BRANDT WTC1051K User Manual [fr]

INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS ................

Page 3

MANUEL D’INSTALLATION,

D’UTILISATION ET D’ENTRETIEN..............Page 10

INSTALLATIONS-, GEBRAUCHS- UND

PFLEGEANLEITUNG ....................................Seite 17

INSTALLATIONS-, BETJENINGS- OG

VEDLIGEHOLDELSESVEJLEDNING..........Side 24

INSTRUKCJA INSTALACJI,

OBSŁUGI I KONSERWACJI ......................Strona 31

,

................................... 38

DK

F

WASHING MACHINE

LAVE-LINGE

WÄSCHMASCHINE

LAVADORA

MÁQUINA DE LAVAR

ROUPA

VASKEMASKINE

WASMACHINE

PRALKA

AUTOMATICÁ PRAČKA

CTPAHA

MAHA

ΠΛΥΝΤΗΡΙΟ ΡΟΥΧΩΝ

- 2 -

Au fil des pages de cette notice, vous découvrirez les

symboles suivants qui vous signaleront :

les consignes de sécurité (pour vous, votre machine ou

votre linge) à respecter impérativement,

un danger électrique,

les conseils et les informations importantes

F

Door deze handleiding heen zult u de volgende symbolen

aantreffen die u aangeven :

de veiligheidsvoorschriften (voor u, uw machine of uw was)

die absoluut moeten worden nageleefd,

gevaar van elektrische aard,

tips en belangrijke informatie

, :

( ,

),

,

,

.

Στις σελίδες που ακολουθούν θα ανακαλύψετε τα

παρακάτω σύµβολα τα οποία επισηµαίνουν:

τις οδηγίες ασφαλείας (για σας, το πλυντήριο ή τα

ρούχα σας) που πρέπει οπωσδήποτε να τηρείτε.

ηλεκτρικό κίνδυνο

τις σηµαντικές πληροφορίες και οδηγίες

I denne betjeningsvejledning vil De støde på følgende

symboler, som betyder:

Sikkerhedsregler (for Dem, maskinen eller vasketøjet),

som skal overholdes.

Elektrisk fare

Vigtige råd og oplysninger

DK

Im Laufe der Seiten geben folgende Symbole Hinweise

auf:

die Sicherheitsvorschriften (für Sie, die Maschine oder die

Wäsche), die unbedingt eingehalten werden müssen,

eine elektrische Gefahr,

Tipps und wichtige Informationen.

D

W treści instrukcji można znaleźć poniższe symbole.

Oznaczają one:

Instrukcje bezpieczeństwa (odnoszące się do pralki i

procesu prania),

które muszą być przestrzegane

Instrukcje bezpieczeństwa dotyczące instalacji

elektrycznej

Ważna porada i informacja

Ao longo das páginas deste manual, descobrirá os

símbolos seguintes que assinalam :

as instruções de segurança (para si, a sua máquina ou a

sua roupa) a respeitar imperativamente,

um perigo eléctrico,

os conselhos e as informações importantes

P

A lo largo de las páginas de este manual, descubrirá los

símbolos siguientes que le señalarán :

las consignas de seguridad (para usted, su máquina o

su ropa) que respetar de modo imperativo,

un peligro eléctrico,

los consejos y las informaciones importantes

E

You will find the following symbols used throughout this

manual. They mean :

Safety instructions (for your machine and your washing),

which must be observed

An electrical risk,

Important advice and information

Na dalších stránkách tohoto návodu naleznete následující

symboly, které vás upozorňují na:

Bezpečnostní doporučení (pro vás, pro vaši pračku a vaše

prádlo), kterými je třeba se bezpodmínečně řídit,

Nebezpečí zásahu elektrickým proudem,

Doporučeni a důležité informace

CZ

- 3 -

Contents

Page

Removing the transport clamps from your machine ..........................3

Installing your machine ............................................................................3

Connecting your machine ........................................................................4

Loading your washing ..............................................................................4

Loading the washing products................................................................4

Programming ......................................................................................5 & 6

Automatic safety devices ........................................................................6

Page

Details of fonctions ..................................................................................7

Modifying a washing programme............................................................7

Incidents that may occur..........................................................................8

Automatic fault diagnostics ....................................................................8

Running maintenance ..............................................................................9

Cleaning the pump filter ..........................................................................9

D2 D3

13

1

1

2

2

a

b

a

b

➀

➁

➀

➁

➃

➂

D1

D4

A

C

B

E

F

G

D

D

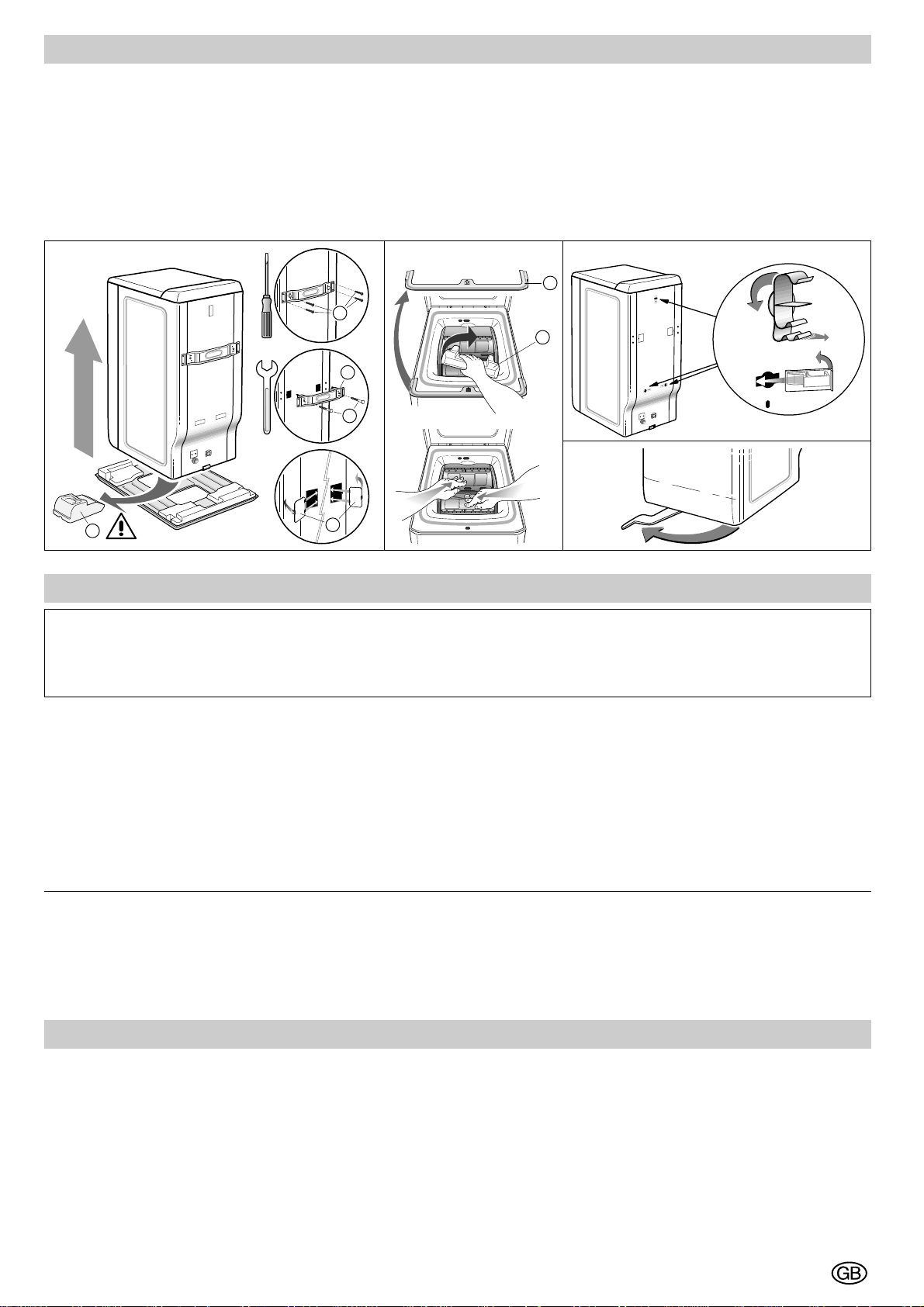

Removing the transport clamps from your machine

see diagrams

D1-D2-D3

1 - Remove the washing machine from its plinth (check that the wedge

supporting the motor is not still inserted in the machine) (

Diagram

D1.➀

)

2 - Remove the 4 screws

with a screwdriver

(Diagram

D1.➁

)

3 - Remove the cross clamp

by removing the 2 screws

(Diagram

D1.➂

)

using a 10 or 13mm spanner (depending on the model).(Ensure

that you remove the two plastic braces fixed on the cross clamp

at the same time as the clamp itself).

Replace the screws

in their initial positions.

4 -

You must block off the two holes using the hole covers provided

(supplied in the accessories bag)

(Diagram

D1.➃

)

5 - Remove the drum-tank assembly locking wedge

(Diagram

D2

)

.

To do this:

- Lift the lid on the machine

- Remove wedge

- Remove wedge

by turning it a quarter turn

- Release the drum doors, locked in the lower position, by pressing

down on both eaves simultaneously.

6 -

Remove the pipe support collars

➀

You must block off the

holes revealed with the hole covers

➁

supplied in the accessories

bag

(Diagram

D3

)

.

Installing your machine

see diagram

D4

BEFORE USING THE MACHINE IN ANY WAY, YOU MUST FIRST PERFORM THE FOLLOWING OPERATIONS.

These comprise removing all the components designed to immobilise the drum in your machine during transport.

These so-called “releasing” operations are necessary for your machine to operate correctly and to conform to the prevailing safety

standards.

If they are not carried out completely, this could cause severe damage to your machine while it is operating.

We would recommend that you keep all the locking components since

these must be refitted if you must subsequently transport your machine

again.

All these components, just like all the components in your machine,

are made of recyclable materials and it is useful to bear this in mind

when you eventually come to dispose of your machine at the end of

its useful life.

Your machine has been scrupulously checked before it left the factory.

You may therefore notice a little water still remaining in the tank or the

products box.

Mounting it on castors:

If your machine is equipped with removable castors, you will be able

to move it quite easily.

To mount it on castors, swivel the lever on the bottom of the machine

from the right to the far left

(Diagram

D4

)

.

The machine must not rest on the “front” castors while it is

operating: remember to return the lever to its initial position.

Levelling the machine:

Use a spirit level to check that the floor is horizontal: maximum slope

2°, i.e. a discrepancy of approximately 1cm over the width and of

1.5cm over the depth of the machine.

Your machine’s surroundings:

If you are installing your machine next to another machine or a unit,

we recommend that you leave a gap between them to allow for air

circulation.

We also strongly recommend that you do NOT:

- Install your machine in a damp, poorly ventilated room.

- Install your machine in an area where it could be subject to water

splashes.

- Install your machine on a carpeted floor.

If you cannot avoid doing this, please take every precaution to avoid

blocking air circulation at the bottom of the machine in order to

ensure that the internal components are well ventilated.

- 4 -

➀

➁➃➂

D5 D6 D7

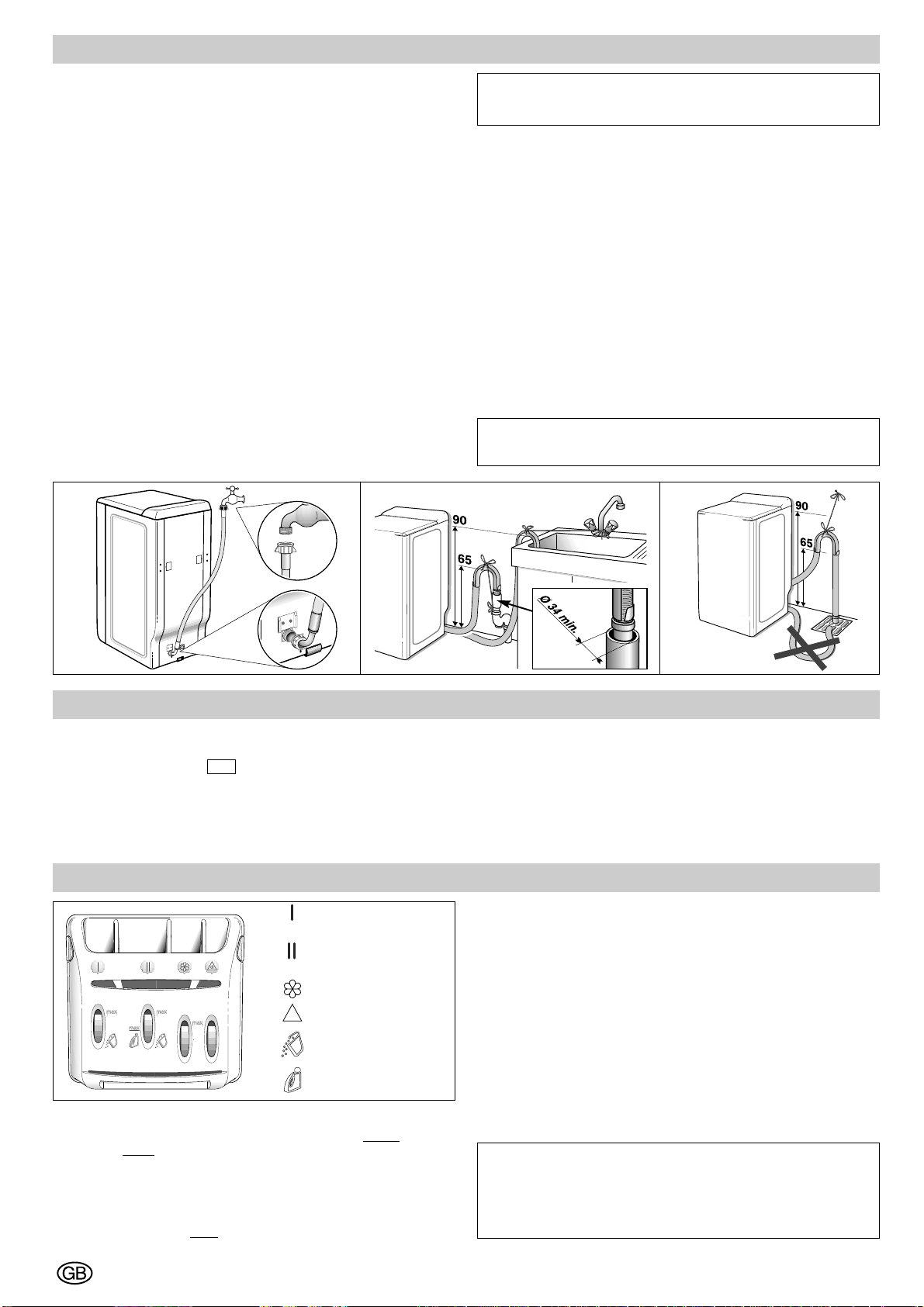

Connecting the cold water supply

Connect the supply hose

(Diagram

D5

)

:

- At one end to the connection on the back of the machine

- On the other end to a tap fitted with a threaded end 20mm dia. x 27

(3/4 BSP).

If you use a self-piercing tap, the useful aperture must have a

minimum diameter of 6mm.

Water supply:

- Minimum water pressure: 0.1 MPa or 1 bar

- Maximum water pressure: 1 MPa or 10 bars

Draining away the waste water

Fit the hose bracket provided inside your machine to the end of the drain

hose and then connect the hose

(Diagram

D6

)

:

• Either, temporarily, over a sink or a bathtub.

• Or permanently to a ventilated U-bend.

If your installation does not have a ventilated U-bend, check that the

connection is not sealed. In fact, to avoid any waste water flowing

back into the machine, you are strongly recommended to leave an air

gap between the machine’s drain hose and the drainpipe.

In any case, the drain hose bracket must be placed at a height of 65 to

90cm higher than the base of the machine.

Ensure that the drain hose is tied firmly in place with cord to avoid

the bracket coming loose during draining and causing a flood.

The waste water can be drained away to the ground provided that the

drain hose passes through a point 65 to 90cm higher than the base of

the machine

(Diagram

D7

)

.

For your safety, you must comply with the instructions below.

Electrical supply

• Before connecting your machine, you must ensure that your

installation’s electrical characteristics match those of your machine

(see the details provided on the information plate affixed to the back

of the machine).

• The electrical installation must comply with the prevailing standards

and the Electricity Board’s regulations in the country concerned,

particularly as regards Earthing and installation in shower rooms.

We cannot be held responsible for any incident caused by the

machine being incorrectly earthed.

Advice on the electrical installation of your machine

• Do not use an extension lead, adapter or multiple socket.

• Never cut out the Earth wire.

• The socket must be readily accessible but out of the reach of children.

If in any doubt, please contact your installer.

Connecting your machine

see diagrams

D5-D6-D7

Your machine conforms to European Directives EEC/73/23 (Low

Voltage Directive) and EEC/89/336 (Electromagnetic Compatibility)

as modified by Directive EEC/93/68.

On any new installation (following a move or resale, etc.), the

machine must be connected using new hoses. The old hoses must

not be reused.

Loading your washing

Before your first wash

Before making your first wash, we recommend that you carry out

a “COTTON 90 wash without pre-wash” and with no washing in the

drum, using a 1/2 measure of your usual detergent in order to

eliminate any residues from manufacturing that may remain in your

machine.

Perform these actions in the following order:

Open the machine

• Check that the “On/Off” button is released.

• Depending on the model, lift the opening handle or press the push

button on the front of the machine.

The lid will open.

• Open the drum by pressing the button on the front door.

Insert your washing

For optimum washing performance, place your washing, preferably

sorted and folded, in the drum, distributing it evenly without heaping it

up. Mix large and small items to obtain an optimum, well-balanced spin.

Close the drum

Ensure that the drum is correctly closed.

Check that the three hooks and the border of the button are fully

visible.

I / O

Loading the washing products

Dispensing the detergent

The amount of detergent to be used depends on the hardness of the

water, the extent to which your washing is soiled and the amount of

washing to be washed.

Please refer to the dosing instructions on your pack of detergent.

Warning: in most cases, the detergent manufacturer’s recommendations

apply to the drum filled to the maximum. Adjust the dosage correctly to

the weight of the washing you have placed in the machine.

These recommendations will help you to avoid using too much detergent,

which causes foam to be produced. Too much foam can reduce your

machine’s performance and increase the length of the washing cycle

and the consumption of water.

Detergents for woollens and delicate fabrics

You are recommended to use an appropriate detergent for washing

these fabrics (avoid placing such detergents directly on the drum because

they have an aggressive action on the metal).

The “WASH” container may contain powder or liquid but liquid

detergent should not be used for programmes WITH

Pre-wash

and/or WITH

“Delayed Start” (depending on the model).

Concentrated softener should be diluted with warm water.

Concentrated bleach must be diluted.

To fill the product containers correctly, place the lid fully open.

Do not exceed the MAX level.

➀

Pre-wash container

(powder)

➁

Wash container

(powder or liquid)

➂

Softener

➃

Bleach

cl

:

POWDERED

DETERGENT

:

LIQUID

DETERGENT

- 5 -

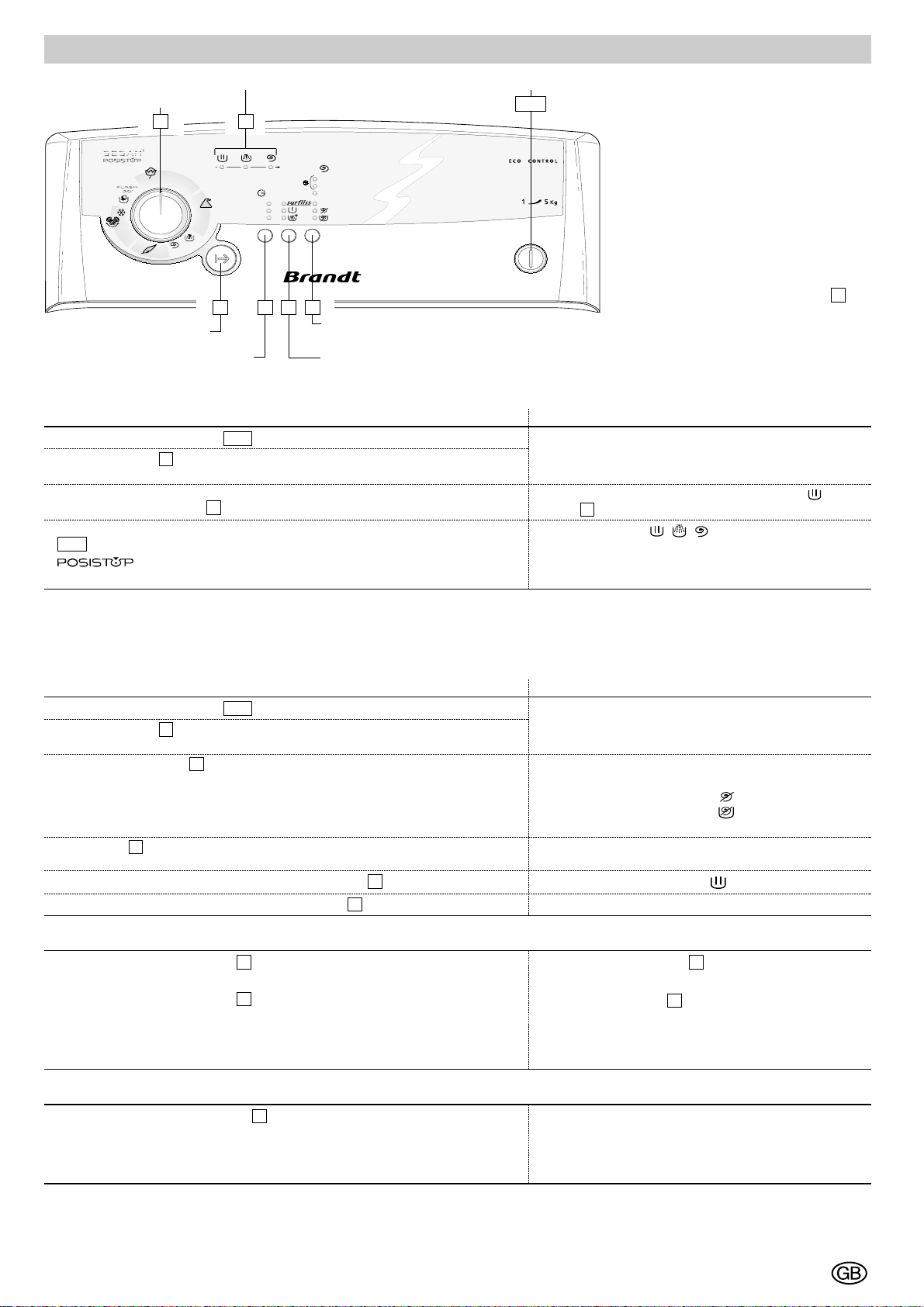

recommended spin speed light

light "800" for example

or light

or light

lights for the options chosen

+ selected spin speed light

light

"3h", "6h" or "9h" light flashes depending on the period selected

(1) -

Before starting your machine, check that the power cable is plugged in and the water tap is open. Also ensure that the drum doors

and the lid are firmly closed.

(2) -

As a safety measure, it is advisable to unplug the power cable and turn off the water tap.

• Depress the "On/Off" button .

• Turn the selector to select the programme and the washing temperature. The

machine proposes the recommended spin speed for the type of fabric selected.

• Use the setting button to select:

- Either to alter the proposed spin speed

- Or drip dry. The cycle will finish with a gentle spin at 100 rpm

- Or stop with the drum full of water. Your machine stops with the drum full of water

before the final spin.

• Use button to select the "Pre-wash", "Extra Rinse" or "Anti-creasing" options,

if required

• Select immediate start by pressing the "Start/Pause" button .

• Or select a start delayed by 3, 6 or 9 hours using button .

3

2

4

5

1

I / O

Programming

Programming a basic washing cycle:

Lights

• Depress the "On/Off" button (1).

• Turn the selector to select the programme and the washing temperature. The

machine proposes the recommended spin speed for the type of fabric selected.

• If the spin speed is acceptable and you do not wish to use any options or delayed

start, press "Start/Pause" The washing cycle will now start.

• At the end of the cycle, the 3 cycle progress lights remain lit. Release the "On/Off"

button and wait 1-2 minutes for the safety device to unlock the lid (2).

: to assist access to your washing , the drum opening automatically

positions itself at the top.

I /O

2

1

I / O

Programming a full washing cycle:

Lights

light flashes

light permanently lit

A

A

Adding or removing an item during the cycle (impossible during spin):

return to initial display• Depress the "Start/Pause" button for at least 1 second.

This can be done at any time during the cycle or during programming, or even

during a pause.

If you do this while the machine is in the waiting period for a delayed start, only

the delayed start is cancelled.

2

Cancelling while programming, washing or during a pause:

Apart from the "On/Off" button, all the

buttons are sensitive and therefore do not

remain depressed.

During programming, all the buttons except

for "Start/Pause" can be kept depressed

but, for more precise adjustment we

recommend that you operate them using a

series of brief presses.

You should operate the "Start/Pause" by

pressing it briefly except when cancelling

the programme* or re-initialising the cycle

counter*, in which case it should be kept

depressed.

(*) Details of the functions are provided in

the following pages.

If one of the cycle progress lights is lit

when you switch on, cancel before you carry

out any other operation.

Warning: the "On/Off" button cannot cancel

a programme.

A

recommended spin speed light

recommended spin speed light + light

(lights all light successively until the cycle is complete)

lights permanently lit

A

For more details on the various functions, please refer to "DETAILS OF THE FUNCTIONS".

Please note: if you have stopped your machine by pressing the "On/Off" button or if there has been a power failure, when power is restored to

your machine, the washing cycle will restart automatically at the point at when the cycle was interrupted.

30˚

60˚

40˚

90˚

60˚

30˚

50˚

30˚

40˚

40˚

40˚

3h

6h

9h

1000 rpm

800

600

400

MADE IN FRANCE

Delayed start setting

Start/Pause: press briefly

Cancel: long press

Spin speed selection

"Anti-creasing", "Pre-wash" and "Extra rinse"

options

On/OffCycle progress

Type of washing and

temperature

I / O

2 3 4 5

A1

• Press the "Start/Pause" button to interrupt the cycle.

• Add or remove the items of laundry

*.

• Press the "Start/Pause" button to restart the cycle.

(*) The lid may take 1-2 minutes to unlock.

If you have selected a “Delayed Start”, you can instantaneously access the drum

at any time during the phase before the washing cycle starts, without having to

interrupt and restart the cycle.

2

2

- 6 -

lights permanently lit

+ flash

lights permanently lit

• When the 2 “ ” lights flash at the end of a cycle, you must clean the pump filter

(see "CLEANING THE FILTER").

• After cleaning the filter, re-initialise the cycle counter by holding down the

"Start/Pause" button until both lights are unlit.

2

Maintaining your washing machine's performance:

Lights

Programming

For more details on the various functions, please refer to "DETAILS OF THE FUNCTIONS".

Please note: if you have stopped your machine by pressing the "On/Off" button or if there has been a power failure, when power is restored to

your machine, the washing cycle will restart automatically at the point at when the cycle was interrupted.

●

1.5

1.0

●

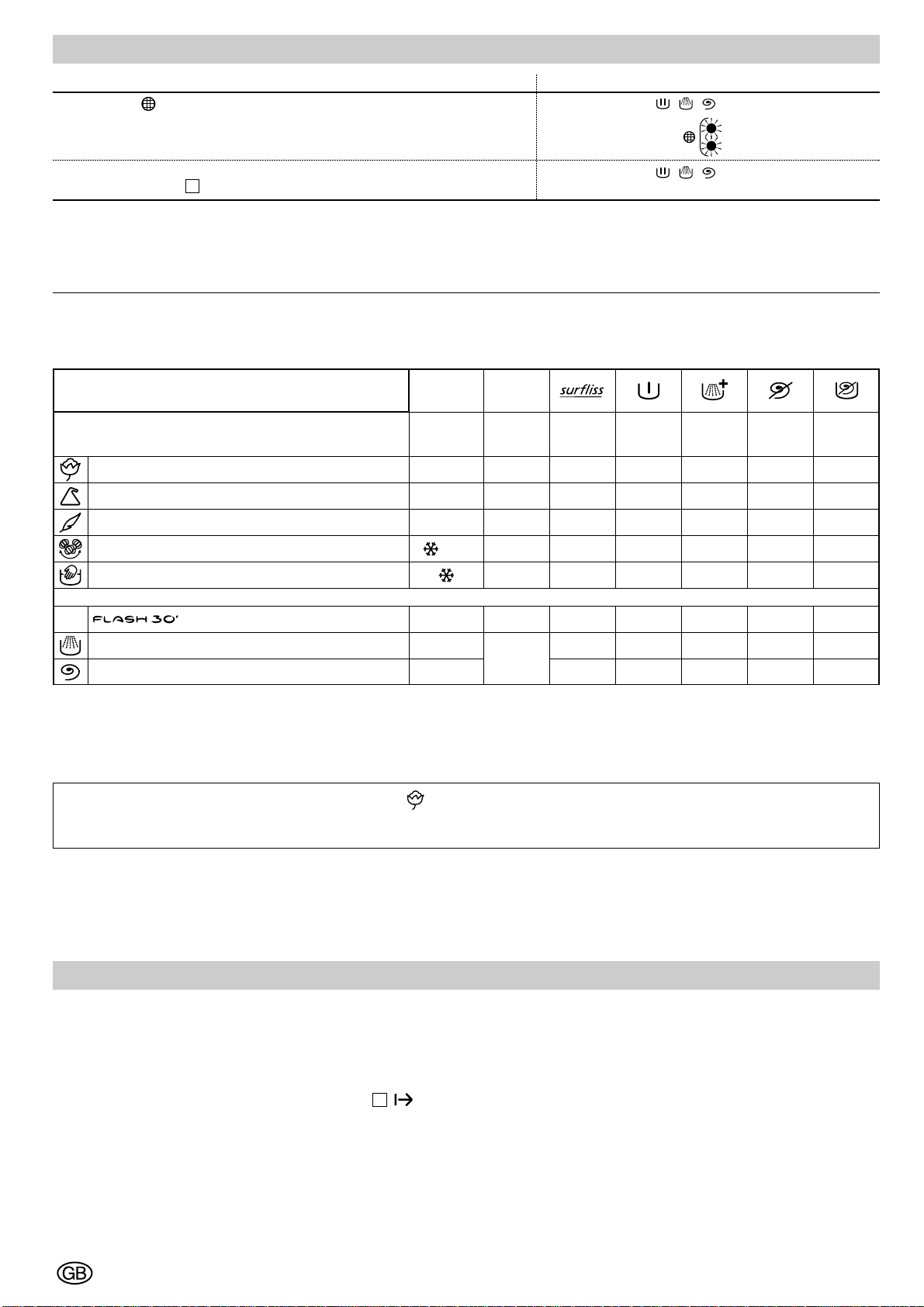

Programmes table

Type of textile

Depending

on the fabric

Full drum

stop

COTTON/WHITES/COLOUREDS 40°- 90°

30°- 60°

30°- 40°

40° 2.5

5.0

●

●

●

●

●

●

●

●

●

●

●

●

2.5

1.0

- 40°

SYNTHETICS

DELICATES

WOOLLENS

HAND-WASHABLE TEXTILES

RINSE only

SPIN only

● :

These functions can be used alone or in combinations: no illogical combinations can be made.

Special programmes

Drip-dry

●

●

●

●

●

Extra

rinse

●

●

Pre-wash

●

●

●

Anti-

creasing

Max. load

(kg)

Temperature

(°C)

Automatic safety systems

STANDARD COMPARISON TESTING PROGRAMME

To comply with the statement on the label, the tests are conducted in accordance with European Directive 92/75/EEC at nominal capacity, ensuring complete use of the CEI

detergent from the start of the washing phase.

Programme ................................................................................ - 60°

Load ....................................................................................................5 kg

Duration ............................................................................................ 1 : 58

Energy. ......................................................................................0.95 kWh

Water ....................................................................................................42 l

Lid opening safety system

:

As soon as washing commences, the lid on your machine is locked.

When the cycle is finished or when the machine has stopped with the

drum full of water, the lid unlocks.

If you have programmed a "Delayed start", the lid is not locked until

the waiting period is over and the cycle starts.

If you wish to open the lid during the cycle, press button " " briefly

and wait 1-2 minutes for the safety system to unlock the lid.

Depending on when you wish to open the lid during the cycle, this time

delay may be a little longer because a cooling down period may also

have to be included.

In fact, to avoid your being severely burnt, the lid safety system will not

open during the cycle unless the temperature inside the machine is

below a certain threshold.

Water safety system:

During operation, constant control of the water prevents any overflows.

Spin safety system:

Your washing machine is fitted with a safety system that restricts the

spin when poor load distribution is detected.

In this case, your washing may be insufficiently spun. Redistribute

your washing in the drum and programme a new spin.

Anti-foam system:

You machine can detect when too much foam is being produced during

spinning.

At such times, spinning stops and the machine drains.

The cycle then restarts, adapting the spin rates and possibly adding

an extra rinse.

2

To select the most suitable programme for your type of washing, follow the instructions on the labels attached to most items.

Please refer to the meanings of the symbols at the end of this manual.

Out of respect for your laundry, the machine prohibits the “Anti-creasing” and “Pre-wash” options being programmed simultaneously, because their

respective washing programmes are incompatible.

- 7 -

During programming:

Before pressing the "Start / Pause" button " ", any modification is

possible.

After the cycle starts:

• You cannot modify the type of textile (for example, change from

"COTTON"

to "SYNTHETICS", "SYNTHETICS" to "DELICATES", etc.).

If you turn the programme selector to a different textile, the

progress cycle light which is lit at the time, will flash for a few

seconds to indicate that the change is forbidden and will not be

effected.

To change the type of textile during the cycle, you must cancel the

current programme and then programme a new cycle.

• On the other hand, provided that the type of textile is the same, you

can change the washing temperature at the start of the washing phase.

• You can change the spin speed throughout the cycle.

• You can select "Drip-dry" and "Full drum stop" up to the end of rinsing

(until the cycle progress light " " goes out).

• You can change the "delayed start" period throughout the whole of

the waiting period up to the point at which the cycle effectively starts.

If you wish to cancel "Delayed start" during this period, press

button until the three

""

lights go out.

Then briefly press button

""

.

The cycle will start immediately.

• You can only activate the " " (Pre-wash) and " " (anti-creasing)

options during the "Delayed start" waiting period.

• You can activate option " " (Extra rinse) up to the point that rinsing

commences (until the cycle progress light " " illuminates).

• You can deactivate all the options at any time during the cycle, provided

that the action they perform has not already been completed.

2

3

A

1

2

Details of functions

Programmes

The main programmes provided by the machine are as follows:

COTTON ""

If your washing comprises hard-wearing white or coloured COTTONS

When washing coloureds do not exceed a maximum temperature

of 60°C.

During the first few minutes of the programme, your machine

automatically evaluates the washing load you have introduced and

adapts the water consumption and the length of the programme

accordingly to provide a perfect wash.

SYNTHETICS ""

If your washing comprises HARD-WEARING SYNTHETICS or MIXED

FIBRES

DELICATES ""

If your washing comprises NETTING, DELICATE FABRICS or FRAGILE

TEXTILES

A programme with a gentle mechanical action and very gentle spin

in accordance with the type of fabric.

BABYWEAR-WOOLLENS ""

If your washing comprises WOOLLENS or MACHINE-WASHABLE

WOOLLENS

”

A programme with agitation and spin phases specially adapted to

these types of fabrics

HAND-WASHABLE TEXTILES ""

If your washing comprises SILK or PARTICULARLY DELICATE FABRICS

A programme with a very gentle mechanical action and no intermediate

spins between rinses.

The cycle ends with a very gentle, progressive spin restricted to 600

rpm.

This programme enables you to refresh a small load of 2.5 kg of lightly

soiled washing composed of WHITES, COTTONS, COLOUREDS or

HARD-WEARING SYNTHETICS.

The cycle time is restricted to around 30 minutes

In this programme, the washing temperature is automatically

programmed at 40°C.

For this programme, the doses of detergent should be reduced

by half.

RINSE ONLY ""

A separate rinse followed by a choice of:

- Either spin and drain

- Or drain only ("Drip-dry" option)

- Or a stop with the drum full of water.

SPIN ONLY ""

This allows a separate spin and drain.

In the case of "Rinse only" followed by a spin or "Spin only", ensure

that you select a suitable spin speed for the type of washing in the

machine.

Options

Anti-creasing

Makes your washing easier to iron.

This option enables your washing to be washed and spun more gently,

while retaining identical washing performance.

Pre-wash

Specially designed for heavily soiled washing (mud, blood, etc.).

A specific initial agitation in cold water precedes a phase of heating to

30°C.

This agitation phase in cold water enables the particles soiling the

washing to be removed before the water is heated.

Detergent must be placed in the " " container in the products box.

Extra rinse

"Especially for sensitive and allergic skin": adds an extra rinse to the

washing cycle.

Delayed start

You can delay the start of your programme by 3, 6 or 9 hours to take

advantage of off-peak rates or finish the cycle at a particular time.

To do this, use button to select the starting time for the cycle.

If you have programmed a "Delayed start", while the machine is waiting

to start, the lights illuminate in various ways according to the waiting

time remaining.

For example, if you have programmed a 9-hour delay, the

"9h"

light

flashes.

Every three hours the flashing light changes position, moving

successively to

"6h"

and then

"3h"

.

5 minutes before the end of the programmed period, the

"3h"

light

starts to flash more rapidly to warn you that the washing cycle is about

to start.

When the

"3h"

light goes out, the programmed time has elapsed

and the cycle starts.

Full drum stop

This is used for textiles that you do not wish to spin or if you foresee

your being absent for a long time after the washing cycle has finished.

When this function is selected, the cycle is interrupted before the final

spin, allowing your washing to soak in the water to avoid creasing.

When the machine stops with the drum full of water, the cycle progress

light

""

flashes.

Then:

- Either you wish to drain and spin.

In which case, use button ""to select a suitable spin speed for

your type of washing. The programme will shut down automatically.

- Or you wish simply to drain.

In which case, use button , to select the drip-dry function (light

"").

5

5

3

Modifying a washing programme

- 8 -

Automatic fault diagnostics

When one of the above faults occurs, please remember to note down which lights are lit so that you can provide your breakdown engineer with

this information during your call, making his work much easier.

The cycle does not start

• You have not pressed the "Start /Pause" button

• There is no power to the machine:

- Check that the plug is correctly in the socket

- Check the circuit breaker and the fuses.

• The water tap is closed

• The machine's lid is not closed properly

A puddle of water forms around the machine

First of all remove the plug and the fuse and shut off the water

supply tap.

While the machine is operating, the permanent level control prevents

the water from overflowing. If, despite this, water comes out of your

machine, it may be that:

• The drain hook is wrongly positioned in the drain pipe.

• The water supply hose is not sealed tightly at the machine or tap end:

- Check that the seals are in place and the connections are tight.

Heavy vibration during spin

• All the transport materials have not been removed correctly from

the machine:

- Check that all the transport wedges have been removed (see

"REMOVING THE TRANSPORT CLAMPS FROM YOUR MACHINE").

• The floor is not level.

• Your machine is resting on its two “front” castors (depending on

the model):

- Reset your machine on its feet by pushing the castor engagement

lever to the right.

The washing is not spun or not spun enough

• You have selected a programme with no spin, for example "Drip-

dry"

• The spin safety system has detected poor distribution of the washing

in the drum:

- Untangle the washing and programme a new spin.

The machine does not drain

• You have programmed "Full drum stop"

• The pump filter is blocked:

- Clean it (see "CLEANING THE FILTER" for the relevant procedure)

• The drain hose is kinked or squashed

The lid does not open

• The programme has not yet finished

The lid remains locked throughout the programme.

The drum doors open very slowly

(On machines fitted with gently opening doors)

• Your machine has not operated for a long time

• It is located in too cold a position.

• Detergent residue (powder) is blocking the hinges

- In all cases, everything returns to normal after the doors have opened

initially.

Incidents that may occur

Some incidents may occur while you are using your machine. These are the points to check:

As a general rule, whatever the anomaly detected, you should

stop the machine, unplug the power cable and shut off the water

tap

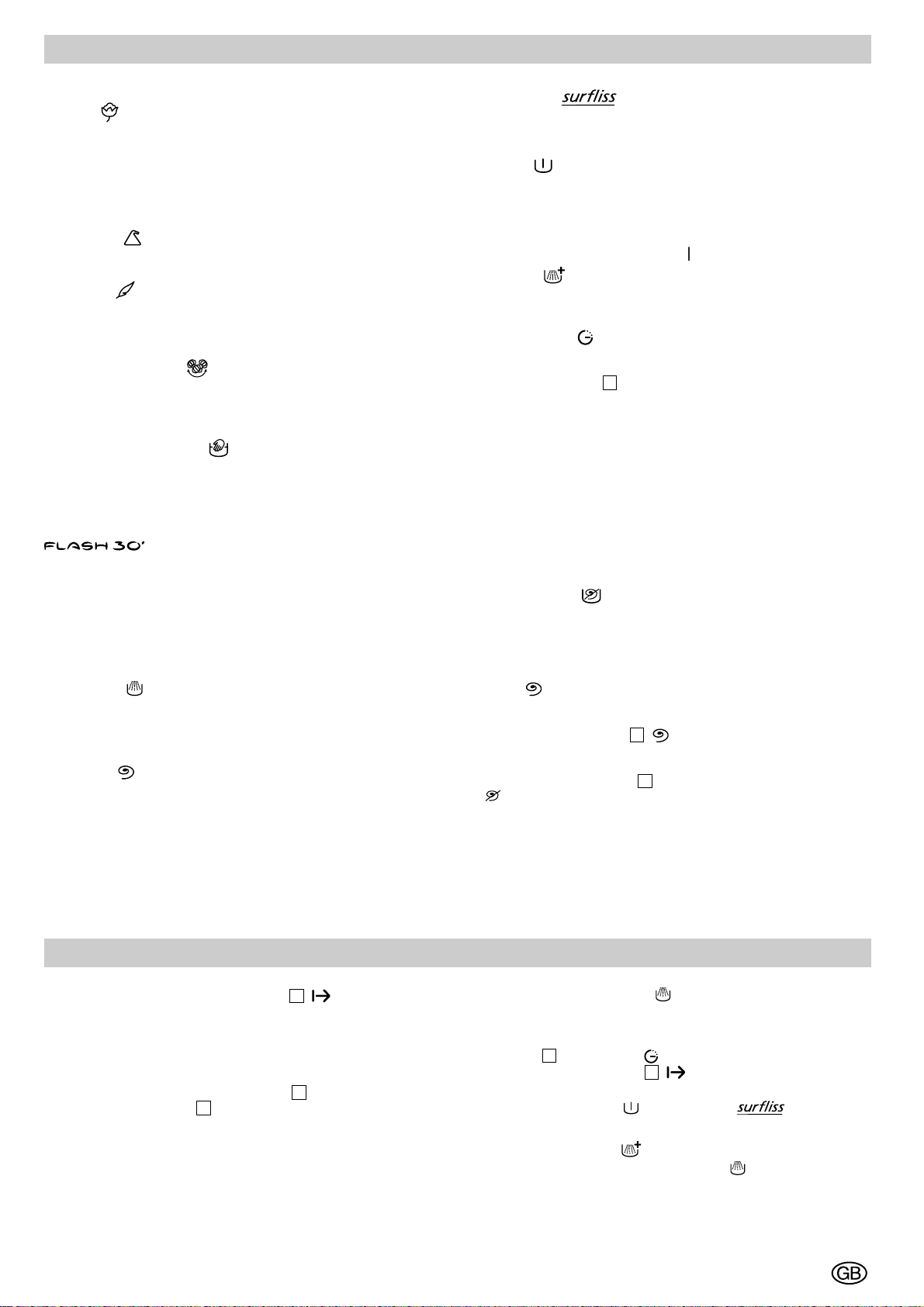

Your machine can automatically detect certain operating faults.

A particular light flashing serving to set the end of the cycle ( ) shows you what the operating fault is:

Flashing

lights

Possible cause / remedy

Filling fault. Check that the water tap is open, then press

button " " again to restart the cycle. If the fault persists,

contact your breakdown engineer.

Draining fault. Clean the pump filter (see "CLEANING THE

FILTER"

for the relevant procedure), then press button

" " again to restart the cycle. If the fault persists, contact

your breakdown engineer.

Heating fault. When this message appears at the end of

the cycle, it indicates that the machine has not achieved

the washing temperature you have selected. Contact your

breakdown engineer.

Programming card fault. For its own protection, your

machine ceases to function. Contact your breakdown

engineer.

Temperature fault. Contact your breakdown engineer.

Flashing

lights

Possible cause / remedy

Drum rotation fault. After switching the machine off, check

whether an item of washing or an object has slipped

between the drum and the tub, causing a blockage (see

"CLEANING THE FILTER"

for details on how to access

the back of the tub). If the fault persists, contact your

breakdown engineer.

Overflow. When this fault is detected, the supply of water

is automatically cut off, the machine drains and the cycle

stops. Contact your breakdown engineer.

Locking fault. Check that the lid is closed correctly, then

press button " " again to restart the cycle. If the fault

persists, contact your breakdown engineer.

Water distribution fault in the products box.Contact your

breakdown engineer.

Fault in the electronic unit. For its own protection, your

machine ceases to function. Contact your breakdown

engineer

1000

800

600

400

400

1000

800

600

1000

800

600

400

400

1000

800

600

1000

800

600

400

1000

800

600

400

400

1000

800

600

1000

800

600

400

400

1000

800

600

400

1000

800

600

- 9 -

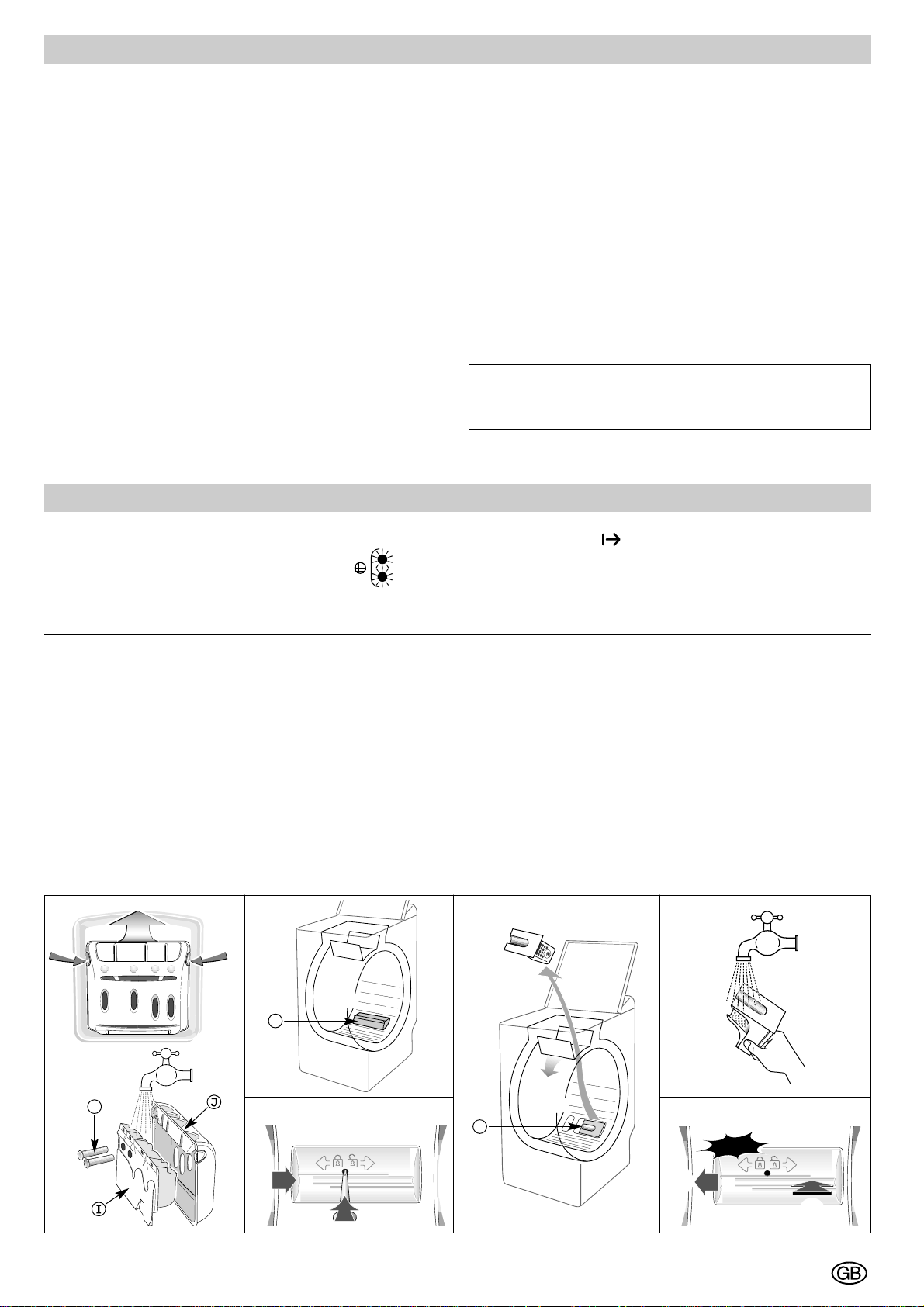

Cleaning the filter

see diagrams

D9-D10-D11-D12-D13

➀

➁

CLANG

➀

➁

Cleaning the pump filter

This filter catches any small objects inadvertently left in the clothes to

avoid their disrupting the pump’s operation.

To clean the filter, proceed as follows:

- Open the drum doors. At the back of the drum, you will see a plastic

component

(Diagram

D9

)

- Unlock this component

(Diagram

D10

)

.

To do this:

• Insert a rod (a pencil or a screwdriver, for instance) into the hole in

component

• While pressing down vertically with the rod, push component

towards the right until it releases from its housing

- Remove component

- Turn the drum slightly towards the front of the machine with the doors

open

(Diagram

D11

)

.

Through the openings freed by removing component

you can now

access the pump filter

.

- Remove it from its housing

(Diagram

D11

)

.

- Remove the various objects that may be inside it.

- Rinse it under the tap

(Diagram

D12

)

.

- Re-insert it by pushing it fully into its housing, after checking that the

housing is clean.

- Re-insert component

, carefully positioning it in the openings at

the back of the drum and pushing it to the left until it is perfectly engaged.

(Diagram

D13

)

.

D8 D9

D10

D11 D12

H

K

D13

L

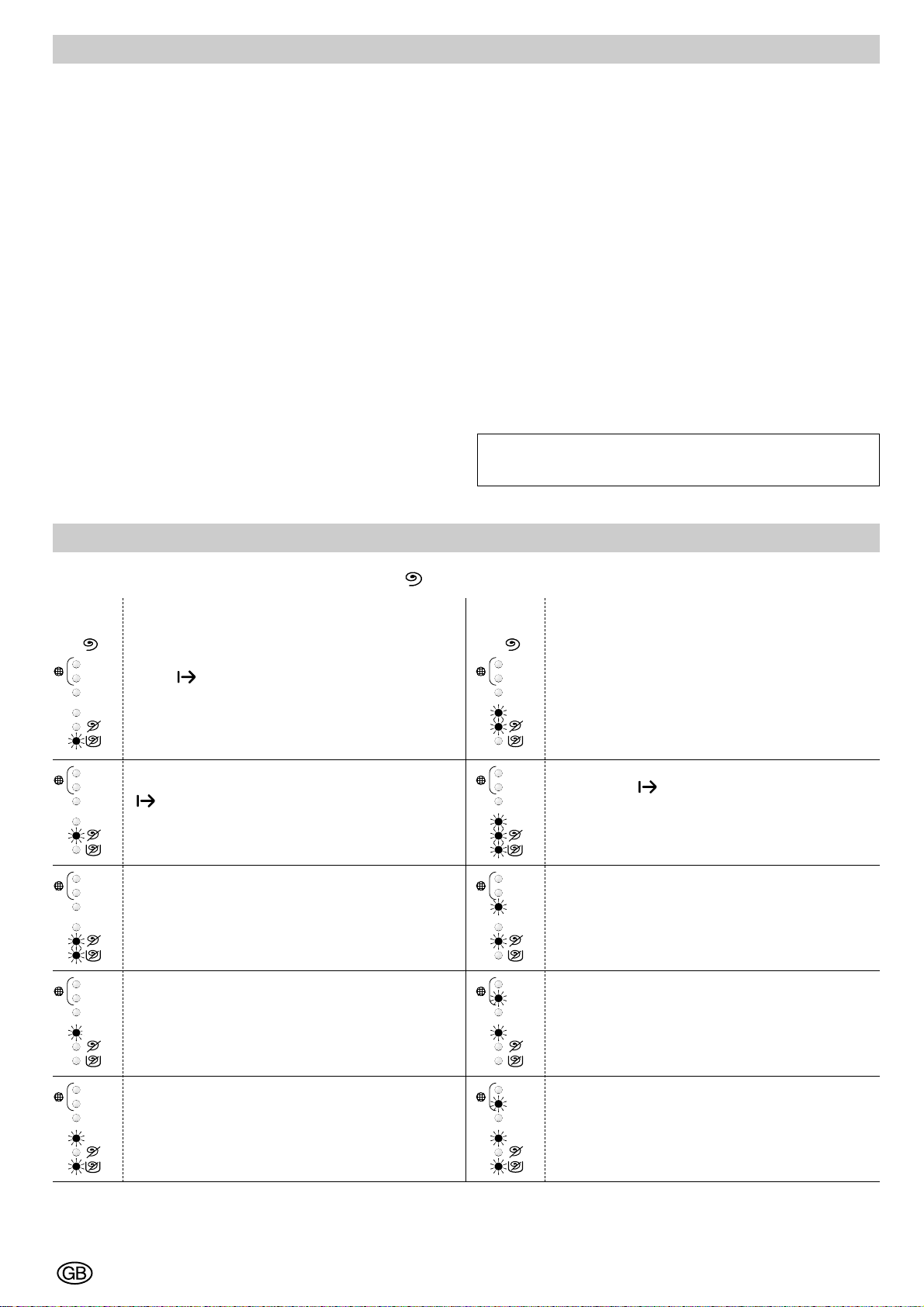

Running maintenance

see diagram

D8

Cleaning the machine

.

To clean the casing:

Use only soap and water.

To clean all the plastic components (control panel, plinth, etc.):

Use only a cloth dampened with water.

In all cases, do not use:

• Abrasive powders

• Metal or plastic sponges

• Alcohol-based products (alcohol, thinners, etc.)

Cleaning the products’ box

(Diagram

D8

)

.

Nettoyez régulièrement la boîte à produits. Pour cela :

- Press the bosses on each side of the box simultaneously to extract it

from its housing.

- Remove the siphons

from the rear of the box

and separate the

box from its front cover

- Rinse everything under the tap (taking care to empty any excess water

remaining inside the box).

- Refit all the box’ components, ensuring that the box section itself is

properly clipped into the cover and then re-insert the complete assembly

into its location under the machine’s lid.

Frost risk

When there is a risk of frost, disconnect the water supply hose and empty

any water remaining in the drain hose by placing this as low as possible

in a basin.

Care of the internal components

To ensure better hygiene, we recommend that you:

• Leave the lid open for a short time after washing.

• Clean the plastic and rubber access components to the tank approximately

once a month using a slightly chlorinated product. Run a rinsing cycle

to remove any residue of this product.

• Run a washing cycle at 90°C at least once a month.

Periodic checks

We recommend that you check the condition of the water supply and

drain hoses. If you notice the slightest cracking, do not hesitate to replace

them with identical hoses available from the manufacturer or his After-

Sales service.

Replacing a water supply hose

When replacing the hose, ensure that the hose is tightly fastened and

that there is a seal at both ends.

Replacing the power cable

For your safety’s sake, this operation must be performed by the

manufacturer’s After-Sales service or a qualified professional

electrician.

After a certain number of cycles, your machine will warn you that you

should clean the drain pump filter.

At the end of the cycle, the following two lights flash:

You must reset the cycle counter to remove this message: if you do not

do this, it will continue to be displayed at the end of every cycle.

To reset the cycle counter when these lights are flashing, depress the

"Start / Pause" button " " until these lights go out.

If you do not clean the pump filter regularly, this can affect your

machine’s performance.

- 10 -

Sommaire

Page

Démontage des brides de transport de votre appareil ....................10

Mise en place de votre appareil ............................................................10

Raccordements de votre appareil ........................................................11

Chargement du linge ..............................................................................11

Chargement des produits de lavage ....................................................11

Programmation ..............................................................................12 et 13

Sécurités automatiques..........................................................................13

Page

Détail des fonctions ................................................................................14

Modification d’un programme de lavage ............................................14

Incidents pouvant survenir ....................................................................15

Diagnostic automatique des défauts....................................................15

Entretien courant ....................................................................................16

Nettoyage du filtre de pompe................................................................16

Démontage des brides de transport de votre appareil

voir dessins

D1-D2-D3

1 - Retirez le lave-linge de son socle (vérifiez que la cale

servant

au maintien du moteur n'est pas restée coincée sous la machine)

(Dessin

D1.➀

)

2 - Enlevez les 4 vis

à l'aide d'un tournevis

(Dessin

D1.➁

)

3 - Déposez la traverse

en ôtant les deux vis

(Dessin

D1.➂

)

à l'aide

d'une clé de 10 ou de 13 mm (suivant le modèle)

(assurez-vous que les deux entretoises en plastique fixées sur la

traverse, sont bien retirées en même temps que cette dernière).

Remontez les vis

à leur emplacement initial.

4 -

Obstruez impérativement les deux trous à l'aide des cache-

orifices

prévus à cet effet (fournis dans le sachet d'accessoires)

(Dessin

D1.➃

)

5 - Retirez la cale d'immobilisation de l'ensemble tambour-cuve

(Dessin

D2

)

.

Pour cela :

- soulevez le couvercle de la machine

- retirez la cale

- enlevez la cale

en la tournant d’un quart de tour

- libérez les portillons du tambour, bloqués en position basse, en

appuyant simultanément sur les deux volets.

6 -

Enlever les colliers support tuyaux

➀

et obstruez impérativement

les trous à l’aide des caches

➁

(fournis dans le sachet d'accessoires)

(Dessin

D3

)

.

Mise en place de votre appareil

voir dessin

D4

AVANT TOUTE UTILISATION, IL EST IMPÉRATIF D'EFFECTUER LES OPÉRATIONS DÉCRITES CI-APRÈS.

Ces opérations consistent à retirer toutes les pièces qui servent à immobiliser la cuve de votre appareil pendant le transport.

Ces opérations dites ”de débridage” sont nécessaires pour le bon fonctionnement de votre appareil et le respect des normes en vigueur

en matière de sécurité.

Si ces opérations n’étaient pas effectuées dans leur totalité, cela pourrait causer des dommages graves à votre appareil pendant son

fonctionnement.

Nous vous conseillons de conserver toutes les pièces de bridage, car il

faudra obligatoirement les remonter si vous devez, par la suite, transporter

votre machine.

Toutes ces pièces ainsi que celles composant l’ensemble de votre machine

sont faites de matériaux recyclables. Il convient d’en tenir compte lors

de leur mise en décharge à la fin de la vie de votre machine.

Avant sa sortie d’usine, votre appareil a été minutieusement contrôlé; il

est donc possible que vous constatiez la présence d’un peu d’eau dans

la cuve ou au niveau des boîtes à produits.

Mise sur roulettes :

Si votre machine est équipée de roulettes escamotables, vous pouvez

la déplacer facilement.

Pour la mise sur roulettes, faites pivoter de la droite jusqu'à l'extrémité

gauche le levier situé au bas de l'appareil

(Dessin

D4

)

.

En fonctionnement, la machine ne doit pas reposer sur ses roulettes

"avant" : n'oubliez pas de ramener le levier dans sa position initiale.

Mise à niveau :

Vérifiez à l'aide d'un niveau que le sol est horizontal : inclinaison maxi

2°, soit un écart d'environ 1 cm mesuré sur la largeur et de 1,5 cm sur

la profondeur de la machine.

Environnement de l’appareil :

Si vous placez votre machine à côté d'un autre appareil ou d'un meuble,

nous vous conseillons de toujours laisser entre eux un espace pour

faciliter la circulation de l’air.

D’autre part, nous vous déconseillons fortement :

- d'installer votre appareil dans une pièce humide et mal aérée.

- d'installer votre appareil dans un lieu où il pourrait être soumis à des

projections d’eau.

- d'installer votre appareil sur un sol en moquette.

Si vous ne pouvez l'éviter, prenez toutes les dispositions pour ne pas

gêner la circulation de l'air à sa base, afin d’assurer une bonne ventilation

des composants internes.

D2 D3

13

1

1

2

2

a

b

a

b

➀

➁

➀

➁

➃

➂

F

D1

D4

A

C

B

E

F

G

D

D

Loading...

Loading...