Page 1

1

BÜCHI Fat Determination B-820/B-821

Contents

Contents

5 Operation 28

5.1 Control, operating and display elements 28

5.2 Operating the unit 31

5.2.1 User configuration 34

5.2.2 Printer configuration 35

5.2.3 System configuration 36

5.2.4 Autosampler configuration 37

5.2.5 Preheating/Separation column conditioning 38

5.2.6 Gas flow rate setup 39

5.2.7 Sample weight and mode adjustment 43

5.2.8 Determination 45

5.2.9 Data output 49

5.2.10 Statistics 51

5.2.11 Clearing data 54

6 Maintenance 55

6.1 Control checks 55

6.2 Replacing the septum in the injection head 55

6.3 Cleaning the FID 56

6.4 Replacing the ignition coil 56

6.5 Checking the formic acid 57

6.6 Installing a new separation column 57

6.7 Changing the printer paper roll 57

6.8 Changing the ribbon 58

6.9 Checking for fractures and cracks 58

6.10 Customer service 58

6.11 Maintenance of the Autosampler 59

6.11.1 General 59

6.11.2 Syringe and syringe needle 59

6.11.3 Replacing the main power fuse 59

7 Taking out of operation 60

7.1 Switching off the unit 60

7.2 Storage/Transport 60

7.3 Disposal 60

8 Replacement parts 61

9 Appendix 62

9.1 Technical data 62

9.2 Error messages 63

9.3 Materials used 64

9.4 FCC requirements (for USA and Canada) 65

9.5 Declaration of conformity 66

1 Scope of delivery 3

2 Safety 7

2.1 Symbols 7

2.2 Requirements for the customer 7

2.3 Proper use 7

2.4 Improper use 8

2.5 General hazards 8

2.6 Safety measures 9

2.7 Handling of gas cylinders in the laboratory 10

2.8 Modifications 10

2.9 Responsibility of the operator 10

3 Function 11

3.1 Operational principles 12

3.2 System description Autosampler B-821 14

3.2.1 Introduction 14

3.2.2 Carousel support 14

3.2.3 Carousel 14

3.2.4 Turntable 14

4 Putting into operation 15

4.1 Accessories 15

4.2 Location of unit 15

4.3 Power connections 16

4.4 Connecting periphery devices 16

4.5 Filling the formic acid 18

4.6 Gas connections 18

4.7 Checking supply lines for leaks 20

4.8 Installing the separation column 21

4.9 Setting the correct gas flow rate 22

4.10 FID ignition 22

4.11 Installation of Autosampler B-821 22

4.11.1 Unpacking and inspection 22

4.11.2 Retrofitting a manual basic system with

an Autosampler 23

4.11.3 Installing the mounting plate 23

4.11.4 Mounting the Autosampler on the B-820 unit 23

4.11.5 Removing the transportation belt 23

4.11.6 Installing the syringe/needle assembly 24

4.11.7 Connecting the signal cable to the B-820 unit 24

4.11.8 Connecting power to the Autosampler B-821 24

4.11.9 Aligning the syringe needle with the injection

head of the B-820 unit 25

4.11.10 Connecting the pneumatics to the Autosampler 26

4.11.11 Installing the solvent reservoir bracket 26

4.11.12 Routing and securing the solvent lines and

the waste line 26

en, Version H (66 pages) Order no.

B-820/B-821 Instructions 96571

Page 2

2

BÜCHI Fat Determination B-820/B-821

Please read these instructions thoroughly

before using the Fat Determination Unit

B-820/B-821. These instructions should

be kept near the unit for general reference.

Section 2 contains important notes on safety,

which must be observed if the Fat Determination Unit is to be operated safely.

Due to continuous improvement and updating, technical specifications may be altered without prior notice. No part of this

document may be reproduced, copied or transmitted in any

way nor by using electronic or optical systems without prior

agreement and written permission of Büchi Labortechnik AG.

All rights reserved. © Büchi Labortechnik AG, 1996, 1999

Page 3

3

BÜCHI Fat Determination B-820/B-821

1 Scope of delivery

1 Scope of delivery

Figure 1: Complete view of B-820/B-821 Figure 2: Complete view of B-820, Manual

Manual basic system

incl. individual

Version B-815 B-820 B-821 Total fat order no. fatty acids order no.

230V 230V 230V - 36925 37628

200V 120V 200V - 37109 37627

120V 120V 230V - 36924 37626

Automatic basic system

incl. individual

Version B-815 B-820 B-821 Total fat order no. fatty acids order no.

230V 230V 230V 230V 36923 37631

200V 120V 200V 230V 37108 37630

120V 120V 230V 230V 36922 37629

System prepared for Autosampler

incl. individual

Version B-815 B-820 B-821 Total fat order no. fatty acids order no.

230V 230V 230V - 37601 37634

200V 120V 200V - 37602 37633

120V 120V 230V - 37603 37632

Autosampler Retrofit 36926

Retrofit Fatty Acids manual 37635

Retrofit Fatty Acids automatic 37636

Table 1: Appliance models

Page 4

4

BÜCHI Fat Determination B-820/B-821

Figure 3: Accessories

햳햲햴햵 햶햹햺

햷햻햾햿햸

1 Scope of delivery

Accessories Manual Basic System

Accessories B-815 (refer to Manual B-815)

Accessories B-820 Manual (refer to Table 2)

Accessories Automatic Basic System

Accessories B-815 (refer to Manual B-815)

Accessories B-820 Automatic (refer to Table 3)

Accessories Autosampler B-821 (refer to Table 4)

Accessories Autosampler Retrofit

Accessories Autosampler B-821 (refer to Table 4)

Accessories retrofit kit (refer to Table 5)

EPROM Set B-821

Accessories Individual Fatty Acids

Separation Column Fatty Acids 37620

Calibration Set Fatty Acids 37622

EPROM Set manual or automatic

Accessories B-820 Manual

1 Soap bubble meter, compl. 햶 34878

1 Separation column "Total Fat" 햻 34916

1 Supply line H2 햳 36134

1 Supply line Air 햲 36135

1 Syringe 10µl 햾 34258

1 High temperature septum (50 off) 햿 34382

4 Vespel seals 햹 34229

2 Threaded column joints 1/4" 햸 34228

2 Fork spanners w.a. flats 8 햵 16522

1 Fork spanner w.a. flats 17 x 19 햴 19831

1 Power cable (PNE, 2.5 m)

available in the following versions: 햷

Type CH 10010

Type Grounded (shock-proof) 10016

Type GB 17835

Type AUS 17836

Type USA, 230 V 33763

1 Instruction manual available in the following languages:

German 96570

English 96571

French 96572

Italian 96573

Spanish 96574

1 Packaging 34560

Table 2: Accessories B-820 Manual

Page 5

5

BÜCHI Fat Determination B-820/B-821

Accessories B-820 Automatic

1 Soap bubble meter, compl. 햶 34878

1 Seperation column "Total Fat" 햻 34916

1 Supply line H2 햳 36134

1 Supply line Air 햲 36135

1 High temperature septum (50 pcs) 햿 34382

4 Vespel seals 햹 34229

2 Threaded column joints 1/4" 햸 34228

2 Fork spanners w.a. flats 8 햵 16522

1 Fork spanner w.a. flats 17 x 19 햴 19831

1 T piece D1/8“ 36845

1 Jumper cord W VDE 30983

1 Power cable (PNE, 2.5 m)

available in the following versions 햷

Type CH 10010

Type Grounded (shock-proof) 10016

Type GB 17835

Type AUS 17836

Type USA, 230 V 33763

1 Instruction manual

available in the following languages:

German 96570

English 96571

French 96572

Italian 96573

Spanish 96574

1 Packaging 34560

Table 3: Accessories B-820 Automatic

1 Scope of delivery

Page 6

6

BÜCHI Fat Determination B-820/B-821

Accessories B-821 Automatic

1 Septum *

1 Cylinder (reservoir) holder *

2 Glass cylinders for rinsing solvent and

waste 37069

1 Carousel 37085

1 Serial number label for carousel 37103

1 Mounting plate *

1 Sample vessel 2ml, compl. (100 ) 37068

4 Washers 16 mm *

2 Fuses 240V, 0.2A *

1 Fuse 250V, 0.5A *

1 Hamilton syringe 37066

1 Needle for Hamilton syringe 37067

1 Tubing PUR 1/8“ L = 3000 *

1 Foam rubber of neoprene length 100mm *

Table 4: Accessories Autosampler B-821

* Compare with spare parts list of the original operating instructions for

the 8200 CX.

Accessories Retrofit Kit

1 Cover for Autosampler 36758

1 Plate for Autosampler 36726

4 Spacers 36727

1 FID cap 34124

1 T piece D1/8“ 36845

2 LZS-K M4*10 10355

3 LZS-K M3*6 20390

3 FAE-SCH M3 10717

3 U-SCH M3 10571

4 SS-K M4*10 20909

1 Jumper cord W VDE 30983

5 Cable binders 2.6*200MM WS 03572

1 LZS-K M5*10 19645

Table 5: Accessories retrofit kit

1 Scope of delivery

Page 7

7

BÜCHI Fat Determination B-820/B-821

2 Safety

This unit has been built in accordance with the state of

engineering and the recognized rules of safety.

Nevertheless, it can still be a source of risks and hazards:

• if used by persons with insufficient training

• if used for purposes other than that for which it is intended.

2.1 Symbols

Stop

Information about hazards which can lead to serious material

damage or cause serious or potentially fatal injury.

Warning

Information about hazards which can be harmful to the user’s

health or lead to material damage.

Please note

Information about technical requirements which if not observed

can lead to malfunctions, inefficiency and production loss.

2.2 Requirements for the customer

The device must only be operated by persons who have the

training or professional experience to comprehend the hazards

that can arise when using the unit.

Personnel without such training or persons currently undergoing a course of training should be trained thoroughly. This

Instruction Manual should be the basis for this training.

2.3 Proper use

The unit is designed and built for use in laboratories. It is intended

to be used for determining the fat content based on fatty

acids or the butyric acid. Its function depends on the Büchi

Extraction Unit B-815: Some microliters of the upper extracted

phase which contains the fatty acids and the internal standard

are injected either manually into the Fat Determination Unit

B-820, or automatically into the Fat Determination Unit with

Autosampler B-821. The detection occurs with a flame

ionization detector (FID). The subsequent evaluation is made

by integrating the total peak areas.

Only original Büchi replacement parts and accessories may

be used. Any modifications to the device or accessories shall

be permitted only upon consultation with and obtaining a

written authorization from the manufacturer.

2 Safety

Page 8

8

BÜCHI Fat Determination B-820/B-821

2 Safety

2.4 Improper use

Any use other than those already listed, and any application

that does not conform with the technical data is deemed to

be improper use. The customer shall bear sole responsibility

for any damage resulting from improper use.

Use of this instrument is strictly prohibited in:

• explosion-proof environments,

• rooms where gas cylinders cannot be stored.

2.5 General hazards

General hazards arise from:

• covering the ventilation slots

• an insufficient distance from the back of the unit to the

wall (see Section 4 "Putting into operation“).

• touching the injection head and the FID (risk of burning).

• improper storage of gas cylinders.

• inadequate installation of connections to gas cylinders.

Apart from authorized maintenance personnel, no one is

allowed to remove any safety devices and covers.

Touching live parts may result in fatal injury!

Electrical danger

Before connecting the unit to power make sure that the operating voltage shown on the serial plate agrees with the mains

voltage.

The power plug may only be inserted into a socket

with grounded contact. Its protective effect may not

be suppressed by an extension line not having a

ground wire.

Warning:

a) Any interruption of the ground wire inside or outside of the

unit or a disconnection of the ground wire may cause

potential problems. Deliberate tampering is prohibited.

b) When opening covers or removing parts, unless this can

be done by hand, live parts may be exposed. Bear in mind

that connecting parts may also be live.

Page 9

9

BÜCHI Fat Determination B-820/B-821

c) Before an alignment, maintenance, repair or replacement

of parts, the unit must be disconnected from all sources of

electric current, whenever it becomes necessary to open

the unit.

If any of the services above must be performed on a powered

on unit, it should only be done by a specialist who is famlilar

with the dangers involved.

d) It should be ensured that only fuses of the type and rated

amperage as indicated are used for replacement. The use

of repaired fuses or short-circuiting the fuse block is

prohibited.

e) If an operation free from danger cannot be ensured, the

unit must be put out of operation and protected from any

unauthorized use.

It can be assumed that an operation free from danger cannot

be ensured any more if:

• the unit shows visible damages,

• the unit does not work any more,

• after long-term storage under inadequate circumstances,

• after having been exposed to considerable strain during

transport.

2.6 Safety measures

The steel lines for hydrogen and synthetic air supplied with

the equipment have different connections to the unit preventing

improper connections.

Please make sure that connections at reduction valves are

correct.

If, due to a lack of gas pressure in the system, the electronic

valves will close preventing any hydrogen or synthetic air leaks.

Personal protective garments must be worn, such as goggles,

gloves and a laboratory coat.

The Instruction Manual is a component of the Fat Determination Unit B-820/B-821 and should remain with the unit for

easy reference by any user. This also applies to the additional

language variants of these instructions, which can be ordered

separately.

2 Safety

Page 10

10

BÜCHI Fat Determination B-820/B-821

2.7 Handling of gas cylinders in the laboratory

Gas cylinders should be handled according to the pertinent

local regulations and provisions. The following are general

safety measures.

1. Protect gas cylinders from excessive heat, mechanical

damage and corrosive substances.

2. Gas cylinders should not be stored or connected in areas

with a major risk of fire.

3. Gas cylinders should be easily accessible at all times.

4. Full and empty gas cylinders should be stored separately

according to the type of gas.

5. Gas cylinders should only be stored and transported with

the protective cap screwed on.

6. Gas cylinders should be protected from falling down and

rolling away.

7. In case of leak and fire: Close cylinder valves immediately.

Cool any overheated cylinder with plenty of water.

8. Only keep as many replacement cylinders in the laboratory

as are necessary for continuous operation.

9. Open cylinder valves slowly.

10. Cylinder valves must neither be oiled nor greased.

11. Close cylinder valves when switching the unit off.

12. Close valves of empty cylinders.

2.8 Modifications

Modifications on the unit or on replacement parts or accessories

as well as the use of any other replacement parts or

accessories as those indicated in this Manual are only permitted

after consulting with Büchi Labortechnik AG and obtaining

written consent.

2.9 Responsibility of the operator

The operator is responsible for instructing personnel. For

manuals in other languages refer to Table 2, Section 1.

The operator should inform the manufacturer about events

relevant to safety which occur with operating the Fat Determination Unit.

2 Safety

Page 11

11

BÜCHI Fat Determination B-820/B-821

3 Function

The Fat Determination Unit B-820, which can be completed

with the Autosampler B-821 (refer to Figure 5) is an instrument

which determines total fat on the basis of fatty acids or individual

fatty acids in organic matrices using a gas-chromatographic

technique.

It is designed to function with the Büchi Extraction Unit B-

815. The temperature program and the evaluation function

are preprogrammed and have an extremely short analysis

run time, enabling the user to carry out the fat determination

process quickly and easily. The appliance is not a universal

gas-chromatograph.

3 Function

Figure 5: Fat Determination Unit B-820, Automatic

Figure 4: Fat Determination Unit B-820, Manual

Page 12

12

BÜCHI Fat Determination B-820/B-821

3 Function

3.1 Operational principles

Figure 6: Diagram

햲

햳

햴 햵

햷

햶

헀

햿

햸

햾

햹

햽

햺

햻

헁

헂

햲 Synthetic air

햳 Hydrogen (percentage purity 5.0)

햴 Pressure reducing valve for synthetic air

햵 Pressure reducing valve for hydrogen

햶 Electronic valve for synthetic air

햷 Electronic valve for hydrogen

햸 Damping tube for synthetic air

햹 Damping tube for hydrogen

햺 Absorption tube

햻 Gas saturation vessel (formic acid 85 %)

햽 Forced-air oven

햾 Separation column

햿 Injection head

헀 Flame ionization detector (FID)

헁 Electronic

헂 Output

Main principle

1. Switch on the unit (the switch is located on the back of

the unit). Perform the input steps as described in Section

5 «Operation».

2. Using a syringe, extract some solution from the upper phase

of the extracted and saponified sample (see operating instructions for Extraction Unit B-815) and inject into the Fat

Determination Unit.

3. A temperature program is performed automatically accor-

ding to the selected method. The fatty acids are separated

from the solvent and internal standard and detected by

the flame ionization detector.

4. An evaluation program, specifically developed for this unit,

calculates the content of total fat of individual fatty acids.

Page 13

13

BÜCHI Fat Determination B-820/B-821

3 Function

Depending on the determination parameters, nine different

determination modes can be selected:

Mode Abbreviat. Description

Factor General Fact.gen Determines the factor that will be necessary for the determination of the

total fat content.

General correction Gen.corr. Determines the fat content of all products. It will still determine milk or

dairy products though, but it is not appropriate for products with a

significant butyric acid content. In this case use "Spec.corr."

Special correction Spec.corr. Determines the fat content for milk or dairy products, or products with a

significant butyric acid content.

Blank value for butyric acid Bl.butyr. Determines the blank value for the butyric acid determination.

Butyric acid factor Fact.b.a. Determines the factor that will be necessary for the determination of the

butyric acid content.

Butyric acid But.acid Simultaneous determination of the butyric acid content, the milk fat

content (optional), and the overall fat content (optional) in all products.

Fatty acid calibration FA-calib. Determines the retention period for six saturated fatty acids (calibration

set “Fatty Acids”).

Fatty acid factor FA-factor Determines the factor that will be necessary for the determination of the

fatty acids

Fatty acids FA-det. Identification and determination of the contents of the individual fatty

acids and calculation of the sum parameter of the saturated, monoand polyunsaturated fatty acids in all products.

Table 6: Overview of the determination modes

Application Column (Order No.) Start temperature /Analysis time Mode

Total fat 34916 130 °C / 8 min. Gen.fact.

130 °C / 8 min. Gen.corr.

90 °C / 10 min. Spec.corr.

90 °C / 10 min. Butyr.con.

Butyric acid 34916 90 °C / 10 min. Bl.butyr.

90 °C / 10 min. Butyr.fact.

90 °C / 10 min. Butyr.con.

Individual fatty acids 37620 150 °C / 41 min. FA-calib.

150 °C / 41 min. FA-fact.

150 °C / 41 min. FA-det.

Table 7: Overview of the determination parameters

The analysis time is calculated from the start of the determination to the re-start of the next determination. The analysis

time therefore contains the following time sectors:

• Separation time for the separation of the fatty acids

• Preheating of the separation column at 260 °C at the end

of the separation

• Conditioning of the column for the next analysis depending

on the mode of determination.

Page 14

14

BÜCHI Fat Determination B-820/B-821

3.2 System description Autosampler B-821

3.2.1 Introduction

The Autosampler is comprised of essentially three modules:

the storage module, the injection tower module, and the pneumatics module. It is mounted on the Büchi Fat Determination

Unit B-820 above the injection head. The Autosampler is

operated through the keypad of the B-820.

The Autosampler is powered through the B-820 via a

connection cable. The power entry module as well as the

power on/off switch and the voltage selector module are

located at the rear of the Autosampler. If you want to connect

the Autosampler directly to the mains, you can adjust voltages

of 100, 120, 230, and 240 Volts and frequencies of 50/60 Hz

at the voltage selector module. Refer to paragraph 4.11.8

(Mains voltage connection to Autosampler B-821) to adjust

your own country’s voltage.

햲 Turntable

햳 Pneumatics module

햴 Power on/off switch

햵 Power entry module

햶 Carousel support

햷 Carousel

햸 Injection tower module

3.2.2 Carousel support

The carrousel support comprises a carousel, a position sensor,

a vial sensor, and the turntable. It is secured to a rotating

hinge on the injection tower. An indicator (LED) is located on

the front side of the carousel support; the LED lights when

the unit is ON.

3.2.3 Carousel

The carousel can hold up to forty-eight sampling vials of

2 ml. It may be removed for placing the vials. The serial number

label which is lettered from 1 through 48 may be glued on the

carousel. A small raised indicator at the center knob marks

the correct position.

3.2.4 Turntable

The turntable is driven by two motors, one to rotate the turntable (clockwise) and another to move the turntable forward

or backward.

The carousel mounts on the turntable and is fixed by a vertical

pin.

Figure 7: Autosampler B-821

3 Function

햲

햳

햴

햵

햶

햷

햸

Page 15

15

BÜCHI Fat Determination B-820/B-821

4 Putting into operation

Unpacking and checking the B-820 unit

Open the carton carefully in order to avoid breaking the glass

of the enclosed separation column, soap bubble meter and

syringe. Unpack the unit with care and check for any possible

damage. It is important that any damage incurred during transit

is determined and reported immediately. If this is the case, a

full statement of facts must be immediately reported to the

shipping agent.

Autosampler B-821

For unpacking and checking refer to Section 4.11.1.

It is advisable to keep the packaging for future transport.

4.1 Accessories

The following accessories necessary to operate the unit are

not included in delivery and cannot be ordered from the manufacturer:

• Hydrogen (percentage purity 5.0, gas cylinder or central

supply)

• Synthetic air (gas cylinder or central supply)

• 2 pressure reducing valves for gas cylinders

• Two G 1/8” connections to the reducing valves

(oxygen and synthetic air)

• Formic acid (85%)

• Stopwatch

• Soap solution

• When using the Autosampler: n-butanol (pure) (for rinsing

the syringe)

4.2 Location of unit

The unit must only be operated in ventilated rooms (window

or artificial ventilation). It must be installed on a stable, clean

and even surface.

For safety reasons and to ensure sufficient cooling of the oven,

the back and side walls of the unit must be placed at least

13 cm (5.2 inch) away from the walls or any other object.

No containers or chemicals should be placed behind the unit

(due to outflow of the hot air).

4 Putting into operation

Page 16

16

BÜCHI Fat Determination B-820/B-821

4.3 Power connections

Check that the voltage of the socket is identical to the voltage

specified on the serial plate. Only connect the unit to a plug

which is grounded. External couplings and extension cables

must be grounded (3-contact couplings, cables and connectors). The ground wire must not be tampered with in any way.

Risks caused by possible internal defects are thus prevented.

Check the frequency of the power supply and adjust the unit

accordingly (see Section 5.2.3, "System configuration“).

4.4 Connecting periphery devices

The unit has three serial and one parallel interface (RS-232C).

This enables connection of a computer, a balance, an external

printer and the Autosampler B-821 to the rear of the unit.

If a balance or printer is connected, the proper balance or

printer type must be entered in the initialization menu under

system configuration or printer configuration (see Section 5.2.3,

"System configuration" or Section 5.2.2, "Printer configuration“).

PC

Any IBM or IBM compatible PC may be used for data output

to a PC. The computer connection cable is available as an

accessory (cable length: 10 meters):

B-820 Computer cable 29502

Balance

The following types can be connected:

Mettler: All AT balances, as well as AE types with

upgraded interface option 012 and hand key

or foot pedal.

Sartorius: All analytical balances of the type MC1 as well

as balances with interface MP8-4.

A&D: FR and HA series.

The interface parameters in B-820 are preset and cannot be

modified.

The balance parameters are as follows:

• 2400 baud

• even parity

•7 bit

• 1 stop bit

• Software handshake

Figure 8: Connection of periphery devices to back of unit

4 Putting into operation

Page 17

17

BÜCHI Fat Determination B-820/B-821

The balance connection cables are available as accessories

(cable length: 9 meters):

B-820 Mettler AE 30699

B-820 Mettler AT 30498

B-820 Sartorius 30760

B-820 A&D 30699

Please consult the balance operating instructions before

making adjustments!

Printer

The following printers can be connected*, whereby the printer

languages (PCL: Printer Control Language; LQ: Epson Emulation) are supported:

• Epson

• Canon

• HP DeskJet

• HP LaserJet

* The following printers have been tested at Büchi:

• Epson Stylus Color 440

• Canon Bubble Jet BJC-600, BJ-200 EX (DIP switch

setting LQ)

• HP DeskJet 550C/690C

• HP LaserJet 4L

The printer connection cable is available as accessories (cable

length: 3 meters, type: Centronics):

B-820 Printer cable 30754

The B-820 supports the IBM character set. Please consult

printer operating instructions before making adjustments!

Autosampler B-821

Installation of the Autosampler is described in Section 4.11.

4 Putting into operation

Page 18

18

BÜCHI Fat Determination B-820/B-821

Figure 9: Gas saturation bottle with formic acid, 85%

4.5 Filling the formic acid

A small gas saturation bottle is located at the back of the unit,

which must be filled with max. 20 ml of formic acid (85%). The

gas saturation bottle must always contain some formic acid

(85%); do not exced arms of vessel. In this way, it is ensured

that the hydrogen is saturated with formic acid vapor.

The gas saturation bottle must be kept tightly

closed in order to ensure that the hydrogen

system is hermetically sealed.

Caution: The bottle is under pressure

- Do not open when the B-820 is in operation/hot

- Do not fill up while the B-820 is in operation/hot

- Do not overfill, max. 20 ml or less 1 cm

below the vessel's arms!

- Only fill when the unit is turned off and is

at room temperature

- Filling under any other circumstances may

lead to system contamination!

4.6 Gas connections

Gases used:

Gas function Gas type Setting pressure

Combustible + hydrogen 5.0 5 bar (72.5 psi)

separating gas

Auxiliary gas synthetic air 5 bar (72.5 psi)

Autosampler synthetic air 5 bar (72.5 psi)

Operating gas

Only use synthetic air, and not compressor air generated and

filtered on-site.

General

Synthetic air and hydrogen from gas cylinders must be equipped with a two-stage pressure reducing valve. The exit ports of

this valve should be threaded. To enable a precise adjustment

of the output pressures, use a pressure reducing valve with a

measuring capacity of 0 to 10 bar (0 to 150 psi). The output

pressures at the valves to the B-820 unit should be 5.0 bar

(72.5 psi) both for synthetic air and for hydrogen.

4 Putting into operation

Newer instrument models

see mark "-MAX-"

Page 19

19

BÜCHI Fat Determination B-820/B-821

4 Putting into operation

Gas supply connection to the B-820

1/8” copper capillaries 햴 with pre-fitted quick-lock couplings

are included in the delivery. To connect the gas supply, the

quick-lock couplings are fitted to the corresponding couplings

(labelled with “H2” and “Synth. Air”) on the back of the B-820.

(See Figure 10: Gas connection layout, Page 19)

Ensure the correct connection of the gas cylinder to the unit.

The following are included in the Büchi delivery:

H2 connection 햲 inc. copper capillary 36134

Air connection 햳 inc. copper capillary 36135

To be supplier by the user:

햵 Hydrogen 5.0

햶 Synthetic air

햷 Cylinder pressure 햸 pressure reducing valve (two-

햹 Required pilot pressure stage) for hydrogen and syn-

thetic air in the range from

0-10 bar ( 0-150 psig)

햺 Connecting parts to the pressure reducing valve

Figure 10: Gas connection layout

}

Page 20

20

BÜCHI Fat Determination B-820/B-821

4 Putting into operation

4.7 Checking supply lines for leaks

After connecting the pressure lines to the unit, open both cylinder valves before switching on the unit, and then close them

again once the pressure is achieved. The pressure indicator

on the pressure reducing valve should remain constant for

approx. 10 minutes. The cylinder valves can be reopened

once this check is completed.

The primary pressure, the tightness of the supply lines and

the gas flow (see Section 4.9, "Setting the correct gas flow

rate“) must be rechecked every time a gas cylinder is changed.

Check the separation column for possible fractures and cracks

before each use. The unit must not be operated if the

separation column is damaged (hydrogen leak).

Page 21

21

BÜCHI Fat Determination B-820/B-821

4.8 Installing the separation column

1. Open the oven door

2. Position the seals, screws and nuts as shown in Figure 11.

3. Figure 12 shows how to fit the separation column. Push

both sides of the column up as far as they will go, hold in

place and tighten nuts by hand.

4. The two nuts must be tightened by ¼ to ½ turn using the

supplied spanner (17”).

Take care not to overtighten nuts as this could break the

glass.

Figure 11: Positioning seals and

screw nuts

Separation column installedInstalling the separation column

4 Putting into operation

The procedure is the same for

the "Fatty Acid column"

Figure 12: Installing the colums

The column should be heated only when gas (H2) is flowing.

Prior to operation, always ensure that the gas supply is opened.

When fitting a new column, always ensure that there is a

septum in the injection head.

After a long period of use (approx. 1,000 injections), the injection zone of the separation column can become soiled, which

can impair the reproducibility of the individual measurements.

A new column must be conditioned before doing any opera-

tions. This requires a preheating period of 120 min. (see

Section 5.2.5, "Preheating/Separation column conditioning“).

The results of the first two injections using a new column can

vary greatly. Therefore, these values should be ignored.

Page 22

22

BÜCHI Fat Determination B-820/B-821

4.9 Setting the correct gas flow rate

The gas pressures are electronically controlled, digitally

displayed and preset to a basic value by the manufacturer.

However, this basic value does not ensure the correct gas

flow rate and must be adjusted after preheating. Therefore,

measure the gas flow rate of the hydrogen and synthetic air

after first commissioning the unit, and adjust the set

value if necessary. The correct gas flow rate should be

checked periodically at minimume when:

• replacing the gas cylinder

• replacing the separation column

• carrying out service work

(see Section 5.2.6, "Gas flow setup“).

4.10 FID ignition

The ignition of the FID is carried out automatically. If required,

it can also be carried out manually by pressing key combination

«SHIFT» / «i».From the top of the FID look for red heating coil.

If the heating coil is defective, use a lighter to ignite the FID

flame.

4.11 Installation of Autosampler B-821

4.11.1 Unpacking and inspection

Autosampler B-821:

Your Autosampler B-821 is shipped and delivered to you in a

carton. To unpack proceed as follows:

1. Place the carton in a way to make sure the top side is up

(arrows).

2. Open and lift the top cover.

3. Use the two hand holes to lift the inner liner from the carton.

4. Do not overlook the syringe which is packed in a separate

small container.

5. Remove the transport protection (See Chapter 4.11.5).

Do not lift the Autosampler by the carousel support to avoid

damaging the hinge of the carousel support (see Figure 16).

Latch of carousel support). Lift only at the lower left and upper

right corners of the Autosampler.

4 Putting into operation

Page 23

23

BÜCHI Fat Determination B-820/B-821

4.11.2 Retrofitting a manual basic system with an

Autosampler

The system may only be retrofitted by authorized service technicians. They have had a thorough professional and technical

training and are aware of the risks which may ensue from

noncompliance with the Safety Regulations.

4.11.3 Installing the mounting plate

The mounting plate and both washers are supplied together

with the Autosampler B-821. For mounting the mounting plate,

proceed as follows:

1. Place the mounting plate on the baseplate to ensure that

all holes align.

2. Secure the mounting plate with both enclosed M4x10

screws and both washers which have an extra large

diameter. The screws go through the holes of the mounting plate and reach the baseplate.

4.11.4 Mounting the Autosampler on the B-820

unit

In order to mount the Autosampler on the B-820 unit proceed

as follows:

1. Place the Autosampler on the mounting plate 햲 just

mounted . Push the Autosampler carefully to cover the

position holes until the threaded bolts with the knurled

screws engage in the holes of the mounting plate 햲.

2. Tighten the quick-lock screws 햳 riveted to the bottom of

the baseplate (refer to Figure 13: Securing the Autosampler).

4.11.5 Removing the transportation belt

In order to protect the syringe carriage from transport damage,

it is secured to the upper stop using a transport security belt.

The transport security belt can be seen if you look at the

Autosampler from above. Cut the transport security belt. The

syringe carriage will fall down slightly. Now remove the transport

security belt carefully from the Autosampler B-821.

Before any subsequent transportation, a transport security

belt must again be used to secure the syringe.

4 Putting into operation

Figure 13: Securing the Autosampler with quick-lock screws

햳

햲

Page 24

24

BÜCHI Fat Determination B-820/B-821

Syringe

mount

assembly

Side

locking

tabs

Solvent

line connection

Syringe

carriage

Figure 14: Syringe/needle mounting hardware

Side

locking

tabs

Syringe

carriage

bracket

Red indicator tab

4.11.6 Installing the syringe/needle assembly

Goggles should be worn during installation

To install the syringe/needle in the Autosampler proceed as

follows:

1. Open syringe mounting assembly by firmly lifting the side

locking tabs simultaneously and raising them to the

upper position. As this may require slight force, hold the

syringe mounting assembly down with the forefingers and

press the tabs simultaneously up with the thumbs. A

red indicator tab shows at the syringe mounting assembly

when the mounting is unlocked.

2. Refer to Figure 14a: Syringe/needle mounting: Guide the

syringe needle through the hole of the needle guide. Then

let the syringe rest on the lower bracket and press the

upper part of the plunger into the top slot.

3. Close the syringe mounting by holding the mounting with

one hand and pressing the side locking tabs down with

the other hand. Check that the mounting is fully closed

before pushing the side locking tabs down. It is closed

when the red signal tab is not visible.

4. Connect the solvent line laterally to the syringe (refer to

Figure 14b: Syringe/needle mounting). Slide the knurled

nut back from the end of the line. Push the line onto the

side connection of the syringe. Then tighten the knurled

nut at the syringe only by hand (do not use a tool).

5. Refer to paragraph 4.11.9 to align the syringe needle with

the injection head of the B-820 unit.

If the solvent line has not been connected correctly or not at

all, solvent may spray from the line.

4.11.7 Connecting the signal cable to the B-820

unit

A data cable is fitted to the Autosampler B-821 which emerges

at the rear of the unit. Insert the cable at the rear of the

B-820 unit into the corresponding interface (refer to Figure 8:

Connection of periphery units at the rear of the unit).

4.11.8 Connecting power to the Autosampler

B-821

Before connecting the Autosampler to the mains check that

the power switch is OFF (0). Then check the voltage rating

(230 V) on the serial number label and the position of the

white pin in the power entry module at the rear of the unit. If

they agree, go to Step 5.

4 Putting into operation

Page 25

25

BÜCHI Fat Determination B-820/B-821

If they do NOT agree, proceed as follows:

1. Remove the cover of the fuse block 햲 .

2. Pull the voltage selector card carefully out of the fuse block

with a needle-nosed pliers.

3. Orient the selector card so that the voltage that is to be

used can be inserted into the fuse block in the direction of

the arrow. Turn the printed side (plastic part on the selector card) to face forward.

4. Replace the cover on the fuse block and check that the

pin is showing in the hole of the desired operating voltage.

5. Connect the power cable to the rear of the Autosampler

and to the B-820 unit (refer to Figure 8: "Connection of

periphery units at the rear of the unit“)

•

4.11.9 Aligning the syringe needle with the

injection head of the B-820 unit

At this stage, the Autosampler has been installed on the B820 unit, the syringe/needle has been fitted and the data cable

has been connected to the B-820 unit. The voltage has been

correctly set and the Autosampler is connected to power.

햲 Latch

햳 Hinge

In order to align the syringe/needle with the injection head of

the B-820 unit proceed as follows:

1. Check that the Autosampler is OFF (0). Press down the

latch (refer to Figure 16: Carousel support) of the carousel

support 5 and swing out the support.

2. Switch the Autosampler ON (I). Lift the syringe cariage slowly

by hand until a click can be heard. Now lower the carriage

until the needle is just a little above the injection head.

3. Loosen the screws of the mounting plate sufficiently to

shift it by hand together with the Autosampler.

4. Align the needle accurately with the injection head. Then

retighten the screws of the mounting plate, so the

Autosampler cannot be moved.

5. Lower the syringe carriage two or three times until the

syringe needle punctures the injection head septum. You

can now check that the syringe and the syringe needle

are properly aligned with one another. Repeat this

procedure each time you replace the syringe/needle.

6. To return the syringe carrier to its rest position, raise the

syringe carrier until a click can be heard. Then lower the

carriage again by a fraction of an inch to rest on the stop.

4 Putting into operation

Figure 15: Power entry module

햲

Figure 16: Latch of carousel support

햲

햳

Page 26

26

BÜCHI Fat Determination B-820/B-821

Figure 17: Gas connection with Autosampler

4.11.10 Connecting the pneumatics to the

Autosampler

Compressed air (approx. 3 bar/40 – 60 psig) is required for the

Autosampler to operate correctly. Use the same synthetic air

which is required for the B-820 unit. For the pneumatic

connection, the T-screw connection 햲 supplied with the Autosampler is installed additionally into the feeding line for

connecting the pneumatics. The 1/8" tubing of polyurethane

supplied with the Autosampler is connected to the T-screw

connection and to the hose nipple located at the rear panel of

the Autosampler.

Before connecting or disconnecting the tubing make sure

that the feeder valves are closed.

This tubing must not be put in front of the oven flap. Affix it to

the top of the B-820.

4.11.11 Installing the solvent reservoir bracket

The bracket holds two solvent bottles of 180 ml each and is

secured on the lower left side of the B-820 unit by means of

an M5*12 screw. For a more secure fix we recommend to

cut the self-adhesive foam rubber part (included in the standard

accessory kit of the Autosampler) into halves and to attach

them to the rear of the bracket (on the left and right side).

4.11.12 Routing and securing the solvent lines and

the waste line

Two solvent lines for rinsing the syringe and one waste line

are already fitted to the Autosampler. To operate the Autosampler, you will only need the line marked with «Sol A», since

only one solvent is used for rinsing the syringe. The bracket

for both solvent reservoirs (included in the standard accessory

kit) takes up the solvent reservoir for rinsing the syringe and

the reservoir for the waste solvent.

4 Putting into operation

햲

B-821

Air

H

2

B-820

Page 27

27

BÜCHI Fat Determination B-820/B-821

4 Putting into operation

To install and secure the lines proceed as follows:

1. All PTFE lines which emerge from the bottom of the

Autosampler are pushed between the cover and the

housing of the B-820 unit and are secured with a cable

binder on the pre-assembled binder base to the rear panel

of the B-820 unit.

Check that the PTFE lines are not routed in front of the air flap

of the oven in the back of the unit.

2. The lines are routed along the bottom of the B-821 unit up

to the solvent reservoirs.

3. Fill a bottle of „n-pure butanol“ or rinsing the syringe.

The reservoirs should be labeled to avoid later confusion.

4. Connect the line marked with «Sol A» to the reservoir

labeled accordingly which contains the solvent for rinsing

the syringe.

5. Connect the waste line to the second reservoir.

Check that the reservoir removing the waste is positioned

below the level of the Autosampler B-821.

Avoid any kinks of the lines.

Page 28

28

BÜCHI Fat Determination B-820/B-821

Ensure that the unit has been commissioned according to

the instructions in Section 4, Putting into operation.

5.1 Control, operating and display elements

The main power switch is located at the back of the unit.

If, in the case of a failure, the current requirement of the unit

increases to more than 12 A, a bimetallic switch interrupts

the circuit, which automatically turns the main power switch

off. After the fault has been rectified, the unit can be operated

by turning it on once again.

The operating panel shows:

햲 Display

햳

Lamp lights up when the unit is ready for an injection or a

gas flow measurement.

햴

Lamp lights up when the determination or preheating

process is running.

햵

Lamp lights up when a failure has occurred.

햶

Each menu command has its own help text which can be

called up via the display.

햷

Pressing this key moves the application one step up on the

menu hierarchy. Exceptions are the sample weight/mode,

the elimination table and the data output table, where pressing the <ESCAPE> key will return you to the main menu.

햸

Moves the cursor up within a menu.

5 Operation

Figure 18: Control, operating and display elements

5 Operation

Page 29

29

BÜCHI Fat Determination B-820/B-821

햹

Moves the cursor down within a menu.

햺

Confirms position of cursor and performs menu command.

햻

Allows selection of a variety of options (e.g. balances, print

system, frequency etc.). In the sample weight table,

pressing the OPTION key copies a field into the next row.

햽

These keys enable input of numeric values and this key

enables you

to cancel input.

햾

Darkens display.

햿

Lightens display.

헀

Manual paper feed.

5 Operation

Page 30

30

BÜCHI Fat Determination B-820/B-821

Use the keyboard to enter sample identification and report

titles and press this key

to cancel.

The key

has the same function as this key, "ENTER".

5 Operation

헂

Page 31

31

BÜCHI Fat Determination B-820/B-821

5.2 Operating the unit

The following flow chart shows the operating structure. This is

followed by a systematic description of all the options provided

by this unit.

The unit contains a help program which can be accessed by

pressing the HELP button.

5 Operation

Page 32

32

BÜCHI Fat Determination B-820/B-821

Version: 3.00af Gas supply on?

User: C.Heiter Press <ENTER> to cont.

C13 : 285 C20 : 1095

C16 : 516 C22 : 1408

C18 : 768 C24 : 1687

SWITZERLAND

Preheating p H2 55kPa

Sample weight/Mode p air 50kPa

Determination T oven 130°C

Data manager T inj. 220°C

Setup T FID 260°C

Sample no: 5 p H2 55kPa

Vial no: 5 p air 50kPa

Switch off: yes T oven 140°C

Start after 62s T inj. 220°C

Main menu T FID 260°C

gen.corr.

Name: coconut oil

Manual sample weight

Automatic sample weight

Factors

Main menu

Stop p H2 55kPa

Main menu p air 50kPa

T oven 260°C

T inj. 220°C

T FID 260°C

Remaining time 1215s

Time: 2400s p H2 55kPa

Start preheating p air 50kPa

Main menu T oven 130°C

T inj. 220°C

T FID 260°C

Determination with autosampler

Determination without autosampler

Sample no: 5 p H2 55kPa

Next number p air: p air 50kPa

T oven 130°C

T inj. 220°C

Main menu T FID 260°C

Ready injection 2 gen.corr.

Name: coconut oil

5 Operation

Manual sample weight

Automatic sample weight

Factors

Calibration

Main menu

Determination "Fatty Acids"

Determination "Total fat"

No Mode Weihgt Weight Weight Conc.

[g] C13[g] C5[g] [%]

1 fact.gen. 0.7055 0.2115 99.8

Name: Factor

2 fact.b.a. 0.055 0.054 99.5

Name: Factor C4

3 but. acid 0.8550 0.2134 0.056

Name: butter

4 gen.corr. 4.3575 0.1245

Name: wheat

5 spec.corr

. 2.3654 0.2056

Name: cheese

"Table of factors"

Factor Fat: 0.953

Factor butyric acid: 1.123

CF: 28.570

Blank value but.acid 0.0031g

Main menu

No Mode Weight Weight Conc.

[g] C13[g] [%]

1 FA-calib.

Name: Calibration

2 FA-factor 0.7133 0.2078 99.7

Name: Factor

3 FA-det. 2.1351 0.2132

Name: milk powder

Factor fatty acids: 1.053

Main menu

Page 33

33

BÜCHI Fat Determination B-820/B-821

Press. system: air p H2 55kPa

Air-pressure: 50kPa p air 50kPa

Main menu T oven 130°C

T inj. 220°C

Wait until ready T FID 260°C

Req. flow H2 + air: 20 ml/2.5s

Printer: HP-Deskjet

Title:

Online intern: no

Online extern: yes

Main menu

Language: English

User: Carmen Heiter

Unit: [%]

Beep: off

Areas: off

Main menu

First sample: 1

Last sample: 25

Clear data

Main menu

Device: Display

First sample: 5

Last sample: 6

Eliminate

Start output

Main menu

Device: Printer int.

First sample: 1

Last sample: 25

Start output

Main menu

Press. system: H2 p H2 55kPa

H2-pressure: 55kPa p air 0kPa

Main menu T oven 130°C

T inj. 220°C

Wait until ready T FID 260°C

Req. flow H2: 10 ml/7s

Gas flow setup

User configuration

Printer configuration

System configuration

Autosampler

Main menu

"Gas flow setup for H2"

short column

User configuration

Printer configuration

System configuration

Baudrate: 9600

Data Bits: 8

Stop Bits: 1

Parity: none

Protocol: none

Main menu

PC-Interface

Autosampler: yes

Injections: 2

Main menu

Autosampler

Balance: Mettler AE

Frequency: 50Hz

Column: Total Fat

Time/Date:

PC-Interface

Main menu

5 Operation

Date: 01.17.03

Time: 17:18

Main menu

Data output p H2 55kPa

Statistic p air 50kPa

Clear data T oven 130°C

Main menu T inj. 220°C

T FID 260°C

Press.system: H2 p H2 250kPa

H2-pressure: 280kPa p air 0kPa

Main menu T oven 150°C

T inj. 220°C

Wait until ready T FID 260°C

Req. flow H2: 10 ml/10s

long column

short column

"Gas flow setup for air"

short column

Press. system: air p H2 280kPa

Air-pressure: 50kPa p air 50kPa

Main menu T oven 150°C

T inj. 220°C

Wait until ready T FID 260°C

Req. flow H2 + air: 20 ml/2.7s

"Data output"

"Statistic"

"Clear Data"

Page 34

34

BÜCHI Fat Determination B-820/B-821

Preheating p H2 55kPa

Sample weight/Mode p air 50kPa

Determination T oven 130°C

Data manager T inj. 220°C

Setup T FID 260°C

5.2.1 User configuration

Position cursor on <Setup>.

Position cursor on <User configuration> command.

Language: English

User: Carmen Heiter

Unit: %

Beep: off

Areas: off

Main menu

Position cursor on <Language>. Use the OPTION key to select

from one of the following languages: English, German,

French, Italian or Spanish.

Position cursor on <User>. The user name can be entered.

Position cursor on <Unit>. The following parameters may be

chosen: [g/100g], [g/kg], [mg/kg], [%], [ppm].

Only the [g/100g] unit is activated for the “Fatty Acids” option.

Position cursor on <Beep>. Use the OPTION key to activate

(on) or deactivate (off) signal buzzer which sounds at end of

a chromatogram.

Position cursor on <Areas>. Use the OPTION key to activate

(on) or deactivate (off) the printing of peak areas at the end of

a chromatogram.

Position cursor on <Main menu>.

Gas flow setup

User configuration

Printer configuration

System configuration

Autosampler

Main menu

5 Operation

Page 35

35

BÜCHI Fat Determination B-820/B-821

Printer: HP Deskjet

Title:

Online intern: no

Online extern: yes

Main menu

5.2.2 Printer configuration

Position cursor on <Setup> .

Position cursor on <Printer configuration>.

Position cursor on <Printer>.

Use the OPTION key to select the following printers:

HP-Deskjet, HP-Laserjet, Canon, EPSON LX-850,

None.

Position cursor on <Title>. An alphanumeric designation can

be entered which will subsequently be printed on each report.

Position cursor on <Online intern>. Use the OPTION key to

activate (yes) or deactivate (no) the internal printer to print

the result after determination.

Position cursor on <Online extern>. Use the OPTION key to

activate (yes) or deactivate (no) the external printer to print

the result after determination.

Position the cursor on <Main menu>.

Gas flow setup

User configuration

Printer configuration

System configuration

Autosampler

Main menu

Preheating p H2 55kPa

Sample weight/Mode p air 50kPa

Determination T oven 130°C

Data manager T inj. 220°C

Setup T FID 260°C

5 Operation

Page 36

36

BÜCHI Fat Determination B-820/B-821

5.2.3 System configuration

Position the cursor on <Setup>.

The cursor is positioned on <Gas flow setup>. Position the

cursor on <System configuration>.

Balance

The cursor is positioned on < Balance>.Use the OPTION key

to select parameters for the following balances: Sartorius (MC1

types as well as balances with interface MP8-4), Mettler AE,

Mettler AT, A & D (FR, HA series) or none.

Frequency

The cursor is positioned on <Frequency>. Use the OPTION

key to select the network frequency (50 Hz or 60 Hz).

Column

The cursor is positioned on <Column>. Use the OPTION key

to select between the fast "total fat" determination with the

short column and the "fatty acid" determination with the long

column.

The cursor is positioned on <Time/Date>.

• The date can be entered

(German: DD.MM.YY; English: MM.DD.YY).

• The correct time can be entered (hours, minutes).

Position the cursor on <PC interface>.

Gas flow setup

User configuration

Printer configuration

System configuration

Autosampler

Main menu

Preheating p H2 55kPa

Sample weight/Mode p air 50kPa

Determination T oven 130°C

Data manager T inj. 220°C

Setup T FID 260°C

Balance: Mettler AE

Frequency: 50Hz

Column: Total Fat

Time/Date

PC-Interface

Main menu

5 Operation

Page 37

37

BÜCHI Fat Determination B-820/B-821

Gas flow setup

User configuration

Printer configuration

System configuration

Autosampler

Main menu

Autosampler: yes

Injections: 2

Main menu

Preheating p H2 55kPa

Sample weight/Mode p air 50kPa

Determination T oven 130°C

Data manager T inj. 220°C

Setup T FID 260°C

5 Operation

Baudrate: 9600

Data Bits: 8

Stop Bits: 1

Parity: None

Protocol: None

Main menu

PC-Interface

This menu is meant for the setup of interface parameters for

the PC interface. The cursor is positioned on Baudrate.The

Baudrate cannot be changed.

Position cursor on Data bits. Press the OPTION key to select

the number of bits for the transmission.

Position cursor on Stop bits. Press the OPTION key to select

<1> or <2>. Press the OPTION key to position parity even/

odd or none.

Position protocol on Software Handshake none or Hardware Handshake RTS/CTS or none.

Position cursor on <Main menu>.

5.2.4 Autosampler configuration

Position cursor on <Setup>.

The cursor is positioned on <Gas flow setup>.

Position cursor on <Autosampler>.

The cursor is positioned on <Autosampler>. Press OPTION

key to select <Manual injection> (no) or <Autosampler>

(yes).

Position cursor on <Injections>. The number of injections per

sample weight may be selected from 1 to 9.

«Total fat» option: max. 9 injections per sample weight.

«Fatty acids» option: max. 6 injections per sample weight.

Position cursor on <Main menu>.

Page 38

38

BÜCHI Fat Determination B-820/B-821

5.2.5 Preheating/Separation column conditioning

If the unit has been turned off for longer than 30 minutes, the

unit must be preheated for 30 minutes before a determination

or gas flow setup procedure is performed.

If a new column has been installed, the preheating period is 2

hours (separation column conditioning).

Carry out the following steps:

Turn on the gas

Turn on the main power switch to activate the unit. The Büchi

logo appears for approx. 2-3 secs.

This is followed by the user menu.

Enter user name and check the output pressure (5 bar +/-

0.5 bar or 72.5 psi +/- 0.7 psi).

The venting flap closes, the main menu appears and the

pressures build up. As soon as the set pressure values are

reached, the heating elements begin to heat up. The cursor

is positioned on <Preheating>.

The actual temperature and pressure values are displayed on

the right.

pH2: Actual pressure for hydrogen

p

air

: Actual pressure for synthetic air

T

Oven

: Actual temperature for oven

T

inj.

: Actual temperature for injection heating

T

FID

: Actual temperature for the flame ionization detector (FID)

Enter the preheating time of 1800 secs (or 7200 secs if the

column needs conditioning). The preheating procedure cannot

be started until the entered set pressure values and set

temperatures have been reached. (Ready LED must be

permanently lit). If this is not the case, an error message will

appear.

Preheating p H2 55kPa

Sample weight/Mode p air 50kPa

Determination T oven 130°C

Data manager T inj. 220°C

Setup T FID 260°C

SWITZERLAND

Version: 3.00af Gas supply on?

User: C.Heiter Press <ENTER> to cont.

SWITZERLAND

5 Operation

Page 39

39

BÜCHI Fat Determination B-820/B-821

Time: 2400s p H2 55kPa

Start preheating p air 50kPa

Main menu T oven 130°C

T inj. 220°C

T FID 260°C

Position the cursor on <Start preheating>.

The preheating procedure is in operation (running LED is lit

up). <Remaining time> shows the remaining preheat time.

If the cursor is positioned on <Stop> and confirmed by pressing

the <ENTER> key, the preheat procedure is interrupted and

the main menu reappears.

The main menu also reappears when the preheating period is

finished. To return directly to the main menu without interrupting

the preheating procedure, press the <ESCAPE> key.

5.2.6 Gas flow rate setup

If the unit has been turned off for longer than 30 minutes, the

unit must be preheated for 30 minutes before the gas flow

rate setup procedure can be performed (see chapter 5.2.5,

"Preheating/Separation“ column conditioning).

The flow rate measurement takes place at an oven temperature

of 130 °C.

Proceed as follows:

Position the cursor on <Setup>.

The cursor is positioned on <Gas flow setup>.

Stop p H2 55kPa

Main menu p air 50kPa

T oven 260°C

T inj. 220°C

T FID 260°C

Remaining time 1215s

Gas flow setup

User configuration

Printer configuration

System configuration

Autosampler

Main menu

Preheating p H2 55kPa

Sample weight/Mode p air 50kPa

Determination T oven 130°C

Data manager T inj. 220°C

Setup T FID 260°C

5 Operation

Page 40

40

BÜCHI Fat Determination B-820/B-821

1. In order to check the hydrogen flow rate, the cursor is

positioned on <Press. system: H2> and the air pressure is

switched off internally (p air: 0 kPa). Connect the soap

bubble meter, containing approx. 2 ml soap solution, to

the FID (see figure 19) and wait until the Ready LED lights

up.

2. Press the bulb to release a soap bubble. Use a stopwatch

to time how long the bubble takes from marker 1 to marker

2 (see figure 20).

When using the short column, the time should be 7 ±

0.1 sec (flow rate: 10 ml/7 ± 0.1 sec).

When using the long column, the time should be 10 ±

0.1 sec (flow rate: 10 ml/10 ± 0.1 sec).

3. If the stopped time deviates from the set time, the

hydrogen pressure must be adjusted accordingly, Position

the cursor on H2 pressure and enter new value. Once the

ready LED lights up, the flow rate can be remeasured.

This procedure should be repeated until the set value has

been achieved.

4. Reposition cursor on <Press. system: H2> and press <Option>. The display now reads <Press. system: Air>.

The pressure values “55 kPa” and “250 kPa” are standard

values, for total fat and fatty acid modes respectively, and

can vary depending on the unit.

Press. system: H2 p H2 55kPa

H2-pressure: 55kPa p air 0kPa

Main menu T oven 130°C

T inj. 220°C

Wait until ready T FID 260°C

Req. flow H2: 10 ml/7 s

Figure 19: Installing the soap bubble meter

5 Operation

Determination "Total Fat" (short column)

Press. system: H2 p H2 280kPa

H2-pressure: 280kPa p air 0kPa

Main menu T oven 150°C

T inj. 220°C

Wait until ready T FID 260°C

Req. flow H2: 10 ml/10 s

Determination "Fatty Acid" (long column)

Page 41

41

BÜCHI Fat Determination B-820/B-821

Press. system: air p H2 55kPa

Air-pressure: 50kPa p air 50kPa

Main menu T oven 130°C

T inj. 220°C

Wait until ready T FID 260°C

Req. flow H2+air 20 ml/2.5 s

Press. system: air p H2 55kPa

Air-pressure: 50kPa p air 50kPa

Main menu T oven 130°C

T inj. 220°C

T FID 260°C

Req-flow H2+air: 20 ml/2.5 s

5. To check the air flow rate, the cursor is positioned on

<Press. system: Air> during which the air pressure is built

up. Wait until the actual pressure value is identical to the

set pressure value on display (Ready LED lights up).

6. Press the bulb to release a soap bubble. Use a stopwatch

to time how long the bubble takes from marker 1 to marker

3 (see figure 20).

When using the short column, the time should be 2.5 ±

0.1 sec (flow rate: 20 ml/2.5 ± 0.1 sec).

When using the long column, the time should be 2.7 ±

0.1 sec (flow rate: 20 ml/2.7 ± 0.1 sec).

7. If the stopped time deviates from the set time, the air

pressure value must be adjusted accordingly (position the

cursor on air pressure and enter new value). Once the

Ready LED lights up, the gas flow should be remeasured.

8. Dismantle the soap bubble meter from the FID.

Wear gloves or use a small towel for dismantling as the screw

is very hot.

Ensure that the soap bubble meter is removed from the FID

before returning to the main menu.

9. Position the cursor on <Main menu>.

While switching to the main menu the FID ignites automatically.

The oven temperature is set again according to the adjusted

mode.

Preheating p H2 55kPa

Sample weight/Mode p air 50kPa

Determination T oven 130°C

Data manager T inj. 220°C

Setup T FID 260°C

5 Operation

Determination "Total Fat" (short column)

Press. system: air p H2 280kPa

Air-pressure: 50kPa p air 50kPa

Main menu T oven 150°C

T inj. 220°C

Wait until ready T FID 260°C

Req. flow H2+air: 20 ml/2.7 s

Determination "Fatty Acid" (long column)

Page 42

42

BÜCHI Fat Determination B-820/B-821

Figure 20: Measuring the gas flow rate with a digital stop watch,

counting in 1/

100

th of a second interval.

10 ml

Marker 3

20 ml

Marker 2

Marker 1

5 Operation

Re-check the gas flow rate and the supply lines for leakages

(see Section 4.7, Checking supply lines for leaks) each time

the gas cylinder or column is changed as well as after service

interventions.

Page 43

43

BÜCHI Fat Determination B-820/B-821

5.2.7 Sample weight and mode adjustment

Position the cursor on <Sample weight/Mode>.

Manual sample weight

If no balance is connected to the B-820, the sample weights

must be entered manually in the sample weight table using

the keypad.

Confirm “Manual sample weight” with “ENTER”. The sample

weight table appears.

Automatic sample weight

For this option, a balance must be connected as described in

Chapter 4.4. Confirm “Automatic sample weight” with

“ENTER”. The sample weight table appears. After selecting

the mode, move the cursor to the next field (Weight [g] with

“ENTER”. When the weight has been transferred, the cursor

moves to the next field in a similar way to the “Manual sample

weight”.

Factors

The current factors are entered here. These valves are

incaporated in the final result. Confirm with “ENTER”. The

factor table will then appear.

Manual sample weight

When the sample weight table appears, the cursor will be

located at the first free sample number (No.). After selecting

the mode, enter the weight (in grams) for each sample and

the internal standards. Confirm each entry with “ENTER”.

Depending on the mode selected, the cursor will automatically

move to the next available field.

Automatic sample weight

When the sample weight table appears, the cursor will be

located at the first free sample number (No.). After selecting

the mode, transfer the weight (in grams) for each sample and

the internal standards for the connected balance type.

Depending on the mode selected, the cursor will automatically

move to the next available field.

Preheating p H2 55kPa

Sample weight/Mode p air 50kPa

Determination T oven 130°C

Data manager T inj. 220°C

Setup T FID 260°C

Manual sample weight

Automatic sample weight

Factors

Main menu

5 Operation

No. Mode Weight Weight Weight Conc.

[g] C13 [g] C5 [g] [%]

1 fact.gen. 0.7055 0.2115 99.8

Name: Factor

2 Fact.b.a. 0.055 0.054 99.5

Name: Factor C4

3 But.acid 0.8550 0.2134 0.056

Name: Butter

4 gen.corr. 4.3575 0.1245

Name: Wheat

5 spec.corr. 2.3654 0.2056

Name: Cheese

Sample weight table

No. Number of the sample in the sample weight table.

Mode Determination mode used, which is selected dependent on the sample type ((See Chapter 3, Table 6). Select the mode with “OPTION” and

confirm with “ENTER”.

Weight [g] Weight of the sample, which is entered in g. Confirm the weight with “ENTER”.

Weight C13 [g] Weight of the internal standard (tridecanoic acid), which is entered in g. Confirm the weight with “ENTER”.

Weight C5 [g] Weight of the internal standard (valeric acid), which is entered in g. Confirm the weight with “ENTER”.

Conc. [%] Concentration of the fat standard (e.g., pork fat, 99.8% or concentration, depending on the standard used) and/or the butyric acid (e.g.,

butyric acid, 99.5% or according to purity used) that will be necessary for the determination of the factor. This column is only selected in the

modes “Gen.fact.”, “FA-fact.” and “Butyr.fact”. It is skipped over in all other modes.

Name Sample identification (sample name) entered from the keypad and confirmed with “ENTER”.

Key for Sample weight table:

Page 44

44

BÜCHI Fat Determination B-820/B-821

Manual sample weight

Automatic sample weight

Factors

Main menu

5 Operation

After the sample identification (Name) has been entered and

been confirmed with “ENTER”, the cursor automatically moves

to the next free cell. In doing this, the mode of the previous

sample will also be transferred, and must be changed - where

required - using the “OPTION” key. The fields “Weight [g]”,

“Weight C13 [g]”, “Weight C5 [g]”, “Conc. [%]” and “Name”

fields of the previous row can be copied into the current row

one after the other by pressing the “OPTION” key.

Within the column, you can move between the fields of each

sample number with “SELECT”.

You can move to the first sample number (No. 1) with the key

combination “SHIFT” + “SELECT” (upward arrow), and to the

last sample number with the key combination “SHIFT” +

“SELECT” (downward arrow). For the “Total Fat” option, the

sample memory contains 75 samples (No. 75), and 48 samples

(No. 48) for the “Fatty acids” option.

After completing the entries, press “ESCAPE” to exit the

Sample Weight table. To switch to the Main Menu, place the

cursor on “Main Menu” with “SELECT” and confirm with

“ENTER”. Or press “ESCAPE” twice after completing the

entries to move directly to the Main Menu.

Select the “Factors” menu with “SELECT”, and confirm with

“ENTER”. The Factors table then appears.

Page 45

45

BÜCHI Fat Determination B-820/B-821

5 Operation

Factors table

Fat factor

Entry of the factor that will be used for the determination in

the “gen.corr.” and “spec.corr.” modes.

Butyric acid factor

Entry of the factor that will be used for the butyric acid

determination in the “but.acid” mode.

CF

Entry of the correlation factor. This factor is required in the

“but.acid” mode for the conversion of the butyric acid content

to the milk fat.

Blank value of the butyric acid

Entry of the blank value in g, which will be required for the

determination of the butyric acid. (“Fact.b.a.” mode).

After completing the entries, press “ESCAPE” to exit the

Factors table. To switch to the Main Menu, place the cursor

on “Main Menu” with “SELECT” and confirm with “ENTER”.

Or press “ESCAPE” twice after completing the entries to move

directly to the Main Menu.

All the inputs made in “Factors” must be updated by the user

himself. A factor will not be automatically overwritten or

changed. The calculation of the results takes place on the

basis of the stored factors. If one of the factors is changed

after the start of the determination, the calculation will always

be carried out with the factors stored at the time of the

evaluation (= end of the analysis run).

5.2.8 Determination

Once the sample weights have been entered, the determination can be started.

Factor Fat: 0.953

Factor butyric acid: 1.023

CF: 28.570

Blank value but. acid 0.0031 g

Main menu

Factors table

Preheating p H2 55kPa

Sample weight/Mode p air 50kPa

Determination T oven 130°C

Data manager T inj. 220°C

Setup T FID 260°C

Page 46

46

BÜCHI Fat Determination B-820/B-821

5 Operation

Determination with the Autosampler

Sample No.

Enter the sample number (from the sample weight table) with

which the determination should be started. Confirm it with

“ENTER”; the cursor moves to the next row. The corresponding sample identification (Name), the injection number (here

the second injection) and the sample-specific determination

mode (“spec.corr.”) will be shown in the display.

Vial No.

Position of the sample (sample vial) in the sample carousel of

the Autosampler, in which the sample (Sample No.) that is to

be determined is located.

It must be ensured that the sample number corresponds to

the content of the sample vial. To facilitate the overview, sample

numbers are selected to be the same as the vial numbers.

Switching off

Can be set to “YES” or “NO” with “OPTION”. “YES” means

that the temperature will be reduced to room temperature

after the end of the last determination, and that the gas feed

for the hydrogen and synthetic air will then be switched off via

the valves. These settings are equivalent to a “STAND-BY”

mode (energy-saving mode). If the system finds itself in “STANDBY” after the last determination, the display will indicate “The

determination finished correctly”.

“The determination finished correctly”

Here, the system will be in a pressure-free condition. The

following work can be carried out:

– Column change

– Septum change in the injector

– Refilling of the gas saturation vessel with formic acid, 85%

(purity)

“NO” means that all temperatures and the gas feed take on

the settings of the “READY” mode after the end of the last

determination (see Chapter 5.1). The “READY” LED indicates

that the system is ready to carry out measurements.

Start

The determination is started with the “START” function (the

cursor must be on “START”) and “ENTER”. This automatically

initiates the rinsing of the syringe and the selection of the

corresponding sample vial. If a “Preheating” should be carried

out, or the system is carrying out a conditioning (“Running”

LED illuminated), the number of seconds remaining before

the first injection can take place will be indicated in the “Start”

line (in this case, 62 seconds).

Sample no: 5 p H2 55 kPa

Vial no: 5 p air 50 kPa

Switch off: yes T oven 140°C

Start after 62s T inj. 220°C

Main menu T FID 260°C

spec.corr

Name: cream cheese

Page 47

47

BÜCHI Fat Determination B-820/B-821

5 Operation

Procedure

The sample will be injected automatically. The corresponding

temperature program runs automatically in the background

according to the determination mode (see Chapter 3, Table

7). At the end of the determination, the venting flap opens;

the oven area will be conditioned in order to prepare the system

for the next determination. The evaluation takes place

automatically, and will be printed out depending on the printer

configuration (see Chapter 5.2.2).

The next injection takes place as soon as “Ready for Injection”

appears in the display (the “READY” LED lights up). This

procedure will continue until there are either no more sample

vials in the carousel or no more sample weights in the sample

weight table.

The number of injections per sample will be entered under

“Autosampler” in the “Setup” menu (see Chapter 5.2.4).

A maximum of 9 injections per sample vial are provided for the

“Total fat” option and a maximum of 6 injections per sample

vial for the “Fatty acids” option.

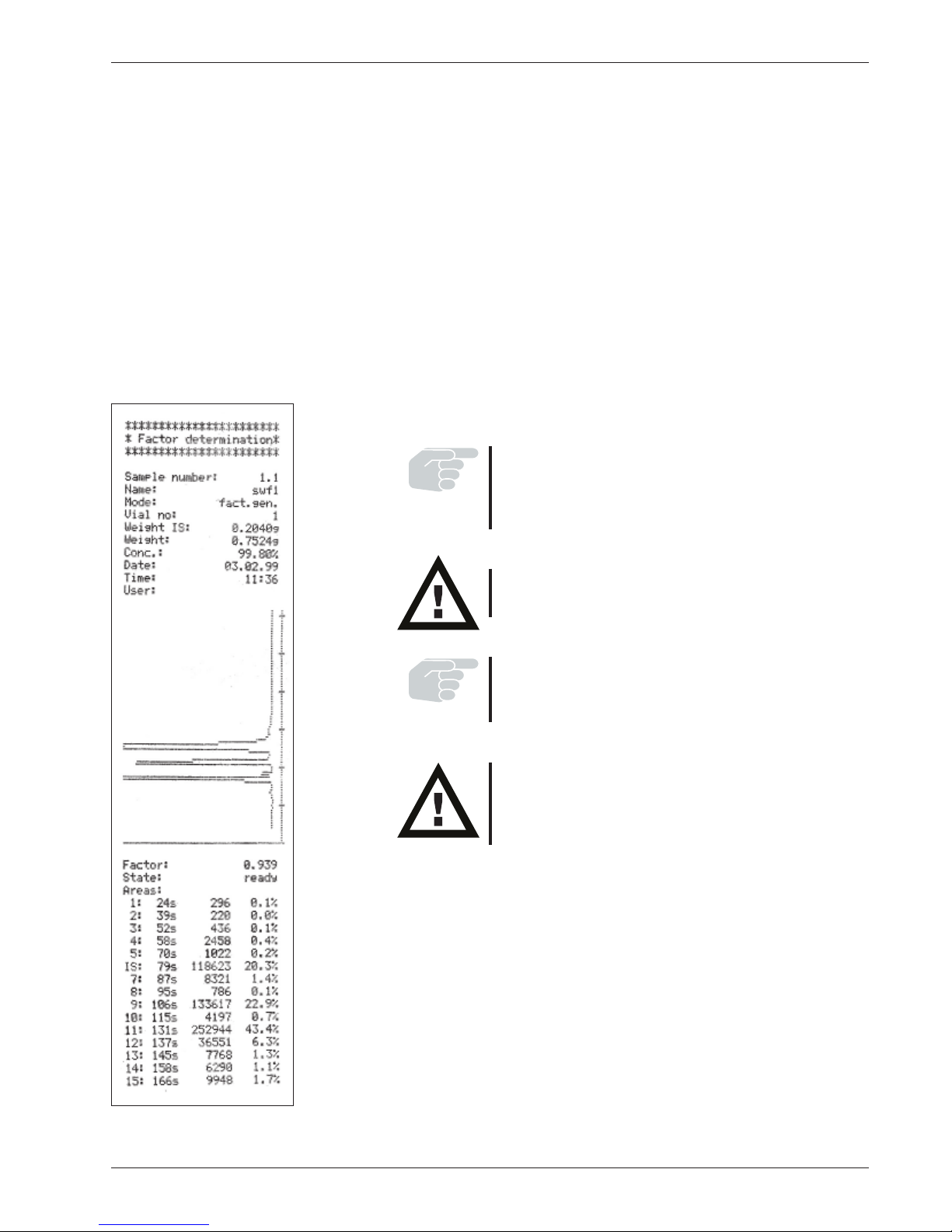

“Memory full” appears if the maximum number of injections