Page 1

Nuvia™ cPrime

™

Hydrophobic

Cation

Exchange Media

Instruction

Catalog

156-3401 156-3404

156-3402 156-3405

156-3403 156-3406

numbers

Manual

Please read the instructions in this manual prior to using

Nuvia cPrime hydrophobic cation exchange media. If you

have any questions or require any further assistance, please

contact your Bio-Rad Laboratories representative.

Page 2

Page 3

Table of Contents

Section

Section

Section

Section

Packing Small

Packing Process Scale

Flow Properties

Buffers

Section

Section

Section

Section

Section

Section

1:

Introduction 1

2 :

Technical Description 2

3 :

Preparation

4 :

Column

Columns

5 :

Column Packing Evaluation 7

6 :

Method Development

7 :

Sanitization

8 :

Storage 11

9:

Regulatory Support 11

10: Ordering

Packing

Information

Columns

and

8

Regeneration 10

11

3

3

3

4

5

6

Page 4

Section

1

Introduction

Nuvia™ cPrime™ hydrophobic cation exchange media are

designed for the process scale purification of a wide variety of

therapeutic proteins. Nuvia cPrime media’s unique selectivity

allows method developers to use hydrophobic and cation

exchange interaction modes to achieve effective purification. More

importantly, the media have a wide design space for binding and

elution, allowing for the development of highly robust methods in

a commercial manufacturing setting. Nuvia cPrime media are built

on a rigid, mechanically and chemically stable macroporus base

matrix with a particle size optimized to deliver exceptional flow

properties, fast mass transfer, and stability. See the Nuvia cPrime

media product information sheet for more product details.

If you have questions or require methods development assistance

with Nuvia cPrime media, contact your local Bio-Rad process

chromatography representative or the Bio-Rad chromatography

technical support group for assistance at 1-510-741-6563.

1

Page 5

Section

2

Technical

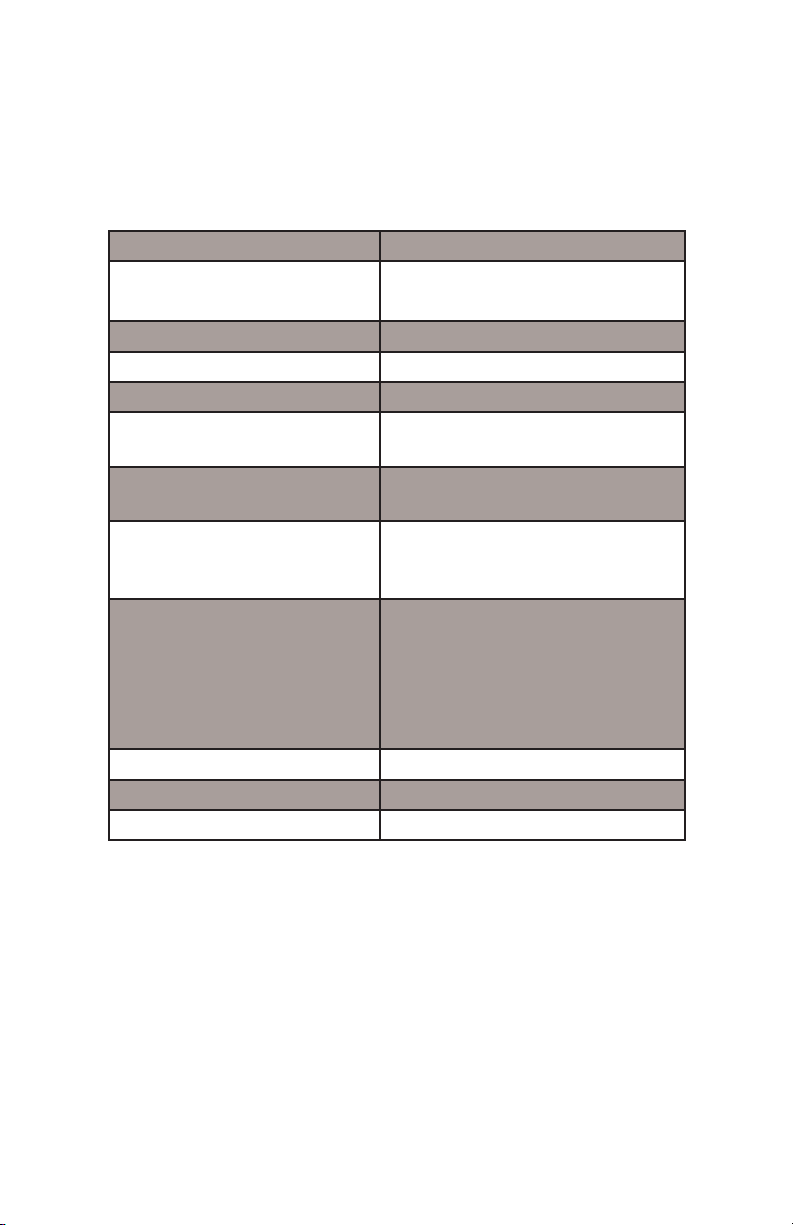

Table 1. Nuvia™ cPrime™ media technical description.

Functional group Hydrophobic cation exchanger

Base matrix composition Macroporous highly crosslinked

Particle size 70 µm ± 10 µm

Dynamic binding capacity* ≥ 40 mg/ml

Ligand density 55–75 µeq/ml

Recommended linear flow

rate range

Pressure vs. flow

performance**

pH stability 2–14 short term

Chemical stability 1.0 N NaOH, 1.0 N HCl, 25%

Shipping solution 20% ethanol

Storage conditions 20% ethanol

Shelf life*** 5 yrs

Description

hydrophilic polymer

50–600 cm/hr

Under 2 bar @ a flow rate of 600

cm/hr

3–13 long term

HOAc, 8 M Urea, 6 M Gu-HCl,

6 M KSCN, 3 M NaCl, 1% Triton

X-100, 2% SDS + 0.25 M NaCl,

20% ethanol, 70% ethanol, 30%

isopropanol

* at 10% breakthrough hIgG.

** 20 cm X 20 cm packed bed (1.17 compression factor).

*** Stored at room temperature in 20% ethanol under accelarated

conditions.

2

Page 6

Section

3

Preparation

Nuvia™ cPrime™ media are supplied fully hydrated in 20% ethanol

as a 50% (v/v) slurry. For column packing, removal of the shipping

buffer is recommended. Small volumes of Nuvia cPrime media are

easily washed in a Büchner funnel with 4–5 volumes of packing

buffer. For large volume preparation, cycle through 3–4 settling and

decanting steps using the column packing buffer in the shipping

container.

Removal of fines from Nuvia cPrime media is not required. If, however,

particle fines have been generated during handling, resuspend the settled

media and remove any opaque or cloudy supernatant before resettling is

complete. Repeat several times until supernatant is clear.

Section

Column

Nuvia™ cPrime™ media can be packed using standard column

packing methods. To pack columns for optimal operation, a

20–50% slurry volume is recommended.

Packing Small Columns

This slurry packing method was designed to pack Nuvia cPrime

media in a conventional laboratory scale column with an internal

diameter of 5–50 mm. All buffers should be degassed. Since a

relatively large volume of slurry is required, a packing reservoir

should be used.

1. Prepare degassed 1.0 M NaCl, 20–50 mM buffer salt (see

2. Decant the shipping solution away from the resin bed as

3. After thorough buffer exchange, prepare an aliquot of Nuvia

4. Seal the cylinder and rotate it to suspend the resin. Caution:

4

Packing

Table 2) referred to herein as the packing buffer.

outlined in Section 3, maintaining an approximate slurry

percentage of 50%.

cPrime media in a graduated cylinder to determine the slurry

percentage.

do not mix with a magnetic stir bar as damage may occur.

Larger amounts of slurry may be mixed with a low-shear

impeller at low to moderate speed.

3

Page 7

5. Using a compression factor of 1.17, calculate the volume of

slurry required for the intended bed height.

a. For example, for a 20 cm bed height using a 50% slurry, the

volume would be:

1.17 (20/0.5) * πr

6. Add a small amount of packing buffer to the column to wet the

bottom frit, then pour in calculated amount of resin slurry.

7. Insert the column flow adaptor and flow pack at a linear velocity of

300–600 cm/hr with packing buffer for at least 10 min. Note the

compressed bed height, stop the flow, and adjust the flow adaptor to

compress the bed to the intended bed height.

8. Equilibrate with at least 3 column volumes (CV) of equilibration

buffer and evaluate column efficiency using your standard operating

procedures or the procedure described in Section 5.

2

Packing Process Scale Columns

After removing the storage buffer (Section 3), prepare a 20–50%

slurry (v/v) with packing buffer (see Table 2). For most process

columns, follow the manufacturer’s recommendations with one

major exception: do not recirculate the Nuvia cPrime media slurry

through the packing pump. Use a low-shear impeller for automatic

mixing or a plastic paddle for manual mixing to avoid damaging the

media. The best overall performance of Nuvia cPrime media will

be obtained with a compression ratio of 1.15–1.20. Compression

factor is defined as settled bed height divided by packed bed

height.

After achieving the desired compression ratio, it is recommended

to condition the column by flowing fresh packing or equilibration

buffer for 3 CV followed by 3 CV in downflow at the chosen

process flow rate. After this flow conditioning step, evaluate

column efficiency using your standard operating procedures or the

procedure described in Section 5.

4

Page 8

Flow Properties

Nuvia cPrime Media vs. Pressure Flow

-0.5

0

0.5

1

1.5

2

2.5

3

0 200 400 600 800 1000 1200

Linea r flow ra te , cm/hr

Pressure, bar

Nuvia cPrime Media DBC (Lactoferrin) vs. Flow Rate

0

10

20

30

40

50

60

70

80

150 300 450 600

Flow rate, cm/h

10% BT DBC, mg/ml

Fig. 1. Nuvia cPrime media pressure vs. flow performance for a

20 cm diameter column and a 20 cm bed height; compression ratio

1.17. Nuvia cPrime media have fast mass transfer properties allowing

users to achieve high productivity at fast flow rates. The media should

be run at the highest linear velocities that allow good separation and are

allowed by the column and chromatography system specifications. A

linear flow rate of 300 cm/hr and a 20 cm bed is a recommended starting

point.

Fig. 2. Effect of flow rate on Nuvia cPrime media binding capacity for

lactoferrin.

Column dimension: 1.1 x 9.6 cm

Sample: 5.25 mg/ml lactoferrin

5

Page 9

Buffers

All buffers commonly used for ion exchange chromatography can

be used with Nuvia cPrime media.

Table 2. Common buffers for cation exchange

chromatography. A buffer concentration of 60 mM is

recommended for most buffers.

Buffer Buffering Range

Acetic acid 4.8–5.2

Citric acid 4.2–5.2

HEPES 6.8–8.2

Lactic acid 3.6–4.3

MES 5.5–6.7

Phosphate 6.5–8.0

Tris 7.5–9.0

6

Page 10

Section

5

Column Packing

After column packing is complete, equilibrate the column with up

to 5 CV equilibration buffer. To test the efficiency of the column

packing operation, inject a sample of a low molecular weight,

unretained compound (for example, acetone or 1 M NaCl) to

determine height equivalent to a theoretical plate (HETP). If acetone

is used as the test marker (use a UV absorbance monitor set at

280 nm), the equilibration buffer must have a salt concentration

<100 mM. If 1 M NaCl is the test marker (use a conductivity

monitor), then the equilibration buffer salt concentration should be

100–200 mM. The sample volume should be 1–3% of the total

column volume. Column testing should be operated using the

same linear velocity used to load and/or elute the sample.

To obtain comparable HETP values among columns, the same

conditions must be applied. Minimum theoretical plate values

should be 1,000–3,000 plates/m for linear velocities of 50–500 cm/

hr.

HETP = L/N

N =

5.54(Ve/W½h)

L = Bed height (cm)

N = Number of

Ve =

Peak elution volume

W

=

Peak

½h

Ve and W

theoretical

width at peak

should

½h

Evaluation

2

plates

or time

always

half

height in

be in the same units

volume

or time

Peaks should be

possible

Peak asymmetry factor calculation:

As =

a = Front section of peak width at 10% of peak

denoting

b = Latter section of peak width at 10% of peak height bisected by line

denoting

As = 0.8–1.8 is acceptable

to 1.

b/a

V

V

symmetrical

Values

of 0.8–1.8 are acceptable.

e

e

and the

7

asymmetry

factor as close as

height

bisected by line

Page 11

Section

6

Method Development

Developing an effective and robust method with Nuvia™ cPrime™

media is straightforward. Below is general information on the

binding and elution mechanism and an approach to guide method

development; results will vary depending on protein of interest and

feed composition.

The binding and elution mechanisms of Nuvia cPrime media

are determined chiefly by pH and salt. The high salt tolerance of

the media often allows for direct loading at high conductivity. An

increase in pH will in most cases achieve elution. Conductivity

is another way to achieve and/or optimize elution and the final

method is often a combination of an increase in pH and/or an

increase/decrease in salt concentration. In some cases, the use of

an elution buffer modifier or a different salt in the elution buffer may

be required for optimal elution, recovery, and resolution.

The schematic below outlines a general method development

rational. In most cases, conducting a few simple DOE experiments

to identify optimal binding and elution conditions will yield an

effective, robust, and scalable method.

8

Page 12

1. Load feed or eluate from previous step directly without

dilution onto the Nuvia cPrime media column. To elute, use an

increasing pH gradient. If satisfactory elution and recovery are

achieved, refine and/or make a step gradient to complete the

step (range pH 4–8, depending on protein).

2. If elution is not satisfactory after step 1, run a salt gradient to

disrupt electrostatic or hydrophobic interactions that may be

preventing elution or broadening the peak. Use the pH where

there was best elution (from step 1). The direction of this salt

gradient (increasing or decreasing) can be easily assessed

and will depend on the relative contributions of ionic vs.

hydrophobic interactions involved in binding.

3. If elution is still unsatisfactory after step 2 of this process,

consider using a modifier such as propylene glycol, urea, or

arginine to disrupt any remaining interactions. Other modifiers

may also be used; in some cases changing to another salt

may also be required.

For further assistance or to discuss method development,

contact Bio-Rad chromatography technical support group

at 1-510-741-6563.

9

Page 13

Section

7

Sanitization

After each chromatography run, the packed media bed should

be washed to remove reversibly bound material and prepare the

column for the subsequent run. This cleaning process is achieved

by washing the column with 2–6 column volumes of 1–2 M

NaCl followed by 2–6 column volumes of 0.1 N NaOH to remove

remaining proteinaceous impurities. Washing should be conducted

until absorbance returns to baseline. The column is now ready to

be sanitized in 1.0 N NaOH.

After sanitization, to equilibrate the column we recommend

applying 4–6 column volumes of a solution such as 60 mM NaOAC

(sodium acetate)

Note: if the column no longer yields reproducible results, the

media may require additional cleaning to remove strongly bound

contaminants. Acceptable cleaning agents include 25% acetic

acid, 8 M urea, 1% Triton X-100, 6 M potassium thiocyanate,

70% ethanol, 30% isopropyl alcohol, 1 N NaOH, or 6 M guanidine

hydrochloride.

and Regeneration

10

Page 14

Section 8

Storage

For long-term storage, Nuvia™ cPrime™ media should be with 0.1 N

NaOH or 20% ethanol.

Section 9

Regulatory Support

A regulatory support file is available for Nuvia™ cPrime™ media. If

you need assistance validating the use of Nuvia cPrime media in a

production process, contact your local Bio-Rad representative.

Section 10

Ordering Information

Catalog numbers Description

156-3401 Nuvia™ cPrime™ Media, 25 ml

156-3402 Nuvia cPrime Media, 100 ml

156-3403 Nuvia cPrime Media, 500 ml

156-3404 Nuvia cPrime Media, 1 L

156-3405 Nuvia cPrime Media, 5 L

156-3406 Nuvia cPrime Media, 10 L

Larger volumes

available

Triton is a

upon request.

trademark

and

special packaging

of

Union Carbide

for

Corporation.

11

industrial applications

are

Page 15

Page 16

Life Science

Group

Sig 121110023853 Rev B US/EG

Bio-Rad

Laboratories, Inc.

Web site ww w.bio-rad.com USA 800 424 6723

Australia 61 2 9914 2800 Austria 01 877 89 01

Belgium 09 385 55 11 Braz il 55 11 5044 5699

Canada 905 364 3435 China 86 21 6169 8500

Czech R epublic 420 241 430 5 32 Denmark 44 52 10 00

Finland 09 804 22 00 France 01 47 95 69 65

Germany 089 31 884 0 Greece 30 210 9532 220

Hong Kong 8 52 2789 3300 Hungary 36 1 459 6100

India 91 124 4029300 Israel 03 963 6050 Italy 39 02 216 091

Japan 03 6361 7000 Korea 82 2 3473 4460

Mexico 52 5 55 488 7670 The Netherlands 0318 540666

New Zealand 64 9 415 228 0 Norway 23 38 41 30

Poland 48 22 331 99 99 Portugal 351 21 472 7700

Russia 7 495 721 14 04 Singapore 65 6415 3188

South Africa 27 861 246 723 Spain 3 4 91 590 5200

Sweden 08 555 1270 0 Switzerland 061 717 95 55

Taiwan 88 6 2 2578 7189 Thailand 800 88 22 88

United Kingdom 020 8328 200 0

Loading...

Loading...