Page 1

Econo System

Instruction

Manual

For

Technical Service

Call Your Local Bio-Rad Office

in the U.S.

t=it•J;1

Calll-800-4BIORAD

( 1-800-424-6723)

9

•)

or

Page 2

Warranty

Model

Serial Number

Date

Warranty Period

Unless otherwise specified, instruments sold by Bio-Rad Laboratories are

warranted for 1 year against defects in materials and workmanship.

If

replace the defective parts without charge. However, the following defects are

specifically excluded:

1.

Defects caused by improper operation.

2.

Repair or modification done by anyone other than Bio-Rad Laboratories

or an authorized agent.

3.

Use with tubings or fittings not specified by Bio-Rad Laboratories for use

with this system.

4. Deliberate

_______________

______________

of

Delivery

any defects should occur during this warranty period, Bio-Rad will

or

-------------

____________

accidental misuse.

_

_

_

5.

Damage caused by disaster.

6.

Damage due to use

7. Damage due to spills.

This warranty does not apply to tubing, fittings, and fuses.

For inquiry or request for repair service, contact Bio-Rad Laboratories after

confirming the model and serial number

For Technical

Call l-800-4BIORAD (1-800-424-6723)

of

improper solvents or samples.

of

your instrument.

Service Call Your Local Bio-Rad Office

or

in the U.S.

Page 3

Table

of

Contents

Section 1

1.1

1.2

Section2

2.1

2.2

2.3

Section 3

3.1

3.2

3.3

Section 4

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

Introduction .................................................................. .

Overview ................................................................................. .

System Components ................................................................ .

Unpacking the Econo System Controller ................... .

Unpacking Instructions ........................................................... .

Voltage Considerations ............................................................ .

Safety Considerations .............................................................. .

1

1

2

3

3

4

5

Econo System Controller:

Physical Description and Control Features ............... .

Front Panel Functions .............................................................. .

Rear

Panel Functions ............................................................... .

Topside Functions .................................................................... .

6

6

7

8

Econo System Controller Connections and Set Up .... 9

Model EP-1 Econo Pump......................................................... 10

Model EM-1 Econo UV Monitor and Optics Module.............

Model

and Model

Model EG-1 Econo Gradient Monitor . . . .... ... . . ...

Model

Model

Solvent Reservoir.....................................................................

Model 1325 Econo (Single-pen) Recorder...............................

Model 1327 Econo (Dual-pen) Recorder.................................

Data Aquisition Systems ............................ .............................. 14

EV-1

2110 Fraction Collector

SV-3

Econo Buffer Selector

SV-5

Valve Pod......................................................

Diverter Valve......................................................

..

. . ...

...

. .......

..

. .

.. ..

...

. .

...

. . ... . .

.....

..

. . .... ...... ... 12

..

11

12

. . . . . 12

13

13

13

13

Section 5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

Section 6

6.1

6.2

Plumbing the System..................................................... 14

Tubing and Fittings . .

Gradient Proportioning Valve and Mixer................................. 16

Model

Model

Manual Sample Injection Valve

and Chromatography Column . . . ... . .

UV Optics Module and Gradient Monitor Flow Cell . . . .

Model

Fraction Collector.....................................................................

EP-1 Econo Pump......................................................... 16

SV-5

Valve Pod.............................................................

SV-3

Diverter Valve ......................................................

..

... . . . . ..... ..... ... . .........

... . ..

.. . ..

. ........ ...........

. . ..... ... . .

.. . ..

..

.. . ..

. . .

..

. . ...

15

17

.. . .. . .. . 18

.. . .. ..

... 20

21

21

Getting Started .............................................................. 21

Connecting System to Power

System Check........................................................................... 22

..

. . . ..... ... . . ... ...... ....

..

..

. . .

..

......

...

..

...

21

Page 4

Section 7

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.9

Programming the System .............................................

Getting Started:

Verification

Econo

!socratic (Single Buffer) Methods............................................

Binary Gradient Formation . ... . . . . .

Peak Detection and Collection .....

Programming Multi-Step Methods

(Using the Econo Buffer Selector)........................................... 35

Programming Multi-Step Methods Which Include a Binary

Gradient (Using the Econo Buffer Selector)............................ 38

Programming Automated

Options While Running A Method . . ..... ...

of

Econo System Software Version...................... 23

System Software Mode Selection................................. 24

..

. .

...

. .....

...

. . ...

..

... . ... . . . .... ...

.. . ...

......

..

..

......

...

..

... ....... ....

Sample Injection............................. 39

..

.... ... . . .... ... . . .

..

. . .

..

..

. .

...

...

..

23

25

28

31

40

Section 8

Section 9

Appendix A

Appendix B

Appendix C

Storage and Maintenance............................................. 42

Thoubleshooting ............................................................. 43

Interfacing and Signals .................................................

45

System Specifications .................................................... 47

Ordering Information................................................... 48

Page 5

Section

1

Introduction

Fig. 1.1. The Automated Econo System.

1.1

Overview

The Automated Econo System consists

matography instruments which can be integrated to form a system. System

components include a complete line

cartridges, fittings, tubing, and valves. Each component has its own stand-alone

features in addition to its role in the system.

The Model ES-1 Econo System Controller integrates the individual com-

ponents into a low pressure chromatography system. The Econo System con-

troller provides the following functions:

• Gradient proportioning and mixing

• Peak detection by threshold

• Programmed control

Buffer Selector is used)

• Waste/collect diverter valve

• 6-port manual injector valve

of

up to 5 solutions (when the Model

of

or

time windows

of

a series

chromatography columns, prepacked

of

free-standing chro-

EV-1

Econo

• Solvent ice bath

These functions supplement those provided by the Model EP-1 Econo

Pump, Model EM-1

Monitor, Model EV-1 Econo Buffer Selector, and Model

Collector. This manual contains the necessary information for setting up and

Econo

UV

Monitor, Model EG-1 Econo Gradient

2110 Fraction

1

Page 6

running the system. In some sections, references will be made to informati1

provided in the component manuals. A binder is provided to help organi

the information.

1.2 System Components

The complete Automated Econo System consists

ponents:

• Model EP-1 Econo Pump

• Model EM

• Model ES-1 Econo System Controller

• Model

• Model EG-1 Econo Gradient Monitor

• Model 2110 Fraction Collector (optional)

• Econo Rack

• Econo System Organizer

• Model SV-3 Diverter Valve

• Model MV-6 6-port Injection Valve

• Model 1325 Econo Recorder (optional)

-1

Econo UV Monitor

EV-1

Econo Buffer Selector

of

the following com-

•

Modell327

The standard Econo System consists

• Model EP-1 Econo Pump

• Model EM-1 Econo UV Monitor

• Model ES-1 Econo System Controller

•

Model2110

• Econo Rack

• Model SV-3 Diverter Valve

• Model MV-6 6-port Injection Valve

• Model 1325 Econo Recorder (optional)

For the Econo System controller to function, it must be connected to the

Model EP-1 Econo Pump. For automated control

Model EV-1 Econo Buffer Selector must be connected to the Econo

controller. Aside from these requirements, UV and gradient monitors, frac-

Econo (Dual-Pen) Recorder (optional)

of

the following components:

Fraction Collector (optional)

of

more than 2 buffers, the

System

2

Page 7

tion collectors, and chart recorders from other manufacturers can

with the system.

See Appendix A for details.

_Section 2

.~_)npacking

2.1

Unpacking Instructions

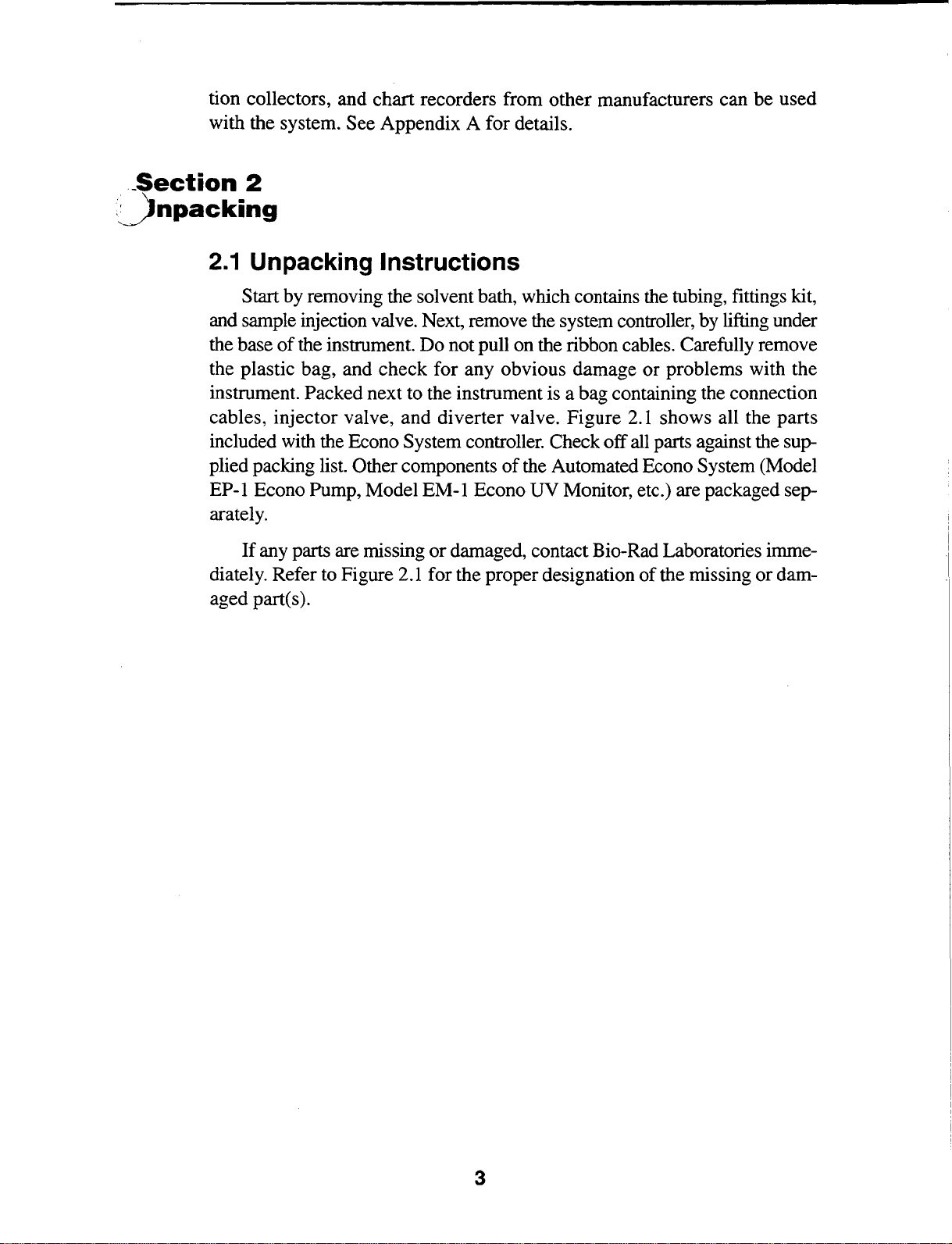

Start by removing the solvent bath, which contains the tubing, fittings kit,

and sample injection valve. Next, remove the system controller, by lifting under

of

the base

the plastic bag, and

instrument.

cables, injector valve, and diverter valve. Figure

included with the Econo System controller. Check off all parts against the supplied packing list.

EP-1 Econo Pump, Model EM-1 Econo UV Monitor, etc.) are packaged separately.

If

diately. Refer to Figure

aged part(s).

the instrument. Do not pull on the ribbon cables. Carefully remove

check

Packed next to the instrument is a bag containing the connection

Other components

any parts are missing

for any obvious damage

or

2.1

for the proper designation

be

used

or

problems with the

2.1

shows all the parts

of

the Automated Econo System (Model

damaged, contact Bio-Rad Laboratories imme-

of

the missing

or

dam-

3

Page 8

Tubing

Fittings Starter Kit

Fraction

Collector_~

Ca~

Chart Recorder

Cable / )

-~

~/

)

Diverter Valve

Injection Valve

Model ES-1 Econo

System Controller

Also includes:

Solvent Reservoir

Instruction Manual w/ Binder

Drain Tube

Fig. 2.1. Parts included with the Model

ES-1

Econo System Controller.

2.2 Voltage Considerations

The Econo System controller receives its power from the Model EP-1

Econo Pump, which is shipped in the

details on voltage conversions to 100 V or 240 V configurations, refer to

the Model

EP-1

Econo Pump manual.

4

120 V or 220 V configuration. For

Page 9

2.3 Safety Considerations

The Econo System controller receives power from the Model EP-1 Econo

Pump through a ribbon connector shown in Figures 3.3 and 4.2. Do not insert

any objects into this connector.

5

Page 10

Section

Econo

System

Physical

3.1

t~!~·li'·'·)

A A

3

Controller:

Description

and

Control

Front Panel Functions

ECONO

0 '0

.!\__;\_;\..

SYSTEM

PEAK

COLLECTOR 0 B

CONTROI.I.ER

0 0

Features

GRADIENT FORMER

0

0(~

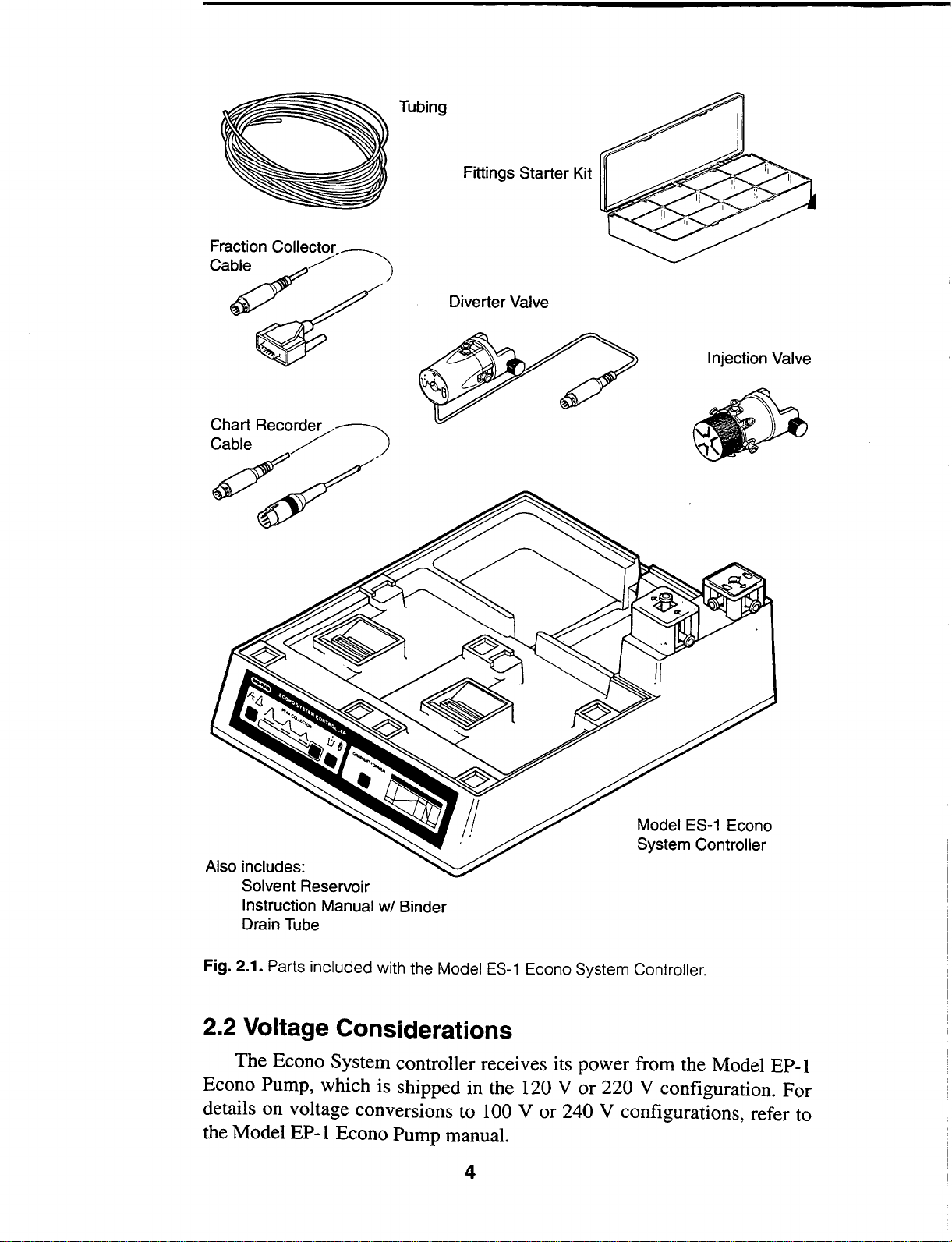

Fig. 3.1. Front panel controls.

~

~ro]O

Display

Gradient Former

Peak Separator Key

0

~

Function

This control is used to pro-

gram binary gradient meth-

ods consisting

steps in tandem with the

integral

valve and mixer. The gradient LED display gives,

quick identification

dient progression.

This key is used to select

between the two peak separation methods, threshold

detection

dows.

of

proportioning

and

up to five

of

gra-

time

win-

~

(o

o o o o

oO

Time Window

Display and Key

6

This key is used to select

up

to three time windows

for

peak separation. During

each

diverter valve is routed to

the fraction collector for

collection

time

window,

of

eluant.

the

Page 11

0 0

LIB

Diverter Valve

Indicator and Key

0 0

0

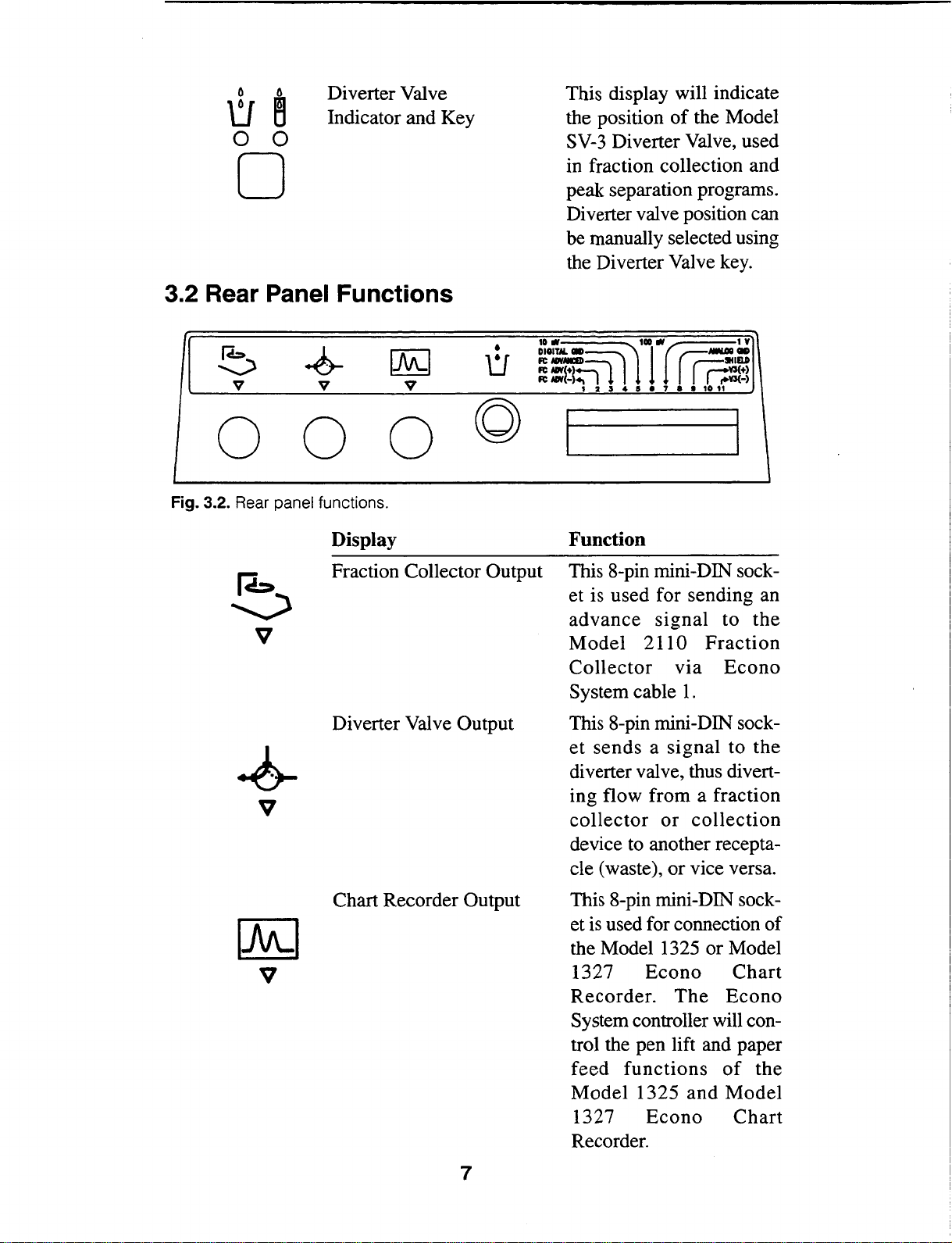

3.2 Rear Panel Functions

~

v

.&

v

~

v

•

LI

This display will indicate

the position

SV-3

Diverter Valve, used

in fraction collection and

peak separation programs.

Diverter valve position can

be manually selected using

the Diverter Valve key.

DIOITM.

CID

~~-~~--~1Y

a

:m:,

11

t234tle7aatou

of

the Model

-.Gil

1 lr

rr:~~

CID

0 0 0

Fig. 3.2. Rear panel functions.

Display Function

Fraction Collector Output This 8-pin mini-DIN sock-

Diverter Valve Output

©

et is used for sending an

advance

Model

Collector

System cable

This 8-pin mini-DIN socket

sends a signal

diverter valve, thus diverting flow from a fraction

collector

device to another receptacle (waste), or vice versa.

signal

2110

vta

or

to

the

Fraction

Econo

1.

to

the

collection

Chart Recorder Output

7

This 8-pin mini-DIN socket

is

used for connection of

the Model

1327

Recorder.

System controller will control the pen lift and paper

feed

Model

1327

Recorder.

1325 or Model

Econo

The

functions

1325

and

Econo

Chart

Econo

of

the

Model

Chart

Page 12

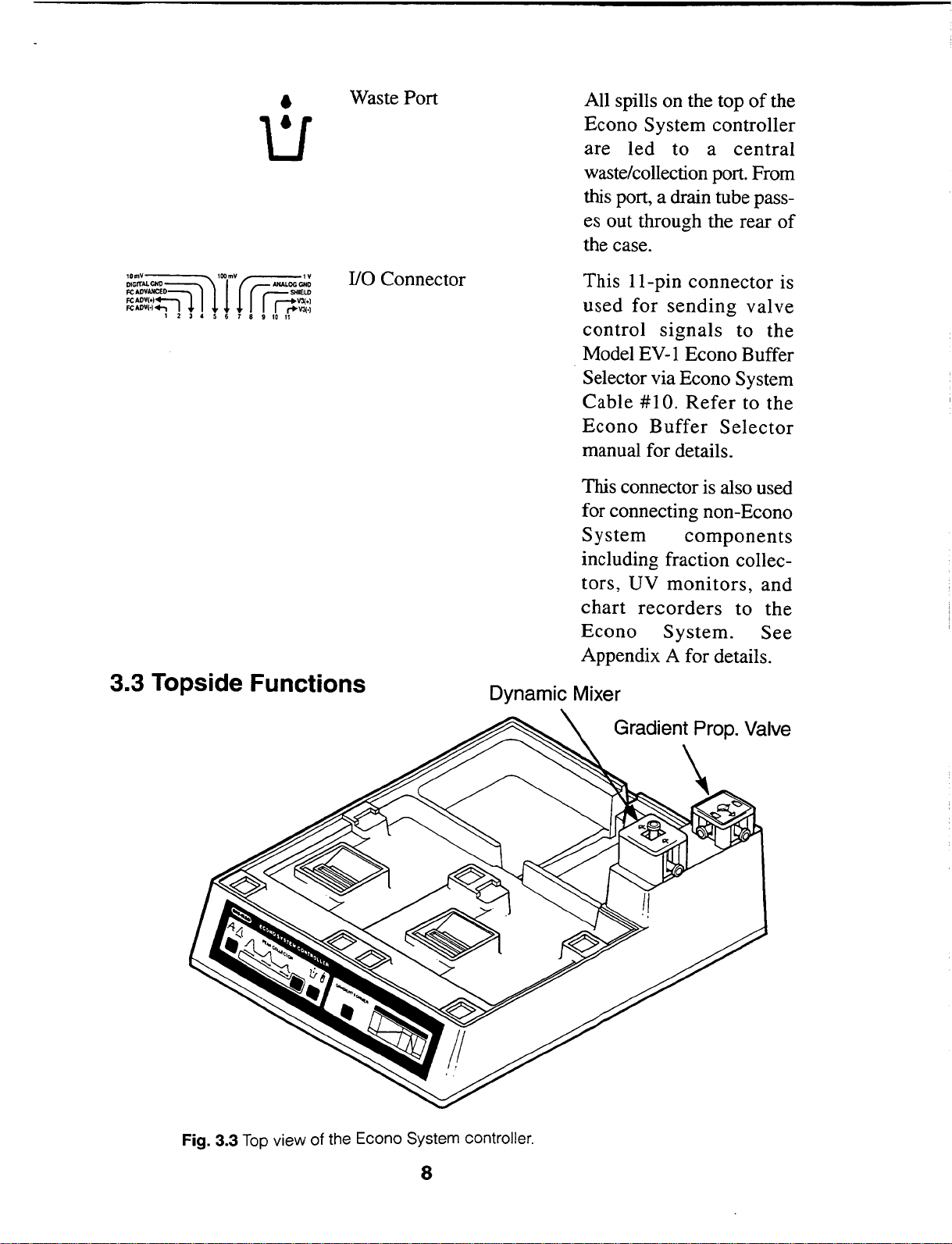

•

LJ

Waste Port

All spills on the top

Econo System controller

are

led

to a

waste/collection port. From

this port, a drain tube pass-

es out through the rear

the case.

of

the

central

of

10mY

DIGITALCHDSll

FCADVAHCED~

FCADV(•)~

FCADYH+, I I

1 2 3 4 5 6 7 8 9

100mV~1Y

1

~~ANALOGGND

rr.

SHIELD

r--*V3(•)

r+\'3{·)

10

11

110 Connector

3.3 Topside Functions

This 11-pin connector is

used

control

Model

Selector via Econo System

Cable

Econo

manual for details.

This connector is also used

for connecting non-Econo

System

including fraction collectors,

chart

Econo

Appendix A for details.

Dynamic Mixer

for

sending

signals

EV-1

UV

recorders

Econo Buffer

#1

0.

Refer

Buffer

components

monitors,

System.

valve

to the

to the

Selector

and

to

the

See

Fig. 3.3 Top view of the Econo System controller.

8

Gradient Prop. Valve

\

Page 13

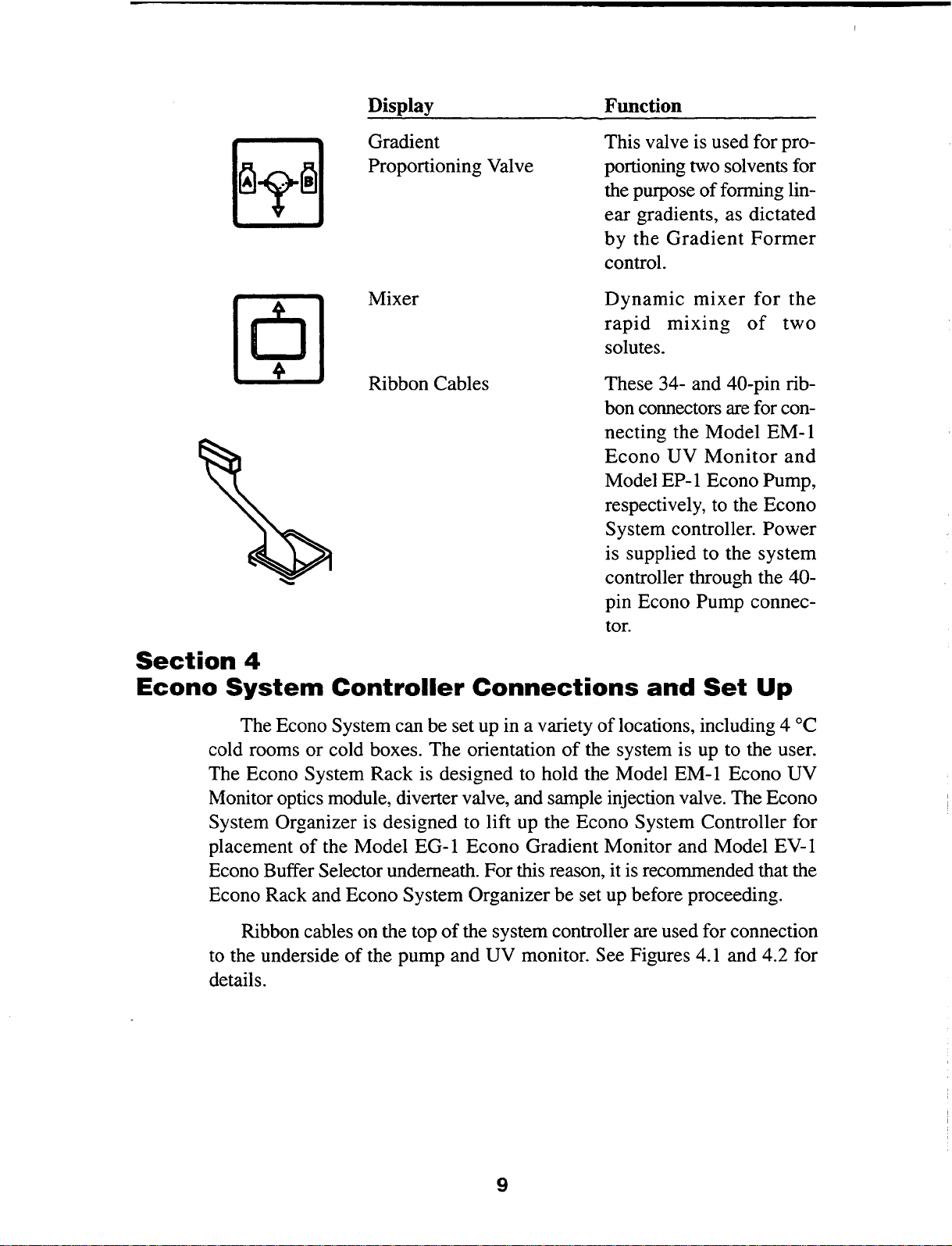

Display

Function

Gradient

Proportioning Valve

Mixer

Ribbon Cables

This valve is used for proportioning two solvents for

the purpose

ear

gradients, as dictated

by

the

control.

Dynamic

rapid

solutes.

These 34- and

bon connectors are for connecting the Model

Econo

Model EP-1 Econo Pump,

respectively, to the Econo

System controller.

is supplied to the system

controller through the

pin Econo Pump connector.

of

forming lin-

Gradient

mixer

mixing

40-pin rib-

UV

Monitor

Former

for

the

of

two

EM-I

and

Power

40-

Section

Econo

System

cold rooms or cold boxes. The orientation

The Econo System Rack is designed to hold the Model EM-1 Econo UV

Monitor optics module, diverter valve, and sample injection valve. The Econo

System Organizer is designed to lift up the Econo System Controller for

placement

Econo Buffer Selector underneath. For this reason, it

Econo Rack and Econo System Organizer be set up before proceeding.

to the underside

details.

4

Controller

The Econo System can be set up in a variety

of

the Model EG-1 Econo Gradient Monitor and Model EV-1

Ribbon cables on the top

of

the pump and UV monitor. See Figures 4.1 and 4.2 for

Connections

of

of

the system controller are used for connection

and

of

locations, including 4

the system is up to the user.

is

recommended that the

Set

Up

oc

9

Page 14

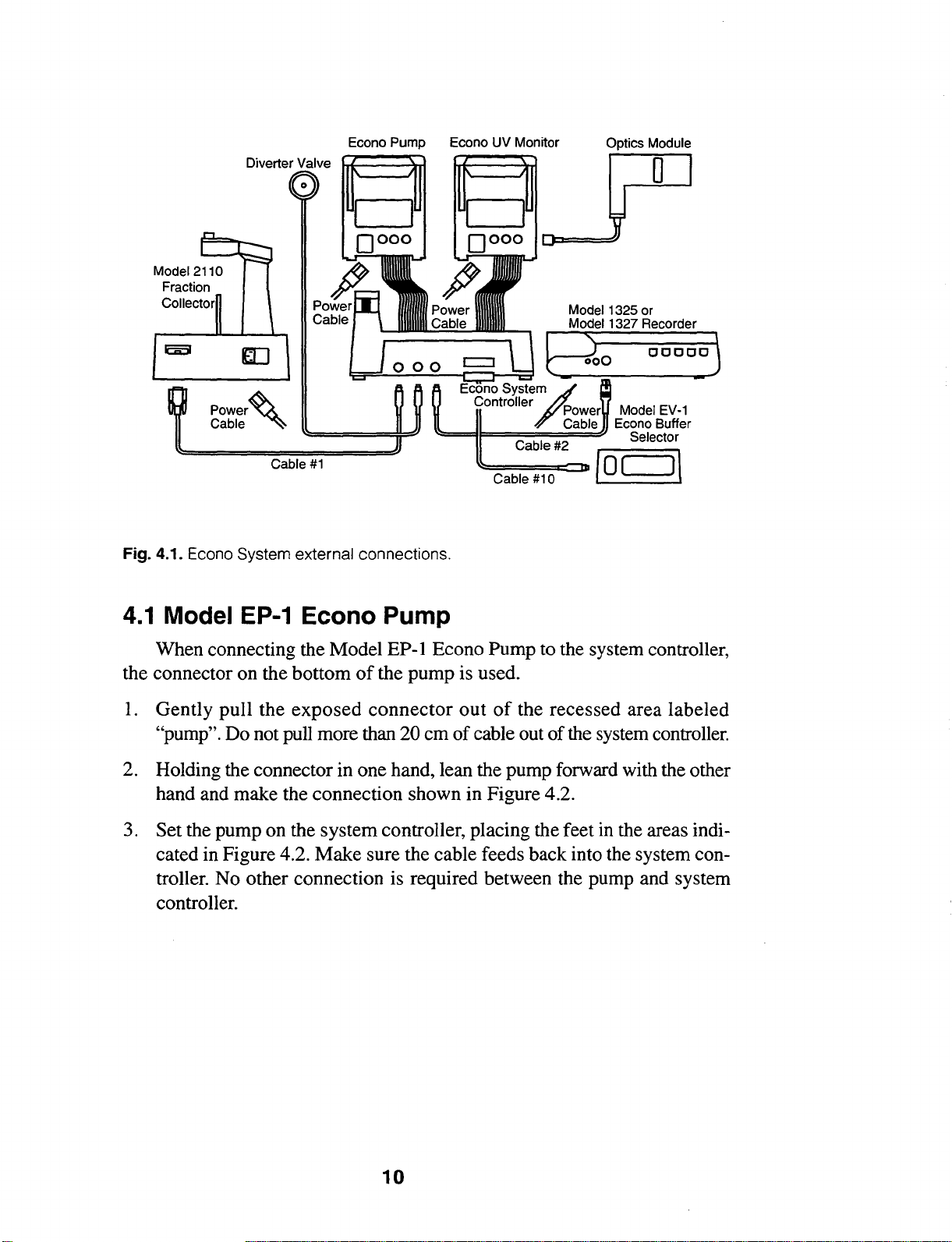

Econo Pump Econo UV Monitor

Diverter

Valve

G

Power~

Cable

"'<\

Cable

#1

Fig. 4.1. Econo System external connections.

~=911==c=a=bl=e

Model

1325 or

Model 1327 Recorder

Systeif

Controller Power Model

Cable Econo Buffer

=#

::i::::::i=i:::P

2

~c=ab=le=#=1

o::c:::::::::J:D

{ 0 [

EV-1

Selector

J\

4.1

Model EP-1 Econo Pump

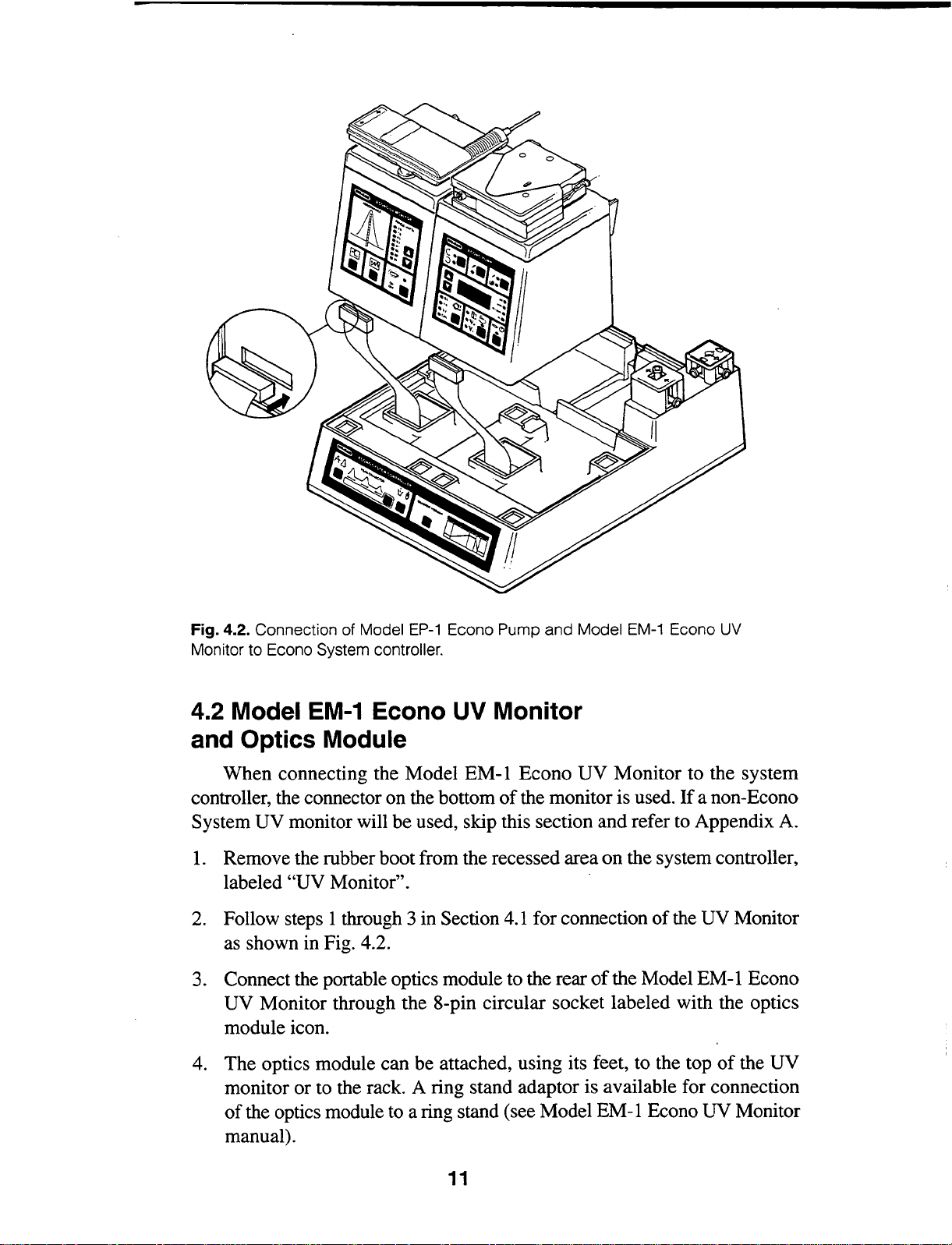

When connecting the Model EP-1 Econo Pump to the system controller,

of

the connector on the bottom

I. Gently pull the

exposed

"pump". Do not pull more than 20 em

the pump is used.

connector

out

of

of

cable out

the recessed area labeled

of

the system controller.

2. Holding the connector in one hand, lean the pump forward with the other

hand and make the connection shown in Figure 4.2.

3. Set the pump on the system controller, placing the feet in the areas indicated in Figure 4.2. Make sure the cable feeds back into the system controller. No other connection is required between the pump and system

controller.

10

Page 15

Fig. 4.2. Connection of Model

Monitor to Econo System controller.

EP-1

Econo Pump

and

Model

EM-1

Econo

UV

4.2 Model

EM-1

Econo UV Monitor

and Optics Module

When connecting the Model

controller, the connector on the bottom

System UV monitor will be used, skip this section and refer to Appendix A.

I. Remove the rubber boot from the recessed area on the system controller,

labeled

2.

Follow steps 1 through 3 in Section 4.I for connection

"UV Monitor".

as shown in Fig. 4.2.

3. Connect the portable optics module to the rear

UV Monitor through the 8-pin circular socket labeled with the optics

module icon.

4. The optics module can be attached, using its feet, to the top

monitor or to the rack. A ring stand adaptor is available for connection

of

the optics module to a ring stand (see Model EM-I Econo UV Monitor

manual).

EM-I

of

Econo UV Monitor to the system

the monitor is used.

of

the Model EM-I Econo

If

a non-Econo

of

the UV Monitor

of

the UV

11

Page 16

4.3 Model

EV-1

Econo Buffer Selector

and Model SV-5 Valve Pod

The Model

System Controller via Econo System Cable 10. Place the Econo Buffer

Selector control unit underneath the Econo

System Organizer is used) or beside the Econo System Controller. Use cable

#10 (supplied with the Econo Buffer Selector) to connect the Econo

socket on the rear panel

nector on the rear panel

The Model

of

the Solvent Reservoir in a variety

the length

Controller, and the buffer reservoirs. See the Econo Buffer Selector manual

for details.

EV-1

SV-5 Valve Pod can be mounted to the Econo Rack or the lip

of

tubing between the valve pod, the mixer on the Econo System

Econo Buffer Selector connects directly

System Controller (if the Econo

of

the Econo Buffer Selector to the 11-pin 1/0 con-

of

the Econo System Controller.

of

locations. For best results, minimize

to

the Econo

System

4.4 Model EG-1 Econo Gradient Monitor

The Model EG-1 Econo Gradient Monitor connects only to the chart

If

recorder.

Econo Gradient Monitor manual for details.

The Econo Gradient Monitor connects to the Model 1325 Econo (SinglePen) Recorder via Econo

Econo Gradient Monitor) to connect the standard DIN connector on the

Model 1325 Recorder to the 8-pin mini-DIN socket labelled with the chart

recorder icon on the rear panel

conductivity are to be monitored, the Model 1327 (dual-pen) Recorder (or

other dual-channel recording device) should be used. Use Econo

Cable 4 (supplied with the Econo Gradient Monitor, 8-pin mini-DIN to

banana plugs) to connect the Econo Gradient Monitor to the banana plug

signal inputs on the chart recorder. Plug the 8-pin mini-DIN end

to the chart recorder socket on the rear panel

Insert the black plug into the ground

voltage

a non-Econo Recorder is to be used, refer to the Model EG-1

System Cable

of

V input for channel 2

the Econo Gradient Monitor.If both UV and

of

2.

Use cable 2 (supplied with the

of

of

the Econo Gradient Monitor.

_l_ input and the red plug into the

the Model 1327 Econo Recorder.

System

cable 4

4.5 Model

Interfacing between the Model2110 Fraction Collector and system controller is achieved by connecting the 9-pin

Model2110 Fraction Collector to the 8-pin mini-DIN socket labeled with the

fraction collector icon on the rear panel of the system controller (refer to

Figure 3.2).

Controller) is used to make this connection. The fraction collector can also

be connected to the 8-pin mini-DIN socket labeled with the fraction collec-

211

Econo

0 Fraction Collector

1/0 connector on the back

System

Cable

1 (supplied with the Econo

of

the

System

12

Page 17

tor icon on the rear

System

fraction collector, refer to Appendix

of

the Model EP-1 Econo Pump. To connect a non Econo ·

A.

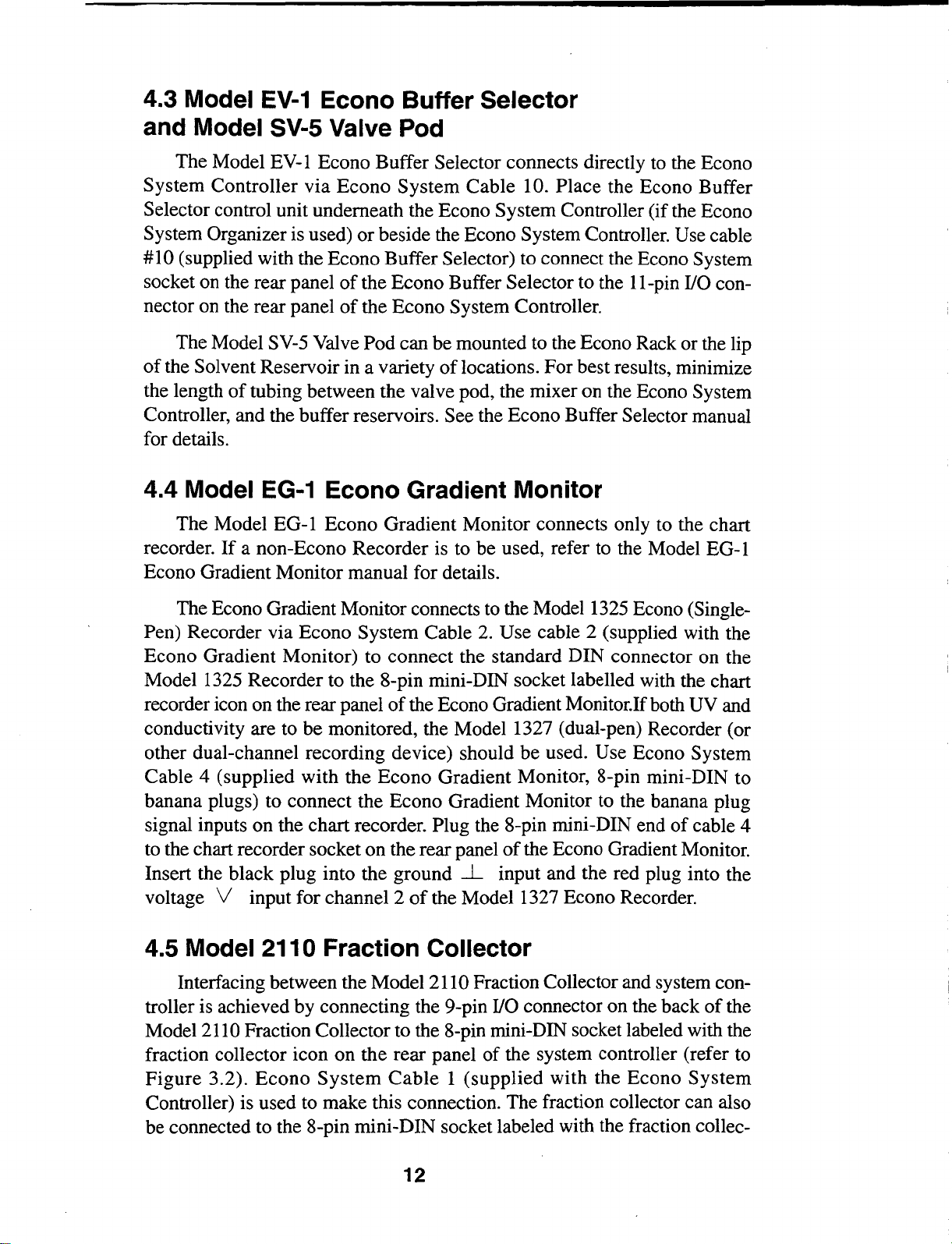

4.6 Model SV-3 Diverter Valve

The Model SV-3 Diverter Valve (Figure 4.3) can be attached to the rack

of

in a variety

are labeled to indicate their functions. The cable for the diverter valve is

attached to the back

et

labeled with the diverter valve icon (refer to Figure 3.2). The diverter

valve can also be connected to the 8-pin mini-DIN socket labeled with the

Diverter Valve icon on the rear

locations depending upon the application. The ports on the valve

of

the system controller using the 8-pin mini-DIN sock-

of

the Model EP-1 Econo Pump.

Fig. 4.3. Model

SV-3

Diverter Valve.

4. 7 Solvent Reservoir

The solvent reservoir sits in the depression in the system controller behind

the pump and

UV monitor.

Be

careful not to trap cables under the reservoir.

4.8 Model 1325 Econo (Single-Pen) Recorder

The Model 1325 Econo Recorder has been designed for use with the

Econo

analog data signal, pen drop, and paper feed command to the recorder. Refer

to the recorder instruction manual for operating details.

1325 Econo Recorder

plied with the system controller to connect the standard DIN connector on the

Model 1325 Econo Recorder to the 8-pin mini-DIN socket labeled with the

chart recorder icon on the rear panel

3.2).

tings labeled in green for automatic control.

System. Through one connection, the system controller will output the

To

connect the Model

to

the system controller, use Econo System Cable 2 sup-

of

the system controller (see Figure

Set all top panel controls

of

the Model1325 Econo Recorder to the set-

4.9 Model 1327 (Dual-Pen) Econo Recorder

The Model 1327 Econo Recorder has been designed for use with the

Econo

analog data signal, pen drop, and paper feed commands to the recorder.

System. Through one connection, the system controller will output the

13

To

Page 18

connect the Model 1327 Econo Recorder to the system controller, use Econo

System Cable 2 (mini-DIN to standard-DIN) to connect the standard-DIN connector on the Model 1327 Econo Recorder to the 8-pin mini-DIN socket

~

labelled with the

Figure 3.2).

icon on the rear panel

of

the system controller (See

4.10 Data Acquisition Systems

The system controller takes into account the use

data acquisition systems, such as the Model 3396A Integrator, or other instruments. The

Econo

Econo System Cable 7. Alternatively,

connected to the System Controller, the 11-pin connector on the rear panel

of

the system controller can be used. See Appendix A for signal specifications.

Section

5

Plumbing

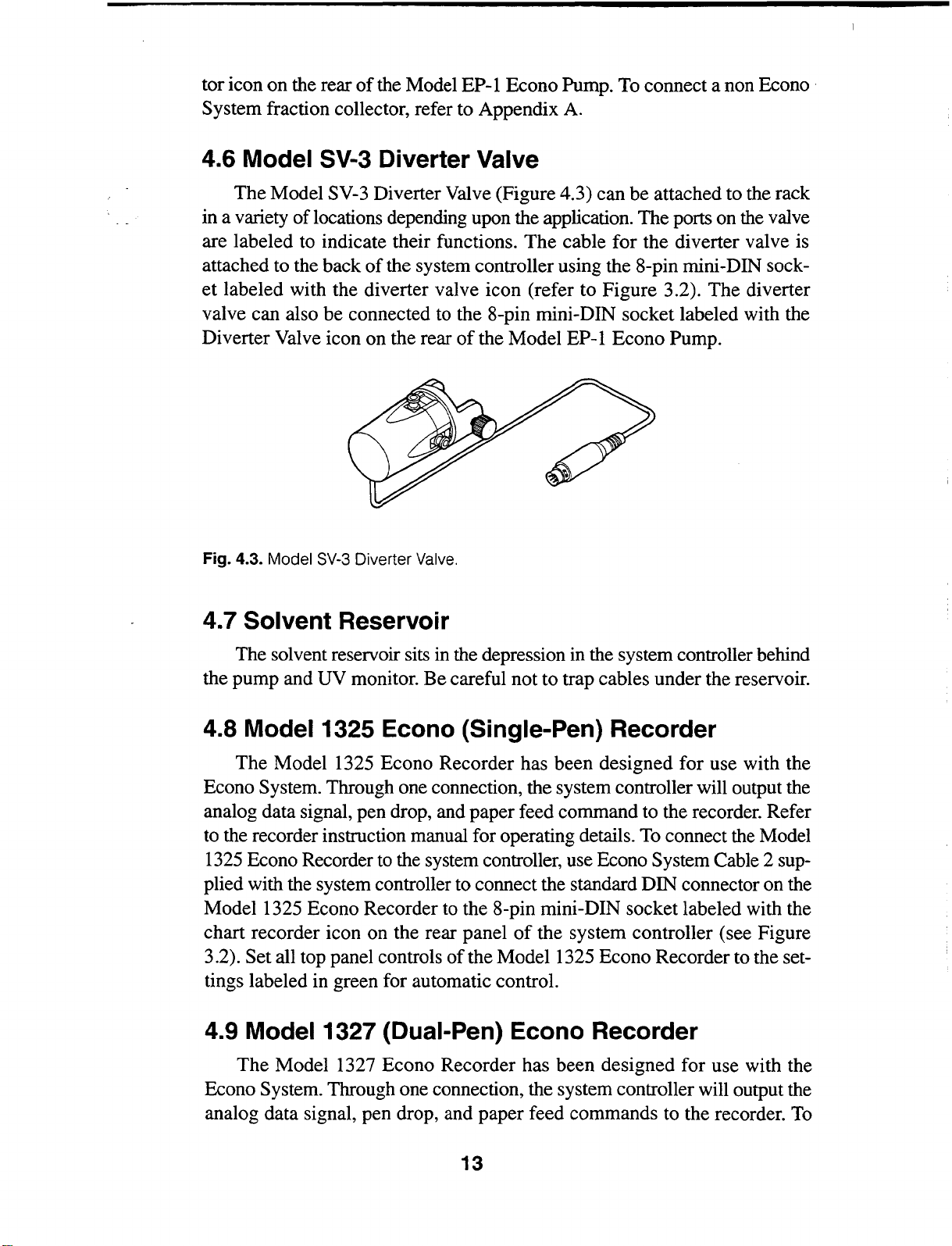

The Econo System can be plumbed quickly and easily. Twenty-five feet

of

Tygon® tubing and a starter tubing fittings kit are included with the system. The kit contains luer fittings for quick tubing connections. Figure 5.1

shows a typical plumbing diagram for the Automated Econo System. Figure

5.2 shows a typical plumbing diagram for the Econo System without the

Econo Buffer Selector and Econo Gradient Monitor.

of

the Econo System with

~

8-pin mini-DIN socket on the rear panel

UV Monitor will output a non-scaled analog signal, accessible through

if

the Econo Buffer Selector is not

the

System

of

the Model EM-I

u

Fig. 5.1. Plumbing diagram for the Automated Econo System.

14

Page 19

u

Fig. 5.2. Plumbing diagram for the Econo System (without Econo Buffer Selector

and Econo Gradient Monitor).

The plumbing arrangement described in this section is by no means the

only way to connect the system. The additional tubing and fittings are supplied to allow the system to be customized for specific applications.

5.1

Tubing and Fittings

The Econo System can be conveniently plumbed with most tubing having inner diameters less than or equal to 3.2 mm

supplied in the plumbing kit is 1.6 mm ID. This should suffice for most

applications. When using 3.2 mm tubing in the pump for increased pump

output, the proportioning valve and mixer should also be plumbed with 3.2

flow.

mm tubing to maintain adequate

manual for tubing compatibilities with the pump.) Figure 5.3 summarizes

the more commonly used fittings.

(Refer to the Model EP-1 Econo Pump

(Ys").

The Tygon tubing

Male luer for system tubing connections

Female luer for pump tubing

.,.

Female 't' connector

1 Male-to-male connector

Fig. 5.3. Fittings for system tubing connections.

15

Page 20

Note: Tubing lock-rings are used only for plumbing the Model EP-1

Econo Pump and are not needed for system tubing connections.

5.2 Gradient Proportioning Valve and Mixer

The length

valve is not critical; however, it is important

be designated buffer A and buffer B.

1.

Insert the barbed end

Connect the male luer fitting to the female luer fitting on the propor-

tioning valve. Make sure that the line from buffer A is connected to the

A port on the proportioning valve. Repeat this process for buffer line B.

Do not overtighten the luer fittings.

2. The connection between the proportioning valve and mixer should be

made with a piece

accuracy

luer fittings

the outlet

Figure 5.1).

5.3 Model

Installation

EP-1 Econo Pump manual. Pre-cut norprene tubing and fittings are supplied

with the pump.

tubing, refer to the following procedure. Note that tubing length varies with

tubing composition. This is to accommodate tubing prestretch, which affects

flow rate calibration and flow reproducibility.

of

tubing between the buffer bottles and the proportioning

to

clearly label which bottles will

of

a male luer fitting into one end

of

tubing less than

of

the gradients formed by the proportioning valve. Affix male

to

both ends

of

the proportioning valve with the inlet

EP-1

of

To

Econo Pump

the tubing in the pump head is described in the Model

make these tubing sections yourself with Tygon, or other

of

the tubing as described above, and connect

10

em long. This

of

the tubing.

is

to maintain the

of

the mixer (see

Warning:

sure the wall thickness is not greater then

greater wall thickness can damage the pump and void your warranty.

1.

Cut the tubing to a length described below. Make sharp, perpendicular cuts.

Tubing

Tygon, Norprene

Silicone

2.

Slip a color-coded lock-ring specific for that size

of

the tubing (see below). Install the female

barbed end

place by sliding the lock-ring over the barbed fitting (see Figure 5.4).

Repeat on the other end

If

using tubing other than the type supplied by Bio-Rad, make

0.8 mm. Using tubing with a

Length

179

mm

+1-

1.3 (7.04"

171

mm

+1-

1.3 (6.75"

of

the fitting into the tubing, and clamp the luer fitting into

of

the tubing.

16

+1-

0.05)

+1-

0.05)

of

tubing onto one end

1uer

fittings by inserting the

Page 21

Lock-Ring

Color

Size

Red

Orange

Yellow

If

a Model

EV-1

Econo Buffer Selector is not being used, the connection

between the pump and the mixer should be made with a section

then

15

em long to maintain accuracy

0.8 mm

1.6

3.2 mm

of

gradients. Affix male luer fittings

mm

(~2")

(YI6")

(Ys")

of

tubing less

to both ends as described above, and connect to the female luer fittings on both

the pump outlet and the mixer.

If

a Model

mixer to the pump. Continue with

EV-1

Econo Buffer Selector is to be used, do not connect the

Section 5.4 for plumbing the Model SV-5

Valve Pod.

Fig. 5.4. Attachment of tubing fittings.

5.4 Valve Pod

The Model SV-5 Valve Pod should be positioned as close as possible to

the mixer on the Econo

of

tubing should be

should already be plumbed through the proportioning valve and mixer on

the Econo

the Econo

System Controller. Connect tubing from the outlet

System controller to the

Pod. Connect tubing from each buffer/sample reservoir (C, D, E) to the corresponding valve port on the Model

the outlet port

of

the valve pod to the Model EP-1 Econo Pump.

System controller and the Econo Pump. The length

of

minimal length and inner diameter. Buffers A and B

of

the mixer on

AlB

inlet port on the Model SV-5 Valve

SV-5 Valve Pod. Connect tubing

17

fro~

Page 22

5.5 Manual Sample Injection Valve

and Chromatography Column

Samples can be introduced into the flow path

of

variety

below.

tem, post-pump; the other allows pre-pump variable injection volumes. The

MV-6 injector valve

three-way valve can be inserted in-line between the pump and the column inlet

or

between the pump and mixer to provide a simple injection port. For details

on automated sample injection, see Section 7.8.

ways. Two methods for manual sample injection are described

One uses preset injection volumes with a classical injection loop sys-

can

be used in both configurations. Alternatively, a

of

the Econo System in a

18

Page 23

Post-Pump Injection with a Sample Loop

1.

The Model MV-6 Injector Valve can be installed in a variety

tions on the rack.

Use the screw fitting on the injector valve housing to

of

loca-

secure the valve.

of

2. Cut a section

tubing long enough to connect the pump and the injec-

tor port. Affix male luer fittings as described above.

of

3. An injection loop

of

tubing

of

a length which corresponds to a desired volume. Table 5.1

a desired volume can be formed by using a section

provides the tubing lengths that correspond to several common loop

volumes.

of

4. Attach a male luer-fitting to each end

the sample loop tube.

5. Connect the inlet line from the pump, sample loop, and outlet line to the

column

as

shown in Figure 5.4. Arrow indicates rotation direction of valve.

Waste

Sample Loop

~

Pump

Fig. 5.5. Tubing connection for post-pump injector valve placement.

Pre-Pump Injection

1.

Install the injector valve on the rack in a location close to the mixer.

2. Disconnect the tubing between the pump and mixer.

3. Connect the mixer to the injector valve, and the injection valve to the

pump, as shown in Figure 5.5. Arrow indicates rotation direction

valve.

Column

of

19

Page 24

Mixer

Sample

Econo

Pump

3-way

Stopcock

Fig. 5.6. Tubing connection for

Table

Tubing

0.8mm

0.8mm

1.6mm

1.6

1.6mm

3.2mm

3.2mm

3.2mm

3.2mm

mm

5.1

Sample Injection Loop Volumes by Tubing ID

10

pre-pump

Loop Tubing

Volume

100

200

200

500

1

500

1

2ml

5ml

injector valve placement.

Jll

Jll

Jll

Jll

ml

Jll

ml

Length

14

em

34em

8.5em

23.5 em

48.5 em

5.9em

12.1

em

24.6 em

62.1

em

Note: Luer fittings and valve internal passages add approximately 60

above volumes.

J..l].

to

5.6 UV Optics Module

and Gradient Monitor Flow Cell

The Model EM-I Econo

as close to the column outlet as possible, to minimize mixing

sample prior to detection. The tubing end used to connect the outlet

matography column should have a female luer fitting attached. Arrows on the

of

top

the optics module are used to indicate flow direction. The tubing ends

to be connected to the inlet

affixed with a male luer fitting. It is important to minimize the length and inner

of

diameter

this section

of

tubing.

UV

Monitor optics module should

and

outlet lines

of

the

UV

20

be

coupled

of

the separated

of

the chro-

monitor should

be

Page 25

Connect the Model EG-1 Econo Gradient Monitor flow cell directly to

or

the inlet

detection.

Warning: Do not overtighten the luer fittings.

5.

7 Model SV-3 Diverter Valve

The Model SV-3 Diverter Valve should be coupled as close as possible

to the UV monitor outlet. The length

length and inner diameter. Connect two sections

fitting on one end and connect to both the collect and waste ports

diverter valve. Direct the tubing from the waste port to an appropriate waste

container. Connect the tubing from the collector port to a fraction collector

or suitable collection device as described in Section 5.8.

outlet port

of

the UV optics module for optimal conductivity

of

tubing used should be

of

tubing with a male luer

of

minimal

of

the

5.8 Fraction Collector

To

connect the diverter valve to the Model2110 Fraction Collector, affix

a male luer fitting to one end

to the female luer fitting to the collection port

Place the other end

drop forming arm. See the Model

ual for details on this connection. Minimizing the length

this connection will improve the accuracy with which peaks are collected.

of

the tubing into the rubber ferrule

of

a length

2110 Fraction Collector instruction man-

of

tubing, and attach this connector

of

the flow diverter valve.

of

the fraction collector

of

tubing used for

Section

Getting

It

is

ule. Refer to Section 2.2

6.1

1.

2.

3.

4. Model EG-1 Econo Gradient Monitor (requires power adaptor)

5.

6. Model 1325

6

Started

After the Econo System is connected and plumbed, it can be powered up.

important that the input voltage match the voltage on the power entry mod-

if

it does not match.

Connecting System to Power

The following line cords need to be connected to power up the system.

Model EP-1 Econo Pump

Model EM-1 Econo UV Monitor

Model

Model 2110 Fraction Collector

power adaptor)

EV-1

Econo Buffer Selector (requires power adaptor)

or

Model 1327 Econo Recorder (optional, both require

21

Page 26

The Model EP-1 Econo Pump will supply the power to the system controller through the ribbon cable connected to the pump base. The Model EM-1

Econo

the gradient monitor, buffer selector, chart recorder and fraction collector. The

UV monitor is powered up with the lamp on. Ensure that the optics module

is plugged into the appropriate socket on the rear panel

The

15

warm up.

UV Monitor is plugged directly into a grounded power source, as are

of

the UV monitor.

UV lamp LED will flash during the first minute

minutes for the UV lamp, and 10 minutes for the gradient monitor to

or

two. Allow at least

6.2 System Check

Before proceeding, it is advisable to check the system for leaks or other

problems.

reservoir containing water. Disconnect any chromatography column during

the test.

To

carry out the test, place buffer lines for buffer A and B into a

0 0

LJ

• 0

0

~

1.

2.

3.

4.

Press the Run/Stop key on the pump front panel.

The run and % light will come on, and the pump

display will read

Press the Waste/Collect key on the system controller

front panel until the waste light is lit. When the valve

cycles between waste and collect, a click should be

If

heard.

controller.

Using the scroll keys on the pump, increase the pump

output to 25%. The pump head should begin to tum.

Over the next 10 minutes, watch for any leaks

bubbles.

tered, press Run/Stop to stop the pump, and repair the

leak and remove air bubbles. Restart the pump.

not, check the connection with the system

If

leaks

0.

or

excessive bubbles are encoun-

or

air

22

Page 27

5.

Press the Purge key on the pump front panel and let

pump operate at

buffer A for several minutes. Again, check for any

leaks in the system. When purging, the diverter valve

be

should

in the waste position.

100% maximum output

(25

rpm)

of

6.

7.

To prime with

Former key (see Figure 3.1) while in the Purge mode.

The Gradient Former indicator light will flash and the

pump display will show a flashing

100% buffer B output.

Note:

E (if the Econo Buffer Selector is being used), the

system must be configured in the Enhanced mode

(See Section 7 .1). Buffers A through E can then be

selected by depressing the Gradient Former key.

Release the key when the desired buffer

on the Econo Buffer Selector display. The valves

will not change until the key is released.

Press the Run/Stop key to stop the pump,

Purge key once more to put the pump into Run mode.

To

prime the buffer lines for buffers C, D, and

100% buffer B, press the Gradient

"b" to indicate

is

displayed

or

the

Section

7

Programming

The Econo System components function in the system configuration

much the same way they do in the stand-alone configuration. For more specific details on the operation

uals supplied with them. This section summarizes the function

in various separation strategies, and various levels

7.1

Getting Started: Verification of Econo System

Software Version

The Model EP-1 Econo Pump must have software version 2.01 or high-

er

to control the Model EV-1 Econo Buffer Selector.

include a Model

does include a Model

sion

of

your system before proceeding:

the

EV-1

System

of

the individual components, refer to the man-

of

If

Econo Buffer Selector, see Section 7

EV-1

Econo Buffer Selector, check the software ver-

of

the system

complexity.

your system does not

.2.

If

your system

23

Page 28

Simultaneously press and hold the Direction Key

and the

Model EP-1 Econo Pump. The four digit LED display on the front panel

play:

If

your Econo Pump displays a number lower than 2.01. it must be

upgraded. Call your local representative for an EP-1 ROM Replacement Kit.

Disconnect the Econo Pump from all connections and replace the ROM following the directions in the

procedure takes about

replacement, please contact your local Bio-Rad representative.

If

your pump currently features software version 2.01 or higher,

ROM upgrade has already been completed, ensure that all connections

between the Econo Pump, Econo

have been completed and the system power is on.

15

"down" Arrow key on the front panel

of

the Econo Pump should dis-

"v2.01"

ROM Replacement Kit. The ROM replacement

minutes.

If

you do not wish to perform the ROM

System Controller and Econo Buffer Selector

or

of

if

the

the

7.2 Econo System Software Mode Selection

Software version 2.01 and higher features two user-selectable programming modes, Standard and Enhanced. The "Enhanced" software mode is

required to use the Model

choice whenever more than two buffers will be controlled, methods longer

than 5 steps or automated sample injection is desired. The "Standard" soft-

is

ware mode

5 steps, including simple binary gradient methods.

the mode

EV-1

of

choice for methods requiring 1-2 buffers, and

Econo Buffer Selector and is the mode

of

1-

To

choose the software mode

1.

_j'o0

@e

2.

tJ~

0 0

0

3.

of

operation:

Stop the pump.

Ensure that the "Gradient Former" light

the "gradient former " button

light off.

While depressing the Diverter Valve Key, press and

hold the Gradient Former Key on the front panel

the Econo System Controller for approximately 3

seconds. The indicator lights on the front panel

Econo

play

Standard Mode or "Enh" for Enhanced Mode.

Pump will flash and the four-digit LED dis-

on

the

pump

will

if

necessary to tum the

display

either

is

off. Press

"Std"

of

of

the

for

24

Page 29

4. To choose a mode, press the Arrow Keys to choose

between

"Std" and "Enh".

5.

~

To accept the selected mode, ensure that it is dis-

played on the four-digit LED display, and press the

Run/Stop Key on the front panel

~

The system will remain in the mode selected until a

different mode is selected (even after power-down.)

The Standard and Enhanced modes have separate

memories. Methods programmed in one mode do

not affect the other.

7.3 lsocratic (Single-buffer) Methods

To

run the system in a simple isocratic mode (use

only the buffer A inlet, use the following procedure.

1.

Ensure that both the Model EP-1 Econo Pump and

Model EM-I Econo UV Monitor are plugged into a

grounded power source. The pump will power up in

UV

the Stop mode, and the

Allow at least

15

minutes warm-up time for the UV

monitor with the lamp

lamp.

of

the Econo Pump.

of

only one buffer) using

on.

o 0.8

0 1.6

03.2

0 CAL

IWCIE (,WPS)

Q

z..o

c

1.0

c o .

.s

"'0·:1~

Cl

0.1

~

"'

.os

"'

...

5\

Q

.01

l.Y..J

01

0

2.

Configure the system

in

the "Std" software mode.

Refer to Section 7.2 for instructions.

3.

Set the desired

UV sensitivity using the arrow keys

on the UV monitor front panel. See the UV monitor

manual for details.

4. When using the system in an isocratic fashion, make

sure that solvent line A

is

being used, and is properly

connected to the proportioning valve. Cap the unused

"B"

port on the proportioning valve.

5.

Calibrate the pump by either choosing one

pre-selected tubing sizes,

or

user-calibrating any

of

three

tubing. See the pump manual for detailed calibration procedures.

6.

With the tubing in place, set the desired pump speed

in ml/min using the arrow keys.

25

Page 30

To

initiate flow, press the Run/Stop key.

To

stop

flow, press once more. Flow rate will be displayed

mllmin. Change the flow to the desired speed

in

while the pump is running by pressing the arrow

keys.

tiB

• 0

0

8

Eluant can be directed

using the two-way diverter valve key located on the

system controller,

plumbed.

Simply press the key

to

suitable collection devices

if

the diverter valve has been

to

light the indicator

light below the figure corresponding to either waste

of

or collect. The default position

the valve is in the

waste position.

Tip: The system can be programmed for automatic shut-off

cratic run. This can be done by programming a total run volume

of

(V

pump will shut off once the total run volume has been delivered. For

detail, see

Tip in the following section.

Time Based Collection

with the Model 211 0 Fraction Collector

To

enable the Model 2110 Fraction Collector:

1.

Connect the fraction collector to the system con-

or

troller

System Cable

Model EP-1 Econo Pump using Econo

1.

the iso-

).

The

1

2.

Press the Fraction Collector key on the Model EP-1

Econo Pump front panel to enter the fraction collector edit mode. In the edit mode, only the flashing

keys are active. Note that the Fraction

indicator lights are flashing, prompting entry

tion size. Enter the fraction size

using the Arrow keys.

entered, press the Fraction Collector key once more

to confirm the fraction size.

3. Enter a void volume

the Arrow keys. See the Model EP-1 Econo Pump

manual for details on the Void Volume (V

tion. Press the Fraction Collector key to confirm this

value and enter the Total Run Volume

If

a void volume is not desired, set V o to zero.

26

(V

After

)

in 1

0

in

Size and

0.1

ml increments

of

ml

frac-

the fraction size is

ml

increments using

)

func-

0

(V

edit mode.

)

1

Page 31

4.

5.

Enter the Total Run Volume (Vt) in 1 ml increments

using the Arrow keys.

the fraction collection scheme is disabled.

data entry, start at Step 2 above. All values previously entered remain in the memory until other values

are entered to replace them.

After entering a

Collection key to confirm the value. The flashing LED

multi-display shows the estimated number

tions to be collected.

If

zero

is

entered and confirmed,

To

resume

Vt

value, press the flashing Fraction

of

frac-

6.

7. For options while running a method, see Section 7.9.

8.

Lf9

le.BFHI

Press the flashing Fraction Collection key once more

to enable the fraction collector.

played in ml/min.

press the

it was not already running. (The fraction collector can

be programmed with the pump running

After the fraction collection program is initiated, the

LED display shows the progression

collection scheme in minutes, to the nearest tenth

minute.

Note: Insure that sample has been injected into the

column before starting a program.

To

abort the fraction collection scheme at any time

during the program, press the Run/Stop key twice.

The pump will stop, and the LED display will read

OFF.

Program Run key after starting the pump, if

To

actuate the fraction collector,

Pump output is dis-

or

stopped.)

of

the fraction

of

a

9.

TIP: The fraction collection control feature

can be used to tum

Simply enter zero for fraction size. After

if

the pump,

The pump will stop automatically when the total run volume has been deliv-

ered.

not already running, then press the flashing Program Run

To

hold a collection program that has begun, press the

lit Program Run key once.

program, press once again.

while the program is on hold will abort the fraction

collection scheme.

of

off

the pump even

if

a fraction collector is not connected.

confirming the V t value entered, start

To

resume the collection

Pressing the Run/Stop key

the Model EP-1 Econo Pump

key.

27

Page 32

7.4 Binary Gradient Formation

The Econo System gradient former functions with the Model EP-1 Econo

Pump and the integral proportioning valve and mixer to form a binary gradient consisting

gradient on the front panel

is by no means the only way to

of

up to five time segments. Note: the graphic display

of

the system controller is provided as a guide,

format

a five segment gradient.

of

and

a

o 0.8

0 1.6

03.2

0 CAL

01

0

1.

The pump must be calibrated in order to form gra-

of

dients. See Section 5.2

the Model EP-1 Econo

Pump manual for details.

2.

Configure the system in the "Std" software mode,

if

not already done. Refer to Section 7.2 for instruc-

tions.

3. The gradient profile can be constructed in the following way:

Inflection

Point Elapsed

I 0

2

3

4

5

6

Time

T2

T3

T4

T5

T6

%B

Bl

B2

B3

B4

B5

B6

4.

5.

Press the gradient key once. The

min

light on the

pump and the pump display will flash "0", to indicate time=O. Press the gradient key once more. The

% light on the pump will flash, along with the light

above the first gradient point on the gradient dis-

0,

or

play. The pump display reads

ly entered value

for initial % B

for%

(B

of

buffer

1)

using the Arrow keys. Confirm

the most recent-

B.

Enter a new value

entry by pressing the Gradient Former key.

The gradient point indicator will then advance to the

next gradient inflection point. Note the flashing

"min" indicator light on the pump. Enter the time

desired for the first gradient step (T2), or leave the

previously entered value unchanged. Confirm this

value by pressing the Gradient Former key.

28

Page 33

6.

The flashing

% LED indicator light prompts entry

of

a % B value for this inflection point (B2). Enter the

new value, and press the Gradient Former key to

confirm this entry and advance to the next gradient

inflection point.

7. Follow steps 4-5 for the remaining gradient points.

8.

9.

10.

If

using fewer than the six inflection points allowed,

scroll through the time and

% points for the remain-

ing gradient inflection points by pressing the Gradient

Former key, without changing the values showing.

Note: The stop indicator light on the pump will flash

at every step during programming to indicate that

this key may be pressed at any time to exit the edit

mode. Upon exit, any changes made to the method

are automatically saved.

After the last % B value has been selected (or left

unchanged) and confirmed, the gradient former will

be enabled, as indicated by the lit Gradient Former

key.

If

a fraction collection program has been entered

previously (note light under the fraction collector

of

icon on pump front panel), the number

fractions

to be collected will be re-estimated and displayed

at this time.

Press the flashing Gradient Former key

a final time. The LED will be lit steadily, indicating

a gradient is programmed and enabled.

At this point, the gradient former

formation.

If

the gradient is not desired, press the

is

set

up

for gradient

Gradient Former key one more time to tum off the

gradient former indicator light.

29

Page 34

To

begin the gradient scheme, press the Run/Stop

If

key to get the pump running.

condition programmed is not

you will hear the proportioning valve clicking as

the system operates at initial gradient conditions.

start the program, press the flashing Program Run

key

on

the pump. The gradient program will begin,

with the LED display showing minutes progressed.

To

observe the other parameters

scroll through with the Arrow keys as described

Section 7.9.

Note: Insure that sample has been injected into the

column before starting a program.

the initial gradient

100% A or 100% B,

To

of

the program,

~n

13. For options while running a method, see

Binary Gradient Time-Based

with

the

Model

The system should be configured in the "Std" mode,

See Section 7.2 for instructions.

0

0.8

orr

0

1.6

03.2

0

0

CAL

oBJ

~

0 v

o

0

v~

0

211

0 Fraction Collector

1.

2.

3.

Calibrate the Model EP-1 Econo Pump as described

in the pump manual.

Enter a fraction collection program as described in

Section 7.3. See Appendix A for connection

fraction collectors.

Program a gradient as described previously.

Collection

Section 7.9.

if

not already done.

of

other

4.

~r7onlo

lQJ~

5.

Start the pump to begin the gradient at initial conditions(%

collection by pressing the flashing

To

discontinue collection only, press the Run/Stop

key twice, and turn off the fraction collector by pressing the Fraction Collector

once more to start the pump, and the Program Run

key to start the gradient at initial conditions.

30

Bl).

Start the binary gradient time-based

Program Run

key.

Then press Run/Stop

key.

Page 35

6.

Note: After the gradient former program has been entered, the total vol-

(Vt)

ume

and estimated number

ed based on the total gradient time and flow rate.

Fraction Collection program to view the adjusted

For options while running a method, see Section 7.9.

of

fractions to be collected will be adjust-

Scroll through the

Vt

and fraction num-

ber values.

7.5 Peak Detection and Collection

The peak detection and separation functions

of

the Econo System allow

the user to discriminate among various chromatographic peaks using either

or

an absorbance threshold programmed into the system,

by setting time

windows, where collection occurs within selected time windows. Both meth-

of

ods

peak collection operate using the Model SV-3 diverter valve, which

functions to divert the eluant stream from a waste line to a collection line. This

collection line can be directed into a fraction collector for more precise peak

breakdown,

gram, gradient former,

tion function.

"Std"

Fig. 7.1. Peak detection and collection features.

or

or

into any suitable collection device. A fraction collection pro-

or

auto shutoff must be used with the peak collec-

Peak detection and collection features may be used in either

"Enh" software modes.

PEAK COLLECTOR

Peak Collection by Threshold

Peak collection on the basis

of

sion

peaks to a fraction collector, while directing non-peak eluant to a

of

threshold detection allows for the diver-

waste container or other collection vessel. This

a peak threshold value in percent full scale

1.

To operate the threshold detection function

UV absorbance.

Econo System, a fraction collection, Vt timer,

gradient formation program must be enabled. See

Section

7.3 and 7.4 for details.

31

is

accomplished by selecting

of

the

or

Page 36

~

~

A:.

)C:

:;~:

..

_;

A

• '0

0

:'0)-

..

,~JU

NO

0

-:~

2.

Press the Peak Collector key until the indicator light

below the threshold icon is flashing. The Pump LED

will read %, prompting entry

for percentage

Arrow keys to scroll up

threshold value. For reference purposes, each green

light on the absorbance display

Econo UV Monitor equals 10%

lights

lit=

50%

of

full-scale absorbance. Use the

or

of

full scale).

down

of

a threshold value

to

select the desired

of

the Model EM-I

of

full scale (five

:A:.

• '0

0

~~

@ ,..

BZJI::·8.3BI..:~

0

08

• 0

0

t!B

• 0

0

o

BJ

~

0

Vo

•

0

v,

0

3. After entry

A

Collection key once more to enable threshold detection. The light below the threshold icon will be lit.

4. To

Run/Stop key, followed by the flashing

Run key.

key twice within 1 second.

5.

•O

>0

6.

When

is in the Waste position, with the light under the

is reached, the diverter valve will switch to Collect,

and a mark

recorder tracing.

If

start

waste icon lit. The pump LED display reads minutes progressed. When the selected threshold value

a void volume has been programmed, the valve

will remain in the waste position for the duration

the

void.

absorbance is above the selected threshold value,

the valve will revert to collect, then back to waste

after the absorbance drops back below the set threshold value. With each valve change, a mark will be

superimposed on the recorder tracing.

of

this threshold value, press the Peak

the

peak

To

Stop the program, press the Run/Stop

Peak Collection is enabled, the diverter valve

will

At

be

the

detection

end

program,

superimposed

of

this time period,

press

Program

on the

the

chart

of

if

the

0

LI

0 0

0

B

7.

The Diverter Valve key allows the user to toggle

back and forth between waste and collect. The Peak

Collection function will override the manual place-

ment

valve has been manually placed into the collect position prior to a peak, when that peak

valve will stay in the collect position, then switch

of

the diverter valve. That is,

if

the diverter

is

detected, the

32

Page 37

to waste on the tail end

value.

of

the peak when the absorbance drops below the set

AA

• '0

8

0

0 0 9

l1 B .

0 0

0

11.

~~0

LQJ~

To change the threshold value during a run, press

·

the

Peak Collection key to enter the edit mode for

by

threshold detection, indicated

under the threshold icon.

indicator lights will now

of

a threshold value in % full-scale absorbance. To

confirm this value, press the

once more. The

changing the threshold setting.

If

the

new

absorbance value currently seen

tor, the diverter valve will switch from collect to

waste, and vice versa

current value.

To terminate the method, press the Run/Stop key

twice within 1 second. For other options while running a method, see Section 7. 9.

pump

threshold

The

show%,

will continue

value

if

the new value is less than the

a flashing light

pump

Peak

is

LED

prompting entry

Collection key

to

greater

by

the

run

than

UV

display

when

the

moni-

Peak

material known to elute at a specific time. The user can select the starting and

ending times for three peaks, as indicated

beneath the three representative peaks (see Figure 7.1). To operate the time

windows method

dient formation feature must be enabled.

Collection by

Peak collection on the basis

AA

0

'i'

0

~0

(•

o o o o

oD

Time

of

peak collection, the fraction collection, V1 timer,

1.

2.

3.

To enter the edit mode for time windows collection,

press the

until the light below the time window icon flashes.

Enter a time value for the starting point for the first

peak in

on the pump.

To

advance to that time window end point, press the

Time Windows key.

Windows

of

time windows will simplify collection

by

the six indicator lights located

Peak Collection key, and continue pressing

0.1 min increments using the Arrow keys

confirm

the

time

window

starting

or

point

of

gra-

and

33

Page 38

/l-6-6

(•

• o o o

oO

4.

Enter the time window endpoint value in

increments using the Arrow keys. Advance to the

next time window starting point by pressing the

Time Windows key.

0.1

min

AA

0

..

0

t!B

• 0

0

~

0

0

5.

6.

7.

if

or

Peak

the

V o is

Repeat steps 2-4 for the remaining two windows,

confirm entry

time window collection feature by pressing the

Collector key. The light beneath the Time Windows

icon will be lit solid, indicating

windows feature.

To

start

Run/Stop key followed by the flashing Program Run

key.

The diverter valve will reside in the waste position

until a time window is reached. At that point, the

valve will switch over to the collect position. The

valve can be manually switched using the Diverter

Valve key. The position determined by the programmed time window feature will override any

manual positioning

superimposed over a time window, the diverter valve

will be in the waste position.

Fraction Collector key.

the

of

that time window and enable the

Time

activation

Windows

of

the valve. However,

program,

To

cancel V

of

press

o'

the time

press the

AA

0 'i'

8.

0

~~o

9.

Changes to the window's start and end points can

be made by stopping the program, scrolling through

the time windows with the Time Windows key, and

entering and confirming the new values as described

Steps 2-4. Pressing the Peak Selector key without

in

changing any

viously entered values and invoke Time Windows.

To

terminate the Time Windows program, press the

Run/Stop

options while running a method, see Section 7.9.

of

the time points will confirm all pre-

key

twice within 1 second.

For

other

34

Page 39

The Time Windows detection function can be run

in tandem with the gradient former to optimize sample collection. Simply program the gradient former

as described above prior to invoking the time win-

dows collection function.

7.6 Programming Multi-Step Methods

(Using the Econo Buffer

Note:

mode

The

Econo System must be configured

for

automated valve control using the Econo Buffer Selector.

Selector)

in

the Enhanced software

you are not familiar with programming the Standard Econo System,

7.1-

7.5

of

please review Sections

10

13

23

33

43

55

55

55

this manual before proceeding.

B

c

D

E

A

A

A

End

If

where:

Table 7.5. A Typical Method Table for a Multi-Step Method. The method outlined

consists of 4 buffers, 1 sample, and 6 steps (7 inflection points).

Programming methods in the Enhanced software mode involves a method

table with a maximum

Table 5.4 and Table 5.4.b.). Each inflection point is defined by an elapsed

(cumulative) time and a buffer/valve position. Any buffer/valve position

may be selected at each inflection point.

A multi-step method is a method which consists

from one buffer to another. The Model

trol up to 5 different buffers (one

can consist

of

up to 8 steps (created by 9 inflection points).

A = Loading Buffer

B

=Sample

C = Elution Buffer

D = Elution Buffer #2

E = Regeneration Buffer

of

9 inflection points (equivalent to 8 steps) (See

of

35

#1

of

a sequence

EV-1

Econo Buffer Selector can con-

which could be a sample) and a method

of

steps

Page 40

o

0.8

0 1.6

03.2

0

CAL

or

0

1.

The Econo Pump must be calibrated: Calibrate the

Model

EP-1 Econo Pump manual.

EP-1 Econo Pump as described in the Model

2.

3.

Press the Run/Stop key to stop the pump.

Press the Gradient Former key once. The pump dis-

play will flash

digit display on the Buffer Selector will flash

cating the first inflection point in the method.

0,

indicating

time=

0. The single

1,

indi-

Note: The Stop indicator light on the pump will flash at every step dur-

to

ing programming

exit the edit mode. Upon exit, any changes made to the method are automatically saved.

4.

indicate that this key may be pressed at any time to

Press the Gradient Former key again. The single-

digit display on the Buffer Selector will still be flash-

1 for inflection

ing

pump

appear on the pump display. (L is used for binary

gradient steps and is explained in Section 7.7.)

will flash, and a letter (A,b,C,d,E,L) will

point

#1. The % light on the

8.

Use the

Confirm the entry by pressing the Gradient Former

key.

The min indicator light on the pump will flash and

the single-digit display on the Buffer Selector will

flash 2, indicating inflection point #2. Using the

Arrow keys, enter the elapsed time desired for the

second inflection point.

Gradient Former key.

The

Arrow

% light on the

keys

to

select a valve

Confirm entry by pressing the

pump

will flash, and a letter

position.

(A,b,C,d,E,L) will appear on the pump display. Use

the Arrow keys to select a new valve position. Press

the Gradient Former key to confirm the entry and

advance to the next inflection point.

Repeat steps 6-7 for the remaining inflection points.

36

Page 41

9.

If

using

points, scroll through the time and % points

remaining method inflection points

Gradient Former key, without changing the values

showing,

Run/Stop key.

*If

viously entered method are not automatically erased.

Ensure

gramming steps will not interfere with the current

method.

After the last elapsed time point has

and confirmed (inflection point

the

"End". Press the Gradient Former key once more

to

enable the method. The Gradient

tor

If

a

entered (the Fraction Collector indicator light

pump

of

will

"F

confirm the gradient program.

indicator light should

fewer

the edit mode is exited, data points from any pre-

that

Buffer

light should be lit.

fraction

front panel will

fractions to

be

re-estimated and the pump display will flash

###".Press

than

the

maximum

or,

exit

the

edit

the

data

points

Selector), the

collection

be

collected

the flashing Gradient

program

be

lit), the estimated

be

lit.

of 9 inflection

by

pressing the

mode

pump

by

pressing

in

the

remaining

been

#9

as displayed

display will flash

Former

was

previously

in

the method entered

Former

The

Gradient Former

for

the

the

pro-

entered

by

indica-

on

the

number

key to

17-nl~

12.

~lQJ

13.

14.

To begin the method, press the Run/Stop key to start

the

pump

start

To

Program Run key on the pump.

The pump display will show a flashing

number

repeat.

to 999. The default for n is

If

a manual sample injection is

method, ensure that sample has been injected into

the column before starting the program.

Press the Program Run key to confirm the entry

"n".

appear on the chart paper.

running at the initial gradient condition.

the

method

of

times the method should automatically

Use the Arrow keys to enter a value from 1

The

method will begin and an event

program,

1.

press

the

"n". "n" is the

necessary

flashing

for

mark

the

of

will

37

Page 42

7.7 Programming Step Methods Which Include

a Binary Gradient (Using the Econo Buffer Selector)

A multi-step method which includes a binary gradient is one

common types

could include:

• column equilibration with a buffer (buffer A)

• automatic injection

• a linear gradient (from 0% buffer B to 100% buffer B)

• column washing with a regeneration buffer (buffer D)

• column washing with a buffer appropriate for column storage (buffer E)

When programming a method, any buffer/valve position may be selected at each inflection point. The relationship between valve positions and

buffers is:

Valve Position:

Buffer:

of

chromatography methods used. For example, such a method

of

a sample (buffer C, >5 ml volume)

A

A

b

b

L

Alb

c

c

of

the most

d

d

E

E

(gradient)

The L (for

inflection point.

Standard software mode.

proportioning and mixing valves on the Econo System Controller before

connecting to the Valve

which a linear binary gradient may be formed. L can be programmed at any

step in the Enhanced method table, and it can be used only once per method

(See Table 7.6.).

"linear") is one choice for the buffer/valve position at each

Lis

identical to the 5-step method that is programmed

Because buffers A and B are plumbed through the

Pod

AlB

inlet port,

Lis

the only valve position in

in

the

38

Page 43

~ection

~<

' . . .

···Point

·:,:

·.

:··

··)

...

:Elapsed time

.'

..

,;

(Dlin)

1

....

0

2 5

3

4

.

5

6

7

8

9

where:

Table 7.6. A

Binary

sample, 7 steps (8 inflection points), and a binary linear gradient

10

15

45

50

60

70

70

Gradient.

i:

=<

ValvefBuffer

>'

,:

,

..

A

c

A

L

A

D

E

E

End

A = Loading Buffer

B = Elution Buffer

C=Sample