Page 1

FACSIMILE EQUIPMENT

SERVICE MANUAL

MODEL: MFC5200C/MFC890

Page 2

© Copyright Brother 2002

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing

from the publisher.

Specifications are subject to change without notice.

Page 3

PREFACE

This publication is a Service Manual covering the specifications, construction, theory of operation,

and maintenance of the Brother facsimile equipment. It includes information required for field

troubleshooting and repair--disassembly, reassembly, and lubrication--so that service personnel

will be able to understand equipment function, to rapidly repair the equipment and order any

necessary spare parts.

To perform appropriate maintenance so that the facsimile equipment is always in best condition

for the customer, the service personnel must adequately understand and apply this manual.

This manual is made up of eight chapters and appendices.

SAFETY INSTRUCTIONS

CHAPTER 1 PARTS NAMES & FUNCTIONS

CHAPTER 2 SPECIFICATIONS

CHAPTER 3 INSTALLATION

CHAPTER 4 THEORY OF OPERATION

CHAPTER 5 MAINTENANCE

CHAPTER 6 DISASSEMBLY/REASSEMBLY, LUBRICATION, AND ADJUSTMENT

CHAPTER 7 MAINTENANCE MODE

CHAPTER 8 TROUBLESHOOTING

Appendix 1. Serial No. Descriptions

Appendix 2. Installation

Appendix 3. EEPROM Customizing Codes

Appendix 4. Firmware Switches (WSW)

Appendix 5. Re-packing Instructions

Appendix 6. Wiring Diagram

Appendix 7. Circuit Diagrams

This manual describes the models and their versions to be destined for major countries. The specifications

and functions are subject to change depending upon each destination.

Page 4

SAFETY INSTRUCTIONS

SAFETY PRINCIPLE

1) Before starting any operations, read this manual thoroughly. Especially read the safety instructions in this

section carefully and ensure that you understand the contents.

2) Perform all the operations by following the procedures described in this manual. Follow all the cautions

and warnings set out in the procedures and on safety labels affixed to the machine. Failure to do so may

result in human injury or equipment damage.

3) Perform only the procedures explained in this manual. Refrain from opening or touching any portions that

are not related to your required operation(s).

4) Repair and replacement of parts should be performed by trained and qualified persons only.

Operators should not attempt to do such repair or replacement work.

5) It must be appreciated that the above-mentioned cautions and warnings do not cover everything because it

is impossible to evaluate all the circumstances of repair situations.

SPECIAL SAFETY INFORMATION

Cautions and warnings are made clear by following the 'Safety Alert Symbols' or 'Signal Words' such as

DANGER, WARNING and CAUTION.

1) SAFETY ALERT SYMBOL

This is the safety alert. When you find this symbol placed on the equipment or marked in this manual, be

aware of the potential of human injuries. Follow the recommended precautions and safety operation

practices.

2) Understanding Signal Words

DANGER is used to indicate the presence of a hazard which will cause severe human injuries or a fatal

accident if the warning is ignored.

WARNING is used to indicate the presence of a hazard or unsafe practices which may cause severe

human injuries or a fatal accident if the warning is ignored.

CAUTION is used to indicate the presence of a hazard or unsafe practices which may cause minor human

injuries if the warning is ignored. CAUTION also calls your attention to safety messages in this manual.

Page 5

3) Follow Safely Instructions

Carefully read all the safety messages set out in this manual and also in the safety warning signs placed

on the equipment. In this manual, the safety instructions (safety alert symbols and signal words) are

enclosed in a rectangular enclosure to bring them to your attention.

Keep the safety signs on the equipment in good condition and ensure none are missing or damaged.

Replace the safety signs if unreadable or damaged. Learn how to operate the equipment and how to use

the controls properly. Do not let anyone operate this equipment without following the instructions. Keep

the equipment in proper working condition.

Unauthorized modification to the equipment may impair the function & safety and affect the life of the

equipment.

Listed below are the various kinds of "WARNING" messages contained in this manual.

4) Caution for the battery

There is a danger of explosion if the battery is incorrectly replaced. Do not replace the battery. Do not

disassemble, recharge or dispose of in fire.

Used battery should be disposed of according to local regulations.

Page 6

WARNING

f

HAZARDOUS VOLTAGE

May cause serious injuries or fatal accidents. Voltage is now applied from the power

supply of machine. There is a danger of electrical shock if you touch the active area

inside the machine.

Be sure to turn the power supply switch OFF and pull the plug out from the power outlet

before starting maintenance work on the machine.

CAUTION

ROTATING PARTS

Be aware of the potential danger of various rollers and take care not to get your fingers or

hand caught into the machine, this can cause serious injuries. Note that the exit roller that

ejects the printed paper is rotating while printing.

Be careful not to get your hair, fingers, hands, sleeve or necktie caught in the machine

while operating the machine.

CAUTION

POWER CORDS & PLUGS

This machine is equipped with a 3-wire power cord fitted with a 3-pronged plug (bi-polar

plug with grounding) for the user’s safety.

Use these power cords in conjunction with a properly grounded electrical outlet to avoid

an electrical shock.

CAUTION

SAFETY INTERLOCK

The scanner unit of this machine have electrical safety interlocks to turn the power of

whenever they are opened.

Page 7

CHAPTER

PARTS NAMES & FUNCTIONS

1

Page 8

CHAPTER 1 PARTS NAMES & FUNCTIONS

CONTENTS

1.1 EQUIPMENT OUTLINE ...................................................................................................1-1

1.2 CONTROL PANEL........................................................................................................... 1-3

Page 9

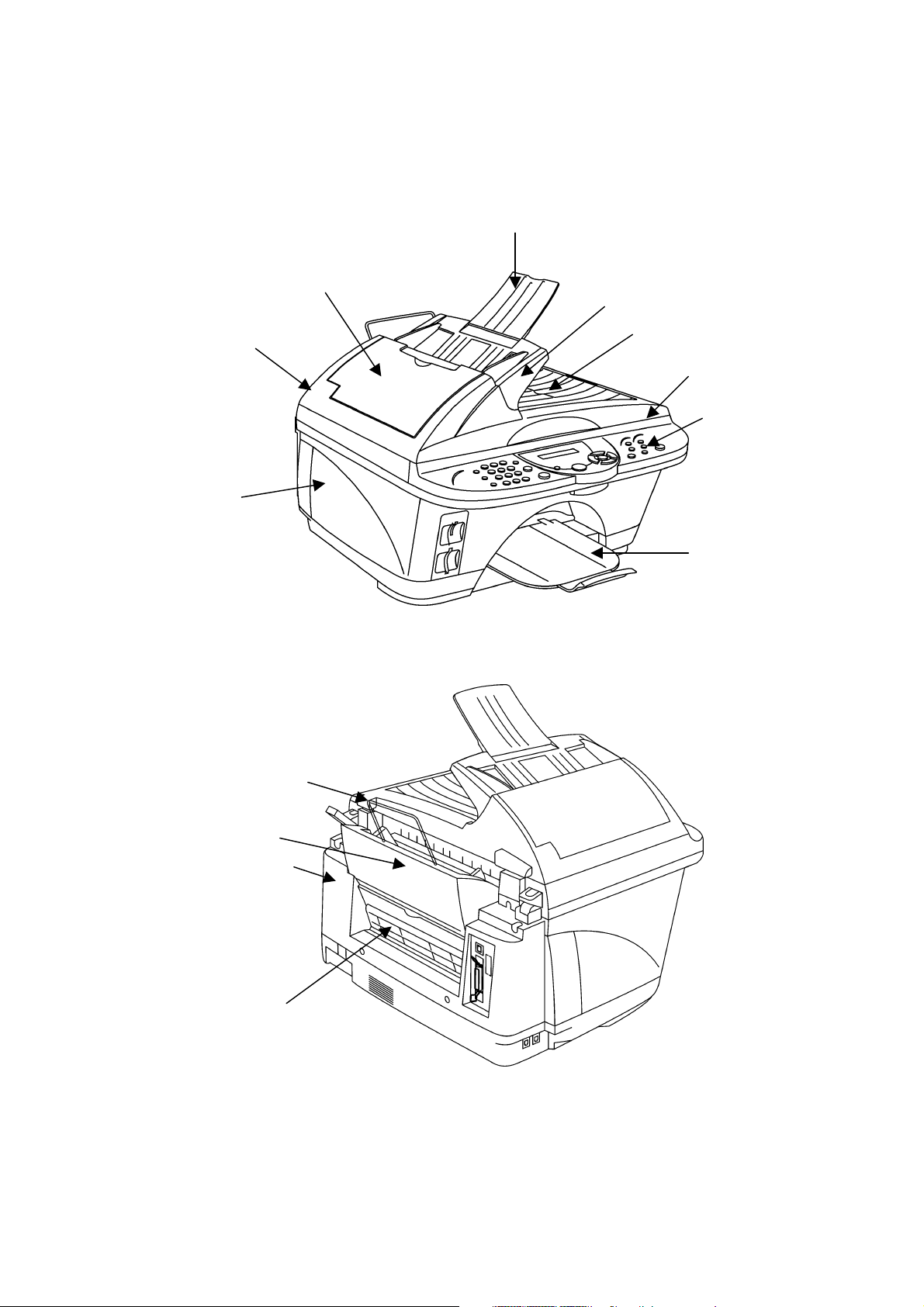

1.1 EQUIPMENT OUTLINE

Front view

3. ADF document support

8. Main cover

Rear view

2. ADF cover

4. Document guide base

5. Document tray

1. ADF

6. Scanner unit

7. Control panel

9. Output paper support

10. Paper support

11. Paper tray

12. Rear cover

13. Manual feed slot

1-1

Page 10

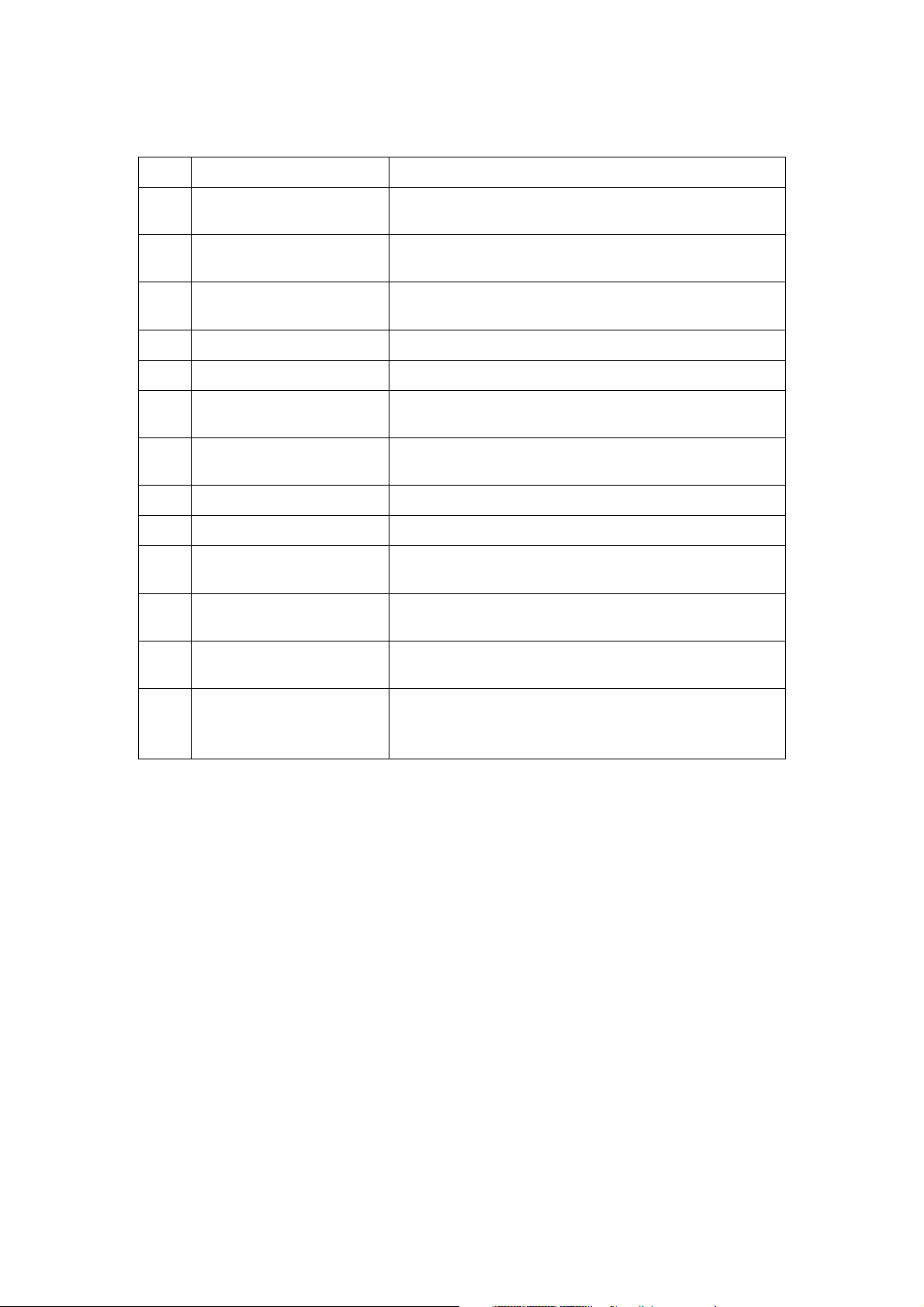

No. Part name Outline of functions

1 ADF

2 ADF cover

3 ADF document support

Automatically feeds the document sheet by sheet to

the reading unit.

Open this cover when removing jammed documents

from the ADF.

Supports the documents fitted to the ADF so that they

do not bend.

4 Document guide base Adjusts the document position to the center of ADF.

5 Document tray Stores the read documents.

6 Scanner unit

7 Control panel

Indicates the whole reading unit including the control

panel. Open this unit when changing the ink cartridge.

Displays the machine operation status and is used to

operate the machine.

8 Main cover Indicates the whole enclosure of the machine.

9 Output paper support Stores the printed sheets of paper.

10 Paper support

11 Paper tray

Supports the paper fitted to the paper tray so that they

do not bend.

Automatically feeds the paper sheet by sheet to the

printing unit.

12 Rear cover

13 Manual feed slot

Indicates the rear enclosure. Open this cover when

doing maintenance work.

Used to feed the paper sheet by sheet manually.

Open the slot cover when removing jammed paper

from the machine.

1-2

Page 11

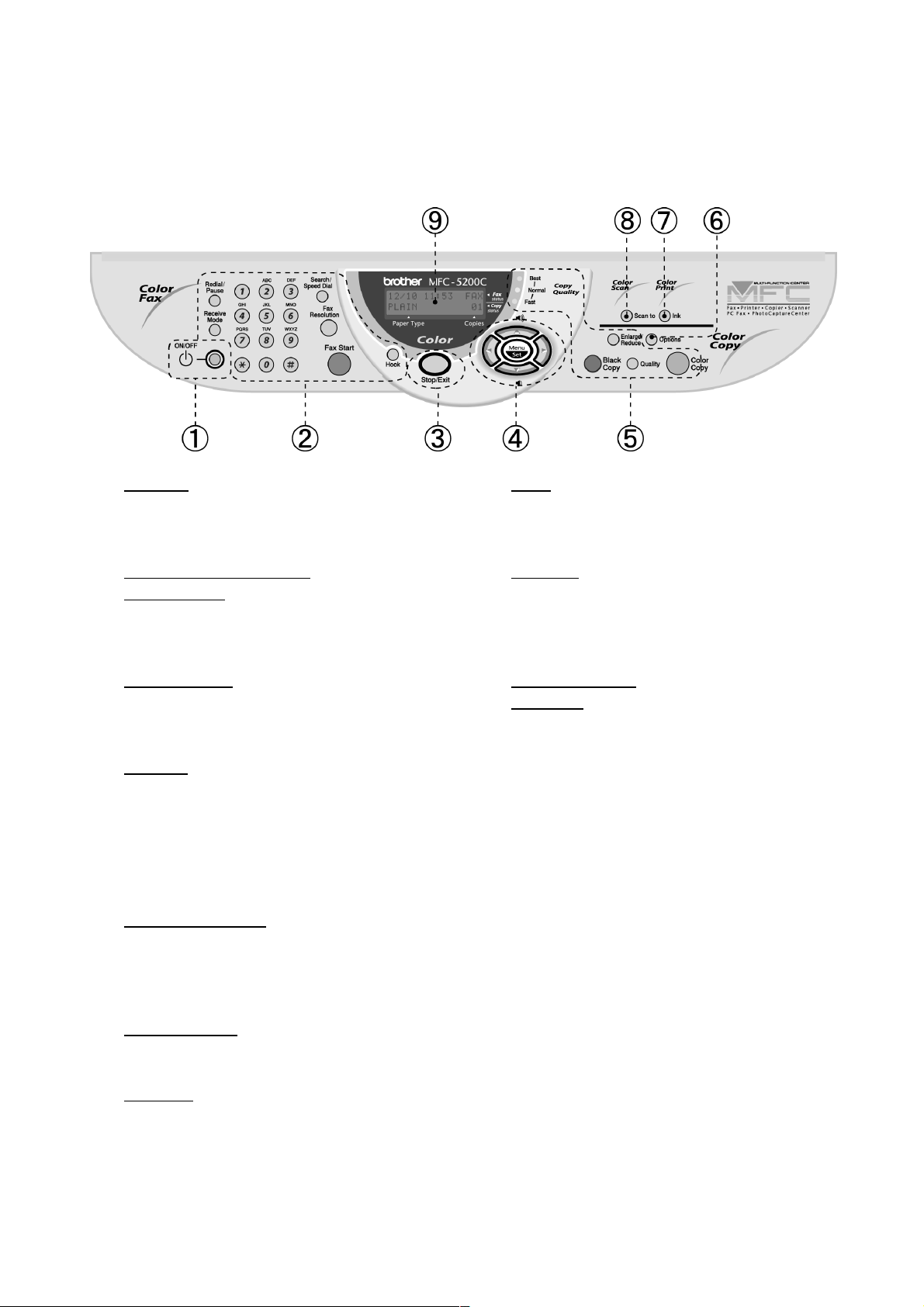

1.2 CONTROL PANEL

ON/OFF

You can turn the MFC on or off.

Fax and telephone keys:

Redial/Pause

Redials the last number you called.

It also inserts a pause in auto dial numbers.

Receive Mode

Use to select how the MFC will handle

incoming calls.

Dial Pad

Use this to dial telephone and fax numbers and

as a keyboard for entering information into the

MFC.

The # key lets you switch the dialing type

during a telephone call from Tone to Pulse

Search/Speed Dial

Lets you look up numbers that are stored in the

Dialing memory. It also lets you dial stored

numbers by pressing # and a two-digit number.

Hook

Lets you dial numbers without picking up the

handset.

Stop/Exit

Stops a fax, cancels an operation or exits from

the Menu.

Navigation keys:

Menu/Set

Lets you access the Menu to program and store

your settings in the MFC.

Press to scroll forward or backward to a menu

selection.

Also, you can use these keys to do an

alphabetical search for the names of stored

numbers.

Volume

Press to scroll through the menus and options.

When using the speaker, you can press these

keys to adjust the volume.

Fax Resolution

Sets the resolution when you send a fax.

Fax Start

Starts an operation, such as sending a fax.

1-3

Page 12

Copy keys (Temporary settings):

Quality

Use this key to temporarily change the quality

for Copying.

Color Print key:

Ink

Lets you clean the print heads, replace an ink

cartridge and check the available ink volume.

Quality indicator lights

These lights show the copy quality you

selected with the Quality key.

Enlarge/Reduce

Lets you enlarge or reduce copies depending

on the ratio you select.

Black Copy

Makes a black-and-white copy.

Color Copy

Makes a full-color copy.

Options

You can quickly and easily select temporary

settings for copying or Photo Capture

TM

Center

.

Scan key:

Scan to

Lets you scan the next original and select the

destination in your computer.

(Such as a Word processing, graphics or E-

mail application, Media card or on a Network.)

Liquid Crystal Display (LCD)

Displays messages on the screen to help you

set up and use your MFC.

1-4

Page 13

CHAPTER

SPECIFICATIONS

2

Page 14

CHAPTER 2 SPECIFICATIONS

CONTENTS

2.1 GENERAL ........................................................................................................................2-1

2.1.1 General Specification ...........................................................................................2-1

2.1.2 Paper Specification ..............................................................................................2-1

2.1.3 Printable Area.......................................................................................................2-3

2.1.4 Environmental Condition ......................................................................................2-4

2.2 OTHERS...........................................................................................................................2-5

Page 15

2.1 GENERAL

2.1.1 General Specification

Memory Capacity

Automatic Document Feeder (ADF) up to 30 sheets (20 lb)

Paper Tray 100 Sheets (20 lb)

Printer Type Ink Jet

Print Method Configuration Piezoelectric ceramic drive with 150 x 4 nozzles

LCD (Liquid Crystal Display) 16 characters x 2 Lines

Operating Environment 50-95ºF (10-35ºC)

Best Print Quality 68-91ºF (20-33ºC)

Power Source 120VAC 50/60Hz (U.S.A., Canadian Version Only)

8MB

240VAC 50/60HZ(Except U.S.A., Canadian Version)

Power Consumption Minimum: under 5 watts

(When Power Switch (ON/OFF) is turned off.)

Standby: under 15 watts

Operating: under 50 watts

Dimensions 19.4 x 18.3 x 14.9 (inches)

492 x 466 x 378 (mm)

Weight 28.6 1b/13 kg

2.1.2 Paper Specification

Recommended paper

Plain Paper: Xerox 4200

Inkjet Paper: KODAK® Premium Inkjet Paper (Matte)

Glossy Paper: JETPRINT PHOTO®

Graphic image paper - Gloss Finish

Transparencies: 3M Transparency Film (CG3410)

2-1

Page 16

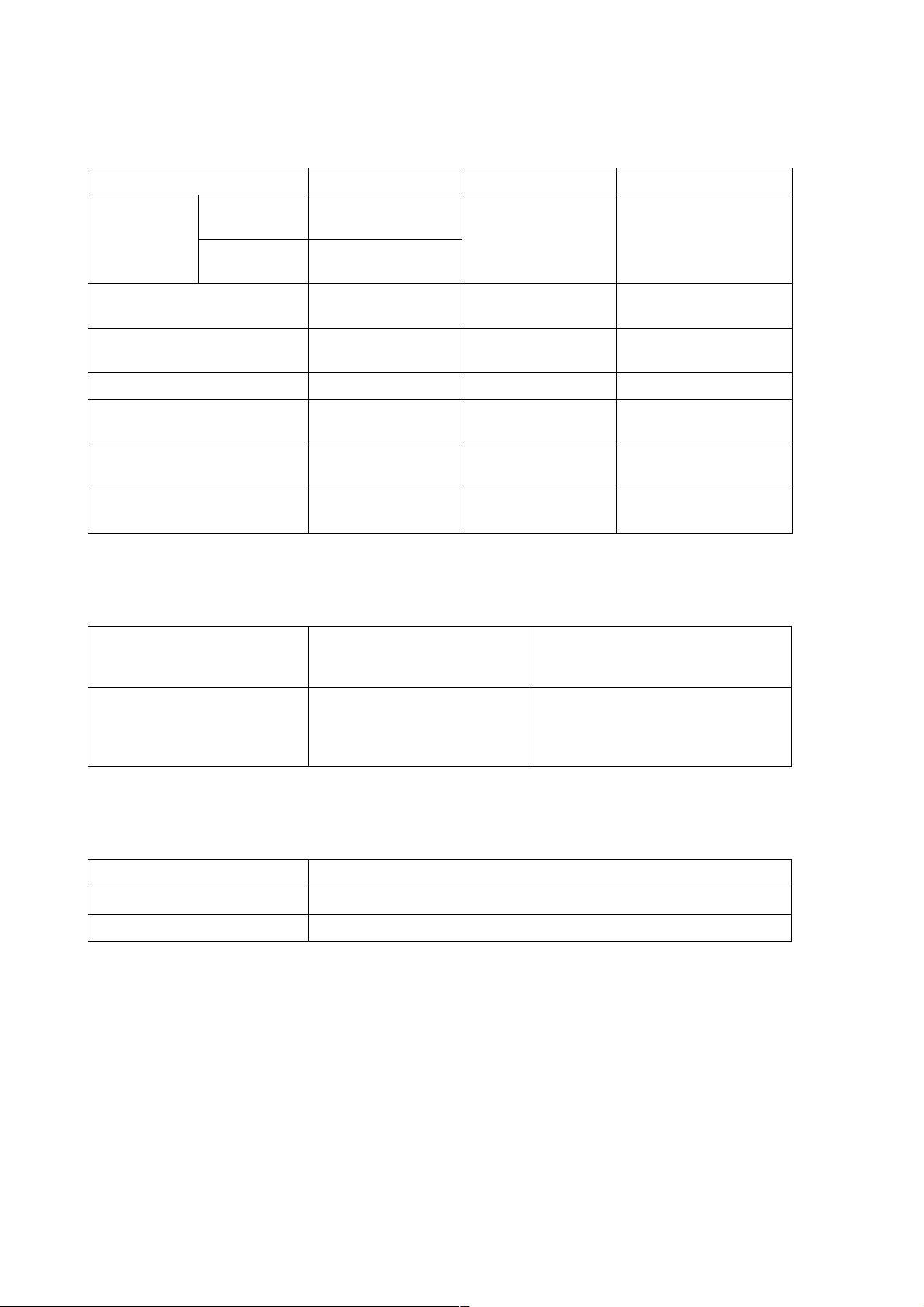

Paper capacity and specifications of the Paper Tray

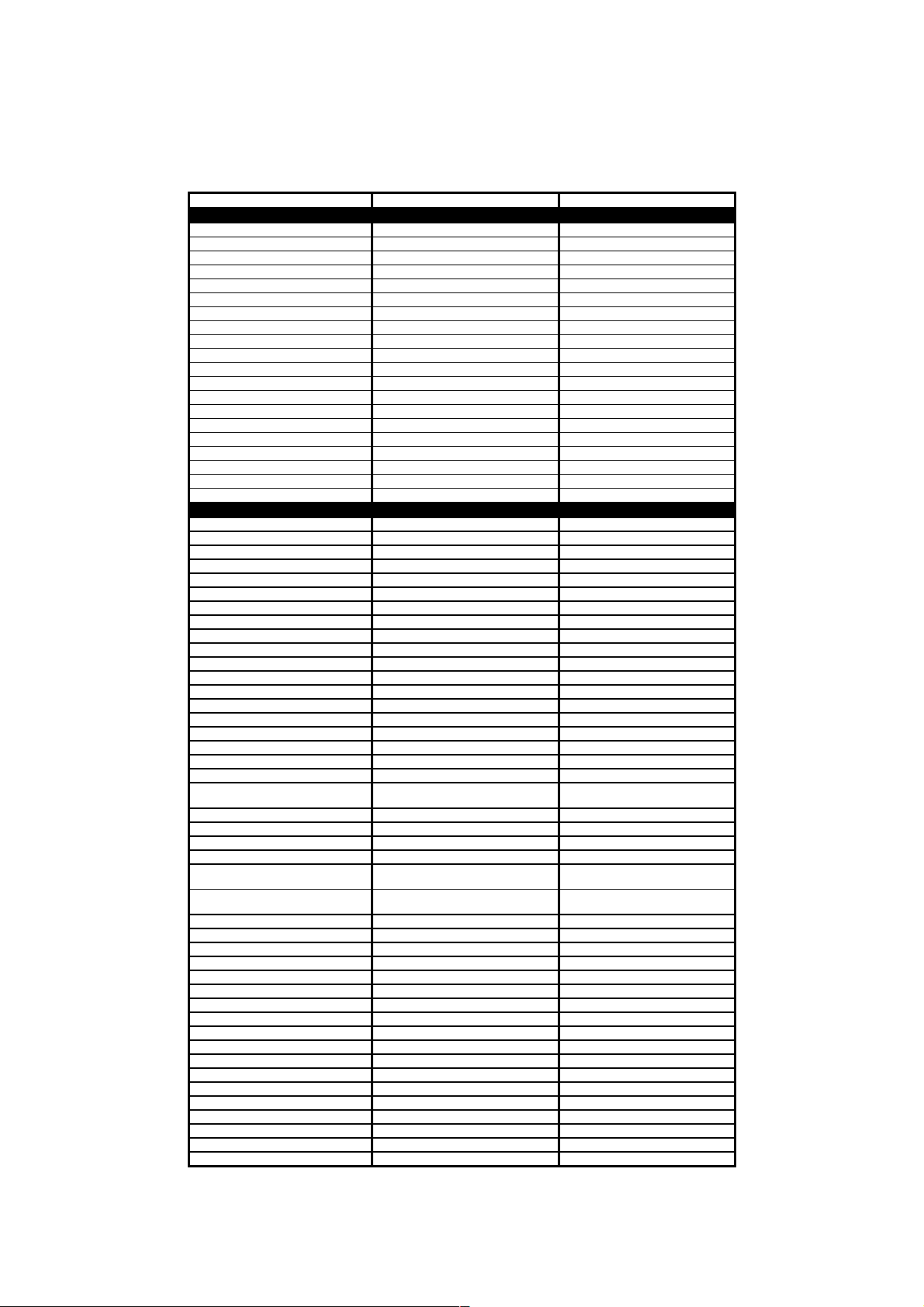

Paper Type Number of sheets Paper Weight Paper Thickness

Letter

Executive

Plain Paper

Legal

Inkjet Paper (Letter) 20

Glossy Paper (Letter) 20

Transparencies (Letter) 10

Envelopes (DL, COM-10, C5,

Monarch)

Postcard 4" x 6" 30

Index Card 5" x 8" 30

Paper stack specifications for the Paper Tray

Paper tray

100 of 20 lb

(80 g/m 2 )

50 of 20 lb

(80 g/m 2 )

10

Up to 0.39 in. (10 mm)

Up to 100 sheets of 20 lb

(80 g/m 2 )

17 to 32 lb

(64 to 120 g/m 2 )

17 to 32 lb

(64 to 120 g/m 2 )

Up to 40 lb

(150 g/m 2 )

Up to 45 lb

(170 g/m 2 )

Up to 32 lb

(120 g/m 2 )

0.003 to 0.006 in.

(0.08 to 0.15 mm)

0.003 to 0.006 in.

(0.08 to 0.15 mm)

Up to 0.007 in.

(0.18 mm)

Up to 0.02 in.

(0.52mm)

Up to 0.009 in.

(0.23 mm)

Up to 0.006 in.

(0.15 mm)

(Transparencies and glossy paper must

Output paper support

Paper specifications for the manual feed slot

Paper Width 3.5 to 8.5 in. (89 to 216 mm)

Paper Height 4 to 14 in. (102 to 356 mm)

Paper Thickness 0.005 to 0.01 in. (0.12 to 0.25 mm)

You have to remove paper from the paper tray and load one sheet at a time.

Up to 50 sheets of 20 lb

(80 g/m 2 )

be picked up from the output paper

support one page at a time to avoid

smudging.)

2-2

Page 17

2.1.3 Printable Area

The printable area depends on the settings in the application you are using. The figures below show the

unprintable areas on cut sheet paper and envelopes.

Paper Paper size Top Bottom Left Right

Fax 0.12 0.47 0.25 0.25

Letter, Legal

Cut sheet

Executive Printer 0.12

Post card 4" x 6" Printer 0.12

Envelopes DL,C5,COM10 Monarch Printer 0.39 0.79 0.12 0.12

* When you set the Near Edge feature to ON.

Printer 0.12

Copy 0.12

0.47

(0.12)*

0.47

(0.12)*

0.47

(0.12)*

0.47

(0.12)*

0.23 0.23

0.23

(0.12)*

0.12 0.12

0.12 0.12

0.23

(0.12)*

Printer depends on the Printer driver.

The figures above are approximate and the printable area may vary depending on the type of cut sheet paper

you are using.

2-3

Page 18

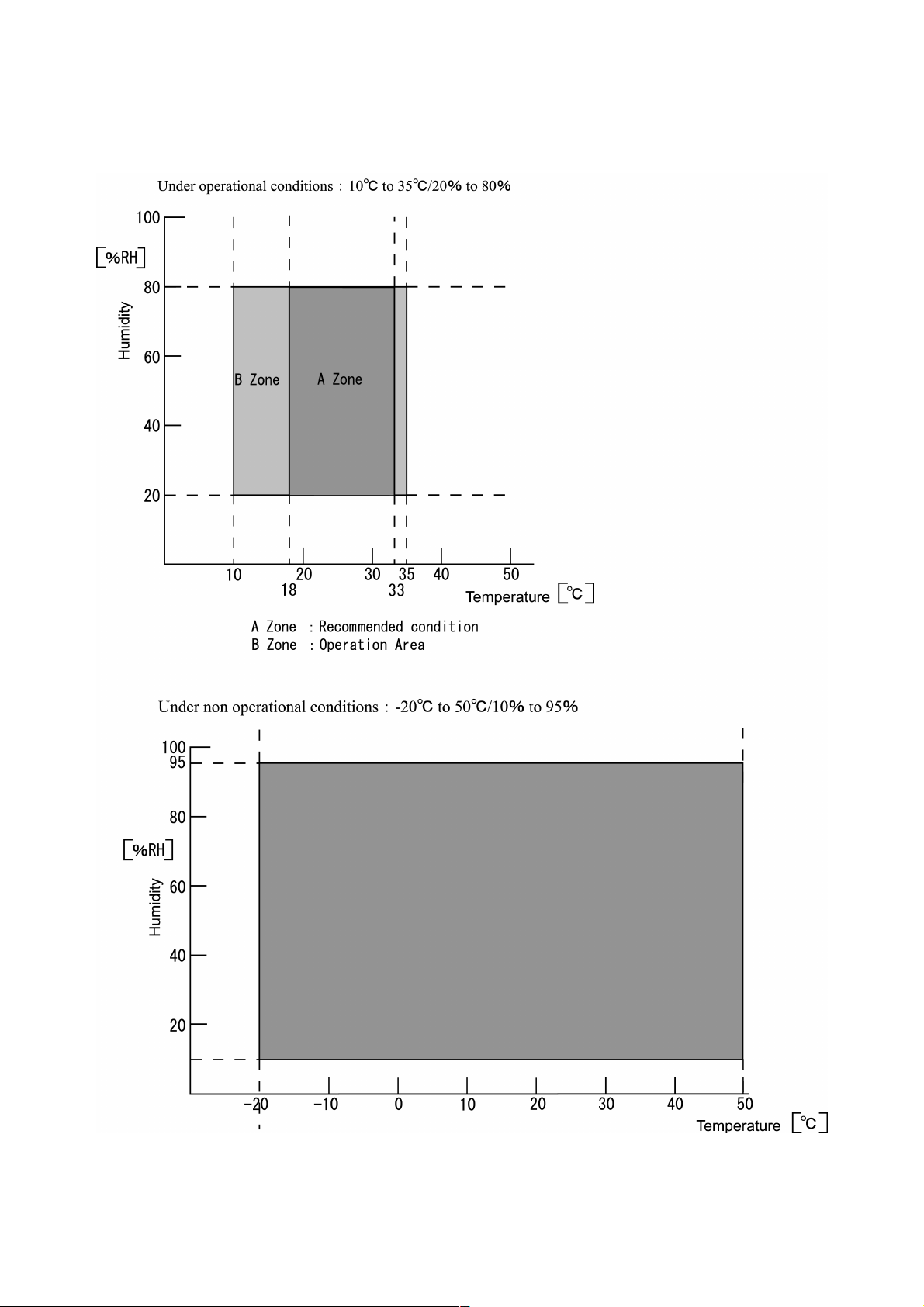

2.1.4 Environmental Condition

2-4

Page 19

2.2 OTHERS

)

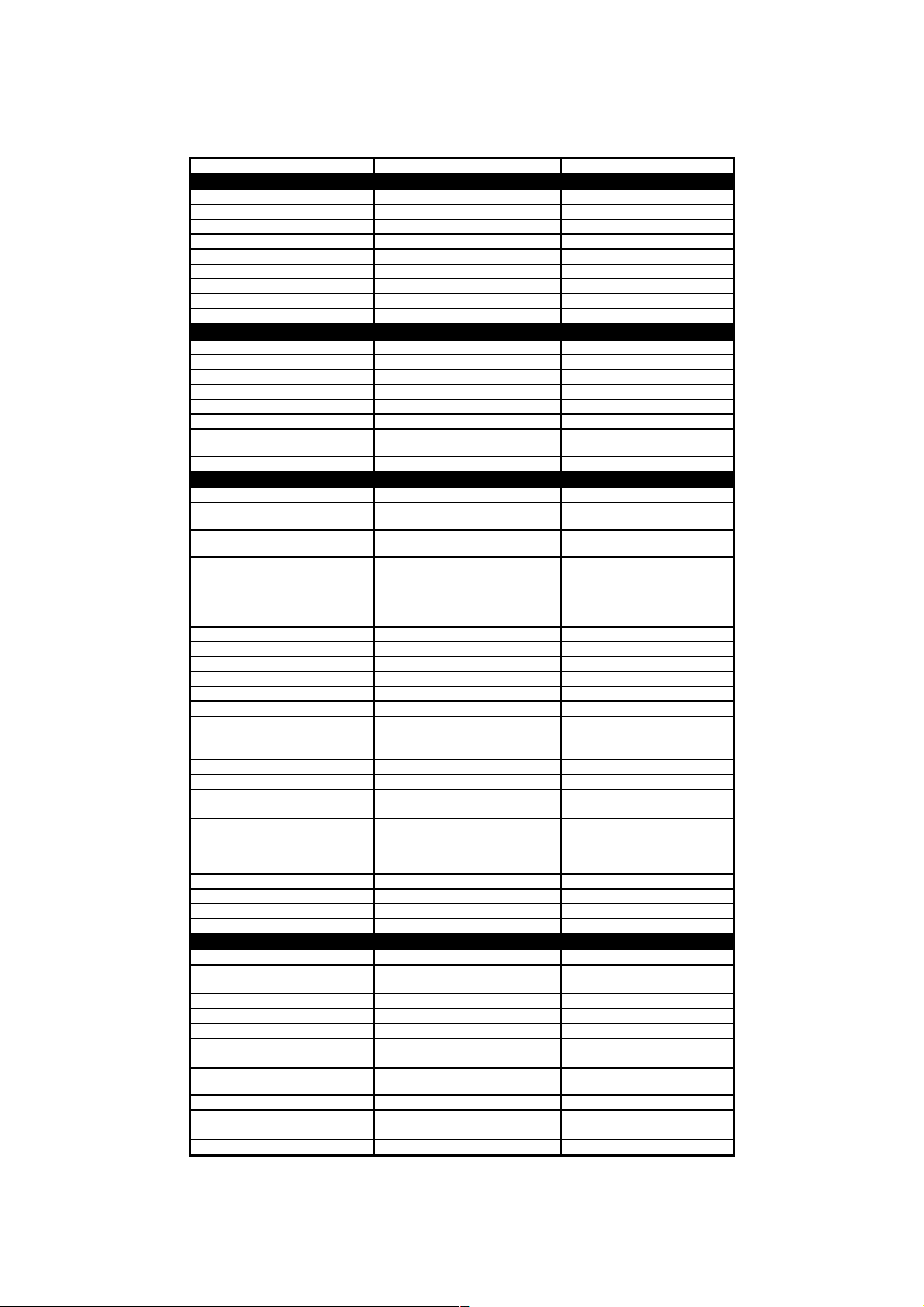

Model Name MFC-5200C MFC-890

TELEPHONE

Automatic Redial Yes(once) Yes

Handset No No

One-Touch Dial 0 0

Speed Dial Max 100 Max 100

Figures of One-Touch & Speed Dial 20 digits 20 digits

Resisterable Number Of Characters 15 char 15 char

Telephone Index Yes(Normal) (TBD) Yes(Normal)

Speaker Phone No(Only Speaker) No(Only Speaker)

Chain Dialing Yes Yes

Caller ID No No

Call Waiting Caller ID No No

Distinctive Ringing Yes Yes

Hold/Mute Key No No

Hook Key Yes TEL/R key (TBD)

Power Failure Dialing No No

Speaker Volume Yes (3 steps + OFF) Yes (3 steps + OFF)

Ring Volume Yes (3 steps + OFF) Yes (3 steps + OFF)

HandSet Volume No No

PBX Feature No Yes

Transfer Method No flash

FAX

Internet FAX LAN Option LAN Option

Data Modem N/A N/A

Easy Receive/Fax Detect Yes Yes

Fax/Tel Switch Yes Yes

Super Fine Yes (Only for Black) Yes (Only for Black)

300dpi Transmission No No

Gray Scale 256 256

Contrast Yes (Auto/S.Light/S.Dark) Yes (Auto/Light/Dark)

Smoothing No No

Call Reservation Over Auto TX No No

Passward Check No No

Enhanced Remote Activate Yes Yes

Multi Resolution Transmission No No

Multi Transmission No No

Next-Fax Reservation Yes (Dual Access) Yes (Dual Access)

Delayed Timer Yes (50 Timer/50 Job) Yes (50 Timer/50 Job)

Polling Yes (Std/Seq) RX/TX Yes (Std/Seq) RX/TX

Quick-Scan key (Memory TX w/o key) (Memory TX w/o key)

Scan Speed (A4:Standard) Approx. 3 sec./page (A4:standard) Approx. 3 sec./page (A4:standard

Memory Transmission(Brother#1

Chart)

Memory Transmission(ITU-T Chart) Yes (400:MMR) Yes (400:MMR)

Broadcasting Yes (150 locations) Yes (150 locations)

Batch Transmission Yes Yes

Auto Reduction Yes Yes

Out-of-Paper Reception (Brother #1

Chart)

Out-of-Paper Reception (ITU-T

Chart)

Dual Access Yes (B&W Only) Yes (B&W Only)

ECM(Error Correction Mode) Yes Yes

ITU SUB Addressing No No

Group Dial Yes (6) Yes (6)

Error Re-Transmission No No

Station ID 1 (20digits/20char) 1 (20digits/20char)

Off Hook Alarm No No

Remote Maintenance Yes Yes

Call Reservation Over Manual TX No No

RX Mode Indication Yes:LCD Yes:LCD

Resolution Indication Yes:LCD Yes:LCD

Memory Security N/A TX Lock

Color FAX (Document nd/Receive) Yes/Yes Yes/Yes

Color FAX (Memory end/Receive) No/Yes No/Yes

Manual Broadcasting Yes Yes

LCD Language English English

Call Manage N/A N/A

E-MAIL FAX(Share Media ervice) N/A N/A

(1/4)

Yes (480:MMR) Yes (480:MMR)

Yes (480:MMR) Yes (480:MMR)

Yes (400:MMR) Yes (400:MMR)

2-5

Page 20

(2/4)

Model Name MFC-5200C MFC-890

LIST/REPORT

Activity Report/Journal Report Yes (up to 200) Yes (up to 200)

Transmission Verification Report Yes Yes

Coverpage Yes Yes

Help List Yes Yes (From MENU)

Call Back Message No No

Caller ID List No No

Auto Dial List Yes(From Menu) Yes (From MENU)

Tel Index List N/A N/A

Order Form ( from MFC) N/A YES(FROM MENU)

INTERFACE

External TAD Interface Yes Yes

Missing Link/PC Interface No No

Host Interface (Serial) No No

Host Interface (IEEE1284) Yes Yes

Host Interface (USB) Yes Yes

LAN Interface Option (10Base-T/100Base-TX) Option (10Base-T/100Base-TX)

Acceptable Media Card Slot

Analog Video Port No No

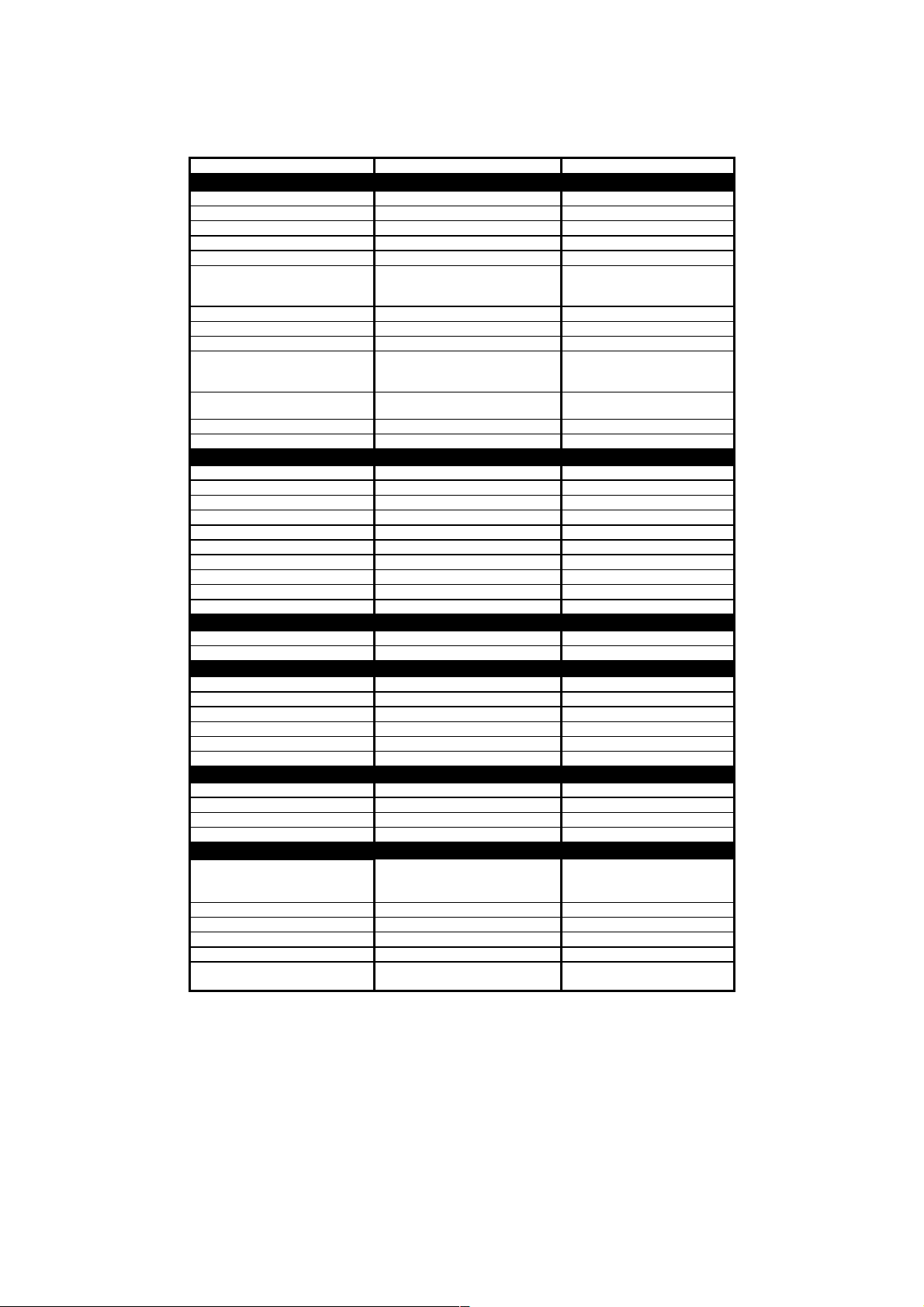

PRINTER

Color/Mono Color/Mono Color/Mono

Engine Type

Resolution(dpi) 2400x1200 /2400x1200 (Mono/Color)

Speed(ppm)

Paper Capacity(sheets) 100 (80gsm) 100(80gsm)

Additional Paper Capacity(sheets) No No

Output Paper Capacity(sheets) 50 50

Standard Print Language Windows GDI Windows GDI

Emulation N/A N/A

Resident Fonts Yes Yes

Fonts Disk Based Yes Yes

Paper Handling Size

Manual Feed Slot Yes (1 sheet feeder) Yes (1 paper feeder)

Other Paper Type OHP, Envelopes OHP, Envelopes

Sheet Weight (Paper Cassette)

(Manual Slot)

Printer Driver

Utility Software N/A N/A

Bundled Cable No No

Variable Dot Print Yes (3 sizes, Min. 5pl) Yes (3 sizes, Min. 5pl)

Shingling Print Yes NO

Color Enhancement Yes (True2Life) Yes (True2Life)

COPY

Color/Mono Color/Mono Color/Mono

Speed(ppm)

Multi Copy(Stack) Yes (Color) or Via PC Yes (Color) or Via PC

Multi Copy(Sort) Yes (Color) or Via PC Yes (Color) or Via PC

Reduction/Enlargement(%) 25 -- 400 in 1% increments 25 -- 400 in 1% increments

Resolution(dpi) Max. 1200x1200 Max. 1200x1200

Resolution Indication LED (Green) -Fast, Normal, Best LED (Green) -Fast, Normal, Best

N in 1 2in1, 4in1/ B&W, Color: A4, LTR only

Poster Yes Yes

Clone N/A N/A

Image Enhancement N/A N/A

Book Copy Supporter N/A N/A

Smart Media/Compact Flash/Memory

Piezo Ink Jet (4 head BH: 150

20/16 (Mono/Color: 450*150)

'10/7 (Mono/Color: 600*300)

'3.5/2.5 (Mono/Color: 600*600)

'1.2/0.9 (Mono/Color: 1200*1200)

'0.6/'0.4(Mono/Color:2400*1200)

Post Card, Photo, Index card

105-185g/m2 (28-49.3 lb)

Win95/98/98SE/Me/2000Professinal/

12/8 (Multiple documents)

Stick

nozzles/color)

LTR, LGL, A4, A5, EXE,

64-120 g/m2 (17 - 32 lb)

NT4.0/XP

MacOS 8.5.1-10.1

15/12 (Multiple copies)

Smart Media/Compact

Flash/Memory Stick

Piezo Ink Jet (4 head BH: 150

nozzles/color)

1200x1200 /2400x1200

(Mono/Color)

20/16 (Mono/Color: 450*150)

'10/7 (Mono/Color: 600*300)

'3.5/2.5 (Mono/Color: 600*600)

'1.2/0.9 (Mono/Color: 1200*1200)

'0.4(Color:2400*1200)

LTR, LGL, A4, A5, EXE,

Post Card, Photo, Index card

64-240 g/m2 (17 - 64 lb)

Win95/98/98SE/Me/2000Professin

12/8 (Multiple documents)

2in1, 4in1/ B&W,color: A4, LTR

Yes

al/NT4.0/XP

MacOS 8.5.1-10.1

15/12 (Multiple copies)

only

2-6

Page 21

(3/4)

Model Name MFC-5200C MFC-890

SCANNER

Color/Mono Color/Mono Color/Mono

Resolution(dpi)(Phisical) CCD: 600x2400(Opt.) CCD: 600x2400(Opt.)

Resolution(dpi) (Logical) 9600(Int.) 9600(Int.)

Speed(ppm) Max. 3sec Max. 3sec

Gray Scale 256 256

TWAIN Compliant&Operating

System

PCI Scanner (Parallel/Serial) Parallel/ USB Parallel/ USB

E-MAIL Scan Key No No

OCR Scan Key No No

Scan Key

Color Depth 36bit-color processing (24bit external)

Pre Feeding No No

Consecutive feeding on ADF Yes (Windows&Mac) Yes (Windows&Mac)

MESSAGE CENTER/MESSAGE MANAGER

ICM Recording Time N/A N/A

Page Memory N/A N/A

OGM (MC;MC Pro;Paging;F/T) N/A N/A

TAD Type N/A N/A

Memo/Recording Conversation N/A N/A

Fax Forwarding Yes (B&W only) Yes (B&W only)

Fax Retrieval Yes (B&W only) Yes (B&W only)

Paging Yes Yes

Remote Access Yes Yes

Toll Saver N/A N/A

MESSAGE CENTER Pro/MESSAGE MANAGER Pro

Fax/Voice Mail Box N/A N/A

Fax/Voice on Demand N/A N/A

MESSAGE CENTER (PC MC)

Fax Forwarding N/A N/A

Paging N/A N/A

ICM Recording Time N/A N/A

OGM MC;MC Pro;Paging N/A N/A

Fax/Voice Mail Box N/A N/A

Fax/Voice on Demand N/A N/A

VIDEO CAPTURE

Video Capture N/A N/A

Video Print N/A N/A

Video Format N/A N/A

Video Fax N/A N/A

PHOTOCAPTURE CENTER

Acceptable Media

Print Yes(Color) Yes(Color)

Media format DPOF, Exif, DCF DPOF, Exif, DCF

Image format TIFF/JPEG/PDF (Scan-to-Card) TIFF,JPEG,PDF(scan-to-card)

Color Enhancement Yes Yes

Media Drive Yes (USB Only)

Win95/98/98SE/Me/2000Professinal/

NT4.0/XP(WIA)

MacOS 8.6-9.2

Yes (Windows Only) + Scan-to-

Image/OCR/

E-mail/Card

Smart Media (3.3V)

Compact Flash (Type-1/2)

Memory Stick

Win95/98/98SE/Me/2000Professin

Yes(Windows Only)+scan-to-

Yes (USB Only) Win98/98Se/ME/

al/NT4.0/

XP (WIA)/MacOS 8.6-9.2

Image/

OCR/E-mail/Card/LAN

36bit-color processing (24bit

external)

Smart Media (3.3V)

Compact Flash (Type-1/2)

Memory Stick

2000/XP/Mac9.0-10.1

2-7

Page 22

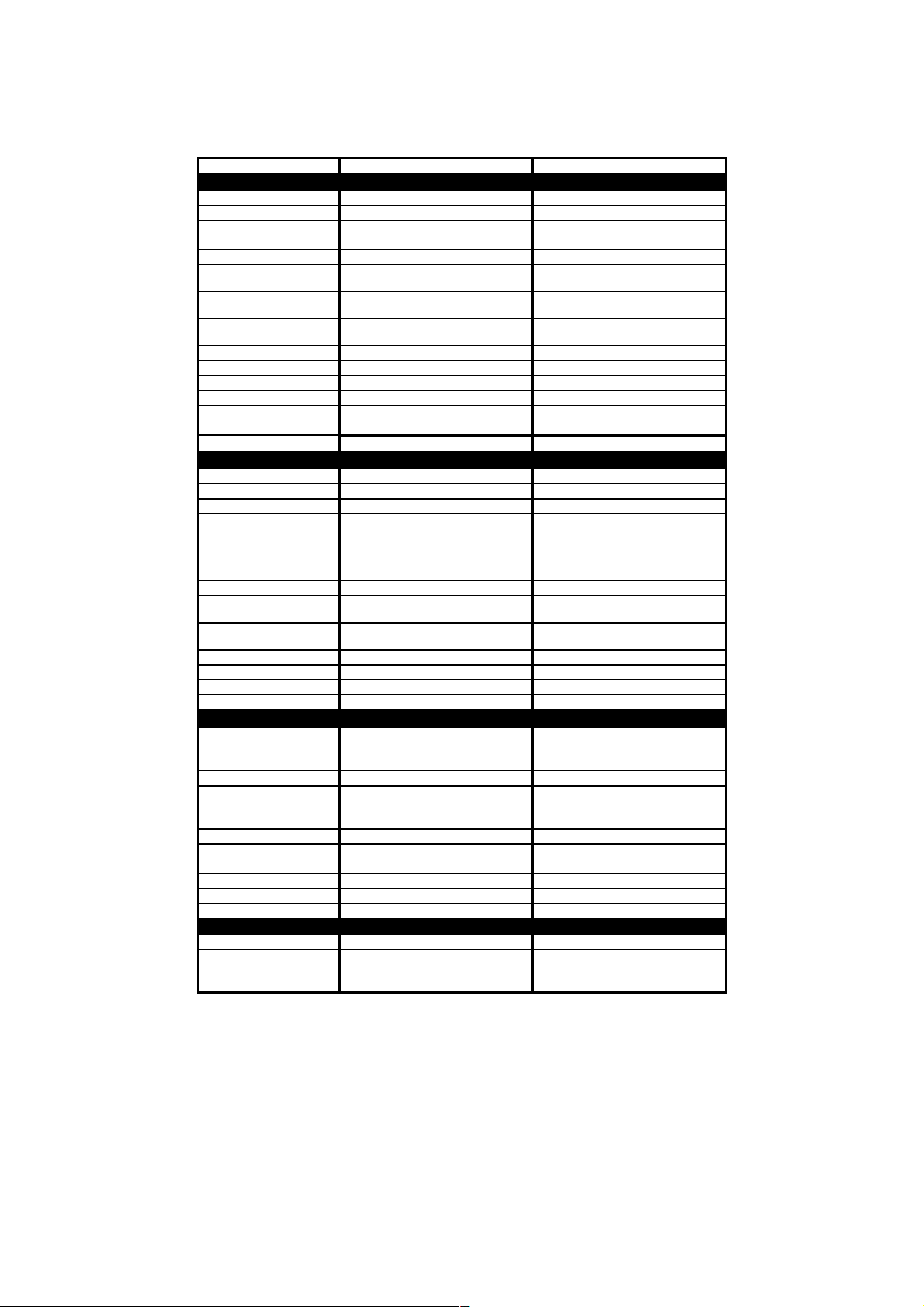

Model Name MFC-5200C MFC-890

Network Specifications

Standard/Option Option Option

Model Name NC-8100h NC-8100h

Support OS version Win95/98/98SE/Me,WinNT4.0/2K

Support OS version Novell NetWare 3.X,4.X,5.X Novell NetWare 3.X,4.X,5.X

Network connection

Support Protocols

TCP/IP Protocols

TCP/IP Protocols LPR/LPD, Port9100, SMTP/POP3 LPR/LPD, Port9100, SMTP/POP3

TCP/IP Protocols SMB(NetBIOS/ IP), IPP, FTP SMB(NetBIOS/ IP), IPP, FTP

TCP/IP Protocols TELNET, SNMP, HTTP, TFTP TELNET, SNMP, HTTP, TFTP

Network Management BRAdmin Professional BRAdmin Professional

Network Management Web Based Management (Reading) Web Based Management (Reading)

Network Management MIB-II as well as Brother private MIB MIB-II as well as Brother private MIB

Format (Scan to LAN) JPEG/PDF/TIFF JPEG/PDF/TIFF

BUNDLED SOFTWARE (For Windows)

Printer Driver Brother Brother

TWAIN Brother Brother

Veiwer Scan Soft Scan Soft Paper Port 8.0 (Win95-XP)

PC Fax

Others N/A N/A

Formats(Import)

Formats(Export)

OCR Yes(ScanSoft TextBridge) Yes(ScanSoft TextBridge)

Pop Up Menu Yes Yes

Remote Setup Yes Yes

PC Diagnostics Yes Yes

BUNDLED SOFTWARE (For iMAC/iBook/G3/G4)

Printer Driver Brother Brother

TWAIN Brother

Veiwer Scan Soft (Mac OS8.6) No

PC Fax

Others No No

Formats(Import) - Formats(Export) - OCR MacOS 8.6 No

Pop Up Menu No No

Remote Setup Yes(MacOS Xv.10.1) Yse (OS Xv.10.1)

PC Diagnostics No No

ACCESSORY

Cartridge 4 colors (each separate tank) 4 colors (each separate tank)

Life / Yield (Draft, 5%

Coverage)

cable No No

Ethernet 10/100BASE-TX Auto

RARP, BOOTP, DHCP, NetBIOS,

Win95/98/98SE/Me/2000Professinal/N

MAX/BMP/PCX/DCX/JPG/TIF/PNG/FPXMAX/BMP/PCX/DCX/JPG/TIF/PNG/FP

MAX/HTM/BMP/PCX/DCX/JPG/TIF/PN

Brother PC Fax (B&W Sending)

Negotiation

TCP/IP, IPX/SPX, AppleTalk,

DLC/LLC

WINS

Brother PC Fax (B&W

Sending/Receiving)

T4.0/XP

G/FPX

MacOS 8.5.1-9.2

BK: 950, CL: 450 BK: 950, CL: 450

Win95/98/98SE/Me,WinNT4.0/

2000Professional/XP

Ethernet 10/100BASE-TX Auto

RARP, BOOTP, DHCP, NetBIOS,

Win95/98/98SE/Me/2000Professinal/N

MAX/HTM/BMP/PCX/DCX/JPG/TIF/PN

Brother PC Fax (B&W Sending)

Negotiation

TCP/IP, IPX/SPX, AppleTalk,

DLC/LLC

WINS

Brother PC Fax (B&W

Sending/Receiving)

T4.0/

XP(Microsoft PC-Fax)

X

G/FPX

Brother

Mac OS 8.6-9.2

MacOS 8.5.1-9.2

(4/4)

2-8

Page 23

CHAPTER

INSTALLATION

3

Page 24

CHAPTER 3 INSTALLATION

CONTENTS

3.1 CONDITIONS REQUIRED FOR INSTALLATION........................................................... 3-1

3.1.1 Environmental Conditions ....................................................................................3-1

3.1.2 Basic Layout of machine Set-up Location............................................................3-1

3.2 UNPACKING THE MACHINE..........................................................................................3-2

3.3 INSTALLATION WORK...................................................................................................3-3

3.3.1 Removing the Protective Parts.............................................................................3-3

3.3.2 Attaching the Paper Supports ..............................................................................3-4

3.3.4 Install Phone Line and Power Cord......................................................................3-5

3.3.5 Installing the Ink Cartridges..................................................................................3-6

3.3.6 Color Block Quality and Alignment Check............................................................ 3-8

Page 25

3.1 CONDITIONS REQUIRED FOR INSTALLATION

Any machine is likely to be influenced by the environment of the set-up location. If the machine is

set-up in an inappropriate location, the machine may not perform as expected. Therefore, the

following factors should be taken into consideration before deciding where to set-up the machine.

3.1.1 Environmental Conditions

The machine should not be set up in the locations referred to in the following items (a) through (d)

which specify inappropriate locations for set-up.

(a) Where it is likely to receive direct sunlight or similar light. (For example, next to a window)

(b) Where it is likely to suffer a big difference in temperature and humidity between the

maximum and minimum levels. (Normal operation environment is within 10 ˚C to 35 ˚C, 20 to

80%RH and without any condensation.)

(c) Where it is likely to be in a draft of cold air from an air-conditioner or warm air from a heater,

or to receive direct radiant heat.

(d) Where it is likely to be excessively dusty or be subject to corrosive gases such as ammonia.

(e) Users should select a location with good ventilation and set the machine on a flat surface.

(f) Users should check that the maximum angle of the set-up location is horizontal to within 1 ˚ .

3.1.2 Basic Layout of machine Set-up Location

Shows the basic layout of the machine set-up location that is suitable for smooth.

3-1

Page 26

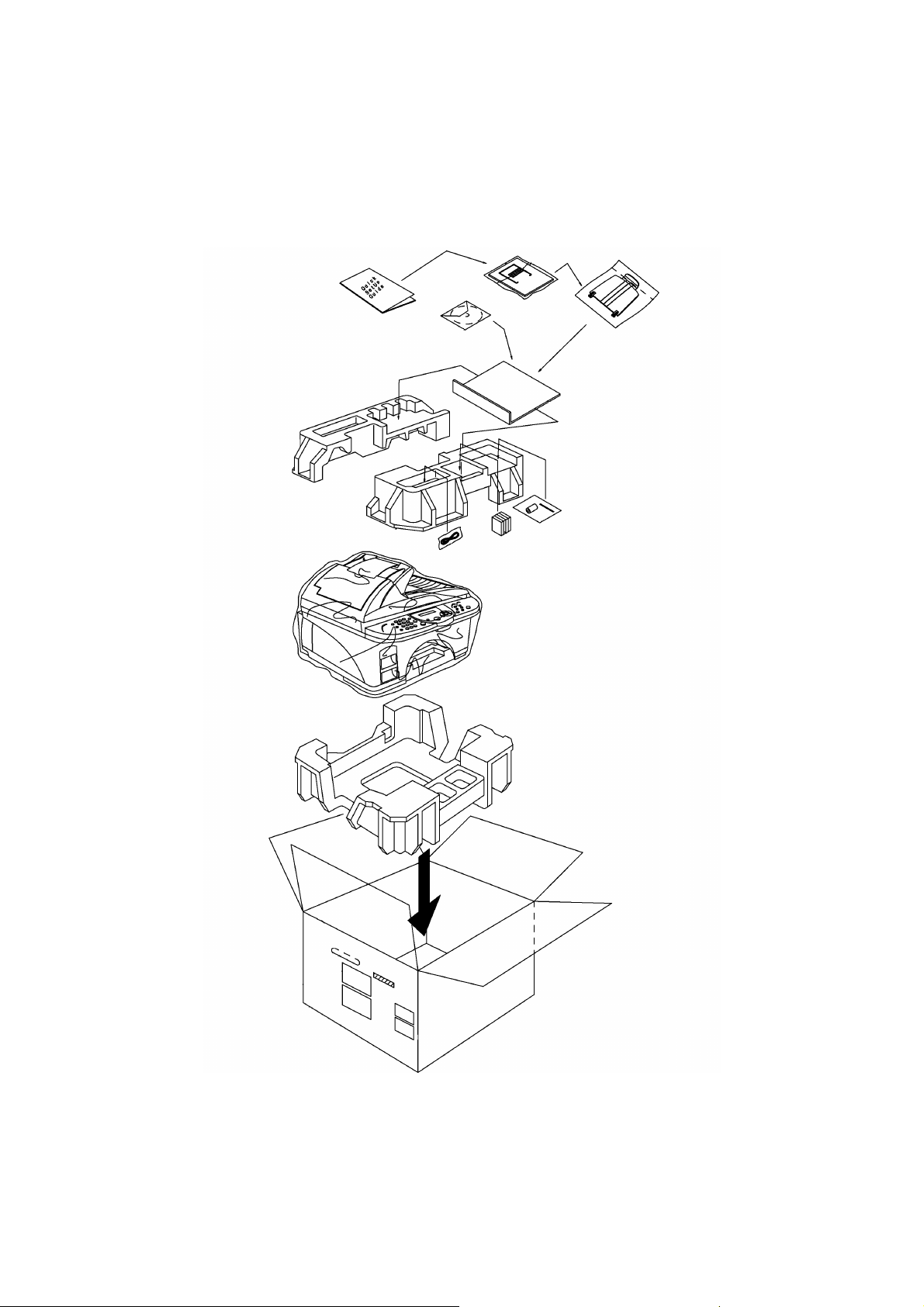

3.2 UNPACKING THE MACHINE

The equipment consists of the following major components:

3-2

Page 27

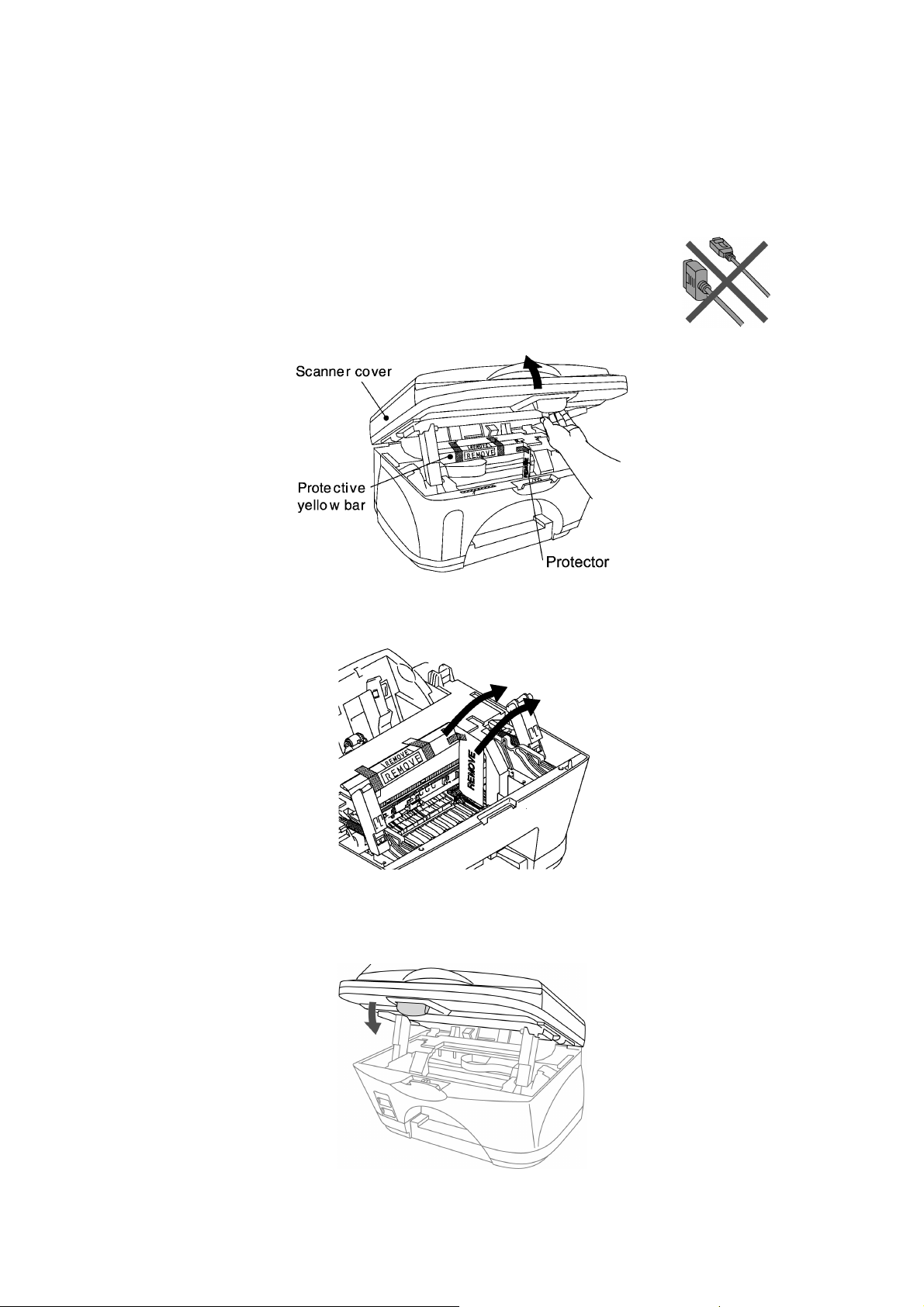

3.3 INSTALLATION WORK

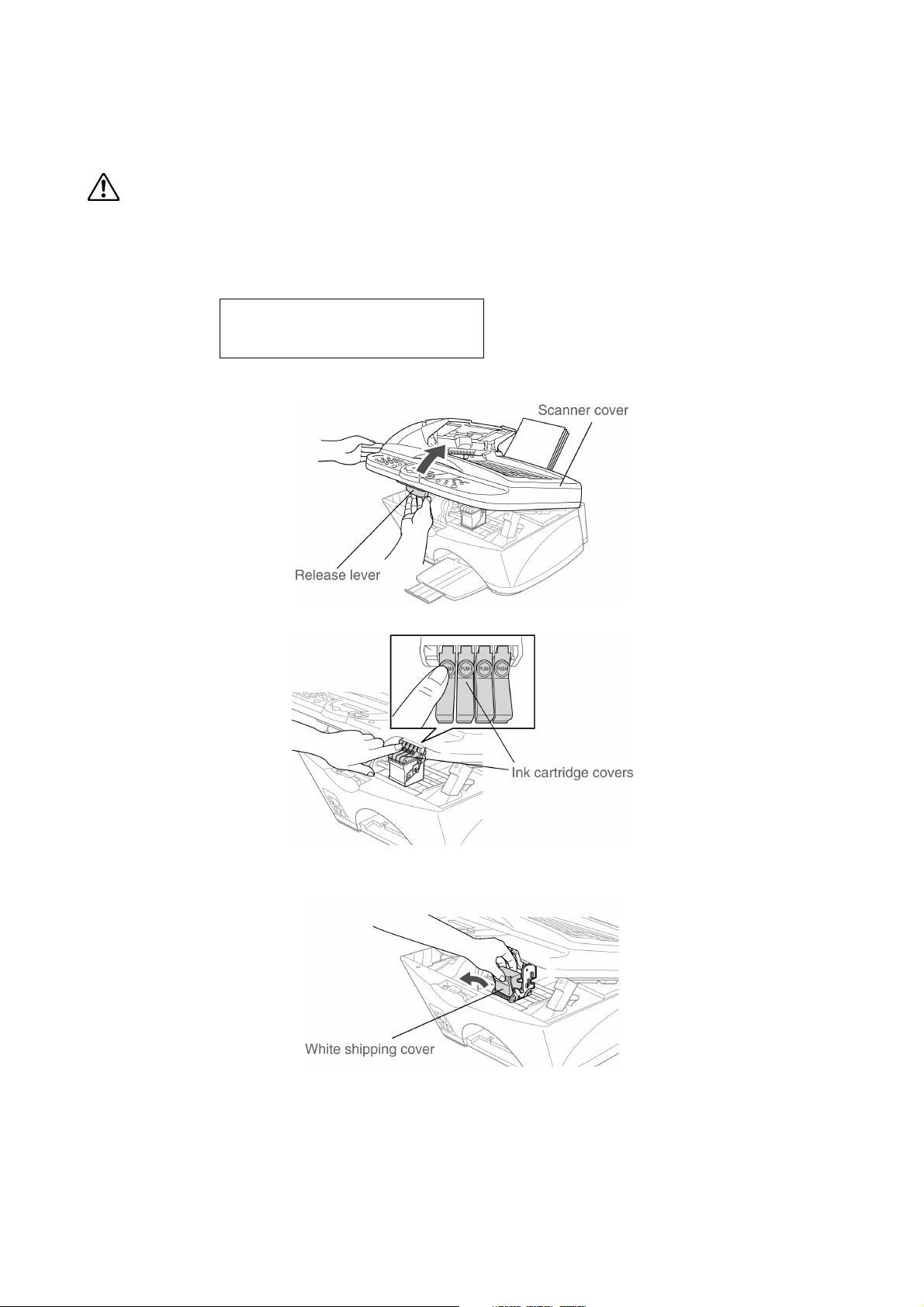

3.3.1 Removing the Protective Parts

Do NOT connect the interface cable.

Connecting the interface cable is done when installing the driver.

(1) Remove the protective seals.

(2) Open the scanner cover by pulling the release lever towards you.

(3) Remove the protector and the protective yellow bar.

Do not throw away the protective yellow bar. You will need it in the future to transport the

machine.

(4) Close the scanner cover.

3-3

Page 28

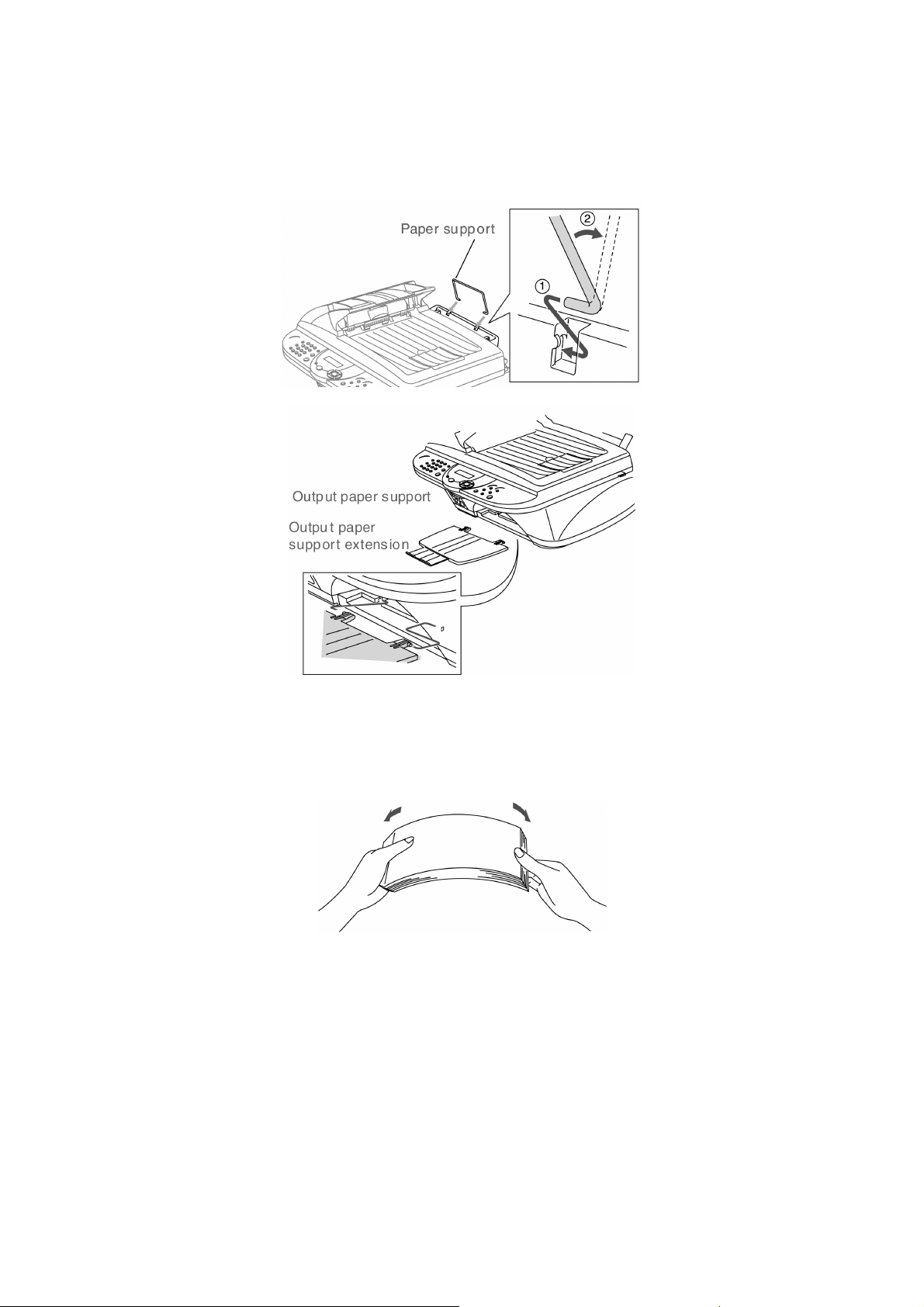

3.3.2 Attaching the Paper Supports

(1) Attach the paper support to the paper tray.

(2) Attach the output paper support to the paper output slot, and then pull out the extension.

3.3.3 Load Paper

(1) Fan the stack of paper well to avoid paper jams and misfeeds.

3-4

Page 29

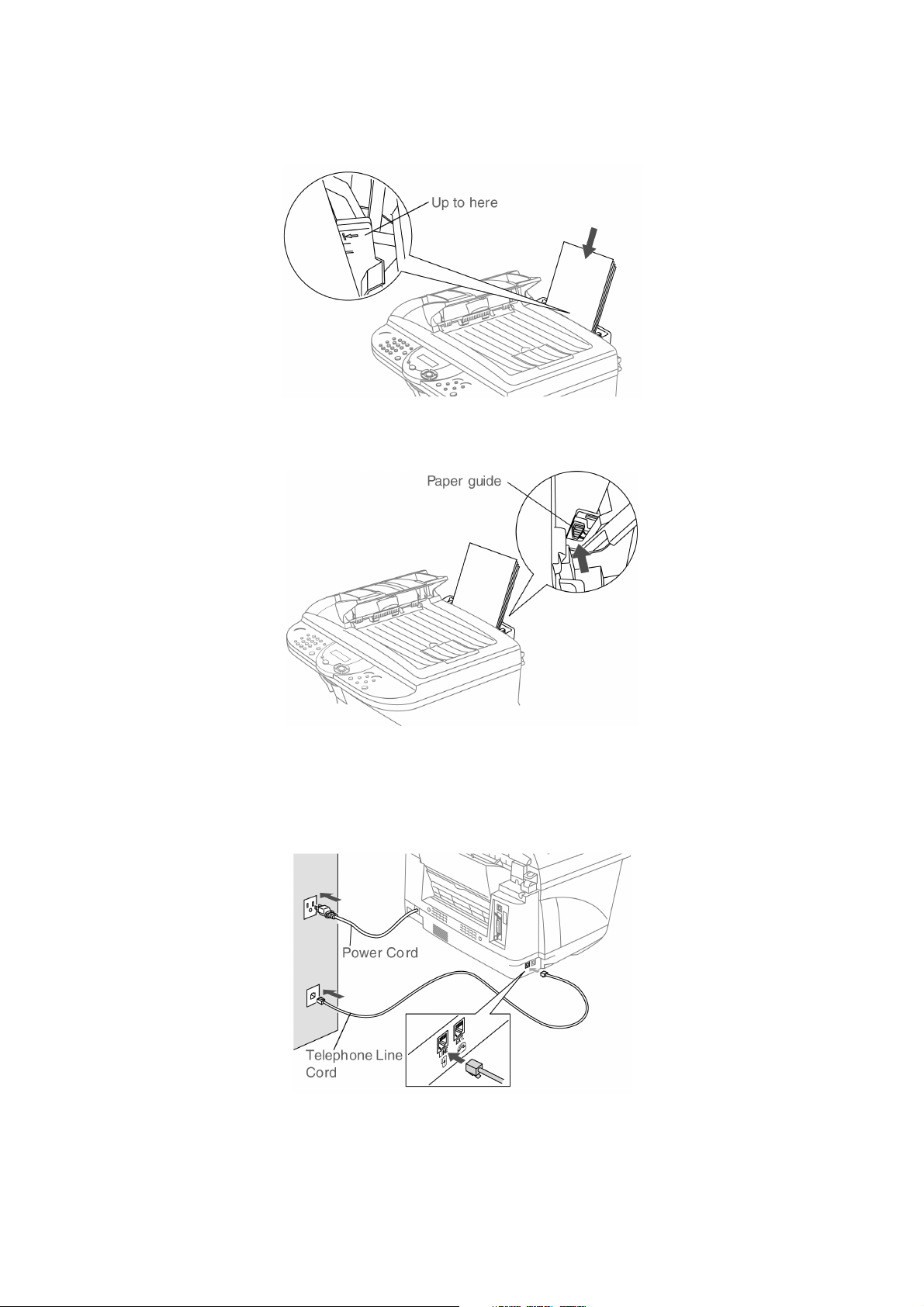

(2) Gently insert the paper.

Make sure the print side is towards you and the paper is below the maximum paper mark.

(3) Press and slide the paper guide to fit the paper width.

3.3.4 Install Phone Line and Power Cord

(1) Connect the power cord.

(2) Connect one end of the telephone line cord to the jack on the machine marked LINE and the

other end to a modular wall jack.

3-5

Page 30

3.3.5 Installing the Ink Cartridges

WARNING

If ink gets in your eyes irrigate them with water immediately, and if irritation occurs consult a doctor.

(1) Make sure that the power is turned on.

The LCD shows;

CHECK CARTRIDGE

Open cover, then...

(2) Open the scanner cover by pulling the release lever towards you.

The print heads will move to the ink replacement position.

(3) Push the four colored ink cartridge covers one at a time so they pop up.

(4) Remove the white shipping cover by pulling it towards you.

The bottom of the white shipping cover is wet with ink that will cause stains, so wipe it clean

before you place it down.

Do not throw away the white shipping cover. You will need it when you transport the

machine.

3-6

Page 31

(5) Take out black ink cartridge.

(6) Carefully remove the sealing tape from the bottom of the ink cartridge.

To prevent spilling ink and staining your hands and clothing, peel the sealing tape gently and

slowly.

Do not touch the ink opening on the cartridge or removed tape.

(7) Gently insert the black ink cartridge in the black ink position.

(8) Press the cover down until it clicks.

(9) Repeat Steps 5 to 8 to install each color ink cartridge. Match the colors of the ink cartridge

covers.

3-7

Page 32

(10) Close the scanner cover. The MFC will enter a head cleaning cycle for approximately six

minutes.

CLEANING

PLEASE WAIT

• DO NOT remove ink cartridges if you do not need to replace them.

If you do so, it may reduce the ink quantity and the MFC will not know the quantity of ink

left in the cartridge.

• DO NOT shake the ink cartridges.

If you do so, the ink may spill when you take off the sealing tape. If ink stains your body or

clothing, wash with soap or detergent immediately.

• DO NOT refill the ink cartridges.

Attempting to use refilled cartridges and using incompatible inks may cause damage to the

print head in this machine and such damage will not be covered by warranty.

Warranty coverage does not apply to problems caused by the use of 3rd party ink or 3rd

party ink cartridges. Use only genuine Brother ink cartridges.

If you mix the colors by installing an ink cartridge in the wrong color position, you must clean

the print head several times after correcting the cartridge installation and before you start

printing.

Once you open an ink cartridge, install it in the machine and use it up within six months of

installation. Use unopened ink cartridges by the expiration date written on the cartridge

package.

If INK EMPTY shows on the LCD after you install the ink cartridges, check to make sure the

ink cartridges are installed correctly.

3.3.6 Color Block Quality and Alignment Check

(1) After the cleaning cycle is finished, the LCD shows;

SET PAPER AND

PRESS FAX START

(2) Make sure the paper is loaded in the paper tray.

Press the Fax Start key.

(3) The MFC starts printing the PRINT QUALITY CHECK SHEET (only during initial ink

cartridge installation).

3-8

Page 33

Step A: Color Block Quality Check

y

y

f

r

Step B: Alignment Check

1. The LCD shows:

IS STEP "A"OK?

1. YES 2.NO

Check the quality of the four color blocks printed

on the sheet. (BLACK/CYAN/YELLOW/

MAGENTA)

2. If the quality is OK for all colors, press the "1"

key on the dial pad to go to STEP B: Alignment

Check.

---OR---

If white horizontal lines appear in some of the color

blocks, press the "2" key on the dial pad and go to

3.

The LCD shows:

IS STEP "B"OK?

1. YES 2.NO

Check the 600 DPI and 1200 DPI test print to see i

No.5 most closely matches the OK sample (No.0).

Press the "1" key if No.5 matches it.

3. The LCD asks you if the print quality is OK for

each color. Press the "1" key or "2" ke

dial pad.

on the

2 BLACK OK?

1.YES 2.NO

When you have finished selecting the "1" ke

(YES) or the "2" key (NO) for magenta, the LCD

shows:

START CLEANING?

1.YES 2.NO

Press the "1" key (YES), and then machine starts

cleaning the colors.

After cleaning is finished, press the Fax

Start key. The machine starts printing PRINT

QUALITY CHECK SHEET again and goes back to

the first step of STAP A.

If another test print number is a better match fo

either 600 DPI or 1200 DPI, press the "2" key to

select NO and go to 2.

2. For 600 DPI, select the number from 1 to 8

that most closely matches the No.0 sample

and enter it using the dial pad.

600DPI ADJUST

SELECT BEST #

3. For 1200 DPI, enter the number from 1 to 8

that most closely matches the No.0 sample.

1200DPI ADJUST

SELECT BEST #

The quality check is now complete.

3-9

Page 34

CHAPTER

THEORY OF OPERATION

4

Page 35

CHAPTER 4 THEORY OF OPERATION

CONTENTS

4.1 OVERVIEW ......................................................................................................................4-1

4.2 MECHANISMS .................................................................................................................4-2

4.2.1 Scanner Mechanism ............................................................................................4-4

4.2.2 Ink Jet Printing Mechanism ..................................................................................4-6

4.2.2.1 Paper pulling-in, registration, feeding, and ejecting mechanisms................4-6

4.2.2.2 Ink jet printing and capping mechanisms.....................................................4-8

4.2.2.3 Purging mechanism ...................................................................................4-11

4.2.2.4 Carriage drive mechanism .........................................................................4-14

4.2.3 Sensors and Actuators.......................................................................................4-15

4.3 CONTROL ELECTRONICS ...........................................................................................4-18

4.3.1 Configuration......................................................................................................4-18

Page 36

4.1 OVERVIEW

Host

Compact Flash

SmartMedia

Memory Stick

Line

Control

panel

NCU

Fax Control Section

ADF unit

- ADF motor

Speaker

Scanner unit

- CCD unit

- CCD motor

Centronics

parallel

interface

Print data

Ink jet printer unit

- Ink jet print head

unit

- Carriage motor

- Carriage ASSY

- Purge unit

USB

interface

Printer Control Section

Paper feeding

mechanism

- Paper feed

motor

Media

station

Power

supply

AC

4-1

Page 37

4.2 MECHANISMS

The facsimile machine is classified into the following mechanisms:

SCANNER MECHANISM - ADF mechanism

INK JET PRINTING MECHANISM - Paper pulling-in, registration, feeding, and ejecting

SENSORS AND ACTUATORS

- Document scanning mechanism

mechanisms

- Ink jet printing and head capping mechanisms

- Purging mechanism

- Carriage drive mechanism

4-2

Page 38

SCANNER MECHANISM

4-3

Ink jet printing and head

capping mechanisms

Purge mechanism

Carriage drive mechanism

Paper pulling-in,

registration, feeding, and

ejecting mechanisms

INK JET

PRINTING

MECHANISM

Page 39

4.2.1 Scanner Mechanism

This mechanism consists of the document guide base, ADF & document cover ASSY and scanner

unit.

The ADF (automatic document feeder) unit contains a separation roller ASSY, document feed

roller ASSY, document ejection roller, ADF motor, and document front and rear sensors.

The scanner unit consists of a scanner top cover, CCD unit, CCD drive mechanism, CCD HP

sensor, and scanner base.

For details about the sensors, refer to Subsection 4.2.3.

Document ejection roller

ADF motor

Document guide base

Document cover

ADF & document cover ASSY

Document feed roller

Separation roller ASSY

CCD drive belt

CCD motor

CCD unit

CCD rail

Scanner top cover

Scanner unit

CCD flat cable

CCD HP sensor

Scanner base

4-4

Page 40

This scanner mechanism supports a dual scanning system.

(1) If you set documents on the document guide base with their faces up and start the scanning

operation, then the ADF motor rotates to pull in those documents into the ADF unit, starting

from the top sheet to the bottom, page by page. Each document curves downwards and turns to

the right with the document feed roller so as to advance above the CCD unit, and then it is fed

out to the document cover with the document ejection roller ASSY.

This way, documents move above the CCD unit being kept in a stationary position.

(2) If you open the ADF & document cover ASSY, put a sheet of document with its face down (or

put a bound book opened) on the glass of the scanner top cover, close the ADF & document

cover ASSY, and start the scanning operation, then the CCD drive mechanism will be driven.

The CCD motor built in the CCD unit rotates. As illustrated below, the CCD drive gear and

idle pulley carry the CCD drive belt on the underside of the CCD unit, so clockwise and

counterclockwise rotations of the CCD motor move the CCD unit to the right and left,

respectively.

In this scanning system, the CCD unit moves horizontally beneath a document being kept in

stationary position.

CCD drive belt

Underside of the

CCD unit turned

upright

CCD unit

turned upright

CCD motor

gear

CCD idle pulley

Scanner base

CCD drive gear

The CCD unit contains a charge coupled device (CCD) image sensor. The cold-cathode

fluorescent lamp illuminates a document and the reflected light of the scanned image data is

transmitted via the mirrors into the lens which reduces the scanned data so as to form the image on

the CCD.

4-5

Page 41

4.2.2 Ink Jet Printing Mechanism

4.2.2.1 Paper pulling-in, registration, feeding, and ejecting mechanisms

The paper pulling-in, registration, feeding, and ejecting mechanisms are driven by a single paper

feed motor located at the left side of the main chassis via the two PF timing belts and gear train.

(See the illustration given on the next page.)

First, the paper feed motor rotates counterclockwise (when viewed from the output gear). The

rotation is transmitted via the PF timing belt L to the PF roller pulley that rotates the paper feed

roller. At the right end of the paper feed roller is the PF roller gear R which is always engaged with

the ASF/purge idle gear. Engaged with the ASF/purge idle gear, the ASF-purge switching gear 23

transmits the rotation via gear 25 and ASF gear train to the ASF roller ASSY. This way, the ASF

roller will pull in paper.

When the ASF roller is pulling in paper, the paper feed roller rotates in the backward direction to

register the leading edge of the pulled-in paper.

Next, the paper feed motor rotates clockwise to rotate the paper feed roller in the forward

direction. The paper will advance through the paper path. During the paper feeding operation, no

rotation is transmitted to the ASF roller because of the planetary gear system built in the ASF

roller ASSY.

The above paper pulling-in and feeding operations take place when the carriage is in printing

operation. If the carriage reaches the purge position, the ASF-purge switching gear 23 will be

disengaged from the gear 25 and engaged with purge bevel gear A. For the purging mechanism,

refer to Subsection 4.2.2.3.

Paper pulling-in

mechanism

Registration &

paper feeding

mechanisms

ASF

ASF roller

ASSY

Paper width sensor

actuator

Registration

sensor actuator

Paper pressure

holders

Paper chute

Paper feed roller

Recording paper

(Carriage)

(Carriage rail)

(Ink cartridges)

Platen

(Print head unit)

Star wheels

Paper ejection

roller

Paper ejecting

mechanism

4-6

Page 42

ASF

ASF roller ASSY

PF timing belt L

PF roller pulley L

ASF shaft

Paper feed roller ASSY

Gear 25

ASF-purge switch gear 23

ASF/purge idle gear

PF roller gear R

Tension plate R

PF timing belt S

Ejection roller pulley

Tension plate F

Paper ejection roller ASSY

Paper feed motor

4-7

Page 43

4.2.2.2 Ink jet printing and capping mechanisms

Carriage encoder

Carriage

motor

Carriage rail

(1) Print head unit

Main chassis

Platen

Carriage PCB

Ink cartridge sensors

Ink cartridges

Ink empty sensor

Carriage

(Star wheels)

(Paper ejection roller)

Print head unit

This machine uses drop-on-demand ink jet printing. The print head has four ink-jet units for four

color inks. Each of those units consists of 150 nozzles, 150 channels covered with piezoelectric

ceramic (PZT), a manifold, and filter. As illustrated below, the pair of nozzle columns is staggered.

Paper feed direction

77/150"

(13.0387 mm)

Carriage travel direction

1/150"

(0.1693 mm)

#1

#2

#149

#150

Black Cyan Yellow Magenta

Ink-jet units

1/150"

(0.1693 mm)

1/75"

(0.3387 mm)

74/75"

(25.0613 mm)

Nozzle Layout (viewed from the bottom)

4-8

Page 44

If the controller issues a print command, a biased voltage will be applied to all electrodes formed

on the surface of the piezoelectric ceramic so that each actuator will be distorted as shown with

broken lines.

If the electrodes on a target channel are deenergized according to drive signals, then the associated

piezoelectric ceramic actuator returns to the previous form so that the ink in the manifold will be

vacuumed out to the channel.

If the voltage is applied again, the piezoelectric ceramic actuator will be distorted again to apply

pressure to the ink in the channel, causing the ink to jet out through the nozzle. The jetted-out ink

drop will be splashed and produce a dot on paper held by the platen.

As the carriage holding the print head unit travels at the printing speed, the controller sends print

command pulses to the piezoelectric actuator driver circuit embedded in the print head unit.

(2) Ink cartridges

The machine uses four ink cartridges (black, cyan, yellow, and magenta) of disposable type to

supply ink to the print head unit. As shown below, an ink cartridge contains an ink-impregnated

urethane foam. If ink-jet print operation or purging operation takes place, ink comes out of the

urethane foam and is supplied to the print head unit through the ink room, filters, and manifold.

For the ink cartridge sensors on the carriage PCB, refer to Subsection 4.2.3.

4-9

Page 45

(3) Head caps

Shown below is a head cap mechanism that prevents the nozzles of the print heads from drying up

when they are not in use.

Upon completion of printing, the carriage travels to the right and moves the head cap holder

provided on the purge unit to the right together. In the head cap holder is a head cap unit which is

supported with a lift lever. The rightward movement of the head cap holder turns the lift lever and

pushes up the head cap unit to the position where the head caps come into tight contact with the

print heads. This way, the nozzles will be capped.

4-10

Page 46

4.2.2.3 Purging mechanism

The purge mechanism is driven by the paper feed motor located at the left side of the main chassis.

As described in Subsection 4.2.2.1, the motor rotation is transmitted to the ASF/purge idle gear at

the right side of the main chassis. Engaged with the ASF/purge idle gear, the ASF-purge switching

gear 23 works as a clutch gear.

When the carriage travels from the left to right to reach the purge position, the tab provided on the

back of the carriage pushes the purge lever on the main chassis to the right (see the illustration

below). Accordingly, the ASF-purge switching gear 23 (which was shifted to the left by the purge

lever) will move to the right by the switching gear spring so as to become disengaged from the

gear 25 and engaged with the purge bevel gear A. (See the illustration given on the next page.)

This engagement will transmit the motor rotation to the purge bevel gear B on the purge unit. This

way, when the carriage is in the purge position, the motor rotation is transmitted to the purge unit.

On the contrary, if the carriage travels from the purge position to the left, the tab on the back of the

carriage releases the purge lever which will be pulled back to the left. The ASF-purge switching

gear 23 will be disengaged from the purge bevel gear A.

4-11

Page 47

During printing: The ASF-purge switching gear 23 is

not engaged with purge bevel gear A (but engaged with

gear 25 in the ASF gear train).

During purging: The ASF-purge

switching gear 23 is engaged with

purge bevel gear A.

When the motor rotation is transmitted to the purge unit, its counterclockwise rotation will drive

the purge cam and its clockwise rotation, the pump switching unit (when viewed from the output

gear of the motor).

When the paper feed motor rotates counterclockwise

When the paper feed motor rotates clockwise

4-12

Page 48

The purge cam is so designed that:

- the carriage lock pops out to lock the carriage before purging and pops in before cleaning with

the head wiper (see the illustration below),

- the pump works to draw out ink from each of the four head nozzles and drain it to the ink

absorber felts, and

- the head wiper comes out to clean the nozzle surface (see the illustration below).

The pump switching cam is so designed that:

- the pump switching unit switches application of the pump's negative pressure between the four

head nozzles in the order of black, cyan, yellow, and magenta nozzles. When the pump

switching cam is in the home position, normal atmospheric pressure will be restored.

The home position of the purge cam and pump switching cam are detected by their HP switches.

For those switches, refer to Subsection 4.2.3.

(1) Carriage lock

If the purge cam is driven, the carriage lock of the purge unit pops out and locks the carriage to

align ink-jet units with the mating head caps during purge operation. After purging but before

cleaning with the head wiper, it pops in to release the carriage. When the power is off, the carriage

lock keeps the print heads pressed against the head caps.

(2) Purging

If activated, the pump draws out ink to purge air bubbles or dust from the inside of the head

nozzles and channels. As the purge cam rotates by one turn, the piston of the pump reciprocates

two strokes. To complete purging of all four nozzles and channels, the purge cam rotates by two

turns ad the piston reciprocates four strokes.

(3) Draining

The pump drains drawn ink into the ink absorber felts.

(4) Cleaning with the head wiper

After purging operation, the head wiper comes out and the carriage moves from the right to left so

as to clean ink remaining on the heads' surface.

(5) Restoring the pump's pressure to normal atmospheric pressure

When the pump switching cam is in the home position, the controller stops to produce negative

pressure and restore the pump's pressure to normal atmospheric pressure.

Carriage lock

Head wiper

(Rear)

Purge unit

Purge cam

4-13

Page 49

4.2.2.4 Carriage drive mechanism

The carriage motor controls horizontal motion. The motor rotation is transmitted via the motor

pulley to the carriage timing belt.

The carriage, which is supported and guided by the carriage rail, is secured to the timing belt.

Clockwise and counterclockwise rotations of the carriage motor move the carriage to the right and

left, respectively.

On the back of the carriage is the carriage encoder which tells the control circuitry the current

carriage position counted based on the carriage motor position by using the encoder strip attached

to the main chassis.

Main chassis

Carriage timing belt

Idle pulley

Carriage

Carriage encoder

Encoder strip

Carriage rail

Carriage motor

Motor pulley

4-14

Page 50

4.2.3 Sensors and Actuators

This machine has the following sensors and thermister.

Sensor name Type Located on

Document front sensor Photosensor

Document rear sensor Photosensor

Document sensor PCB in

the ADF

Document cover open sensor Mechanical switch Document cover

Scanner open sensor Photosensor Control panel PCB ASSY

Registration sensor Photosensor Driver PCB

Paper width sensor Photosensor Driver PCB

Manual feed slot cover sensor Mechanical switch ASF

CCD HP sensor Photosensor CCD PCB on the CCD unit

Ink empty sensor Photosensor Sensor support

Ink cartridge sensors Mechanical switches

Carriage encoder Photosensor

Carriage PCB

Head thermister Thermister

Purge cam HP switch Mechanical switch

Purge unit

Pump switching cam HP switch Mechanical switch

• Document front sensor which detects the presence of documents.

• Document rear sensor which detects the leading and trailing edges of pages to tell the control

circuitry when the leading edge of a new page has reached the starting position and when the

scan for that page is over.

• Document cover open sensor which detects whether the document cover is closed.

• Scanner open sensor which detects whether the scanner unit is closed.

• Registration sensor which detects the leading and trailing edges of paper, which allows the

controller to determine the registration timing and check paper jam.

• Paper width sensor which detects whether the paper width is "A4-size or wider" or "narrower

than A4-size."

• Manual feed slot cover sensor which detects whether the manual feed slot cover is closed.

• CCD HP sensor which detects whether the CCD unit is placed in the home position.

• Ink empty sensor which detects at the start of printing whether any of the four ink cartridges is

near empty. According to this sensor signal, the controller may display "NEAR EMPTY XXX"

message.

• Ink cartridge sensors, each of which detects whether an ink cartridge is loaded.

• Carriage encoder which detects the current carriage position and carriage travel speed. If the

carriage travels speed varies abnormally, the controller regards it as a paper jam.

4-15

Page 51

• Head thermister which allows the controller to control the temperature of the print heads.

According to the change of the thermister's internal resistance monitored, the control circuitry

regulates the drive voltage applied to the piezoelectric ceramic actuators on each print head

since the viscosity of the ink varies depending upon the temperature.

• Purge cam HP switch which detects whether the purge cam is in the home position.

• Pump switching cam HP switch which detects whether the pump switching cam is in the home

position.

These photosensors (except the ink empty sensor that is a reflection type) are a photointerrupter

consisting of a light-emitting diode and a light-sensitive transistor. Each of them has an actuator

separately arranged as shown on the next page.

4-16

Page 52

(Document cover)

Document front sensor actuator

Document front sensor

(Document sensor PCB)

Document rear sensor actuator

Document rear sensor

Document cover open sensor

(Main PCB)

Registration sensor

Registration sensor

actuator

Paper width sensor

Paper width sensor actuator

(Driver PCB)

Manual feed slot cover sensor

CCD HP sensor

CCD HP sensor plate

Scanner open sensor

Scanner open sensor actuator

(Control panel PCB)

(Purge unit)

Purge cam HP switch

Pump switching cam HP switch

Ink empty sensor

(Sensor support)

Ink cartridge sensors

Location of Sensors and Actuators

Carriage PCB

(On this PCB is a head thermister also.)

Carriage encoder

(Carriage)

4-17

Page 53

4.3 CONTROL ELECTRONICS

4.3.1 Configuration

The hardware configuration of the facsimile machine is shown below. The wiring diagram is given

in Appendix 6.

Compact Flash

SmartMedia

Memory Stick

Media PCB

22-pin

21-pin

Control panel PCB

ASSY

(Scanner open

sensor)

Document cover

open sensor

ADF UNIT

Document sensor PCB

(Document front sensor

and document rear sensor)

ADF motor

Registration sensor

Paper width sensor

Driver PCB

PC

External telephone

SCANNER UNIT

10-pin

Line

7-pin

Parallel I/F

NCU PCB

CCD unit

(CCD motor)

(CCD HP sensor)

LAN (option)

Speaker

Manual feed

slot cover sensor

Maindriver

connector

USB

7-pin

(10-pin)*

60-pin

2-pin

2-pin

SDRAM

8MB

Print head PCB

Print head

Print head

Print head

Print head

Main PCB

MODEM

ASIC

INK JET PRINTER UNIT

ROM

4/8 MB

SUB GA

EEPROM

DC motor driver

Stepping motor driver

Configuration of Facsimile Machine

3-pin

2-pin

4-pin

4-pin

13-pin

Carriage PCB

Sensor support

Purge unit

Purge cam HP switch

Pump switching cam HP switch

Power supply PCB

4-18

Ink cartridge sensors

Carriage encoder

Head thermister

Ink empty sensor PCB

Carriage motor

Paper feed motor

AC line

* 7-pin: American models

10-pin: Other models

Page 54

CHAPTER

MAINTENANCE

5

Page 55

CHAPTER 5 MAINTENANCE

CONTENTS

5.1 CLEANING.......................................................................................................................5-1

5.1.1 Cleaning the purge unit ........................................................................................5-1

5.1.2 Cleaning the print head unit .................................................................................5-1

5.1.3 Cleaning the scanner glass ..................................................................................5-2

5.1.4 Cleaning the printer platen ...................................................................................5-2

5.2 REPLACING THE INK CARTRIDGE...............................................................................5-3

Page 56

5.1 CLEANING

5.1.1 Cleaning the purge unit

(1) Unplug the machine's power cord from the wall socket.

(2) Plug the power cord again. When you hear the carriage moving out of the home position for

initialization, then unplug the power cord again. The carriage will stop at the middle of the

travel.

(3) Open the scanner unit.

(4) Clean the four head caps and wiper of the purge unit with a "Rubycel" stick that is a head

cleaner stick provided as a spare part.

NOTE: Do not use a cotton swab that may leave lint on the cleaned sections. Lint left on the

purge unit will affect the print performance.

NOTE: Use a new Rubycel stick and do not use the used one for any other purge units.

NOTE: During the cleaning jobs, take care not to touch the head caps or wiper directly by

hand or scratch their surfaces. Do not remove them from the head cap holder.

5.1.2 Cleaning the print head unit

(1) Remove the print head unit from the carriage.

(2) Soak a Rubycel stick in "Glycerol cleaner."

(3) Clean the printing surface of the print head unit by rolling the Rubycel stick lightly on the

printing surface.

NOTE: Do not use a cotton swab that may leave lint on the cleaned sections. Lint left on the

purge unit will affect the print performance.

NOTE: Use a new Rubycel stick and do not use the used one for any other print heads.

NOTE: During the cleaning jobs, take care not to scratch the surface of the print head.

5-1

Page 57

5.1.3 Cleaning the scanner glass

Unplug the machine and lift the document cover. Open the document cover. Clean the scanner

glass, the glass strip under the film and the white film with isopropyl alcohol on a soft lint-free

cloth.

5.1.4 Cleaning the printer platen

Unplug the machine from the AC power outlet before cleaning the printer platen.

Clean your machine printer platen, wipe it with a soft lint free cloth that is dry.

5-2

Page 58

5.2 REPLACING THE INK CARTRIDGE

m

Your machine is equipped with an optical sensor that automatically monitors the ink level in each

color cartridge. When the sensor detects an ink cartridge is running out of ink, the machine will

notify you with a message on the LCD.

The LCD shows you which color cartridges are low or empty. Be sure to follow the LCD prompts

so you replace the color cartridges in the appropriate order.

When the ink cartridges are running low, you must use the Ink key to begin the cartridge

replacement (Steps 1 to 3). If the ink is empty, skip to Step 4.

1. Press Ink key.

2. Press

3. Press Menu/Set key.

If one or more ink cartridges are empty, for example Black, the LCD shows "INK EMPTY

BLACK" and "PLS OPEN COVER".

4. Pull the Scanner cover release lever and lift the Scanner cover.

5. Press the appropriate colored ink cartridge cover to open it, and then remove the ink cartridge.

6. Open the new ink cartridge bag for the color shown on the LCD, and then take out the ink

cartridge.

7. Hold the new ink cartridge as shown in the

illustration, and then peel the sealing tape fro

the side of the ink cartridge. Carefully peel the

tape in the direction away from you.

or to choose "2.REPLACE INK".

To prevent spilling ink and staining your hands

and clothing, remove the sealing tape gently.

8. Each color has its own correct position. Insert the new ink cartridge into its carriage, and then

close the ink cartridge cover by pressing until it clicks.

5-3

Page 59

9. After installing the ink cartridges, close the Scanner cover. Your machine prepares for a "head

cleaning" and goes online. The LCD prompts you to verify a new ink cartridge was inserted

for each color you removed.

Example: "DID YOU CHANGE BLCK? 1.YES 2.NO". If the ink cartridge you installed is not

a brand new one, please make sure to select 2.

10. For each new cartridge, press 1 on the dial pad to reset the ink dot counter for that color

automatically.

The machine will enter a cleaning cycle for approximately 3 minutes for each replaced

cartridge. The LCD alternately shows CLEANING and PLEASE WAIT.

When the machine completes the cleaning cycle, the LCD returns to Standby mode (date and

time).

5-4

Page 60

CHAPTER

DISASSEMBLY/REASSEMBLY,

LUBRICATION, AND ADJUSTMENT

6

Page 61

CHAPTER 6 DISASSEMBLY/REASSEMBLY, LUBRICATION,

ADJUSTMENT

CONTENTS

6.1 DISASSEMBLY/REASSEMBLY .....................................................................................6-1

Safety Precautions.......................................................................................................6-1

Tightening Torque List......................................................................................................6-2

Preparation ..................................................................................................................6-4

How to Access the Object Component........................................................................ 6-4

Disassembly Order Flow..............................................................................................6-5

6.1.1 Print Head Unit.....................................................................................................6-6

6.1.2 ADF Cover and Document Guide Base .............................................................6-12

6.1.3 ADF Components on the Upper ADF Chute......................................................6-13

6.1.4 ADF Components on the Lower ADF Chute......................................................6-18

6.1.5 Document Cover Open Sensor and ADF Document Output Support

Extension............................................................................................................6-23

6.1.6 Manual Feed Slot Cover and Rear Cover..........................................................6-24

6.1.7 Main PCB Shield Case and Scanner Unit (Together with Document Cover) ....6-25

6.1.8 Control Panel ASSY ...........................................................................................6-30

6.1.9 Disassembly of the Control Panel ASSY ...........................................................6-31

6.1.10 Disassembly of the Scanner Unit .......................................................................6-32

6.1.11 Edge Cover, Scanner Links and Their Guides...................................................6-37

6.1.12 Main Cover .........................................................................................................6-38

6.1.13 Media Module (Media Cover, Media PCB, and Frame) and Media Flat

Cables ................................................................................................................6-39

6.1.14 Main PCB and its Shield Frame.........................................................................6-41

6.1.15 ASF and ASF roller ASSY..................................................................................6-43

6.1.16 FG Plates, Power Supply PCB, and NCU PCB .................................................6-45

6.1.17 Speaker.............................................................................................................. 6-47

6.1.18 Purge Unit ..........................................................................................................6-48

6.1.19 Driver PCB .........................................................................................................6-50

Page 62

6.1.20 Encoder Strip, Idle Pulley Holder, and Carriage Motor......................................6-53

6.1.21 Harness Support Film L, Head Flat Cables, Carriage Rail, and Carriage

ASSY..................................................................................................................6-55

6.1.22 Purge-Related Parts (Purge Lever, Purge Shaft, and ASF-Purge Switching

Gear 23) .............................................................................................................6-62

6.1.23 Paper Pressure Holders.....................................................................................6-63

6.1.24 Paper Chute .......................................................................................................6-65

6.1.25 Star Wheel Support and Platen..........................................................................6-65

6.1.26 Flushing Foam Case ..........................................................................................6-67

6.1.27 Main Chassis......................................................................................................6-68

6.1.28 Ink Empty Sensor PCB ......................................................................................6-69

6.1.29 Paper Feed Motor, PF Timing Belts, PF Roller Pulley L, Paper Feed Roller,

Ejection Roller Pulley, and Paper Ejection Roller ..............................................6-70

6.1.30 Extension Tube, Ink Absorber Box and its Felts, and Antistatic Brush..............6-73

6.1.31 Harness Routing.................................................................................................6-75

6.2 LUBRICATION...............................................................................................................6-78

6.3 ADJUSTMENT ...............................................................................................................6-86

Page 63

6.1 DISASSEMBLY/REASSEMBLY

r

p

d

Safety Precautions

To prevent the creation of secondary problems by mishandling, observe the following precautions

for maintenance work.

(1) If you unpack the package sent

from the user, first check that the

top edge of the head wiper is

flush with that of the head cap

unit before turning on the

machine. If the head wipe

rotrudes or is out of place,

lightly pull up the head wiper an

move it towards the head cap unit

to retract it.

(2) Unplug the power cord from the power outlet before replacing parts or units. When having

access to the power supply, be sure to unplug the power cord from the power outlet.

(3) Be careful not to lose screws, washers, or other parts removed for parts replacement.

(4) Do not remove gears from the document feed roller ASSY (shown on page 6-14) or document

ejection roller ASSY (shown on page 6-19) if at all possible. Once removed, they will become

unusable and new gears will have to be put back in.

(5) When using soldering irons and other heat-generating tools, take care not to damage the resin

parts such as wires, PCBs, and covers.

(6) Before handling the PCBs, touch a metal portion of the machine to discharge static electricity;

otherwise, the electronic parts may be damaged due to the electricity charged in your body.

Head wiper

Head cap unit

(7) When transporting PCBs, be sure to wrap them in conductive sheets such as aluminum foil.

(8) Be sure to reinsert self-tapping screws correctly, if removed.

(9) Tighten screws to the torque values listed on the following pages.

(10) When connecting or disconnecting cable connectors, hold the connector bodies not the cables.

If the connector has a lock, always slide the connector lock to unlock it.

(11) Before reassembly, apply the specified lubricant to the specified points. (Refer to Subsection

6.2 in this chapter.)

(12) After repairs, check not only the repaired portion but also that the connectors and other related

portions function properly before operation checks.

(13) Once the print head unit prints, it will start head locking operation after five seconds from the

end of printing. The head locking operation will take 5 to 10 seconds. NEVER unplug the

power cord before the machine completes the head locking operation; doing so will make the

print head unit unusable and require replacement with a new print head unit.

When you receive the machine from the user or when you pack it for sending it back to the

user, check the head locking state.

6-1

Page 64

Tightening Torque List

Location Screw type Q'ty Tightening torque

N•m (kgf•cm)

ADF thickness adjuster Taptite, pan B M3x6 1 0.39 ±0.10 (4 ±1)

Upper ADF chute Taptite, cup B M3x10 2 0.69 ±0.10 (7 ±1)

Lower ADF chute Taptite, cup B M3x10 2 0.69 ±0.10 (7 ±1)

Grounding wire Taptite, cup B M3x10 1 0.69 ±0.10 (7 ±1)

ADF drive unit Taptite, cup B M3x8 2 0.69 ±0.10 (7 ±1)

ADF motor Screw, pan (s/p washer) M3x6 1 0.69 ±0.10 (7 ±1)

Rear cover Screw, bind B tite 4x12 4 0.98 ±0.10 (10 ±1)

Main PCB shield case Taptite, cup B M3x10 1 0.59 ±0.10 (6 ±1)

Taptite, cup S M3x6 1 0.78 ±0.10 (8 ±1)

Grounding wire Taptite, cup S M3x6 1* 0.59 ±0.10 (6 ±1)

(from the scanner unit)

CCD flat cable guide film Taptite, cup B M3x10 1 0.59 ±0.10 (6 ±1)

Document cover Taptite, bind B M4x12 2 0.98 ±0.20 (10 ±2)

Hinge base R Taptite, cup B M3x10 3 0.69 ±0.10 (7 ±1)

Hinge L Taptite, cup B M3x10 3 0.59 ±0.10 (6 ±1)

Control panel ASSY Taptite, cup B M3x12 6 0.39 ±0.10 (4 ±1)

Scanner open sensor PCB Taptite, cup B M3x8 1 0.49 ±0.10 (5 ±1)

Reinforcement plate Taptite, cup B M3x6 7 0.39 ±0.10 (4 ±1)

Control panel PCB Taptite, cup B M3x6 2 0.39 ±0.10 (4 ±1)

Scanner top cover Taptite, cup B M4x12 4 0.98 ±0.20 (10 ±2)

Guide plate Taptite, cup B M3x8 3 0.69 ±0.10 (7 ±1)

CCD HP sensor plate Taptite, cup B M3x8 1 0.69 ±0.10 (7 ±1)

Flat cable clamp Taptite, cup B M3x8 2 0.69 ±0.10 (7 ±1)

Edge cover Taptite, cup B M3x10 4 0.59 ±0.10 (6 ±1)

Scanner link guides Taptite, cup B M3x10 2 0.59 ±0.10 (6 ±1)

Main cover Screw, bind B tite M4x12 3 0.98 ±0.10 (10 ±1)

Taptite, cup B M3x10 1 0.59 ±0.10 (6 ±1)

Media PCB frame (To main chassis) Taptite, cup S M3x6 2 0.78 ±0.10 (8 ±1)

Media cover (To lower cover) Taptite, cup B M3x10 1 0.59 ±0.10 (6 ±1)

Media PCB frame (To media cover) Taptite, cup B M3x10 2 0.59 ±0.10 (6 ±1)

Media PCB Taptite, cup S M3x6 3 0.59 ±0.10 (6 ±1)

Main PCB shield frame Taptite, cup S M3x6 3 0.78 ±0.10 (8 ±1)

Centronics interface Screw, pan M3x6 2 0.39 ±0.05 (4 ±0.5)

USB Screw, pan M3x6 1 0.39 ±0.05 (4 ±0.5)

Main PCB Taptite, cup S M3x6 4 0.78 ±0.10 (8 ±1)

ASF Taptite, cup S M3x6 5 0.78 ±0.10 (8 ±1)

Separation pad ASSY Taptite, bind B M3x10 2 0.59 ±0.10 (6 ±1)

Manual feed slot cover sensor Taptite, cup B M3x8 1 0.59 ±0.10 (6 ±1)

FG plate R (To main chassis) Taptite, cup S M3x6 1 0.78 ±0.10 (8 ±1)

(To NCU/PS shield) Taptite, cup S M3x6 1 0.59 ±0.10 (6 ±1)

FG plate L (To main chassis) Taptite, cup S M3x6 1 (2)* 0.78 ±0.10 (8 ±1)

NCU/PS shield box Taptite, cup B M3x10 2 0.59 ±0.10 (6 ±1)

Upper NCU/PS shield Taptite, cup S M3x6 3 0.59 ±0.10 (6 ±1)

AC cord grounding wire Screw, pan (washer) M4x8DB 1 0.59 ±0.10 (6 ±1)

Power supply PCB Taptite cup S M3x6 4 0.59 ±0.10 (6 ±1)

NCU PCB Taptite, cup S M3x6 1 0.59 ±0.10 (6 ±1)

* The FG plate L is secured with two screws together with the grounding wire coming from the scanner unit.

6-2

Page 65

Location Screw type Q'ty Tightening torque

N•m (kgf•cm)

Purge unit support Taptite, cup B M3x10 1 0.59 ±0.10 (6 ±1)

Purge unit Taptite, cup B M3x8 2 0.59 ±0.10 (6 ±1)

Purge unit stopper Taptite, cup B M3x8 1 0.59 ±0.10 (6 ±1)

Driver PCB Taptite, cup S M3x6 4 0.78 ±0.10 (8 ±1)

Idle pulley holder Screw, pan (s/p washer) M3x6 1 0.69 ±0.10 (7 ±1)

Shoulder screw 1 0.78 ±0.10 (8 ±1)

Taptite, cup S, M3x6 1 0.78 ±0.10 (8 ±1)

Carriage motor Screw, pan (s/p washer) M3x6 2 0.69 ±0.10 (7 ±1)

Paper chute Shoulder screw 1 0.78 ±0.10 (8 ±1)

Taptite, cup S M3x6 1 0.78 ±0.10 (8 ±1)

Sensor support (Ink empty sensor) Taptite, cup S M3x6 1 0.78 ±0.10 (8 ±1)

Star wheel support Taptite, pan B M3x10 2 0.59 ±0.10 (6 ±1)

Main chassis Screw, bind B tite M4x12 4 0.98 ±0.10 (10 ±1)

Ink empty sensor PCB Taptite, cup B M3x8 1 0.59 ±0.10 (6 ±1)

Tension plate R Screw, pan (s/p washer) M3x6 1 0.69 ±0.10 (7 ±1)

Paper feed motor Screw, pan (s/p washer) M3x6 2 0.69 ±0.10 (7 ±1)

Tension plate F Screw, pan (s/p washer) M3x6 1 0.69 ±0.10 (7 ±1)

6-3

Page 66

Preparation

Prior to proceeding to the disassembly procedure,

(1) Unplug

(2) Remove

NOTE: Do not remove the ink cartridges when disassembling the machine except when removing

the print head unit.

Telephone line cord

- the modular jack of the telephone line,

- the PC interface cable if connected (Not shown below), and

- the modular jack of an external telephone set if connected (Not shown below).

- the input paper support and

- the output paper support.

Input paper support

Output paper support

How to Access the Object Component

• On the next page is a disassembly order flow which helps you access the object components. To

remove the purge unit, for example, first find it on the flow and learn its number (

case). You need to remove parts numbered

• Unless otherwise specified, the disassembled parts or components should be reassembled in the

reverse order of removal.

in this

, , , and so as to access the purge unit.

6-4

Page 67

Disassembly Order Flow

Document

pressure bar

ADF motor

Document feed roller ASSY

Gear cover

Separation roller ASSY

ADF components on the

upper ADF chute

6.1.3

Main PCB shield case

Manual feed slot cover

Rear cover

6.1.6

ADF cover

6.1.2

6.1.15

6.1.7

Document guide base

6.1.2

Pressure rollers

Upper ADF chute

Separation rubber unit

ADF thickness adjuster

6.1.8

(NOTE 1)

ASF

- ASF roller ASSY

6.1.7

Document guide clips

Document ejection roller

ASSY

(NOTE 5)

Document sensor actuators

Document sensor PCB

ADF components on the

lower ADF chute

6.1.4

Control panel PCB with

scanner open sensor PCB

Reinforcement plate

FPC key

LCD

-----

Control panel ASSY

6.1.9

6.1.5

6.1.5

Keys

ADF document

output support

extension

Document cover

open sensor

(NOTE 2)

Document cover

Hinges

Scanner unit

6.1.10

Scanner unit with document cover

6.1.7

Lower ADF chute

Pinch rollers

(NOTE 4)

6.1.8