BBK 934S Service Manual

SERVICE MANUAL

bbk934S

CONTENTS

1. SAFETY PRECAUTIONS |

1 |

2.PREVENTION OF ELECTRO STATIC DISCHARGE(ESD)TO ELECTROSTATICALLY

|

SENSITIVE(ES)DEVICES |

1 |

3. |

CONTROL BUTTON LOCATIONS AND EXPLANATIONS |

2 |

4. |

PREVERTION OF STATIC ELECTRICITY DISCHARGE |

3 |

5. |

ASSEMBLING AND DISASSEMBLING THE MECHANISM UNIT |

4 |

5.1 |

OPTICAL PICKUP UNIT EXPLOSED VIEW AND PART LIST |

4 |

5.2 |

BRACKET EXPLOSED VIEW AND PART LIST |

6 |

5.3 |

MISCELLANEOUS |

7 |

6. |

ELECTRICAL CONFIRMATION |

8 |

6.1 |

VIDEO OUTPUT (LUMINANCE SIGNAL) CONFIRMATION |

8 |

6.2 |

VIDEO OUTPUT(CHROMINANCE SIGNAL) CONFIRMATION |

9 |

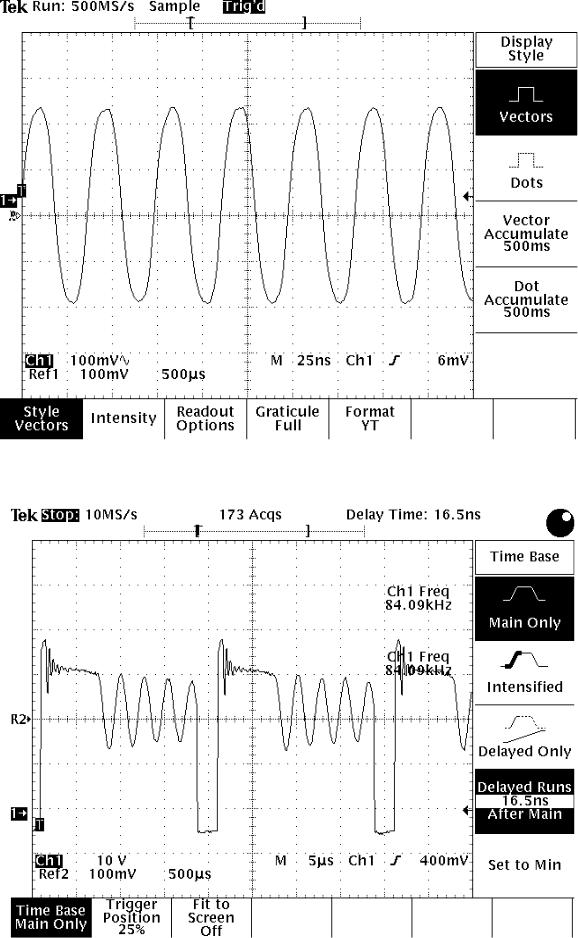

7. |

MPEG BOARD CHECK WAVEFORM |

10 |

8. |

IC BLOCK DIAGRAM & DESCRIPTION |

11 |

8.1 |

MT1336 |

11 |

8.2 |

MT1379 |

19 |

8.3 |

AM29LV160D |

35 |

8.4 |

HY57V641620HG |

40 |

9. |

SCHEMATIC & PCB WIRING DIAGRAM |

43 |

10. |

SPARE PARTS LIST |

57 |

1.1 GENERAL GUIDELINES

1.When servicing, observe the original lead dress. if a short circuit is found, replace all parts which have been overheated or damaged by the short circuit.

2.After servicing, see to it that all the protective devices such as insulation barrier, insulation papers shields are properly installed.

3.After servicing, make the following leakage current checks to prevent the customer from being exposed

to shock hazards.

Some semiconductor(solid state)devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive(ES)Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and semiconductor chip components. The following techniques should be used to help reduce the incidence of component damage caused by electro static discharge(ESD).

1.Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your body by touching a known earth ground. Alternatively, obtain and wear a commercially availabel discharging ESD wrist strap, which should be removed for potential shock reasons prior to applying power to the unit under test.

2.After removing an electrical assembly equipped with ES devices,place the assembly on a conductive surface such as alminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4.Use only an anti-static solder removal device. Some solder removal devices not classified as anti-static

(ESD protected)can generate electrical charge sufficient to damage ES devices.

5.Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6.Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable conductive material).

7.Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity(ESD).

notice (1885x323x2 tiff)

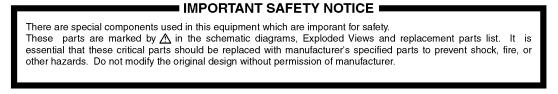

3.Control Button Locations and Explanations

Front Panel Illustration

6 |

7 |

8 |

9 |

2 |

3 |

4 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 11 12 13 14

|

POWER switch |

6 |

Disc tray |

2 |

MIC 1 jack |

7 |

Remote control signal sensor |

3 |

MIC 2 jack |

8 |

OPEN/CLOSE button |

4 |

MIC VOLUME 1 knob |

9 |

VFD display window |

5 |

MIC VOLUME 2 knob |

10 |

PLAY/PAUSE button |

11 STOP/BAND button

12FUNCTION button

13DVD MODE PREV button TUNER MODE TUNING button

TUNING button

14DVD MODE: NEXT button TUNER MODE: TUNING button

button

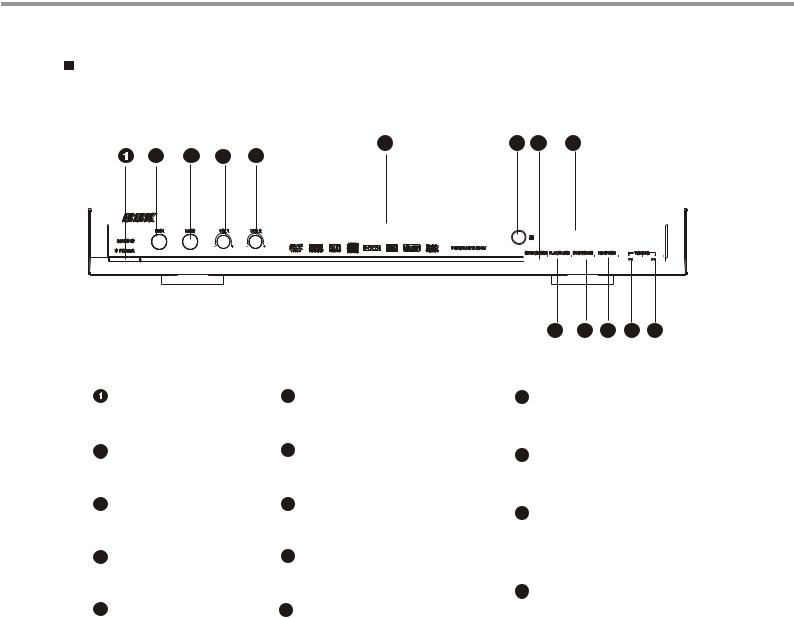

The laser diode in the traverse unit (optical pickup)may brake down due to static electricity of clothes or human body. Use due caution to electrostatic breakdown when servicing and handling the laser diode.

4.1.Grounding for electrostatic breakdown prevention

Some devices such as the DVD player use the optical pickup(laser diode)and the optical pickup will be damaged by static electricity in the working environment.Proceed servicing works under the working environment where grounding works is completed.

4.1.1. Worktable grounding

1.Put a conductive material(sheet)or iron sheet on the area where the optical pickup is placed,and ground the sheet.

4.1.2.Human body grounding

1 Use the anti-static wrist strap to discharge the static electricity from your body.

safety_3 (1577x409x2 tiff)

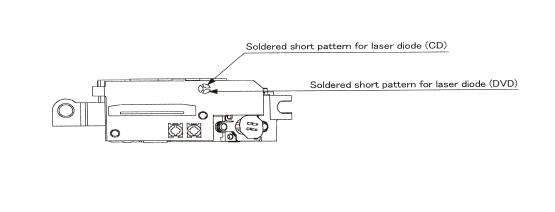

4.1.3.Handling of optical pickup

1.To keep the good quality of the optical pickup maintenance parts during transportation and before installation, the both ends of the laser diode are short-circuited.After replacing the parts with new ones, remove the short circuit according to the correct procedure. (See this Technical Guide).

2.Do not use a tester to check the laser diode for the optical pickup .Failure to do so willdamage the laser diode due to the power supply in the tester.

4.2. Handling precautions for Traverse Unit (Optical Pickup)

1.Do not give a considerable shock to the traverse unit(optical pickup)as it has an extremely high-precise structure.

2.When replacing the optical pickup, install the flexible cable and cut is short land with a nipper. See the optical pickup replacement procedure in this Technical Guide. Before replacing the traverse unit, remove the short pin for preventingstatic electricity and install a new unit.Connect the connector as short times as possible.

3.The flexible cable may be cut off if an excessive force is applied to it.Use caution when handling the cable

4.The half-fixed resistor for laser power adjustment cannot be adjusted. Do not turn the resistor.

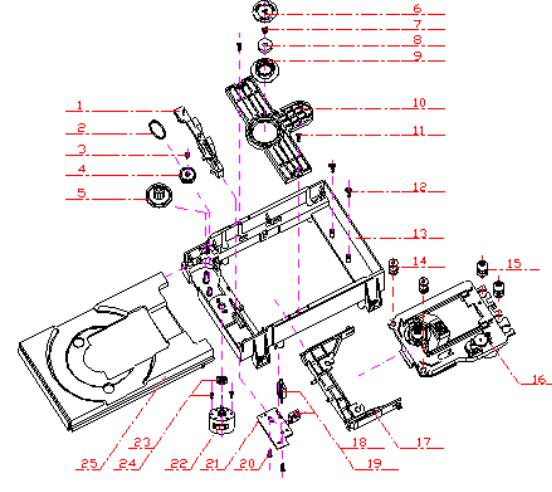

5.1 Optical pickup Unit Explosed View and Part List

Pic (1)

Materials to Pic (1)

No. |

PARTS CODE |

PARTS NAME |

Q ty |

|

|

|

|

|

14692200 |

SF-HD60 |

1 |

1 |

1EA0311A06300 |

ASSY, CHASSIS, COMPLETE |

1 |

2 |

1EA0M10A15500 |

ASSY, MOTOR, SLED |

1 |

Or |

1EA0M10A15501 |

ASSY, MOTOR, SLED |

1 |

3 |

1EA2451A24700 |

HOLDER, SHAFT |

3 |

4 |

1EA2511A29100 |

GEAR, RACK |

1 |

5 |

1EA2511A29200 |

GEAR, DRIVE |

1 |

6 |

1EA2511A29300 |

GEAR, MIDDLE, A |

1 |

7 |

1EA2511A29400 |

GEAR, MIDDLE, B |

1 |

8 |

1EA2744A03000 |

SHAFT, SLIDE |

1 |

9 |

1EA2744A03100 |

SHAFT, SLIDE, SUB |

1 |

10 |

1EA2812A15300 |

SPRING, COMP, TYOUSEI |

3 |

11 |

1EA2812A15400 |

SPRING, COMP, RACK |

1 |

|

|

|

|

21 |

1EA0B10B20100 |

ASSY, PWB |

1 |

Or |

1EA0B10B20200 |

ASSY, PWB |

1 |

|

|

|

|

31 |

SEXEA25700--- |

SPECIAL SCREW BIN+-M2X11 |

3 |

32 |

SEXEA25900--- |

SPECIAL SCREW M1.7X2.2 |

2 |

33 |

SFBPN204R0SE- |

SCR S-TPG PAN 2X4 |

2 |

34 |

SFSFN266R0SE- |

SCR S-TPG FLT 2.6X6 |

1 |

35 |

SWXEA15400--- |

SPECIAL WASHER 1.8X4 X0.25 |

2 |

Note : This parts list is not for service parts supply.

5.2 Bracket Explosed View and Part List

Materials to Pic(2) |

Pic (2) |

|

|

||

1.bracket |

14. front silicon rubber |

|

2.belt |

15. Back silicon rubber |

|

3.screw |

16. Pick-up |

|

4.belt wheel |

17. Pick-up |

|

5.gearwheel |

18. switch |

|

6.iron chip |

19. Five-pin flat plug |

|

7. |

Immobility mechanism equipment |

20. screw |

8. Magnet |

21. PCB |

|

9. |

Platen |

22. motor |

10. |

Bridge bracket |

23. Motor wheel |

11. screw |

24. screw |

|

12. screw |

25.tray |

|

13. |

Big bracket |

|

Before going process with disassembly and installation, please carefully both peruse the chart and confirm the materials.

5.3 MISCELLANEOUS

5.3.1 Protection of the LD(Laser diode)

Short the parts of LD circuit pattern by soldering.

5.3.2 Cautions on assembly and adjustment

Make sure that the workbenches,jigs,tips,tips of soldering irons and measuring instruments are grounded,and that personnel wear wrist straps for ground.

Open the LD short lands quickly with a soldering iron after a circuit is connected.

Keep the power source of the pick-up protected from internal and external sources of electrical

noise.

Refrain from operation and storage in atmospheres containing corrosive gases (such as H2S,SO2, NO2 and Cl2)or toxic gases or in locations containing substances(especially from the organic silicon,cyan, formalin and phenol groups)which emit toxic gases.It is particularly important to ensure that none of the above substances are present inside the unit.Otherwise,the motor may no longer run.

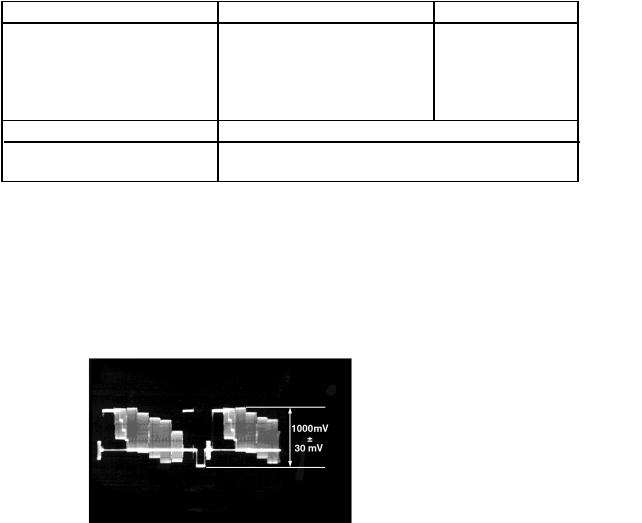

6.1. Video Output (Luminance Signal) Confirmation |

|

|

DO this confirmation after replacing a P.C.B. |

|

|

Measurement point |

Mode |

Disc |

|

Color bar 75% |

DVDT-S15 |

Video output terminal |

PLAY(Title 46):DVDT-S15 |

or |

|

PLAY(Title 12):DVDT-S01 |

DVDT-S01 |

Measuring equipment,tools |

Confirmation value |

|

200mV/dir,10 sec/dir |

1000mVp-p±30mV |

|

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohms. 2.Confirm that luminance signal(Y+S)level is 1000mVp-p±30mV

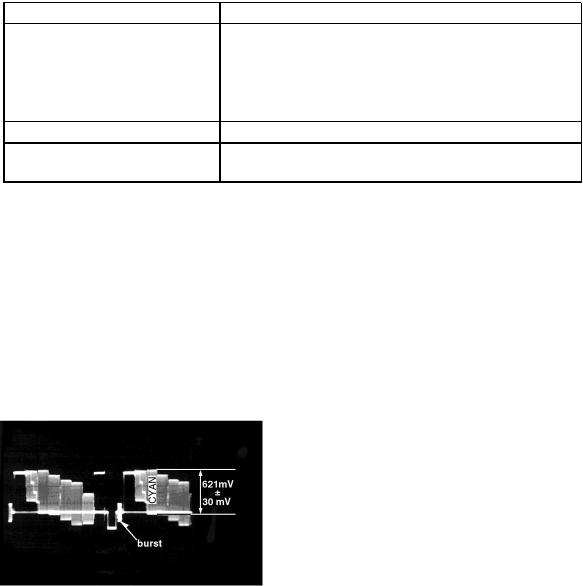

Do the confirmation after replacing P.C.B. |

|

|

Measurement point |

Mode |

Disc |

|

Color bar 75% |

DVDT-S15 |

Video output terminal |

PLAY(Title 46):DVDT-S15 |

or |

|

PLAY(Title 12):DVDT-S01 |

DVDT-S01 |

Measuring equipment,tools |

Confirmation value |

|

Screwdriver,Oscilloscope |

|

|

200mV/dir,10 sec/dir |

621mVp-p±30mV |

|

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohme.

2.Confirm that the chrominance signal(C)level is 621 mVp-p±30mV

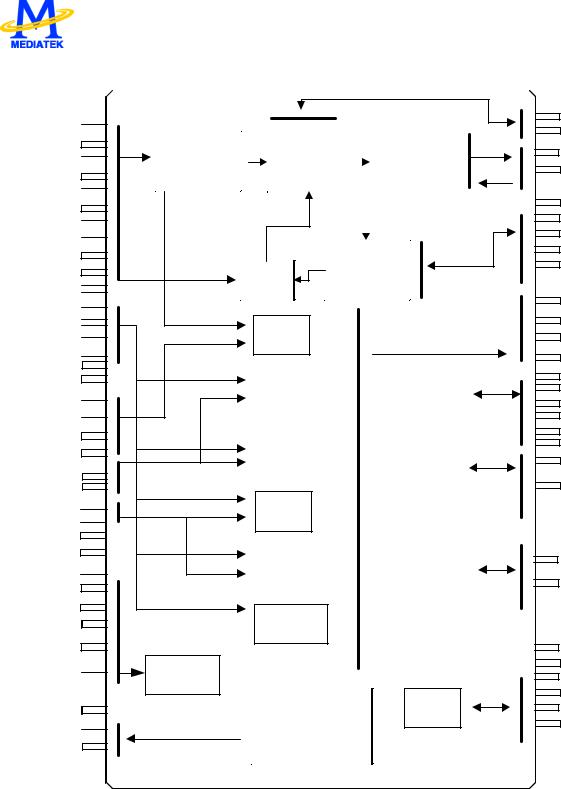

MT1336

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE |

MTK CONFIDENTIAL, NO DISCLOSURE |

GENERAL DESCRIPTION

M T 1 3 3 6 i s a h i g h p e r f o r m a n c e C M O S a n a l o g f r o n t -e n d I C f o r b o t h C D _ R O M d r i v e r u p t o 4 8 X S a n d

D V D - R O M d r i v e r u p t o 1 6 X S . I t a l s o s u p p o r t s D V D- R A M r e a d u p t o 4 X S V e r s i o n 2 . I t c o n t a i n s s e r v o a m p lifiers

t o g e n e r a t e f o c u s i n g e r r o r , 3-b e a m t r a c k i n g e r r o r , 1 b e a m r a d i a l p u s h -p u l l s i g n a l , R F l e v e l a n d S B A D f o r s e r v o f u n c t i o n s . I t a l s o i n c l u d e s D P D t r a c k i n g e r r o r s i g n a l f o r D V D _ R O M a p p l i c a t i o n . F o r D V D- R A M d i s k s , t h e r e a r e also Differential Push -P u l l ( D P P ) m e t h o d f o r g e n e r a t i n g t r a c k i n g s i g n a l a n d D i f f e r e n t i a l A s t i g m a t i c D e t e c t i o n ( D A D ) f o r p r o c e s s i n g f o c u s i n g s i g n a l . P r o g r a m m a b l e e q u a l i z e r a n d A G C c i r c u i t s a r e a l s o i n c o r p o r a t e d i n t h i s c h i p t o o p t i m i z e r e a d c h a n n e l p e r f o r m a n c e . I n a d d i t i o n , t h i s c h i p h a s d u a l a u t o m a t i c l a s e r p o w e r c o n t r o l c i r c u i t s f o r D V D- R O M ( D V D-R A M ) a n d C D -R O M s e p e r a t e l y a n d r e f e r e n c e v o l t a g e g e n e r a t o r s t o r e d u c e e x t e r n a l c o m p o n e n t s . P r o g r a m m a b l e f u n c t i o n s a r e i m p l e m e n t e d b y t h e a c c e s s o f i n t e r n a l r e g i s t e r t h r o u g h b i -d i r e c t i o n a l serial port to configure modes selection.

FEATURES

n |

R F e q u a l i z e r w i t h p r o g r a m m a b l e f c f r o m 3 M H z t o 7 0 M H z a n d p r o g r a m m a b l e b o o s t f r o m 3 d B t o |

|

13dB. |

n |

M T 1 3 3 6 s u p p o r t s a t l e a s t e i g h t d i f f e r e n t k i n d s o f p i c k-u p h e a d s w i t h v e r s a t i l e i n p u t c o n f i g u r ation for |

|

both RF input stages and servo signal blocks. |

nVersatile on -line AGC.

n3 beams tracking error signal generator for CD_ROM application.

nOne beam differential phase tracking error (DPD) generator for DVD_ROM application.

nDifferential push pull tracki ng error (DPP) generator for DVD_RAM application.

nFocusing error signal generator for CD-ROM, DVD-ROM and DVD-RAM (DAD method).

nRF level signal generator.

nSub-beam added signal for 3 beams CD_ROM.

nOne beam push -pull signal generator for central servo application.

nHigh speed RF envelop detection circuit with bandwidth up to 400KHz for CD-ROM.

nDefect and Blank detection circuits.

nDual automatic laser power control circuits with programmable level of LD monitor voltage.

nVref=1.4V voltage and V2ref=2.8V voltage generators.

nV20=2.0V voltage for pick -up head reference.

nBi-directional serial port to access internal registers.

MT1336

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE |

MTK CONFIDENTIAL, NO DISCLOSURE |

||

|

|

|

|

DVDA

CDA

DVDB

CDB

DVDC

CDC

DVDD

CDD  DVDRFIN

DVDRFIN

DVDRFIP MA  MB

MB  MC

MC  MD

MD  SA

SA  SB

SB  SC

SC

SD

DPFN

DPFO

IR

DPDMUTE

TPI

TNI

CDFOP

CDFON

RFGC

RFGCU

RFGCI

AGC1

AGC2

AGC3

RFSUBO

WOBSO

V20

V2REFO

VREFO

ATTENUATORINPUTMUX

WOBBLE

DET

VGA |

|

|

|

EQ |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ENVELOP

DETECTOR

AGC

DPD

|

|

PCS |

SBAD |

|

|

|

|

|

|

|

|

TE |

|

|

|

DVD |

|

|

|

|

|

|

APC |

|

||

|

|

|

RF

LEVEL

|

|

|

FE |

|

CD |

|

|

|

|

|

APC |

|

|

|

|

|

|

CENTRAL

SERVO

SERIAL

PORT

REF and 2VREF

Voltage Generator

OSP

OSN

RFOP

RFON

LRFRP

DEFECT

HRFRP

CRTP CRTPLP

CSO

LVL

TEO

FEO

REFCOS HALLCOS COSPHI REFSIN HALLSIN SINPHI

MDI2

LDO2

MDI1

LDO1

UDGATE IDGATE VFO13

SDATA

SLCK

SDEN

MT1336 FUNCTION BLOCKS DIAGRAM

|

MT1336 |

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE |

MTK CONFIDENTIAL, NO DISCLOSURE |

WOBSO |

|

|

|

1 |

|

|

|

|

|

WVDD |

|

2 |

||

AGNDX |

|

3 |

||

AGNDX |

|

|

4 |

|

AVDDO |

|

5 |

||

RFOP |

|

|

6 |

|

|

|

|

|

|

RFON |

|

7 |

||

AGNDO |

|

|

|

8 |

|

|

|||

TM1 |

|

|

9 |

|

|

|

|||

TM2 |

|

10 |

||

|

|

|

||

TM3 |

|

|

11 |

|

AGNDT |

|

12 |

||

|

|

|

||

TM4 |

|

13 |

||

AVDDT |

|

|

14 |

|

|

|

|

|

|

V2REFO |

|

15 |

||

VREFO |

|

16 |

||

V20 |

|

17 |

||

FEO |

|

18 |

||

LVL |

|

19 |

||

|

|

|

|

|

CSO |

|

20 |

||

|

|

|

||

TEO |

|

21 |

||

|

||||

VDDP |

|

22 |

||

|

||||

DEFECT |

|

23 |

||

|

||||

LRFRP |

|

24 |

||

|

||||

HRFRP |

|

25 |

||

|

||||

CRTP |

|

26 |

||

CRTPLP |

|

|

27 |

|

|

|

|

|

|

TRLPA |

|

28 |

||

TRLP |

|

29 |

||

HTRC |

|

30 |

||

GNDP |

|

31 |

||

DPFN |

|

32 |

||

DPFO |

|

33 |

||

|

||||

AGNDX |

|

34 |

||

|

||||

AGNDX |

|

35 |

||

|

||||

AGNDX |

|

36 |

||

|

||||

VDD |

|

37 |

||

|

||||

VFO13 |

|

38 |

||

WGND |

RFSUBO |

LDO2 |

LDO1 |

MDI1 |

MDI2 |

AGC3 |

AGC2 |

WAVDD |

AGC1 |

WAGND |

SGND |

|

TNI |

TPI |

SVDD |

CDFON |

CDFOP |

SD |

SC |

AVDD |

IR |

AGND |

SB |

SA |

MD |

MC |

||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

128 |

127 |

126 |

|

125 |

|

124 |

123 |

|

122 |

121 |

120 |

|

119 |

118 |

117 |

116 |

115 |

114 |

113 |

112 |

|

111 |

110 |

109 |

108 |

107 |

106 |

105 |

104 |

103 |

||||||||||||||||||||||||||||||||

MT1336

DVD-ROM

With

DVD_RAM

Read

39 |

40 |

41 |

|

42 |

|

43 |

|

44 |

|

45 |

46 |

|

47 |

|

48 |

|

49 |

|

50 |

51 |

52 |

53 |

54 |

55 |

|

56 |

57 |

58 |

59 |

|

60 |

|

61 |

62 |

63 |

64 |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GND |

UDGATE |

HDGATE |

IO0 |

IO1 |

IO2 |

IO3 |

IO4 |

IO5 |

IO6 |

IO7 |

IO8 |

IO9 |

IOA IOB |

VDDS |

XCK16M |

SCLK |

GNDS SDEN |

SDATA |

RST |

DPDMUTE |

AGNDP |

AGNDX |

AVDDP |

|||||||||||||||||||||||||||||||||||||||||

102  MB

MB

101  MA

MA

100  DVDA

DVDA

99  DVDB

DVDB

98  DVDC

DVDC

97  DVDD

DVDD

96  DVDRFIP

DVDRFIP

95  DVDRFIN

DVDRFIN

94  CDA

CDA

93  CDB

CDB

92  CDC

CDC

91  CDD

CDD

90  OSN

OSN

89  OSP

OSP

88  RFGC

RFGC

87  RFGCU

RFGCU

86  RFGCI

RFGCI

85  CEQP

CEQP

84  CEQN

CEQN

83  AGNDX

AGNDX

82  AGNDX

AGNDX

81  MON

MON

80  MOP

MOP

79  SW1

SW1

78  SW2

SW2

77  SWO

SWO

76  SINPHI

SINPHI

75  REFSIN

REFSIN

74  HALLSIN

HALLSIN

73  AGNDM

AGNDM

72  REFCOS

REFCOS

71  HALLCOS

HALLCOS

70  COSPHI

COSPHI

69  AVDDM

AVDDM

68  AGNDX

AGNDX

67  AVDDF

AVDDF

66  VCON

VCON

65  AGNDF

AGNDF

MT1336 PIN ASSIGNMENT

|

|

|

|

|

|

|

MT1336 |

|

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE |

|

MTK CONFIDENTIAL, NO DISCLOSURE |

||||||

|

|

|

|

|

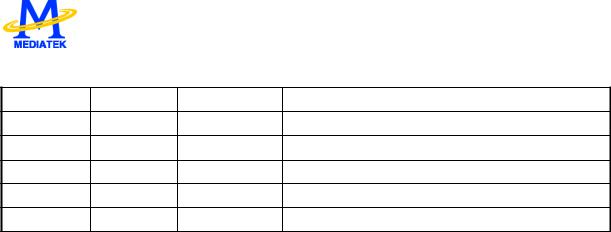

MT1336 PIN DESCRIPTIONS |

|

|

|

|

|

|

|

|

|

|

||

Pin Numbers |

|

|

Symbol |

Type |

Description |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LQFP128 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

RF Flag Interface |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

23 |

|

|

DEFECT |

Digital Output |

Flag of bad data output status |

|

|

|

|

|

|

|

|

|

|

|

|

RF SIO interface |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

56 |

|

|

SCLK |

Digital Input |

RF serial clock input |

|

|

|

|

|

|

|

|

|

|

|

|

58 |

|

|

SDEN |

Digital Input |

RF serial data enable |

|

|

|

|

|

|

|

|

|

|

|

|

59 |

|

|

SDATA |

Digital IO |

RF serial data IO |

|

|

|

60 |

|

|

RST |

Digital input |

Reset (active high) |

|

|

|

|

|

|

|

|

|

|

|

|

55 |

|

|

XCK16M |

Digital Input |

16.9MHz for verification |

|

|

|

|

|

|

|

|

|

|

|

|

RF SERVO interface |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

40 |

|

|

UDGATE |

Digital |

Input |

Con trol signal for DVD-RAM |

|

|

|

|

|

|

|

|

|

|

|

41 |

|

|

IDGATE |

Digital |

Input |

Control signal for DVD -RAM |

|

|

|

|

|

|

|

|

|

|

|

38 |

|

|

VFO13 |

Digital |

Input |

DVD -RAM Header signal |

|

|

|

|

|

|

|

|

|

|

|

RF |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

100 |

|

|

DVDA |

Analog input |

AC coupled DVD RF signal input |

A |

|

|

|

|

|

|

|

|

|

|

|

99 |

|

|

DVDB |

Analog Input |

AC coupled DVD RF signal input |

B |

|

|

|

|

|

|

|

|

|

|

|

98 |

|

|

DVDC |

Analog Input |

AC coupled DVD RF signal input |

C |

|

|

|

|

|

|

|

|

|

|

|

97 |

|

|

DVDD |

Analog Input |

AC coupled DVD RF signal input |

D |

|

|

|

|

|

|

|

|

|

|

|

95 |

|

|

DVDRFIN |

Analog Input |

AC coupled DVD RF signal input |

RFIN |

|

|

|

|

|

|

|

|

|

|

|

96 |

|

|

DVDRFIP |

Analog Input |

AC coupled DVD RF signal input |

RFIP |

|

|

|

|

|

|

|

|

|

|

|

94 |

|

|

CDA |

Analog Input |

AC coupled CD RF signal input |

A |

|

|

|

|

|

|

|

|

|

|

|

93 |

|

|

CDB |

Analog Input |

AC coupled CD RF signal input |

B |

|

|

|

|

|

|

|

|

|

|

|

92 |

|

|

CDC |

Analog Input |

AC coupled CD RF signal input |

C |

|

|

|

|

|

|

|

|

|

|

|

91 |

|

|

CDD |

Analog Input |

AC coupled CD RF signal input |

D |

|

|

|

|

|

|

|

|

|

||

90 |

|

|

OSN |

Analog |

RF Offset cancellation capacitor connecting |

|

||

|

|

|

|

|

|

|

||

89 |

|

|

OSP |

Analog |

RF Offset cancellation capacitor connecting |

|

||

|

|

|

|

|

|

|

||

85 |

|

|

CEQP |

Analog |

RF Offset cancellation capacitor connecting |

|

||

|

|

|

|

|

|

|

||

84 |

|

|

CEQN |

Analog |

RF Offset cancellation capacitor connecting |

|

||

|

|

|

|

|

|

|

||

88 |

|

|

RFGC |

Analog |

RF AGC loop capacitor connecting for DVD -ROM |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MT1336 |

|

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE |

MTK CONFIDENTIAL, NO DISCLOSURE |

||||||

|

|

|

|

|

|

|

|

87 |

|

RFGCU |

|

Analog |

RF AGC loop capacitor connecting for DVD -RAM |

|

|

|

|

|

|

|

|

|

|

86 |

|

RFGCI |

|

Analog |

RF AGC loop capacitor connecting for DVD -RAM |

|

|

|

|

|

|

|

|

|

|

101 |

|

MA |

|

Analog Input |

DC coupled DVD-RAM main-beam RF signal input |

A |

|

|

|

|

|

|

|

|

|

102 |

|

MB |

|

Analog Input |

DC coupled DVD-RAM main-beam RF signal input |

B |

|

|

|

|

|

|

|

|

|

103 |

|

MC |

|

Analog Input |

DC coupled DVD-RAM main-beam RF signal input |

C |

|

|

|

|

|

|

|

|

|

104 |

|

MD |

|

Analog Input |

DC coupled DVD-RAM main-beam RF signal input |

D |

|

|

|

|

|

|

|

|

|

105 |

|

SA |

|

Analog Input |

DC coupled DVD-RAM sub-beam RF signal input |

A |

|

|

|

|

|

|

|

|

|

106 |

|

SB |

|

Analog Input |

DC coupled DVD-RAM sub-beam RF signal input |

B |

|

|

|

|

|

|

|

|

|

110 |

|

SC |

|

Analog Input |

DC coupled DVD-RAM sub-beam RF signal input |

C |

|

|

|

|

|

|

|

|

|

111 |

|

SD |

|

Analog Input |

DC coupled DVD-RAM sub-beam RF signal input |

D |

|

|

|

|

|

|

|

|

|

108 |

|

IR |

|

Analog |

External current bias resistor (R=20K) |

|

|

|

|

|

|

|

|

|

|

119 |

|

AGC1 |

|

Analog |

Wobble AGC loop1 capacitor |

|

|

|

|

|

|

|

|

|

|

121 |

|

AGC2 |

|

Analog |

Wobble AGC loop2 capacitor |

|

|

|

|

|

|

|

|

|

|

122 |

|

AGC3 |

|

Analog |

Wobble AGC loop3 capacitor |

|

|

|

|

|

|

|

|

|

|

127 |

|

RFSUBO |

|

Analog output |

Header push-pull RF output signal |

|

|

|

|

|

|

|

|

|

|

1 |

|

WOBSO |

|

Digital output |

Wobble signal output |

|

|

|

|

|

|

|

|

|

|

6 |

|

RFOP |

|

Analog output |

RF positive output |

|

|

|

|

|

|

|

|

|

|

7 |

|

RFON |

|

Analog output |

RF negative output |

|

|

|

|

|

|

|

|

|

|

TRACKING ERROR |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

32 |

|

DPFN |

|

Analog |

DPD amplifier negative input |

|

|

|

|

|

|

|

|

|

|

33 |

|

DPFO |

|

Analog |

DPD amplifier output |

|

|

|

|

|

|

|

|

|

|

61 |

|

DPDMUTE |

|

Digital input |

DPD mute control input |

|

|

|

|

|

|

|

|

|

|

116 |

|

TNI |

|

Analog Input |

3 beam satellite PD signal negative input |

|

|

|

|

|

|

|

|

|

|

115 |

|

TPI |

|

Analog Input |

3 beam satellite PD signal positive input |

|

|

|

|

|

|

|

|

|

|

21 |

|

TEO |

|

Analog Output |

Tracking error output |

|

|

|

|

|

|

|

|

|

|

FOCUSING ERROR & RF LEVEL |

& CENTRAL SERVO SIGNAL |

|

|

||||

|

|

|

|

|

|

|

|

112 |

|

CDFOP |

|

Analog Input |

CD focusing error positive input |

|

|

|

|

|

|

|

|

|

|

113 |

|

CDFON |

|

Analog Input |

CD focusing error negative input |

|

|

|

|

|

|

|

|

|

|

18 |

|

FEO |

|

Analog Output |

Focusing error output |

|

|

|

|

|

|

|

|

|

|

19 |

|

LVL |

|

Analog Output |

RF level output |

|

|

|

|

|

|

|

|

|

|

20 |

|

CSO |

|

Analog output |

Central servo signal output |

|

|

|

|

|

|

|

|

|

|

ALPC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MT1336 |

|

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE |

MTK CONFIDENTIAL, NO DISCLOSURE |

|||

|

|

|

|

|

124 |

MDI1 |

Analog Input |

Laser power monitor input |

|

|

|

|||

|

|

|

|

|

125 |

LDO1 |

Analog Ou tput |

Laser driver output |

|

|

|

|

|

|

123 |

MDI2 |

Analog Input |

Laser power monitor input |

|

|

|

|

|

|

126 |

LDO2 |

Analog Output |

Laser driver output |

|

|

|

|

|

|

RFRIPPLE |

|

|

|

|

|

|

|

|

|

26 |

CRTP |

Analog |

RF top envelop filter capacitor connecting |

|

|

|

|

|

|

27 |

CRTPLP |

Analog |

Defect level filter capacitor connecting |

|

|

|

|

|

|

25 |

HRFRP |

Analog output |

High frequency RF ripple output or Blank detector’s output |

|

|

|

|

|

|

24 |

LRFRP |

Analog output |

Low frequency RF ripple output |

|

|

|

|

|

|

POWER |

|

|

|

|

|

|

|

|

|

67, 69 |

AVDD |

Power |

Master PLL Filter power |

|

|

|

|

|

|

65, 73 |

AGND |

GND |

GND for Master PLL Filter |

|

|

|

|

|

|

64 |

AVDD |

Power |

DPD Power |

|

|

|

|

|

|

62 |

AGND |

GND |

DPD GND |

|

|

|

|

|

|

109 |

AVDD |

Power |

RF path Power |

|

|

|

|

|

|

107 |

AGND |

GND |

RF path GND |

|

|

|

|

|

|

114 |

SVDD |

Power |

Servo Power |

|

|

|

|

|

|

117 |

SGND |

GND |

Servo GND |

|

|

|

|

|

|

2,120 |

WAVDD |

Power |

Wobble Power |

|

|

|

|

|

|

128,118 |

WAGND |

GND |

Wobble GND |

|

|

|

|

|

|

5 |

AVDDO |

Power |

Power for RF output |

|

|

|

|

|

|

8 |

AGNDO |

GND |

GND for RF output |

|

|

|

|

|

|

14 |

AVDDT |

Power |

Power for Trimming PAD |

|

|

|

|

|

|

12 |

AGNDT |

GND |

GND for Trimming PAD |

|

|

|

|

|

|

22 |

VDDP |

Power |

Peak Detection Power |

|

|

|

|

|

|

31 |

GNDP |

GND |

Peak Detection GND |

|

|

|

|

|

|

37,54 |

VDD |

Power |

Serial I/O Power |

|

|

|

|

|

|

39,57 |

GND |

GND |

Serial I/O GND |

|

|

|

|

|

|

REFERENCE VOLTAGE |

|

|

|

|

|

|

|

|

|

16 |

VREFO |

Analog output |

Reference voltage 1.4V |

|

|

|

|

|

|

15 |

V2REFO |

Analog output |

Reference voltage 2.8V |

|

|

|

|

|

|

17 |

V20 |

Analog Output |

Reference voltage 2.0V |

|

|

|

|

|

|

|

|

|

|

|

MT1336 |

|

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE |

MTK CONFIDENTIAL, NO DISCLOSURE |

|||||

|

|

|

|

|

|

|

ALPC TRIMMING |

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

|

TM1 |

Analog input |

Trimming pin for ALPC1 |

|

|

|

|

|

|

|

|

|

10 |

|

TM2 |

Analog input |

Trimming pin for ALPC1 |

|

|

|

|

|

|

|

|

|

11 |

|

TM3 |

Analog input |

Trimming pin for ALPC2 |

|

|

|

|

|

|

|

|

|

13 |

|

TM4 |

Analog input |

Trimming pin for ALPC2 |

|

|

|

|

|

|

|

|

|

HIGH SPEED TRACK COUNTING |

|

|

|

|

||

|

|

|

|

|

|

|

29 |

|

TRLP |

Analog |

Low-pass filter capacitor connecting |

|

|

|

|

|

|

|

|

|

28 |

|

TRLPA |

Analog |

Low-pass filter capacitor connecting |

|

|

|

|

|

|

|

|

|

30 |

|

HTRC |

Digital output |

High speed track counting digital output |

|

|

|

|

|

|

|

|

|

PCS |

|

|

|

|

|

|

|

|

|

|

|

|

|

74 |

|

HALLSIN |

Analog input |

Negative input of amplifier for hall sensor signal |

|

|

|

|

|

|

|

|

|

75 |

|

REFSIN |

Analog input |

Positive input of amplifier for hall sensor signal |

|

|

|

|

|

|

|

|

|

76 |

|

SINPHI |

Analog output |

Amplifier output for hall sensor signal |

|

|

|

|

|

|

|

|

|

71 |

|

HALLCOS |

Analog input |

Negative input of amplifier for hall sensor signal |

|

|

|

|

|

|

|

|

|

72 |

|

REFCOS |

Analog input |

Positive input of amplifier for hall sensor signal |

|

|

|

|

|

|

|

|

|

70 |

|

COSPHI |

Analog output |

Amplifier output for hall sensor signal |

|

|

|

|

|

|

|

|

|

FOR MONITOR ONLY |

|

|

|

|

||

|

|

|

|

|

|

|

81 |

|

MON |

Analog |

output |

|

|

|

|

|

|

|

|

|

80 |

|

MOP |

Analog |

output |

|

|

|

|

|

|

|

|

|

66 |

|

VCON |

Analog |

output |

|

|

|

|

|

|

|

|

|

77 |

|

SWO |

Analog |

output |

Output from mux of SW1 & SW2 |

|

|

|

|

|

|

|

|

78 |

|

SW2 |

Analog |

input |

External input for servo input select |

|

|

|

|

|

|

|

|

79 |

|

SW1 |

Analog |

input |

External input for servo input select |

|

|

|

|

|

|

|

|

FOR SERIAL I/O |

|

|

|

|

|

|

|

|

|

|

|

|

|

42 |

|

IO0 |

|

|

|

|

|

|

|

|

|

|

|

43 |

|

IO1 |

|

|

|

|

|

|

|

|

|

|

|

44 |

|

IO2 |

|

|

|

|

|

|

|

|

|

|

|

45 |

|

IO3 |

|

|

|

|

|

|

|

|

|

|

|

46 |

|

IO4 |

|

|

|

|

|

|

|

|

|

|

|

47 |

|

IO5 |

|

|

|

|

|

|

|

|

|

|

|

MT1336

PRELIMINARY, SUBJ ECT TO CHANGE WITHOUT NOTICE |

MTK CONFIDENTIAL, NO DISCLOSURE |

48IO6

49IO7

50IO8

51IO9

52IOA

53IOB

Loading...

Loading...