Brother BAS-411, BAS-415 Service Manual

SERVICE

MANUAL

FOR

BAS

-4

11

BAS -415

SINGLE HEAD ELECT RONIC EMBROIDERY

MACHINE

I

· ·

.

~

-

From the library of: Superior Sewing Machine & Supply LLC

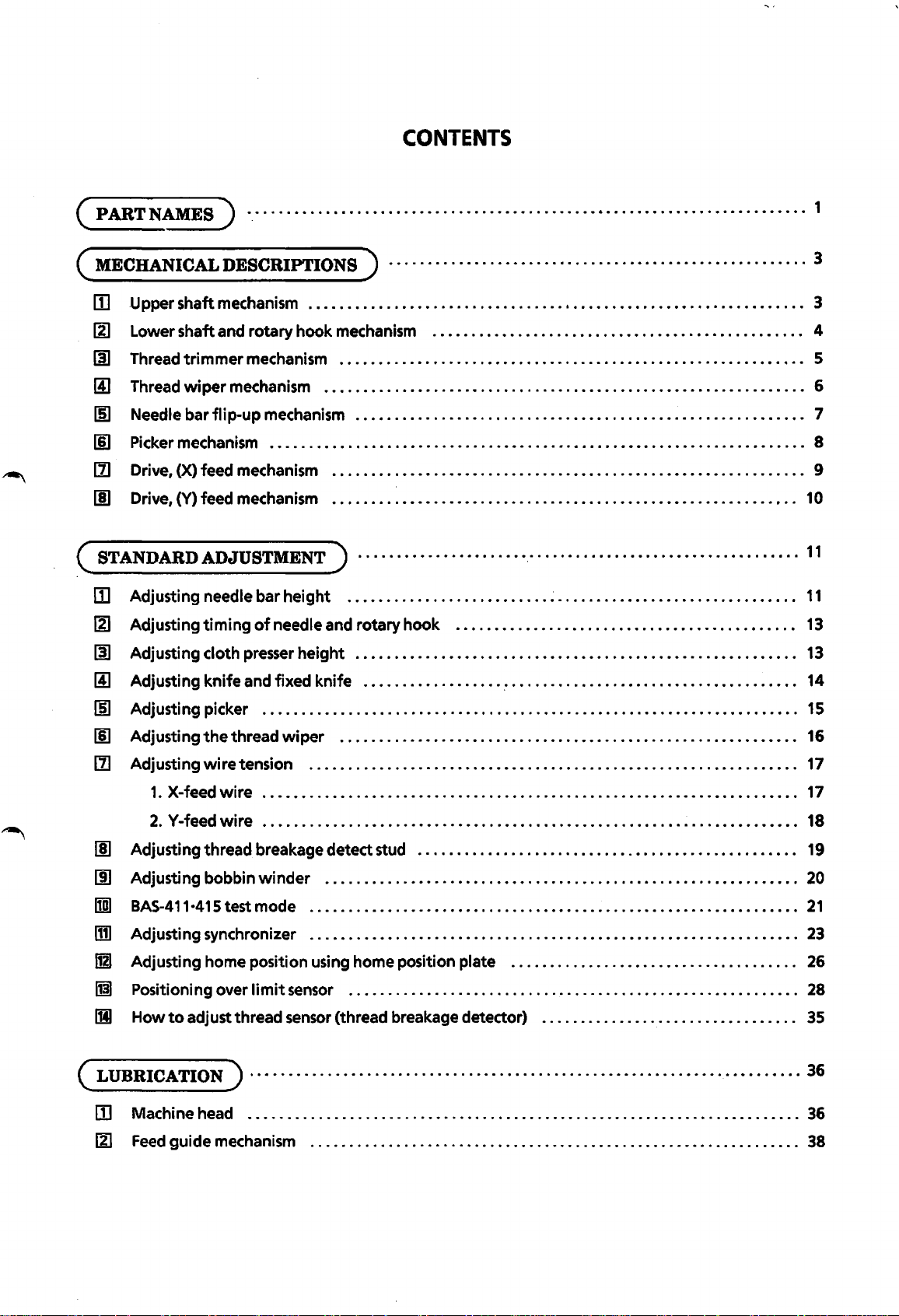

CONTENTS

(

PART

NAMES )

·.

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1

( MECHANICAL

DESCRIPTIONS ) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3

[I] .upper

shaft

mechanism . . . . . • . . . . . . . . . . . . . . . . . • • . . . . . . . . • . . . . . . . . . . • . . • • . . • . . . . . . . . . . . . 3

00

Lower

shaft

and

rotary

hook

mechanism . . . . . . • • • • • . . . . . . . . . . . . . . . • . . . • • . . • • . . . . . . . • . . . . 4

00

Thread

trimmer

mechanism . • . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . • • • • • • . • 5

[j]

Thread

wiper

mechanism . • . . • . . . . . . . . . . . . . . • . • . . . . . . . . . . . . . . . . . . . • • • • • . • • . • . . . . . . . • . . . 6

[§] Needle

bar

flip-up

mechanism . . • • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . • • • . • • . 7

[§] Picker mechanism • . . . . . . . . . . . . . . . . . . . . . . . . . . . • . • • . . . . . . . • . . . . . . . • . • . . • • . • . . . . . . • . . . . . . 8

[1]

Drive, (X)

feed

mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • • • . . . . • . . . • . . . . . . . . . . . . . . . • . 9

[I]

Drive, (Y)

feed

mechanism . . . . . . . . . . . . . . . . . . . . • . • . . . . . . . . . . . . . . . . • . • . . • . . . . . . . . . . . . • • . 10

( STANDARD ADJUSTMENT ) · · · · · · · · · · · · · · · · · · · · ·

·.

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

11

[I]

Adjusting

needle

bar

height

...•..............••......

~

. . . . . . . . . • • . . . . . . . . • . . • • • • • • • • •

11

~

Adjusting

timing

of

needle and

rotary

hook

. . • . . . • • . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . • • • • . • 13

00

Adjusting

cloth

presser

height

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . • . . . . . . . . . . . . . . . . • . 13

[j]

Adjusting

knife

and

fixed

knife

. • . . . . . . . . . . . . . • • . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . . . 14

[§]

Adjusting

picker . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . . . . . . . . . • • • • . . 15

[§]

Adjusting

the

thread

wiper

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . • . . . . . . . . . • . . . . . . . • • 16

[1]

Adjusting

wire

tension

.....•.................•........................••...•.•...••••

17

1.

X-

feed

wire

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . • . . . . . . • . . . . . . . . . . . . . • . • • • • • . 17

2.

Y

-feed

wire

. . . . . . . . . . . . . . • . . . . . . . . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . . . . . . • . . . . 18

00

Adjusting

thread

breakage

detect

stud

..........................•.•.....•.•............

19

00

Adjusting

bobbin

winder

...................•.........................................

20

lim

BAS-411·415

test

mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • • • • • • . . . . • . . . . . . . . .

21

In]

Adjusting

synchronizer . . . . . . . • . • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . 23

1m

Adjusting

home

position

using

home

position

plate

. . . . . . . . . . . . . . . . • . . . • . . . . . . . . . • . . . . . . 26

lj}

Positioning

over

limit

sensor

...................................•..••..•...............

28

IB1

How

to

adjust

thread

sensor (thread breakage detector) . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . 35

( LUBRICATION ) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 36

[I]

Machine

head . . . . . . . . . . . . . . . . . . . . . . . . • . . . • . . . . . . . . . . . . . . . . . . . . . . • • • • • . . • . . . . . . . . . . . . 36

~

Feed

guide

mechanism

.......................................•........•..............

38

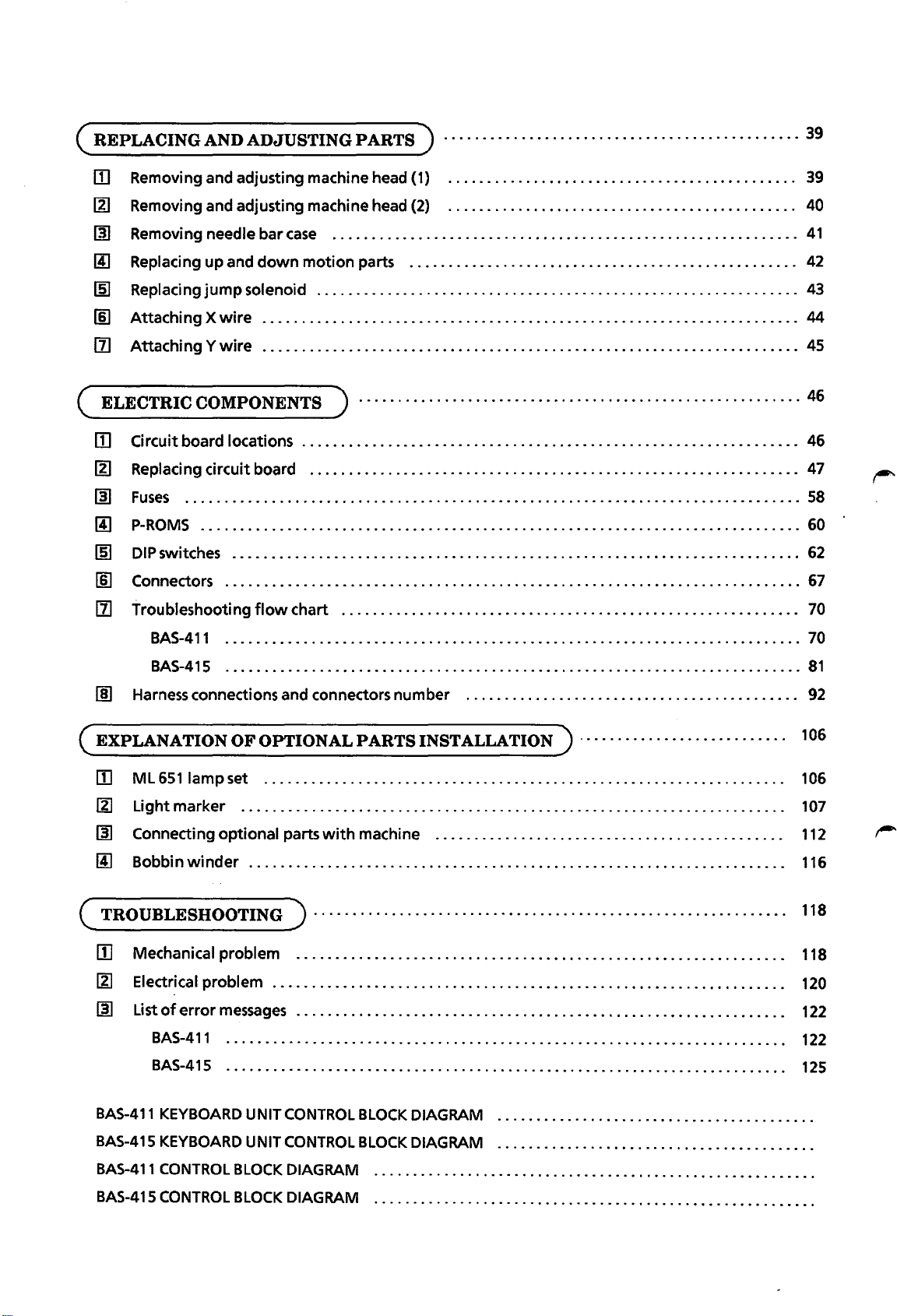

From the library of: Superior Sewing Machine & Supply LLC

(

REPLACINGANDADJUSTINGPARTS)

· · · ·

··

· · · · · · · · · · · · ·

··

· · · ·

··

· · · · · · · ·

··

· · · · · · ·

··

39

[I]

Removing and

adjusting

machine head (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

~

Removing and

adjusting

machine head (2) .

..

. . . . .

..

.

..

..

. . . . . . .

..

. . . . .

.. ..

..

.. .. ..

. . . . 40

lm

Removing needle

bar

case

............................................................

41

1!1

Replacing

up

and

down

motion

parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

~

Replacing

jump

solenoid

..............................................................

43

[§]

Attaching

X

wire

.....................................................................

44

[1]

Attaching

Y

wire

.....................................................................

45

(

ELECTRIC

COMPONENTS ) · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 46

[!)

Circuit

board

locations

...•............................................................

46

~

Replacing

circuit

board

...............................................................

47

00

Fuses

...............................................................................

58

(!]

P-ROMS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

~

DIP switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

[§]

Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

[1]

troubleshooting

flowchart

...........................................................

70

BAS-411

..........................................................................

70

BAS-415

..........................................................................

81

00

Harness connections and connectors

number

...........................................

92

(

EXPLANATIONOFOPTIONALPARTSINSTALLATION)

· · · · · · · · · · · · · · · · · · · · · · · · · · · 106

[]]

ML

6511amp set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

~

Light

marker

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

00

Connecting

optional

parts

with

machine . . . . . .

..

..

. . . . . . . . . . . . .

.. ..

. . . .

..

. .

..

. . . . .

..

. 112

1!1

Bobbin

winder

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

(

TROUBLESHOOTING)·····························································

118

[!) Mechanical

problem

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

~ Electrical

problem

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

00

List

of

error

messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

BAS-411 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

BAS-415 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

BAS-411 KEYBOARD

UN

IT CONTROL

BLOCK

DIAGRAM

BAS-415 KEYBOARD UNIT CONTROL

BLOCK

DIAGRAM

BAS-411 CONTROL

BLOCK

DIAGRAM

BAS-41

5 CONTROL

BLOCK

DIAGRAM

.........................................................

.........................................................

From the library of: Superior Sewing Machine & Supply LLC

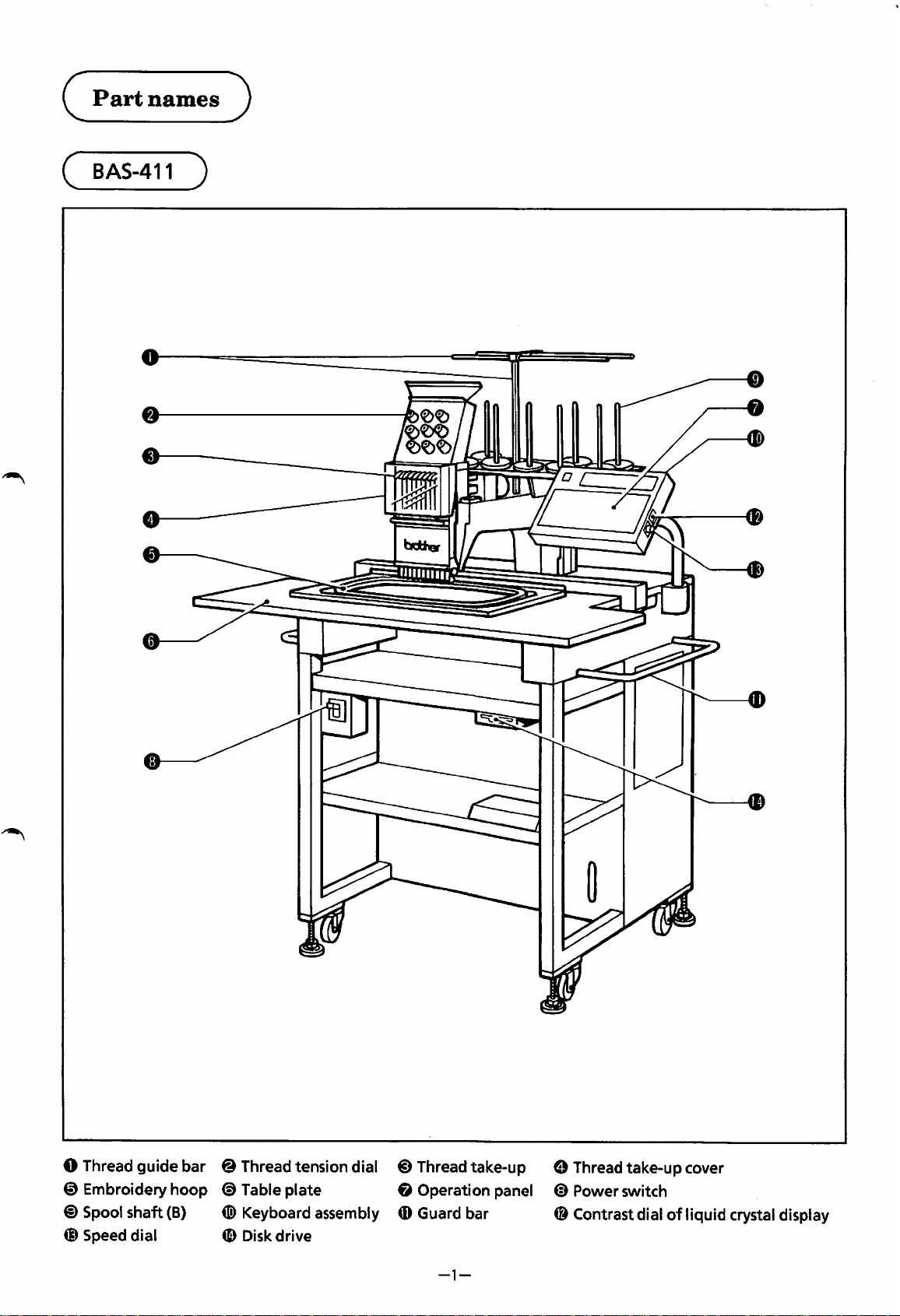

(

Part

names

)

(

BAS-411

)

0 Thread

guide

bar

@ Thread tension dial

@)

Thread take-up

0 Embroidery

hoop

<9

Table plate 6 Operation panel

@)Spool

shaft

(B)

(!) Keyboard assembly

CD

Guard bar

@ Speed dial

4D

Disk drive

-1-

0 Thread take-up cover

@)

Power switch

48

Contrast dial

of

liquid

crystal display

From the library of: Superior Sewing Machine & Supply LLC

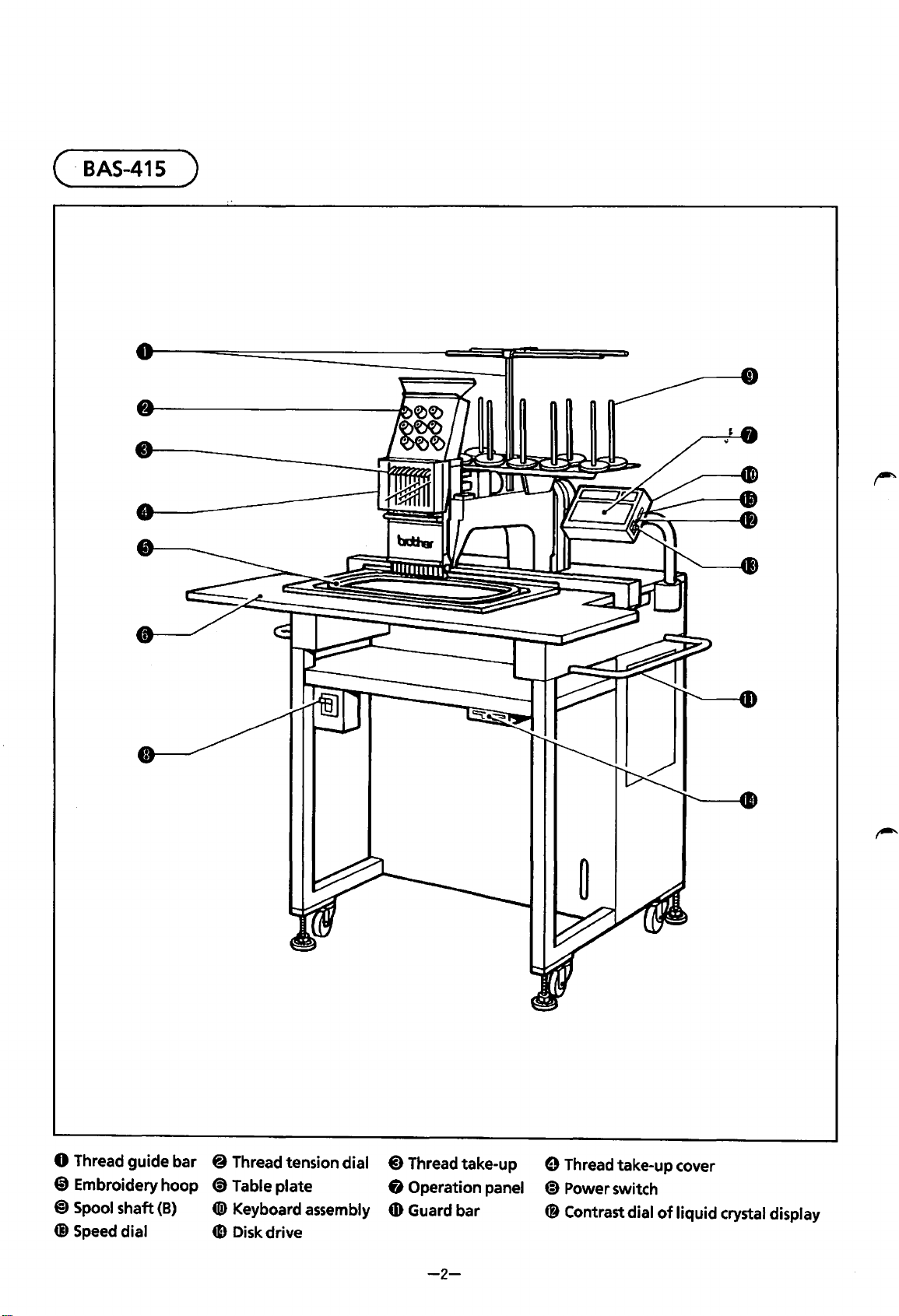

( ·

BAS-415

)

0 Thread

guide

bar 8 Thread tension dial

@)

Thread take-up

@ Embroidery

hoop

(!) Table

plate

8 Operation panel

@)

Spool

shaft

(B)

tD)

Keyboard assembly

4D

Guard bar

Q) Speed dial

4D

Disk drive

-2-

8 Thread take-up cover

~

Power switch

C8

Contrast dial

of

liquid

crystal display

From the library of: Superior Sewing Machine & Supply LLC

(MECHANICAL

DESCRIPTIONS )

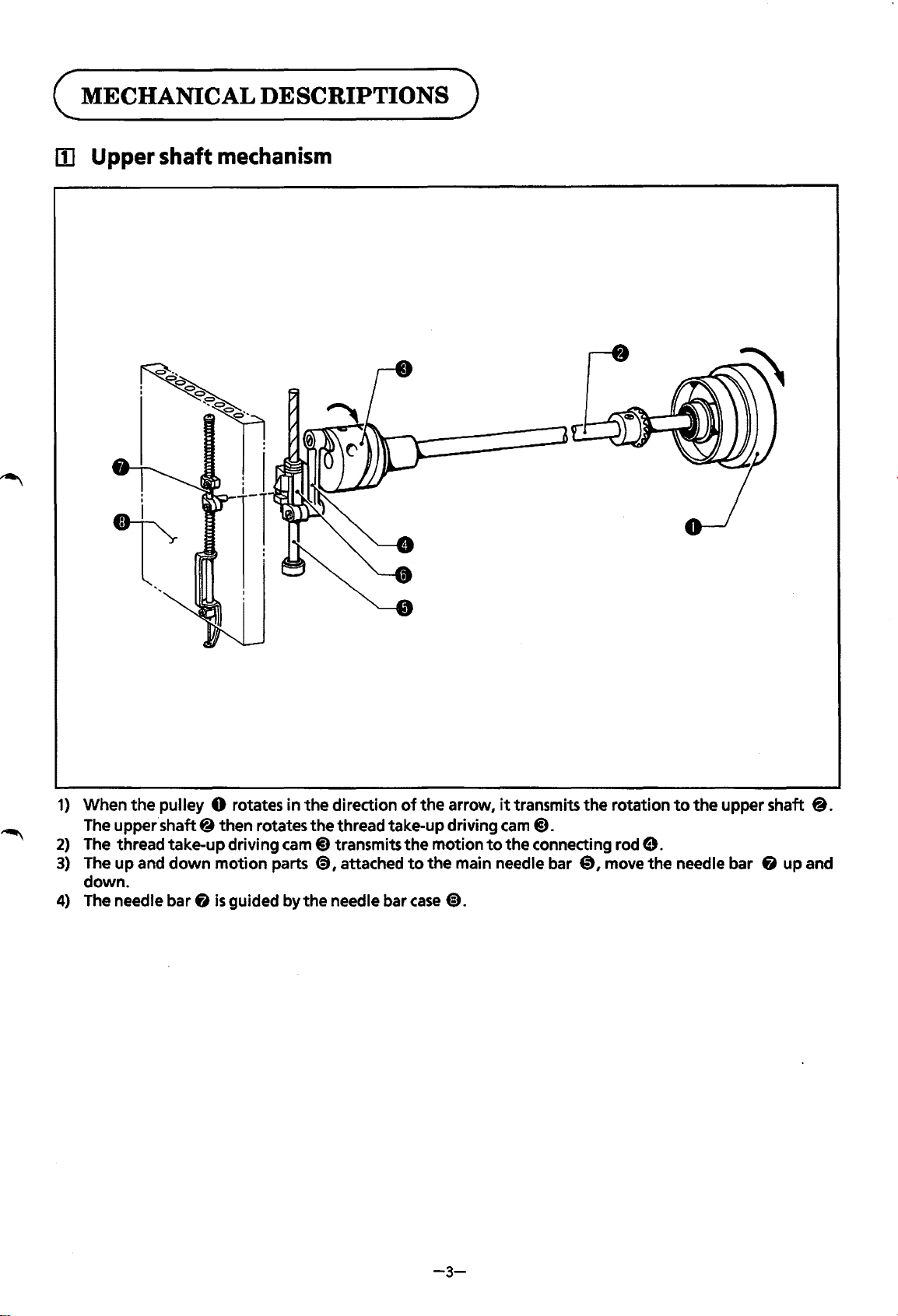

lii Upper shaft

mechanism

1)

When

the

pulley 0 rotates

in

the

direction

of

the

arrow,

it

transmits

the

rotation

to

the

upper shaft

8.

The upper.shaft 8 then rotates

the

thread take-up driving

cam

@).

2)

The thread take-up driving

cam@)

transmits

the

motion

to

the

connecting rod

9.

3)

The

up

and

down

motion

parts

<9,

attached

to

the

main needle bar

0,

move

the

needle bar 8 up and

down.

4)

The needle bar 8

is

guided by

the

needle bar

case

@).

-3-

From the library of: Superior Sewing Machine & Supply LLC

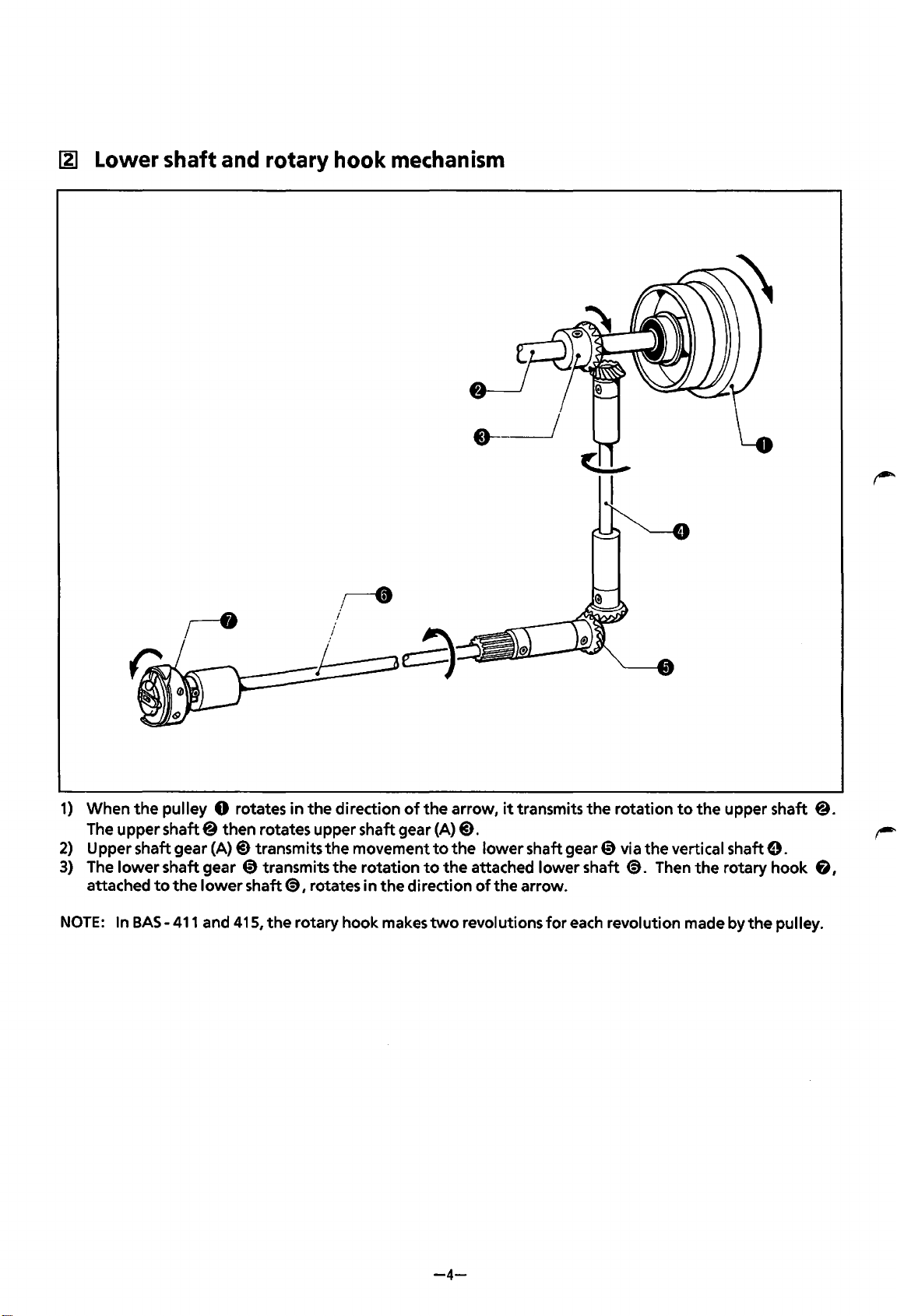

~

Lower shaft and rotary hook mechanism

1)

When

the

pulley 0 rotates

in

the

direction

of

the

arrow,

it

transmits

the

rotation

to

the

upper shaft @.

The upper

shaft@

then rotates upper shaft gear (A)@).

2)

Upper shaft gear

(A)@)

transmits

the

movement

to

the

lower

shaft gear 0 via the vertical shaft

e.

3)

The

lower

shaft gear 0 transmits

the

rotation

to

the

attached lower shaft

@).

Then

the

rotary hook

6,

attached

to

the

lower

shaft@), rotates in

the

direction

of

the arrow.

NOTE:

In BAS-

411

and 415,

the

rotary hook makes

two

revolutions

for

each revolution made by

the

pulley.

-4-

From the library of: Superior Sewing Machine & Supply LLC

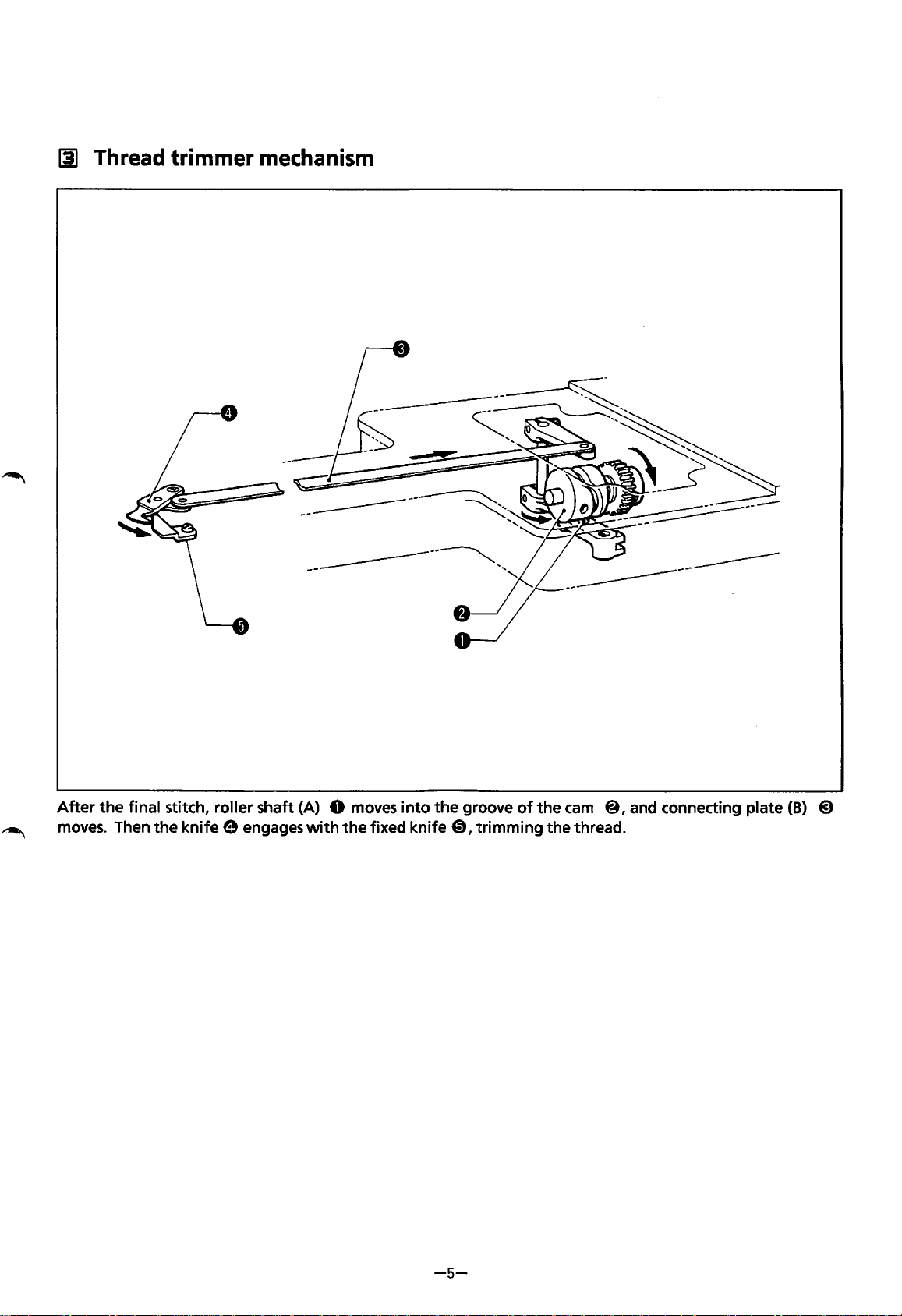

~

Thread trimmer

mechanism

-------------------

After

the

final stitch, roller shaft (A) 0

moves

into

the

groove

of

the

cam

@,and connecting plate

(B)

@)

~

moves.

Then the knife 0 engages

with

the fixed knife

0,

trimming the thread.

-5-

From the library of: Superior Sewing Machine & Supply LLC

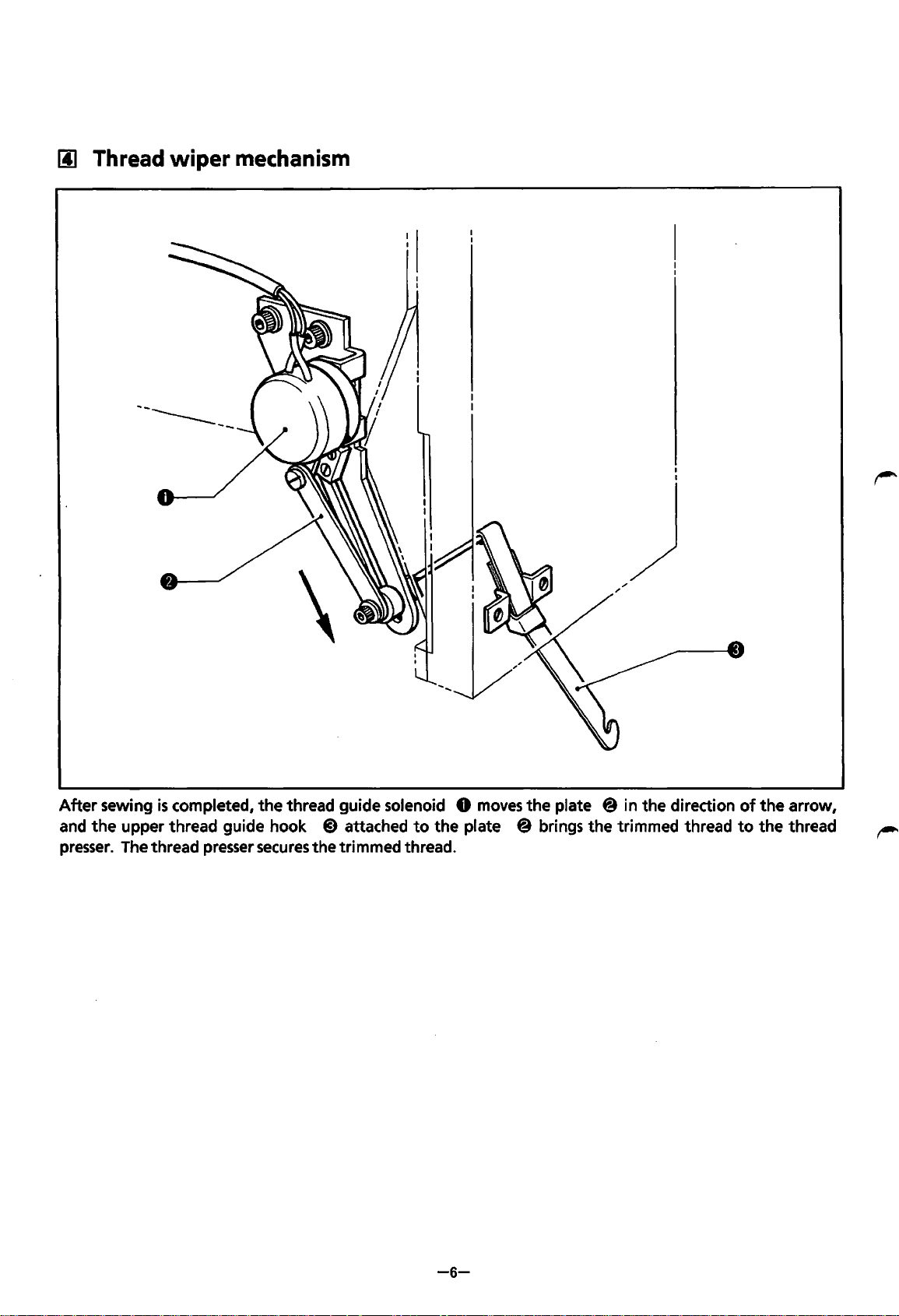

II]

Thread

wiper

mechanism

~--------

After

sewing

is

completed,

the

thread guide solenoid 0

moves

the

plate

@in

the direction

of

the

arrow,

and

the

upper thread guide hook

@)

attached

to

the plate @ brings the trimmed thread

to

the

thread

presser.

The thread presser

secures

the trimmed thread.

-6-

From the library of: Superior Sewing Machine & Supply LLC

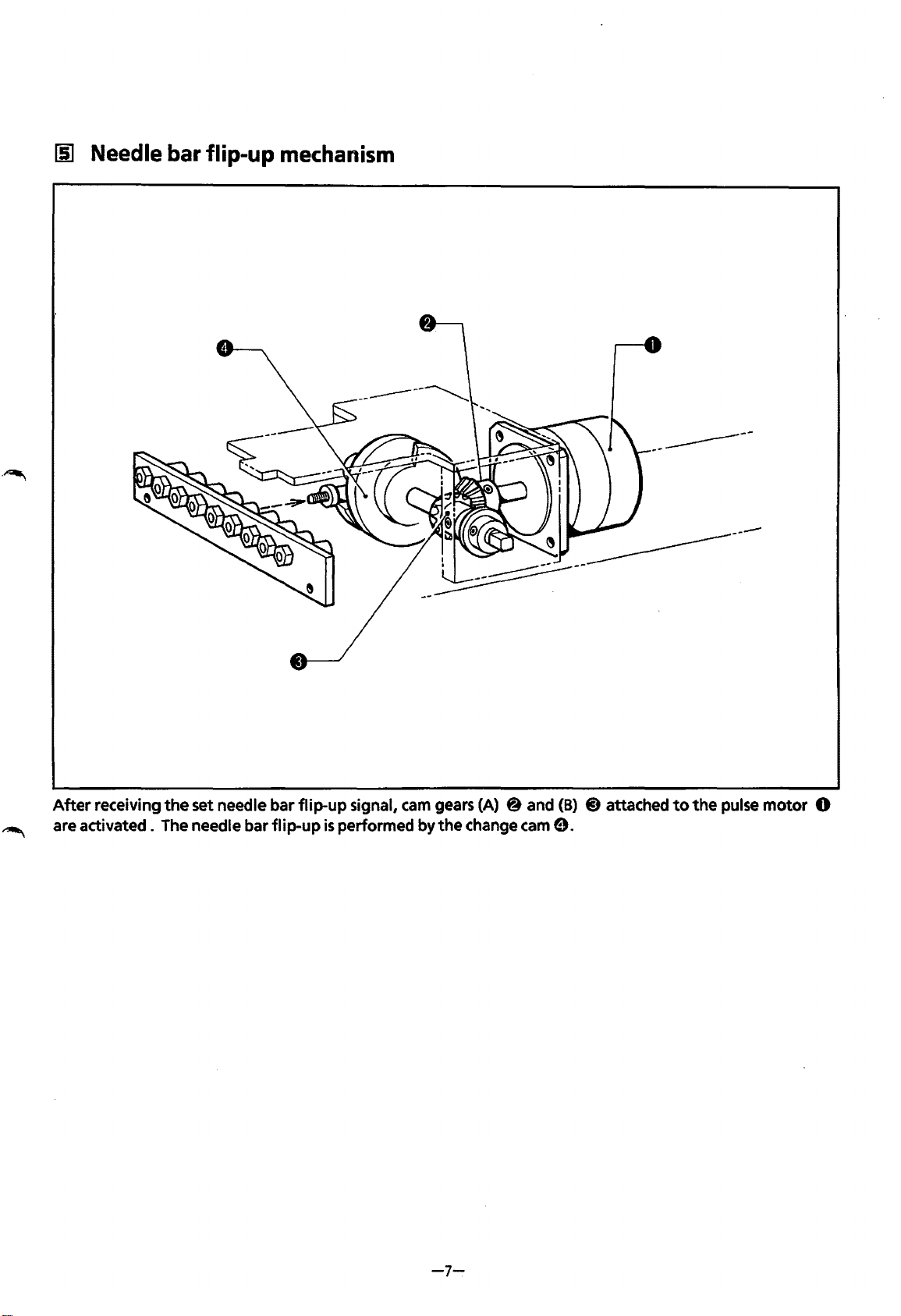

[§]

Needle

bar

flip-up

mechanism

~~------

After

receiving

the

set needle bar

flip-up

signal,

cam

gears (A) 8 and

(B)

@)

attached

to

the

pulse

motor

0

are

activated.

The needle bar

flip-up

is

performed

by

the

change cam

9.

-7-

From the library of: Superior Sewing Machine & Supply LLC

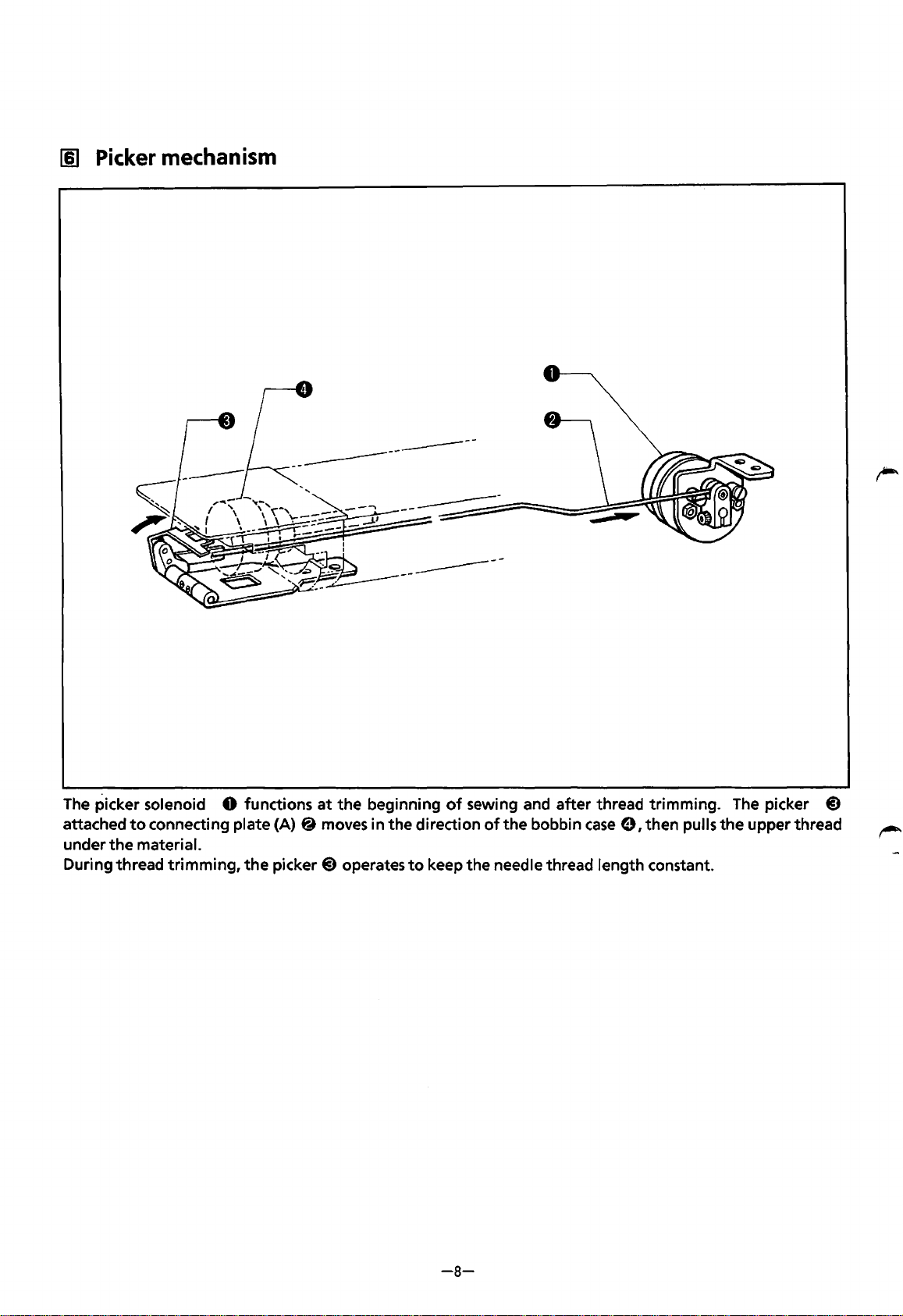

[§]

Picker

mechanism

------------

The

picker solenoid 0 functions

at

the

beginning

of

sewing and after thread trimming.

The

picker

@)

attached

to

connecting plate

(A)@

moves in the direction

of

the bobbin

case

e, then pulls the upper thread

under

the

material.

During thread trimming,

the

picker@) operates

to

keep the needle thread length constant.

-8-

From the library of: Superior Sewing Machine & Supply LLC

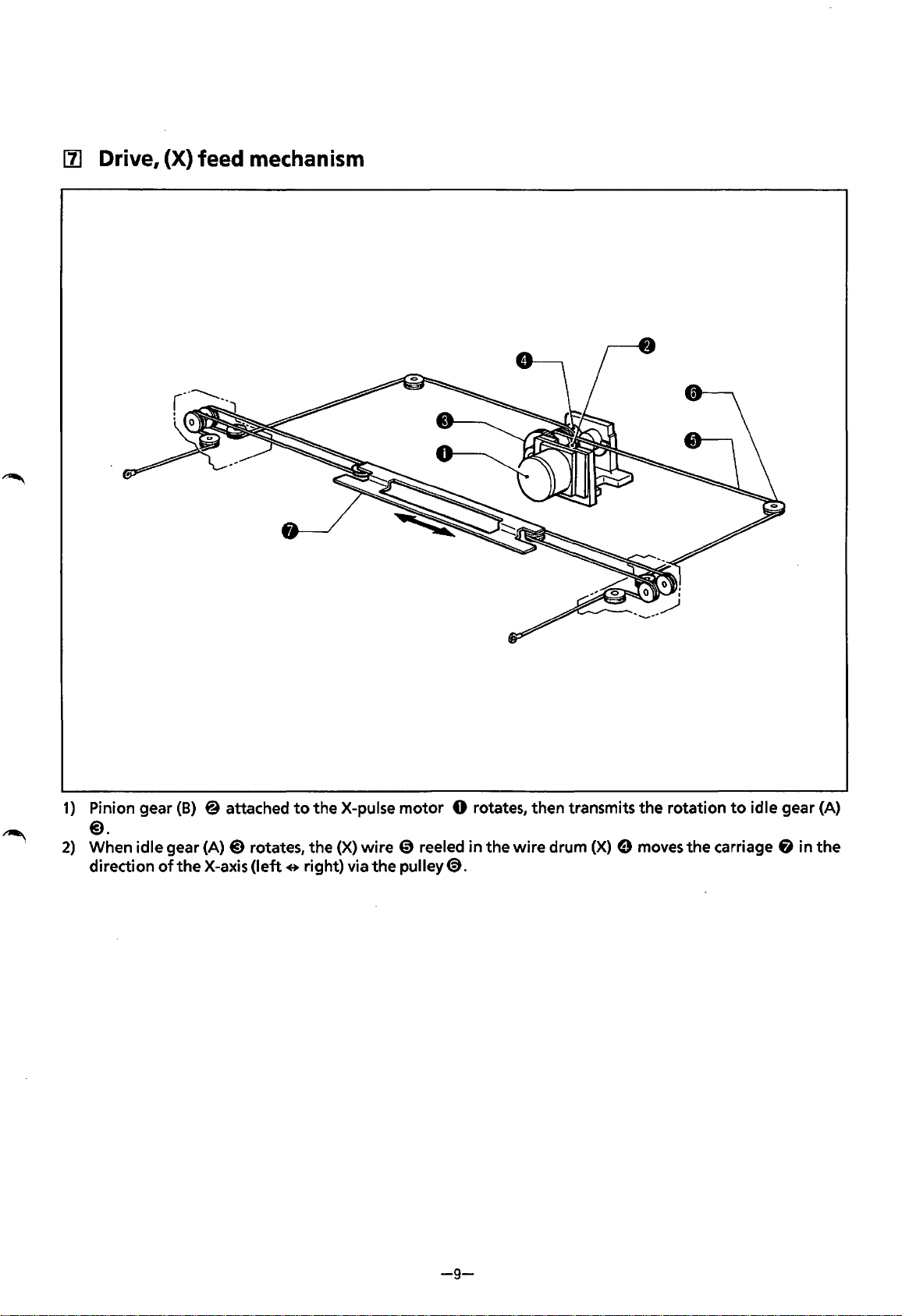

[1]

Drive, (X) feed mechanism

1)

Pinion gear

(B)

@ attached

to

the X-pulse motor 0 rotates, then transmits the rotation

to

idle gear (A)

@).

2)

When idle gear (A)@) rotates, the (X) wire

CD

reeled in the wire drum

(X)

e moves

the

carriage & in

the

direction

of

the

X-axis

(left

e right) via

the

pulley

<9.

-9-

From the library of: Superior Sewing Machine & Supply LLC

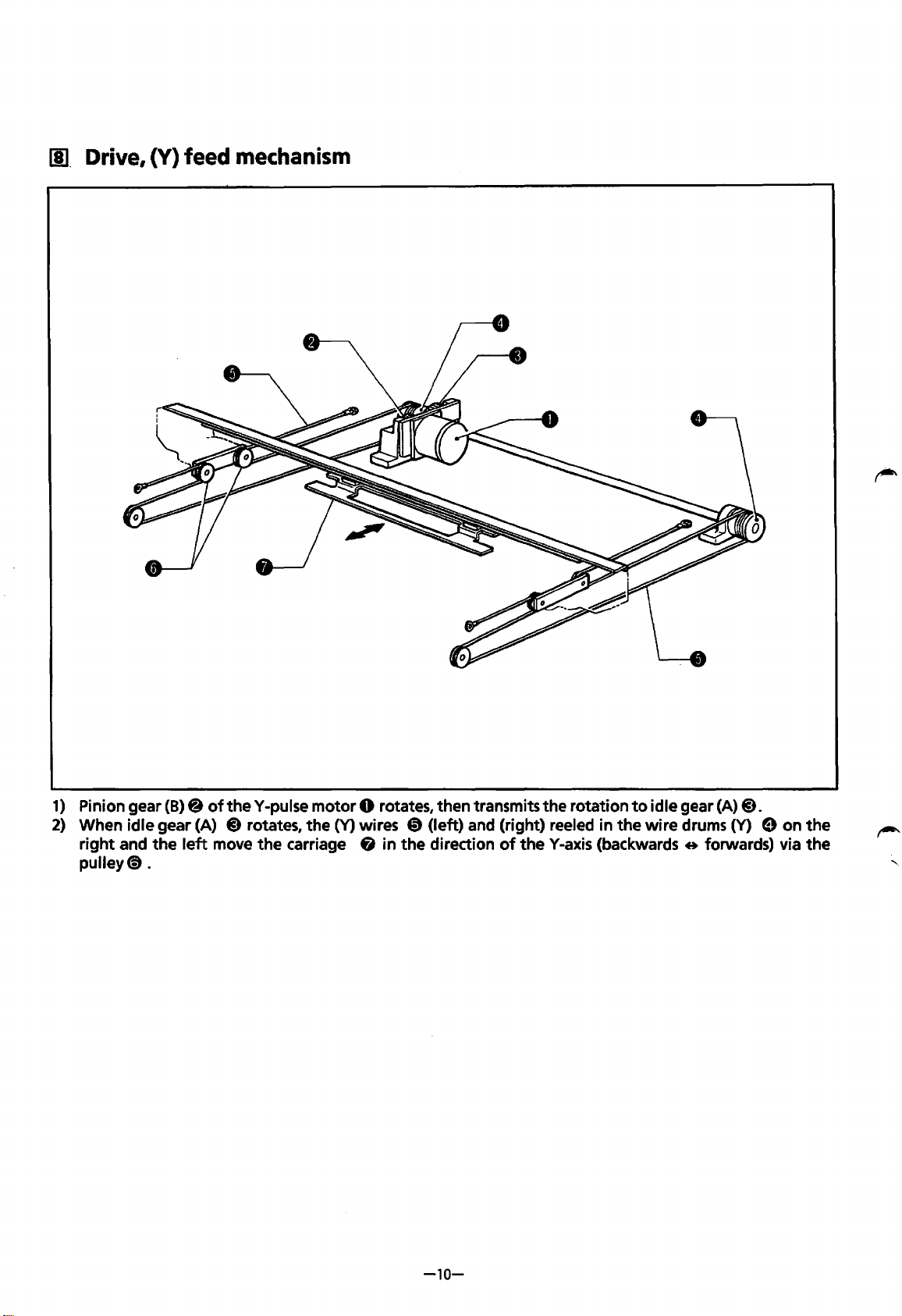

[II.

Drive, (Y) feed

mechanism

1)

Pinion gear (B)@

of

theY-pulse motor 0 rotates, then transmits the rotation

to

idle gear

(A)@).

2) When idle gear (A) @)rotates, the

(Y)

wires @)(left) and (right) reeled in

the

wire drums

(Y)

8 on

the

right

and the

left

move the carriage

fi

in the direction

of

theY-axis (backwards e forwards) via the

pulley8.

-10-

From the library of: Superior Sewing Machine & Supply LLC

c

STANDARD

ADJUSTMENT

)

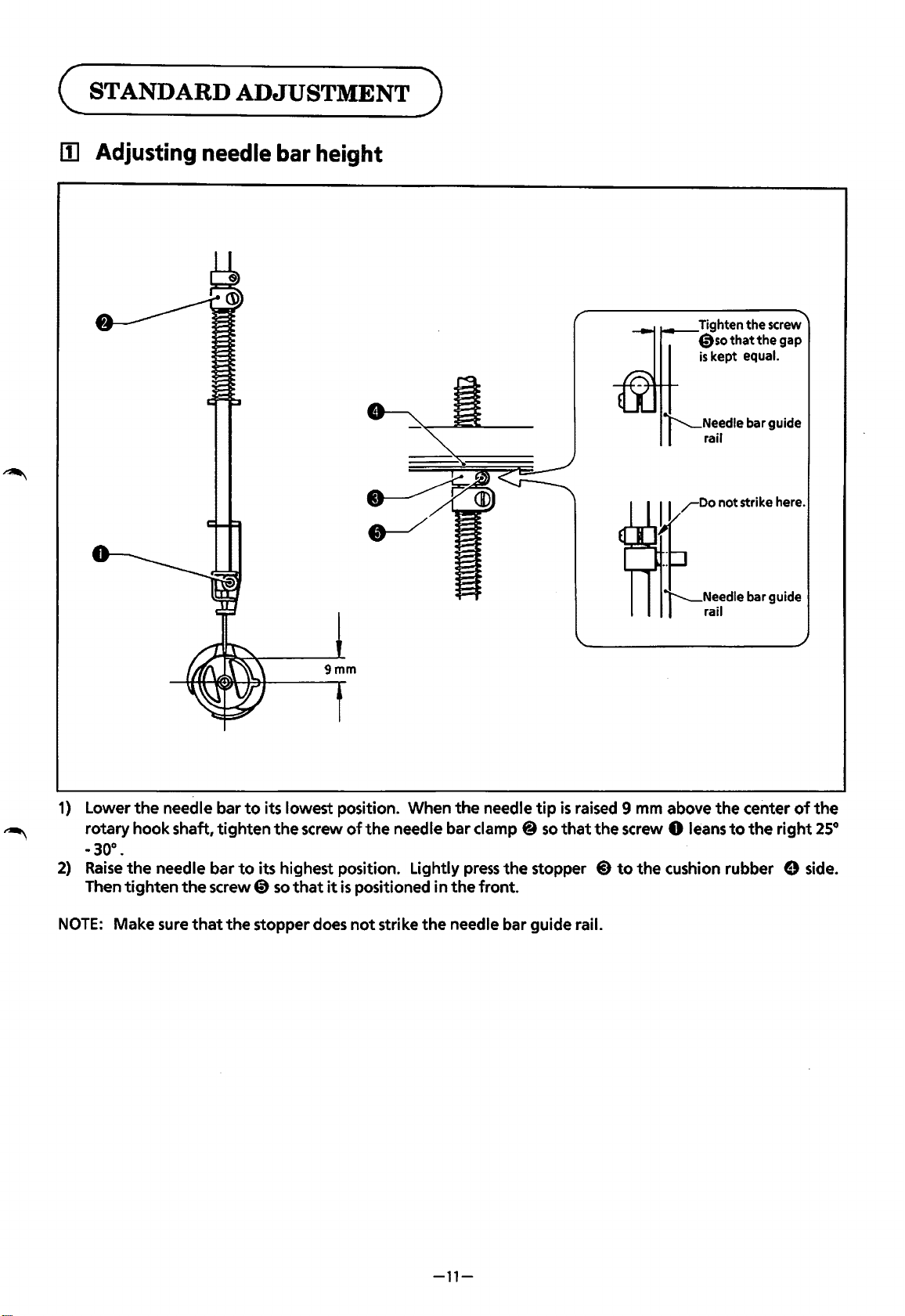

lii

Adjusting

needle

bar

height

Tighten the screw

0so

that

the

gap

is

kept equal.

1)

Lower

the

needle bar

to

its lowest position. When

the

needle

tip

is

raised 9 mm above

the

center

of

the

~

rotary hook shaft,

tighten

the

screw

of

the

needle bar clamp @

so

that

the

screw 0 leans

to

the

right

25°

-30°.

2)

Raise

the

needle bar

to

its highest position. Lightly

press

the

stopper

@)

to

the

cushion rubber 9 side.

Then

tighten

the

screw 0

so

that

it

is

positioned in

the

front.

NOTE:

Make sure

that

the

stopper does

not

strike

the

needle bar guide rail.

-11-

From the library of: Superior Sewing Machine & Supply LLC

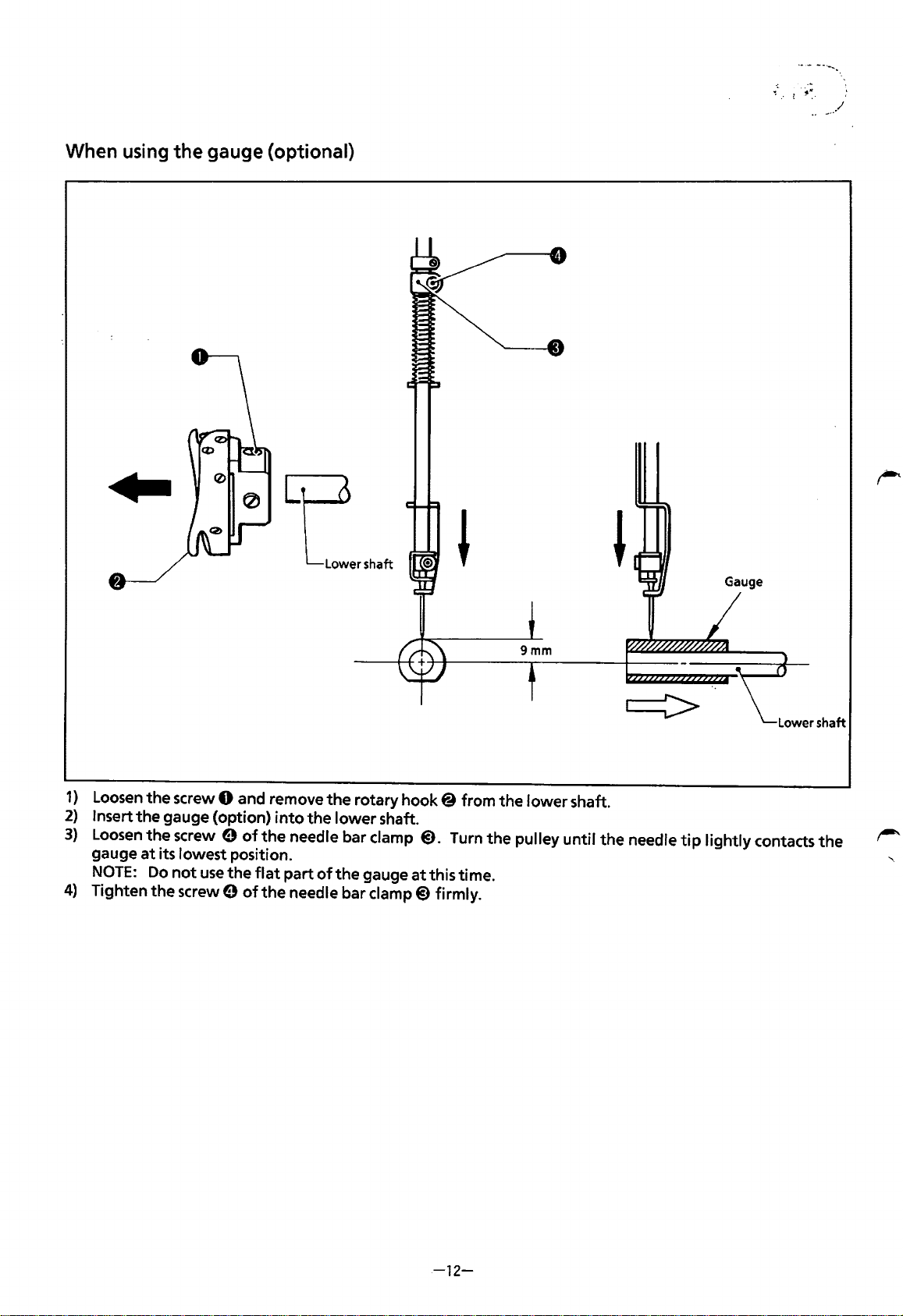

When using

the

gauge (optional)

Gauge

1)

Loosen

the screw 0 and remove

the

rotary

hook@

from the lower shaft.

2)

Insert the gauge (option)

into

the lower shaft.

3)

Loosen

the

screw e

of

the

needle bar clamp

@).

Turn

the

pulley until the needle

tip

lightly contacts

the

gauge

at

its lowest position.

NOTE:

Do

not

use

the

flat

part

of

the

gauge

at

this time.

4)

Tighten

the

screw 9

of

the

needle bar

clamp@)

firmly.

-12-

From the library of: Superior Sewing Machine & Supply LLC

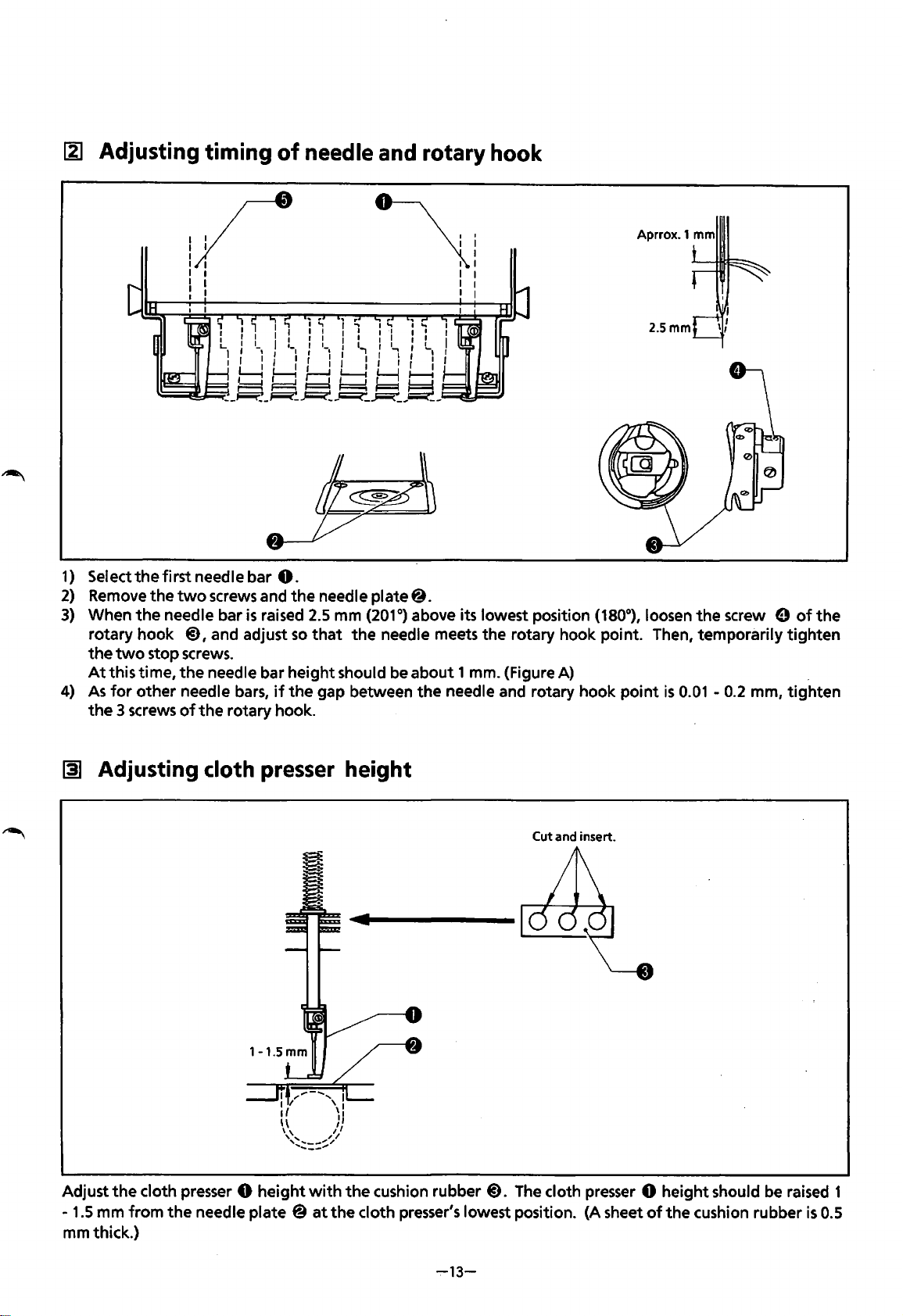

~ Adjusting timing

of

needle and rotary hook

1/

I I

I

I

I

I I

I I

: I

1)

Selectthefirstneedlebar

0.

\

I

I

I

I

I I

I I

I I

2)

Remove

the

two

screws and

the

needle plate@.

Aprrox.1 mm

2.5mm

3)

When

the

needle bar

is

raised

2.5

mm

(201°)

above its lowest position (180°), loosen

the

screw 0

of

the

rotary hook

@),

and adjust

so

that

the

needle meets

the

rotary hook point. Then, temporarily

tighten

the

two

stop screws.

At

this time,

the

needle bar height should be about 1 mm. {Figure A) .

4)

As

for

other needle bars,

if

the

gap between

the

needle and rotary hook

point

is

0.01

-

0.2

mm,

tighten

the

3 screws

of

the

rotary hook.

~

Adjusting cloth presser height

Cut and insert.

Adjust

the

cloth presser 0

height

with

the

cushion rubber

@).

The cloth presser 0 height should be raised 1

-

1.5

mm

from

the

needle plate @

at

the

cloth presser's lowest position. {A sheet

of

the

cushion rubber

is

0.5

mmthick.)

~13-

From the library of: Superior Sewing Machine & Supply LLC

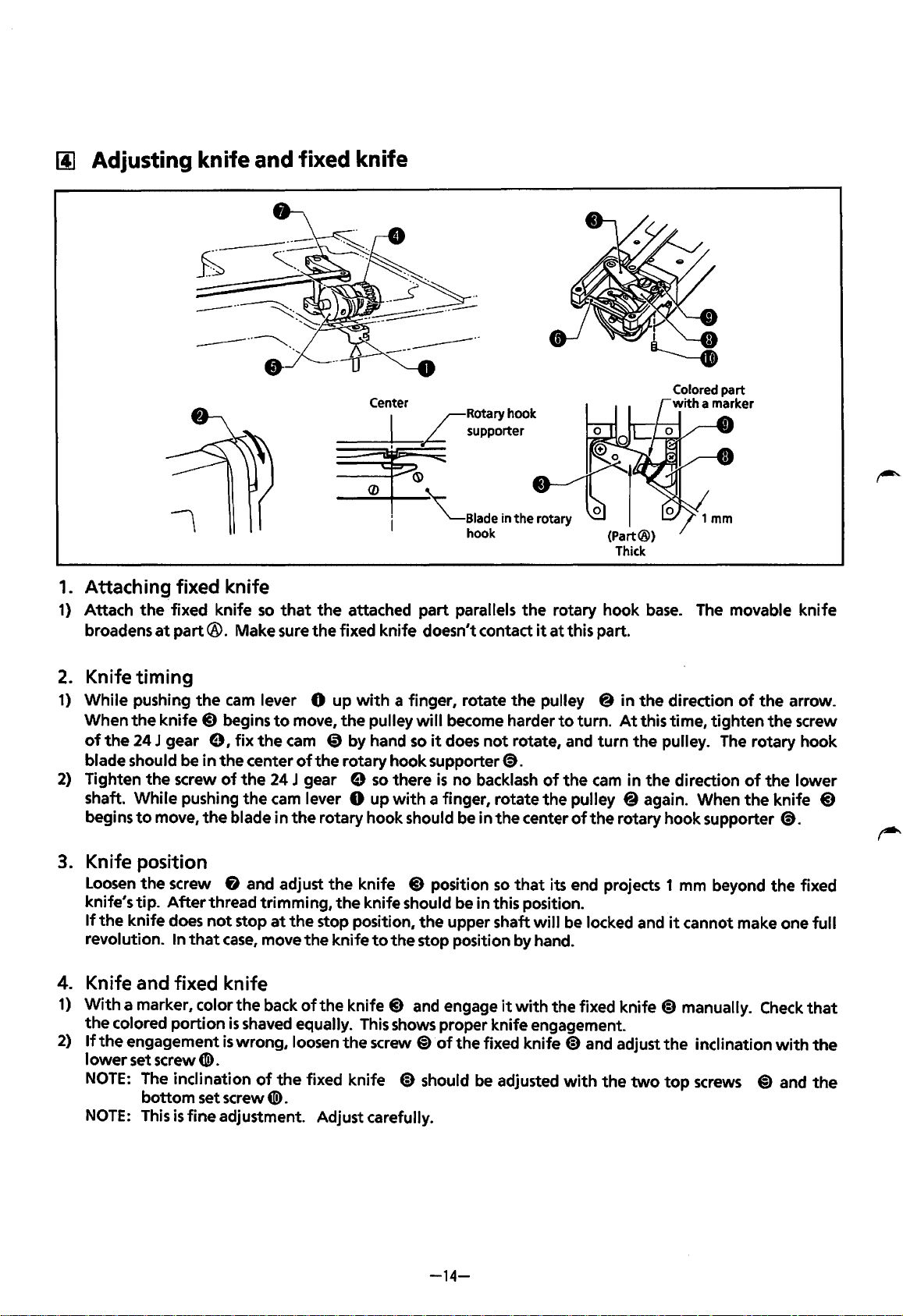

(j] Adjusting knife

and

fixed knife

1.

Attaching fixed knife

1)

Attach

the

fixed knife

so

that

the

attached part parallels

the

rotary hook

base.

The movable knife

broadens

at

part®.

Make sure

the

fixed knife doesn't contact

it

at

this part.

2.

Knife timing

1)

While pushing

the

cam

lever 0 up

with

a finger, rotate

the

pulley @ in

the

direction

of

the

arrow.

When

the

knife

@)

begins

to

move,

the

pulley

will

become harder

to

turn.

At

this time, tighten

the

screw

of

the

24 J gear e I

fix

the

cam

CD

by hand

so

it

does

not

rotate, and

turn

the

pulley.

The

rotary hook

blade should be in

the

center

of

the rotary hook supporter@).

2)

Tighten

the

screw

of

the

24 J gear e

so

there

is

no backlash

of

the

cam

in

the

direction

of

the

lower

shaft. While pushing

the

cam

lever 0 up

with

a finger, rotate

the

pulley @again. When

the

knife

@)

begins

to

move,

the

blade in

the

rotary hook should be in

the

center

of

the

rotary hook supporter

@).

3.

Knife position

Loosen

the

screw & and adjust

the

knife

@)

position

so

that

its end projects 1 mm beyond

the

fixed

knife's tip.

After

thread trimming,

the

knife should be in this position.

If

the

knife does

not

stop

at

the

stop position,

the

upper shaft

will

be locked and

it

cannot make one

full

revolution. In

that

case,

move

the

knife

to

the

stop position by hand.

4.

Knife and fixed knife

1)

With

a marker, color

the

back

of

the

knife

@)

and engage

it

with

the fixed knife

@)

manually.

Check

that

the

colored portion

is

shaved equally.

This

shows proper knife engagement.

2)

If

the

engagement

is

wrong, loosen

the

screw

@)

of

the

fixed knife

@)

and adjust

the

inclination

with

the

lower

set screw

CD).

NOTE:

The inclination

of

the

fixed knife @)should

be

adjusted

with

the

two

top

screws

@)

and

the

bottom set screw

CD).

NOTE:

This

is

fine adjustment. Adjust carefully.

-14-

~-

From the library of: Superior Sewing Machine & Supply LLC

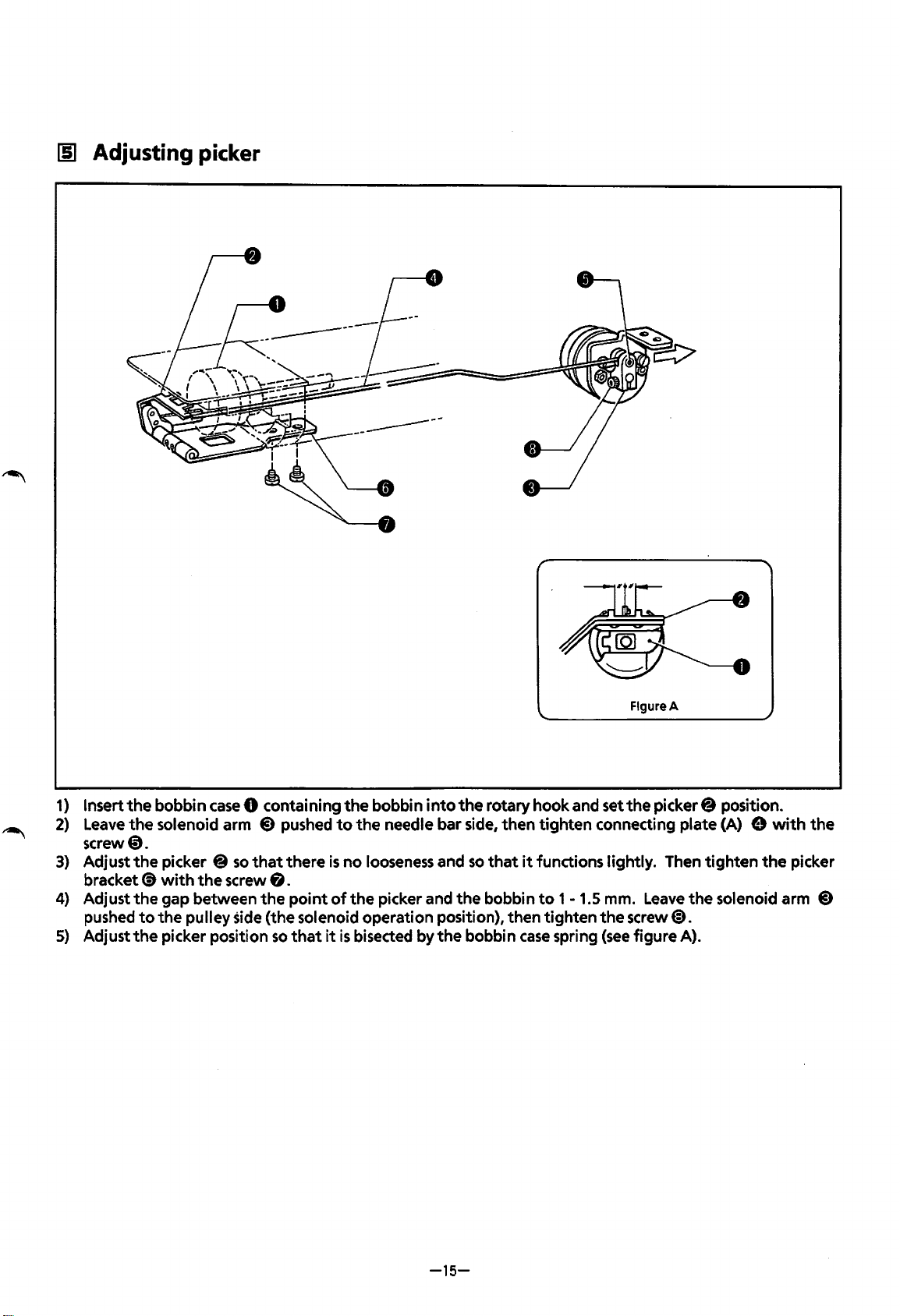

1§1

Adjusting

picker

Figure A

1)

Insert

the

bobbin

case

0 containing

the

bobbin

into

the

rotary hook and set

the

picker@ position.

2)

Leave

the

solenoid arm

@)

pushed

to

the

needle bar side, then

tighten

connecting plate (A) e

with

the

screw0.

3)

Adjust

the

picker @

so

that

there

is

no

looseness and

so

that

it

functions lightly. Then

tighten

the

picker

bracket(!)

with

the

screw

8.

4)

Adjust

the

gap between

the

point

of

the

picker and

the

bobbin

to

1

-1.5

mm.

Leave

the

solenoid arm

@)

pushed

to

the

pulley side (the solenoid operation position), then tighten

the

screw@).

5)

Adjust

the

picker position

so

that

it

is

bisected by

the

bobbin

case

spring

(see

figure A).

-15-

From the library of: Superior Sewing Machine & Supply LLC

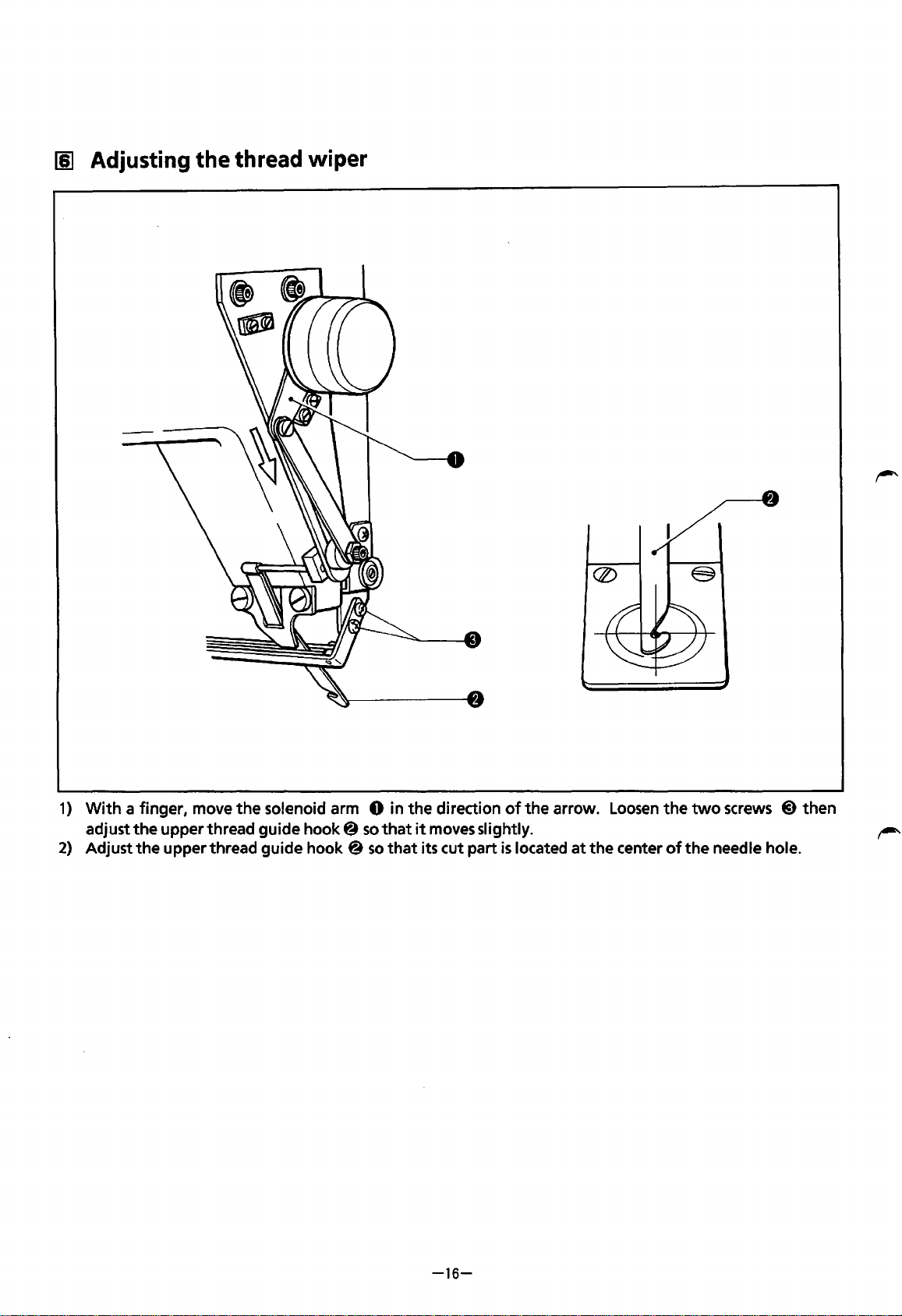

[§]

Adjusting

the

thread wiper

1)

With

a finger, move

the

solenoid arm 0 in

the

direction

of

the

arrow.

Loosen

the

two

screws @ then

adjust

the

upper thread guide

hook@

so

that

it

moves slightly.

2)

Adjust

the

upper thread guide hook @

so

that

its cut part

is

located

at

the

center

of

the

needle hole.

-16-

From the library of: Superior Sewing Machine & Supply LLC

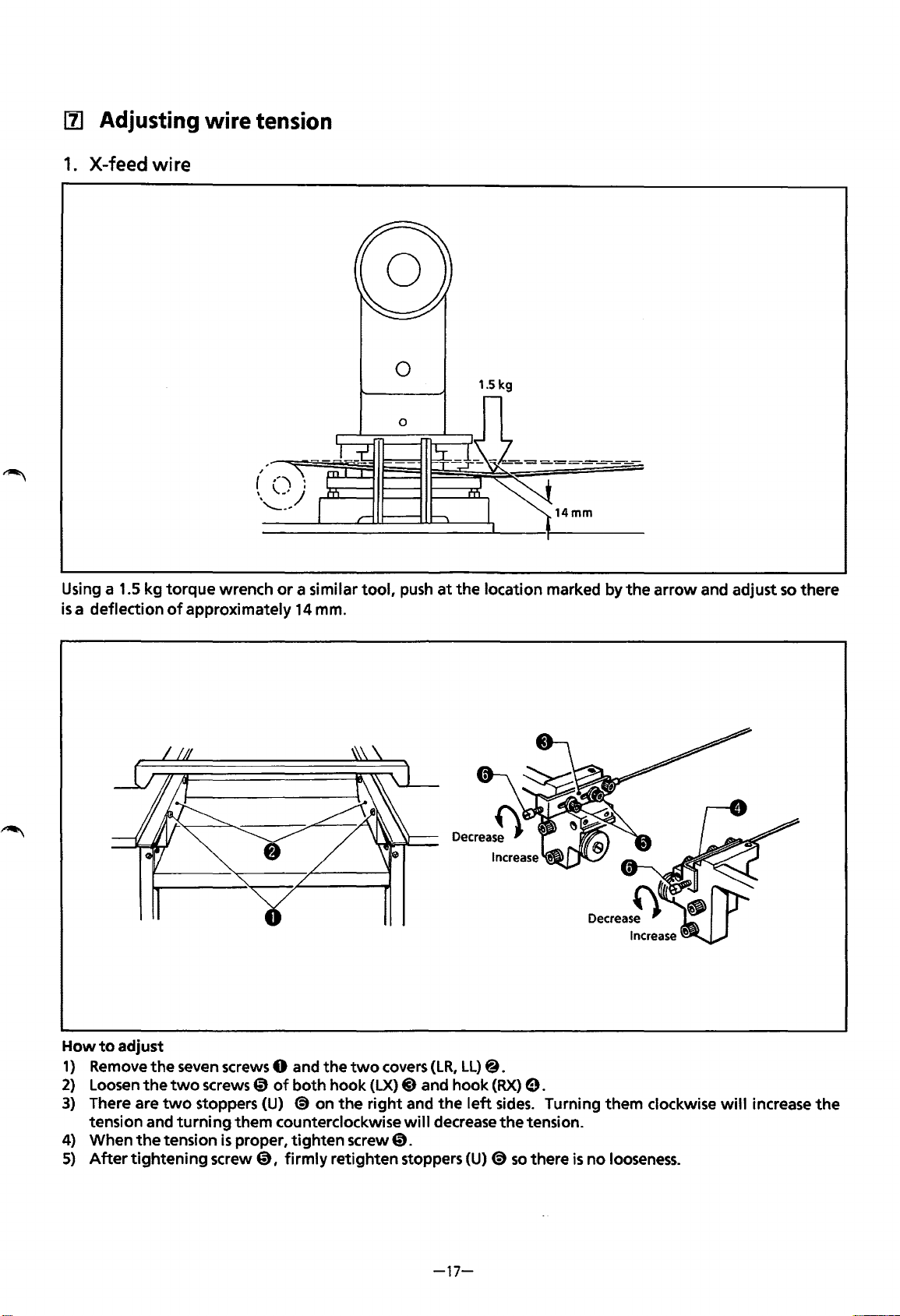

111

Adjusting

wire

tension

1.

X-feed wire

0

1.5 kg

Using a 1.5 kg

torque

wrench

or

a similar

tool,

push

at

the

location marked by

the

arrow

and adjust

so

there

is

a deflection

of

approximately

14

mm.

How

to

adjust

1)

Remove

the

seven screws 0 and

the

two

covers

(LR,

LL)@.

2)

Loosen

the

two

screws 0

of

both

hook

(LX)

@)

and hook

(RX)

0.

3)

There are

two

stoppers (U)

(S)

on

the

right

and

the

left

sides.

Turning them clockwise

will

increase

the

tension and

turning

them counterclockwise

will

decrease

the

tension.

4) When

the

tension

is

proper,

tighten

screw

0.

5)

After

tightening

screw

0,

firmly

retighten stoppers

(U)

(S)

so

there

is

no

looseness.

-17-

From the library of: Superior Sewing Machine & Supply LLC

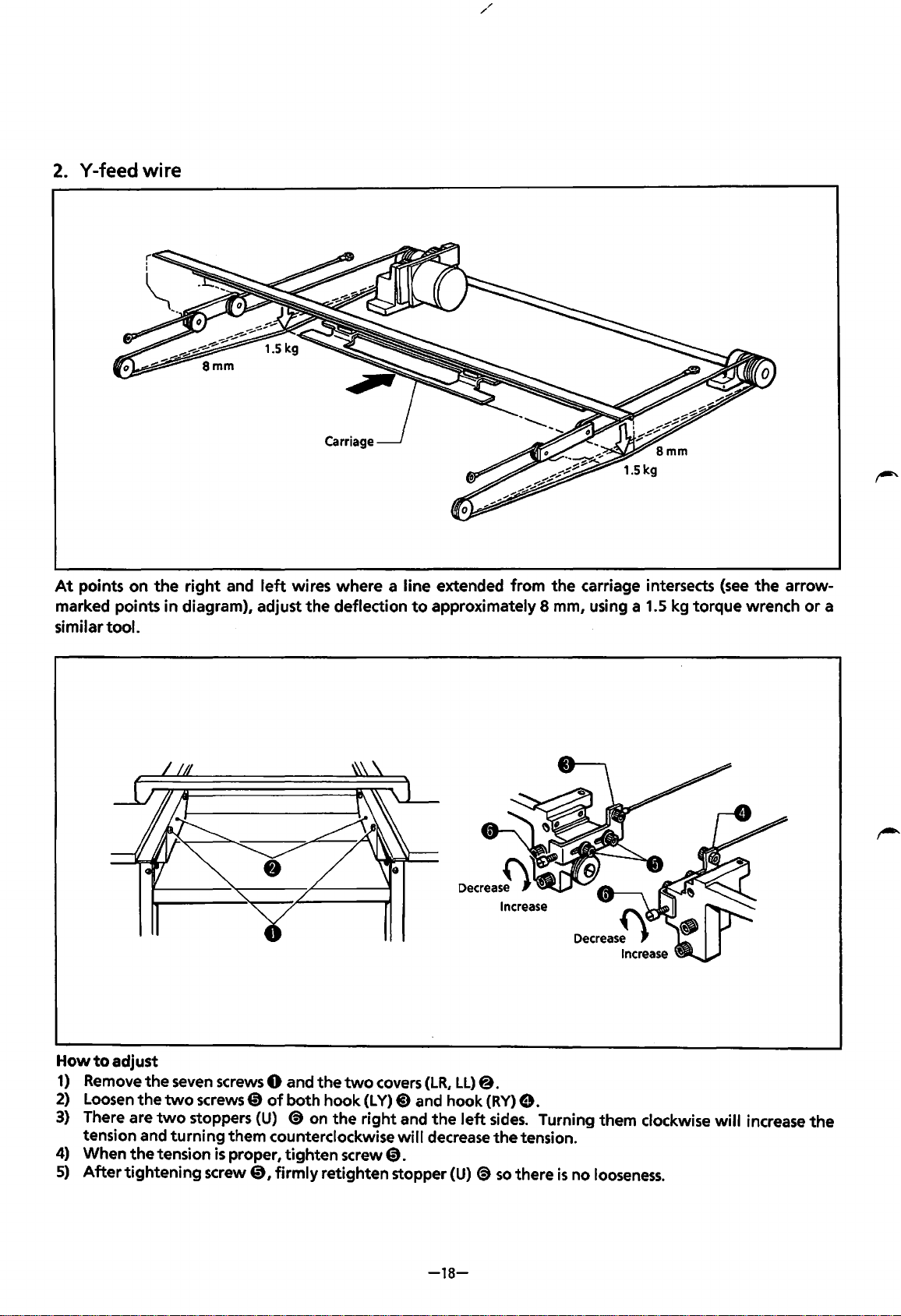

2.

Y-feed wire

At

points

on

the

right

and

left

wires where a line extended from

the

carriage intersects

(see

the

arrow-

marked points

in

diagram), adjust

the

deflection

to

approximately 8

mm,

using a 1.5 kg torque wrench

or

a

similar

tool.

How

to

adjust

1)

Remove

the

seven

screws 0 and

the

two

covers

(LR,

LL)

@.

2)

Loosen

the

two

screws

CD

of

both hook

(L

Y)

@)

and hook

(RY)

8.

3)

There are

two

stoppers

(U)

(S)

on

the

right

and

the

left

sides.

Turning them clockwise

will

increase

the

tension and

turning

them counterclockwise

will

decrease

the

tension.

4)

When

the

tension

is

proper,

tighten

screw@.

5)

After

tightening

screw@,

firmly

retighten stopper

(U)

(S)

so

there

is

no

looseness.

-18-

From the library of: Superior Sewing Machine & Supply LLC

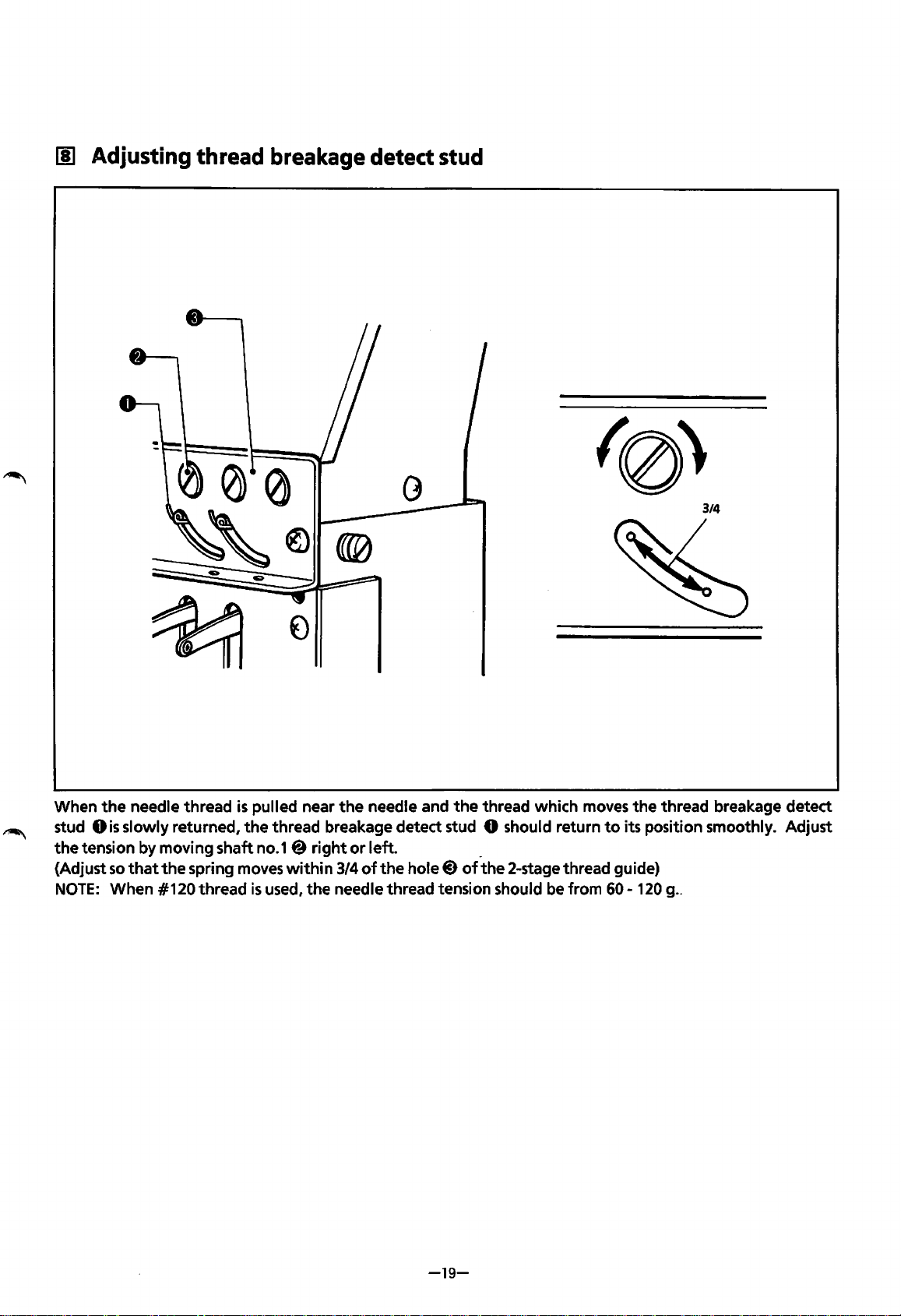

[!] Adjusting thread breakage detect

stud

3/4

When

the

needle thread

is

pulled near

the

needle and

the

thread which moves

the

thread breakage detect

stud

Ois

slowly returned,

the

thread breakage detect stud 0 should return

to

its position smoothly. Adjust

the

tension by moving shaft no.1@

right

or

left. _

{Adjust

so

that

the

spring moves

within

3/4

of

the

hole@)

of

the

2-stage thread guide)

NOTE:

When #120 thread

is

used,

the

needle thread tension should be from

60-

120

g

..

-19-

From the library of: Superior Sewing Machine & Supply LLC

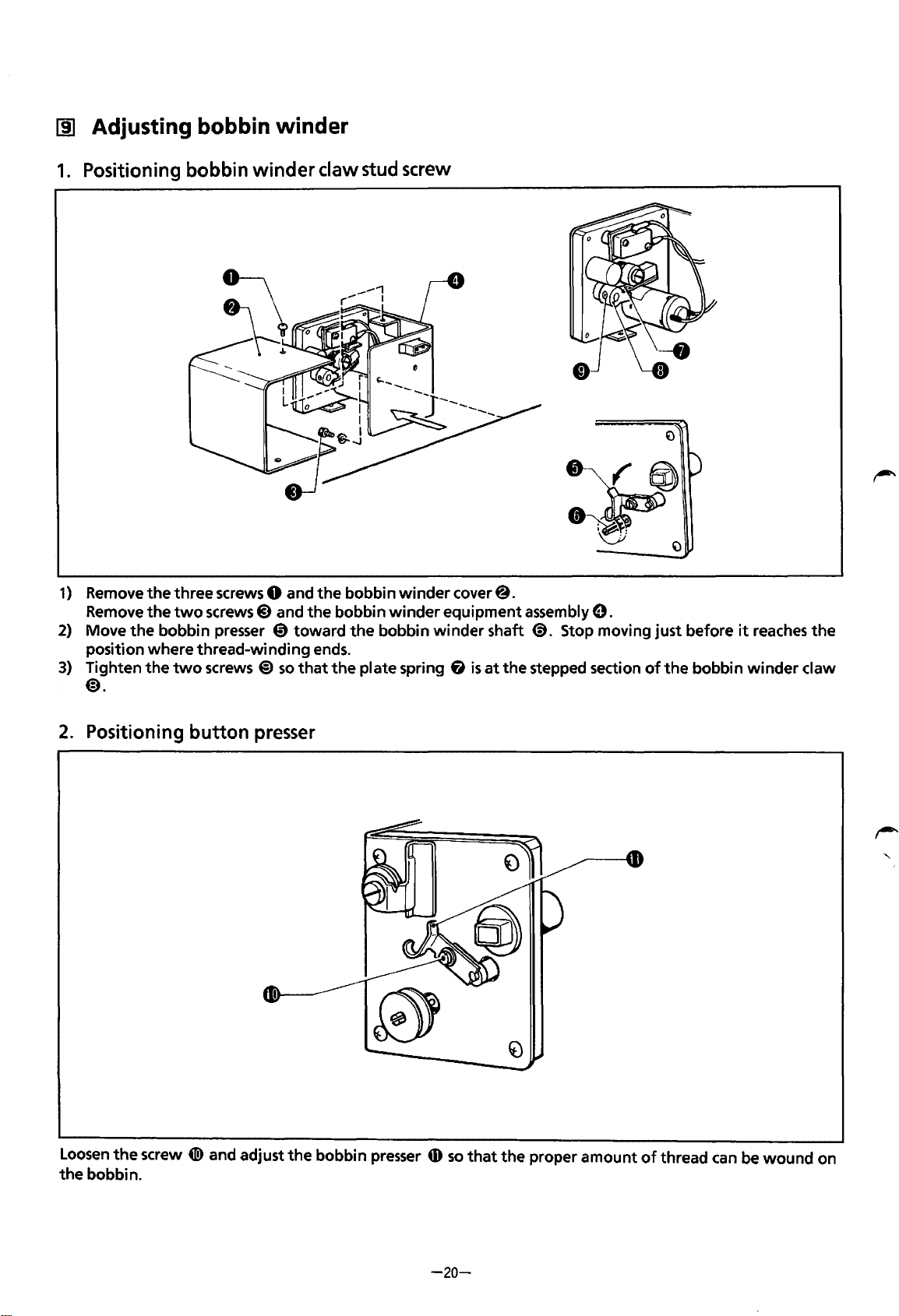

[j] Adjusting bobbin winder

1.

Positioning bobbin

winder

claw stud screw

1)

Remove

the

three screws 0 and

the

bobbin

winder

cover@.

Remove

the

two

screws 8 and

the

bobbin

winder

equipment assembly

9.

2)

Move

the

bobbin presser @)toward

the

bobbin

winder

shaft

<9.

Stop moving just before

it

reaches

the

position where thread-winding ends.

3)

Tighten

the

two

screws

@)

so

that

the

plate spring

fi

is

at

the stepped section

of

the

bobbin

winder

claw

@).

2.

Positioning

button

presser

Loosen

the

screw

41!)

and adjust

the

bobbin presser

tD

so

that

the

proper

amount

of

thread

can

be

wound

on

the

bobbin.

-20-

From the library of: Superior Sewing Machine & Supply LLC

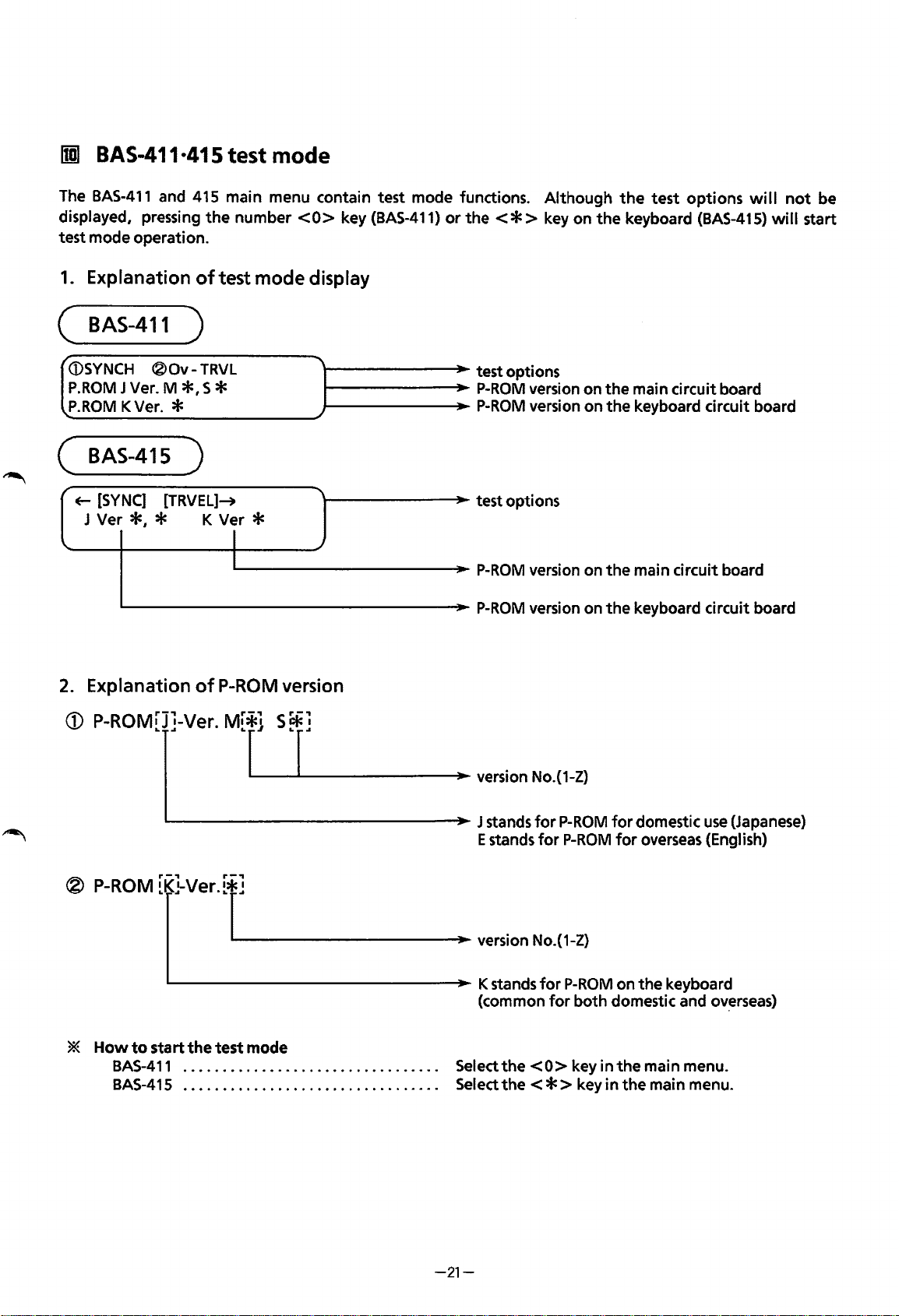

rml

BAS-411·415 test mode

The

BAS-411

and 415 main menu contain test mode functions. Although

the

test

options

will

not

be

displayed, pressing

the

number

<0>

key

(BAS-411)

or

the<*>

key on

the

keyboard

(BAS-415)

will

start

test mode operation.

1.

Explanation

of

test mode display

(

BAS-411

)

/

(i)SYNCH

®Ov-

TRVL

P.ROM

J Ver. M

*•

S *

P.ROM

K Ver. *

( BAS-415 )

~

[SYNC]

[TRVEL]~

J Ver

*,

* K Ver *

I

l--------J~~oo-

test options

1------~_..~

P-ROM

version on

the

main circuit board

1--------J~~oo-

P-ROM

version on the keyboard circuit board

\--------"'JIIoo-

test options

IL...------------J~~oo-

P-ROM

version on

the

main circuit board

'------------------J~~oo-

P-ROM

version on

the

keyboard circuit board

2.

Explanation

of

P-ROM

version

CD

P-ROM[]J]-Ver.

M[*r.j_S~.....__r]

___

....,.

- - •: version No.(1-Z)

- J stands

for

P-ROM

for

domestic

use

(Japanese)

E stands

for

P-ROM

for

overseas (English)

®

P-ROM

[K[}Ver.[r.__]

_______

_....,..

- : version

No.(1-Z)

'---------------~-

K stands

for

P-ROM

on the keyboard

(common

for

both domestic and

ov~rseas)

*

Howtostartthetestmode

BAS-411

.................................

Selectthe<O>keyinthemainmenu.

BAS-41

5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Select

the

< * > key in

the

main menu.

-21-

From the library of: Superior Sewing Machine & Supply LLC

3.

Explanation

of

test menu

1)

( ____

~

___ s __ v __ N

__

c ___ H

_____

)

The

menu

for

adjusting

the

needle

position

detecting

synchronizer

on

the

machine

upper

shaft.

2)

(

____

®

___

r

___

r

__

a

__

v

___

e

__

l

____

_,)

The

menu

for

adjusting

the

position

of

the

overtravel sensor.

Pressing

alphanumeric

keys < 1 >

or

< 2 > will set

the

machine

into

one

of

the

test

modes.

After

adjustment,

press

the

<END>

key

to

return

to

the

main

menu. (BAS-411·415)

-22-

From the library of: Superior Sewing Machine & Supply LLC

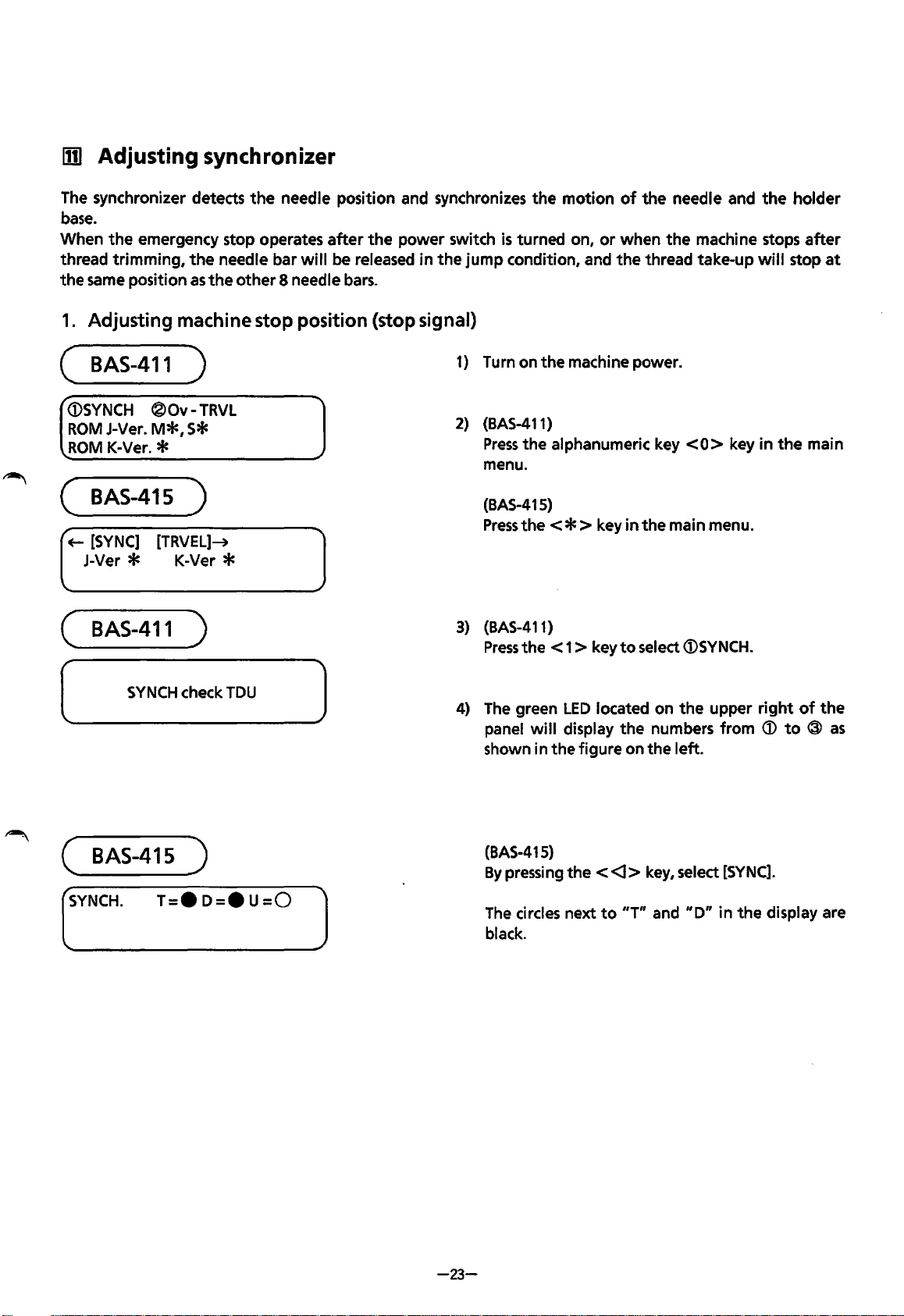

IDJ

Adjusting synchronizer

The

synchronizer detects

the

needle position and synchronizes

the

motion

of

the

needle and

the

holder

base.

When

the

emergency stop operates

after

the

power switch

is

turned on,

or

when

the

machine stops

after

thread trimming,

the

needle bar

will

be released in

the

jump

condition, and

the

thread take-up

will

stop

at

the

same position

as

the

other

8 needle bars.

1.

Adjusting machine stop position (stop signal)

(

BAS-411

)

<DSYNCH

®Ov-

TRVL

ROM

J-Ver.

M*,

S*

ROM

K-Ver. *

(

BAS-415

)

+-

[SYNC]

[TRVEL]-+

J-Ver * K-Ver *

(

BAS-411

)

(

SYNCH

check

TDU

(

BAS-415

)

)

(_SY_N_C_H·

__

T_=_·_D_=_•_U_=_O

__

]

1) Turn on

the

machine power.

2)

(BAS-411)

Press

the

alphanumeric key

<0>

key

in

the

main

menu.

(BAS-415)

Press

the<*>

key

in

the main menu.

3)

(BAS-411)

Press

the

< 1 > key

to

select

<DSYNCH.

4)

The

green

LED

located on

the

upper

right

of

the

panel

will

display

the

numbers from

<D

to

®

as

shown in

the

figure on

the

left.

-23-

(BAS-415)

By

pressing

the

<

<l>

key, select

[SYNC].

The

circles next

to

"T"

and

"D"

in

the

display are

black.

From the library of: Superior Sewing Machine & Supply LLC

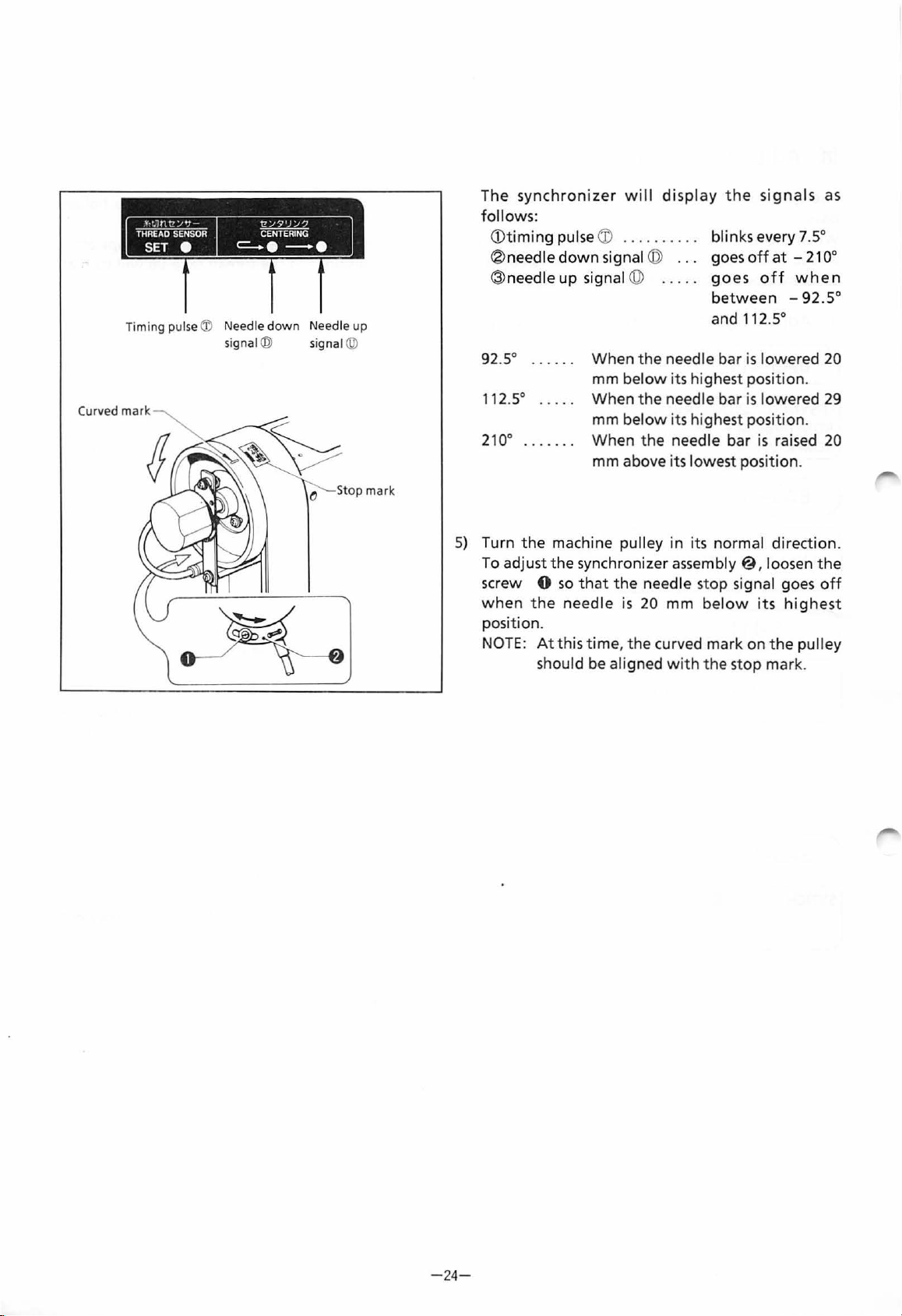

Timing pulse ® N

ee

dle do

wn

N

ee

dl e up

si

gnal@

si

gnal @

Curved mark

Stop

mar

k

The

synchronizer

wi

ll

disp

l

ay

the

signals

as

follows:

<D

timing

pulse

CD

.

...

.

....

.

® needle

down

signal ©

..

.

@needle

up

signal @

bl

in

ks every 7.5°

goes

off

at

-

21

oo

goes

off

when

between

-92.5

°

and 112.5°

92

.5° . . . . . . When t he needle bar

is

lowered 20

112S

mm

below

its highest position.

When the

needle bar is lowered

29

mm b

elow

its highest

pos

i

tio

n.

210

° . . . . . . .

When

the needle bar

is

raised

20

mm above its lowest position.

5)

Turn

the

machine pulley in i

ts

normal direct

ion

.

-24

-

To adjust

the

synchronizer

assem

bl

y@

, loosen the

sc

rew

0

so

th

at

the

needle s

top

si

gnal goes

off

when

the ne ed

le

is

20 mm bel

ow

it

s

highe

st

pos

ition

.

NOTE:

At

this time, the curved mark on

the

pulley

should

be aligned wi

th th

e st

op

mark.

From the library of: Superior Sewing Machine & Supply LLC

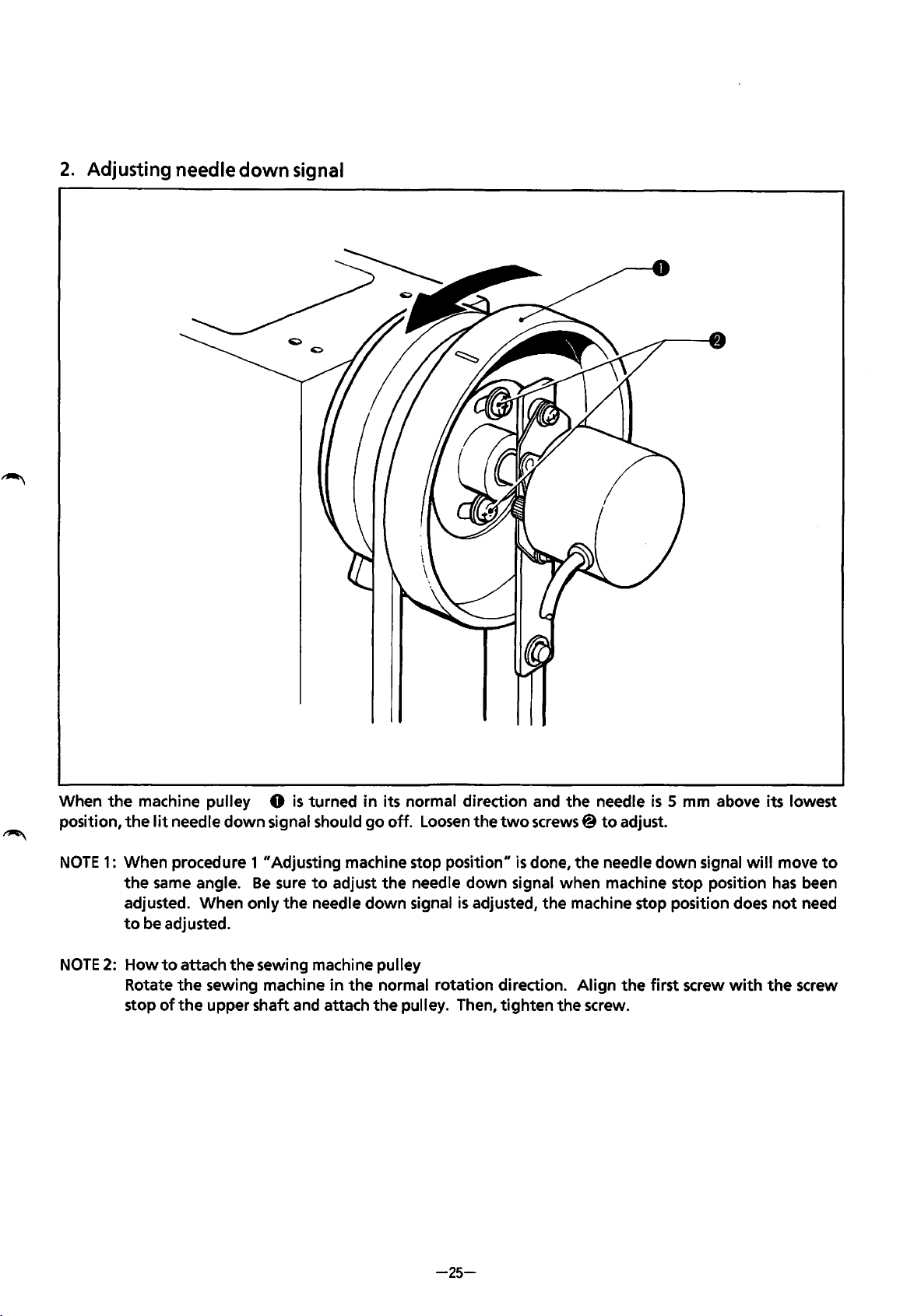

2.

Adjusting needle down signal

When

the

machine pulley 0

is

turned

in

its normal direction and

the

needle

is

5 mm above its lowest

position,

the

lit

needle

down

signal should

go

off.

Loosen

the

two

screws@

to

adjust.

NOTE

1:

When procedure 1 "Adjusting machine stop position"

is

done,

the

needle

down

signal

will

move

to

the

same

angle.

Be

sure

to

adjust

the

needle down signal when machine stop position

has

been

adjusted. When only

the

needle

down

signal

is

adjusted,

the

machine stop position does

not

need

to

be adjusted.

NOTE

2: How

to

attach

the

sewing machine pulley

Rotate

the

sewing machine

in

the

normal rotation direction. Align

the

first screw

with

the

screw

stop

of

the

upper shaft and attach

the

pulley. Then,

tighten

the

screw.

-25-

From the library of: Superior Sewing Machine & Supply LLC

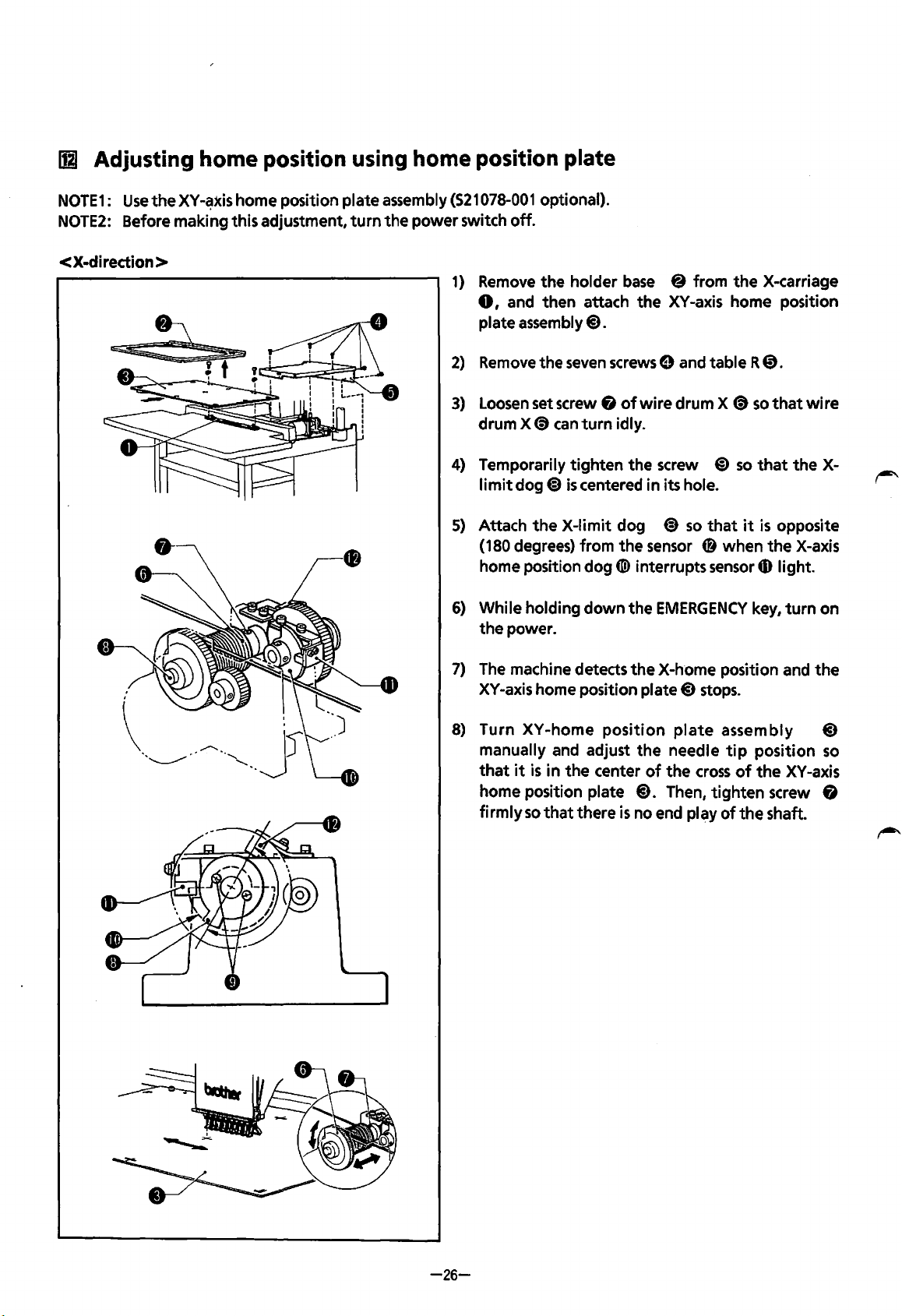

Ill

Adjusting

home

position using home position plate

NOTE1:

Use

the

XY-~xis

home position plate assembly

(521078-001

optional).

NOTE2:

Before making this adjustment,

turn

the power switch

off.

< X-direction >

1)

Remove

the holder

base

8 from

the

X-carriage

0,

and then attach the

XY

-axis home position

plate

assembly@).

2)

Remove

the

seven

screws

0 and table R

0.

3)

Loosen

set screw &

of

wire drum X

<9

so

that

wire

drum X

<9

can

turn

idly.

4)

Temporarily tighten the screw

@)

so

that

the

X-

limit

dog~

is

centered in its hole.

5)

Attach

the

X-limit dog

~

so

that

it

is

opposite

(180 degrees) from

the

sensor

CD

when

the

X-axis

home position

dog([!) interrupts

sensor

4D

light.

6)

While holding down the

EMERGENCY

key,

turn

on

the power.

7)

The

machine detects

the

X-home position and

the

XY-axis home position plate@)

stops.

8)

Turn XY-home

position

plate

assembly

@)

-26-

manually and adjust

the

needle

tip

position

so

that

it

is

in

the

center

of

the

cross

of

the

XV

-axis

home position plate

@).

Then, tighten screw &

firmly

so

that

there

is

no end play

of

the

shaft.

From the library of: Superior Sewing Machine & Supply LLC

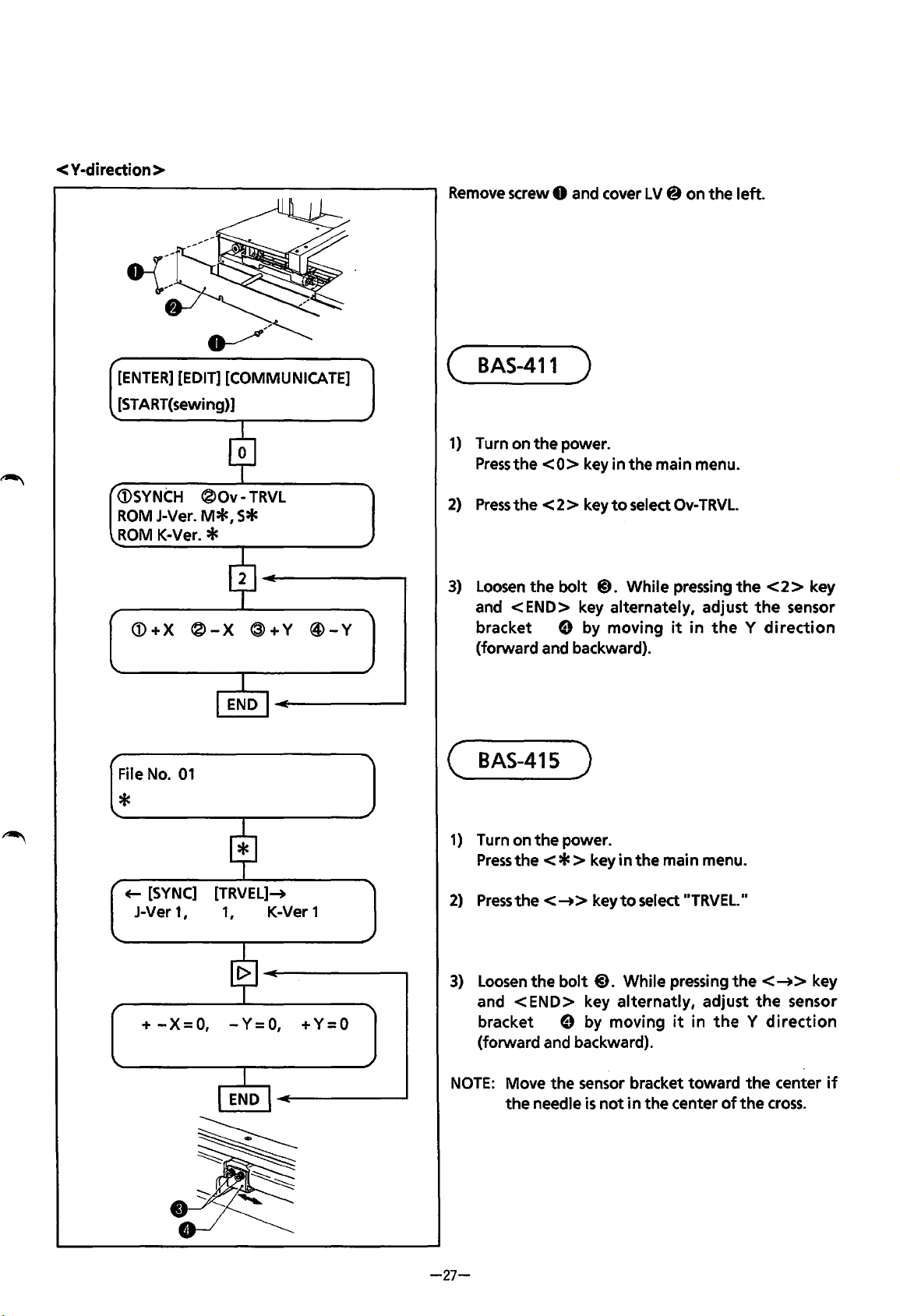

< Y·diredion >

[ENTER]

[EDIT]

[COMMUNICATE]

[START(sewing)]

<DSYNCH

®Ov-

TRVL

ROM

J-Ver.

M*,

S*

ROM

K-Ver. *

<D+X

®-X

®+Y

@-Y

File

No.

01

*

~

[SYNC]

[TRVEL]-+

J-Ver 1 I 1

1

K-Ver 1

+

-X=

0,

- Y =

0,

+ Y = 0

Remove

screw 0 and cover LV@ on the left.

(

BAS-411

)

1)

Turn on the power.

Press

the

<0>

key in the main menu.

2)

Press

the

< 2 > key

to

select

Ov-

TRVL.

3)

Loosen

the

bolt

@).

While pressing

the

<2>

key

and

<END>

key alternately, adjust

the

sensor

bracket

e by moving

it

in

the

y

direction

(forward and backward).

(

BAS-415

)

1)

Turn on

the

power.

Press

the<*>

key

in

the main menu.

2)

Press

the<-+>

key

to

select

..

TRVEL.

..

3)

Loosen

the bolt@). While pressing

the<-+>

key

and

<END>

key alternatly, adjust

the

sensor

bracket

e by moving

it

j n

the

y

direction

(forward and backward).

NOTE:

Move the sensor bracket toward

the

center

if

the

needle

is

not

in

the center

of

the

cross.

-27-

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...