Page 1

Control Panels

B6512/B5512/B4512/B3512 (B5512E/B4512E/B3512E)

en

Installation Manual

Page 2

Page 3

Control Panels Table of contents | en 3

Table of contents

1

1.1 Listings and approvals 8

1.1.1 UL 8

1.1.2 ULC 8

1.1.3 Security Industry Association (SIA) 8

1.1.4 Department of Defense (DoD) 8

1.1.5 Department of Energy 8

1.1.6 California State Fire Marshal (CSFM) 8

1.1.7 National Institute of Standards and Technology (NIST) 8

1.1.8 Federal Communications Commission (FCC) Rules 9

1.1.9 Industry Canada (IC) 9

1.2 Safety 9

1.2.1 Lightning 10

1.2.2 Power 10

2

2.1 About documentation 12

2.1.1 Related documentation 12

2.2 Bosch Security Systems, Inc. product manufacturing dates 14

3

4

5

5.1 Install the enclosure and wiring label 18

5.2 Install the control panel 19

5.2.1 Mount the control panel 19

5.2.2 Connect earth ground 20

5.2.3 Configure OUTPUT A using the jumper 20

5.3 Control panel to module wiring overview 21

6

6.1 Primary (AC) power 22

6.2 Secondary (DC) power 22

6.2.1 Install the battery 22

6.2.2 Battery maintenance 24

6.2.3 Battery supervision 24

6.2.4 Battery discharge and recharge schedule 24

6.3 B520 Auxiliary Power Supply 24

6.3.1 SDI2 address settings 25

6.3.2 Supervision 25

6.3.3 Auxiliary power supply trouble conditions 25

6.3.4 Installation and control panel wiring (B520) 25

6.3.5 Powered device and battery wiring 26

7

7.1 B430 Plug-in Telephone Communicator 28

7.1.1 Supervision 28

7.1.2 Installation and module wiring (B430) 28

7.1.3 Diagnostic LEDs 29

7.2 Phone jack location 29

7.3 Telephone line monitor 30

7.4 Called party disconnect 30

Certifications, approvals, listings, and safety 8

Introduction 12

System overview 15

Installation checklist 16

Control panel installation 18

Power supply 22

Telephone communications 28

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 4

4 en | Table of contents Control Panels

7.5 Communication failure 31

8

IP communications 32

8.1 On-board Ethernet connection 32

8.1.1 Supervision 32

8.1.2 Local RPS programming 32

8.1.3 On-board Ethernet diagnostic LEDs 33

8.2 Conettix Plug-in Cellular Communicators 34

8.2.1 Supervision 34

8.2.2 Installation and module wiring (B44x) 34

8.2.3 Signal strength and diagnostic LEDs 35

8.3 B426 Ethernet Communication Module 36

8.3.1 Address and emulation settings 36

8.3.2 Supervision 36

8.3.3 B426 module faults 36

8.3.4 Local RPS programming 37

8.3.5 Installation and control panel wiring (B426) 37

8.3.6 Diagnostic LEDs 38

8.4 B450 Conettix Plug-in Communicator Interface 40

8.4.1 SDI2 address settings 40

8.4.2 Supervision 40

8.4.3 Installation and control panel wiring (B450) 40

8.4.4 Diagnostic LEDs 41

8.5 Compatible receivers for IP communication 42

9

Keypads, keyswitches, keyfobs and transmitters 44

9.1 Keypads 44

9.1.1 B915 Basic Keypad 44

9.1.2 B920 Two-line Alphanumeric Keypad 44

9.1.3 B921C Two-line Capacitive Keypad with Inputs 44

9.1.4 B930 ATM Style Alphanumeric Keypad 44

9.1.5 B942 Touch Screen Keypad 44

9.1.6 Shortcuts and custom functions 45

9.1.7 Address settings 45

9.1.8 Supervision 45

9.1.9 Installation and control panel wiring (keypads) 45

9.1.10 Sensor loops overview and wiring (B921C/B942/B942W only) 46

9.1.11 Output wiring (B942/B942W only) 47

9.1.12 Troubleshooting 47

9.2 Keyswitches 47

9.2.1 Operation 47

9.2.2 Installation and control panel wiring (keyswitches) 48

9.3 RADION keyfobs and Inovonics pendant transmitters 48

10

On-board outputs 50

10.1 Circuit protection 50

10.2 Total available power 50

10.3 Open collector outputs 50

10.4 Continuous power outputs 51

11

Off-board outputs 52

11.1 B308 Octo-output Module 52

11.1.1 SDI2 address settings 52

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 5

Control Panels Table of contents | en 5

11.1.2 Supervision 52

11.1.3 Installation and control panel wiring (B308) 53

12

On-board points 54

12.1 Point sensor loops 54

12.1.1 Single EOL (and no EOL) resistor circuit style 54

12.1.2 Dual EOL resistor circuit style 55

12.2 Point response time 56

13

Off-board points 57

13.1 B208 Octo-input Module 57

13.1.1 SDI2 address settings 57

13.1.2 Supervision 57

13.1.3 Installation and control panel wiring (B208) 57

13.1.4 Sensor loops overview and wiring 58

13.2 Test off-board points 61

13.3 Extra Point events 61

13.4 Missing point conditions 61

14

Wireless modules 62

14.1 B810 receiver 62

14.1.1 SDI2 address settings 62

14.1.2 Supervision 62

14.1.3 Installation and control panel wiring (B810) 62

14.2 B820 SDI2 Inovonics Interface Module 63

14.2.1 SDI2 address settings 63

14.2.2 Supervision 63

14.2.3 Installation and control panel wiring (B820) 63

15

Access control 65

15.1 B901 65

15.1.1 Address settings 65

15.1.2 Supervision 65

15.1.3 Installation and control panel wiring (B901) 65

15.2 Card reader wiring 66

16

Program and test the control panel 67

16.1 Program the control panel 67

16.2 Perform walk tests 67

16.2.1 Fire walk test 67

16.2.2 Intrusion walk test 67

16.2.3 Service walk test 68

16.2.4 Invisible walk test 68

17

18

Control panel board overview 70

System wiring diagrams 72

18.1 System wiring overview 72

18.2 Battery lead supervision wiring 74

18.3 2-wire smoke wiring (B201) 75

18.4 2-wire smoke wiring (D125B) 76

18.5 Notification appliance circuit wiring 76

18.6 SDI2 devices general system wiring 78

18.6.1 SDI2 bus wiring recommendations 78

18.7 Wiring label 81

19

Approved applications 82

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 6

6 en | Table of contents Control Panels

19.1 Optional compatible equipment 82

19.1.1 Burglar applications 82

19.1.2 Bank safe and vault applications 82

19.1.3 Fire applications 85

19.1.4 Enclosures 86

19.2 Combination fire and intrusion alarm systems 87

19.3 Compatible UL listed components 87

19.4 Standby battery requirements and calculations 89

19.4.1 Household Fire Warning equipment 91

19.5 UL 365 - Police Station Connected Burglar Alarm Units and Systems 92

19.6 UL 636 - Holdup Alarm Units and System 92

19.7 Required values to achieve 180s (ULC)/200s (UL) supervision interval 92

19.8 ULC 93

20

Keypad Installer menu 94

20.1 [1] Program menu (Programming) 100

20.1.1 [1] Reporting > [1] Phone menu parameters 100

20.1.2 [1] Reporting > [2] Network menu parameters 101

20.1.3 [1] Reporting > [3] Routing menu parameters 102

20.1.4 [1] Reporting > [4] Personal Note menu parameters 103

20.1.5 [2] Network > [1] Ethernet > (choose the bus module or on-board) > [1] Module

104

Parameters menu

20.1.6 [2] Network > [1] Ethernet > (choose the bus module or on-board) > [2] Address

105

Parameters menu

20.1.7 [2] Network > [1] Ethernet > (choose the bus module or on-board) > [3] DNS

106

Parameters menu

20.1.8 [2] Network > [2] Cellular > (choose the SDI2 cellular module or plug-in module) 106

20.1.9 [3] RPS > [1] RPS Passcode menu parameters 107

20.1.10 [3] RPS > [2] RPS Phone Number menu parameters 108

20.1.11 [3] RPS > [3] RPS IP Address menu parameters 108

20.1.12 [3] RPS > [4] RPS Port Number menu parameters 108

20.1.13 [4] Area Options menu parameters 108

20.1.14 [5] Keypad menu parameters 110

20.1.15 [6] Users menu parameters 111

20.1.16 [7] Points menu parameters 112

20.1.17 [8] Disable Programming menu 118

20.2 [2] Wireless menu 119

20.2.1 [1] RF Point Menu> [1] Enroll Point RFID 119

20.2.2 [1] RF Point Menu> [2] Replace Point RFID 119

20.2.3 [1] RF Point Menu> [3] Remove Point RFID 119

20.2.4 [2] RF Repeater Menu > [1] Add Repeater 120

20.2.5 [2] RF Repeater Menu > [2] Replace Repeater 120

20.2.6 [2] RF Repeater Menu > [3] Remove Repeater 120

20.2.7 [3] RF Diagnostic Menu > [1] RF Points 120

20.2.8 [3] RF Diagnostic Menu > [2] RF Repeater Menu 121

20.3 [3] Diags menu 121

20.3.1 [1] Wireless 121

20.3.2 [2] Network menu 122

20.3.3 [3] Cellular menu 122

20.3.4 [4] IP Camera 122

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 7

Control Panels Table of contents | en 7

20.3.5 [5] Cloud 123

20.4 [4] Service Bypass (Serv Byp) menu 123

20.5 [5] Versions menu 123

20.6 [6] Cloud menu 124

21

Specifications 125

21.1 Wire requirements 127

22

Appendix 128

22.1 Address settings 128

22.1.1 B208 address settings 128

22.1.2 B308 address settings 128

22.1.3 B901 address settings 129

22.1.4 B91x address settings 129

22.2 Reporting and device number information 130

22.2.1 Report format definitions 130

22.2.2 SDI2 address information 139

22.2.3 Device numbers (zzz, dddd) 139

22.2.4 Communication Trouble device numbers (zzzz) 140

22.2.5 Special User IDs (uuuu, iiii) 140

22.2.6 Keypad alarm virtual point numbers (ppp, pppp) 140

22.3 AutoIP 141

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 8

8 en | Certifications, approvals, listings, and safety Control Panels

1 Certifications, approvals, listings, and safety

This section provides certification and approval listings and safety information.

1.1 Listings and approvals

This document includes the section Approved applications, page 82. Refer to this section for

guidelines on installing the control panels in Underwriters Laboratories Inc. (UL) and firespecific applications.

1.1.1 UL

Listed for:

– UL 365 - Police Station Connected Burglar Alarm Units and System

– UL 609 - Local Burglar Alarm Units and System

– UL 636 - Holdup Alarm Units and System

– UL 985 - Household Fire Warning System Units

– UL 1023 - Household Burglar Alarm Units and System

– UL 1076 - Proprietary Burglar Alarm Units and System

– UL 1610 - Central Station Burglar Alarm Units

– UL 1635 - Digital Alarm Communicator System Units

1.1.2 ULC

Listed for:

– ULC C1023 - Household Burglar Alarm System Units

– ULC C1076 - Proprietary Burglar Alarm Units and System

– ULC S303 - Local Burglar Alarm Units and System

– ULC S304 - Central and Monitoring Station Burglar Alarm Units

– ULC S545 - Residential Fire Warning System Control Units

– ULC S559 – Fire Signal Receiving Centres and Systems

1.1.3 Security Industry Association (SIA)

Listed for Control Panel Standard - Features for False Alarm Reduction ANSI/SIA CP-01-2010.

1.1.4 Department of Defense (DoD)

The B6512/B5512/B4512/B3512 control panels were granted approval for Department of

Defense (DoD) installations in Sensitive Compartmented Information Facilities (SCIF).

1.1.5 Department of Energy

This control panel operates on a transformer that has been reviewed by a third party and

deemed to be compliant to the Department of Energy, U.S. Energy Conservation Standard for

External Power Supplies (found in section 10 CFR 430.32(w)(1)(i) of the Federal Code) as an

indirect device.

1.1.6 California State Fire Marshal (CSFM)

Listed for Household Fire Alarm.

1.1.7 National Institute of Standards and Technology (NIST)

When communicating via a network, listed for Advanced Encryption Standard (AES), Federal

Information Processing Standards Publication 197 (FIPS 197).

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 9

Control Panels Certifications, approvals, listings, and safety | en 9

1.1.8 Federal Communications Commission (FCC) Rules

Part 15

This equipment was tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment.

This equipment generates, uses, and can radiate radio frequency energy; and if not installed

and used according to the instructions, can cause harmful interference to radio

communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in

which case the user is required to correct the interference at his or her own expense.

Part 68

The B430 module by Bosch Security Systems, Inc. is registered with the Federal

Communication Commission (FCC) under Part 68, for connection to the public telephone

system using an RJ31X or RJ38X phone line connection jack installed by the local telephone

company.

Do not connect registered equipment to party lines or coin-operated telephones. Notify the

local telephone company and provide the following information before connecting the control

panel to the telephone network:

– The particular line to which you connect the module

– Make (Bosch Security Systems, Inc.), model (B6512/B5512/B4512/B3512), and serial

number of the control panel

– FCC registration number: ESVAL00BB430

– Ringer eq: 0.0B

1.1.9 Industry Canada (IC)

ICES-003 - Information Technology Equipment

This Class B digital equipment meets all requirements of the Canadian interference-causing

equipment regulations.

Cet appareil numérique de la Class A respecte toutes les exifences de règlement sue le

matériel brouilleur du Canada.

CS-03 - Compliance Specification for Terminal Equipment

The B430 module by Bosch Security Systems, Inc. meets the applicable Industry Canada

technical specifications. The Ringer Equivalence Number (REN) is an indication of the

maximum number of devices allowed to be connected to a telephone interface. The

termination of an interface may consist of any combination of devices subject only to the

requirement that the sum of the RENs of all the devices not exceed five.

Le présent matériel est conforme aux spécifications techniques applicables d'Industrie

Canada.

L'indice d'équivalence de la sonnerie (IES) sert à indiquer le nombre maximal de terminaux qui

peuvent être raccordés à une interface téléphonique. La terminaison d'une interface peut

consister en une combinaison quelconque de dispositifs, à la seule condition que la somme

d'indices d'équivalence de la sonnerie de tous les dispositifs n'excède pas cinq.

1.2 Safety

Notice!

After system installation and any control panel programming, perform a complete system test.

A complete system test includes testing the control panel, all devices, and communication

destinations for proper operation.

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 10

10 en | Certifications, approvals, listings, and safety Control Panels

!

!

!

1.2.1 Lightning

The control panel design significantly reduces the adverse effects of lightning. Taking

installation precautions can further reduce these adverse effects.

Effects of lighting

Electronics involved in a direct lightning strike or near a lightning strike can show adverse

effects. When lightning strikes, several things happen:

– An electromagnetic wave spreads from the center point of the strike inducing high

voltages onto nearby conductors.

– The voltage changes substantially on electrical grounds near the lightning strike.

– High voltages are induced onto anything directly struck by lightning.

The effects of lightning can include trouble events, alarm events, and physical damage.

Installation precautions

To minimize the undesirable effects from lightning:

– Do not run wiring outside the building.

– If you install the unit in a metal building, keep the wiring at least 2 ft (0.61 m) away from

external metal surfaces. Make a proper earth ground connection.

– Earth ground the unit correctly. Do not use an electrical ground or telephone ground.

– Avoid running wires near telephone, data, or power lines. Locating control panel wiring at

least 2 ft (0.61 m) away helps reduce the effects of lightning.

– When your data lines must cross the path of AC or other wiring, cross perpendicular to

the lines.

Warranty regarding lightning

The warranty does not cover physical damage due to lightning.

1.2.2 Power

Caution!

Remove all power (AC and battery) before making any connections. Failure to do so might

result in personal injury and/or equipment damage.

Caution!

Do not short-circuit the terminals of the transformer: Shorting the terminals opens the

internal fuse, causing permanent failure. Connect the transformer to the control panel’s AC

power terminals before plugging it into the power source.

Notice!

Plan ahead

Route telephone, SDI2 bus wiring, and sensor loop wiring away from any AC conductors,

including the transformer wire. AC wiring can induce noise and low level voltage into adjacent

wiring.

Warning!

High current arcs are possible. The positive (red) battery lead and the terminal labeled BAT+

can create high current arcs if shorted to other terminals or the enclosure. Use caution when

working with the positive lead and the terminal labeled BAT+. Always disconnect the positive

(red) lead from the battery before removing it from the terminal labeled BAT+.

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 11

Control Panels Certifications, approvals, listings, and safety | en 11

!

!

Caution!

The battery terminals and wire are not power limited. Maintain a 0.250 in (6.4 mm) space

between the battery terminals, battery wiring, and all other wiring. Battery wiring cannot

share the same conduit, conduit fittings, or conduit knockouts with other wiring.

Caution!

Exceeding the maximum output ratings or installing the transformer in an outlet that is

routinely switched off causes heavy discharges. Routine heavy discharges can lead to

premature battery failure.

Notice!

Use sealed lead acid batteries only

The charging circuit is calibrated for lead-acid batteries. Do not use gel-cell or NiCad

batteries.

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 12

12 en | Introduction Control Panels

!

!

2 Introduction

This section includes an introduction to documents for this product and other documentrelated instructions.

2.1 About documentation

This document contains instructions for a trained installer to properly install, configure, and

operate this control panel, and optional peripheral devices. Review this document before

beginning the installation to determine the hardware and wiring requirements for the features

used.

(Bosch Security Systems, Inc. recommends that installers follow good wiring practices such as

those described in NFPA 731, Standard for the Installation of Electronics Premises Security

Systems.)

Throughout this document, the words “control panel” refer to all control panels covered by

this document (B6512/B5512/B5512E/B4512/B4512E/B3512/B3512E).

Notifications

This document uses Notices, Cautions, and Warnings to draw your attention to important

information.

Notice!

These include important notes for successful operation and programming of equipment, or

indicate a risk of damage to the equipment or environment.

Caution!

These indicate a hazardous situation which, if not avoided, could result in minor or moderate

injury.

Warning!

These indicate a hazardous situation which, if not avoided, could result in death or serious

injury.

Copyright

This document is the intellectual property of Bosch Security Systems, Inc. and is protected by

copyright. All rights reserved.

Trademarks

All hardware and software product names used in this document are likely to be registered

trademarks and must be treated accordingly.

2.1.1 Related documentation

Control panel documents

Control Panels (B5512/B4512/B3512) Release Notes*

Control Panels (B5512/B4512/B3512) Installation and System Reference Guide (this document)

(P/N: F01U287180)

Control Panels (B9512G/B8512G/B5512/B4512/B3512) Owner’s Manual (P/N: F01U287181)*

Control Panels (B5512/B4512/B3512) Program Entry Guide (P/N: F01U287183)

+

+

+

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 13

Control Panels Introduction | en 13

Control Panels (B5512/B4512/B3512) UL Installation Guide (P/N: F01U287185)*

Control Panels (B5512/B4512/B3512) SIA Quick Reference Guide (P/N: F01U287184)*

+

+

Control Panels (B9512G/B8512G/B6512/B5512/B4512/B3512) ULC Installation Guide (P/N:

F01U321698)*

*Shipped with the control panel.

+

Located on the documentation CD shipped with the control panel.

Keypad documents

Basic Keypad (B915) Installation Guide (P/N: F01U297873)*

Two-line Alphanumeric Keypad (B920) Installation Guide (P/N: F01U265450)*

Two-line Capacitive Keypad with Inputs (B921C) Installation Guide (P/N: F01U297887)*

ATM Style Alphanumeric Keypad (B930) Installation Guide (P/N: F01U265451)*

Touch Screen Keypad (B942/B942W) Installation Guide (P/N: F01U294527)*

*Shipped with the keypad.

Optional module documents

2-wire Powered Loop Module (B201) Installation and Operation Guide (P/N: F01U301248)*

Octo-input Module (B208) Installation and Operation Guide (P/N: F01U265456)*

Octo-output Module (B308) Installation and Operation Guide (P/N: F01U265458)*

Conettix Ethernet Communication Module (B426) Installation and Operation Guide (P/N:

F01U281208)*

+

Plug-in Telephone Communicator (B430) Installation Guide Installation Guide (P/N:

F01U265454)*

Conettix Plug-in Cellular Communicator (B440) Installation and Operation Guide (P/N:

F01U265455)*

Conettix Plug-in CDMA Cellular Communicator (B441) Installation and Operation Guide (P/N:

F01U282233)*

Conettix Plug-in GPRS Cellular Communicator (B442) Installation and Operation Guide (P/N:

F01U283180)*

Conettix Plug-in HSPA+ Cellular Communicator (B443) Installation and Operation Guide (P/N:

F01U283181)*

Conettix Plug-in Communicator Interface (B450) Installation and Operation Guide (P/N:

F01U300740)*

+

Auxiliary Power Supply (B520) Installation and Operation Guide (P/N: F01U265445)*

RADION receiver SD (B810) Installation Guide (P/N: F01U261834)*

SDI2 Inovonics Interface Module (B820) Installation Guide (P/N: F01U265460)*

*Shipped with the module.

+

Located on the documentation CD shipped with the module.

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 14

14 en | Introduction Control Panels

2.2 Bosch Security Systems, Inc. product manufacturing dates

Use the serial number located on the product label and refer to the Bosch Security Systems,

Inc. website at http://www.boschsecurity.com/datecodes/.

The following image shows an example of a product label and highlights where to find the

manufacturing date within the serial number.

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 15

Control Panels System overview | en 15

B430

Plug-in Telephone Communicator

provides a single

telephone RJ-45 connector

to allow communication

over telephone lines.

Control

Panel

On-board Points

1 to 8

B44x

Conettix Plug-In Cellular

Communicator allows

communication over

a cellular network.

B208

Octo-input modules allow

the addition of up to 8

input devices.

B308

Octo-output modules allow

the addition of up to 8

output devices.

B520

Auxiliary Power Supply modules

expand power by connecting to

an SDI2 device bus or

other 12 volt devices.

B810

RADION receiver SDs

connect RADION wireless devices

to the control panel

.

B820

SDI2 Inovonics Interface modules

interface with an Inovonics

wireless receiver.

B91x/B92x/B93x/B94x

Use keypads to operate

the control panel by area.

B5512 control panels support up to 4 areas.

B4512 control panels support up to 2 areas.

B3512 control panels support 1 area.

Each area can have its own account number

or you can group together areas

with a common account number.

B450

Conettix Plug-In Communicator

Interface allows communication

over a cellular network through

the SDI2 bus.

B426

The B426 provides off-board

communication over a network.

3 System overview

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 16

16 en | Installation checklist Control Panels

4 Installation checklist

Before installing and operating the control panel, read these instructions. If you do not read

and understand these explanations, you will not be able to install and operate the device

properly. The instructions do not eliminate the need for training by authorized personnel.

Install, operate, test and maintain this device according to the control panel Installation and

System Reference Guide (this document). Failure to follow these procedures may cause the

device not to function properly. Bosch Security Systems Inc. is not responsible for any devices

that are improperly installed, tested or maintained.

The control panel Installation and System Reference Guide (this document) does not contain

special information about local requirements and safety issues. Information on such issues is

provided only to the extent that it is needed for operation of the device. Ensure that you are

familiar with all safety-related processes and regulations in your area. This also includes how

to act in the event of an alarm and the initial steps to take if a fire breaks out. The operating

instructions should always be available on site. It is a required part of the system and must be

given to the new owner if the system is ever sold.

Use the workflow and checkboxes below as you complete steps. Each step includes

references for more detailed information.

Install the enclosure and wiring label

– Install the enclosure and wiring label, page 18

Install the control panel

– Mount the control panel, page 19

– Connect earth ground, page 20

– Configure OUTPUT A using the jumper, page 20

Install and wire for telephone communication

– Telephone communications, page 28

Install and wire for IP communications

– IP communications, page 32

Install and wire the battery and the transformer

– Power supply, page 22

Begin to charge the battery while you install other devices

– Charge the battery

Install and wire arming devices

– Keypads, keyswitches, keyfobs and transmitters, page 44

Install and wire outputs

– On-board outputs, page 50

– Off-board outputs, page 52

Install and wire inputs

– On-board points, page 54

– Off-board points, page 57

– Wireless modules, page 62

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 17

Control Panels Installation checklist | en 17

Complete the installation

– Program and test the control panel, page 67

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 18

18 en | Control panel installation Control Panels

1 2 3

4

22 5

2

3

5 Control panel installation

This section explains how to mount the control panel enclosure, how to mount the control

panel into the enclosure, and provides an overview of how to wire modules to the control

panel.

5.1 Install the enclosure and wiring label

Refer to Enclosures, page 86 to determine if the application requires a specific enclosure.

Installing the enclosure:

1. Remove any knockouts prior to installing the control panel.

2. Mount the enclosure in the desired location. Use all enclosure mounting holes. Refer to

the mounting instructions supplied with the selected enclosure.

3. Pull the wires into the enclosure.

4. Install the supplied Enclosure Wiring Label (B5512/B4512/B3512) on the inside of the

enclosure door.

Notice!

Electromagnetic interference (EMI) can cause problems on long wire runs.

Figure5.1: Enclosure and control panel mounting (B10 shown)

Callout ᅳ Description

1 ᅳ Control panel wiring label

2 ᅳ Enclosure mounting holes (4)

3 ᅳ Module mounting locations (4)

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 19

Control Panels Control panel installation | en 19

2

3

3

4 ᅳ Tamper switch mounting location

5 ᅳ Control panel mounting location

5.2 Install the control panel

This section includes instructions to mount the control panel in the enclosure, connect earth

ground, and make other control panel connections.

5.2.1 Mount the control panel

1. Identify the control panel mounting location in the enclosure.

Figure5.2: B10 and B11 control panel placement locations

Callout ᅳ Description

1 ᅳ B10 Medium Control Panel Enclosure

2 ᅳ B11 Small Control Panel Enclosure

3 ᅳ Mounting clip locations for the control panel

2. Snap the four supplied plastic standoffs onto four enclosure support posts. If using the

B12 Mounting Plate for D8103 Enclosure, attach the standoffs to the plate support posts.

Do not attach the standoffs with screws at this time.

Figure5.3: Standoff attachment

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 20

20 en | Control panel installation Control Panels

P1

P1

P1

OUTPUT A (C terminal) = AUX PWR

COM AUX

OUTPUT A (C terminal) = COM

OUTPUT A (C terminal) = DRY

COM AUX

COM AUX

COM AUX

P1

TMPR

1 COM 2 7 COM 83 COM 4 5 COM 6

RESET

ETHERNET

COM AUX R Y G B

PWR A B COM

+ BAT -18VAC

B C

OUTPUT

NO C NC

OUTPUT A

7 COM 8

C

OUTPUT

B

USB

ETHERNET

100BASE-T

LINK

COMMUNICATION MODULE 1

1 k End of Line Resistors

Voltage Ranges

ON-BOARD POINTS

3.7 - 5.0 VDC

2.0 - 3.0 VDC

0.0 - 1.3 VDC

Open

Normal

Short

3 COM 4 5 COM 61 COM 2

R Y G B

SDI2

Device Bus

18 VAC

OUTPUT A

AUX

- 12 V +

3. Place the control panel on top of the standoffs. Align the holes in the corners of the

control panel with the openings at the top of each standoff. Secure the control panel to

the standoffs with supplied, self-threading screws.

Figure5.4: Mount control panel on standoffs

4. If using the B12 Mounting Plate for D8103 Enclosure, rest the hook tabs on the mounting

plate hooks within the enclosure. Secure the lock-down tab to the plate mounting hole

with the screw provided.

5.2.2 Connect earth ground

5.2.3 Configure OUTPUT A using the jumper

When planning your installation, carefully consider the use of OUTPUT A. OUTPUT A is a form

C relay. You can configure the common terminal (C) of Output A (OUTPUT A) using the

jumper:

– To provide +12 VDC (AUX power)

– To be a COM terminal (parallel to all COM terminals)

– To be a dry contact (no voltage, not common)

The control panel ships with the jumper in the default position, AUX power. (OUTPUT A, ‘C’

terminal providing AUX PWR). To reconfigure the ‘C’ terminal as a COM terminal (parallel to all

COM terminals), remove the door covering the jumper pins, and move the jumper to the left

two pins. The OUTPUT A LED lights when OUTPUT A is active. Refer to the figure below or to

the Enclosure Wiring Label (B5512/B4512/B3512) to set the OUTPUT A jumper.

Figure5.5: OUTPUT A jumper configuration options (B5512 shown)

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 21

Control Panels Control panel installation | en 21

PWR A B COM PWR A B COM

TMPR

1 COM 2 7 COM 83 COM 4 5 COM 6

RESET

ETHERNET

COM AUX R Y G B

PWR A B COM

+ BAT -18VAC

B C

OUTPUT

NO C NC

OUTPUT A

7 COM 8

C

OUTPUT

B

USB

ETHERNET

100BASE-T

LINK

COMMUNICATION MODULE 1

1 k End of Line Resistors

Voltage Ranges

ON-BOARD POINTS

3.7 - 5.0 VDC

2.0 - 3.0 VDC

0.0 - 1.3 VDC

Open

Normal

Short

3 COM 4 5 COM 61 COM 2

R Y G B

SDI2

Device Bus

18 VAC

BATTERY OUTPUT A

AUX

- 12 V +

OUTPUT A

OUTPUT A

Jumper Under Cover

AUX PWR

COM

DRY

PWR A B COM PWR A B COM

TMPR

1 COM 2 7 COM 83 COM 4 5 COM 6

RESET

ETHERNET

COM AUX R Y G B

PWR A B COM

+ BAT -18VAC

B C

OUTPUT

NO C NC

OUTPUT A

7 COM 8

C

OUTPUT

B

USB

ETHERNET

100BASE-T

LINK

COMMUNICATION MODULE 1

1 k End of Line Resistors

Voltage Ranges

ON-BOARD POINTS

3.7 - 5.0 VDC

2.0 - 3.0 VDC

0.0 - 1.3 VDC

Open

Normal

Short

3 COM 4 5 COM 61 COM 2

R Y G B

SDI2

Device Bus

18 VAC

BATTERY OUTPUT A

AUX

- 12 V +

OUTPUT A

OUTPUT A

Jumper Under Cover

AUX PWR

COM

DRY

5.3 Control panel to module wiring overview

In the following sections, this document provides instructions for wiring devices to your

control panel. You can use interconnect or terminal wiring.

Using terminal wiring

For terminal wiring, use 18 AWG to 22 AWG (1.02 mm to 0.65 mm) wire.

Figure5.6: SDI2 devices daisy chained with terminal wiring (B5512 shown)

Using interconnect wiring

Interconnect wiring connectors parallel the SDI2 terminals (labeled on the control panel). In

installations with multiple SDI2 modules, using interconnect wiring makes the installation

quicker and easier than using terminal strip wiring. You use any combination of terminal and

interconnect wiring to wire multiple modules in parallel, but do not wire a single module to

the control panel using both terminal and interconnect wiring.

The interconnect wiring connectors are "keyed" (interconnect wiring plug can fit in only one

direction).

Figure5.7: SDI2 devices daisy chained with interconnect wiring (B5512 shown)

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 22

22 en | Power supply Control Panels

6 Power supply

This section provides information on installing and maintaining primary power, batteries, and

auxiliary power.

6.1 Primary (AC) power

The control panel uses an 18 VAC, 22 VA internally fused transformer (CX4010) for its primary

power source. The control panel draws 125 mA when idle and 155 mA when in the alarm

state. The auxiliary power available for powered devices is 800 mA.

Surge protection

Transient suppressors and spark gaps protect the circuit from power surges. This protection

relies on the ground connection at the earth ground terminal marked with the icon. Ensure

that you connect the terminal to a proper ground.

Refer to Connect earth ground, page 20.

AC power fail

The system indicates an AC power failure when the VAC terminals do not have sufficient

voltage. The AC Fail Time parameter sets the amount of time without AC power before the

control panel reports the failure, and the amount of time after the power returns before the

control panel reports restored power.

Self diagnostics at power up and reset

The system performs a series of self-diagnostic tests of hardware, software, and programming

at power up and at reset. The self-diagnostics tests complete in approximately 10 to 30 sec.

If the control panel fails any test, a System Trouble message appears at the keypads.

6.2 Secondary (DC) power

A 12 V sealed lead-acid rechargeable battery (such as the D126/D1218) supplies secondary

power to maintain system operation during interruptions of primary (AC) power.

Notice!

Use sealed lead acid batteries only

The charging circuit is calibrated for lead-acid batteries. Do not use gel-cell or NiCad

batteries.

Extra batteries

To increase battery back-up time, connect a second 12 V battery in parallel to the first battery.

Use a D122/D122L Dual Battery Harness to ensure proper and safe connection.

D1218 Battery

The D1218 is a 12 V, 18 Ah battery for use in applications requiring extended battery standby

time. The control panel does not support more than 18 Ah.

6.2.1 Install the battery

1. Place the battery upright in the base of the enclosure.

2. Locate the red and black leads supplied in the hardware pack.

3. Connect the black battery lead to BAT- and then to the negative (-) side of the battery.

4. Connect the red battery lead to BAT+, and then to the positive (+) side of the battery.

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 23

Control Panels Power supply | en 23

!

!

1

2

3

4

5

6

7

TMPR

1 COM 2 7 COM 83 COM 4 5 COM 6

RESET

ETHERNET

COM AUX

R Y G B

PWR A B COM

+ BAT -

18VAC

B C

OUTPUT

NO C NC

OUTPUT A

7 COM 8

C

OUTPUT

B

USB

ETHERNET

100BASE-T

LINK

COMMUNICATION MODULE 1

1 k End of Line Resistors

Voltage Ranges

ON-BOARD POINTS

3.7 - 5.0 VDC

2.0 - 3.0 VDC

0.0 - 1.3 VDC

Open

Normal

Short

3 COM 4 5 COM 61 COM 2

R Y G B

SDI2

Device Bus

18 VAC

BATTERY OUTPUT A

AUX

- 12 V +

OUTPUT A

OUTPUT A

Jumper Under Cover

AUX PWR

COM

DRY

Warning!

High current arcs are possible. The positive (red) battery lead and the terminal labeled BAT+

can create high current arcs if shorted to other terminals or the enclosure. Use caution when

working with the positive lead and the terminal labeled BAT+. Always disconnect the positive

(red) lead from the battery before removing it from the terminal labeled BAT+.

Caution!

The battery terminals and wire are not power limited. Maintain a 0.250 in (6.4 mm) space

between the battery terminals, battery wiring, and all other wiring. Battery wiring cannot

share the same conduit, conduit fittings, or conduit knockouts with other wiring.

Figure6.1: Non-power-limited wiring (B5512 shown)

Callout ᅳ Description

1 ᅳ Conduit required for use with external batteries

2 ᅳ To CX4010 UL Listed Class 2 Transformer 18 VAC 22 VA 60 Hz

3 ᅳ 0.25 in (6.4 mm) minimum

4 ᅳ Battery terminals. BAT- is non-power limited

5 ᅳ Battery wires

6 ᅳ 12 V sealed lead-acid rechargeable battery (D126/D1218)

7 ᅳ Sensor loop wires

Charge the battery

Connect the battery and then the transformer to allow the control panel to charge the battery

while you complete the installation.

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 24

24 en | Power supply Control Panels

!

6.2.2 Battery maintenance

Use 12 VDC sealed lead-acid rechargeable battery (7 Ah or 18 Ah). The control panel supports

up to 18 Ah of battery. If you use two batteries, they must have the same capacity and you

must connect them using the D122/D122L Dual Battery Harness.

Replace the batteries every 3 to 5 years. If you install two batteries, replace them both at the

same time.

Record the date of installation directly on the battery.

Caution!

Exceeding the maximum output ratings or installing the transformer in an outlet that is

routinely switched off causes heavy discharges. Routine heavy discharges can lead to

premature battery failure.

6.2.3 Battery supervision

The battery charging float level occurs at 13.65 VDC. If the battery voltage drops below 12.1

VDC, the control panel sends a LOW BATTERY report, if programmed to do so.

When the battery voltage drops to 10.2 VDC, the keypad or keypads show low battery

messages. The control panel (if programmed for power supervision) sends a Battery Low

report in the Modem4 communication format. It sends a Low System Battery (302) report in

the Contact ID format.

When battery voltage returns to 13.4 V, the keypads stop showing the low battery messages. If

the control panel is programmed for power supervision, it sends a BATTERY RESTORAL report

in the Modem4 communication format or a Control Panel Battery Restored to Normal (302)

report in the Contact ID format.

If programmed for power supervision, the control panel adds a missing battery event to the

event log. If programmed for battery fault reports, the control panel sends a Battery Missing/

Dead report in the Modem4 communication format, or Control Panel Battery Missing (311)

report in the Contact ID format.

6.2.4 Battery discharge and recharge schedule

Discharge cycle

13.65 VDC - Charging float level.

12.1 VDC - Low Battery Report, if programmed.

10.2 VDC - Minimum operational voltage.

Recharge cycle

AC ON - Battery charging begins and AC Restoral Reports sent.

13.4 V - Battery Restoral Report sent. Battery float charged.

6.3 B520 Auxiliary Power Supply

The optional B520 provides up to 2 A of 12 VDC standby power for Fire and Burglar

applications. For Burglar applications, an additional 2 A of alarm power is available, allowing 2

A of standby current and up to 4 A of alarm current.

The B6512 and B5512 support up to 4 B520 modules. The B4512and B3512 support up to 2

B520 modules.

Connect a B520 to the SDI2 bus on the control panel using terminals. This section includes

basic installation instructions. For detailed installation instructions, refer to the Auxiliary Power

Supply Module (B520) Installation Guide for complete installation instructions, and for battery

standby time calculations, refer to the B520 Auxiliary Power Supply Module Battery Standby

Chart within the installation guide.

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 25

Control Panels Power supply | en 25

!

!

6.3.1 SDI2 address settings

Notice!

The module reads the address switch setting only during module power up. If you change the

setting after you apply power to the module, you must cycle the power to the module in order

for the new setting to take effect.

If multiple B520 modules reside on the same system, each B520 module must have a unique

address.

6.3.2 Supervision

The control panel supervises B520 on the SDI2 bus.

With any failure to receive an expected response from a B520, all keypads show a system

fault. The control panel sends a module trouble report to the central station (if configured for

module trouble reports).

6.3.3 Auxiliary power supply trouble conditions

Each auxiliary power supply module on the SDI2 bus monitors several conditions including AC

status, battery status, over current status, and a tamper input. Each of these conditions

produces a unique system trouble condition at all keypads. The control panel sends a module

trouble report to the central station (if configured for module trouble reports).

6.3.4 Installation and control panel wiring (B520)

The power supply draws approximately 15 mA (+/- 1 mA) from the control panel.

Ensure that there is enough power for the module and other powered devices you want

connected to the system.

Refer to On-board outputs, page 50.

Caution!

Remove all power (AC and battery) before making any connections. Failure to do so might

result in personal injury and/or equipment damage.

Install the module

1. Set the module address using the address switches before you install it in the enclosure.

2. Insert the plastic mounting clips onto the appropriate standoff locations inside the

enclosure or on a mounting skirt, when required.

3. Mount the module onto the plastic mounting clips and then secure it using the supplied

mounting screws.

Wire to earth ground

To help prevent damage from electrostatic charges or other transient electrical surges,

connect the system to earth ground before making other connections. Recommended earth

ground references are a grounding rod or a cold water pipe. When grounding, run wire as

close as possible to grounding device.

Caution!

Do not use telephone or electrical ground for the earth ground connection. Use 14 AWG (1.8

mm) to 16 AWG (1.5 mm) wire when making the connection.

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 26

26 en | Power supply Control Panels

SDI2 OUT

SDI2 IN

PWR A B COM PWR A B COM

1

2

3

R

Y

G

B

7 COM 8

C

OUTPUT

B

1 k End of Line Resistors

Voltage Ranges

ON-BOARD POINTS

3.7 - 5.0 VDC

2.0 - 3.0 VDC

0.0 - 1.3 VDC

Open

Normal

Short

3 COM 4 5 COM 61 COM 2

R Y G B

SDI2

Device Bus

AUX

- 12 V +

TMPR

1 COM 2 7 COM 83 COM 4 5 COM 6

RESET

COM AUX

R Y G B

PWR A B COM

B C

OUTPUT

Figure6.2: B520 earth ground wiring

Callout ᅳ Description

1 ᅳ B520 Auxiliary Power Supply Module

2 ᅳ 14 AWG - 16 AWG (1.8 mm - 1.5 mm) wire

3 ᅳ Ground device (grounding rod or cold water pipe)

Wire to the control panel

When wiring a module to a control panel, use the terminal strip labeled with PWR, A, B, and

COM for SDI2 IN to wire to corresponding control panel SDI2 terminals.

Use 12 AWG to 22 AWG (2 mm to 0.65 mm) wire.

Figure6.3: B520 to the control panel wiring (B5512 shown)

Callout ᅳ Description

1 ᅳ Control panel

2 ᅳ B520 Auxiliary Power Supply Module

3 ᅳ Terminal strip wiring

6.3.5 Powered device and battery wiring

Wire to SDI2 powered devices

When wiring the output of a B520 to a SDI2 module, you can use either the SDI2 OUT terminal

strip labeled with PWR, A, B, and COM to wire to terminals labeled PWR, A, B, and COM on

the next module, or you can use the interconnect cable (included). Wiring the output of a

B520 to a SDI2 device provides power to the device while passing through data between the

control panel and the device.

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 27

Control Panels Power supply | en 27

PWR A B COM

2

4

PWR A B COM

SDI2 OUT

SDI2 IN

PWR A B COM PWR A B COM

1

2

3

SDI2 OUT

SDI2 IN

PWR A B COM PWR A B COM

1

R Y G B

BATT 1

BATT 2

R

B

R B

+ -

1

23

+ -

Figure6.4: B520 to powered devices - terminal strip or interconnect wiring connector

Callout ᅳ Description

1 ᅳ B520 Auxiliary Power Supply Module

2 ᅳ Powered device (SDI2 module)

3 ᅳ Terminal strip wiring

4 ᅳ Interconnect wiring (P/N: F01U079745)

Wire to batteries

Wiring the B520 to BATT 1 is required for proper operation of standby power for the B520

module. Wiring the second battery (BATT 2) is optional. If a B520 is configured for two

batteries as the standby power source, then BATT 2 is also required for proper operation.

BATT 2 must have the same capacity and rating as BATT 1. Maximum standby power cannot

exceed 36 Ah.

Figure6.5: B520 BATT terminals wiring

Callout ᅳ Description

1 ᅳ B520 Auxiliary Power Supply Module

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

2 ᅳ Battery 2 (BATT 2) - (12 V nominal lead acid)

3 ᅳ Battery 1 (BATT 1) - (12 V nominal lead acid)

Page 28

28 en | Telephone communications Control Panels

!

7 Telephone communications

The control panel supports telephone communications through the B430 Plug-in Telephone

Communicator.

7.1 B430 Plug-in Telephone Communicator

The B430 Plug-in Telephone Communicator provides communication over PSTN. The module

provides a single telephone interface RJ-45 connector for connecting the phone line. The

module plugs directly into the control panel with no additional connections required.

The control panel supports one plug-in module plugged directly into the control panel board.

This section includes basic installation instructions. For detailed installation instructions, refer

to the Plug-in Telephone Communicator (B430) Installation Guide.

Notification

The B430 module by Bosch Security Systems, Inc. is registered with the Federal

Communication Commission (FCC) under Part 68, for connection to the public telephone

system using an RJ31X or RJ38X phone line connection jack installed by the local telephone

company.

Do not connect registered equipment to party lines or coin-operated telephones. Notify the

local telephone company and provide the following information before connecting the control

panel to the telephone network:

– The particular line to which you connect the module

– Make (Bosch Security Systems, Inc.), model (B6512/B5512/B4512/B3512), and serial

number of the control panel

– FCC registration number: ESVAL00BB430

– Ringer eq: 0.0B

7.1.1 Supervision

The control panel supervises the phone line. You can configure the supervision time using

RPS.

7.1.2 Installation and module wiring (B430)

Ensure that there is enough power for the module and other powered devices you want

connected to the system.

Refer to On-board outputs, page 50.

Caution!

Remove all power (AC and battery) before making any connections. Failure to do so might

result in personal injury and/or equipment damage.

Install the module

The module plugs into a connector and is held in place with a plug-in module retention clip.

The module handle and support on top of the module hold the unit during installation.

Plug the module into a control panel by aligning the module with the control panel’s on-board

connector. The retention clip has a locking device to help hold the card in position. Pull the

locking device back. Align the PCB metal contacts with the on-board connector. Push the

module into place. The retention clip snaps closed and secures the module in place.

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 29

Control Panels Telephone communications | en 29

31

2

4

Wire to the phone line

Figure7.1: PTSN module wiring (B5512 shown)

Callout ᅳ Description

1 ᅳ Premises telephone

2 ᅳ Incoming Telco line

3 ᅳ Installer telephone test set

4 ᅳ RJ-45 phone connector

7.1.3 Diagnostic LEDs

The module uses a green LED to indicate when the module is on or off hook or the line is

ringing (incoming phone call).

Flash pattern Function

OFF Standby

ON Line seized

Flash Ringing detect (incoming phone call)

Tab.7.1: PTSN diagnostic LED patterns

7.2 Phone jack location

To prevent jamming of signals, wire the RJ31X or RJ38X jack before the premises telephone

system to support line seizure. Install the jack on the street side of the telephone switch,

wired ahead of any PBX equipment. Line seizure temporarily interrupts normal telephone

usage while the control panel sends data. After installation, confirm that the control panel

seizes the line, acquires dial tone, reports correctly to the receiver, and releases the telephone

line to the in-house telephone system.

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 30

30 en | Telephone communications Control Panels

6

4

3

5

1 2

Figure7.2: RJ31X wiring

Callout ᅳ Description

1 ᅳ Outside Telco

2 ᅳ Premises telephone

3 ᅳ Bar short removed on Telco connector block insertion – positions 1 and 4 and 5 and 8

4 ᅳ RJ31X jack

5 ᅳ Telco connector block

6 ᅳ To control panel

7.3 Telephone line monitor

The B430 module has a built-in telephone line monitor that tests the telephone line for voltage

and current. The normal voltage on a telephone line is approximately 48 VDC (24 VDC for

some telephone systems).

If the module senses trouble, it starts a programmable telephone line trouble timer, which

continues to run as long as the monitor detects trouble. It resets to zero when the control

panel senses a normal line. If the timer reaches the delay time in the Phone Supervision

program item, it begins a telephone line trouble response. Programming determines what the

response is. For programming information, refer to Phone Parameters in RPS Help or in the

control panel Program Entry Guide.

Notice!

Bad Line Might Test OK

The telephone line monitor uses voltage levels to test the status of the telephone line. In

some instances, a given telephone line might be out of service without affecting the voltage

on the line. The telephone line monitor cannot recognize this trouble condition.

7.4 Called party disconnect

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Telephone companies provide “called party disconnect” to allow the called party to terminate

a call. The called party must go on hook (hang up) for a fixed interval before a dial tone is

available for a new call. This interval varies with telephone company equipment. Control panel

firmware allows for “called party disconnect” by adding a 35-seconds “on hook” interval to the

Page 31

Control Panels Telephone communications | en 31

dial tone detect function. If the control panel does not detect a dial tone in 7 seconds, it puts

the telephone line on hook for 35 seconds to activate “called party disconnect,” goes off hook,

and begins a seven-seconds dial tone detect. If no dial tone is detected, the control panel

dials the number anyway. Each time the control panel dials the number, the control panel

records this as an attempt.

7.5 Communication failure

If the control panel has a backup route configured and the first two attempts to reach the

receiver over the primary phone line fail, the system switches to the backup route. When it

switches to the backup route, it sends a trouble event, and the event that triggered the

telephone call to the central station follows.

After ten unsuccessful attempts to reach the receiver, the control panel enters communication

failure. The control panel clears any reports queued for the failed route and generates a

COMM FAIL event that shows on the keypads. A trouble sounder can be programmed to

annunciate at the keypads.

One hour after a COMM FAIL event, the control panel attempts to send a COMM RSTL event.

If a communication failure still occurs, the keypad trouble sounds again.

Notice!

UL Canada Compliance set to Yes

If the UL Canada Compliance parameter is set to yes, the control panel does not clear

pending reports before generating a COMM FAIL event. It continues to queue the reports for

the failed route until the one of the failed routes in the route group is restored. If the queue

reaches the capacity of panel event log, the oldest reports are cleared (overwritten).

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 32

32 en | IP communications Control Panels

8 IP communications

IP communication

The control panel can use on-board Ethernet (IP) connection (the on-board Ethernet port is

excluded on “E” versions) to communicate with a Conettix D6600 or a Conettix D6100IPv6

Communications Receiver/Gateway.

The control panel can optionally use a Conettix Plug-in Cellular Communicator (B440/B441/

B442/B443).

Using Conettix IP communication offers a secure path that includes anti-replay/antisubstitution features and provides enhanced security with up to AES 256-bit encryption (using

Cipher Block Chaining (CBC)).

The control panel supports Domain Name System (DNS) for both remote programming and

central station communication. DNS provides ease of use, eliminating the need to use static IP

addresses as your reporting destination, and accommodates a simple solution for central

station disaster recovery. The control panel supports both IPv6 and IPv4 networks.

Notice!

For premises equipment used in the communication path, such as routers, use only UL listed

equipment.

8.1 On-board Ethernet connection

The built-in Ethernet port on the control panels allows for a network connection without the

need for additional modules. The port supports both 10 Base-T (10 Mb) and 100 Base-TX (100

Mb) standards. The port supports full duplex, half duplex, and HP AUTO_MDIX communication,

using a standard Ethernet cable. Optionally use this connection for central station reporting,

automation, and programming.

8.1.1 Supervision

The control panel supervises its on-board Ethernet connection when the control panel uses

the on-board Ethernet in any of the four route groups as part of either the primary route or the

backup route, or when the control panel uses the connection as the automation device.

Supervision ensures reliable operation of the Ethernet port.

If supervised and the on-board Ethernet does not respond to control panel supervision polls,

then a system fault message appears at the keypads.

8.1.2 Local RPS programming

Use the on-board Ethernet connection to locally connect with RPS. This connection method

requires a direct IP connection from the RPS computer to the on-board Ethernet port.

Connecting the control panel to RPS using IP Direct:

1. If the control panel does not use the Ethernet for IP communication, perform Steps 2 and

3. If the control panel does use the Ethernet for IP communication, power down the

control panel and remove the Ethernet cable that connects the control panel to the

network.

2. Connect the control panel to the RPS computer using the Ethernet ports and a standard

Ethernet cable, and apply power to the control panel, if applicable. Within 2 minutes, the

RPS computer assigns an IP address using AutoIP.

3. In RPS, open the control panel account and click the Connect button. From the Connect

Via drop-down list select IP Direct. Click Connect. Once connected, perform the

necessary tasks, and disconnect when finished.

4. Reconnect the cable used for IP communication, if applicable.

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 33

Control Panels IP communications | en 33

1

2

ETHERNET

MODULE 1

MODULE

RELEASE

USB

ETHERNET

100BASE-T

LINK

E 1

For more information on using AutoIP, refer to AutoIP, page 141.

8.1.3 On-board Ethernet diagnostic LEDs

The control panel includes the following on-board LEDs to assist with troubleshooting the onboard Ethernet connection.

Figure8.1: On-board Ethernet and LEDs (B5512 shown)

Callout ᅳ Description

1 ᅳ 100BASE-T LED (green)

2 ᅳ LINK LED (yellow)

Refer to the following tables for information on the 100BASE-T and LINK LEDs.

Flash pattern Function

Communicating at 100 Mb

On Steady

Communicating at 10 Mb.

Off

Tab.8.2: 100BASE-T LED descriptions

Flash pattern Function

Plugged into an Ethernet network.

On Steady

Communication in progress.

Flashing

Unplugged from an Ethernet network, or the Ethernet

network is not available.

Off

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Tab.8.3: LINK LED descriptions

Page 34

34 en | IP communications Control Panels

!

8.2 Conettix Plug-in Cellular Communicators

Cellular plug-in communicators provide communication between the control panel and central

monitoring stations or RPS using a cellular network. The module also sends and receives SMS

messages for personal notification or system configuration.

The control panel supports one Connetix plug-in cellular module (directly plugged into control

panel or plugged into a B450).

Connect a module using the plug-in module connector or using a B450 (refer to the Conettix

Plug-in Communicator Interface (B450) Installation and Operation Guide and B450 Conettix Plugin Communicator Interface, page 40). This section includes basic installation instructions. For

detailed instructions, refer to the corresponding Conettix plug-in module document listed in

Related documentation, page 12.

8.2.1 Supervision

The control panel supervises a plug-in cellular communicator when the control panel uses the

module in any of the four route groups as part of either the primary route or the backup route,

and the control panel uses the module to route any personal notifications. Supervision

ensures reliable operation between the module and the control panel.

If supervised and the module does not respond to control panel supervision polls, then a

system fault message shows on the keypads. The control panel sends a corresponding report

to the central station.

8.2.2 Installation and module wiring (B44x)

Ensure that there is enough power for the module and other powered devices you want

connected to the system.

Refer to On-board outputs, page 50.

Caution!

Remove all power (AC and battery) before making any connections. Failure to do so might

result in personal injury and/or equipment damage.

Install the module

The module plugs into a connector and is held in place with a plug-in module retention clip.

The module handle and support on top of the module hold the unit during installation.

Plug the module into a control panel by aligning the module with the control panel’s on-board

connector. The retention clip has a locking device to help hold the card in position. Pull the

locking device back. Align the PCB metal contacts with the on-board connector. Push the

module into place. The retention clip snaps closed and secures the module in place.

Wire to the antenna

The module has a threaded connector for connection to an antenna. Route the antenna cable

through a wire knockout in the top of the enclosure. Connect the antenna cable to the

module. Secure the antenna cable to the outside of the enclosure.

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 35

Control Panels IP communications | en 35

Figure8.2: Plug-in cellular module wiring (B440 and B5512 shown)

8.2.3 Signal strength and diagnostic LEDs

Five LED patterns indicate that you correctly secured the module in the control panel, and

indicate the signal strength obtained by the module.

LED Function

Indicates the overall status of the device.

Blue

Indicates an unacceptable signal strength

level.

Red

Indicates a marginal signal strength level.

Yellow

Indicates a good signal strength level.

Green (1 light)*

Indicates a very good signal strength level.

Green (2 lights)

* One green LED indicates the minimum installation level.

Tab.8.4: Cellular module signal strength LED patterns

A single blue Status LED indicates the module status.

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 36

36 en | IP communications Control Panels

Flash pattern Function

Normal state. Indicates normal operation.

Flashes

once every 1 sec

Communication error state. Indicates the

3 quick flashes

Off

Tab.8.5: Cellular module diagnostic LED patterns

module is unable to communicate on the

cellular network.

LED trouble state. Module is not powered, or

some other trouble condition prohibits the

module from controlling the heartbeat LED.

8.3 B426 Ethernet Communication Module

The B426 Conettix Ethernet Communication Module is a four-wire powered SDI2 device that

provides connection for two-way communication over Ethernet networks to the control panels.

The control panel supports one module.

The B426 Conettix Ethernet Communication Module connects to the SDI2 bus on the control

panel using the SDI2 terminals, or using the SDI2 interconnect wiring connector. This section

includes basic installation instructions. For detailed installation instructions, refer to the

Conettix Ethernet Communication Module (B426) Installation and Operation Guide (P/N:

F01U281208).

8.3.1 Address and emulation settings

Notice!

The module reads the address switch setting only during module power up. If you change the

setting after you apply power to the module, you must cycle the power to the module in order

for the new setting to take effect.

Set the address switch to 1.

8.3.2 Supervision

The control panel supervises in two ways:

– Module supervision. The control panel supervises the module through polling. If the

module does not respond to the control panel polling, the control panel declares the

device missing.

– Communication supervision. The control panel supervises the communication path by

polling the central station receiver. If the poll is missed from either side, a communication

fault is declared both at the control panel and the central station receiver.

8.3.3 B426 module faults

With a B426 installed, several services become available to the control panel. Any break in the

Ethernet connection to a supervised B426 results in a system fault at the keypads indicating

Open Cable trouble.

If a Domain Name Server (DNS) is available on the network, a failure to resolve an individual

Network Address hostname results in a system fault at the keypads indicating DNS ERROR ##.

The error number represents the communication module and destination combination that

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 37

Control Panels IP communications | en 37

!

failed. Refer to RPS Help or the control panel’s Program Entry Guide for details on

communication module/destination combinations. The keypad shows a failure to resolve the

domain name used for RPS Network Address.

If a B426 fails all communication with the DNS, a system fault indicating Network Module #

Address Error shows on all keypads and the control panel sends a trouble event to the central

stations, if enabled.

8.3.4 Local RPS programming

Use the B426 IP Direct connect feature to locally connect with RPS. This connection method

requires a direct IP connection from the RPS computer to the B426 Ethernet port.

Connecting the B426 to RPS using IP Direct:

1. If the B426 does not use the Ethernet for IP communication, perform Steps 2 and 3. If the

B426 does use the Ethernet for IP communication, power down the B426 and remove the

Ethernet cable that connects it to the network.

2. Connect the B426 to the RPS computer using the Ethernet ports and a standard Ethernet

cable, and apply power to the B426, if applicable. Within 2 minutes, the RPS computer

assigns an IP address using AutoIP.

3. In RPS, open the control panel account and click the Connect button. From the Connect

Via drop-down list select IP Direct. Click Connect. Once connected, perform the

necessary tasks, and disconnect when finished.

4. Reconnect the cable used for IP communication, if applicable.

For more information on using AutoIP, refer to AutoIP, page 141.

8.3.5 Installation and control panel wiring (B426)

Ensure that there is enough power for the module and other powered devices you want

connected to the system.

Refer to On-board outputs, page 50.

Caution!

Remove all power (AC and battery) before making any connections. Failure to do so might

result in personal injury and/or equipment damage.

Install the module

1. Set the module address to one using the address switch before you install it in the

enclosure.

2. Install the module in the enclosure with the control panel or in an adjacent enclosure that

is no more than 1000 ft (305 m) using 18 AWG to 22 AWG (1.02 mm to 0.65 mm) wire

from the control panel.

3. Use the screws provided with the module to secure the module in the enclosure.

Wire the module

When you wire an SDI2 module to a control panel, you can use either the terminal strip

labeled with PWR, A, B, and COM to wire to corresponding SDI2 terminals labeled on the

control panel, or you can use the interconnect wiring connector and the included interconnect

cable.

For terminal wiring, use 18 AWG to 22 AWG (1.02 mm to 0.65 mm) wire.

Notice!

Use either the terminal strip wiring or interconnect wiring to the control panel. Do not use

both. When connecting multiple modules, you can combine terminal strip and interconnect

wiring connectors in series.

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

Page 38

38 en | IP communications Control Panels

R

Y

G

B

R

Y

G

B

7 COM 8

C

OUTPUT

B

1 k End of Line Resistors

Voltage Ranges

ON-BOARD POINTS

3.7 - 5.0 VDC

2.0 - 3.0 VDC

0.0 - 1.3 VDC

Open

Normal

Short

3 COM 4 5 COM 61 COM 2

R Y G B

SDI2

Device Bus

AUX

- 12 V +

TMPR

1 COM 2 7 COM 83 COM 4 5 COM 6

RESET

COM AUX

R Y G B

PWR A B COM

B C

OUTPUT

7 COM 8

C

OUTPUT

B

1 k End of Line Resistors

Voltage Ranges

ON-BOARD POINTS

3.7 - 5.0 VDC

2.0 - 3.0 VDC

0.0 - 1.3 VDC

Open

Normal

Short

3 COM 4 5 COM 61 COM 2

R Y G B

SDI2

Device Bus

AUX

- 12 V +

TMPR

1 COM 2 7 COM 83 COM 4 5 COM 6

RESET

COM AUX

R Y G B

PWR A B COM

B C

OUTPUT

3

R

Y

G

B

1

1

2

4

2

R

Y

G

B

2

1

Figure8.3: B426 to control panel wiring - terminal strip or interconnect wiring connector (B5512 shown)

Callout ᅳ Description

1 ᅳ Control panel

2 ᅳ Module

3 ᅳ Terminal strip wiring

4 ᅳ Interconnect cable (P/N: F01U079745) (included)

The module has an Ethernet RJ-45 port for connection to an Ethernet network. Connect an

Ethernet cable between the Ethernet jack on the module and a network jack.

Figure8.4: B426 to Ethernet wiring

Callout ᅳ Description

1 ᅳ B426 module

2 ᅳ Ethernet cable

8.3.6 Diagnostic LEDs

The B426 includes the following on-board LEDs to assist with troubleshooting:

– Heartbeat (system status).

– RX (receive).

– TX (transmit).

Refer to B426 module overview for Ethernet link LED locations.

2017.04 | 15 | F.01U.287.180 Installation Manual Bosch Security Systems, Inc.

Page 39

Control Panels IP communications | en 39

Flash pattern Function

Normal state. Indicates normal operation state.

Flashes once every 1 sec

Communication error state. Indicates a bus communication

3 quick flashes every 1 sec

error. The module is not receiving commands from the

control panel.

Trouble state. Indicates a trouble condition exists.

On Steady

LED trouble state. Module is not powered, or some other

trouble condition prohibits the module from controlling the

Off

Tab.8.6: Heartbeat LED descriptions

heartbeat LED.

Flash pattern Function

Occurs when the module receives a message over the

network connection – UPD, TCP, or DNS.

RX (Receive) Flashing

Occurs when the module sends a message over the

network connection – UPD, TCP, or DNS.

TX (Transmit) Flashing

Tab.8.7: RX and TX LEDs descriptions

LINK (yellow) LED pattern 100Mb (green) LED pattern Function

No Ethernet link

Off Off

10Base-T link

On Steady

Off

10Base-T activity

Off

Flashing

100Base-TX link

On Steady On Steady

100Base-TX activity

Flashing

Tab.8.8: Ethernet Link LEDs descriptions

Bosch Security Systems, Inc. Installation Manual 2017.04 | 15 | F.01U.287.180

On Steady

Page 40

40 en | IP communications Control Panels

!

8.4 B450 Conettix Plug-in Communicator Interface

The B450 gives the ability to connect more than one cellular plug-in communicator to the

control panel by providing an interface to the control panel’s SDI2 wiring.

The B450 supports one cellular plug-in module.

The B450 connects to the SDI2 bus on the control panel using the SDI2 terminals, or using the

SDI2 interconnect wiring connector. This section includes basic installation instructions. For

detailed installation instructions, refer to the Conettix Plug-in Communicator Interface (B450)

Installation and Operation Guide.

8.4.1 SDI2 address settings

Notice!

The module reads the address switch setting only during module power up. If you change the

setting after you apply power to the module, you must cycle the power to the module in order

for the new setting to take effect.

The control panel supports one module. Set the address switch to 1 to use the module with

the control panel.

8.4.2 Supervision

The control panel supervises in two ways:

– Module supervision. The control panel supervises the module through polling. If the

module does not respond to the control panel polling, the control panel declares the

device missing.

– Communication supervision. The control panel supervises the communication path by

polling the central station receiver. If the poll is missed from either side, a communication

fault is declared both at the control panel and the central station receiver.

8.4.3 Installation and control panel wiring (B450)

Ensure that there is enough power for the module and other powered devices you want

connected to the system.

Refer to On-board outputs, page 50.

Caution!

Remove all power (AC and battery) before making any connections. Failure to do so might

result in personal injury and/or equipment damage.

Insert the communication module

Insert the desired communication module into the slot of the B450 until you hear the module

“click” into place.

Install the module

1. Set the module address to one using the address switch before you install it in the

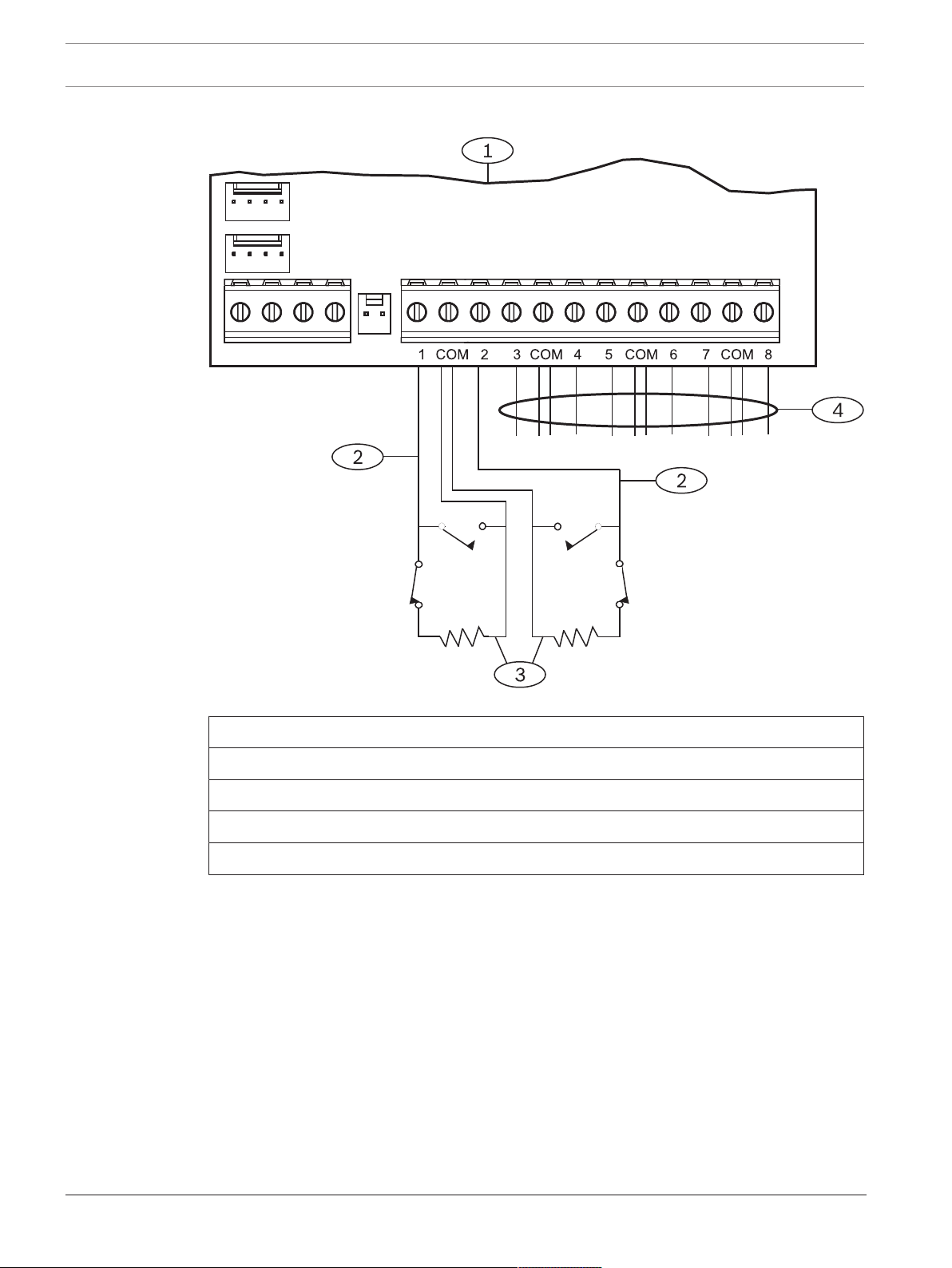

enclosure.