BINDER UF V 500 User Manual

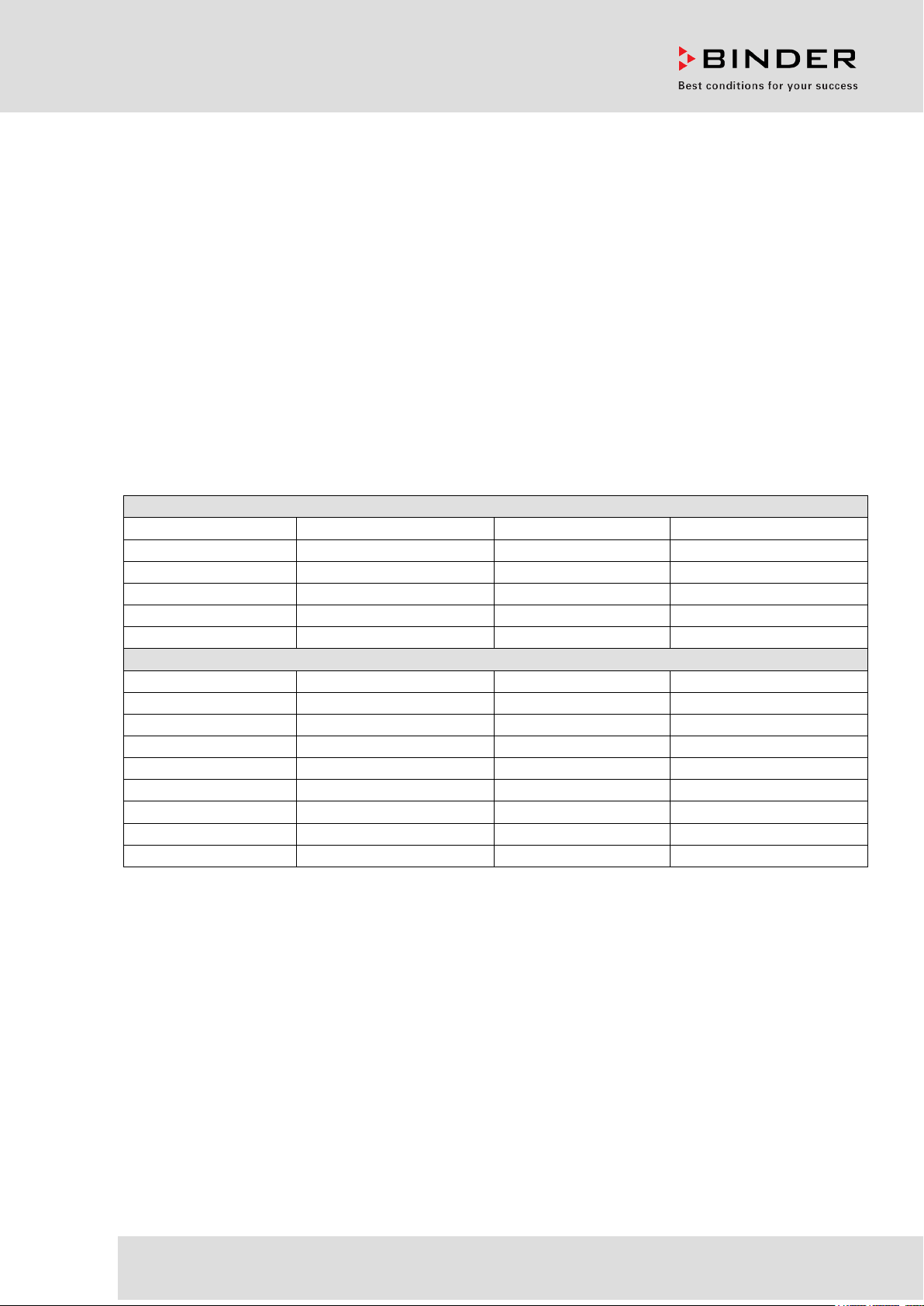

UF V with RFID

Model

Art. No.

Door hinges

Voltage

UF V 500 (E2)

9020-0232, 9120-0232

right

230 V

UF V 500 (E2.1)

9020-0236, 9120-0236

right

230 V

UF V 500 (E2.1)

9020-0213, 9120-0213

left

230 V

UF V 700 (E2.1)

9020-0233, 9120-0233

right

230 V

UF V 700 (E2.1)

9020-0237, 9120-0237

left

230 V

UF V UL with Advanced Voltage Booster and Data Logger

Model

Art. No.

Door hinges

Voltage

UF V 500-UL (E2.1)

9020-0235, 9120-0235

right

115 V

UF V 500-UL (E2.1)

9020-0222, 9120-0222

left

115 V

UF V 500-UL (E2.1)

9020-0234, 9120-0234

right

208-240 V

UF V 500-UL (E2.1)

9020-0220, 9120-0220

left

208-240 V

UF V 700-UL (E2.1)

9020-0239, 9120-0239

right

115 V

UF V 700-UL (E2.1)

9020-0218, 9120-0218

left

115 V

UF V 700-UL (E2.1)

9020-0238, 9120-0238

right

208-240 V

UF V 700-UL (E2.1)

9020-0216, 9120-0216

left

208-240 V

Operating Manual

Translation of the Original Operating Manual

ULTRA.Guard™

Ultra Low Temperature Freezers UF V

with RP1 Controller

BINDER GmbH

Address Post office box 102

D-78502 Tuttlingen

Tel. +49 7462 2005 0

Fax +49 7462 2005 100

Internet http://www.binder-world.com

E-mail info@binder-world.com

Service Hotline +49 7462 2005 555

Service Fax +49 7462 2005 93 555

Service E-Mail service@binder-world.com

Service Hotline USA +1 866 885 9794 or +1 631 224 4340 x3

Service Hotline Asia Pacific +852 39070500 or +852 39070503

Service Hotline Russia and CIS +7 495 98815 17

Issue 03/2013 Art. No. 7001-0083

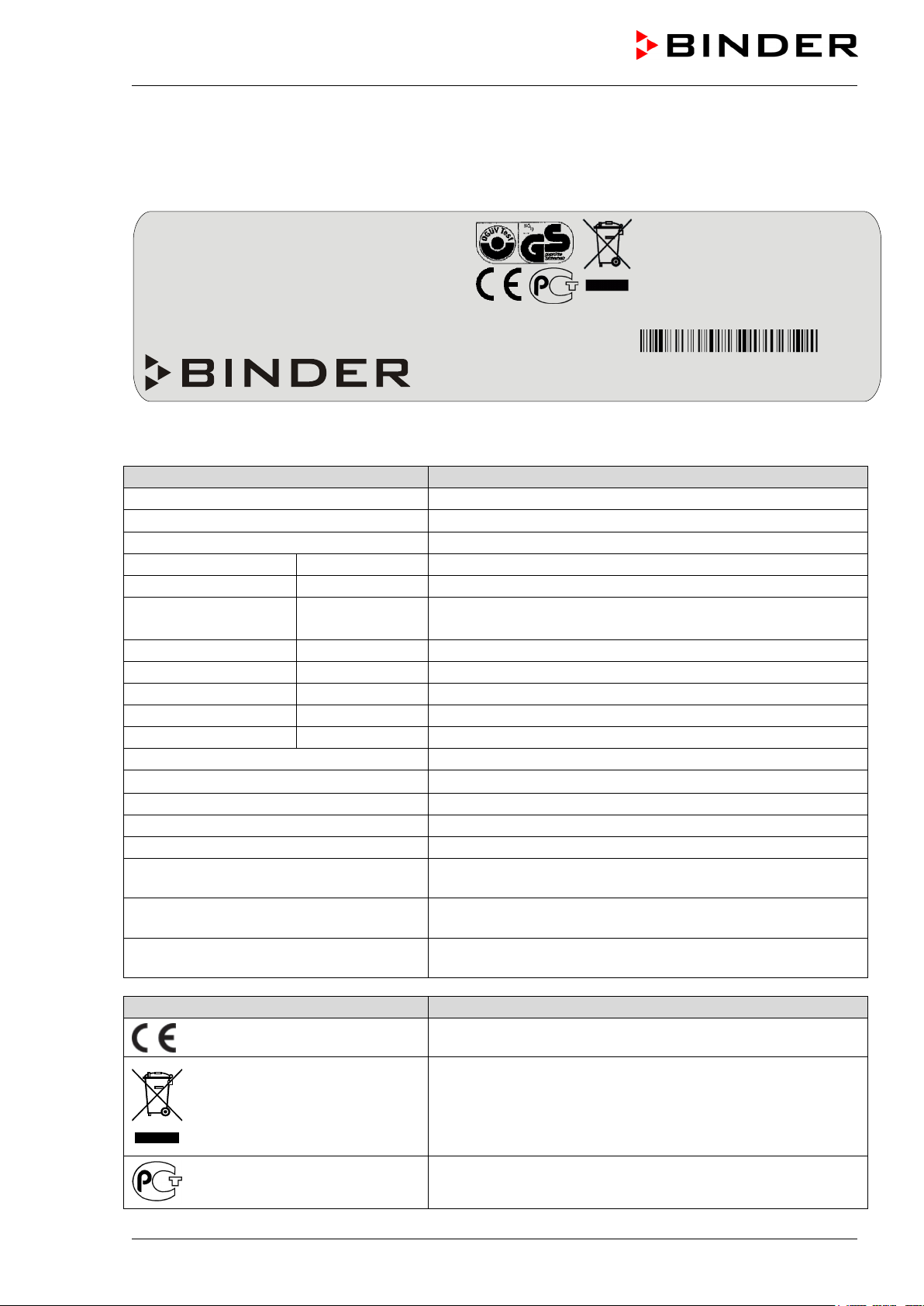

EG – KONFORMITÄTSERKLÄRUNG

EC – declaration of conformity

EC - DECLARATION OF CONFORMITY

Anbieter / Supplier / Fournisseur:

CE - DECLARATION DE CONFORMITE

BINDER GmbH

Anschrift / Address / Adresse:

Bezeichnung der Maschine /

Denomination of the machine /

Dénomination de la machine:

Typenbezeichnung / Type / Type:

Die oben beschriebene Maschine ist konform mit folgenden EG-Richtlinien (gemäß Veröffentlichung im Amtsblatt der europäischen Kommission):

The machine described above is in conformity with the following EC guidelines (as published in

the Official Journal of the European Union):

La machine décrite ci-dessus est conforme aux directives CE suivantes (selon leur publication

dans le Journal officiel de l’Union européenne):

Maschinenrichtlinie

2006/42/EG

Machinery directive

2006/42/EC

Directive Machines

2006/42/EC

EMV-Richtlinie

2004/108/EG

EMC Directive

2004/108/EC

Directive CEM

2004/108/CE

Richtlinie 2006/42/EG des Europäischen Parlaments und des Rates vom 17.

Mai 2006 über Maschinen und zur Änderung der Richtlinie 95/16/EG (Neufassung)

Directive 2006/42/EC of the European Parliament and of the Council of 17

May 2006 on machinery, and amending Directive 95/16/EC (recast)

Directive 2006/42/CE du Parlement Européen et du Conseil du 17 mai 2006

relative aux machines et modifiant la directive 95/16/CE (refonte)

Richtlinie 2004/108/EG des Europäischen Parlaments und des Rates vom

15. Dezember 2004 zur Angleichung der Rechtsvorschriften der Mitgliedstaaten über die elektromagnetische Verträglichkeit und zur Aufhebung der

Richtlinie 89/336/EWG.

Directive 2004/108/EC of the European Parliament and of the Council of 15

December 2004 on the approximation of the laws of the Member States

relating to electromagnetic compatibility and repealing Directive 98/336/EEC.

Im Mittleren Ösch 5, D-78532 Tuttlingen

Ultra-Tiefkühlschränke / Freezer

Ultra low temperature freezers

Congélateurs à ultra-basse température

UF V 300, UF V 500, UF V 700

Directive 2004/108/CE du Parlement Européen et du Conseil du 15 décembre 2004 relative au rapprochement des législations des États membres

concernant la compatibilité électromagnétique et abrogeant le directive

98/336/CEE.

Die oben beschriebene Maschine entspricht aufgrund ihrer Konzipierung und Bauart sowie in der von uns

in Verkehr gebrachten Ausführung den einschlägigen grundlegenden Sicherheits- und Gesundheitsanforderungen der genannten EG-Richtlinien.

The machine described above is conform to the mentioned EC directives in regard to the relevant safety

and health demands due to its conception and its style of construction as well as to the version put onto

market by us.

La machine décrite ci-dessus correspond aux demandes de sécurité et de santé des directives citées de

la Communauté Européenne due à sa conception et construction et dans la réalisation mise sur le marché par nous.

Die oben beschriebene Maschine trägt entsprechend die Kennzeichnung CE.

The machine described above, corresponding to this, bears the CE-mark.

La machine décrite ci-dessus, en correspondance, porte l’indication CE.

UF V (E2+E2.1) 03/2013 page 2/112

1 / 3

Sicherheit / safety / sécurité:

Sicherheit von Maschinen. Elektrische Ausrüstung von Maschinen. Teil 1:

Die oben beschriebene Maschine ist konform mit folgenden harmonisierten Normen:

The machine described above is in conformity with the following harmonized standards:

La machine décrite ci-dessus est conforme aux normes harmonisées suivantes:

EN 61010-1:2010 Sicherheitsbestimmungen für elektrische Mess-, Steuer-, Regel- und

Laborgeräte – Teil 1: Allgemeine Anforderungen (DIN EN 61010-1:2011,

VDE 411-1:2011)

Safety requirements for electrical equipment for measurement, control,

and laboratory use – Part 1: General requirements (IEC 61010-1:2010,

BS EN 61010-1:2010)

Règles de sécurité pour appareils électriques de mesurage, de régulation

et de laboratoire – Partie 1: Prescriptions générales (CEI 61010-1:2010,

NF EN 61010:2011)

EN ISO 12100:2010 Sicherheit von Maschinen - Allgemeine Gestaltungsleitsätze - Risikobeur-

teilung und Risikominderung (DIN EN ISO 12100:2011)

Safety of machinery - General principles for design - Risk assessment

and risk reduction (BS EN ISO 12100:2010)

Sécurité des machines - Principes généraux de conception -Appréciation

du risque et réduction du risque (NF EN ISO 12100:2010)

EN ISO 13732-3:2008 Ergonomie der thermischen Umgebung – Bewertungsverfahren für Reak-

tionen des Menschen bei Kontakt mit Oberflächen. Teil 3: Kalte Oberflächen (DIN EN ISO 13732-3:2008)

Ergonomics of the thermal environment – Methods for the assessment of

human responses to contact with surfaces. Part 3: Cold surfaces (BS EN

ISO 13732-3:2008)

Ergonomie des ambiances thermiques – Méthodes d'évaluation de la

réponse humaine au contact avec des surfaces. Partie 3: Surfaces froides (NF EN ISO 13732-3:2008)

EN ISO 13849-1:2008 Sicherheit von Maschinen. Sicherheitsbezogene Teile von Steuerungen.

Teil 1: Allgemeine Gestaltungsleitsätze (DIN EN ISO 13849-1:2008)

Safety of machinery. Safety-related parts of control systems. Part 1:

General principles for design (BS EN ISO 13849-1:2008)

Sécurité des machines – Parties des systèmes de commande relatives à

la sécurité – Partie 1: principes de conception généraux (NF EN ISO

13849-1:2008)

EN ISO 13849-2:2008 Sicherheit von Maschinen. Sicherheitsbezogene Teile von Steuerungen.

Teil 2: Validierung (DIN EN ISO 13849-2:2008 + Berichtigung 1:2009)

Safety of machinery. Safety-related parts of control systems. Part 2: Vali-

dation (BS EN ISO 13849-2:2008)

Sécurité des machines. Parties des systèmes de commande relatives à

la sécurité. Partie 2: Validation (NF EN ISO 13849-2:2008)

EN 60204-1:2006 + A1:2009

+ Corr. :2010

Allgemeine Anforderungen (DIN EN 60204-1:2007 + A1:2009 + Berichtigung 1:2010)

Safety of machinery. Electrical equipment of machines. Part 1: General

requirements (IEC 60204-1:2005 mod. + A1:2008 + Corr. :2010, BS EN

60204-1:2006 + A1:2009)

Sécurité des machines - Équipement électrique des machines - Partie 1 :

règles générales (CEI 60204-1:2005 mod. + A1:2008, NF EN 602041:2006 + A1:2009)

2 / 3

UF V (E2+E2.1) 03/2013 page 3/112

EMV / EMC / CEM:

P. M. Binder

B. Hofmann

EN 61326-1:2006 + Corr.

1:2008 + Corr. 2:2010

Elektrische Mess-, Steuer-, Regel- und Laborgeräte - EMVAnforderungen - Teil 1: Allgemeine Anforderungen (DIN EN 613261:2006 + Berichtigung 1:2008 + Berichtigung 2:2011)

Electrical equipment for measurement, control and laboratory use - EMC

requirements - Part 1: General requirements (IEC 61326-1:2005 + Corr.

1:2008 + Corr. 2:2010, BS EN 61326-1:2006+ A1:2008)

Matériel électrique de mesure, de commande et de laboratoire - Exigences relatives à la CEM - Partie 1: Exigences générales (CEI 613261:2005 + AC1:2008, NF EN 61326-1:2006 mod.)

EN 61326-2-2:2006 Elektrische Mess-, Steuer-, Regel- und Laborgeräte – EMV-

Anforderungen. Teil 2-2: Besondere Anforderungen - Prüfanordnung,

Betriebsbedingungen und Leistungsmerkmale für ortsveränderliche Prüf-,

Mess- und Überwachungsgeräte in NiederspannungsStromversorgungsnetzen. (DIN EN 61326-2-2:2006)

Electrical equipment for measurement, control and laboratory use – EMC

requirements. Part 2-2: Particular requirements - Test configurations,

operational conditions and performance criteria for portable test, measuring and monitoring equipment used in low-voltage distribution systems.

(IEC 61326-2-2:2005, BS EN 61326-2-2:2006)

Matériel électrique de mesure, de commande et de laboratoire – Exigences relatives à la CEM. Partie 2-2: Exigences particulières - Configurations d’essai, conditions de fonctionnement et critères d’aptitude à la

fonction des matériels portatifs d’essai, de mesure et de surveillance

utilisés dans des systèmes de distribution basse tension. (CEI 61326-22:2005 + AC1:2007, NF EN 61326-2-2:2006)

D-78532 Tuttlingen, 27.03.2013

BINDER GmbH

Geschäftsführender Gesellschafter

Managing Director

Directeur général

Leiter F & E

Director R & D

Chef de service R&D

3 / 3

UF V (E2+E2.1) 03/2013 page 4/112

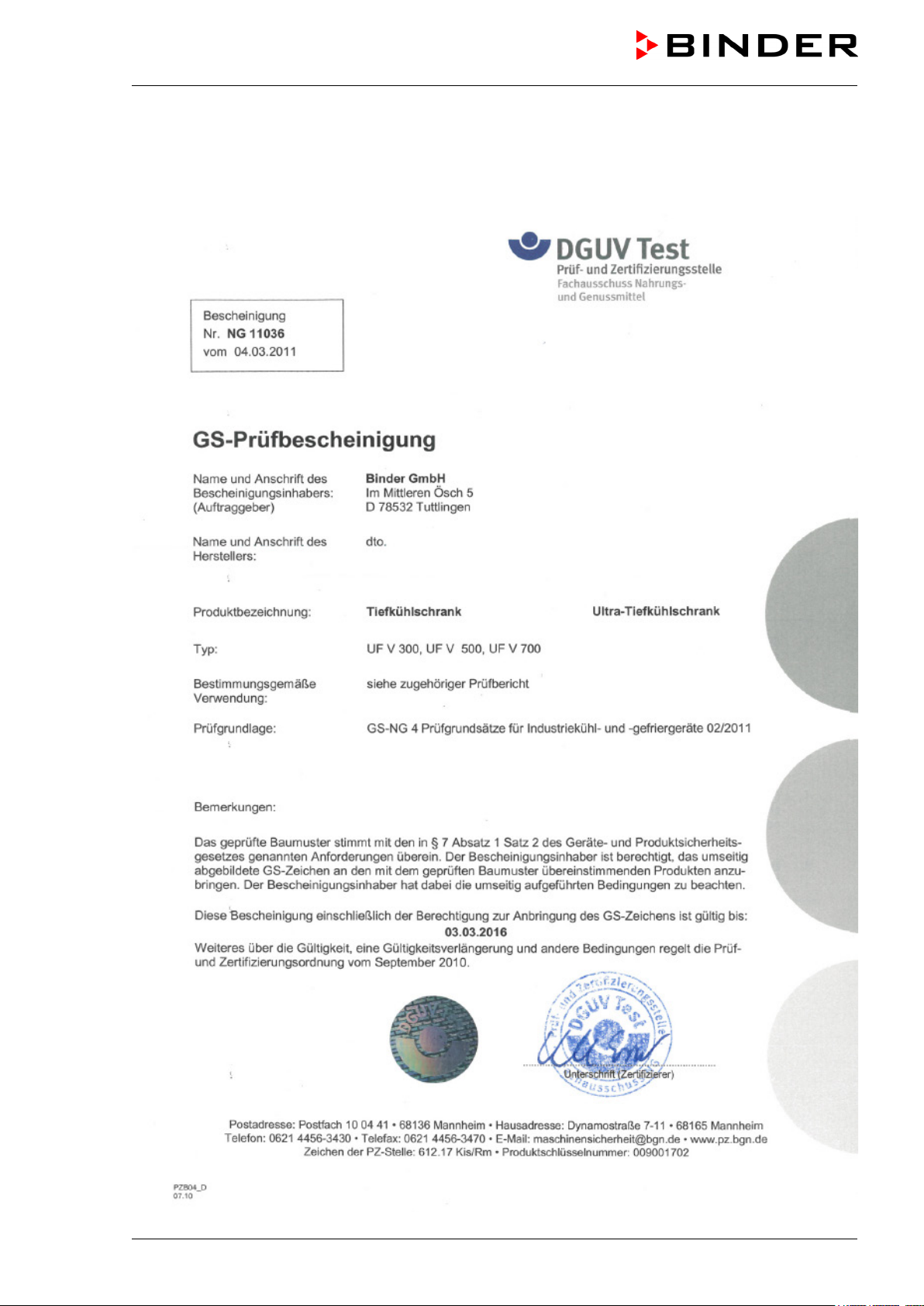

Certificate for the GS mark of conformity of the “Deutsche Gesetzliche Unfallversicherung e.V.“ (German Social Accident Insurance) DGUV

Note: When mounting the optional CO2 emergency cooling, the GS mark is no longer valid

UF V (E2+E2.1) 03/2013 page 5/112

UF V (E2+E2.1) 03/2013 page 6/112

Product registration

UF V (E2+E2.1) 03/2013 page 7/112

Contents

EC – declaration of conformity ...................................................................................................................... 2

Certificate for the GS mark of conformity of the “Deutsche Gesetzliche Unfallversicherung e.V.“

(German Social Accident Insurance) DGUV ....................................................................................... 5

Product registration ....................................................................................................................................... 7

1. SAFETY ................................................................................................................ 11

1.1 Legal considerations ......................................................................................................................... 11

1.2 Structure of the safety instructions .................................................................................................... 11

1.2.1 Signal word panel ........................................................................................................................ 11

1.2.2 Safety alert symbol ...................................................................................................................... 12

1.2.3 Pictograms ................................................................................................................................... 12

1.2.4 Word message panel structure .................................................................................................... 13

1.3 Localization / position of safety labels at the unit .............................................................................. 13

1.4 Type plate ......................................................................................................................................... 14

1.5 General safety instructions on installing and operating the UF V freezer ........................................ 15

1.6 Intended use ..................................................................................................................................... 17

1.7 Operating instructions ....................................................................................................................... 17

1.8 Measures to prevent accidents ......................................................................................................... 18

2. UNIT DESCRIPTION ............................................................................................ 19

2.1 Unit overview ..................................................................................................................................... 21

2.2 Housing of the automatic door mechanism with operator panel ...................................................... 23

2.3 Key switch (main power switch) ........................................................................................................ 24

2.4 RP1 controller ................................................................................................................................... 25

2.5 Connection panel on the unit rear ..................................................................................................... 26

2.6 Unit doors .......................................................................................................................................... 27

2.6.1 Outer door .................................................................................................................................... 27

2.6.2 Compartment doors ..................................................................................................................... 27

2.6.3 Emergency release of the outer door .......................................................................................... 27

2.7 Drain well for condensate during defrosting (option) ........................................................................ 29

3. COMPLETENESS OF DELIVERY, TRANSPORTATION, STORAGE, AND

INSTALLATION .................................................................................................... 30

3.1 Unpacking, and checking equipment and completeness of delivery ................................................ 30

3.2 Guidelines for safe lifting and transportation .................................................................................... 31

3.2.1 Moving the freezer inside a building ............................................................................................ 31

3.2.2 Transport outside a building ........................................................................................................ 32

3.3 Storage .............................................................................................................................................. 33

3.4 Location of installation and ambient conditions ................................................................................ 33

3.5 Adjusting the vertically adjustable castors ........................................................................................ 34

4. INSTALLATION AND CONNECTIONS................................................................ 36

4.1 Operating instructions ....................................................................................................................... 36

4.2 Spacers for rear wall distance ........................................................................................................... 36

4.3 Fixing to achieve earthquake safety (optional) ................................................................................. 37

4.4 10 mm access port prepared to be finalized by the user (UF V (E2.1), UF V-UL (E2.1)) ................ 38

4.5 Adjustable shelves ............................................................................................................................ 39

4.6 Electrical connection ......................................................................................................................... 41

4.7 Advanced voltage booster (regular with UF V UL, option for UF V)) ................................................ 41

5. START UP ............................................................................................................ 42

5.1 Preset factory parameters ................................................................................................................. 42

5.2 Operating the automatic door mechanism ........................................................................................ 42

5.3 Door locking with key (option for UF V UL) ....................................................................................... 43

UF V (E2+E2.1) 03/2013 page 8/112

5.4

GUARD.CONTROL: RFID personal access control of the automatic door mechanism

(standard for UF V, option for UF V UL) ........................................................................................... 44

5.4.1 Indication of the door condition .................................................................................................... 44

5.4.2 Overview of LED indications of the RFID personal access control ............................................. 45

5.4.3 Cards for access control .............................................................................................................. 45

5.4.4 Operating the RFID access control .............................................................................................. 46

5.4.5 Reading out the door opening data with the GUARD.CONTROL Reader Kit

(Art. no. 8012-0789) ..................................................................................................................... 47

5.4.6 Resetting the entire system ......................................................................................................... 47

5.5 Behavior after turning on the unit ...................................................................................................... 48

6. SETTING THE TEMPERATURE SET POINT AT THE CONTROLLER RP1 ....... 49

7. PLACING SAMPLES IN STORAGE IN THE FREEZER ...................................... 50

8. CONTROLLER RP1 OPERATING MODES ......................................................... 51

8.1 Selecting and setting the operating functions ................................................................................... 51

8.2 Operating mode HAND ..................................................................................................................... 52

8.3 Operating mode USER: Advanced settings ...................................................................................... 53

8.4 Operating mode LOCK: Locking/unlocking of the operating functions’ settings by operating mode

HAND ................................................................................................................................................ 57

8.4.1 Locking the operating functions of operating mode HAND ......................................................... 57

8.4.2 Temporally unlocking the operating functions of operating mode HAND .................................... 57

8.4.3 Permanently unlocking the operating functions of operating mode HAND ................................. 58

8.5 Performance during and after power failure and shut down ............................................................. 58

9. SAFETY CONTROLLER (TEMPERATURE SAFETY DEVICE) .......................... 59

9.1.1 Setting the safety controller set point ........................................................................................... 59

10. INDICATIONS AND ALARM FUNCTIONS (AUTO-DIAGNOSTIC SYSTEM) ..... 61

10.1 Indications and alarm functions overview ......................................................................................... 61

10.2 Resetting the alarm messages ......................................................................................................... 61

10.3 Safety controller temperature alarm.................................................................................................. 62

10.4 Temperature tolerance range alarm (too high and too low temperature) ......................................... 63

10.5 Door open alarm ............................................................................................................................... 64

10.6 Messages from the battery management system ............................................................................. 65

10.7 Power failure alarm ........................................................................................................................... 67

10.8 Temperature sensor failure ............................................................................................................... 68

10.9 Further error messages .................................................................................................................... 69

10.10 Zero-voltage relay alarm output ........................................................................................................ 70

11. CO2 EMERGENCY COOLING (OPTION) ............................................................ 71

11.1 Connecting and exchanging the CO2 pressure cylinder ................................................................... 72

11.2 Operating the CO2 emergency cooling system ................................................................................. 73

11.3 Alarm messages ............................................................................................................................... 75

12. DATA MONITORING AND RECORDING ............................................................ 77

12.1 Ethernet interface (option) ................................................................................................................ 77

12.2 Communication software APT-COM™ 3 DataControlSystem (option) ............................................ 77

12.3 Analog output for temperature .......................................................................................................... 77

12.4 Additional Pt 100 temperature sensor (option) with output to Lemo socket ..................................... 78

12.5 Circular chart recorder (option) ......................................................................................................... 78

12.6 Data logger (standard with UF V UL, option for UF V) ..................................................................... 79

12.7 BINDER GSM Box for remote alarms (option) ................................................................................. 79

13. UNIT INVENTORY AND ACCESSORIES ............................................................ 80

13.1 Storage rack systems (option) .......................................................................................................... 80

13.1.1 Side access racks ........................................................................................................................ 80

13.1.2 Sliding drawer racks ..................................................................................................................... 80

UF V (E2+E2.1) 03/2013 page 9/112

13.1.3

Cryo boxes and dividers .............................................................................................................. 81

13.1.4 Cardboard dividers for cryo boxes ............................................................................................... 81

13.1.5 Polypropylene cryo boxes with dividers and codification, transparent ........................................ 81

14. MAINTENANCE, CLEANING, AND SERVICE .................................................... 82

14.1 Immediate aid, service ...................................................................................................................... 82

14.2 Maintenance intervals, service .......................................................................................................... 82

14.3 Cleaning and decontamination ......................................................................................................... 83

14.3.1 Cleaning ....................................................................................................................................... 83

14.3.2 Decontamination .......................................................................................................................... 84

14.4 Maintenance work by the customer .................................................................................................. 86

14.4.1 Checking and cleaning the condenser air filter ............................................................................ 86

14.4.2 Cleaning the condenser ............................................................................................................... 87

14.4.3 De-icing and defrosting ................................................................................................................ 87

14.5 Sending the unit back to BINDER GmbH ......................................................................................... 88

15. DISPOSAL............................................................................................................ 88

15.1 Disposal of the transport packing ..................................................................................................... 88

15.2 Decommissioning .............................................................................................................................. 89

15.3 Disposal of the unit in the Federal Republic of Germany ................................................................. 89

15.4 Disposal of the unit in the member states of the EC except for the Federal Republic of Germany . 90

15.5 Disposal of the unit in non-member states of the EC ....................................................................... 91

16. TROUBLESHOOTING ......................................................................................... 92

17. OVERVIEW OF ALL CONTROLLER INDICATIONS ........................................... 94

17.1 Indications of setting menus ............................................................................................................. 94

17.2 Information and alarm messages...................................................................................................... 95

18. TECHNICAL DESCRIPTION ................................................................................ 97

18.1 Factory calibration and adjustment ................................................................................................... 97

18.2 Over current protection ..................................................................................................................... 97

18.3 Battery replacement .......................................................................................................................... 97

18.4 UF V (E2 / E2.1) technical data ........................................................................................................ 98

18.5 Equipment ....................................................................................................................................... 100

18.6 Optional equipment, accessories and spare parts ......................................................................... 101

18.7 Dimensions UF V 500 (E2) ............................................................................................................. 104

18.8 Dimensions UF V 500 (E2.1) .......................................................................................................... 105

18.9 Dimensions UF V 700 (E2.1) .......................................................................................................... 106

19. CONTAMINATION CLEARANCE CERTIFICATE ............................................. 107

19.1 For units located outside North America and Central America....................................................... 107

19.2 For units in North America and Central America ............................................................................ 110

UF V (E2+E2.1) 03/2013 page 10/112

Dear Customer,

For the correct operation of the ULTRA.Guard™ ultra-low temperature freezer UF V, it is important that

you read this operating manual completely and carefully and observe all instructions as indicated. Failure

to read, understand and follow the instructions may result in personal injury. It can also lead to damage to

the unit and/or poor equipment performance.

1. Safety

This operating manual is part of the components of delivery. Always keep it handy for reference.

The freezer should only be operated by laboratory personnel especially trained for this purpose and famil-

iar with all precautionary measures required for working in a laboratory. To avoid injury and damage observe the safety instructions in the operating manual.

WARNING

Failure to observe the safety instructions.

Serious injuries and unit damage.

Observe the safety instructions in this operating manual

Carefully read the complete operating instructions for the ultra-low temperature freezer.

1.1 Legal considerations

This operating manual is for informational purposes only. It contains information for installing, start-up,

operation and maintenance of the product. Note: the contents and the product described are subject to

change without notice.

Understanding and observing the instructions in this operating manual are prerequisites for hazard-free

use and safety during operation and maintenance. In no event shall BINDER be held liable for any damages, direct or incidental arising out of or related to the use of this manual.

This operating manual cannot cover all conceivable applications. If you would like additional information,

or if special problems arise that are not sufficiently addressed in this manual, please ask your dealer or

contact us directly by phone at the number located on page one of this manual

Furthermore, we emphasize that the contents of this operating manual are not part of an earlier or existing agreement, description, or legal relationship, nor do they modify such a relationship. All obligations on

the part of BINDER derive from the respective purchase contract, which also contains the entire and exclusively valid statement of warranty administration. The statements in this manual neither augment nor

restrict the contractual warranty provisions.

1.2 Structure of the safety instructions

In this operating manual, the following safety definitions and symbols indicate dangerous situations in

accordance with the standards ISO 3864-2 and ANSI Z535.6.

1.2.1 Signal word panel

Depending on the probability of serious consequences, potential dangers are identified with a signal

word, the corresponding safety color, and if appropriate, the safety alert symbol.

DANGER

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious (irreversible) injury.

UF V (E2+E2.1) 03/2013 page 11/112

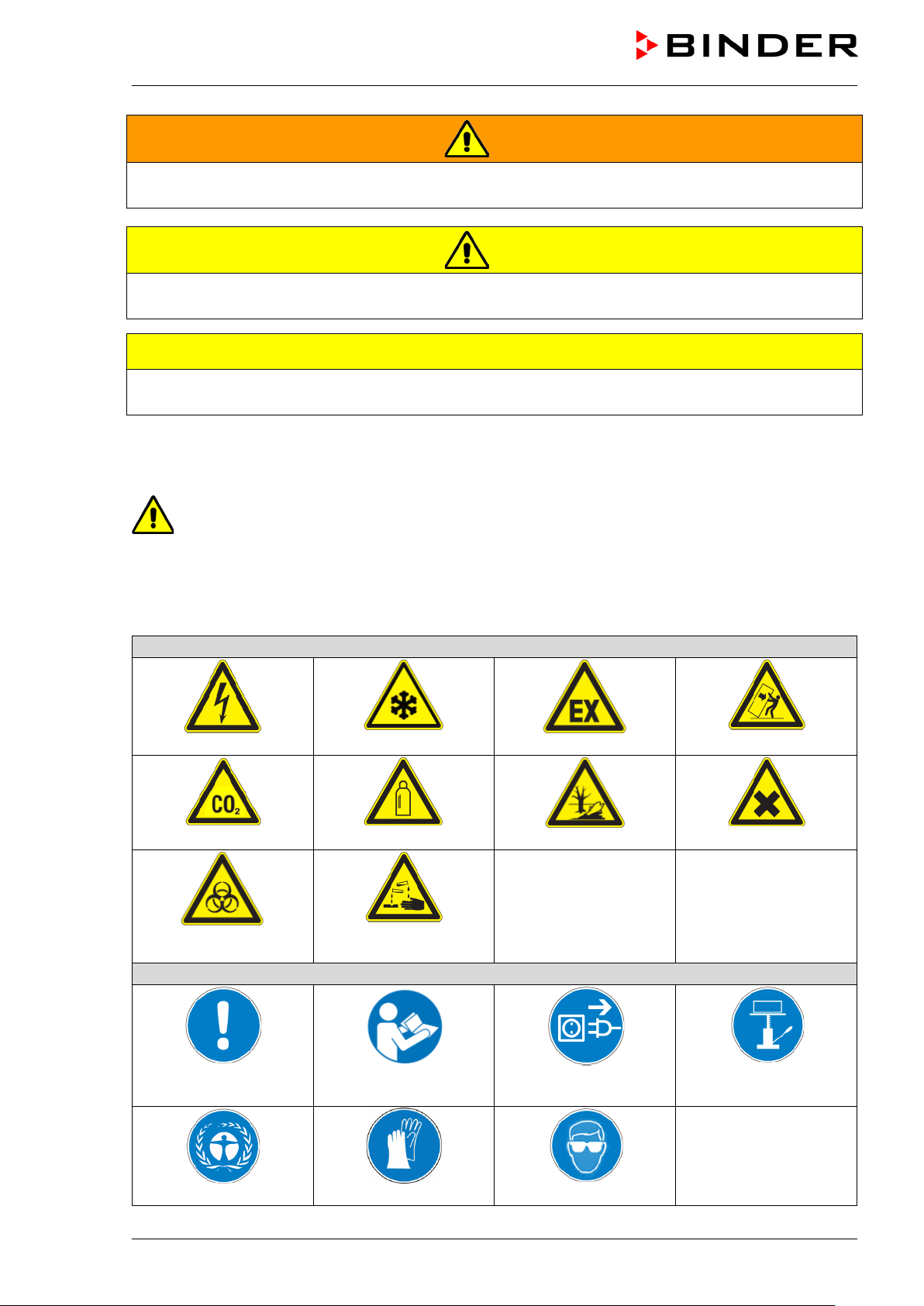

Warning signs

Electrical hazard

Explosive atmosphere

Pollution Hazard

or chemical burns

Mandatory action signs

plug

Environment protection

Wear protective gloves

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

(irreversible) injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in moderate or minor

(reversible) injury

CAUTION

Indicates a potentially hazardous situation, which, if not avoided, may result in damage to the product

and/or its functions or to property in its proximity.

1.2.2 Safety alert symbol

Use of the safety alert symbol indicates a risk of injury.

Observe all measures that are marked with the safety alert symbol in order to avoid death or

injury.

1.2.3 Pictograms

suffocation hazard

CO

2

Biohazard

Very cold surface

Gas cylinders

Risk of corrosion and /

Stability hazard

Harmful substances

Mandatory regulation

UF V (E2+E2.1) 03/2013 page 12/112

Read operating

instructions

Disconnect the power

Wear safety goggles

Lift with mechanical

assistance

Prohibition signs

water

Pictograms (Warning signs)

Service label

Figure 1: Position of labels

Do NOT touch

Do NOT spray with

Information to be observed in order to ensure optimum function of the product.

Do NOT climb

1.2.4 Word message panel structure

Type / cause of hazard.

Possible consequences.

∅ Instruction on how to avoid the hazard: prohibition

Instruction on how to avoid the hazard: mandatory action

Observe all other notes and information not necessarily emphasized in the same way, in order to avoid

disruptions that could result in direct or indirect injury or property damage.

1.3 Localization / position of safety labels at the unit

The following labels are located on the unit:

Very cold surface

on the freezer UF V 700 (E2.1)

Replace safety labels that are no longer legible. Contact BINDER Service for these replacements.

UF V (E2+E2.1) 03/2013 page 13/112

Keep safety labels complete and legible.

Indications of the type plate (example)

Information

BINDER

Manufacturer: BINDER GmbH

UF V 500

Model UF V 500

ULTRA.GUARD ULT Freezer

“ULTRA.GUARD” ultra-low temperature freezer

Serial No.

00-00000

Serial No. 00-00000

Built

2011

Year of construction 2011 (example)

Nominal temperature

-86 °C

-123°F

Enclosure protection

IP 20

IP type of protection 20 acc. to EN 60529

Temp. safety device

DIN 12880

Temperature safety device acc. to standard DIN 12880

Class

---

(Class of temperature safety device)

Art. No.

9020-0236

Art. No. 9020-0236

Project No.

---

(Special application acc. to project no.)

1.10 kW

Nominal power 1.10 kW

230 V 1 N ~

Nominal voltage 230 V ± 10 %, single-phase unit

4.8 A

Nominal current 4.8 Amp

50 Hz

Power frequency 50 Hz

Max. operating pressure 28 bar

Max operating pressure 28 bar in the refrigerating system

Stage 1 R 404A – 0,365 kg

Refrigerant for cooling 1st stage: R 404A, filling weight: 0.365

kg

Stage 2 R 508B – 0,35 kg

Refrigerant for cooling 2nd stage: R 508B, filling weight: 0.350

kg

Contains fluorinated greenhouse gases

covered by the Kyoto Protocol.

Contains fluorinated greenhouse gases covered by the Kyoto

Protocol

Symbol on the type plate

Information

Nominal temperature

-86°C

1.10 kW

Max. operating pressure 28 bar

-123°F

230 V 1 N ~

Stage 1: R 404 A - 0,365 kg

Enclosure protection

Temp. safety device

IP 20

DIN 12880

4,8 A

50 Hz

Stage 2: R 508 B - 0,35 kg

Contains fluorinated greenhouse gases

Class

covered by the Kyoto Protocol.

Art. No.

9020-0236

GS mark not valid with mounted

Built

2011

ULTRA.GUARD ULT Freezer

D 78532 Tuttlingen / Germany

Internet: www.binder-world.com

E2.1 Made in Germany

1.4 Type plate

The type plate sticks to the left side of the unit, bottom right-hand.

Project No.

option CO2 emergency cooling

Tel. + 49 (0) 7462/ 2005-0

UF V 500 Serial No. 00-00000

Figure 2: Type plate (example UF V 500 (E2.1) standard unit)

Nominal temperature

UF V (E2+E2.1) 03/2013 page 14/112

CE conformity marking

Electrical and electronic equipment manufactured / placed on

the market in the EC after 13 August 2005 and to be disposed of in a separate collection according to directive

2002/96/EC on waste electrical and electronic equipment

(WEEE).

The equipment is certified in the GOST R certification system

of GOSTSTANDARD Russia.

Symbol on the type plate

Information

LABORATORY EQUIPMENT

43KM

CAUTION

GS mark of conformity of the “Deutsche Gesetzliche Unfallversicherung e.V. (DGUV), Fachausschuss Nahrungs- und Genussmit-

GS mark not valid with mounted

option CO

emergency cooling

2

tel, Prüf- und Zertifizierungsstelle im DGUV Test“ (German Social

Accident Insurance (DGUV), Expert Committee for the food processing industry, Testing and Certification Body in DGUV). When

mounting the optional CO

emergency cooling, the GS mark of

2

conformity is no longer valid.

(UL units only)

The equipment is certified by Underwriters Laboratories Inc.

cording to standards CAN/CSA-C22.2 No. 61010-1, 2

2004-07 (Electrical Equipment for Measurement, Control, and

Laboratory Use; Part 1: General Requirements); UL 61010-1, 2

nd

Edition,

®

ac-

nd

Edition, 2005-07-22 (Electrical Equipment for Measurement, Control, and Laboratory Use; Part 1: General Requirements)

1.5 General safety instructions on installing and operating the UF V freezer

With regard to operating the freezer and to the installation location, please observe the guideline

BGI/GUV-I 850-0 on safe working in laboratories (formerly BGR/GUV-R 120 or ZH 1/119 laboratory

guidelines issued by the employers’ liability insurance association) (for Germany).

BINDER GmbH is only responsible for the safety features of the unit provided skilled electricians or qualified personnel authorized by BINDER perform all maintenance and repair, and if components relating to

chamber safety are replaced in the event of failure with original spare parts.

To operate the unit, use only original BINDER accessories or accessories from third-party suppliers authorized by BINDER. The user is responsible for any risk caused by using unauthorized accessories.

CAUTION

Danger of overheating.

Damage to the unit.

∅ Do NOT install the unit in unventilated recesses.

Ensure sufficient ventilation of the installation site for dispersal of the heat.

Leakage of refrigerant in the event of a unit defect.

Danger to the environment.

Ensure sufficient ventilation of the installation site.

Do not operate the freezer in hazardous locations.

DANGER

UF V (E2+E2.1) 03/2013 page 15/112

Explosion hazard.

Danger of death.

∅ Do NOT operate the unit in potentially explosive areas.

∅ KEEP explosive dust or air-solvent mixtures AWAY from the unit.

The freezer does not does not dispose of any measures of explosion protection.

DANGER

Explosion hazard.

Danger of death.

∅ Do NOT introduce any substance into the freezer which is combustible or explosive at

working temperature.

∅ NO explosive dust or air-solvent mixture in the inner chamber.

Any solvent contained in the charging material must not be explosive or inflammable. I.e., irrespective of

the solvent concentration in the steam room, NO explosive mixture with air must form. The temperature

inside the chamber must lie below the flash point or below the sublimation point of the charging material.

Familiarize yourself with the physical and chemical properties of the charging material.

Familiarize yourself with any potential health risks caused by the charging material. Take adequate

measures to exclude any risk prior to putting the freezer into operation.

WARNING

Contamination with toxic, infectious or radioactive substances.

Danger of intoxication.

Danger of infection.

Protect the interior of the unit against contamination by toxic, infectious or radioactive

substances.

Take appropriate measures when bringing in or taking out toxic, infectious or radioac-

tive substances.

DANGER

Electrical hazard.

Danger of death.

∅ The unit must NOT become wet during operation or maintenance.

The freezers were produced in accordance with VDE regulations and were routinely tested in accordance

to VDE 0411-1 (IEC 61010-1).

CAUTION

The inner surfaces become very cold during operation.

Danger of injury by freezing on.

∅ Do NOT directly touch the inner surfaces or the charging material during operation.

∅ AVOID skin contact with the inner surfaces and accessory equipment.

Wear protective gloves when opening the inner doors and during manipulation.

UF V (E2+E2.1) 03/2013 page 16/112

WARNING

Stability hazard.

Danger of injury.

Damage to the unit and the charging material.

Housing cover breakaway.

∅ Do NOT climb on the lower housing cover.

∅ Do NOT load the lower housing cover with heavy objects while the unit door is open.

1.6 Intended use

ULTRA.Guard™ ultra-low temperature freezers UF V are technical equipment and intended solely for use

at work. They are suitable are designed for safe storage of varied materials at temperatures up to –86 °C

/ -122,8 °F, especially for long-term storage of biological, medical, and chemical samples at constant low

temperature. They are suitable for the domains Pharmacy, Medicine, Life Sciences, plastic industry, electronic components, food etc.

Freezers are designed for storage of harmless materials. None of the components of the charging material must be able to form an explosive mixture with air.

Following the instructions in this operating manual and conducting regular maintenance work

(chap. 14) are part of the intended use.

Other applications are not approved.

WARNING: If customer should use a freezer running in non-supervised continuous operation, we strongly recommend in case of inclusion of irrecoverable specimen or samples to

split such specimen or samples and store them in at least two chambers, if this is feasible.

1.7 Operating instructions

Depending on the application and location of the unit, the operator of the freezer must provide the relevant information for safe operation of the unit in a set of operating instructions.

Keep these operating instructions with the unit at all times in a place where they are clearly

visible. They must be comprehensible and written in the language of the employees.

UF V (E2+E2.1) 03/2013 page 17/112

1.8 Measures to prevent accidents

The operator of the ULTRA.Guard™ ultra-low temperature freezer UF V must observe the following regulation: Occupational Safety Regulations. Operation of refrigeration units, heat pumps and cooling systems

(GUV-R 500 chap. 2.35) (for Germany).

Following measures have been taken by the manufacturer in order to prevent ignition and explosions:

• Indications of the type plate

See operating manual chap. 1.4

• Operating manual

An operating manual is available for each freezer.

• Temperature monitoring

The freezer has a temperature display which can be read from outside.

An additional temperature safety device is built into the device. A visual and an audible signal (buzzer)

show exceeding of the temperature.

• Safety, measurement and control devices

The safety, measuring, and control devices are easily accessible.

• Electrostatic charge

The interior parts are grounded.

• Protection against touchable surfaces

Tested according to EN ISO 13732-3:2008.

• Floors

See operating manual chap. 3.4 for installation

• Cleaning

See operating manual chap. 14.3.

• Examinations

The freezer has been inspected by the “Deutsche Gesetzliche Unfallversicherung e.V. (DGUV), Fachausschuss Nahrungs- und Genussmittel, Prüf- und Zertifizierungsstelle im DGUV Test“ (German

Social Accident Insurance (DGUV), Expert Committee for the food processing industry, Testing and

Certification Body in DGUV) and bears the GS mark.

The GS mark is omitted if the chamber is equipped with the optional CO2 emergeny cooling.

UF V (E2+E2.1) 03/2013 page 18/112

2. Unit description

The ULTRA.Guard™ ultra-low temperature freezers UF V were produced with great care using the latest

tools for development and production. They were optimized for safe long-term storage of samples in the

ultra-low temperature range and reach the minimum temperature of -86 °C / -122.8 °F in approx. 9 hours.

You can operate the freezer in a temperature range from -86 °C / -122.8 °F up to -40 °C / -40 °F.

The UF V units are regularly equipped with the progressive RFID system (optional for UF V UL), offering

personalized access control. The UF V UL units are regularly equipped with the advanced voltage booster AVC (option for UF V) and a data logger (option for UF V).

The freezers are available with the door hinged on right or left and for several different voltages.

Easy opening and closing door mechanism and access control

A pushbutton permits opening the automatic door mechanism without using your hands. A pull-tight function automatically closes the outer door when slightly open. For personalized access control, the freezer

door is RFID controlled (standard with UF V, option for UF V UL) and an optional door locking with key is

available (option for UF V UL).

The freezer is regularly equipped with a key switch (main power switch) to switch on and off the unit.

Controller

For temperature control, the freezer is equipped with the microprocessor controller RP1 with a digital

display. The controller keypad can be locked (keyboard locking). Temperature setting is accurate to one

degree. The controller is mounted at eye level.

The controller offers an error diagnostics system generating audible and visual warning and alarm messages. During power failure, alarm function and control remain active during 72h. The controller provides

password protection for the setting menus. Testing the alarm functions is always possible.

The controller monitors ambient temperature and issues an alarm if it exceeds an adjustable value.

A counter of operating hours / weeks is included.

Housing

The inner chamber and the inside of the insulated outer door are made of stainless steel (material no.

1.4301 (V2A) in Germany). The housing is RAL 7035 powder-coated. All corners and edges are also

completely coated. The inner surfaces are smooth and therefore easy to clean. Easy front access permits

filter cleaning without tools. A 10 mm access port prepared to be finalized by the user and an additional

optional access port serves to introduce a cable and sensor of a measuring device.

The buildup of ice in the door area is minimal due to perfect closing of the inner and outer doors and a

heating of the outer door gasket. Precise spatial distribution of the cold in the interior ensures storage of

all samples at an identical storage temperature. The prevention of thermal bridges protects against defrosting. The combination of vacuum insulation panels (V technology) and CFC-free polyurethane foaming maximizes the cold storage capacity.

The freezer has four compartment doors. You can insert stainless steel shelves are make optimum use of

the interior. You can flexibly arrange the shelves to use the interior in a variable and optimum manner.

Inventory racks (stainless steel storage racks with cryo boxes, chap. 13) are optionally available.

Vertically adjustable castors with locks serve to move the freezer and then place it safely at its destination.

UF V (E2+E2.1) 03/2013 page 19/112

Cooling system

The powerful, energy-efficient and low-noise refrigerating machine uses the refrigerants R404a and

R508b. They are completely free of HCFCs (hydrochlorofluorocarbons) and CFCs (chlorofluorocarbon)

and not inflammable.

st

Control of the two-stage refrigerating machine: The 1

nd

stage cooling turns on depending on the temperature.

2

stage cooling immediately turns on. In addition, the

Safety

Thanks to the standard overtemperature safety device, the set temperature is maintained also in case of

a controller failure.

In case of power failure at -80 °C / -112 °F, a temperature of -60 °C / -76 °F will not be exceeded in an

empty freezer for at least 3 hours, in a loaded freezer (measured with a 30 kg / 66 lb water load) for approx. 7 hours.

The freezer is equipped with a rechargeable battery (12 V, 7.2 Ah). Battery voltage is regularly monitored.

An alarm indicates too low battery voltage. You can check battery voltage in the “USER” menu.

The advanced voltage booster provides automatic voltage compensation through a buck/boost converter

(standard with UF V UL, option for UF V, chap. 4.7).

An error diagnostics system monitors the unit functions and generates audible and visual warning and

alarm messages. The door is monitored for being closed.

The CO

emergency cooling (option, chap. 11) offers additional refrigeration, i.e., following introduction of

2

a heat load, in case of a power failure or failure of the cooling system.

Data monitoring and recording

The freezer is regularly equipped with a zero-voltage relay alarm output (chap. 10.10) and with an analog

output (chap. 12.3) for integration into customer systems. An additional independent Pt100 temperature

sensor with output on Lemo socket is available (option, chap. 12.4). The freezer can be optionally

equipped with an Ethernet interface (option, chap. 12.1) for computer communication, enabling monitoring via a network. The BINDER communication software APT-COM™ 3 DataControlSystem (option,

chap. 12.2) permits networking of up to 30 units and connection to a computer, as well as recording and

representing temperature data.

A circular chart recorder (option for UF V UL, chap. 12.5) or a data logger with USB port that is independent from the chamber controller (standard with UF V UL, option for UF V, chap. 12.6) serve to independently record the temperature values, data given out in compliance with FDA guideline 21 CFR part

11.

UF V (E2+E2.1) 03/2013 page 20/112

(A)

2.1 Unit overview

(B)

(C)

(D)

(E)

Figure 3: Freezer UF V 700 (E2.1), front view

(A) Outer door

(B) Housing of the automatic door mechanism and controller (description chap. 2.2, for emergency

release see chap. 2.6.3)

(C) Compressor housing

(D) Air filter grille (checking and cleaning the filter chap. 14.4.1)

(E) Vertically adjustable castors (adjustment chap. 3.5)

UF V (E2+E2.1) 03/2013 page 21/112

(F)

(G)

(C)

(D)

(F)

(B)

(A)

Figure 4: Freezer UF V 700, with open outer door

(A) Outer door

(B) Housing of the automatic door mechanism and controller (description chap. 2.2, for emergency

release see chap. 2.6.3)

(C) Compressor housing

(D) Air filter grille (checking and cleaning the filter chap. 14.4.1)

(E) Vertically adjustable castors (adjustment chap. 3.5)

(F) Compartment with variable shelf

(G) Compartment door

UF V (E2+E2.1) 03/2013 page 22/112

Left unit side

Front view

Left unit side

Front view

(1)

(1)

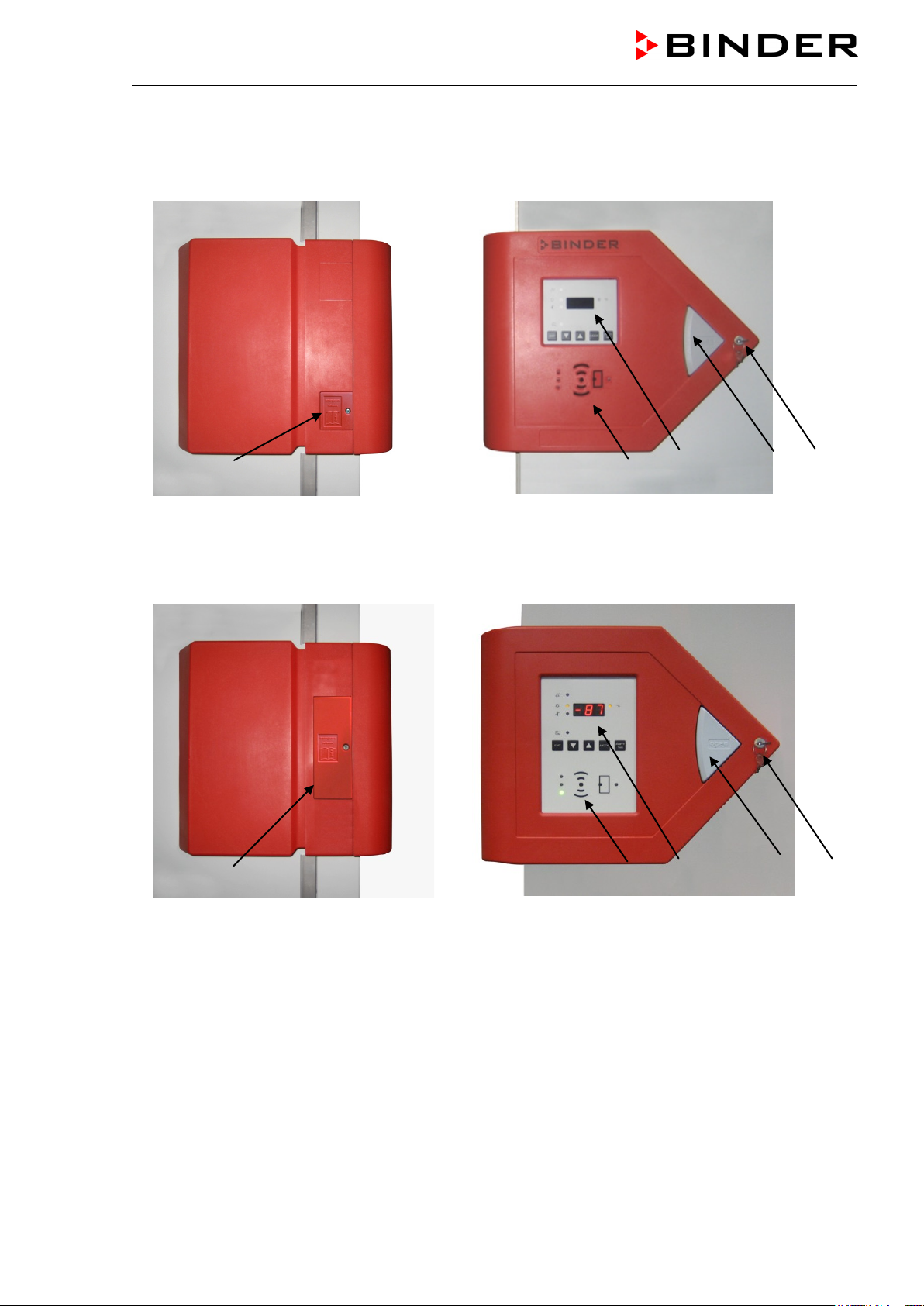

2.2 Housing of the automatic door mechanism with operator panel

(2) (3) (4) (5)

Figure 5: UF V (E2): Housing of automatic door mechanism with emergency release cover, operator pan-

el of controller RP1, RFID control of the automatic door mechanism, and door locking with key (option)

(2) (3) (4) (5)

Figure 6: UF V (E2.1): Housing of automatic door mechanism with emergency release cover, operator

panel of controller RP1, RFID control of the automatic door mechanism, and door locking with key (op-

tion)

(1) Emergency release cover

(2) GUARD.CONTROL: RFID control of the automatic door mechanism (standard with UF V, option for

UF V UL, chap. 5.4)

(3) Operator panel of controller RP1

(4) Push-button “OPEN” to open the door

(5) Door locking with key (option for UF V UL, chap. 5.3)

UF V (E2+E2.1) 03/2013 page 23/112

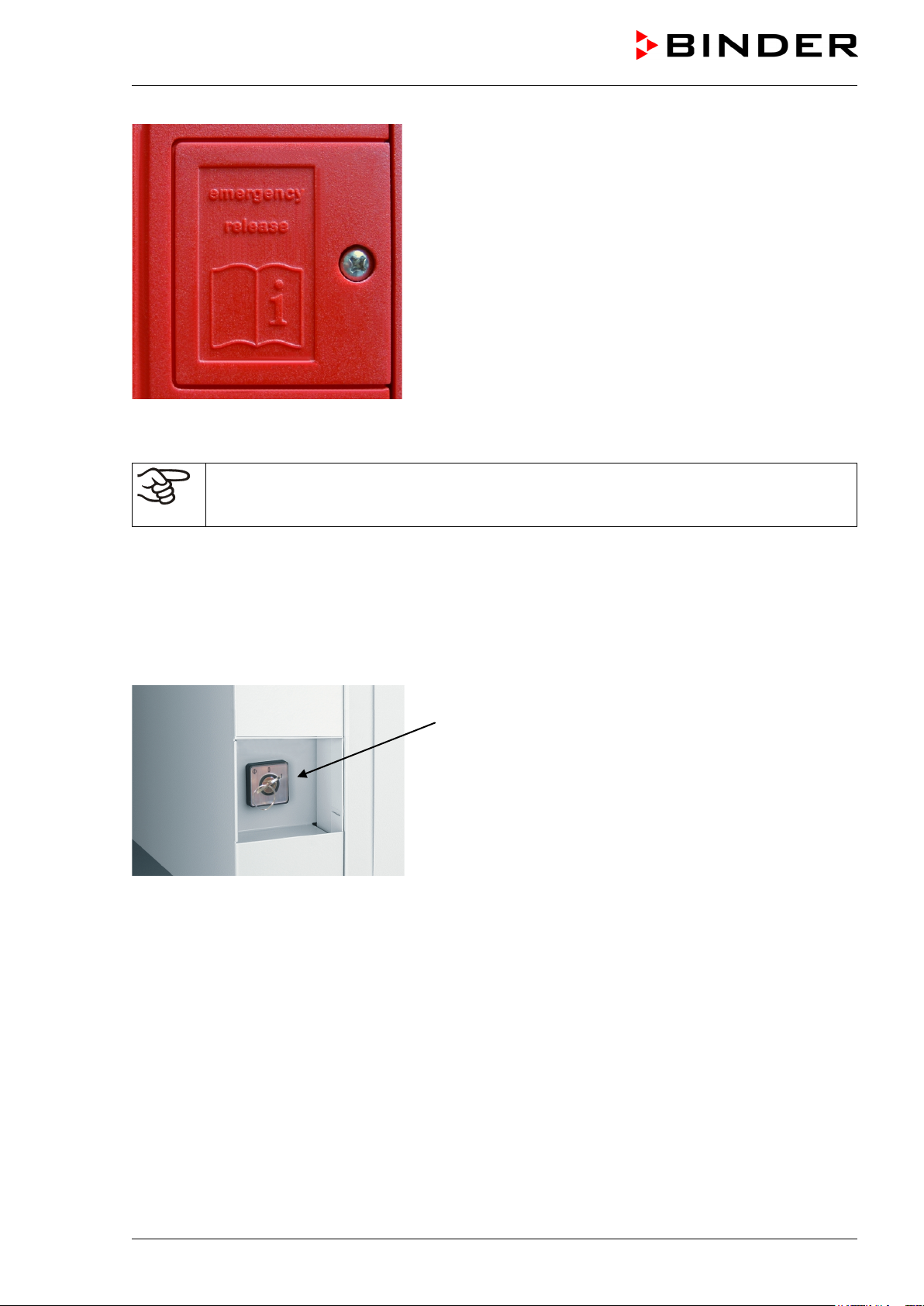

Figure 7: Emergency release cover

Following power connection / turning on the unit or closing the door, you can open the door

again only after approx. 30 seconds. This is to protect the electromechanical door mechanism against damage.

2.3 Key switch (main power switch)

Key switch (6)

Figure 8: Position of the key switch (6) on the right side of

the unit

(6) Key switch (main power switch)

You can remove the key of the key switch (main power switch) in der ON position as well as in the OFF

position.

UF V (E2+E2.1) 03/2013 page 24/112

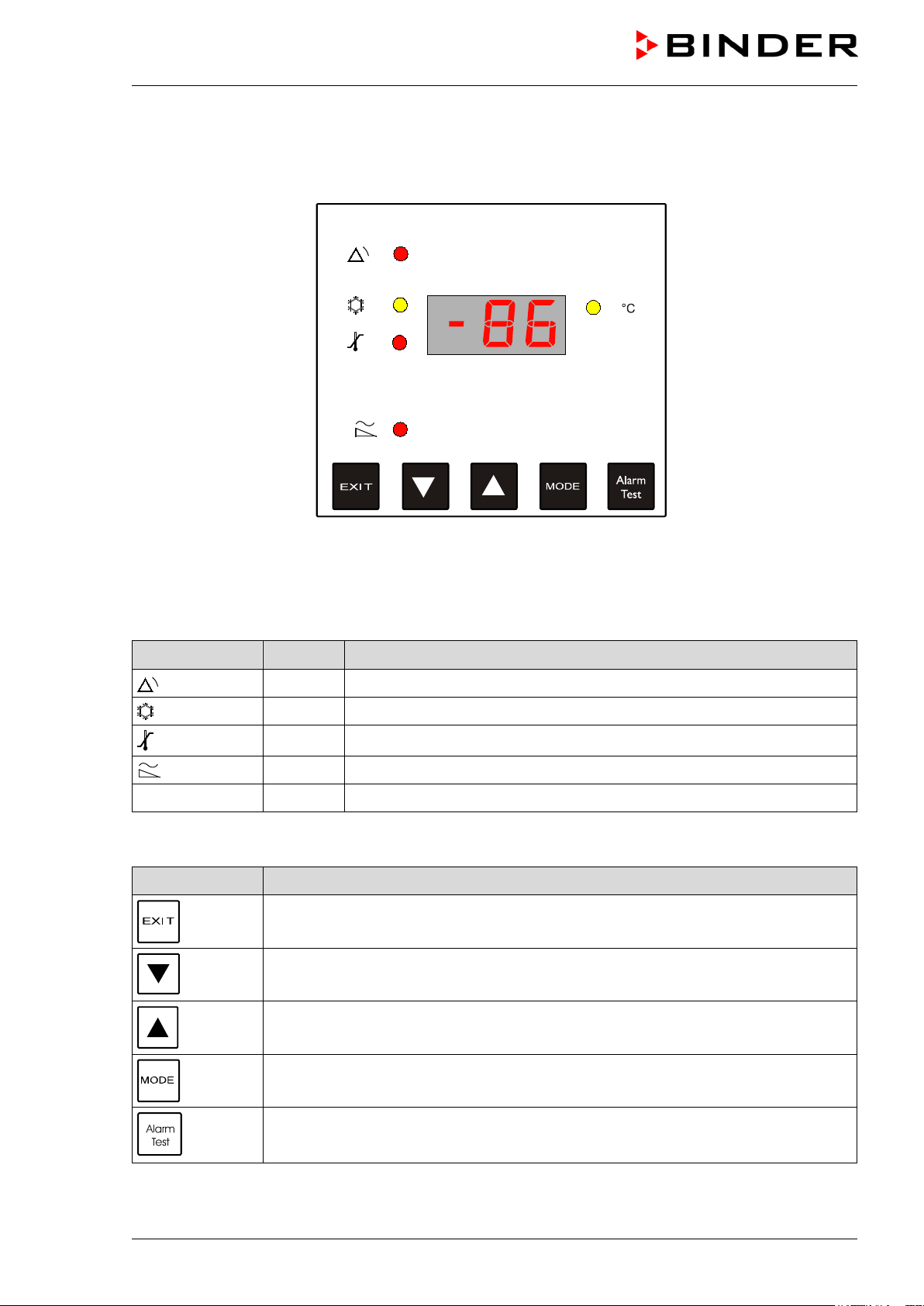

2.4 RP1 controller

The controller RP1 controls the temperature inside the freezer.

Figure 9: Overview controller RP1

Controller alarm and status LEDs

Symbol LED Meaning

red General alarm

yellow Intensive cooling active

red Temperature alarm

red Power failure, no battery connected, battery voltage too low

°C yellow Display of a temperature value in °C

Controller buttons

Button Function

Switch off the alarm sound, reset alarm messages, call up the previous operating

function

Reduce value

Increase value

Confirm entry and call up next operating function

Switching on / off the alarm test (switching on: press down for 5 sec. switching off:

press down briefly)

UF V (E2+E2.1) 03/2013 page 25/112

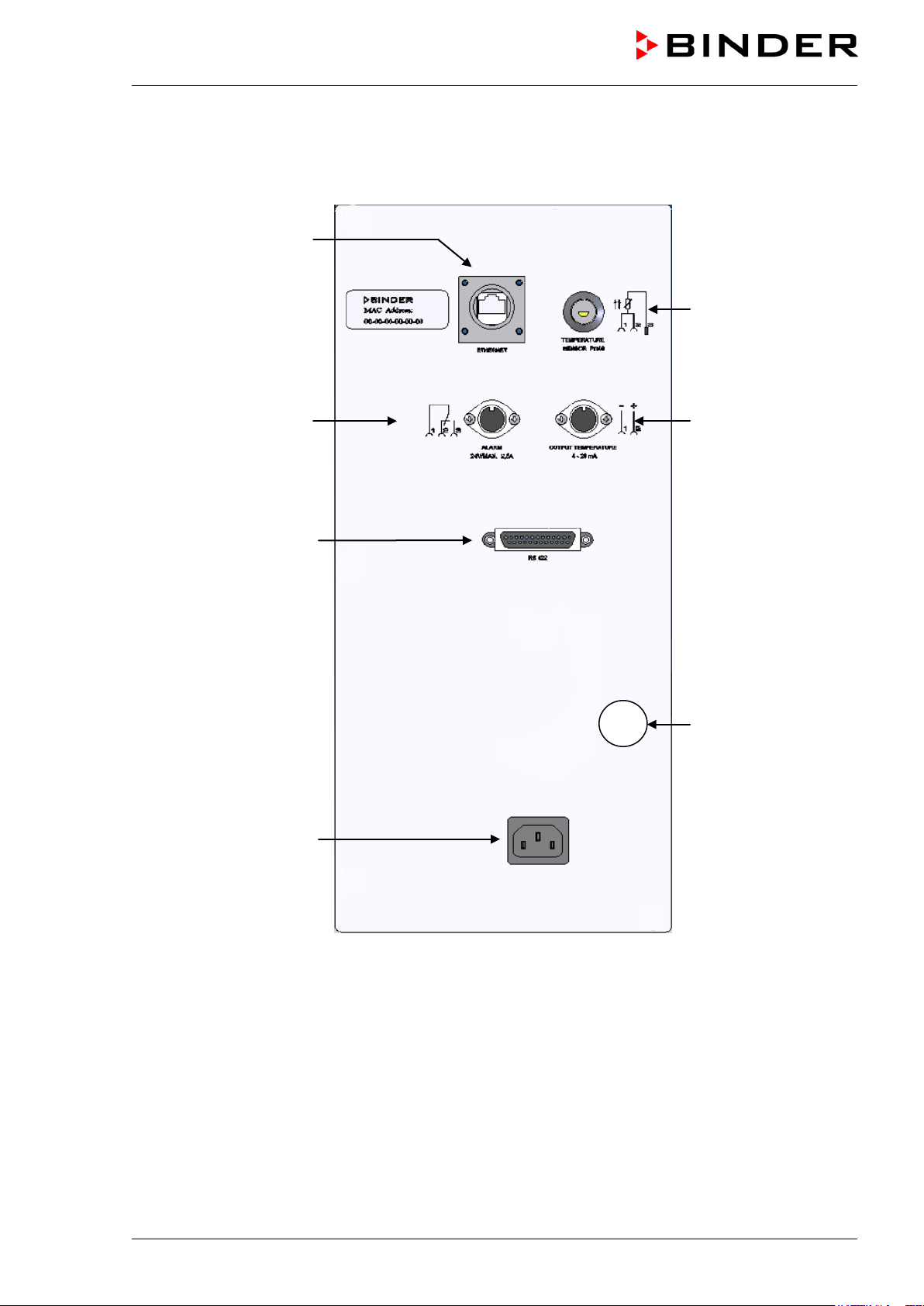

2.5 Connection panel on the unit rear

(7)

(8)

(9)

(11)

(12)

(13)

(10)

Figure 10: Rear connection panel of the freezer UF V (E2 / E2.1)

(7) Ethernet interface for computer communication (option, chap. 12.1)

(8) Connection socket for zero-voltage relay alarm contact (chap. 10.10)

(9) RS 422 interface for computer communication

(10) Connection socket for IEC connector cable with internal locking system

(44) Connection socket for additional Pt 100 temperature sensor (option, chap. 12.4)

(12) Connection socket for analog output 4-20 mA (chap. 12.3)

(13) Connection socket for the electrical connection of the CO

emergency cooling (option, chap. 11)

2

UF V (E2+E2.1) 03/2013 page 26/112

2.6 Unit doors

2.6.1 Outer door

The outer gasket of the freezer outer door is heated. The door must be closed while the unit is operating

normally in order to ensure stable conditions in the inner chamber.

You can operate the automatic door mechanism (chap. 5.2) without using your hands:

• Open: Firmly press the push-button “OPEN” e.g. with your elbow

• Close: Firmly press on the door for at least 2 seconds e.g., with your shoulder, until the automatic door

lock is activated and closes the door tightly. The door then pulls tight automatically.

Following power connection / turning on the unit or closing the door, you can open the door

again only after approx. 30 seconds. This is to protect the electromechanical door mechanism against damage.

Delay time for the temperature tolerance range alarm :

After closing the outer door, the tolerance range alarm is switched off for a programmable

delay time. This prevents alarms being constantly triggered during the unstable operating

phase after opening the outer door.

The outer door is available hinged left or right.

DANGER

Risk of locking in a person.

Danger of death.

Before closing doors, make sure that nobody is inside.

Pull the power plug before entering the interior (e.g. for cleaning purposes), thereto pull

the locking button on the plug (Figure 23).

2.6.2 Compartment doors

The freezer interior is divided into in 4 compartments, which are isolated against the surrounding with

doors. This permits bringing in or removing the samples of an individual compartment without remarkably

affect temperature in the other compartments.

The compartment doors remain closed by magnetism when opening the outer door without need for closing them mechanically.

Open the inner doors as shortly as possible to avoid a temperature rise inside the freezer. The maximum

angle of aperture is 90°.

2.6.3 Emergency release of the outer door

In case of power failure or a motor fault, you can open the unit door using the emergency release cover

(1). It is fixed with a cross tip screw.

Following an emergency release, the door can be closed again only by a service technician. Carry out the

emergency release only in emergency and make sure that unfreezing of the samples can be prevented.

UF V (E2+E2.1) 03/2013 page 27/112

CAUTION

• Turn off the freezer at its

the locking button on the

to unscrew the Phillips

screw of the Emergency

Remove the emergency

• Use a fork wrench SW8 to

unscrew both screw nuts

A suitable fork wrench is

It is located at a

filter grille (D) behind the

• Remove the lock bolt from

• Now you can open the unit

Danger of destruction of samples.

Carry out the emergency release only in emergency.

Ensure that a service technician is available and/or that the samples can be stored

cold.

Proceeding for emergency release

main power switch and pull

the power plug, thereto pull

plug (Figure 23).

• Use a suitable screwdriver

release cover

•

release cover

(M5).

•

supplied.

magnetic holder inside the

upper edge.

the door

door.

UF V (E2+E2.1) 03/2013 page 28/112

After the error has been removed, a service technician can close the door. Please contact BINDER Service.

Note: The freezer offers the possibility of an electrical emergency release, which can be performed by a

qualified technician. Advantage: With the return of the power supply, operation can continue. Contact

BINDER service.

2.7 Drain well for condensate during defrosting (option)

The drain well collects the dripping water when defrosting.

Strong magnets on the drain well sides fix it on the unit.

Attach the drain well to the freezer. Its first level rests on the lower housing panel. The gasket is aligned

to the bottom edge of the freezer interior.

Figure 11: Freezer with drain well (option)

While defrosting use adhesive tape to keep the door above the drain well (drain off position). Now the

melted condensate flows into the drain well.

Place a reservoir below the hole at the front left corner of the drain well, so that the water can drain off.

Figure 12: Unit door in drain off position above the drain well

UF V (E2+E2.1) 03/2013 page 29/112

Lift the unit using technical devices (fork lifter) from the pallet. Set the fork lifter laterally

3. Completeness of delivery, transportation, storage, and installa-

tion

3.1 Unpacking, and checking equipment and completeness of delivery

After unpacking, please check the unit and its optional accessories, if any, based on the delivery receipt

for completeness and for transportation damage. Inform the carrier immediately if transportation damage

has occurred.

Caution: The drain well is placed under the unit between the castors. Please remove it before unpacking

the freezer!

CAUTION

Sliding or tilting of the unit.

Damage to the unit.

∅ Do NOT lift the unit using the door, the housing of the automatic door mechanism or

the lower housing.

∅ Do NOT lift the unit by hand.

∅ Do NOT transport the unit horizontally.

Keep the unit in upright position. Max. angle of inclination during transport: 10°.

or from the rear in the middle of the unit. Make sure to place all the lateral supports of

the unit on the forks (check: the fork protrudes at the opposite unit side).

Wear suitable shoes (safety shoes).

The final tests of the manufacturer may cause traces of the shelves on the inner surfaces. This has no

impact on the function and performance of the unit.

Please remove any transportation protection devices and adhesives in/on the unit and on the doors and

remove the operating manuals and accessory equipment.

Remove any protective lamination sheet on the inner metal surfaces prior to commissioning.

Wait at least 8 hours following transport with technical devices (chap. 3.2.2) before start-up.

If you need to return the unit, please use the original packing and observe the guidelines for safe lifting

and transportation (chap. 3.2).

For disposal of the transport packing, see chap. 15.1.

Scope of delivery

• Ultra-low temperature freezer UF V

• 2 keys for the main power switch (key switch)

• 3 shelves,12 shelf holders and 3 fixing plates with screws

• DIN plug for the zero-voltage relay alarm output

• Starter set RFID cards (master card, switch-off card, 3 user cards) (standard with UF V, option for

UF V UL)

• Data logger (standard with UF V UL, option for UF V)

• 2 spacers for rear wall distance.

• Operating manual

UF V (E2+E2.1) 03/2013 page 30/112

Loading...

Loading...