Page 1

Model type:

CDE129ALL

Commercial code:

32570

page 1

Page 2

General notes

Technical Documentation guidelines

-------------------------------------------------------------------------------------------------------------------------------

You can find herewith some generic information to simplify cunsulting of technical documentation:

1. Models of same range share the same exploded views, which report the richest set of spare parts:generally, a model does not necessarly have a

related spare part for each particular shown on exploded views.

2. Some spare parts can not be represented directly on the exploded views (instruction booklets, specific kit, etc...). You can find those codes in the

spare parts list with the same reference of particular where spares are installed or with references 099, 999. Instruction booklets, once managed,

appear with 000 reference.

3. On the higher right site of each exploded view there is a serial number which indicates the beginning of the production of certain range:some

models might have more than an exploded view for a given category, each distinguished by a different serial no.and linked to another spare parts

list, In this case, serial no. is required to supply the right spare part code. Exploded view to be considered is the one with a more recent serial no.

but previous than the one of the model that needs assistance.

4.Exploded views might require further updates even after publishing. Addition of new spares will go on following the already existing numeration

references. Revision number of an exploded view is shown into last four digits of serial number into upper right hand corner.

5.The spare parts list associated to an exploded view shows related codes of spares managed for a certain model; for each spare part other

informations are available:

REF: reference no of spare into a table; SUBSTITUTE: list of spare(s) which can replace a code but that keeps same functional characteristics

INDUSTRIAL CODE: list of variables of a model (shown into model label) where such spare is used; NOTICE: code of information(s) to refer to

complete technical intervention, track for changes or to find correct spare part code.

6. Some notices, into a same section are generic therefore cannot be directly linked to a spare part. In order to assist a model in the best way as

possible, it is helpful to pay attention to all notices and constantly verify documentation updates

7.Technical documentation cover shows model name and its commercial codes

page 2

Page 3

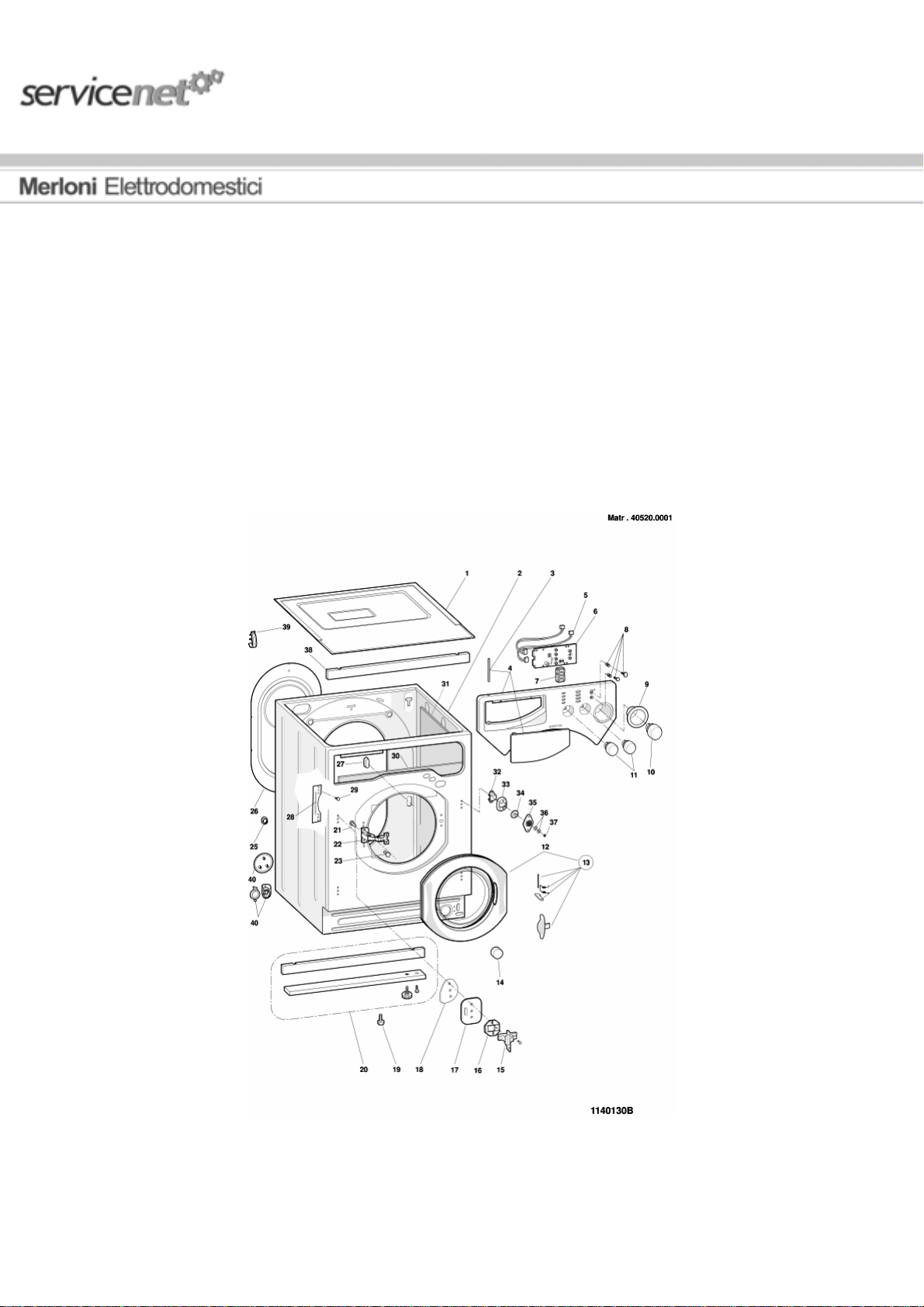

pdf_tavola_title_ENG

cod. 1140130B

page 3

Page 4

Spare parts list

Spare parts list cod. 1140130B

Ref. Code Substitute Industrial code Description Notice

000 C00084868 door fixing - template

000 C00087354 installation hinge kit (20121)

000 C00111083 user instruct.bookl it-gb-fr-de

000 C00111084 user instruct.bookl nl-es-pt

001 C00084883 cabinet cover

002 C00090573 cabinet white

003 C00065186 pivot pin - drawer front

004 C00111086 control panel + handle

005 C00109854 wiring dashboard lbe evoii

006 C00109856 led card evoii incasso ariston n1040338

007 C00110055 silicone push buttons

008 C00110116 white pushbutton on-off/reset

009 C00111091 knob timer disc

010 C00109846 wash timer-components knob

011 C00109847 temperature knob white

011 C00111078 dry timer knob aml cde evoii

012 C00087818 door frame and glass assy

108.5x5 mm ab

cde129all

lbe kit

assy - white

013 C00065250 door handle kit

014 C00087353 rubber buffer h=29,5 mm grey

015 C00056261 furniture door hinge

016 C00087348 hinge support shim 11,8 mm

017 C00087350 hinge plate spacer shim 5 mm

018 C00055735 door hinge support

page 4

Page 5

019 C00110512 foot - rear m8 h = 3,7cm

020 C00084867 kit base x built-in washing-

021 C00074149 bolt m4x9 tesrfr

022 C00064541 hinge assy-outer case/door

023 C00065185 bolt m4,5 x 11

024 C00046666 collar for drain hose

025 C00065871 blanking plug

025 C00089419 blanking plug 6.5 mm

026 C00099313 rear cover - white

027 C00084817 blanking plate-rear(test plug)

028 C00064539 hinge plate door

032 C00058277 1 C00058030 bolt plate

033 C00058030 kit magnet fore sight

034 C00033428 magnet

035 C00045656 magnet support

036 C00045655 magnet regulation washer

machines

180

037 C00024221 push on fix ring

038 C00085004 door strip - white

039 C00064550 dain hose holder

040 C00089803 blanking plug d = 53 mm

page 5

Page 6

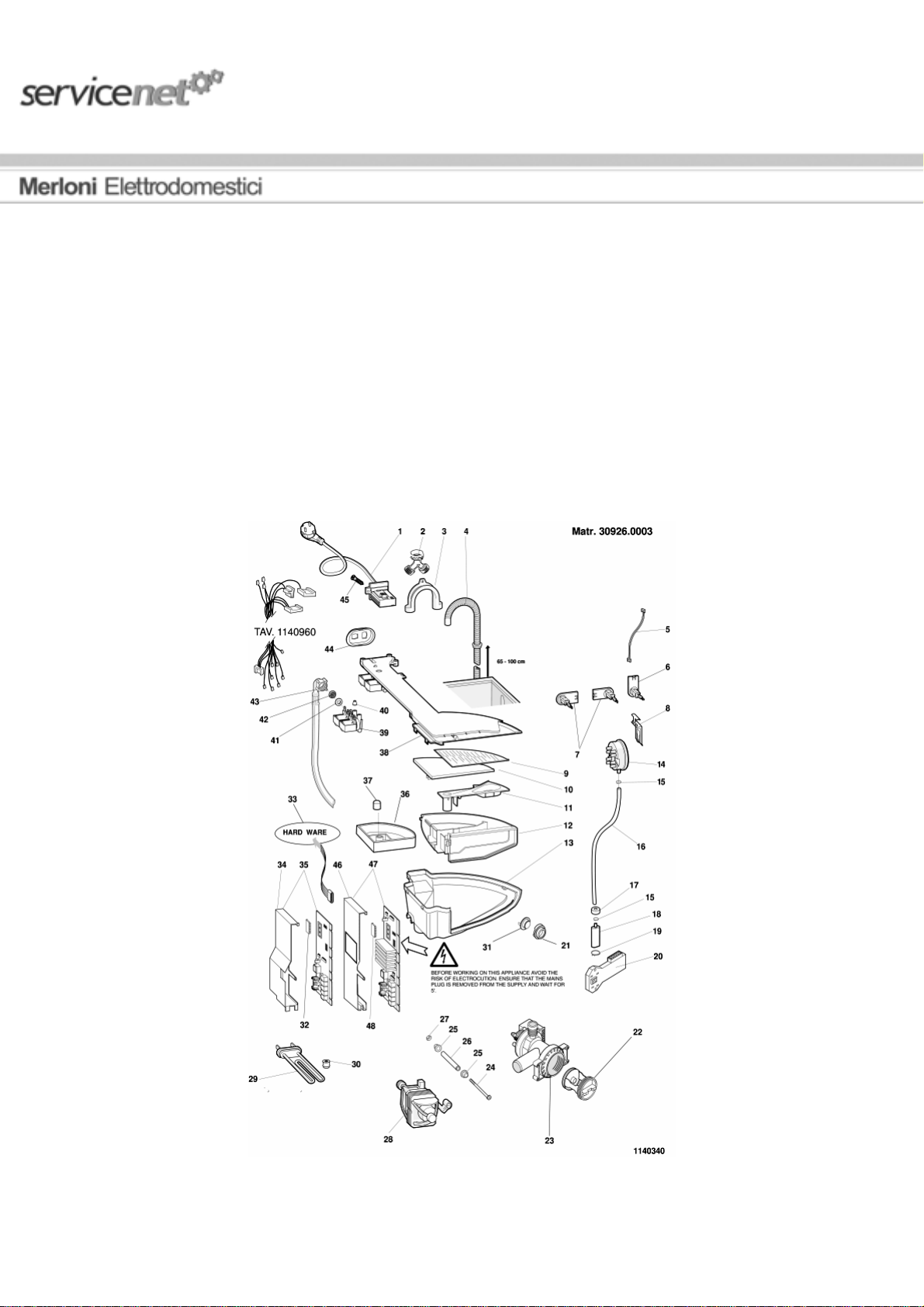

pdf_tavola_title_ENG

cod. 1140340

page 6

Page 7

Spare parts list

Spare parts list cod. 1140340

Ref. Code Substitute Industrial code Description Notice

001 C00094203 supply cable 1,5mt shuko 3 f

004 C00027466 drain hose - to sink l=1860mm

005 C00095750 wiring dashboard avl avsl avxl

006 C00087067 programme select bitron 16

007 C00085195 potentiometer 8 pos. idc rast

008 C00064537 support - pressure switch

012 C00046148 soap dispenser drawer (rotary)

013 C00092176 dispenser body

014 C00110327 pressure switch 1 l. +

015 C00092412 hose clamp

016 C00092170 air trap hose 470mm. evo ii

017 C00019755 anti-vibration bush (foam)

018 C00092173 air trap x oko

020 C00065185 bolt m4,5 x 11

020 C00085194 door interlock

021 C00014917 grommet - thermostat

022 C00045023 filter handle

evo2

positions

2,5

antiowerflow

022 C00045025 filter seal

022 C00045027 filter element kit

023 C00092264 self cleaning pump

024 C00074152 bolt m6x30

025 C00019682 rubber bush 20 mm - motor

026 C00074153 spacer motor support l= 187

mm

page 7

Page 8

027 C00040932 self locking nut m6

028 C00094023 motor three phase cim2-55

028 C00097258 tacho generator for motor

029 C00066086 heating element+termal cut-

030 C00058523 pillar retainer-heating element

031 C00053573 temperature sensor ("control")

033 C00066292 insulated tweezers

033 C00084943 1 C00099862 serial cable lb2000 - pc

033 C00095669 housing seriale evoii - lb2000 -

038 C00111093 hopper cover 1e 3u ev

039 C00111094 2-way electrovalve 1e-3u 7 l

041 C00005572 sealing washer-mains inlet

042 C00005781 inlet hose filter

043 C00003070 mains inlet hose cold 25c

044 C00084840 electrovalve support 1 ev

045 C00092348 self-scraping screw 3,5x8

046 C00094047 support cover 3 f

ceset

out 1700w/230v

- white

pc

eccentric

hose

10bar 1500 mm

046 C00094049 bracket for module 3 f

047 C00097554 module less eeprom wd mf

048 C00111076 eeprom cde129all evoii s/w

2,74

28325700002

page 8

Page 9

pdf_tavola_title_ENG

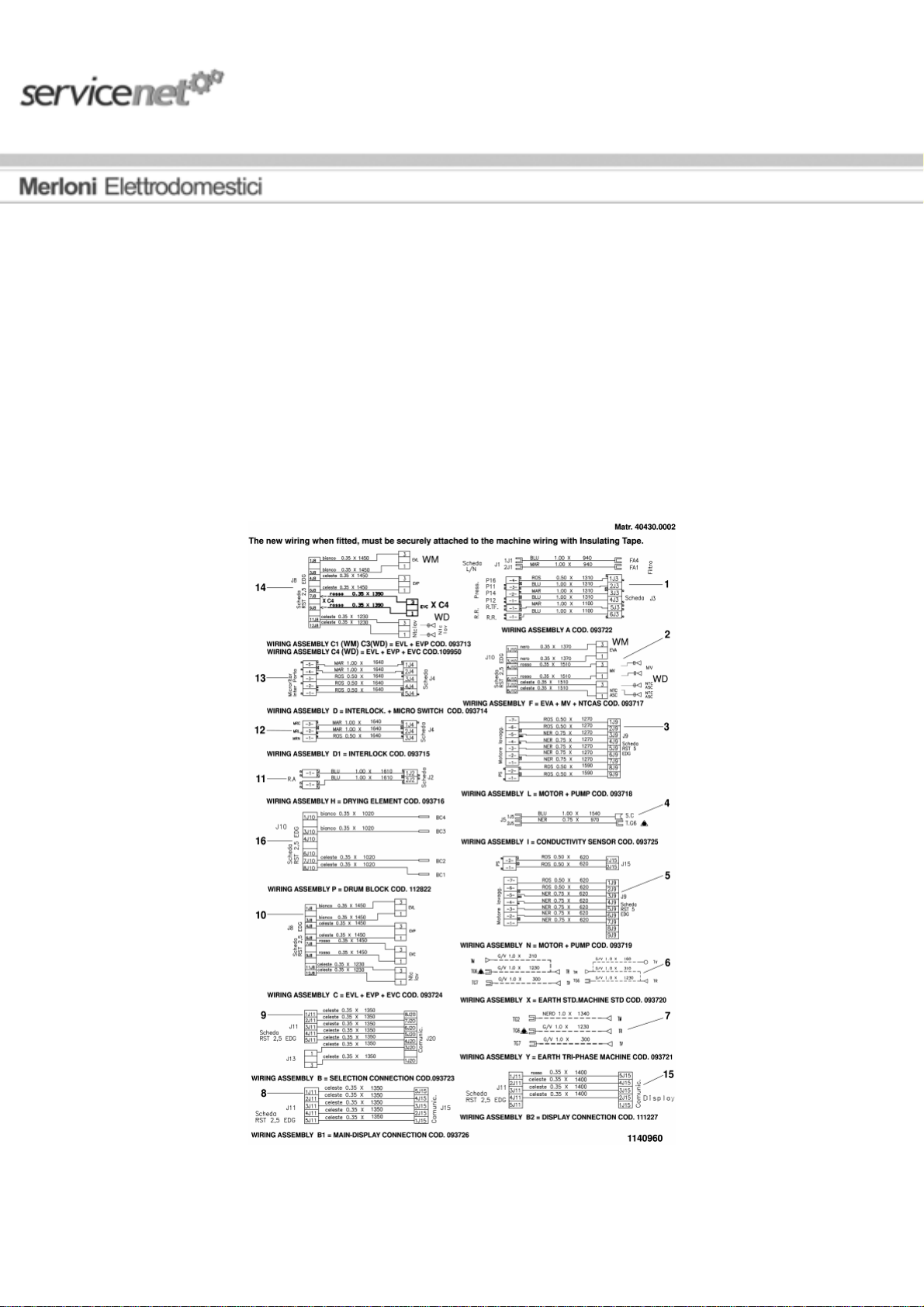

cod. 1140960

page 9

Page 10

Spare parts list

Spare parts list cod. 1140960

Ref. Code Substitute Industrial code Description Notice

001 C00093722 wiring base a 240000700a0

002 C00093717 wiring eva + mv + ntcas

003 C00093718 wiring ml + ps 240000700l0

007 C00093721 wiring terra 240000700y0

008 C00093726 wiring comunic. display

011 C00093716 wiring ras - ra 240000700h0

012 C00093715 wiring mr mr 240000700d1

014 C00093713 wiring evl + evp 240000700c1

240000700f0

240000700b1

page 10

Page 11

pdf_tavola_title_ENG

cod. 1180240

page 11

Page 12

Spare parts list

Spare parts list cod. 1180240

Ref. Code Substitute Industrial code Description Notice

001 C00064786 bolt m8x20 tefl

002 C00013563 bearing 25 x52 x 15 6205-2z

003 C00064785 bolt m8x22 tb6lt

004 C00002591 bearing 20x47x14

005 C00096186 standard oil seal cv4

006 C00080651 rear support

007 C00088408 bolt

008 C00087811 upper counterweight 8,2 kg

009 C00080761 1 C00064517 tank cradle channel-top dx wd

010 C00080650 front support

011 C00080652 bolt m8x36 tefl. zig. p/p

012 C00064515 anchorage pad - suspension

013 C00080660 suspension spring - tank

014 C00080653 spacer

015 C00080762 door bellows

017 C00064546 clamping ring - bellows seal

017 C00064547 bellows clamp (tank front)

dx/sx-aml

spring

front

018 C00092178 front counterweight

020 C00094312 hose tank to filter oko ws - abs

022 C00091148 clamp d=79 mm

023 C00065152 nut romob m6x20x1,6

024 C00030443 1 C00047136 nut romob m8

025 C00093848 cradle outer- set

page 12

Page 13

026 C00093885 shock absorber 120 n 8,15 mm

027 C00064789 wash paddles (extractable) 46

028 C00092263 1 C00094097,1 C00094280 outer- set 46 l. cv5-b5 ld

031 C00092273 hose dispenser to tank

032 C00096077 bearing spider assembly

033 C00074211 drum pulley d=210 mm h=20

034 C00074218 belt l=1046 mm h8

099 C00001109 loctite 270 10 gr.

099 C00033026 ambljgon grease ta 100 gr.

l

mm

page 13

Page 14

pdf_tavola_title_ENG

cod. 1180410

page 14

Page 15

Spare parts list

Spare parts list cod. 1180410

Ref. Code Substitute Industrial code Description Notice

001 C00087921 screw amsp m3.5x30t.e.(s/n

002 C00080775 thermal cut-out cable

003 C00080767 temperature sensor

004 C00080768 o-ring d= 27 x 23,5 x 1,78 wd

005 C00080765 dryer heating element 1200

006 C00032847 blower manifold seal

007 C00033210 hose clamp fastex 350 mm x

008 C00032845 restrictor seat

009 C00080960 self blocking nut m5

010 C00080959 connection gasket

010 C00097378 connection gasket

011 C00080771 clip

012 C00080773 fixing screw for lint filter

013 C00080772 lint filter

014 C00080774 hose clamp

30617.0001)

watt 230 volt

7.8 mm

015 C00080770 steam condenser

016 C00080769 hose electrovalve condenser

017 C00032844 seal - condenser / tank

018 C00038358 bolt m8x16 (dry loc)

019 C00032972 blower fixing nut

020 C00080658 blower fan for motor (087920-

021 C00054790 screw trilob m5 x 16 tcb t.e. st

022 C00087919 blower manifold kit

097339)

s/n30617.0001

page 15

Page 16

023 C00087920 dryer fan motor 230v 50hz s/n

025 C00080652 bolt m8x36 tefl. zig. p/p

30617.0001

page 16

Page 17

Notices

n1040242

Power card with welded eeprom.

-------------------------------------------------------------------------------------------------------------------------------

From serial number 20304.0001, IDC power card with welded eeprom is used to ensure the perfect connection of all parts, in the Comunanza,

Teverola and Brembate factories.

To replace the module with welded eeprom, it will be necessary to use the eeprom indicated in the SAT document of the model concerned.

To replace the module on a unit with welded eeprom (Cod. 084838, 089405, 089404, 089416, 089074, and 090505), both the SAT module and the

eeprom are required, because the latter cannot be reused.

n1040296

List of EVOII FAULTS and troubleshooting

-------------------------------------------------------------------------------------------------------------------------------

If a fault occurs on the washing machine then the self test function will

display this, or the new hardware key may be used to show the fault.

The type of fault can be signalled in different ways:

• on AVD models the fault is shown directly on the machine display.

• On AVL models the fault is signalled by LEDs.

2.10.4 Reading of Faults signalled by LEDs

When the machine has a fault:

1. The door is locked

2. The door lock indicator flashes quickly (surely > 1 Hz)

3. The control panel LEDs flash, to signal the fault, according to the table fig. 01.

page 17

Page 18

The example shown in the fig. 02 (Example Fault F03) below indicates which

LEDs flash if the machine has a Fault F03

List of faults, malfunctions and Warnings:

F01: Triac Motor short circuit

• Check for any water leaks that can reach connector J9 short circuiting the

relevant contacts

• Check the motor terminal block (a possible problem due to chemical work

residuals corroding the contacts that can cause a short circuit)

• Replace Card

F02: Motor blocked, Tachometrics in Short Circuit/Open

• Check motor if blocked

• Check the efficiency of J9 connector on the card

• Check the tachometric winding checking an ohm resistance reading of 115

- 170 ohm between pins 1 and 2 on wiring connector J9. In case of short

circuit, open circuit check the wiring between pins 1 and 2 of J9 relevant

to the tachometrics. With a three-phase motor, make sure there is ohm

continuity between J9 pins 6 and 7.

• Replace motor

• Replace card

F03: Detected: NTC Open or in Short Circuit or wash heater relay stuck (signalled in

presence of full load)

• Check efficiency of J8 connector contacts on the card

• Check NTC verifying that the ohmic resistance value at room temperature

20°C is approx. 20Kohm on J8 wiring connector pin 11 and 12.

• If the measurement is incorrect check J8/NTC wiring continuity. Check the

same parameter directly on NCT

• Replace NTC

page 18

Page 19

• Replace Card.

F04: Simultaneous empty and overflow (pressure switch stuck on empty). If the

pressure switch contact is stuck on empty the washing machine loads water until

reaching the overflow. The drain pump is automatically started by the contact on

the overflow pressure switch.

• Check the efficiency of J3 connector contacts on the card.

• Check pressure switch status checking J3 wiring connector pins:

- 2-4 ohm continuity - tub empty

- 2-3 ohm continuity - full tub

- 2-1 ohm continuity - tub overfilled, at least halfway up door glass

• Check wiring of connector J3/pressure switch

• Replace pressure switch

• Replace card.

F05: Detected: Pump Blocked or pressure switch empty not reached

• Check the efficiency of J9 connector contacts on the card checking the

presence of 220V current between pins 8 and 9.

• Check pump: if fed

• Check Pump Filter + wall drain

• Change Pump

• Replace Card.

F06: Not on AVD and AVL

F07: Detected: No Absorption Wash Heating Element (the fault is only signalled

with the pressure switch on empty)

• Check the efficiency of J3 connector contacts on the card

• Check the continuity of the wash heater on J3 connector pins 5 and 6. The

1800w 230V heating element has a resistance of 25 ohm.

• Check the connection of pressure switch J3 connector pins 2 and 3: there

page 19

Page 20

must not be ohm continuity (shared with full load).

• Check the connection of pressure switch J3 connector pins 2 and 4: there

must be ohmic resistance

• Replace Heating Element

• Replace Pressure Switch

• Replace Card.

F08: Wash Heater Relay Stuck (signalled in presence of empty) or pressure switch

stuck on Full (simultaneously empty and full)

• Check the efficiency of J3 connector contact on the card

• Check pressure switch status checking J3 wiring connector pins 2 and 4

ohm continuity (it must only be present with tub empty) and pins 2 and 3

ohm continuity (it must only be present with water in the drum) and pins 2

and 1 ohm continuity (it must only be present with water in the tub above

normal level, at least halfway up door glass).

• Check wiring J3/pressure switch

• Check connection of heating element J3 connector pins 5 and 6.

• Replace pressure switch

• Replace Card

F09: Detected: Machine Setup Error (eeprom error)

• In case of production card with eeprom soldered: replace card and eeprom

• In case of replacement of eeprom and card, check the correct housing of

eeprom on card base.

F10: No full and empty signal

• Check the efficiency of J3 connector contacts on the card

• Check pressure switch status checking J3 wiring connector pins:

- 2-4 ohm continuity - tub empty

- 2-3 ohm continuity - full tub

- 2-1 ohm continuity - tub overfilled, at least halfway up door glass

page 20

Page 21

• Check wiring of connector J3/Pressure switch

• Replace Pressure Switch

• Replace Card.

F11: Detected: No Pump Feedback (Drain pump disconnected or winding broken)

• Check the efficiency of J9 connector contacts on the card

• Check continuity of the Pump on J15 connector pins 1 and 2 (in case of

washing machine with Easy Door function) or on J9 connector pins 8 and 9

(in case of conventional door lock), checking resistive value equal to 170 ohm.

• Check wiring of connector J15 (or J9)/Pump

• Replace Pump

• Replace Card.

F12: No Communication Display Card/LED-Main Card

• Check the efficiency of contacts on card of J11 connector

• Check the continuity of J11 connector-display card 5-pin connector

• Replace Main Card

• Replace Display Card/LED.

F17: Door lock unfed/open (with Easy Door)

• Check the presence of 230V mains power on J4 wiring connector inserted

on board between pins 3 and 4, (not present with machine on standby)

the presence of power from 230V door lock between pins 3 and 5

• Check the ohm continuity of door microswitch (with door closed on and

off) on J4 connector inserted on the board between pins 1 and 2

• Check continuity of J4/door lock wiring

• Check door hooking

• Replace door lock

• Replace card.

F17: Door lock unfed/open (conventional door lock, not Easy Door)

page 21

Page 22

• Check the presence of 230V mains power onJ4 wiring connector inserted

on board between pins 2 and 3, (not present with machine on standby)

the presence of power from 230V door lock between pins 3 and 1

• Check door hooking

• Replace door lock.

• Replace card

F18: DSP (Digital Signal Processor) / microprocessor error

• Replace card

n1040338

-------------------------------------------------------------------------------------------------------------------------------

page 22

Page 23

n1040338

-------------------------------------------------------------------------------------------------------------------------------

page 23

Page 24

Electric schemes and links

Cod. 16001817900

page 24

Page 25

Legend

Legend: 16001817900

page 25

Page 26

Electric schemes and links

Cod. 21500759700

page 26

Page 27

Legend

Legend: 21500759700

page 27

Loading...

Loading...