Page 1

1 | Overview

The B520 Auxiliary Power Supply Module provides up to 2A of

12 VDC power for Fire and Burglar standby power applications.

For Burglar applications, an additional 2A of alarm power is

available, allowing 2A of standby current and up to 4A of alarm

current. You can connect more than one Aux Power Supply

module to the control panel by wiring them in parallel. Refer to

Figure 3.6.

The module’s address switches provide a tens and ones value

for the module’s address. For single-digit address numbers 1

through 9, set the tens switch to 0 and the ones digit to the

appropriate number. Figure 2.1 shows the address switches

setting for addresses 12.

3 | Installation

After you set the address switches for the proper address,

install the module in the enclosure, and then wire it to the

control panel, SDI2 expansion modules,

and/or other 12 VDC devices.

NOTICE!

Remove all power (AC and battery) before making any

connections. Failure to do so might result in personal

injury and/or equipment damage.

3.1 | Mount the module in the enclosure

(models B10, D2203, AE1, and AE2)

3.1.1 | Wire the grounding wire

(models B10, D2203, AE1, and AE2)

Insert the grounding wire lug onto the bolt, and secure it

with a nut and a washer. Insert the other end of grounding

wire onto the enclosure door hinge. Refer to Figure 3.2.

3.2.2 | Mount the module onto the

mounting plate

Insert the plastic mounting clips onto the appropriate

standoff locations on the mounting plate. Place the B520

against the plastic mounting clips and then secure it using

the supplied mounting screws. Refer to Figure 3.4.

7

7

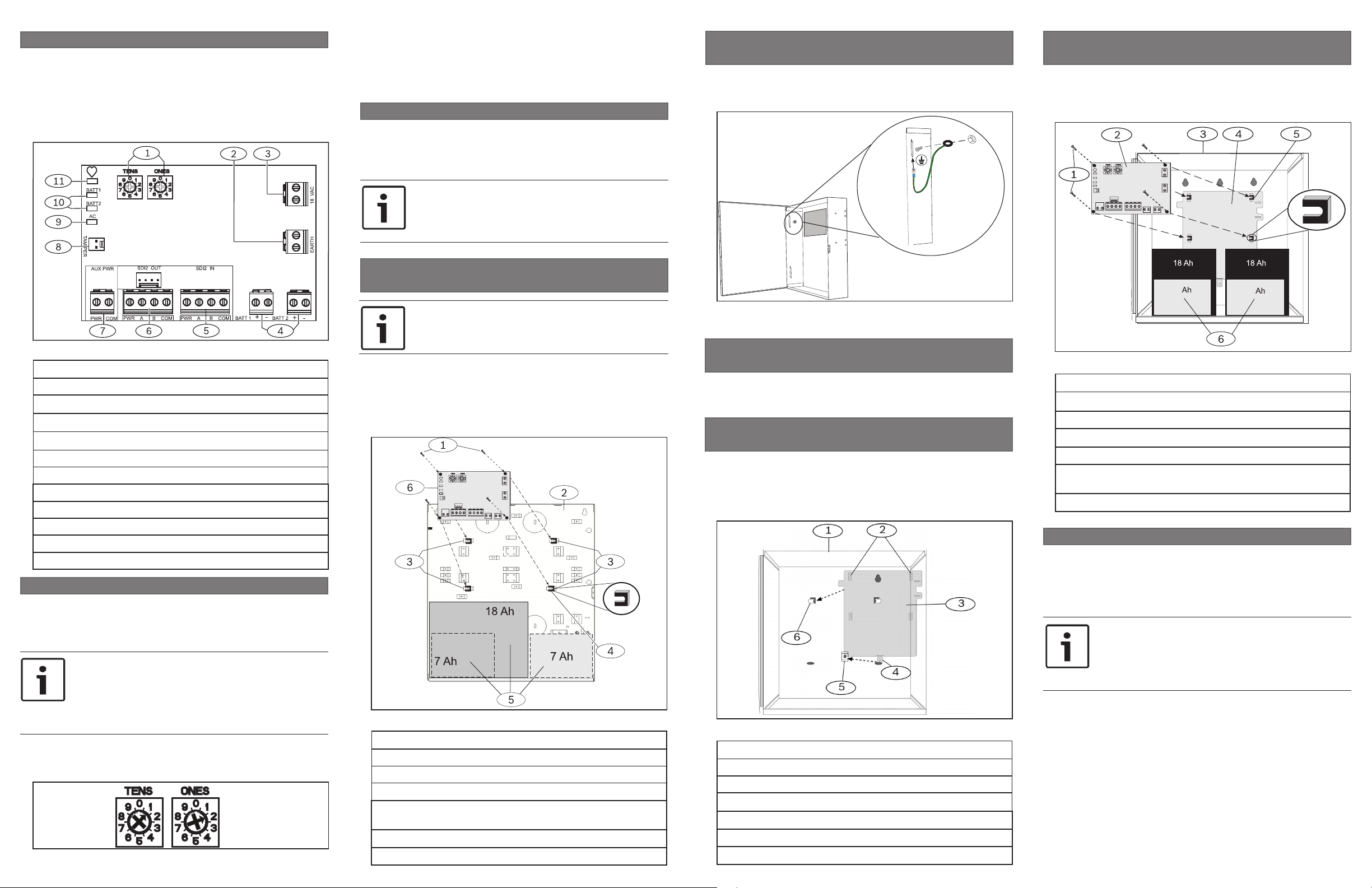

Figure 1.1: Board overview

Callout ― Description

1 ― Address switches

2 ― EARTH ground connector terminal

3 ― 18 VAC transformer input terminal (TR1850)

4 ― BATT 1 and BATT 2 terminals

5 ― SDI2 IN terminals (from control panel)

6 ― SDI2 OUT terminals and interconnect wiring connector

7 ― Auxiliary power terminals

8 ― Tamper switch connector

9 ― AC LED (green)

10 ― BATT 1 and BATT 2 LEDs (green)

11 ― Heartbeat LED (blue)

2 | SDI2 address settings

Two address switches determine the address for the B520

Auxiliary Power Supply Module. The control panel uses the ad-

dress for communications. Use a slotted screwdriver to set the

address switches.

NOTICE!

The module reads the address switch setting only

during power up. If you change the switches after

you apply power to the module, you must cycle the

power to the module in order for the new setting to

be enabled.

Set the address switches per the control panel conguration. If

multiple B520 modules reside on the same system, each B520

module must have a unique address.

Figure 2.1: Address switches

NOTICE!

Do not use B10 or D2203 enclosures for Commerical

Fire applications.

Insert the plastic mounting clips onto the appropriate

standoff locations inside the enclosure. Refer to Figure 3.1.

Mount the module onto the plastic mounting clips and then

secure it using the supplied mounting screws. B10, D2203,

AE1, and AE2 enclosure installations can hold up to two 7 Ah

batteries, or one 18 Ah battery.

Figure 3.1: Mounting the module in the enclosure

Callout ― Description

1 ― Mounting screws (4)

2 ― B10, D2203, AE1, and AE2 enclosures (back panel)

3 ― Standoff locations

4 ― Plastic mounting clips (4) (snapped onto enclosure

standoffs)

5 ― Batteries (up to two 7 Ah or one 18 Ah batteries)

6 ― B520 module

Figure 3.2: Wiring the grounding wire (B10 shown)

3.1 | Mount the module in the enclosure

(model D8103)

Mounting in the D8103 enclosure requotes the B12 mounting

plate.

3.1.1 | Mount the B12 mounting plate

in the enclosure (model D8103)

Place the B12 mounting plate in the back of the D8103

enclosure, and set the tabs of the D8103 into the

enclosure’s two mounting skirt hooks. Secure the lock

down tab to the skirt mounting hole with the provided

screw. Refer to Figure 3.3.

Figure 3.3: Mounting plate onto the D8103 enclosure

Callout ― Description

1 ― D8103 enclosure (also applicable for BATB-40)

2 ― Support posts (2)

3 ― Mounting plate

4 ― Lock down tab

5 ― Plate mounting hole

6 ― Mounting plate hooks (2)

Figure 3.4: Mounting the B520 onto the mouting plate

Callout ― Description

1 ― Mounting screws (4)

2 ― B520 module

3 ― D8103 Enclosure (applicable for BATB-40 as well)

4 ― B12 mounting plate

5 ― Plastic mounting clips (4) (fastened to the mounting

plate standoffs)

6 ― Batteries (holds up to two 7 Ah or two 18 Ah batteries)

3.3 | Wire the earth ground terminal

To help prevent damage from electrostatic charges or other

transient electrical surges, connect the system to earth ground

before making other connections. Recommended earth ground

references are a grounding rod or a cold water pipe. When

grounding, run wire as close as possible to grounding device.

NOTICE!

Do not use telephone or electrical ground for the

earth ground connection. Use 14 AWG (1.8 mm)

to 16 AWG (1.5 mm) wire when making the

connection.

Page 2

2

1

18 VAC

EARTH

3

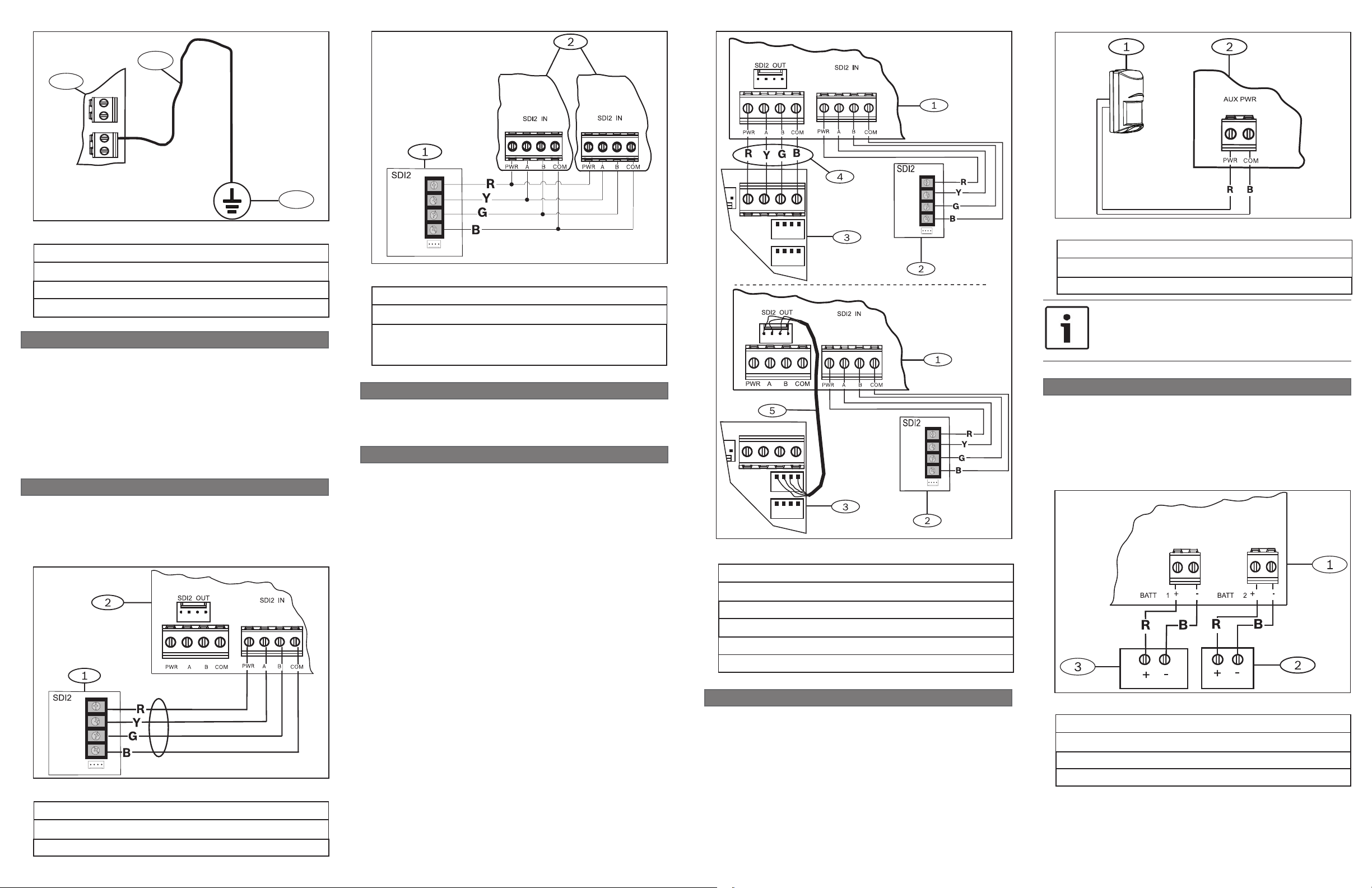

Figure 3.5: Wiring the earth ground connection

Callout ― Description

1 ― B520 module

2 ― 14 AWG - 16 AWG (1.8 mm - 1.5 mm) wire

3 ― Ground device (grounding rod or cold water pipe)

3.4 | Mount and wire the tamper switch

You can connect an enclosure optional door tamper switch

for one module in an enclosure.

Installing the optional tamper switch:

1. Mount the ICP-EZTS Tamper Switch (P/N: F01U009269)

into the enclosure’s tamper switch mounting location. For

complete instructions, refer to EZTS Cover and Wall Tamper

Switch Installation Guide (P/N: F01U003734).

2. Plug the tamper switch wire onto the module’s tamper

switch connector. Refer to Figure 1.1.

3.5 | Wire to the control panel

When you wire a B520 to a control panel, use the terminal

strip labeled SDI2 IN with PWR, A, B, and COM to wire to the

designated terminals, according to the compatible control

panel conguration. Ensure the wiresattache properly.

Figures 3.5 through 3.8 for all wiring congurations.

Refer to

Figure 3.6: Installing multiple modules

Callout ― Description

1 ― Compatible Bosch control panel SDI2 bus connection

2 ― B520 module (Refer to the control panel’s Installation

and System Reference Guide for multiple module

congurations.)

3.6 | Wire to powered devices

After wiring the module to the control panel, wire it to the

powered devices.

3.6.1 | Wire to powered SDI2 devices

When you wire the output of a B520 to a SDI2 module, you can

use either the terminal strip of the SDI2 OUT terminal labeled

with PWR, A, B, COM, or you can use the interconnect wiring

connectors. Refer to Figure 3.7.

Figure 3.8: Wiring the AUX power terminal to devices

Callout ― Description

1 ― Compatible Bosch peripheral device

2 ― B520 module

NOTICE!

When used to power a local security annunciator

(e.g. bell) or a DACT, the B520 must be installed in

the D8108A Attack Resistant Enclosure.

3.7 | Wire to the batteries

You must wire the B520 to BATT 1 for proper operation of

standby power for the B520 module. Wiring the second

battery (BATT 2) is optional. If a control panel is congured

for two batteries as the standby power source, then BATT 2 is

also required for proper operation. BATT 2 must have the same

capacity, and same rating as BATT 1. Maximum Standby power

cannot exceed 36 Ah. Refer to Figure 3.9.

Figure 3.7 Using terminal strip or interconnect cable wiring

Figure 3.6: Wiring the module to the control panel

Callout ― Description

1 ― Compatible Bosch control panel SDI2 bus connection

2 ― B520 module

Callout ― Description

1 ― B520 module

2 ― Compatible Bosch control panel SDI2 bus connection

3 ― SDI2 module

4 ― Terminal strip wiring (SDI2)

5 ― Interconnect cable (P/N: F01U079745) (included)

3.6.2 | Wire to powered non-SDI2 devices

The AUX PWR power terminals provide auxiliary power

capabilities for additional peripheral devices such as PIR’s

and Keypads. When you wire the B520 to an added peripheral

device, use the AUX PWR terminal strip labeled with PWR and

COM. Refer to Figure 3.8.

Figure 3.9 Wiring the batteries

Callout ― Description

1 ― B520 module

2 ― Battery 2 (BATT 2) - (12 V nominal lead acid)

3 ― Battery 1 (BATT 1) - (12 V nominal lead acid)

Page 3

3.7 | Wire to the transformer

You must wire the plug-in transformer to 18 VAC B520 for

proper operation of the B520 module. Refer to Figure 3.10.

Figure 3.10: Wiring the transformer

Callout ― Description

1 ― B520 module

2 ― TR1850 plug-in transformer

4 | Battery congurations and calculations

To determine the battery standby usage, reference the Table 4.1.

Battery Size (AH’s) for Commercial Fire Applications:

To select the proper battery size, compare the current

calculations from Table 5.1 against the highest current

available for the standby hours required. If the current from

“Total A” or “Total B” exceeds the highest value in that

column, then a second B520 is required to split the current

load.

Battery Size (AH’s) for Burglar Applications:

To select the proper battery size, compare the current

calculations from Table 5.1 against the highest current

available for the standby hours required. If the current from

“Total A” exceeds the highest value in that column, or the

current from “Table B” exceeds 4A, then a you must split the

current load with a second B520.

NOTICE!

The battery terminals and wire are not power limited.

A 0.25 in (6.4 mm) space must be maintained between

the battery terminals, battery wiring, and all other

wiring. Battery wiring cannot share the same conduit,

conduit ttings, or conduit knock-outs with other

wiring. All external connections are power-limited

except battery terminals. All external connections are

supervised.

A

Standby current (mA)

Maximum current (mA)

Model # Quantity

used

B208 35 x Quantity = 35 x Quantity =

B308* 22 x Quantity = 22 x Quantity =

B420** 100 x Quantity = 100 x Quantity =

B426 100 x Quantity = 100 x Quantity =

B820 100 x Quantity = 110 x Quantity =

D185 245 x Quantity = 300 x Quantity =

D1255/D1255B 106 x Quantity = 206 x Quantity =

D1256/D1257 106 x Quantity = 206 x Quantity =

D1255RB 106 x Quantity = 225 x Quantity =

D1256RB 106 x Quantity = 225 x Quantity =

D1257RB 106 x Quantity = 225 x Quantity =

D1260/D1260B 140 x Quantity = 250 x Quantity =

B920 35 x Quantity = 85 x Quantity =

B930 35 x Quantity = 85 x Quantity =

D720 20 x Quantity = 100 x Quantity =

D8128D 25 x Quantity = 50 x Quantity =

D8129*** 20 x Quantity = 20 x Quantity =

D9210C**** 110 x Quantity = 110 x Quantity =

DX4010V2***** 50 x Quantity = 55 x Quantity =

DX4020 80 x Quantity = 84 x Quantity =

ITS-DX4020-G 65 x Quantity = 200 x Quantity =

Other devices

* (digital section = 22 mA) + (Qty of relays x 16 mA) = total current. (Add 16 mA for each relay being used).

** 10BaseT Ethernet: 90 mA max, 100BaseT Ethernet: 100 mA max.

*** The In Alarm calculation for the D8129 Is: 20 X Qty + (16.25 x number of relays).

**** Use 110 mA + reader current. Do not exceed 260 mA.

***** UL requires the DX4010V2 be used for programming only.

Table 4.1: Current rating chart for standby calculations

Enclosures BATT 1 BATT 2 BATT 1 BATT 2

D2203, B10, AE1, AE2 18 Ah N/A 7 Ah 7 Ah (optional)

D8103, BATB-40 18 Ah 18 Ah (optional) 7 Ah 7 Ah (optional)

Table 4.2: Typical battery conguration

4 8 24 24 48 60 72 80

24 24 24 48 48 48 72 72

Rechargeable battery size (AH) Maximum output standby current

7 1.135 0.575 0.100 0.169

14 (+2 7 Ah) 1.600 1.100 0.330 0.403 0.176 0.131 0.101

18 1.800 1.220 0.460 0.536 0.243 0.184 0.145 0.126

36 (+2 18 Ah) 2.000 1.790 0.710 0.950 0.520 0.424 0.345 0.306

Each unit Quantity Total Each unit Quantity Total

Total A = Total B =

Battery conguration #1 Battery conguration #2

Standby hours

Recharge Hours

B

In alarm

5 | LED descriptions

The B520 module includes the following on-board LEDs to

assist with troubleshooting issues (refer to Figure 1.1 for the

location of the LEDs):

– Heartbeat (system status). Refer to Table 5.1.

– BATT 1 and BATT 2. Refer to Table 5.2.

– AC IN. Refer to Table 5.3.

For troubleshooting steps based on the LEDs, refer to

Section 7.

Flash pattern Function

Flashes once

every 1 sec

3 quick ashes

every 1 sec

On Steady LED trouble state: Module is not

Off

Table 5.1: Heartbeat (blue) LED descriptions

Flash pattern Function

Flashes once

every 1 sec

3 quick ashes

every 1 sec

On Steady Normal state. Indicates normal operation

Off Battery missing.

Table 5.1: BATT 1 and BATT 2 (green) LEDs descriptions

Flash pattern Function

Flashes once

every 1 sec

3 quick ashes

every 1 sec

On Steady Normal state. Indicates normal operation

Table 5.1: AC (green) LED descriptions

Normal state: Indicates normal operation

state.

Communication error state: Indicates

(the module is in a “no communication

state”) resulting in an SDI2

communication error.

powered (for OFF Steady only), or some

other trouble condition prohibits the

module from controlling the heartbeat

LED.

Low battery.

Battery charger failure.

state.

Low or failed AC.

Battery test performing.

state.

Table 4.3: B520 Auxiliary Power Supply Module battery standby chart

Page 4

6 | Show the rmware version

9 | Certications

11 | Next

10 | Specications

To show the rmware version using an LED ash pattern:

– If the optional tamper switch is installed:

With the enclosure door open, activate the tamper switch

(push and release the switch).

– If the optional tamper switch is NOT installed: Momentarily

short the tamper pins.

Refer to Figure 6.1 for an example of ash patterns.

Figure 6.1: Firmware LED ash patterns

When the tamper switch is activated (closed to open), the

heartbeat LED stays OFF for 3 sec before indicating the

rmware version. The LED pulses the major, minor, and

micro digits of the rmware version, with a 1 sec pause after

each digit.

Flashing patterns do not start until the tamper is open

(short is removed). The following is an example: The version

1.4.3 would be shown as LED ashes:

[3 second pause] *___****___*** [3 second pause, then

normal operation].

7 | Troubleshooting

Flash pattern Corrective action

Heartbeat – 3 quick

ashes every 1 sec

BATT 1 (BATT 2) – 3

quick ashes every

1 sec

AC Flashing Measure the AC voltage before

Table 7.1: LED troubleshooting patterns

1. Check wiring, ensure secure

connection.

2. Control panel might be

programmed incorrectly.

3. Address switches do not match

the control panel. Verify address

selections.

Measure the voltage at the battery

terminals. If the voltage is above

13.3 VDC, and is a fully charged

battery, the condition restores once

some of the energy is drained from

the battery. If the battery voltage is

low, the B520 might be damaged.

and after the transformer. If there

is voltage before and none after,

replace the transformer.

8 | Conguration

Use Remote Programming Software (RPS) to program the

control panel to work with the module. For programming

parameter descriptions, options, and defaults, refer to RPS Help.

Region

US UL 365 - Police Station Connected Burglar Alarm

Units and Systems

UL 609 - Local Burglar Alarm Units and Systems

UL 636 - Hold Up Alarm Units

UL 864 - Control Units and Accessories for Fire

Alarm Systems

UL 985 - Household Fire Warning System Units

UL 1023 - Household Burglar Alarm System

Units

UL 1076 - Proprietary Burglar Alarm Units and

Systems

UL 1610 - Central Station Burglar Alarm Units

FCC Part 15 Class B

Canada CAN/ULC S303 - Local Burglar Alarm Units and

Systems

CAN/ULC S304 - Signal Receiving Centre and

Premise Alarm Control Units

CAN/ULC S545 - Residential Fire Warning Con-

trol System

ULC-ORD C1023 - Household Burglar Alarm

System Units

ULC-ORD C1076 - Propriety Burglar Alarm Unit

and Systems

ICES-003 - Digital Apparatus

Dimensions 4.5 in x 6.94 in x 1.15 in

(11.43 cm x 17.62 cm x 2.9 cm)

Output voltage (rated

range)

AC line input voltage

frequency

Current available

(maximum)

Current drawn from

the control panel

Battery Input 2 separate 12 V lead acid batter-

Operating temperature +32°F to +120°F (0°C to +49°C)

Relative humidity 5% to 93% at +90°F (+32°C) non-

Storage temperature -4° to 140° F (-20° to 60°C)

Transformer power

supply

Transformer wiring 12-18 AWG

Terminal wire size 12 AWG to 22 AWG

SDI2 wiring *Maximum distance - Wire size:

Compatibility B5512/B4512/B3512 control

Usage Intended for indoor/dry use

Copyright

This document is the intellectual property of Bosch Security

Systems, Inc. and is protected by copyright. All rights reserved.

Trademarks

All hardware and software product names used in this

document are likely to be registered trademarks and must be

treated accordingly.

Bosch Security Systems, Inc. product manufacturing dates

Use the serial number located on the product label and refer to

the Bosch Security Systems, Inc. website at

http://www.boschsecurity.com/datecodes/.

11.5 - 12.2 VDC (special

application)

120 VAC +10/-15% (60 Hz) 0.5 A

2.0 A SDI2 Out and AUX Power

(combined)

(up to 4.0 A of alarm current for

Burglar Applications)

15 mA

ies (7-18 Ah) 4.0 A max available

from charger.

condensing

TR1850 - (18 VAC, 50 VA)

TR1850-CA - (18 VAC, 50 VA) for

Canada

(2 mm to 0.65 mm)

(Unshielded wire only)

1000 ft (305 m) - 22 AWG (0.65

mm)

1000 ft (305 m) - 18 AWG (2 mm)

*Maximum wiring distance from the

panel to the last SDI2 module can

not exceed 1000 ft.

panels

GV4 Series control panels

D8103 Enclosure (requires B12)

D8108A Attack Enclosure

(requires B12)

B10 Enclosure

D2203 Enclosure

BATB-40 Enclosure (requires B12)

AE1/AE2 Enclosure

Auxiliary Power Supply Module

B520

en Installation Guide

Bosch Security Systems, Inc.

130 Perinton Parkway

Fairport, NY 14450

USA

www.boschsecurity.com

© 2013 Bosch Security Systems, Inc. F.01U.265.445 | 02 | 2013.08

Loading...

Loading...