Page 1

ControlNet Coupler

BK7000

Version: 0.9.1

Last change: 2006-10-30

Page 2

Contents

1. Foreword 2

Notes on the documentation 2

Liability Conditions 2

Delivery conditions 2

Copyright 2

Safety Instructions 3

State at Delivery 3

Description of safety symbols 3

Contents

2. Basic information 4

The Beckhoff bus terminal system 4

The interfaces 6

Power supply 6

Power supply to the power contacts 6

Power contacts 6

Fieldbus connection 6

Configuration interface 7

K-bus contacts 7

Supply isolation 7

The operating modes 8

Mechanical design 9

Electrical data 11

The peripheral data in the process image 12

Starting operation and diagnostics 14

Run times and reaction times 16

3. ControlNet coupler BK7000 in the ControlNet 17

Introducing the system 17

The transfer medium: plugs and cables 18

Configuring the master 18

Config data of the Assembly object 20

Calculating rules for terminal bus input and output data sizes 21

Configuration with RS Networx 1.06 22

Save the configuration 23

Configuration with RS Networx 1.03 23

4. Appendix 24

Sample arrangement of a process image in the bus coupler 24

Representation of analog signals in the process image 26

5. Support and Service 28

Beckhoff's branch offices and representatives 28

Beckhoff Headquarters 28

1 BK 7000

Page 3

Foreword

Foreword

Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering

who are familiar with the applicable national standards. It is essential that the following notes and explanations are followed when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with performance data, standards or other characteristics. None of the statements of this manual represents a

guarantee (Garantie) in the meaning of § 443 BGB of the German Civil Code or a statement about the

contractually expected fitness for a particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In

the event that it contains technical or editorial errors, we retain the right to make alterations at any time

and without warning. No claims for the modification of products that have already been supplied may be

made on the basis of the data, diagrams and descriptions in this documentation.

Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH apply.

Copyright

©

This documentation is copyrighted. Any reproduction or third party use of this publication, whether in

whole or in part, without the written permission of Beckhoff Automation GmbH, is forbidden.

BK 7000 2

Page 4

i

Foreword

Safety Instructions

State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH.

Description of safety symbols

The following safety symbols are used in this documentation. They are intended to alert the reader to the

associated safety instructions..

This symbol is intended to highlight risks for the life or health of personnel.

Danger

This symbol is intended to highlight risks for equipment, materials or the environ-

Attention

Note

ment.

This symbol indicates information that contributes to better understanding.

3 BK 7000

Page 5

Basic information

Basic information

Up to 64 bus terminals

each with 2 I/O channels

for any form of signal

Decentralized wiring of the

I/O level

IPC as control unit

Bus couplers for all current

bus systems

Standard C rail assembly

Modularity

Display of channel status

The K-bus

End terminal

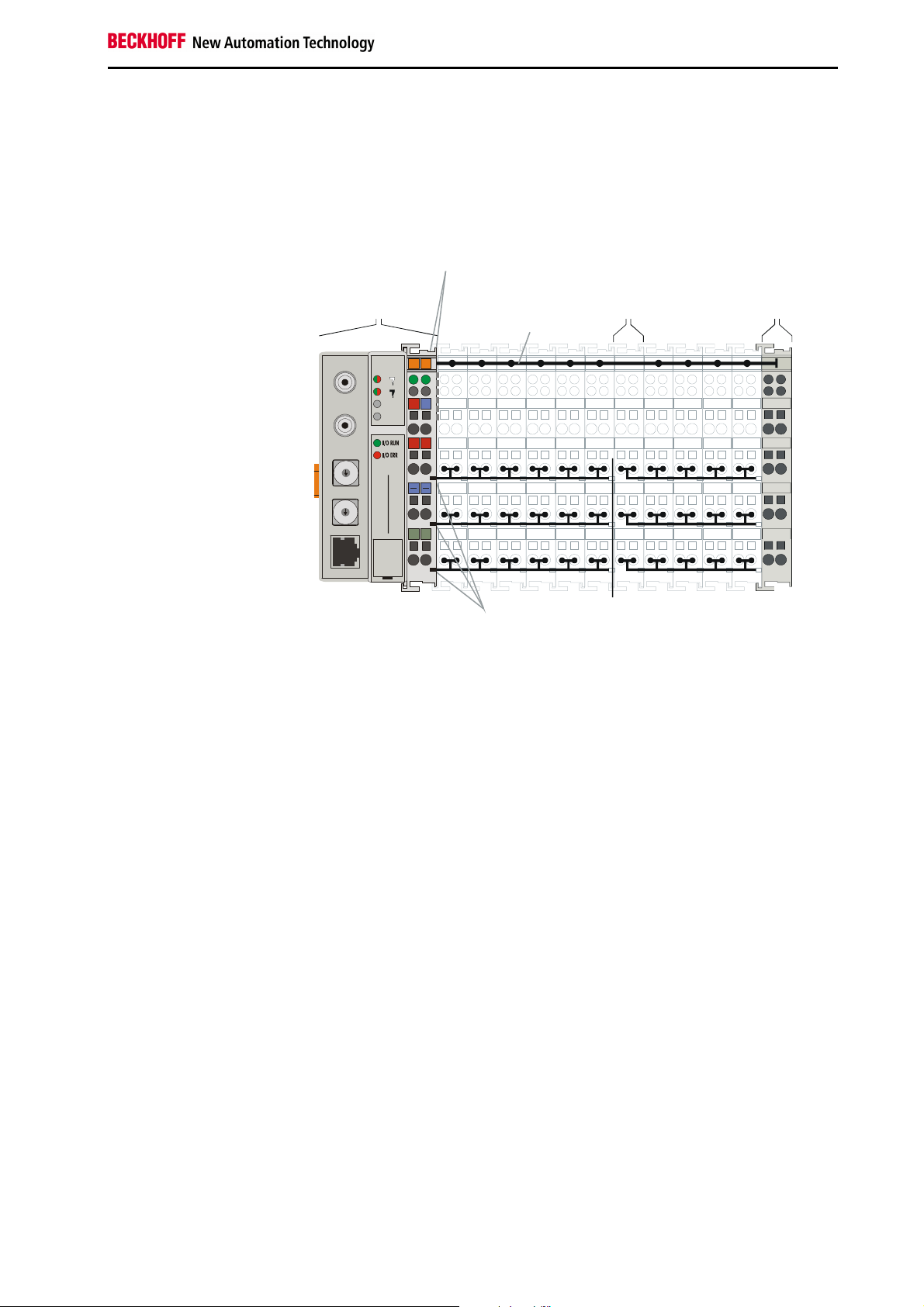

The Beckhoff bus terminal system

The bus terminal system is the universal connecting link between a fieldbus system and the sensor/actor level. A unit consists of a bus coupler,

which is the interface to the fieldbus, and up to 64 electronic terminals, of

which the last is an end terminal. Terminals, each with two I/O channels,

are available for any form of technical signal and can be combined as desired. The various types of terminal are all constructed in the same way, so

that the planning costs are kept extremely low. The height and depth of the

construction are calculated for compact terminal cabinets.

Fieldbus technology makes it possible to use compact control architectures. The I/O level does not need to be taken right up to the control unit.

Sensors and actors can be connected decentrally with minimal lengths of

cable. You can position the control unit at any convenient location in the

installation. Using an industrial PC as control unit makes it possible to implement the operating and monitoring element as part of the control hardware, so the control unit can be located on an operating desk, control point

or similar. The bus terminals constitute the decentralized input/output level

of the control unit in the switch cabinet and its subordinate terminal cabinets. As well as the sensor/actor level, the power unit of the equipment is

also controlled via the bus system. The bus terminal replaces a conventional terminal as the cabling level in the switch cabinet; the switch cabinet

can be made smaller.

The Beckhoff bus terminal system combines the advantages of a bus system with the functionality of compact terminals. Bus terminals can be used

on all current bus systems and serve to reduce the diversity of parts in the

control unit, while behaving like the conventional standard units for the

relevant bus system and supporting the entire range of functionality of the

bus system.

The simple and compact assembly on a standard C rail, and the direct

cabling of actors and sensors without cross connections between the terminals, serve to standardize the installation, as does the uniformly designed labeling.

The small size and great flexibility of the bus terminal system mean that

you can use it anywhere that you could use a terminal and use any type of

connection – analog, digital, serial or direct sensors.

The modular construction of the terminal row, using bus terminals with

various functions, limits the number of unused channels to at most one per

function. Two channels to a terminal is the optimum solution for the number

of unused channels and the cost per channel. The possibility of using

power input terminals to provide separate power supplies also helps to

minimize the number of unused channels.

The integrated light-emitting diodes close to the sensor/actor indicate the

status of each channel.

The K-bus is the path taken by data within the terminal row. The bus coupler carries the K bus through all the terminals by means of six contacts on

the side walls of the terminals, and the end terminal terminates the K bus.

The user does not need to know anything about the function of the K bus

or the internal operation of terminals and bus couplers. There are numerous software tools available which provide for convenient planning, configuration and operation.

BK 7000 4

Page 6

isolation

contacts

ControlNet

Powersupply

Potential

1

1

Basic information

Power input terminals

for

separately powered groups

The principle of the bus

terminal

Three power contacts pass the operating power to the following terminals.

You can use power input terminals to subdivide the terminal row as desired

into groups, each with a separate power supply. These power input terminals are not taken into account for addressing the terminals, you can insert

them at any position along the terminal row.

You can install up to 64 terminals on a terminal row, including power input

terminals and the end terminal.

bus coupler for the input Bus end

BK7000 bus coupler terminal

terminal

Terminal bus

ControlNet

x1

5

6

4

7

3

8

2

9

0

x10

5

6

4

7

3

8

2

9

0

00X0

A

B

24V

0V

+ +

BK7000

BECKHOFF

PE

PE

Bus couplers for various

fieldbus systems

PotentialPower

You can use a variety of bus couplers to attach the electronic terminal row

quickly and easily to the various fieldbus systems, and you can also subsequently convert to a different fieldbus system. The bus coupler deals with

all the necessary monitoring and control tasks for operating the attached

bus terminals, indeed all the operation and configuration of the bus terminals is carried out via the bus coupler. The fieldbus, K bus and I/O level are

electrically isolated.

If the exchange of data across the fieldbus is temporarily interrupted, logic

states are preserved, digital outputs are cleared and analog outputs revert

to a reset value which can be individually configured for each output when

the equipment is set up.

5 BK 7000

Page 7

Basic information

Bus coupler / power contacts

+

PE

PE

8

7

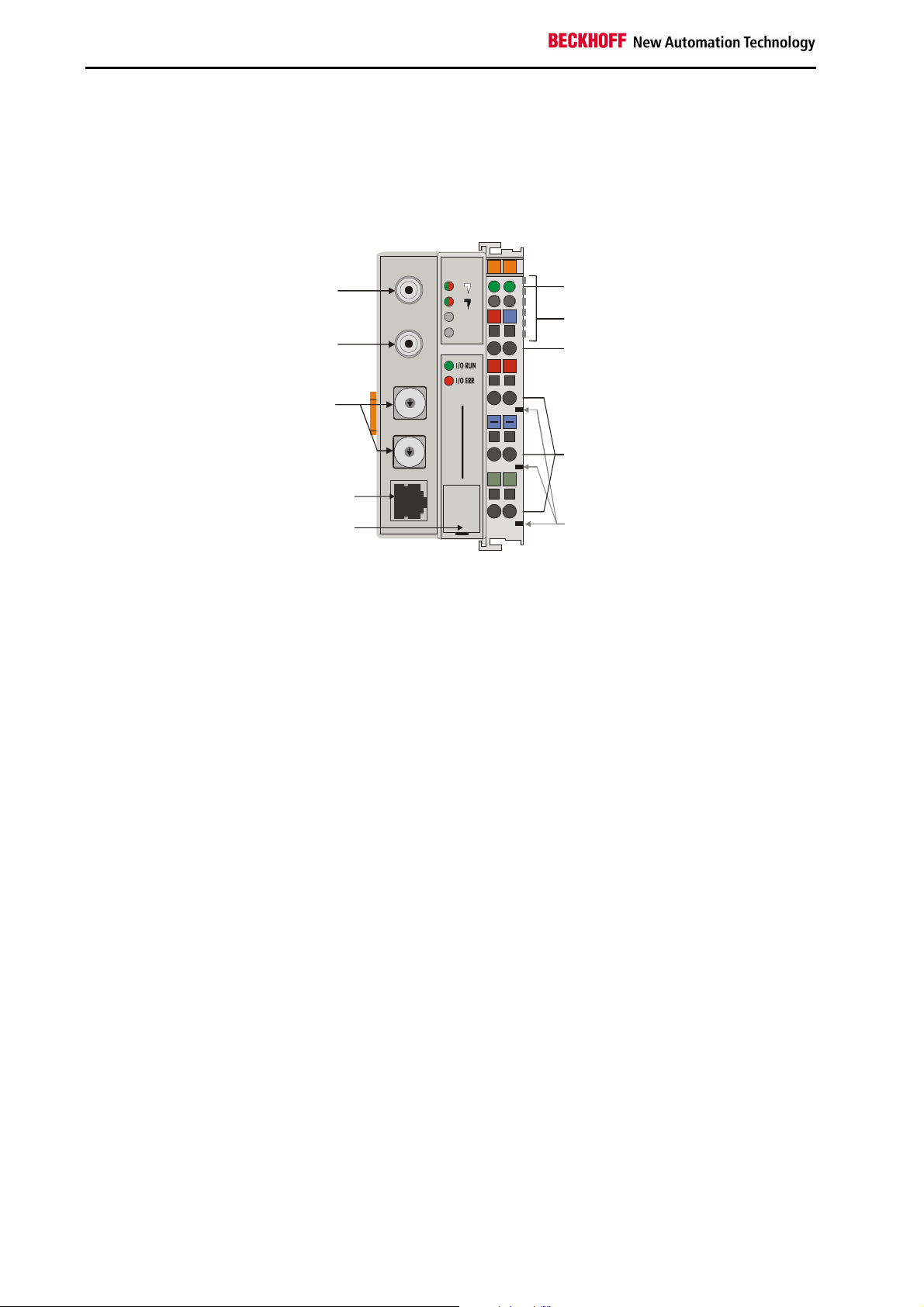

The interfaces

There are six ways of making a connection to a ControlNet bus coupler.

These interfaces are designed as plug connections and spring terminals.

The ControlNet coupler

BK7000

Field Bus

Connector A

ControlNet

A

B

00X0

24V

0V

Power LEDs

Terminal bus

Field Bus

Connector B

Address

Selector

Network Access

+

x1

5

6

4

7

3

8

2

9

1

0

x10

5

6

4

3

2

9

1

0

BK7000

BECKHOFF

Power supply bus coupler

24 V DC / GND

Input

power contacts

Port (NAP)

Configuration

Interface

power contacts

24 V DC on the topmost

terminals

Power supply

The bus couplers need an operating power of 24 V DC which is connected

via the topmost spring terminals, labeled "24 V” and "0 V”. This power supply serves not only the electronic components of the bus coupler but (via

the K bus) also the bus terminals. The power supply of the bus coupler

circuitry and that of the K-bus (Terminal bus) are electrically isolated from

the voltage of the field level.

Lower 3 terminal pairs for

power input

maximum 24 V

maximum 10 A

Power supply to the power contacts

The six lower connections with spring terminals can be used to supply

power to the peripherals. The spring terminals are connected in pairs to the

power contacts. The power supply to the power contacts has no connection to the power supply of the bus couplers. The power input is designed

to permit voltages up to 24 V. The pair-wise arrangement and the electrical

connection between the feed terminal contacts makes it possible to loop

through the wires connecting to different terminal points. The load on the

power contact may not continuously exceed 10 A. The current capacity

between two spring terminals is the same as the capacity of the connecting

wires.

Spring contacts at the side

Power contacts

On the right-hand side face of the bus coupler are three spring contacts

which are the power connections. The spring contacts are recessed in slots

to prevent them from being touched. When a bus terminal is connected,

the blade contacts on the left-hand side of the bus terminal are connected

to the spring contacts. The slot and key guides at the top and bottom of the

bus couplers and bus terminals ensure reliable location of the power contacts.

Control-Net connectors

Fieldbus connection

On the left-hand side there are two ControlNet connectors A and B and a

NAP-Port. You will find a detailed description of the fieldbus interfaces in

another part of this manual (In the chapter "The transfer medium: plugs

and cables”).

BK 7000 6

Page 8

Periphery level

Bus terminals

Bus coupler

24 V DC

Serial interface under the

front flap

6 contacts at the side

3 supply groups:

fieldbus

K-bus

peripheral level

Setting up the power levels

in the bus terminal system

Configuration interface

On the lower part of the front face you will find the standard bus couplers

which are fitted with an RS232 interface. The miniature plug can be attached to a PC by means of a connection cable and the configuration software KS2000. This interface enables you to configure the analog channels.

You can also access the functionality of the configuration interface via the

fieldbus by means of the PLC interface communications.

K-bus contacts

The connections between the bus coupler and the bus terminals are effected by gold contacts at the right-hand side of the bus coupler. When the

bus terminals are plugged together, these gold contacts automatically

complete the connection to the bus terminals. The K bus is responsible for

the power supply to the electronic components of the K bus in the bus terminals, and for the exchange of data between the bus coupler and the bus

terminals. Part of the data exchange takes place via a ring structure within

the K bus. Disengaging the K bus, for example by pulling on one the bus

terminals, will break this circuit so that data can no longer be exchanged.

However, there are mechanisms in place which enable the bus coupler to

locate the interruption and report it.

Supply isolation

The bus couplers operate with three independent supplies. The input

power supplies the electrically isolated K-bus circuitry in the bus coupler

and the K-bus itself. The power supply is also used to generate the operating power for the fieldbus.

Note: All the bus terminals are electrically isolated from the K bus, so that

the K-bus is completely electrically isolated.

Basic information

Terminal bus

Field bus

7 BK 7000

Page 9

Basic information

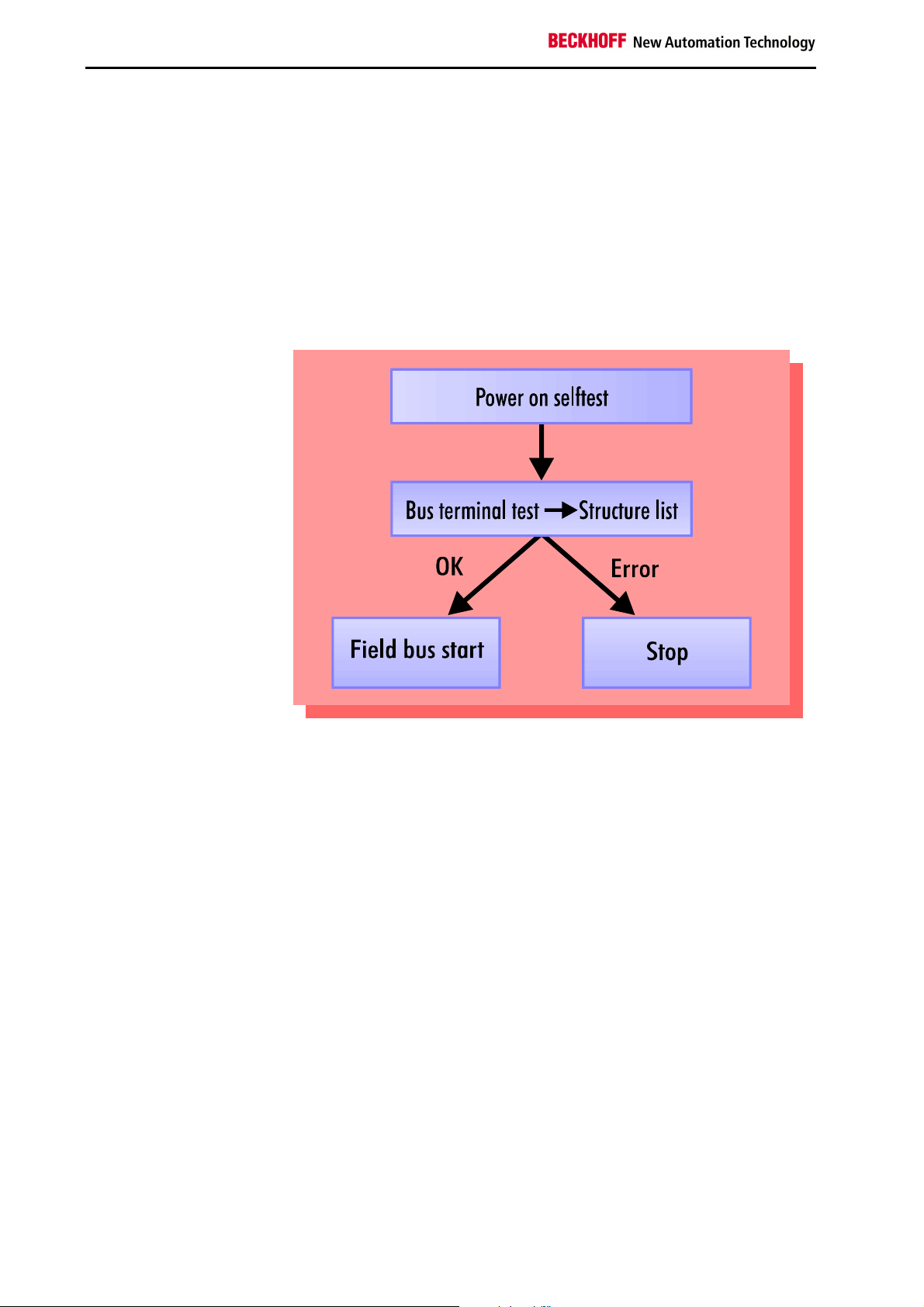

Start-up behavior of the bus

coupler

The operating modes

When it is first switched on the bus coupler carries out a self-test to check

the functions of its components and the communications of the K bus, and

while this is going on the red I/O LED will flash. When the self-test has

been completed successfully, the bus coupler will begin to test the attached bus terminals (the "bus terminal test”) and read in the configuration

from which it constructs an internal structure list, which is not accessible

from outside. If an error occurs the bus coupler will enter the operating

mode "STOP”. If the start-up sequence is completed without errors the bus

coupler will enter the mode "fieldbus start”.

The bus coupler reports the error by means of the IO-ERR-LED. Clearing

the error returns the bus coupler to its normal operating mode.

BK 7000 8

Page 10

+

+

PE

PE

1

0

0

49

12

00

.1

PE

PE

Mechanical design

The Beckhoff bus terminal system is remarkable for its compact construction and high degree of modularity. W hen you design the installation you

will need to plan for one bus coupler and some number of bus terminals.

The dimensions of the bus couplers do not depend on the fieldbus system.

If you use large plugs, for example like some of the bus plugs used for the

Profibus, they may protrude above the overall height of the cabinet.

Dimensions of a

bus coupler

ControlNet

A

B

Basic information

00X0

24V

0V

E0

.0

Assembly and connections

x1

5

6

4

7

94

3

8

2

9

1

0

x10

5

6

4

7

3

8

2

9

1

0

BK7000

BECKHOFF

+ +

The overall width of the construction is the width of the bus coupler, including the bus end terminal, plus the width of the installed bus terminals. The

bus terminals are 12 mm or 24 mm wide, depending on their function. Depending on the gauge of cables used the overall height of 68 mm may be

overstepped by about 5 mm to 10 mm by the cables at the front.

It takes only a slight pressure to latch the bus coupler and the various bus

terminals onto a supporting 35mm C rail and a locking mechanism then

prevents the individual housings from being removed. You can remove

them without effort if you first release the latching mechanism by pulling the

orange tab. You should carry out work on the bus terminals and the bus

coupler only while they are switched off: if you plug or unplug components

while the power is on you may briefly provoke some undefined state (and,

for instance, reset the bus coupler).

You can attach up to 64 bus terminals in series on the right-hand side of

the bus coupler. When you assemble the components, make sure that you

mount the housings so that each slot comes together with the corresponding key. You cannot make any functional connections merely by pushing

the housings together along the supporting track. When they are correctly

mounted there should be no appreciable gap between the adjacent housings.

The right-hand side of a bus coupler is mechanically similar to a bus terminal. There are eight connections on the top which can be used to connect

to thick-wire or thin-wire lines. The connection terminals are spring loaded.

You open a spring terminal by applying a slight pressure with a screwdriver

or other pointed tool in the opening above the terminal and you can then

insert the wire into the terminal without any obstruction. When you release

the pressure the terminal will automatically close and hold the wire securely and permanently.

9 BK 7000

Page 11

Basic information

Insulation test

PE power contacts

The connection between bus couplers and bus terminals is automatically

effected by latching the components together. The K bus is responsible for

passing data and power to the electronic components of the bus terminals.

In the case of digital bus terminals, the field logic receives power via the

power contacts. Latching the components together has the effect that the

series of power contacts constitutes a continuous power track. Please refer

to the circuit diagrams of the bus terminals: some bus terminals do not loop

these power contacts through, or not completely (e.g. analog bus terminals

or 4-channel digital bus terminals). Each power input terminal interrupts the

series of power contacts and constitutes the beginning of a new track. The

bus coupler can also be used to supply power to the power contacts.

The power contact labeled "PE” can be used as protective earth or ground.

This contact stands proud for safety reasons and can carry short-circuit

currents of up to 125A. Note that in the interests of electromagnetic compatibility the PE contacts are capacitively connected to the supporting

track. This may lead to spurious results and even damage to the terminal

when you test the insulation (e.g. insulation test for breakdown using a

230V mains supply to the PE line). You should therefore disconnect the PE

line on the bus coupler while you carry out insulation tests. You can disconnect other power supply points for the duration of the test by drawing

the power supply terminals out from the remaining row of terminals by at

least 10mm. If you do this, there will be no need to disconnect the PE connections.

The protective earth power contact ("PE”) may not be used for any other

connections.

BK 7000 10

Page 12

Electrical data

The electrical data specific to the fieldbus is given in this chapter. The following table lists an overview of all data:

Technical data BK7000

Voltage supply

Input current

Starting current

Output current K bus

Configuration possibility

Number of bus terminals

Digital peripheral signals

Analog peripheral signals

Peripheral bytes

Bus connection

Baud rates

Voltage power contact

Current load power con.

Max. voltage capacity

Weight approx.

Operating temperature

Storage temperature

Relative humidity

Vibration /shock resistance

EMC resistance burst / ESD

Orientation for mounting

Type of fuse

24 V DC (20 V...29 V DC)

70 mA + (total K-Bus current)/4

500 mA max.

2.5 x continuos current

1750 mA max.

by KS2000 or the controller

64

256 inputs/outputs

256 inputs/outputs

512 bytes I and 512 bytes O

Two BNC-connectors (ControlNet A and B) and 1 NAP-Port

5 MBaud (ControlNet V1.5)

24V DC / AC max.

10 A max.

500 Veff (power contact / supply voltage/field bus)

170g

0°C ... +55°C

-20°C ... +85°C

95% non-condensing

conforms to IEC 68-2-6 / IEC 68-2-27

conforms to EN 50082 (ESD,Burst) / EN50081

Any

IP20

Current consumption on the

K-Bus

For operation of the K-bus electronics, the bus terminals require energy

from the K-bus that is supplied by the bus coupler. Refer to the catalog or

the corresponding data sheets of the bus terminals for details of the K-bus

current consumption. In doing so, pay attention to the maximum output

current of the bus coupler that is available for powering the bus terminals.

Using a special power supply terminal (KL9400), power can be fed back

into the K-bus at any chosen point. If you wish to use a power supply terminal, please contact Beckhoff’s technical support. .

Basic information

11 BK 7000

Page 13

Basic information

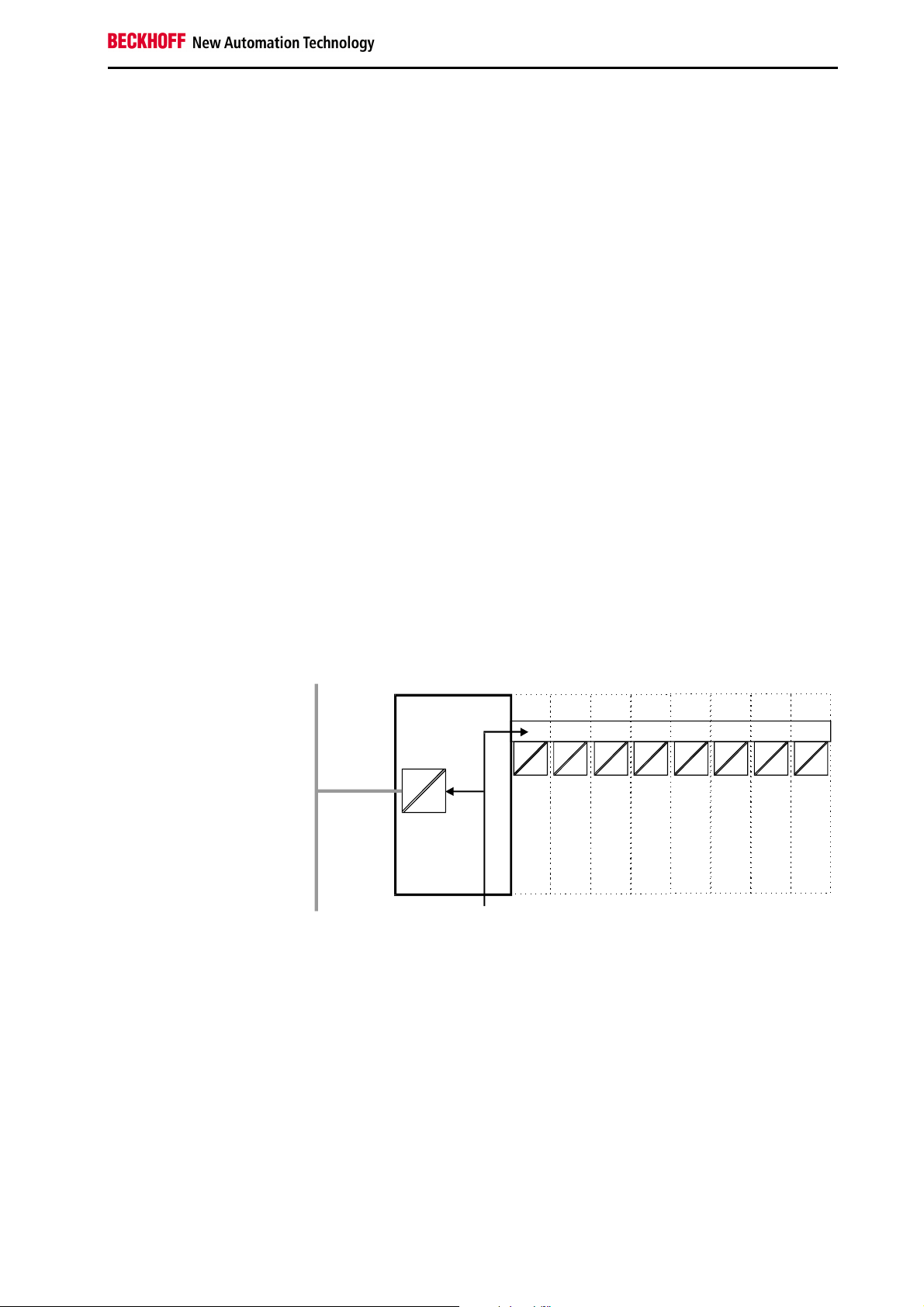

The peripheral data in the process image

When the bus coupler is first switched on it determines the configuration of

the attached input/output terminals and automatically assigns the physical

slots of the input/output channels to the addresses in the process image.

The bus coupler sets up an internal list of assignments in which each of the

input and output channels has a specific position in the process image. A

distinction is made here between input and output and between bit-oriented

(digital) and byte-oriented (analog, or complex) signal processing.

It also forms two groups, whereby one contains only inputs and the other

only outputs. In each group, the byte-oriented channels take the lowest

addresses, in ascending order, and these are then followed by the bitoriented channels.

Digital signals

(bit-oriented)

Digital signals are bit-oriented. This means that one bit of the process image is assigned to each digital channel. The bus coupler sets up a block of

memory containing the current input bits and arranges to immediately write

out the bits from a second block of memory which belongs to the output

channels.

The precise assignment of the input and output channels to the process

image of the control unit is explained in detail in the Appendix by means of

an example.

Analog signals

(byte-oriented)

The processing of analog signals is always byte-oriented and analog input

and output values are stored in memory in a two-byte representation. The

values are held as "SIGNED INTEGER” or "twos-complement”. The digit

"0” represents the input/output value "0V”, "0mA” or "4mA”. When you use

the default settings, the maximum value of the input/output value is given

by "7FFF” hex. Negative input/output values, such as -10V, are represented as "8000” hex and intermediate values are correspondingly proportional to one another. The full range of 15-bit resolution is not realized at

every input/output level. If you have an actual resolution of 12 bits, the

remaining three bits have no effect on output and are read as "0” on input.

Each channel also possesses a control and status byte in the lowest value

byte. If the control/status byte is mapped in the control unit has to be configured in the master configuration software. An analog channel is represented by 2 bytes user data in the process image.

Special signals and

interface

A bus coupler supports bus terminals with additional interfaces, such as

RS232, RS485, incremental encoder, etc.. These signals can be regarded

in the same way as the analog signals described above. A 16-bit data

width may not be sufficient for all such special signals; the bus coupler can

support any data width.

Default assignment of

inputs and outputs to the

process image

When the bus coupler is first switched on it determines the number of attached bus terminals and sets up a list of assignments. This list distinguishes between analog channels and digital channels and between input

and output; which are grouped separately. The assignments begin immediately to the left of the bus coupler. The software in the bus coupler creates the assignment list by collecting the entries for the individual channels

one at a time, counting from left to right. These assignments distinguish

four groups:

Function type of the channel Assignment level

1.

2.

3.

4

Analog outputs byte-wise assignment

Digital outputs bit-wise assignment

Analog inputs byte-wise assignment

Digital inputs bit-wise assignment

BK 7000 12

Page 14

Analog inputs/ouputs are representative of other complex multi-byte signal

bus terminals (RS232, SSI sensor interface, ...)

Overview of the subdivision of the process image in the bus coupler:

Output data in the

bus coupler

Ox+1

O0

...

byte-oriented data

...

Ox

bit-oriented data

Ox+y

Input data in the

bus coupler

Ix+1

I0

...

byte-oriented data

...

Ix

...

bit-oriented data

...

Ix+y

Data consistency

Data which contains no contradictions is said to be consistent. The following consistency is required here: 1. The high byte and low byte of an analog value (word consistency), 2. The control/status byte and the corresponding parameter word for accessing the register. The interaction of the

peripherals with the control unit means that data can initially be guaranteed

consistent only within an individual byte: the bits which make up a byte are

read in together, or written out together. Byte-wise consistency is quite

adequate for processing digital signals but is not sufficient for transferring

values longer than eight bits, such as analog values. The various bus systems guarantee consistency to the required length. It is important to use

the appropriate procedure for importing this consistent data from the master bus system to the control unit. You will find a detailed description of the

correct procedure in the User Guide of the appropriate bus system, in particular in the description of the standard master units that are installed. The

chapters of this manual which deal with the fieldbus refer to the most

common of these standard units.

Processing complex signals

All byte-oriented signal channels such as RS232, RS485 and incremental

encoder, can use byte lengths greater than two. Apart from the actual difference in length, the procedure is always comparable with that for analog

signals. In the configuration software for the bus masters of the second

generation (from around 09.96), the corresponding channel can be selected directly from the "GSD file". The configuration software automatically

ensures the settings for maintaining data consistency.

Basic information

13 BK 7000

Page 15

Basic information

Starting operation and diagnostics

When the bus coupler is first switched on it at once checks the attached

configuration. A correct start-up procedure is indicated by the red LED "I/O

ERR” going out. If this LED flashes, this indicates a fault somewhere in the

terminals. You can determine the actual error code by observing the speed

of flashing and number of flashes. This will enable you to clear the fault

quickly. You will find a detailed description in the chapter "The diagnostic

LEDs”.

The diagnostic LEDs

The bus coupler has a status display consisting of two groups of LEDs.

The upper group has four LEDs which indicate the mode of the installed

fieldbus. The significance of these "fieldbus status LEDs” is explained in

the appropriate chapters of this manual; they correspond to the usual displays for fieldbuses.

There are two more green LEDs at the top right-hand side of the bus coupler to indicate the supply voltage. The left-hand LED shows the 24V supply of the bus coupler. The left-hand LED shows the supply to the power

contacts.

Local errors

Two LEDs, the "I/O LEDs”, which are situated below the fieldbus status

LEDs described above, are used to display the operating mode of the bus

terminals and the connection to these bus terminals. The green LED lights

up to indicate error-free operation, where "error-free” implies that communication with the fieldbus system is also operating correctly. The red LED

flashes at two different rates to indicate a fault, whereby the specific error

is encoded in the pattern of flashes, as follows.

Code of flashes

Rapid flashing

First slow sequence

Second slow sequence

Start of the error code

Type of error

Location of error

Error

Error co-

1 pulse

2 pulses

3 pulses

4 pulses

5 pulses

>= 6 pulses

Error argument Description

de

0

1

2

0

n (n > 0)

0 Terminal bus command error

0

n

N Terminal bus error during register commu-

ControlNet specific, will be described later

EEPROM checksum error

I/0 line buffer overflow

Unknown data type

Programmed configuration

Invalid table entry/bus coupler

Invalid table comparison (terminal n)

Terminal bus data error

Rupture point after terminal n (0: coupler)

nication with terminal n

in this document

Location of error

The number of flashes corresponds to the position of the last bus terminal

before the error, not counting passive bus terminals such as power input

terminals.

The bus coupler will carry on flashing the error code even when you have

cleared the fault and its operating mode will remain at "Stop”. The only way

to restart the bus coupler is by switching the power supply off and on

again.

You should not plug or unplug bus terminals from the series without first

turning off the power. The circuitry of the bus terminals and the bus coupler

is largely protected against damage, but if you modify the assembly while it

is under power, malfunctions and damage cannot be ruled out.

BK 7000 14

Page 16

If a fault occurs during normal operation, the error code will not be output

on the LEDs until the bus coupler has been requested to diagnose the bus

terminals. This diagnostic request is generated after the equipment is

switched on.

Fieldbus errors

The fieldbus status LEDs A and B indicate the current ControlNet bus

status of the corresponding channel. The other two LEDs are reserved for

the future.

Priority indicator state how to view cause

Highest

Lowest

both steady off viewed together reset or no power

(1)

2

both steady red viewed together failed link interface

3

alternating red /

green

4

alternating red /

off

5

steady off viewed independently channel disabled or channel not supported

6

flashing red /

green

7

flashing red / off viewed independently link fault or no MAC frames received

8

flashing green /

off

steady green viewed independently normal operation

(9)

viewed together self test

viewed together bad node configuration (such as duplicate MAC ID)

viewed independently invalid link configuration

viewed independently temporary channel error, or listen-only

Please note that there is an association between the green I/O LED and

the fieldbus. The I/O LED lights up when access is made to the internal K

bus. The green I/O LED is not lit until data begins to be exchanged via the

fieldbus.

The bus coupler does, however, interrogate the configuration of the bus

terminals after power on and does not exchange any data with the terminals. That is to say, the red I/O LED goes off after an error-free start up

without the green I/O LED having to light up. Then, the green I/O LED does

not light up until data transfer is begun via the field bus.

If a terminal bus error occurs during operation, the procedure followed conforms to the reaction to the terminal bus errors parameterisation. If the

terminal bus error already occurs during start up, the slave does not assume ControlNet data transfer.

Basic information

15 BK 7000

Page 17

Basic information

1

2

Run times and reaction times

Transfer of the signals from the input to the controller and from the control-

ler to the outputs requires a run time. This is composed of various components. Transfer from the controller to the scanner, transfer through the

ControlNet and transfer from the bus coupler to the outputs. This applies

analogously to the return distance.

Controller / Scanner

Please refer to the data provided by the scanner manufacturer for details of

the reaction time from the controller to the master. These times are comparatively short and normally do not need to be considered.

The reaction time on the ControlNet depends on the NUT and the transfer

rate

K-Bus reaction time

The reaction time on K-Bus is determined by movement and backing up of

the data. The following table contains measured values for typical setups.

Extrapolation to larger quantities is possible.

Terminals fitted on the bus coupler Run time on the K-bus

Digital

OUT

4 0 0

8 0 0

12 0 0

16 0 0

20 0 0

24 0 0

28 0 0

32 0 0

0 4 0

0 8 0

0 12 0

0 16 0

0 20 0

0 24 0

0 28 0

0 32 0

4 4 0

8 8 0

12 12 0

16 16 0

20 20 0

24 24 0

28 28 0

32 32 0

4 4

4 4

Digital

IN

Analog

IN/OUT

(KL3202)

(KL3202)

T_Zyklus

(us)

150

170

170

200

200

220

220

245

150

180

180

200

200

230

230

250

170

195

220

250

275

300

325

350

630

700

BK 7000 16

Page 18

ControlNet coupler BK7000 in the ControlNet

ControlNet coupler BK7000 in the ControlNet

Introducing the system

The deterministic control network is a serial communication system for

communication between devices that wish to exchange time-critical application information in a deterministic and predictable manner. These devices include simple I/O devices, such as sensors/actuators as well as complex control devices such as robots, programmable logic controllers, welders, process controllers, etc. Unlike general-purpose communication systems that rely on the destination delivery model, this network uses the producer/consumer model. The producer/consumer model allows the exchange of time-critical application information between a sending device

(e.g., the producer) and many receiving devices (e.g., the consumers) without the need to send the data multiple times to multiple destinations. This

is accomplished by attaching a unique identifier to each piece of application information that is being produced onto the network medium. Any device that requires a specific piece of application information simply filters the

data on the network medium for the appropriate identifier. Many devices

can receive the same produced piece of application information from a

single producing device. The deterministic control network provides a high

degree of protocol efficiency by utilising an implied token passing mechanism. This mechanism allows all devices equal access to the network without the network overhead associated with passing a “token” to each device granting it permission to send data. The protocol utilises a time-based

Scheduling mechanism that provides network devices with deterministic

and predictable access to the medium while preventing network collisions.

This scheduling mechanism allows time-critical data, which is required on a

periodic, repeatable and predictable basis, to be produced on a predefined

schedule without the loss of efficiency associated with continuously requesting or “polling” for the required data. The network protocol supports

an additional mechanism that allows data that is not time-critical in nature

or that is only required on a occasional basis to utilise any available network time. This unscheduled data is transmitted after the production of the

time-critical data has been completed and before the beginning of the next

scheduled production of time-critical data.

17 BK 7000

Page 19

ControlNet coupler BK7000 in the ControlNet

The transfer medium: plugs and cables

Physics of the transmission

Setting the station

Addresses

Address selector

The physical data transfer is defined in the ControlNet standard.

The BK7000 supports redundant media access with the two BNC connectors A and B. Additionally a monitor or configurating system can be connected over the NAP-Port.

The station address is set by way of the rotary switches on the left of the

bus coupler. The address is set as a decimal number. The top rotary switch

stands for the units position and the bottom one stands for the tens position

of the address. (Example: station address 18: bottom rotary switch = 1, top

rotary switch = 8). To ensure that the rotary switch setting is saved by the

BK7000 it must be reset (by briefing interrupting the power supply or by

means of a software reset).

Configuring the master

The assembly object of the BK7000 represents the process image buffer of

the terminal bus inputs and outputs. The data of this buffer can be sent or

received over a single connection. Assembly objects are used to produce

(terminal bus inputs) and/or consume (terminal bus outputs) data to/from

the network.

So the inputs and ouputs of the terminals will be connected to the ControlNet with the assembly object. All output data will be sent from the scanner

in one scheduled telegram and all input data will be sent to the scanner in

another scheduled telegram.

BK 7000 18

Page 20

To set up this connection, the following parameters of the FwdOpenservice have to be adjusted:

Net O->T connection

parameters

Net T->O connection

parameters

Transport class /

trigger

Connection path

network connection type Multicast

fixed/variable Fixed

priority Scheduled priority

size No of bytes (word-aligned) of the terminal bus output

network connection type Point-To-Point

fixed/variable Fixed

priority Scheduled priority

size No of bytes (word-aligned) of the terminal bus input

client / server Client

transport type Cyclic

transport class Class 1

class 0x04

connection point inputs 0x00

connection point outputs 0x00

electronic key, vendor ID 0x006C

electronic key, product ty-

pe

electronic key, product co-

de

ControlNet coupler BK7000 in the ControlNet

data (depending on the calculating rules for terminal

bus input and output data) + 4 bytes scanner status +

2 bytes transport header

data (depending on the calculating rules for terminal

bus input and output data) + 4 bytes adapter status + 2

bytes transport header

0x0080

0x1B58

19 BK 7000

Page 21

ControlNet coupler BK7000 in the ControlNet

The status code and objectic specific status code of the FwdOpenResponse can report the following codes:

Status

code

0x00

0x01

0x01

0x01

0x01

0x01

0x25

0x25

0x25

0x05

0x01

0x01

0x01

0x01

0x01

0x01

0x01

0x01

0x01

0x01

0x06

0x01

0x01

0x01

0x01

Object specific

status code

Not available Connection successful Off

0x0100 Connection already in use Fast, 8*slow, 1*slow

0x0113 Connection Manager out of connections Fast, 8*slow, 2*slow

0x0108 Unsupported connection type Fast, 8*slow, 3*slow

0x0103 Transport type not supported Fast, 8*slow, 4*slow

0x0117 Nonexistant instance number Fast, 8*slow, 5*slow

0x0114 Electronic key in IOI failed (Vendor ID) Fast, 8*slow, 6*slow

0x0115 Electronic key in IOI failed (Product type) Fast, 8*slow, 7*slow

0x0114 Electronic key in IOI failed (Product code) Fast, 8*slow, 8*slow

0x0000 invalid class Fast, 8*slow, 9*slow

0x0400 Terminal bus fault Fast, 8*slow, 10*slow

0x0109 Connection size mismatch Fast, 8*slow, 11*slow

0x011A Application out of connections Fast, 8*slow, 12*slow

0x1000 Bad config data size Fast, 8*slow, 13*slow

0x1001 Bad config data word 0 Fast, 8*slow, 14*slow

0x1002 Bad config data word 1 Fast, 8*slow, 15*slow

0x1003 Bad config data word 2 fast, 8*slow, 16*slow

0x1004 Bad config data word 3 fast, 8*slow, 17*slow

0x1010 Config buffer overflow fast, 8*slow, 18*slow

0x0315 Invalid segment in path fast, 9*slow, 1*slow

0x0000 Not all expected data sent in the connection path fast, 9*slow, 1*slow

0x0110 Connection unconfigured step 1 fast, 9*slow, 3*slow

0x0110 Connection unconfigured step 2 fast, 9*slow, 4*slow

0x0110 Connection unconfigured step 3 fast, 9*slow, 5*slow

0x0110 Connection unconfigured step 4 fast, 9*slow, 6*slow

Meaning Displayed by blinking

IO-ERR LED:

Config data of the Assembly object

Sending the config data is optional, but they must consist of 4 words when

sent.

Word Meaning (default value is printed in bold type)

0

Reserved: must be 0

1 Bit 0: 2-Byte-PLC-interface off (0) / on (1)

Bit 1: 2-Byte-Diag-interface off (0) / on (1)

2 Bit 0: Terminal bus auto-reset off (0) / on (1)

Bit 1: Terminal diagnosis off (0) / on (1)

Bit 4: Digital terminal diagnosis mapped to input data on (0) / off (1)

3 Bit 2: Complex terminals are mapped with data only, if possible (0) / completely (1)

Bit 3: Complex terminals are mapped in Intel- (0) / Motorola (1) format

Bit 5: Complex terminals are mapped without (0) / with ( 1) word-alignment

Bit 6: Terminal bus will be synchronous to the Receive-connection (0) / free running (1)

Undescribed bits are reserved for internal or future use and must not be

changed.

The config data are stored in the bus coupler’s registers 0..3 in table 0. If

no config data are sent, the values are read from these registers. The registers can be read and written using the bus coupler configuration software KS2000.

BK 7000 20

Page 22

Calculating rules for terminal bus input and output data

sizes

There are three options for mapping analog terminals and other complex

terminals: data only (if possible), complete without word-alignment, or

complete with word-alignment. The input and output data sizes depend on

which mapping option is chosen.

If no config data are sent when connecting the Assembly object, the

BK7000 will at first try to use the most recently used mapping option. Failing that, it will try the options in the following order, choosing the first option that will make the data sizes match with the sizes received from the

scanner. This option will then be stored in the register table.

Rule 1

Analog terminals are mapped with data only. Other complex terminals are

mapped with data only if applicable, otherwise they are mapped completely, without word-alignment.

Rule 2

All complex terminals are mapped completely, without word-alignment.

Rule 3

Analog terminals are mapped with data only, other complex terminals are

mapped with data only if applicable, otherwise they are mapped completely, with word-alignment.

Rule 4

All complex terminals are mapped completely, with word-alignment.

If config data are sent when connecting the Assembly object, the input and

output data sizes are calculated using the selected option.

If the 2-Byte-PLC-interface or the 2-Byte-Diag-interface are enabled by the

config data, 2 additional bytes of input and output data are needed for each

enabled interface.

The data of the Assembly object have the following stucture:

Offset (in bytes) Meaning Remark

0

Transport header

2

Scanner / Adapter status

6

2-Byte-PLC-interface Optional

8

2-Byte-Diag-Interface Optional

10

Complex terminals (left to right)

10 + size of complex terminals

Digital terminals (left to right)

Note that the terminal data begin at offset 8 or 6 if any or both of the optional interfaces are disabled.

ControlNet coupler BK7000 in the ControlNet

21 BK 7000

Page 23

ControlNet coupler BK7000 in the ControlNet

Configuration with RS Networx 1.06

Make sure that beckhoff.hwx is registered with regsvr32.exe. This needs to

be done only once. If you aren’t sure whether this has been done already,

skip to step 2.

Select BK7000 from the list of communication products to add it to the configuration. If the BK7000 isn’t in the list as shown, you need to perform step

1.

BK 7000 22

Open the ControlNet configuration of the controller (PLC-5/20C in the example), and insert a device connection to the BK7000.

Page 24

ControlNet coupler BK7000 in the ControlNet

Set the input and output data size for the BK7000 according to the connected terminals and the desired mapping. Set the config size to 0 for default

settings or 4 for custom settings.

Save the configuration

Configuration with RS Networx 1.03

With RS Networx 1.03 the BK7000 in standard will not be supported. The

BK7000 can be configured like an 1771 ACN®15-I/O-adapter from AllenBradley. Instead of the assembly object the BK7000 in 1771-Mode supports two objects: the rack object for digital terminals and the 1771-generic

module for anlog terminals.

The input and output size of the digital object must be the number of words

of the digital inputs/outputs.

The input and output size of the analog object must be the number of

words of the analog inputs/outputs. The same rules as for the assembly

object will be used for the analog object.

For the digital object insert a discrete rack in the ControlNet configuration,

for the analog object insert a module and select the „1771-Generic“module.

The config size in the 1771-Mode must be zero.

23 BK 7000

Page 25

Appendix

Sample arrangement of a process image in

Appendix

the bus coupler

For this configuration

the bus coupler will create

the list of assignments

shown below

Area for byte-oriented

data, analog outputs

The following example will illustrate the assignment of input/output channels to the process image. Our sample construction is to consist of the

following bus terminal components:

Position Function component on the track

POS01

POS02

POS03

POS04

POS05

POS06

POS07

POS08

POS09

POS10

POS11

POS12

POS13

POS14

POS15

POS16

POS17

POS18

POS19

POS20

POS21

Besides transfer of the user information signal, when using analog terminals the control/status byte is also available via the process image by parameterisation of a three-byte channel (see PROFIBUS-DP).

Relative byte

address

6, 7,

10, 11

Bus coupler

2-channel digital input

2-channel digital input

2-channel digital input

2-channel digital input

2-channel digital input

2-channel digital output

2-channel digital output

2-channel digital output

2-channel analog input

2-channel analog output

2-channel analog output

2-channel analog input

Power input terminal

2-channel digital input

2-channel digital input

2-channel digital input

2-channel digital output

2-channel digital output

2-channel analog output

End terminal

Bit position Process image in

the control unit

0, 1

none O0, O1 POS11

2, 3

none O2, O3 POS11

4, 5

none O4, O5 POS12

none O6, O7 POS12

8, 9

none O8, O9 POS20

none O10, O11 POS20

Position in the

block

BK 7000 24

Page 26

Area for bit-oriented data,

digital outputs

Relative byte

address

Area for byte-oriented

data, analog inputs

Relative byte

address

Area for bit-oriented data,

digital inputs

Relative byte

address

The items POS14 and POS21 are not relevant to data exchange and do

not appear in the list. If a byte is not fully used, for example O13, the bus

coupler pads its remaining bits with zeroes.

Overview of the distribution of the process image in the bus coupler:

Output data

in the bus coupler

O0

...

byte-oriented data

...

O11

O12

bit-oriented data

O13

Input data

in the bus coupler

I0

...

byte-oriented data

...

I3

I4

...

bit-oriented data

...

I5

Bit position Process image in

the control unit

12

0 O12 POS07

12

1 O12 POS07

12

2 O12 POS08

12

3 O12 POS08

12

4 O12 POS09

12

5 O12 POS09

12

6 O12 POS18

12

7 O12 POS18

13

0 O13 POS19

13

1 O13 POS19

Bit position Process image in the

control unit

0, 1

none I0, I1 POS10

2, 3

none I2, I3 POS13

Bit position Process image in the

control unit

4

0 I4 POS02

4

1 I4 POS02

4

2 I4 POS03

4

3 I4 POS03

4

4 I4 POS04

4

5 I4 POS04

4

6 I4 POS05

4

7 I4 POS05

5

0 I5 POS06

5

1 I5 POS06

5

2 I5 POS15

5

3 I5 POS15

5

4 I5 POS16

5

5 I5 POS16

5

6 I5 POS17

5

7 I5 POS17

Appendix

Position in the

block

Position in the

block

Position in the

block

25 BK 7000

Page 27

Appendix

Representation of analog signals in the

The base addresses I0 and O0 listed here are used as relative addresses

or addresses in the bus coupler. If you have an appropriate superordinate

Profibus system you can use the bus master to enter these addresses at

any desired position in the process image of the control unit. You can use

the configuration software of the master to assign the bytes to the addresses in the process image of the control unit.

process image

I/O bytes of an analog

channel in the process

image

Significance of the

control/status bytes

for accessing

the register model

In the standard case, the analog signals are presented as follows: to input

bytes or to output bytes of the process image are needed for each analog

channel. The two bytes represent the value as unsigned interger, i.e. 15

bits with the sign. The data format is used independently of the actual resolution. Example: with a resolution of 12 bits in the case of analog values in

the positive and negative value ranges, the four least significant bits are of

no importance. If the value of the analog signal is only positive, the sine bit

(bit 15, MSB) is always "0". In this case, the 12 bits of the analog value are

represented in bit 14 to bit 3. The three least significant bits are of no importance.

By configuration via the Profibus master software or the KS2000 software,

the bus coupler can represent all or individual analog channels in an extended mode. Optionally, the control and status byte of a channel can also

be inserted. The least significant byte of three bytes has control and status

functions. The other two bytes become inputs and outputs. Various operating modes can be set with the control byte. The 6 least significant bits of

the control and status byte can be used as addressing bits. Addressing

serves to read and write a register set inside the terminal. The register set

has 64 registers. The settings are stored permanently

Output byte 1 Output byte 0 Control byte

Input byte 1 Input byte 0 Status byte

BIT 7 0 = NORMAL MODE, 1 = CONTROL MODE

BIT 6

BIT 5

BIT 4

BIT 3

BIT 2

BIT 1

BIT 0

0 = READ, 1 = WRITE

Register address, MSB

Register address

Register address

Register address

Register address

Register address, LSB

BK 7000 26

Page 28

15

0

GA

Register set of an

63

analog channel

47

31

16

0 Length Type

The significance of the registers and status bytes is explained in the data

sheets for the corresponding bus terminals. The construction of the module

is identical for bus terminals with more extensive signal processing.

User area

OFF SET

IN

Factory settings

Software

version

Type

Secondary process image

Appendix

27 BK 7000

Page 29

Support and Service

Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available

fast and competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her

internet pages: http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH

Eiserstr. 5

33415 Verl

Germany

phone: + 49 (0) 5246/963-0

fax: + 49 (0) 5246/963-198

e-mail: info@beckhoff.com

web: www.beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you no only with the application of individual Beckhoff products, but also with other, wide-ranging services:

• support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

hotline: + 49 (0) 5246/963-157

fax: + 49 (0) 5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

•

spare parts servive

• hotline service

hotline: + 49 (0) 5246/963-460

fax: + 49 (0) 5246/963-479

e-mail: service@beckhoff.com

BK 7000 28

Loading...

Loading...