Page 1

Version: 3.5.1

Date: 2006-02-10

BK3xx0 - Bus Coupler for

PROFIBUS DP

Page 2

Page 3

Contents

Contents

BK3xx0 - Bus Coupler for PROFIBUS DP

1. Foreword

Notes on the Documentation 3

Safety Instructions 4

Documentation Issue Status 5

2. Product Overview 6

Technical Data 6

Technical Data (Optical Fibres) 9

System Overview 10

PROFIBUS - Introduction 12

PROFIBUS DP 12

PROFIBUS DPV1 14

3. Mounting and Wiring 15

Mechanical Installation 15

Dimensions 15

Assembly 16

Wiring 17

Potential groups, insulation testing and PE 17

Power Supply and Potential Groups 19

PROFIBUS Cabeling 22

PROFIBUS Connection 22

PROFIBUS Cabling 24

4. Parameterisation and Commissioning 26

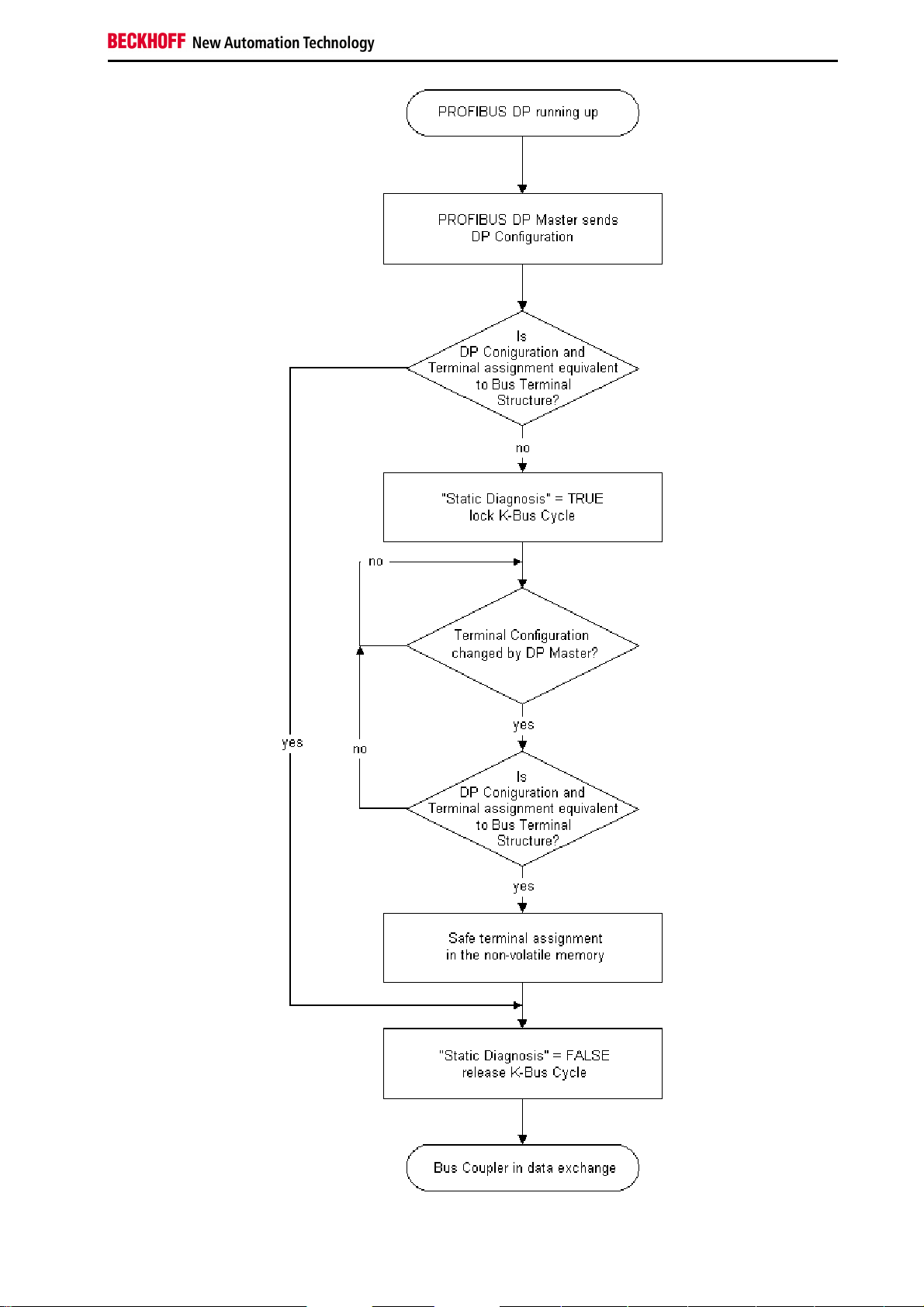

Start-up behaviour of the Bus Coupler 26

The Bus Coupler's UserPrmData 27

Technical Data - Summary 29

Configuration 30

Configuration - CfgData 30

Configuration of the Coupler Modules 31

Configuration of Complex Modules 32

Configuration of Digital Modules 34

GSD Files 35

Configuration Software KS2000 37

Configuration with TwinCAT 38

Configuration with S7 41

Configuration: Siemens S7 Controller 41

Configuration: Siemens S7 Controller BK3120 42

Fieldbus Components 1

Page 4

Contents

5. PROFIBUS DP Comunication 47

Cyclic Data Exchange 47

Process Data, Process Image 47

K-Bus Cycle 49

DPV1 - Acyclic Data Transfer 53

DPV1 Interface 53

Assignment of the DPV1 Slot Number 54

DPV1 at the Coupler 55

Module Assignment 55

Firmware Information 56

Terminal Composition 57

K-Bus Status 58

Cycle Time Measuring 59

6. Diagnosis and Error Handling 60

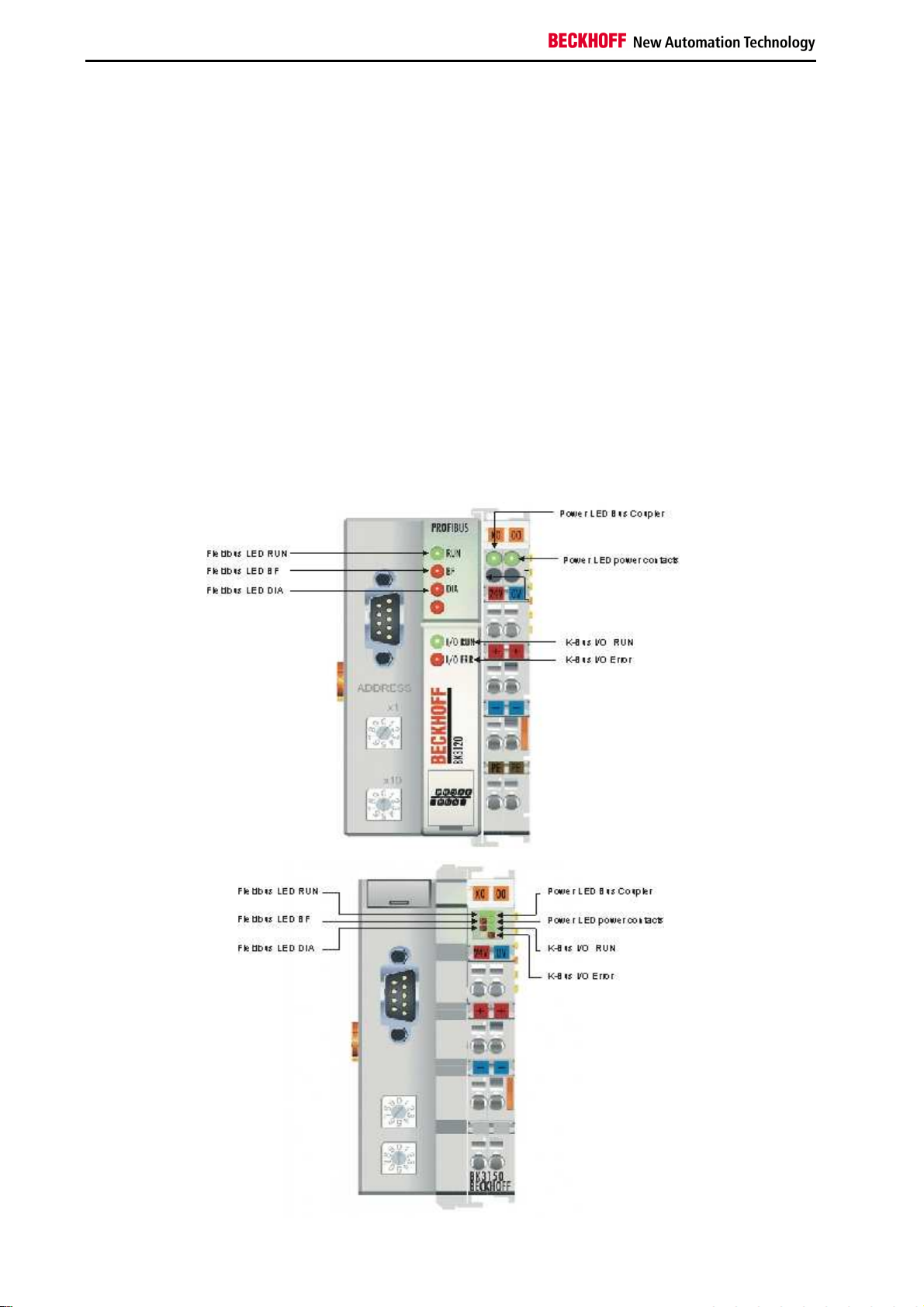

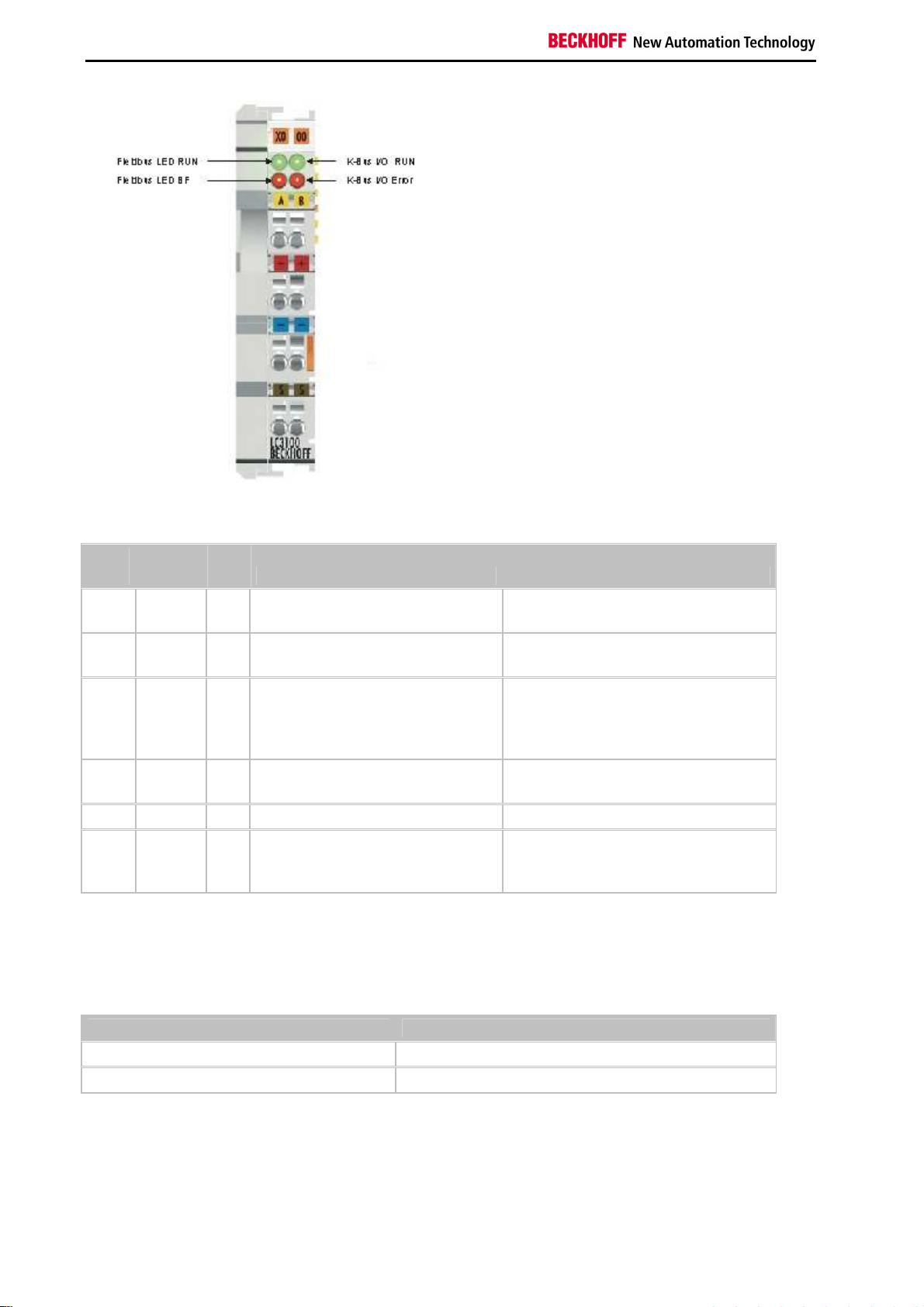

LEDs 60

Overview 60

DP Diagnostic 65

DP Diagnostic Data (DiagData) 65

Errors during DP Start-up 68

Reaction to PROFIBUS Error 70

K-Bus Diagnostic 71

K-Bus Interruption 71

Terminal Diagnostics 72

7. Extended Functions 73

2-byte PLC Interface 73

Word Alignment 74

Deactivating the CfgData Check 75

Multi-Configuration Mode 76

Changing the Size of the Process Data 80

Implementation Levels of the Bus Coupler in

Multi-Configuration Mode 82

8. Appendix 88

General Operating Conditions 88

Approvals 90

Bibliography 91

List of Abbreviations 92

Support and Service 93

2 Fieldbus Components

Page 5

Notes on the Documentation

1. Foreword

Notes on the Documentation

This description is only intended for the use of trained specialists in control and automation engineering who are

familiar with the applicable national standards. It is essential that the following notes and explanations are followed

when installing and commissioning these components.

Liability Conditions

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for

safety, including all the relevant laws, regulations, guidelines and standards.

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with performance data,

standards or other characteristics. None of the statements of this manual represents a guarantee (Garantie) in the

meaning of § 443 BGB of the German Civil Code or a statement about the contractually expected fitness for a

particular purpose in the meaning of § 434 par. 1 sentence 1 BGB. In the event that it contains technical or editorial

errors, we retain the right to make alterations at any time and without warning. No claims for the modification of

products that have already been supplied may be made on the basis of the data, diagrams and descriptions in this

documentation.

© This documentation is copyrighted. Any reproduction or third party use of this publication, whether in whole or in

part, without the written permission of Beckhoff Automation GmbH, is forbidden.

Fieldbus Components 3

Page 6

Notes on the Documentation

Safety Instructions

Safety Rules

The responsible staff must ensure that the application or use of the products described satisfy all the requirements for

safety, including all the relevant laws, regulations, guidelines and standards.

State at Delivery

All the components are supplied in particular hardware and software configurations appropriate for the application.

Modifications to hardware or software configurations other than those described in the documentation are not

permitted, and nullify the liability of Beckhoff Automation GmbH.

Personnel Qualification

This description is only intended for the use of trained specialists in control and automation engineering who are

familiar with the applicable national standards.

Description of safety symbols

The following safety symbols are used in this operating manual. They are intended to alert the reader to the

associated safety instructions.

This symbol is intended to highlight risks for the life or health of personnel.

Danger

This symbol is intended to highlight risks for equipment, materials or the environment.

Warning

This symbol indicates information that contributes to better understanding.

Note

4 Fieldbus Components

Page 7

Notes on the Documentation

Documentation Issue Status

Version Status

3.5.1 Notes about UL certification added

3.5 BK3150 with firmware version B0 added

3.03 Corrections in the context of the translation into the english language

3.02 GSD files updated for BK3110, BK3120, BK3520

3.01 Configuration examples for operation under Siemens S7 expanded.

3.0 For BK3010 with firmware version B9

For BK3110 with firmware version B9

For BK3120 with firmware version B9

For BK3500 with firmware version B9

For BK3520 with firmware version B9

For LC3100 with firmware version B9

Fieldbus Components 5

Page 8

Notes on the Documentation

2. Product Overview

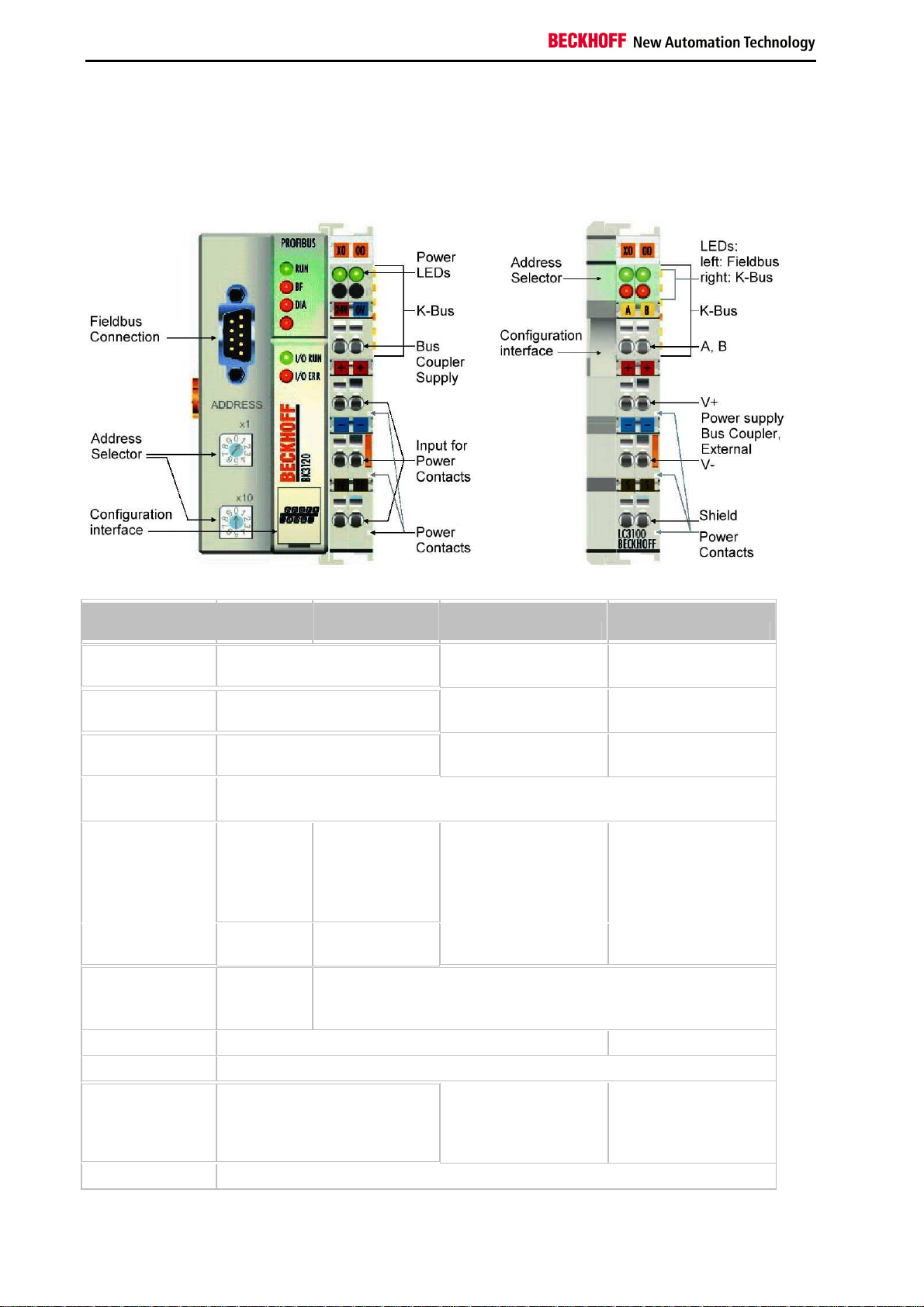

Technical Data

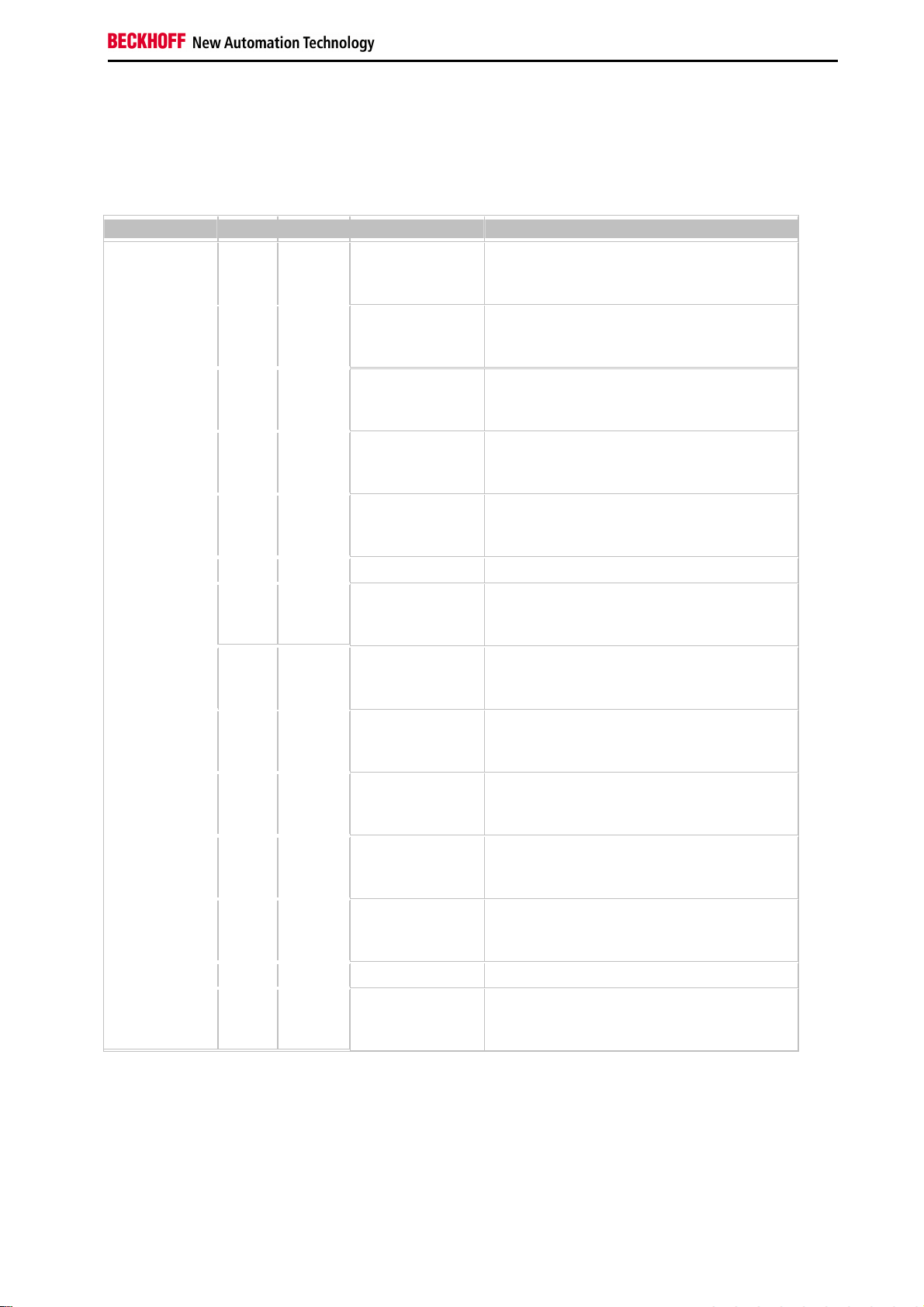

Technical data BK3000, BK3010, BK3100, BK3110, BK3120, LC3100

BK3000,

Type

Number of Bus

Terminals

Digital peripheral

signals

Analog peripheral

signals

Configuration

possibility

Maximum number

of bytes

(inputs and

outputs)

Baud rate

(automatic

detection)

Bus connection 1 x D-sub plug, 9-pin with shielding spring-loaded terminals

Power supply 24 VDC (-15 % /+20 %)

Input current 70 mA + (total K-Bus current)/4,

Starting current 2.5 x continuous current

BK3010

64 64 (255 with K-Bus

512 inputs/outputs max. 1020

128 inputs/outputs (BK3x00) max. 64 inputs/outputs -

Via the KS2000 configuration software or the controller

BK3000: 244

bytes

BK3010: 32

bytes

up to max.

1.5 MBaud

max. 500 mA (BK3x00)

70 mA + (total K-Bus current)/4,

max. 200 mA (BK3x10)

BK3100,

BK3110 BK3120 LC3100

64

extension)

256 inputs/outputs

inputs/outputs

BK3100:

64 bytes (DP and

FMS operation)

128 bytes (DP

operation only)

BK3110: 32 bytes

up to max. 12 MBaud

128 bytes 32 bytes

70 mA + (total K-Bus

current)/4, max. 500 mA

70 mA + (total K-Bus

current)/4, max. 200 mA

6 Fieldbus Components

Page 9

Notes on the Documentation

Type

BK3000,

BK3010

BK3100,

BK3110 BK3120 LC3100

K-Bus current up to 1750 mA (BK3x00)

1750 mA 500 mA

500 mA (BK3x10)

Power contact voltage

maximum 24 VDC

(Up)

Power contact current

maximum 10 A

load (Up)

Recommended fuse

maximum 10 A

(Up)

Electrical isolation power contact / supply / fieldbus power supply / fieldbus

Dielectric strength 500 V

(power contact / supply / fieldbus) 500 V

rms

(supply /

rms

fieldbus)

Weight approx. 170 g approx. 150 g approx. 170 g approx. 100 g

Permissible ambient

0 °C … +55 °C

temperature

(operation)

Permissible ambient

-25 °C … +85 °C

temperature (storage)

Permissible relative

95 % (no condensation)

humidity

Vibration / shock

according to EN 60068-2-6 / EN 60068-2-27, EN 60068-2-29

resistance

EMC resistance Burst /

according to EN 61000-6-2 (EN 50082) / EN 61000-6-4 (EN 50081)

ESD

Protection class IP 20

Installation position variable

BK3150

Fieldbus Components 7

Page 10

Notes on the Documentation

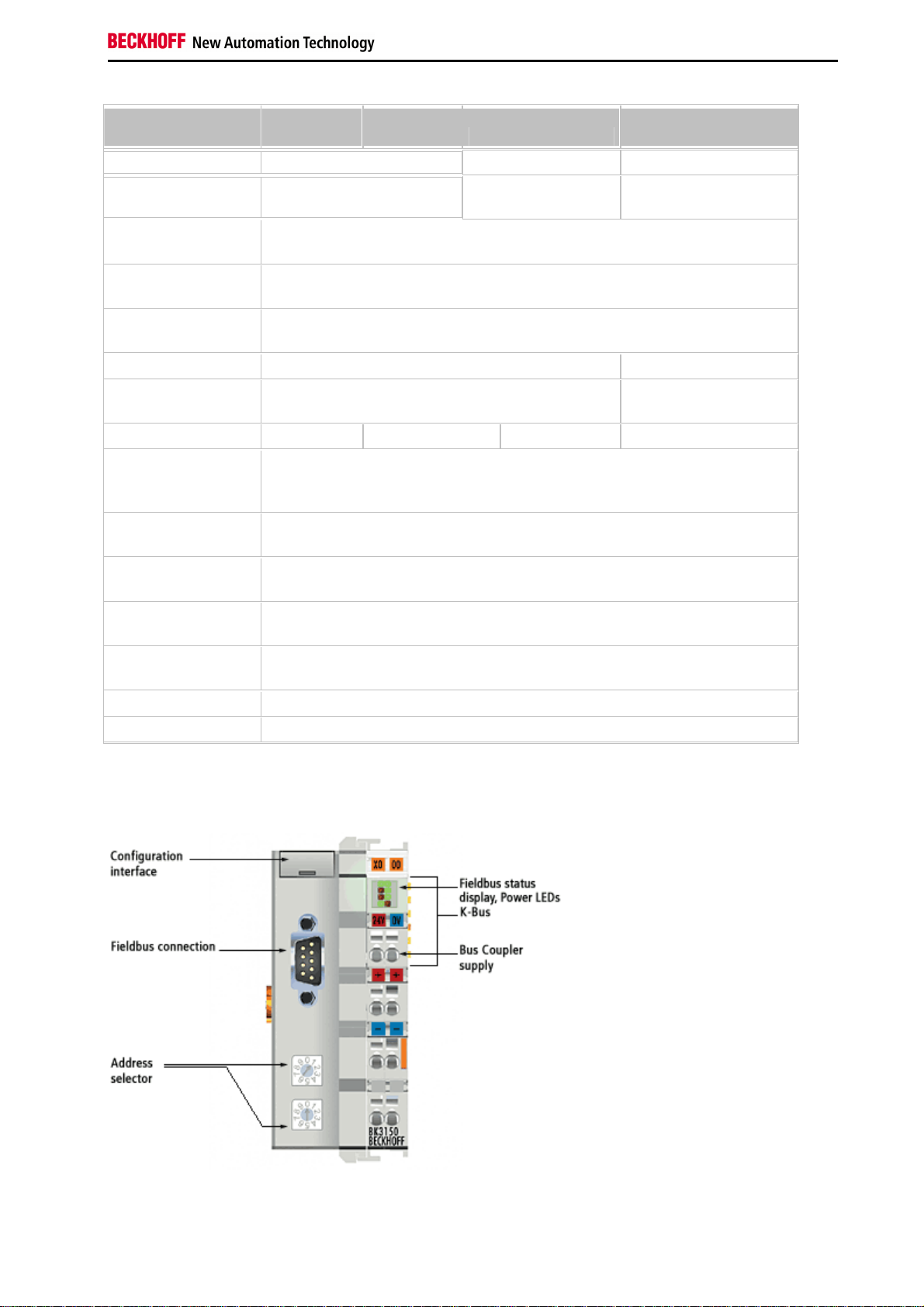

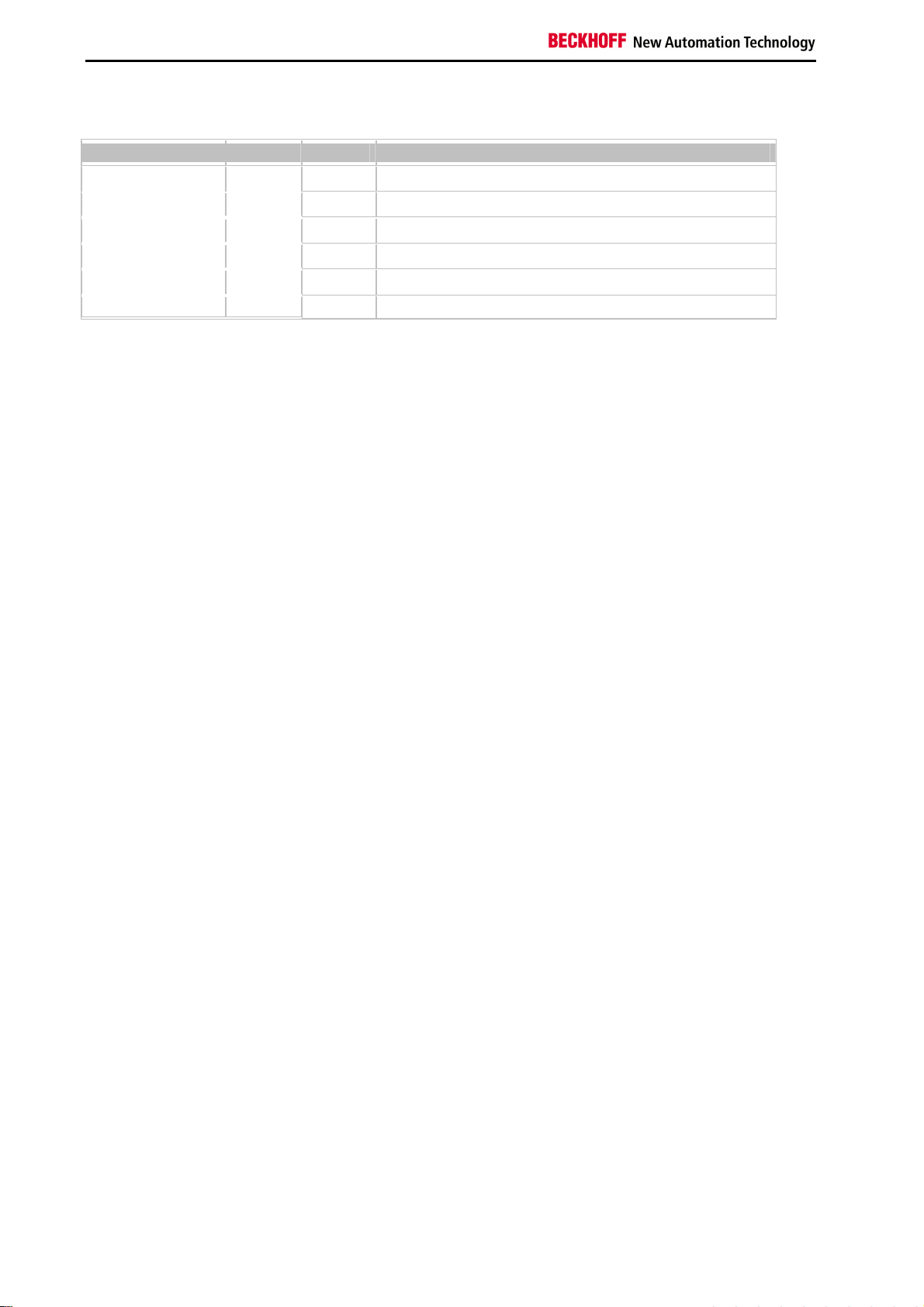

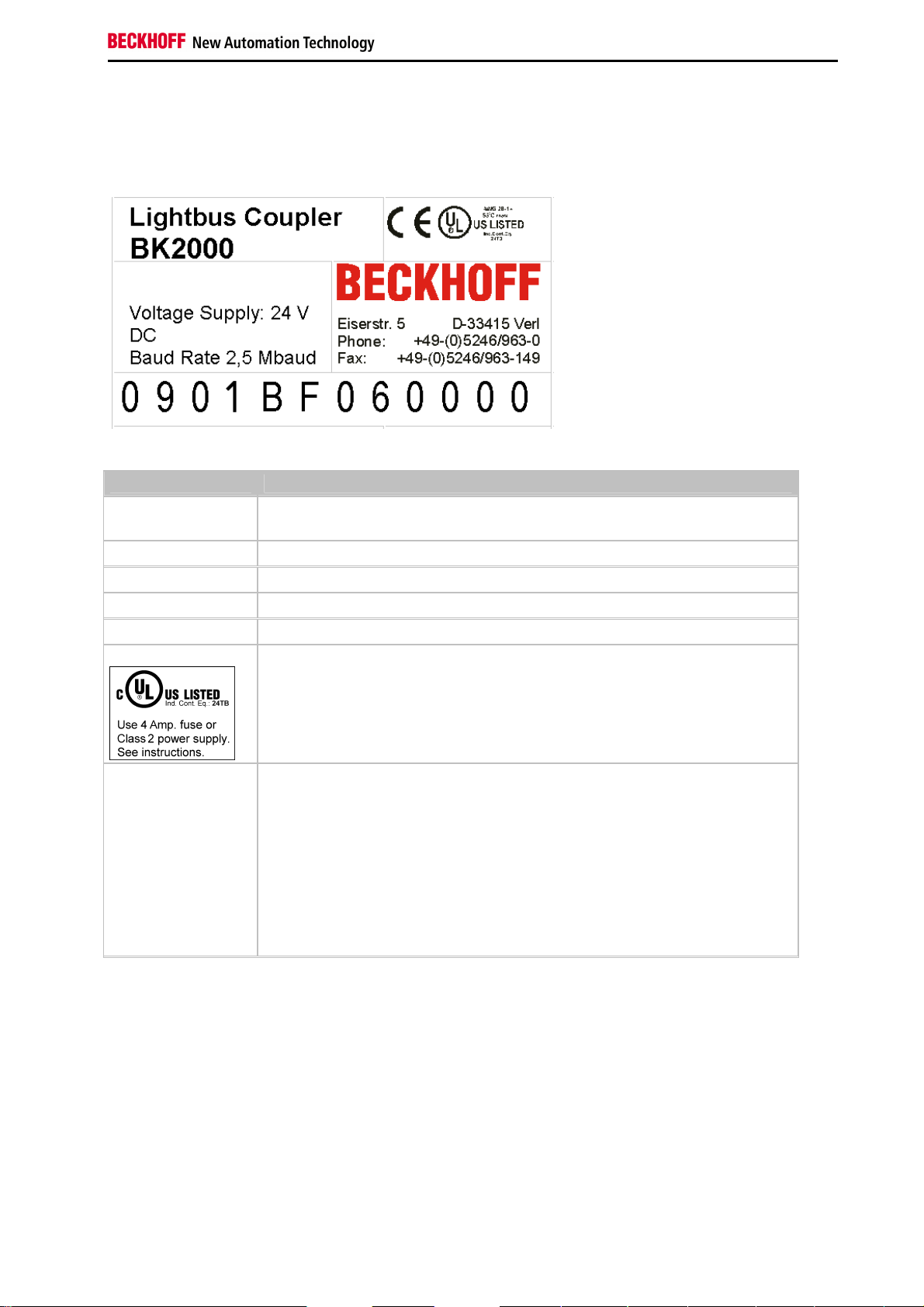

Technical data BK3150

Type BK3150

Number of Bus Terminals 64 (255 with K-Bus extension)

Digital peripheral signals max. 1020 inputs/outputs

Analog peripheral signals max. 64 inputs/outputs

Configuration possibility Via the KS2000 configuration software or the controller

Maximum number of bytes

128 Byte (DP operation only)

(inputs and outputs)

Baud rate (automatic detection) up to max. 12 MBaud

Bus connection 1 x D-sub plug, 9-pin with shielding

Power supply (Us)

24 VDC (-15 % /+20 %) To meet the UL requirements use a 4 A fuse or

a power supply that has to satisfy NEC class 2!

Input current (Us) 70 mA + (total K bus current)/4, max. 320 mA

Starting current (Us) 2,5 x continuous current

Recommended fuse maximum 10 A

K-Bus power supply up to 1000 mA

Power contact voltage maximum 24 VDC

Power contact current load maximum 10 A

Electrical isolation power contact / supply / fieldbus

Dielectric strength 500 V

(power contact / supply / fieldbus)

rms

Weight app. 100 g

Permissible ambient temperature

0 °C … +55 °C

(operation)

Permissible ambient temperature

-25 °C … +85 °C

(storage)

Permissible relative humidity 95 % (no condensation)

Vibration / shock resistance according to EN 60068-2-6 / EN 60068-2-27, EN 60068-2-29

EMC resistance Burst / ESD according to EN 61000-6-2 / EN 61000-6-4

Protection class IP 20

Installation position variable

8 Fieldbus Components

Page 11

Notes on the Documentation

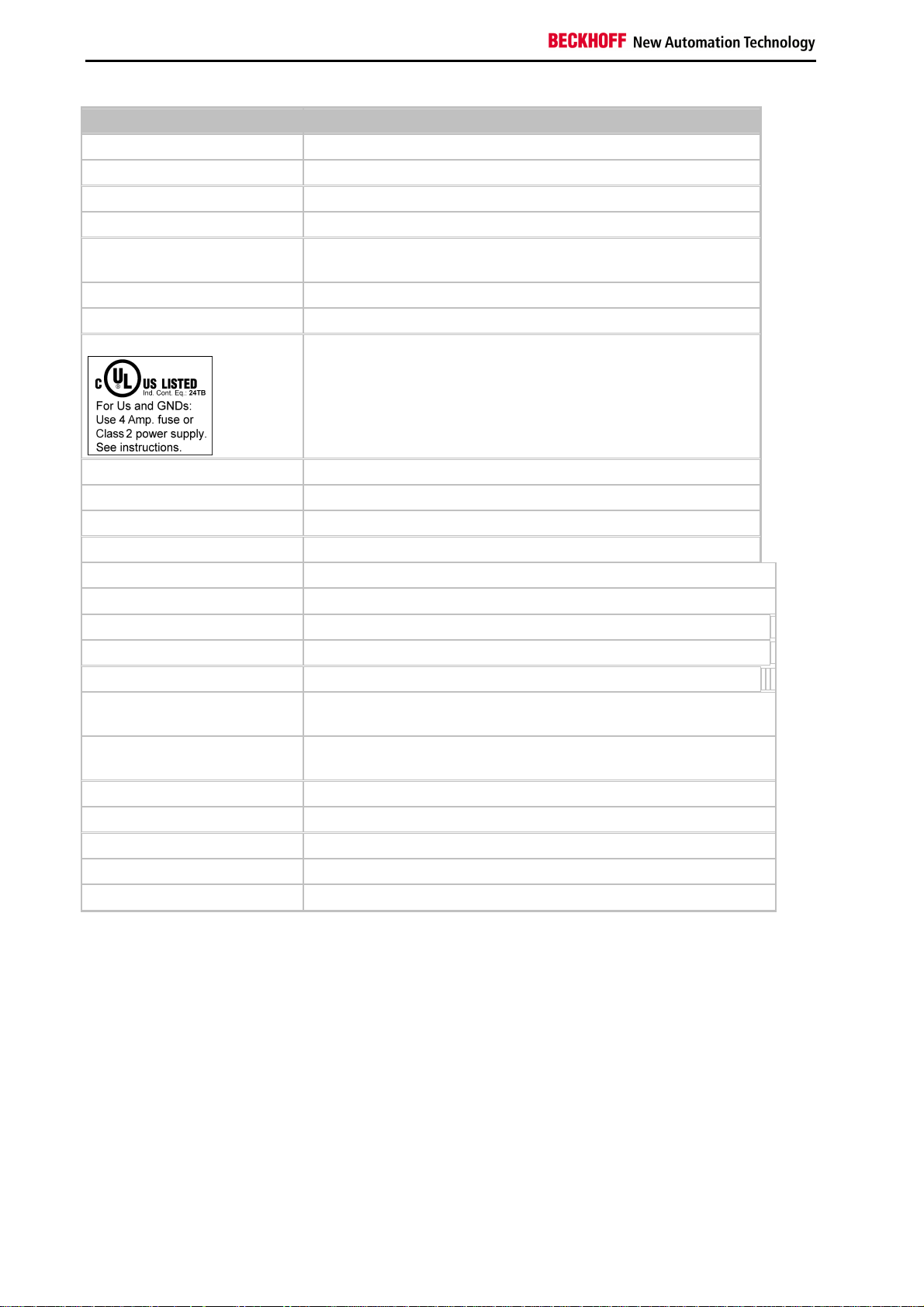

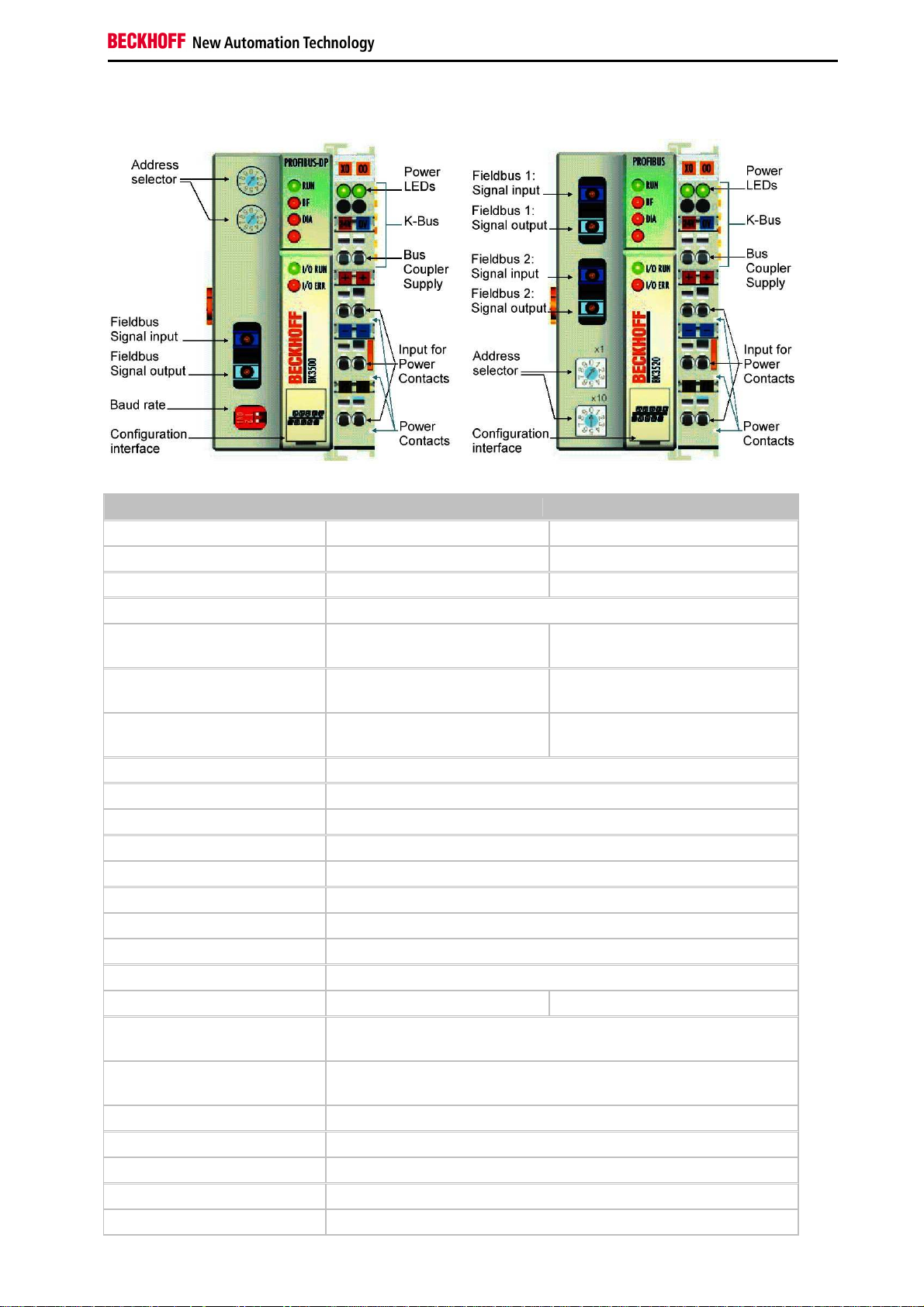

Technical Data (Optical Fibres)

Technical data

Type BK3500 BK3520

Number of Bus Terminals 64 64 (255 with K-Bus extension)

Digital peripheral signals max. 512 inputs/outputs max. 1020 inputs/outputs

Analog peripheral signals max. 64 inputs/outputs max. 64 inputs/outputs

Configuration possibility Via the KS2000 configuration software or the controller

Maximum number of bytes

(inputs and outputs)

Baud rates up to max. 1.5 Mbaud (manual

Bus connection 1 x optical fibre with 2 HP

Power supply 24 VDC (-15 %/+20 %)

Input current 70 mA + (total K-Bus current)/4, 500 mA, 500 mA max.

Starting current 2.5 x continuous current

Recommended fuse maximum 10 A

K-Bus power supply up to 1750 mA

Power contact voltage maximum 24 VDC

Power contact current load maximum 10 A

Electrical isolation power contact / supply / fieldbus

Dielectric strength 500 V

Weight approx. 170 g approx. 170 g

Permissible ambient temperature

(operation)

Permissible ambient temperature

(storage)

Permissible relative humidity 95 % (no condensation)

Vibration / shock resistance according to EN 60068-2-6 / EN 60068-2-27, EN 60068-2-29

EMC resistance Burst / ESD according to EN 61000-6-2 (EN 50082) / EN 61000-6-4 (EN 50081)

Protection class IP 20

Installation position variable

128 bytes 128 bytes

up to max. 12 Mbaud (automatic

setting)

Simplex connectors

(power contact / supply / fieldbus)

rms

0 °C … +55 °C

-25 °C … +85 °C

detection)

2 x optical fibres with 2 HP Simplex

connectors each

Fieldbus Components 9

Page 12

Notes on the Documentation

The Beckhoff Bus Terminal System

Up to 64 Bus Terminals each having 2 I/O channels for each signal form

The Bus Terminal system is the universal interface between a fieldbus system and the sensor / actuator level. A unit

consists of a Bus Coupler as the head station, and up to 64 electronic series terminals, the last one being an end

terminal. For each technical signal form, terminals are available each having two I/O channels, and these can be

mixed in any order. All the terminal types have the same mechanical construction, so that difficulties of planning and

design are minimized. The height and depth match the dimensions of compact terminal boxes.

Decentralized wiring of each I/O level

Fieldbus technology allows more compact forms of controller to be used. The I/O level does not have to be brought to

the controller. The sensors and actuators can be wired decentrally, using minimum cable lengths. The controller can

be installed at any location within the plant.

Industrial PCs as controllers

The use of an Industrial PC as the controller means that the operating and observing element can be implemented in

the controller’s hardware. The controller can therefore be located at an operating panel, in a control room, or at some

similar place. The Bus Terminals form the decentralized input/output level of the controller in the control cabinet and

the subsidiary terminal boxes. The power sector of the plant is also controlled over the bus system in addition to the

sensor/actuator level. The Bus Terminal replaces the conventional series terminal as the wiring level in the control

cabinet. The control cabinet can have smaller dimensions.

Bus Couplers for all usual bus systems

The Beckhoff Bus Terminal system unites the advantages of a bus system with the possibilities of the compact series

terminal. Bus Terminals can be driven within all the usual bus systems, thus reducing the controller parts count. The

Bus Terminals then behave like conventional connections for that bus system. All the performance features of the

particular bus system are supported.

Assembly on standardized C mounting rails

The easy, space-saving, assembly on a standardized C-rail, and the direct wiring of actuators and sensors, without

cross-connections between the terminals, standardizes the installation. The consistent labelling scheme also

contributes.

The small physical size and the great flexibility of the Bus Terminal system allows it to be used wherever a series

terminal is also used. Every type of connection, such as analog, digital, serial or the direct connection of sensors can

be implemented.

Modularity

The modular assembly of the terminal strip with Bus Terminals of various functions limits the number of unused

channels to a maximum of one per function. The presence of two channels in one terminal is the optimum

compromise of unused channels and the cost of each channel. The possibility of electrical isolation through potential

feed terminals also helps to keep the number of unused channels low.

Display of the channel state

The integrated LEDs show the state of the channel at a location close to the sensors and actuators.

10 Fieldbus Components

Page 13

Notes on the Documentation

K-Bus

The K-Bus is the data path within a terminal strip. The K-Bus is led through from the Bus Coupler through all the

terminals via six contacts on the terminals’ side walls. The end terminal terminates the K-Bus. The user does not

have to learn anything about the function of the K-Bus or about the internal workings of the terminals and the Bus

Coupler. Many software tools that can be supplied make project planning, configuration and operation easy.

Potential feed terminals for isolated groups

The operating voltage is passed on to following terminals via three power contacts. You can divide the terminal strip

into arbitrary isolated groups by means of potential feed terminals. The potential feed terminals play no part in the

control of the terminals, and can be inserted at any locations within the terminal strip.

Up to 64 terminals can be used within one terminal strip. This count does include potential feed terminals, but not the

end terminal.

Bus Couplers for various fieldbus systems

Various Bus Couplers can be used to couple the electronic terminal strip quickly and easily to different fieldbus

systems. It is also possible to convert to another fieldbus system at a later time. The bus coupler performs all the

monitoring and control tasks that are necessary for operation of the connected Bus Terminals. The operation and

configuration of the Bus Terminals is carried out exclusively by the Bus Coupler. Nevertheless, the parameters that

have been set are stored in each Bus Terminal, and are retained in the event of voltage drop-out. Fieldbus, K-Bus

and I/O level are electrically isolated.

If the exchange of data over the fieldbus is prone to errors or fails for a period of time, register contents (such as

counter states) are retained, digital outputs are cleared, and analog outputs take a value that can be configured for

each output when commissioning. The default setting for analog outputs is 0 V or 0 mA. Digital outputs return in the

inactive state. The timeout periods for the Bus Couplers correspond to the usual settings for the fieldbus system.

When converting to a different bus system it is necessary to bear in mind the need to change the timeout periods if

the bus cycle time is longer.

The interfaces

A Bus Coupler has six different methods of connection. These interfaces are designed as plug connectors and as

spring-loaded terminals.

Fieldbus Components 11

Page 14

Notes on the Documentation

PROFIBUS - Introduction

PROFIBUS DP

In PROFIBUS DP systems, a master (PLC, PC etc.) usually communicates with a large number of slaves (I/Os,

drives etc.). Only the master may here actively access the bus (send telegrams on its own initiative), while a DP slave

only sends telegrams when it is requested to do so by a master.

DP StartUp

Before the master and slave can cyclically exchange data, the parameter and configuration data is transmitted from

the master to the slaves during the DP StartUp phase. After the parameter and configuration data has been sent, the

master interrogates the slave's diagnostic data until the slave indicates that it is ready for data exchange. Depending

on the extent of the calculations that the slave must carry out after receiving the parameter and configuration data, it

can take up to a few seconds before it is ready for data exchange. For this reason the slave possesses the following

states:

Parameter data

The parameter data is sent from the master to the slave in the SetPrmLock request telegram. The SetPrmLock

response telegram does not contain any data, and therefore consists of a single byte, the short acknowledgement.

The parameter data consists of DP parameters (e.g. the setting of the DP watchdog or checking the IdentNumber

(unique to each DP device)), of DPV1-/DPV2 parameters and of application-specific parameters that only have to be

transmitted once during the StartUp. If an error is found in the parameter data, this is indicated in the diagnostic data,

and the slave either remains in or enters the WAIT-PRM state.

Configuration data

The configuration data is sent from the master to the slave in the ChkCfg request telegram. The ChkCfg response

telegram does not contain any data, and therefore consists of a single byte, the short acknowledgement. The

configuration data describes the assignment of the DP modules to the cyclic I/O data that is to be exchanged

between the master and slave via the Data_Exchange telegram in the cyclic data exchange phase. The sequence of

the DP modules added to a slave in the DP configuration tool determines the sequence of the associated I/O data in

the Data_Exchange telegram.

Diagnostic data

The diagnostic data is requested by the master using a SlaveDiag request telegram without any data. The slave

replies with the diagnostic data in a SlaveDiag response telegram. The diagnostic data consists of the standard DP

diagnostics (e.g. the state of the slave, the IdentNumber) and of application-specific diagnostic data.

Cyclic data exchange

The heart of the PROFIBUS DP protocol is cyclic data exchange, during which the master carries out an exchange of

I/O data with every slave during a PROFIBUS DP cycle. This involves the master sending the outputs to each slave

with a DataExchange request telegram, while the slave replies with the inputs in a DataExchange response telegram.

This means that all the output and/or input data is transmitted in one telegram, in which the DP configuration (the

sequence of DP modules) specifies the assignment of the output and/or input data to the slave's actual process data.

Diagnosis during cyclic data exchange

A slave can send a diagnostics signal to the master during cyclic data exchange. In this case, the slave sets a flag in

the DataExchange response telegram, whereby the master recognises that there is new diagnostic data in the slave.

It then fetches that data in the SlaveDiag telegram. This means that diagnostic data is not transmitted to the controller

with the cyclic I/O data in real-time, but is always at least one DP cycle later.

12 Fieldbus Components

Page 15

Notes on the Documentation

Synchronisation with Sync and Freeze

The Sync and Freeze commands in the GlobalControl request telegram (broadcast telegram) allow the master to

synchronise the activation of the outputs (Sync) or the reading of the inputs (Freeze) in a number of slaves. When the

Sync command is used, the slaves are first switched into Sync mode (a process that is acknowledged in the

diagnostic data). The I/O data is then exchanged sequentially with the slaves in the DataExchange telegram.

Transmitting the Sync command in the GlobalControl telegram then has the effect of causing the slaves to generate

the most recently received outputs. In Freeze operation a Freeze command is first sent in the GlobalControl

telegram, in response to which all the slaves latch their inputs. These are then fetched sequentially by the master in

the DataExchange telegram.

States in the master

The master distinguishes between the CLEAR state (all outputs are set to the Fail_Safe value) and the OPERATE

state (all outputs have the process value). The Master is usually switched into the CLEAR mode when, for instance,

the PLC enters STOP.

Class 1 and Class 2 DP Masters

The Class 1 master refers to the controller that carries out cyclic I/O data exchange with the slaves, while a Class 2

master is a B&B device that generally only has read access to the slaves' I/O data.

Fieldbus Components 13

Page 16

Notes on the Documentation

PROFIBUS DPV1

PROFIBUS DPV1 refers primarily to the acyclic read and write telegrams, with which data sets in the slave are

acyclically accessed. A distinction between a Class 1 and a Class 2 master is also made for DPV1. The difference

between acyclic Class 1 (C1) and Class 2 (C2) connections is that the acyclic C1 connection is established during the

DP StartUp phase of cyclic DP operation. Once the slave has reached the WAIT-CFG state it is possible for acyclic

DPV1-C1 read and write telegrams to be sent from the master to the slave, whereas the C2 connection is established

separately, independently of the cyclic DP connection. This is usually carried out by a second (C2) master so that, for

instance, a manufacturer-specific project configuration and diagnostic tool can access the slave's data.

When two masters are used, however, is must always be borne in mind that these share bus access (a token is

exchanged), so that time relationships are less favourable than in the case of a single master system.

14 Fieldbus Components

Page 17

Notes on the Documentation

3. Mounting and Wiring

Mechanical Installation

Dimensions

The system of the Beckhoff Bus Terminals is characterized by low physical volume and high modularity. When

planning a project it must be assumed that at least one Bus Coupler and a number of Bus Terminals will be used.

The mechanical dimensions of the Bus Couplers are independent of the fieldbus system.

The total width in practical cases is composed of the width of the Bus Coupler with the KL9010 Bus End Terminal and

the width of the Bus Terminals in use. Depending on function, the Bus Terminals are 12 or 24 mm wide. The front

wiring increases the total height of 68mm by about 5 to 10 mm, depending on the wire thickness.

BK30x0, BK35x0, KL3110,

Mechanical data

Material polycarbonate, polyamide (PA 6.6)

Dimensions (W x H x D) 50 mm x 100 mm x 68 mm 44 mm x 100 mm x

Mounting on 35 mm C-rail conforming to EN50022 with lock

Side by side mount. by

means of

Marking standard terminal block marking and plain language side (8 mm x 47 mm, not

BK3120 BK3150 LC3100

21 mm x 100 mm x

68 mm

double slot and key connection

BK3150)

68 mm

Fieldbus Components 15

Page 18

Notes on the Documentation

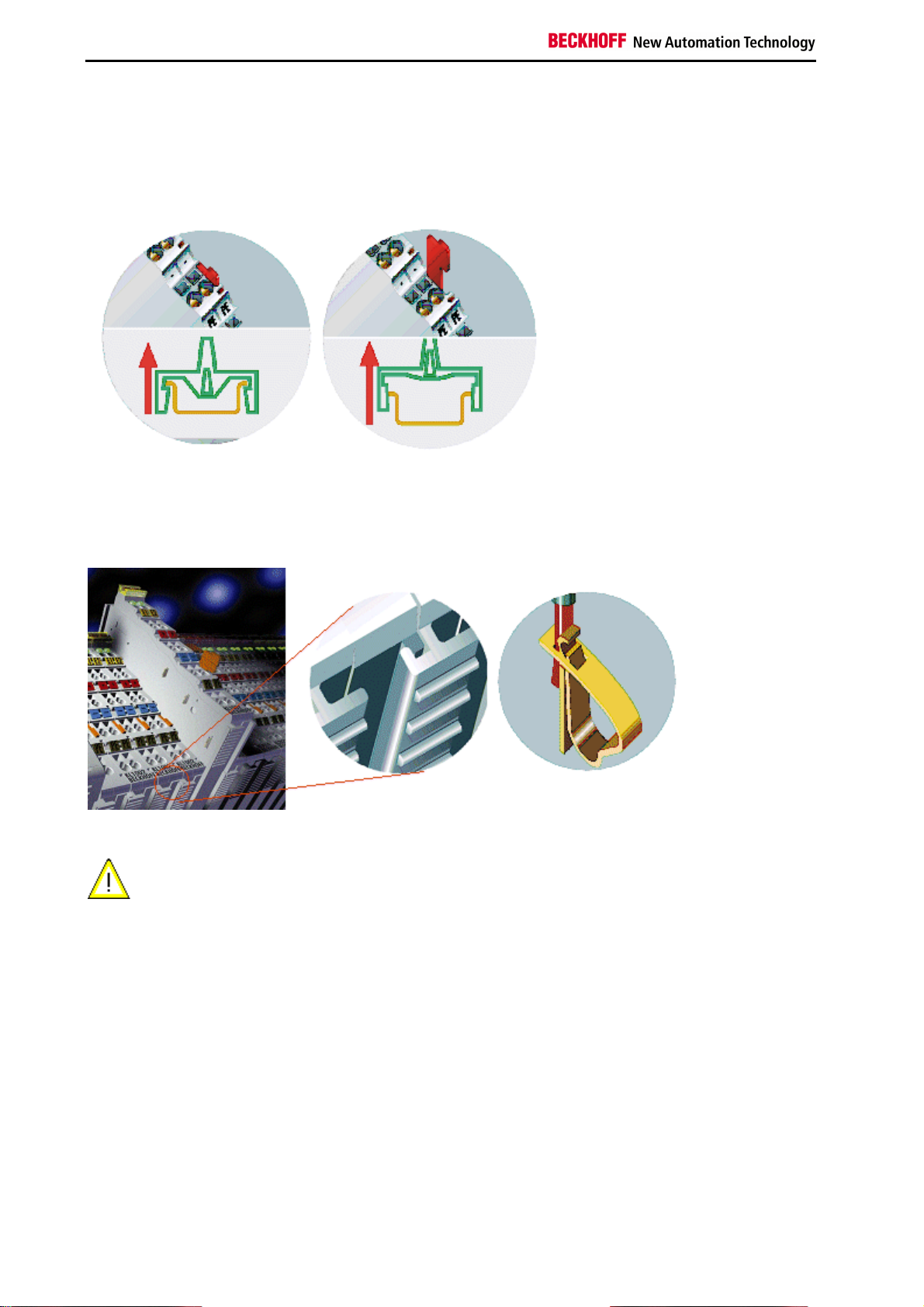

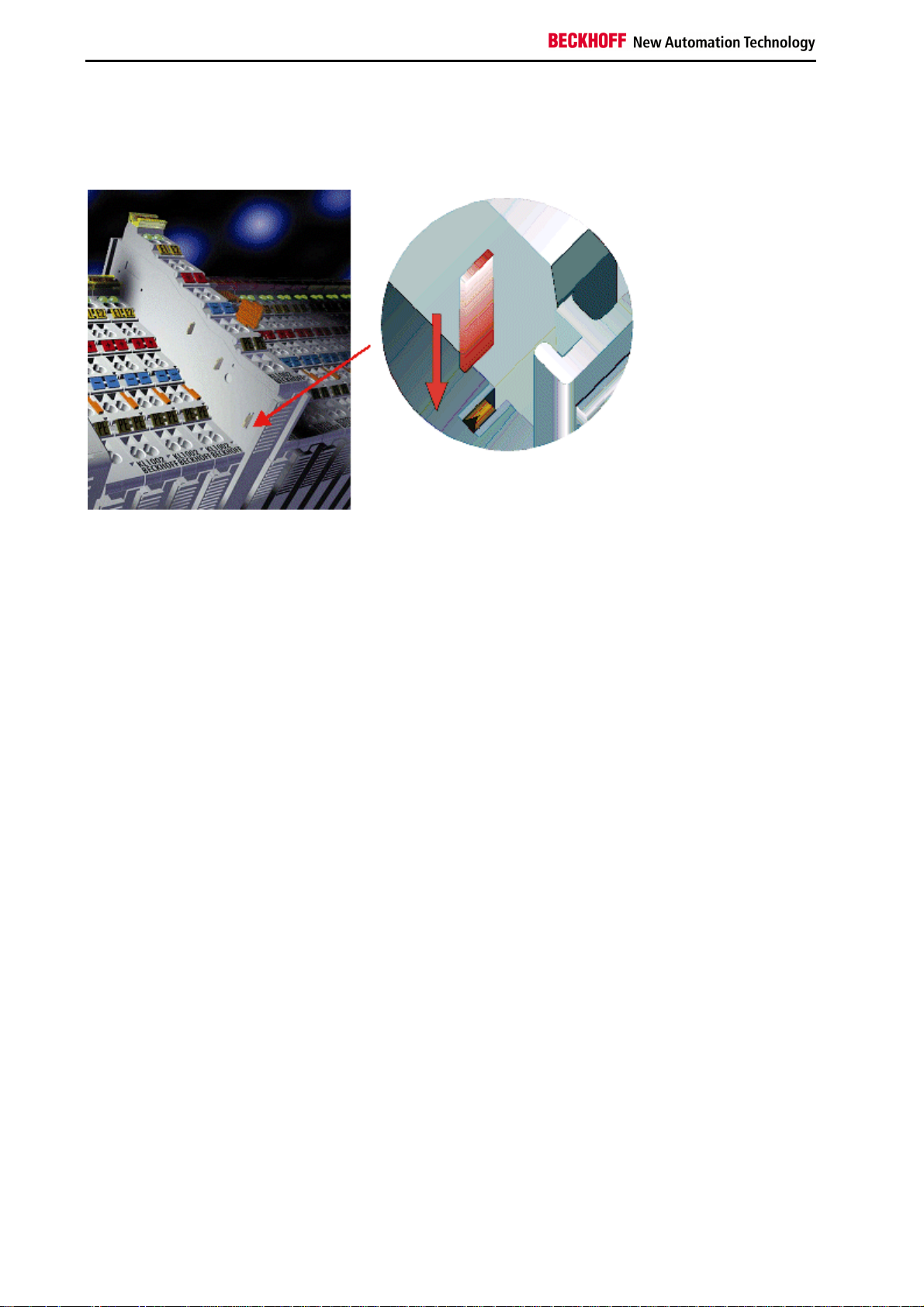

Installation

The Bus Coupler and all the Bus Terminals can be clipped, with a light press, onto a 35 mm mounting rail. A locking

mechanism prevents the individual housings from being pulled off again. For removal from the mounting rail the

orange colored tension strap releases the latching mechanism, allowing the housing to be pulled off the rail without

any force.

Up to 64 Bus Terminals can be attached to the Bus Coupler on the right hand side. When plugging the components

together, be sure to assemble the housings with groove and tongue against each other. A properly working

connection can not be made by pushing the housings together on the mounting rail. When correctly assembled, no

significant gap can be seen between the attached housings.

Insertion and removal of Bus Terminals is only permitted when switched off. The electronics

Warning

in the Bus Terminals and in the Bus Coupler are protected to a large measure against

damage, but incorrect function and damage cannot be ruled out if they are plugged in under

power.

The right hand part of the Bus Coupler can be compared to a Bus Terminal. Eight connections at the top enable the

connection with solid or fine wires from 0.08 mm² to 2.5 mm². The connection is implemented with the aid of a spring

device. The spring-loaded terminal is opened with a screwdriver or rod, by exerting gentle pressure in the opening

above the terminal. The wire can be inserted into the terminal without any force. The terminal closes automatically

when the pressure is released, holding the wire securely and permanently.

16 Fieldbus Components

Page 19

Notes on the Documentation

Wiring

Potential Groups, Insulation Testing and PE

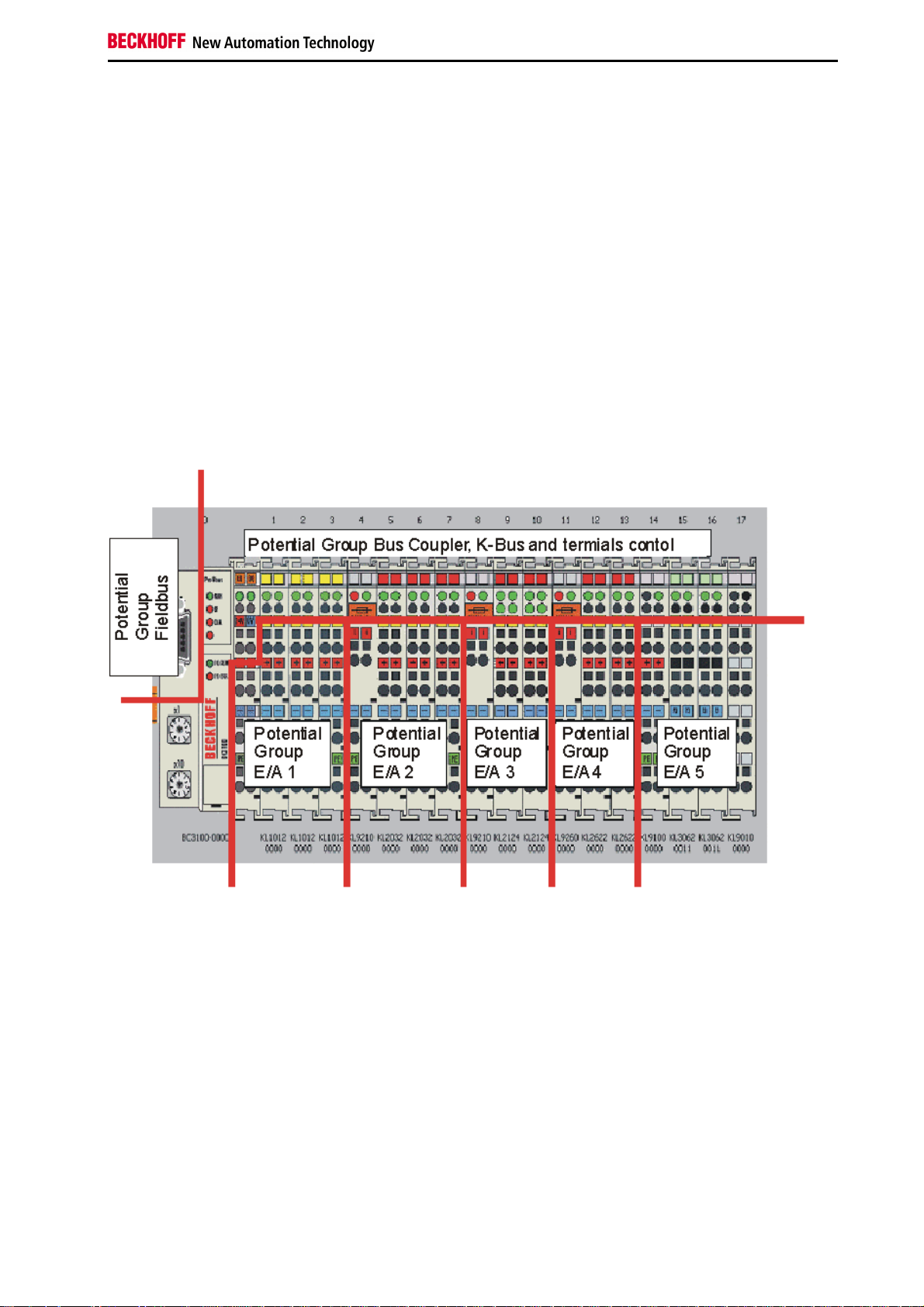

Potential groups

The Beckhoff Bus Terminals stations usually have three different potential groups:

•

The fieldbus interface is electrically isolated (except for individual Low Cost couplers) and forms the first potential group

•

Bus Coupler / Bus Terminal Controller logic, K-Bus and terminal logic form a second galvanically separated

potential group

•

The inputs and outputs are supplied via the power contacts and form further potential groups.

Groups of I/O terminals can be consolidated to further potential groups via potential supply terminals or separation

terminals.

Insulation testing

The connection between the Bus Coupler / Bus Terminal Controller and the Bus Terminals is automatically realized

by pushing the components together. The transfer of the data and the supply voltage for the intelligent electronics in

the Bus Terminals is performed by the K-Bus. The supply of the field electronics is performed through the power

contacts. Plugging together the power contacts creates a supply rail. Since some Bus Terminals (e.g. analog Bus

Terminals or 4-channel digital Bus Terminals) are not looped through these power contacts (or not completely) the

Bus Terminal contact assignments must be considered.

The potential feed terminals interrupt the power contacts, and represent the start of a new supply rail. The Bus

Coupler / Bus Terminal Controller can also be made use of to feed the power contacts.

Fieldbus Components 17

Page 20

Notes on the Documentation

PE power contacts

The power contact labelled PE can be used as a protective earth. For safety reasons this contact mates first when

plugging together, and can ground short-circuit currents of up to 125 A.

It should be noted that, for reasons of electromagnetic compatibility, the PE contacts are capacitively coupled to the

mounting rail. This can both lead to misleading results and to damaging the terminal during insulation testing (e.g.

breakdown of the insulation from a 230 V power consuming device to the PE conductor). The PE conductor to the

Bus Coupler / Bus Terminal Controller must be disconnected for the insulation testing. In order to uncouple further

feed locations for the purposes of testing, the feed terminals can be pulled at least 10 mm out from the connected

group of other terminals. In that case, the PE conductors do not have to be disconnected.

The PE power contact must not be used for other potentials.

18 Fieldbus Components

Page 21

Notes on the Documentation

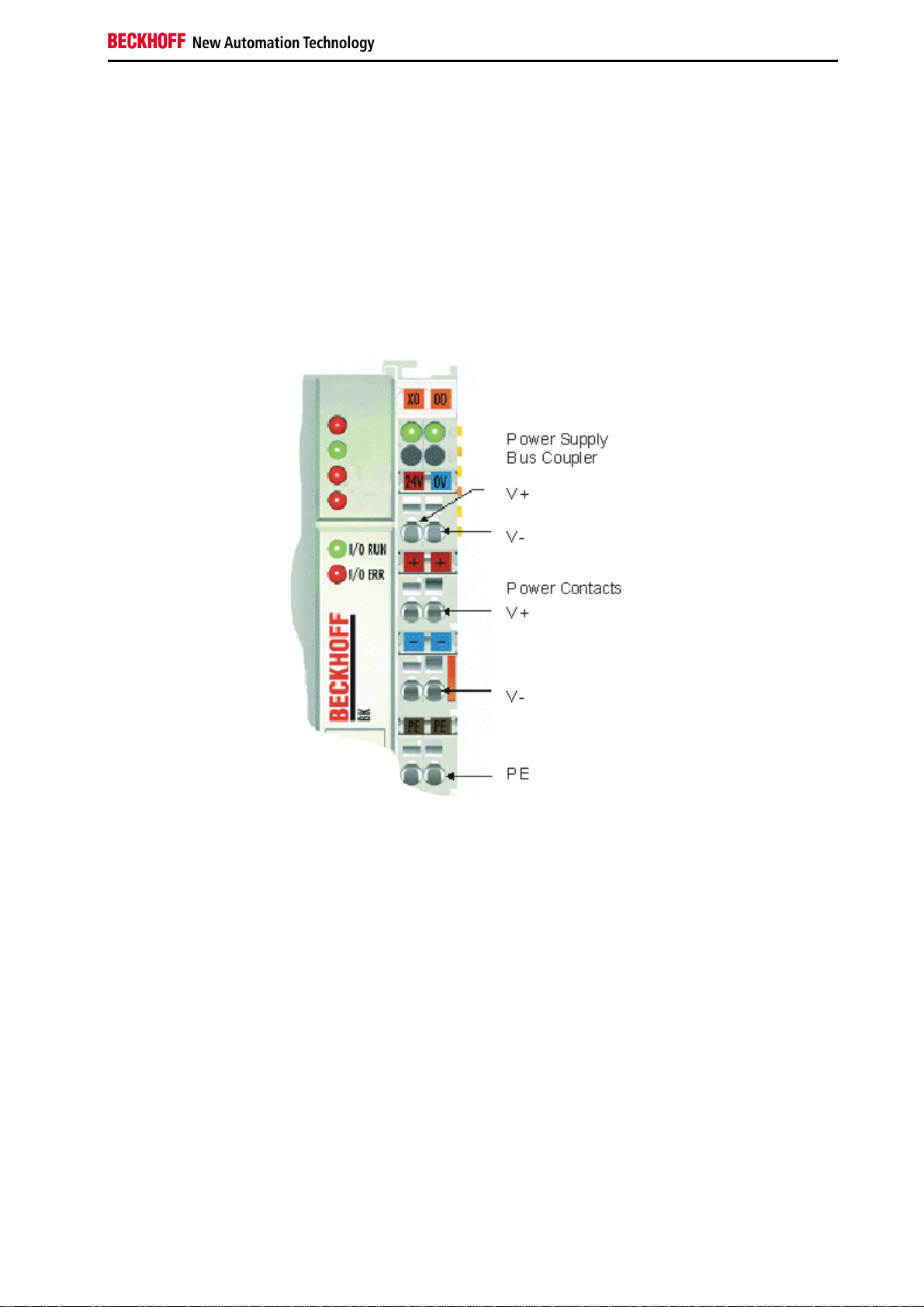

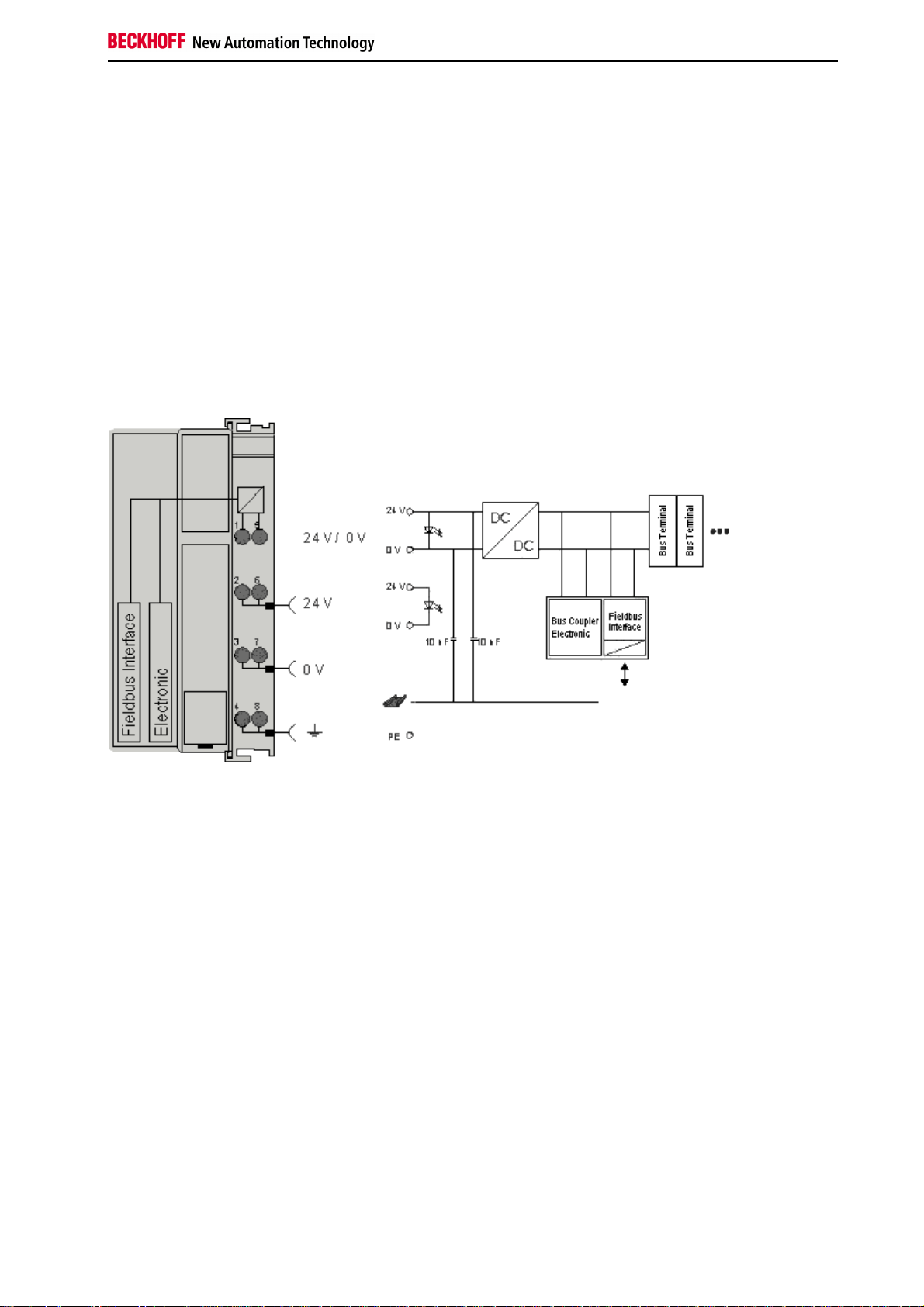

Power Supply

Bus Coupler / Bus Terminal Controller and Bus Terminal

Supply (Us)

BKxx00, BKxx10, BKxx20 and LCxxxx

The Bus Coupler / Bus Terminal Controller require a 24 VDC supply for their operation.

The connection is made by means of the upper spring-loaded terminals labeled 24 V and 0 V. This supply voltage

feeds the Bus Coupler / Bus Terminal Controller electronics and, over the K-Bus, the electronics of the Bus

Terminals. It is electrically separated from the potential of the field level.

Fieldbus Components 19

Page 22

Notes on the Documentation

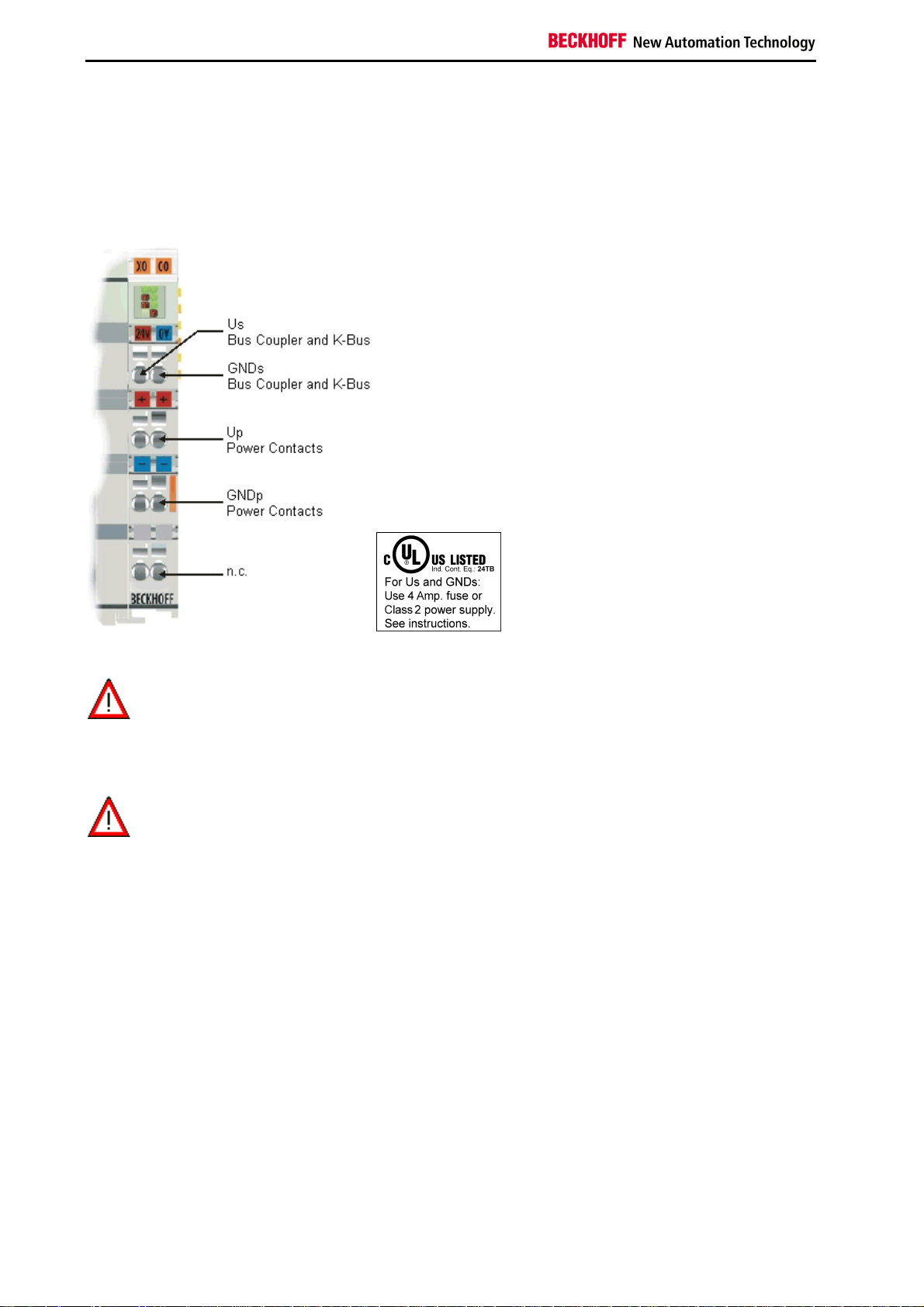

BKxx50 and BKxx51

The Bus Coupler / Bus Terminal Controller require a 24 VDC supply for their operation. To meet the UL requirements

use 4 A fuse or class 2 power supply!

The connection is made by means of the upper spring-loaded terminals labeled Us and GNDs. This supply voltage

feeds the Bus Coupler / Bus Terminal Controller electronics and, over the K-Bus, the electronics of the Bus

Terminals. It is electrically separated from the potential of the field level.

UL requirements

For the compliance of the UL requirements Us should only be supplied

•

Danger

To meet the UL requirements, Us must not be connected to unlimited power sources!

Danger

by a 24 VDC supply voltage, supplied by an isolating source and protected by

means of a fuse (in accordance with UL248), rated maximum 4 Amp.

•

by a 24 VDC power source, that has to satisfy NEC class 2.

A NEC class 2 power supply shall not be connected in series or parallel with another (class 2) power source!

Power contacts supply (Up)

The bottom six connections with spring-loaded terminals can be used to feed the supply for the peripherals. The

spring-loaded terminals are joined in pairs to a power contact. The feed for the power contacts has no connection to

the voltage supply for the Bus Coupler / Bus Terminal Controller.

The spring-loaded terminals are designed for wires with cross-sections between 0.08 mm² and 2.5 mm².

The assignment in pairs and the electrical connection between feed terminal contacts allows the connection wires to

be looped through to various terminal points. The current drawn from the power contact must not exceed 10 A for

long periods. The current carrying capacity between two spring-loaded terminals is identical to that of the connecting

wires.

Power contacts

On the right hand face of the Bus Coupler / Bus Terminal Controller there are three spring contacts for the power

contact connections. The spring contacts are hidden in slots so that they can not be accidentally touched. By

attaching a Bus Terminal the blade contacts on the left hand side of the Bus Terminal are connected to the spring

contacts. The tongue and groove guides on the top and bottom of the Bus Coupler / Bus Terminal Controller and of

the Bus Terminals enables that the power contacts mate securely.

20 Fieldbus Components

Page 23

Notes on the Documentation

Configuration and Programming Interface

The Bus Coupler / Bus Terminal Controller have an RS232 interface at the bottom of the front face. The miniature

connector can be joined to a PC and the KS2000 configuration software with the aid of a connecting cable. The

interface permits the Bus Terminals to be configured, for example adjusting the amplification factors of the analog

channels. The interface can also be used to change the assignments of the bus terminal data to the process image in

the Bus Coupler. The functionality of the configuration interface can also be reached via the fieldbus using string

communication facility.

Electrical isolation

The Bus Coupler / Bus Terminal Controller operate by means of three independent potential groups. The supply

voltage feeds the K-Bus electronics and the K-Bus itself. The supply voltage is also used to generate the operating

voltage for the fieldbus interface.

Remark: All the Bus Terminals are electrically isolated from the K-Bus. The K-Bus is thus electrically isolated from

everything else.

Fieldbus Components 21

Page 24

Notes on the Documentation

PROFIBUS Cabeling

PROFIBUS Connection

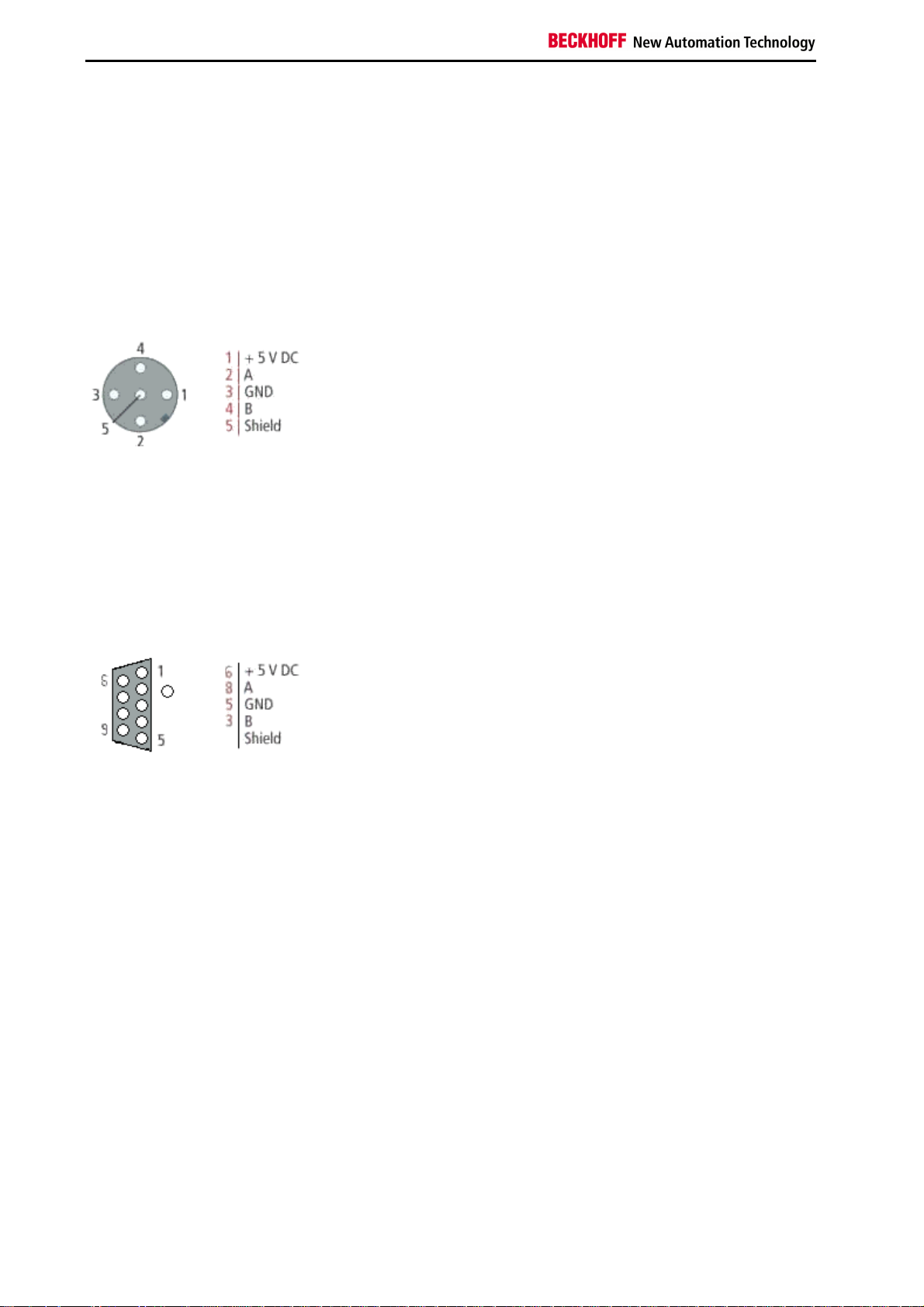

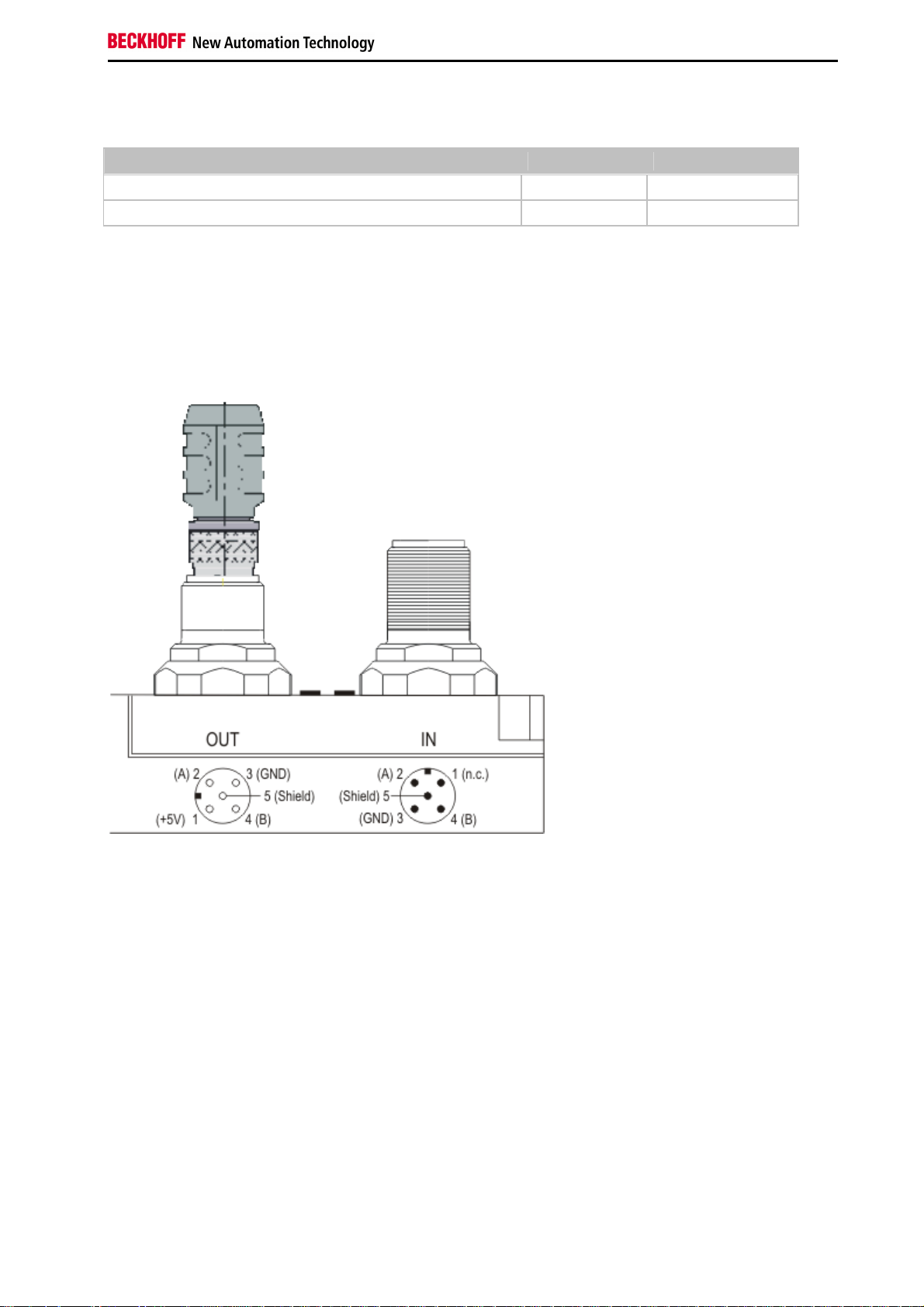

M12 circular connector

The M12 socket is inverse coded, and has five pins. Pin 1 is 5 VDC and 3 is GND for the active termination resistor.

These must never be misused for other functions, as this can lead to destruction of the device. Pin 2 and pin 4 are

the Profibus signals. These must never be swapped over, as this will prevent communication. Pin 5 is the shield, and

this is capacitatively coupled to the Fieldbus Box chassis.

M12 socket pin assignment

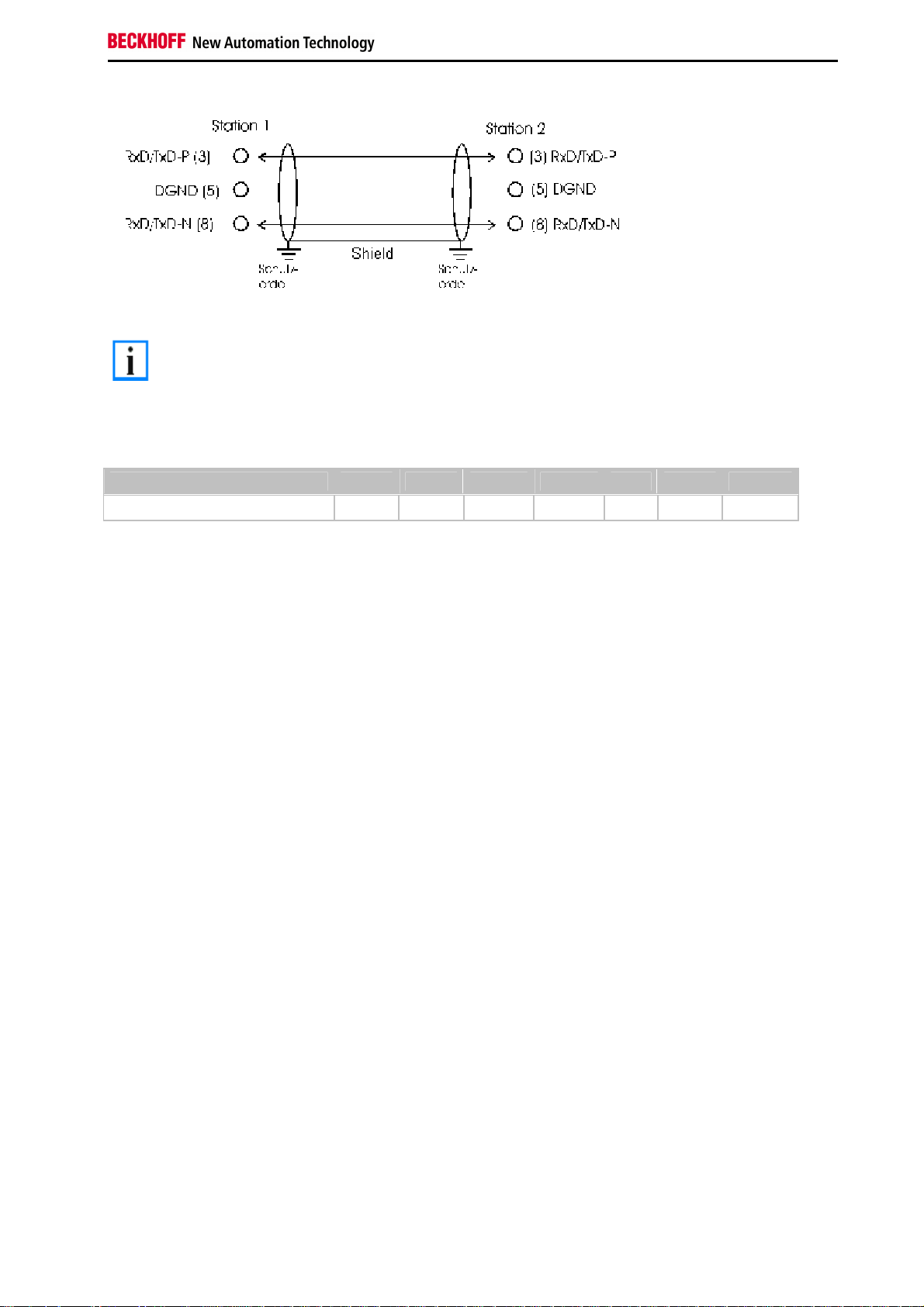

Nine pole D-Sub

Pin 6 is 5 VDC und Pin 5 is GND for the active termination resistor. These must never be misused for other functions,

as this can lead to destruction of the device. Pin 3 and pin 8 are the Profibus signals. These must never be swapped

over, as this will prevent communication. Shield is connected to the D-Sub housing that is coupled with lowresistance to the mounting rail.

D-Sub socket pin assignment

22 Fieldbus Components

Page 25

Notes on the Documentation

Profibus conductor colors

Profibus conductors M12 D-Sub

B red Pin 4 Pin 3

A green Pin 2 Pin 8

Connection of FieldbusBox modules

The connection of the Fieldbus Box modules is done direct or via a T-piece (or Y-piece).

The B318 series does have a male and female connector, that means no external T-piece is required. The supply

voltage (+5VDC) for the termination resistor is only supplied via the female M12 connector. The termination resistor

ZS1000-1610 is only available with male connector, therefore the incoming PROFIBUS line should end in a female

connector.

Two T-pieces are available:

•

ZS1031-2600 with +5VDC on male and female connector for the termination resistor

•

ZS1031-2610 with +5VDC only on the female connector

Fieldbus Components 23

Page 26

Notes on the Documentation

PROFIBUS Cabling

Physical aspects of the data transmission are defined in the Profibus standard (see Profibus layer 1: Physical Layer).

The types of area where a fieldbus system can be used is largely determined by the choice of the transmission

medium and the physical bus interface. In addition to the requirements for transmission security, the expense and

work involved in acquiring and installing the bus cable is of crucial significance. The Profibus standard therefore

allows for a variety of implementations of the transmission technology while retaining a uniform bus protocol.

Cable-based transmission

This version, which accords with the American EIA RS-485 standard, was specified as a basic version for

applications in production engineering, building management and drive technology. A twisted copper cable with one

pair of conductors is used. Depending on the intended application area (EMC aspects should be considered) the

screening may be omitted.

Two types of conductor are available, with differing maximum conductor lengths (see the RS-485 table).

RS485 - Fundamental properties

RS-485 transmission according to the Profibus standard

Network topology Linear bus, active bus terminator at both ends, stubs are possible.

Medium Screened twisted cable, screening may be omitted, depending upon the

environmental conditions (EMC).

Number of stations 32 stations in each segment with no repeater. Can be extended to 127 stations

with repeater

Max. bus length without

repeater

Max. bus length with

repeater

Transmission speed

(adjustable in steps)

Plug connector 9-pin D-Sub connector for IP20

100 m at 12 MBit/s

200 m at 1500 KBit/s, up to 1.2 km at 93.75 KBit/s

Line amplifiers, or repeaters, can increase the bus length up to 10 km. The number

of repeaters possible is at least 3, and, depending on the manufacturer, may be up

to 10.

9.6 kBit/s; 19.2 kBit/s; 93.75 kBit/s; 187.5 kBit/s; 500 kBit/s; 1500 kBit/s; 12 MBit/s

M12 round connector for IP65/67

Cabling for Profibus DP and Profibus FMS

Note the special requirements on the data cable for baud rates greater than 1.5 MBaud. The correct cable is a basic

requirement for correct operation of the bus system. If a simple 1.5 Mbaud cable is used, reflections and excessive

attenuation can lead to some surprising phenomena. It is possible, for instance, for a connected Profibus station not

to achieve a connection, but for it to be included again when the neighboring station is disconnected. Or there may be

transmission errors when a specific bit pattern is transmitted. The result of this can be that when the equipment is not

operating, Profibus works without faults, but that there are apparently random bus errors after start-up. Reducing the

baud rate (< 93,75 kBaud) corrects this faulty behavior.

If reducing the baud rate does not correct the error, then in many cases this can indicate a wiring fault. The two data

lines maybe crossed over at one or more connectors, or the termination resistors may not be active, or they may be

active at the wrong locations.

Installation is made a great deal more straightforward if pre-assembled cables from

Note

BECKHOFF are used! Wiring errors are avoided, and commissioning is more rapidly

completed. The BECKHOFF range includes fieldbus cables, power supply cables, sensor

cables and accessories such as terminating resistors and T-pieces. Connectors and cables

for field assembly are nevertheless also available.

24 Fieldbus Components

Page 27

Notes on the Documentation

In systems with more than two stations all devices are wired in parallel. It is essential that

Note

the bus cables are terminated with resistors at the conductor ends in order to avoid

reflections and associated transmission problems.

Distances

The bus cable is specified in EN 50170. This yields the following lengths for a bus segment.

Baud rate in kbits/sec 9.6 19.2 93.75 187.5 500 1500 12000

Cable length in m 1200 1200 1200 1000 400 200 100

Stubs up to 1500 kbaud <6.6 m; at 12 Mbaud stub segments should not be used.

Bus segments

A bus segment consists of at most 32 devices. 126 devices are permitted in a Profibus network. Repeaters are

required to refresh the signal in order to achieve this number. Each repeater is counted as one device.

IP-Link is the subsidiary bus system for Fieldbus Boxes, whose topology is a ring structure. There is an IP master in

the coupler modules (IP230x-Bxxx or IP230x-Cxxx) to which up to 120 extension modules (IExxxx) may be

connected. The distance between two modules may not exceed 5 m. When planning and installing the modules,

remember that because of the ring structure the IP-Link master must be connected again to the last module.

Installation guidelines

When assembling the modules and laying the cables, observe the technical guidelines provided by the Profibus User

Organization (Profibus Nutzerorganisation e.V.) for Profibus DP/FMS (see www.profibus.com).

Checking the Profibus wiring

A Profibus cable (or a cable segment when using repeaters) can be checked with a few simple resistance

measurements. The cable should meanwhile be removed from all stations:

1. Resistance between A and B at the start of the lead: approx. 110 Ohm

2. Resistance between A and B at the end of the lead: approx. 110 Ohm

3. Resistance between A at the start and A at the end of the lead: approx. 0 Ohm

4. Resistance between B at the start and B at the end of the lead: approx. 0 Ohm

5. Resistance between screen at the start and screen at the end of the lead: approx. 0 Ohm

If these measurements are successful, the cable is okay. If, in spite of this, bus malfunctions still occur, this is usually

a result of EMC interference. Observe the installation notes from the Profibus User Organization (www.profibus.com).

Fieldbus Components 25

Page 28

Notes on the Documentation

4. Parameterisation and Commissioning

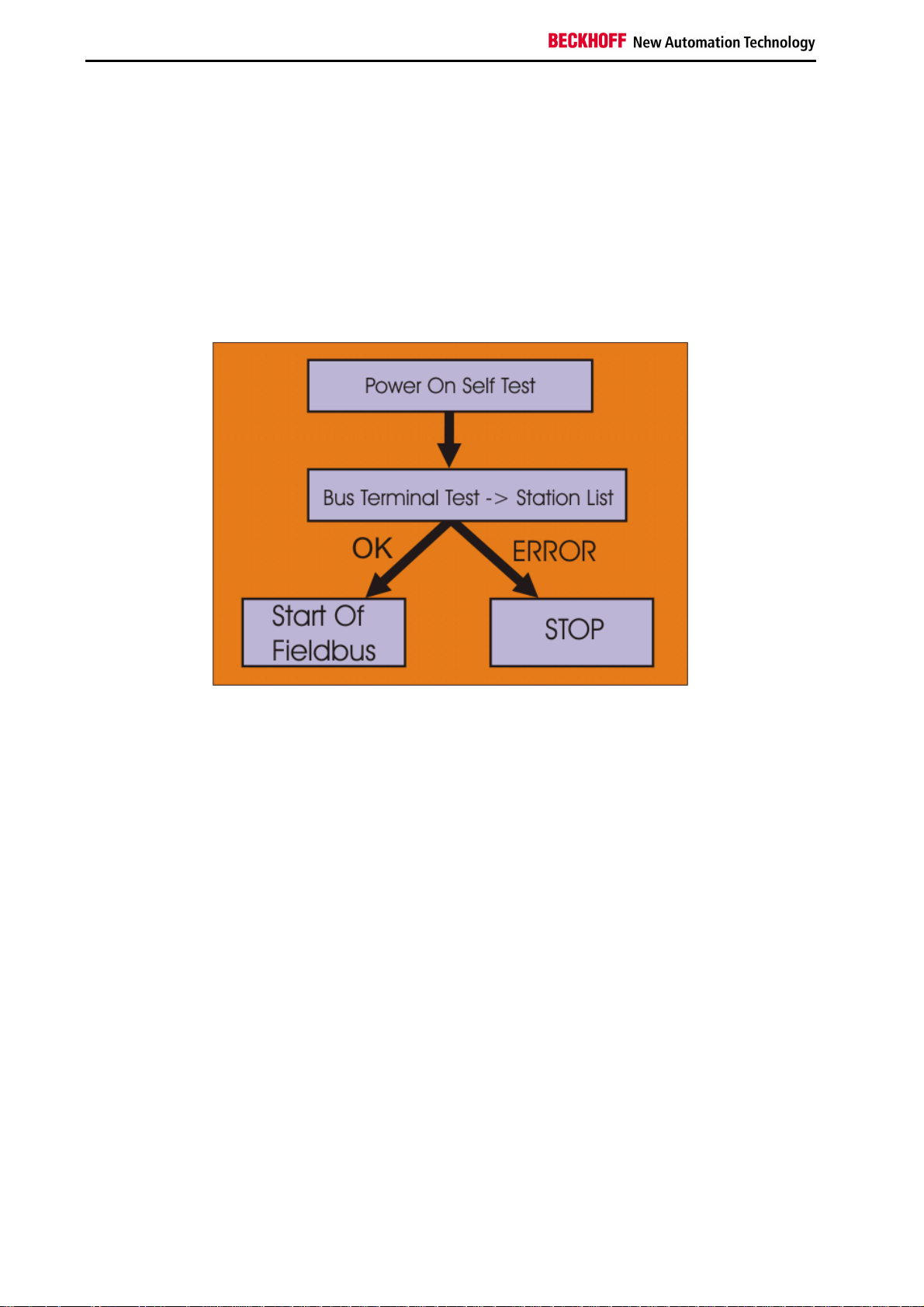

Start-up Behaviour of the Bus Coupler

Immediately after being switched on, the Bus Coupler checks, in the course of a self test, all the functions of its

components and the communication on the K-Bus. The red I/O LED blinks while this is happening After completion of

the self-test, the Bus Coupler starts to test the attached Bus Terminals (the Bus Terminal Test), and reads in the

configuration. The Bus Terminal configuration is used to generate an internal structure list, which is not accessible

from outside. In case of an error, the Bus Coupler enters the STOP state. Once the start-up has completed without

error, the Bus Coupler enters the fieldbus start state.

The Bus Coupler can be made to enter the normal operating state by switching it on again once the fault has been

rectified.

26 Fieldbus Components

Page 29

Notes on the Documentation

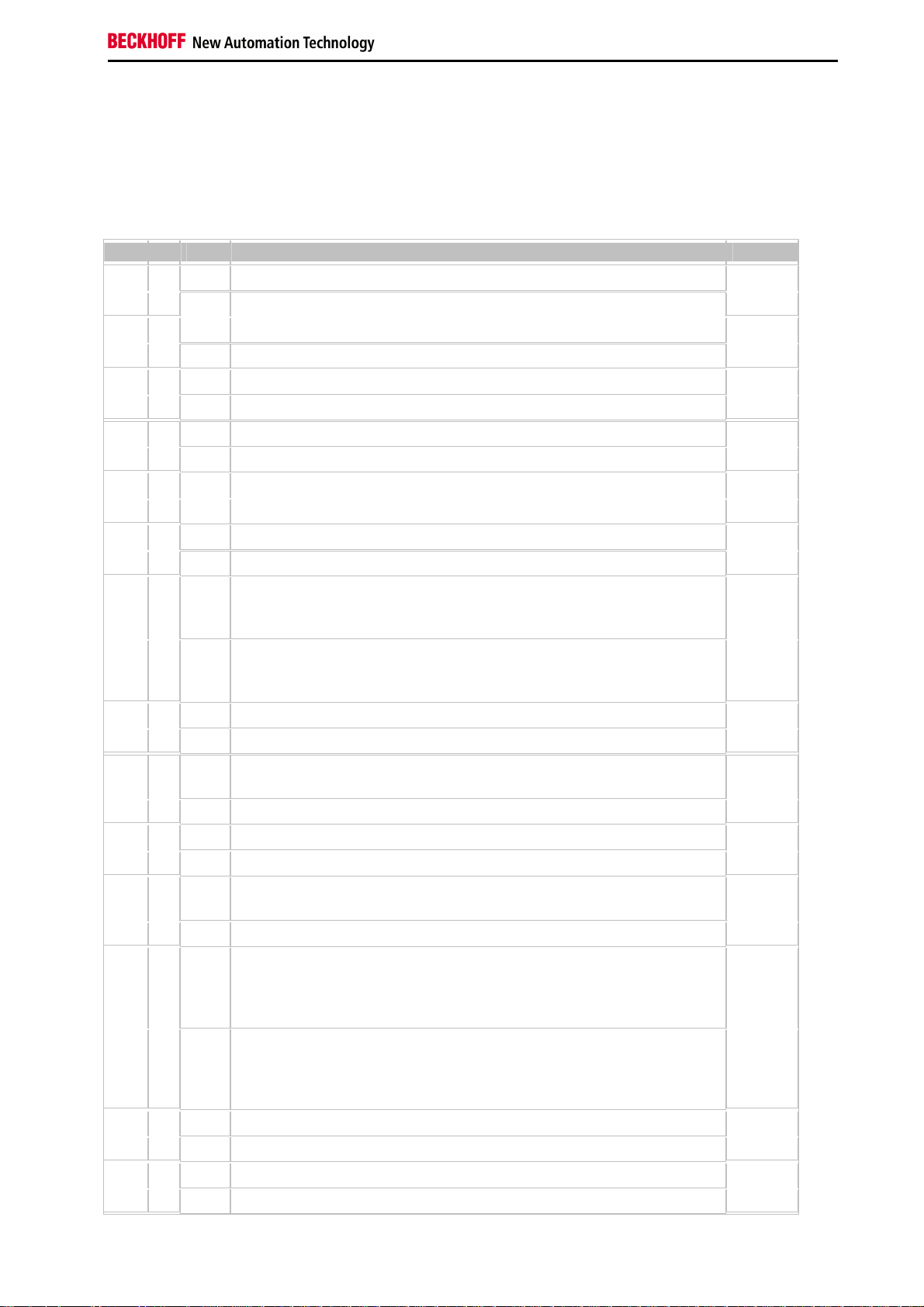

The Bus Coupler's UserPrmData

The following settings can be made in the Bus Coupler's UserPrmData. So that a more easily understood GSD file is

obtained in 90% of applications, some of the settings are only contained in text form in the extended GSD file, and

these are indicated in the last column by Extended. The standard settings are contained both in the standard and the

extended GSD file.

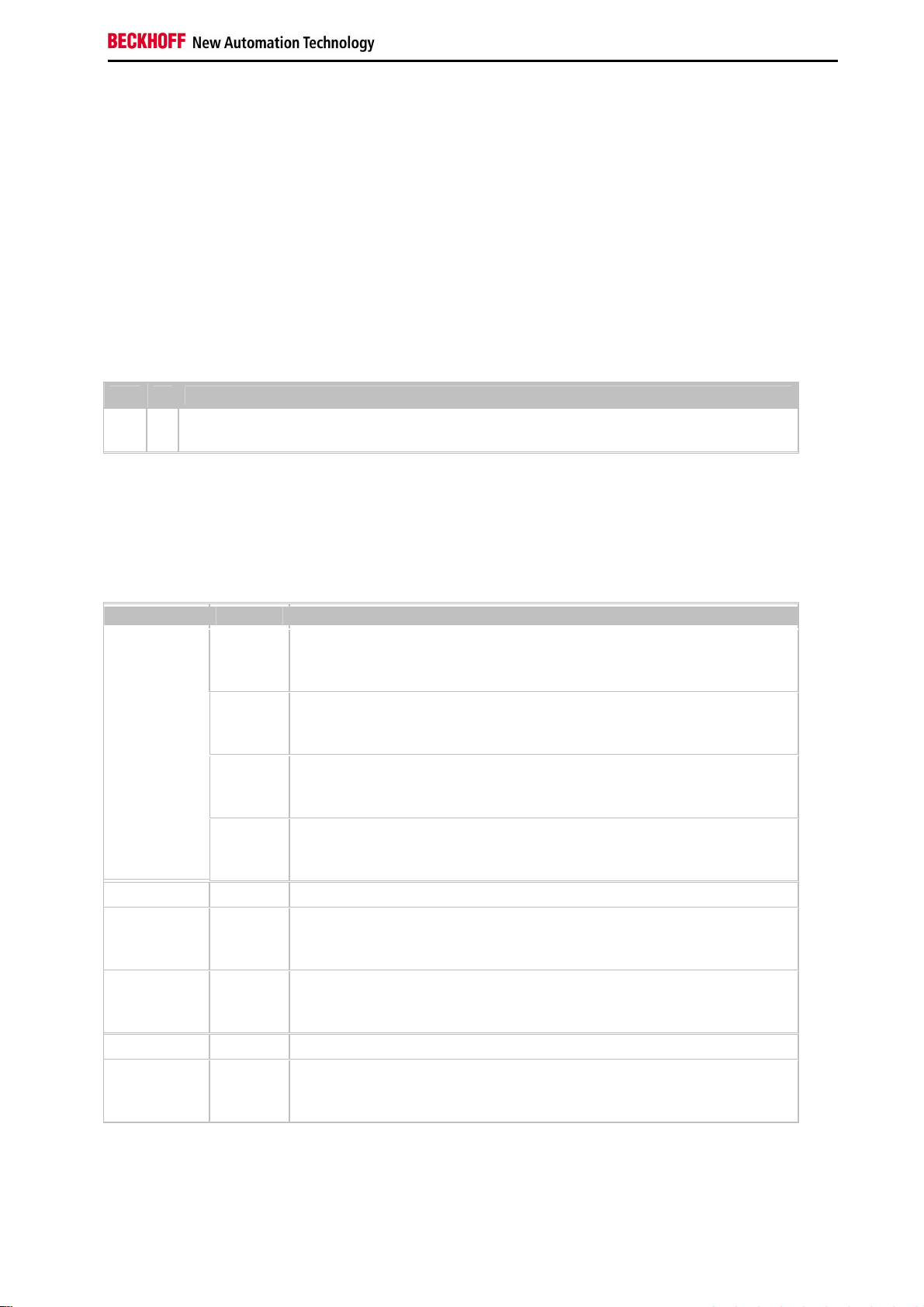

Byte Bit Value Description GSD file

0

3 6

7 0

7 4

9 2

MSAC_C1 connection is not active (default) 0 7

bin

1

MSAC_C1 connection is active (see DPV1)

bin

0

CfgData checking is active (default) 1 0

bin

1

CfgData checking deactivated (see Deactivating the CfgData checking)

bin

0

Diagnostic data is transferred in a form compatible with the BK3100 2 3

bin

1

Diagnostic data is transferred in a form compatible with DPV1 (default)

bin

0

Multi-configuration mode is not active (default) 3 3

bin

1

Multi-configuration mode is active (see Multi-configuration mode)

bin

0

K-Bus cycle counter is not active (default) 3 4

bin

1

K-Bus cycle counter is active (see K-Bus cycle)

bin

0

Dummy output byte not active (default) 3 5

bin

1

Dummy output byte is active (see K-Bus cycle)

bin

0

In multi-configuration mode, the coupler sets the Stat_Diag bit in the

bin

diagnostic data if the configuration is not consistent, and does not yet enter

data exchange (default).

1

In multi-configuration mode the coupler also enters data exchange even when

bin

the configuration is not consistent, although K-Bus cycles are not yet

executed (see Multi-configuration mode)

0

2-byte PLC interface not activated (default) 5 0

bin

1

2-byte PLC interface is active (see 2-byte PLC interface)

bin

0

Response to K-Bus error: manual K-Bus reset (default) (see K-Bus

bin

interruption)

1

Response to K-Bus error: automatic K-Bus reset

bin

0

Terminal diagnosis is not active (default) (see Terminal diagnosis) 7 1

bin

1

Terminal diagnosis is active

bin

0

Diagnostic data for digital terminals included in process image (default) (see

bin

Terminal diagnosis)

1

Diagnostic data of digital terminals not in the process image (default)

bin

0

Analog modules are mapped in compact form (only showing the input and/or

bin

output user data) (this is the default, only relevant when CfgData checking

has been deactivated, otherwise the terminals are set by means of the

CfgData) (see Deactivation of CfgData checking)

1

Analog modules are mapped in complex form (with control/status for register

bin

access and with the same data length in inputs and outputs) (only relevant

when CfgData checking has been deactivated, otherwise the terminals are set

by means of the CfgData)

0

Representation in INTEL format 9 3

bin

1

Representation in Motorola format (default)

bin

0

K-Bus mode slow FreeRun (default) (see K-Bus cycle) 9 4

bin

1

K-Bus mode fast FreeRun

bin

Standard

Extended

Extended

Extended

Extended

Extended

Extended

Extended

Standard

Standard

Standard

Extended

Standard

Standard

Fieldbus Components 27

Page 30

Notes on the Documentation

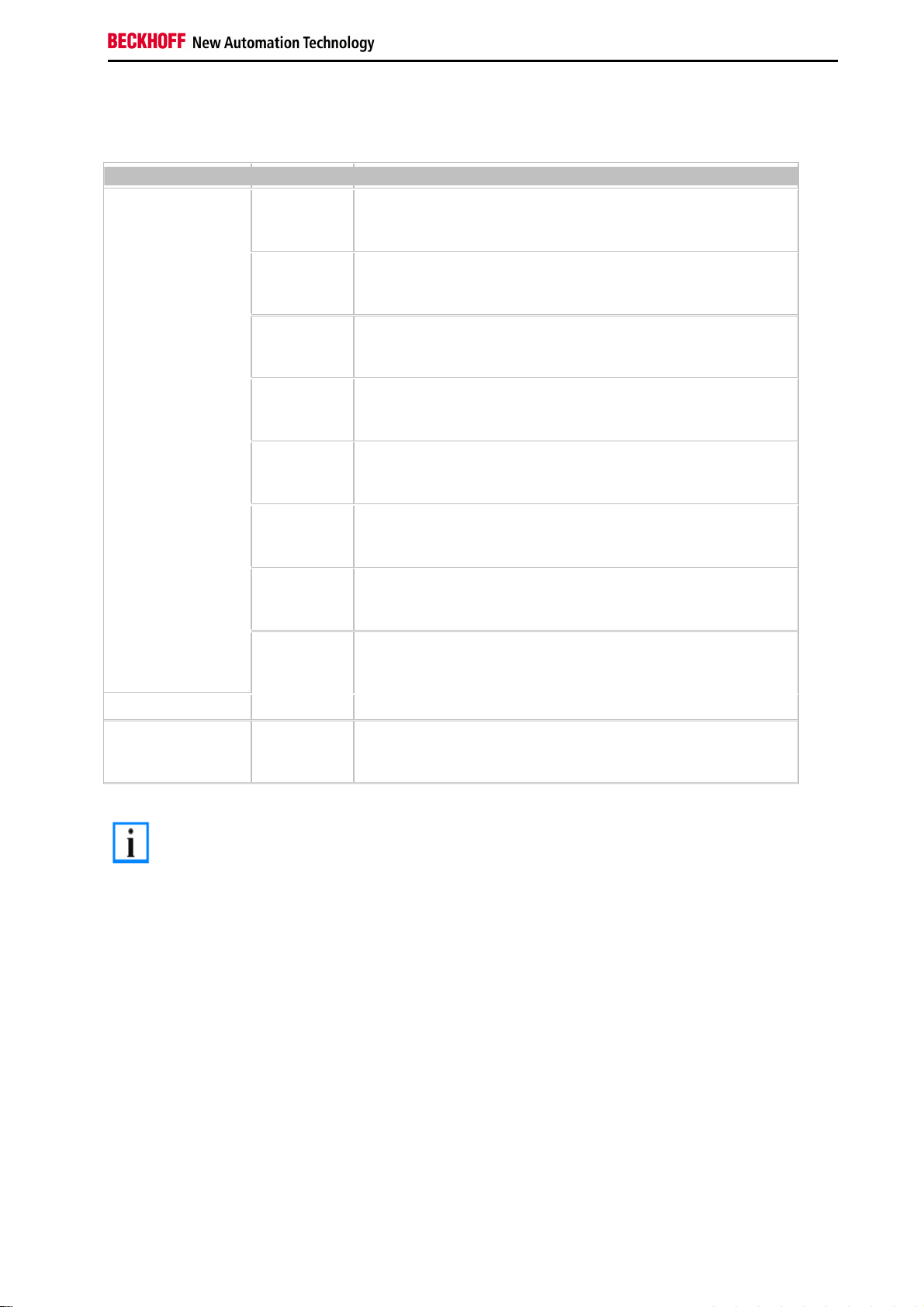

Byte Bit Value Description GSD file

0

10 0-

1

WORD alignment inactive (default) 9 5

bin

1

WORD alignment active (see WORD alignment)

bin

0

K-Bus mode is synchronous (see K-Bus cycle) 9 6

bin

1

K-Bus mode FreeRun (default)

bin

00

Reaction to PROFIBUS error: K-Bus cycle is abandoned (default, digital

bin

outputs become 0, complex outputs are set to a configured substitute value)

Extended

Standard

Standard

(see Reaction to PROFIBUS errors)

01

Reaction to PROFIBUS error: K-Bus outputs become 0

bin

10

Reaction to PROFIBUS error: K-Bus outputs remain unchanged

bin

00

10 2-

3

11 3-6 X Maximum length of the diagnostic data. Allowed values: 16, 24, 32, 40, 48,

Reaction to K-Bus error: DP data exchange is abandoned (default) (see K-

bin

Bus interruption)

01

Reaction to K-Bus error: DP inputs set to 0

bin

10

Reaction to K-Bus error: DP inputs remain unchanged

bin

Standard

Extended

56, 64 (see Terminal diagnosis)

0

12 0-

1

If K-Bus mode is synchronous: standard synchronous mode (default) (see K-

bin

Bus cycle)

01

If K-Bus mode is synchronous: synchronous mode with optimised input

bin

Extended

update (one cycle)

10

If K-Bus mode is synchronous: synchronous mode with optimised input

bin

update (two cycles)

12 4-7 0

Maximum DP buffer lengths not changed Extended

bin

12 4-7 15 The maximum DP buffer lengths are changed using the values from

Extended

UserPrmData 37-40 (see Multi-configuration mode)

13 0-7 X Delay time (in µs) high byte (see K-Bus cycle) Extended

14 0-7 X Delay time (in µs) low byte (see K-Bus cycle) Extended

15-

X Assignment of Bus Terminals 1 to 64 (see Multi-configuration mode) Extended

30 0-7

31-

- reserved Extended

36 0-7

37 0-7 X Maximum length of the input data (see Multi-configuration mode) Extended

38 0-7 X Maximum length of the output data (see Multi-configuration mode) Extended

39 0-7 X Maximum length of the diagnostic data (see Multi-configuration mode) Extended

40 0-7 X Maximum length of the configuration data (see Multi-configuration mode) Extended

41-

X Assignment of terminals 65 to 128 (see Multi-configuration mode) Extended

56 0-7

28 Fieldbus Components

Page 31

Notes on the Documentation

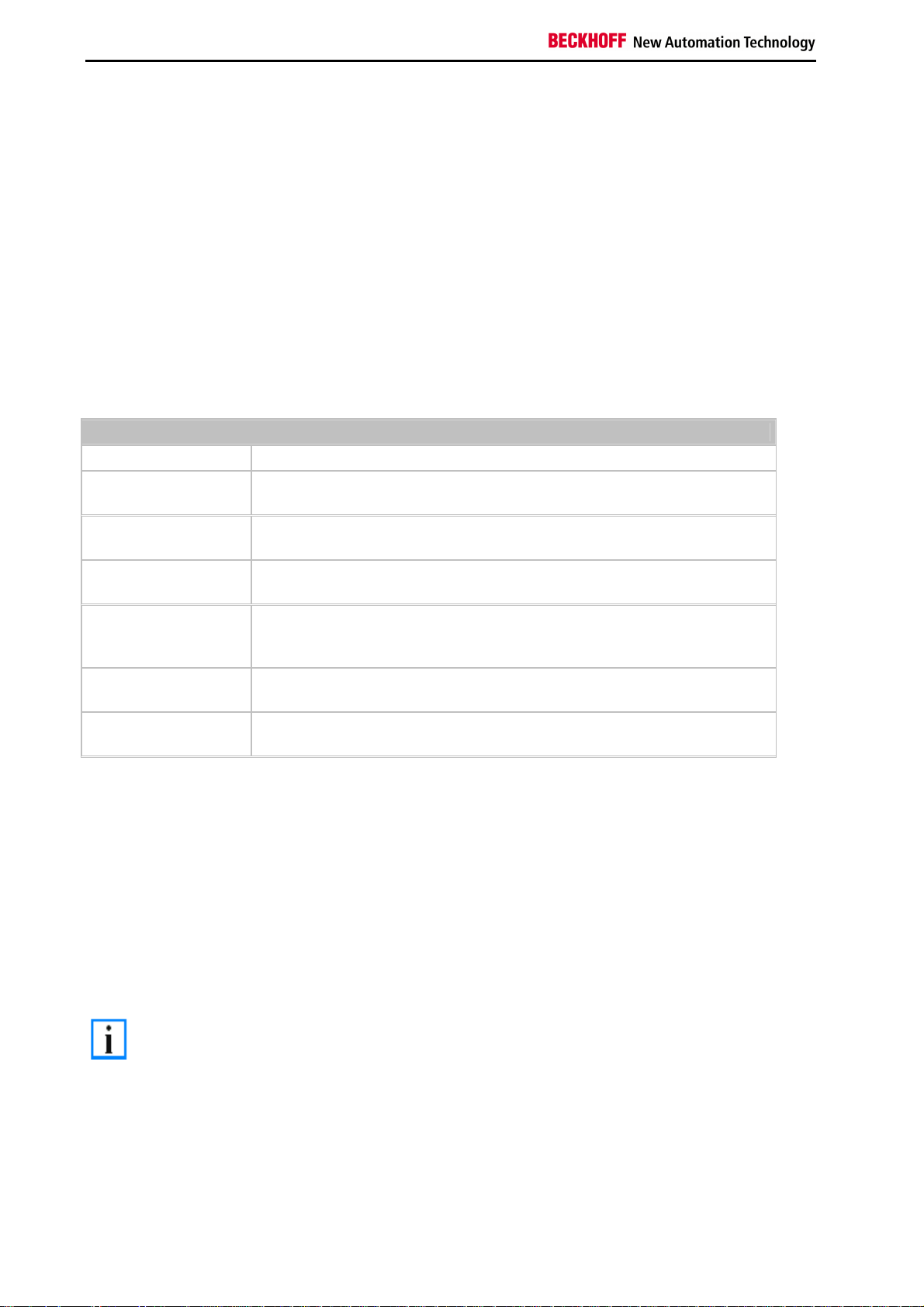

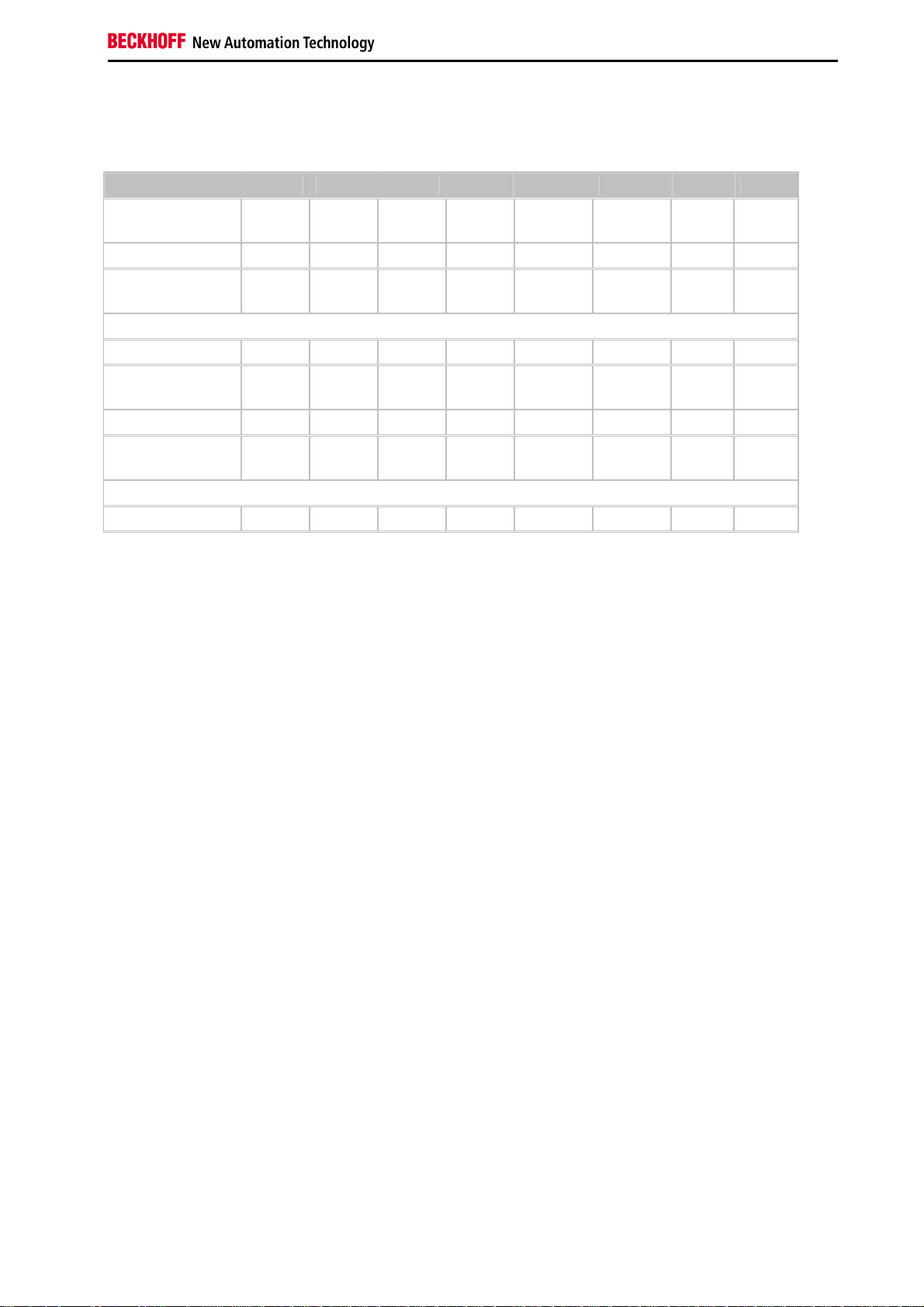

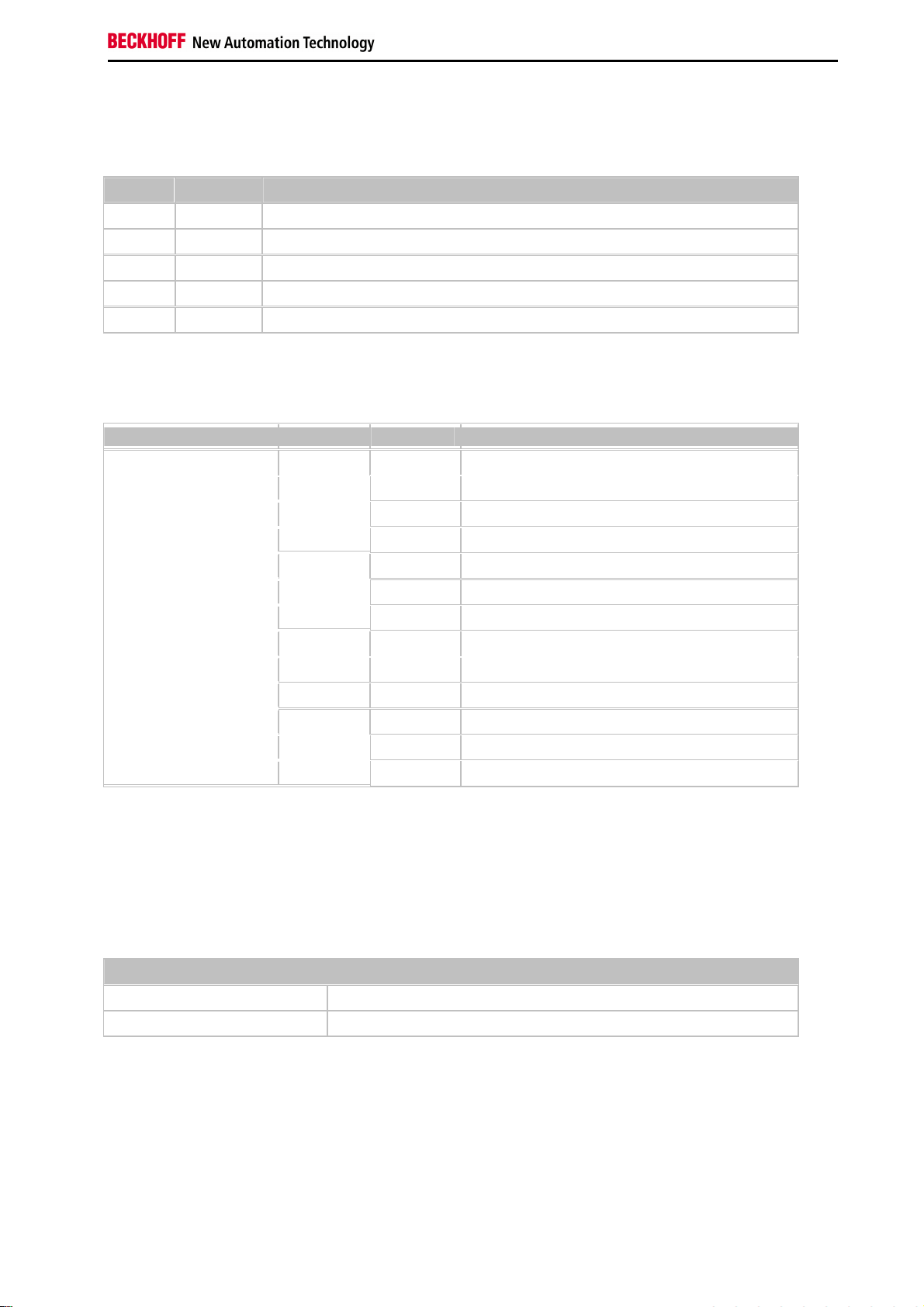

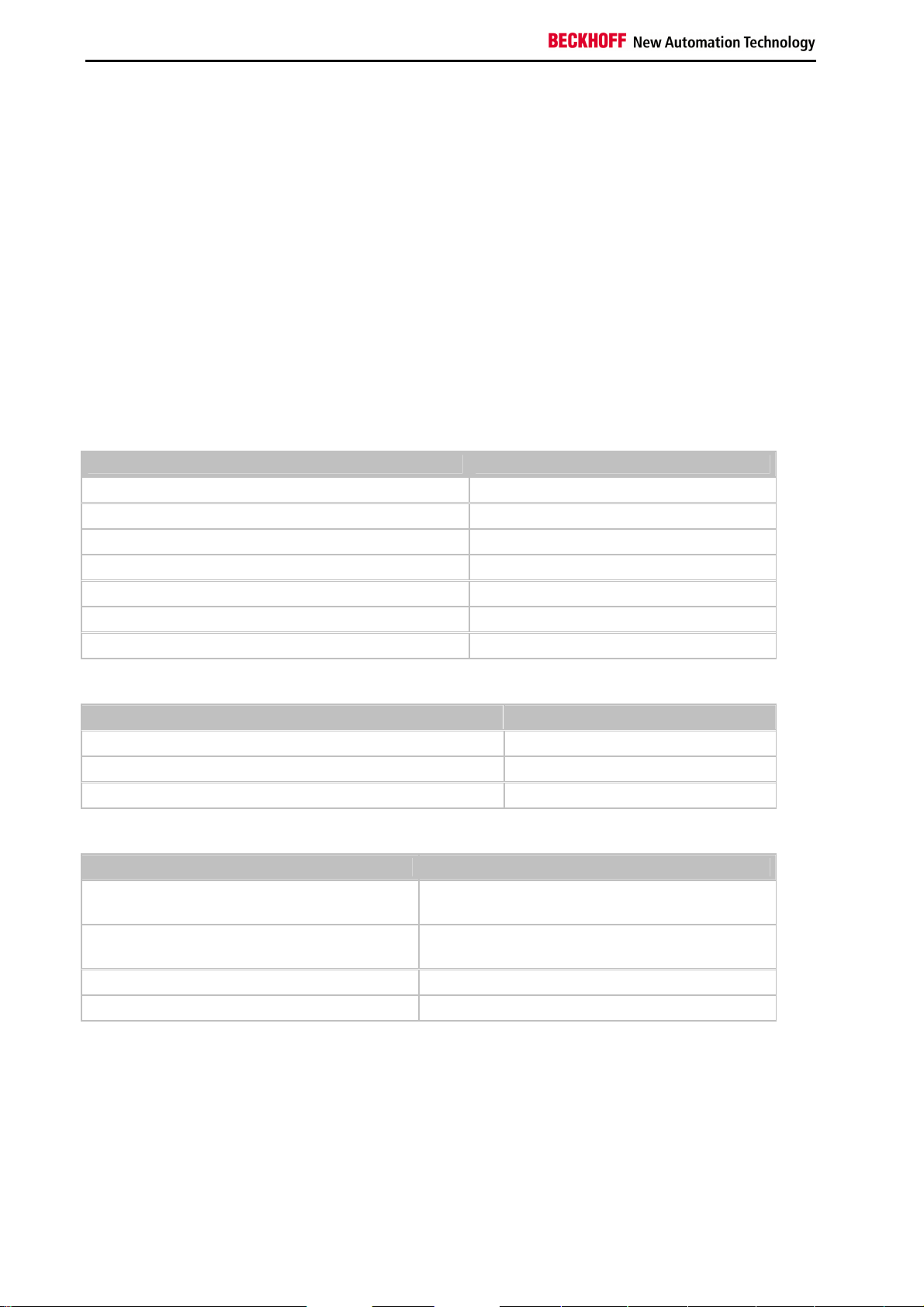

Technical Data - Summary

Technical data

Description BK3010 BK3110 BK3120 BK3150 BK3500 BK3520 LC3100 BC3100

Number of Bus

Terminals

Baud rate [Mbaud] 1.5 12 12 12 1.5 12 12 12

Physical basis RS 485 RS 485 RS 485 RS 485 Optical

UserPrm Data

DPV1 Services x x x x x x x x

Multi-configuration

mode

Word Align x x x x

Byte oriented Bus

Terminals

Distributed control

PLC IEC 6 1131-3 x

64 64 255 255 64 255 64 64

Optical

fibres

x x x x x x x

x x x x x

fibres

RS 485 RS 485

Fieldbus Components 29

Page 32

Notes on the Documentation

Configuration

Configuration - CfgData

The CfgData is generated from the modules inserted in the DP configuration tool. When modules are added, the

following rules are to be observed:

Sequence of DP modules to be added in the DP configuration tool

Modules for the coupler's functions

Complex function modules

Digital function modules

For TwinCAT applications, these rules are followed by the TwinCAT system manager. It adds the terminals or IE

modules in the sequence in which they are plugged in, and the modules for functions are added automatically if the

corresponding function is activated in the UserPrmData.

30 Fieldbus Components

Page 33

Notes on the Documentation

Configuration of the Coupler Modules

The DP modules for the following Bus Coupler functions are to be added first in the DP configuration tool if the

associated function is activated (if the function is not activated, the corresponding DP module is not to be added):

Function module Activation of the function

2-byte PLC

interface

K-Bus cycle

counter

Dummy output

byte

The 2-byte PLC interface is activated via the UserPrmData (byte 5, bit 0). By default it is

not active.

The K-Bus cycle counter is activated via the UserPrmData (byte 3, bit 3). By default it is

not active.

The dummy output byte is activated via the UserPrmData (byte 3, bit 5). By default it is

not active.

Fieldbus Components 31

Page 34

Notes on the Documentation

Configuration of Complex Modules

After the DP modules for the activated functions of the Bus Coupler have been added to the Bus Coupler in the DP

configuration tool, the next step is for the complex terminals (KL15xx, KL25xx, KL3xxx, KL4xxx, KL5xxx, KL6xxx,

KL8xxx) to be added in the sequence in which they are plugged in, regardless of whether digital terminals are

plugged in between the complex terminals, or of how many there may be:

Complex function

module Description

KL1501 KL1501

KL2502 KL2502

KL2521 KL2521

KL3351 compact KL3351 - only the 16 bit input value is transmitted

KL3351 complex KL3351 - 24 bits of input/output are transmitted, so

that access can be had to the terminal's registers in

addition to transmission of the 16 bit input value

KL3361 KL3361 0xFB (in GSD file)

KL3xx2 compact All KL3xx2 - only the 16 bit input value of each

channel is transmitted

KL3xx2 complex Old KL3xx2 - 24 bits of input/output are transmitted

for each channel, so that access can be had to the

terminal's registers in addition to transmission of the

16 bit input value

KL3xx4 compact All KL3xx4 - only the 16 bit input value of each

channel is transmitted

KL3xx4 complex Old KL3xx4 - 24 bits of input/output are transmitted

for each channel, so that access can be had to the

terminal's registers in addition to transmission of the

16 bit input value

KL4xx2 compact All KL4xx2 - only the 16 bit output value of each

channel is transmitted

KL4xx2 complex Old KL4xx2 - 24 bits of input/output are transmitted

for each channel, so that access can be had to the

terminal's registers in addition to transmission of the

16 bit input value

KL4xx4 compact All KL4xx4 - only the 16 bit output value of each

channel is transmitted

KL4xx4 complex Old KL4xx4 - 24 bits of input/output are transmitted

for each channel, so that access can be had to the

terminal's registers in addition to transmission of the

16 bit input value

Associated CfgData

(as hex code)

0xB4 (in GSD file)

0xB5 (alternatively)

0xF2 (alternatively)

0xB5 (in GSD file)

0xB2, 0xB2 (alternatively)

0xF2 (alternatively)

0xB2 (in GSD file)

0xF1 (alternatively)

0x51 (in GSD file)

0x50, 0x50 (alternatively)

0xB5 (in GSD file)

0xB2, 0xB2 (alternatively)

0xF2 (alternatively)

0x51 (in GSD file)

0x50, 0x50 (alternatively)

0xB5 (in GSD file)

0xB2, 0xB2 (alternatively)

0xF2 (alternatively)

0x53 (in GSD file)

0x51, 0x51(alternatively)

0x50, 0x50, 0x50, 0x50

(alternatively)

0xBB (in GSD file)

0xB5, 0xB5 (alternatively)

0xB2, 0xB2, 0xB2, 0xB2

(alternatively)

0xF5 (alternatively)

0x61 (in GSD file)

0x60, 0x60 (alternatively)

0xB5 (in GSD file)

0xB2, 0xB2 (alternatively)

0xF2 (alternatively)

0x63 (in GSD file)

0x61, 0x61 (alternatively)

0x60, 0x60, 0x60, 0x60

(alternatively)

0xBB (in GSD file)

0xB5, 0xB5 (alternatively)

0xB2, 0xB2, 0xB2, 0xB2

(alternatively)

0xF5 (alternatively)

32 Fieldbus Components

Page 35

Notes on the Documentation

Complex function

module Description

KL5001 compact KL5001 - only the 32 bit input value is transmitted

Associated CfgData

(as hex code)

0x93 (in GSD file)

0xD1 (alternatively)

KL5001 complex KL5001 - 40 bits of input/output are transmitted, so

that access can be had to the terminal's registers in

addition to transmission of the 40 bit input value

KL5051 KL5051

0xB4 (in GSD file)

0xB5 (alternatively)

0xF2 (alternatively)

0xB5 (in GSD file)

0xF2 (alternatively)

KL5101 KL5101

0xB5 (in GSD file)

0xF2 (alternatively)

KL5111 KL5111

0xB5 (in GSD file)

0xF2 (alternatively)

KL5121 KL5121

0xB5 (in GSD file)

0xF2 (alternatively)

KL5151 KL5151

0xB5 (in GSD file)

0xF2 (alternatively)

KL5302 KL5302

0xB5 (in GSD file)

0xF2 (alternatively)

KL6001 KL6001

0xB5 (in GSD file)

0xF2 (alternatively)

KL6011 KL6011

0xB5 (in GSD file)

0xF2 (alternatively)

KL6021 KL6021

0xB5 (in GSD file)

0xF2 (alternatively)

KL6051 compact KL6051 - only the 32 input bits and 32 output bits are

transmitted

KL6051 complex KL6051 - 48 input bits and 48 output bits are

transmitted, so that in addition to the 40 input bits

0xB3 (in GSD file)

0xF1 (alternatively)

0xB5 (in GSD file)

0xF2 (alternatively)

and the 40 output bits, access can also be had to the

terminal's registers

KL6061 KL6061

0xBA (in GSD file)

0xF5 (alternatively)

KL6201 (PAB 6) KL6201 - 6 bytes input and output process data is

0x35 (in GSD file)

transferred (ASI slaves 1-11)

KL6201 (PRM PAB 6) KL6201 - 6 bytes parameter interface and 6 bytes

0xF2,0x35 (in GSD file)

input and output process data is transferred (ASI

slaves 1-11)

KL6201 (PAB 16) KL6201 - 16 bytes input and output process data is

0x3F (in GSD file)

transferred (ASI slaves 1-31)

KL6201 (PRM PAB 16) KL6201 - 6 bytes parameter interface and 16 bytes

0xF2,0x3F (in GSD file)

input and output process data is transferred (ASI

slaves 1-31)

KL6801 KL6801

0xB5 (in GSD file)

0xF2 (alternatively)

KL8001 KL8001

0xBB (in GSD file)

0xF5 (alternatively)

Fieldbus Components 33

Page 36

Notes on the Documentation

Configuration of Digital Modules

After the DP modules for the activated functions of the Bus Coupler and the complex terminals (KL15xx, KL25xx,

KL3xxx, KL4xxx, KL5xxx, KL6xxx, KL8xxx) have been added to the Bus Coupler in the DP configuration tool in the

sequence in which they are plugged in, the digital terminals follow. In the case of digital terminals, it is only necessary

for the total of the digital inputs and outputs of the modules that have been added to agree with the number of digital

inputs and outputs that are plugged in:

Example:

4 x KL1408 = 32 digital input bits

2 x KL2408 = 16 digital output bits

3 x KL1114 = 12 digital input bits

2 x KL2114 = 8 digital output bits

4 x KL1012 = 8 digital input bits

1 x KL2012 = 2 digital output bits

=> 52 digital input bits and 26 digital output bits

The following combinations of DP modules could, for instance, now be added in the DP configuration tool to the Bus

Coupler:

Alternative 1

8 digital input bits

8 digital input bits

8 digital input bits

8 digital input bits

8 digital input bits

8 digital input bits

8 digital input bits

8 digital output bits

8 digital output bits

8 digital output bits

8 digital output bits

Alternative 2

56 digital input bits

32 digital output bits

Other alternatives are possible, provided the total of digital inputs is 56 bits (the next number larger than 52 divisible

by 8) and that the sum of the digital inputs is 32 bits (the next number larger than 26 divisible by 8).

34 Fieldbus Components

Page 37

Notes on the Documentation

GSD Files

The following GSD files are to be used in order to link the PROFIBUS coupler in the DP configuration tool:

Standard GSD files

The standard GSD file contains all the important and fundamental properties required for operation of any master

controller. The Bus Coupler can be parameterised in a clear and comprehensible manner with this GSD file.

Bus Coupler German English as from firmware

BK3000 BK30becf.GSD BK30becf.GSE BN

BK3010 BK3010.GSD BK3010.GSE B9

BK3100 BK31bece.GSD BK31bece.GSE BT

BK3110 BK3110.GSD BK3110.GSE B9

BK3120 BK3120.GSG BK3120.GSE B9

BK3150 BK3150.GSG BK3150.GSE B0

BK3500 BK3500.GSD BK3500.GSE B9

BK3520 BK3520.GSD BK3520.GSE B9

LC3100 LC3100.GSD LC3100.GSE B9

BC3100 BC3100.GSD BC3100.GSE C3

Extended GSD files

Additional settings are necessary for certain applications. These extended GSD files contain a large number of

additional parameterisation options. It should be noted, however, that a thorough knowledge of the master controller

along with excellent familiarity with the Beckhoff bus terminal system is necessary here.

Bus Coupler German English as from firmware

BK3010 BK3010x.GSD BK3010x.GSE B9

BK3110 BK3110x.GSD BK3110x.GSE B9

BK3120 BK3120x.GSG BK3120x.GSE B9

BK3150 BK3150x.GSG BK3150x.GSE B0

BK3500 BK3500x.GSD BK3500x.GSE B9

BK3520 BK3520x.GSD BK3520x.GSE B9

LC3100 LC3100x.GSD LC3100x.GSE B9

BC3100 BC3100x.GSD BC3100x.GSE C3

Note on the extended GSD file:

Note

The GSD file contains a maximum of 244 bytes of input, output and configuration data.

These are the maximum values. Below are the default of values and the setting options.

Fieldbus Components 35

Page 38

Notes on the Documentation

DP buffer Default Maximum size

Inputs 128 244

Outputs 128 244

Diagnostic Data 64 64

Configuration data 64 244

The sizes can be adjusted through the PrmData. The length is modified in steps of 8 bytes.

Example:

If it is desired to increase the size of the input data, other sizes must be reduced to compensate.

If we have 20 x 4 channel KL3314 thermocouples, then in compact mapping we find 20 Bus Terminals * 4 channels *

2 bytes per channel = 20 * 4 * 2 = 160 bytes

160 bytes is larger than the 128 byte default figure - settings must therefore be modified.

Set PrmData byte 12 bits 4-7 to 15 dec or 0xF hex, set byte for 37 to 160 (input data) and byte 38 to 96 (output data).

36 Fieldbus Components

Page 39

Notes on the Documentation

KS2000 Configuration Software

The KS2000 configuration software permits configuration, commissioning and parameterization of bus couplers, of

the affiliated bus terminals and of Fieldbus Box Modules. The connection between bus coupler/Fieldbus Box Module

and the PC is established by means of the serial configuration cable or the fieldbus.

Configuration

You can configure the Fieldbus stations with the Configuration Software KS2000 offline. That means, setting up a

terminal station with all settings on the couplers and terminals resp. the Fieldbus Box Modules can be prepared

before the commissioning phase. Later on, this configuration can be transferred to the terminal station in the

commissioning phase by means of a download. For documentation purposes, you are provided with the breakdown

of the terminal station, a parts list of modules used and a list of the parameters you have modified. After an upload,

existing fieldbus stations are at your disposal for further editing.

Parameterization

KS2000 offers simple access to the parameters of a fieldbus station: specific high-level dialogs are available for all

bus couplers, all intelligent bus terminals and Fieldbus Box modules with the aid of which settings can be modified

easily. Alternatively, you have full access to all internal registers of the bus couplers and intelligent terminals. Refer to

the register description for the meanings of the registers.

Commissioning

The KS2000 software facilitates commissioning of machine components or their fieldbus stations: Configured settings

can be transferred to the fieldbus modules by means of a download. After a login to the terminal station, it is possible

to define settings in couplers, terminals and Fieldbus Box modules directly online. The same high-level dialogs and

register access are available for this purpose as in the configuration phase.

The KS2000 offers access to the process images of the bus couplers and Fieldbus Box modules.

•

Thus, the coupler's input and output images can be observed by monitoring.

•

Process values can be specified in the output image for commissioning of the output modules.

All possibilities in the online mode can be used in parallel with the actual fieldbus mode of the terminal station. The

fieldbus protocol always has the higher priority in this case.

Fieldbus Components 37

Page 40

Notes on the Documentation

Configuration via TwinCAT

The TwinCAT automation software is a complete automation solution for PC-compatible computers. TwinCAT turns

any compatible PC into a real-time controller, an IEC 61131-3 Multi-PLC, NC positioning system, the corresponding

programming environment and user interface. TwinCAT supports several different PROFIBUS DP PC cards.

Beckhoff recommends the PROFIBUS DP PCI master card FC3101, which can also be obtained as a two-channel

version (FC3102).

System Manager

The TwinCAT System Manager Tool is used to configure the FC310x PROFIBUS DP PCI card. The System Manager

provides a representation of the number of programs of the TwinCat PLC systems, the configuration of the axis

control and of the connected I/O channels as a structure, and organises the mapping of the data traffic.

For applications without TwinCAT PLC or NC, the TwinCAT System Manager configures the programming interfaces

for a wide range of application programs:

•

ActiveX control (ADS-OCX) for e.g. Visual Basic, Visual C++, Delphi, etc.

•

DLL interface (ADS-DLL) for e.g. Visual C++ projects

•

Script interface (ADS script DLL) for e.g. VBScript, JScript, etc.

The TwinCAT System Manager has the following properties:

- Bit-wise association of server process images and I/O channels

- Standard data formats such as arrays and structures

- User defined data formats

- Continuous variable linking

- Drag and Drop

- Import and export at all levels

38 Fieldbus Components

Page 41

Notes on the Documentation

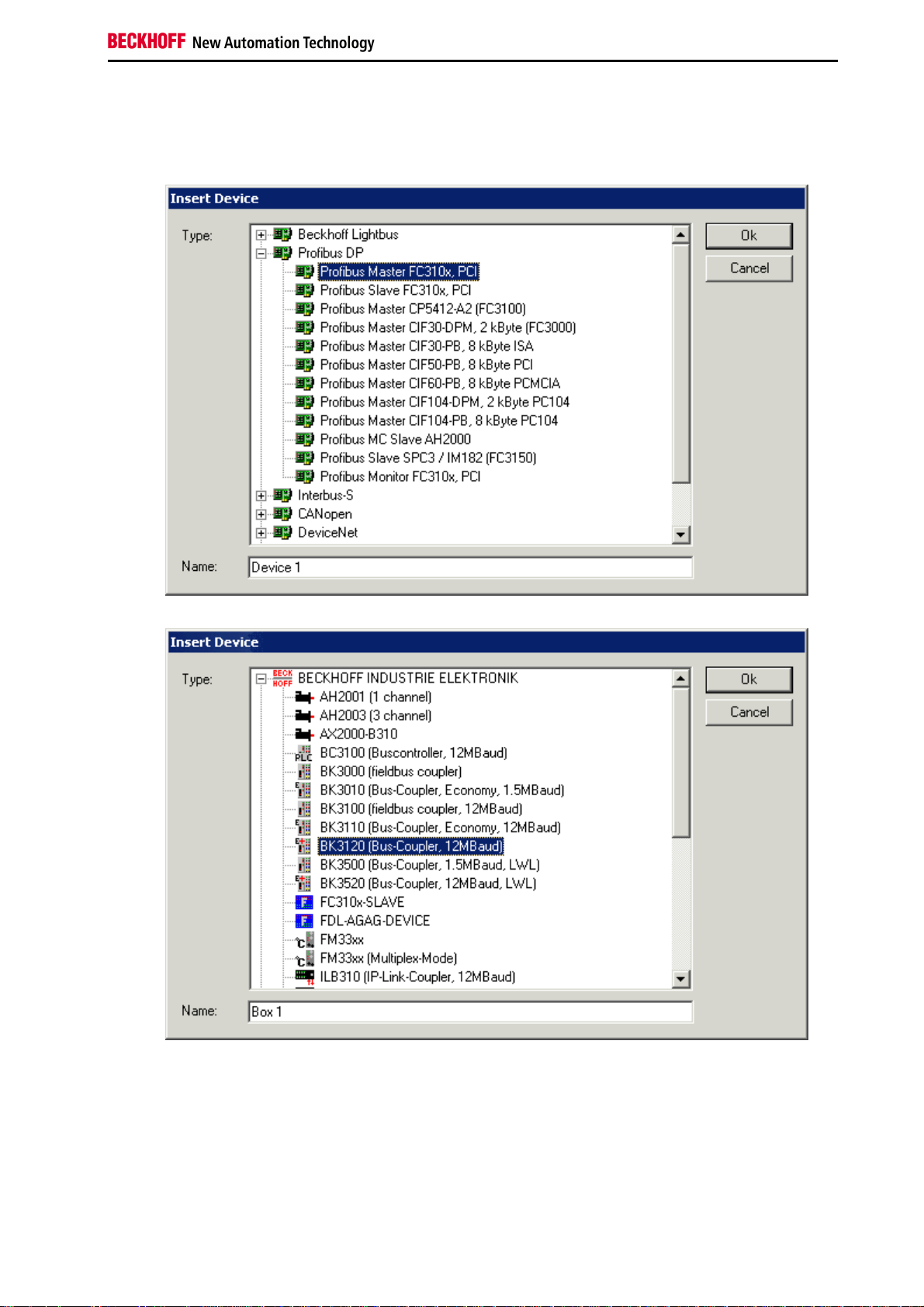

Procedure when configuring the PROFIBUS DP

input/output modules

1. The corresponding PROFIBUS DP master PC card is selected first, and inserted into the I/O configuration.

2. Following the master card, the bus nodes are then inserted:

Fieldbus Components 39

Page 42

Notes on the Documentation

3. The appropriate Bus Terminals are now inserted at the PROFIBUS DP Bus Coupler.

40 Fieldbus Components

Page 43

Notes on the Documentation

Configuration with S7

Configuration: Siemens S7 Controller

Inserting the images

In order to assign an image to the devices in the Siemens software, they must be copied into the

Step7\S7Data\ncbmp directory.

Busklemn.bmp

Busklems.bmp

Inserting the GSD files

•

Go to Extras\Install new GSD in the hardware catalog for your Step7.

•

Select the directory in which the Beckhoff GSD is located, and import the files.

•

You will then find them in the hardware catalog under Profibus DP\Other field devices\I/O.

Fieldbus Components 41

Page 44

Notes on the Documentation

Configuration: Siemens S7 Controller BK3120

Parameter data for the BK3120

Settings

Parameter data Denomination

DPV1 service (class 1) DPV1 Services

Reaction to Bus Terminal error Reaction to Bus Terminal error

Terminal bus diagnostics PROFIBUS diagnosis

Digital terminal diagnostic data Digital Bus Terminal diagnostics

Data format Data format

K-Bus mode K-Bus update

Fast FreeRun mode Fast FreeRun mode

Reaction to DP errors Reaction to fieldbus error

Reaction to K-Bus errors Reaction to K-Bus errors

42 Fieldbus Components

Page 45

Notes on the Documentation

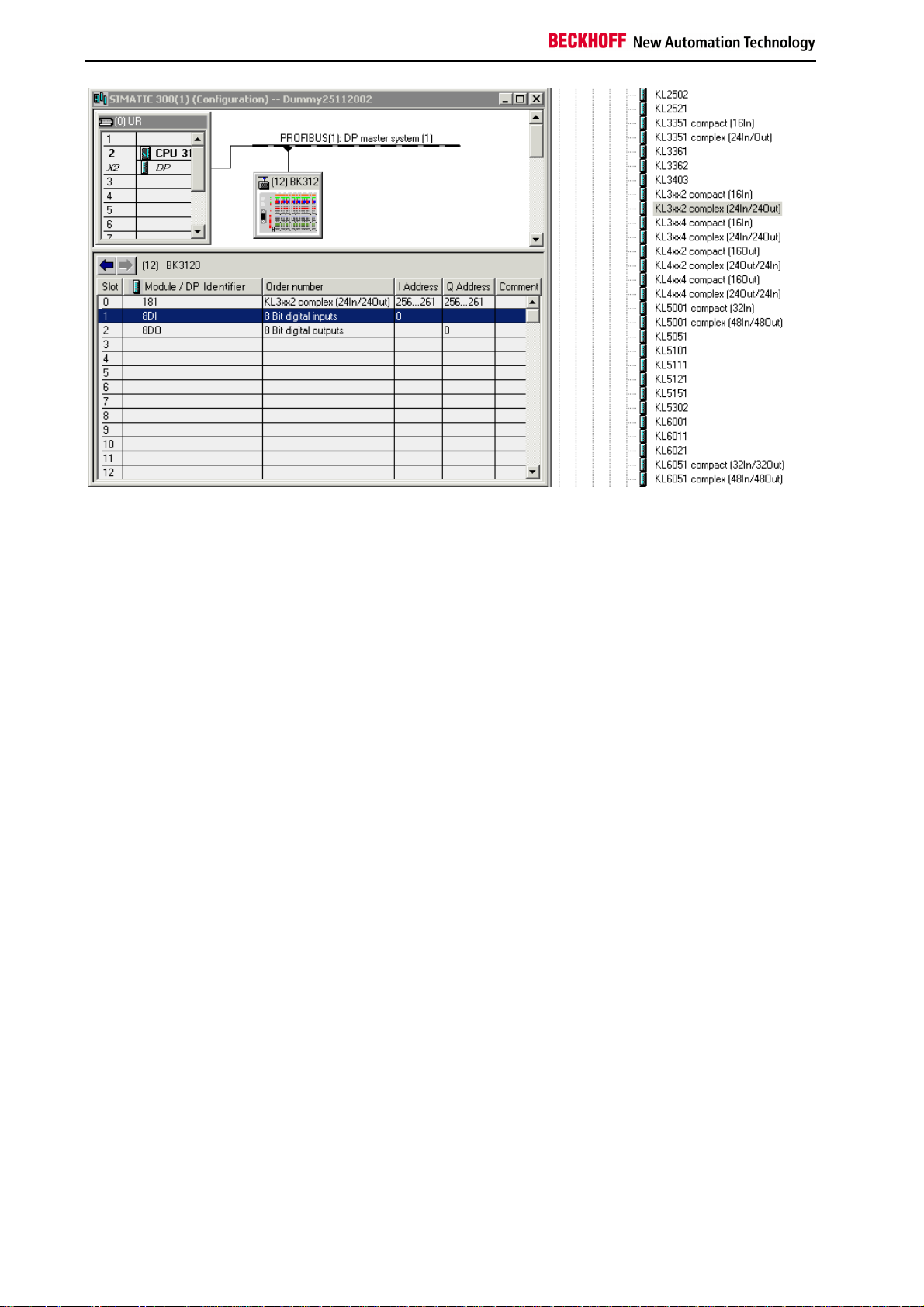

Configuration of the BK3120 module with digital

inputs/outputs only

Example 1:

1 x BK3120

10 x KL1xx4

1 x KL9100 (is not entered, as this Bus Terminal is entirely passive)

11 x KL2xx4

1 x KL9010 (is not entered, as this Bus Terminal is entirely passive)

The sum total of digital bytes must be added together and entered.

Digital inputs

10 x KL1xx4, i.e. 10 x 4 bits = 40 bits

40 bits / 8 = 5 bytes, i.e. 5 x 8 bits entered or 1 x 40 bits or 1 x 8 bits + 1 x 32 bits etc. (see Fig. 2 and Fig. 3)

Digital outputs

11 x KL2xx4, i.e. 10 x 4 bits = 44 bits

44 bits / 8 = 5.5 bytes - rounded up to 6 bytes, i.e. 6 x 8 bits entered or 1 x 48 bits or 1 x 8 bits + 1 x 40 bits etc. (see

Fig. 2 and Fig. 3)

Fig. 2: Example of the entry of individual bytes. Note: Each individual byte requires one byte of ConfigData. In the

BK3120 a maximum of 64 bytes of configuration data is available.

Fieldbus Components 43

Page 46

Notes on the Documentation

Fig. 3: Example of the entry of a group of associated bytes.

44 Fieldbus Components

Page 47

Notes on the Documentation

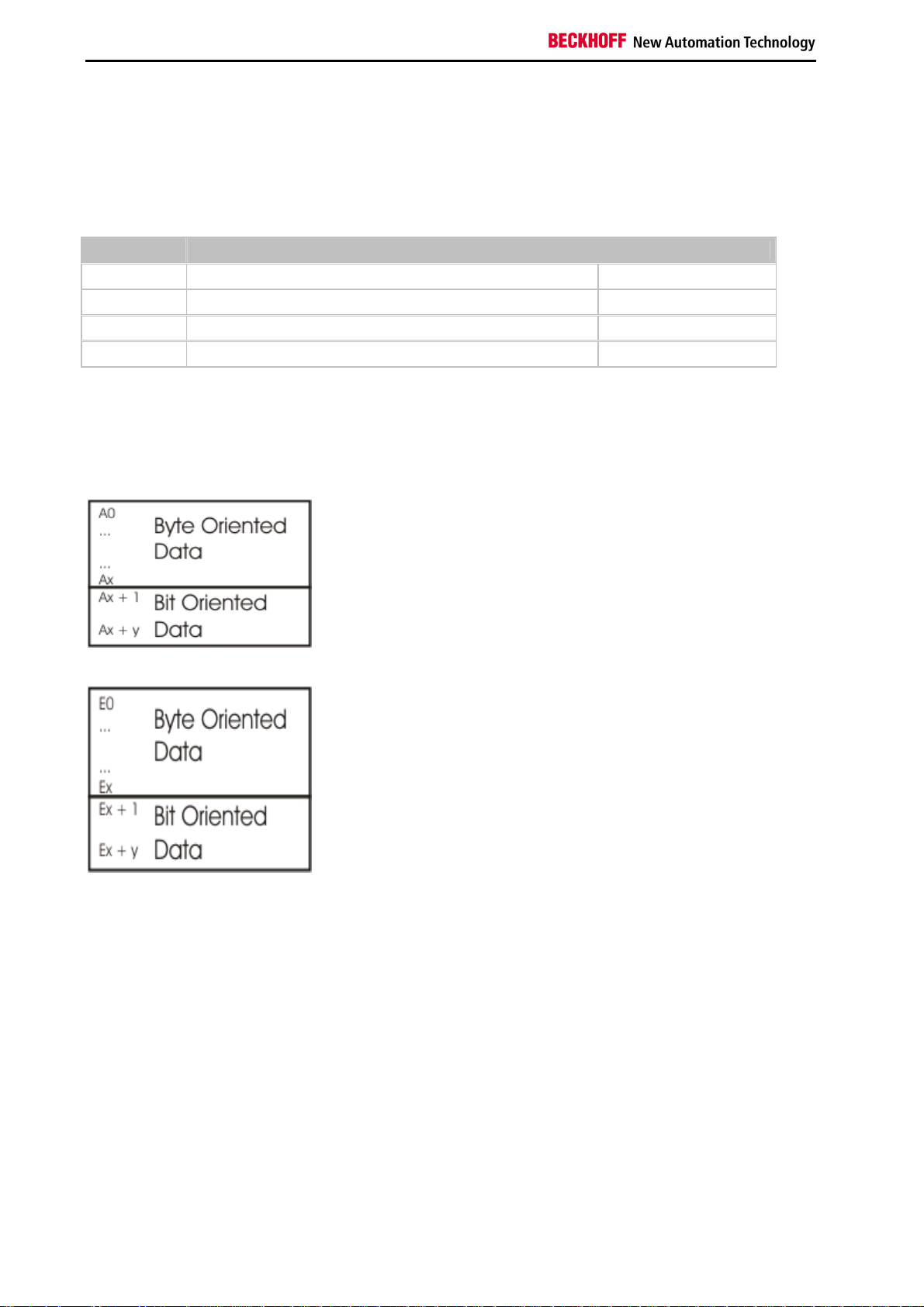

Configuration of the BK3120 module with complex and digital

input/outputs

Byte-oriented modules are the first to be mapped into the process image, and for this reason all the complex modules

must first be entered in the sequence in which they are plugged into the Bus Coupler. For some byte-oriented Bus

Terminals, it is possible to distinguish between compact and complex mapping.

Compact - only user data

Complex - user data plus status (for extended diagnosis) and control (for register communication)

Finally the digital signals are entered and rounded up to a whole byte.

Example 2.a:

1 x BK3120

2 x KL1012

1 x KL2022

1 x KL3312 compact mapping

1 x KL9010

Fig. 2a: Example of the KL3312 compact Bus Terminal

Example 2.b:

1 x BK3120

2 x KL1012

1 x KL2022

1 x KL3312 complex mapping

1 x KL9010

Fieldbus Components 45

Page 48

Notes on the Documentation

Example of the KL3312 complex Bus Terminal

46 Fieldbus Components

Page 49

Notes on the Documentation

5. PROFIBUS DP Comunication

Cyclic Data Exchange

Process Data, Process Image

The Bus Coupler includes different memory areas, each having a capacity of 256 words. Telegrams passing over the

Lightbus can specifically access any desired memory cell. The control and status bytes in the Lightbus telegrams can

be used to distinguish between two relevant regions of the memory and to address them separately. In order to

initiate a Bus Coupler update, the value in the control and status bytes must be 0x10, while the data byte must

contain the constant 80hex. It is possible to access the Bus Coupler data after this. For this purpose the control and

status byte contains the value 0x30. Two bytes can be written and two bytes can be read simultaneously with one

access. The process is described in detail in the following sections.

After being switched on, the Bus Coupler determines the configuration of the inserted input/output terminals. The

assignment of the physical slots for the input/output channels and the addresses in the process image is carried out

automatically by the Bus Coupler.

The Bus Coupler creates an internal assignment list, in which the input/output channels have a specific position in the

process image of the Bus Coupler. A distinction is made here according to inputs and outputs, and according to bitoriented (digital) and byte-oriented (analog or complex) signal processing.

Two groups are created, one for inputs and the other for outputs. Each group has the byte-oriented channels in

ascending sequence, starting from the lowest address, and these are followed by the bit-oriented channels.

Digital signals (bit-oriented)

The digital signals are bit-oriented. This means that one bit in the process image is assigned to each channel. The

Bus Coupler creates a memory area containing the current input bits, and ensures that the bits in a second (output)

memory area dedicated to the output channels are written out immediately, following the update command.

The details of the assignment of the input and output channels to the controller's process image is explained fully with

the aid of an example in the appendix.

Analog signals (byte-oriented)

The processing of analog signals is always byte-oriented. Analog input and output values are represented in memory

by two bytes each. Values are represented in SIGNED INTEGER format. The number 0 stands for the input/output

value 0 V, 0 mA or 4 mA. The maximum value of an output or input value is represented, according to the standard

settings, by 0x7FFF. The intermediate values are correspondingly proportional. A range with a resolution of 15 bits is

not achieved for all inputs and outputs. If the actual resolution is 12 bits, the last three bits have no effect in outputs,

while as inputs they are read as 0. Each channel also has a control and status byte. The control and status byte is

the most significant byte in the most significant word. An analog channel is represented by 4 bytes in the process

image, of which 3 bytes are used. In the BK3000 and BK4000 only 2 bytes are occupied in the process image of the

corresponding bus system for each analog channel. The Bus Terminal's control and status bytes can also be

included through appropriate configuration of the Bus Coupler and Bus Terminals.

Special signals and interfaces

The Bus Coupler supports Bus Terminals with other interfaces such as RS232, RS485, incremental encoder and

others. These signals can be considered similarly to the analog signals named above. For some special signals the

bit width of 16 is not sufficient. The Bus Coupler can support any byte width. It is necessary to consider how data

consistency is ensured when accessing these values. This means that update commands must not be issued nor

must the Bus Coupler be placed into the free running mode between the accesses.

Fieldbus Components 47

Page 50

Notes on the Documentation

Default assignment of the inputs and outputs to the process image

Once it has been switched on, the Bus Coupler finds out how many Bus Terminals are inserted, and creates an

assignment list. The analog and digital channels, divided into inputs and outputs, are assembled into separate parts

of this list. The assignment starts on the left next to the Bus Coupler. The software in the Bus Coupler collects

consecutively the individual entries for each of the channels in order to create the assignment list counting from left to

right. Four groups are distinguished in the assignment:

Group Functional type of the channel Assignment

1 analog outputs byte-wise

2 digital outputs bit-wise

3 analog inputs byte-wise

4 digital inputs bit-wise

All complex Bus Terminals are represented by analog inputs or outputs.

Overview of the distribution of the process image within the Bus Coupler

Output data in the Bus Coupler

Input data in the Bus Coupler

48 Fieldbus Components

Page 51

Notes on the Documentation

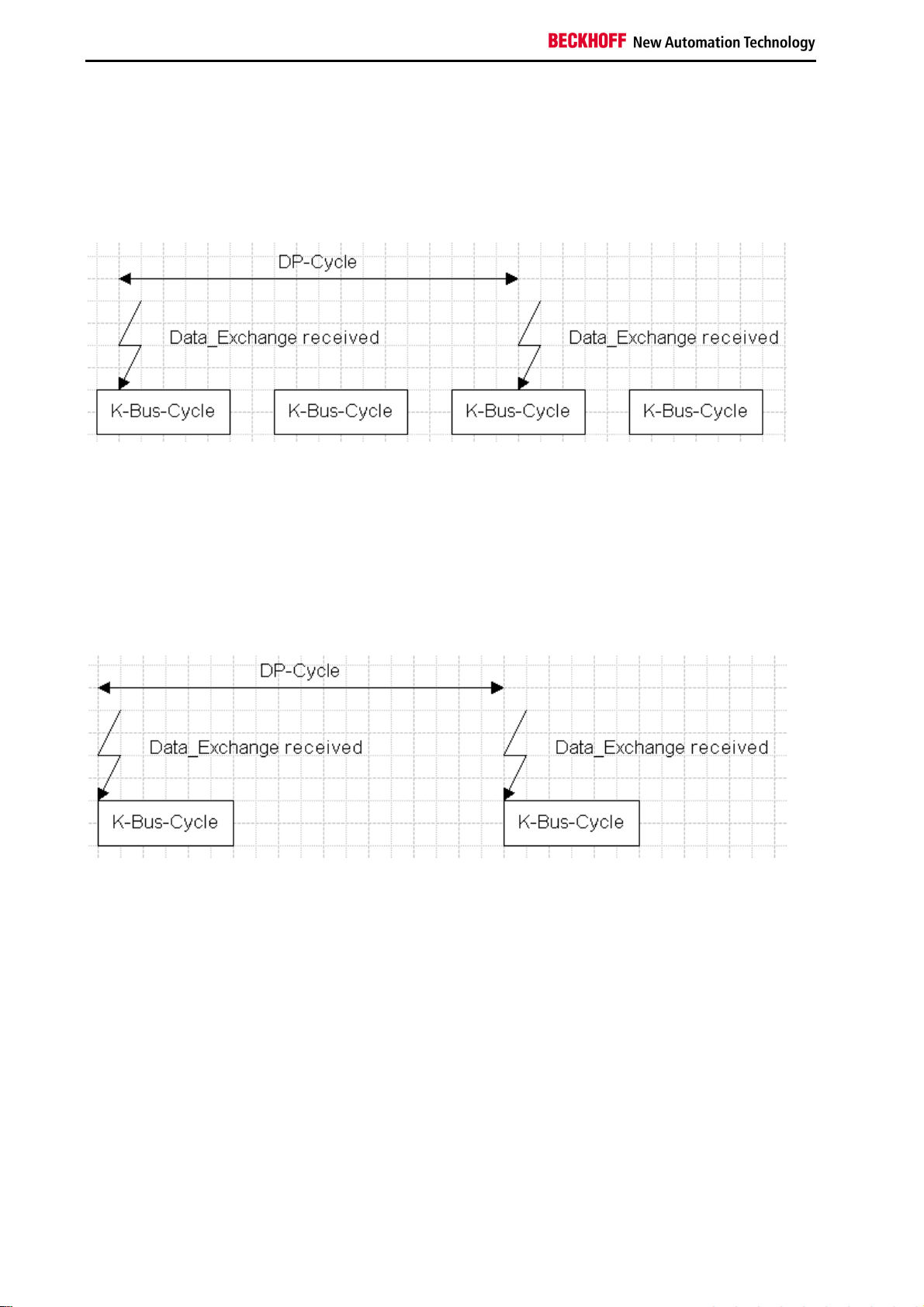

K-Bus Cycle

The K-Bus cycle can be set to run freely (FreeRun mode) or synchronously (synchronous mode) with respect to the

DP cycle. The K-Bus cycle for the DP coupler consists of the following parts:

The K-Bus cycle time can be calculated to a precision of approximately 10% by means of the following formula (4channel terminals or terminals with more than 6 bytes of data (exception: ASI terminal KL6201, which has more than

12 bytes of data) require two or more K-Bus cycles. The number of K-Bus cycles is in register ?? of table 90):

Tcyc (in µs) = number of K-Bus cycles x (600 + number of

digital channels x 2.5 + number of analog

input channels x 32 + number of analog output channels x 42)

The K-Bus cycle time can be read via DPV1. If TwinCAT is used, this is possible on the "Beckhoff" tab of

the DP coupler in the System Manager.

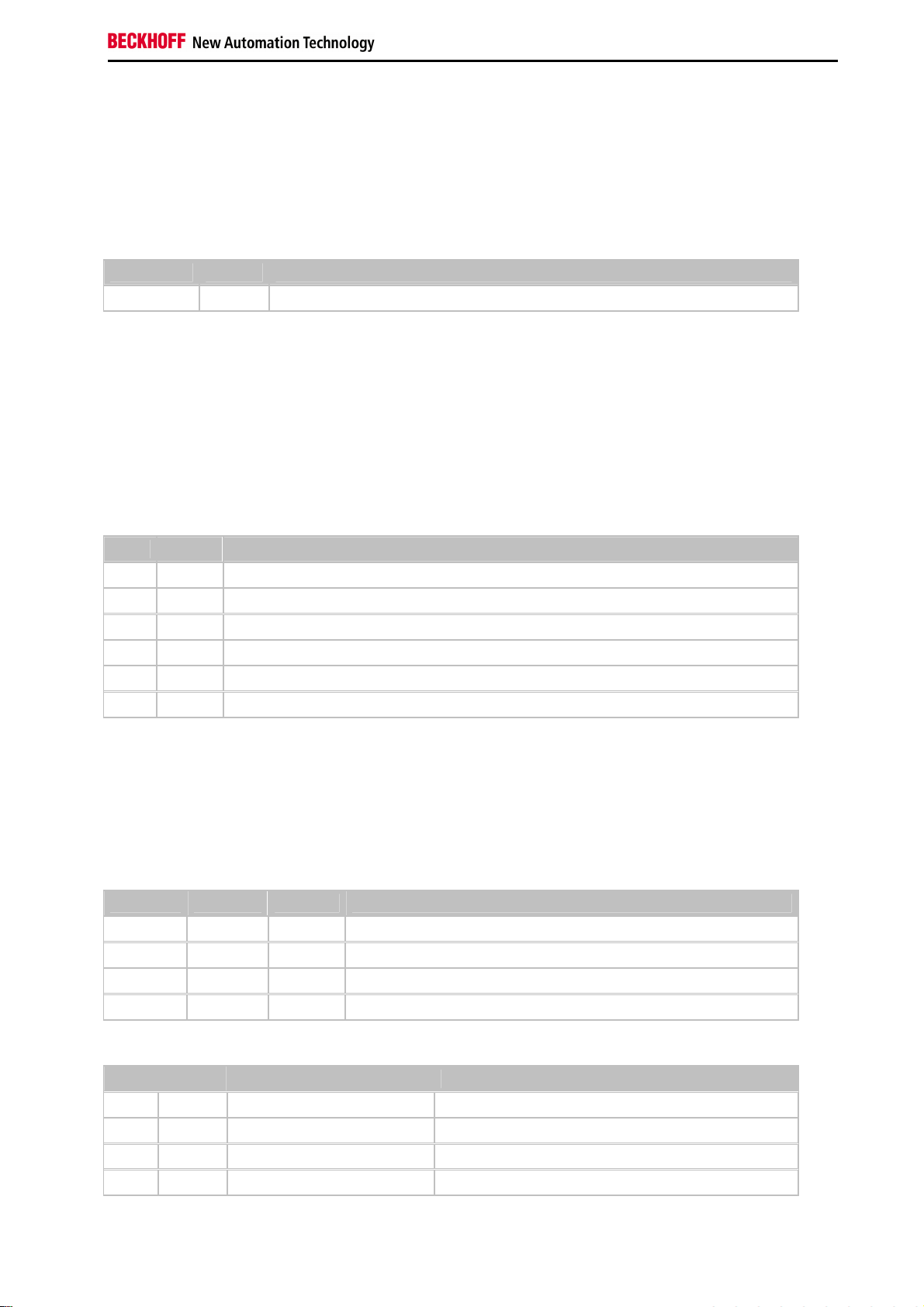

K-Bus modes

The K-Bus mode (the type of synchronisation between the K-Bus cycles and the DP cycle) is set via the

UserPrmData:

Byte 9, bit 4 Byte 9, bit 6 Byte 12, bit 0 Byte 12, bit

1 K-Bus mode

1

0

bin

1

1

bin

0

0

bin

0

0

bin

0

0

bin

0

bin

0

bin

0

bin

1

bin

0

bin

0

bin

0

bin

0

bin

0

bin

1

bin

bin

bin

bin

bin

bin

Slow FreeRun

Fast FreeRun

Synchronous

Synchronous with optimised input update, one

cycle

Synchronous with optimised input update, two

cycles

FreeRun mode

Slow FreeRun (default setting)

In the FreeRun mode there is no synchronisation between the K-Bus cycle and the DP cycle. It is a

characteristic feature of the Slow FreeRun mode that the K-Bus cycle is called from the main task. Acyclic

communication or events result in heavy jitter in the K-Bus cycle (KS2000, DPV1, terminal diagnosis,

etc.), because all of these functions are also called from the main task.

Fieldbus Components 49

Page 52

Notes on the Documentation

Fast FreeRun