Instruction Manual

Catalog # 171-203001

For use with Bio-Plex Manager™ software version 5.0 and higher with

MCV plate IV, or for use with Bio-Plex Manager software 4.0/4.1 with

MCV plate III.

For technical support, contact your local Bio-Rad office or,

in the US, call 1-800-4BIORAD (1-800-424-6723)

For research use only. Not for diagnostic procedures.

Table of Contents

Section 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Section 2 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . .2

Section 3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Section 4 Storage and Handling . . . . . . . . . . . . . . . . . . . . . . . . .3

Section 5 Principle of Optics Validation . . . . . . . . . . . . . . . . . . .3

Section 6 Principle of Reporter Validation . . . . . . . . . . . . . . . . .4

Section 7 Principle of Classify Validation . . . . . . . . . . . . . . . . . .7

Section 8 Principle of Fluidics Validation . . . . . . . . . . . . . . . . . .8

Section 9 Software Utility Installation . . . . . . . . . . . . . . . . . . . .8

Section 10 Procedure for Performing Validation . . . . . . . . . . . . .9

10.1 One-Step Procedure for all Validation Parameters . . . . . . . . . .9

10.2 Validation of Optics Alignment . . . . . . . . . . . . . . . . . . . . . . . .12

10.3 Validation of Fluidics Integrity . . . . . . . . . . . . . . . . . . . . . . . .14

10.4 Validation of Reporter Channel Performance . . . . . . . . . . . . .15

10.5 Validation of Classify Efficiency . . . . . . . . . . . . . . . . . . . . . . .17

10.6 Generating a Validation Report . . . . . . . . . . . . . . . . . . . . . . .18

10.7 Validation Kit Report Form Example . . . . . . . . . . . . . . . . . . .19

Section 11 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . .21

Section 12 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . .21

Section 13 Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Section 1

Introduction

Qualification of analytical instruments is a formal process of documenting that an

instrument is fit for its intended use and that it is kept maintained and calibrated.

The Bio-Plex

®

validation kit is used for operational qualification (OQ) of the Bio-Plex

suspension array system. The validation kit is designed to validate the operation of

all of the primary components of the system and is a valuable tool that allows the

user to discriminate between assay and instrumentation problems.

The Bio-Plex validation kit consists of beads to evaluate the following components

of the Bio-Plex suspension array system: 1) optics alignment, 2) integrity of fluidics,

3) reporter channel performance, and 4) classify efficiency. A brief definition of the

parameter and the principle of each procedure is described, along with complete

procedures for evaluating each of the primary components. An explanation of the

potential impact of each process on a typical Bio-Plex cytokine assay is included to

assist the user in assay troubleshooting and development.

1

Section 2

Product Description

The following reagents are included in the Bio-Plex®validation kit 4.0:

Reagent Quantity

Optics validation bead set:

Optics beads 1 and 2 2 x 10 ml black bottles

(1x10

5

beads/ml)

Fluidics validation bead set:

Fluidics bead 1 and 2 2 x 10 ml black bottles

(1x10

5

beads/ml)

Reporter validation bead set:

Reporter blank, 1, 2, 3, 4, 5, and 6 6 x 10 ml white bottles

(1x10

5

beads/ml)

Classify validation bead set:

Classify bead A(1), B(4), C(40), D(54), E(100) 5 x 10 ml black bottles

(1x10

5

beads/ml)

NNoottee:: TThhee BBiioo--PPlleexx vvaalliiddaattiioonn kkiitt aallssoo iinncclluuddeess aa BBiizzCCaarrdd CCDD,, wwhhiicchh ccoonnttaaiinnss lloott--

ssppeecciiffiicc pprroodduucctt

ssppeecciiffiiccaattiioonnss..

The following materials are required but not supplied:

Bio-Plex MCV plates

Bio-Rad catalog #171-203032, MCV plate III, for use with Bio-Plex Manager

4.0/4.1 (standard or security software)

Bio-Rad catalog #171-203033, MCV plate IV, for use with Bio-Plex Manager 5.0

and later (standard or security software)

Bio-Plex Suspension Array System

Bio-Rad catalog #171-000001, 171-000002, 171-000003, 171-00004,

171-000005, 171-000006, 171-000007, or 171-000009

Bio-Plex Calibration Kit

Bio-Rad catalog #171-203060, includes Cal1 and Cal2 calibration beads for

approximately 50 daily calibration routines

mini vortexer

sterile distilled water

70% isopropanol

10% bleach

bulb pipets

2

Section 3

Specifications

Specifications for the Bio-Plex®validation kit may differ from lot to lot. Please refer

to the package insert provided with your validation kit for specifications.

Section for Software Installation

The Bio-Plex validation kit 4.0 includes a BizCard CD containing files with the

specifications for the validation beads along with additional information. The file

information is automatically loaded into Bio-Plex Manager™ 4.0 and later versions

upon installation.

Section 4

Storage and Handling

The Bio-Plex®validation kit beads are stable if stored at 4°C protected from light.

When using the Bio-Plex validation kit, remove beads from storage and dispense

into the MCV plate. Return to 4°C storage immediately following use to preserve

shelf life. All components are guaranteed for 18 months from the date of

manufacture when stored as specified in this manual.

Section 5

Principle of Optics Validation

Principle

The Bio-Plex

®

array reader is a laser-based fluorescence detection system

containing sensitive optics components. Alignment of the laser/optics system is

critical for optimal instrument performance. A method for the assessment of the

optics alignment is included in the validation kit. Acceptable specifications for the

alignment procedure are listed in the product insert.

Impact on Assay Performance

The alignment of the optics bench of the Bio-Plex array reader is critical for proper

assay performance. Misalignment of the reporter optics path can result in 1)

reduced assay sensitivity or 2) poor well-to-well assay precision. Misalignment of

the classification optics path can lead to 1) increased read times or 2)

misclassification of one assay into another, leading to false positive or negative

results. Correlation studies have been performed to determine the direct effect of

misalignment on assay performance.

3

Section 6

Principle of Reporter Validation

Principle

The reporter (RP1) channel is the fluorescence channel used for assay quantitation

(See Bio-Plex

®

system hardware manual for more information regarding the

principle of Bio-Plex technology). Therefore, validation of this component of the

Bio-Plex system is a critical part of operational qualification. R-phycoerythrin (R-PE)

is the primary reporter molecule used in Bio-Plex assays. A series of beads dyed

with varying intensities of a fluorochrome spectrally matched to R-phycoerythrin are

used for this procedure.

The primary reporter channel performance parameters are as follows: dynamic

range, linearity, slope, accuracy, and instrument threshold (sensitivity) of the reporter

channel response. Each of these parameters is related directly to the performance

of the Bio-Plex array reader and has defined acceptable specifications. Definitions

for the parameters and the applicability to a typical assay performed on the

Bio-Plex array reader are listed below. If any of the parameters are not within the

specified range, contact Bio-Rad technical support for assistance.

High Versus Low PMT Calibration and Validation

Some assays may require quantitating a range of analyte concentrations greater

than what can be achieved running the instrument at a single PMT setting. In these

cases, the samples may be run with different detector channel PMT settings: a high

RP1 target setting and a low RP1 target setting. They are set differently depending

on your version of Bio-Plex Manager™ software.

For Bio-Plex Manager 4.0/4.1, the targets are set during calibration of the

instrument. Using the high RP1 target will allow for the ability to quantitate lower

concentrations of analyte, while using the low RP1 target allows for the ability to

quantitate higher concentrations of analyte. For Bio-Plex Manager 5.0 and later,

calibration is performed using the low RP1 target and the high RP1 target is then

selected during the validation setup.

Dynamic Range of Reporter Channel

Definition

The theoretical maximum dynamic range of the Bio-Plex array reader can be

represented by the maximum number of channels in the A/D converter. Currently,

the available range of channels is from 0 to 32,767, or about 4.5 decades on a log

scale. These channels are represented by FI, or Fluorescence Intensity units. The

dynamic range of the Bio-Plex array reader is measured by taking the log of the

fluorescence intensity value of the highest reporter bead minus the fluorescence

intensity of the blank bead. This value is the calibrated dynamic range of the

instrument and is always less than 4.5 log decades because the highest intensity

bead in the validation kit that is read is less than 32,767 FI units, while the blank

bead gives a reading that is greater than zero FI units.

4

Impact on Assay Performance

It is desirable for the range of the instrument to be greater than the range of the

assay. In most experiments, the dynamic range of the assay is far less than that of

the instrument. However, in some assays, the same or different analytes may be

present in greater than 4.5 log differences in concentration. When this is the case,

the sample can be rerun at different PMT settings to extend the overall dynamic

range of the measurements.

Linearity of Reporter Channel

Definition

The reporter validation bead set is utilized to construct a plot where the reporter

channel median fluorescence intensity values are plotted against the corresponding

expected fluorescent intensity values (as determined on an independent calibrated

instrument). Instrument linearity is expressed as the coefficient of determination or

R-squared (R

2

) value.

Impact on Assay Performance

The linearity of the instrument response may directly affect a typical standard or

calibration curve in a Bio-Plex assay, thereby impacting the unknown values

extrapolated from that curve. If the R

2

value is not within acceptable limits, it may

be necessary to realign the optics or check the response of the reporter

photomultiplier tube.

Accuracy of Reporter Channel Response

Definition

The accuracy of the reporter channel response is a more stringent measurement of

the linearity than the R

2

value. Simply stated, the accuracy of the reporter channel

response is the percent difference that the regression line is away from the

expected fluorescence intensity data point values.

Impact on Assay Performance

Since accuracy is also a measurement of the linearity of the instrument response,

the same principles that apply to linearity also apply to accuracy of the reporter

channel response. The accuracy data is evaluated in combination with optics

alignment to determine if the Bio-Plex reader will perform according to

specifications. It is possible for the accuracy value to fall out of specification before

the linearity parameter. This is expected due to the fact that the accuracy parameter

is a more sensitive measurement of linearity than the R

2

value. These data are

correlated with optics alignment data as well as assay performance to determine

when the array reader will not perform according to specifications.

Slope of the Reporter Channel Response

Definition

The slope of the regression line resulting from the plotting of reporter channel mean

fluorescent values against expected relative fluorescence is related to the dynamic

range of the instrument. The slope of the regression line is a function of the

response of the reporter channel photomultiplier tube.

5

Impact on Assay Performance

The slope of the regression line is directly related to the dynamic range of the

instrument. The slope yields direct information about the response of the

photomultiplier tube. If the photomultiplier tube signal saturates at low

fluorescence values, the dynamic range of the instrument is affected. The slope

of the line impacts the dynamic range and the range, in turn, impacts the

quantifiable range of an assay.

Instrument Threshold (Sensitivity)

Definition

Every instrument has an inherent level of background noise. Noise can be

attributed to the laser, the PMT, the amplification electronics or the fluidics. The

instrument threshold (sensitivity) of the Bio-Plex array reader is one way to

demonstrate noise of the system. It is defined as the reporter channel signal of a

blank bead that contains no reporter dye.

Impact on Assay Performance

The instrument threshold level demonstrated using the Bio-Plex validation kit is a

low fluorescence intensity value. The typical background or zero standard of a

Bio-Plex cytokine assay falls at a median fluorescence intensity of ~100. This is a

desired result, as the instrument threshold should not limit the assay sensitivity. If

the instrument threshold is too close to zero, then a low assay signal may be

masked; if too high, then the linearity and dynamic range may be compromised.

6

Section 7

Principle of Classify Validation

Principle

Bio-Plex

®

technology relies on the ability of the Bio-Plex array reader to

discriminate between assay beads impregnated with varying ratios of 2

fluorescent dyes. This is the concept whereby multiplexing within a single well

may occur. The periodic evaluation of the classify efficiency is necessary to

complete the Bio-Plex array reader qualification process. A series of beads with

varying ratios of the classification dyes are analyzed on the Bio-Plex array reader

and the efficiency of multiplexing is quantitated. A classify efficiency of >80% is

required for optimal results. Doublet Discriminator (DD) efficiency is a measure of

the percentage of the classify beads that fall within the DD gates. The DD gates

are used to distinguish single beads from bead clusters, bead fragments or other

small particles passing in front of the detector. Greater than 75% of the beads

should fall within the gates for optimal results.

Impact on Assay Performance

Inefficient classification of beads may have several potential effects on an assay. If

a bead region exhibits a classify efficiency of less than 80%, the read time of a

96-well plate may be increased. The Bio-Plex array reader tabulates a specified

number of defined events in each region for each well sampled. If the percentage

of beads within a specific region is low, the time required to count is increased,

therefore the total time to read an entire plate is prolonged. Extremely prolonged

assay read times could impact well-to-well precision, since the kinetics of a

sandwich assay, for example, are not 100% stable over a period of several hours.

Another potential impact of inefficient classification is the misclassification of one

assay bead into another bead region. This could yield false positive or negative

results for a particular assay. A DD efficiency of less than 75% may increase the

read time of the assay and affect results in the same manner as a low classify

efficiency.

7

Section 8

Principle of Fluidics Validation

Principle

The fluidics system of the Bio-Plex

®

array reader requires routine maintenance to

prevent clogging and other malfunctions. Strict adherence to the maintenance

procedures is mandatory for optimal instrument performance. An assessment of

the integrity of the fluidics is automatically performed in the fluidics validation

procedure. In the fluidics validation test, a sample of beads is analyzed followed

by a sample of buffer to assess the carryover of beads from one well to another.

This procedure should be performed once per week to ensure that assay results

are not adversely affected. The fluidics path, including the sample needle, must

be completely free of debris and excess beads for optimal array reader

performance.

Impact on Assay Performance

If a system is exhibiting a high level of carryover due to valve malfunction or a

partially clogged sample needle, a significant percentage of beads may be carried

over from one well to another. This phenomenon may adversely affect the median

fluorescent intensity values. For example, if a well with a high median fluorescent

intensity (FI) is read immediately prior to a well with a low median FI, the signal in

the well with the low fluorescent intensity may shift upward. This phenomenon

only occurs in extreme cases since the median fluorescent intensity statistic is

robust and is not easily shifted by the introduction of a population of beads with a

significantly different median FI.

Section 9

Software Utility Installation

Introduction

This section provides instructions for installing the control number information

from the BizCard CD contained in the validation kit into the Bio-Plex Manager™

database. The BizCard CD contains the control number, expiration date, and

specifications for your validation kit.

Procedure

1. Exit Bio-Plex Manager prior to proceeding.

2. Insert the BizCard-CD into the CD Rom drive of your computer. The

installation program should start automatically. The application can also be

launched through Windows Explorer by double clicking on the file

“InstallControlNumbers.exe”.

8

3. If the control numbers on the BizCard CD already exist in the database, you

will receive the message that the control numbers are already installed and

the program will exit. Click on the OK button and remove the BizCard CD.

4. If the control numbers on the BizCard CD are not found in the database, you

will see a dialog asking you to press OK to install the control numbers with

their specifications. Click on the OK button.

5. A dialog box will appear informing you that control numbers installation is

complete. You may now proceed with validation in Bio-Plex Manager using

the current control number.

Section 10

Procedure for Performing Validation

Introduction

This section provides instructions for use of the Bio-Plex

®

validation kit 4.0 using

either Bio-Plex Manager™ 4.0/4.1 software with MCV plate III or Bio-Plex

Manager 5.0 and later with MCV plate IV. Either software version provides a fully

automated validation routine that sequentially performs all the validation tests

without further user intervention. To perform all validations in a single step, follow

instructions in Section 10.1. If you wish to perform an individual validation routine,

consult Sections 10.2–10.5.

NNoottee:: IInn tthhee ffoolllloowwiinngg iinnssttrruuccttiioonnss aallll rreeffeerreenncceess ttoo tthhee MMCCVV ppllaattee wwiitthhoouutt

ssppeecciiffyyiinngg IIIIII oorr IIVV i

innddiiccaattee tthhee pprroocceedduurree iiss uusseedd ffoorr eeiitthheerr ccoonnffiigguurraattiioonn.. AAllll

ppiiccttuurreess aarree uuppddaatteedd ttoo rreefflleecctt tthhee nneewwe

esstt MMCCVV ppllaattee,, bbuutt ddooeess nnoott iimmppllyy tthhaatt

tthheerree iiss aannyy ddiiffffeerreennccee iinn ppeerrffoorrmmaannccee..

10.1 One-Step Procedure for all Validation Parameters

Procedure

1. Turn on the Bio-Plex array reader, microplate platform, and computer as

specified in the Bio-Plex hardware and Bio-Plex Manager user manuals.

2. Perform start-up procedure as directed.

3. Calibrate Bio-Plex array reader using Cal1 and Cal2 beads found in the

Bio-Plex calibration kit according to the Bio-Plex Manager software manual.

NNoottee:: BBee ssuurree ttoo ccaalliibbrraattee iimmmmeeddiiaatteellyy bbeeffoorree vvaalliiddaattiioonn.. IIff yyoouu aarree uussiinngg BBiioo--PPlleexx

MMaannaaggeerr 44..0

0//44..11,, uussee eeiitthheerr tthhee hhiigghh oorr llooww RRPP11 ttaarrggeett ffoorr CCaall22 ccaalliibbrraattiioonn

ddeeppeennddiinngg oonn tthhee ttyyppee ooff aassssaayy bbeeiin

ngg ppeerrffoorrmmeedd.. IIff yyoouu aarree uussiinngg BBiioo--PPlleexx

MMaannaaggeerr 55..00,, tthhee ccaalliibbrraattiioonn iiss ddoonnee oonn llooww RRPP11 ttaarrggeett.. SSeelleec

cttiioonn ooff hhiigghh RRPP11

ttaarrggeett iiss ddoonnee iinn tthhee vvaalliiddaattiioonn ssccrreeeenn..

4. Remove all validation bead sets from 4°C storage and vortex each bottle for

30 sec. This is very important for proper validation.

9

5. In Bio-Plex Manager software, select

IInnssttrruummeenntt

from the main menu. Select

VVaalliiddaattiioonn

from the pull-down menu. The following dialog box will appear

(Figure 1A):

Fig. 1A. Main validation dialog.

6. Enter user name and control number. Select

AAllll

. Select

OOKK

. The following

dialog box will appear (Figure 1B):

Fig. 1B. All validation dialog.

10

7. Place 5 drops of each bead into the respective wells on the MCV plate (see

Figure 2 below or Figure 1B). Store beads at 4°C as soon as possible after

use. Protect the beads from light.

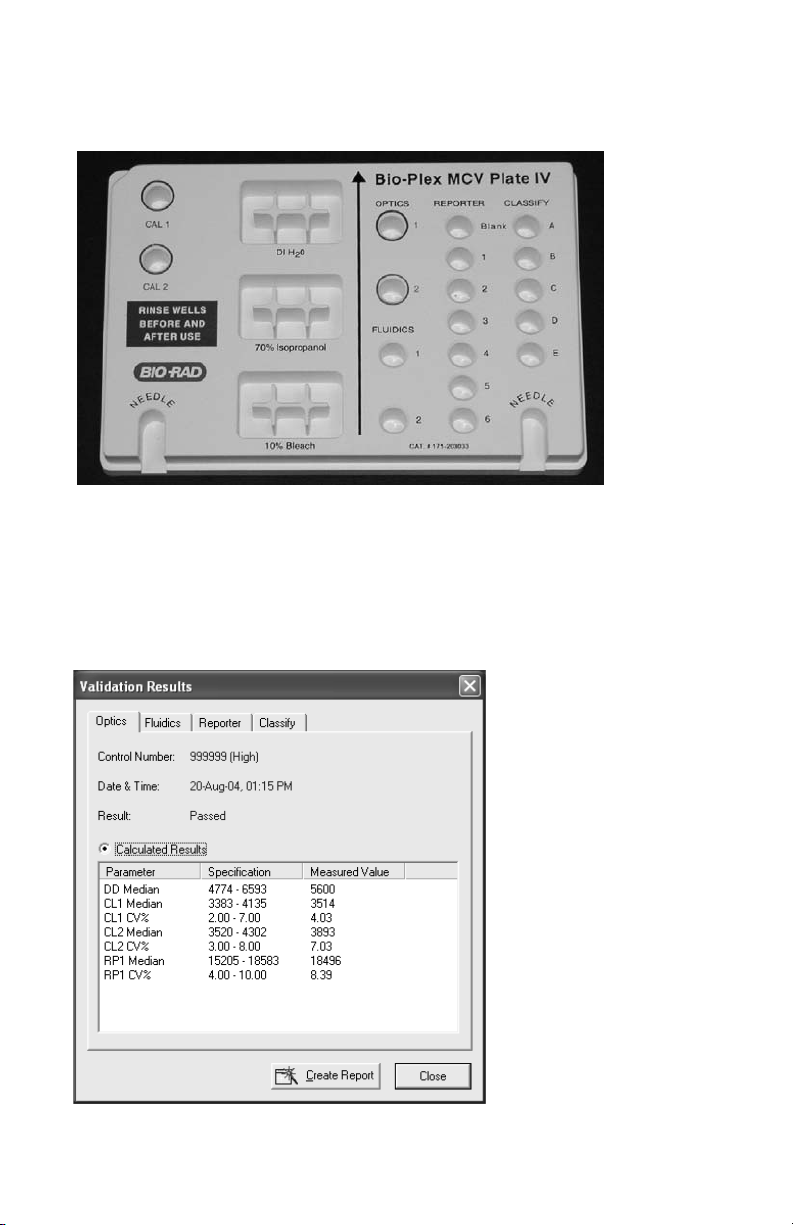

Fig. 2. MCV plate IV.

8. Select the

EEjjeecctt

button in the dialog box to eject the plate holder.

9. Place the MCV plate in the microplate platform.

10. Select

OOKK

to begin all validation procedures.

11. When the procedure has completed, the results will be displayed in a dialog

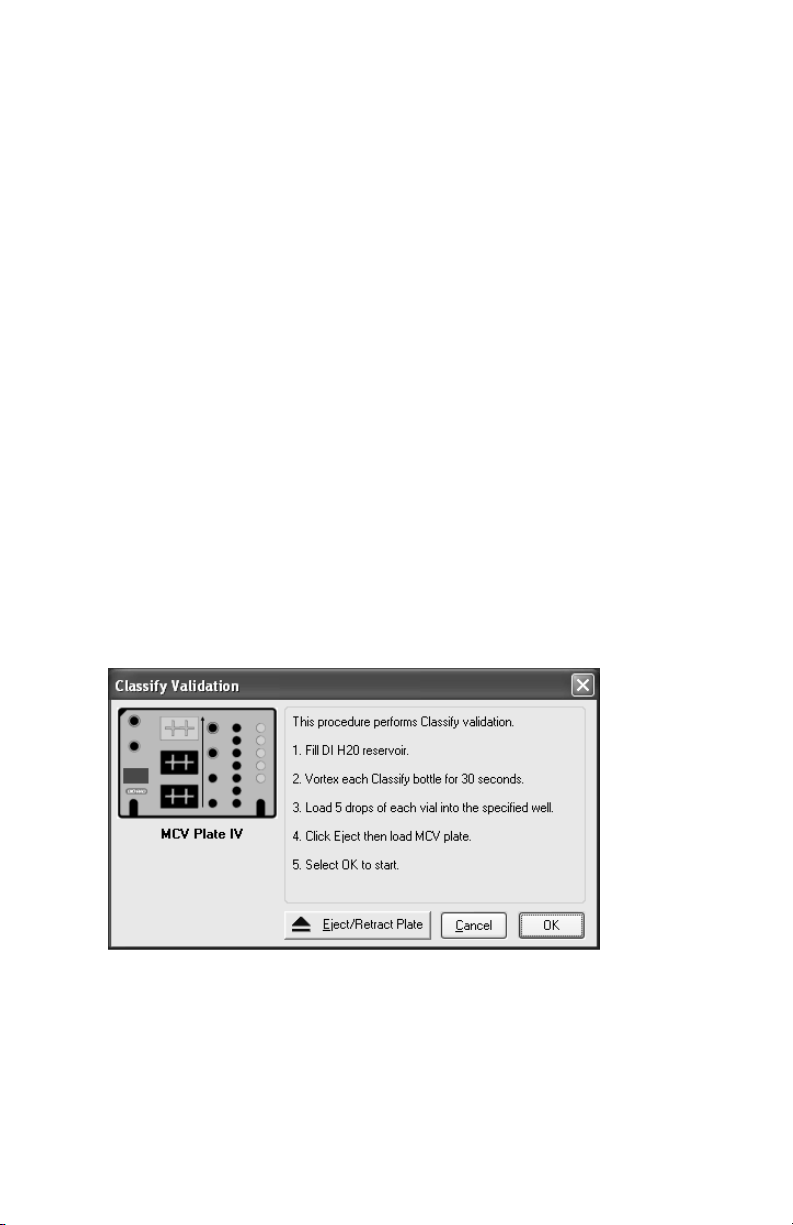

box, as shown in Figure 3:

Fig. 3. Validation results.

11

12. Check the results for each validation. If specifications are not met for any

validation, repeat that validation. If the value again is not within the

specification range, contact Bio-Rad technical support for assistance.

13. The following sections describe the steps for performing the individual

validations (optics, fluidics, reporter, or classify).

14. Validation results are also logged into a validation log in Bio-Plex Manager. To

access this log, select

VViieeww

from the main menu then

VVaalliiddaattiioonn LLoogg

. Each

type of validation is stored in a separate log for the purpose of tracking data

over time. See the Bio-Plex Manager user manual for your software version

for more information on using the validation log.

10.2 Validation of Optics Alignment

Procedure

1. If not already done, follow the procedure for start-up and calibration of the

Bio-Plex system.

NNoottee:: BBee ssuurree ttoo ccaalliibbrraattee iimmmmeeddiiaatteellyy bbeeffoorree vvaalliiddaattiioonn.. IIff yyoouu aarree uussiinngg BBiioo--PPlleexx

MMaannaaggeerr 44..00//4

4..11,, uussee eeiitthheerr tthhee hhiigghh oorr llooww RRPP11 ttaarrggeett ffoorr CCaall22 ccaalliibbrraattiioonn

ddeeppeennddiinngg oonn tthhee ttyyppee ooff aassssaayy bbeeiinngg

ppeerrffoorrmmeedd.. IIff yyoouu aarree uussiinngg BBiioo--PPlleexx

MMaannaaggeerr 55..00,, tthhee ccaalliibbrraattiioonn iiss ddoonnee oonn llooww RRPP11 ttaarrggeett.. SSeelleecctti

ioonn ooff hhiigghh RRPP11

ttaarrggeett iiss ddoonnee iinn tthhee vvaalliiddaattiioonn ssccrreeeenn..

2. Remove the optics validation bead set from 4°C storage and vortex each

bottle for 30 sec.

3. Place 5 drops each of optics beads 1 and 2 into the respective wells on the

MCV plate.

4. Store optics beads at 4°C as soon as possible after use. Protect the beads

from light.

5. In Bio-Plex Manager software, select

IInnssttrruummeenntt

from the main menu. Select

VVaalliiddaattiioonn

from the pull-down menu.

6. Enter user name and control number. Select

OOppttiiccss

. Select

OOKK

. The

following dialog appears (Figure 4):

12

Fig. 4. Optics validation dialog.

7. Select the

EEjjeecctt

button in the dialog box to eject the plate holder.

8. Place the MCV plate in the microplate platform.

9. Select

OOKK

to begin the optics validation procedure.

10. When the procedure has been completed, the results will be displayed in a

dialog box, as shown in Figure 5:

Fig. 5. Optics validation results.

13

10.3 Validation of Fluidics Integrity

Procedure

1. If not already done, follow the procedure for start-up and calibration of the

Bio-Plex system.

NNoottee:: BBee ssuurree ttoo ccaalliibbrraattee iimmmmeeddiiaatteellyy bbeeffoorree vvaalliiddaattiioonn.. IIff yyoouu aarree uussiinngg BBiioo--PPlleexx

MMaannaaggeerr 44..00//4

4..11,, uussee eeiitthheerr tthhee hhiigghh oorr llooww RRPP11 ttaarrggeett ffoorr CCaall22 ccaalliibbrraattiioonn

ddeeppeennddiinngg oonn tthhee ttyyppee ooff aassssaayy bbeeiinngg

ppeerrffoorrmmeedd.. IIff yyoouu aarree uussiinngg BBiioo--PPlleexx

MMaannaaggeerr 55..00,, tthhee ccaalliibbrraattiioonn iiss ddoonnee oonn llooww RRPP11 ttaarrggeett.. SSeelleecctti

ioonn ooff hhiigghh RRPP11

ttaarrggeett iiss ddoonnee iinn tthhee vvaalliiddaattiioonn ssccrreeeenn..

2. Select

IInnssttrruummeenntt

, then

VVaalliiddaattiioonn

from the main menu and select

FFlluuiiddiiccss

in

the dialog box.

3. Enter user name and control number. Select OK. The following dialog box

will then appear (Figure 6):

Fig. 6. Fluidics validation dialog.

4. Add 5 drops each of fluidics beads 1 and 2 to the designated wells on the

MCV plate.

5. Select the

EEjjeecctt

button in the dialog box to eject the plate holder.

6. Place the MCV plate in the microplate platform.

7. Select

OOKK

to begin the fluidics validation procedure.

8. When the procedure has been completed, results will appear in a dialog box,

as shown in Figure 7:

14

Fig. 7. Fluidics validation results.

9. If value is not within the specification range, repeat the procedure. If value

again is not within the specification range, contact Bio-Rad technical support

for assistance.

10.4 Validation of Reporter Channel Performance

Procedure

1. If not already done, follow the procedure for start-up and calibration of the

Bio-Plex system.

NNoottee:: BBee ssuurree ttoo ccaalliibbrraattee iimmmmeeddiiaatteellyy bbeeffoorree vvaalliiddaattiioonn.. IIff yyoouu aarree uussiinngg BBiioo--PPlleexx

MMaannaaggeerr 44..00//4

4..11,, uussee eeiitthheerr tthhee hhiigghh oorr llooww RRPP11 ttaarrggeett ffoorr CCaall22 ccaalliibbrraattiioonn

ddeeppeennddiinngg oonn tthhee ttyyppee ooff aassssaayy bbeeiinngg

ppeerrffoorrmmeedd.. IIff yyoouu aarree uussiinngg BBiioo--PPlleexx

MMaannaaggeerr 55..00,, tthhee ccaalliibbrraattiioonn iiss ddoonnee oonn llooww RRPP11 ttaarrggeett.. SSeelleecctti

ioonn ooff hhiigghh RRPP11

ttaarrggeett iiss ddoonnee iinn tthhee vvaalliiddaattiioonn ssccrreeeenn..

2. Remove the reporter validation bead set from 4°C storage and vortex each

bottle for 30 sec.

3. Place 5 drops of each reporter bead into the corresponding reporter well

labeled as Blank, 1, 2, 3, 4, 5, and 6 in the MCV plate.

4. Store reporter beads at 4°C as soon as possible after use. Protect the beads

from light.

5. Fill the DI H

2

O and 70% isopropanol reservoirs.

6. Select

IInnssttrruummeenntt

from the main menu. Select

VVaalliiddaattiioonn

from the pull-down

menu. A dialog will appear. Enter user name and control number. Select

RReeppoorrtteerr VVaalliiddaattiioonn

. Select

OOKK

. The following dialog will appear (Figure 8):

15

Fig. 8. Reporter validation dialog.

7. Select the Eject icon in the dialog box to eject the plate holder.

8. Place the MCV plate in the microplate platform.

9. Select OK to start the reporter validation procedure.

10. When the procedure is completed, values will appear in a dialog box, as

shown in Figure 9:

Fig. 9. Reporter validation results.

11. The results will also be logged into a validation log in Bio-Plex Manager

software. See the Bio-Plex Manager user manual for your software version for

more information on using the validation log.

16

12. Repeat procedure if values are not within the specification range. If values

are again not within acceptable specification ranges, contact Bio-Rad

technical support for assistance.

10.5 Validation of Classify Efficiency

Procedure

1. If not already done, follow the procedure for start-up and calibration of the

Bio-Plex system.

NNoottee:: BBee ssuurree ttoo ccaalliibbrraattee iimmmmeeddiiaatteellyy bbeeffoorree vvaalliiddaattiioonn.. IIff yyoouu aarree uussiinngg BBiioo--PPlleexx

MMaannaaggeerr 44..00//4

4..11,, uussee eeiitthheerr tthhee hhiigghh oorr llooww RRPP11 ttaarrggeett ffoorr CCaall22 ccaalliibbrraattiioonn

ddeeppeennddiinngg oonn tthhee ttyyppee ooff aassssaayy bbeeiinngg

ppeerrffoorrmmeedd.. IIff yyoouu aarree uussiinngg BBiioo--PPlleexx

MMaannaaggeerr 55..00,, tthhee ccaalliibbrraattiioonn iiss ddoonnee oonn llooww RRPP11 ttaarrggeett.. SSeelleecctti

ioonn ooff hhiigghh RRPP11

ttaarrggeett iiss ddoonnee iinn tthhee vvaalliiddaattiioonn ssccrreeeenn..

2. Remove the classify validation bead set from 4°C storage and vortex each

bottle for 30 sec.

3. Place 5 drops of each classify bead into the corresponding classify well

labeled as A, B, C, D, and E in the MCV plate.

4. Store stock vials at 4°C as soon as possible after use. Protect beads from

light.

5. Select

IInnssttrruummeenntt

from the main menu. Select

VVaalliiddaattiioonn

from the pull-down

menu.

6. Enter the User name and select control number. Select

CCllaassssiiffyy VVa

alliiddaattiioonn

.

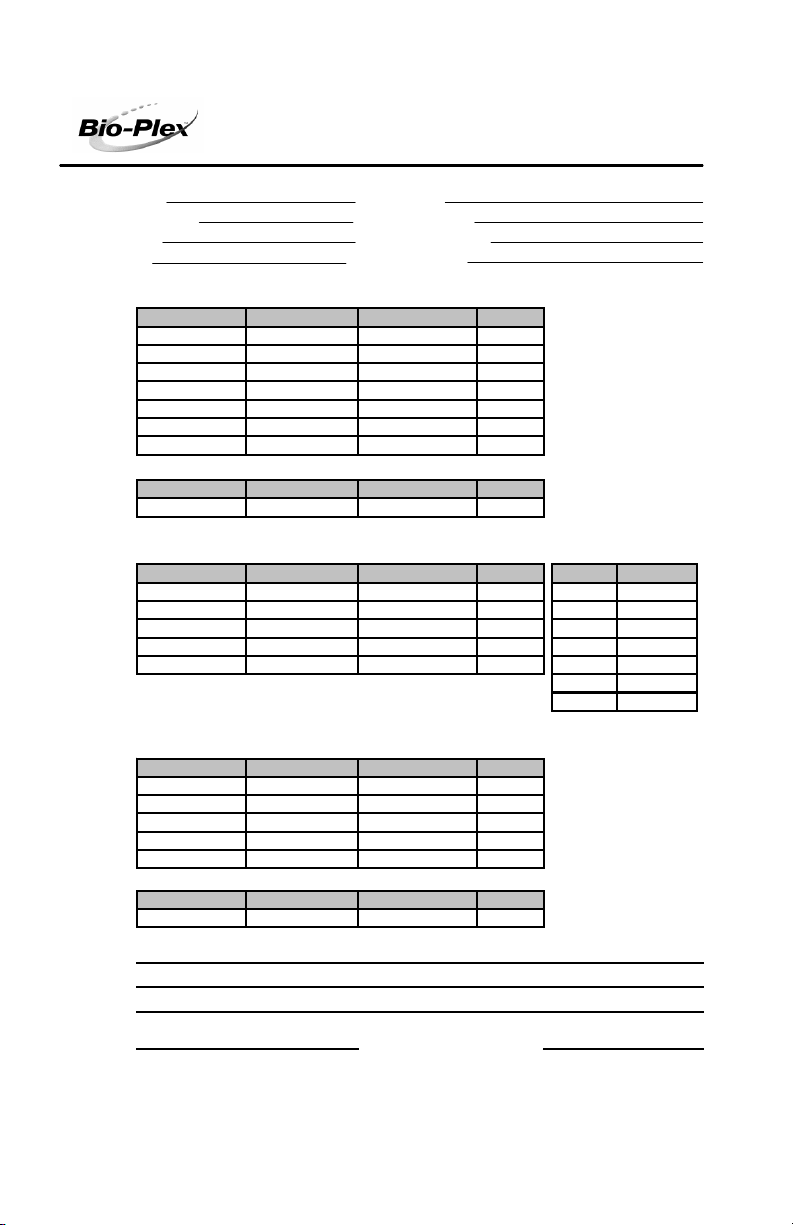

Select OK. The following dialog box will appear (Figure 10):

Fig. 10. Classify validation dialog.

7. Select the Eject button to eject the plate holder.

8. Place the MCV plate on the microplate platform.

9. Select

OOKK

to start the classify validation procedure.

17

10. When the procedure is completed, values will be displayed in a dialog box as

shown below (Figure 11). The classify efficiency and DD efficiency results

may be accessed in this view.

Fig. 11. Classify validation results.

11. The results will also be logged into a validation log in Bio-Plex Manager

software. To access this log, select

VViieeww

from the main menu then

VVaalliiddaattiioonn

LLoogg

. Each type of validation is stored in a separate log for the purpose of

tracking data over time. See the Bio-Plex Manager software user guide for

your version of software for more information on using the validation log.

12. If any values do not meet specifications, repeat the procedure. If values are

again not within specifications, contact Bio-Rad technical service for

assistance.

10.6 Generating a Validation Report

Procedure

The results from each validation procedure are sent to a validation log in Bio-Plex

Manager software. This log may be used to create individual reports as well as

track multiple validation results over time. Each type of validation is logged into a

separate view: optics validation, fluidics validation, reporter validation and classify

validation. You may maneuver through each of the views using either the main

menu items or the toolbar icons. The specifications for each control number of

the validation kit are also shown in a separate window below the results. If All

Validation was selected, an entry matching the specific date and time will

appear in each of the validation logs. All of the validation results for a specific

date and time will be included in a created report. The entire log may be printed

by selecting

PPrriinntt

then

RReessuullttss

from the main menu.

A general procedure for creating a report from the validation log is shown below.

For more detailed instructions on the use of the validation log, consult the

Bio-Plex Manager user guide.

18

1. Open Bio-Plex Manager software by clicking on the application icon on the

desktop.

2. Select

VViieeww

from the main menu then select

VVaalliiddaattiioonn LLoogg

from the pulldown

menu. The validation log will open.

3. Choose the desired validation log by using the main menu or the toolbar icons

for optics, fluidics, reporter and classify validation.

4. Click on the desired entry in the validation log. The selected row will be

highlighted in black.

5. Select the create report icon. A report will automatically be generated in

Microsoft Excel.

6. Print the report in Excel by selecting

FFiillee

then

PPrriinntt

from the main menu.

Alternatively, you may use the

PPrriinntt

button in Excel.

10.7 Validation Kit Report Form Example

The following is a sample validation report from Bio-Plex Manager software. Note

that the values included here are for demonstration purposes only. Consult your

product insert for values specific to your product control number.

19

your product insert for values specific to your product control number..

Parameter Specification Measured Value Pass/Fail

DD Median 4774 - 6593 6133 Pass

CL1 Median 3383 - 4135 3615 Pass

CL1 CV% 2.00 - 7.00 3.52% Pass

CL2 Median 3520 - 4302 3883 Pass

CL2 CV% 3.00 - 8.00 6.93% Pass

RP1 Median 3509 - 4290 3878 Pas s

RP1 CV% 4. 00 - 10.00 8.89% Pass

Para meter Specification Me asure d Val ue Pass/Fa il

% Carryover < or = 4.0% 1.3% Pas s

A. Ca lculate d Va lue s B. Ra w Va l ue s

Para meter Specification Me asure d Val ue Pass/Fa il Bea d Media n FI

Dynamic Range 4.33 - 4.45 4.40 Pass Blank 2

Linearity > 0.995 1.000 P ass 1 8

Slope 33.94 - 39.42 37.57 Pas s 2 54

Acc uracy > 90.00% 96.94% Pass 3 656

Threshold < 6 MFI 2 Pass 4 1576

5 4453

6 25059

A. Classify Effici ency

Classify Bead Specification Measured Value Pass/Fail

Bead A (1) > 80.0% 98.1% P ass

Bead B (4) > 80.0% 93.5% P ass

Bead C (40) > 80. 0% 90.5% Pas s

Bead D (54) > 80. 0% 95.3% Pas s

Bead E (100) > 80.0% 93.0% Pass

B. DD Efficie ncy

Para meter Specification Me asure d Val ue Pass/Fa il

DD Efficienc y > or = 75. 0%

96.7% Pass

Comments :

Reviewed by : Date:

III. Reporter Validation

IV. Classify Validation

II. Fluidics Validation

Test Performed by : JPoc ekay

Date/Time: 04-Aug-04 11:55 AM

Expi ration Dat e: 15-Oc t-06

Reader Serial #: LX10000266002

Access Level: Unrestricted

Validat ion Kit Control #: 999999 (Low)

RP1 Target Value: 3885

RP1 PMT Voltage: 571.67

Result: Passed

Result: Passed

Result: Passed

Result: Passed

I.Optics Validation

Suspension Array System Validation Report

20

Section 11

Troubleshooting Guide

Problem Cause Solution

Optics validation Problem with the Repeat the procedure.

procedure shows optical component of If value is still out of

value outside of the array reader range, contact Bio-Rad

acceptable range technical support.

Reporter validation Problem with the Repeat the procedure.

procedure shows optical component of If value is still out of

value outside of the array reader range, contact Bio-Rad

acceptable range technical support.

Classify validation Problem with the Repeat the procedure.

procedure shows calibration or If values are still out of

value outside of optical component range, contact Bio-Rad

acceptable range of the array reader technical support.

Fluidics validation Problem with fluidics Repeat procedure. If

procedure shows lines, valves or value is still out of range,

value outside sample needle of contact Bio-Rad

of acceptable range array reader technical support.

Section 12

Ordering Information

Catalog # Description

171-203001 Bio-Plex Validation Kit 4.0, includes optics validation,

reporter validation, classify validation, and fluidics validation bead

sets for approximately 50 calibration routines

171-203060 Bio-Plex Calibration Kit, includes Cal1 and Cal2 calibration

beads for approximately 50 daily calibration routines

171-203032 Bio-Plex MCV Plate III, for use with Bio-Plex Manager 4.0 or

4.1 (standard or security software) and validation kit 4.0

171-203033 Bio-Plex MCV Plate IV, for use with Bio-Plex Manager 5.0

(standard or security software) and later versions and validation

kit 4.0

21

Section 13

Reference

Alder, Henry: Introduction to Probability and Statistics. Alder HL and Roessler EB

(eds) W.H. Freeman, San Francisco, p118 (1968).

The Bio-Plex®suspension array system includes fluorescently labeled microsperes and instrumentation

licensed to Bio-Rad Laboratories, Inc. by the Luminex Corporation. By purchasing this kit, which contains

fluorescent labeled microsphere beads authorized by Luminex, you, the customer, acquire the rights under

Luminex’s patent rights* to use certain portions of this kit, including without limitation the microsphere beads

contained herein, only with Luminex’s laser-based fluorescent analytical test instrumentation known under the

name of Luminex 100, for example as marketed by Bio-Rad Laboratories, Inc., in the Bio-Plex system.

* Including, but not limited to US patent 5,981,180; 6,046,807; 6,057,107

Certain Bio-Plex validation kit components are licensed under US patent 5,723,218

22

4110185 Rev B

Bio-Rad

Laboratories, Inc.

Life Science

Group

Bulletin 0000 US/EG Rev A

Web site www.bio-rad.com USA 800 4BIORAD Australia 61 02 9914 2800

Austria 01 877 89 01 Belgium 09 385 55 11 Brazil 55 21 3237 9400

Canada 905 712 2771 China 86 21 6426 0808

Czech Republic 420 241 430 532 Denmark 44 52 10 00

Finland 09 804 22 00

Greece 30 210 777 4396 Hong Kong 852 2789 3300

Hungary 36 1 455 8800 India 91 124 4029300 Israel 03 963 6050

Italy 39 02 216091 Japan 03 5811 6270 Korea 82 2 3473 4460

Mexico 52 555 488 7670 The Netherlands 0318 540666

New Zealand 0508 805 500 Norway 23 38 41 30 Poland 48 22 331 99 99

Portugal 351 21 472 7700 Russia 7 495 721 14 04

Singapore 65 6415 3188 South Africa 27 861 246 723

Spain 34 91 590 5200 Sweden 08 555 12700 Switzerland 061 717 95 55

Tai w an 886 2 2578 7189 United Kingdom 020 8328 2000

France 01 47 95 69 65 Germany 089 318 84 0

00-0000 0000 Sig 1106

Loading...

Loading...