Page 1

Model EG-1

Econo Gradient

Monitor

Instruction

Manual

Catalog Numbers

731-8151

731-8150

Page 2

Warranty

Model _________________________________________

Serial Number __________________________________

Date of Delivery_________________________________

Warranty Period _________________________________

Unless otherwise specified, instruments sold by Bio-Rad are under

warranty for 1 year against defects in materials and workmanship.

If any defects should occur during this warranty period, Bio-Rad will

replace the defective parts without charge. However, the following defects

are specifically excluded:

1. Damage caused by improper operation.

2. Repair or modification done by anyone other than Bio-Rad

Laboratories or their authorized agent.

3. Deliberate or accidental misuse.

4. Damage caused by disaster.

5. Damage due to use of improper solvent or sample.

6. Damage due to spills.

This warranty does not apply to fittings, tubing, and fuses.

For inquiry or to request repair service, contact Bio-Rad Laboratories

after confirming the model and serial number of your instrument.

For Technical Service, call your local Bio-Rad Office or, in the U.S.,

call 1-800-4BIORAD (1-800-424-6723).

Page 3

Table of Contents

Section 1 Safety ............................................................................. 1

Section 2 Introduction.................................................................. 2

Section 3 Unpacking ..................................................................... 3

Section 4 Description and Features............................................ 4

4.1 Front Panel Functions ............................................................. 4

4.2 Rear Panel Sockets................................................................. 6

4.3 Flow Cell ................................................................................ 7

Section 5 Setting Up ..................................................................... 7

5.1 Flow Cell Installation............................................................. 7

5.2 Connecting the Model EG-1 Econo Gradient

Monitor to Recording Equipment........................................... 7

Section 6 General Operation....................................................... 8

6.1 Conductivity Mode................................................................. 9

6.2 Gradient Mode........................................................................ 9

Section 7 Care and Maintenance................................................ 10

Section 8 Troubleshooting............................................................ 11

Appendix A Fuse Replacement ........................................................ 13

Appendix B Rear Panel Connections .............................................. 13

Appendix C Technical Specifications............................................... 14

Appendix D Ordering Information.................................................. 15

Page 4

Section 1

!

Safety

Disconnect supply before servicing. No user serviceable parts inside.

Refer servicing to Bio-Rad service personnel.

This instrument is intended for laboratory use only.

This product conforms to the “Class A” standards for electromagnetic

emissions intended for laboratory equipment applications. It is possible

that emissions from this product may interfere with some sensitive

appliances when placed nearby or in the same circuit as those appliances. The user should be aware of this potential and take appropriate

measures to avoid interference.

1

Page 5

Section 2

Introduction

Fig. 1.1. Model EG-1 Econo Gradient Monitor.

The Model EG-1 Econo Gradient Monitor is a high quality, easy to use,

conductivity and gradient monitor for liquid chromatography. The monitor

consists of a control unit and an external flow cell. The flow cell is fitted

with luer connectors for rapid tubing connections. It can be connected to

the outlet of an Econo-Column®chromatography column or an Econo-Pac

Cartridge.

®

In the Conductivity mode, the Econo Gradient Monitor functions as a

standard conductivity monitor with numerical output in Siemens*. In the

Gradient mode, gradient end-points (e.g. buffer A and buffer B) can be

programmed, relative gradient progress is displayed on the Bar Graph,

numerical output is displayed in Siemens, and full scale output to a chart

recorder is automatically adjusted.

The Model EG-1 Econo Gradient Monitor functions as a stand-alone

instrument or as an integral part of any chromatography system.

For technical specifications, refer to Appendix C.

*1 Siemen = 1 Mho = 1/Ohm

2

Page 6

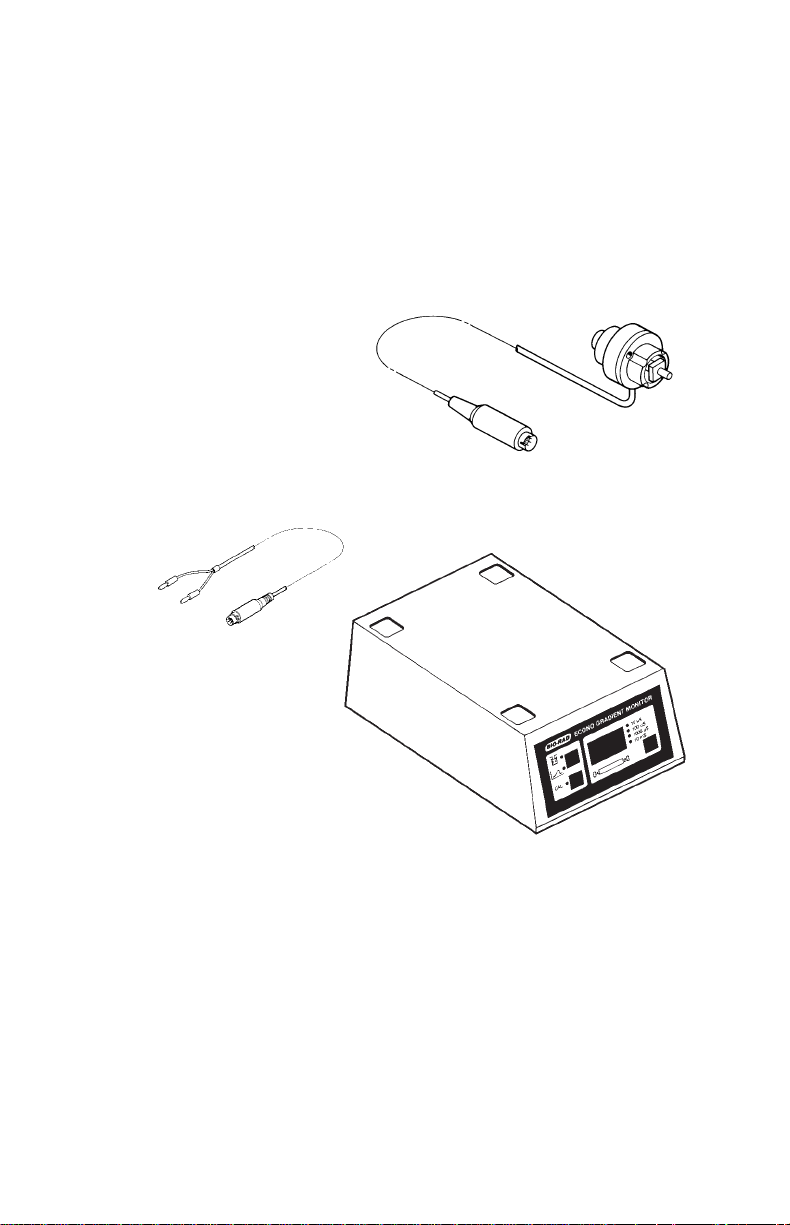

Section 3

Unpacking

Carefully remove the contents of the shipping box, and check for any

obvious damage or problems with the instrument. Figure 2.1 shows the

parts included with the Model EG-1 Econo Gradient Monitor. Check of f all

parts against the supplied packing list.

If any parts are missing or damaged, contact Bio-Rad Laboratories

immediately.

Flow Cell

Cable 4

Control Unit

Also includes: Instruction Manual, 3 male luer fittings and 3 female luer fittings.

Fig. 2.1. Parts supplied with the Model EG-1 Econo Gradient Monitor.

Note: The Model EG-1 Econo Gradient Monitor requires a power

adaptor. If you did not receive one, contact your local Bio-Rad

representative.

3

Page 7

Section 4

Description and Features

The Model EG-1 Econo Gradient Monitor consists of a control unit and

a flow cell. The control unit houses the electronics and user interface. The

flow cell connects to the control unit and is external for flexible placement.

The following tables and illustrations describe the features of the

Model EG-1 Econo Gradient Monitor.

4.1 Front Panel Functions

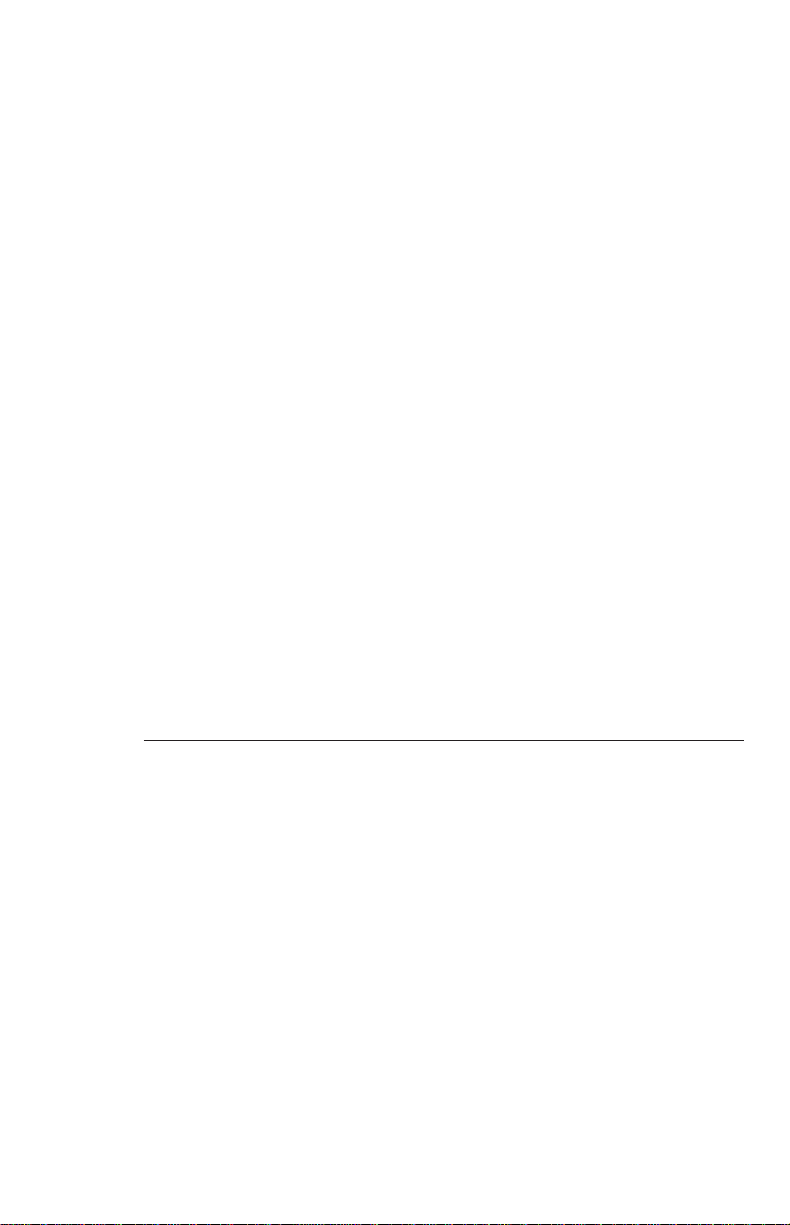

Fig. 3.1. Front panel controls.

Display Function

Range Selector In the Conductivity mode, the

Range Selector allows the user to

select one of four range settings

between 10 micro-Siemens

and 10 milli-Siemens full scale.

The strip chart recorder output

will be scaled accordingly.

3-Digit Display The 3-digit display shows con-

ductivity in Siemens, in accordance with the range selected.

4

Page 8

Display Function

Bar Graph In the Conductivity mode, the Bar

Graph provides a graphic representation of the buffer conductivity relative to the lower and upper

limits of the selected range. In the

Gradient mode, the Bar Graph

provides an indication of the

buffer conductivity relative to

buffer A and B. Aflashing red

LED at either end of the Bar

Graph indicates an out of range

condition.

Mode Selector Allows selection of Conductivity

or Gradient mode.

Gradient For use only in the Gradient

Calibration mode. The Gradient Calibration

key activates a routine which

allows the user to enter conductivity values for buffer A and

buffer B by passing the desired

“A” and “B” solutions through

the flow cell. The values for A

and B are automatically established as “0” and 100% full scale

and chart recorder output is

scaled accordingly.

5

Page 9

4.2 Rear Panel Sockets

Fig. 3.2. Rear panel sockets.

The rear panel of the Model EG-1 Econo Gradient Monitor control unit

contains an On/Off power switch and four sockets for electrical

connections (see Figure 3.2). Abrief description of each socket follows.

Display Function

Power Entry For connection of the 12 VDC

power adaptor.

Signal Output For connection of chart recorders,

Socket integrators and computers to the

Model EG-1 Econo Gradient

Monitor using standard Bio-Rad

cables. See Section 4.2 and

Appendix B.

Flow Cell For connection of the flow cell’s

Socket Signal Cable.

Remote Socket This feature is not implemented

in the Model EG-1.

6

Page 10

4.3 Flow Cell

Fig. 3.3. The flow cell.

Inlet/Outlet Ports A male and a female luer fitting on either end of the

Signal Cable For connection of the flow cell to the socket on

Section 5

Setting Up

flow cell allow rapid tubing connection. The flow

cell can be used with flow in either direction. Note:

the luer fittings may be unscrewed and replaced with

1/4”-28 threaded flat-bottom fittings.

the rear panel of the control unit.

5.1 Flow Cell Installation

Place the flow cell as close as possible to the column outlet and/or any

other detection devices (e.g. a UV flow cell, if used) and connect the flow

cell’s Signal Cable to the flow cell socket on the rear panel of the

control unit.

If the monitor is to be used in conjunction with the Model EM-1

Econo UV Monitor, connect the gradient monitor flow cell directly to the

inlet or outlet port of the portable optics module for optimal detection.

If the Econo Gradient Monitor is to be used with other UV monitors, the

flow cell should be placed as close as possible to the UV detection device.

5.2 Connecting the Model EG-1 Econo Gradient

Monitor to Recording Equipment

The Model EG-1 Econo Gradient Monitor is shipped with System

Cable 4, which connects the Econo Gradient Monitor to channel 2 of the

7

Page 11

Model 1327 Econo Recorder. The cable also connects the Econo Gradient

Monitor to other recording devices which use banana plug connectors.

Connecting the Model EG-1 Econo Gradient Monitor to a

Model 1327 (dual pen) Econo Recorder

The Model EG-1 Econo Gradient Monitor must be connected to channel 2 of the Model 1327 Econo Recorder. Use System Cable 4 to connect

the Econo Gradient Monitor to the banana plug signal inputs on the rear

panel of the Econo Recorder. Plug the 8-pin mini-DIN end of cable 4 to

the socket on the rear panel of the Econo Gradient Monitor. Insert the

black banana plug into the ground input and the red banana plug into

the voltage input for channel 2 of the Model 1327 Econo Recorder.

Connecting the Model EG-1 Econo Gradient Monitor to Other

Chart Recorders

Use System Cable 4 to connect the Model EG-1 Econo Gradient

Monitor to recording devices which accept banana plugs. Insert the 8-pin

connector into the signal output socket on the rear panel of the Model

EG-1 Econo Gradient Monitor. At the other end of the cable are two

banana plugs. The red plug is the positive output, and the black plug is the

negative, or ground. These plugs should fit directly into the input sockets

of most chart recorders.

The signal output socket on the rear panel of the Model EG-1

Econo Gradient Monitor is an 8-pin circular mini-DIN and is intended for

use with Econo System components. For those wishing to interface the

Model EG-1 Econo Gradient Monitor with equipment such as integrators

or chart recorders which do not utilize banana plug connectors, System

Cable 7 (available separately) may be used. System Cable 7 has an 8-pin

mini-DIN at one end, for connection to the Model EG-1 Econo Gradient

Monitor, and loose wires at the other. See Appendix B for the pin configuration of the 8-pin mini-DIN signal output socket.

Section 6

General Operation

1. Make sure all the electrical connections and

plumbing have been done properly (See Section 4).

Allow the monitor to warm up for approximately

10 minutes.

2. The Econo Gradient Monitor powers up in either

the Conductivity mode or the Gradient mode. Use

the Mode Selector key to select the desired mode.

8

Page 12

6.1 Conductivity Mode

In the Conductivity mode, the numerical LED displays the conductivity (in Siemens) of the solution in the flow cell, and the LED indicator

light indicates the range selected. The Bar Graph gives an

indication of the conductivity relative to the range setting currently chosen

(thereby giving an indication of the relative position of the chart recorder

pen).

1. Press the Range Selector key to select a range

which will include the expected maximum conductivity of the solutions to be used.

2. If the monitor is connected to a strip chart

recorder, set the recorder range to 1 V. The full

scale reading on the recorder corresponds to the

selected range setting on the monitor.

An out of range condition is indicated by a flashing numerical “999”

display and flashing red LED’s at either end of the Bar Graph.

6.2 Gradient Mode

In the Gradient mode, the numerical LED displays the conductivity (in Siemens) of the solution in the flow cell. The range is automatically

determined based on the conductivity values for buffers A and B (entered

during calibration). Full scale output to a chart recorder or integrator is

adjusted automatically, assuring the gradient trace will not move of f the top

of the chart paper. Once the gradient monitor is calibrated, the Bar Graph

will indicate buffer conductivity relative to the conductivity

values for buffer A and B.

Calibrating Gradient End Points

The gradient monitor should be calibrated every time the buffers are

changed, if a new batch of buffers is prepared, or if the buffers are one day

or more old.

1. Press the CAL key once. The gradient mode, “A”

LED, and CAL indicator lights will flash.

2. Pass buffer Athrough the flow cell using a pump or

syringe until the conductivity reading stabilizes. (A

flashing CAL indicates the monitor is calibrating.)

3. Press the CAL key to accept the conductivity value

for buffer A. The gradient mode, “B” and CAL

indicator lights will immediately begin to flash.

9

Page 13

4. Pass buffer B through the flow cell until the conductivity reading stabilizes. (A flashing CAL indicates the monitor is calibrating.)

5. Press the CAL key to accept the conductivity

value for buffer B.

Note: If the 3-digit display reads “Err”, the conduc-

tivity valves for buffer A and B are too close

together to use the Gradient mode. Press the

and use the Conductivity mode.

When steps 1-5 above are complete, the Bar Graph will

indicate the buffer conductivity in the flow cell relative to the conductivity

values set for buffer A and B. The gradient monitor output is automatically

calibrated to 0 to 1 V based on the values set for buffer A and B. (Insure

that the recorder input is set to 1V full scale.)

If the conductivity of the buffer in the flow cell falls outside the values

set for buffers A and B, a red indicator light will appear on the Bar Graph.

Section 7

Care and Maintenance

Mode Selector key to cancel calibration

The Model EG-1 Econo Gradient Monitor requires very little maintenance to assure reliable operation. Following are general procedures for

maintenance of the control unit and flow cell.

10

Page 14

Model EG-1 Econo Gradient Monitor Control Unit and Flow Cell:

The control unit may be left on continually (power consumption is negligible).

Although the cases are chemical resistant, spills and splashes may

cause precipitates to form on the component cases. Use a squirt bottle

and soapy water to wash down the outer cases of the instrument.

Flow Cell

Clean the outside surface of the flow cell as described above.

The flow cell should be cleaned periodically with 1 M NaOH at 1

ml/min for 5 min. (SDS, 1 M HCl, 1 M NaOH, EtOH, and acetone will

not harm the Model EG-1 Econo Gradient Monitor flow cell.)

When the flow cell is not in use, disconnect, and clean out dissolved

salts using a syringe filled with deionized water.

Store the flow cell by injecting a dilute solution (15-25%) of ethanol or

isopropanol into the cell to prevent microbial growth. Use the end caps

provided to seal the flow cell’s inlet and outlet ports. Always rinse the

flow cell with water prior to the introduction of aqueous buffers. To

prevent the formation of salt crystals and solute deposits, do not allow

the flow cell to dry out.

Section 8

Troubleshooting

Problem Possible Cause Solution

Baseline drift or Bubbles in flow cell Use degassed buffers.

noisy signal Check for loose plumb-

ing connections

Dirty flow cell Clean flow cell; insure

that buffers are free of

particulate material

(See Section 6)

Bubbles passing Use degassed buffers.

through flow cell Check for loose plumb-

ing connections

Column not Equilibrate and/or

equilibrated or dirty regenerate column

11

Page 15

Problem Possible Cause Solution

Larger or smaller than Chart recorder input Check chart recorder

expected gradient voltage set incorrectly settings (See Sections

profile 4.2 and 5)

If using Gradient Re-calibrate the

mode, buffer A and gradient mode

B values not set

correctly

Ghost peaks appear in Charged sample No problem

gradient profile detected (e.g. protein)

Air bubbles passing Use degassed buffers.

through flow cell Check for loose plumb-

ing connections

Chart recorder Chart recorder is not Check connections (See

not responding connected properly Sections 3.2 and 4.2)

Full scale of recorder Set recorder range to

set too high 1 V

Recorder has bottomed Readjust pen position

out

Flow cell not Check flow cell

connected in-line plumbing

No power Faulty power Check power cable

connection connection

Blown fuse Check fuses (See

Appendix A)

Unit not switched on Check power on/off

switch on rear panel

Conductivity Dirty flow cell Clean flow cell (See

measurements with Section 6)

same buffer appear

to decrease over time

12

Page 16

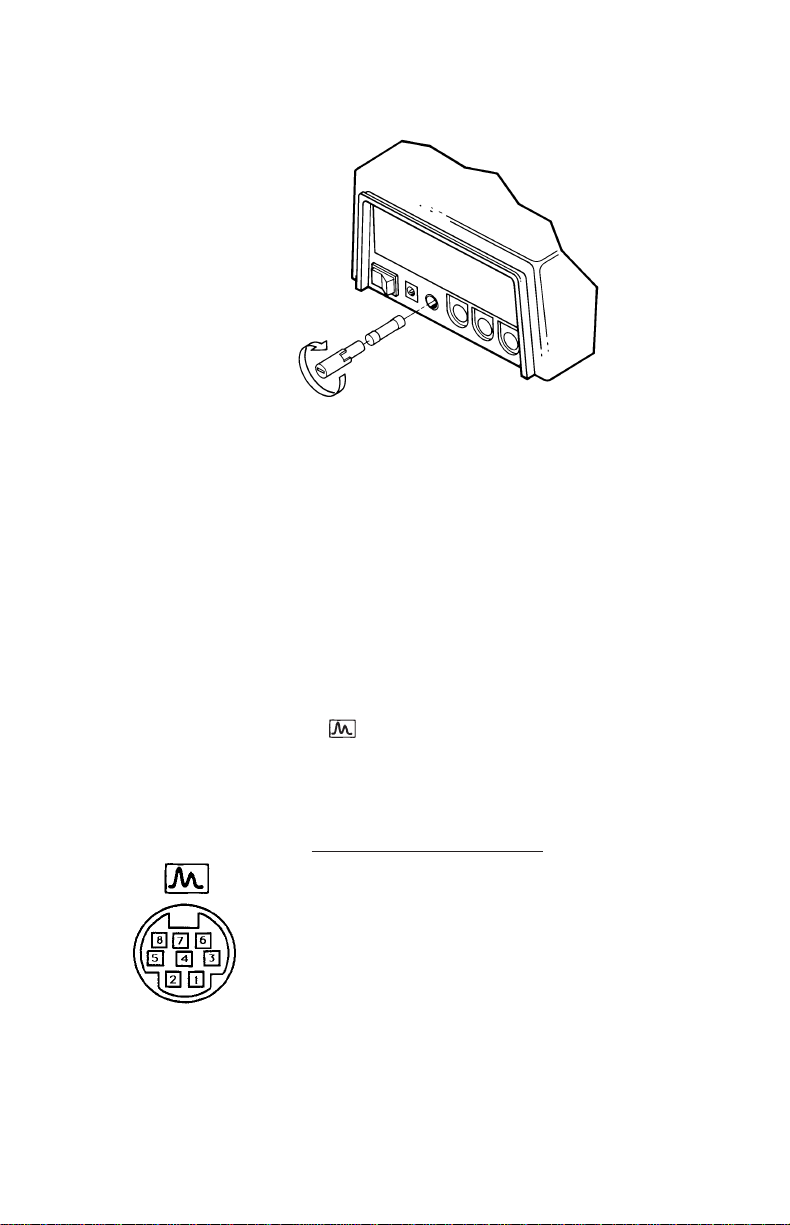

Appendix A

Fuse Replacement

Figure A. Fuse removal.

1. Disconnect unit from power source.

2. Remove the fuse cover with a small-blade screwdriver or similar tool.

3. Pull the fuse holder out of the fuse compartment and, if necessary,

replace the fuse. Use 5 mm x 20 mm fuse, type T, 1A.

4. Reinsert the fuse holder, with fuse, into the fuse compartment.

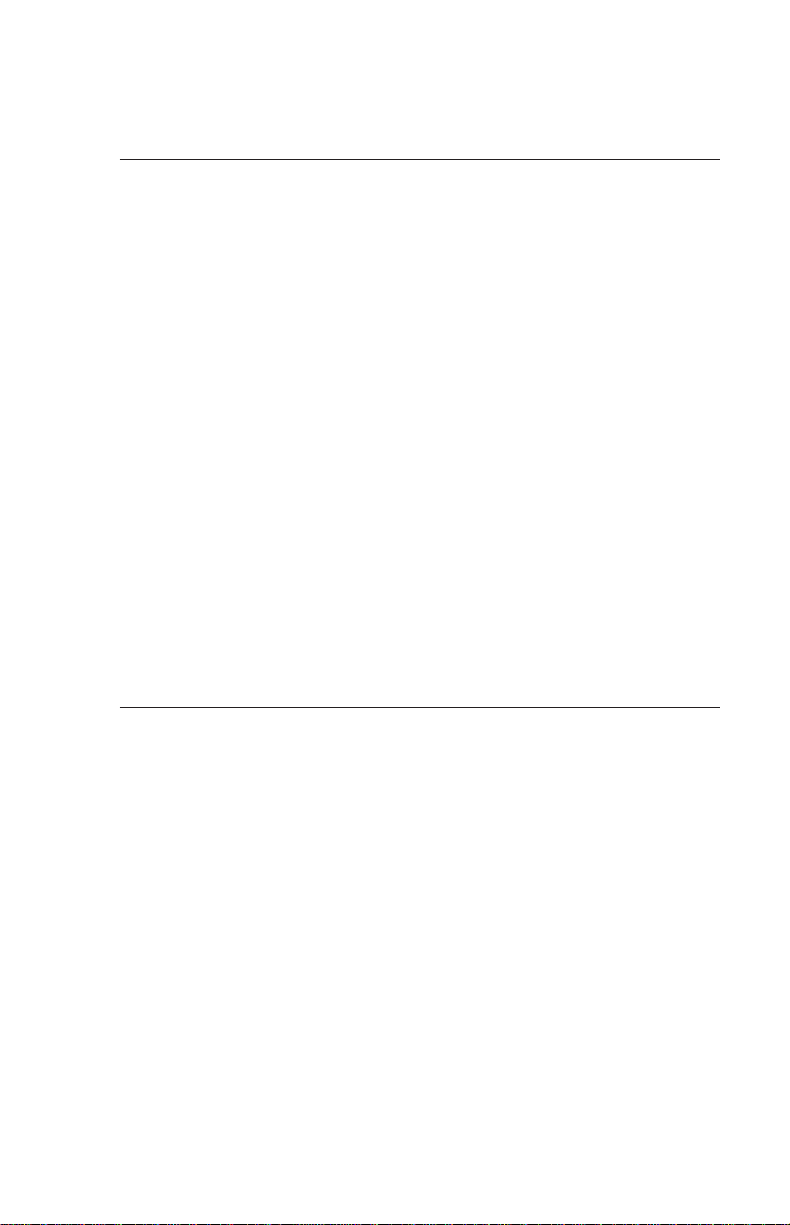

Appendix B

Rear Panel Connections

The signal output socket is an 8-pin circular mini-DIN. The fol-

lowing information is provided for those wishing to interface the Model

EG-1 Econo Gradient Monitor with equipment such as integrators or chart

recorders which do not utilize banana plug connectors.

Pin Function

1 No Contact

2 No Contact

3 No Contact

4 No Contact

5 Chart Recorder (+)

6 Chart Recorder (-)

Pin configuration

7 No Contact

8 No Contact

13

Page 17

Appendix C

Technical Specifications

General

Operating mode Conductivity, in units of Siemens (See

Operating temperature 4-40 °C

Sensitivity ranges (full scale) 0-10µS, 0-100µ S, 0-1000µS, 0-10mS

Output signal 0-1 Volt

Power requirements 90-264 V, 50-60 Hz (depending upon

Power consumption 20W maximum

Noise Short Term: < 0.1 µ S

Linearity +/-0.5 % full scale

Accuracy +/-2 % full scale

Drift < 0.5 µ S/hour/°C

Dimensions

Control Unit: 15.60 x 22.86 x 8.89 cm (W x L x H)

Flow Cell: 3.1 cm diameter by 3.8 cm length

Weight Control Unit: 600g

Case Material Chemical and fire resistant polypropylene

Regulatory CSA: C22.2 No. 151-M1986

Compliance: TÜV: EN61010-1:1993

Section 1)

power adaptor used)

Long Term: < 0.5 µ S

CE: EN55011: 1991 Class A

EN50082-2:1995

Flow cell

Type Flow through, externally mounted

Temperature compensation 0-60 °C

Internal volume 8 µl, swept volume

Cell constant Approximately 40*

Maximum operating pressure 60 psi, 4 bar, or 0.41 mPa

Cable length 1.22 M

Wetted Parts Titanium, Kel-F and Tefzel

Fittings Removable luer (Will also accept 1/4”-28

flat bottom fittings)

* Most applications do not require an exact cell constant. If it is necessary

to determine the exact cell constant, Bio-Rad‘s Conductivity Standard,

catalog number 167-0445, can be used.

14

Page 18

Appendix D

Ordering Information

Model EG-1 Econo Gradient Monitor

731-8151 Econo Gradient Monitor, Model EG-1, with 100-120 V

power adaptor (catalog number 731-8270) and flow cell

(catalog number 731-8155)

731-8150 Econo Gradient Monitor, Model EG-1, requires power

adaptor, includes flow cell (catalog number 731-8155)

731-8155 Flow Cell, Model EG-1, 1 cell

731-8270 Power Adaptor, 100-120 V, for USA, Canada, Japan,

Mexico, Taiwan, Latin America

731-8271 Power Adaptor, 220-240 V, for Europe (except the UK)

and other countries not specifically listed

731-8272 Power Adaptor, 220-240 V, for UK, Australia, New

Zealand

Cables

731-8264 System Cable 4, 8-pin mini-DIN to banana plugs (for con-

nection of Econo Gradient Monitor to Model 1327

Recorder or other recording devices which accept banana

plug connectors)

731-8267 System Cable 7, 8-pin mini-DIN to breakout, for connec-

tion of Econo Gradient Monitor to recording devices which

do not use banana plug connectors.

Tubing

731-8210 Silicone Tubing, 0.8 mm ID, 0.8 mm wall, 10 m

731-8211 Silicone Tubing, 1.6 mm ID, 0.8 mm wall, 10 m

731-8212 Silicone Tubing, 3.2 mm ID, 0.8 mm wall, 10 m

731-8214 Tygon Tubing, 0.8 mm ID, 0.8 mm wall, 10 m

731-8215 Tygon Tubing, 1.6 mm ID, 0.8 mm wall, 10 m

731-8207 PharMed®Tubing, 0.8 mm ID, 1.0 mm wall, 10 m

731-8208 PharMed Tubing, 1.6 mm ID, 1.0 mm wall, 10 m

731-8209 PharMed Tubing, 3.2 mm ID, 1.0 mm wall, 10 m

Fittings

731-8220 Low Pressure Fittings Kit, includes over 17 different fit-

tings and stopcocks (250 fittings total)

Tygon and PharMed are registered trademarks of the Norton Company.

15

Page 19

Life Science

Group

Web site www.bio-rad.com USA (800) 4BIORAD Australia 02 9914 2800

Austria (01) 877 89 01 Belgium 09-385 55 11 Brazil 55 21 507 6191

Canada (905) 712-2771 China 86-10-8201-1366/68 Denmark 45 44 52-1000

Finland 358 (0)9 804 2200 France 01 47 95 69 65 Germany 089 318 84-177

Hong Kong 852-2789-3300 India (91-124) 6398112/113/114 Israel 03 951 4124

Italy 34 91 590 5200 Japan 03-5811-6270 Korea 82-2-3473-4460

Latin America 305-894-5950 Mexico 52 5 534 2552 to 54

The Netherlands 0318-540666 New Zealand 64-9-4152280 Norway 47-23-38-41-30

Russia 7 095 979 98 00 Singapore 65-2729877 Spain 34-91-590-5200

Sweden 46 (0)8-55 51 27 00 Switzerland 061-717-9555 United Kingdom 0800-181134

00-000 0000 Sig 1200Bulletin 0000 US/EG Rev A

Bio-Rad

Laboratories

M7318150 Rev H

Loading...

Loading...