Page 1

Operation Manual

Glass Oven

B�585

096981

en

Page 2

Page 3

Glass Oven B-585

Contents

Contents

1 Scope of delivery 2

1.1 Glass oven for drying 2

1.2 Glass oven for ball tube (Kugelrohr) distillation 3

2 Safety 5

2.1 Symbols 5

2.2 Requirements to be met by the customer 5

2.3 Proper use 5

2.4 Improper use 6

2.5 General hazards 6

2.6 Safety measures 7

2.7 Over-temperature protection 7

3 Function 8

3.1 Working with the glass ovens 8

4 Putting into operation 10

4.1 Installation location 10

4.2 Power connections 10

4.3 Installation of the glass parts and

the drive unit 10

5 Operation 11

5.1 Overview program structure 11

5.2 Basic display arrangement 12

5.3 Operation of the B-585 Drying 16

5.4 Operation of the B-585 Kugelrohr 19

5.5 Accessories: Sublimation and freeze drying 22

5.6 Converting the Glass Oven configurations 23

6 Maintenance 26

6.1 Cleaning 26

6.2 Service 26

6.3 Customer service 26

7 Taking out of operation 27

7.1 Storage / Transport 27

7.2 Disposal 27

8 Replacement parts 28

8.1 B-585 Drying configuration replacement parts 28

8.2 B-585 Kugelrohr configuration

replacement parts 29

8.3 Sublimation accessory replacement parts 29

9 Appendix 30

9.1 Technical data 30

9.2 Error massages 30

9.3 Materials used 31

9.4 Declaration of conformance 32

Please read these instructions thoroughly before using the Glass

Oven B-585. Keep these instructions in the imme diate vicinity

of the device so that they can be referred to at any time.

Chapter 2 contains important safety advice. These infor mation

is vital to the safe operation of the glass oven.

The right to make technical changes without notice is re served. No portion of these instructions may be repro du ced in

any man ner, nor may it be edited, copied or distri buted using

any electro nic or optical systems without the expres sed written

consent of Büchi Labortechnik AG.

All rights reserved.

Copyright © Büchi Labortechnik AG, 2004

EN Version G

as of Software-Version 1.1 (32 pages) Order Code

B-585 Instructions 096981

1

Page 4

Glass Oven B-585

1 Scope of delivery

1 Scope of delivery

1.1 Glass oven for drying

Description

B-585 Drying Order Code

Drying oven B-585

100 V - 230 V / 50/60 Hz 46600

Additional package contents:

Fig. 1: B-585 Drying

2 Replacement fuses 3,15 AT

1 Drying accessory complete 37010

1 Mains cable PNE, 1.5m

Typ CH 10010

Typ Schuko 10016

Typ GB 17835

Typ USA 10023

Typ AUS 17836

Fig. 2: Ball tube drive complete

1 Instructions

German 96980

English 96981

French 96982

Italian 96983

Spanish 96984

Optional accessories

1 Complete ball tube drive for con verting to a ball tube distillation oven 46617

(Kugelrohr) incl. cooling device

1 Complete sublimation accessory for

conversion to the Sublimation configuration 37133

1 Communication cable 46728

B-585 / V-500

Fig. 3: Sublimation accessory complete

2

Page 5

Glass Oven B-585

Fig. 4: B-585 Kugelrohr configuration

1 Scope of delivery

1.2 Glass oven for ball tube (Kugelrohr) distillation

Description

B-585 Kugelrohr configuration Order Code

Kugelrohr destillations oven B-585

100 V - 230 V / 50/60 Hz 46601

d

Fig. 5a: Glass Accessories including with B-585 Kugelrohr configuration

a

b

Additional package contents:

1 30 ml rotation drying flask with

vapour duct and clip a 37143

1 20 ml ball tube with vapour duct and

clips b 37107

1 Replacement gasket for the ball tube

drive d 37288

1 60 g tube of vacuum grease 48197

2 Replacement fuses 3,15 AT

2 GL 14 hose nipples 37287

1 Iris diaphragm cpl. e 46605

1 Cooling unit compl. c 46616

1 3-wire power cord. 1.5m

Type CH 10010

Type Schuko 10016

Type GB 17835

Type USA 10023

Type AUS 17836

1 Instructions

German 96980

English 96981

French 96982

Italian 96983

Spanish 96984

e

Fig. 5b/c: Other Accessories including with B-585 Kugelrohr configuration

c

3

Page 6

Glass Oven B-585

1 Scope of delivery

Optional accessories

1 10 ml ball tube

with vapour duct and clips 37118

1 40 ml ball tube

with vapour duct and clips 37117

1 Drying accessory for converting to the

Fig. 6a: 10 ml ball tube

B-585 Drying model 37010

1 Complete sublimation accessory for

converting to the B-585 Sublimation model 37133

1 Freeze drying accessories 46710

Fig. 6b: 40 ml ball tube

Fig. 6c: Drying accessory

Fig. 6d: Complete sublimation accessory

Fig. 6e: The freeze drying accessory

4

Page 7

Glass Oven B-585

2 Safety

2 Safety

The device has been built using state art techniques and in accordance with the recognized safety regulations. There are no

risks or hazards associated with the use of this device if used

according to the instructions.

2.1 Symbols

Stop

Information about hazards which can lead to serious material

damage or cause serious or potentially fatal injury.

Warning

Information about hazards which can be harmful to your health

and lead to material damage.

Please note

Information about technical requirements. Non-obser vance can

lead to malfunctions, inefficiency and lost production.

2.2 Requirements to be met by the customer

The device may only be used by laboratory personnel and other

persons who, due to their training or experience, can recognize

the hazards associated with operating the device.

Personnel without this type of training or persons currently in

training require careful instruction. This instruction can be considered to be the basis for this instruction manual.

When working with solvents whose composition is not known,

it is the management’s responsibility to obtain information from

the appropriate persons about possible hazards associated with

using such solvents.

2.3 Proper use

The device has been designed and built as a laboratory device.

Appropriate uses of the device are for the drying, distillation,

sublimation and freeze-drying of small quantities of substance

from room temperature up to 300°C.

5

Page 8

Glass Oven B-585

2 Safety 7Glass Oven B-585

2.4 Improper use

Using the device for any other purpose other than those stated

above or using in any application that does not correspond to

the technical data is considered to be improper usage.

Any damage resulting from such use is the sole responsibility

of the operator.

Using the device in the following situations is especially prohibi ted:

• Using the device in rooms which require explosion-proof

equipment.

• Testingsampleswhich,throughimpact,friction,heatorspar-

king, may explode or ignite (for example, explosives, etc.).

• Usinginconjunctionwithsolventscontainingperoxides

2.5 General hazards

General hazards arise from:

• Whenusingwithmixtureswithunknowncompositionorim-

puri ties.

• Flammablesolvents(attendtheburningpoint)

• Toxicgases,whichcanresultduringoperation.

• Flammablegasesorsolventfumesinoraroundthedevice.

• Damagedglassware.

• When the device is too close to the wall (see Chapter 4,

Putting into operation)

• Touchingtheheatingelements,causingburns.

• Squeezingsbyinappropriateretractingandextendingofthe

drive or adjustment of the heating angle.

• Storageoftheunitinconnedplaceswhenhot.

Rotation drive

Care must be taken to ensure that hair, clothing, jewelry or any

other article is prevented from entering any rotating parts of

the instrument.

Removing the cover using common hand tools is - except for

authorized maintenance personnel, prohibited. The device may

not be put into operation if the glassware is damaged.

It may be fatal if any high voltage parts of the device are touched!

Use of dry ice

Dry ice can cause serious burns if allowed to come into contact

with skin or eyes. Appropriate protective clothing must be worn.

NB Dry ice will foam strongly if allowed to come into contact

with acetone.

6

Page 9

2 Safety

2.6 Safety measures

It is required that you wear protective gear such as pro tective

glasses, gloves and a lab coat.

These instructions must be available at all times to the operating

personnel at the location where the device has been installed,

as it is considered to be a component of the glass oven. This

is al so true of the copies of the in s tructions in other languages,

which may be ordered separately at a later date.

Modifications

Modifications to the device or to the replacement parts or acces sories, as well as using any replacement parts or acces sories

ot her than those mentioned in these in struc tions, is only allo wed

with the express written consent of Büchi Labortechnik AG.

Responsibilities of the Management

The management is responsible for instructing its per son nel. To

help in this task, you can order these instructions in several

other languages.

Protective Shield

The protective shield mounted on the device does not serve to

completely protect the operator from coming into contact with

hot glass elements. It is only there to protect the operator from

burns occurring due to carelessness.

2.7 Over-temperature protection

The device has an over-temperature cut-out for the protection

of samples and the oven. This protective device switches the

heating off in the event of the oven temperature reaching 320°C:

•Foradditionalinformation,pleasesee.

Troubleshooting; Chapter 9.2 Error messages

Page 10

Glass Oven B-585

3 Function

3 Function

3.1 Working with the glass ovens

The core of the glass oven comprises two borosilicate glass

tubes lying one within the other. The outer tube (1) protects

against damage to the heating tube, and at the same time

prevents contact with parts that are electrically live. A metal

screen (2) around the outer jacket provides additional protection. The transparent, electrically conductive semi-conductor

coating, does the actual heating. Temperatures up to 300°C

are attained, the oven temperature being monitored via an

integral temperature sensor (4). A lock nut (5) can be used

to tilt the oven and to secure it in a suitable position.

The basic equipment can be used for drying,

distilling and sublimating, if the appropriate accessories are used.

To avoid thermal damage to, or decomposition of, samples

requires gentle heating techniques. Conventionally, this has

been done by heating the sample via an intermediate medium

(e.g. water or oil) whose temperature is regulated just above

the required setpoint for the sample. In bulb-tube distillations,

a semi-conductor coating is used to provide direct, yet still

gentle, heating. The product may be heated directly because

the heat source provides evenly across the entire surface

of the heater. Because the thermal capacity and the thermal

conductivity of the vapour-coated glass are significantly better than those of the gas/atmosphere outside, most of the

heat given off is taken up by the glass and radiated inwards.

There are further advantages in addition to the gentle heating:

Because 75% of the heat is supplied to the product through

radiation and only 25% via heated gas, the oven heats up

very quickly and also cools down relatively quickly when it is

switched off. In addition, because the semi-conductor is fully

transparent, the sample can be observed during the drying

process, so that any decomposition can be identified quickly

and any necessary countermeasures can be taken in time.

8

Page 11

Glass Oven B-585

a

b

3 Function

c

d

Fig. 7: Function principle of the glass oven

a Jacket tube

b Heat protection

c Heating tube

d Temperature sensor

The electrically conductive semiconductor layer operates at

supply voltage. There is a possibility for fatal injuries when the

outer jacket tube has been removed.

9

Page 12

4 Putting into operation

Glass Oven B-585

4 Putting into operation

Please inspect the package for any damage while un packing.

Any damage suspected of having occur red during transportation

should be reported imme diately to the appropriate authorities

(ditributor, post office, railroad or trucking company).

The original packaging should be saved in case it is required

at a later date.

4.1 Installation Location

The device must be set up on a clean, stable and level surface.

The device may not be used in rooms meant for use with explosive gases.

For safety reasons, there must be at least 30 cm between

the wall or other equipment and the rear and sides of the device.

No containers, chemicals or other devices should be placed

behind the device.

4.2 Power connections

Check to ensure that the voltage coming out of the electrical

socket agrees with the voltage stated on the devices ratings

plate. The glass oven must always be connected to an earthed

electrical socket. External couplings and extension cords must

have an earth wire (3-pole couplings, cords and sockets). It is

prohibited to cut or interrupt the earth wire. to avoid the risk of

damage to the device, or personal injury.

In a vertical operation care must be taken to ensure that every

cable of the B-585 not gets in contact with the heating element.

Discription of the interface:

Drive:

Vac Pump:

B-585/V-500 to a vacuum pump V-500

Air Pump:

Method (not availlabel at Büchi)

4.3 Installation of the glass parts and

the drive unit

interface for the drive unit

interface for communications cable

interface for air pump Mettler for the KF-

10

For installation of the different parts please see chapter 5.6

"Converting the Glass Oven".

Page 13

Glass Oven B-585

5 Operation

5 Operation

5.1 Overview of program structure

WORKING DISPLAY

MODE

- program

- manual

VACUUM CONTROL

Yes / No

PROGRAMS

- load

- view

- edit

- delete

UNIT OF TEMPERATURE

°C / ° F

CONTRAST

0 - 100%

OPTIONS

LANGUAGE

- English

- Spanish

- German

- Italian

- French

- Japanese

Fig. 8: Overview of program structure B-585

11

Page 14

Glass Oven B-5855 Operation

a)

h

e

b

c

a

g

f

d

i

j

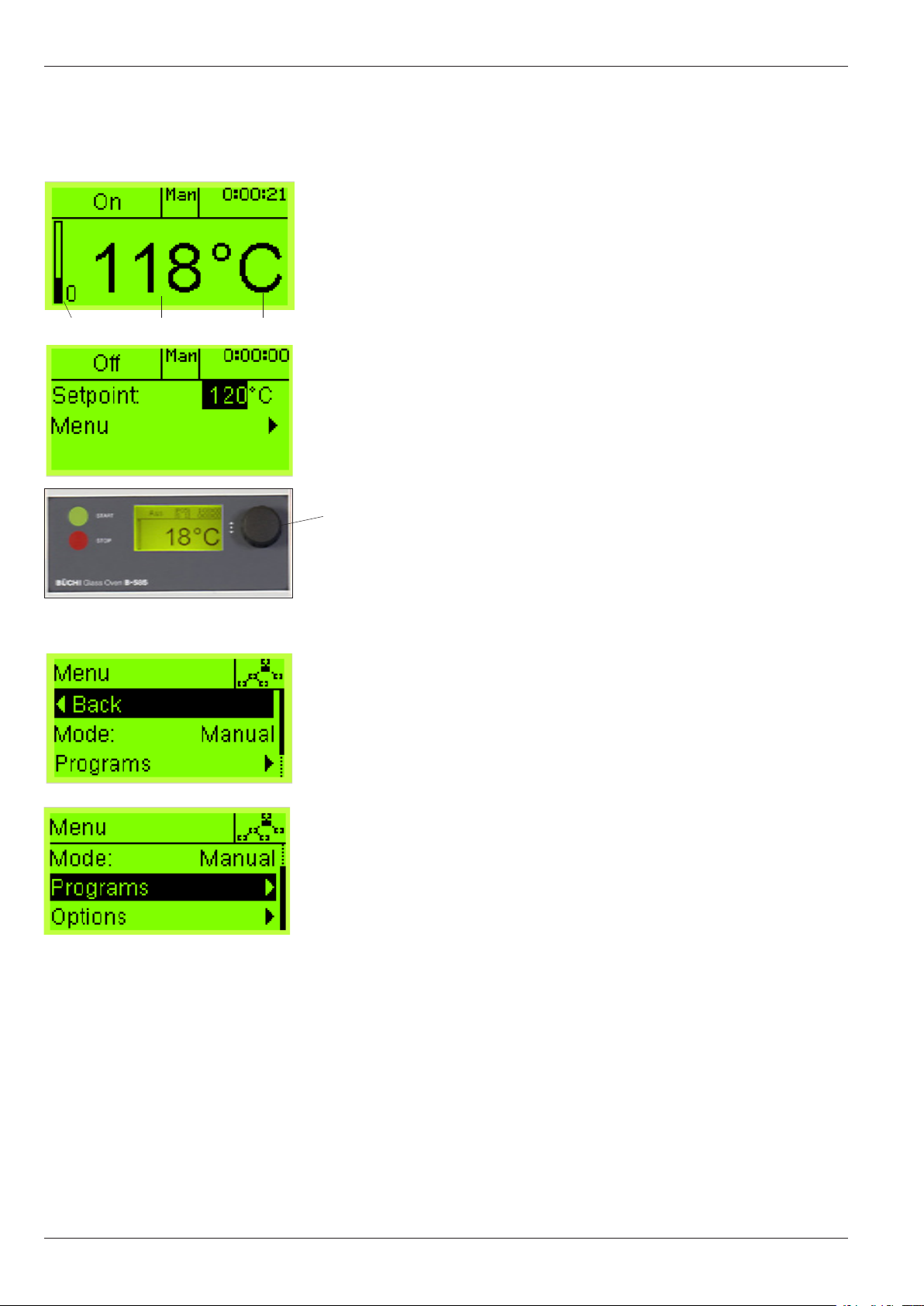

5.2. Basic display arrangement

a Active mode information

b

Operating condition

c

Actual temperature

d

Temperature unit of measurement

e

Graphic display of heating intensity

f

Display of the elapsed time

g

Set point adjustment

h Menu adjustment

i Graphical display, shows level indication of the user

j

Multifunction button

By pressing and turning the Multifunction botton allows

access to the working menu where changes and modifications can be made. Pressing the Multifunction botton again

activates the set point. An existing value can be modified

by turning the Multifunction botton and is stored by pressing the botton again. The cursor will jump forward to the

display menu.

By turning the Multifunction botton you get back

to the actual working menu or access another

control mode. It is possible to change/create,

delete, read or load a program profile in the menu

program or change the main settings.

12

Page 15

Glass Oven B-585

5 Operation

5.2.1 Operation of the B-585 in manual mode

Cchanging the actual temperature and the speed

of rotation in manual mode.

By pressing the Multifunction botton the user gets into the

working menu, where the changes to the actual temperature

set point and the rotation speed can be made. Pressing the

Multifunction botton again activates the menu set point. To

select the desired temperature turn the button. By pressing

the Multifunction botton the selected temperature will be

stored. The cursor will then jump forwards to the rotation

speed or (if no rotation speed is available) to the menu.

5.2.2 Selection of the rotation speed before

operation

The rotation speed can be pre-selected prior to a run with

real samples. Select ”speed of rotation” from the working

menu and confirm the desired value by rotating and then

pressing the Multifunction button.

The motor will now start running at the newly adjusted speed.

Note, if the new chosen speed is not confirmed within 10

seconds, then the value automatically reverts to the previously stored value. Pushing the ”stop” button causes the

motor to stop.

5.2.3 Change/build or delete a program profile

in manual working mode.

Even when the instrument is working in manual mode , a

program can be created, deleted or changed.

Whilst the instrument is in operation, the program points to

”load program” and ”mode of operation” can not be chosen.

13

Page 16

5 Operation

Glass Oven B-585

5.2.4 General information about the menu

functions:

On the menu item language it is possible to choose between

the following languages: English, Spanish, Italian, French,

German and Japanese.

On the menu item contrast it is possible to optimize the

display.

On the menu item temperature it is possible to choose either

Fahrenheit or °Celsius.

On the menu item Vac. pump it is possible to switch the

vacuum pump on or off directly from the B-585, (Requires

Büchi vacuum pump V-500 series with the B-585/V-500

cable). The cable has to be connected at the plug socket

in the middle.

Fig. 9: Angle 3

5.2.5 Adjusting the working angle of the oven

The working angle of the oven can be adjusted by the release handle.

Fig. 10: Working angle

14

5.2.6 Working at room temperature

To operate at room temperature, select the value ”RT”

from the Setpoint values. This setting switches the heating

circuitry off.

Page 17

Glass Oven B-585

b

e

c

a

d

f

g

5 Operation

5.2.7 Operation of the B-585 in the program mode

Fundamental arrangement of the display:

a

Information about the active mode and current stage of

the program (I, II or III)

b

Operating condition

c

Actual temperature

d

Temperature unit of measurement

e

Graphical heating display

f

Indication of the remaining time to the end of the program

g

Indication of the remaining time in the current program

step

Program load, edit select, delete, view:

By turning the Multifunction button, the display will change to

the working menu. By choosing the menu ”program” existing

programs can be checked, deleted or modified.

To load an existing program, turn the Multifunction button to

load and confirm it by pressing the button. The cursor will

jump to the next selection. By turning the buton again the

stored programs are shown (P01, P02...) . By pressing the

button, the chosen program will be confirmed. Now it shows

the working display. To start the chosen program press the

green button start.

5.2.8 Change or create a program:

If the cursor is on position change/new, a new program can

be built or an existing program can be changed.

By confirming choose the cursor will get to the existing pro-

grams. (P01, P03, new.....).

After choosing the program the cursor jumps to step1. Pressing the Multifunction button allows the user to change the

temperature or time. The cursor jumps to the temperature

display. It is now possible to make any desired changes.

Press the button to enter the chosen temperature and the

cursor will then jump to the time display. Continue accordingly as for the temperature setting.

If a new program is created, an empty memory positions

are will be offered. If all of the 10 memory position

occupied, then an existing program must be either

edited and saved to store the desired parameters,

or one must be deleted before a new program can

be created and stored.

At any time, even during a run, any program stored in memory (apart from the one currently loaded), can be edited or

deleted. New programs can also be created.

15

Page 18

Glass Oven B-585

5 Operation

5.3 Operation of the B-585 Drying Oven

Please ensure that the device has been correctly put into operation according to Chapter 4, Putting into operation.

5.3.1 Operational and display elements

a

k

i

j

Fig. 11: B-585 Drying

e

c

d

h

f

g

b

a

Unit sockets with main fuses

b

Main power switch

c

Digital display showing the current temperature

d

Multifunction botton for setting the desired oven

tempe rature

e

Pilot lamp, illuminated when heating is turned on

f

Lever used to open the iris diaphragm

g

Glass ball cooling apparatus

h

Holder for the save contact of the furnace

i Start

j Stop

k Lever of the adjustment of the inclination of the furnace

angel

r

16

5.3.2 Drying

The glass oven can also be used to dry solid substances.

Unlike permanently installed drying cabinets, the drying oven

only has to heat up a small volume. It requires less energy,

reaches the desired temperature more quickly, and thereby

reduces the time for drying. Moreover, if used as a vacuum

oven, it has a significantly tighter seal than a drying cabinet

and can therefore maintain a better vacuum. There are three

methods used for drying direct drying, indirect drying, and

rotary drying. The drying accessory is used for direct and

indirect drying, the rotary flask for rotary drying.

Page 19

Glass Oven B-585

5 Operation

a

Fig. 12: Direct Drying A

ed

c

5.3.3 Filling with the Material to be Dried

The drying accessory consists of three parts. While the drying

is in progress, the drying tube a into which the product is

put (either directly or inside a container), is in the oven. The

end cap b that catches the moisture evaporated off can be

b

filled with desiccants to improve the drying effect. A stopcock c is used to evacuate or aerate the sample chamber.

The aluminum flange ring d joins the two glass sections

in a screwed joint, sealing them vacuum-tight. The flange

ring e is also used to hold the drying accessory in position

within the glass oven. This drying accessory does not rotate.

The material to be dried can be placed in the drying tube in various ways. The method chosen depends mainly on the amount

of substance.

Example A

A large quantity of the material to be dried is placed directly in

the drying tube. With this method, existing glass boats, metal

dishes, etc., may be used. This drying method should not be

used for hygroscopic samples, as these may absorb moisture

during transfer to another container after having been dried.

Fig. 14: Rotation Drying Flask C

Example B

The material to be dried is placed in its container and the container is placed in the drying tube. The drying oven must be

operated in the vertical position for this method. The advantage

of this method is that the substance does not need to be transferred from one container to another after drying, and that its

container can be sealed im me dia tely after drying.

Fig. 13b: Indirect Drying BFig. 13a: Indirect Drying A

Example C

A hard surface layer is created while drying some sub stan ces

which increases the drying time dramatically. This can be avoided by rotating the container regularly. It is therefore recommended to use the notched rotation drying flask which can only

be used in conjunction with an electrical ball tube

drive.

17

Page 20

Glass Oven B-5855 Operation

Fig. 15: Drying Tube

a

5.3.4 Placing the Drying Tube in the Drying Oven

If the material to be dried has been placed in the drying tube

according to Chapter 5..., the tube and the end cap are screwed together. The entire assembly is then placed in the drying

oven and fastened with the screw a . You should ensure that

the stopcock is vertical and that the reservoir in the end cap is

directed downwards.

The oven temperature must be set for drying and, if necessary,

the vacuum must be connected. After drying, aeration follows,

either using the air in the environment or using an inert protective

gas using the corresponding gas connection. The assembly is

taken out of the oven and left to air-cool.

Fig. 16: Desiccant

5.3.5 Working with Desiccants

The drying of substance samples containing water can be accelerated and optimized by using desiccants such as silica

gels, CaCl2 or P2O5. Such desiccants are placed in the rear part

of the end cap. When filling with a free-flowing desiccant, you

must make sure that the end cap remains clean between the

aeration stopcock and the flange. If dust particles adhere to the

sides, then the end cap must be cleaned afterwards. Otherwise,

there is the danger that of these particles will be taken with the

flow of air when aerating the evacuated drying tube, thereby

adding impurities to the material to be dried.

The safety guidelines on the original packaging of the P2O5/

CaCl2 should be observed.

18

Page 21

Glass Oven B-585

e

a

j

m

n

c

d

k

f

g

l

i

h

b

5 Operation

5.4 Operation of the B-585 Kugelrohr

Please ensure that the device has been correctly put into operation according to Chapter 4, Putting into operation

5.4.1 Operational and display elements

a

Unit sockets with main fuses

b Main power switch

c Digital display showing the current temperature

d Multifunction botton for setting the desired oven tem-

perature and the rotation speed

e Pilot display for heating

f Lever used to open the iris diaphragm

g Glass ball cooling apparatus

h Glass cook for aeration

i Drive unit for rotating the glass ball

Fig. 17: B-585 Kugelrohr

j Lever for setting the angle of the oven

k Holder for the save contact of the furnace

l Lever for adjusting the vapour duct

m Start

n Stop

5.4.2 Kugelrohr / Distillation

The glass oven can be used for two types of distillation: single

distillation and fractional distillation. The fractional distillation

is a bulb to bulb distillation that uses three of four bulbs and

bulb cooling. The single distillation may be done either as a

bulb to bulb distillation using two bulbs and bulb cooling, or

with a condenser with a cooling coil and a collection flask,

In this latter application, the glass oven may be viewed as a

small rotary evaporator. Common to all three types of distillation is the fact that they all work using the bulb-tube drive.

Bulb to bulb distillation uses a tube that consists of as many

bulbs as there are components in the mixture.

19

Page 22

Glass Oven B-585

5 Operation

5.4.3 Cooling

For substances with a low boiling point, air-cooling is not

always sufficient to make the vapour condense in the balls

outside of the oven area. In this case, it is recom men ded to

use a cooling appa ratus. You can fill the dish with tap water,

ice-water, an ice-salt mixture, dry ice or a dry ice-alcohol

mixture.

The cooling dish is designed so that either a small glass ball

can be cooled by turning the dish sideways, or two small

or one large glass ball can be cooled by turning the dish

length-wise.

The cooling dish is made of polyethylene. This material is

not re sistant to chlorinated solvents. For this reason, cooling

mixtu res containing these types of solvents may not be used.

The dish schould be prevented from coming into contact

Fig. 18: Cooling device

with the metal flange.

Fig. 19 :

c

Assembly of the vapour duct

a

b

e

d

Dry ice and dry ice-alcohol mixtures will cause injury and

burns if they come in contact with skin.

If dry ice-solvent mixtures are used, then there must always

be dry ice in the solvent as long as the temperature in the

glass oven is higher than 50°C.

5.4.4 Assembly/disassembly of the vapour duct

The vapour duct is inserted into the drive unit as follows:

First the union nut a and the clamping cone b are mounted. The vapour duct c is then pushed from the left into the

drive unit d until it passes the vacuum seal on the right side

of the housing. Use the stop e to tighten the union nut, the

vapou r duct has now been assembled.

The contact surface of the vacuum seal together with the

vapour duct are then lightly greased and inserted into

the vacuum mount attached to the right side of the housing.

Repeat the greasing of the vapour duct as required.

20

Page 23

Glass Oven B-585

5 Operation

5.4.5 Working procedure for a simple distillation

The liquid to be distilled is placed in the vertical glass tube

with having only a single ground-glass joint using a pipette.

The glass tube can be filled up to the „max“ mark. The

desired number of glass balls are connected to each other

and secured against unwanted release with the clips. The

ball tube is connected to the vapour duct and pushed into

the oven. The aperture is closed and the electrical drive is

tur ned on. The oven temperature is increased until distilla tion

begins. This temperature can be anywhere between 10-40

°C above the sample's boiling point.

If you are distilling in a vacuum, then the ground-glass joints

must be lightly greased.

If the user is only interested in the distilled product and not in

the residue, the first ball that is sticking out of the oven can

be cooled. The platform with cooling dish which is mounted

on the device can be used to accomplish this. By connecting

the glass stopcock to a vacuum source, the boiling point of

thermolabile substances can be suitably reduced.

If the goal of the distillation is the distilled product and not

the residual product in the oven, then you should regulate

the vacuum and not operate under high vacuum conditions

In order to guarantee the longest possible lifespan of the

glass balls, the iris diapharm aperture should not be closed

so tightly that it makes contact with the glass ball or joints

when the rotation drive is turned on.

5.4.6 Working procedure for a rough separation

of a mixture with several components

Mixtures can be partially separated if the difference in the

boiling points between the individual components is fairly

large (> 20C°). All of the glass balls are placed in the oven

except for the glass ball farthest right. The temperature is

increased until distillation begins. The first fraction is caught

in the far right ball. If the vo lu me of the first fraction stops

increasing, then the distillation of the fraction with the lowest

boiling point is complete. The next ball is pulled out of the

oven and the temperature is

increased again.

When working with thermolabile substance, it is also recommended that the boiling point is lowered by connecting to

a suitable vacuum source.

Fig. 20: Aeration stopcook

5.4.7 Aeration

After having finished vacuum distillation (position A), the device is turned off and the aeration cock is turned to position

B. You may now turn off the vacuum pump. By turning to

position C, the distil lation chamber is aerated either with the

air in the environment or, with the corresponding connection,

a safe, inert gas.

21

Page 24

Glass Oven B-585

5 Operation

5.4.8 Working procedure for rotation drying

The vapor duct used for the ball tube distillation must be removed and the vapour duct for rotation drying installed in order to

do rotation drying. See Chapter 5.2.3 for information on how

to convert the device.

The material to be dried is placed in the drying flask and the

tube is connected to the vapour duct. The tube is then placed

in the oven and the temperature and speed of rotation are set.

Fig. 21: Rotation drying flask

It is also possible here to work under a vacuum.

5.5 Accessories: Sublimation and freeze drying

5.5.1The sublimation accessory

The vapour pressure of a liquid increases with rising temperature. The same principle applies also to some types of

solid materials. Many of them evaporate when warming up

d

a

c

without previous liquefaction. This feature is called sublimation. Compounds undergoing sublimation change directly from

solid phase to gaseous phase, by-passing the liquid phase.

e

When the gaseous phase is cooled, the liquid phase is again

by-passed and the material condenses as a crystalline solid.

b

Fig. 22 : Sublimation accessory

f

The sublimation accessory is inserted into the drying tube

(2) instead of the end cover with the bottle connection (1).

The solid re-sublimates out on the cooling finger (3), which

is cooled with water supplied at the inlet at the side, (4) and

removed again at the inlet at the top . A stopcock (5) has

been installed to permit evacuation and aeration, Because

sublimations are generally carried out under vacuum, care

must be taken to see that the O-ring flange gasket (6) has

been inserted properly into the holder. Like the drying accessory, the complete sublimation accessory is inserted into

the oven.

5.5.2 Principle of the sublimation

In sublimation, the mixture that is to be cleaned is put into

the drying flask and spread out, The cooling finger is then

introduced into the drying flask and properly sealed with the

flange bolting. When working under vacuum, it is necessary

to check that the gasket ring is properly seated in its groove.

Next, the sublimation accessory is inserted into the drying

oven. The cooling water is connected up and vacuum applied. The inlet and the side should be selected as the cooling

water inlet. Sublimation is then started by switching the heater

on. The temperature is steadily raised until the substance

re-sublimates on the cooling finger. Once sublimation has

been completed, the heater is switched off and the flask is

aerated. The sublimation accessory is pulled from the oven

and cooled. The sublimate can now be removed from the

cooling finger.

22

Page 25

Glass Oven B-585

Fig. 23: The freeze drying accessory

5 Operation

5.5.3 The freeze drying accessory

The freeze drying process is a technical procedure for the

removal of water. The aqueous solution is cooled down,

until it freezes to ice. Now the air pressure over the ice is

decreased by connecting a vacuum source, whereby the ice

is sublimated from the frozen solution. The dryed material

can be resolved again in water.

The freezing drying process is the most careful and safest

procedure, in order to dry products. The physical phenomenon of sublimation is used.

5.5.4 Operation method of freeze drying

The first step of each freee drying process is the complete

freezing of the product which preferably happens in the

freeze drying tube.

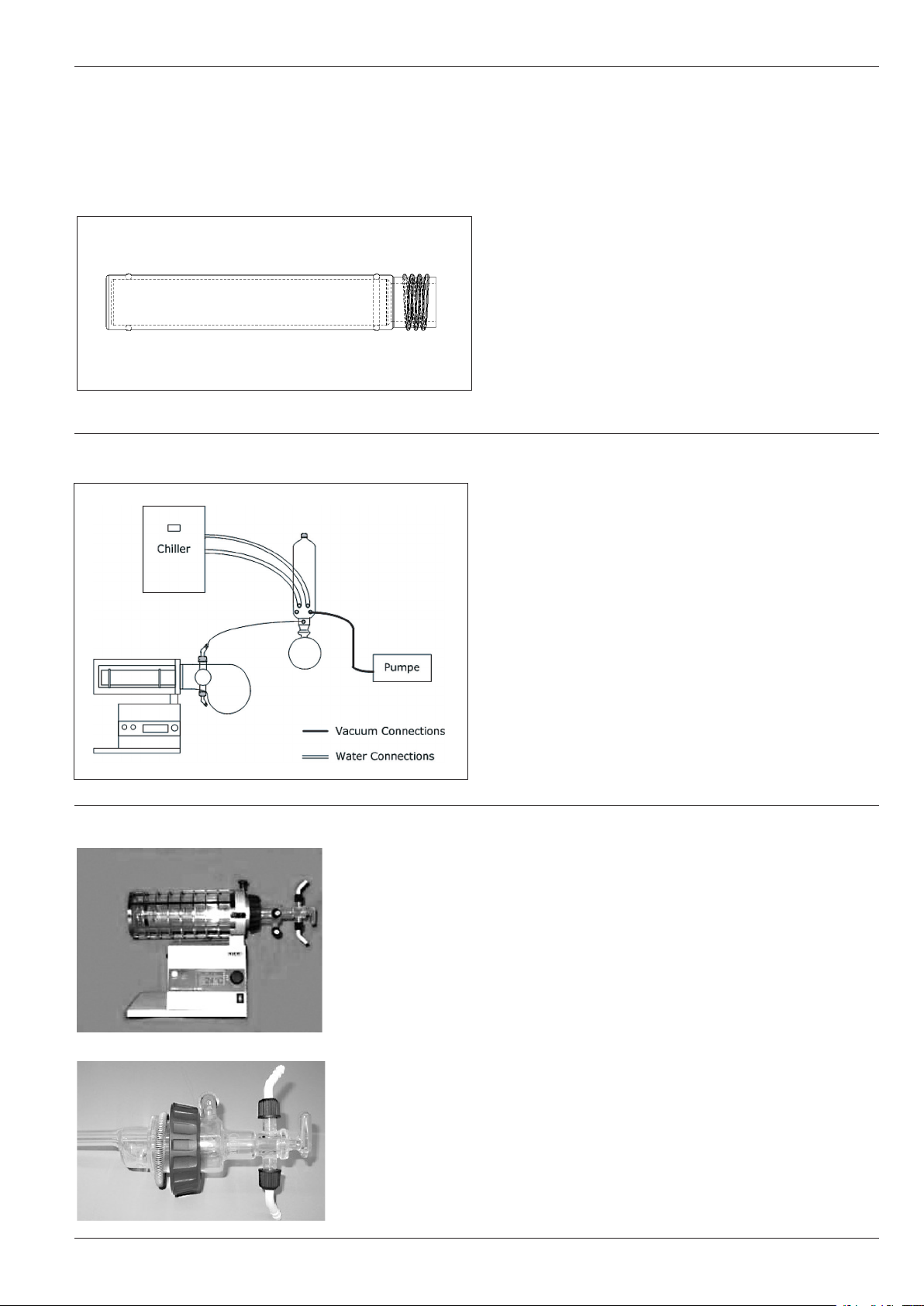

Fig. 24: Scheme of freeze drying

Before the freezing drying process starts, the system (pump,

Chiller) must have reached steady state. The chiller must be

cooled down to operation temperature of -30°C to -40°C

and the vaccum pump should be warm, before evacuation.

If the samples is in frozen condition in the freeze drying tube,

the B-585 is evacuated. The vacuum which can be chosen

depends upon the freezing point of the product. Set a vacuum pressure, which ensures a product temperature 10

degrees below the melting point during the drying process.

5.6 Converting the Glass Oven

5.6.1 From the drying configuration to sublimati-

on configuration

With the help of the sublimation accessory samples that sublime onto the cooling finger may be separeted from a mixture.

For additional cooling of the cooling finger, water can be used.

When using cooling water, the upper hose connection should

always be used as the water’s outlet.

Fig. 25: Glass oven with sublimation accessory

Sublimation processes usually require the use of vacuum. Ensure

that the O-ring seal is inserted properly into its groove before

the two glass parts are flanged together.

Once the sublimation has finished, switch off and leave the

instrument to cool down. Pull out the drying accessory and

install the flange on the sublimation accessory.

23

Page 26

Glass Oven B-585

5 Operation

5.6.2 From drying to freeze drying

The freeze drying accessory is immersed into the drying

accessory and the vacuum is put on.

5.6.3 From drying configurationto Kugelrohr

configuration

First of all switch off the instrument and let it cool down (if

it is necessary)

Fig. 26a:

Fig. 26b: Screw on sleeves

Removing drying accessory

The complete drying part has to be removed

· screw in the two sleeves, to faciliate the moving of the

drive unit.

· The iris diaphragm can be screwed on

Fig. 26c: Iris diaphragm with fixing screw

24

Page 27

Glass Oven B-585

2

7

1

Fig. 26d: Drive unit with sleeves positioned

5

4

5 Operation

· To install the drive unit, remove the connection (2) at the

end of the rods (1), insert the rods into the openings (3)

on the glass oven. Fix up the connection (2) again on

the rods.

3

· The cooling plate assembly (4) is fastened to the openings (5) in the support frame

Fig. 26e: Cooling device

Fig. 26f: Socket for plug in the drive unit

The connection cable (7) for the drive unit has to be plugged

into the lower plug socket (6) on the left side of the instrument (drive).

6

5.6.4 From Kugelrohr configuration to drying

configuration

Converting from ball tube distillation to drying is done by following the instructions in Chapter 5.3.2 in the opposite order.

To find out how to operate the drying oven, see Chapter 5.3.

25

Page 28

Glass Oven B-5856 Maintenance

6 Maintenance

All guidelines which are meant to keep the glass oven in working

order should be followed. This also includes a periodic cleaning

and checking for any visible damage.

6.1 Cleaning

The housing of the B-580 glass oven is coated with paint. Clean

only with dry rag or a rag moistened with alcohol.

While cleaning the oven, you should make sure that the iris dia phra gm does not become dirty.

The inner oven space is best clea ned with a moist rag. Any kind

of solvent may be used to do so.

Never rinse the oven out with running water or wash it using a

lot of water. Water could get between the outer and inner glass

layers where the heater is and cause an electrical short circuit.

If water should accidentally get in the iris diaphragm, you should

dry it out by placing the entire oven in a vacuum (vacuum drying

cabinet) at 40°C for several hours before you start using it again.

6.2 Service

The service of the device is limited to the ball tube drive, in which

the vacuum gasket and the rubber seal in the GL 14 may leak

after prolonged usage.

6.3 Customer service

The device may only be serviced by authorized service personnel. Such persons will have undergone fundamental technical

trai ning and have knowledge of the hazards associated with

not fol lowing the safety precautions. Büchi customer service

centres have device-specific service instructions which can only

be obtai ned by authorized personnel.

The addresses of the official Büchi customer service centres can

be found on the back cover of these instructions. Contact one

of these locations in case you encounter malfunctions or if you

have technical questions, or application-specific problems.

The Customer Service Department of the Büchi company is

available for the following services:

• Replacementparts(pleaseusethepartnumberslistedinthe

replacement parts list in the Appendix)

• Repairservices

• Maintenanceservices

• Technicalconsulting

26

Page 29

Glass Oven B-585 7 Taking out of operation

7 Taking out of operation

The device must be cooled down and thoroughly cleaned.

7.1 Storage/Transport

The device must be stored and transported in the original packaging, and must be thoroughly clean.

7.2 Disposal

To dispose of the glass oven in an environmentally friendly manner, you will find a list of the materials of all major parts in Chapter

9, Appendix. This guarantees that you can separate the parts

for recycling. To dispose of electrical parts, refer to the appropriate guidelines. You also must observe the regional and local

laws regarding disposal.

27

Page 30

Glass Oven B-5858 Replacement parts

complet Nr. 37010

02970

37287

36765

8 Replacement parts

Only original replacement parts that guaran tee the safe use and

functionality of the device. The use of replace ment parts and

supplies other than Büchi replace ment parts and supplies is only

allowed with the consent of the manufactu rer. For assembly and

dis assem bly purposes, replacement parts may only be used

accor ding to the descriptions in Chapter 6, Maintenance. The

manu facturing of this product, as described in these in struc tions, is prohibited.

8.1 B-585 Drying configuration replacement parts

Drying accessory complete 37010

Drying tube 02965

Flange ring 02970

10 Device fuses 3,15 AT 19659

End cap for drying 36765

Stopcock 37132

Set compr. Flange screw, spring and flange seal 37285

Set STJ clips (12 pieces) 37286

Set hose nipples GL 14 (4 pieces) 37287

02965

Fig. 27: Drying unit complete

37132

3728637285

28

Page 31

Glass Oven B-585 8 Replacement parts

8.2 B-585 Kugelrohr configuration replacement

37118

37101

37102

37286

37073

parts

Description Order Code

10 ml ball tube (Ns 14.5/23)

with vapour duct and clips 37118

37107

37104

37106

37286

37073

20ml ball tube (Ns 14.5/23)

with vapour duct and clips 37107

37117

37143

Fig. 28: Kugelrohr

Fig. 29: Hose connection assembly with stopcock

36478

37288

36480

36771

36479

37286

37286

37286

37132

37287

37073

37125

40ml ball tube (Ns 14.5/23)

with vapour duct and clips 37117

Rotation drying flask with vapour duct and

clip 37143

Communication cable B-585/V-5xx 46728

10 Device fuses 3,15 AT 19659

Connection piece 36771

Stopcock 37132

Cooling dish 37152

Set STJ (12 pieces) 37286

Set hose nipples GL14 (4 pieces) 37287

Set vacuum gaskets (5 pieces) 37288

Nozzle cap 36824

Chlambing cone 36770

complet 37133

36766

02965

Fig. 30: Sublimation accessory complet

37285

37287

37286

37132

8.3 Sublimation accessory replacement parts

Complete sublimation accessory 37133

Drying tube 02965

Flange ring 02970

Sublimation insert 36766

Cock 37132

Set flange screw, spring, gasket 37285

Set STJ (12 pieces) 37286

Set hose nipples GL14 (4 pieces) 37287

29

Page 32

Glass Oven B-585

9 Appendix

9 Appendix

9.1 Technical data

Supply voltage 100 - 230 VAC +/-10 %

Frequency 50/60 Hz

Power max. 450 W

Pin assignment Pin 1: Ground (Gnd)

Pin 2: + 24 V DC

Pin 3 to 8: not assigned

Warm-up time ca. 10 min. (from 20°C to 300°C)

Temperature regulation range 40-300°C

Temperature accuracy +/- 5°C (in the middle of the oven at 300°C)

Drying Drying volume max. 100-250 ml

Dimensions 410 x 300 x 300 (width x depth x heigth)

Weight 9.5 kg

Kugelrohr Distillation volume max. 10-60ml

Rotational speed 0-50 rpm.

Dimensions 650 x 300 x 300 (width x depth x heigth)

Weight 11.5 kg

Ambient temperature 5-40°C

Installation category II

Pollution degree 2

Environmental conditions for indoor use only, altitude up to 2000 m.

maximum relativ humidity 80% for temperatures up to 30°C

decreasin linearly to 50% relative humidity at 40°C

9.2 Error messages

Error message Possible cause Remedy

Main switch dors not Device is turned off, power supply Switch on the device, check power supply

light up voltages is missing or fuse defective voltage and fuses

No temperature Display or print defective Check power supply voltage/fuses and replace them,

indication send device to service center

Oven does not heat Nopower supply voltage or fuses Check heating leed,

defective

Motor does not turn Device is turned off, no mains voltage Switch on the instrument,

or fuses devective, motor set is on checkt the controll cable,

0 r/min, controll cable is not pluged please contact the service department

in properly,

E1 Internal temperature sensor defective Please contact service department

E2 Internal temperature sensor defective Please contact service department

E3 Internal temperature sensor defective Please contact service department

E9 Heating cefective Please contact service department

E10-11 Heating cefective Please contact service department

30

Page 33

Glass Oven B-585

9.3 Materials used

Description Materials Material code

Housing Steel sheet metal ST 12

Heating tube Borosilicate glass

Glass jacket tube Borosilicate glass

Cooling dish Hard-polyethylene HD-PE

Heater fixture (site) Aluminium ALMGSI 1

Kugelrohr-Insert Aluminium ALMGSI 1

Kugelrohr-housing Polyacetal POM

Heating flange Aluminium ALMGSI 1

9 Appendix

31

Page 34

Glass Oven B-585

9 Appendix

32

Loading...

Loading...