Atlantic alféa excellia duo 11, alféa excellia duo 16, alféa excellia duo 14, WOYK160LCT, MH excellia duo Installation And Operating Manual

...

alféa excellia duo

Document n° 1572-4 ~ 12/12/2013

FR NL DE EN IT

Heat pump air/water

split 2 services

Outdoor unit Hydraulic unit

WOYG112LCT 023167

WOYG140LCT

WOYK112LCT

WOYK140LCT

WOYK160LCT

ES PT PL PT PT

Installation and

operating manual

intended for professionals

To be saved for

future consultation

atlantic-comfort.com

Subject to modications without notice.

Non contractual document.

Heat pump air/water split 2 services alféa excellia duo

" This device requires for its installation, the intervention of qualied personnel with a certicate of

capacity for handling refrigerants.

Contents

Description of the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Package . . . . . . . . . . . . . . . . . . . . . . . . 4

Denitions . . . . . . . . . . . . . . . . . . . . . . . 4

Specications . . . . . . . . . . . . . . . . . . . . . 5

Description. . . . . . . . . . . . . . . . . . . . . . . 9

Operating principle . . . . . . . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Regulation installation and maintenance conditions . . 12

Unpacking and reservations . . . . . . . . . . . . . 12

Receipt . . . . . . . . . . . . . . . . . . . . 12

Handling . . . . . . . . . . . . . . . . . . . 12

Containment of refrigerant circuits . . . . . . 12

Accessories provided . . . . . . . . . . . . . 12

Installation position . . . . . . . . . . . . . . . . . 13

Installation of the outdoor unit . . . . . . . . . . . . 13

Installation precautions . . . . . . . . . . . . 13

Outdoor unit positioning . . . . . . . . . . . 14

Condensate drain hose . . . . . . . . . . . . 14

Installing the hydraulic unit . . . . . . . . . . . . . 15

Installation precautions . . . . . . . . . . . . 15

Refrigeration connections . . . . . . . . . . . . . . 16

Rules and precautions . . . . . . . . . . . . 16

Refrigeration connections. . . . . . . . . . . 17

Creating the arings . . . . . . . . . . . . . 17

Shaping the refrigeration pipes . . . . . . . . 17

Connecting the ared connections . . . . . . 17

Filling the installation with gas . . . . . . . . . . . . 19

Commissioning procedure . . . . . . . . . . 19

Sealing test . . . . . . . . . . . . . . . . . . 20

Additional charge . . . . . . . . . . . . . . . 21

Pump down operation (Refrigerant collecting

operation) outdoor unit . . . . . . . . . . . . 21

Hydraulic connecting . . . . . . . . . . . . . . . . 22

General . . . . . . . . . . . . . . . . . . . . 22

Connecting to the DHW circuit . . . . . . . . 23

Rinsing out the installation . . . . . . . . . . 24

Filling and purging the installation . . . . . . 24

Connecting the Fan convector

or dynamic radiator circuit . . . . . . . . . . 24

Thermal insulation . . . . . . . . . . . . . . . . . . 25

Heating circulation pump speed settings . . . . . . 26

Electrical connections . . . . . . . . . . . . . . . . 28

Characteristic of the electrical supply . . . . . 28

General remarks on electrical connections . . 28

Overview of all the electrical connections . . 29

Cable section and protection rating . . . . . . 29

Electrical connections

on the single phase outdoor unit side. . . . . 30

Electrical connections

on the 3- phase outdoor unit side . . . . . . . 31

Electrical connections

on the hydraulic unit side . . . . . . . . . . . 32

Outdoor sensor . . . . . . . . . . . . . . . . . . . 36

Room thermostat and/or room control unit . . . . . 36

Installing a room sensor . . . . . . . . . . . 36

Installing a room control unit . . . . . . . . . 36

Fan convectors or dynamic radiators area . . 36

Commissioning . . . . . . . . . . . . . . . . . . . 36

Conguring room thermostat . . . . . . . . . . . . 37

Conguring room control unit . . . . . . . . . . . . 37

- 2 -

Installation and operating manual "1572 - EN"

Heat pump air/water split 2 services alféa excellia duo

Regulation system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

User interface, Room control unit (option) and

Room thermostat (option) . . . . . . . . . . . . . . 38

Description of the display . . . . . . . . . . . . . . 40

Temperature control . . . . . . . . . . . . . . . . . 40

Set to . . . . . . . . . . . . . . . . . . . . . 40

Parametering the setting . . . . . . . . . . . . . . 42

General . . . . . . . . . . . . . . . . . . . . 42

Setting parameters . . . . . . . . . . . . . . 42

Recommended settings according

to the heat emitters installation . . . . . . . . 42

List of function lines

(settings, diagnosis, status) . . . . . . . . . . 43

Overall hydraulic layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Electrical wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Faults displayed on the hydraulic unit . . . . . . . . 62

Information display . . . . . . . . . . . . . . . . . 63

Faults displayed on the single phase outdoor unit . 64

Faults displayed on the 3-phase outdoor unit . . . . 65

Maintenance of the installation . . . . . . . . . . . . . . . . . . . . . . . . 66

Hydraulic checks . . . . . . . . . . . . . . . . . . 66

Maintenance of the DHW tank. . . . . . . . . . . . 66

Emptying the hot water tank . . . . . . . . . 66

Descaling . . . . . . . . . . . . . . . . . . . 66

Checking the outdoor unit . . . . . . . . . . . . . . 66

Electrical checks . . . . . . . . . . . . . . . . . . . 66

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Emptying the hydraulic unit . . . . . . . . . . . . . 67

Distribution valve . . . . . . . . . . . . . . . . . . 67

ACI check . . . . . . . . . . . . . . . . . . . . . . 67

Instructions for the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Quick-start procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Start-up check-list . . . . . . . . . . . . . . . . . . 68

Before starting-up . . . . . . . . . . . . . . . 68

Starting-up . . . . . . . . . . . . . . . . . . 69

Installation and operating manual "1572 - EN" - 3 -

Settings sheet . . . . . . . . . . . . . . . . . . . . 70

Start-up data sheet . . . . . . . . . . . . . . . . . 71

Heat pump air/water split 2 services alféa excellia duo

Packing list

Heat pump (HP) Outdoor unit Hydraulic unit

Model Code Model Code Model Code

alféa excellia duo 11 Single phase 522676 WOYG112LCT 700117

alféa excellia duo 14 Single phase 522677 WOYG140LCT 700142

alféa excellia duo 11 3-phase 522684 WOYK112LCT 700118

alféa excellia duo 14 3-phase 522685 WOYK140LCT 700143

alféa excellia duo 16 3-phase 522686 WOYK160LCT 700163

MH

excellia duo

023167

Optional equipment

• 2nd circuit kit (code 074011)

for connecting 2 heating circuits.

• Regulation extension kit (code 075311)

to manage a 2nd heating circuit, swimming pool etc...

• Boiler connection kit (code 073990)

for connecting a boiler to the heat pump.

• Single phase electrical back-ups kit (code 073985) or

3-phase electrical back-ups kit (réf. 073987).

• Room thermostat T37 (code 075308),

Room thermostat T55 (code 073951),

Room thermostat radio T58 (code 075313)

- for correcting the ambient temperature.

• Room control unit T75 (code 073954),

Room control unit radio T78 (code 074061)

for correcting the ambient temperature and

programming the heat pump.

• Anti-vibration blocks (code 523574).

• White PVC oor support (code 809532) or

Black rubber oor support (code 809536).

• Swimming pool kit (code 074726).

• Cooling kit (code 075312).

• High ow rate circulating pump kit (code 074077)

for the installation of 1 circuit oor heating

(with model > 13 kW).

Scope of application

This heat pump provides:

- Heating in winter,

- Control of two heating circuits*,

- Production of domestic hot water.

- Installation with boiler connection* as a

supplementary heating for the coldest days.

or

- the addition of electrical back-ups*, for extra heating

on the coldest days.

- Cooling in summer* (for oor heating-cooling system

or fan-convectors).

- Heating the swimming pool*.

* : These options require the use of additional kits

(see para "Optional equipment").

1 Description of the unit

1.1 Package

• 1 package: Outdoor unit.

• 1 package: Hydraulic unit and outdoor sensor.

- 4 -

1.2 Denitions

- Split: The heat pump consists of two elements

(an outdoor unit for outdoor and a hydraulic unit for

inside the dwelling).

- Air/water: The surrounding air is the energy source.

This energy is transmitted to the water in the heating

circuit by the heat pump.

- Inverter: the fan and compressor speeds are modulated

according to the heating requirements. This technology

enables you to save on energy and operate on a singlephase power supply, whatever the heat pump's output,

by avoiding heavy intensities on start-up.

- COP (coefcient of performance): this is the relationship

between the energy transmitted to the heating circuit

and electrical energy consumed.

Installation and operating manual "1572 - EN"

Heat pump air/water split 2 services alféa excellia duo

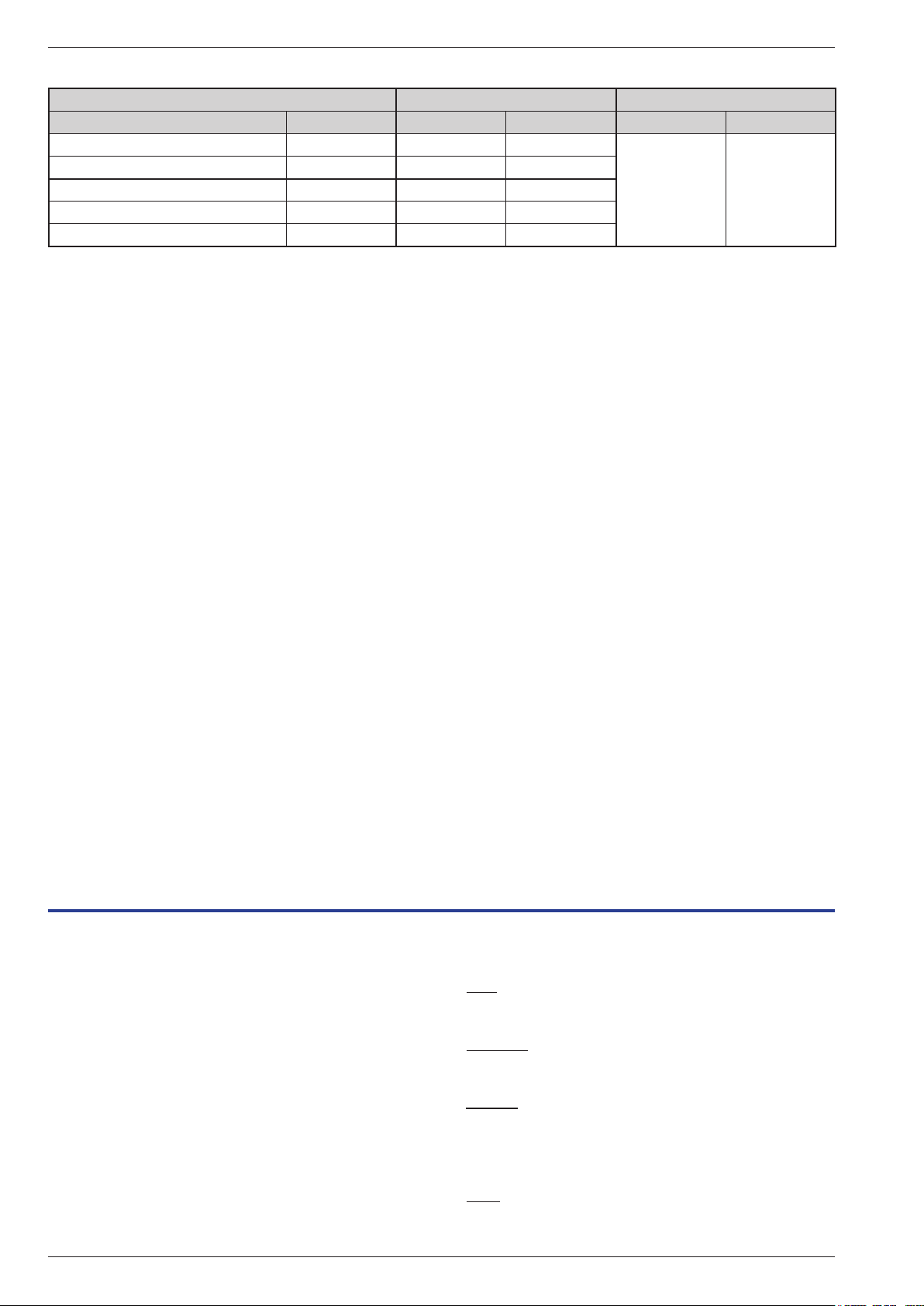

1.3 Specications

Designation model alfea excellia duo

11

Single phase

Nominal heating performances (outdoor temperature/ initial temperature)

Heat output

+7 °C / +35 °C - Floor heating system kW 10,80 13,50 10,80 13,00 15,17

-7 °C / +35 °C - Floor heating system kW 10,38 11,54 10,38 12,69 12,98

+7 °C / +45 °C - Low temperature radiator kW 9,05 11,32 9,90 12,34 12,75

-7 °C / +45 °C - Low temperature radiator kW 9,16 11,45 9,98 10,74 12,95

+7 °C / +55 °C - Radiator kW 7,59 9,48 9,29 10,81 12,71

-7 °C / +55 °C - Radiator kW 7,57 9,20 9,27 10,02 11,99

Power absorbed

+7 °C / +35 °C - Floor heating system kW 2,54 3,23 2,51 3,11 3,70

-7 °C / +35 °C - Floor heating system kW 4,32 5,13 4,28 5,13 5,40

+7 °C / +45 °C - Low temperature radiator kW 2,82 3,69 2,99 3,81 3,97

-7 °C / +45 °C - Low temperature radiator kW 4,58 5,92 4,63 5,14 6,37

+7 °C / +55 °C - Radiator kW 3,07 3,95 3,52 4,49 5,04

-7 °C / +55 °C - Radiator kW 4,57 5,08 5,09 5,64 6,89

Coefcient of performance (COP) (+7 °C / + 35 °C) 4,25 4,18 4,30 4,18 4,10

Electrical characteristics

Supply voltage (50 HZ) V 230 400

Maximum current for appliance A 22 25 8,5 9,5 10,5

Nominal current A 11,4 14,2 3,7 4,8 5,5

Maximum current of the Heating electrical back-ups A 13,05 / 26,1 3x13

Power of the Heating electrical back-ups (option) kW ajustable 3 or 6 kW (Single phase) 9 kW (3-phase)

Real power absorbed by the fan W 2x100 2x104

Real power absorbed by the circulation pump W 37,5

Maximum power absorption by the outdoor unit W 5060 5750 5865 6555 7245

Electrical back-up power DHW W 1500

Hydraulic circuit

Maximum operating pressure Heating bar 3

Maximum operating pressure Domestic hot water tank bar 10

Hydraulic system ow rate 4°C<Δt<8°C (nominal conditions) l/h 1170 / 2340 1460 / 2920 1170 / 2340 1460 / 2920 1650 / 3290

Various

Weight of outdoor unit kg 92 99

Weight of hydraulic unit (empty / full of water) kg 146 / 350

Water capacity of the hydraulic unit / of the domestic tank l 24 / 190

Noise level at 1 m 1 (hydraulic unit) dB 39

Sound power level according to EN 12102 2 (hydraulic unit) dB 46

Noise level at 1 m 1 (outdoor unit) dB 42 43 39 41 42

Sound power level according to EN 12102 2 (outdoor unit) dB 69 70 66 68 69

Heating system operating limits

Outdoor temperature mini / maxi °C -25 / +35

Initial max. heating water temperature Floor heating system °C 45

Initial max. heating water temperature Low temperature radiator °C 60

Refrigeration circuit

Diameter of "Gas" pipes inches 5/8

Diameter of "Liquid" pipes inches 3/8

Factory charge of refrigerant R410A 3 g 2500

Maximum operating pressure bar 41,5

Minimum / Maximum length of pipes

4

m 5 / 15

Maximum length of pipes 5 / Maximum level difference m 20 / 20

1

Sound pressure level in (x)m of the device, 1,5m of the ground,

the open eld.

2

The sound power level is a laboratory measure of the emitted

sound power but contrary to the noise level, it doesn't correspond to

the measure of the felt.

3

Refrigerant R410A (as per the standard EN 378.1).

4

Factory charge of refrigerant R410A.

5

Taking into account the possible additional load of refrigeration uid

R410A (see "Additional charge", page 21)

14

Single phase

11

3-phase

14

3-phase

16

3-phase

Installation and operating manual "1572 - EN" - 5 -

Heat pump air/water split 2 services alféa excellia duo

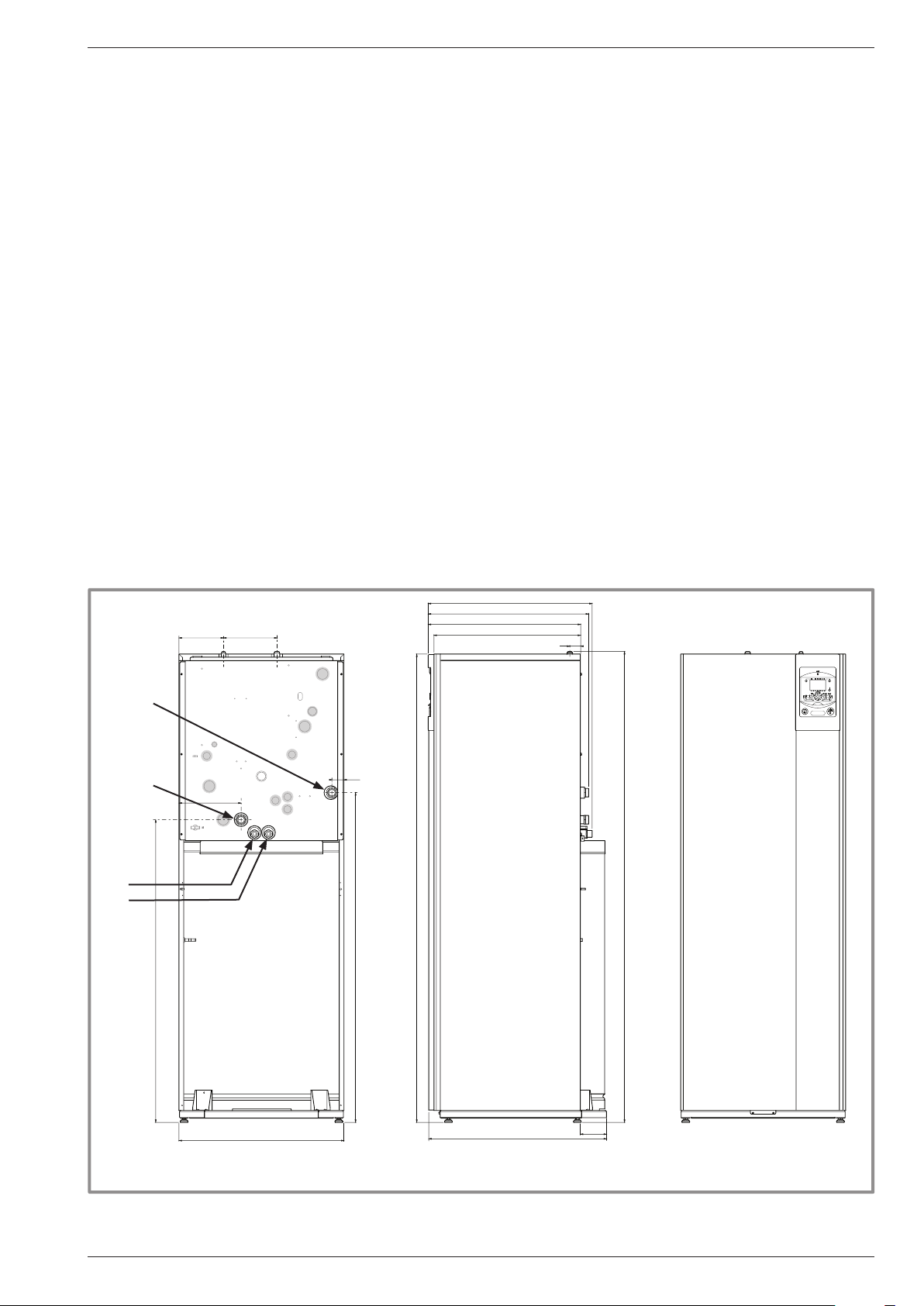

" Outside unit,

Model excellia duo

11 & 14 Single phase

650

Air

370

" Outside unit,

Model excellia duo

11, 14 & 16 3-phase

31 77900330 12

Air

Air

400

Side view

Overflow hole (Ø 20) 4Ø10)Holes

3/8”

5/8”

196

99

147

170

Sight of lower part

9

Front view

Top view

650

Air

1290

21

31 12330

Air

Air

400

Side view

370

Overow hole (ø 20)

Sight of lower part

4 Holes (ø 10)

900

1290

21

9

Front view

- 6 -

Top view

gure 1 - Dimensions in mm

Installation and operating manual "1572 - EN"

Heat pump air/water split 2 services alféa excellia duo

" Hydraulic unit

Heating return

Heating ow

DHW

DCW

1189

175 210

244

47

1296

1840

644

630

599

576

43

1850

648

Back view

698

Side view Front view

103

Blockage in the hydraulic unit, see gure 13, page 15.

gure 2 - Dimensions in mm

Installation and operating manual "1572 - EN" - 7 -

-50

-25025 50 75

°C

Heat pump air/water split 2 services alféa excellia duo

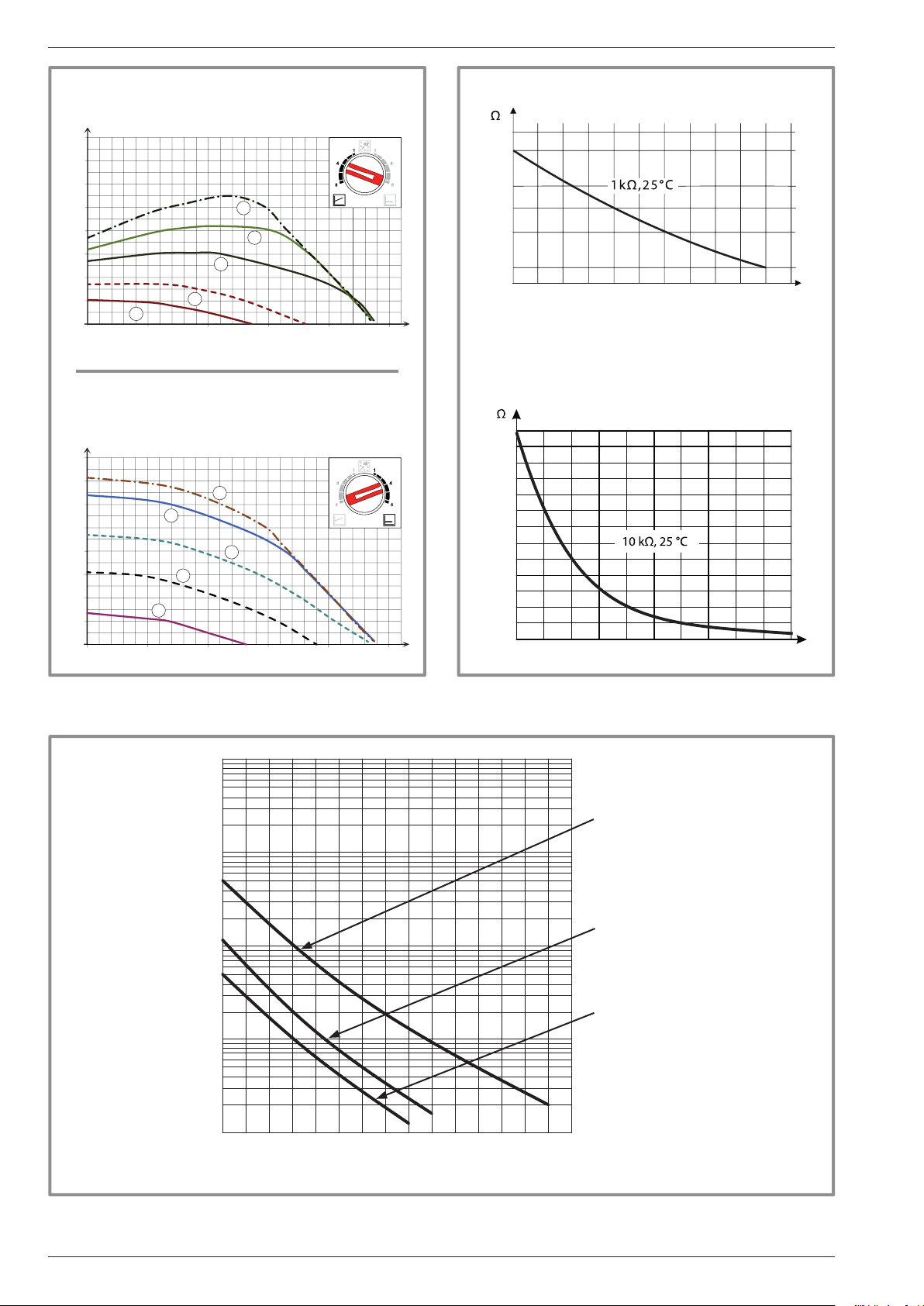

Variable pressure

mCE

8

7

6

5

4

3

2

1

0

0 0,5 1 1,5 2

1

55

3

1

1 mbar=10 mmCE=100 Pa

88

77

Constante pressure

mCE

8

7

6

5

4

3

2

1

0

0 0,5 1 1,5 2

77

1

88

55

3

1

1 mbar=10 mmCE=100 Pa

Outdoor sensor QAC34

43907

10000

2490

1000

338

3

3

/h

1,5 20,50

m

m/h

Heat pump return sensor

Heat pump ow sensor

32500

30000

27500

25000

22500

20000

17500

15000

12500

10000

7500

5000

2500

3

3

/h

1,5 20,50

m

m/h

0

0102030405060708090 100

°C

gure 3 - Hydraulic pressures and ow rates available

10000

1000

Ohmic value (kΩ)

100

10

1

-20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130

gure 4 - Ohmic values of the sensors

(Hydraulic module)

- Compressor

- Discharge

- Condensation

- Outside

- Evaporator outlet

- Evaporator center

- Compressor casing

Temperature °C

- 8 -

gure 5 - Ohmic values of the sensors (outside unit)

Installation and operating manual "1572 - EN"

Heat pump air/water split 2 services alféa excellia duo

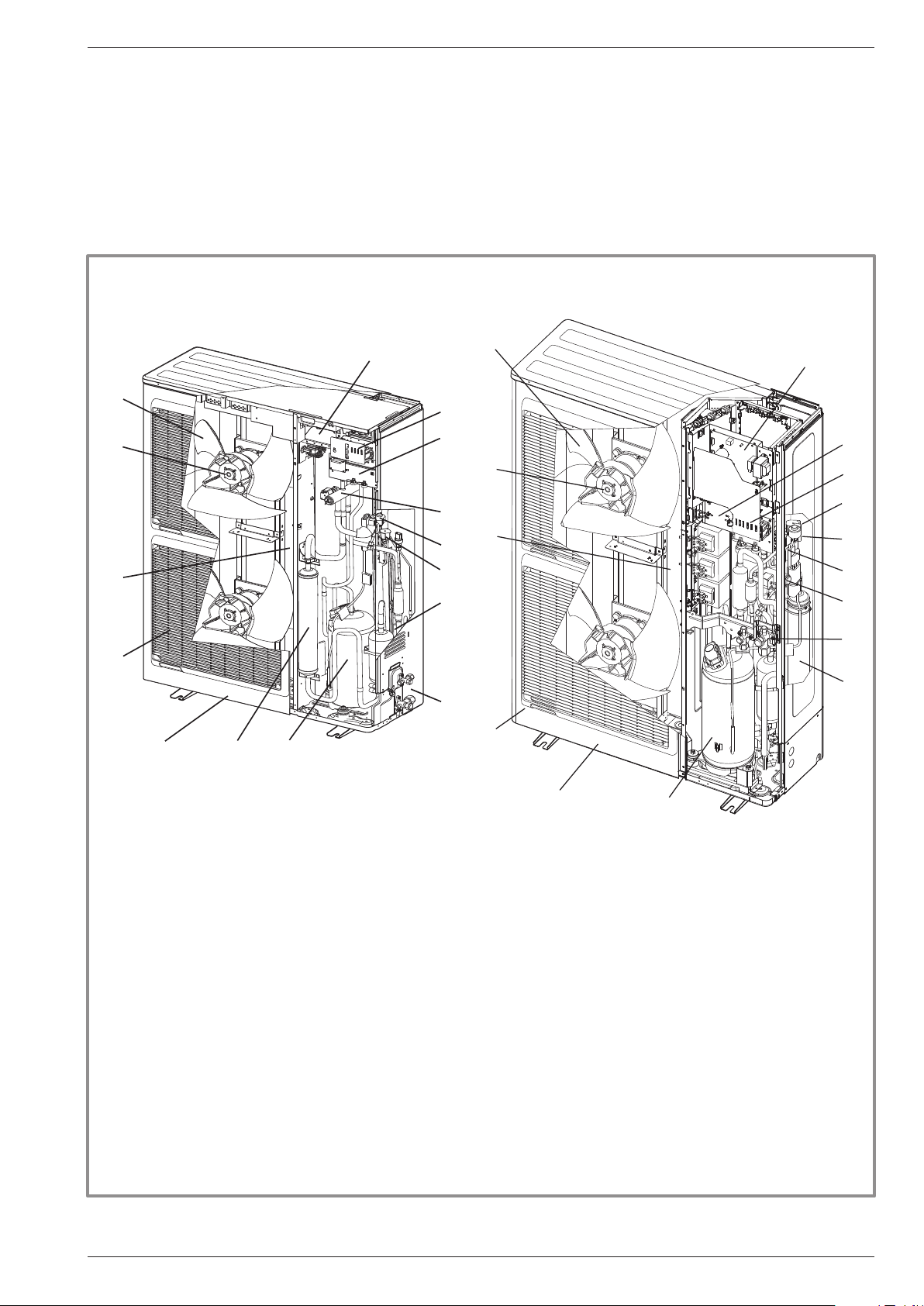

1.4 Description

" Model excellia duo 11 & 14

single phase

1

2

13

8

12

6

10

" Model excellia duo 11, 14 & 16

3-phase

WO*K1**LCT

5

4

7

15

14

9

13

1

3

4

2

5

14

15

9

7

3

11

6

11

8

12

Legend :

1 - Low-noise, high-output fan.

2 - Electric variable speed "inverter" motor.

3 - "Inverter" control module.

4 - Vacuum start (pump down) and control light.

5 - Connection terminal blocks (power and interconnection).

6 - Refrigerant accumulator bottle.

7 - Cycle reversing valve.

8 - Anti-corrosion treated bodywork.

9 - Electronic expansion valve.

10 - Noise and temperature insulated "inverter" compressor.

11 - Refrigeration connection valves (ared connectors) with protective caps.

12 - Holding tank with condensate drain hole.

13 - High-performance exchange surface evaporator ;

anti-corrosion treated hydrophilic aluminium ns and grooved copper tubes.

14 - Solenoid valve for liquid injection.

15 - Electric expansion valve for liquid injection.

gure 6 - Outdoor unit components

10

Installation and operating manual "1572 - EN" - 9 -

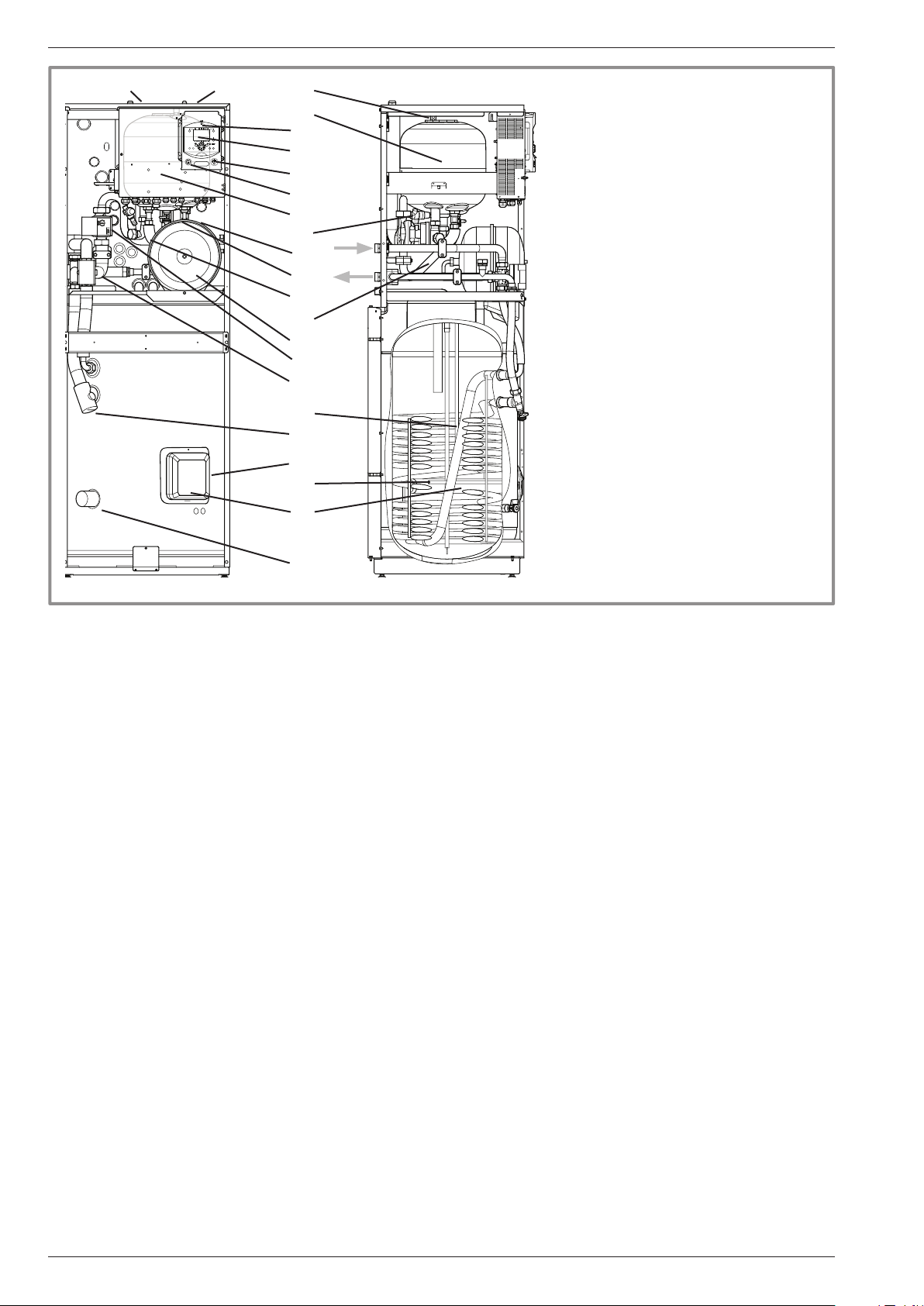

Heat pump air/water split 2 services alféa excellia duo

6 7

13

15

18

2

12

3

1

10

9

21

23

14

4

5

22

9

11

17

16

Legend :

1 - Electric box.

2 - Regulator / User interface.

3 - Start/stop switch.

4 - Hydraulic pumping unit.

5 - Distribution valve.

8

6 - Gas refrigeration connection.

7 - Liquid refrigeration connection.

8 - Condensation sensor.

9 - Drain valve.

10 - Safety valve.

11 - Safety thermostat.

12 - Manometer.

13 - Manual drainer.

14 - Expansion vessel.

15 - Condenser.

16 - Electrical back-ups DHW.

17 - ACI.

18 - ACI card.

Sensors :

21 - Water ow sensor.

22 - DHW sensor.

23 - Water return sensor.

9

gure 7 - Hydraulic unit components

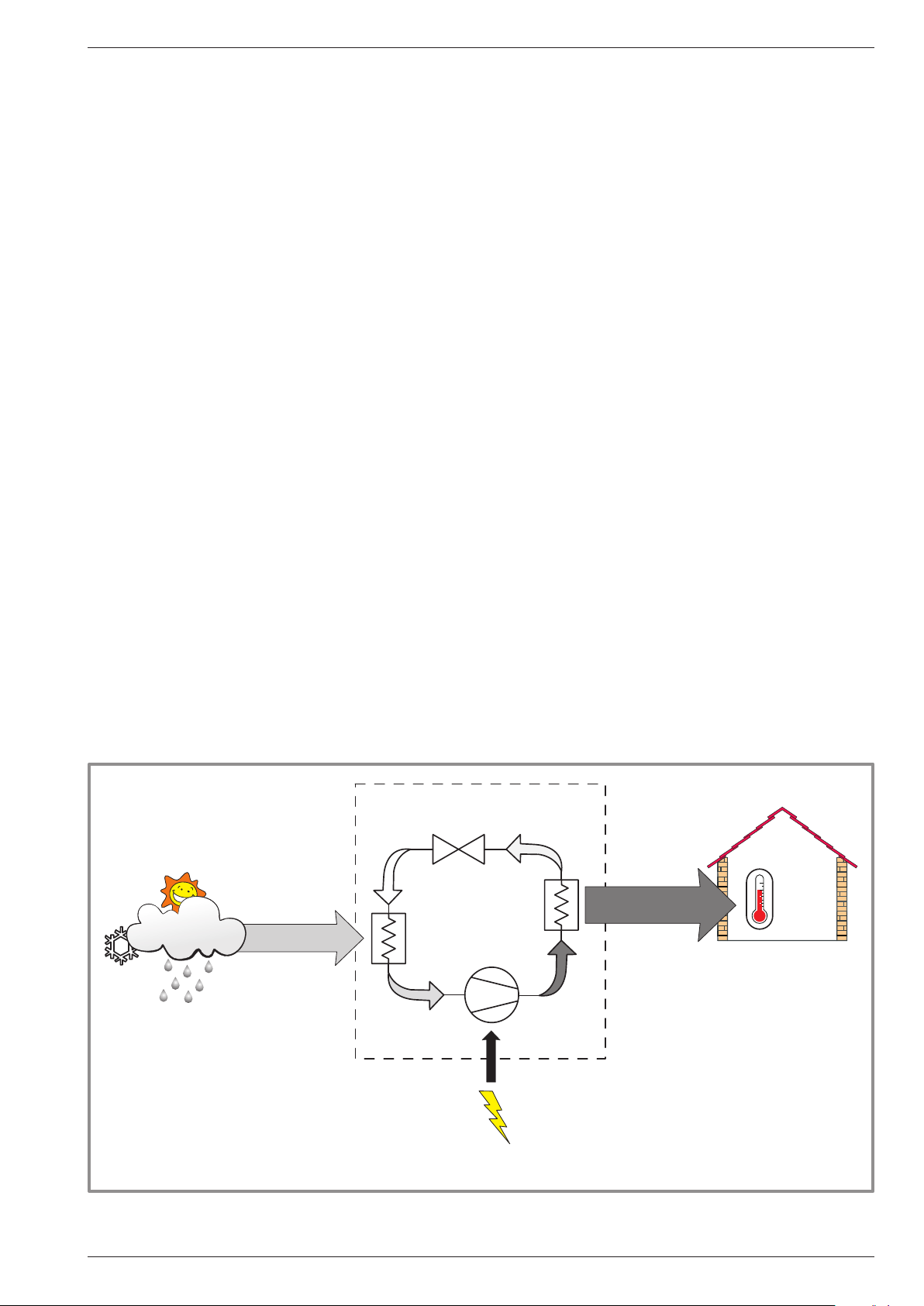

1.5 Operating principle

The heat pump transmits the energy contained in the

surrounding air into the dwelling to be heated.

The heat pump consists of four main elements, in which

a refrigerant uid (R410A) circulates.

- In the evaporator (ref. 13, gure 6, page 9) :

The energy is taken from the surrounding air and is

transmitted to the refrigerant. Because it has a low

boiling point, it changes from the liquid state to the

vapour state, even in cold weather (down to -15 °C

outdoor temperature).

- In the compressor (ref. 10, gure 6, page 9) :

The vaporised refrigerant brought to high pressure

and takes on more calories.

- In the condenser (ref. 15, gure 7) :

The energy in the refrigerant is transmitted to the

heating circuit. The refrigerant returns to liquid state.

- In the expansion valve (ref. 9, gure 6, page 9) :

The lique ed refrigerant is brought back to low pressure

and returns to its initial temperature and pressure.

The heat pump is equipped with a controller, which

controls the room temperature based on the outdoor

temperature measurement and governed by the

temperature control. The room thermostat (option)

provides a corrective action for the temperature control.

The hydraulic unit can be optionally tted with an

electrical back-up system or boiler connection which

starts up in order to provide addtional heating during the

coldest periods.

• Regulation functions

- The heating circuit's initial temperature is controlled by

the temperature control.

- The power of the outdoor unit is modulated according

to ow heating temperature via the "inverter"

compressor.

- Control of the electrical back-up heating (option).

- The daily timer program enables you to de ne

the periods for comfortable or reduced ambient

temperature.

- Summer/winter mode switchover is automatic.

- Control of the supplementary boiler* (option).

- The room thermostat (option)*: provides a corrective

action for the temperature control.

- Control of a second heating circuit*.

- Domestic hot water: Heating time programme, control

of the operation of the DHW circulation pump.

- Managing the cooling*.

- Control of swimming pool heating*.

* If the heat pump is equipped with optional equipment and the

associated kits.

• Protection functions

- Anti-legionella cycle for domestic hot water.

- Anti-corrosion protection with titanium anode (ACI).

- Frost protection: Frost protection cuts in if the low-

temperature point of the heating circuit falls below 5 °C

(provided that the heat pump's electrical power supply

is not interrupted).

- 10 -

Installation and operating manual "1572 - EN"

Heat pump air/water split 2 services alféa excellia duo

• Domestic hot water (DHW) operating principle

Two domestic hot water (DHW) temperatures can be

parametered: nominal temperature (line 1610 to 55 °C)

and reduced temperature (line 1612 to 40 °C).

The default heat pump program (line 560, 561 and 562)

is set for nominal temperature from 0:00 to 5:00 and

from 14:30 to 17:00 and for reduced temperature for the

rest of the day. This optimizes electrical consumption

while ensuring comfortable availability of hot water.

Setting for reduced temperature can be useful to prevent

the DHW from switching on too often and for too long

during the day.

The production of domestic hot water (DHW) is triggered

when the temperature in the tank falls 7°C (setting from

line 5024) below the set temperature.

The heat pump produces the domestic hot water, which

is then additively heated, if required, by electrical backup heating inside the tank. To ensure a DHW setting

over 45°C, the electrical back-up heating or the boiler

must be left on.

Depending on how the parameter (1620) is set, nominal

temperature can be reached 24h/day or only at night or

depending on the heat pump programme.

If the contract concluded with the energy provider

includes a subscription to day/night tariff, the electrical

backup is subordinate to the supplier’s power tariff and

the comfort temperature may only be reached at night.

If no particular contract is concluded, the comfort

temperature can be reached at any time, including

during the day

The production of DHW takes priority over heating;

nevertheless the production of DHW is controlled by

cycles that control the times assigned to the heating

and the production of DHW in the event of simultaneous

demand.

A function to switch from "reduced" to "nominal"

is provided on the front of the user interface.

(see ref. 1, gure 42, page 38).

Anti-legionella cycles can be programmed.

• Fan convectors with integrated control system

Do not use a room sensor in the area.

Energy from the air

PAC

HP

Dt

Cn

Ev

Electrical

energy

consumed

gure 8 - Heat pump operating principle

Cp

1kW

Heat produced

COP 4

4kW

20 °C

HP - Heat pump

Ev - Evaporator

Cp - Compressor

Cn - Condenser

Dt - Expansion valve

Installation and operating manual "1572 - EN" - 11 -

Heat pump air/water split 2 services alféa excellia duo

2 Installation

2.1 Regulation installation

and maintenance conditions

The appliance must be installed and the maintained

by an approved professional in accordance with the

prevailing regulations and code of practice, in particular:

- The legislation on the handling of refrigerants.

- Heating installation with oor heating system.

- Low voltage electrical installations - Rules.

2.2 Unpacking and reservations

2.2.1 Receipt

Carefully check, in the carrier's presence, the general

appearance of the appliances and check that the

outdoor unit is not laid on its side or back.

In the case of any dispute, state any appropriate

reservations to the carrier in writing within 48 hours and

send a copy of this letter to the After-Sales service.

2.2.2 Handling

The outdoor unit should not be laid on its side or back

during transport.

If not kept upright during transport, the appliance could

be damaged through displacement of the refrigerant

and deformation of the compressor suspension.

Any damage caused by transportation of the unit lying

down is not covered by the warranty.

If necessary the outdoor unit may be tilted only during

manual handling (to go through a door or use a staircase).

This operation must be conducted very carefully and

the appliance must be immediately restored to upright

position.

2.2.3 Containment of refrigerant circuits

All refrigerant circuits fear contamination from dust and

moisture. If such pollutants introduced into refrigeration

circuit, they can contribute to degrade the reliability of

the heat pump.

" It’s necessary to ensure correct containment

connections and refrigerant circuits (hydraulic

unit, outdoor unit).

" In case of subsequent failure and expertise, the

nding of the presence of moisture or foreign

objects into the compressor oil would lead to

systematic exclusion of warranty.

- Check upon receipt that the ttings and the refrigeration

circuit caps mounted on hydraulic unit and outdoor unit

are properly seated and locked (impossible to loosen

bare hands). If this’s not the case, tighten them using

an against wrench.

- Check also that the refrigerant connections are

sealed (plastic caps or tubes crushed at the ends

and soldered). If the caps must be removed during

installation (tubes cut by example), put back them as

soon as possible.

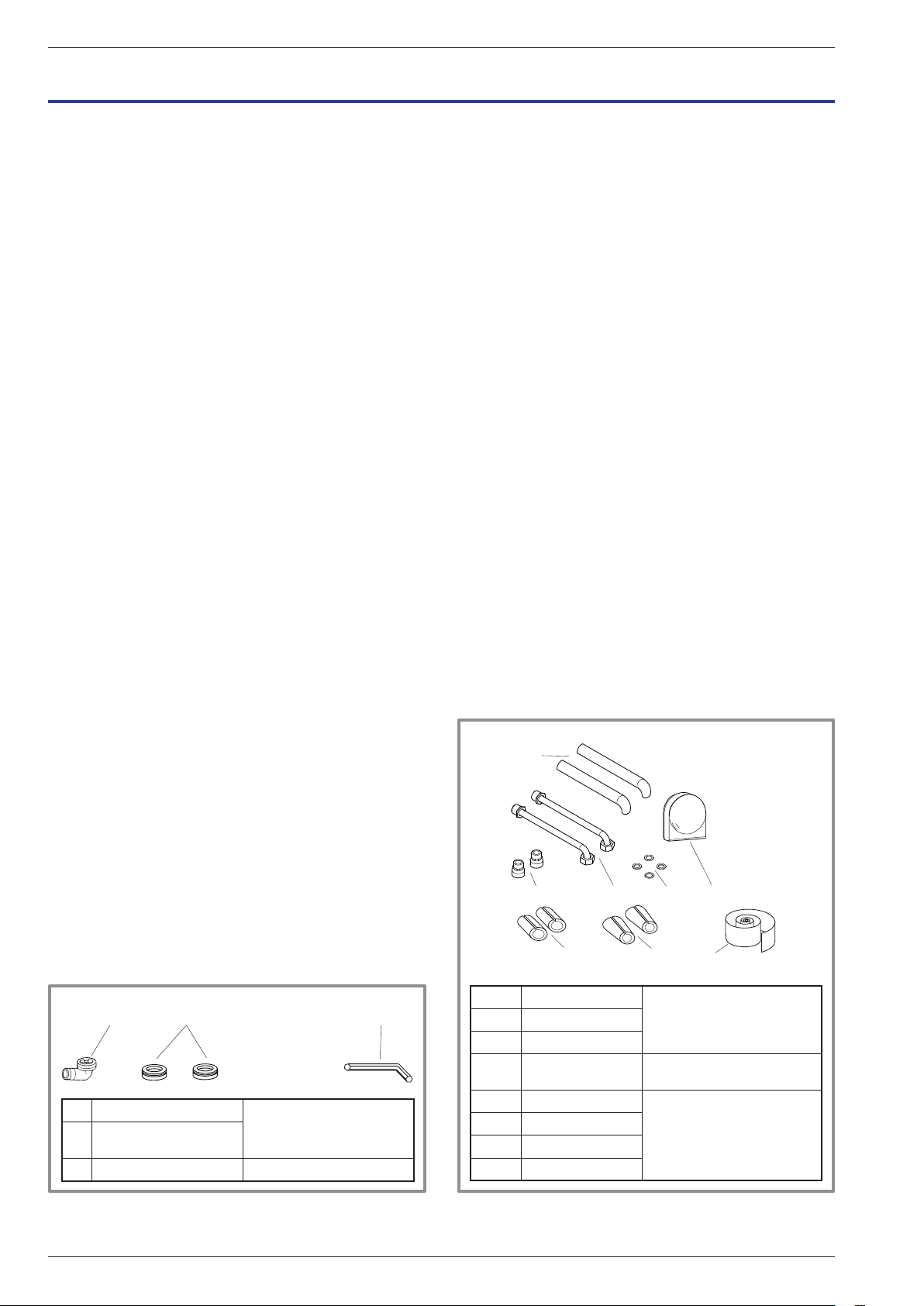

2.2.4 Accessories provided

Accessories provided with the outdoor unit (gure 9).

Accessories provided with the hydraulic unit (gure 10).

10

5

1

7

3

1

1 Elbow

Plug (x 2)(Depending

2

on the model)

3 Hex / Allen key To open the valves

gure 9 - Accessories provided with the outdoor unit gure 10 - Accessories provided with the hydraulic unit

2

3

For draining away the

condensates

4

1 Dielectric ttings

2 DHW pipes

3 Gaskets

4 Outdoor sensor

7 Insulation right

8 Insulation conical

9 Insulation tape

10 Insulation tube

2

3

8

for connection to the DHW

circuit

to monitor the outside

temp

to isolate the connections

and tubes

9

64

- 12 -

Installation and operating manual "1572 - EN"

Heat pump air/water split 2 services alféa excellia duo

2.3 Installation position

The choice of the position for installation is particularly

important insofar as any later movement is a delicate

operation requiring the intervention of a qualied person.

Choose the site of the outdoor unit and the hydraulic

unit after discussion with the customer.

Observe the maximum and minimum distances between

the hydraulic unit and the outdoor unit (gure 18, page 18),

the guarantee of the performances and the system's

service life depend on this.

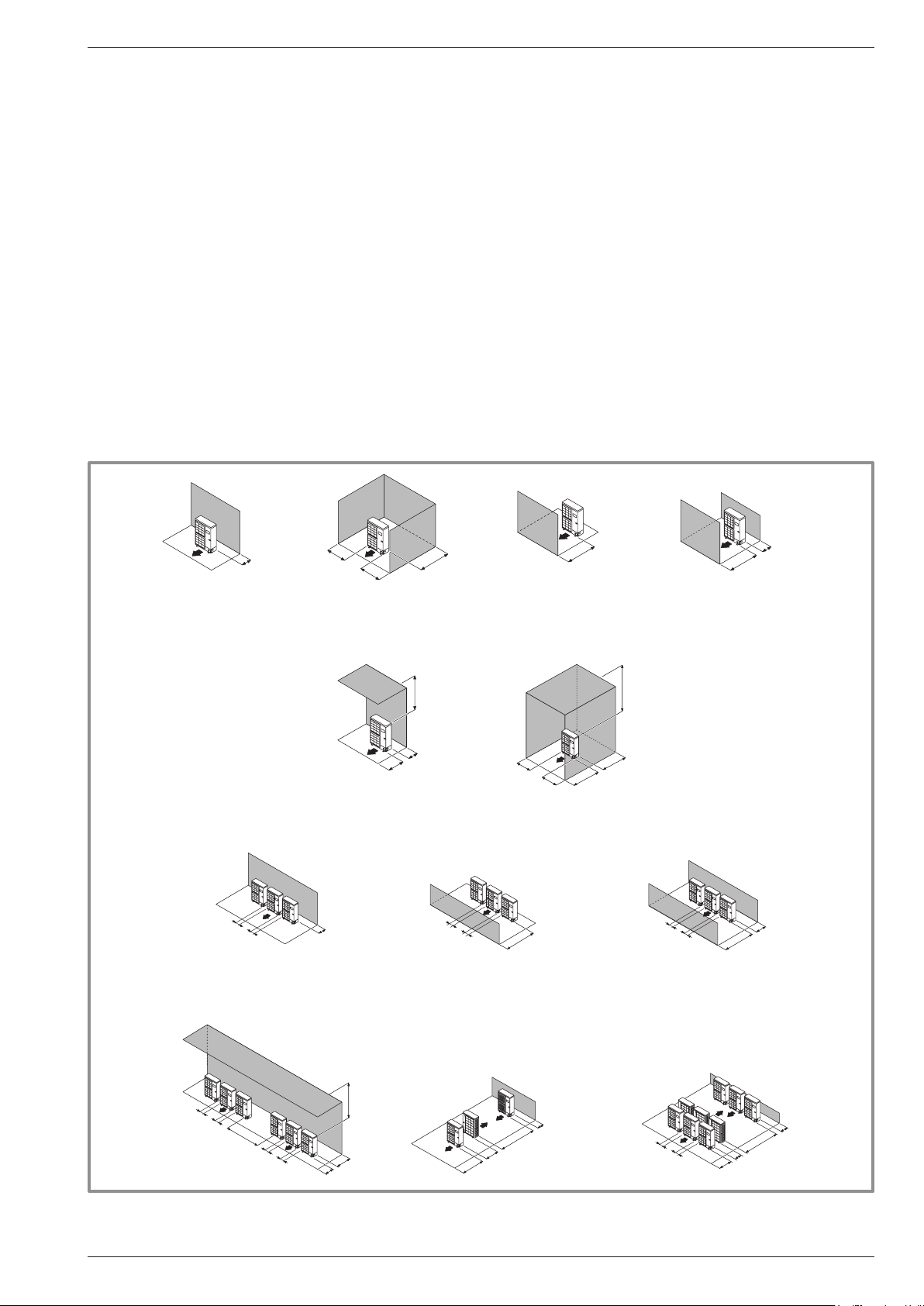

2.4 Installation of the outdoor unit

2.4.1 Installation precautions

The outdoor unit must only be installed outdoor

(outdoors). If a shelter is required, it must have

broad openings on the 4 walls and observe the

installation clearances (gure 11).

• Choose a site that is preferably sunny and sheltered

from strong cold predominant winds (mistral,

tramontana, etc…).

• The unit must be easily accessible for future installation

and maintenance work (gure 11).

• Ensure that it is possible to make the connections to

the hydraulic unit easily.

• The outdoor unit is able to withstand bad weather but

avoid installing in a position where it is likely to be

exposed to signicant dirt or owing water (under a

defective gutter for example).

• Water may drain away from the outdoor unit when it

is operating. Do not install the appliance on a paved

terrace; choose a well-drained place (e.g. gravel

or sand). If the installation is in an area where the

temperature can be lower than 0°C for a long period,

check that the presence of ice does not present any

danger. A drainage pipe can also be connected to the

outdoor unit (gure 12).

250

Minimum

250

or more

150

200

300

200

1000

300

Max. 500

250

250

or more

Minimum

300

250

1500

or more

Minimum

250

1000

or more

Minimum

Max. 500

500

1500

250

250

or more

Minimum

1000

or more

Minimum

500

1500

or more

Minimum

150

500

Max.300

1500

1000

600

150

2000

or more

Minimum

250

250

or more

Minimum

1500

600

3000

or more

Minimum

600

250

Minimum

250

or more

1500

250

Minimum

250

or more

gure 11 - Minimum installation clearances around outside unit (all models)

Installation and operating manual "1572 - EN" - 13 -

Heat pump air/water split 2 services alféa excellia duo

• Nothing should obstruct the air circulation through the

evaporator and from the fan (gure 11).

• Keep the outdoor unit away from heat sources and

inammable products.

• Make sure the appliance not disturb the surrounding

area or users (noise level, draught generated, low

temperature of the air being blown out, with the risk of

freezing plants in its path).

• The surface on which the appliance is installed must:

- be permeable (soil, gravel, etc),

- support its weight easily,

- provide a solid xing and

- not transmit any vibration to the dwelling.

(Anti-vibratory blocks are available as an option).

• The wall bracket can not be used in conditions likely to

transmit vibrations, ground position is preferred.

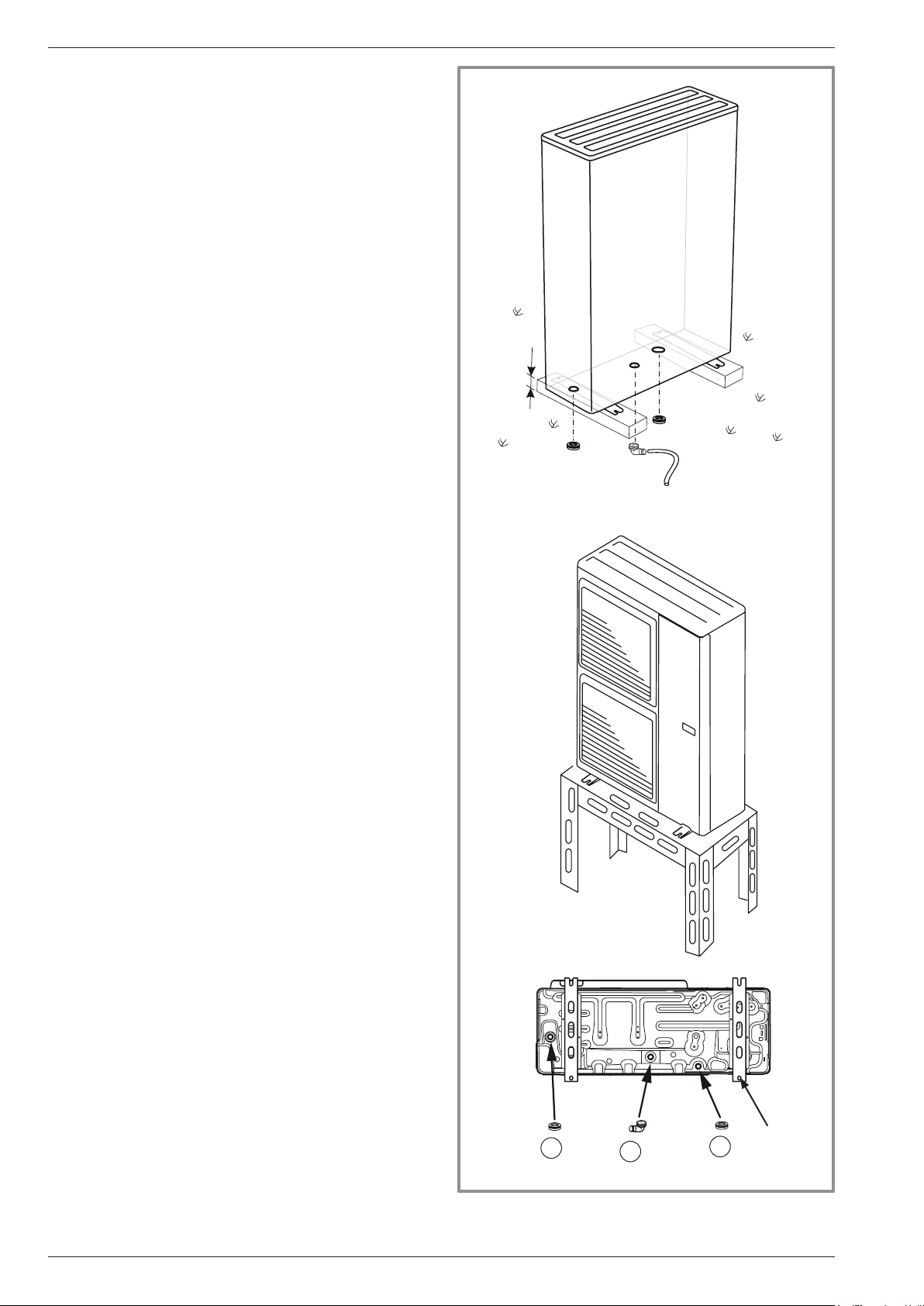

2.4.2 Outdoor unit positioning

The outdoor unit must be raised at least 50 mm above

ground level. In areas prone to snow, this height should

be increased but should not exceed 1,5 m (gure 12).

- Fasten the outdoor unit by means of screws and

rubber tightening or toothed lock washers to avoid

their coming loose.

" Warning

In the area with heavy snowfall, if the intake and outlet

of outdoor unit is blocked with snow, it might become

difcult to get warm and it is likely to cause of the

breakdown.

Please construct a canopy and a pedestral or place the

unit on high stand (local congured).

- Set the unit on a strong stand, such as one made of

concrete blocks to minimize shock and vibration.

- Do not set the unit directly on the ground because it will

cause trouble.

* In regions subject to frequent snow,

(H) must be greater than the average snow layer

2.4.3 Condensate drain hose

(see gure 12).

If the use of a discharge pipe is imperative:

- Use the elbow provided (C) to connect a 16mm-

diameter hose for draining away the condensate.

- Use the stopper or stoppers provided (B) to block the

opening of the condensate tank.

Allow for the condensate to ow away under the force of

gravity (waste water, rain water, gravel bed).

" If the installation is made in an area where

the temperature can be lower than 0°C for

a long period, provide the drain pipe with a

trace resistance to avoid it icing up. The trace

resistance must heat not only the pipe but

also the bottom of the appliance's condensate

collection tank.

4 holes

B

gure 12 - Positioning of the outside unit,

draining away the condensate

C

B

(ø 12 mm)

- 14 -

Installation and operating manual "1572 - EN"

Heat pump air/water split 2 services alféa excellia duo

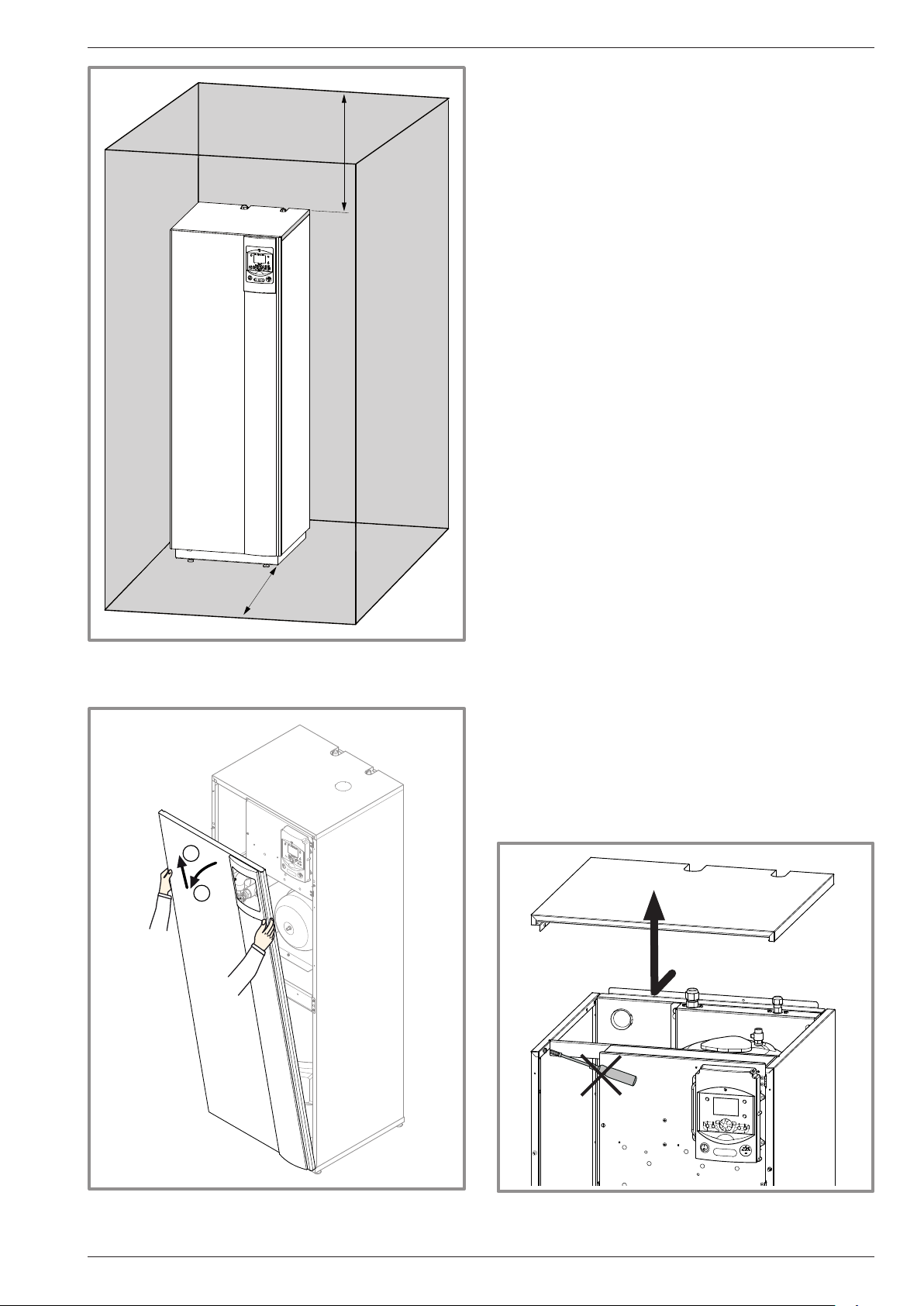

2.5 Installing the hydraulic unit

2.5.1 Installation precautions

1800 mm

300 mm

125 mm

• The room in which the appliance operates must

comply with the prevailing regulations.

• To facilitate maintenance and to allow access to the

various components, we recommend that you provide

sufcient space all around the hydraulic unit (gure 13).

• Be careful not to bring inammable gas near to the

heat pump during its installation, in particular when

it requires brazing. The appliances are not reproof

and should therefore not be installed in a potentially

explosive atmosphere.

- To avoid condensation inside the condenser, remove

the refrigerant circuit caps only when building the

refrigerant connections.

- If the refrigerant connection only occurs at the end of

the installation, be sure that the refrigerant circuit caps*

remain in place and tight throughout the installation

duration.

* (hydraulic unit side and outdoor unit side)

- After every intervention on the refrigeration circuit and

before nal connection, take care to replace the plugs

in order to avoid any pollution from the refrigeration

circuit (The sealing with tape is prohibited).

1000 mm

gure 13 - Minimum installation clearances

around the hydraulic module

and distances to the combustible partitions

2

1

Front view

gure 14 - Open the front cover gure 15 - Removing the cover

Installation and operating manual "1572 - EN" - 15 -

Heat pump air/water split 2 services alféa excellia duo

2.6 Refrigeration connections

" This appliance uses refrigerant R410A.

Comply with the legislation for handling refrigerants.

2.6.1 Rules and precautions

• After every intervention on the refrigeration circuit and

before nal connection, take care to replace the plugs in

order to avoid any pollution from the refrigeration circuit.

• Minimum necessary tools

- Set of manometers (Manifold) with hoses exclusively

reserved for HFCs (Hydrouorocarbons).

- Vacuum gauge whith isolation valves.

- Vacuum pump specially for HFCs (use of a traditional

vacuum pump is authorized if, and only if, it is tted

with a non-return valve on the suction side).

- Flaring tool.

- Pipe-cutter.

- Deburring tool.

- Wrenches.

- Refrigerant gas leak detector certied (sensitivity 5g/year).

" Provision on using tools that have been in

contact with HCFCs (R22 for example) or CFCs.

" The manufacturer declines any liability with

regard to the guarantee if the above instructions

are not observed.

• Flared connections

" Lubrication with mineral oil (for R12, R22)

is forbidden.

- Only lubricate with polyolester refrigeration oil (POE).

If POE is not available, t without lubrication.

• Brazing on the refrigeration circuit (if necessary)

- Silver brazing (40% minimum recommended).

- Brazing only under dry nitrogen internal ux.

• To eliminate any lings in the pipes, use dry nitrogen

to avoid introducing any humidity that may adversely

affect the appliances operation. In general, take every

precaution to avoid humidity penetrating into the

appliance.

• Proceed to insulate the "Gas" and "Liquid" pipes to

avoid any condensation. Use pipe insulators resistant

to temperatures over 90°C. In addition if the humidity

level in areas where the refrigeration pipes are

installed is expected to exceed 70%, protect the pipes

with pipe insulators. Use an insulating material thicker

than 15mm if the humidity level is 70~80%, and an

insulating material thicker than 20mm if the humidity

exceeds 80%. If the recommended thicknesses are

not observed under the conditions described above,

condensation will form on the surface of the insulation

material. Lastly, take care to use pipe insulators

whose thermal conductivity is 0.045 W/mK or less

when the temperature is 20°C. The insulation must be

impermeable to resist the passage of steam during the

defrosting cycles (breglass wool is prohibited).

Coat the ared surface

with POE refrigeration oil.

Do not use mineral oil.

- 16 -

Installation and operating manual "1572 - EN"

Heat pump air/water split 2 services alféa excellia duo

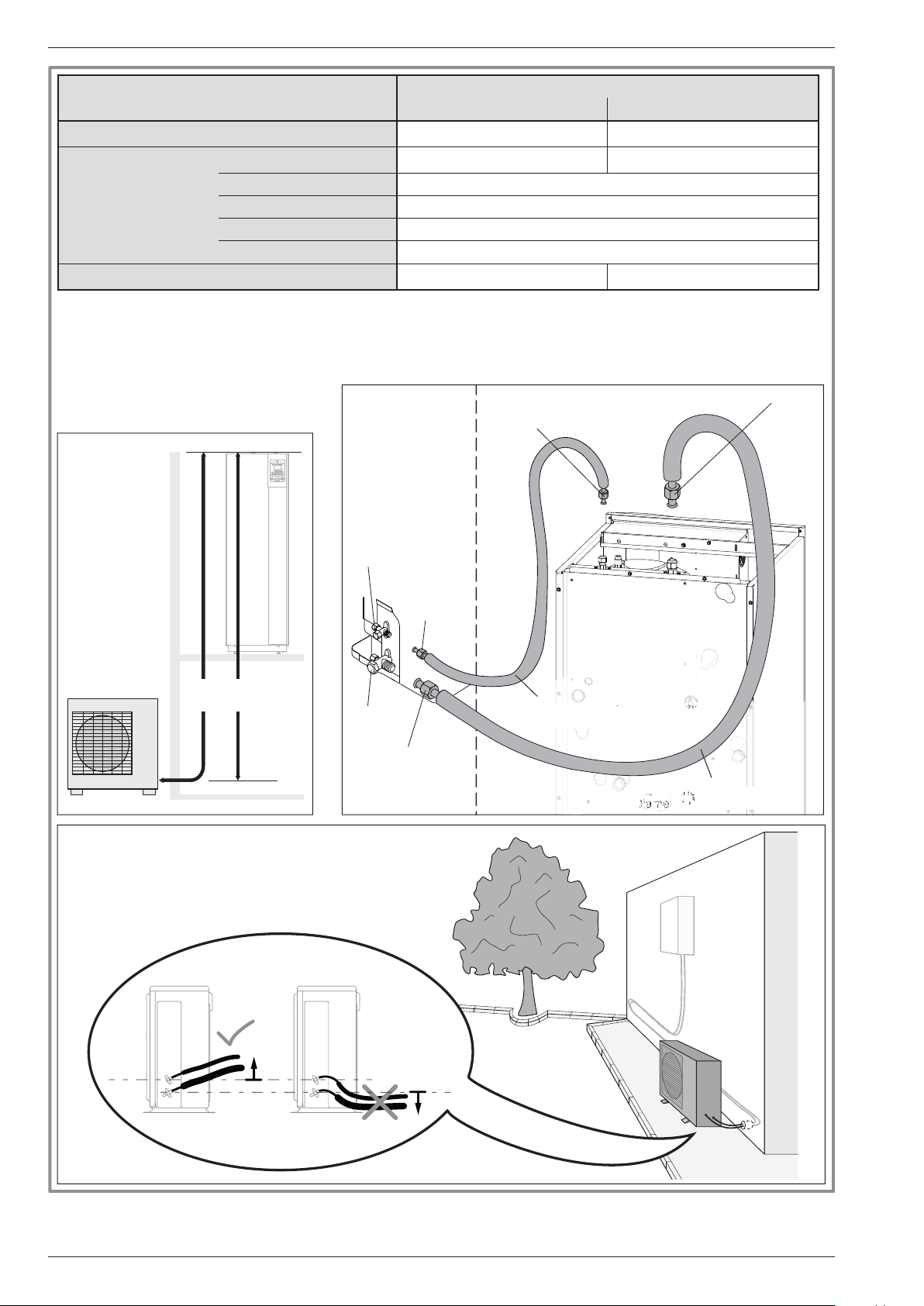

2.6.2 Refrigeration connections

The outdoor unit must be connected to the hydraulic unit

only with copper pipes and connections (refrigeration

quality), insulated separately.

Comply with the pipe diameters and the permitted pipe

lengths (gure 18).

The minimum length of the refrigeration connections

is 5 m for correct operation.

The appliance will be excluded from guarantee if it is

used with refrigeration connections less than 5 m long.

If the refrigeration connections are exposed to

weathering or UV- and the insulation is not strong, it is

necessary to provide protection.

Manipulate the pipes and take them through walls with

protective plugs in place.

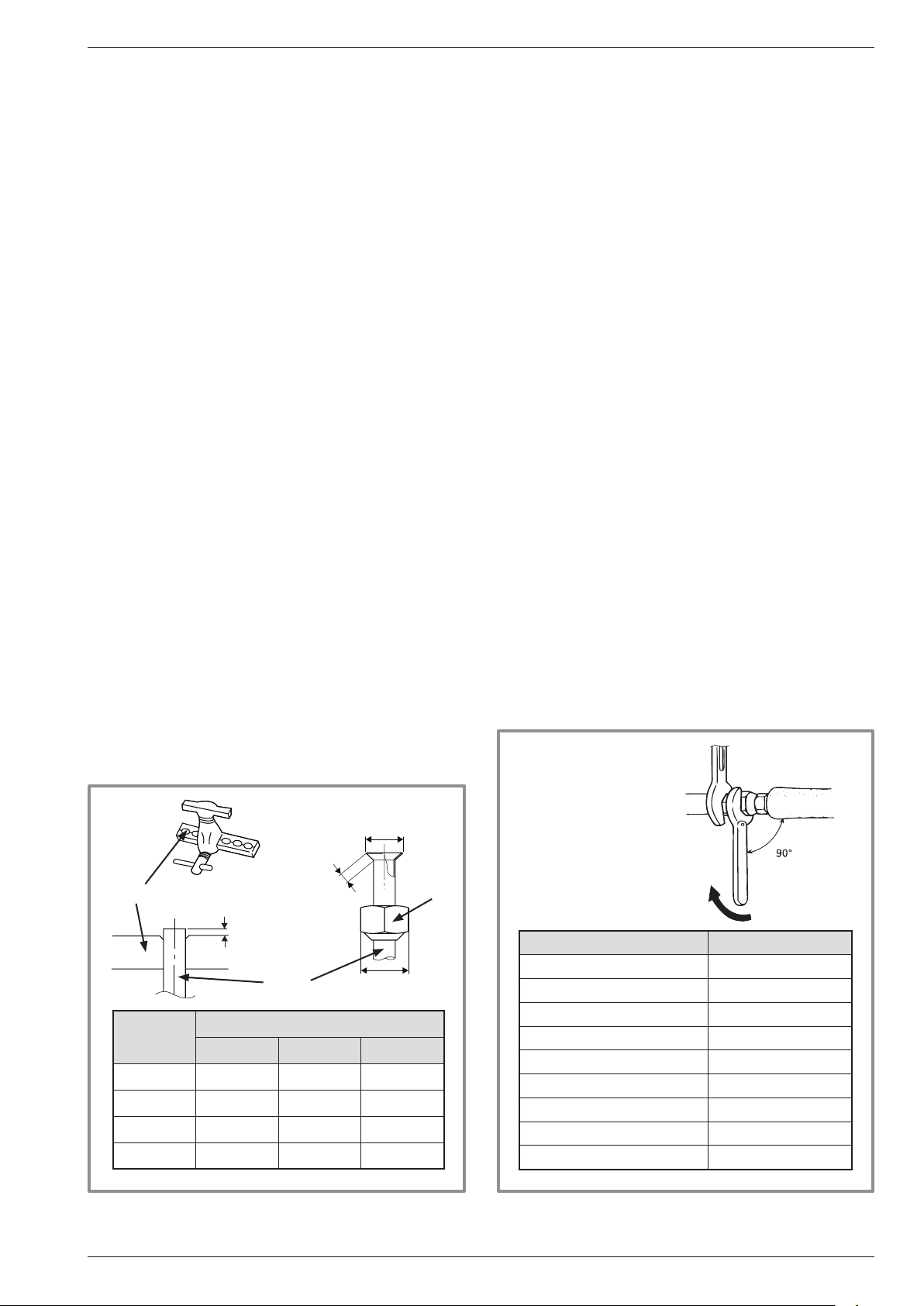

2.6.3 Creating the arings

- Cut the pipe to an appropriate length with a pipe-cutter

without deforming it.

- Carefully deburr it, holding the pipe towards the bottom

to avoid introducing lings into the pipe.

- Remove the ared connection nut situated on the

valve to be connected and slip the pipe into the nut.

- Proceed to are, letting the pipe overow the aring

tool.

- After aring, check the condition of the working

radius (L). This must not show any scratch or trace of

any fracturing. Also check the dimension (B).

2.6.4 Shaping the refrigeration pipes

The refrigeration pipes must be shaped only on a

bending machine or with a bending spring in order to

avoid any risk of crushing or breaking them.

" Warning !

• Remove the insulation material locally to bend the

pipes.

• Do not bend the copper to any angle over 90°.

• Never bend pipes more than 3 times in the same

position otherwise traces of fracturing may appear

(from strain-hardening the metal).

2.6.5 Connecting the ared connections

" Connections must be made the day of the lling

the installation with gas (see para. "Filling the

installation with gas", page 19).

" Take particular care positioning the tube opposite

its connector so as not to risk damaging the

threads. A carefully aligned connector can be tted

easily by hand without much force being required.

" The refrigeration circuit is very sensitive to dust

and humidity: check that the area around the

connection is clean and dry before removing the

plugs protecting the refrigeration connectors.

- Remove the plugs from the pipes and the refrigeration

connections.

- Present the pipe to the ared connector and screw the

nut by hand while holding the connector with a wrench

until contact.

- Comply with the indicated tightening torques.

B

Flaring tool

Hose

dimensions in mm

ø Hose

L B 0/

6,35 (1/4") 1,8 to 2 9,1 17

9,52 (3/8") 2,5 to 2,7 13,2 22

12,7 (1/2") 2,6 to 2,9 16,6 26

15,88 (5/8") 2,9 to 3,1 19,7 29

gure 16 - Flaring for are connections

L

C

-0,4

Holding wrench

Flare

nut

C

Torque wrench

Designation Tightening torque

Flare nut 6,35 mm (1/4") 14 to 18 Nm

Flare nut 9,52 mm (3/8") 33 to 42 Nm

Flare nut 12,7 mm (1/2") 50 to 62 Nm

Flare nut 15,88 mm (5/8") 63 to 77 Nm

Plug (A) 3/8", 1/4" 20 to 25 Nm

Plug (A) 1/2" 25 to 30 Nm

Plug (A) 5/8" 30 to 35 Nm

Plug (B) 3/8", 5/8" 10 to 12 Nm

Plug (B) 1/2", 1/4" 12,5 to 16 Nm

gure 17 - Tightening torque

Installation and operating manual "1572 - EN" - 17 -

DL

Heat pump air/water split 2 services alféa excellia duo

HP model alféa excellia duo Single phase & 3-phase

gas uid

Outdoor unit connections 5/8" 3/8"

Diameter (D1) 5/8" (D2) 3/8"

Refrigeration

connections

Minimum length (L) 5

Maximum length* (L) 15

Maximum length** (L) 20

Maxi level difference**(D) 20

Hydraulic unit connections 5/8" 3/8"

* : without additional charge of R410A.

** : Taking into account the possible additional load of refrigerant R410A (see para. "Additional charge", page 21).

HP

HP

Outdoor unit

Liquid

valve

Flare

Gas

valve

Flare

nut

nut

Flare nut

"Liquid" refrigeration connection

Diameter D2

Hydraulic unit

“Gas” refrigeration connection

Diameter D1

Flare nut

- 18 -

gure 18 - Connecting the ared connections (Pipe diameters and permissible lengths)

Installation and operating manual "1572 - EN"

Jeu de manomètres

Heat pump air/water split 2 services alféa excellia duo

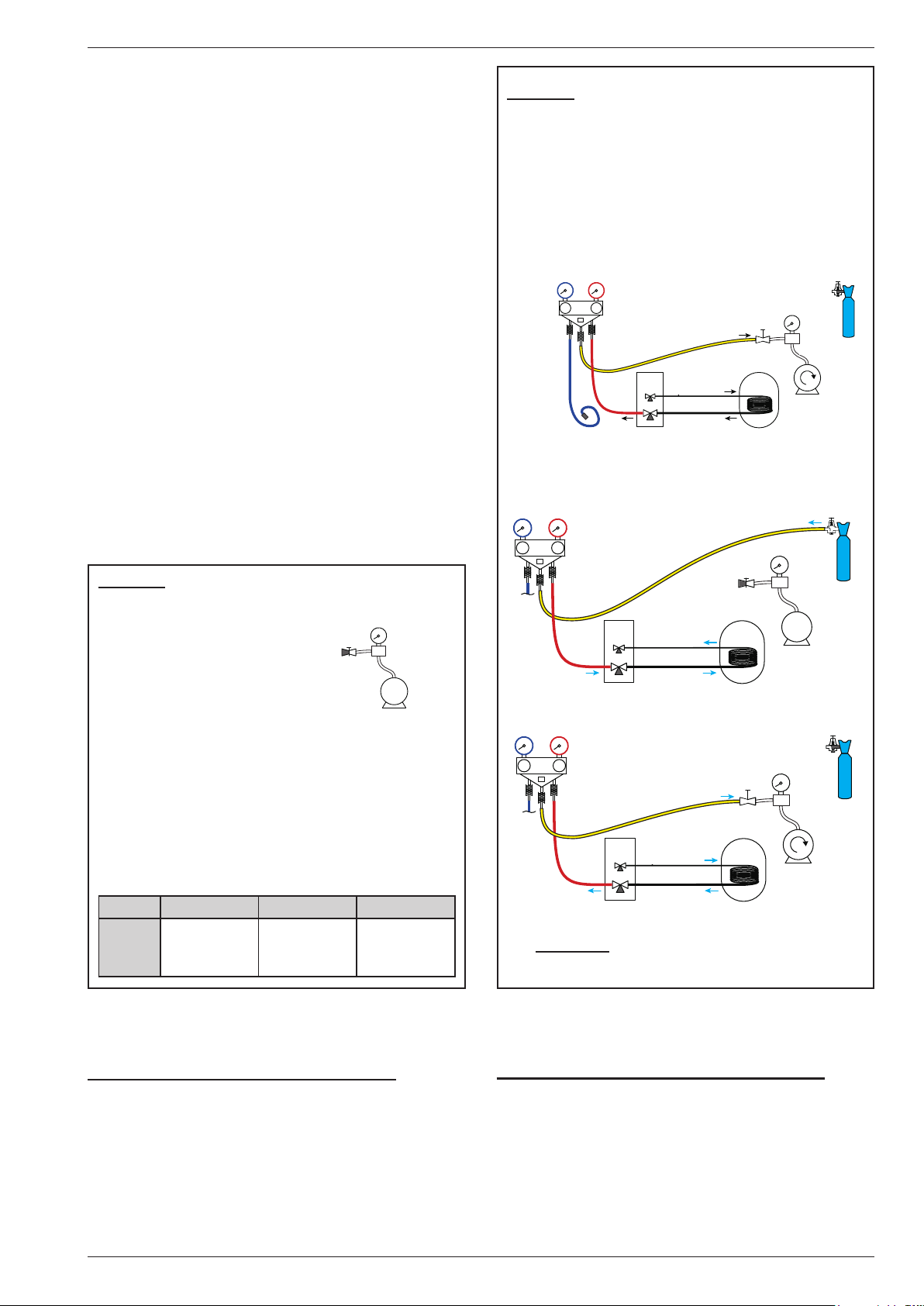

2.7 Filling the installation with gas

" This operation is reserved for installers familiar

with the legislation for handling refrigerants.

" Creating a vacuum with a vacuum pump is

essential (see ANNEX 1).

" Never use equipment used beforehand with any

refrigerant other than a HFC.

" Remove the refrigerant circuit caps only when

building the refrigerant connections.

" Unfavorables conditions :

- If the outdoor temperature is between +5 and

+10 °C, it’s obliged to have a vacuum gauge for

validate the pump down operation and use method

3 empty. (see ANNEX 2).

- If the outdoor temperature is below +5 °C,

it’s strongly not recommended to do the lling the

installation with gas.

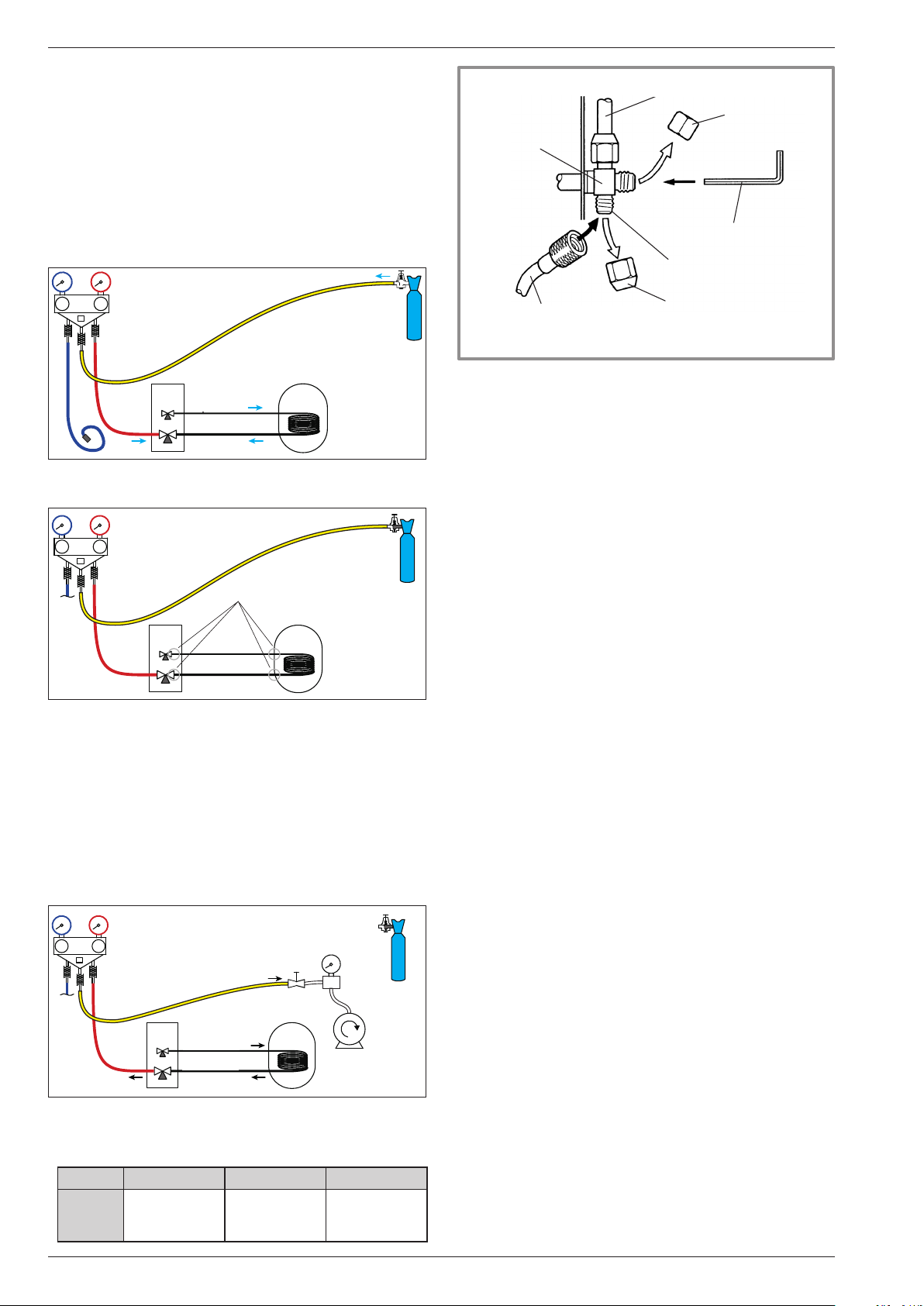

ANNEX 2

Method 3 empty

- Connect the high pressure hose to the Manifold,

("Gas" connection). A valve must be mounted on

the exible hose from the vacuum pump in order

to isolate it.

a) Pump down to the desired value (see table ANNEX 1),

Manometer kit

(Manifold)

(manifold)

Low

Basse

pressure

pression

Lo

Hi

Haute

pressure

pression

High

UE

Connection

Liaison...

Liquid

liquide

gaz

Gas

MH

Vacuum gauge

Vacuomètre

Vacuum pump

Pompe à vide

b) Stop the vacuum pump, close the valve end of

the service hose (yellow). Connect the hose to the

expansion valve of the nitrogen bottle, inject 2 bars,

close the exible hose valve,

ANNEX 1

Method for calibration and control of a vacuum

pump

- Check the oil level of the

vacuum pump.

- Connect the vacuum pump

with the vacuum gauge

Flexible

Clogged

exible

bouché

hose

Vacuum

gauge

Vacuomètre

Vacuum

Pompe

pump

à vide

according to the scheme.

- Pump down during 3 minutes.

- After 3 minutes, the pump reaches its threshold

value and the vacuum gauge needle does not move.

- Compare the obtained pressure with the value of the

table. Depending on the temperature, this pressure

must be less than the value indicated in the table.

=> If it’s not the case, replace the gasket, exible

hose or the pump.

T °C 5°C<T<10°C 10°C<T<15°C 15°C < T

Pmax

- bar . .

- mbar

. . . 0.009 . . .

. . . . . 9 . . . . .

. . . 0.015 . . .

. . . . 15 . . . .

. . . 0.020. . .

. . . .20 . . . .

Nitrogen

Hi

Haute

pressure

pression

High

UE

Connection

Liaison...

Liquid

liquide

Gas

gaz

MH

Lo

Azote

c) Reconnect the exible hose to the vacuum pump,

turn on and gradually open the hose valve.

Lo

Hi

Haute

pressure

pression

High

UE

Connection

Liaison...

Liquid

liquide

gaz

Gas

MH

d) Repeat this at least three times.

" Reminder : It’s strictly forbidden to perform

these operations with refrigerant.

2.7.1 Commissioning procedure

• Check before connecting

"Gas" connection control (large diameter).

- Connect the "Gas" connection to the outdoor unit.

- Blow dry nitrogen into the "Gas" connection and

observe this end:

If water or impurities emerge, use a new refrigerant

connection.

Otherwise, perform the are and connect immediately

the refrigerant connection to the hydraulic unit.

Installation and operating manual "1572 - EN" - 19 -

"Liquid" connection control (small diameter).

- Connect the "Liquid" connection to the outdoor unit.

- Blow dry nitrogen into "Gas" connection – condensor

- "Liquid" connection assembly and Observe this

end (Outdoor unit side).

If water or impurities emerge, use a new refrigerant

connection.

Otherwise, perform the are and connect immediately

the refrigerant connection to the outdoor unit.

Heat pump air/water split 2 services alféa excellia duo

• First seal test

- Remove the protective plugs (B) from the charging

hole (Schrader) in the "Gas" valve (large diameter).

- Connect the high pressure hose to the Manifold.

- Connect the bottle of nitrogen to the Manifold

(Use only dry nitrogen type U).

- Pressurize the refrigerant circuit with nitrogen

(10 bar maximum) ("Gas" connection – condensor "Liquid" connection assembly).

- Let the circuit under pressure for 30 minutes.

Nitrogen

Hi

Haute

pressure

pression

High

UE

Connection

Liaison...

Liquid

liquide

Gas

gaz

MH

Lo

Azote

Max. 10 bar

10 bars max.

during 30 mn mini.

30 mn mini

- Search for leaks with a leak detector product, repair

and repeat the test.

Hi

Haute

pressure

pression

High

UE

Leak control

Liaison...

liquide

gaz

Vanne fermée,

Contrôle pression

Contrôle

d’étanchéité

MH

Closed valve,

pressure control

Lo

- When the pressure is stable and leakage is excluded,

drain nitrogen letting a pressure above atmospheric

pressure (0,2 to 0,4 bar).

• Creating a vacuum and lling the refrigeration

connections with gas

- If necessary, calibrate the Manifold gauge to 0 bar.

Adjust the vacuum gauge to the atmospheric pressure

(around 1013 mbar).

- Connect the vacuum pump to the Manifold. Connect

a vacuum gauge if the vacuum pump is not equipped.

Hi

Haute

pressure

pression

High

UE

Liaison...

Connection

Liquid

liquide

gaz

Gas

MH

Vacuum gauge

Vacuomètre

Vacuum pump

Vacuum pump

Pompe à vide

Lo

- Create a vacuum until the residual pressure* in the

circuit falls below the value given in the following table.

(* measured with the vacuum gauge).

T °C 5°C<T<10°C 10°C<T<15°C 15°C < T

Pmax

- bar . .

- mbar

. . . 0.009 . . .

. . . . . 9 . . . . .

. . . 0.015 . . .

. . . . 15 . . . .

. . . 0.020 . . .

. . . .20 . . . . .

Refrigeration connecxion (Gas)

Refrigeration connexion

Plug (A)

3-way valve

Hex / Allen key of 4mm

Load orifice

Service hose (blue)

High pressure hose (red)

fitted with valve push-button

gure 19 - Connection of the hose on the "Gaz" valve

Plug (B)

- Let the pump continue to operate for another

30 minutes minimum after reaching the vacuum.

- Close the Manifold valve and then stop the vacuum

pump without disconnecting any of the hoses in

place.

" If the outdoor temperature is between +5 and

+10 °C, use method 3 empty (see ANNEX 2).

- Remove the access plugs (A) from the valve controls.

- If an additional charge is requires, add the additional

charge before lling the hydraulic unit with gas. Please

refer to the para. "Additional charge", page 21.

- First of all fully open the "Liquid" valve (small)

and then the "Gas" valve (large) using a hex key

(counterclockwise direction) without forcing

excessively against the stop.

- Remove the hose rapidly to the Manifold.

- Ret the 2 original caps (be sure they are clean) and

tighten them to the recommended tightening torque

(gure 17, page 17). The sealing is performed in the

caps only metal to metal.

The outdoor unit does not contain any additional

refrigerant, enabling the installation to be purged.

Flushing is strictly forbidden.

2.7.2 Sealing test

The sealing test must be performed with a certied gas

detector (sensitivity 5g/year).

Once the refrigeration circuit has been gassed as

described above, check that all the refrigeration connectors

are gas-tigh (4 connectors). If the arings have been made

correctly, there should be no leaks. Eventually, check the

tightness of the refrigerant valves caps.

" If there is a leak:

- Bring the gas into the outdoor unit (pump down).

The pressure should not drop below atmospheric

pressure (0 bar to read on Manifold) so as not to

contaminate the recovered gas with air or moisture.

- Make the connection again.

- Repeat the commissioning procedure.

- 20 -

Installation and operating manual "1572 - EN"

Heat pump air/water split 2 services alféa excellia duo

2.7.3 Additional charge

50 g of R410A

per additional meter

Length of

the connections

Additional charge none 250 g

15 m 20 m max.

The charge in the outdoor units corresponds to the

maximum distances between the outdoor unit and the

hydraulic unit dened in page 18. If the distances

are greater, an additional charge of R410A is required.

The additional charge depends on the distance

between the outdoor unit and the hydraulic unit for

each type of appliance. The additional charge of R410A

must necessarily be made by an approved refrigeration

engineer.

• Example of additional charge :

An outdoor unit 17 m away from the hydraulic unit will

require an additional charge of :

Additional charge = (17 - 15) x 50 = 100 g.

The charge must be introduced after creating the

vacuum and before the hydraulic unit is lled with gas,

as follows :

- Disconnect the vacuum pump (yellow hose) and

connect a bottle of R410A instead in the liquid

extraction position.

- Open the bottle’s valve.

- Bleed the yellow hose by loosening it slightly on the

Manifold side.

- Place the bottle on scales with a minimum accuracy

of 10 g. Note the weight.

- Carefully open the blue valve slightly and check the

value shown on the scales.

- As soon as the value displayed has dropped by the

value for the calculated additional charge, close the

bottle and disconnect it.

- Then rapidly disconnect the hose connected to the

appliance.

- Proceed to ll the hydraulic unit with gas.

" Warning

• Only use R410A !

• Only use tools suitable for R410A

(set of manometers).

• Always charge in the uid phase.

• Never exceed the length or the maximum difference

in level.

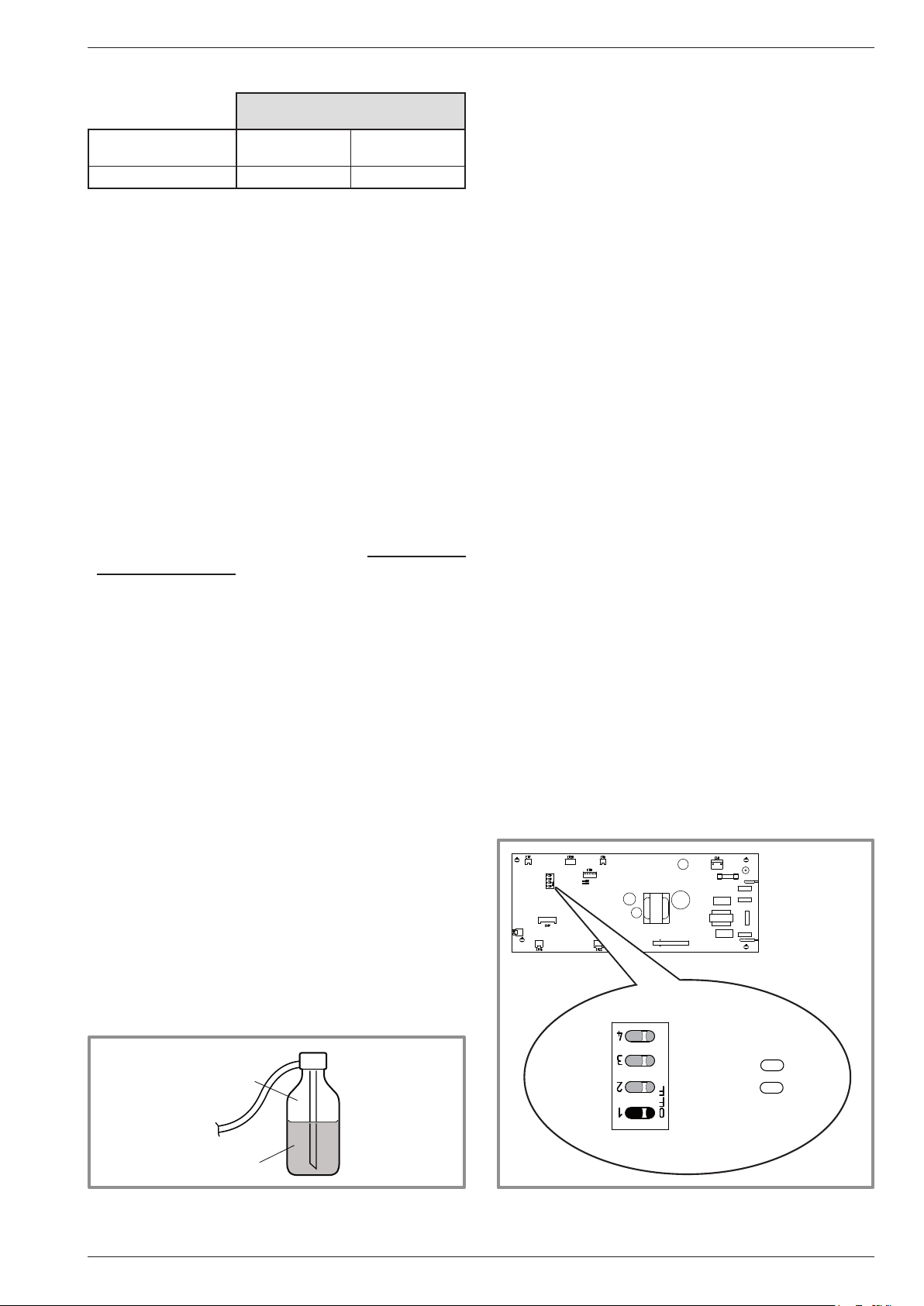

2.7.4 Pump down operation (Refrigerant collecting

operation) outdoor unit

Perform the following procedures to collect the

refrigerant.

- 1- Turn OFF the start/stop switch

(ref. 3, gure 7, page 10).

- 2- Remove the front panel.

Then turn ON the DIP SW 1 on the interface card.

- 3- Turn ON the start/stop switch.

(Green and Red LED on the board start ashing ;

1 sec. on / 1 sec. off repeated).

- 4- The outdoor unit begins cooling operation

about 3 minutes after switching ON.

Close the "Liquid" valve on the outdoor unit 1 minute

after operation starts.

- 5- Close the "Gas" valve on the outdoor unit

1-2 minutes after closing the "Liquid" valve, while the

outdoor unit keeps running.

- 6- Disconnect the power supply.

Remarks :

- Make sure to turn OFF the start/stop switch before

touching DIP SW.

- The pump down operation cannot be activated even

if DIP SW is changed while heat pump's power is on.

- Do not forget to turn back DIP SW 1 on the interface

card to OFF, after the pump down operation has been

completed.

- When the pump down operation is repeated,

temporarily turn OFF the start/stop switch after opening

the closed valves (both "Liquid" and "Gas").

- Then turn ON the start/stop switch again after

2-3 minutes and perform the pump down operation.

Interface card

DIP SW

LED2

Gas

R410A

OFF

ON

Liquid

gure 21 - "Gas" bottle R410A

Installation and operating manual "1572 - EN" - 21 -

gure 20 - Location of DIP switches and diodes

on the hydraulic unit interface card

(green)

LED1

(red)

Heat pump air/water split 2 services alféa excellia duo

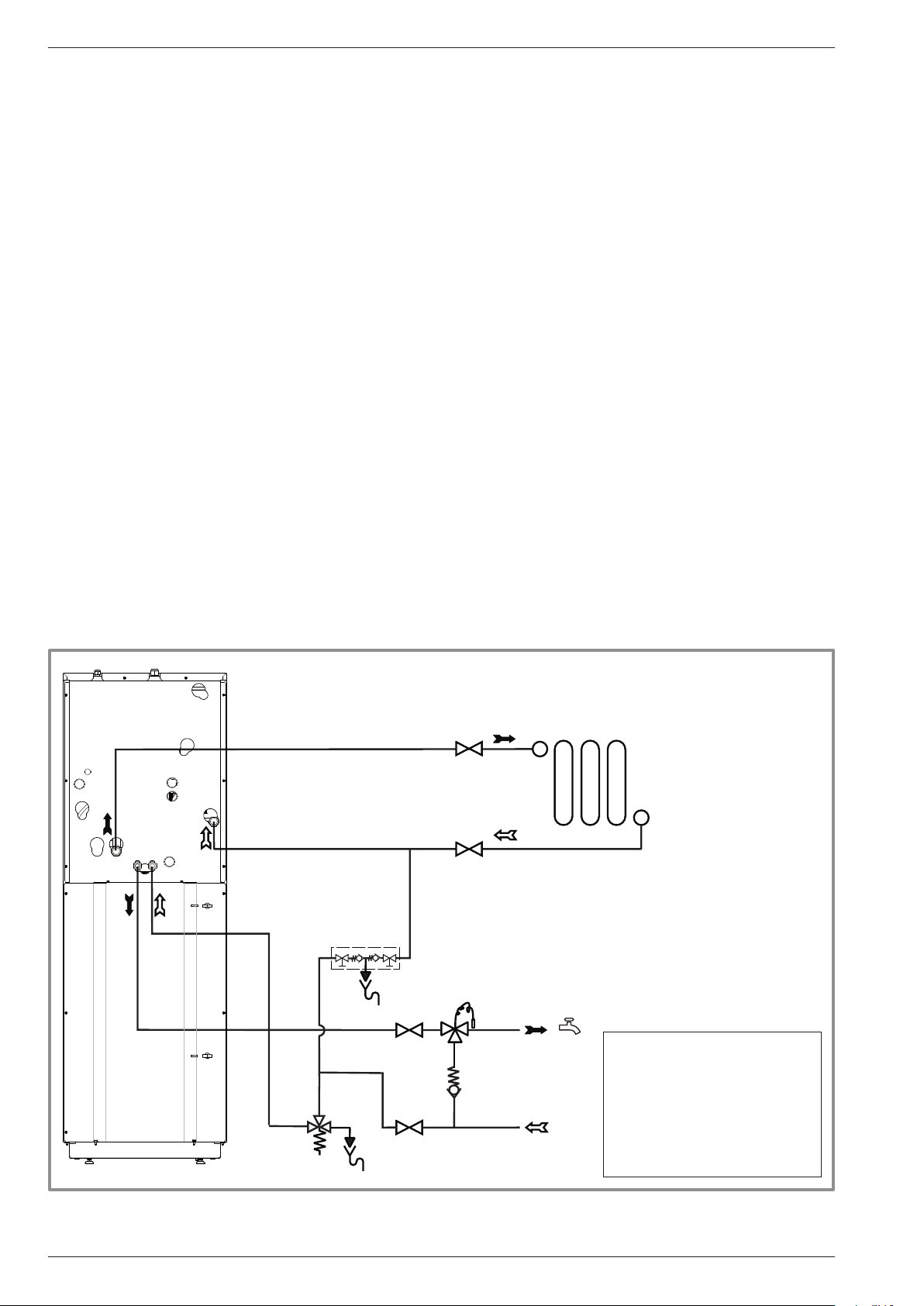

2.8 Hydraulic connecting

2.8.1 General

The connection must comply with good trade practice

according to local building regulations.

The heating circulating pump is built into the hydraulic unit.

Connect the central heating pipes to the appliance,

complying with the direction of circulation.

The pipe between the heat pump and the heat collector

must be at least one inch in diameter (26x34 mm).

Calculate the diameter of the pipes according to the

ow rates and the lengths of the hydraulic systems.

Tightening torque: 15 to 35 Nm.

Use union connectors to facilitate removing the hydraulic

unit.

Preferentially use connection hoses to avoid transmitting

noise and vibrations to the building.

Connect the drains from the drain valve and the safety

valve to the main sewer system.

Verify the correct functioning of the expansion system.

Control the vessel pressure (precharge 1 bar) and the

safety valve setting.

Reminder: Seal everything when tting in accordance

with prevailing trade practice for plumbing work:

- Use suitable seals (bre seals, o-rings).

- Use Teon tape or hemp.

- Use sealing paste (synthetic depending on the case).

The use of glycol is not necessary. If you are using a

glycol/water mix, provide for an annual check on the

quantity of glycol. Use monopropylene glycol only.

Never use monoethylene glycol.

" In certain installations, the presence of different

metals can cause corrosion problems; the

formation of metal particles and sludge in the

hydraulic circuit is then seen.

" In this case, it is advisable to use a corrosion

inhibitor in the proportions indicated by its

manufacturer.

- Please refer to the chapter "Treatment of domestic

and heating water" in our price catalogue.

" It is also necessary to ensure that the treated

water does not become aggressive.

Ø 26x34

1" Male

Ø 20x27

3/4" Male

GS

D

MT

CAR

R1

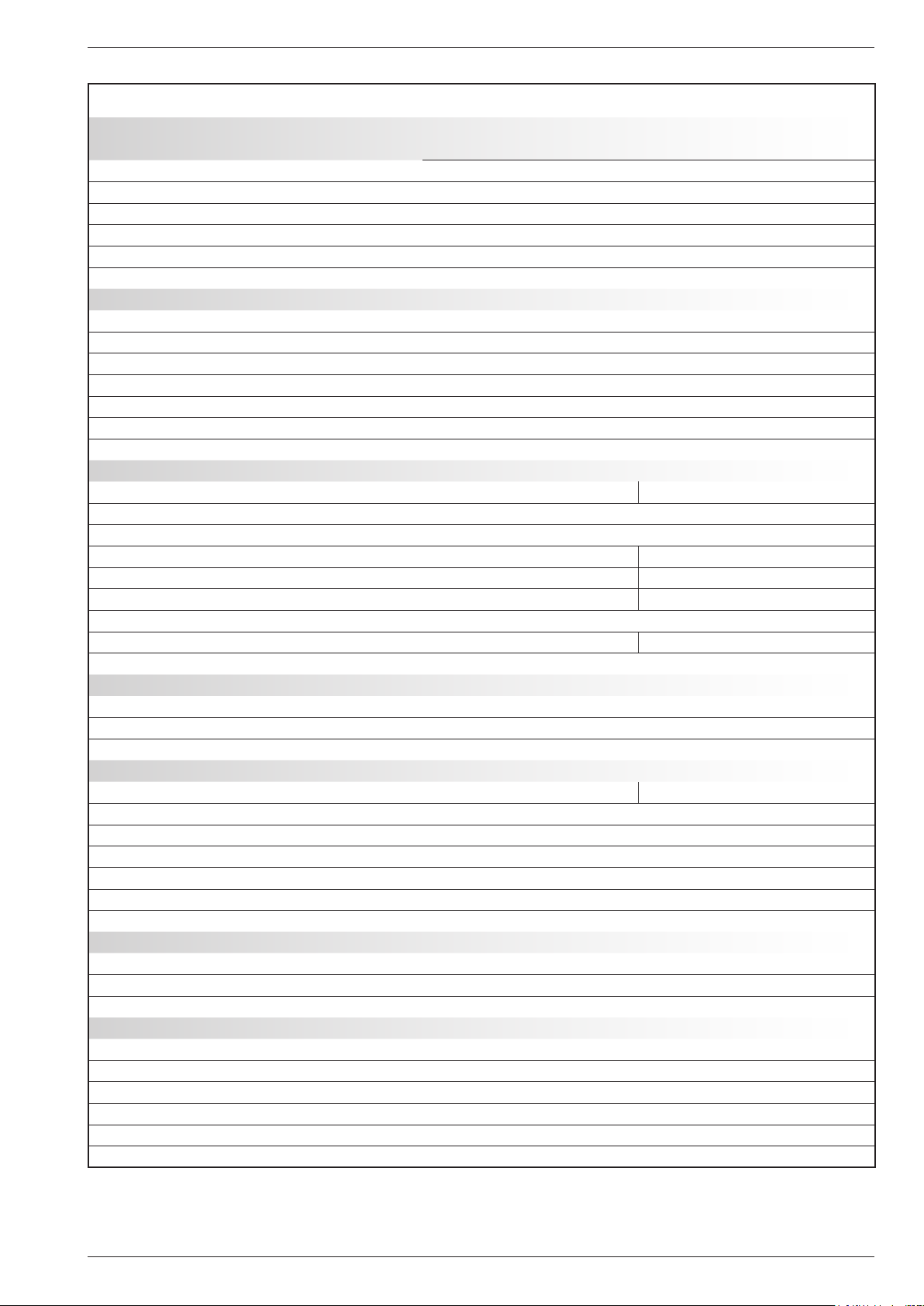

Legend:

CAR : Non-return valve.

D : Shut-off.

GS : Safety unit.

MT : Thermostatic mixer valve.

R1 : Heating circuit.

- 22 -

gure 22 - Overall hydraulic layout

Installation and operating manual "1572 - EN"

Loading...

Loading...