Page 1

ECONO

PUMP

GRADIENT

Econo Gradient Pump

Instruction Manual

Page 2

Safety

SAFETY

!

Caution/Warning

Disconnect power to the Econo Gradient Pump before

servicing. No user-serviceable parts are inside the unit.

Refer servicing to Bio-Rad service personnel.

The Bio-Rad Econo Gradient Pump is certified to meet the I.E.C.

1010-1* standard for safety of laboratory equipment. Certified

products are safe to use when operated in accordance with the

instruction manual. This safety certification does not extend to other

chromatography equipment or accessories not I.E.C. 1010 certified,

even when connected to this Bio-Rad Econo Gradient Pump.

This instrument is intended for laboratory use only.

The Bio-Rad Econo Gradient Pump conforms to the “Class A“

standards for Electromagnetic Emissions, intended for laboratory

equipment applications. It is possible that emissions from this product

may interfere with some sensitive appliances when placed nearby or

on the same circuit as those appliances. The user should be aware

of this potential and take appropriate measures to avoid interference.

This instrument should not be modified or altered in any way.

Alteration of this instrument will void the manufacturer’s warranty,

void the I.E.C. 1010 certification, and create a potential safety hazard

for the user.

Bio-Rad is not responsible for any injury or damage caused by the

use of this instrument for purposes other than for which it is intended

or by modifications of the instrument not performed by Bio-Rad or an

authorized agent.

*I.E.C. 1010 is an internationally accepted electrical safety standard for

laboratory instruments.

i

Page 3

Table of Contents

TABLE OF CONTENTS

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Section 1 Introduction . . . . . . . . . . . . . . . . . . . . 1

Section 2 Unpacking and Setting Up . . . . . . . . . 2

2.1 Unpacking Instructions . . . . . . . . . . . . . 2

2.2 Voltage Conversion . . . . . . . . . . . . . . . 3

Section 3 Physical Description and Control Features 4

3.1 Front Panel Functions . . . . . . . . . . . . . 4

3.2 Rear Panel Functions . . . . . . . . . . . . . . 8

Section 4 Tubing Selection and Installation . . . . 10

4.1 Tubing Selection . . . . . . . . . . . . . . . . . . 10

4.2 Tubing Installation . . . . . . . . . . . . . . . . 12

4.3 Platen Adjustment . . . . . . . . . . . . . . . . 13

Section 5 System Operation . . . . . . . . . . . . . . . . 14

5.1 Remote Mode . . . . . . . . . . . . . . . . . . . . 14

5.2 Setup Mode . . . . . . . . . . . . . . . . . . . . . 14

5.3 Manual Mode . . . . . . . . . . . . . . . . . . . . 20

5.3.1 Setting Flow Rate or Motor Speed 20

5.3.2 Setting Buffer Gradient . . . . . . . 20

5.3.3 Setting Auxiliary Valve Control . 21

5.4 Program Mode . . . . . . . . . . . . . . . . . . . 21

5.5 Running a Program . . . . . . . . . . . . . . . 23

5.5.1 Holding a Run . . . . . . . . . . . . . 24

5.5.2 Pausing a Run . . . . . . . . . . . . . 24

5.5.3 Aborting a Run . . . . . . . . . . . . . 24

5.5.4 Power Failure While in Run Mode 25

Section 6 Operation with other Bio-Rad Instruments 24

Section 7 Cleaning and Maintenance . . . . . . . . . 27

7.1 Fuse Replacement and Voltage Conversion 33

Section 8 Troubleshooting . . . . . . . . . . . . . . . . . 35

Section 9 Embedded Functions . . . . . . . . . . . . . 38

9.1 Firmware Confirmation . . . . . . . . . . . . . 38

9.2 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Appendix A Technical Specifications . . . . . . . . . . 39

Appendix B Connection to Other Instruments . . . 41

iii

Page 4

Appendix C Warranty . . . . . . . . . . . . . . . . . . . . . . . 43

Appendix D Ordering Information . . . . . . . . . . . . . 44

Table of Contents

iv

Page 5

Introduction

1.0 INTRODUCTION

The Econo Gradient Pump (EGP) is a two-channel, bi-directional,

variable speed peristaltic pump for low-pressure chromatography and

general laboratory use. It offers a full range of features to facilitate

ease of use as a stand-alone pump or as a part of the BioLogic

Duo-Flow System running software version 3.0 or later..

As a stand-alone pump, the EGP delivers flow rates from 2 µl/min to

40 ml/min using a single channel of 0.51 mm or dual channels of 3.2

mm ID tubing respectively. The EGP has the ability to self-calibrate

the flow rate for 0.51, 0.8, 1.6, and 3.2 mm ID tubing, displaying pump

output in ml/min. The pump can be programmed to start or stop

Bio-Rad fraction collectors and chart recorders.

A membrane key panel with graphic icon displays allows easy user

interface. The EGP will store one program in its non-volatile memory.

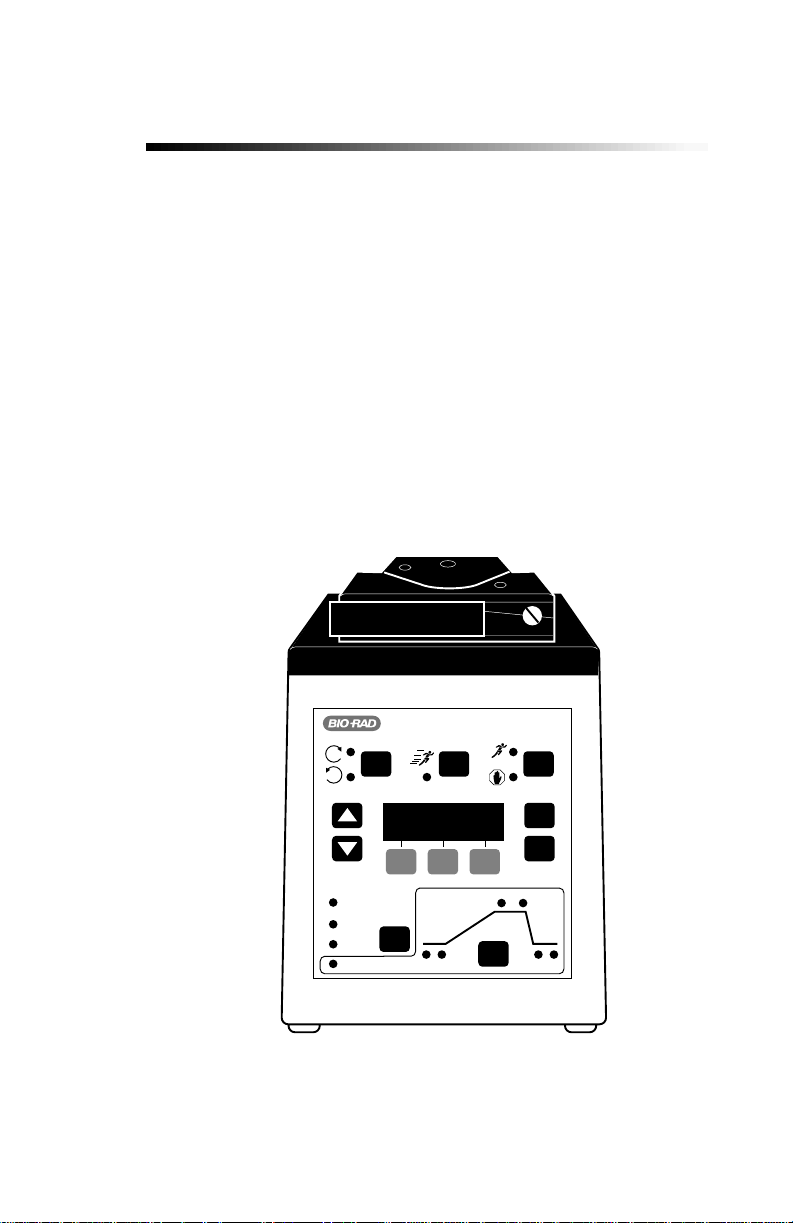

ECONO GRADIENT PUMP

Reverse

Remote

Setup

Manual

Program

Mode

RunPurge

Next

Cancel

Step

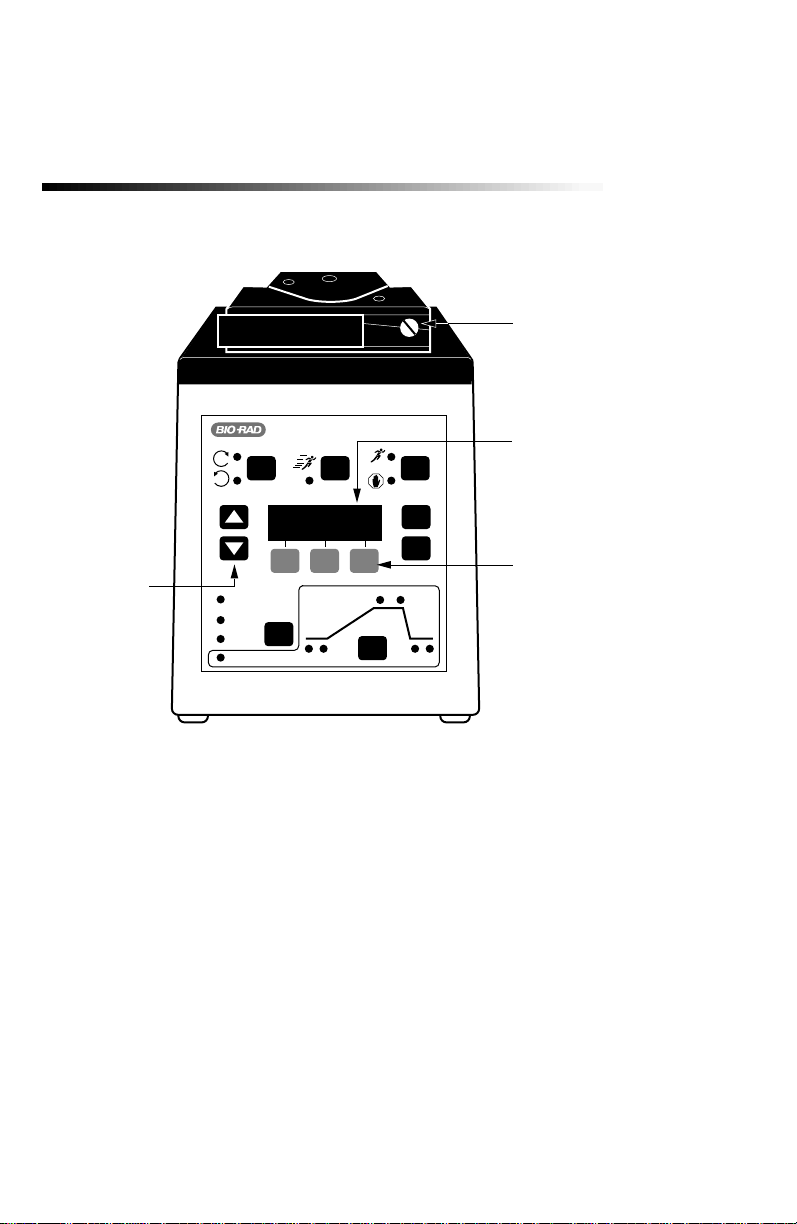

Figure 1-1. Econo Gradient Pump.

1

Page 6

Unpacking

2.0 UNPACKING AND SETTING UP

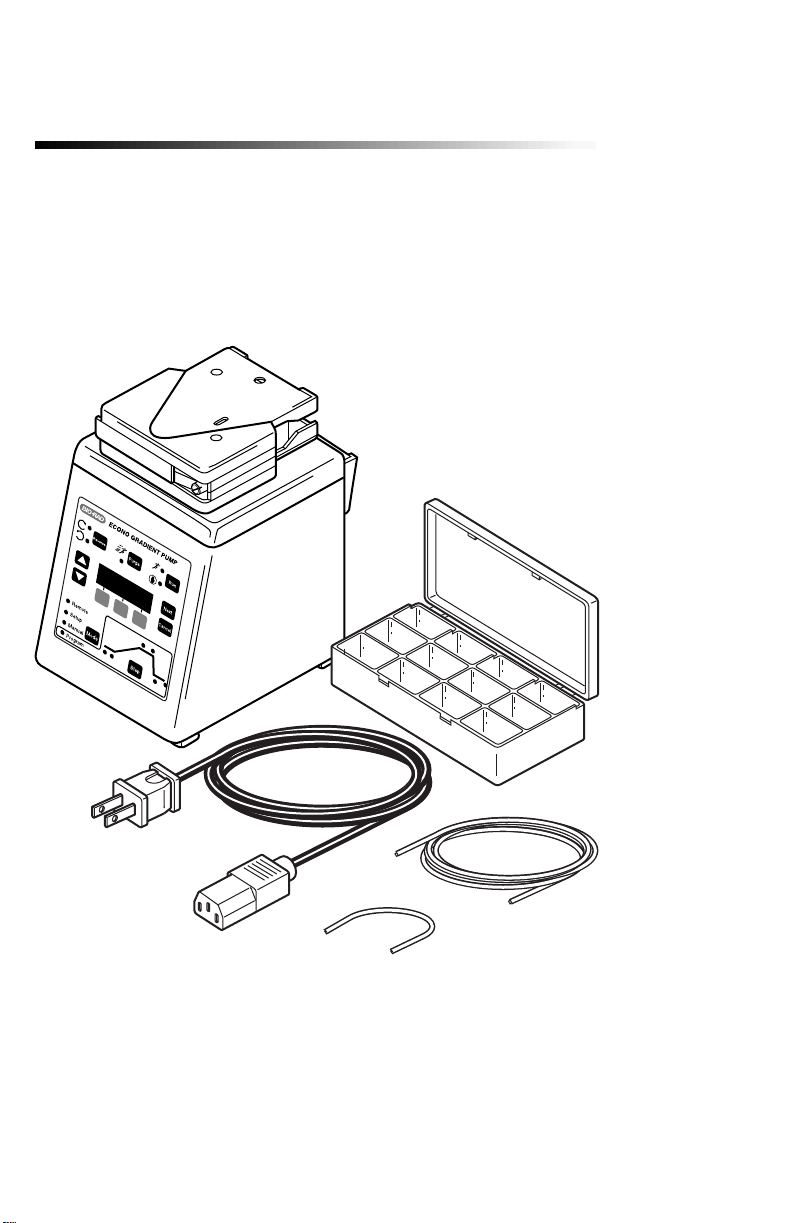

2.1 UNPACKING INSTRUCTIONS

Carefully remove the unit from the shipping box, lifting from the

handle on the back of the pump or from the bottom of the instrument.

Remove the plastic bag and inspect the instrument for any external

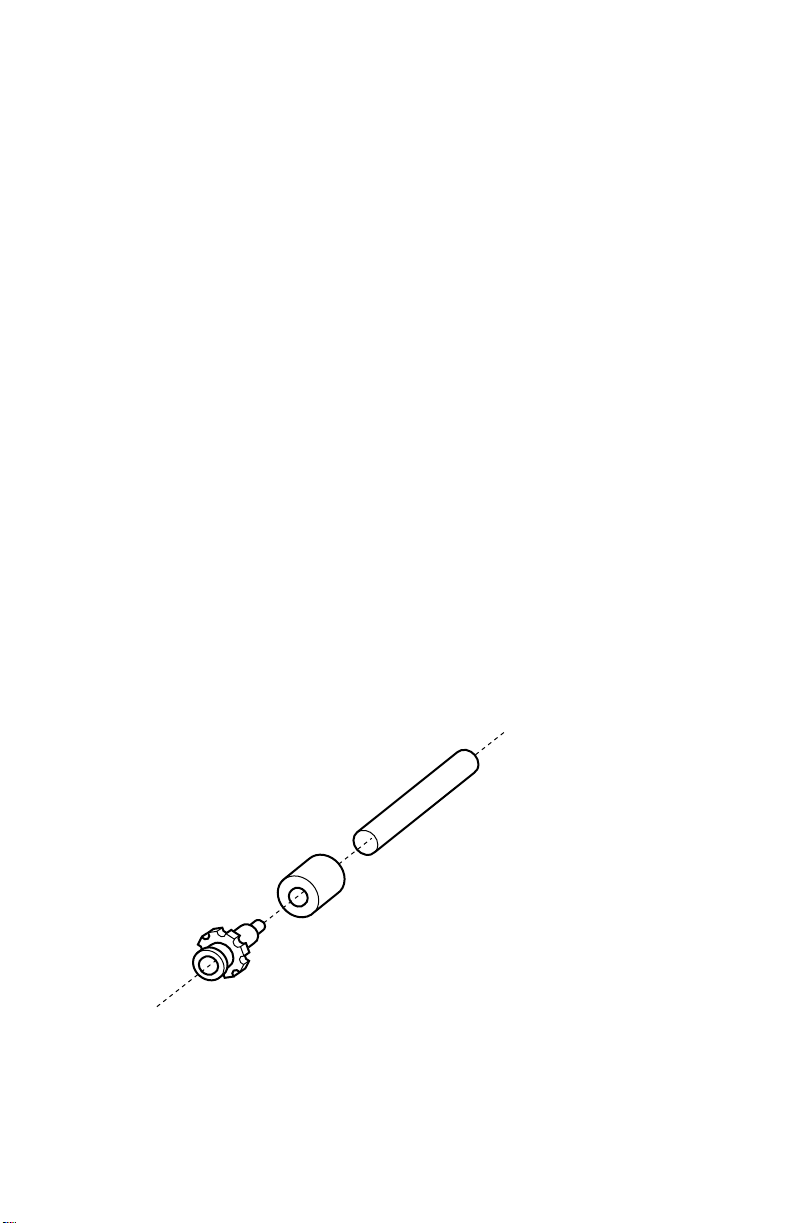

damage. Figure 2-1 shows the contents of the box.

Model EGP

Econo Pump

Low-Pressure

Fittings Kit

Power Cord

Pumphead

Tubing

Figure 2-1. Parts supplied with the Econo Gradient Pump.

2

System

Tubing

Page 7

Unpacking

Your Econo Gradient Pump was carefully tested at the factory and

was shipped in good working order. If any part is missing or

damaged, contact your local Bio-Rad office immediately.

2.2 VOLTAGE CONVERSION

Warning: The Econo Gradient Pump is shipped in its 100/120 V

configuration. To operate at 220/240 V, refer to the procedure in

section 7, Cleaning and Maintenance, to make the conversion.

Failure to follow this procedure may result in damage to the unit and

invalidation of the warranty.

3

Page 8

3.0 PHYSICAL DESCRIPTION AND CONTROL

FEATURES

3.1 FRONT PANEL FUNCTIONS

Figure 3-1. Front Panel Controls and Displays.

Description

4

Platen

Arrow Keys

ECONO GRADIENT PUMP

Reverse

Remote

Setup

Mode

Manual

Program

LCD Display

RunPurge

Next

Cancel

Soft Keys

Step

Page 9

Front Panel Function

[LCD; see figure 3-1] LCD Display

This display has two rows of 16 characters.

Different windows will appear on this display

depending on the requests made by the

user. Some windows will display operating

parameters, while others will allow entry of

variables such as flow rates, valve position

and programming steps. Choices are shown

in the lower row, above one of the three soft

keys. A selection is indicated in uppercase

letters.

Soft Keys

These keys are used to select choices

displayed on the LCD. A selection is

indicated in uppercase letters. Pressing and

holding a soft key and an arrow key acts to

accelerate the action of the arrow keys.

Arrow Keys

These keys are used for setting system

parameters when programming the system,

and for selecting which parameter to display

when running the pump. A value input with

the arrow key can be erased or accepted

with the Cancel and Next keys respectively.

Pressing and holding an arrow key will

accelerate the action of the arrow keys.

Next Key

Pressing Next will accept any values

displayed in the current window and

advance to the next window.

Description

5

Next

Page 10

Description

Front Panel Function

Cancel Key

Cancel

Pressing Cancel will clear an entry that has

been input with either the arrow or soft keys.

If no entry has been made, the previous

window will be displayed. This allows

passage through the windows in the reverse

direction.

Run/Stop Key

Run

This key is used to start or stop the pump in

both Manual mode and Program mode

operation. The pump will run in the clockwise

direction by factory default. The green and

red LEDs are illuminated when the Econo

Gradient Pump is running or stopped,

respectively. The direction can be changed

using the Reverse Direction key, when the

pump is stopped.

Reverse

6

Reverse Direction Key

This key changes the direction of pump

head rotation. The Econo Gradient Pump

must be stopped before the direction can be

changed. This key is not operable when the

pump is running. The yellow and orange

LEDs are illuminated when the pump is

running clockwise (CC) and counterclockwise (CCW), respectively.

Page 11

Front Panel Function

Purge Key

Purge

Mode

This key is used to prime and purge tubing

lines without disturbing the primary speed

setting of the pump. When Purge is pressed,

the pump will run at maximum speed (25

rpm), leaving the connected Gradient Mixer

and Aux valve operating and the fraction

collector and chart recorder off. The yellow

purge LED is illuminated when purging. This

key is not operable when the pump is

running in Program mode. Purge can be

stopped by pressing the Purge or Run keys.

Mode Key

Four different operation modes are

available: Remote, Setup, Manual, and

Program modes. These modes are

described in Section 6, System Operation.

Description

Step Key and LEDs

Step

[Platen; see figure 3-1] Platen Screw

Up to six program steps can be used. This

key selects the active step for programming.

The Step LEDs indicate which of the six

steps is active.

This is the screw on the pumphead

assembly. Proper adjustment of the platen

pressure increases flow stability, minimizes

flow pulsation, and prolongs the life of the

tubing. It should be adjusted 3-5 turns,

depending on tubing diameter. Refer to

section 4.3 for more details.

7

Page 12

Description

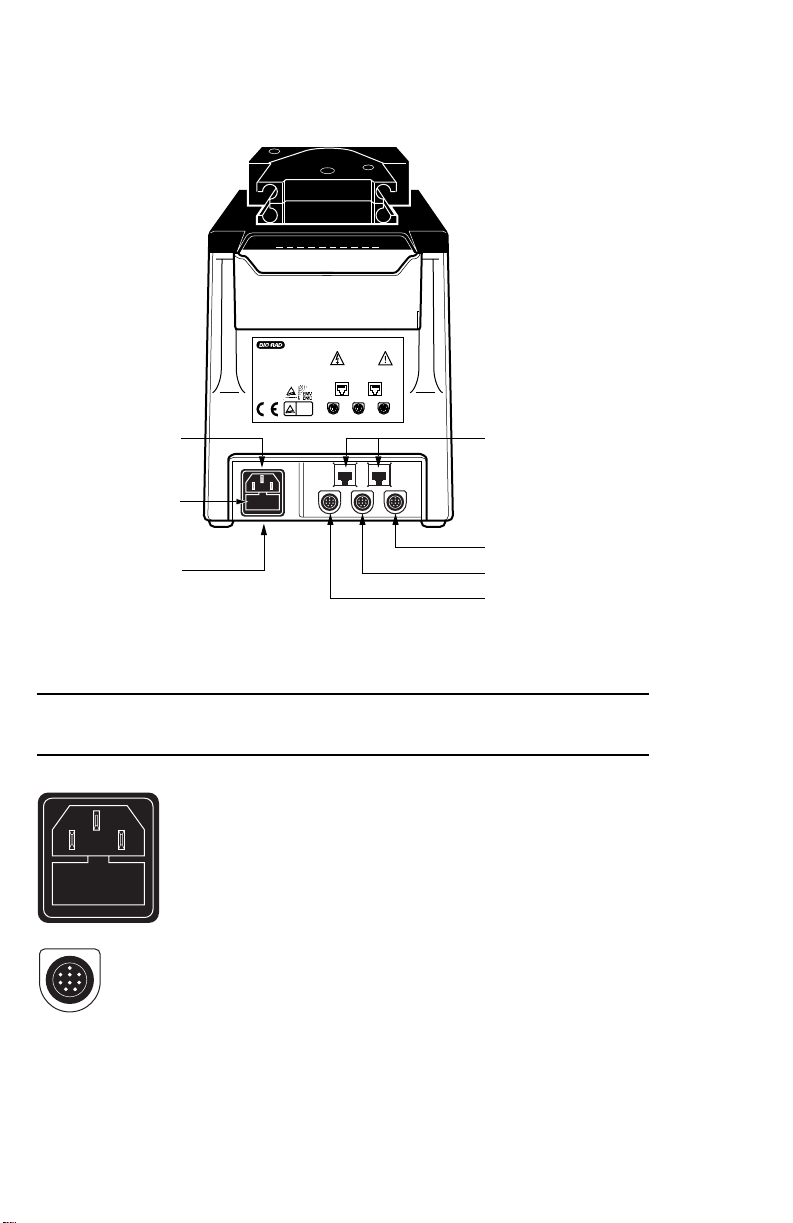

3.2 REAR PANEL FUNCTIONS

Made in U.S.A.

Model No. Econo Gradient Pump

Serial No. 491 BR

AC Voltage

Max Current

0.4 A

0.2 A

Frequency

50-60 Hz

50-60 Hz

Fuse Type

0.4 A

0.2 A

EN

61010-1

Power

Entry Module

Fuse Holder

CAUTION

WARNING

Warning: Disconnect supply before servicing.

Advertissement:: Couper l'alimentation avant

l'entretien et depannage.

INSTR BUS

INSTR BUS

AUX VALVE

I/O

MIXER

Instrument

Bus

Power Switch

(Located

Under the Unit)

Figure 3-2. Rear panel connectors.

Display Function

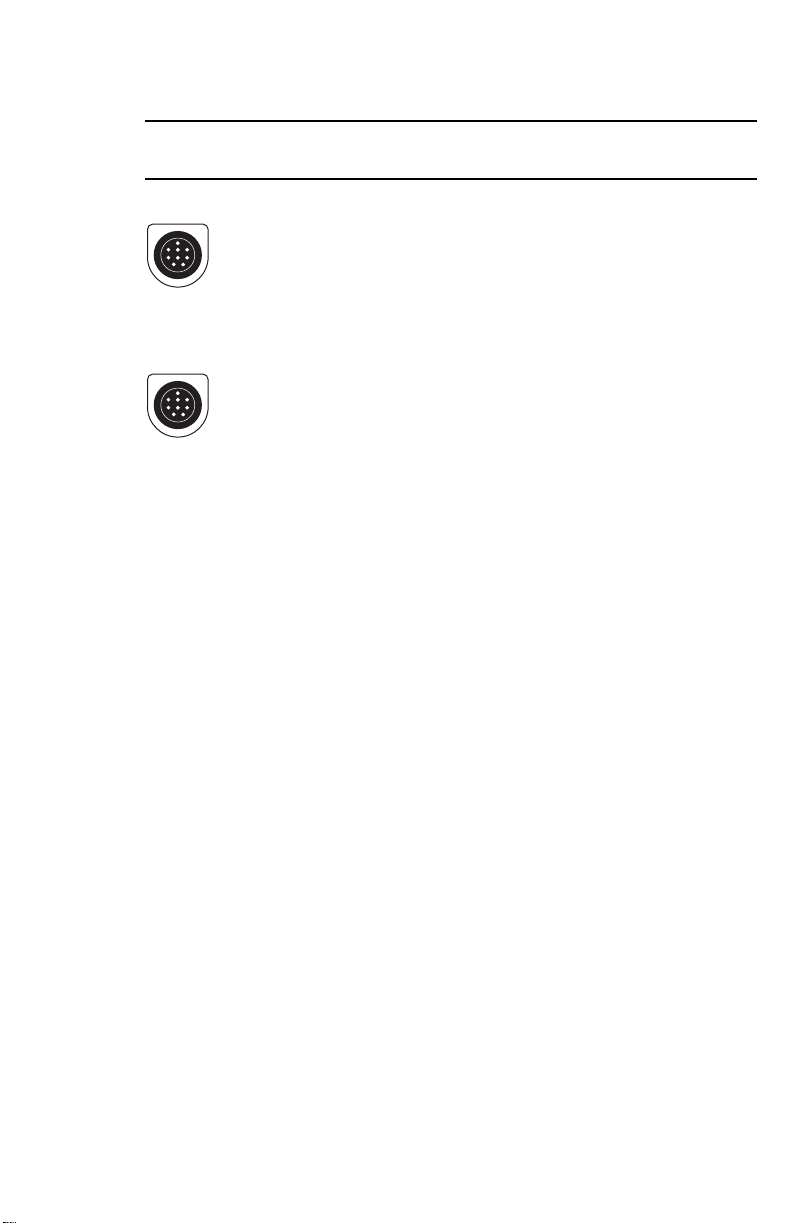

Power Entry Module

Grounded 3-pin receptacle for the power

cord. Also contained within is a two-position

(100-120 V/220-240 V) fuse holder.

Gradient Mixer Connector

This 8-pin outlet controls the Gradient Mixer

used for making binary linear gradients.

Mixer

Aux Valve

I/O

8

Page 13

Display Function

Aux Valve Connector

This 8-pin connector controls auxiliary

valves such as the optional SV-3 Diverter

valve or the optional Splitter valve.

I/O Connector

This 8-pin outlet provides start signals to the

Model 1327 Chart Recorder, the Model 2110

Fraction Collector, or the Model 2128

Fraction Collector. Simultaneous control of

both the Model 2110 and the Model 1327, or

the Model 2128 and the Model 1327, can be

accomplished via the 2110-Y cable and the

2128-Y cable respectively. I/O connector

pinouts are given in Appendix B. A TTL input

is also present which allows the pump to be

started remotely.

Description

[base; see figure 3-2] The underside of the Econo Gradient Pump

contains the power switch.

9

Page 14

4.0 TUBING SELECTION AND INSTALLATION

4.1 TUBING SELECTION

The Econo Gradient Pump may be used with most flexible tubing

having an inner diameter less than or equal to 3.2 mm (1/8”), and a

wall thickness of 1.0 mm or less, including Silicone, Tygon, and

PharMed. Silicone tubing, the most inert of the three, is suitable for

aqueous and polar solutions. Tygon is suitable for most aqueous

solutions. It will generally have the shortest lifetime of the three and

should not be used for the pumphead. PharMed is the longest lasting

of the three, and will provide the most consistent flow rate over time.

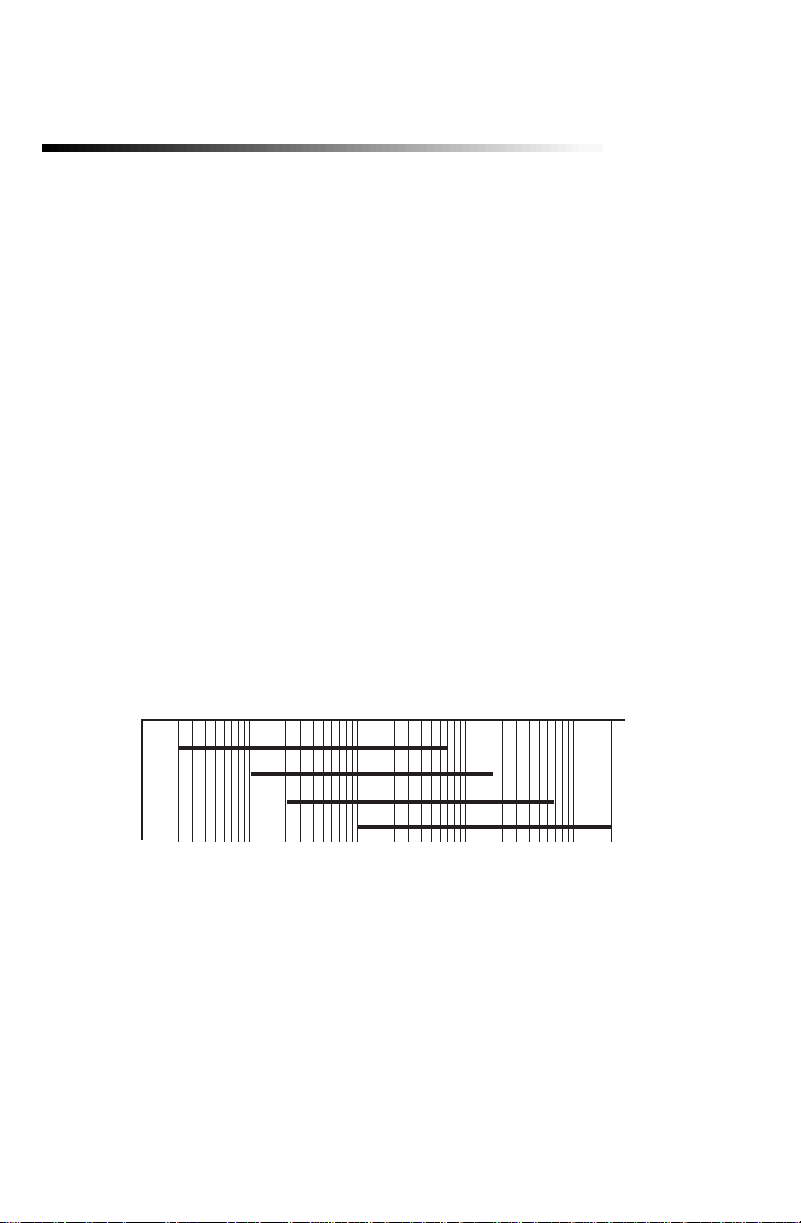

Figure 4-1 shows approximate flow rate ranges with different tubing

sizes. Flow rates above 20 ml/min may be obtained by plumbing two

channels of 3.2 mm tubing through the pump and joining them at the

output.

Very low flow rates can be achieved with tubing having ID as small as

0.51 mm. Tubing this small must be jacketed inside larger tubing and

requires an adapter. These items are included in the optional splitter

valve kit.

Figure 4-1. Approximate Flow Rate Ranges.

Tubing length and the amount of tubing prestretch have a significant

effect on both flow rate calibration and reproducibility of flow. The

PharMed tubing supplied with the Econo Gradient Pump has been

cut to a predetermined length to accommodate tubing prestretch.

(Silicon tubing in precut lengths is also available from Bio-Rad. See

ordering information in Appendix D.)

Tubing Selection

10

m

TUBING SIZE

(ID x WALL)

.001 .002 .005 .01

0.51 x 0.8 mm

0.8 x 0.8 mm

1.6 x 0.6 mm

3.2 x 0.8 mm

FLOW RATE RANGE (ml/min)

.02 .05 .10 20.20 .5 1.0 2510

ml/

Page 15

Tubing Selection

When using tubing other than precut tubing from Bio-Rad, the tubing

must be cut to the following lengths to accommodate prestretch:

Tubing Length

Tygon, PharMed 179 mm +/- 1.5 (7.04” +/- 0.05)

Silicone 171 mm +/- 1.5 (6.75” +/- 0.05)

Install tubing onto the pump head as described in Section 4.2.

Warning: If using tubing other than the type supplied by BioRad, make sure the wall thickness is not greater than 1.0

mm. Using tubing with a greater wall thickness can damage

the pump and void your warranty.

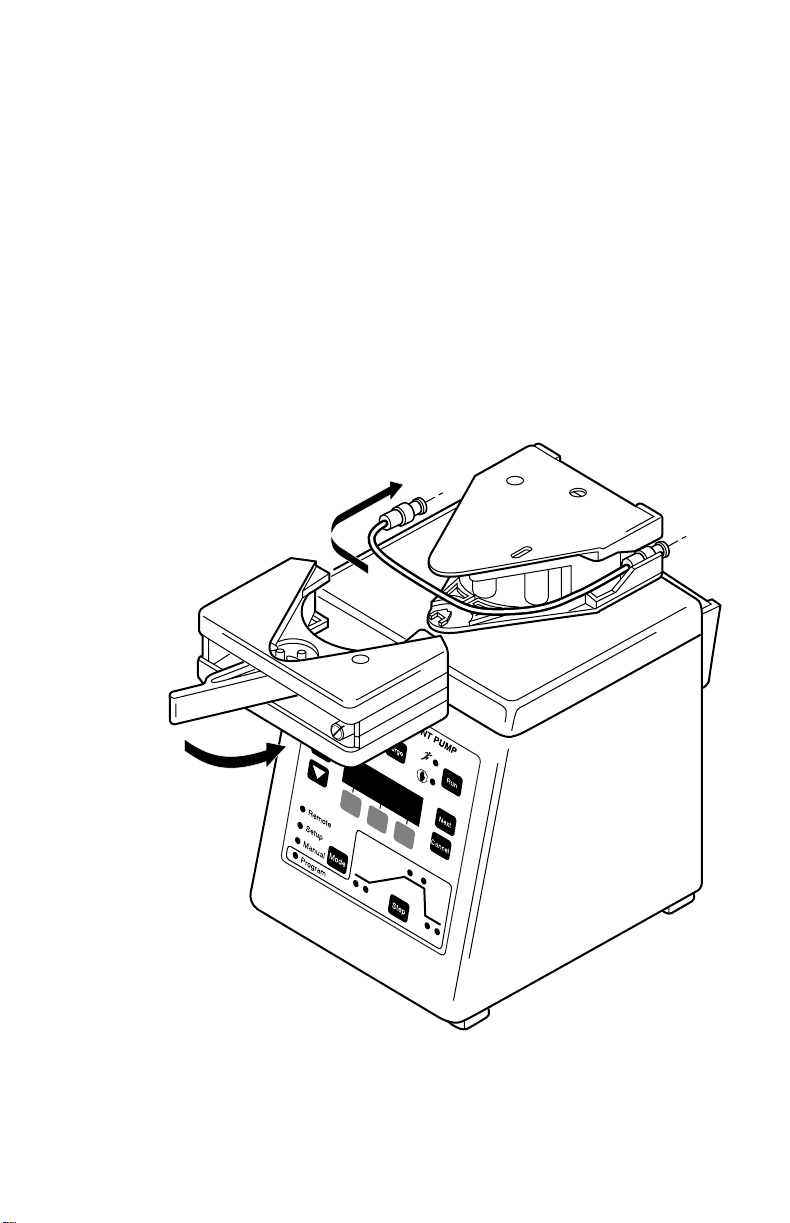

Figure 4-2. Tubing installation.

11

Page 16

Tubing Selection

4.2 TUBING INSTALLATION

1. Referring to Figure 4-2, pull the platen cam lever away from the

pump head to unlock the platen and slide the platen away from

the pump head frame assembly, exposing the rollers.

2. Slip a lock-ring onto one end of the tubing. See below for the size

and color of each lock-ring. Insert a barbed female luer fitting into

the same end until the tubing reaches the flange of the fitting.

Clamp the luer-fitting into place by sliding the lock ring along the

tubing over the barbed fitting (see Figure 4-3). Repeat on the

other end of tubing.

Note: Use of lock-rings is required only when operating at

pressures above 10 psi.

Tubing ID Lock-Ring Color

0.51 mm (.02”)* None Required

0.8 mm (1/32”) Red

1.6 mm (1/16”) Orange

3.2 mm (1/8”) Yellow

*

The 0.51 mm ID tubing is placed inside the 3.2 mm ID tubing, thus no lockrings are required for the smaller tubing.

12

Figure 4-3. Attachment of tubing fittings.

Page 17

3. Insert one end of the tubing into the tubing retaining bracket of

the pump head. Lightly pull the tubing around the rollers to

remove slack. Attach the other end of tubing into the tubing

retaining bracket on the opposite side of the pump head.

4. Slide the platen back into the pump head frame assembly until it

rests up against the tubing. Press the cam lever in toward the

pump head, locking the platen up against the tubing and rollers.

The platen may be inserted with the cam lever on the left or the

right.

4.3 PLATEN ADJUSTMENT

Proper adjustment of the platen pressure increases flow stability,

minimizes flow pulsation, and prolongs the life of the tubing.

Once the tubing is installed, completely loosen the platen adjustment

screw counterclockwise until the stop is reached. Use the information

in the table below to determine the appropriate number of turns that

are required.

Overtightening the platen adjustment screw will reduce flow rate and

shorten tubing life. If the platen is too loose, flow rate will decrease as

backpressure increases. The platen must be adjusted each time

pumphead tubing is replaced.

Tubing ID Number of Turns

from Fully Open

0.8 mm (1/32”) 5

1.6 mm (1/16”) 4

3.2 mm (1/8”) 3

Tubing Selection

13

Page 18

System Operation

5.0 SYSTEM OPERATION

There are four modes of system operation:

• Remote

• Setup

• Manual

• Program, including running the system

5.1 REMOTE MODE

The Econo Gradient Pump can be connected to the BioLogic

Duo-Flow Workstation running software version 3.0 or later with an

Instrument bus cable (System cables 17, 18, 19, or 21). When the

BioLogic assumes control of the Econo Gradient Pump, the Econo

Gradient Pump is automatically set to Remote Mode. In Remote

Mode, the Econo Gradient Pump keys provide limited control,

allowing only basic observation of Econo Gradient Pump operating

parameters.

5.2 SETUP MODE

Each of the pump’s features can be customized in Setup mode.

While the pump is stopped, plug in the desired valves (i.e., Gradient

Mixer, SV-3 Diverter valve, or Splitter valve) into the connectors on

back. (Note, these valves must be plugged in before any run requiring

them is started.) Then press the Mode key until the Setup LED is

illuminated. Each of the Setup windows is discussed on the following

pages.

Note: When a selection is made, it will be displayed in capital

letters.

14

Page 19

System Operation

Screen 1. Flow Rate Selection.

Use the soft keys to select either RPM (revolutions per minute) or

ml/m. This information will be used in writing a protocol from the

Program mode and in using the Manual mode.

• If RPM is selected, the user may control the pump speed in

revolutions per minute (RPM). Pressing Next skips to screen 9.

• If ML/M is selected, the user is required to calibrate the pump.

This choice enables the user to control the pump speed in ml/m.

Pressing Next continues to screen 2.

1 Flow rate

RPM ml/m

Screen 2. Pump Calibration.

The tubing ID is selected here. Calibration can be accomplished by

either entering the tubing ID or actually measuring the flow rate.

• If you select “Tube ID” pressing Next continues to screen 3.

• If you select “flow” pressing Next skips to screen 4.

2 Calibrate by

TUBE ID flow

Note: Flow rate depends on condition of tubing, platen adjustment,

and back pressure. For maximum flow rate accuracy, calibrate the

flow rate as the tubing ages or becomes worn, when the tubing is

replaced, if the platen is readjusted, or if back pressure changes

significantly.

Screen 3. Pump Calibration by Tubing ID.

The tubing ID can be entered here. Use the arrow keys or the center

softkey to scroll through the available tubing ID choices. The pump

calibration is estimated from this. Enter the tubing ID and press Next

to accept the value and advance to screen 6.

3 Enter tube ID

___ mm

15

Page 20

System Operation

16

Screen 4. Pump Calibration by Measured Flow.

Pressing the left or right soft keys will start the pump for the selected

time. Collect the pump effluent in a graduated cylinder. During

calibration, the pump runs at half speed (12.5 RPM). Typical volumes

collected after a 2-minute run are 20 ml, 6.4 ml, 1.7 ml, and 700 µl for

tubing IDs of 3.2 mm, 1.6 mm, 0.8 mm, and 0.51 mm respectively.

The volume collected is entered in screen 5.

4 Start cal run

2m 20m

The time remaining in the calibration run will be displayed as shown

below. It is not necessary to run a calibration to completion.

Time = _min: _s

End ABORT

• End: Ends volume collection and continues to screen 5,

permitting flow rate calibration, before the timer reaches 0

minutes.

• Abort: Ends volume collection and returns to screen 1,

disallowing flow rate calibration.

Screen 5. Calibrated Volume.

When the calibration run ends, enter the volume of liquid that was

collected.

5 Volume ?

_ ml

Press Next to accept the entered value and advance to screen 6.

Press Cancel to return to screen 4 and repeat the calibration.

Page 21

Screen 6. Selecting Units for Programming.

Programming steps can be described in either units of time (in

minutes) or volume (in ml).

6 Program Steps

TIME vol

Pressing the left soft key selects time; the right key selects volume.

Pressing Next advances to screen 8 if a Splitter valve is present or

screen 9 if a Splitter valve is not present.

Screen 7 (not displayed). This is available for future upgrades.

Screen 8. Splitter Valve Period Selection.

The Econo Gradient Pump automatically detects the presence of a

splitter valve. The default period is 2 seconds. This parameter, in

conjunction with the “%-split” parameter, may be varied for stream

splitting, process sampling, or on-line biological activity assays. More

information is included in the splitter valve instruction manual. If you

are uncertain about this value, accept the default of 2 seconds and

adjust it later according to your application needs.

8 Split period

__ sec

Enter a new value for the split period and press Next to advance to

screen 9.

System Operation

17

Page 22

System Operation

Screen 9. Biologic System Address Number.

The Econo Gradient Pump can be connected to the BioLogic HR or

BioLogic Duo-Flow workstation via an Instrument bus cable (System

cables 17, 18, 19, or 21). When connected, the address of the Econo

Gradient Pump must correspond to the address recognized by the

BioLogic System. This address is only relevant when the Econo

Gradient Pump is connected to the BioLogic System. The default

address is 1.

9 Address #

001

Use the arrow keys to enter a new address, and press Next to accept

and advance to screen 10.

Screen 10. Revolutions Counter.

The performance of the peristaltic tubing degrades with use. This

revolution counter provides a measure of wear experienced by the

tubing. The relation between revolutions and tube life must be

empirically determined because it is dependent on several factors

including load, tubing type and platen pressure.

10 Revolutions=

Reset ___

Pressing the Reset softkey resets the counter back to 0. Pressing

Next will accept the displayed value and advance to screen 11.

Screen 11. LCD Contrast.

The LCD display contrast is set here.

11 LCD Contrast

__%

Use the arrow keys to enter the desired contrast and press Next to

advance to screen 12.

18

Page 23

System Operation

Screen 12. Beeper.

The beeper can be switched on or off at the user’s discretion. The

beeper, which beeps on each key press, can be disabled.

12 Beeper

ON off

Using the soft keys, select the desired option and press Next to

accept and advance to screen 13.

Screen 13. Erase Program Option.

The Econo Gradient Pump will store one program in its non-volatile

memory. The program stored in the Program mode can be erased by

selecting the “yes” option. This is useful for writing a new protocol.

Pressing Next will erase the program if “yes” has been selected.

13 Erase Program

yes NO

Screen 14. Selecting a Fraction Collector.

Three choices are available: NONE, 2110, and 2128 Fraction

Collectors. The choices are selected using the arrow keys. These are

operated by the pump only when they are connected to the pump’s

I/O port. Press Next to proceed to the last setup screen.

14 Fraction

collector: NONE

Final Setup Screen.

The final Setup screen allows you to exit setup by pressing the Mode

key. Alternatively, the Mode key may be pressed to exit Setup at any

of the preceding screens.

Press MODE to

exit Setup

19

Page 24

5.3 MANUAL MODE

The Econo Gradient Pump and attached devices can be controlled

using the pump’s front panel membrane keys and LCD display while

in Manual mode. Press the Mode key until the Manual LED is

illuminated. Up to three parameters (depending on how many

optional devices are connected to the Econo Gradient Pump) can be

controlled. Choose a field on the LCD by pressing the corresponding

soft key. The selected parameter can be adjusted using the arrow

keys. Pressing the Up arrow key will raise the value of the parameter,

pressing the Down arrow key will lower the value. Pressing and

holding a soft key acts to accelerate the action of the arrow keys.

5.3.1 Setting Flow Rate or Motor Speed

Either RPM or ml/min will be displayed, depending on the setting in

Setup, screen 1. Flow rate or motor speed is selected by pressing the

left soft key. The speed is adjusted by depressing the arrow keys. If

neither a Gradient Mixer nor an auxiliary valve are connected, the

LCD looks like this:

RPM Selected Flow Rate Selected

RPM ml/m

3.45 6.40

5.3.2 Setting Buffer Gradient

Buffer gradient (%B) is selected by pressing the center soft key. This

option is only available if the Gradient Mixer is connected to the

pump’s Mixer connector. The percent of the gradient is adjusted using

the arrow keys. Pressing and holding a softkey acts to accelerate the

action of the arrow keys.

ml/m %B

3.45 0

System Operation

20

Page 25

System Operation

5.3.3 Setting Auxiliary (SV-3 or Splitter) Valve Control

Control for an auxiliary valve is selected by pressing the right soft key.

This option is available if a valve is connected to the Auxiliary port on

back of the Econo Gradient Pump. The valve type is automatically

recognized. The SV-3 diverter valve must be connected if you wish to

program a collection window with either the model 2110 or 2128

Fraction collector. With an auxiliary valve and Gradient Mixer

attached, the LCD display would look like this:

with Mixer and Diverter valve with Mixer and Splitter valve

ml/m %B Divert ml/m %B Split

3.45 100 WASTE 3.45 100 100%

5.4 PROGRAM MODE

The Econo Gradient Pump can be programmed to perform up to six

sequential steps automatically. Selections made in the Setup screen

will be reflected in the Program screen. The Program screen will

display the program step (either time or volume), the %B if a Gradient

Mixer is present, and the flow rate/motor speed (RPM.) For the first

program step, the time (or volume) parameter is -0- and is not

editable. Here is an example of a Program screen where volume and

flow rate have been selected in Setup and a Gradient Mixer is

connected.

ml %B ml/m

-0- 15 5.0

21

Page 26

System Operation

Each field may be selected with the corresponding soft key. The

arrow keys are then used to increment or decrement the value.

Pressing the Step key or the Next key will accept the displayed

values and advance to the next step. The program end occurs when

either 6 steps have been entered, or two identical steps (pressing

Step twice) are entered sequentially.

If an auxiliary valve is present, a screen will appear after

programming is completed.

If an SV-3 diverter valve is connected, then a fraction collection

window will appear. The units will be either in minutes (m) or

volume (ml.)

from COLLECT to

2m 10m

In this example, the valve will be in the DIVERT position from t =

2min to t = 10min, diverting the eluant stream to the fraction

collector. All other times, it will be in the WASTE position, diverting

the eluant stream to waste. Fraction collection size is programmed

directly at the fraction collector faceplate.

If a splitter valve is connected, then a split per cent window appears

splitter

25%

In this example, 25% of the eluant stream is split into another

receptacle such as a microplate or secondary fraction collector.

Pressing the Step key scrolls through each step, illuminating the LED

for that step and allowing the user to observe and edit the program.

At the AUX Valve screen, LEDs for all the programmed steps are

illuminated. The program may be deleted using the ERASE function

in Setup mode.

22

Page 27

System Operation

5.5 RUNNING A PROGRAM

To start a program (be sure to enter the Program mode by using the

Mode key), press the Run key. This will start the run. By using the

right soft key, the Run screen can show time elapsed or time

remaining on the run. If program steps are in volume, elapsed or

remaining volume will also be displayed.

Time elapsed Time remaining

__m: __s __mm: __s

__ml elapsed __ml left

Pressing the Next key will show the current gradient conditions:

with Mixer and Diverter valve with Mixer and Splitter valve

ml/m %B Divert ml/m %B Split

If the program is allowed to finish normally, the Econo Gradient Pump

beeps and displays the following screen:

Program Finished

Pressing any key will put the Econo Gradient Pump into Manual

mode.

The run may be interrupted by pressing the Next key twice. Doing so

brings up the following screen:

Hold Pause Abort

23

Page 28

System Operation

5.5.1 Holding a Run

Pressing the Hold key displays the following screen:

Holding ___%B

CONTINUE Abort

When holding, the pump runs indefinitely at the current programmed

conditions. Selecting Continue will continue the run. Selecting Abort

will stop the run, leaving the pump in Program mode, and indicate, by

the Step LED, which step was running at the time Abort was pressed.

5.5.2 Pausing a Run

Pausing a run stops the pump and displays the following screen:

Paused ...

Continue Abort

Selecting Continue will continue the run. Selecting Abort will stop

the run leaving the pump in Program mode and indicating, by the

Step LED, which step was running at the time. Press any key to

return to the Manual mode.

5.5.3 Aborting a Run

Aborting a run displays the following screen:

Program Aborted

The run is stopped, and the pump remains in Program mode and

indicates, by the Step LED, which step was running at the time. Press

any key to return to the Manual mode.

24

Page 29

5.5.4 Power Failure While in Run Mode

In the event of a power failure while a Program is running, the LCD

display will indicate:

Power Failure!

CONTINUE stop

If Stop is selected, the program that was running is aborted.

Pressing any key on the front panel will display the Manual mode. If

Continue is selected, the program that was running is resumed at the

point where the power failure occurred.

System Operation

25

Page 30

6.0 OPERATION WITH OTHER BIO-RAD

INSTRUMENTS

The Econo Gradient Pump (EGP) may be used with other

chromatography components (the Model 2110 or Model 2128 fraction

collectors and the Model 1327 Chart recorder), and with the BioLogic

Duo-Flow System running software version 3.0 or later, the high

resolution liquid chromatography systems. Each of these connections

is discussed in the following table. Refer also to Figure 6-1 for

system cabling and to Figure 6-2 for system plumbing.

Table 6-1. Connecting the Econo Gradient Pump

to other Bio-Rad instruments

Model 2128 Fraction Collector

1. This cable connects the EGP (mini-DIN I/O

socket) to the 15-pin D-connector on the fraction

collector and transmits “start” and “stop” signals.

If the Model 1327 Chart Recorder is present,

connect the cable’s remaining end to the chart

recorder. If the chart recorder is not present,

then place this portion of the cable aside.

2. Power up the EGP and the fraction collector (and

the chart recorder, if present.)

3. Enter the fraction collector’s Standard mode and

set all fraction collector parameters from its

faceplate.

The EGP will automatically start the fraction

collector when a programmed run is started. If

the SV-3 diverter valve is connected to the EGP,

then fraction collection will begin at the point in

the program when the diverter valve is in the

DIVERT position.

Other Instruments

26

Cable #23

Catalog #

731-9009

Page 31

Model 2128 Fraction Collector (continued)

Alternatively, one may use the Model 2128 Diverter

Valve; it will respond to the program in the Model

2128 Fraction Collector itself, not from the EGP.

If HOLD is selected during the program, then the

pump will continue pumping at the current conditions

and fraction collection will continue as programmed.

If PAUSE is selected during the program, then the

pump and fraction collector will stop.

The pump and fraction collector will resume when

CONTINUE is selected.

Model 2110 Fraction Collector

1. This cable connects the EGP (mini-DIN I/O

socket) to the 9-pin D-connector on the Model

2110 Fraction Collector and transmits “start” and

“stop” signals.

If the Model 1327 Chart Recorder is present,

connect the cable’s remaining end to the chart

recorder. If the chart recorder is not present,

then place this portion of the cable aside.

2. Power up the EGP and the fraction collector (and

the chart recorder, if present.)

3. Select collection by time or by drops by pressing

the Time/Drop key on the fraction collector’s

faceplate.

When the EGP is running in Manual mode, the

2110 fraction collector will not start automatically.

It may be started from is own faceplate if fraction

collection is required.

Other Instruments

27

Cable #22

Catalog #

731-9010

Page 32

Model 2110 Fraction Collector (continued)

When a programmed run is started, the EGP will

automatically start the fraction collector. If the SV-3

diverter valve is connected to the EGP, then fraction

collection will begin at the point in the program when

the diverter valve is in the FRAC position.

If HOLD is selected during the program, then the

pump will continue pumping at the current conditions

and fraction collection will continue as programmed.

If PAUSE is selected during the program, then the

pump and fraction collector will stop.

The pump and fraction collector will resume when

CONTINUE is selected.

Model 1327 Chart Recorder

As described above, these cables connect fraction

collectors and the Model 1327 Chart Recorder to the

EGP. The fraction collector part of the cable should

be put aside if a fraction collector is not present. The

EGP will automatically start and stop the chart

recorder. The parameters should be set at the chart

recorder itself.

If a fraction collector is present, then the fraction

collector marks are superimposed on the UV trace

directly.

If HOLD is selected during the program, then the

pump will continue pumping at the current conditions

and the chart recorder will continue recording.

Other Instruments

28

Either

Cable #22

(Catalog #

731-9010)

or

Cable #23

(Catalog #

731-9009)

Page 33

Other Instruments

Model 1327 Chart Recorder (continued)

If PAUSE is selected during the program, then the

pump and chart recorder will stop.

The pump and chart recorder will resume when

CONTINUE is selected.

Model EM-1 UV Monitor

None A connection is not required between the pump and

the EM-1 UV Monitor. To record UV data onto the

Model 1327 Chart Recorder, use cable #4, 8-pin

mini-DIN to banana plug cable. It is supplied with the

UV Monitor. The banana plugs plug into Channel 1 of

the chart recorder. The UV trace will be displayed by

the blue pen.

Model EG-1 Gradient Monitor

None A connection is not required between the pump and

the EG-1 Gradient Monitor. To record the gradient

data onto the Model 1327 Chart Recorder, use cable

#4, 8-pin mini-DIN to banana plug cable. It is

supplied with the Gradient Monitor. The banana

plugs plug into Channel 2 of the chart recorder. The

gradient trace will be displayed by the red pen.

29

Page 34

Other Instruments

BioLogic Duo-Flow System

One of these

four System

(bus) Cables:

Cable #17

4-ft (1.2m)

(Catalog #

750-0650)

Cable #18

12-ft (3.7m)

(Catalog #

750-0651)

Cable #19

30-ft (9.2m)

(Catalog #

750-0652)

Cable #21

100-ft (30m)

(Catalog #

750-0655)

The EGP can be controlled by the BioLogic Duo-Flow

System provided that the BioLogic System firmware

is version 3.0 or higher.

Connect the EGP to the Duo-Flow Workstation using

a bus cable of the appropriate length.

The EGP may be used either as a user-defined

device or specifically as a sample loading pump.

30

Page 35

Figure 6-1. System Cabling.

Other Instruments

31

GRADIENT

MODEL 1327

CHART RECORDER

CABLE 22 OR 23

BIOLOGIC DUO-FLOW

WORKSTATION

ECONO

PUMP

GRADIENT

MIXER

DIVERTER OR

SPLITTER

VALVE

MODEL 2110 FRACTION COLLECTOR

OR

MODEL 2128 FRACTION COLLECTOR

MIXER

AB

Page 36

Figure 6-2. System Plumbing.

Other Instruments

32

ECONO GRADIENT PUMP

MIXER

AB

GRADIENT

MIXER

ECONO

GRADIENT PUMP

MODEL EM-1

UV OPTICS MODULE

MODEL 2128

FRACTION

COLLECTOR

MODEL EG-1

GRADIENT

MONITOR

MODEL 2110

FRACTION

COLLECTOR

Page 37

7.0 CLEANING AND MAINTENANCE

The Econo Gradient Pump requires very little maintenance to assure

reliable operation. The procedures outlined below will insure

maximum pump life:

• Check tubing regularly for signs of cracking and wear. If any

exist, replace the tubing.

• For optimal tubing life, use a slow to medium pump speed. To

increase throughput, increase tubing size to obtain the desired

output.

• When not in use, tubing should be removed from the pump to

prevent deformation of the tubing. Remove the platen and relax

the tubing by unhooking one end of the tubing from the tubing

bracket.

• To prevent the formation of precipitates around the pump head

and on the membrane key panel, promptly remove any spills.

Clean with deionized water.

• If an auxiliary valve or the Gradient Mixer is used, rinse it with

deionized water after each use. Store them in 20% EtOH for longterm storage. Do not expose the valves to pressures greater than

20psi.

• If using the pump at 4°C, leave the pump on (not necessarily

running) to mitigate condensation within the pump.

7.1 Fuse Replacement and Voltage Conversion

To replace a fuse, see Figure 7-1 and follow these steps:

1. Disconnect the power cord from the unit.

2. Remove the fuse drawer with a small-blade screwdriver or similar

tool.

3. Pull the fuse holder out of the fuse drawer and replace the fuses

with ones having the correct current rating. Use 0.40 A slow-blow

fuses for 100/120 V operation; 0.20 A slow-blow fuses for

220/240 V operation. The 0.20A fuses are packaged in a plastic

bag and taped to the exterior of the pump.

Maintenance

33

Page 38

4. The fuse socket in the fuse drawer is removable. Turn the socket

such that the correct voltage shows through the window.

5. Reinsert the fuse drawer into the power entry module, with the

locking tab to the left. Press gently until it snaps into place.

6. Insert the power cord plug into the power entry module. Plug the

power cord into a properly grounded outlet.

Figure 7-1. Fuse Replacement and Voltage Conversion.

Maintenance

34

Power Entry Module

Voltage Selector

Fuse Drawer

Window

220

110

Page 39

Troubleshooting

8.0 TROUBLESHOOTING

Problem Possible Cause Solution

Pump displays Power outage If you wish to continue a run in

“Power Failure!” progress, press the Continue

soft key. The LCD will display

the program at the time of the

power failure. Pressing the

Stop soft key will display the

message “Program Aborted”.

You may now operate the

pump

as normal.

Pump will No power Verify that power cord is

not run (no LEDs lit) plugged in and the power

switch is turned on.

Fuses Check that proper fuses are

installed and intact.

Insure that the calibration

indicator light is not flashing.

For pump to run, this light must

either be off or steadily lit.

Mode Econo Gradient Pump must be

in either Manual or Program

mode to start.

Liquid remains Platen not Adjust the platen by turning

stationary adjusted it counter clockwise until it is

in tubing completely loosened, then

rotate three to five full turns

clockwise. See section 4.3,

Platen Adjustment.

Clogged tubing, Check tubing, fittings, and

valves, or fittings valves for obstructions.

Damaged tubing Check pump tubing. Replace

damaged tubing.

35

Page 40

Troubleshooting

Problem Possible Cause Solution

Flow rate not Pump tubing Replace tubing.

consistent damaged or

worn out

Platen adjustment Adjust the platen by turning

incorrect it counter clockwise until it is

completely loosened, then

rotate three to five full turns

clockwise. See section 4.3,

Platen Adjustment.

Wrong tubing size Refer to Figure 4-1 for

selection

selected criteria.

Select proper ID tubing within

Setup.

Large change in Re-calibrate flow within Setup.

back pressure or

fluid viscosity

Restriction on inlet Detach the inlet tubing and

side Gradient Mixer. Rinse with

deionized water.

Excessive Platen too tight Adjust the platen by turning

wear on tubing it counter clockwise until it is

completely loosened, then

rotate three to five full turns

clockwise. See section 4.3,

Platen Adjustment.

36

Page 41

Troubleshooting

Problem Possible Cause Solution

Cannot Pump must be Insure that pump is stopped.

calibrate stopped in order to

pump calibrate pump

RPM has been Select Flow Rate in screen 1 of

selected Setup.

Valves do not Pump is off Turn on the pump.

respond or

actuate Valve cabled to Mixer and/or Aux valve must be

wrong connector plugged in to its correct socket.

Chart recorder Pump is off Turn on the pump.

or fraction

collector does Valve cabled to Chart recorder or fraction

not respond wrong connector collector must be plugged in to

its correct connector.

Wrong fraction Setup screen 14 allows choice

collector specified of a Model 2110, 2128 or none.

in setup Select the appropriate choice.

The proper Valves plugged See section 3.2 to plug valves

valves do not into wrong port. into the correct port.

appear on the

display

EGP program Wrong device Ensure that only the fraction

starts plugged into I/O collector or chart recorder is

unexpectedly port plugged into the I/O port.

Ensure that pin #3 is not

shorted.

37

Page 42

Embedded Functions

9.0 EMBEDDED FUNCTIONS

During a technical service call, you may be asked to perform tasks

which require you to press combinations of keys. These tasks are

defined below.

9.1 FIRMWARE CONFIRMATION

To check the version of firmware installed in the Econo Gradient

Pump, power up the Econo Gradient Pump. During power up, the

firmware version is displayed. The checksum (CS) is also displayed.

9.2 RESET

To initiate a reset, press all three soft keys simultaneously and hold

for 3 seconds. This will reset all stored values to the factory defaults.

38

Page 43

APPENDIX A

TECHNICAL SPECIFICATIONS

Number of channels 2

Flow rate range (per channel) 0.002 - 20 ml/min (depending on

tubing diameter)

Pump head speed 0.05 to 25 rpm maximum

Tubing diameter 0.19 mm ID to 3.2 mm ID;

maximum 1 mm wall thickness

Speed adjustment increment 0.01 RPM

Speed stability 0.2% at 10 RPM

Speed accuracy 0.1% at 10 RPM

Maximum counterpressure 30 psi (2 kg/cm2or bars)

Motor DC speed controlled, 25 watts

Line voltage 90-132 VAC

180-264 VAC

47-63 Hz

Dimensions 143 x 202 x 222 mm

(W x D x H) with pumphead

Weight 3.5 kg

Operating temperature 4 to 40 °C

Material of construction polypropylene and other solvent

resistant plastics

Regulatory Compliance TÜV: EN61010-1:1993

CE: EN55011:1991 Class A

EN50082-2:1997

EN50081-2:1994

ENV50204:1995

Specifications

39

Page 44

Gradient Mixer

Range 0-100% B

Increment 1% B

Valve control

SV-3 Diverter Valve Waste and divert positions.

Splitter Valve 0-100%

Fraction Collectors

Model 2110 Run, hold, pause, stop

Model 2118 Run, hold, pause, stop

Chart Recorder

Model 1327 Dual pen recorder, paper feed

start/stop, pen up/down

Specifications

40

Page 45

APPENDIX B

CONNECTION TO OTHER INSTRUMENTS

The I/O connector on the rear panel of the pump is for the operation

of the fraction collectors and chart recorder (see Figure 3-2). Output

signals are TTL compatible. To use these signals for non-Bio-Rad

devices, you must insure that the circuit external to the Econo

Gradient Pump does not draw more than 15 milliamperes of current.

The following table describes the rear panel mini-DIN connector

pinouts for this I/O connector.

Table B-1. I/O mini-DIN Connector Pinouts

Selected Fraction Collector

Pin# Name None 2110 2128

1 PS held HIGH held HIGH held HIGH

starts 1327 starts 1327 starts 1327

2 RUN --- 2.5 s held LOW

LOW PULSE starts 2128

resets 2110

3 FCNTRL1 held LOW held LOW held LOW

starts EGP starts EGP starts EGP

program program program

4 START --- 120 ms LOW held LOW

PULSE starts 2128

toggles between

start and stop

Other Instruments

41

PIN #7

PIN #8

PIN #5

PIN #2

PIN #4

PIN #6

PIN #3

PIN #1

Page 46

Other Instruments

Selected Fraction Collector

Pin# Name None 2110 2128

5 no contact no contact no contact

6 ER/PD held LOW held LOW held LOW

starts 1327 starts 1327 starts 1327

7 Ground Signal Signal Signal

Ground Ground Ground

8 no contact no contact no contact

42

Page 47

APPENDIX C

WARRANTY

The Econo Gradient Pump is warranted for one year against defects

in materials and workmanship. If any defects should occur during this

warranty period, Bio-Rad will replace the defective parts without

charge. However, the following defects are specifically excluded:

1. Defects caused by improper operation.

2. Repair or modification done by anyone other than Bio-Rad

Laboratories or their authorized agent.

3. Use with tubings or fittings not specified by Bio-Rad Laboratories

for use with this pump.

4. Deliberate or accidental misuse.

5. Damage caused by disaster.

6. Damage due to use of improper solvent or sample.

This warranty does not apply to tubing, fittings, and fuses.

For inquiry or request for repair service, contact Bio-Rad Laboratories

after confirming the model and serial number of your instrument.

For Technical Service Call Your Local Bio-Rad Office or in the U.S.

Call 1-800-4BIORAD (1-800-424-6723).

Warranty

43

Page 48

APPENDIX D

ORDERING INFORMATION

Catalog

Number Product Description

Econo Gradient Pump

731-9001 Econo Gradient Pump 100/120 V

731-9002 Econo Gradient Pump 220/240 V

731-9004 Econo Gradient Pump Rack and Column Clamp Set

731-9005 EGP Column Clamp Set, replacement

731-8322 Model SV-3 Diverter Valve

731-8323 Gradient Mixer

731-8320 Sample Injection Valve

731-9011 Splitter Valve Kit

731-9012 Model SPL3-2 Splitter Valve

731-9013 Splitter Valve Tygon Sleeve Assembly

731-9014 Splitter Valve PEEK Adapter Assembly

731-9015 Splitter Valve Flow Dampner Assembly

731-9008 Econo Gradient Pump Instruction Manual

731-8160 Model EM-1 Econo UV Monitor, 110/120 V, includes

control module, optics module, filters for 280 and 254 nm

wavelengths, System Cable 4, fittings starter kit.

731-8162 Model EM-1 Econo UV Monitor, 220/240 V.

731-8151 Model EG-1 Econo Gradient Monitor, includes 100/120V

(USA) power adaptor, flow cell, System Cable 4.

731-8150 Model EG-1 Econo Gradient Monitor, without power

adaptor, includes flow cell, System Cable 4.

100-1908 Fuses for 100Volt operation, quantity 2. Specifications

are 0.4A, 250V, 5x20mm, Type T (Time-Lag),

I2T=2.4A2s.

100-1909 Fuses for 220Volt operation, quantity 2. Specifications

are 0.2A, 250V, 5x20mm, Type T (Time-Lag),

I2T=0.3A2s.

Ordering Information

44

Page 49

Catalog

Number Product Description

Tubing and Accessories

731-8210 Silicone Tubing, 0.8 mm ID, 0.8 mm wall, 10 m

731-8211 Silicone Tubing, 1.6 mm ID, 0.8 mm wall, 10 m

731-8212 Silicone Tubing, 3.2 mm ID, 0.8 mm wall, 10 m

731-8213 Tygon tubing, 0.51 mm ID, 0.8 mm wall, 10 m

731-8214 Tygon Tubing, 0.8 mm ID, 0.8 mm wall, 10 m

731-8215 Tygon Tubing, 1.6 mm ID, 0.8 mm wall, 10 m

731-8207 PharMed Tubing, 0.8 mm ID, 1.0 mm wall, 10 m

731-8208 PharMed Tubing, 1.6 mm ID, 1.0 mm wall, 10 m

731-8209 PharMed Tubing, 3.2 mm ID, 1.0 mm wall, 10 m

731-9007 Peristaltic Pumphead Tubing, includes two precut

lengths each of Pharmed tubing, 0.8, 1.6, and 3.2 mm ID.

731-8240 Silicone Tubing Kit, 0.8 mm ID, 20 precut lengths and 4

sets of fittings.

731-8241 Silicone Tubing Kit, 1.6 mm ID, 20 precut lengths and 4

sets of fittings.

731-8242 Silicone Tubing Kit, 3.2 mm ID, 20 precut lengths and 4

sets of fittings.

731-8247 PharMed Tubing Kit, 0.8 mm ID, 20 precut lengths and 4

sets of fittings.

731-8248 PharMed Tubing Kit, 1.6 mm ID, 20 precut lengths and 4

sets of fittings.

731-8249 PharMed Tubing Kit, 3.2 mm ID, 20 precut lengths and 4

sets of fittings.

731-8220 Low Pressure Fittings Kit, includes over 250 male and

female luer connectors, 2- and 3-way stopcocks, and

tubing connectors.

PharMed and Tygon are the registered trademarks of the Norton Company.

Ordering Information

45

Page 50

Catalog

Number Product Description

731-9006 Low Pressure, Small Fittings Kit. Contains a subset of

the fittings found in catalog # 731-8220, including barbto-female and male luer for 0.8, 1.6, and 3.2 mm tubing,

slip fittings, and both female and male luer plugs.

Cables

731-8264 System Cable 4, 8-pin mini-DIN to banana cable. To

connect Econo UV Monitor or Econo Gradient Monitor to

the Model 1327 Chart Recorder.

731-9009 System Cable 23, Y-cable. To connect both a Model

2128 Fraction Collector and Model 1327 Chart Recorder

to the Econo Gradient Pump.

731-9010 System Cable 22, Y-cable. To connect both a Model 2110

Fraction Collector and Model 1327 Chart Recorder to the

Econo Gradient Pump.

750-0650 System Cable 17 (bus cable), 4 feet (1.2 m)

750-0651 System Cable 18 (bus cable), 12 feet (3.7 m)

750-0652 System Cable 19 (bus cable), 30 feet (9.2 m)

750-0655 System Cable 21 (bus cable), 100 feet (30 m)

Model 2110 Fraction Collector

731-8122 Model 2110 Fraction Collector, 100/120 V

731-8120 Model 2110 Fraction Collector, 220/240 V

Model 2128 Fraction Collector

731-8123 Model 2128 Fraction Collector, 100/120 V

731-8124 Model 2128 Fraction Collector, 220/240 V

Bio-Rad sells a complete line of integrated chromatography systems

for protein purification. For more information on the BioLogic System

family of products, contact your local Bio-Rad representative.

Ordering Information

46

Page 51

S

cience

p

800

us

a

(01)

Canada

(

000

and

089 318 8

7

3300

ael

4

590 5200

03-58

ea

8

60

ca

co

52 5 53

e Netherlands

0666

64-9

30

095 979 98 00

590-5200

Sweden

d

06

9555

0800-181134

0

US/EG

A

Bio-R

ad

aboratories

L

Life

Grou

ulletin 0000

Rev

Web sitewww.bio-rad.com USA(800) 4BIORAD Australia 02 9914 2

tri

A

Finl

Hong Kong 852-2789Italy 34 91

Latin Ameri

Th

877 89 01

905) 712-2771 45 44 52-1

India Isr

0318-54

ia 7

46 (0)8-55 51 27 00 Switzerlan

Singapore65-2729877 Spain34-91-

11-6270 Kor

Mexi

1-717-

2-2-3473-44

4 2552 to 54

-4152280 Norway 47-23-38-41-

United Kingdom

00-000 0000 Sig 120

4006161 Rev B

4-17

03 951 412

Loading...

Loading...