Page 1

MultivaporTM P-6/P-12

Operation Manual

093156 en

Page 2

Page 3

Table of contents

Table of contents

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.1 Reference documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.2 Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1 User qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Safety warnings and safety signals used in this manual . . . . . . . . . . . . . . . . . 9

2.5 Product safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.1 Instrument-related hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.2 Other hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.3 Personal protective equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.4 Safety elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 General safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.1 Instrument configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.2 Ordering matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1.3 Standard accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1.4 Standard accessory glassware . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.1.5 Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2 Materials used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.3 Technical data overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4 Solvent table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Read this manual carefully before installing and running your system and note the safety precautions

in chapter 2 in particular. Store the manual in the immediate vicinity of the instrument, so that it can be

consulted at any time.

No technical modifications may be made to the instrument without the prior written agreement of

BUCHI. Unauthorized modifications may affect the system safety or result in accidents.

This manual is copyright. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of

this manual without prior written agreement is also prohibited.

The English manual is the original language version and serves as basis for all translations

into other languages. Other language versions can be downloaded at www.buchi.com.

3 Multivapor™ Operation Manual, Version E

Page 4

Table of contents

4 Description of function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1 Functional principle of the Multivapor . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.1.1 Functional principle of the stand-alone unit . . . . . . . . . . . . . . . . . . . . . . 28

4.1.2 Functional principle of the Multivapor-Rotavapor edition. . . . . . . . . . . . . . . . 29

4.1.3 Controls of the Multivapor (stand-alone) . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1.4 Display of the Multivapor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.1.5 Rear connections of the Multivapor . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 Multivapor platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3 Crystal rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4 Sample preparation rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.5 Blank adapters (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.6 PE frits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.7 Adapter spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.8 Sample transfer plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.9 Vacuum cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4.10 Protective shield (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.11 Condensation (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

4.12 High-boiling solvents - Woulff bottle (optional) . . . . . . . . . . . . . . . . . . . . . 36

4.13 Vacuum solution (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.14 Connection to a rotary evaporator (optional). . . . . . . . . . . . . . . . . . . . . . 37

4.15 Refrigerated receiver (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5 Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.1 Installation site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.2 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.3 Commissioning the Multivapor basic instrument. . . . . . . . . . . . . . . . . . . . 39

5.3.1 Commissioning the crystal rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.3.2 Assembling the Woulff bottle (optional) . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.3 Anti-seismic tie-down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.4 Glass assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.4.1 Type S and type C condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.4.2 Condenser assembly with the refrigerated receiver (optional) . . . . . . . . . . . . . 41

5.5 Tube connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.5.1 Cooling water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.5.2 Vacuum tubes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.6 Commissioning the Multivapor-Rotavapor edition . . . . . . . . . . . . . . . . . . . 44

5.7 Functional test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.7.1 Vacuum tightness test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4 Multivapor™ Operation Manual, Version E

Page 5

Table of contents

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1 Settings at the Multivapor platform . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.1 Selecting a preset temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.1.2 Changing/switching off the preset temperature . . . . . . . . . . . . . . . . . . . . 47

6.1.3 Setting the rotational speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2 Sample preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.2.1 Heating up the instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.2.2 Sample preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.3 Selecting the distillation conditions . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.4 Distillation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.5 Optimizing the vacuum conditions (optional). . . . . . . . . . . . . . . . . . . . . . 51

6.5.1 Manual vacuum control and solvent library (V-850/V-855) . . . . . . . . . . . . . . . 51

6.5.2 Pressure gradients (V-855) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.5.3 Automatic distillation (V-855) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.6 Optimizing the distillation conditions. . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.7 When the distillation “dies out” . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.8 At the end of a run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.1 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2 Tube connections and joints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.3 Sealing system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.3.1 Cleaning the seals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.3.2 Replacing the tube adapter seals . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7.3.3 Replacing the conical adapter O-rings. . . . . . . . . . . . . . . . . . . . . . . . . 56

7.3.4 Cleaning the vacuum cover and replacing the corresponding O-rings . . . . . . . . . 57

7.4 Crystal rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7.5 Glass components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7.6 PE frits (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.1 Malfunctions and their remedy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8.2 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9 Shutdown, storage, transport and disposal . . . . . . . . . . . . . . . . . . . . . . . . 62

9.1 Storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.2 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.3 Health and safety clearance form . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.1 Basic instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.2 Evaporation unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10.3 Adapter sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.4 Condenser assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.5 Various glass parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.6 Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

11 Declarations and requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

11.1 FCC requirements (for USA and Canada) . . . . . . . . . . . . . . . . . . . . . . . 73

11.2 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5 Multivapor™ Operation Manual, Version E

Page 6

1 About this manual

This manual describes the Multivapor P-6 and P-12 and provides all information required for its safe

operation and to maintain it in good working order.

It is addressed in particular to laboratory personnel and operators.

NOTE

The symbols pertaining to safety (WARNINGS and ATTENTIONS) are explained in chapter 2.

1.1 Reference documents

For information on the Rotavapor, the vacuum controller and the vacuum pump, please refer to the

corresponding manuals available in English, German, French, Spanish and Italian:

• Rotavapor R-210/215, Operation Manual numbers 93076–93080

• Vacuum Controller, Operating Manual numbers 93081–93085

• Vacuum Pump, Operating Manual numbers 93090–93094

1 About this manual

1.2 Trademarks

The following product names and any registered and unregistered trademarks mentioned in this

manual are used for identification purposes only and remain the exclusive property of their respective

owners:

®

is a registered trademark of Dionex Corporation

ASE

• Multivapor™ is a trademark of BÜCHI Labortechnik AG

• Rotavapor

®

is a registered trademark of BÜCHI Labortechnik AG

6 Multivapor™ Operation Manual, Version E

Page 7

1.3 Abbreviations

Chemicals:

EPDM: Ethylenepropylenedimonomer

FEP: Combination of tetrafluoroethylene and hexafluoropropylene

FFKM: Perfluoro caoutchouc

FKM: Fluoric caoutchouc

PBT: Polybutyleneterephthalate

PE: Polyethylene

PEEK: Polyetheretherketone

PET(P): Polyethyletherphtalate

PETP: Polyethylterephthalate

PFA: Perfluoroalkoxy

PTFE: Polytetrafluoroethylene

PUT: Polyurethane

Miscellaneous:

rpm: revolutions per minute

P+G: PLASTIC+GLAS is a unique protective layer for glass components. It offers improved mechan-

ical rupture resistance and increases protection against broken glass whilst ensuring no sample

is lost in the event of the receiving flask being damaged.

1 About this manual

7 Multivapor™ Operation Manual, Version E

Page 8

2 Safety

This chapter highlights the safety concept of the Multivapor and contains general rules of behavior and

warnings from hazards concerning the use of the product.

The safety of users and personnel can only be ensured if these safety instructions and the safetyrelated warnings in the individual chapters are strictly observed and followed, therefore, the manual

must always be available to all persons performing the tasks described herein.

2.1 User qualification

The instrument may only be used by laboratory personnel or other persons who on account of training

or professional experience have an overview of the dangers which can develop when operating the

instrument.

Personnel without this training or persons who are currently being trained require careful supervision.

The present Operation Manual serves as a basis for training.

2 Safety

2.2 Proper use

The instrument has been designed and built for laboratory use only. It serves for activities associated

with the parallel evaporation of multiple samples by means of heating under vacuum, with or without

regulation by a vacuum controller. The vacuum is typically applied by a PTFE diaphragm vacuum

pump.

Alternatively, the instrument can be used in combination with a rotary evaporator. In this case

the Multivapor serves as an accessory and is connected via an interface to the condenser of the

Rotavapor.

2.3 Improper use

Applications beyond those described above are improper. Furthermore, applications which do not

comply with the technical data are also considered improper. The operator bears the sole risk for any

damages caused by such improper use.

The following applications are expressly forbidden:

• Use of the instrument in rooms which require ex-protected instruments.

• Use as a calibrating instrument for other instruments.

• Preparation of samples which can explode or inflame due to shock, friction, heat or spark formation.

• Use in high pressure situations.

• Processing of hard, brittle and abrasive materials (e.g. stones, sherds, soil samples, etc.) which

may destruct the sample tubes.

• Use of the instrument for digestions (e.g. Kjeldahl).

8 Multivapor™ Operation Manual, Version E

Page 9

2.4 Safety warnings and safety signals used in this manual

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying levels of

hazard seriousness of risks related to personal injury and property damage. All signal words, which are

related to personal injury are accompanied by the general safety sign.

For your safety it is important to read and fully understand the below table with the different signal

words and their definitions!

Sign Signal word Definition Risk level

DANGER

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

2 Safety

★★★★

WARNING

CAUTION

NOTICE

no

Supplementary safety information symbols may be placed in a rectangular panel on the left to the

signal word and the supplementary text (see below example).

Space for

supplementary

safety

information

symbols.

Indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

Indicates a hazardous situation which, if not avoided, may result

in minor or moderate injury.

Indicates possible property damage, but no

practices related to personal injury.

!

SIGNAL WORD

Supplementary text, describing the kind and level of hazard / risk seriousness.

• List of measures to avoid the herein described hazard or hazardous situation.

• ...

• ...

(property damage only)

★★★☆

★★☆☆

★☆☆☆

Table of supplementary safety information symbols

The below reference list incorporates all safety information symbols used in this manual and their

meaning.

Symbol Meaning

General warning

Electrical hazard

9 Multivapor™ Operation Manual, Version E

Page 10

Symbol Meaning

Explosive gases, explosive environment

Harmful to life-forms

Hot item, hot surface

Explosive substance

2 Safety

Device damage

Inhalation of substances

Flammable substances

Fragile items / content

Do not dispose of in household trash

Wear protective mask

Wear laboratory coat

10 Multivapor™ Operation Manual, Version E

Page 11

2 Safety

Symbol Meaning

Wear protective goggles

Wear protective gloves

Additional user information

Paragraphs starting with NOTE transport helpful information for working with the device / software or

its supplementaries. NOTEs are not related to any kind of hazard or damage (see example below).

NOTE

Useful tips for the easy operation of the instrument / software.

2.5 Product safety

The Multivapor is designed and built in accordance with current state-of-the-art technology, however,

risks to users, property, and the environment can arise when the instrument is used carelessly or

improperly.

The manufacturer has determined residual dangers emanating from the instrument

• if the instrument is operated by insufficiently trained personnel.

• if the instrument is not operated according to its proper use.

Appropriate warnings in this manual serve to make the user alert to these residual dangers.

2.5.1 Instrument-related hazards

Pay attention to the following safety notices:

!

Risk of minor or moderate burns when handling hot parts.

• Do not touch hot parts or surfaces (especially the heating plate with up to 95 °C)

!

Death or serious injuries by formation of explosive atmospheres (peroxides) inside the instrument.

• Directly withdraw released fumes and gaseous substances by sufficient ventilation at filling

• Before operation, check all gas connections for correct installation

• Establish inert system atmosphere before processing substances that can form explosive or

reactive gases or powders

• Check for proper earth connection to lead off electrostatic charges

CAUTION

WARNING

11 Multivapor™ Operation Manual, Version E

Page 12

2 Safety

2.5.2 Other hazards

Risk of glass breakage by excessive strains.

• Mount all glassware parts without strains

• Check glassware for proper fixing regularly and readjust fixing points if necessary

• Do not use defective glassware

• Use the protective shield (optional)

Risk of instrument damage by wrong mains supply.

• External mains supply must meet the voltage given on the type plate

• Check for sufficient grounding

Death or serious burns by flammable vapors.

• Remove all sources of flammable vapors

• Do not store flammable chemicals in the vicinity of the device

!

NOTICE

NOTICE

WARNING

2.5.3 Personal protective equipment

Always wear personal protective equipment such as protective eye goggles, protective clothing and

gloves. The personal protective equipment must meet all requirements of the supplementary data

sheets for the chemicals used.

!

WARNING

Death or serious poisoning by contact or incorporation of harmful substances.

• Wear safety goggles

• Wear safety gloves

• Wear a laboratory coat

12 Multivapor™ Operation Manual, Version E

Page 13

2.5.4 Safety elements

Electronics

• The heating plate is equipped with an electronic over-temperature protection. It controls the

temperature limit (the actual heating plate temperature may not exceed the set temperature by

2 °C for more than 2 minutes) and the function of the temperature sensor.

• The heating plate is equipped with safety fuses.

Parts in direct contact with the instrument

• Combi clip for fixing the vacuum joint.

• Ball joint clip for safe fixing of the receiving flask.

• Rods and holder for attaching the condensation assemblies.

Glass

• Use of high quality, inert 3.3 borosilicate glass.

• Use of tube clips GL-14 for preventing glass breakage.

• PLASTIC+GLAS (P+G) is a unique protective layer for glass components. It offers improved

mechanical damage resistance and increases protection against broken glass. It also makes sure

that the solvent in the receiving flask is not spilled, if the flask is damage. All glass parts of the

condenser assembly are P+G coated.

2 Safety

Anti-seismic tie-down

• The instrument is equipped with a tie-down to fix it in the event of an earthquake.

• Optional

• The protective shield (optional but recommended accessory) protects operators in case of accidents from broken glass, solvent splashes, hot water, explosion or implosion.

2.6 General safety rules

Responsibility of the operator

The head of laboratory is responsible for training his personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which might

occur during the operation of the instrument. Legal regulations, such as local, state and federal laws

applying to the instrument must be strictly followed.

Duty of maintenance and care

The operator is responsible for ensuring that the instrument is only operated in proper manner and

that maintenance, service, and repairs are performed with care, on schedule and by authorized

personnel only.

Spare parts to be used

Use only recommended consumables and spare parts for maintenance to ensure continued optimum

system performance and reliability. Any modifications to the spare parts used are only allowed with the

prior written permission of the manufacturer.

Modifications

Modifications to the instrument are only permitted after prior consultation with and written approval

obtained from the manufacturer. Modifications and upgrades should only be carried out by an authorized BUCHI technical engineer. The manufacturer reserves the right to decline any claim resulting from

unauthorized modifications.

13 Multivapor™ Operation Manual, Version E

Page 14

3 Technical data

This chapter introduces the reader to the Multivapor and its main components. It contains technical

data, requirements and performance data.

3.1 Scope of delivery

Check the scope of delivery according to the order number.

NOTE

For detailed information on the listed products, see www.buchi.com or contact your local dealer.

3.1.1 Instrument configurations

The Multivapor is a compact parallel evaporation system with either 6 or 12 position, referred to as

Multivapor P-6 or Multivapor P-12, respectively. Both setups are availble in different configurations

implying peripherals such as condenser units, vacuum pumps/controllers and a rotary evaporator

interface.

3 Technical data

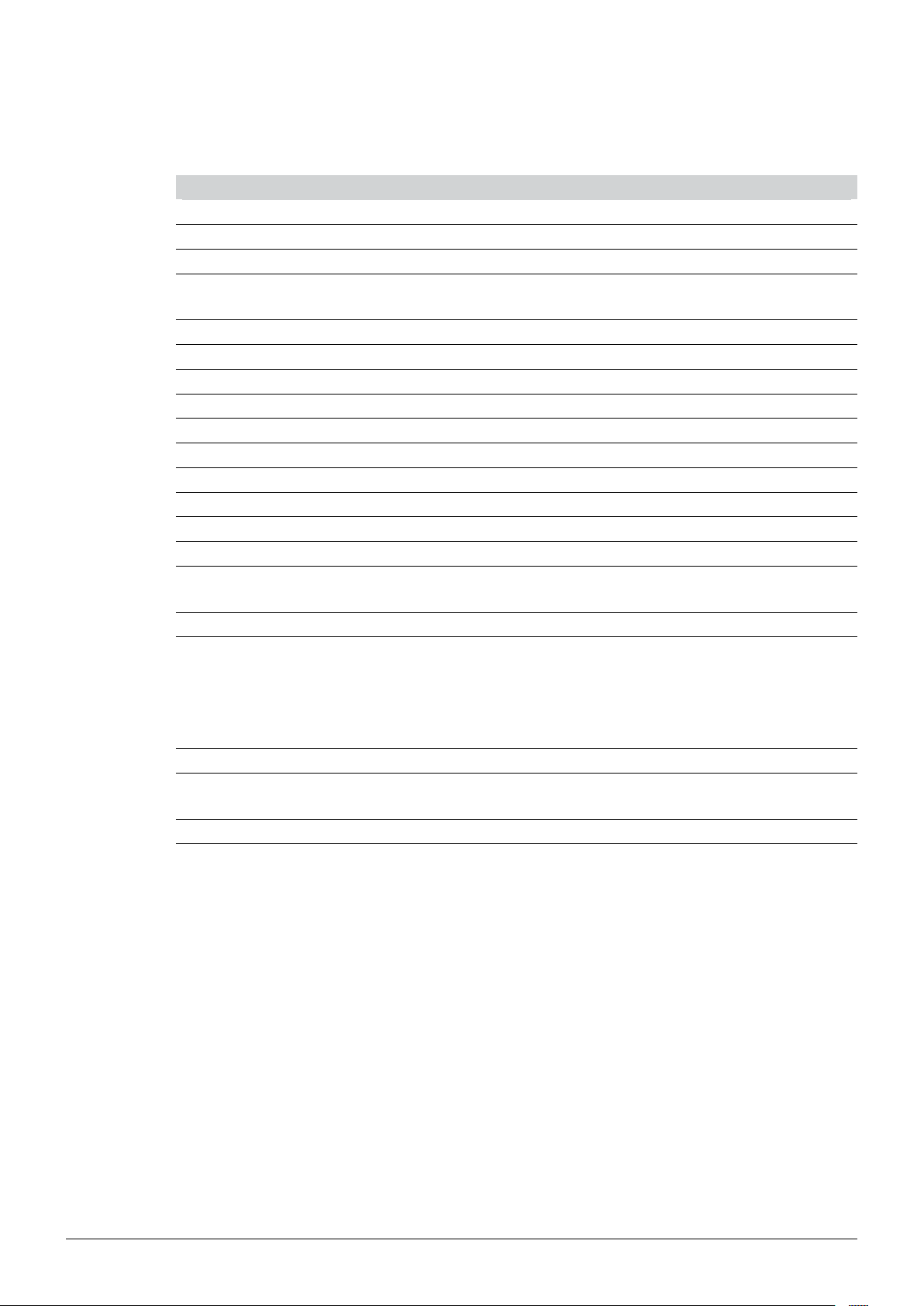

Multivapor Basic

Multivapor platform with the crystal rack, vacuum cover, tube adapters, transfer and sample prepara-

tion rack, P+G coated condenser and receiving flask.

14 Multivapor™ Operation Manual, Version E

Page 15

3 Technical data

Table 3-1: Items included in the Basic configuration

Product Order number

Multivapor platform

220–240 V

100–120 V

Crystal rack

P-6

P-12

Vacuum cover

P-6

P-12

Tube adapters

BUCHI Standard P-6 (6 pieces)

BUCHI Standard P-12 (12 pieces)

Glassware

BUCHI Standard vessel P-6 (6 pieces)

BUCHI Standard vessel P-12 (25 pieces)

Transfer rack

P-6

P-12

Sample preparation rack

P-6

P-12

Condenser unit, P+G coated

type S, 1 l

type S, 2 l

type C, 1 l

type C, 2 l

–

–

11057500

11057505

49773

49615

11056598

11057082

49774

49662

49250

49251

49783

49755

48889

48890

48887

48888

Multivapor Professional

The difference between the EasyVac and the Professional configuration is that the latter comprises an

additional secondary condenser for the vacuum pump and the vacuum controller V-855.

Table 3-3: Items included in the Professional

configuration

Product Order number

Multivapor P-6/P-12 Basic –

V-700/V-855, Woulff bottle and secondary

post pump condenser (type according to

71311 or

71312

the primary condenser)

15 Multivapor™ Operation Manual, Version E

Page 16

3 Technical data

Multivapor Rotavapor

In contrast to the stand-alone configurations described before, this setup is connected to an already

installed rotary evaporator. Delivery therefore includes the Multivapor with a Rotavapor set to combine

it with the condenser of the rotary evaporator.

Table 3-4: Items included in the Rotavapor

configuration

Product Order number

Multivapor platform

220–240 V

100–120 V

Crystal rack

P-6

P-12

Vacuum cover

P-6

P-12

Tube adapters

BUCHI Standard P-6 (6 pieces)

BUCHI Standard P-12 (12 pieces)

Glassware

BUCHI Standard vessel P-6 (6 pieces)

BUCHI Standard vessel P-12 (25 pieces)

Transfer rack

P-6

P-12

Sample preparation rack

P-6

P-12

–

–

11057500

11057505

49773

49615

11056598

11057082

49774

49662

49250

49251

49783

49755

Rotavapor adapter set 48740

NOTE

The Rotavapor is not included in the Rotavapor configuration.

16 Multivapor™ Operation Manual, Version E

Page 17

3.1.2 Ordering matrix

In this section the items accessible by the ordering matrix are listed.

NOTE

The standard plastic material is PETP, however, for very harsh conditions such as trifluoric acid (TFA)

PEEK is available as a highly resistant alternative. In this case configure the system without evaporation unit and tube adapters (position „00“ in the matrix section „evaporation unit“) and order the

corresponding items separately as accessory.

Order number:

MP

x x x x x x x

3 Technical data

Number of sample positions

Product

1: Multivapor P-12

2: Multivapor P-6

Order number:

x x x x x x x

MP

Voltage

Product

1: 220–240 V

2: 100–120 V

17 Multivapor™ Operation Manual, Version E

Page 18

Order number:

MP

x x

x x x x x

1

Order number:

x x x x x x

MP

3 Technical data

Protective shield

Product Order number

Protective shield P-6, P-12 48784

Evaporation unit, tube adapter, glassware

Product

01: Configuration with evaporation unit (i.e. crystal rack

and vacuum cover), set of tube adapters for BUCHI’s

standard sample tubes, preparation/transfer rack,

set of BUCHI’s standard sample tubes (ø 60 mm for

P-6, ø 25 mm for P-12).

99: Configuration with evaporation unit but without

tube adapters and glassware. The corresponding

adapters have to be ordered separately according

to the Multivapor Adapter Guide.

00: Configuration without evaporation unit, without

preparation/transfer rack and without adapters and

glassware. This is the recommended choice to set

up a PEEK system instead of a PETP system. The

corresponding items have to be ordered separately

as accessory (not via the ordering matrix).

18 Multivapor™ Operation Manual, Version E

Page 19

Order number:

x x x x x x

MP

3 Technical data

Condenser assembly, P+G coated

Product Order number

Type S condenser for tap water or a

recirculating chiller.

S1: Condenser with 1 l receiving flask 48889

S2: Condenser with 2 l receiving flask 48890

Type C condenser (cold trap) for dry-ice

cooling:

C1: Cold trap with 1 l receiving flask

48887

C2: Cold trap with 2 l receiving flask 48888

R0: Rotavapor adapter set 48740

19 Multivapor™ Operation Manual, Version E

Page 20

Order number:

x x x x x x x

MP

3 Technical data

Vacuum solution

Product Order number

Comprises a Woulff bottle to trap particles and droplets

before the vacuum inlet.

V-700, V-855 with secondary condenser

according to the type of the primary

71311 or

71312

condenser

3.1.3 Standard accessories

Table 3-5: Standard accessories

Product Order number

Crystal rack P-6 11057500

Crystal rack P-12 11057505

Vacuum cover P-6, PETP*

Vacuum cover P-6, PEEK**

Vacuum cover P-12, PETP*

Vacuum cover P-12, PEEK**

49773

49710

49615

48845

*equipped with EPDM O-rings

(FKM enclosed)

**equipped with FFKM O-rings

20 Multivapor™ Operation Manual, Version E

Page 21

3 Technical data

Table 3-5: Standard accessories (cont.)

Product Order number

Sample preparation rack P-6 49783

Sample preparation rack P-12 49755

Transfer plate P-6 49251

Transfer plate P-12 49250

Transfer plate P-6 for P-12 adapter 11055146

Table 3-6: Multivapor adapter P-12

Product Order number

Adapter carrier PETP 11057171

Adapter carrier PEEK 11057179

Set of 12 gaskets 11057468

Multivapor and Syncore tool 11057214

Table 3-7: Documentation

Product Order number

Application booklet 48858

Installation/Operation guide 93163

Multivapor IQ/OQ, English 48822

Operation Manual:

English 93156

German 93157

French 93158

Italian 93159

Spanish 93160

21 Multivapor™ Operation Manual, Version E

Page 22

3.1.4 Standard accessory glassware

3 Technical data

1

Fig. 3.1: Overview over the available BUCHI glassware and the corresponding adapters

Sample tubes available from BUCHI

2

3 4

5

6

Adapter set (12) **

PETP PEEK

7

8

Seals **

a BUCHI tube P-12, 60 mL (25 pcs) 49662 11057082 11057178 11057468 (12)

b ASE/PSE tube, 60 mL (72 pcs) 49535 11057082 11057178 11057468 (12)

c Test tube ø 25 mm (50 pcs) 38469 48873 * 49733 (12)

P-12

d Test tube ø 20 mm (100 pcs) 42845 48778 * 48779 (12)

e Test tube ø 16 mm (100 pcs) 38543 48770 * 48773 (12)

f BUCHI tube P-6, 220 mL (6 pcs) 49774 11056598 11057243 11057469 (6)

g ASE/PSE tube, 240 mL (10 pcs) 52672 11056585 * 48853 (12)

P-6

h ASE/PSE tube, 60 mL (72 pcs) 49535 11056585 * 48853 (12)

*available on request **number of items included in the set given in brackets

22 Multivapor™ Operation Manual, Version E

Page 23

3.1.5 Optional accessories

3 Technical data

Table 3-8: Optional accessories

Product Order number

Protective shield P-6/P-12 48784

Set of 60 PE frits P-6/P-12, ø 10 mm 44856

Blank adapters to close vacant positions

P-6, PETP, 6 pieces

P-6, PEEK, 6 pieces

P-12, PETP, 12 pieces

P-12, PEEK, 12 pieces

Set of Woulff bottle including holder and

49729

49730

48791

48796

11057282

tube

Spare glass for Woulff bottle 11056926

Spare tube 11057283

Set of 1 gasket and 1 O-ring for Woulff

11057990

bottle

23 Multivapor™ Operation Manual, Version E

Page 24

3.2 Materials used

Table 3-9: Materials used

Component Material designation

Housing Multivapor PUT foam

Heating plate Aluminium, anodized

Protective ring heating plate EPDM

Crystal rack Aluminium, borosilicate glass

Standard tube adapters PETP

PEEK tube adapters PEEK

Seals for tube adapters PTFE

Standard vacuum cover PETP

Alternative vacuum cover PEEK

Vacuum cover seal EPDM

O-ring for the vacuum cover adapter EPDM and FKM or FFKM (optional)

Vacuum tube Ribbed PFA with PTFE

Protective shield Polycarbonate

3 Technical data

Table 3-8: Optional accessories (cont.)

Product Order number

F-100, 230 V; 50/60 Hz (400 W) 11056460

F-100, 115 V; 50/60 Hz (400 W) 11056461

F-108, 230 V; 50/60 Hz (800 W) 11056464

F-108, 115 V; 50/60 Hz (800 W) 11056465

seals

24 Multivapor™ Operation Manual, Version E

Page 25

3 Technical data

Table 3-10: Range of application for the O-rings of the conical adapters

EPDM FKM FKKM PEEK PET(P) P FA PTFE

Acetaldehyde B D A A A A A

Acetic acid A B A A A A A

Acetic acid anhydride B D A A A A A

Acetone A D A A B A A

Benzene D A A A A A A

Butanol B A A A B A A

Chloroform D A A A B A A

Diethyl ether C C A A A A A

Dimethylformamide A - A A B A A

Dimethylbenzene (Xylol) D A A A A A A

Dioxane B - A A A A A

Ethanol A A A A A A A

Ethyl acetate B D A A - A A

Hexane C A A A A A A

Isobutanol A A A A A A A

Isopropanol A A A A A A A

Methanol A B A A A A A

Methylene chloride D A A A D A A

Nitrobenzene C B A B D A A

Phenol B A A B C A A

Propanol A A A A A A A

Sulphuric acid, fuming C A A C C A A

Carbon tetrachloride D A A A A A A

Tetrahydrofurane B D A A A A A

Toluene D A A A A A A

Triethylamine C A A A - - -

Trichloroethane D A A A A - -

Trichloroacetic acid B - - A - A A

Vinylidene chloride D - A A B - -

Aq. HBr, sat. B A A C - A A

Aq. HCl, sat. A A A B A A A

Aq. ammonia solution A D A A A A A

Aqueous caustic soda A B A A B A A

Aqueous nitric acid B A A B B A A

*A: very good resistance, B: moderate resistance, C: poor resistance, D: very poor resistance

NOTE

Table 3-10 refers to the chemical resistance of the solid material in liquids. However, the resistance

against the corresponding vapors is significantly better. Tabled values may vary by changing temperature and pressure.

The PETP vacuum cover is equipped with EPDM O-rings. A set of 12 FKM O-rings is enclosed.

Alternatively, there are highly resistant FFKM O-rings available. The PEEK vacuum cover is equipped

with FFKM O-rings by default.

25 Multivapor™ Operation Manual, Version E

Page 26

3.3 Technical data overview

Table 3-11: Technical data

Dimensions ( W×H×D) 270×400×400 mm

Weight P-6: 22 kg, P-12: 21 kg

Connection voltage 100 – 120 or 220 – 240 VAC ± 10%

Fuse T 3.1 A L 250 V (220–240 V)

Power consumption max. 800 W

Mains connection 3-pole (P, N, E) via power cord

Frequency 50/60 Hz

Installation category II

Degree of protection IP21

Pollution degree 2

Rotation speed range P-6: 0– 370 rpm, P-12: 0 – 485 rpm

Temperature control range 20 – 95 °C

Temperature accuracy ± 3 °C (instrument calibrated at 20 °C)

Display Set and actual temperature

Max. size of sample tube P-6: OD 16 – 60 mm, L = 110 – 150 mm;

Max content of sample tube P-6: 160 mL, P-12: 30 mL

Environmental conditions

Temperature

Altitude

Humidity

Temperature resistance P+G ca. -70 °C – 60 °C

Temperature resistance

P+G low temperature

Temperature resistance protective shield < 160 °C

3 Technical data

T 6.3 A L 250 V (100–120 V)

P-12: OD 15 – 30 mm, L = 15 – 150 mm

for indoor use only

5 – 40 °C

up to 2000 m

maximum relative humidity 80% for temperatures up to

31 °C, and then linearly decreasing to 50% at 40 °C

-80 °C – 50 °C

26 Multivapor™ Operation Manual, Version E

Page 27

3.4 Solvent table

Table 3-12: Solvent table

Solvent Formula Molar mass

Acetone C3H6O 58.1 553 56 0.790 556

n-Amylalcohol, n-pentanol C

Benzene C

n-Butanol, tert-butanol C

2-Methyl-2-propanol C

Chlorobenzene C

Chloroform CHCl

Cyclohexane C

Diethylether C

1,2-Dichloroethane C

1,2-Dichloroethylene (cis) C

1,2-Dichloroethylene (trans) C

Diisopropyl ether C

Dioxane C

DMF (dimethylformamide) C

Acetic acid C

Ethanol C

Ethylacetate C

Heptane C

Hexane C

Isopropylalcohol C

Isoamylalcohol-3-methyl-1-butanol C

Methylethylketone C

Methanol CH

Methylene chloride, dichloromethane CH

Pentane C

n-Propylalcohol C

Pentachloroethane C

1,1,2,2-Tetrachloroethane C

Tetrachlorocarbon CCl

1,1,1-Trichloroethane C

Tetrachloroethylene C

THF (tetrahydrofurane) C

Toluene C

Trichloroethylene C

Water

Xylene (mixture) C

o-Xylene C

m-Xylene C

p-Xylene C

3 Technical data

Evaporation energy

in g / mol

O 88.1 595 37 0.814 11

5H12

6H6

4H10

4H10

6H5

6H12

4H10

2H4Cl2

2H2Cl2

2H2Cl2

6H14

4H8O2

3H7

2H4O2

2H6

4H8O2

7H16

6H14

3H8

5H12

4H8

4

2CI2

5H12

3H8

HCl

2

2H2Cl4

2H3Cl3

2Cl4

4H8

7H8

HCl

2

78.1 548 80 0.877 236

O 74.1 620 118 0.810 25

O 74.1 590 82 0.789 130

Cl 112.6 377 132 1.106 36

119.4 264 62 1.483 474

3

84.0 389 81 0.779 235

O 74.0 389 35 0.714 850

99.0 335 84 1.235 210

97.0 322 60 1.284 479

97.0 314 48 1.257 751

O 102.0 318 68 0.724 375

88.1 406 101 1.034 107

NO 73.1 153 0.949 11

60.0 695 118 1.049 44

O 46.0 879 79 0.789 175

88.1 394 77 0.900 240

100.2 373 98 0.684 120

86.2 368 69 0.660 360

O 60.1 699 82 0.786 137

O 88.1 595 129 0.809 14

O 72.1 473 80 0.805 243

O 32.0 1227 65 0.791 337

84.9 373 40 1.327 850

72.1 381 36 06.26 850

O 60.1 787 97 0.804 67

202.3 201 162 1.680 13

5

167.9 247 146 1.595 35

153.8 226 77 1.594 271

4

133.4 251 74 1.339 300

165.8 234 121 1.623 53

O 72.1 67 0.889 357

92.2 427 111 0.867 77

131.3 264 87 1.464 183

3

in J / g

H2O 18.0 2261 100 1.000 72

8H10

8H10

8H10

8H10

106.2 389 25

106.2 144 0.880

106.2 139 0.864

106.2 138 0.861

Boiling point

at 1013 mbar

Density

in g / cm

Vacuum in mbar for

3

boiling point at 40 °C

27 Multivapor™ Operation Manual, Version E

Page 28

4 Description of function

This chapter explains the basic principle of the Multivapor P-6 and P-12 and provides a functional

description of the assemblies.

4.1 Functional principle of the Multivapor

The Multivapor is a 6 or 12 position parallel evaporator for simultaneous evaporation of up to

6×150 mL or 12×30 mL sample volume, referred to as Multivapor P-6 or Multivapor P-12, respectively. The basis of this procedure is solvent evaporation and condensation in vacuo using orbital

horizontal movement to produce a strong vortex in each sample tube. Distillation is usually performed

under vacuum to increase performance and reduce the boiling temperature preventing sample

decomposition.

The Multivapor is available as a stand-alone unit or in combination with a rotary evaporator, providing a

clever synergy enhancing solution by having two instruments, the Multivapor and the Rotavapor, share

the same condenser and vacuum assembly. The two configurations Multivapor P-6 and Multivapor

P-12 are not interchangeable as the orbital movement of the platform is different in order to guarantee

a smooth and safe operation.

4 Description of function

4.1.1 Functional principle of the stand-alone unit

4

Fig. 4.2: Overview of the stand-alone edition. The two different Multivapor configurations - Multivapor P-6 and Multivapor P-12 - are indicated by intersecting the figure.

2

1

3

28 Multivapor™ Operation Manual, Version E

Page 29

4 Description of function

a Evaporation area

The solvent is heated by means of a heating plate. Horizontal orbital movement of the heating plate

results in a thorough vortex of the mixture within the test tubes. Thus, the solvent surface is increased

which in turn leads to a higher evaporation rate and reduction of boiling retardation.

b Cooling area

Each sample is individually connected to the vacuum cover with glassware specific adapters. The

vapor is collected and then transferred to the condenser via a ribbed PFA vacuum tube. In the

condenser the heat required for transmitting the solvent from the liquid into the gas phase is transferred to the coolant. Water, dry-ice in acetone or any coolant suitable for a recirculating chiller is

typically used for this purpose.

c Receiving flask

The condensed vapor is collected in the receiving flask. It is recommended to empty the flask after

each run. For evaporation of solvent mixtures or at low temperatures an optional refrigerated receiver

is recommended to prevent re-evaporation of the condensate. This reduces the evaporation time and

prevents interruption between runs.

d Vacuum

The evaporation performance is dependant on the pressure, the temperature of the solvent and the

coolant, and the vortex. In order to evaporate solvent at a given temperature and revolution, pressure

needs to be reduced accordingly via a vacuum pump. A vacuum controller regulates the pump by

continuously reducing the vacuum until the set point is reached. This task is performed either manually

or automatically.

4.1.2 Functional principle of the Multivapor-Rotavapor edition

2

1

3

Fig. 4.3: Combination of the Multivapor P-6/P-12 with the Rotavapor R-215

The vacuum tube of the Multivapor is connected to the T-piece a which is installed between the

condenser and receiver of the Rotavapor. The key feature of this setup is that the condenser assembly

b, the vacuum pump c and the vacuum controller d are shared between both the Multivapor and

the Rotavapor. Therefore both single evaporation of large flasks and parallel evaporation of small test

tubes is achievable with the same setup using little space. However, simultaneous performance of

both tasks is neither feasible nor advisable due to physical reasons, as the cooling capacity of the

4

5

29 Multivapor™ Operation Manual, Version E

Page 30

condenser cannot cope with the amount of vapor produced. During operation of the Multivapor, the

Rotavapor side has to be closed using an empty evaporation flask e.

4.1.3 Controls of the Multivapor (stand-alone)

5

4 Description of function

a Main switch

b Temperature display

c Knob for temperature regulation

d Knob for rotational speed

e Holder for the vacuum cover

3

2

1

Fig. 4.4: Overview of the Multivapor controls

4.1.4 Display of the Multivapor

Fig. 4.5: Display of the Multivapor

4

The display shows both the actual and the set

temperatures. If the actual temperature is below

the set temperature, the indication “heating”

appears.

30 Multivapor™ Operation Manual, Version E

Page 31

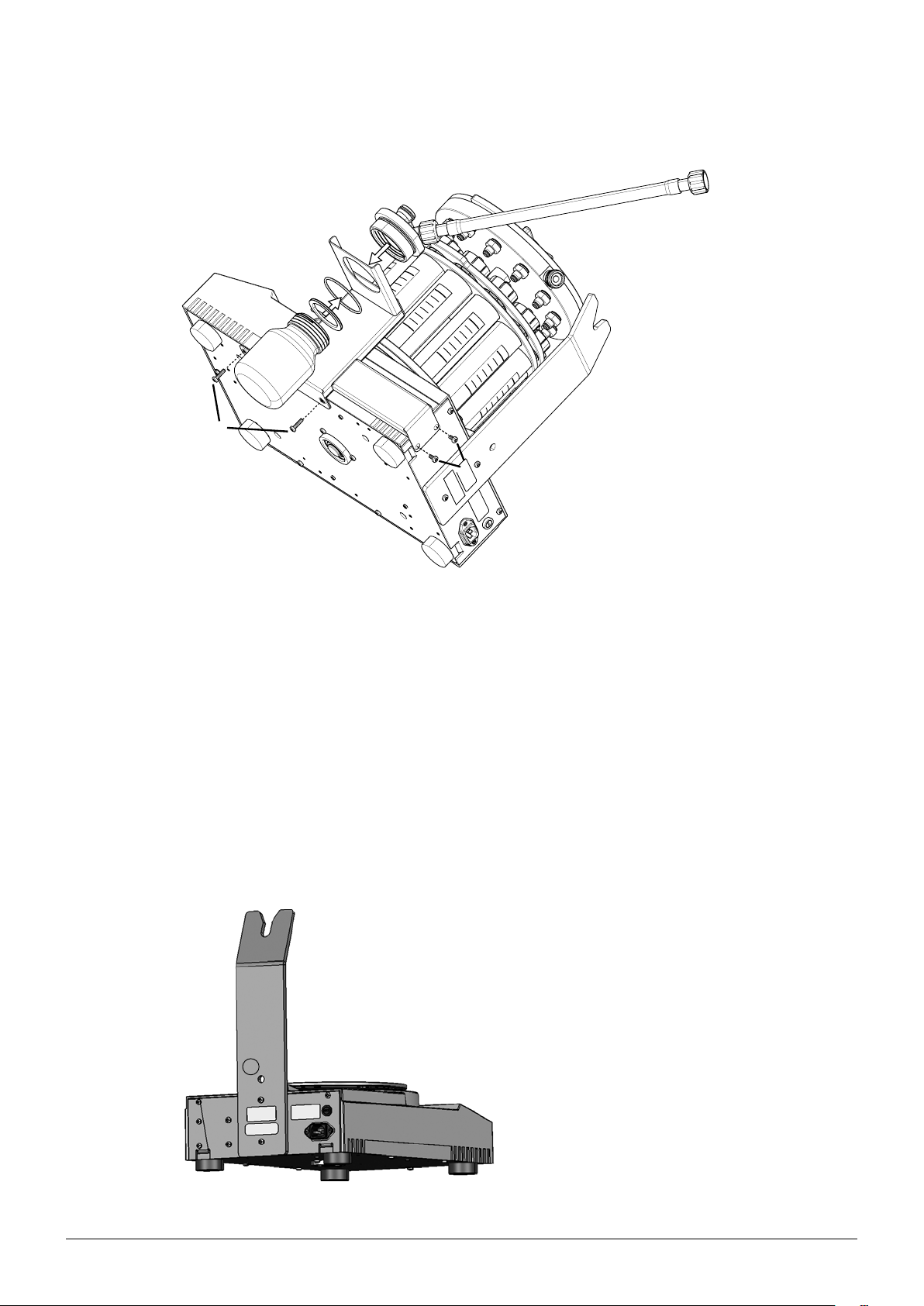

4.1.5 Rear connections of the Multivapor

Fig. 4.6: Rear connection of the Multivapor

4.2 Multivapor platform

4 Description of function

a Mains supply

b Main fuse

2

1

The platform is available with a 220–240 V and a

100–120 V power supply. The temperature and

orbital movement of the heating plate are individually adjusted via the corresponding control

knobs. The temperature is limited to 95 °C to

prevent evaporation of water which is used as

heat transfer medium. Both the set and actual

temperature of the heating plate are shown in

the display.

The horizontal orbital speed of the heating plate

is indicated by a graduation (0…10) and ranges

from 0 to 370 rpm for the Multivapor P-6, or 0 to

485 rpm for the Multivapor P-12.

A black rubber gasket a prevents contamination of the instrument interior with liquids.

1

Fig. 4.7: Multivapor platform

31 Multivapor™ Operation Manual, Version E

Page 32

4.3 Crystal rack

4 Description of function

The crystal rack a is fixed onto the heating

plate and operates as a heat transition between

the heating plate and the sample tubes. It comprises 6 or 12 glass cylinders accommodated

circularly to provide full supervision. A level

indication designates the optimal filling level for

water, which serves as the heating medium.

A further advantage of the crystal rack compared to the widely used metal racks is the

compatibility with all kind of sample tubes differing in shape, diameter and length.

1

Fig. 4.8: Multivapor with the crystal rack

4.4 Sample preparation rack

1

4

Fig. 4.9: Sample preparation rack with the transfer plate and test tubes with the corresponding adapters

The sample preparation rack a serves as support for the transfer rack b including 6 or 12

sample tubes c.

The tubes are equipped with specific adapters

d which seal the test tubes effectively with the

3

2

vacuum cover.

32 Multivapor™ Operation Manual, Version E

Page 33

4.5 Blank adapters (optional)

Fig. 4.10: Blank adapters

4 Description of function

If less than the maximum number of samples are

being evaporated, the vacant positions need to

be occupied either with empty sample tubes or

with the optional blank adapters. These adapters consist of a closed bottom side but the

same outer dimensions as the standard adapters.

It is not necessary to distribute the samples

equally across the crystal rack. It is therefore

possible to accommodate the front positions

with the samples and the back positions with the

blank adapters.

For very harsh conditions, such as evaporation

of trifluoro acetic acid (TFA), the adapters are

also available in PEEK.

4.6 PE frits

Fig. 4.11: PE frits

4.7 Adapter spring

In order to reduce contamination of the vacuum

cover by foaming samples or boiling retardation,

an optional porous PE frit can be placed into

the tube adapters closing the vapor duct. This

measure also allows sample adsorption onto

silica for chromatographic purposes (dry loading)

by retaining the silica inside the tube.

Springs on the top of the tube adapters are

optionally used to facilitate the opening of the

vacuum cover.

Fig. 4.12: Adapter spring

33 Multivapor™ Operation Manual, Version E

Page 34

4.8 Sample transfer plate

Fig. 4.13: Simultaneous sample transfer using the transfer plate

4 Description of function

As the test tubes are tightly fixed to the transfer

plate, the whole assembly is transferred at once

into the crystal rack. This allows a preceding

equilibration of the instrument.

4.9 Vacuum cover

2

The samples are sealed with the vacuum cover

a via the adapters b. The cover serves as

vacuum manifold collecting the vapor from each

sample individually in grooved channels. This

reduces the chance of cross-contamination

1

significantly. A descending drain is connected to

the condenser assembly by means of a ribbed

PFA vacuum tube.

Fig. 4.14: Multivapor with the crystal rack and the corresponding vacuum cover

34 Multivapor™ Operation Manual, Version E

Page 35

4.10 Protective shield (optional)

4 Description of function

The protective shield protects the user from

splashes of hot medium and debris from the

sample tubes in the case of implosion or explosion.

Fig. 4.15: Protective shield

4.11 Condensation (optional)

Fig. 4.16: Type C (left) and type S (right) condenser assemblies

There are two types of condensers available.

Type C condensers (left) are used with dryice/acetone and type S condensers (right)

are connected to tap water or a recirculating

chiller. Both are equipped with a P+G coating

to provide maximum safety. The receiving flask

is available in 1 or 2 l capacity. Alternatively, an

insulated refrigerated receiver with an internal

cooling coil can be used in combination with

a type S condenser. This allows evaporation

of solvent mixtures with different boiling points

without interruption between fractions.

35 Multivapor™ Operation Manual, Version E

Page 36

4.12 High-boiling solvents - Woulff bottle (optional)

To prevent boiling retardation and for highboiling solvents which tend to condense in the

vacuum tube as well as for solvents which tend

to foam an optional solvent reservoir – the socalled Woulff bottle – can be fixed at the rear of

the instrument. The vapor is then first transferred

from the cover to the bottle and then further to

the condenser assembly.

Fig. 4.17: Woulff bottle installed

4 Description of function

4.13 Vacuum solution (optional)

Evaporation under vacuum is performed by

means of a vacuum pump. With the V-700 PTFE

diaphragm pump an ultimate vacuum of less

than 10 mbar is achieved, which is more than

sufficient for most applications.

Sophisticated vacuum control is gained using

the V-850 or V-855 controller. The latter includes

gradient functions, solvent libraries and automatic vacuum control algorithms.

Fig. 4.18: Recommended vacuum solution for use with the Multivapor

36 Multivapor™ Operation Manual, Version E

Page 37

4.14 Connection to a rotary evaporator (optional)

Fig. 4.19: A resource-sharing combination of the condenser, the vacuum pump and the controller with both the Rotavapor and the Multivapor

4 Description of function

In addition to the stand-alone unit, the Multivapor can be used in combination with a rotary evaporator.

The vapor is then first transferred to the condenser assembly of the Rotavapor with the help of the

T-piece. The vacuum is generated by the vacuum pump and regulated by the controller.

The glass T-piece used for this setup is compatible with all BUCHI products and the major manufacturers of rotary evaporators. The prerequisite for a compatibility is the presence of an S35 spherical

joint between the condenser and the receiving flask.

4.15 Refrigerated receiver (optional)

The refrigerated receiver keeps the solvent at a

low temperature throughout the run. It is essentially a horizontal cylindrical receiving flask with

an insulation jacket and an internal cooling loop.

The cooling loop is connected to a recirculating

chiller and keeps its content at a low temperature. A curved U-tube serves as a level indicator

and allows the flask to be emptied without disconnection. The total volume of the flask is 2.5 l.

Fig. 4.20: Cooled receiver with type S condenser

37 Multivapor™ Operation Manual, Version E

Page 38

5 Putting into operation

This chapter describes the installation of the Multivapor and gives instructions on initial start-up.

NOTE

Inspect the instrument for damages during unpacking. If necessary, prepare a status report immediately to inform the postal company, railway company or transport company. Keep the original

packaging for future transport.

5.1 Installation site

Place the instrument on a stable, horizontal surface and consider the maximum product dimensions.

NOTE

The shaking platform moves horizontally in an orbital manner with up to 485 rpm (for the P-12) which

may lead to considerable shaking of the surface. For this reason ensure that the surface is stable.

It is not necessary to place the instrument in a fume hood, however, the exhaust gas from the vacuum

pump should be directed toward a fume hood.

5 Putting into operation

5.2 Electrical connections

Risk of instrument damage by wrong mains supply.

• External mains supply must meet the voltage given on the type plate

• Check for sufficient grounding

NOTICE

38 Multivapor™ Operation Manual, Version E

Page 39

5.3 Commissioning the Multivapor basic instrument

5.3.1 Commissioning the crystal rack

5 Putting into operation

Fig. 5.21: Installation of the crystal rack onto the heating plate

Remove any particles from the heating plate and the bottom side of the crystal rack. Place the rack

onto the heating plate with the indentation to the front.

Put the rack back on the instrument - the three pins have to be aligned with the openings in the

bottom of the rack and the notches 1 on the rack have to point to the front side (a little left from the

middle) of the instrument.

Pull and hold the locking device 2.

Turn the rack a little counter clockwise and let the locking device go 3.

Turn the rack further counter clockwise, until the locking device snaps into place.

Optionally you can fix the the rack with the supplied four screws 2.

Check the rack for a tight mounting!

39 Multivapor™ Operation Manual, Version E

Page 40

5.3.2 Assembling the Woulff bottle (optional)

5 Putting into operation

Fig. 5.22: Assembling the Woulff bottle

1

Fix the Woulff bottle holder on the bottom of the instrument by replacing the existing screws with the provided

longer screws.

2

Fix the Woulff bottle holder on the rear side of the instrument by replacing the existing screws with the provided longer screws.

Add the cover of the Woulff bottle from above to the holder.

Fix the cover from below on the holder with the provided O-ring.

Place the gasket from below into the cover.

Screw the bottle into the holder.

Connect the delivered tube on the left angled connector of the cover.

Connect the tube from the condenser to the Woulff bottle on the right straight connector (not connected in the

figure).

5.3.3 Anti-seismic tie-down

a Hole to fix the instrument in earthquake-sus-

ceptible regions.

1

Fig. 5.23: Anti-seismic tie-down

40 Multivapor™ Operation Manual, Version E

Page 41

5.4 Glass assembly

5 Putting into operation

Risk of glass breakage by excessive strains.

• Mount all glassware parts without strains

• Check glassware for proper fixing regularly and readjust fixing points if necessary

• Do not use defective glassware

• Use the protective shield (optional)

5.4.1 Type S and type C condenser

1

NOTICE

Install the condenser assemblies on the provided support or on a stable laboratory rod

ensuring that the stand base is oriented in the

direction of the condenser.

Secure the receiving flask with the clip a provided for this purpose.

1

Fig. 5.24: Installation of the condenser assembly on the support

5.4.2 Condenser assembly with the refrigerated receiver (optional)

The refrigerated receiver a can be used as an

alternative to the receiving flask and is secured

using the clip b. The internal cooling loop is

connected to a cooling source c (tap water or

recirculating chiller).

2

1

Fig. 5.25: Type S condenser with the refrigerated receiver

3

41 Multivapor™ Operation Manual, Version E

Page 42

5.5 Tube connections

5.5.1 Cooling water

When connecting the white cooling water tubes (silicon), consider the following:

• Use GL-14 tube clips.

• The tubes used must all have the same inner diameter (approximately 6 mm).

• For safety reasons, secure the tubes with commercial tube pivoting clamps or cable binders.

• To save cooling water and/or reduce the temperature of the coolant, a recirculating chiller like the

F-100/F-108 is recommended.

• Check the tubes from time to time and replace them if they become brittle.

5 Putting into operation

4

2

3

5 1

a Coolant in

b Secondary condenser (optional)

c Refrigerated receiver (optional)

Fig. 5.26: Liquid flow direction for primary condenser and post-pump secondary condenser

d Primary condenser

e Coolant out

NOTE

It is important to connect the coolant with the secondary condenser first and then with the primary

condenser as the temperature rise in the coolant primarily takes place in the latter.

When the type C condenser is used no tube connections for cooling are required.

42 Multivapor™ Operation Manual, Version E

Page 43

5.5.2 Vacuum tubes

When establishing the vacuum tube (red rubber) connections proceed as follows:

• Use GL-14 tube clips.

• The tubes used must all have the same inner diameter (approximately 5 mm).

• Keep vacuum tubes as short as possible.

• When operating with the Vacuum Controller V-850/V-855 and the Vacuum Pump V-700/V-710

connect a Woulff bottle between the vacuum source and the Multivapor.

• When operating with a pump other than a V-700/V-710, connect a valve unit to the V-850/V-855 to

control the vacuum.

• Tubes do not need to be secured.

• Check the tubes from time to time and replace them if they become brittle.

5 Putting into operation

6

5

1

2

a Vacuum cover out

b Woulff bottle at Multivapor (optional)

c Condenser vacuum joint

Fig. 5.27: Standard vacuum connections with condenser and V-700/V-855 vacuum solution

3

4

d Woulff bottle at vacuum pump (optional)

e Woulff bottle connection to vacuum pump

f Woulff bottle connection to vacuum controller

4

43 Multivapor™ Operation Manual, Version E

Page 44

5.6 Commissioning the Multivapor-Rotavapor edition

The T-piece is inserted between the condenser

and the receiving flask of the rotary evaporator

and fixed with the clip. The vacuum tube is connected to the SVL 22 joint of the T-piece.

5 Putting into operation

Fig. 5.28: Commissioning the Multivapor-Rotavapor edition

NOTE

As the system has to be closed in order to generate a vacuum, the vapor duct on the rotary evaporator must be sealed with an empty flask during operation.

5.7 Functional test

Once all of described installation steps have been completed proceed with the following functional test

to correctly operate the instrument.

5.7.1 Vacuum tightness test

NOTE

The vacuum tightness test can only be carried out with a vacuum controller installed or when a pressure measuring device (manometer) is installed between the pump and the Multivapor.

1. Start the instrument and adjust the desired rotational speed, e.g. position 8.

2. Apply a vacuum of a preset value, e.g. 100 mbar.

3. Stop the vacuum and measure the pressure increase ∆p within 2 min.

4. The instrument is tight if ∆p < 10 mbar within 2 min.

To tighten the instrument, proceed as follows:

1. Close the vacuum tube from the vacuum pump to the condenser and check the leak rate of the

pump. In case of a leak consult the operation manual of the vacuum pump.

2. Close the vacuum tube at the vacuum tube side of the condenser with a blind cap and check the

leak rate of the condenser assembly. In case of a leak check the seals of the vacuum tube and the

GL-14 caps. Grease the glass joints if necessary.

3. Close the conical adapters of the vacuum cover using the blank adapters. In case of a leak

exchange the seals of the ribbed vacuum tube and/or the O-rings at the conical adapters. In case

of chemically affected O-rings, change the material of the O-rings according to Table 3-5.

4. Verify the quality of the sample tubes. They must not be chipped.

5. Check if the seals for the tube adapters are sound and correctly placed. In case of a leak exchange

44 Multivapor™ Operation Manual, Version E

Page 45

5 Putting into operation

the corresponding seals. The adapter seals have to be exchanged regularly. The corresponding

spare parts are listed in section 10.3.

NOTE

Overtightening the lock nuts on the conical adapters of the vacuum cover and sample tubes will

scarcely remedy a leak problem, but would decrease the lifetime of the parts. The problem is more

readily solved by checking the quality of the corresponding seals, i.e. the adapter seals and/or the

conical O-rings.

Risk of thread damage by overtightening

• Do not use a wrench with a long lever arm when exchanging the conical adapters due to

Fig. 5.29: Tightening the lock nuts on the conical adapters

NOTICE

physical or chemical damage

45 Multivapor™ Operation Manual, Version E

Page 46

6 Operation

This chapter explains the operating elements and possible operating modes. It gives instructions on

how to operate the Multivapor properly and safely.

6.1 Settings at the Multivapor platform

Variable parameters of the instrument are the temperature and rotational speed of the horizontal

movement of the heating plate.

6 Operation

Risk of glass breakage by excessive strains.

• Mount all glassware parts without strains.

• Check glassware for proper fixing regularly and readjust fixing points if necessary

• Do not use defective glassware.

• Use the protective shield (optional).

Risk of instrument damage by lack of heating medium in the crystal rack.

• Make sure that there is always heating medium within the crystal rack when the instrument is

Risk of minor or moderate burns when handling hot parts.

• Do not touch hot parts or surfaces (especially the heating plate with up to 95 °C).

• Make sure that no liquid can overflow from the glass cylinders when the samples tubes are

• Use the protective shield (optional) to shield hot parts.

NOTICE

NOTICE

switched on and the actual temperature is below the set temperature.

CAUTION

!

submerged.

NOTE

The display specifies the temperature of the water in the glass cylinder. During evaporation heat is

transferred from the heating medium to the condenser eventually, which may result in a considerable temperature drop of up to 15 °C in the water bath. This fact has to be taken into account when

selecting an appropriate coolant temperature inside the condenser.

46 Multivapor™ Operation Manual, Version E

Page 47

6.1.1 Selecting a preset temperature

A preset temperature setting ensures that the heating bath temperature cannot be changed either

accidentally or deliberately during the evaporation process.

To switch to the preset mode, proceed as follows:

• Switch off the instrument.

• Turn the adjusting knob to the 95 °C (max) position.

• Switch on the instrument. The set temperature setting flashes on the display.

• Turn the knob to the desired set temperature, e.g. 60 °C within 10 seconds and wait until the set

temperature setting stops flashing.

• This set temperature is now retained whenever the heating bath is switched on and cannot be

changed with the adjusting knob anymore.

6.1.2 Changing/switching off the preset temperature

To change or switch off the preset temperature, proceed as follows:

• Switch off the instrument.

• Turn the adjusting knob to the 0 °C (min) position.

• Switch on the instrument. The preset temperature setting is now deleted and the temperature can

be selected via the knob again.

6 Operation

6.1.3 Setting the rotational speed

!

Risk of minor or moderate injuries due to wrong rotation speed adjustment!

• Do not exceed 370 rpm if using the P-12 platform with the P-6 configuration. Otherwise

strong vibration will damage the P-12 and glass cylinders.

NOTE

As soon as the power plug is connected and the main switch is turned on, the platform moves horizontally in an orbital manner according to the setting adjusted at the corresponding knob.

The rotational speed of the moving platform ranges from 0 to 370 rpm for the Multivapor P-6 and from

0 to 485 rpm for the Multivapor P-12. Within this range even fairly viscous samples are thoroughly

agitated by strong vortex action. For most applications a constant rotational speed at position 8 is

sufficient.

The absolute value of the rotational speed is not displayed. The indication 0…10 on the platform

is linearly increasing from 0 corresponding to 0 rpm to 10 corresponding to 370 rpm or 485 rpm,

respectively.

NOTE

Once optimized, the vortex action remains constant throughout the evaporation process, given that

the shape and inner diameter of the sample tubes is constant. Changing glassware geometries, e.g.

to conical bottoms (the so-called Falcon tubes) or rounded tubes, may alter the efficiency of agitation which may result in boiling retardation. It is therefore advisable to adjust the rotational speed

during the process.

CAUTION

47 Multivapor™ Operation Manual, Version E

Page 48

6.2 Sample preparation

6.2.1 Heating up the instrument

Fig. 6.30: Filling distilled water to a level where strong agitation during operation is obtained

6 Operation

Distilled water is added to each glass cylinder

on the crystal rack to transfer the heat from the

heating plate to the sample tube. Equal amounts

of water must be added to each cylinder to

provide a uniform heat transfer. A level indication

designates the optimum volumes depending on

the type of sample tube.

Turn on the heating as soon as each position

is filled. It takes approximately 20 min to equilibrate the system, i.e. until the water temperature

remains constant.

NOTE

• The water volume is the decisive parameter for optimal heat transfer, therefore it is not advisable

to add too much water. Heat transferred into the sample decreases with an increasing volume.

This is mainly the result of insufficient mixing of the heating medium. Therefore, fill in only as much

water so that the sample vessel dips into the heating medium by 2 to 3 cm. Optimize the rotation

to obtain a vigorous vortex for both the sample and the heating medium.

• To reach equilibrium turn on the instrument and set it to the desired evaporation temperature

20 min prior to the distillation process.

6.2.2 Sample preparation

The installation and sealing of the sample tube is carried out as follows:

Risk of lifetime shortening of the adapter seals and the quick lock nut.

• Fix all connections only hand tight.

• Avoid overtightening.

NOTICE

• Use the Multivapor tool for removing the

insert of the adapter and for changing the

gasket.

48 Multivapor™ Operation Manual, Version E

• Use the optional PE frits for foam and splash

protection.

• To remove the optional PE frits from the tube

adapter, push a thin object from the top

through the hole.

Page 49

6 Operation

• Screw the adapter onto the tube. • Place the sample tube into the transfer plate.

Make sure that it snaps in place.

• Occupy all positions or use the blank

adapters instead (optional).

• Transfer the whole assembly at once into the

pre-heated crystal-rack.

• Close the vacuum cover. • Tighten the vacuum cover using the quick

lock.

Fig. 6.31: Sample preparation

49 Multivapor™ Operation Manual, Version E

Page 50

6.3 Selecting the distillation conditions

To achieve optimal distillation conditions, the distillation energy supplied by the heating platform must

be removed by the condenser. To ensure this, operate the instrument according to the following

general rule:

Heating medium: 55 °C

How are these conditions achieved?

• Set the temperature of the instrument to 55 °C.

• Use a recirculating chiller to set the temperature of the coolant to max. 10 °C or use a dry-ice

condenser (type C) alternatively.

• The coolant flow is adjusted to approx. 600 – 800 mL/min.

• Define the operating vacuum according to the boiling point of the solvent which in this particular

example is 30 °C. The corresponding pressure can be deduced from the enclosed Solvent Table or

from the Solvent Library implemented in the Vacuum Controller V-850/V-855.

25 °C

Vapor: 30 °C

6 Operation

20 °C

Coolant: max. 10 °C

This rule can be extrapolated to higher temperatures, e.g. according to the following example:

Heating plate: 75 °C

Δ T ≥ 20 °C

Δ T ≥ 25 °C

25 °C

Vapor: 50 °C

20 °C

Coolant: max. 30 °C

Fig. 6.32: Schematic depiction of the relative temperature drop within the distillation setup

NOTE

The 25/20 °C rule indicates that during operation the displayed temperature does not correspond to

the temperature of either the vapor or the sample mixture. During distillation there is a temperature

drop relative to the display of approx. 10 °C for the sample and approx. 25 °C for the vapor.

The distillation conditions of the Multivapor are therefore not directly comparable to that of the

Rotavapor as the heat transfer in the latter, from heating bath to sample flask, is more efficient

compared to that observed in the Multivapor. At identical set temperatures, the actual temperature

of the Multivapor sample would be approx. 15 °C less than the Rotavapor sample.

50 Multivapor™ Operation Manual, Version E

Page 51

6.4 Distillation

Before operating the system, the following conditions must be fulfilled:

• All electrical connections are established correctly.

• All vacuum and coolant connections are established correctly. The latter being secured with cable

binders.

• All seals are inserted correctly.

• Water is filled in according to the level indication.

To start operating the system proceed as follows:

• Switch on the instrument.

• Set the temperature (recommended: 50 – 80 °C).

• Adjust the coolant flow (recommended: 5 – 20 °C, 600 – 800 mL/min).

• As soon as the instrument is equilibrated (after approx. 20 min), place the sample tubes into the

crystal rack. Use empty sample tubes or blank adapters (optional) to occupy vacant positions.

• Close the vacuum cover and screw it hand tight.

• Set the rotational speed (recommended: pos. 8 - 10).

• Turn on the vacuum pump and controller.

• Set the vacuum according to the 25/20 °C rule.

• Wait approx. 5 min after the vacuum has reached the set point. The temperature of the sample

may, depending on the set temperature, drop during initial evaporation, resulting in a slight subsequent readjustment of the vacuum conditions.

• If the distillation does not start, carefully reduce the vacuum gradually or increase the temperature at the instrument. Check the efficiency of the condenser and make sure that the vapor is not

directly sucked into the pump.

6 Operation

NOTE

In general the smaller the test tubes the higher the risk of boiling retardation. In order to prevent

contamination of the vacuum cover apply a pressure gradient to reduce the pressure gradually (see

chapter 6.5.2) and/or use the optional PE frits as splash and foam protection.

6.5 Optimizing the vacuum conditions (optional)

There are three distinct ways to evaporate multiple samples in parallel with the Multivapor using

either the Vacuum Controller V-850 or V-855. The main functions are described briefly in the following

sections. For further information please consult the corresponding Operation Manual.

6.5.1 Manual vacuum control and solvent library (V-850/V-855)

Choose the temperature according to the 25/20 °C rule. The corresponding pressure is best derived

from the Solvent Library. This is achieved as follows:

• Open the Solvent Library. • Select the corresponding

solvent.

51 Multivapor™ Operation Manual, Version E

• Set the instrument temperature.

Page 52

6.5.2 Pressure gradients (V-855)

Setting the pressure manually to the boiling point involves the risk of boiling retardation. To minimize

this risk, it is strongly recommended to program a pressure gradient that slowly converges to the optimized ultimate vacuum. This is achieved as follows:

• Select the Gradient mode. • Program the first step. • Program additional steps and

6 Operation

terminate the programming

by selecting “Yes”.

The corresponding gradient can be stored for future recall and displayed at any time. For further

information please consult the operation manual

of the vacuum controller.

Fig. 6.33: Pressure gradient for distillation of ethanol at 65 °C (instrument setting)

It is often desirable to dry any remaining solid

sample immediately after solvent evaporation.

For routine procedures it is advisable to implement this step directly into the gradient program.

This reduces the amount of instrument handling

and keeps supervision to a minimum.

Fig. 6.34: Example of a gradient setting with a drying step subsequent to the solvent evaporation

NOTE

A direct drying step without interruption of the distillation process is only possible if the distilled

solvent is kept at low temperature, i.e. below the corresponding boiling point of the ultimate vacuum

setting. This is achieved by using an ice bath or the optional refrigerated receiver in combination with

a recirculating chiller.

Pressure gradients are also an ideal tool for complex mixtures with low-boiling components which

52 Multivapor™ Operation Manual, Version E

Page 53

tend to foam or splash. A preceding terrace at high pressure for approx. 10 min usually significantly

reduces the risk of splashing or foaming.

6.5.3 Automatic distillation (V-855)

1

6 Operation

The method of choice to evaporate even complex

sample mixtures automatically is the EasyVac mode,

implemented in the Vacuum Controller V-855. The

EasyVac algorithm is based on relative pressure

changes over time and therefore requires no additional

accessory for operation.

It is possible to interrupt the algorithm at any time by

pressing the P↑ button b and resuming the automatic

process by pressing the H Off button a. This is a very

helpful measure to reduce foaming and splashing for

2

delicate mixtures.

Fig. 6.35: Automatic distillation

NOTE

A tight system, i.e. ∆ p < 5 mbar per minute, is an essential prerequisite for the proper operation of

EasyVac.

6.6 Optimizing the distillation conditions