Page 1

Bio-Plex Manager™ Software 6.1

User Guide

Page 2

Page 3

Bio-Plex Manager™

Software 6.1 User Guide

Bio-Rad Laboratories, Inc., 2000 Alfred Nobel Drive,

Hercules, CA 94547 · 1-800-424-6723

10022815 Rev B

Page 4

Bio-Plex Manager Software 6.1 User Guide

BIO-RAD TECHNICAL SUPPORT DEPARTMENT

The Bio-Rad Technical Support Department in the U.S. is open Monday through Friday,

5:00 a.m. to 5:00 p.m., Pacific Standard Time. Worldwide technical support is available on

the Web at www.consult.bio-rad.com.

Phone: 1-800-424-6723, option 2

Fax: 1-510-741-5802

Email: LSG.TechServ.US@Bio-Rad.com (U.S.)

LSG.TechServ.Intl@Bio-Rad.com (International)

Web: www.consult.bio-rad.com

NOTICE

No part of this publication may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopy, recording, or any information storage or

retrieval system, without permission in writing from Bio-Rad.

Bio-Rad reserves the right to modify its products and services at any time. This user guide

is subject to change without notice. Although prepared to ensure accuracy, Bio-Rad

assumes no liability for errors or omissions, or for any damage resulting from the

application or use of this information.

The following are trademarks of Bio-Rad Laboratories: Bio-Rad, Bio-Plex, and Bio-Plex

Manager. Luminex, xMAP, and xPONENT are trademarks of Luminex Corporation.

Windows is a trademark of Microsoft Corporation. Pentium is a trademark of Intel

Corporation.

No rights or licenses under any of Luminex Corporation’s patents are granted by or shall

be implied from the sale or acquisition of this Bio-Plex system containing Luminex

technology (the “System”) to you, the end-user. By using this System, you agree that (i) the

System is sold only for use with fluorescently labeled microsphere beads authorized by

Luminex (“Beads”), and (ii) you obtain rights under Luminex’s patents to use this System

by registering this System with Bio-Rad in accordance with the instructions accompanying

this System and by Bio-Plex Manager Software 6.1 User Guidepurchasing a kit containing

Beads.

Copyright © 2001–2011 by Bio-Rad Laboratories. All rights reserved.

ii

Page 5

Bio-Plex Manager Software 6.1 User Guide

Table of Contents

Chapter 1. Bio-Plex Suspension Array System Overview . . . . . 1

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Advantages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

For More Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Bio-Rad Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 2. Bio-Plex Manager™ Software Overview . . . . . . . . . 5

Software Editions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Software Licenses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Compatibility with Luminex Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General Workflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Quick Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Types of Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Key Software Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 3. Software Installation . . . . . . . . . . . . . . . . . . . . . . . . 11

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Required Screen Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Microsoft.NET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Bioplexdata.mdb File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Luminex LXR Directory and Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Hardware Protection Key (HASP Key). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Uninstalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 4. Starting the System . . . . . . . . . . . . . . . . . . . . . . . . . 15

Starting Bio-Plex Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connecting with the Array Reader and Microplate Platform . . . . . . . . 16

Communication between the Array Reader and Microplate Platform . 17

Disconnecting and Reconnecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

iii

Page 6

Bio-Plex Manager Software 6.1 User Guide | Table of Contents

Disconnecting with Sleep Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Menu and Toolbars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Status Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Quick Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Sample Needle Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 5. Controlling the System . . . . . . . . . . . . . . . . . . . . . . 25

Bio-Plex MCV Plate IV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Optics Warm Up and Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Opening the Calibration Dialog Box . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Selecting/Entering Calibration Control Numbers . . . . . . . . . . . . . . . . . 30

Setting Up the Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Performing the Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Logging the Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Start Up and Calibrate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Wash Between Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Remove Air Bubbles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Unclog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Validation Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Validation Kit Control Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Setting Up a Validation Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Control Number Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Validation Type Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Performing a Validation Run. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Validation Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Validation Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Platform Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

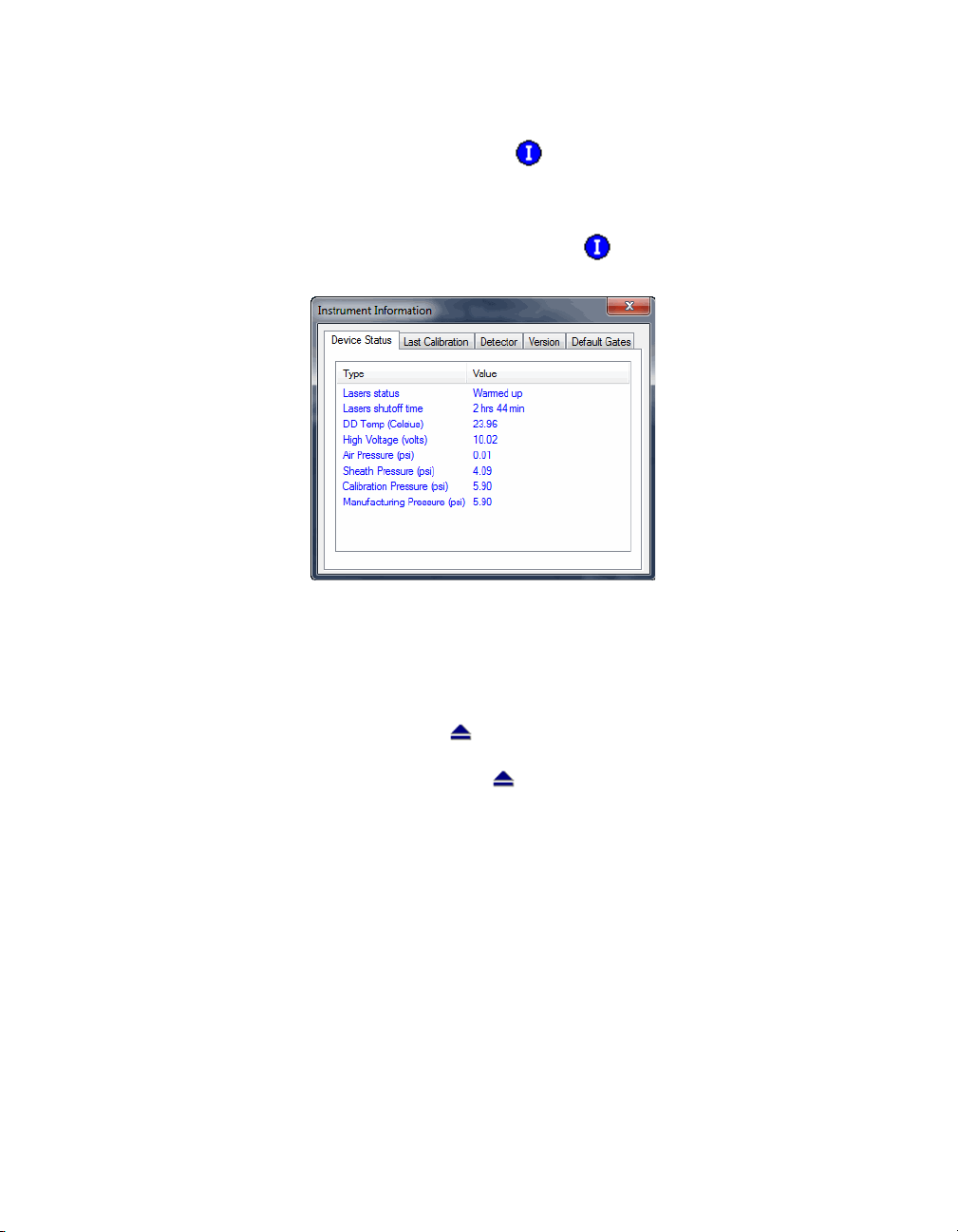

Instrument Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Eject/Retract Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Additional Instrument Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Cancel Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Instrument Operations Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

iv

Page 7

Bio-Plex Manager Software 6.1 User Guide

Chapter 6. Preparing Protocols . . . . . . . . . . . . . . . . . . . . . . . . . 53

Protocol Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Creating/Opening Protocol Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Saving Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Reducing the File Size of Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Multi-Assay Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Uses for Multi-Assay Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Creating a Multi-Assay Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Changing a Protocol from Single to Multi-Assay . . . . . . . . . . . . . . . . . 57

Protocol Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Step 1. Describe Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Step 2. Select Analytes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Step 3. Format Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Plate Groupings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Step 4. Enter Standards Info . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Standard Lots. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Step 5. Enter Controls Info (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . 96

Step 6. Enter Sample Info (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Chapter 7. Running Protocols . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Run Protocol Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Bead Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Sample Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Reservoir Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Skip Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Standard Curve Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Advanced Run Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Bead Map Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Sample Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Save Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Sampling Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Doublet Discriminator Gates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Plate Loading Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Running the Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Status Bar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Manually Stopping a Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Generating Results from a Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Histogram and Bead Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Histogram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Bead Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

v

Page 8

Bio-Plex Manager Software 6.1 User Guide | Table of Contents

Bead Map Display Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Raw Data Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Bead Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Sampling Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Raw Data Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Set Number Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Other Table Formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Copying the Raw Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Rerun/Recovery Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Chapter 8. Using the Security Edition . . . . . . . . . . . . . . . . . . . 125

Bio-Plex Manager™ Security Edition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Background on 21 CFR Part 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Standard Mode vs. Secure Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Installing and Starting Bio-Plex Manager Security Edition . . . . . . . . . . . . . . . 127

Users, Passwords, and User Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

User Level Restrictions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Enabling and Disabling Secure Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

User Authentication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Electronic Records . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

File Security and Validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Calibration, Validation, and Instrument Operations Logs . . . . . . . . . . . . . . . . 131

Secure Protocol and Results Files . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Unsigned Protocol and Results Files . . . . . . . . . . . . . . . . . . . . . . . . . 131

Signed Protocol and Results Files . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Document ID Number and Signature . . . . . . . . . . . . . . . . . . . . . . . . . 134

Adjusting the Number of Unknown Samples in a Protocol . . . . . . . . 135

Generating a Results File from a Protocol File. . . . . . . . . . . . . . . . . . 136

Audit Trail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Viewing the Audit Trail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Protected Directories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Locking Bio-Plex Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Logging Off. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Chapter 9. Analyzing the Results . . . . . . . . . . . . . . . . . . . . . . 143

Results Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Opening a Results File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Saving a Results File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

vi

Page 9

Bio-Plex Manager Software 6.1 User Guide

Reducing the Size of a Results File . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Results Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Custom Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Viewing/Changing the Protocol Settings . . . . . . . . . . . . . . . . . . . . . . 148

Changing the Doublet Discriminator Gate Range . . . . . . . . . . . . . . . 149

Raw Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Setting the Plate ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Exporting the Raw Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Raw Data Table Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Printing the Raw Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Report Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Display Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Report Table Column Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Obs/Exp * 100 Column. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Concentration in Range Column . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Showing/Hiding Outliers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Resizing the Columns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Context Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Sorting Report Table Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Copying the Report Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Printing the Report Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Exporting the Report Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Export Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Export a Subset of the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Export Preferences. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Use Multiple Worksheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Exclude Standard Curves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Exclude Column Headers/Footers . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Exclude Table Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Standard Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Regression Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Linear vs. Logistic Regression Methods . . . . . . . . . . . . . . . . . . . . . . 173

Copying the Standard Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Exporting the Standard Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Printing the Standard Curve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Graphing Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Choosing Graph Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Viewing Information within Graphs. . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Adding New Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Editing an Existing Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

vii

Page 10

Bio-Plex Manager Software 6.1 User Guide | Table of Contents

Deleting a Graph. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Exporting Graphs to Other Applications . . . . . . . . . . . . . . . . . . . . . . 184

Adjusting Your Graphs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Printing Graphs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Document Export Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Bio-Plex XML Export . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Output CSV File Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Using Stylesheets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Command Line Export . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Exporting the Document . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Importing Luminex xPONENT Output Files. . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Exporting Results Data to Bio-Plex Data Pro™ . . . . . . . . . . . . . . . . . . . . . . . 195

Chapter 10. Standard Curve Optimizer . . . . . . . . . . . . . . . . . . 199

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Standard Curve Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Concentration in Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Determining Outliers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Recommended Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Standard Curve Optimizer Report . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Residual Variance and Fit Probability. . . . . . . . . . . . . . . . . . . . . . . . . 204

Logistic Weighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Chapter 11. Data Normalization . . . . . . . . . . . . . . . . . . . . . . . 207

Normalization Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Selecting Internal Controls/Housekeeping Genes . . . . . . . . . . . . . . . 208

Assigning a Control Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Report Table Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Predefined Normalization Report Schemes . . . . . . . . . . . . . . . . . . . . 211

Normalization Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Calculations Based Upon Your Settings . . . . . . . . . . . . . . . . . . . . . . 212

Normalization Factor Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Security Edition: User Access by Function . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Normalization Formulas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Norm Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

viii

Page 11

Bio-Plex Manager Software 6.1 User Guide

Norm Ratio’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Norm Ratio’’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Normalized Fluorescence Values (Norm FI) . . . . . . . . . . . . . . . . . . . . 225

Ratio (Simple) and the Grouping Function . . . . . . . . . . . . . . . . . . . . . 226

Basic Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Microspheres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Reporter Fluorochromes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Fluidics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Excitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Microsphere Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Microsphere Dispersion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Probe Sonicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Bath Sonicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Enumeration of Microsphere Suspensions . . . . . . . . . . . . . . . . . . . . 230

Microsphere Separation Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Microsphere Agitation During Assay . . . . . . . . . . . . . . . . . . . . . . . . . 231

Microsphere Stability and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Software Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Reporting Problems to Bio-Rad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Report Table Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

ix

Page 12

Bio-Plex Manager Software 6.1 User Guide | Table of Contents

x

Page 13

Bio-Plex Manager Software 6.1 User Guide

1 Bio-Plex Suspension

Array System Overview

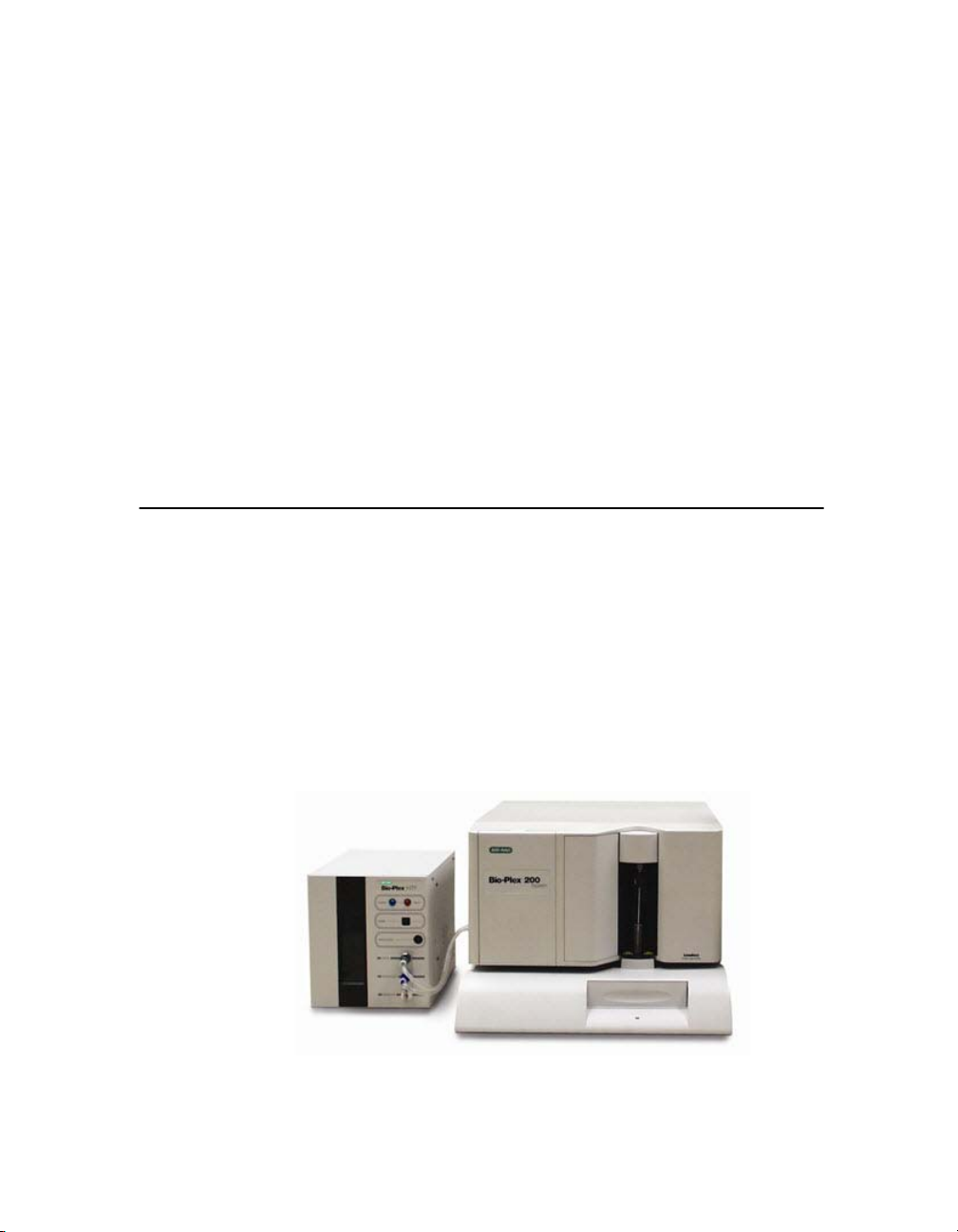

The Bio-Plex® suspension array system is a flow-based dual-laser system for

simultaneously identifying and quantitating up to 100 different analytes in a

single biomolecular assay (xMAP technology). The system detects and

measures molecules bound to the surfaces of fluorescent microspheres,

providing highly accurate, real-time digital analysis of serum or culture media

samples as small as 50 μl. This allows quantitative analysis of a wide variety of

cell biology assays, including immunoassays, complex genetic assays, and

enzymatic assays.

The Bio-Plex suspension array system consists of a fully integrated array

reader and microplate platform, with an optional HTF (high-throughput

fluidics) sheath delivery module.

Figure 1. Bio-Plex array reader and microplate platform, with optional HTF

1

Page 14

Bio-Plex Manager Software 6.1 User Guide | Components

The system also includes validation and calibration reagents, a selection of

cytokine and phosphoprotein assays, sample preparation reagents, and a

computer running Bio-Plex Manager

phase, diabetes, cancer and isotyping assays have been introduced with this

version of the software.

Check www.bio-rad.com/bio-plex/x-plex for newly-available assays and

reagents.

The assays contain sets of microscopic color-coded beads, each of which is

conjugated with a different reactant.

Reactants can include:

•DNA

• Enzyme substrates

• Receptors

•Antigens

• Antibodies

These can be used to create, for example, a capture sandwich immunoassay.

To perform a multiplex reading, samples are mixed with conjugated

microsphere and reactant mixtures; next, fluorescent reporter molecules are

added. The assays are loaded into the wells of a 96-well microtiter plate, and

the plate is inserted into the microplate platform. The platform and array

reader are controlled by a computer running Bio-Plex Manager software.

The detection system in the array reader uses two lasers to analyze the

microspheres in a flow stream. The first laser identifies each microsphere and

its associated analyte based on the fluorescent signature of the microsphere,

and the second measures the amount of analyte, using the reporter molecules

attached to the analytes. When the reading is complete, Bio-Plex Manager

displays the raw data and generates detailed summary reports.

™

6.1 software. New angiogenesis, acute

Components

A certified Bio-Rad service engineer will install the complete Bio-Plex

suspension array system at your site, including the array reader, microplate

platform, and computer. The system setup procedure is described in

“Bio-Plex 200 System Hardware Instruction Manual”, available for download

from the Bio-Rad website.

The Bio-Plex suspension array system includes the following components:

• Array reader

• Microplate platform

• Bio-Plex MCV Plate IV (required for Bio-Plex Manager 5.0 and later)

2

Page 15

Advantages

•Bio-Plex reservoir

• Pentium-class PC, preinstalled with operating system, Microsoft

Excel, Microsoft Internet Explorer, Microsoft.NET, and Bio-Plex

Manager Instrument Control software

• Software package containing Bio-Plex Manager CD-ROM and a

hardware protection key

• Instrument manual for array reader and microplate platform

• Sheath fluid bottle

• Sample needles (two long)

• Protective shield

• Waste bottle

• Communications cable to connect the reader to the computer

• Communications cable from microplate platform to the computer

• Computer monitor

• Power cords

• Computer keyboard

• Computer mouse

• HTF (High Throughput Fluidics), if selected

• Communications cable from the reader to the HTF, if HTF is present

The Bio-Plex suspension array system comes with these reagents:

• Bio-Plex Calibration Kit (CAL1 and CAL2)

• Bio-Plex Validation Kit 4.0 (optics, fluidics, reporter, and classify

components)

• Sheath fluid

Advantages

With the Bio-Plex suspension array system, you can:

• Simultaneously quantitate up to 100 different analytes from culture

media and serum samples as small as 50 μl

• Automatically analyze all the samples in a 96-well microtiter plate—

yielding up to 9,600 data points—in about 30 minutes

• Instantly customize your experiments by mixing Bio-Plex assays or

creating your own assays

• Analyze results, prepare reports, and print and/or export data

immediately after each reading

• Provide a complete electronic audit trail of data generation and

analysis in a secure digital environment with multilevel account

access, that is compliant with the Code of Federal Regulations,

Title 21, Part 11, “Electronic Records; Electronic Signatures”

3

Page 16

Bio-Plex Manager Software 6.1 User Guide | For More Information

For More Information

For more on the principles and concepts of the Bio-Plex suspension array

system, see Basic Concepts in the Appendix on page 227.

Bio-Rad Technical Support

Bio-Rad Technical Support in the United States is open Monday through

Friday, 5:00 a.m. to 5:00 p.m., Pacific Time. Worldwide technical support is

available on the Web at www.consult.bio-rad.com.

Phone: (800) 424-6723, option 2

Fax: (510) 741-5802

E-mail:LSG.TechServ.US@Bio-Rad.com (U.S.)

LSG.TechServ.Intl@Bio-Rad.com (International)

Web: http://www.consult.bio-rad.com

4

Page 17

Bio-Plex Manager Software 6.1 User Guide

2 Bio-Plex Manager™

Software Overview

Bio-Plex Manager™ 6.1 software runs on a computer installed with the

Windows XP or Windows 7 operating system, and requires a hardware

protection key, also known as a HASP key, installed on either the computer

itself or the computer network system. The software features a standard

Windows interface, with pulldown menus, toolbars, and keyboard shortcuts.

Bio-Plex Manager comes in two editions—Standard Edition and Security

Edition—and with three available licenses: Instrument Control, Desktop, and

Network, described below. The computer included with the Bio-Plex

suspension array system comes preinstalled with a compatible operating

system and a Bio-Plex Manager Standard Edition, Instrument Control license.

Software Editions

Bio-Plex Manager software comes in two editions:

• Standard Edition gives all users equal access to all features of the

software with no restrictions and no electronic audit trail

• Security Edition provides different levels of user access to various

features and creates a complete electronic audit trail of all data

generation and analysis. The Security Edition can be run in Secure

Mode, with all the security features enabled, or Standard Mode,

which behaves like the Standard Edition of the software

5

Page 18

Bio-Plex Manager Software 6.1 User Guide | Software Licenses

NOTE: Bio-Plex Manager Security Edition must be installed on the Windows

XP Professional or Windows 7 operating system for full security and

functionality.

Software Licenses

Bio-Plex Manager software is available with three different licenses:

• Instrument Control (previously called Workstation) license enables

the software to control the array reader and microplate platform

and to collect, analyze, and output data

• Desktop license enables the software to analyze data files but not

control the array reader and platform. The instrument

communication and control functions are not available with this

license

• Network license provides Desktop licenses to multiple users over

a computer network. The Desktop license enables the software to

analyze data files but not control the array reader and platform

This user guide assumes that you are using the Standard Edition with an

Instrument Control license, unless otherwise noted. The Security Edition user

levels and restrictions are described in detail in the Appendix on page 219.

Compatibility with Luminex Software

Bio-Plex Manager 6.1 is compatible with Luminex xPONENT software.

Because the Luminex LXR library has been updated, older Luminex IS 2.3

software will not function once you upgrade to Bio-Plex Manager 6.1. You

must upgrade your Luminex IS 2.3 software to the current version in order to

run both applications on the same machine.

If you install Bio-Plex Manager 5.0 or later on a computer with Luminex

xPONENT software, note the following:

• To avoid communication conflicts with the array reader and

platform, do not run Bio-Plex Manager and Luminex software at

the same time.

• If you switch between the two software applications, you must

recalibrate the array reader before acquiring data.

6

Page 19

ANALYZING LUMINEX DATA IN BIO-PLEX MANAGER

Start up and calibrate array reader

Create a protocol by specifying analytes, plate, and standards

Run the protocol

Review results and generate reports

Print and/or export the data

Bio-Plex Results Generator 3.0 converts CSV Output files from xPONENT 3.1

and 4.0 into Bio-Plex Manager data files. You can analyze the converted

results on any computer running Bio-Plex Manager 4.0 or later. You can make

the files available to an entire workgroup by placing them on a public server.

With earlier versions of Bio-Plex Manager, you had to separately install

Bio-Plex Results Generator. Beginning with Bio-Plex Manager 6.1, Bio-Plex

Results Generator is automatically included in the Bio-Plex Manager

installation.

The Bio-Plex Results Generator 3.0 application (RBXGenerator_3.exe) is

included as a separate product on the Bio-Plex Manager 6.1 software CD.

This allows you to install it on a machine that does not have a Bio-Plex

Manager installation. There is also a help file (Bio-Plex Results Generator 3.0

Online Help) to walk you through installing the Results Generator and setting

up Luminex protocols for conversion.

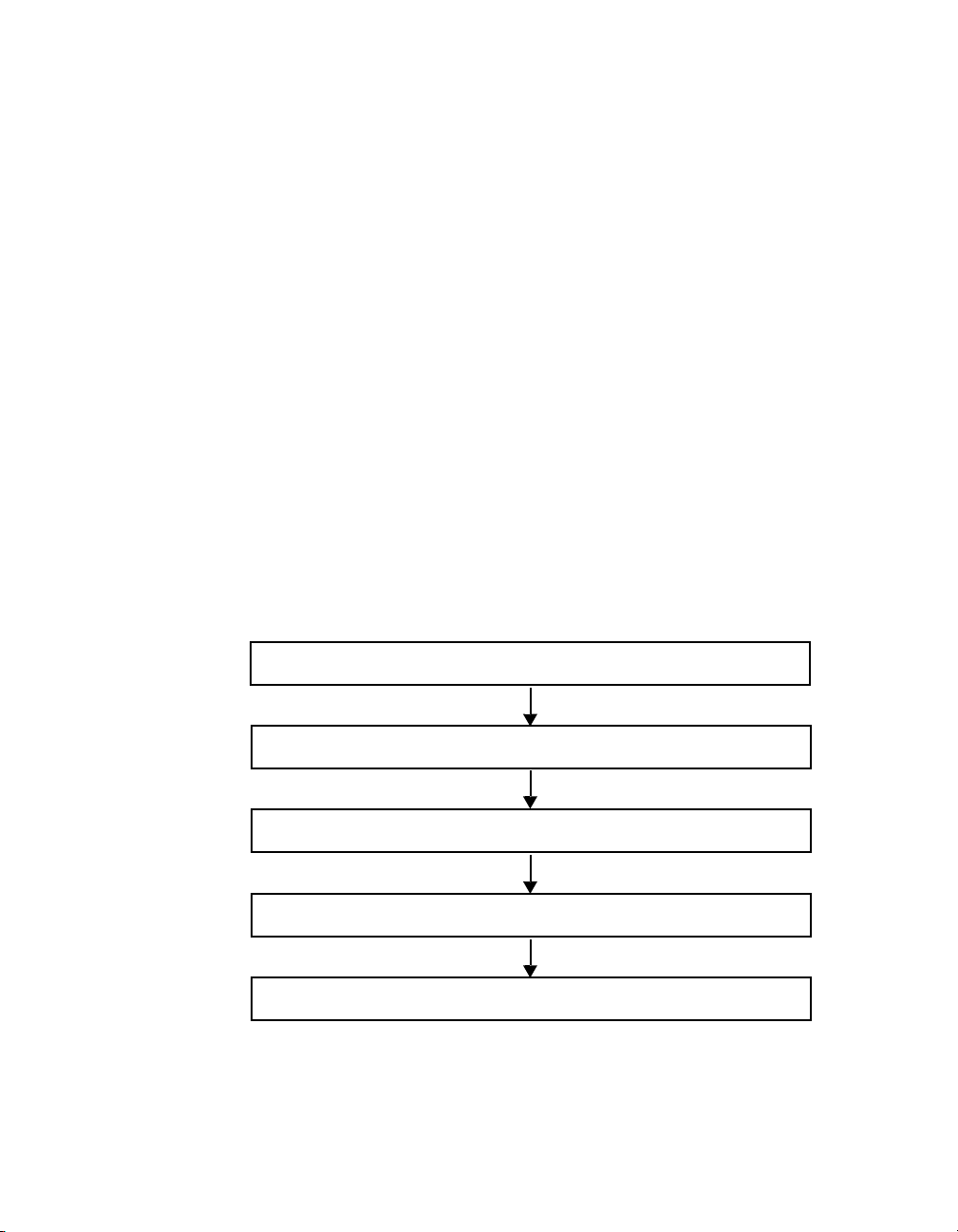

General Workflow

To collect, analyze, and output data using Bio-Plex Manager software, follow

the general steps outlined below.

.

General Workflow

Figure 2. Bio-Plex Manager software workflow

7

Page 20

Bio-Plex Manager Software 6.1 User Guide | General Workflow

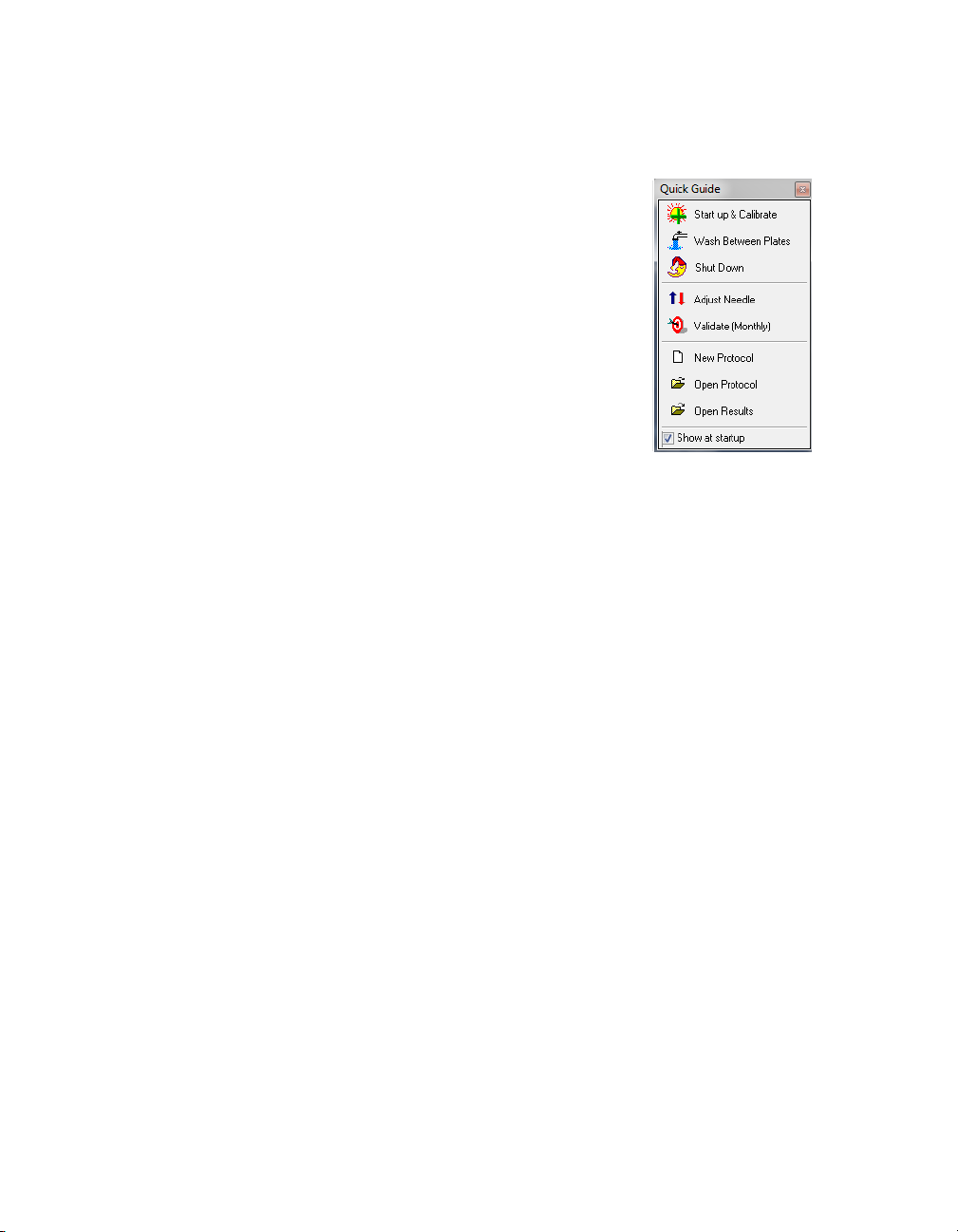

Quick Guide

The Quick Guide, which displays automatically at

startup, is designed to guide you through the typical

Bio-Plex Manager workflow, from startup and

calibration through shut down.

Commands, such as Start up & Calibrate, open dialog

boxes that contain choices to guide you through the

procedures.

Figure 3. Quick Guide

8

Page 21

Types of Files

There are two main types of files created and used by Bio-Plex Manager:

• Protocol files (see page 53) contain the settings and controls for

reading a microplate

• Results files (see page 143) contain the data from each reading,

and tools and reports for analyzing that data

The application database file (bioplexdata.mdb) is installed on your hard drive

or file server when you install the software. This database contains calibration,

validation, and instrument operation information. See page 13 for more detail.

Key Software Features

Bio-Plex Manager 6.1 is a single integrated software package that has:

Comprehensive instrument functions

• Data collection

• Maintenance

• Validation

• Automatic error detection and logging

Comprehensive data display

• Raw data presentation including tables, bead maps and histograms

• Customizable tabular presentations

• Customizable standard curve and bar graph displays

Comprehensive Calculations

• Data normalization (internal controls for gene expression analysis)

• Auto calculation and display of usable assay range

• Multiple standard curve fitting options, including Brendan

Scientific, StatLIA, Logistic 5PL.

Comprehensive and versatile automated export options

• Excel (now including optional standard curve graphs)

• Comprehensive .xml file

• New Luminex CSV (comma-separated values) output

• New customizable reports through style sheets

• New custom report for export to custom macros

CFR 21 Part 11 compliance

• User access management

• Comprehensive audit trail and instrument logs

• Secure documents (results files and protocols)

Types of Files

9

Page 22

Bio-Plex Manager Software 6.1 User Guide | Key Software Features

10

Page 23

Bio-Plex Manager Software 6.1 User Guide

3 Software Installation

Install, or reinstall, Bio-Plex Manager™ 6.1 software as described in the

following section. If you need to upgrade your software from a previous

version, see the “Bio-Plex Manager 6.1 Software Upgrade and Configuration

Guide” to determine the part number of your upgrade kit.

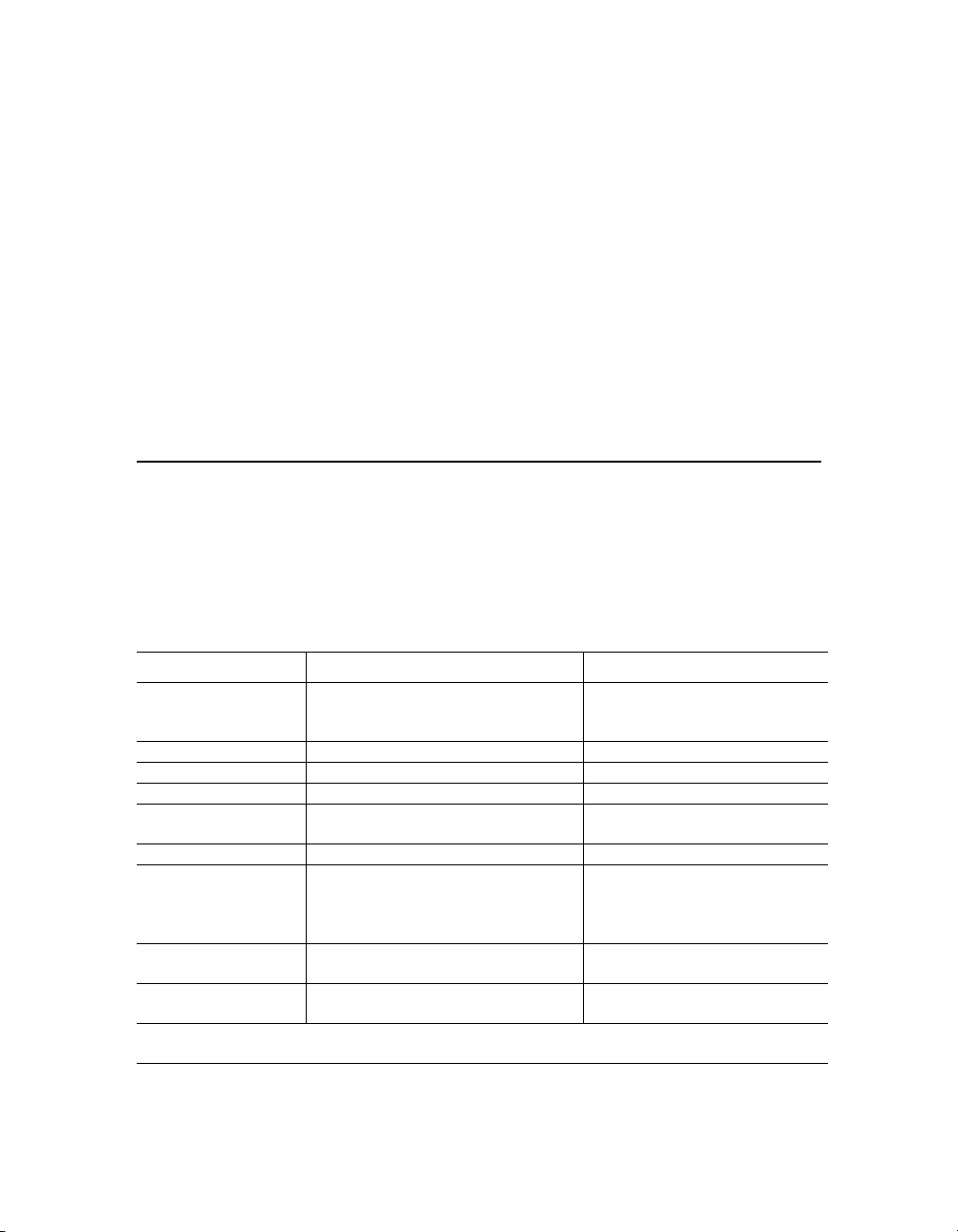

System Requirements

Component Minimum Recommended

Operating system Windows XP (XP Professional required

for running Security Edition) or

Windows 7 (32-bit)

Processor Pentium 4 or equivalent, 2.8 GHz Core 2, 2.6 GHz or higher

Hard disk space 80 GB 160 GB

System memory 1 GB 2 GB

Screen resolution 1024 x 768 (Windows XP)

1280 x 1024 (Windows 7)

Screen colors 256 colors 24-bit True Color

Ports for connecting

instrument (required for

Instrument Control

license only)

Port for connecting

the HASP key

Other software Internet Explorer 6.0 or later

NOTE: For Windows 7, the Instrument Control version of Bio-Plex Manager 6.1 can be run only on

32-bit; it is not compatible with 64-bit.

1 RS232 serial port and

1 USB port

1 USB port 1 USB 2.0 port

Microsoft Excel 2003 or later

Windows XP Professional

1280 × 1024

1 RS232 serial port and 1 USB 2.0

port

Internet Explorer 8.0

Microsoft Excel 2007

11

Page 24

Bio-Plex Manager Software 6.1 User Guide | Software Installation

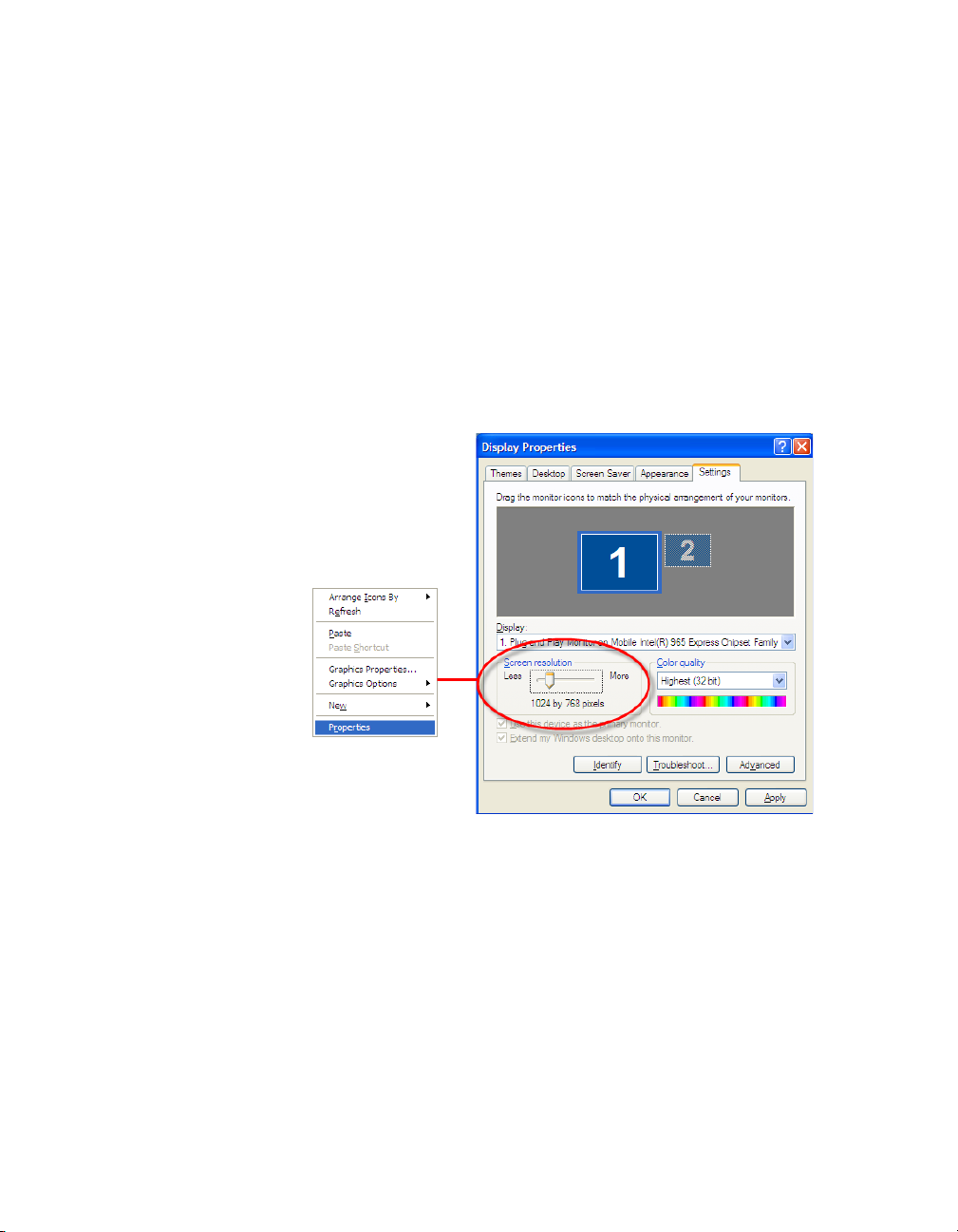

Required Screen Resolution

Your computer screen resolution must be set to at least 1024 x 768 pixels for

correct display of the Bio-Plex Manager interface. The status bar and some

dialog boxes will not display properly at lower resolutions. If your display is

currently set to a lower resolution:

1. Go to the Windows Start menu, select Settings, and select Control

Panel.

2. Open the Display control panel.

3. In the Display Properties dialog, select the Settings tab (see Figure 3).

4. Drag the Screen Area slider to the right (toward More) until you have

selected 1024 x 768 pixels. Click OK to accept the settings.

12

Figure 4. Changing the screen resolution settings

Page 25

Installing the Software

To install or reinstall the software, insert the Bio-Plex Manager CD into the

CD-ROM drive on your computer.

NOTES

• Before installing Bio-Plex Manager 6.1, we recommend that you

first uninstall any existing version of Bio-Plex Manager on your

computer

• We recommend that you turn off any antivirus protection software

before installation. Such software, if active, can greatly slow the

progress of the installation. If you are unable to turn off your

antivirus protection software, allow 15 minutes for complete

installation. Do not cancel the installation during this period

The Bio-Plex Manager Installation Program opens, displaying a navigation

screen for performing the installation.

Microsoft.NET

Microsoft.NET is automatically installed on your computer when you install

Bio-Plex Manager. It is required to support the logistic curve-fitting features of

Bio-Plex Manager.

Installing the Software

Bioplexdata.mdb File

During installation, you will be prompted to save the application database file

(bioplexdata.mdb) to a location on your hard drive or a file server. This

database file contains logs of calibration, validation, and instrument

operations activity for your instrument.

• For more information about the Calibration Log, see page 34

• For more information about the Validation Log, see page 45

• For more information about the Instrument Operations Log, see

page 51

You can save the bioplexdata.mdb file to any folder on your computer. The

default location is the Bio-Plex Manager application folder. If your computer is

connected to multiple instruments, each instrument must have a separate

bioplexdata.mdb file saved in a different folder.

For more information about the calibration, validation, and instrument

operations logs in Bio-Plex Manager 6.1 Security Edition, see Controlling the

System on page 25.

13

Page 26

Bio-Plex Manager Software 6.1 User Guide | Software Installation

NOTE: The bioplexdata.mdb file is not compatible with versions of Bio-Plex

Manager earlier than 4.0. If you have an earlier version of the software,

installing 4.0 or later will copy the data from your existing database file

(bioplex.mdb) into the new database. A copy of your old database will remain

in the application folder.

Luminex LXR Directory and Files

A directory called Luminex is automatically created in the Program Files folder

on your computer during installation. Inside this folder is a folder called LXR

that contains various applications for monitoring and communicating with the

array reader and platform. A Windows service called LXService is also

installed and started. This service enables automatic communication with the

instrument when you open Bio-Plex Manager.

Hardware Protection Key (HASP Key)

A hardware protection key, also known as a HASP key, is required to run

Bio-Plex Manager. The HASP key determines the license (Instrument Control,

Desktop, or Network) and the edition (Standard or Security) of your Bio-Plex

Manager. A complete list of HASP key part numbers and the software versions

they enable is in the Bio-Plex Manager 6.1 Software Upgrade and

Configuration Guide.

Instrument Control or Desktop HASP keys must be attached to a USB port on

the computer running the software. Network HASP keys must be attached to

a USB port on the network file server computer.

The HASP key has a driver that is automatically installed when you install BioPlex Manager.

Uninstalling

To uninstall Bio-Plex Manager from your computer, use the Windows Add/

Remove Programs function. Click the Windows Start button, select Settings,

select Control Panel, double-click Add/Remove Programs, and follow the

instructions for removing the program.

14

Page 27

Bio-Plex Manager Software 6.1 User Guide

4 Starting the System

Before starting Bio-Plex Manager™ 6.1 software, make sure the Hardware

Protection Key is attached to your computer, and switch on the array reader,

the HTF (if one is being used), and the microplate platform. This turns on the

optics inside the array reader and enables communication between the array

reader and software.

NOTE: Avoid using other applications while Bio-Plex Manager is

communicating with the array reader. Running other applications may

interrupt communication between Bio-Plex Manager and the array reader.

Starting Bio-Plex Manager

To start Bio-Plex Manager, click the application icon on your desktop

or select Bio-Plex Manager 6.1 from the Programs directory on your Windows

Start menu. The software opens and attempts to connect to the array reader

and platform.

15

Page 28

Bio-Plex Manager Software 6.1 User Guide | Starting Bio-Plex Manager

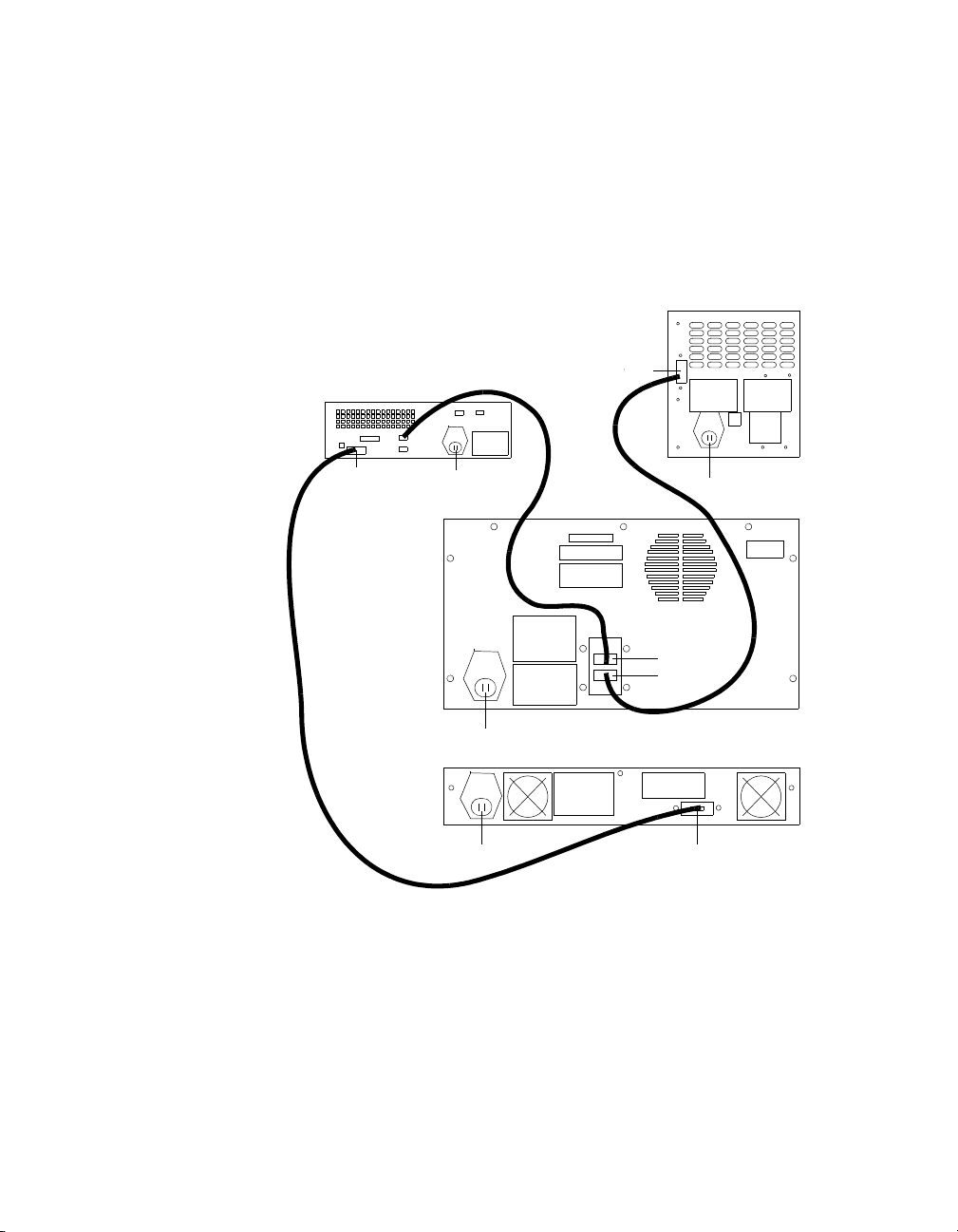

Microplate Platform

Power

Serial port

Array Reader

Power

P1

P2

HTF

Computer

Serial

port

Power

Serial port Power

USB1

USB2

Connecting with the Array Reader and Microplate Platform

The computer running Bio-Plex Manager software is connected to the array

reader by a USB cable, and to the microplate platform by a serial cable. See

the figure below for a diagram of the cable connections.

16

Figure 5. System cable connections

Page 29

Starting Bio-Plex Manager

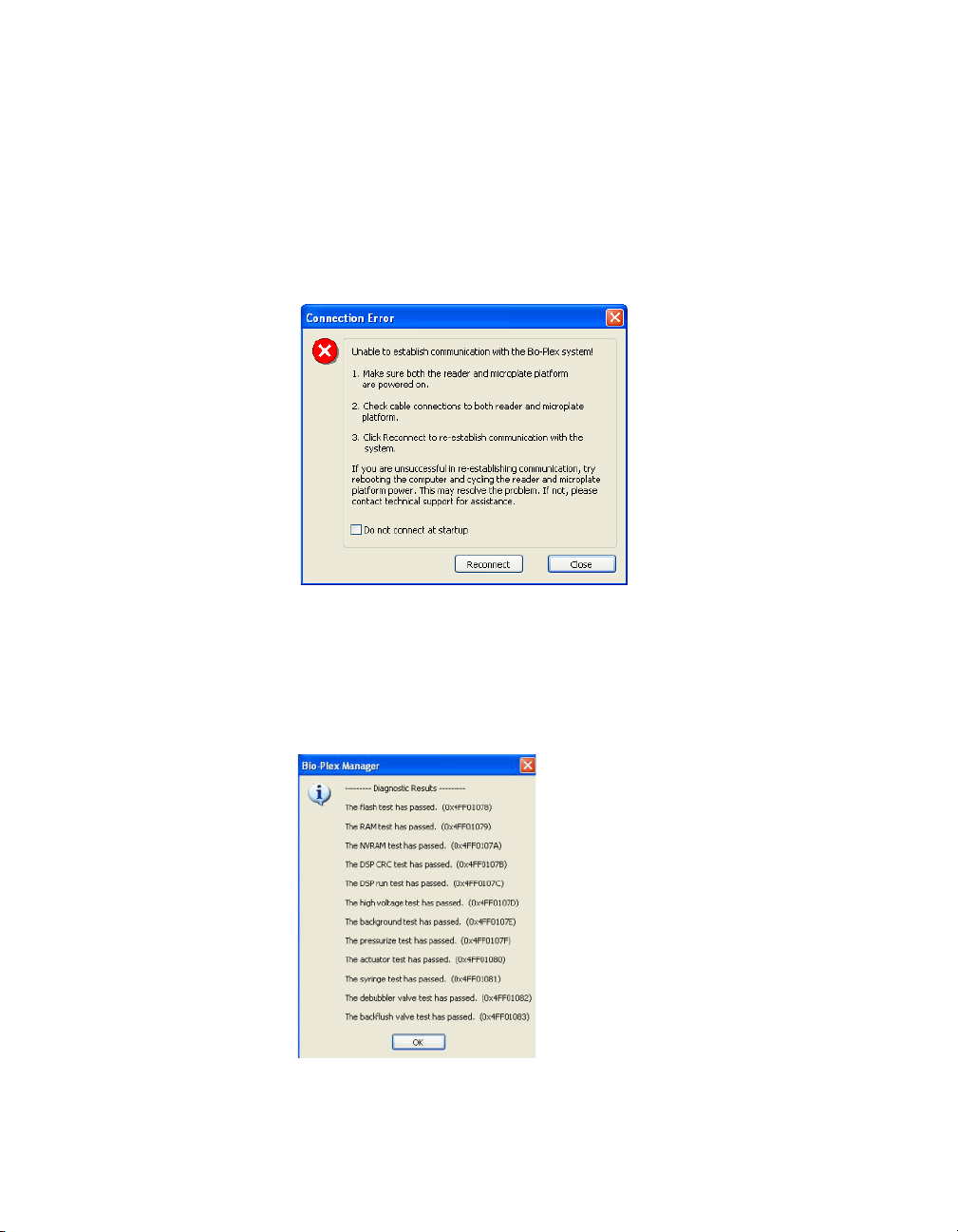

Communication between the Array Reader and Microplate Platform

Communication between the computer and the array reader and microplate

platform is automatically established when you open Bio-Plex Manager. If

Bio-Plex Manager is unable to communicate with the instrument, a dialog box

prompts you to check the cable connections.

Figure 6. Connection Error dialog

Make sure the instrument is turned on, check the cable connections, and then

click Reconnect in the dialog. If you are still unable to connect, try restarting

the computer, array reader, and platform. You can also choose the Run

Diagnostic option found under the Instrument menu. This produces a report

which can help Bio-Rad Technical Support determine the cause of the

problem.

Figure 7. Run Diagnostics Report

17

Page 30

Bio-Plex Manager Software 6.1 User Guide | Starting Bio-Plex Manager

If you do not want to automatically connect to the array reader and platform

when you open the software, select the Do not connect at startup checkbox.

This is useful if you are not connected to an instrument or want to use the

software without connecting to the instrument. To re-enable automatic

connection at startup, select Reconnect from the Instrument menu (see next

section).

Disconnecting and Reconnecting

Communication between the computer and the array reader and platform is

closed when you exit Bio-Plex Manager. If you need to disconnect from the

array reader and platform without shutting down Bio-Plex Manager software

(for example, to troubleshoot the instrument), go to the Instrument menu and

select Disconnect.

To reconnect to the array reader and platform while Bio-Plex Manager is

running, select Reconnect from the Instrument menu. This dialog also enables

automatic connection each time you start the software, if it has been disabled

(see previous section).

18

Page 31

Disconnecting with Sleep Mode

When your computer goes into sleep mode, the instrument is disconnected

from Bio-Plex Manager. When you awaken your computer from sleep mode,

you will not be able to reestablish the connection to the instrument using the

Reconnect option on the Instrument menu, and you will need to restart BioPlex Manager.

Bio-Plex Manager overrides any sleep mode settings on your computer.

Therefore, as long as it is running, your computer will not go into sleep mode.

However, Bio-Plex Manager does not prevent you from actively putting your

computer into sleep mode. It is recommended that you do not do this as long

as Bio-Plex Manager is running.

Menu and Toolbars

Bio-Plex Manager includes a menu bar and main toolbar at the top of the

application window.

The pulldown menus contain all the major functions of the software. Note that

these menus change depending on whether you are displaying a Protocol

window, a Results window, or neither.

You can move quickly between any number of open Bio-Plex Manager

windows. Hold down the Ctrl key, then press Tab.

The main toolbar includes the major instrument controls, including Start up &

Calibrate, Shut Down, Wash, Unclog, etc. The various Protocol and Results

windows also contain their own toolbars, with commands specific to those

windows. These are described in greater detail in the following chapters.

Menu and Toolbars

Status Bar

The Instrument Status Bar shows the current state of the instrument

(Calibration, Warm Up, Ready, Pressurizing, etc.). It includes a Cancel button

for canceling the current operation (see page 51).

Figure 8. Instrument status bar

When the array reader performs an operation, the time remaining for the

operation shows in the instrument status bar.

19

Page 32

Bio-Plex Manager Software 6.1 User Guide | Quick Guide

The Bio-Plex Manager software status bar is below the instrument status bar,

and provides information about the command under the cursor. This

information is continuously updated as you move your cursor over the

software window.

The software status bar also shows the current user and, if you are using the

Security Edition of the software, whether you are in Secure Mode (shown as a

"locked" symbol ) or Standard Mode (shown as "unlocked" ). See

page 5 of this manual, and the Bio-Plex Manager 6.1 Software Upgrade and

Configuration Guide for more information about the Security Edition.

The software status bar also shows the Caps Lock, Scroll Lock, and Num

Lock keyboard status.

Quick Guide

When Bio-Plex Manager first opens, a Quick Guide toolbar appears in the

upper right corner of the screen. You can use the Quick Guide to guide you

through the typical workflow, from start up and calibration through shut down.

20

Figure 9. Bio-Plex Quick Guide

By default, the Quick Guide opens automatically when you start Bio-Plex

Manager. To disable, deselect the Show at startup checkbox at the bottom of

the guide.

To open the Quick Guide after closing, select Quick Guide from the View

menu.

Page 33

Sample Needle Adjustment

See the Bio-Plex 200 System Hardware Instruction Manual or the Luminex

manual for instructions on installing the sample needle.

WARNING: To protect hands and fingers, keep them out of the microplate

platform when the needle is not in the down position.

The height of the sample needle must be adjusted when the microplate type

has changed, and/or when the sample needle is replaced. The MCV plate

included with your system provides a method for adjusting sample needle

height for standard flat-bottom plates (catalog #171-025001), filter plates

(Millipore catalog #MSBVS1210), or PCR plates.

Follow these steps to adjust the sample needle height.

1. Turn on the array reader and microplate platform.

2. Launch the Bio-Plex Manager software.

3. Click Instrument in the menu bar and choose Adjust Needle. The

following dialog box appears.

Sample Needle Adjustment

Figure 10. Adjust Needle dialog

4. Click Eject/Retract to eject the plate holder.

5. Place the MCV plate on the microplate platform with the black arrow

facing toward the array reader.

6. Click on the Eject/Retract button to retract the plate.

7. Tape the access door of the microplate platform open. It will be

necessary to be able to see inside the access door.

21

Page 34

Bio-Plex Manager Software 6.1 User Guide | Sample Needle Adjustment

Needle height

adjustment

thumbscrew

8. Select the plate type to adjust the needle height appropriately. Choose

Standard Plate if you are using a Bio-Plex Pro™ flat-bottom microplate

for magnetic beads or the Millipore filter plate. Your other choice is PCR

Plate.

9. In the Adjust Needle window, click on the Up/Down button. The needle

will move to the down position.

10. With the needle in the down position, loosen the needle height

adjustment thumbscrew at the top of the needle so that the needle

housing can move up and down freely.

NOTE: All adjustments to the needle height must be made when the needle is

in the down position.

Figure 11. Sample needle assembly

22

11. By holding onto the needle height adjustment thumbscrew on the

needle arm, manually move the needle so that it just touches the

bottom of the needle adjustment well of the MCV plate. Move the

needle up and down gently a couple of times to verify that the needle is

barely touching the bottom of the well.

12. Tighten the needle height adjustment thumbscrew so that it is no longer

possible to manually move the needle up and down. Take care to

ensure that the needle does not move while you are tightening the

screw. Do not overtighten.

13. In the Adjust Needle window, click on the Up/Down button to move the

needle up and down. Look inside the microplate platform at the MCV

plate. The needle should just touch the MCV plate at the bottom of the

cutout (use flashlight for better viewing). Readjust the needle height if

necessary.

14. Save these settings. This allows Bio-Plex Manager to warn you which

type of plate the system will use, before it starts a run.

15. When the needle is adjusted properly, click the Eject button.

16. Remove the MCV plate from the microplate platform.

Page 35

Sample Needle Adjustment

17. Perform a Wash Between Plates step to remove any air introduced into

the lines.

23

Page 36

Bio-Plex Manager Software 6.1 User Guide | Sample Needle Adjustment

24

Page 37

Bio-Plex Manager Software 6.1 User Guide

5 Controlling the System

This chapter covers the Bio-Plex Manager™ 6.1 software commands that

control basic system functions, such as instrument start up, warm up,

calibration, validation, and shut down.

NOTE: The startup, warm up, and calibration functions must be performed

prior to running an assay with Bio-Plex Manager, all of which together take

about 45 minutes. The Start up & Calibrate function allows you to complete

these steps with one command.

WARNINGS:

• The sheath fluid container and the waste fluid container should be

closely monitored

• The sheath fluid bottle must be placed at the same level as the

array reader, unless you are using the Bio-Plex High-Throughput

Fluidics (HTF) or Luminex Sheath Delivery System (SDS). The fluid

level should be below the air inlet connection and above the sheath

outlet connection. Always check the sheath fluid level before

starting a run or procedure

• If you are using the Bio-Plex HTF or Luminex SDS, it should sit on

the counter next to the array reader, while the sheath fluid cube

should be placed 3-4 feet below the array reader (for example, on

the floor)

• The waste fluid container receives waste from the system. Do not

allow the waste container to overflow. Empty the waste bottle each

time the sheath fluid bottle is filled. The waste container should be

placed on the bench next to the instrument. Never place this

container on top of the instrument. All waste containers should

have vented caps

25

Page 38

Bio-Plex Manager Software 6.1 User Guide | Controlling the System

Wells highlighted

in yellow

Bio-Plex MCV Plate IV

Bio-Plex Manager 5.0 and later requires the use of the Bio-Plex MCV

(Maintenance, Calibration and Validation) Plate IV. This plate contains wells

marked for the different types of fluids used in validation, washing, calibration,

and other functions. The Bio-Plex MCV Plate IV has been modified from the

previous MCV plate to work with Bio-Plex Validation Kit 4.0 and its Reporter

and Classify bead sets. It also includes two open needle wells for adjusting

needle heights for microplates or PCR plates.

NOTE: Bio-Plex Manager 5.0 and later require the use of the Bio-Plex MCV

Plate IV, the Bio-Plex Validation Kit 4.0, and the Bio-Plex Calibration Kit.

26

Figure 12. Bio-Plex MCV Plate IV

When a particular procedure such as calibration requires you to add solutions

to the Bio-Plex MCV Plate IV, the dialog box describing the procedure

includes a diagram of the MCV Plate IV with the wells to be loaded highlighted

in blinking yellow.

Figure 13. Highlighted wells in diagram indicate wells to be filled

Page 39

Start Up

Startup is a series of fluidic functions that prepares the array reader to acquire

data. This process requires the Bio-Plex MCV Plate IV, distilled water, and

70% isopropanol. Startup takes approximately 10 minutes.

NOTE: The startup procedure can be performed while the optics are warming

up, but no validations, calibrations or runs should be performed before the

optics are warmed up. This takes an estimated time of 30 minutes.

Click the Start Up button on the main toolbar or select the command

from the Instrument menu. Follow the step-by-step directions in the dialog

box for preparing the MCV Plate IV.

Start Up

Figure 14. Start Up dialog

Insert the prepared plate into the microplate platform and click OK to begin

the startup process.

27

Page 40

Bio-Plex Manager Software 6.1 User Guide | Controlling the System

Optics Warm Up and Shut Down

To ensure accurate and reproducible results, the optics (that is, the lasers) in

the array reader must warm up for at least 30 minutes prior to calibration,

validation, and reading assays. Optics warm up begins when you first turn on

the array reader.

You can proceed with the array reader startup procedure described in the

previous section while the optics are still warming up. However, if you try to

perform calibration, validation, or an assay reading, you will receive a warning

message.

You can cancel the warm up procedure using the Cancel Operation command

on the Instrument menu or the Cancel button in the status bar; however, this is

not recommended. Results for identical readings may vary if the optics have

not reached optimal operating temperature.

NOTE: If you attempt to start a reading during warm up, you can eject the

plate carrier using the Eject/Retract Plate command on the main toolbar

and remove the plate for storage until warm up is complete, without canceling

the warm up procedure.

If the array reader is idle for more than four hours, the optics automatically

power down (though the array reader itself remains on). Depending on the

length of the shutdown, a full 30-minute warm up period may be required

before more readings can be taken.

28

Click the Warm Up button

to begin warm up after automatic power down

menu

If you attempt to perform a reading after automatic power down, you receive a

warning message and the optics begin warming up.

on the main toolbar or from the Instrument

.

Page 41

Calibration

Calibration of the array reader is essential for optimal performance and dayto-day reproducibility of results. Calibration is required:

• Each day after the startup procedure is complete and the optics

have warmed up

• If the array reader temperature changes by more than 2ºC during

the course of the day. (If the temperature changes by more than

2ºC, a message box prompts you to recalibrate)

• Before data acquisition, if you switch between Bio-Plex Manager

and Luminex software installed on the same computer (see page 6)

NOTE: Before calibrating, make sure that optics warm up is complete.

The Bio-Plex Calibration Kit contains calibration microspheres (CAL1 and

CAL2 beads) with stable fluorescent intensities in the RP1, CL1, and CL2

wavelength ranges. The calibration process uses these microspheres to

adjust voltage settings for optimal and consistent microsphere classification

and reporter readings over time and across different instruments. Current

calibrated settings are automatically applied to any new session.

Calibration using Bio-Plex Manager requires the Bio-Plex MCV Plate IV, CAL1

beads and CAL2 beads from the Bio-Plex Calibration Kit, and distilled or

deionized water. The CAL1 beads calibrate the array reader's doublet

discriminator and classification channels, while the CAL2 beads calibrate the

array reader's reporter channel for reporter fluorescence detection.

Calibration

29

Page 42

Bio-Plex Manager Software 6.1 User Guide | Controlling the System

Opening the Calibration Dialog Box

To begin calibration, click the Calibrate button on the main toolbar or

select Calibrate from the Instrument menu. The Calibrate dialog box opens.

30

Figure 15. Calibrate dialog

At the top of the dialog box, enter your name in the field. If you are using the

Security Edition of the software in Secure Mode, your user name will be listed

and grayed out.

The time and date of the last calibration using Bio-Plex Manager are listed, as

is the temperature at the time of that calibration. If the temperature has not

changed by more than 2ºC in a single day, it is not necessary to recalibrate the

instrument.

Next, select the calibration type by clicking on the CAL1 & CAL2, CAL1 Only,

or CAL2 Only button. You should perform both CAL1 and CAL2 calibration

daily.

Selecting/Entering Calibration Control Numbers

Under Select Control Numbers in the Calibrate dialog box, you can either

select existing control numbers for your CAL1 and CAL2 microspheres, or

enter new control numbers.

Page 43

Calibration

Select existing control numbers from the pulldown list, and the target values

for the control numbers appear in the appropriate fields.

When you receive a new Bio-Plex Calibration Kit, you must add the new CAL1

and CAL2 control numbers and target values to the Calibrate dialog. These

numbers are printed on the bottles containing the beads.

NOTE: It is critical that you enter the correct target values for your CAL1 and

CAL2 calibrators. Entering incorrect values results in an incorrectly calibrated

array reader, which adversely impacts assay results.

To add a new CAL1 control number, click the Add button under CAL1 Control

Number in the Calibrate dialog. The Add New CAL1 Control Number dialog

box opens.

Figure 16. Adding a new CAL1 control number

In the dialog, enter the control number from the CAL1 bottle in the Enter

Control Number field. If the expiration date is printed on the bottle, select the

option button next to the date field under Expiration Date and click the

pulldown button next to the field to open the calendar selection box.

Figure 17. Calendar selection box

Scroll through the calendar using the scroll buttons at the top. Click to select a

particular date. Use the up/down arrow keys to highlight and change

individual date components.

31

Page 44

Bio-Plex Manager Software 6.1 User Guide | Controlling the System

Next, enter the DD, CL1, and CL2 target values for the control number, as

printed on the bottle, in the appropriate fields.

NOTE: Use only the DD target value on the Bio-Plex CAL1 bottle. Using

Bio-Rad’s calibrators is highly recommended, because other manufacturers’

DD target values have not been validated.

Click Add to close the dialog box and save your changes.

To add a new CAL2 control number, click the Add button under CAL2 Control

Number in the Calibrate dialog box. The Add New CAL2 Control Number

dialog box opens.

32

Figure 18. Adding a new CAL2 control number

In the dialog, enter the control number from the CAL2 bottle in the field. Select

the expiration date, if printed on the bottle, as described above. Next, enter

the Low RP1 target value for the control number, as printed on the bottle, in

the RP1 field.

NOTE: The CAL2 calibration bottle label lists two RP1 (also known as PMT, for

photomultiplier tube) target values: Low RP1 and High RP1. The High RP1

target value cannot be used in Bio-Plex Manager 5.0 or higher. All calibration

is done at the Low RP1 target value, which must fall between 3000 and 4000.

The High RP1 target value remains on the bottle label because it can be used

with earlier versions of Bio-Plex Manager. Assays that require calibration using

the High RP1 target value can be run by selecting the checkbox labeled “Run

at High RP1 Target” in the Run Protocol window.

When you are done, click Add to close the dialog box and save your changes.

Your new control numbers are added to the selection lists in the main

Calibrate dialog.

To delete a particular control number, first select it in the Calibrate dialog box,

and then click the Delete button.

Page 45

Calibration

Setting Up the Calibration

When you have specified the control numbers of your calibration

microspheres and specified the type of calibration you want to perform (CAL1

& CAL2, CAL1 Only, or CAL2 Only), click OK in the Calibrate dialog.

Another dialog box lists step-by-step instructions for preparing the Bio-Plex

MCV Plate IV.

Figure 19. Preparing the Bio-Plex MCV Plate IV for CAL1 & CAL2 calibration

NOTES: When preparing the MCV Plate IV, do the following:

• Important: Before vortexing, remove the calibration beads from 2 to

8°C (36 to 46°F) storage, and allow them to warm to room

temperature. Vortex each bottle for 30 seconds. Proper suspension

of the microspheres is essential for efficient calibration

• Never dilute the calibration beads, and be careful to limit their

exposure to light. Store at 2 to 8°C immediately following

calibration

• Load 6 drops of beads (approximately 200 μl) per reservoir (CAL1

or CAL2)

•The DI H

deionized water

O well of the MCV Plate IV holds about 3 ml of distilled or

2

33

Page 46

Bio-Plex Manager Software 6.1 User Guide | Controlling the System

Number of beads per second should be 100 or higher

Performing the Calibration

Click the Eject/Retract Plate button to eject the microplate platform plate

carrier. Place the MCV Plate IV in the carrier with the arrow facing toward the

platform, and then retract the plate. Click OK to start the calibration process.

As calibration proceeds, the status bar at the bottom of the Bio-Plex Manager

window monitors the progress of calibration. The number of beads per

second should be 100 or higher. Fewer beads per second may indicate a

problem with the fluidics system.

Figure 20. Status bar during calibration

Because calibration beads are highly concentrated, calibration is followed by

three wash cycles using distilled water.

An alert box notifies you whether calibration has succeeded or failed. You also

receive an alert which informs you how many days have elapsed since you

last ran a validation procedure.

If the calibration process failed, check the MCV Plate IV to verify that the

correct beads were added to the wells. Then perform a fluidics wash and

repeat the above steps. For more information, consult the Troubleshooting

chapter.

Logging the Calibration

The Calibration Log provides a list of past calibration dates and times, results,

instrument settings, and other data obtained by Bio-Plex Manager. These data

are stored in a log file called bioplexdata.mdb. By default, the file is saved in

the main Bio-Plex Manager application folder on your computer.

NOTE:

This database is not compatible with versions of Bio-Plex Manager earlier

than 4.0. If you have an earlier version of Bio-Plex Manager, installing version 4.0

or later copies data from your existing database (bioplex.mdb) into the new

database. A copy of the old database remains in the application folder.

34

Page 47

Calibration

To open the Calibration Log, go to the View menu and select Calibration Log.

The Calibration Log viewer opens.

Figure 21. Calibration Log viewer

Each calibration is listed by date and time. If you are using Bio-Plex Manager

Security Edition in Secure Mode, the User and Access Level columns list

information about the user who was logged into the application when each

calibration was performed. The Result column notes the result of each

calibration, including whether it passed or failed.

NOTE: If you see a drastic change in a detector's voltage from one calibration

to the next, it could indicate a problem with the instrument. A steadily

increasing detector voltage may indicate that the laser is decreasing in

intensity.

On the toolbar, click Calibration Detail to display additional information

for each calibration, including bead count, system temperature and pressure,

and the reader software and firmware versions. Click Calibration Log to

return to the default view.

For CAL1-only calibrations, the RP1 column displays an entry of NA (not

applicable). For CAL2-only calibrations, the DD, CL1, and CL2 columns

display entries of NA.

35

Page 48

Bio-Plex Manager Software 6.1 User Guide | Controlling the System

To print the calibration report, select Print from the File menu. Print Preview

displays the report as it will appear in a printout. Print Setup allows you to

select some standard print settings.

36

Page 49

Start Up and Calibrate

Each time you use Bio-Plex Manager, the array reader must go through the

start up, warm up, and calibration procedures. The Start up & Calibrate

command allows you to perform these steps with a single command. Click the

Start up & Calibrate button on the Quick Guide or main toolbar, or select the

command from the Instrument menu.

Refer to the following for more information on the individual functions:

• Start Up on page 27

• Optics Warm Up and Shut Down on page 28

• Calibration on page 29

If you prefer, you may perform each function separately. The individual

functions are available on the main toolbar or from the Instrument menu.

Start Up and Calibrate

37

Page 50

Bio-Plex Manager Software 6.1 User Guide | Controlling the System

Wash Between Plates

You should wash the fluidics lines between each plate reading to prevent

traces of sample or other debris from building up inside the system.

Click the Wash Between Plates button on the Quick Guide or main

toolbar, or select the command from the Instrument menu. A dialog box

guides you through the steps for preparing the MCV Plate IV for a wash

procedure.

Figure 22. Steps for washing between plate readings

Add 70% isopropanol and distilled water to the appropriate reservoirs, insert

the plate in the microplate platform, and click OK. This procedure performs a

series of fluidics operations and takes several minutes. After initial system

pressurization (5 to 20 seconds), the time remaining in the operation displays

in the Bio-Plex Manager status bar.

38

Page 51

Remove Air Bubbles

Microscopic air bubbles in the cuvette may cause a sudden shift in the bead

regions during an assay reading. If the array reader detects such a shift, the

reading stops and you are prompted to perform an alcohol wash to force air

bubbles out of the system.

Click the Remove Bubbles button on the main toolbar or select the

command from the Instrument menu. A dialog box guides you through the

steps for preparing the MCV Plate IV for the procedure.

Figure 23. Steps for removing air bubbles from the fluidics system

Add 70% isopropanol and distilled water to the appropriate reservoirs, insert

the plate in the microplate platform, and click OK. This procedure performs a

series of fluidics operations and takes several minutes. After initial system

pressurization (5 to 20 seconds), the time remaining in the operation displays

in the Bio-Plex Manager status bar.

Remove Air Bubbles

39

Page 52

Bio-Plex Manager Software 6.1 User Guide | Controlling the System

Unclog

If the array reader detects an unusually low bead count during a reading, you

are prompted to perform an Unclog operation to remove possible

obstructions from the fluidics lines.

1. Click the Unclog button on the main toolbar or select the command

from the Instrument menu. An instruction box guides you through

preparation of the MCV Plate IV.

Figure 24. Steps for unclogging the fluidics system

40

2. Add 70% isopropanol solution and distilled water to the appropriate

reservoirs.

3. Add 5 drops of CAL1 beads to the CAL1 reservoir.

4. Insert the plate in the microplate platform, and click OK.

This procedure performs a series of fluidics operations and reads a sample of

CAL1 beads to verify that the fluidics are operating properly. It takes several

minutes. After initial system pressurization (5 to 20 seconds), the time

remaining in the operation displays in the Bio-Plex Manager status bar.

Page 53

Validation

Validation of the array reader is a formal process for documenting that the

instrument is fit for its intended use and that it is kept in a state of

maintenance and calibration.

NOTE: Validation is performed after startup and calibration have been

performed. Validation is dependent on successful calibration for accuracy.

You should perform a validation reading:

•Once a month

• Each time you move the array reader, or