Page 1

DeviceNet Coupler

BK5200, BK5210, LC5200

Technical Documentation

Version 1.3

2006-10-24

Page 2

Please note the following

Target group

Safety requirements

This description is only intended for the use of trained specialists in control

and automation engineering who are familiar with the applicable national

standards.

The responsible staff must ensure that the application or use of the

products described satisfy all the requirements for safety, including all the

relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are,

however, constantly under development. For that reason the documentation is not

in every case checked for consistency with performance data, standards or other

characteristics, and does not represent an assurance of characteristics in the sense

of § 459, Para. 2 of the German Civil Code. In the event that it contains technical or

editorial errors, we retain the right to make alterations at any time and without

warning. No claims for the modification of products that have already been supplied

may be made on the basis of the data, diagrams and descriptions in this

documentation.

This manual is copyrighted. Any reproduction or third party use of this protected

©

publication, whether in whole or in part, without the written permission of Elektro

Beckhoff GmbH, is forbidden.

BK52x0

Page 3

Table of contents

Table of contents

1. Foreword 4

Notes on the documentation 4

Liability Conditions 4

Delivery conditions 4

Copyright 4

Safety Instructions 5

State at Delivery 5

Description of safety symbols 5

2. Basic Principles 6

The Beckhoff Bus Terminal System 6

The interfaces 8

Power supply 8

Power contact feed points 9

Power contacts 9

Fieldbus connection 9

Configuration interface 9

K-Bus contacts 9

Electrical isolation 10

Operating modes of the Bus Coupler 11

Mechanical construction 12

Technical data 14

Peripheral data in the process image 16

Start-up procedure and Diagnostics 18

3. BK5200, BK5210, LC5200 DeviceNet 20

Introduction to the system 20

Configuring the Bus Coupler 22

Connector Pin assignment / DeviceNet connection 23

Data exchange 24

Light-emitting diodes 25

Vendor ID 26

DeviceNet Group 26

Bus cable: length, assignment 27

Electrical isolation 28

4. Appendix 29

Example: composition of a process image in the Bus Coupler 29

5. Support and Service 32

Beckhoff's branch offices and representatives 32

Beckhoff Headquarters 32

BK52x0 3

Page 4

Foreword

Foreword

Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering

who are familiar with the applicable national standards. It is essential that the following notes and

explanations are followed when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with

performance data, standards or other characteristics. None of the statements of this manual represents a

guarantee (Garantie) in the meaning of § 443 BGB of the German Civil Code or a statement about the

contractually expected fitness for a particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In

the event that it contains technical or editorial errors, we retain the right to make alterations at any time

and without warning. No claims for the modification of products that have already been supplied may be

made on the basis of the data, diagrams and descriptions in this documentation.

Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH apply.

Copyright

©

This documentation is copyrighted. Any reproduction or third party use of this publication, whether in

whole or in part, without the written permission of Beckhoff Automation GmbH, is forbidden.

4 BK52x0

Page 5

i

Foreword

Safety Instructions

State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH.

Description of safety symbols

The following safety symbols are used in this documentation. They are intended to alert the reader to the

associated safety instructions..

This symbol is intended to highlight risks for the life or health of personnel.

Danger

This symbol is intended to highlight risks for equipment, materials or the

Attention

environment.

This symbol indicates information that contributes to better understanding.

Note

BK52x0 5

Page 6

Basic Principles

Basic Principles

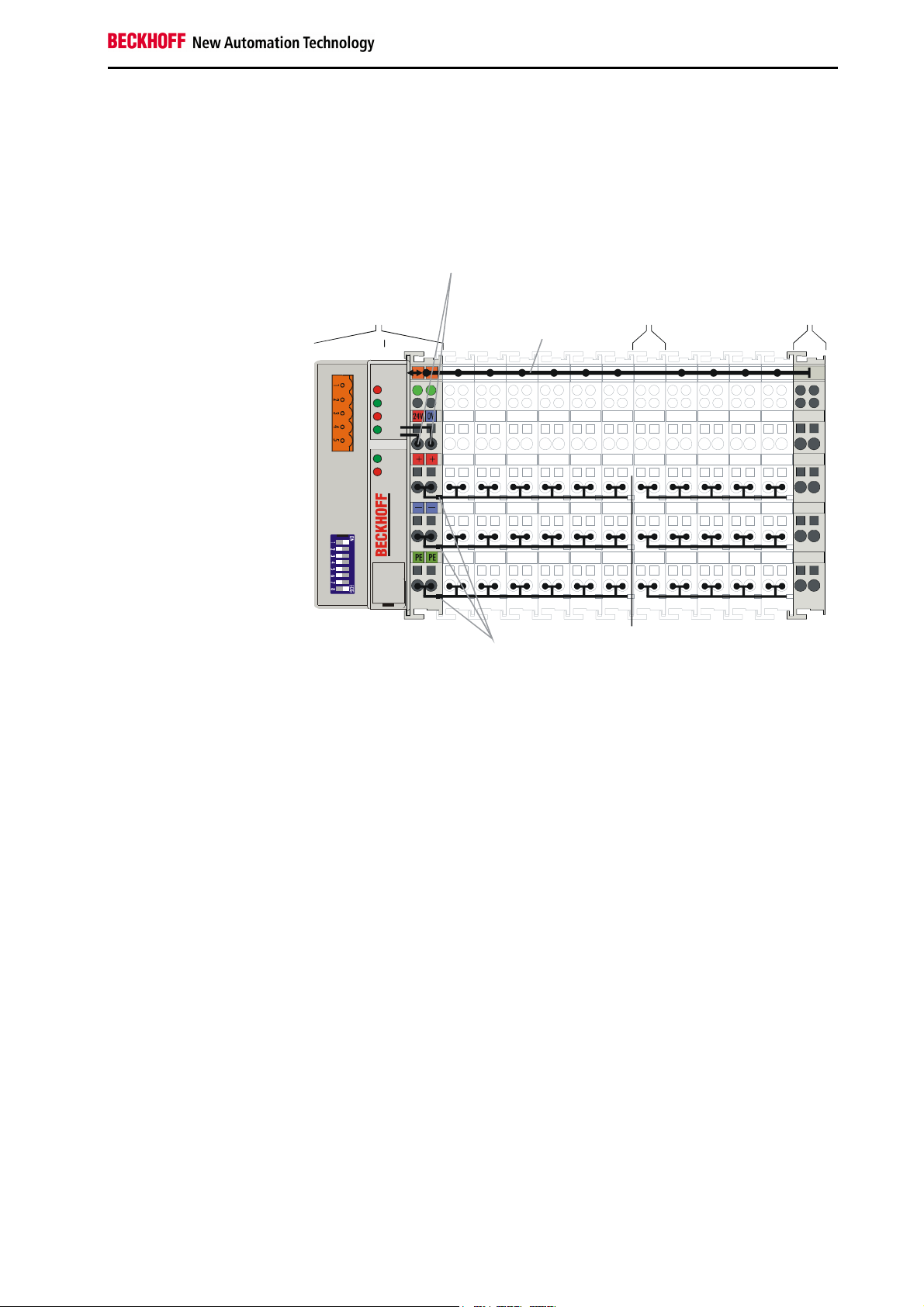

Up to 64 Bus Terminals

each having 2 I/O channels

for each signal form

de-centralised wiring of the

I/O level

IPC as controller

Bus Couplers for all usual

bus systems

Standard C - rail assembly

Modularity

Display of the channel state

K-Bus

End terminal

The Beckhoff Bus Terminal System

The Bus Terminal system is the universal interface between a fieldbus

system and the sensor / actuator level. A unit consists of a Bus Coupler as

the head station, and up to 64 electronic series terminals, the last one

being an end terminal. For each technical signal form, terminals are

available each having two I/O channels, and these can be mixed in any

order. All the terminal types have the same mechanical construction, so

that difficulties of planning and design are minimised. The height and depth

match the dimensions of compact terminal boxes.

Fieldbus technology allows more compact forms of controller to be used.

The I/O level does not have to be brought to the controller. The sensors

and actuators can be wired de-centrally, using minimum cable lengths. You

can locate the controller installation anywhere within the plant. The use of

an Industrial PC as the controller means that the operating and observing

element can be implemented in the controller’s hardware. The controller

can therefore be located at an operating panel, in a control room, or at

some similar place. The Bus Terminals form the de-centralised input/output

level of the controller in the control cabinet and the subsidiary terminal

boxes. The power sector of the plant is also controlled over the bus system

in addition to the sensor/actuator level. The Bus Terminal replaces the

conventional series terminal as the wiring level in the control cabinet. The

control cabinet can have smaller dimensions.

The Beckhoff Bus Terminal system unites the advantages of a bus system

with the possibilities of the compact series terminal. Bus Terminals can be

driven within all the usual bus systems, thus reducing the controller parts

count. The Bus Terminals then behave like conventional connections for

that bus system. All the performance features of the particular bus system

are supported.

The easy, space-saving, assembly on a standard C-rail, and the direct

wiring of actuators and sensors, without cross-connections between the

terminals, standardises the installation. The consistent labelling scheme

also contributes.

The small physical size and the great flexibility of the Bus Terminal system

allows it to be used wherever a series terminal is also used. Every type of

connection, such as analog, digital, serial or the direct connection of

sensors can be implemented.

The modular assembly of the terminal strip with Bus Terminals of various

functions limits the number of unused channels to a maximum of one per

function. The presence of two channels in one terminal is the optimum

compromise of unused channels and the cost of each channel. The

possibility of electrical isolation through potential feed terminals also helps

to keep the number of unused channels low.

The integrated LEDs show the state of each channel at a location close to

the sensors and actuators.

The K-Bus is the data path within a terminal strip. The K-Bus is led through

from the Bus Coupler through all the terminals via six contacts on the

terminals‘ side walls. The end terminal terminates the K-Bus. The user

does not have to learn anything about the function of the K-Bus or about

the internal workings of the terminals and the Bus Coupler. Many software

tools that can be supplied make project planning, configuration and

operation easy.

6 BK52x0

Page 7

isolation

contacts

DeviceNet

Power supply

Potential

Basic Principles

Potential feed terminals for

electrically isolated groups

The principle of the Bus

Terminal

The operating voltage is passed on to following terminals via three power

contacts. You can divide the terminal strip into arbitrary isolated groups by

means of potential feed terminals. The feed terminals play no part in the

control of the terminals, and can be inserted at any locations within the

terminal strip.

Up to 64 terminals may be located in a terminal strip, including the potential

feed terminals and end terminal.

Bus Coupler for the feed Bus end

BK5200 Bus Coupler terminal

terminal

K-Bus

DeviceNet

OVERFL

MS

RUN

BUS OFF

NS

CONNECT

I/O RUN

I/O ERR

BK5200

Bus couplers for various

fieldbus systems

PotentialPower

Various Bus Couplers can be used to couple the electronic terminal strip

quickly and easily to different fieldbus systems. It is also possible to

convert to another fieldbus system at a later time. The Bus Coupler

performs all the monitoring and control tasks that are necessary for

operation of the connected Bus Terminals. The operation and configuration

of the Bus Terminals is carried out exclusively by the Bus Coupler.

Fieldbus, K-Bus and I/O level are electrically isolated.

If the exchange of data over the fieldbus fails for a time, counter states are

retained, digital outputs are cleared, and analogue outputs take a value

that can be separately configured for each output when commissioning.

BK52x0 7

Page 8

Basic Principles

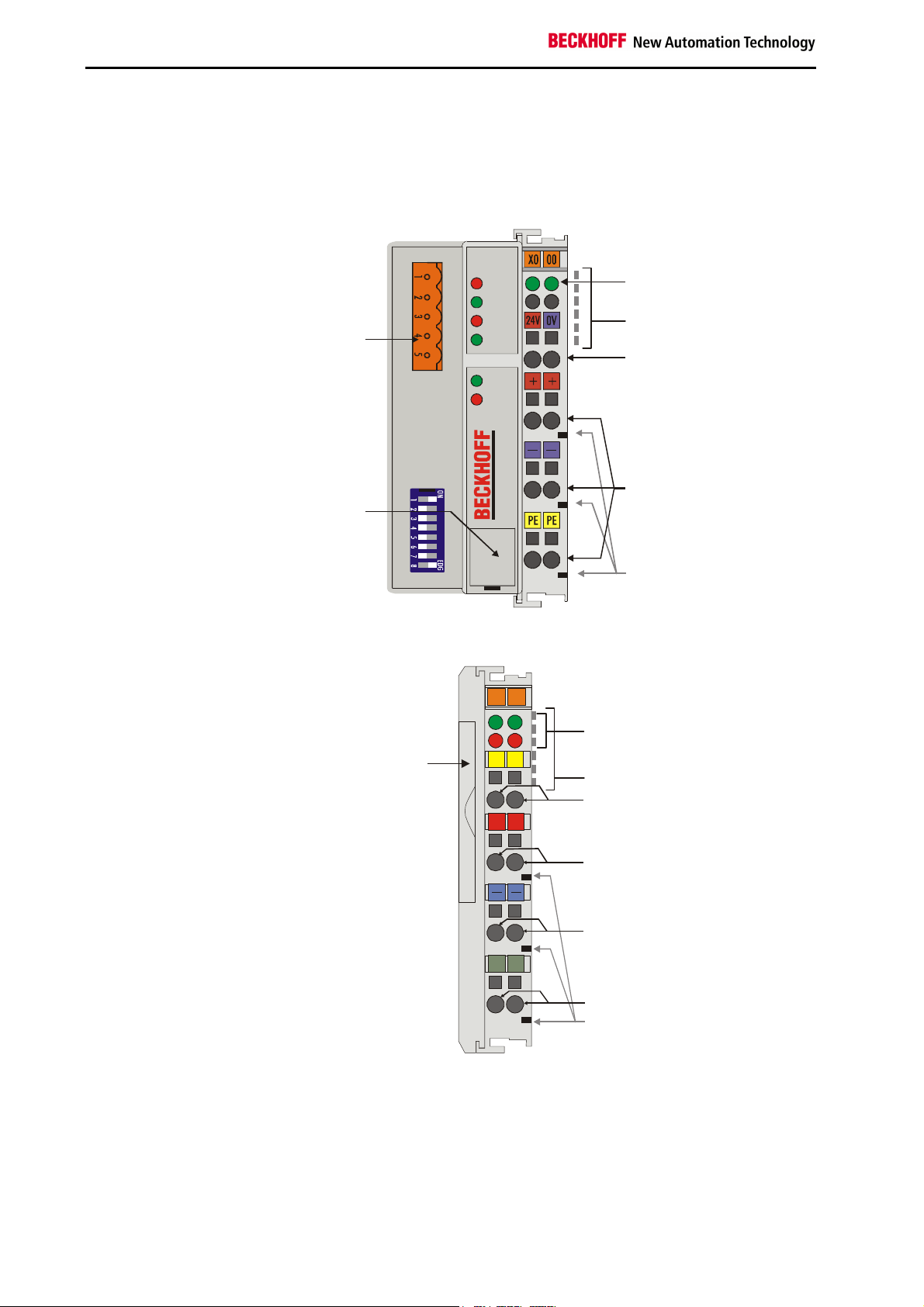

Power LEDs

Bus Coupler / Power

Power supply for

C+

C-

00

X0

LC5200

Beckhoff

K-Bus

CAN-H, CAN-L

Power contacts

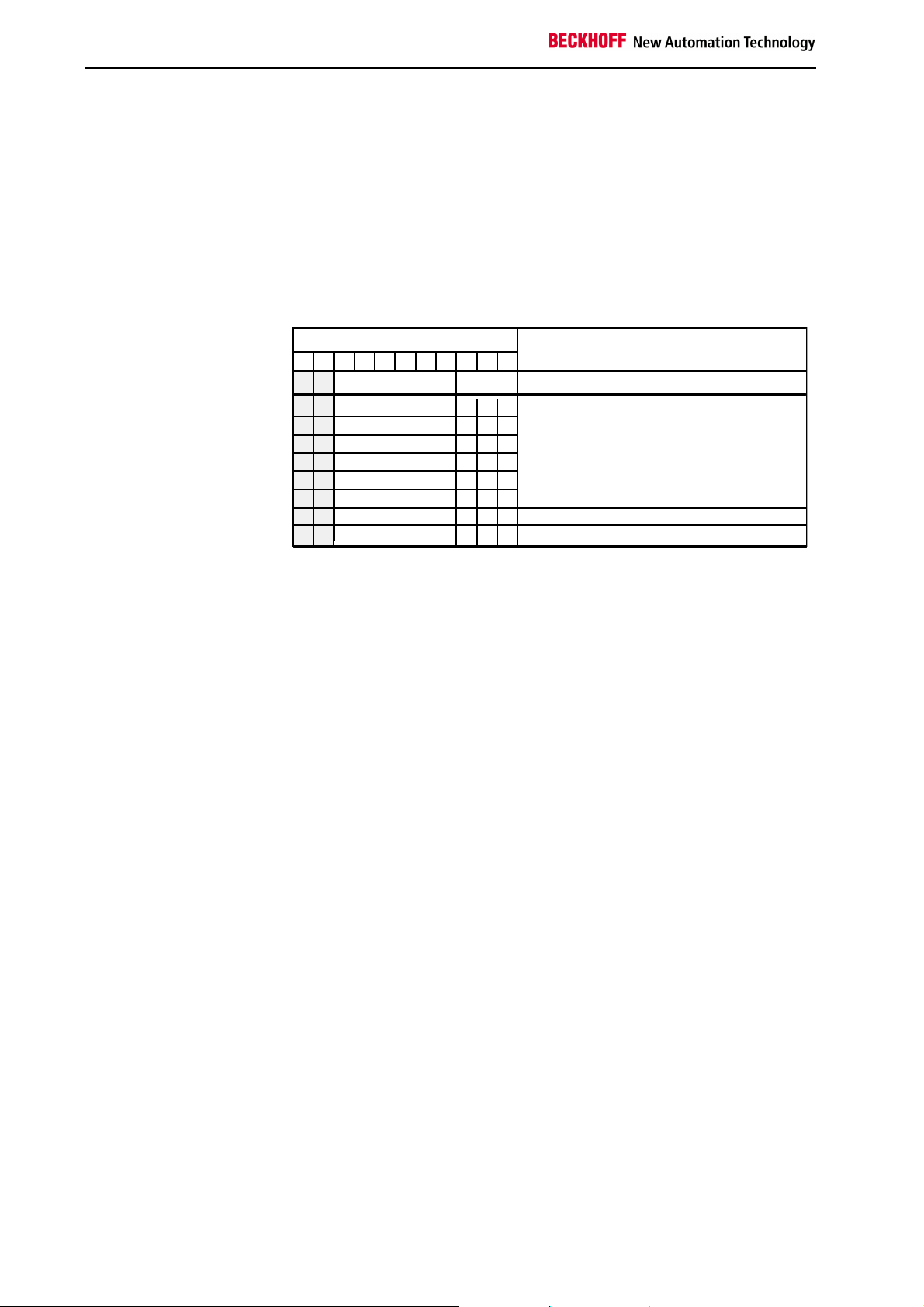

The DeviceNet Coupler

BK5200 / BK5210

The interfaces

A Bus Coupler has six different methods of connection. These interfaces

are designed as plug connectors and as spring-loaded terminals.

DeviceNet

connector

DeviceNet

OVERFL

MS

RUN

BUS OFF

NS

CONNECT

I/O RUN

I/O ERR

contacts

K-Bus

Power supply

Bus Coupler

24 V DC / GND

The DeviceNet coupler

LC5200

ConfigurationInterface

BK5200

Input

Power contacts

Power contacts

The LC5200 Bus Coupler integrates the bus connection into the springloaded terminals.

0201

left:

fieldbus LEDs

right:

Address

K-Bus LEDs

selector

+ +

V+

Bus Coupler

and field level

V-

BK5200, BK5210:

24 V DC to the topmost

terminals “24 V” and “0 V”

8 BK52x0

S S

Screen

Power supply

The Bus Couplers require a 24 V DC supply for their operation. In the case

of the BK52x0 Bus Couplers the connection is made by means of the

upper spring-loaded terminals labelled “24 V” and “0 V”. This supply

voltage feeds not only the Bus Coupler electronics via the K-Bus, but also

the Bus Terminals. In the BK52x0 Bus Couplers the voltage supply for the

bus coupler electronics and that of the K-bus are electrically isolated from

the field level potentials.

Page 9

Basic Principles

LC5200:

24V DC to the centre

terminal pairs

Bottom 3 terminal pairs for

feed

Maximum 24 V

Maximum 10 A

Spring contacts on the side

BK5200, BK5210: 5 pin

open style connector

LC5200: Bus connection

via spring loaded terminals

Serial interface under the

front cover

6 contacts on the side

The LC5200 Bus Coupler is supplied via the two central terminal pairs. The

power contacts pass the supply voltage on to the field level.

Power contact feed points

The bottom six connections with spring-loaded terminals can be used to

feed the supply for the peripherals. The spring-loaded terminals are joined

in pairs to a power contact. The feed for the power contacts has no

connection to the voltage supply for the bus coupler (BK52x0). The design

of the feed permits voltages of up to 24 V. The assignment in pairs and the

electrical connection between feed terminal contacts allows the connection

wires to be looped through to various terminal points. The current drawn

from the power contact must not exceed 10 A for long periods. The current

rating between two spring-loaded terminals is identical to that of the

connecting wires.

Power contacts

On the right hand face of the Bus Coupler there are three spring contacts

for the power contact connections. The spring contacts are hidden in slots

so that they can not be accidentally touched. By attaching a Bus Terminal

the blade contacts on the left hand side of the Bus Terminal are connected

to the spring contacts. The tongue and groove guides on the top and

bottom of the Bus Coupler and of the Bus Terminals guarantees that the

power contacts mate securely.

Fieldbus connection

The BK52x0 Bus Couplers have a recessed front surface on the left hand

side. The DeviceNet connection plug can be inserted here. A full

description of the fieldbus interfaces is found elsewhere in this manual.

In the LC5200 Bus Coupler the bus is connected directly at the upper

terminal pair.

Configuration interface

The BK52x0 Bus Couplers have an RS232 interface at the bottom of the

front face, whereas on the LC5200 it is located under the cover on the side.

The miniature connector can be joined to a PC with the aid of a connecting

cable and the KS2000 configuration software. The interface allows the

analog channels to be configured and also permits firmware updating.

The functionality of the configuration interface can also be reached via the

fieldbus using the object attributes for the register communication.

K-Bus contacts

In order to connect the Bus Coupler and Bus Terminals the Bus Coupler

has gold contacts on the right hand side. When the Bus Terminals are

pushed together the gold contacts automatically make the connection

between the Bus Terminals. The voltage supply to the K-Bus electronics in

the Bus Terminals and the data exchange between the Bus Coupler and

the Bus Terminals is carried out by the K-Bus. A part of the data exchange

takes place via a ring structure within the K-Bus. Opening the K-Bus, e.g.

by pulling out one of the Bus Terminals, opens the ring. Data exchange is

no longer possible. Special mechanisms nevertheless allow the Bus

Coupler to identify the location of the interruption and to report it.

BK52x0 9

Page 10

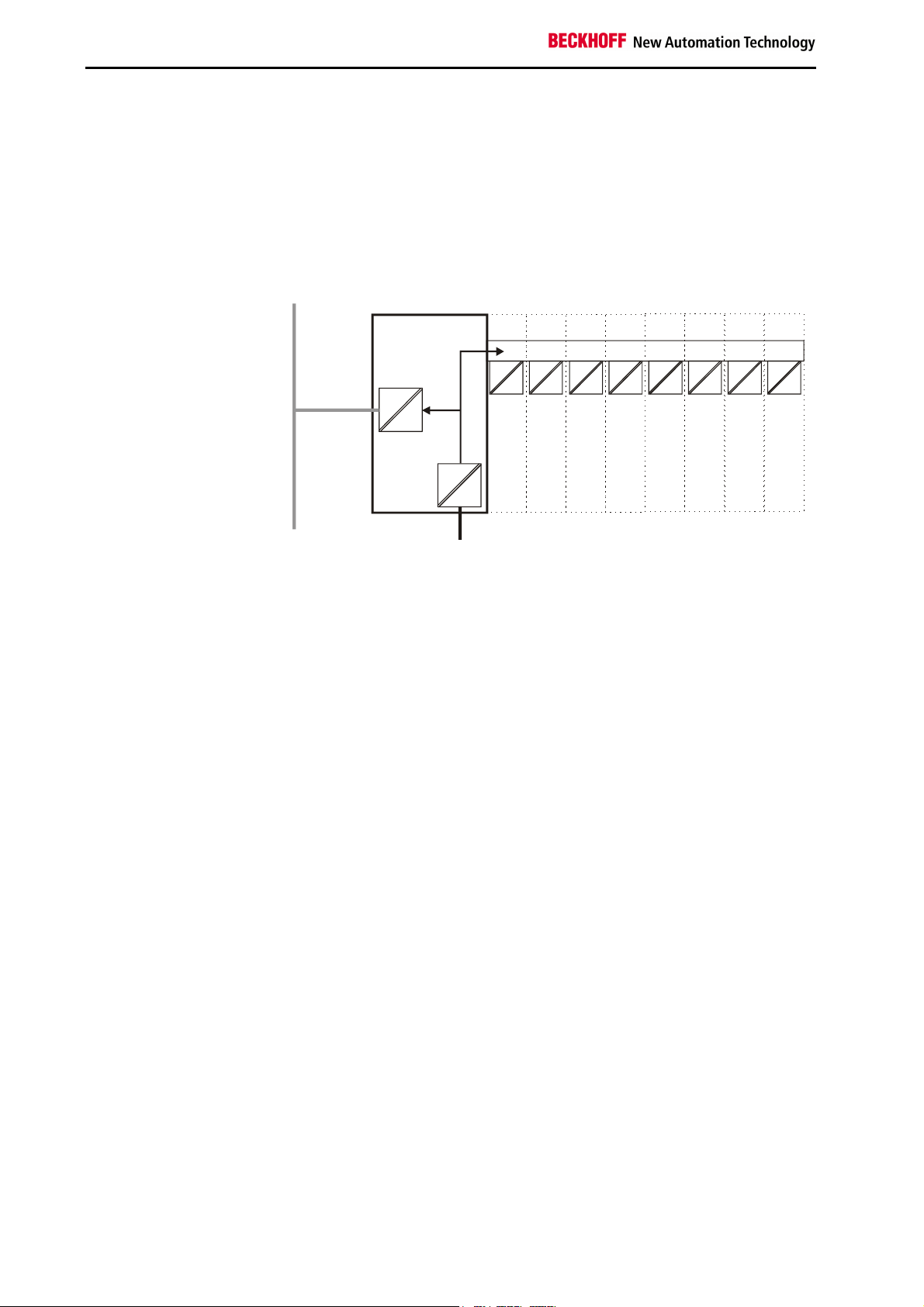

Basic Principles

Periphery level

Bus Terminals

Bus Coupler

24 V DC

BK5200, BK5210:

3 potential groups:

Fieldbus

K-Bus

Peripheral level

BK5200, BK5210:

Structure of the potential

levels in the Bus Terminal

system

Electrical isolation

The Bus Couplers operate by means of three independent potential

groups. The supply voltage feeds the K-Bus electronics in the Bus Coupler

and the K-Bus itself, which are electrically separate. The supply voltage is

also used to generate the operating voltage for the fieldbus.

Remark: All the Bus Terminals are electrically isolated from the K-Bus. The

K-Bus is thus electrically isolated from everything else.

Fieldbus

K-Bus

LC5200:

The LC5200 does not provide electrical isolation from the fieldbus and

peripheral level. If the peripheral level nevertheless needs to have an

electrically isolated implementation, this can easily be achieved through the

use of isolating terminals (KL9xxx).

10 BK52x0

Page 11

Bus Terminal test Structure list

Start-up behaviour of the

Bus Coupler

Operating modes of the Bus Coupler

Immediately after being switched on, the Bus Coupler checks, in the

course of a “self test”, all the functions of its components and the

communication on the K-Bus. The red I/O LED blinks while this is

happening After completion of the self-test, the Bus Coupler starts to test

the attached Bus Terminals (the ”Bus Terminal Test”), and reads in the

configuration. The Bus Terminal configuration is used to generate an

internal structure list, which is not accessible from outside. In case of an

error, the Bus Coupler enters the “STOP“ state. Once the start-up has

completed without error, the Bus Coupler enters the "fieldbus start" state.

Basic Principles

Power on selftest

The Bus Coupler reports the error to the master by means of the status

byte in the DeviceNet diagnostics (see section "Data exchange"). Clearing

the error returns the Bus Coupler to its normal operating mode.

BK52x0 11

Page 12

Basic Principles

02

01

+

+

S

S

C+

C-

00

X0

LC5100

Beckhoff

21

Mechanical construction

The system of the Beckhoff Bus Terminals is characterised by low physical

volume and high modularity. When planning a project it must be assumed

that at least one Bus Coupler and a number of Bus Terminals will be used.

The mechanical dimensions of the Bus Couplers are independent of the

fieldbus system.

Bus Coupler dimensions

Assembly and connection

The total width in practical cases is composed of the width of the Bus

Coupler with the bus end terminal and the width of the Bus Terminals in

use. Depending on function, the Bus Terminals are 12 or 24 mm wide. The

front wiring increases the total height of 68 mm by about 5 to 10 mm,

depending on the wire thickness.

The Bus Coupler and all the Bus Terminals can be clipped, with a light

press, onto a 35 mm C-mounting rail. A locking mechanism prevents the

individual housings from being pulled off again. For removal from the

mounting rail the orange coloured tension strap releases the latching

mechanism, allowing the housing to be pulled off the rail without any force.

Work should only be carried out on the Bus Terminals and the Bus Coupler

when switched off. Pulling out and inserting under power can cause

undefined states to be temporarily caused. (A reset of the Bus Coupler, for

example.)

Up to 64 Bus Terminals can be attached to the Bus Coupler on the right

hand side. When plugging the components together, be sure to assemble

the housings with groove and tongue against each other. A properly

working connection can not be made by pushing the housings together on

the mounting rail. When correctly assembled, no significant gap can be

seen between the attached housings.

The right hand part of the Bus Coupler can be compared to a Bus

Terminal. Eight connections on the top permit connection with solid or fine

wires. The connection is implemented with the aid of a spring device. The

spring-loaded terminal is opened with a screwdriver or rod, by exerting

gentle pressure in the opening above the terminal. The wire can be

inserted into the terminal without any force. The terminal closes

automatically when the pressure is released, holding the wire securely and

permanently.

12 BK52x0

Page 13

Basic Principles

Insulation testing

PE power contacts

The connection between the Bus Coupler and the Bus Terminals is

automatically realised by pushing the components together. The transfer of

the data and the supply voltage for the intelligent electronics in the Bus

Terminals is performed by the K-Bus. The field electronics are supplied in

the case of the digital Bus Terminals through the power contacts. Plugging

together the power contacts creates a supply rail. Note the circuit diagrams

for the Bus Terminals, since some Bus Terminals do not loop these power

contacts through, or only do so partially (e.g. analog Bus Terminals or 4

channel digital Bus Terminals). The potential feed terminals interrupt the

power contacts, and represent the start of a new supply rail. The Bus

Coupler can also be made use of to feed the power contacts.

The power contact labelled “PE” can be used as a protective earth. For

safety reasons this contact mates first when plugging together, and can

ground short-circuit currents of up to 125 A. Note that, for reasons of

electromagnetic compatibility, the PE contacts are capacitively coupled to

the mounting rail. This can both lead to misleading results and to damaging

the terminal during insulation testing. (e.g.: breakdown of the insulation

from a 230 V power user to the PE conductor.) The PE conductor to the

Bus Coupler must be disconnected for the insulation testing. In order to

uncouple further feed locations for the purposes of testing, the feed

terminals can be pulled at least 10 mm out from the connected group of

other terminals. In that case, the PE conductors do not have to be

disconnected.

The “PE” power contact must not be used for other potentials.

BK52x0 13

Page 14

Basic Principles

Technical data

Electrical data

The DeviceNet couplers differ in the level of the facilities they offer. The

fieldbus-specific electrical data is listed in this section. The following data

differs between the Standard, the Economy and the Low-Cost versions

(BK5200, BK5210 and LC5200). Compatibility with DeviceNet is ensured in

all cases, but the Economy and Low-Cost versions have a restricted

number of I/O points. This is why it is not possible to connect anything

other than digital inputs and outputs.

System data DeviceNet (BK5200, BK5210, LC5200)

Number of I/O modules

Transmission medium

Length of the cable

Transmission rate

Operating modes

Device Net type

64

Screened, twisted copper wire with power supply, 5-pin

500 m 250 m 100 m

125 kbaud 250 kbaud 500 kbaud

Bit Strobe, Polling, Cyclic, Change of State (COS)

Communications adapter

Technical data BK5200 BK5210

Number of Bus Terminals

Digital peripheral signals

Analog peripheral signals

Possibility of configuration

Maximum number of bytes

Bus connection

Power supply

Input current

Starting current

Recommended back-up fuse

K-Bus power supply up to

Power contact voltage

Power contact current load

Dielectric strength

Weight approx.

Operating temperature

Storage temperature

Relative humidity

Vibrations/Shock resistance

EMC resistance burst/ESD

Installation position

Protection class

64

256 inputs/outputs 256 inputs/outputs

128 inputs/outputs --Via KS2000 or the controller

512 bytes input, 512 bytes output 32 bytes input, 32 bytes output

1 x open pluggable connector, 5-pin, included

24 V DC (20...29 V DC), via bus cable 11… 25V (conforms to DeviceNet

specification)

70 mA + (total K-Bus current)/4

500 mA max.

approx. 2.5 x continuous current

≤ 10 A

1750 mA 500 mA

24 V DC max.

10 A max.

500 Veff (power contact / supply voltage Bus Coupler)

150 g 130 g

0°C ... +55°C

-25°C ... +85°C

95% , no condensation

conforms to IEC 68-2-6/IEC 68-2-27

conforms to EN 50082 (ESD, burst)/EN 50081

any

IP20

14 BK52x0

Page 15

Technical data LC5200

Number of Bus Terminals

Digital peripheral signals

Analog peripheral signals

Possibility of configuration

Maximum number of bytes

Bus connection

Power supply

Input current

Starting current

Recommended back-up fuse

K-Bus power supply up to

Power contact voltage

Power contact current load

Electrical isolation

Size

Weight approx.

Operating temperature

Storage temperature

Relative humidity

Vibrations/Shock resistance

EMC resistance burst/ESD

Installation position

Protection class

64

256 inputs/outputs

Via KS2000 or the controller

32 bytes input and 32 bytes output

directly to spring-loaded terminals

24 V DC (20...29 V DC), via bus cable 11…25V (conforms to DeviceNet

specification)

70 mA + (total K-Bus current)/4

500 mA max.

approx. 2.5 x continuous current

≤ 10 A

500 mA

24 V DC max.

10 A max.

none between power supply/fieldbus/power contacts

similar to the Bus Terminal housing, width 21 mm

100 g

0°C ... +55°C

-25°C ... +85°C

95% , no condensation

conforms to IEC 68-2-6/IEC 68-2-27

conforms to EN 50082 (ESD, burst)/EN 50081

any

IP20

Basic Principles

BK52x0 15

Page 16

Basic Principles

Digital signals

(bit-oriented)

Analog signals

(byte-oriented)

Special signals and

interfaces

Default assignment of

inputs/outputs to the

process image

Peripheral data in the process image

After being switched on, the Bus Coupler determines the configuration of

the inserted input/output terminals. The assignment of the physical slots for

the input/output channels and the addresses in the process image is

carried out automatically by the Bus Coupler.

The Bus Coupler creates an internal assignment list, in which the

input/output channels have a specific position in the process image. A

distinction is made here according to inputs and outputs, and according to

bit-oriented (digital) and byte-oriented (analog or complex) signal

processing.

Two groups are created, one for inputs and the other for outputs. Each

group has the byte-oriented channels in ascending sequence starting from

the lowest address. The bit-oriented channels are placed after this block.

The digital signals are bit-oriented. This means that one bit in the process

image is assigned to each channel. The Bus Coupler creates a memory

area containing the current input bits, and ensures that the bits in a second

memory area dedicated to the output channels are written out immediately.

The details of the assignment of the input and output channels to the

controller's process image is explained fully with the aid of an example in

the appendix.

The processing of analog signals is always byte-oriented. Analog input and

output values are represented in memory by two bytes each. Values are

represented in SIGNED INTEGER or two‘s complement format. The

number "0" stands for the input/output value "0 V", "0 mA" or "4 mA". The

maximum value of an output or input value is represented, according to the

standard settings, by "7FFF" (hex). Negative input or output values, e.g. 10 V, are represented from "1000" (hex). The intermediate values are

correspondingly proportional. A range with a resolution of 15 bits is not

achieved for all inputs and outputs. If the actual resolution is 12 bits, the

last three bits have no effect in outputs, while as inputs they are read as

"0". Each channel also has a control and status byte. The control and

status byte is the highest value byte. Version 2.0 of the DeviceNet coupler

does not permit the control and status byte to be read. An analog channel

is represented in the process image by 2 bytes. The following versions

permit expansion of a channel's data width by means of the KS2000

configuration software.

A Bus Coupler supports Bus Terminals with other interfaces such as

RS232, RS485, incremental encoder and others. These signals can be

considered similarly to the analog signals named above. For some special

signals the bit width of 16 is not sufficient. The Bus Coupler can support

any byte width.

Once it has been switched on, the Bus Coupler finds out how many Bus

Terminals are inserted, and creates an assignment list. The analog and

digital channels, divided into inputs and outputs, are assembled into

separate parts of this list. The assignment starts on the left next to the Bus

Coupler. The software in the Bus Coupler collects the individual entries for

each of the channels in order to create the assignment list counting from

left to right.

16 BK52x0

Page 17

Four groups are distinguished in the assignment:

Functional type of the channel Assignment level

1.

2.

3.

4

Analog outputs assignment by bytes

Digital outputs assignment by bits

Analog inputs assignment by bytes

Digital inputs assignment by bits

Complex multi-byte signal Bus Terminals are represented as analog inputs

or outputs.

The distribution of the process image in the Bus Coupler in overview:

Output data in the Bus

Coupler

O0

...

byte-oriented data

...

Ox

Ox+1

bit-oriented data

Ox+y

Input data in the Bus

Coupler

I0

...

byte-oriented data

...

Ix

Ix+1

...

bit-oriented data

...

Ix+y

The path from the I/Os to

the DeviceNet process

image

Basic Principles

Data consistency

Data whose content is all correctly associated is said to be consistent.

Examples of data items that belong together are: 1. the high and low bytes

of an analog value (word consistency), and 2. a control/status byte and the

associated parameter word for access to the registers. Data consistency in

BK52x0 17

Page 18

Basic Principles

the interaction of peripheral devices and their controllers is, in a basic

sense, only assured for a single byte. In other words, the bits of a byte are

written or read together. Byte consistency is sufficient for handling digital

signals. Whenever values have a length of more than 8 bits, analog values

for instance, the consistency must be extended. The different bus systems

guarantee consistency up to the required length. Correct transfer of the

consistent data from the bus system master to the controller is important.

The corresponding manual for the bus system will provide a detailed

description of the correct procedure, in particular the description of the

master interfaces used. Those chapters of this manual that deal with the

fieldbus refer to the most widespread interfaces.

Complex signal processing

All the byte-oriented signal channels such as RS232, RS485 or

incremental encoders operate to some extent with byte lengths of more

than two. Apart from the difference in length, they are always handled

similarly to the analog signals.

Start-up procedure and Diagnostics

After switching on, the Bus Coupler immediately checks the connected

configuration. Error-free start-up is signalled by the red "I/O ERR“ LED

being extinguished. If the “I/O ERR” LED blinks, an error in the area of the

terminals is indicated. The error code can be determined from the

frequency and number of blinks. This permits rapid rectification of the error.

There is a detailed description in the section on "The diagnostic LEDs".

The diagnostic LEDs

The Bus Coupler has two groups of LEDs for the display of status. The

upper group with four LEDs indicates the status of the respective fieldbus.

The significance of the “fieldbus status“ LED is explained in the relevant

sections of this manual - it conforms to conventional fieldbus displays.

On the upper right hand side of the Bus Couplers are two more green

LEDs that indicate the supply voltage. The left hand LED indicates the

presence of the 24 V supply for the Bus Coupler. The right hand LED

indicates the presence of the supply to the power contacts.

Local errors

Two LEDs, the “I/O LEDs”, in the area below the field bus status LEDs

referred to above, serve to indicate the operating status of the Bus

Terminals and the connections to these terminals. The green LED lights up

in order to indicate fault-free operation. The red LED blinks with two

different frequencies in order to indicate an error. The error is encoded in

the blinks as follows:

Blink code

Fast blinking

First slow sequence

Second slow sequence

Start of the error code

Error code

Error code argument

18 BK52x0

Page 19

Error location

Error code Error code

1 pulse

2 pulses

3 pulses

4 pulses

5 pulses

6 pulses

The number of pulses in the first sequence indicates the error type, while

the second sequence indicates the position of the last Bus Terminal before

the fault. Passive Bus Terminals, such as a power feed terminal, are not

included in the count.

In the case of some errors, rectification does not cause the Bus Coupler to

leave the blink sequence. The Bus Coupler stays in the "Stop" state. The

Bus Coupler can only be re-started either by switching the power supply off

and on again, or by a scanner reset.

Insertion and removal of Bus Terminals is only permitted when switched

off. The electronics in the Bus Terminals and in the Bus Coupler are

protected to a large measure against damage, but incorrect function and

damage cannot be ruled out if they are plugged in under power.

The occurrence of a fault in the course of operation does not immediately

trigger the display of error codes by the LEDs. The Bus Coupler must be

requested to diagnose the Bus Terminals. The diagnostic request is

generated at power-up or through an access by the fieldbus to the Bus

Coupler. This means that if no data is being exchanged over DeviceNet

when a bus terminal is removed from the system, the Bus Coupler will not

necessarily report an error.

Basic Principles

Description

argument

0

1

2

0

n (n > 0)

0 Terminal bus command error

0

n

n Terminal bus error in register communication

0

n (n > 0)

EEPROM checksum error

Inline code buffer overflow

Unknown data type

Programmed configuration

Incorrect table entry / Bus Coupler

Incorrect table comparison (terminal n)

Terminal bus data error

Break behind terminal n (0: Coupler)

with terminal n

Special fieldbus error

BK52x0 19

Page 20

BK5200, BK5210, LC5200 DeviceNet

BK5200, BK5210, LC5200 DeviceNet

DeviceNet

BK5200, BK5210:

Bus power and terminal

power are supplied

separately.

Both power supplies must

be connected.

Introduction to the system

DeviceNet is an open system based on CAN, developed by Bosch a few

years ago. CAN was primarily intended for the transfer of data within

automobiles, and millions of CAN chips have since been installed. The

disadvantage of using CAN in automation technology is that it does not

define an application layer. It specifies only the physical layer and data

security layer.

DeviceNet specifies a uniform application layer and this makes it possible

to use the CAN protocol for industrial applications. ODVA (the Open

DeviceNet Vendor Association) is an independent association which

supports manufacturers and users of the DeviceNet system. ODVA

ensures that all devices which conform to the specification can operate

together in one system, regardless of their manufacturer.

Controller

DeviceNet

Other

Device Configuration

Devices

Input/Output

Devices

Motor

Starter

Drive

Sensor

Allen-Bradley

SMC

Motor

Controller

Pushbutton

Cluster

Bar Code Scanner

Examples of DeviceNet in use

CAN’s bit arbitration procedure makes it theoretically possible to operate

communication networks using master/slave and multimaster access

methods. The BK5200 Bus Coupler with the corresponding software

release B2 supports master/slave operation (in polling mode), with the Bus

Coupler functioning as slave. Subsequent releases of the Bus Coupler

software will also support multimaster operation.

The BK5200 and BK5210 Bus Couplers are not supplied with power via the

DeviceNet bus cable. The Bus Coupler and the peripherals (the Bus

Terminals) must be wired up using the connections on the top right-hand

side (this is explained in the introductory pages). This enables you to

isolate the bus electrically from the peripherals. If you wish, you can

connect the power supply of the bus cable to the peripheral side and

dispense with the decentralised power supply.

The LC5200 Bus Coupler is supplied with power via the DeviceNet bus

cable. This means that there is no electrical isolation between the bus and

the peripherals. If the peripheral level nevertheless needs to have an

electrically isolated implementation, this can easily be achieved through the

use of isolating terminals (KL9xxx).

20 BK52x0

Page 21

Bus cable

The bus cable consists of two pairs of shielded twisted-pair wires, one for

the data transfer and one for the power supply. The latter can carry

currents of up to 8 amperes. The maximum possible length of a line

depends essentially on the baud rate. If you choose the highest Baud rate

(500 kbaud) you are restricted to lines of at most 100 m. With the lowest

Baud rate (125 kbaud) you will be able to use cable with an overall length

of 500 m.

Power Tap

24 Volt

Power

Supply

BK5200, BK5210, LC5200 DeviceNet

Power Conductor

Signal Conductor

Parameterisation

Node

Node Node

Node

Node Node

The bus cable may consist of a main line with branch lines up to 6m long. It

is important that both ends of the main line should carry 121 Ω terminating

resistors. You can operate up to 64 devices on one line. If you want to be

able to plug and unplug Bus Couplers while the equipment is in operation

you should attach the terminating resistors permanently to the bus cable.

Special DeviceNet configuration software should be used to parameterise

the system. The user places the parameterisation data in the master with

this software. When it is first switched on, the master will compare its

stored settings with the actual configurations of each of the stations. The

exchange of user data between master and slave will not be initiated

unless all the parameters agree. Setting the parameters for the master is

carried out directly via the DeviceNet connection. The DeviceNet system

does not use a separate interface such is provided for other fieldbusses.

BK52x0 21

Page 22

BK5200, BK5210, LC5200 DeviceNet

Configuring the Bus Coupler

Set all the DIP switches to the desired configuration before you switch on

the Bus Coupler. Switches 7 and 8 are used to set the baud rate, as shown

in the following table.

Setting the DIP switches

Setting the baud rate

Setting the MAC ID

Switch on the Bus Coupler

Setting baud rates 1 2 3 4 5 6 7 8

125 kbaud

250 kbaud

500 kbaud

(Default) 125 kbaud

off off

on off

off on

on on

DIP switches 1 to 6 are used to set the MAC ID, where switch 1 is the

lowest value bit 20, and switch 6 the highest value bit 25. The bit is set

when the switch is ON.

You can select the MAC ID from the range 0 to 63.

When you have set all the DIP switches to the desired configuration you

can switch on the Bus Coupler. Any changes you make to the switches

while the system is in operation will have no effect until the next time it is

switched on.

22 BK52x0

Page 23

Power supply

C+

C-

00

X0

Beckhoff

CAN-L

Screen

Connector Pin assignment / DeviceNet

connection

DeviceNet connection

BK5200, BK5210:

Bus power and terminal

power are supplied

separately.

Both power supplies must

be connected.

A 5-pin plug is supplied to connect the DeviceNet bus cable. When it is

plugged into the Bus Coupler, pin 1 is at the top. The figure shows the

socket in the Bus Coupler. The power supplied by this plug is isolated from

the power supply of the terminal to the right of the Bus Coupler. Both

power sources must be connected before the system can operate.

BK5200, BK5210, LC5200 DeviceNet

DeviceNet connection

LC5200

Connection diagram for the

LC5200 Bus Coupler

Pin assignment of DeviceNet

connection

1

2

3

4

5

V+

CAN-H

GND

CAN-L

V-

In the low cost LC5200 coupler, the CAN wires are connected directly to

the contact points 1 (CAN-H, marked with C+) and 5 (CAN-L, marked with

C-). V+ is placed on the terminal locations 2 and 6. V- is placed on the

terminal locations 3 and 7. The screen can optionally be connected to

contact points 4 or 8, which are connected to the top hat rail via an R-C

network.

0201

CAN-H

+ +

V+

V-

S S

.

BK52x0 23

Page 24

BK5200, BK5210, LC5200 DeviceNet

Byte 0

Byte n

Object from master to the Bus Coupler

Object from Bus Coupler to the master

Data string from the

DeviceNet master to the

Bus Coupler:

first byte-oriented data, and

then bit-oriented data.

4 bytes for 2-channel

analog output terminals

2 bits for 2-channel digital

output terminals

First the data from all the

analog outputs

Then the data for the digital

outputs is transmitted in

bytes

Some of the bits in the last

byte may be unused

Data exchange

Data is transferred between masters and slaves in the form of objects. The

Bus Coupler recognises two objects: an input object and an output object.

You can use the configuration software to map the input/output bytes onto

specific memory areas in the controller. The Bus Coupler uses a consistent

algorithm to correlate the object data to the peripherals. Various examples

of correlations between addresses and peripherals are explained in the

appendix. A (data) object which is transferred from the DeviceNet master

to the Bus Coupler must begin with the byte-oriented values, which is the

data for the analog output terminals. The bit-oriented data for digital

outputs may not be transmitted until all the byte-oriented values have been

sent.

Analog outputs receive 16 bits of data, i.e. two bytes, for each channel. An

analog output terminal with 2 channels must therefore receive 4 bytes. A

digital output terminal with 2 channels needs a total of 2 bits of data, one

for each channel.

The first 4 bytes of an object which is transferred to the terminal strip are

assigned to the first analog output terminal, which is the analog output

terminal nearest to the Bus Coupler. Other terminals which are located

between the Bus Coupler and the first analog output terminals are

disregarded. The next four bytes of the object go to the second analog

output terminal in the terminal strip. Any other terminals between the first

and second analog output terminals are disregarded.

When the last analog output terminal in the terminal strip has received its

data, the digital outputs are served. Data is always transferred in the form

of bytes, so the next byte from the data string contains data for 8 digital

outputs. Bit 0 and bit 1 are assigned to channels 1 and 2 of the first digital

output terminal after the Bus Coupler. Other types of terminal which are

located in between are ignored.

Bits 2 and 3 go to the 2 channels of the second digital output terminal, bits

4 and 5 to the third and bits 6 and 7 to the fourth. There may be other

terminals located between these digital output terminals, and if so they will

be disregarded.

Additional bytes are read from the data string until the last digital output in

the terminal strip has been dealt with. If the total number of digital outputs

is not a multiple of 8, there will be a number of bits left over in the last data

byte; these will be discarded.

24 BK52x0

Status byte

Byte n

. . . . . .

. . . . . .

Bit data

. . . . . .

Bit data

. . . . . .

. . . . . .

. . . . . .

. . . . . .

Byte data

. . . . . .

Byte data

Byte 0

Page 25

BK5200, BK5210, LC5200 DeviceNet

Object from the Bus

Coupler to the DeviceNet

master for transferring the

input data:

first byte-oriented data,

and then bit-oriented data.

Status byte at the end of

the object sent to the

master

Status byte=0: I/O RUN

Status byte=1: I/O ERR

LED "RUN"

LED "OVERFL"

LED "CONNECT"

LED "BUS OFF"

LED "I/O RUN"

LED "I/O ERR"

LED "I/O ERR"

The object sent by the Bus Coupler to the DeviceNet master also contains

the byte-oriented data at the beginning, followed by the bit-oriented data.

Transfers in this direction also include a status byte, which comes right at

the end of the object.

The byte-oriented data contains the values from the analog inputs and the

bit-oriented data the values from the digital inputs.

The first four bytes contain the data from the first analog input terminal in

the terminal strip, where each pair of bytes is the 16 bit value of one input.

The next four bytes correspond to the next analog input terminal and so on,

analogously to the procedure described above.

After the byte-oriented data from all the analog inputs come the values

from the digital inputs. Eight digital inputs are transferred in each byte. As

before, if the total number of digital inputs in the terminal strip is not a

multiple of 8, the last data byte will contain one or more superfluous bits.

An extra status byte is transferred at the end of each string sent by the Bus

Coupler to the DeviceNet master, and this returns the status of the terminal

strip. Its value corresponds to the status displayed on the I/O LEDs on the

Bus Coupler: while the terminal strip is functioning correctly, the LED ”I/O

RUN” will be lit and the status byte will contain the value 0; as soon as an

error occurs, the LED ”I/O ERR” will light up and the status byte will contain

the value 1.

Light-emitting diodes

Module status LEDs ”MS”

The green LED flashes: Configuration is incorrect

The green LED is permanently lit: Status is OK.

The red LED flashes: Receive queue overflow

The red LED is permanently lit: Status is OK.

Network status LEDs ”NS”

The green LED flashes: Bus Coupler is ready for

communication, but not yet

assigned to the master.

The green LED is permanently lit: Bus Coupler is assigned to the

master, data is being exchanged.

The red LED flashes: Timeout on I/O connection

The red LED is permanently lit: BUS OFF: CAN error, devices

have identical node addresses.

Input/output status ”I/O”

The green LED is lit: The Bus Terminals are working

correctly.

The red LED is lit: I/O error, a Bus Terminal or an

internal K-Bus with a fault.

The red LED flashes: The Bus Terminals are being

configured

BK52x0 25

Page 26

BK5200, BK5210, LC5200 DeviceNet

Vendor ID

The vendor ID is # 108.

DeviceNet Group

The BK5200, BK5210 and LC5200 Bus Couplers are exclusively Group 2

devices.

IDENTIFIER BITS

9

10

1 0

1

1

1

1

1

1

1

1

78

0

0

0

0

0

0

Destination MAC ID Reserved for Predefined Master/Slave Connection Management

0

Destination MAC ID

0

Overview of the identifiers used

6

MAC ID

MAC ID

MAC ID

MAC ID

MAC ID

MAC ID

MAC ID

MESSAGE ID

4

5

3

Group 2

Message ID

0 0 0

0 0 1

0 1 0

0 1 1

1 0 0

1 0 1

1 1 0

1 1 1

1

Group 2 Messages

Group 2 Message Identifier

Duplicate MAC ID Check Message

0

2

MEANING

26 BK52x0

Page 27

0

White EIA 395A within wire/cable limits

Bus cable: length, assignment

The maximum length of cable which can be used depends on the selected

baud rate. The following lengths should be understood as the total length

of the main line plus any branch lines.

125 kbaud 500 m

250 kbaud 250 m

500 kbaud 100 m

Length of

Thin Cable

Used

(meters)

BK5200, BK5210, LC5200 DeviceNet

100

80

125k baud

60

40

20

500k

250k baud

baud

0 50 100 150 200 250 300 350 400 450 500

Length of Thick Cable Used (meters)

L

+ 5 x L

thick

L

+ 2.5 x L

thick

L

+ L

thick

where L

= 500 at 125Kbaud

thin

= 250 at 250Kbaud

thin

= 100 at 500Kbaud

thin

is the length of thick cable and Lthin

thick

is the length of thin cable.

Braid Shield

Data Insulation

Color: W hite

A L/M Y

Shield

Data Insulation

Color: B lue

Jacket

DC Power Insulation

Color: Bl ack

AL /MY

Shield

Drain W ire

DC Power Insulation

Color: Red

The cable consists of two shielded wire pairs. One pair carries out the

transmission. The second pair distributes the supply power.

BK52x0 27

V+

CAN_H

SHIELD

CAN_L

V-

Connector wiring information

Red P.M.S. #207C

Blue P.M.S. #297C

Black P.M.S. #426C

Page 28

BK5200, BK5210, LC5200 DeviceNet

Node/App

Network

Node

Electrical isolation

BK5200, BK5210

The Bus Coupler BK5200 have electrical isolation between the DeviceNet

bus cable and the communication electronics of the Bus Coupler.

24 Power supply

Local source

BK5200 Block diagram

Specific

uP / CAN

Local

Supply

LC5200:

drain/shield

signal

power

Isolation

barrier

Power

Supply

Transceiver

Power Tap

Optical

Isolators

Shield

no

function

5V Reg

MWP

V+

V-

Potential levels of the BK5200 and BK5210

The LC5200 does not provide electrical isolation from the fieldbus and

peripheral level. If the peripheral level nevertheless needs to have an

electrically isolated implementation, this can easily be achieved through the

use of isolating terminals (KL9xxx).

28 BK52x0

Page 29

Example: composition of a process image

Appendix

in the Bus Coupler

With this configuration, the

Bus Coupler sets up the

following assignment list

Area for byte-oriented data,

analog outputs

An example shows the assignment of in- and output channels to the

process image. The sample construction is to consist of the following

assembly of Bus Terminals:

Position Functional groups on the rail

POS01

POS02

POS03

POS04

POS05

POS06

POS07

POS08

POS09

POS10

POS11

POS12

POS13

POS14

POS15

POS16

POS17

POS18

POS19

POS20

POS21

By default, DeviceNet only supports signal channels that are 16 bits

wide. The STATUS/CONTROL BYTE is not available. This means, for

instance, that an analog input terminal with 2 channels appears with 2

x 16 bits in the process image. The images have corresponding

differences with respect to byte addresses and assignments.

Relative byte

address

0, 1

2, 3

4, 5

6, 7,

8, 9

10, 11

Bus Coupler

Digital inputs, 2 channels

Digital inputs, 2 channels

Digital inputs, 2 channels

Digital inputs, 2 channels

Digital inputs, 2 channels

Digital outputs, 2 channels

Digital outputs, 2 channels

Digital outputs, 2 channels

Analog inputs, 2 channels

Analog outputs, 2 channels

Analog outputs, 2 channels

Analog inputs, 2 channels

Power feed terminal

Digital inputs, 2 channels

Digital inputs, 2 channels

Digital inputs, 2 channels

Digital outputs, 2 channels

Digital outputs, 2 channels

Analog outputs, 2 channels

End terminal

Bit position Controller process

image

none O0, O1 POS11

none O2, O3 POS11

none O4, O5 POS12

none O6, O7 POS12

none O8, O9 POS20

none O10, O11 POS20

Position in the

block

Appendix

BK52x0 29

Page 30

Appendix

Area for bit-oriented data,

digital outputs

Relative byte

address

12

12

12

12

12

12

12

12

13

13

Area for byte-oriented data,

analog inputs

Relative byte

address

0, 1

2, 3

4,5

5,7

Area for bit-oriented data,

digital inputs

Relative byte

address

4

4

4

4

4

4

4

4

5

5

5

5

5

5

5

5

6

6

Positions POS14 and POS21 are not relevant to data exchange. They do

not appear in the list. If a byte is not fully utilised, e.g. E8, the Bus Coupler

pads the remaining bits of the byte with zeros.

Bit position Controller process

image

0 O12 POS07

1 O12 POS07

2 O12 POS08

3 O12 POS08

4 O12 POS09

5 O12 POS09

6 O12 POS18

7 O12 POS18

0 O13 POS19

1 O13 POS19

Bit position Controller process

image

none I0, I1 POS10

none I2, I3 POS10

none I4, I5 POS13

none I6, I7 POS13

Bit position Controller process

image

0 I4 POS01

1 I4 POS01

2 I4 POS02

3 I4 POS02

4 I4 POS03

5 I4 POS03

6 I4 POS04

7 I4 POS04

0 I5 POS05

1 I5 POS05

2 I5 POS06

3 I5 POS06

4 I5 POS15

5 I5 POS15

6 I5 POS16

7 I5 POS16

0 I6 POS17

1 I6 POS17

Position in the

block

Position in the

block

Position in the

block

30 BK52x0

Page 31

The distribution of the process image in the Bus Coupler in overview:

Output data in the Bus

Coupler

O0

...

byte-oriented data

...

A11

O12

bit-oriented data

O13

Input data in the Bus

Coupler

I0

...

byte-oriented data

...

E3

I4

...

bit-oriented data

...

I6

The base addresses I0 and O0 listed here are used as relative addresses

or addresses in the Bus Coupler. If you have an appropriate superordinate

DeviceNet system, you can use the bus master to enter these addresses at

any desired position in the controller's process image. You can use the

configuration software of the master to assign the bytes to the addresses in

the process image of the controller.

Appendix

BK52x0 31

Page 32

Support and Service

Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available

fast and competent assistance with all questions related to Beckhoff products and system solutions.

Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her

internet pages: http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

Beckhoff Headquarters

Beckhoff Automation GmbH

Eiserstr. 5

33415 Verl

Germany

phone: + 49 (0) 5246/963-0

fax: + 49 (0) 5246/963-198

e-mail: info@beckhoff.com

web: www.beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you no only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

• support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

hotline: + 49 (0) 5246/963-157

fax: + 49 (0) 5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

•

spare parts servive

• hotline service

hotline: + 49 (0) 5246/963-460

fax: + 49 (0) 5246/963-479

e-mail: service@beckhoff.com

32 BK52x0

Loading...

Loading...