

abschalten und Leitungen entlüften.

Gefahr durch elektrische Spannung!

• Vor Eingriffen in das Gerät oder die Anlage, Spannung

abschalten und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte beachten!

deutsch

26

Bei abfallendem Druck im System besteht

Verletzungsgefahr!

• Druckabfall vermeiden!

• Druckversorgung möglichst großvolumig ausführen,

auch bei vorgeschalteten Geräten wie z. B. Druckreglern, Wartungseinheiten, Absperrventilen.

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten:

• Dass die Anlage nicht unbeabsichtigt betätigt werden

kann.

• Installations- und Instandhaltungsarbeiten dürfen nur

von autorisiertem Fachpersonal mit geeignetem Werkzeug ausgeführt werden.

• Nach einer Unterbrechung der elektrischen oder pneumatischen Versorgung ist ein definierter oder kontrollierter Wiederanlauf des Prozesses zu gewährleisten.

• Das Gerät darf nur in einwandfreiem Zustand und

unter Beachtung der Bedienungsanleitung betrieben

werden.

• Für die Einsatzplanung und den Betrieb des Gerätes

müssen die allgemeinen Regeln der Technik eingehalten werden.

deutsch

27

HINWEIS!

Elektrostatisch gefährdete Bauelemente /

Baugruppen!

Das Gerät enthält elektronische Bauelemente, die gegen

elektrostatische Entladung (ESD) empfindlich reagieren.

Berührung mit elektrostatisch aufgeladenen Personen

oder Gegenständen gefährdet diese Bauelemente. Im

schlimmsten Fall werden sie sofort zerstört oder fallen

nach der Inbetriebnahme aus.

• Beachten Sie die Anforderungen nach EN 61340-5-1

und 5-2, um die Möglichkeit eines Schadens durch

schlagartige elektrostatische Entladung zu minimieren

bzw. zu vermeiden!

• Elektronische Bauelemente nicht bei anliegender Versorgungsspannung berühren!

Das Gerät Typ 8605 wurde unter Einbeziehung

der anerkannten sicherheitstechnischen Regeln

entwickelt und entspricht dem Stand der Technik.

Trotzdem können Gefahren entstehen.

Bei Nichtbeachtung dieser Bedienungsanleitung und ihrer

Hinweise sowie bei unzulässigen Eingriffen in das Gerät

entfällt jegliche Haftung unsererseits, ebenso erlischt die

Gewährleistung auf Geräte und Zubehörteile!

deutsch

Typ 8605

Page 9

28

5. ALLGEMEINE HINWEISE

5.1. Kontaktadressen

Deutschland

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@de.buerkert.com

International

Die Kontaktadressen finden Sie auf den letzten Seiten der

gedruckten Bedienungsanleitung.

Außerdem im Internet unter: www.burkert.com

5.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des Typs 8605 unter Beachtung der

spezifizierten Einsatzbedingungen.

5.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 8605

finden Sie im Internet unter: www.buerkert.de

deutsch

29

6. SYSTEMBESCHREIBUNG

6.1. Vorgesehener Einsatzbereich

Der Typ 8605 ist für den dauerhaften Einsatz in Industrie-in Industrieumgebung konzipiert, insbesondere in den Bereichen der

Steuer- und Regeltechnik.

6.2. Allgemeine Beschreibung

Die Digitale Ansteuerelektronik für Proportionalventile Typ

8605 (im Folgenden Ansteuerelektronik Typ 8605 genannt)

steuert alle Bürkert - Proportionalventile mit einem Maximalstrom im Bereich von 40 ... 2000 mA.

Sie wandelt ein externes Normsignal in ein pulsweitenmoduliertes Spannungssignal (PWM) um, mit dem die Magnetspule

des Proportionalventils beaufschlagt wird. Jedem Wert des

Eingangssignals ist dabei ein bestimmter Wert des mittleren

Spulenstroms zugeordnet. Über den Spulenstrom ist die

Öffnung des Ventils proportional einstellbar.

deutsch

30

6.3. Bauformen des Gerätes

6.3.1. Typ 8605

Gerätesteckdoseausführung

Bild 1: Typ 8605 Gerätesteckdoseausführung

Aufsteckbare Version auf Ventile mit Steckerbild A (zum

Beispiel die Typen: 2832, 2833, 2834, 2835, 2836, 2853,

2863, 2865, 2873, 2875, 6022, 6023, 6024, 6223).

Die Bedieneinheit kann nach dem Einstellvorgang abgenommen werden. Bei Betrieb der Ansteuerelektronik 8605

in Gerätesteckdoseausführung ohne Bedieneinheit wird der

Betriebszustand durch zwei LEDs angezeigt.

Gerätevarianten:

• Variante 1 für Ventile mit einem Maximalstrom von

200...1000 mA

• Variante 2 für Ventile mit einem Maximalstrom von

500...2000 mA

deutsch

31

6.3.2. Typ 8605

Hutschienenausführung

Bild 2: Typ 8605 Hutschienenausführung

Separate Elektronik in Gehäuse für Hutschienenmontage

nach DIN EN 50022. Diese Bauform eignet sich für alle

Proportionalventile im angegebenen Strombereich. Die

Bedieneinheit ist nicht abnehmbar.

Gerätevarianten:

• Variante 1 für Ventile mit einem Maximalstrom von

40 ... 220 mA

• Variante 2 für Ventile mit einem Maximalstrom von

200 ... 1000 mA

• Variante 3 für Ventile mit einem Maximalstrom von

500 ... 2000 mA

deutsch

Typ 8605

Page 10

32

7. TECHNISCHE DATEN

7.1. Betriebsbedingungen

Spannungsversorgung 12...24 V DC ±10 %

Restwelligkeit 5 %

Leitungsaufnahme ca. 1 W

Ausgangsstrom (zum Ventil) max. 2 A

Betriebstemperatur -10 ... 60 ºC / 14 ...140 ºF

Störfestigkeit nach EN50082-2

Störausstrahlung nach EN50081-2

Strombereich je nach

Ausführung für Ventile 40 ... 220 mA,

200 ... 1000 mA,

500 ... 2000 mA

Normsignaleingang

Spannung (0 ... 5, 0 ... 10 V) Eingangimpedanz > 20 kW

Strom (0 ...20, 4 ... 20 mA) Eingangimpedanz <200 W

deutsch

33

Gehäuse: Hutschienenausführung

Schutzart IP40 (DIN EN 60529)

Werkstoffe Polyamid / PBT

Maße LxBxH: 97 x 27 x 57 mm

Gehäuse: Gerätesteckdoseausführung

Schutzart IP65 (DIN EN 60529)

Werkstoffe Polyamid / PC

Maße LxBxH: 70 x 32 x 42,5 mm

deutsch

34

8. MONTAGE

8.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch hohen Druck in der Anlage!

• Vor dem Lösen von Leitungen und Ventilen den Druck

abschalten und Leitungen entlüften.

Verletzungsgefahr durch Stromschlag!

• Vor Eingriffen in das Gerät oder die Anlage, Spannung

abschalten und vor Wiedereinschalten sichern!

• Die geltenden Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte beachten!

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Montage!

• Die Montage darf nur autorisiertes Fachpersonal mit

geeignetem Werkzeug durchführen!

Verletzungsgefahr durch ungewolltes Einschalten

der Anlage und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach der Montage einen kontrollierten Wiederanlauf

gewährleisten.

deutsch

35

8.2. Elektrische Anschlüsse

8.2.1. Typ 8605

Gerätesteckdoseausführung

Typ 8605 mit Gerätesteckdoseausführung wird über eine

4-polige Klemmleiste im Gerät elektrisch angeschlossen.

Kabel-Durchmesser 6 ... 8 mm

Kabel-Querschnitt max. 0,75 mm

2

Kabel-Anschlüsse Kabelverschraubung oder Steck-

verbinder M12, 4-polig

Normsignal (+)

Normsignal (-)

GND

12 ... 24 V DC

Bild 3: Anschluss Klemmleiste

deutsch

Typ 8605

Page 11

36

Normsignal (+)

Normsignal (-)

12 ... 24 V DC

GND

Bild 4: Anschluss Steckverbinder

Schraube M3 mit max. 0,3 Nm anziehen

Bild 5: Typ 8605 - Montage an das Ventil

deutsch

37

HINWEIS!

Achten Sie beim Verschrauben mit dem Ventil (Gerätesteckdoseausführung) auf einwandfreien Sitz der

Dichtung.

Ziehen Sie die Schraube M3 nicht zu fest an (max. 0,3 Nm),

da sich das Gehäuse sonst verformt und eine einwandfreie Bedienung der Tasten nicht mehr gewährleistet ist.

8.2.2. LEDs bei Betrieb ohne

Bedieneinheit

Bei Betrieb der Ansteuerelektronik Typ 8605 Gerätesteckdoseausführung ohne Bedieneinheit wird der Betriebszustand

durch zwei LEDs angezeigt.

LED grün: Gerät in Betrieb

LED gelb: Strom durch Ventil

Bild 6: LEDs bei Ausführungen ohne Bedieneinheit

deutsch

38

8.2.3. Typ 8605

Hutschienenausführung

Typ 8605 Hutschienenausführung wird über Klemmleisten

elektrisch angeschlossen.

Klemmleiste Kabel-Querschnitt

2-polig Für Ventil max. 1,5 mm

2

3-polig Für RS232- bzw.

RS485-Schnittstelle

max. 0,5 mm

2

4-polig Für Spannungsversorgung

und Normsignal

max. 1,5 mm

2

1

2

5

6

3

4

7

8

9

Bild 7: Anschluss Klemmleiste

Legende:

1 12 ... 24 V DC 6 Ventil

2 GND 7 RS485-B/T x D

3 Normsignal (-) 8 RS485-A/R x D

4 Normsignal (+) 9 GND

5 Ventil

deutsch

39

9. REINIGUNG

Reinigen Sie die Ansteuerelektronik Typ 8605 mit den

üblichen Reinigungsmitteln. Verwenden Sie keine alkalischen

Reiniger, da diese schädigende Auswirkungen auf die verwendeten Werkstoffe haben.

10. VERPACKUNG, TRANSPORT,

LAGERUNG

HINWEIS!

Transportschäden!

Unzureichend geschützte Geräte können durch den

Transport beschädigt werden.

• Gerät vor Nässe und Schmutz geschützt in einer stoßfesten Verpackung transportieren.

• Eine Über- bzw. Unterschreitung der zulässigen Lagertemperatur vermeiden.

Falsche Lagerung kann Schäden am Gerät

verursachen.

• Gerät trocken und staubfrei lagern!

• Lagertemperatur. -40 …+ 55 °C.

deutsch

Typ 8605

Page 12

40

10.1. Außerbetriebnahme

Setzen Sie die Ansteuerelektronik Typ 8605 wie folgt außer

Betrieb:

→ Das System entlüften.

→ Die Spannungsversorgung abschalten

→ Die Ansteuerelektronik demontieren

→ Die Ansteuerelektronik in der Originalverpackung oder

einer anderen geeigneten Verpackung aufbewahren.

10.2. Wieder-Inbetriebnahme

Nehmen Sie die Ansteuerelektronik Typ 8605 wie folgt wieder

in Betrieb:

→ Die Ansteuerelektronik vor der Wieder-Inbetriebnahme

entpacken und aklimatisieren.

→ Danach wie im Kapitel „8. Montage“ beschrieben

vorgehen.

11. ENTSORGUNG

→ Gerät und die Verpackung umweltgerecht entsorgen.

HINWEIS!

Umweltschäden durch von Medien kontaminierte

Geräteteile.

• Die nationalen Abfallbeseitigungsvorschriften einhalten.

deutsch

Typ 8605

Page 13

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifications

techniques.

© 2008 – 2012 Bürkert Werke GmbH

Operating Instructions 1201/05_EU-ml_00805637/ Original DE

Type 8605

Régulateur électronique numérique pour vannes

proportionnelles

Instructions de Service

Français

42

1. QUICKSTART

Les instructions de service décrivent le cycle de vie complet

de l‘appareil. Conservez ces instructions de sorte qu‘elles

soient accessibles à tout utilisateur et à disposition de tout

nouveau propriétaire.

Informations importantes sur la sécurité!

Lisez attentivement le démarrage rapide. Respectez

avant tout les chapitres « 3. Utilisation conforme » et « 4.

Consignes de sécurité fondamentales ».

• Le démarrage rapide doit être lu et compris.

Le démarrage rapide explique de manière exemplaire le

montage et la mise en service de l’appareil.

La description complète de l’appareil est fournie dans les

instructions de service pour le type 8605.

Les instructions de service se trouvent sur le CD

ci-joint ou sur Internet sous:

www.burkert.fr

Fiches Techniques Type 8605

1.1. Définition du terme « appareil »

Le terme « appareil » utilisé dans ces instructions désigne

toujours le positionneur électromagnétique type 8791.

français

43

2. SYMBOLES

Les moyens de représentation suivants sont utilisés dans les

présentes instructions de service.

DANGER !

Met en garde contre un danger imminent !

• Le non-respect peut entraîner la mort ou de graves

blessures.

AVERTISSEMENT !

Met en garde contre une situation éventuellement

dangereuse !

• Le non-respect peut entraîner de graves blessures ou

la mort.

ATTENTION !

Met en garde contre un risque possible !

• Le non-respect peut entraîner des blessures légères ou

de moyenne gravité.

REMARQUE !

Met en garde contre des dommages matériels !

Conseils et recommandations importants.

→ identifie une opération que vous devez effectuer.

français

Page 14

44

3. UTILISATION CONFORME

L’utilisation non conforme du type 8605 peut présenter des dangers pour les personnes, les installations proches et l’environnement.

• L‘appareil est conçu pour la commande de Bürkert

vannes proportionnelles.

• L‘appareil ne doit pas être exposé au rayonnement

solaire direct.

• L’appareil ne doit pas être installé et utilisé en plein air.

• Il convient de régler la fréquence MLI adaptée à la vanne

pour garantir le fonctionnement parfait de l’appareil. Vous

trouverez le tableau avec les valeurs de réglage sur la

page d’accueil Bürkert www.buerkert.fr → Type 8605.

• L‘utilisation doit se faire dans le respect des données

admissibles spécifiées dans les documents contractuels et les instructions de service ainsi que des conditions d‘exploitation et d‘utilisation décrites au chapitre

« 7. Caractéristiques techniques ».

• L’appareil peut être utilisé uniquement en association

avec les appareils et composants étrangers recommandés et homologués par Bürkert.

• Les conditions pour l’utilisation sûre et parfaite sont

un transport, un stockage et une installation dans les

règles ainsi qu’une parfaite utilisation et maintenance.

• Veillez à ce que l‘utilisation du types 8605 soit toujours

conforme.

français

45

4. CONSIGNES DE SÉCURITÉ

FONDAMENTALES

Ces consignes de sécurité ne tiennent pas compte :

• Des hasards et des événements pouvant survenir lors du

montage, de l‘exploitation et de l‘entretien des appareils.

• Des prescriptions de sécurité locales que l‘exploitant est tenu

de faire respecter par le personnel chargé du montage.

Danger avec haute pression !

• Avant de desserrer les tuyauteries et les vannes, coupez la pression et purgez l’air des conduites.

Danger présenté par la tension électrique !

• Avant d’intervenir dans l’appareil ou l’installation, coupez la tension et empêchez toute remise sous tension

par inadvertance !

• Veuillez respecter les réglementations en vigueur pour

les appareils électriques en matière de prévention des

accidents ainsi qu’en matière de sécurité !

français

46

La pression dans le système peut chuter lors des

commutations!

• Empêcher la chute de pression.

• Concevoir une alimentation en pression du plus grand

volume possible, y compris pour les appareils en amont

comme les régulateurs de pression, les unités de maintenance, les vannes d’arrêt, par exemple.

Situations dangereuses d’ordre général.

Pour prévenir les blessures, respectez ce qui suit :

• L’installation ne peut pas être actionnée par

inadvertance.

• Les travaux d’installation et de maintenance doivent

être effectués uniquement par des techniciens qualifiés et habilités disposant de l’outillage approprié.

• Après une interruption de l’alimentation électrique ou

du fluide, un redémarrage défini ou contrôlé du process doit être garanti.

• L’appareil doit être utilisé uniquement en parfait état et

en respectant les instructions de service.

• Les règles générales de la technique sont à appliquer

pour l’opérationnel et l’utilisation de l’appareil.

français

47

REMARQUE!

Eléments/sous-groupes sujets aux risques

électrostatiques !

• L’appareil contient des éléments électroniques sensibles

aux décharges électrostatiques (ESD). Ces éléments

sont affectés par le contact avec des personnes ou des

objets ayant une charge électrostatique. Au pire, ils sont

immédiatement détruits ou tombent en panne après mise

en service.

• Respectez les exigences selon DIN EN 61340-5-1 /

5-2 pour minimiser ou éviter la possibilité d’un dommage

causé par une soudaine décharge électrostatique !

• Ne pas toucher les composants électroniques lorsque

la tension d’alimentation est présente !

Le modèle 8605 a été développé dans le respect

des règles reconnues en matière de sécurité et

correspond à l'état actuel de la technique. Néanmoins, des risques peuvent se présenter.

Le non-respect de ces instructions de service avec ses

consignes ainsi que les interventions non autorisées sur

l'appareil excluent toute responsabilité de notre part et

entraînent la nullité de la garantie légale concernant les

appareils et les accessoires !

français

Type 8605

Page 15

48

5. INDICATIONS GÉNÉRALES

5.1. Adresses

Allemagne

Bürkert Fluid Control Systems

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tél. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail : info@de.buerkert.com

International

Les adresses se trouvent aux dernières pages des instructions

de service imprimées.

Egalement sur internet sous : www.burkert.com

5.2. Garantie légale

La condition pour bénéficier de la garantie légale est l’utilisation conforme du type 8605 dans le respect des conditions

d’utilisation spécifiées.

5.3. Informations sur Internet

Vous trouverez sur Internet les instructions de service et fiches

techniques relatives au type 8605 : www.buerkert.fr

français

49

6. DESCRIPTION DU SYSTÈME

6.1. Domaine d’utilisation

Le régulateur électronique de type 8605 est conçu pour

une utilisation durable dans un environnement industriel,

notamment dans les domaines des techniques de commande

et de régulation.

6.2. Description générale

Le régulateur électronique numérique pour vannes proportionnelles de type 8605 (ci-après Régulateur électronique de

type 8605) est conçu pur la régulation de toutes les vannes

proportionnelles Bürkert avec une max. courant allant de

40 à 2000 mA.

Il transforme un signal normalisé externe en un signal de

tension avec modulation de largeur d’impulsions (MLI),

appliqué à la bobine d’électroaimant de la vanne proportionnelle. Une certaine valeur du courant de bobine moyen est

attribuée à chaque valeur du signal d’entrée. L’ouverture de

la vanne est réglable en proportion via le courant de bobine.

français

50

6.3. Forme de l’appareil

6.3.1. Type 8605 exécution

connecteur

Fig. 1 : Type 8605 exécution connecteur

Exécution enfichable sur vannes avec schéma de connexion A

(par ex. types 2832, 2833, 2834, 2835, 2836, 2853, 2863,

2865, 2873, 2875, 6022, 6023, 6024, 6223).

Dans le cas de l’utilisation du régulateur électronique 8605

en exécution avec connecteur sans unité de commande, le

mode de service est indiqué par deux LED.

Variantes :

Deux variantes sont disponibles:

• Variante 1 pour vannes avec une max. courant de

200 - 1000 mA,

• Variante 2 pour vannes avec une max. courant de

500 - 2000 mA.

français

51

6.3.2. Type 8605 exécution profilé

chapeau

Fig. 2 : Type 8605 exécution profilé chapeau

Système électronique séparé dans le boîtier pour montage

en profilé chapeau selon la norme DIN EN 50022. Cette

forme convient pour toutes les vannes proportionnelles dans

la plage de puissance indiquée.

Variantes :

• Variante 1 pour vannes avec une max. courant de

40 - 220 mA,

• Variante 2 pour vannes avec une max. courant de

200 - 1000 mA,

• Variante 3 pour vannes avec une max. courant de

500 - 2000 mA.

français

Type 8605

Page 16

52

7. CARACTÉRISTIQUES

TECHNIQUES

7.1. Conditions d‘exploitation

Alimentation de tension 12...24 V DC ± 10%

Ondulation résiduelle 5 %

Puissance absorbée

(sans vanne) ca. 1 W

Courant de sortie

(vers la vanne) max. 2 A

Température de service -10 ... 60 ºC / 14 ... 140 ºF

Immunité au brouillage selon EN50082-2

Émissions parasites selon EN50081-2

Plage de max. courant

pour les vannes 40 ... 220 mA,

200 ... 1000 mA,

500 ... 2000 mA

Signal d’entrée normalisé

Tension (0 ... 5, 0 ... 10 V) Impédance d’entrée > 20 kW

Intensité (0 ... 20, 4 ... 20 mA) Impédance d’entrée <200 W

français

53

Boîtier exécution profilé chapeau

Degré de protection selon IP40 (DIN EN 60529)

Matériaux Polyamide / PBT

Dimensions LxLxH: 97 x 27 x 57 mm

Boîtier exécution connecteur

Degré de protection selon IP65 (DIN EN 60529)

Matériaux Polyamide / PC

Dimensions LxLxH: 70 x 32 x 42,5 mm

français

54

8. MONTAGE

8.1. Consignes de sécurité

DANGER!

Danger avec haute pression !

• Avant de desserrer les tuyauteries et les vannes, coupez la pression et purgez l’air des conduites.

Danger présenté par la tension électrique !

• Avant d’intervenir dans l’appareil ou l’installation, coupez la tension et empêchez toute remise sous tension

par inadvertance !

• Veuillez respecter les réglementations en vigueur pour

les appareils électriques en matière de prévention des

accidents ainsi qu’en matière de sécurité !

AVERTISSEMENT!

Risque de blessures dû à un montage !

• Le montage doit être effectué uniquement par un personnel qualifié et habilité de l’outillage approprié !

Risque de blessures dû à la mise en marche involontaire de l‘installation et le redémarrage non contrôlé!

• Empêchez tout actionnement involontaire de

l‘installation.

• Garantissez un redémarrage contrôlé après le

montage.

français

55

8.2. Branchements électriques

8.2.1. Type 8605 exécution le

connecteur

Le raccordement électrique du type 8605 avec exécution

connecteur se fait au moyen d’une borne plate à 4-pôles.

Câble diamètre 6 ... 8 mm

Câble section max. 0,75 mm

2

Raccords câbles Raccord à vis pour câble ou

connecteur M12, 4-pôles

Signal normalisé (+)

Signal normalisé (-)

GND

12 ... 24 V DC

Fig. 3 : Raccordement sur la borne plate

français

Type 8605

Page 17

56

Signal normalisé (+)

Signal normalisé (-)

12 ... 24 V DC

GND

Fig. 4 : Raccordement sur le connecteur

Serrer la vis M3 avec 0,3 Nm maximum.

Fig. 5 : Montage de l’exécution connecteur sur la vanne

français

57

REMARQUE!

En vissant le raccord avec la vanne (exécution

connecteur), s’assurer de la position correcte des joints.

Ne pas serrer la vis M3 trop fort (0,3 Nm maximum),

car sinon le boîtier risque de se déformer et le fonctionnement correct des touches ne sera plus garanti.

8.2.2. LED sans unité de commande

Lorsque l’électronique de commande du type 8605 avec

connecteur est utilisée sans unité de commande, l’état de

fonctionnement est signalé par deux LED.

LED verte : L’appareil en service

LED jaune : Courant par la vanne

Fig. 6 : LED pour versions sans unité de commande

français

58

8.2.3. Type 8605 exécution profilé

chapeau

Le branchement électrique du régulateur de type 8605 en

exécution profilé chapeau se fait au moyen de bornes plates.

Borne plate Section de câble

2-pôles Pour vanne max. 1,5 mm

2

3-pôles Pour interface RS232 ou

RS485

max. 0,5 mm

2

4-pôles Pour alimentation de

tension et signal normalisé

max. 1,5 mm

2

1

2

5

6

3

4

7

8

9

Fig. 7 : Raccordement sur la borne plate

Légende:

1 12 ... 24 V DC 6 Vanne

2 GND 7 RS485-B/T x D

3 Signal normalisé (-) 8 RS485-A/R x D

4 Signal normalisé (+) 9 GND

5 Vanne

français

59

9. NETTOYAGE

Utiliser les produits de nettoyage habituels pour le nettoyage

du régulateur électronique de type 8605. Ne pas utiliser de

détergents alcalins, car ils attaquent les matières utilisées.

10. EMBALLAGE, TRANSPORT,

STOCKAGE

REMARQUE !

Dommages dus au transport !

Les appareils insuffisamment protégés peuvent être

endommagés pendant le transport.

• Transportez l'appareil à l'abri de l'humidité et des impuretés et dans un emballage résistant aux chocs.

• Evitez le dépassement vers le haut ou le bas de la température de stockage admissible.

Un mauvais stockage peut endommager l'appareil.

• Stockez l'appareil au sec et à l'abri des poussières !

• Température de stockage : -40 … +55 °C.

10.1. Mise hors service

Mettre le régulateur électronique de type 8605 hors service

de la manière suivante:

→ Purger le système.

français

Type 8605

Page 18

60

→ Couper la tension d’alimentation.

→ Démonter le régulateur électronique de type 8605.

→ Conserver le régulateur électronique dans son emballage

d’origine ou dans un autre emballage approprié.

10.2. Remise en service

Remettre le régulateur électronique de type 8605 en service

de la manière suivante:

→ Déballer et acclimater le régulateur électronique de type

8605 avant la remise en service.

→ Procéder ensuite comme indiqué dans le chapitre

« 8. Montage ».

11. ELIMINATION

→ Eliminez l’appareil et l’emballage dans le respect de

l’environnement.

REMARQUE !

Dommages à l'environnement causés par des pièces

d'appareil contaminées par des fluides.

• Respectez les prescriptions en matière d’élimination

des déchets et de protection de l’environnement en

vigueur.

• Respectez les prescriptions nationales en matière

d’élimination des déchets.

français

Type 8605

Loading...

Loading...