Page 1

Operation Manual

Nano

Spray Dryer B�90

093261

en

Page 2

Page 3

Table of contents

Table of contents

1 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1 User qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Safety warnings and safety signals used in this manual . . . . . . . . . . . . . . . . . 8

2.5 Product safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.1 General hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.2 Warning labels on housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5.3 Safety measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5.4 Built-in safety elements and measures . . . . . . . . . . . . . . . . . . . . . . . . 14

2.6 General safety rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1 Scope of application and delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.1 Standard instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.1.2 Standard accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1.3 Standard accessories with the Nano Spray Dryer B-90 Advanced. . . . . . . . . . . 19

3.1.4 Optional accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3 Materials used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4 Description of function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1 Functional principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1.1 Drying gas circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1.2 Spray drying process overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2 Spray generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3 Heating system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.4 Drying air generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.4.1 Compressed air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.4.2 Aspirator in blowing mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4.5 Sample feed circulation with peristaltic pump . . . . . . . . . . . . . . . . . . . . . 29

4.6 Particle collector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.7 Outlet filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.8 Inert Loop B-295 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.9 Dehumidifier B-296 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.10 Connection at the Nano Spray Dryer B-90 . . . . . . . . . . . . . . . . . . . . . . 33

Read this manual carefully before installing and running your system and note the safety precautions

in chapter 2 in particular. Store the manual in the immediate vicinity of the instrument, so that it can be

consulted at any time.

No technical modifications may be made to the instrument without the prior written agreement of

BUCHI. Unauthorized modifications may affect the system safety or result in accidents.

This manual is copyright. Information from it may not be reproduced, distributed, or used for competitive purposes, nor made available to third parties. The manufacture of any component with the aid of

this manual without prior written agreement is also prohibited.

If you need another language version of this manual, you can download available versions

at www.buchi.com.

3 B-90 Operation Manual, Version B

Page 4

Table of contents

5 Putting into operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.1 Installation site. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.2 Installing the Nano Spray Dryer B-90 . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.1 Tall set-up with long metal bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.2.2 Short set-up with short metal bars . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.3 Sub-assembly installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.3.1 Lifting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.3.2 Electrode assembly installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.3.3 Glass cylinder installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3.4 Heater module installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.4 Spray head assembling and installation . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4.1 Spray head assembling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.4.2 Spray head installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.5 Peristaltic pump and feed tubing installation. . . . . . . . . . . . . . . . . . . . . . 47

5.5.1 Peristaltic pump height adjustment and fixation . . . . . . . . . . . . . . . . . . . . 48

5.5.2 Pump bed adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.5.3 Feeding tube installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.6 Drying gas supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.6.1 ‘open loop’ air supply configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.6.2 ‘closed loop’ gas supply configuration. . . . . . . . . . . . . . . . . . . . . . . . . 53

5.6.3 Outlet filter installation/replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.7 Aspirator installation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.7.1 Aspirator in ‘open loop’ configuration . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.7.2 Aspirator in ‘closed loop’ configuration . . . . . . . . . . . . . . . . . . . . . . . . 55

5.8 Inert Loop B-295 installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.8.1 Main device installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.9 Dehumidifier B-296 installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.9.1 Dehumidifier B-296 in ‘open loop’ configuration . . . . . . . . . . . . . . . . . . . . 59

5.9.2 Dehumidifier B-296 in ‘closed loop’ configuration with out Inert Loop B-295 . . . . . 60

5.9.3 Adsorption column installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.10 Final installation check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.11 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.1 Starting up the instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.2 Main screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.3 Menu structure overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.4 Display elements and menu functions . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.4.1 Operating controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.4.2 View parameters menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.4.3 Gas mode selection menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.4.4 Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

6.4.5 Firmware calibration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.4.6 Firmware info menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.5 Starting a spray drying process . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

6.6 Optimizing parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.7 End of spray drying process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.8 Collecting the particles from the collector cylinder . . . . . . . . . . . . . . . . . . . 72

4 B-90 Operation Manual, Version B

Page 5

Table of contents

6.9 Other operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.9.1 Inert Loop B-295 operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6.9.2 Dehumidifier B-296 operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

6.10 Using the Nano Spray Dryer Records software on a PC. . . . . . . . . . . . . . . . 76

7 Maintenance and repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

7.1 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.2 Housing condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.3 Glass component conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

7.4 Oxygen sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.5 Sealing conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.6 Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.6.1 Spray head and tube connections. . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.6.2 Outlet filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.6.3 Inert Loop B-295 and Dehumidifier B-296. . . . . . . . . . . . . . . . . . . . . . . 86

8 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.1 Error messages and their remedy . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.2 Malfunctions and their remedy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

9 Shutdown, storage, transport and disposal . . . . . . . . . . . . . . . . . . . . . . . . 91

9.1 Storage and transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.2 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

10 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.1 Spray head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

10.2 Glass parts and mounting items. . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

10.3 Particle collector, heater and lifting device items . . . . . . . . . . . . . . . . . . . . 96

10.4 Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.5 Tubing and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10.6 Inert Loop B-295, Dehumidifier B-296 and Adsorption Column . . . . . . . . . . . . 98

11 Declarations and requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

11.1 FCC requirements (for USA and Canada) . . . . . . . . . . . . . . . . . . . . . . .100

11.2 Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

5 B-90 Operation Manual, Version B

Page 6

1 About this manual

This manual describes the Nano Spray Dryer B-90 and provides all information required for its safe

operation and to maintain it in good working order. It is addressed to laboratory personnel in particular.

Abbreviations

EPDM Ethylene Propylene Dimonomer

FFKM Perfluoroelastomers

FPM Fluoroelastomer

PEEK Polyetheretherketone

PTFE Polytetrafluoroethylene (Teflon)

PE Polyethylene

PVC Polyvinylchloride

1 About this manual

6 B-90 Operation Manual, Version B

Page 7

2 Safety

This chapter highlights out the safety concept of the instrument and contains general rules of behavior

and warnings from direct and indirect hazards concerning the use of the product.

For the users safety, all safety instructions and safety messages in the individual chapters shall

be strictly observed and followed. Therefore, the manual must always be available to all persons

performing the tasks described herein.

2.1 User qualification

The instrument may only be used by laboratory personnel and other persons who on account of

training and professional experience know of the potential dangers that can develop when operating

the instrument.

Untrained personnel, or persons who are currently being trained, require careful supervision by a qualified person. The present Operation Manual serves as a basis for training.

2 Safety

2.2 Proper use

The Nano Spray Dryer B-90 and the Nano Spray Dryer B-90 Advanced have been designed and built

as laboratory instruments.

• The Nano Spray Dryer B-90 serves to spray-dry aqueous solutions or suspensions in ‘open loop’

with compressed air as drying gas.

• The Nano Spray Dryer B-90 Advanced can additionally process organic solvent solutions or

suspensions in ‘closed loop’ when combined with the Inert Loop B-295. Processing in ‘closed

loop’ requires N2 or CO2 as an inert gas.

The output particle size of the Nano Spray Dryer B-90 is between 300 nm–5 µm. Thus, the instrument is ideally suited to encapsulate particles and nano particles (<100 nm) from a solution or

suspension.

If the instrument is used with potentially toxic or hazardous substances in ‘open loop’, it has to be

installed inside a closed fume hood or glove box. In such cases, the complete processing and system

handling has to be performed within the ventilated box to avoid toxication and other hazardous situations to the user and the environment.

In any case, all exhausts leaving the exhaust gas tubing have to be lead away instantly by a ventilation

system, to remove possibly hazardous substances and fumes from the working area. The ventilation

system has to be equipped with safety measures such as outlet filters to avoid contamination of the

environment. When the Nano Spray Dryer B-90 is used in combination with other instruments (e.g.

Aspirator) all related manuals are to be fully observed.

7 B-90 Operation Manual, Version B

Page 8

2.3 Improper use

Applications not mentioned in section 2.2 are considered to be improper. Applications which do not

comply with the technical data (see section 3 of this manual) are also considered to be improper.

The operator bears the sole risk for any damages or hazards caused by improper use!

The following uses are expressly forbidden:

• Use of gases with unknown chemical composition.

• Spray drying of biohazard materials such as viruses or bacteria.

• Spray drying of organic solvents in ‘open loop’ and without the Inert Loop B-295.

• Installation or use of the instrument in rooms, which require ex-protected instruments.

• Spray drying of substances which might explode or ignite due to the processing and the selected

parameters of the Nano Spray Dryer B-90 or installed sub systems.

• Use of samples which might produce oxygen during the processing.

2 Safety

2.4 Safety warnings and safety signals used in this manual

DANGER, WARNING, CAUTION and NOTICE are standardized signal words for identifying levels of

hazard seriousness of risks related to personal injury and property damage. All signal words, which are

related to personal injury are accompanied by the general safety sign.

For your safety it is important to read and fully understand the below table with the different signal

words and their definitions!

Sign Signal word Definition Risk level

Indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation which, if not avoided, may

result in minor or moderate injury.

Indicates possible property damage, but no practices

related to personal injury.

no

DANGER

WARNING

CAUTION

NOTICE

★★★★

★★★☆

★★☆☆

★☆☆☆

(property damage only)

Supplementary safety information symbols may be placed in a rectangular panel on the left to the

signal word and the supplementary text (see below example).

!

SIGNAL WORD

Space for

supplementary

safety

information

symbols.

8 B-90 Operation Manual, Version B

Supplementary text, describing the kind and level of hazard / risk seriousness.

• List of measures to avoid the herein described, hazard or hazardous situation.

• ...

• ...

Page 9

2 Safety

Table of supplementary safety information symbols

The below reference list incorporates all safety information symbols used in this manual and their

meaning.

Symbol Meaning

General warning

Electrical hazard

Explosive gases, explosive environment

Harmful to life-forms

Hot item, hot surface

Device damage

Inhalation of substances

Pressurized gas/air

Ozone formation

Wear protective mask

9 B-90 Operation Manual, Version B

Page 10

Wear laboratory coat

Wear protective goggles

Wear protective gloves

Heavy weight, lifting requires more than one person

2 Safety

Additional user information

Paragraphs starting with NOTE transport helpful information for working with the device / software or

its supplementaries. NOTEs are not related to any kind of hazard or damage (see example below).

NOTE

Useful tips for the easy operation of the instrument / software.

2.5 Product safety

Safety warnings in this manual (as described in section 2.4) serve to make the user alert and to avoid

hazardous situations emanating from residual dangers by giving appropriate counter measures.

However, risks to users, property and the environment can arise when the instrument is damaged,

used carelessly or improperly.

2.5.1 General hazards

The following safety messages show hazards of general kind which may occur when handling the

instrument. The user shall observe all listed counter measures in order to achieve and maintain the

lowest possible level of hazard.

Additional warning messages can be found whenever actions and situations described in this manual

are related to situational hazards.

10 B-90 Operation Manual, Version B

Page 11

2 Safety

!

Danger

Death by suffocation or serious poisoning by inhalation of inert gases.

• Do not inhale inert gases

• Directly withdraw released gases and gaseous substances by sufficient ventilation

• Only operate the instrument in ventilated environments

• Before operation, check all parts, connections and sealings involved in the gasflow for proper

sealing

• Exchange worn out or defective parts immediately

!

Danger

Death or serious poisoning by gases or particles due to O2– sensor or filter malfunction

• Exchange defective O2– sensor immediately

• Exchange O2– sensor regularly within the specified maintenance intervals

• Exchange clogged filters immediately

• Exchange filters regularly within the specified maintenance intervals

• Dispose of filter immediately

!

Danger

Death or serious poisoning by inhalation or incorporation of dried particles during spray process.

• Wear safety goggles

• Wear safety gloves

• Wear a suitable protective mask

• Wear a laboratory coat

• Check for proper sealing before use

• Do not inhale dried particles

• Stop drying gas flow before opening the drying circuit

11 B-90 Operation Manual, Version B

Page 12

!

Danger

Death or serious poisoning by inhalation or incorporation of dried particles at recovery.

• Wear safety goggles

• Wear safety gloves

• Wear a suitable protective mask

• Wear a laboratory coat

• Do not inhale dried particles

• Stop drying gas flow before opening the drying circuit

• Only recover particles in sufficiently ventilated flue or glove-box

• Do not disperse the dried particles

• Do not clean dusty parts with compressed air

2 Safety

!

Warning

Death or serious injuries by use in explosive environments.

• Do not operate the instrument in explosive environments

• Do not operate the instrument with explosive gas mixtures

• Before operation, check all gas connections for correct installation

• Directly withdraw released gases and gaseous substances by sufficient ventilation

!

Warning

Death or serious poisoning by contact or incorporation of harmful substances at use.

• Before operation, check the instrument for correct assembling

• Before operation, inspect sealings and tubes for good condition

• Exchange worn out or defective parts immediately

• Exchange clogged filters immediately

• Only operate the instrument in ventilated environments

• Directly withdraw released gases and gaseous substances by sufficient ventilation

• Perform a dry-run without sample material and check for gas leakages

12 B-90 Operation Manual, Version B

Page 13

!

Caution

Risk of minor poisoning by inhalation of ozone.

• Directly withdraw released gases and gaseous substances by sufficient ventilation

Caution

!

Risk of minor or moderate burnings when handling hot parts.

• Do not touch hot parts

• Let the system cool down for some minutes after use

2 Safety

Risk of instrument short-circuits and damage by liquids.

• Do not spill liquids over the instrument or its component parts

• Wipe off any liquids instantly

• Place the sample vessel onto the designated reservoir-plate on top of the instrument

• Ensure a safe positioning of the sample vessel

• Do not move the instrument when it is loaded with liquid

• Keep external vibrations away from the instrument

Risk of instrument damage by internal overpressure.

• External supply pressure must meet the system specifications

• Exchange clogged filters immediately

• Dispose of filter immediately

Risk of instrument damage by wrong mains supply.

• External mains supply must meet the voltage given on the type plate

• Check for sufficient grounding

Notice

Notice

Notice

13 B-90 Operation Manual, Version B

Page 14

2.5.2 Warning labels on housing

The below warning label can be found at the gas outlet connector on the right side of the Nano Spray

Dryer B-90.

Meaning

Ozone formation in the electric field of the electrostatic particle collector when using oxygen containing

gases as drying gas (like air). Withdraw gases via fume hood or equivalent ventilation system directly.

2 Safety

2.5.3 Safety measures

Always wear personal protective equipment such as protective eye goggles, protective clothing, inhalation protection and gloves when working with the instrument.

2.5.4 Built-in safety elements and measures

Heating

• Overheating protection circuit.

• Automatic temperature control of heater and inlet temperature.

Spraying

• Automatic spray control.

• Light barrier, to detect the correct placement of the particle collector.

• Overpressure leakage detection.

High voltage and electrostatic charges

• Safety current limitation.

• Internal grounding to arrest electrostatic charges.

Air/Gas

• Automatic processing interruption when system pressure is too low.

• Outlet filter to protect the environment contamination of fine dust particles via exhaust gas tubing.

14 B-90 Operation Manual, Version B

Page 15

Glass

• High temperature resistance and high transparency borosilicate glass.

Pressure

• Automatic pressure control at outlet filter.

• Over pressure safety valve (opens at 300 mbar).

Optional system configuration with Inert Loop B-295

• Overpressure leakage detection.

• Safe gas condition (< 6 % O2 content) is detected and enables the regulation of the drying gas

mixture via a communication cable.

2.6 General safety rules

Responsibility of the operator

The head of the laboratory is responsible for training his/her personnel.

The operator shall inform the manufacturer without delay of any safety-related incidents which might

occur during operation of the instrument. Legal regulations, such as local, state and federal laws

applying to the instrument must be strictly followed.

2 Safety

Duty of maintenance and care

The operator is responsible for the proper condition of instrument at use and that maintenance,

service and repair jobs are performed with care and on schedule by authorized personnel only.

Spare parts to be used

Use only genuine consumables and genuine spare parts for maintenance to assure good system

performance and reliability. Any modifications to the spare parts used are only allowed with the prior

written permission of the manufacturer.

Modifications

Modifications to the instrument are only permitted after prior consultation with and with the written

approval of the manufacturer. Modifications and upgrades shall only be carried out by an authorized

BUCHI technical engineer. The manufacturer will decline any claim resulting from unauthorized modifications.

15 B-90 Operation Manual, Version B

Page 16

3 Technical data

This chapter introduces the reader to the instrument and its specifications. It contains the scope of

delivery, technical data, requirements and performance data.

3.1 Scope of application and delivery

The Nano Spray Dryer B-90 is available in two different set-ups:

Nano Spray Dryer B-90 Basic

• For aqueous applications with air in ‘open loop’

Nano Spray Dryer B-90 Advanced

• For solvent applications in combination with Inert Loop B-295

• Optional use with Dehumidifier B-296

• Equipped with additional oxygen safety circuit and gas regulation valves

• Accessories are solvent resistant

3 Technical data

The scope of delivery can only be checked according to the individual delivery note and the listed

order numbers.

NOTE

For additional information about the listed products, see www.buchi.com or contact your local

dealer.

3.1.1 Standard instrument

Table 3-1: Standard instrument

Product Order no.

Nano Spray Dryer B-90 Basic

50 – 60 Hz, 100 – 240 V

Nano Spray Dryer B-90 Advanced

50 – 60 Hz, 100 – 240 V

11055320

11055321

16 B-90 Operation Manual, Version B

Page 17

3.1.2 Standard accessories

3

3 Technical data

Table 3-2: Standard accessories

Product Order no.

Spray head 051510

Spray head holder 051508

✕

Set of 3 spray caps 4.0 µm 051747

Set of 3 spray caps 5.5 µm 051748

Set of 3 spray caps 7.0 µm 051749

HV–Electrode protected 11055174

Protective grid for HV–Electrode 051680

Peristaltic pump complete 051735

17 B-90 Operation Manual, Version B

Page 18

3 Technical data

Table 3-2: Standard accessories (cont.)

Product Order no.

① Spray cylinder 051511

② Glass cylinder extension 051549

Glass insulation cylinder (no picture) 051663

1

Heater complete 051504

Lifting device 051607

«Nano Spray Dryer Records» Software 051776

18 B-90 Operation Manual, Version B

Page 19

Operation Manual

Nano

Spray Dryer B�90

3 Technical data

Table 3-2: Standard accessories (cont.)

Product Order no.

Outlet filter 051656

Operation Manual:

English 093261

German 093262

French 093263

Italian 093264

Spanish 093265

093261

Deckblatt B-90_en.indd 1 08.07.2009 09:44:56

en

3.1.3 Standard accessories with the Nano Spray Dryer B-90 Advanced

Table 3-3: Standard accessories with the B-90

Product Order no.

Oxygen sensor 046348

Tygon tubing MH 2075 transparent (per m) 046314

Tygon tubing F 4040 A yellow (per m) 046315

Upgrade set Nano Spray Dryer B-90

Basic to Advanced

NOTE

Upgrade set is for organic solvent operation in ‘closed loop’ with the Inert Loop B-295 or Dehumidifier B-296. The upgrade set includes solvent resistant tubing, inert gas regulation valves,

oxygen sensor with oxygen analyser. The installation requires support of a BUCHI service enginee r.

Advanced (for ‘closed loop’ operation)

11055748

19 B-90 Operation Manual, Version B

Page 20

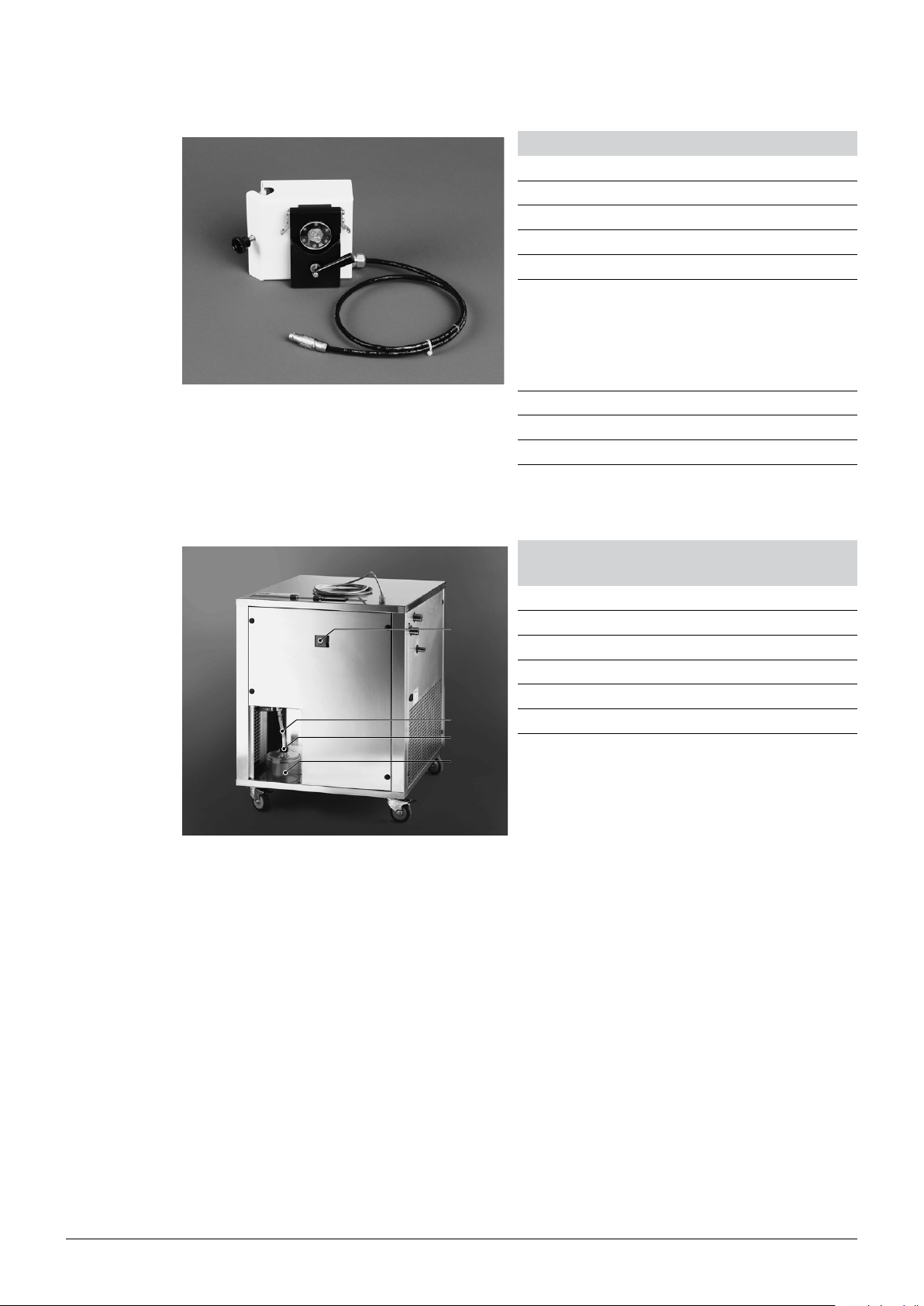

3.1.4 Optional accessories

3 Technical data

Table 3-4: Optional accessories

Product Order no.

Inert Loop B-295, 50 Hz, 200 V 044779

Inert Loop B-295, 50 Hz, 230 V 044701

Inert Loop B-295, 60 Hz, 200 V 046345

Inert Loop B-295, 60 Hz, 230 V 046344

Upgrade set B–295 for closed cycle 051783

Dehumidifier B-296, 50/60 Hz, 230 V 040188

Dehumidifier B–296, 50/60 Hz, 200 V 040181

Upgrade set B–296 for closed cycle 051780

Aspirator complete, incl. inlet filter 051700

20 B-90 Operation Manual, Version B

Page 21

3 Technical data

Table 3-4: Optional accessories (cont.)

Product Order no.

Inlet filter 011235

Air maintenance unit 004366

Oil-free air compressor, 230V / 50Hz 027907

Oil-free air compressor, 230V / 60Hz 11055736

Trolley 041257

21 B-90 Operation Manual, Version B

Page 22

3.2 Technical data

Table 3-5: Technical data Nano Spray Dryer B-90

Power consumption max. 1500 W

Connection voltage 100–240 VAC ± 10 %

Input fuse 12 A

Frequency 50 / 60 Hz

Heating capacity max. 1400 W

Max. inlet temperature 120 °C

Evaporating capacity max. 0.2 l/h H2O

Drying gas flow 80–160 l/min

N2 or CO2 inert gas input pressure max. 2 bar

Spray caps (hole diameters) 4.0 µm, 5.5 µm, 7.0 µm

Mean droplet size range 8–21 µm

Mean particle size range 300 nm–5 µm

Mean residence time 1–4 sec.

Interface USB II

IP degree of protection (two digits) IP 42

3 Technical data

Table 3-4: Optional accessories (cont.)

Product Order no.

Stand plate 051775

(higher rates with organic solvents are possible)

Explanation of protection level:

4 Protection provided by the enclosure against access

to hazardous parts (e.g., electrical conductors,

moving parts) and the ingress of solid foreign objects

with a diameter of > 1mm.

2 Protection of the equipment inside the enclosure

against harmful ingress of dripping water when tilted

up to 15°.

Overvoltage category II

Environmental conditions:

Pollution degree 2 (for indoor use only)

Temperature 5–40 °C

Altitude (above sea level) up to 2000 m

Humidity (curve parameter) Maximum relative humidity 80 % up to 31 °C, then

decreasing linearly to 50 % relative humidity at 40 °C

22 B-90 Operation Manual, Version B

Page 23

Table 3-5: Technical data Nano Spray Dryer B-90 (cont.)

Dimensions (W × H × D)

Short set-up 58×110×55 cm

Tall set-up 58×150×55 cm

Weight

Short set-up 65 kg

Tall set-up 70 kg

Table 3-6: Technical data Inert Loop B-295

Power consumption max. 1.4 kW

Connection voltage 200–230 V ± 10 %

Frequency 50/60 Hz

Min. outlet temperature down to -25 °C

Rate of cooling 800 W at -10 °C

Dimensions (W×H×D) 60×70×84.5 cm

Weight 95 kg

3 Technical data

Table 3-7: Technical data Dehumidifier B-296

Power consumption 700 W

Connection voltage 200/230 V ± 10 %

Frequency 50/60 Hz

Min. outlet temperature + 2 °C

Rate of cooling 600 W at 0 °C

Dimensions (W×H×D) 35×40×60 cm

Weight 36 kg

Table 3-8: Technical data Aspirator

Power consumption max. 1000 W

Connection voltage 200–240 V ± 10 %

Input fuse FST 5×20 T8A L 250 V

Frequency 50/60 Hz

Dimensions (W×H×D) 47,5×30×32 cm

Weight 20 kg

IP degree of protection (two digits) IP 20

Explanation of protection level:

2 Protection provided by the enclosure against access

to hazardous parts (e.g., electrical conductors,

moving parts) and the ingress of solid objects up to

12 mm, e.g. persons fingers.

0 No protection against ingress of liquids.

23 B-90 Operation Manual, Version B

Page 24

3.3 Materials used

Table 3-9: Materials used

Component Material designation

Glass assembly 3.3 borosilicate glass

Heater Aluminum and stainless steel

Spray head Stainless steel

Spray cap membrane Stainless steel

Spray cap o-ring EPDM75

Feeding tubes Silicone and tygon

Tube connector at feeding tube PEEK

Particle collecting tube Stainless steel polished

HV–electrode Stainless steel

Sealings for spray and glass cylinder Silicone

3 Technical data

24 B-90 Operation Manual, Version B

Page 25

4 Description of function

This chapter explains the basic working principle of the Nano Spray Dryer B-90 Basic (‘open loop’

only) and the Nano Spray Dryer B-90 Advanced (equipped with O2-sensor and inert gas regulation valves for ‘closed loop’ mode). It also shows how the instruments are structured and provides a

general functional description of their assemblies.

4.1 Functional principle

The Nano Spray Dryer B-90 models have been designed to produce particles out of a solution or

suspension with a particle size between 0,3 µm–5 µm by drying or encapsulation at a yield rate of up

to 90 %. The output particle size depends mainly upon the chosen spray cap. The Nano Spray Dryer

B-90 also allows processing of nano particles (<100 nm) in nanosuspensions or emulsions e.g. for

encapsulation. The drying gas flow and the product stream are described below.

4.1.1 Drying gas circuit

4 Description of function

The sprayed liquid is accompanied by a co-current gas flow. For highest yields, a controlled gas

flow at a sufficient quality and a defined temperature is required. To ensure this, a flow regulator and

heating loop has been implemented

a The drying and transport gas enters the instrument

a

Drying gas inlet

via the “Drying gas inlet”.

b The gas flow is monitored by a “Flow meter”

which influences the “Gas regulator”.

Gas regulator

b

Flow meter

Feed pump

c Subsequently the “Electrical heater” heats up the

gas to the desired drying temperature.

c

Electrical heater

Spray head

d Via the “Inlet temperatur sensor” the heater is

regulated to achieve the desired gas temperature.

d

Inlet temp. sensor

e The “Relative pressure sensor” compares the in-

ternal to the environmental pressure. In the event

of a massive pressure loss (e.g. a leakage) this

f

safety loop

Drying cylinder

sensor stops the drying process.

f In ‘closed loop’ mode, as part of the safety loop

Electrical particle

collector

the “Oxygen sensor” supervises the percentage of

oxygen in the drying gas. In emergency, it stops

the process.

Oxygen sensor

e

Rel. pressure sensor

g The “Outlet temperature sensor” is located after

the particle collector. The temperature drop

g

Outlet temp. sensor

h

Outlet filter

i

Drying gas outlet

between inlet and outlet temperature sensor is

measured as a process value.

h The “Outlet filter” is a safety relevant item. It re-

tains possibly harmful particles towards the environment in ‘open loop’. In ‘closed loop’ the outlet

filter is an essential part for cleaning the recycled

gas from unwanted residues and impurities.

i The “Drying gas outlet” works as an exhaust.

25 B-90 Operation Manual, Version B

Page 26

Optional drying gas recycling in ‘closed loop’ mode:

In ‘closed loop’ mode of the Nano Spray Dryer B-90 Advanced the “Drying gas outlet” i is connected

via the Inert Loop B-295 or Dehumidifier B-296 and Aspirator to the “Drying gas inlet” a.

4.1.2 Spray drying process overview

The drying process takes place inside the drying cylinder. A drying gas flow is established and tiny

droplets of sample material are injected by the spray head. The sample material is dried by the hot

gas. Because of the tiny particle size, an electrical field of sufficient power is needed to retrieve

the particulate material from the drying gas flow. The following scheme informs about the different

processing stages in general.

Drying gas inlet

Gas regulator

safety loop

Flow meter

Electrical heater

Inlet temp. sensor

Drying cylinder

Electrical particle

c

d

collector

a

Feed pump

b

Spray head

4 Description of function

a The “Feed pump” constantly feeds the “Spray head”

with liquid sample material.

b The “Spray head” produces finest droplets and in-

jects them into the “Drying cylinder”.

c The heated drying gas enters laminar from the top

into the “Drying cylinder”. Consequently, the injected

drops of sample material are gently dried to solid

particles.

d The “Electrical particle collector” retrieves the dried

solid particles by an electrostatic field.

e The exhaust gas leaves the spray dryer via the “Out-

let filter” which retains free particles from the gas.

Oxygen sensor

Rel. pressure sensor

Outlet temp. sensor

e

Outlet filter

Drying gas outlet

26 B-90 Operation Manual, Version B

Page 27

4 Description of function

pull pull

Processing inside the drying cylinder

The following draft offers a more detailed view about the basic spray drying process. The drying

gas (a) passes the heater (b) and the vertically or angular aligned spray head (e). The injected

micro doplets of the sample material are dried while beeing vortexed in the gas flow inside the spray

cylinder (f). An electric field is generated by high voltage between the collecting electrode (h) and

the HV-electrode (i). While the HV-electrode deflects the particulate material, the collecting electrode

attracts them. Thus, particles are depositing at the inside of the collecting electrode (g).

a

c

f

h

i

4.2 Spray generation

The Nano Spray Dryer B-90 uses piezotechnology to generate precisely controlled micro droplets

from bulk liquids without the use of propellants.

b

e

j

k

g

d

l

a Drying gas inlet (optional with inlet filter and Aspira-

tor)

b Electrical heater

c Inlet temperature sensor

d Display/Control

e Spray head (angular or vertical installation)

f Spray cylinder and drying section

g Finished product at particle collecting electrode

h Particle collecting electrode

i HV–electrode

j Outlet temperature sensor

k Outlet filter

l Drying gas outlet (in ‘closed loop’ connected to Inert

Loop B-295 and Aspirator)

push

NOTE

The smaller the mesh size, the smaller the ejected droplets and dried particles. Since the vibrations

frequency is fixed, a smaller mesh size will have less throughput per time.

4.3 Heating system

The compact heater module provides optimal energy input to heat the drying gas up to 120 °C. The

heating system consists of an electrically heated porous metal foam to minimize the heat–up time and

to generate a laminar gas flow towards the drying section. The heating control is based on a pluggable PT–1000 temperature sensor.

push

The spray head includes a piezoelectric actuator with

a thin stainless steel membrane. The membrane has

an array of micron-sized holes (spray meshes of 4.0,

5.5 or 7.0 µm hole size) and vibrates at ultrasonic

frequency (60 kHz). Because of these vibrations

the membrane eject precisely sized droplets at high

speed.

27 B-90 Operation Manual, Version B

Page 28

4.4 Drying air generation

In ‘open loop’ mode the required drying air can be either supplied by an in-house compressed air

supply, an oil-free compressor or a BUCHI Aspirator (see section 3.1.4, Optional accessories).

4.4.1 Compressed air supply

In ‘open loop’ configuration, compressed air is used as standard drying gas. The air maintenance unit

(order no. 004366) is additionally recommended to assure gas of clean, dry and oil free quality. A pressure regulating valve is required to match the instruments input pressure value.

Nano Spray Dryer B-90

Basic

4 Description of function

Air maintenance unit

T

IN

P

Product

T

OUT

a Compressed air source

b Optional air maintenance unit

c Pressure regulating valve

4.4.2 Aspirator in blowing mode

If there is no compressed air available in the laboratory, the BUCHI Aspirator unit with inlet filter (order

no. 051700) can be used to establish the required drying air flow rate. The Aspirator can be connected

directly to the inlet of the Nano Spray Dryer B-90 without a pressure regulating valve. In case of higher

ambient humidity use the Dehumidifier B-296 to achieve dry air.

Feed

Control

FI

Outlet filter

c

Exhaust gas

Compressed

air

b (optional)

a

NOTE

If the humidity of the air is too high, the current in the particle collector could be too low.

Air inlet filter

The air inlet filter is required to avoid any contamination of the instruments by fine particles in the lab

environment. It is to be connected to the inlet of the Aspirator, so the instrument aspirates filtered

ambient air. The filter consists of a stainless steel grid for outer protection and an ultra filter based on a

glass fibre textile (filter class S according to DIN 24184).

28 B-90 Operation Manual, Version B

Page 29

Nano Spray Dryer B-90

Basic

Feed

T

IN

Control

Dehumidifier

B-296

T

COOL

4 Description of function

c (optional)

Aspirator

P

Product

T

OUT

a Inlet filter to filter out dust and particles

b Aspirator as air supply source

c Optional Dehumidifier B-296

FI

Condensate

Exhaust gas

Outlet filter

NOTE

The Aspirator is also used with a Nano Spray Dryer B-90 Advanced in ‘closed loop’ configuration

with the Inert Loop B-295 or Dehumidifier B-296 to recirculate the inert gas (N2 or CO2).

4.5 Sample feed circulation with peristaltic pump

The peristaltic pump circulates the sample feed between the product vessel and the spray head. It

assures a constant substance feeding for the spray generation.

b

a

Inlet filter

NOTE

Dry run of the pump and the spray head does not damage the instrument or parts of it in the

medium term.

4.6 Particle collector

Solid particles are accumulated at the wall of the cylindrical particle collecting electrode by a strong

electrical field. The electrical field is generated via high voltage.

4.7 Outlet filter

The outlet filter (order no. 051656) prevents environmental pollution by particles. It is installed inside

the housing of the Nano Spray Dryer B-90. See section 5.5.1 for information about access and

exchange.

29 B-90 Operation Manual, Version B

Page 30

4.8 Inert Loop B-295

The Inert Loop B-295 is an accessory to enable the safe spray drying of organic solvents in a ‘closed

loop’ configuration. It comprises a cooling unit with pressure and oxygen monitoring elements and

safety controls. Communication to the Nano Spray Dryer B-90 Advanced is established via a communication cable.

Product

4 Description of function

a

Exhaust gas

T

COOL

Dehumidifier

a Exhaust gas to fume hood or glove box ventilation

outlet

b Solvent condensate

B-296

c Condensation and cooling unit

c

b

Functional principle:

• The inert drying gas (N2 or CO2) is loaded with solvent from the spray drying process.

• The loaded gas enters the Inert Loop B-295 and is cooled down in its internal preheat exchanger.

• The solvent is condensed in the refrigerator and collected in a closed bottle.

• Subsequently, the cleaned and cooled gas stream is heated up in the preheat exchanger and flows

back through an Aspirator to the Nano Spray Dryer B-90 Advanced.

Dehumidifier B-296

If mixtures of organic solvents and water are used in ‘closed loop’ configuration, BUCHI strongly

recommends to install the additional Dehumidifier B-296. The Dehumidifier B-296 is condensing

the water to prevent water from entering the Inert Loop B-295. This is necessary to protect the heat

exchanger in the refrigerator from water freezing and potential damage.

30 B-90 Operation Manual, Version B

Page 31

4.9 Dehumidifier B-296

The Dehumidifier B-296 is an accessory which can dry filtered gas at constant and reproducible

humidity conditions with a dew point of 3 to 5 °C. The humidity condensates while passing the refrigerator of the Dehumidifier B-296 and is being collected in a closed condensate bottle.

‘open loop’ inlet air conditioning

In ‘open loop’ configuration with Aspirator and Inlet filter the Dehumidifier B-296 has to be connected

to the gas inlet of the Nano Spray Dryer B-90 for inlet air conditioning. The dried, cooled air enters the

spray dryer subsequently.

4 Description of function

Nano Spray Dryer B-90

Basic

Feed

T

IN

P

Product

T

OUT

Outlet filter

a Air inlet through filter

b Aspirator in blowing mode

c Dehumidifier B-296 to condensate humidity

d Dry air output towards Nano Spray Dryer B-90

Control

FI

c

Dehumidifier

B-296

T

COOL

d

Condensate

Exhaust gas

e Condensed water output to collecting flask

e

b

Aspirator

Inlet filter

a

31 B-90 Operation Manual, Version B

Page 32

4 Description of function

Use in ‘closed loop’

The Dehumidifier B-296 in ‘closed loop’ set-up allows spray drying of water-organic solvent mixtures,

oxygen sensitive substances or flammable powders under safe conditions.

Nano Spray Dryer B-90

Advanced

T

IN

P

Product

T

OUT

Feed

Control

FI

Outlet filter

O

Dongle

2

a

a Inert gas input

b Dehumidifier B-296 to condensate humidity

c Condensate output to collecting flask

e

CO

2

d

Aspirator

Condensate

c

Exhaust

gas

Dehumidifier

B-296

T

Cool

b

N

2

d Aspirator to establish gasflow

e Dongle to substitute the missing Inert Loop B-295

signals

Suitable spray drying conditions:

• Water-organic solvent mixture with up to 20 % organic solvent content

• For high boiling solvents mixtures (bp > 70 °C) with up to 50 % organic solvent content

In this configuration the used inert gas (N2 or CO2) is loaded with water-solvent mixture residues from

the spray drying process. After the cooling and drying process the gas flows back to the spray dryer.

NOTE

To increase the efficiency of the dehumidifier significantly, it is recommended to use the optional

preheat exchanger (order no. 040059). The preheat exchanger also safes energy by heating up the

cooled, dehumidified gas again.

32 B-90 Operation Manual, Version B

Page 33

4.10 Connection at the Nano Spray Dryer B-90

Front connections

Socket label: Description:

a b c d

a HIGH VOLTAGE Socket for particle collector

b T

c B-295 Inert Loop B-295 communi-

d USB Port for data records to PC

OUT

4 Description of function

with plug thread for reliable

plug locking

Outlet temperature sensor

socket

cation socket; also used for

the dongle to substitute

missing communication when

operating with Dehumidifier

B-296

Rear and side connections

k

j

e

f

m

l

i

Socket label: Description:

e GAS OUT Gas outlet / exhaust

f N

2

N2 input in ‘closed loop’

mode

g AIR (CO2) Air or CO2 (‘closed loop’) inlet

h GAS IN Air inlet in ‘open loop’ mode

i Not labelled Gas tube to heater

j Not labelled Socket for mains plug

k Fuses Resettable fuses

l T

IN

Inlet socket for temperature

sensor

m HEATER Socket for heater plug

n Pressure relief valve Overpressure safety valve

(opens at a system pressure

> 300 m bar)

g

h

n

33 B-90 Operation Manual, Version B

Page 34

5 Putting into operation

This chapter describes how the instrument has to be installed. It also gives instructions for the initial

startup.

NOTE

Inspect the instrument for damages during unpacking. If necessary, prepare a status report immediately to inform the postal company, railway company or transportation company. Keep the original

packaging for future transportation.

5.1 Installation site

Put the instrument on a stable, horizontal surface. Consider the maximum product dimensions

and weight. Installation on a mobile trolley is also possible. Obtain the environmental conditions as

described in section 3.2, technical data.

5 Putting into operation

NOTE

T o cut the power in case of an emergency by unplugging, the instruments or any other items must

not block the mains plug!

!

Warning

Death or serious injuries by use in explosive environments.

• Do not operate the instrument in explosive environments

• Do not operate the instrument with explosive gas mixtures

• Before operation, check all gas connections for correct installation

• Directly withdraw released gases and gaseous substances by sufficient ventilation

Caution

!

Risk of minor or moderate injury by heavy weight of the instrument.

• Consult a second person to transport the instrument

• Do not drop the instrument

• Place the instrument on a stable, even and vibration-free surface

• Keep limbs out of crushing zone

34 B-90 Operation Manual, Version B

Page 35

5.2 Installing the Nano Spray Dryer B-90

Switch off the instrument and remove the power cord before any work described in section 5.

5.2.1 Tall set-up with long metal bars

NOTE

Parts (a – e) and the black holders (i), are factory pre-installed.

5 Putting into operation

9

a Screw the four lower metal bars into the housing basement with a flat spanner.

b Fix the four adjusting rings onto the previously installed metal bars.

c Mount four short headless screws onto the lower metal bars. Use a hex-wrench to screw them

tightly in.

d Screw the middle metal bars tightly onto the lower ones.

e Mount four short headless screws onto the middle metal bars. Use a hex-wrench to screw them

tightly in.

f Screw the four upper metal bars onto the middle ones and screw them tightly together.

g Mount the four long headless screws onto the upper metal bars. Use a hex-wrench to screw

them tightly in.

h Put the four counter nuts upside-down and onto the long headless screws on top of the bars and

turn them clockwise to the lowest possible position.

i To install the bar holders, first screw the holder base at the housing. Use the metal bars for align-

ment. Subsequently attach the side of the holders with the side caps and three screws.

35 B-90 Operation Manual, Version B

Page 36

5.2.2 Short set-up with short metal bars

NOTE

Parts (a – e) and the black holders (g), are factory pre-installed.

5 Putting into operation

a Screw the four lower metal bars into the housing basement with a flat spanner.

b Fix the four adjusting rings onto the previously installed metal bars.

c Mount four short headless screws onto the lower metal bars. Use a hex-wrench to screw

them tightly in.

d Screw the middle metal bars tightly onto the lower ones.

e Mount the four long headless screws onto the upper metal bars. Use a hex-wrench to screw

them tightly in.

f Put the four counter nuts upside-down and onto the long headless screws on top of the bars and

turn them clockwise to the lowest possible position.

g To install the bar holders, first screw the holder base at the housing. Use the metal bars for align-

ment. Subsequently attach the side of the holders with the side caps and three screws.

36 B-90 Operation Manual, Version B

Page 37

5.3 Sub-assembly installations

Switch off the instrument and remove the power cord before any installation work.

5.3.1 Lifting device

a

5 Putting into operation

a Position the lifting device, using the three bottom

sided timing holes, onto the matching knobs at the

instrument’s basement.

b Rotate the lifting device some degrees clockwise to

fix it tightly by hand. The lever has to be positioned

towards the front.

d

c

b

e

70 mm

c Screw the gas outlet part onto the lifting device with

two hex-wrench screws.

d Take the small o-ring from the set of sealings (order

no. 051775). Place it on the sealing seat of the gas

outlet part.

e Install the outlet temperature sensor at the gas

outlet part. For the correct installation depth keep

the sensor housing approximately 70 mm out of the

gas outlet part. Use a flat spanner to fix the screw

fitting of the sensor housing tightly

Subsequently connect the outlet temperature sensor

plug to socket (see section 4.10, socket b).

37 B-90 Operation Manual, Version B

Page 38

5.3.2 Electrode assembly installation

Caution

!

Risk of minor or moderate injury by electric shock.

• Switch off the instrument before connecting or disconnecting the high-voltage cable

• Do not touch the high-voltage cable with wet hands

• Use only damage free cabling

NOTE

Before installing the electrode, clean all parts a to e thoroughly.

5 Putting into operation

a Position the flat seal at the particle collector

basement.

b Position the metal collecting tube electrode

on the collector basement and assure electrical contact. The broader uncoated stripe

at the lower outer side is to be installed

towards the base.

c Install the insulation glass cylinder on the

collector basement.

d Place the assembly on the lifting device.

38 B-90 Operation Manual, Version B

Page 39

5 Putting into operation

e Use the protective grid holder to carefully

insert the HV-electrode into its seat at the

bottom plate of the particle collector. Clean

and dry this part before installation.

f To unlock the protective grid, open the

spring lock at the handling knob first.

Carefully lift off the grid from the HVelectrode in a vertical upwards movement.

Finally, connect the electrical cable of the

particle collector to the high voltage socket

at the frontside of the instrument (see section

4.10, socket a) and fix it hand-tight.

39 B-90 Operation Manual, Version B

Page 40

5 Putting into operation

5.3.3 Glass cylinder installation

!

Risk of minor or moderate cuts when handling damaged glass parts.

• Handle glass parts with care

• Visually inspect every glass part before mounting

• Exchange damaged glass parts immediately

• Do not touch cracks or bits of broken glass with bare hands

7

Caution

g Put the plastic distance sheet on top of the

electrode cylinder.

h Put the centerpiece holder on the plastic

distance sheet.

i Adjust the four screw rings on the metal

bars to touch the underside of the distance

sheet. Fix them tightly with an hex-wrench.

Finally, remove the plastic distance sheet again

by pulling it out towards the front.

After correct installation it is possible to remove

the complete electrode cylinder assembly

towards the front.

NOTE

Clean all glass parts before mounting to avoid cross contamination.

Cylinder assembly tall set-up

a Mount a flat sealing ring on the bottom of the lower

glass cylinder.

b Place the glass cylinder on the centerpiece holder.

2

c Position the glass-to-glass sealing on top of the

lower glass cylinder. The smaller diameter has to be

on top towards the spray cylinder.

d Position the second flat sealing ring on top of the

spray cylinder.

e Place the spray cylinder on top of the glass-to-glass

sealing.

All sealings are part of the sealing set (order no. 051778).

40 B-90 Operation Manual, Version B

Page 41

5

Cylinder assembly short set-up

2

5 Putting into operation

a Mount a flat sealing ring on the bottom of the spray

cylinder.

b Position the second flat sealing ring on the spray

cylinder.

c Place the spray cylinder on the centerpiece holder.

All sealings are part of the sealing set (order no. 051778).

5.3.4 Heater module installation

Special mounting

tool in position.

Caution

!

Risk of minor or moderate burning when handling hot parts.

• Do not touch hot parts

• Let the system cool down for some minutes after use

The special mounting tool serves as a mounting gauge

for the correct distance of all mounted parts between

2

lifting device and heater.

• Put the lever arm of the lifting device into the end

a of the tool first. The tool and the handle are

equipped with holes. Line up all holes and insert

a hex-wrench through the holes to stabilize the

correct tool position.

• Use the left metal bar to support the tool end b.

The lifting device is now in mounting height for the

heater module installation.

41 B-90 Operation Manual, Version B

Page 42

5 Putting into operation

c Mount the inlet temperature sensor at the heater

module. Keep the temperature sensor end about

4

70 mm out of the screw connection. Use a flat

spanner to tighten the screw fitting.

d Place the heater module on the metal screw bars.

NOTE

• Position four hex nuts from top onto the metal

bar ends with a narrow gap towards the heater

module.

• Position the hex nuts from below the heater with

approximately the same narrow gap towards the

heater module.

All nuts must be tightened

crosswise only!

5

Make sure the spray cylinder is in-line with the heater

module and that the sealing is properly placed

between.

e–f Tighten the hex counter nuts above and below

the heater crosswise. Do not overtighten the

nuts.

g Remove the mounting tool from the lifting device

after installation.

Final steps:

• Connect the electrical cable of the heater to the

back side of the instrument (see section 4.10,

socket m).

• Connect the inlet temperature sensor to its socket

at the back side of the instrument (see section 4.10,

socket l).

• Connect the drying gas tubing to the inlet of the

heater module. Use a hose clamp for fixation.

• Connect the drying gas tubing between the heater

inlet and the connector nipple inside the instrument

(open the upper back panel of the instrument to get

access).

42 B-90 Operation Manual, Version B

Page 43

5.4 Spray head assembling and installation

The spray head is a major part of the whole spray drying process. To ensure proper function and

highest yield, dry and clean conditions of all parts during assembling and installation are required. For

detailed cleaning information see section 8.6.1.

Caution

!

Risk of minor or moderate burning when handling hot parts.

• Do not touch hot parts

• Let the system cool down for some minutes after use

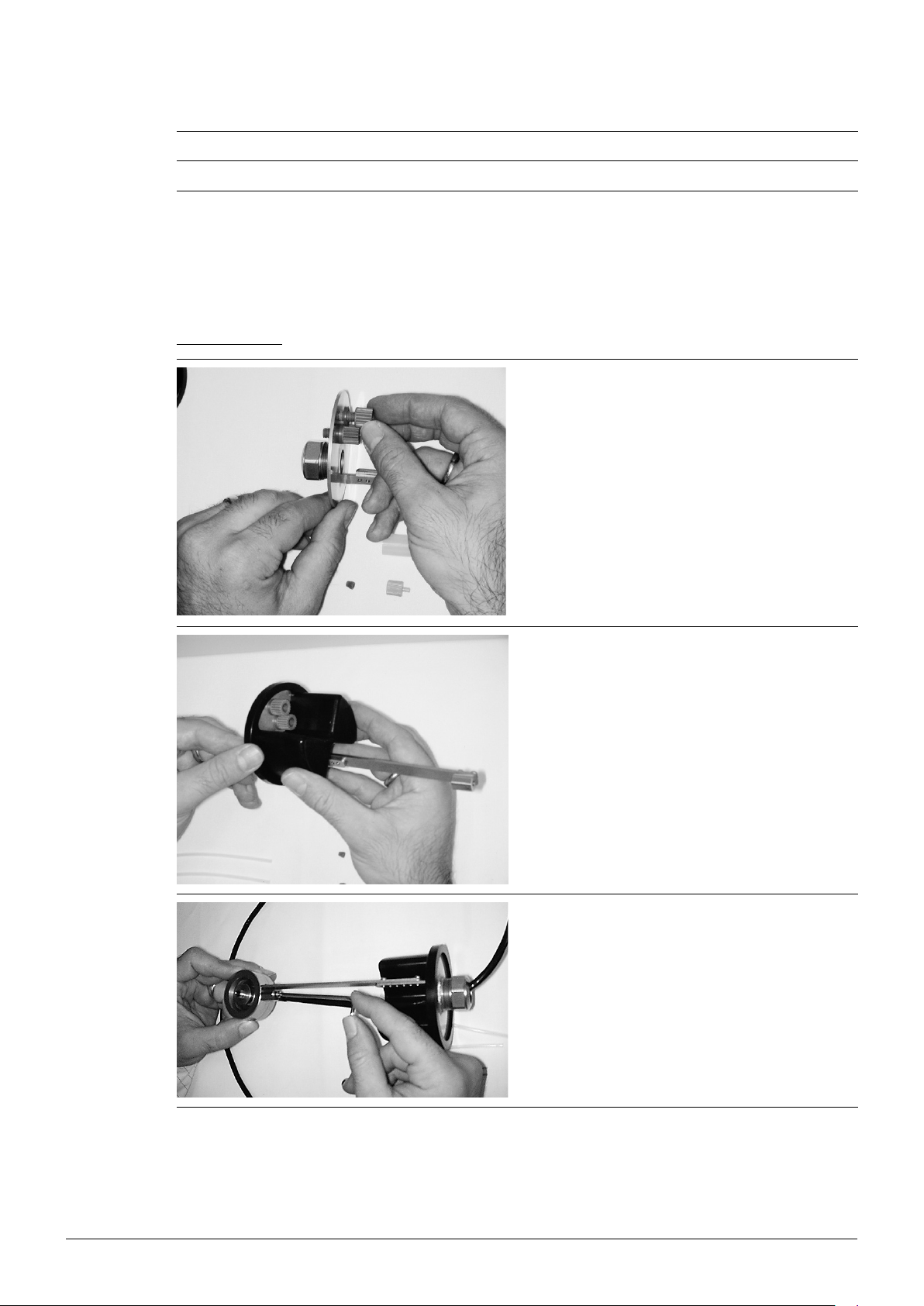

5.4.1 Spray head assembling

5 Putting into operation

c

a

k

a Spray head

b Screw M3; torx

b

j

d

e

f g h i

c Rubber sealing

d Head holder

e Seal for electrical cable

f Fitting

g Silicone seal (o-ring)

h Ferrules

i Tube connector

43 B-90 Operation Manual, Version B

Page 44

5 Putting into operation

j Feed tubing

k Spray cap

NOTE

• Only use original BUCHI parts for installation.

• Small parts (e–j) are available in the set „Set of feed tubing connections complete“ with

order no. 051768.

Assembly steps

1. Put the “Silicone seal” g onto the two

“Fittings” f and screw them into the head

holder hand-tight.

2. Introduce the “Rubber sealing” c onto the

head holder.

3. Mount the spray head at the “Head holder”

d. See also section 5.3.2 for details.

4. Insert the electrical cable through the cable

hole of the “Head holder”.

44 B-90 Operation Manual, Version B

Page 45

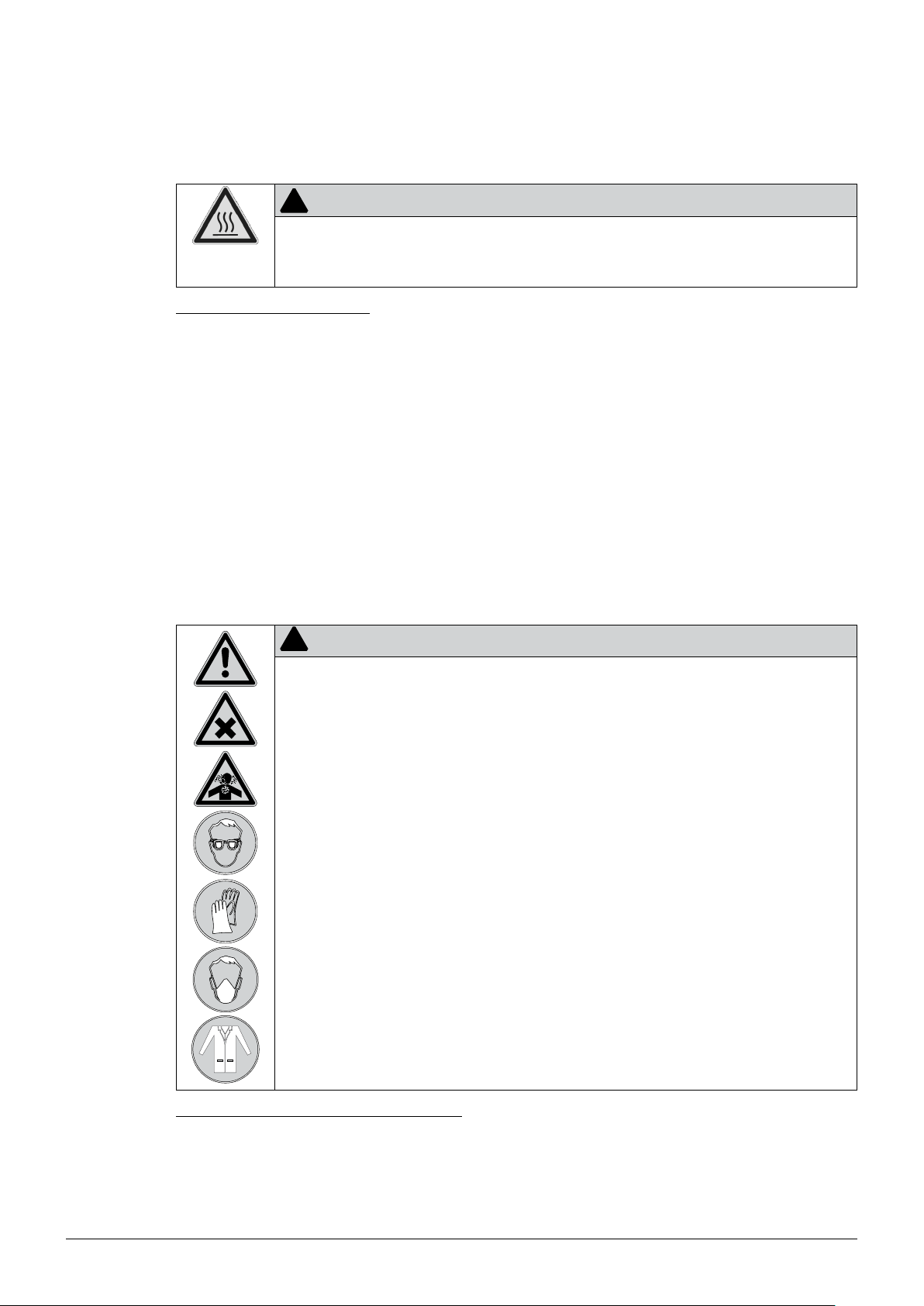

5 Putting into operation

5. Introduce the “Seal for electrical cable” e

and tighten the cable bushing using a flat

spanner.

6. Introduce the “Feed tubing” j through the

spray head.

7. Screw the “Spray cap” k onto the spray

head.

8. Introduce the “Feed tubing” k into the

“Fittings” f. Attach the “Ferrules” h to the

“Feed tubing”.

9. Mout the “Tube connectors” i at the

“Fittings”.

45 B-90 Operation Manual, Version B

Page 46

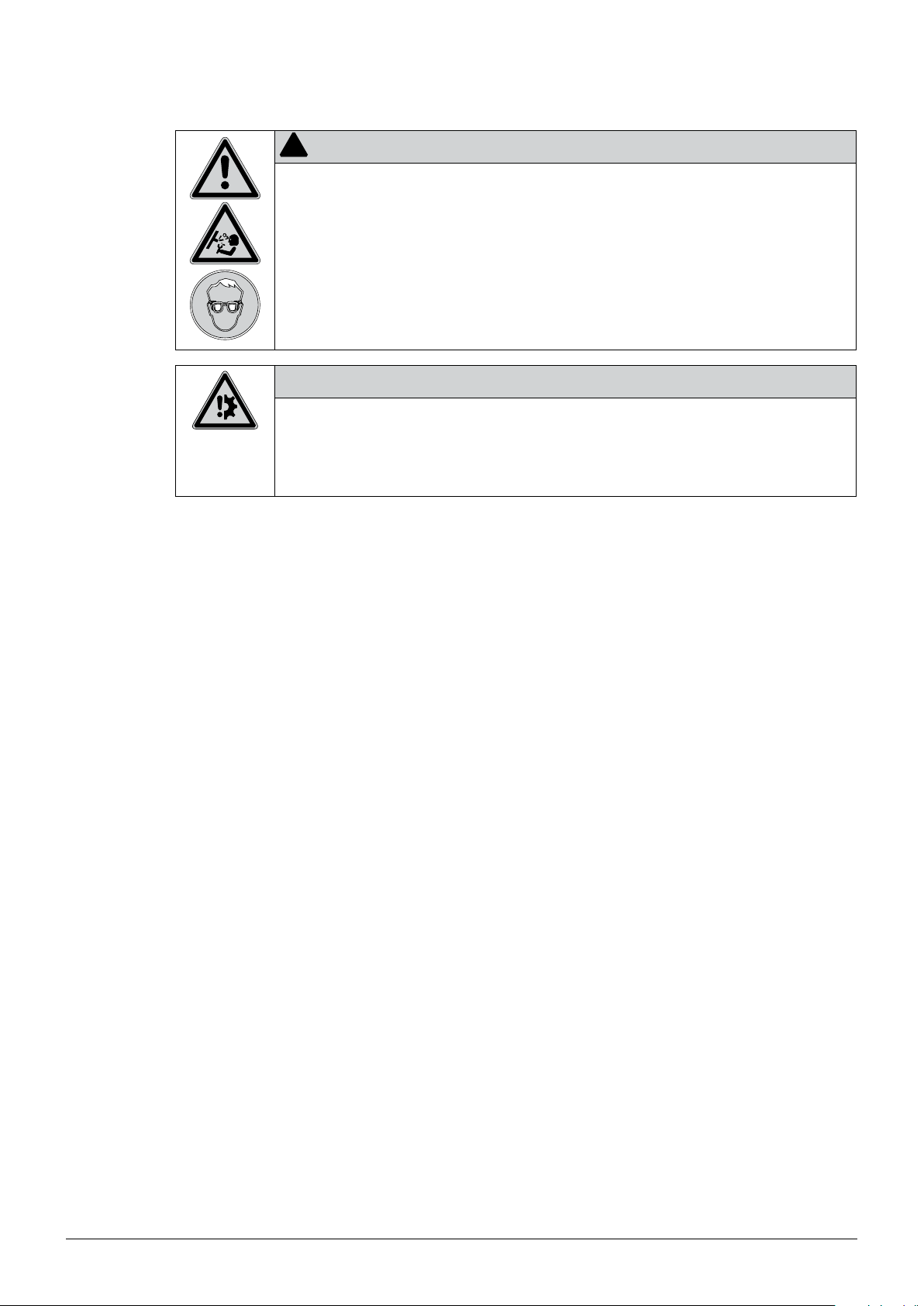

5 Putting into operation

A

b

a

NOTE

Tighten the spray cap and washer assembly with a torque of 7 Nm.

10. Use the mounting tool a and the BUCHI

torque wrench b for the installation of the

spray cap.

Installation steps:

11. Use the thumb screw and fixate the

mounting tool at one of the lower metal bars

of the Nano Spray Dryer B-90.

12. Mount the spray cap on the spray head

hand-tight.

13. Put the spray head through the hole of the

mounting tool.

14. Use the BUCHI torque wrench to fasten the

spray cap at the spray head with a torque of

7 Nm.

15. Remove the spray head with the mounted

spray cap from the mounting tool.

16. Remove the mounting tool from the metal

bar.

17. Install the spray head on the spray cylinder.

18. Align the “Tube connectors” i and the electrical cable connection vertically, so that the

head is spraying downwards.

19. Mount the spray head in the shown order (A

to B) and in the direction of the arrow.

20. Connect the spray head cable to the socket

labelled with “SPRAY” at the housing front.

46 B-90 Operation Manual, Version B

Page 47

5.4.2 Spray head installation

The spray head can be mounted at the spray head holder in either an angular or horizontal position.

The most appropriate position depends on the sample product and its spray drying requirements. In

all three angular positions the thermal load of the spray head is considerably decreased because the

spray head is out of the central flow of the hot drying gas. This makes the angular position an option

for spraying heat-sensitive materials.

1

30°

30°

30°

30°

5 Putting into operation

For angular spray head position:

• To set the angulation of the spray head holder

remove the angulation screw a first. Then swivel

the spray head holder to the desired angle (30°,

45° or 60°) and reattach the screw in the chosen

angle. Fasten the screw again.

• To mount the spray head, use a small torx screw

(M3×16) to fix it at the holder b.

45°

45°

30°

30°

60°

60°

For vertical spray head position:

To mount the spray head in vertical position c, use a

small torx screw to fix it at the holder.

5.5 Peristaltic pump and feed tubing installation

The peristaltic pump uses a pulley drive to transport liquids through the tubing. The pump design is

dry run safe. During the spray drying process it constantly feeds the spray head with sample liquid.

Risk of instrument short-circuits and damage by liquids.

• Do not spill liquids over the instrument or parts of it

• Wipe off any liquids instantly

• Place the sample vessel onto the designated reservoir-plate on top of the instrument

• Ensure a safe positioning of the sample vessel

• Do not move the instrument when it is loaded with liquid

• Keep external vibrations away from the instrument

Notice

47 B-90 Operation Manual, Version B

Page 48

5.5.1 Peristaltic pump height adjustment and fixation

1

2

3

1

2

5 Putting into operation

a Mount the peristaltic pump on a metal bar and fix it with the thumb screw.

b To adjust the height, unfasten the thumb screw and move the pump to the optimal height. Fasten

the thumb screw again to fixate the pumps position.

c Connect the power cable of the pump to the socket labelled with “PUMP” at the housing front.

5.5.2 Pump bed adjustment

a Turn the lever horizontally to the left. Pre-adjust the pump bed to working position for liquid

transport with a hex-wrench. The correct position depends on the thickness of the transport tube

material.

b Place the tube in the pump mechanism. Swivel the lever towards the locking of the pump bed.

The pump is set up correctly when the tube is squeezed between the pulleys without damaging

the tube.

48 B-90 Operation Manual, Version B

Page 49

5.5.3 Feeding tube installation

1

2

Steps before installation:

• Switch off the Nano Spray Dryer B-90.

• Place the sample vessel on the top cover of the instrument or on the stand plate.

• Choose the silicone tubing for aqueous applications or alternatively the appropriate tygon type for

other solvents (see also Table 5-1 for a list of most common solvents).

5 Putting into operation

Sample vessel

a Install the feeding tube at the peristaltic pump first. Make sure the plastic manifold is seated in the

right holder of the pump mechanism (see example photo below).

Connect the tube to the spray head. The inlet and outlet positions depend on the internal tubing

of the spray head.

Place the free end of the tube in the sample vessel.

b Connect a second tube at the spray head and place its free end in the sample vessel.

49 B-90 Operation Manual, Version B

Page 50

5 Putting into operation

Example photo with attached feeding tube and adapter piece (transparent adapter on the pump inlet at the right side).

Table 5-1: Choosing the feeding tube material

Solvent Silicone tube Tygon MH 2075 Tygon F 4040 A

Methanol suitable suitable suitable

Ethanol suitable suitable suitable

Acetone unsuitable suitable unsuitable

Toluene unsuitable unsuitable suitable

Isopropanol suitable suitable suitable

Chloroform unsuitable unsuitable unsuitable

Dichloromethane unsuitable unsuitable unsuitable

THF unsuitable unsuitable unsuitable

Ethylacetate unsuitable suitable unsuitable

Hexane unsuitable unsuitable suitable

Water suitable suitable suitable

50 B-90 Operation Manual, Version B

Page 51

5.6 Drying gas supply

The kind of drying gas supply (air or inert gases) depends on the kind of processed sample material. There are significant differences between ‘open loop’ and ‘closed loop’ configuration of supply

and exhaust gases. Strictly follow the configuration descriptions in this section as well as the defined

proper and improper use in section 2 for safe operation.

Death by suffocation or serious poisoning by inhalation of inert gases.

• Do not inhale inert gases

• Directly withdraw released gases and gaseous substances by sufficient ventilation

• Only operate the instrument in ventilated environments

• Before operation, check all parts, connections and sealings involved in the gasflow for proper

• Exchange worn out or defective parts immediately

!

sealing

5 Putting into operation

Danger

!

Warning

Death or serious poisoning by contact or incorporation of harmful substances at use.

• Before operation, check the instrument for correct assembling

• Before operation, inspect sealings and tubes for good condition

• Exchange worn out or defective parts immediately

• Exchange clogged filters immediately

• Only operate the instrument in ventilated environments

• Directly withdraw released gases and gaseous substances by sufficient ventilation

• Perform a dry-run without sample material and check for gas leakages

Warning

!

Death or serious injuries by compressed gas.

• Depressurize gas circuit before any modification

• Wear safety goggles

Risk of instrument damage by wrong gas supply.

• All labels at gas connections must be clearly ledgible

• Before operation, check all gas connections for correct installation

• External supply pressure must meet the system specifications

51 B-90 Operation Manual, Version B

Notice

Page 52

5.6.1 ‘open loop’ air supply configuration

In ‘open loop’, compressed air or the Aspirator in blowing mode with inlet filter is required to establish

the necessary drying gas overpressure. To ensure the optimal drying air performance in this operation mode, the supplied air has to be dry and free of impurities. If this can not be guaranteed, BUCHI

recommends the use of a Wilkerson air maintenance unit (see next picture).

When working with pressurized gases:

• Turn off the pressure source and remove the power cord before installation work.

• Depressurize all system parts and supply tubes.

NOTE

If there is no compressed air available, the compressed air can also be supplied by an oil-free

compressor.

a

b

c

5 Putting into operation

a Coarse filter

b Submicron filter

c Activated charcoal filter

a

The optional Wilkerson air unit is to be installed between a compressed air source and the Nano Spray

Dryer B-90 air inlet. For installation, see documentation

of the Wilkerson air maintenance unit!

The drying air connection is located on the right side of

the instrument (see section 4.10 for details). The connections are made via Polypress and Solaflex tubing

in combination with clamp fittings. Any exhaust gases

must be safely withdrawn (e.g. through a fume hood).

a GAS OUT (Polypress with clamp fitting)

b GAS IN (Polypress/Solaflex with clamp fitting)

c Flow regulation valve (only necessary with direct

compressed air supply)

b

c

52 B-90 Operation Manual, Version B

Page 53

5.6.2 ‘closed loop’ gas supply configuration

The Nano Spray Dryer B-90 Advanced has been designed to be used in ‘closed loop’. This mode is

universal and can be used to spray dry aqueous as well as solvent mixtures with air or inert gas under

safe conditions. To ensure the optimal drying gas performance in this operation mode the supplied

gas has to be dry and free of impurities.

a

b

5 Putting into operation

The drying gas connections are located on the right

side of the instrument (see section 4.10 for details).

The connections are made via Polypress and Solaflex

tubing in combination with clamp fittings and via quick

coupling connection. The kind of connection depends

on the type socket and the transported gases. The

output gas is recycled by an Inert Loop B-295/Dehumidifier B-296. In ‘closed loop’ mode, the Aspirator

works as a recirculating pump to establish a constant

gas flow.

c

5.6.3 Outlet filter installation/replacement

The Nano Spray Dryer B-90 is equipped with a safety outlet filter. This particle filter (order no. 051656)

has an efficiency of 99.9 % for particles < 1 µm. The filter should be replaced when clogged. This is

indicated by a strong pressure drop (see also the error messages in chapter 8.1). Switch off the instrument, remove the power cord before installation work and depressurize the system and all supply

tubes.

!

Danger

Death or serious poisoning by gases or particles at O2– sensor or filter malfunction

• Exchange defective O2– sensor immediately

• Exchange O2– sensor regularly within the specified maintenance intervals

• Exchange clogged filters immediately

• Exchange filters regularly within the specified maintenance intervals

• Safely dispose filter immediately

a GAS OUT (Polypress with clamp fitting)

b N2 (quick coupling)

c AIR (CO2) (quick coupling)

d GAS IN (Polypress with clamp fitting)

Risk of instrument damage by internal overpressure.

• External supply pressure must meet the system specifications

• Exchange clogged filters immediately

• Safely dispose filter immediately

53 B-90 Operation Manual, Version B

Notice

Page 54

5 Putting into operation

• Disconnect the power cord from the mains.

• Gently pull off the back panel of the housing and put

it aside. The outlet filter is now directly accessible.

• Loosen the hose clamps to remove the filter element.

• Put in the new filter and fasten the hose clamps

again.

• Connect the power cord to the mains. The device

can now be switched on.

NOTE

The filter has a designated gas flow direction. To ensure maximum throughput and filter lifetime it

should be installed correctly. The designated flow direction is indicated by an arrow on the filter

housing. For correct alignment, the arrow has to point towards the gas outlet connector of the Nano

Spray Dryer B-90 when installing the filter. After exchange, dispose used filter according to local

regulations immediately.

5.7 Aspirator installation modes

To establish the required instrument input pressure for the drying medium flow, the output of the

Aspirator can be used in blowing mode. The Aspirator can be part of an ‘open loop’ configuration. In

‘closed loop’ the use of an Aspirator is required.

5.7.1 Aspirator in ‘open loop’ configuration

b

c

d

a

Installation steps

1. Disconnect the power cord from the mains and depressurize all system parts.

2. Connect the air inlet filter (011235) to the aspirators air inlet a

3. Connect the air outlet b to the Nano Spray Dryer B-90 gas inlet.

4. Connect the power cord to the mains. The device can now be switched on.

a Air inlet with filter

b Air outlet towards gas inlet connector of the Nano

Spray Dryer B-90 in Polypress design

c Output flow-through selector (frequency based

regulation)

d Mains socket, switch and fuse box

The Aspirator has a bench top dimension of