Page 1

LONG INACTIVITY

OF THE BATTERY

If the vehicle remains unused for more than

fifteen days, it is necessary to recharge the

battery, in order to prevent its sulphation, see

page 75 (RECHARGING THE BATTERY).

It is important to check the charge periodically (about once a month), during the winter or when the vehicle remains unused, in

order to prevent the deterioration of the battery.

♦ Recharge it completely with a normal

charge, see page 75 (RECHARGING THE

BATTERY).

If the battery remains on the vehicle, disconnect the cables from the terminals.

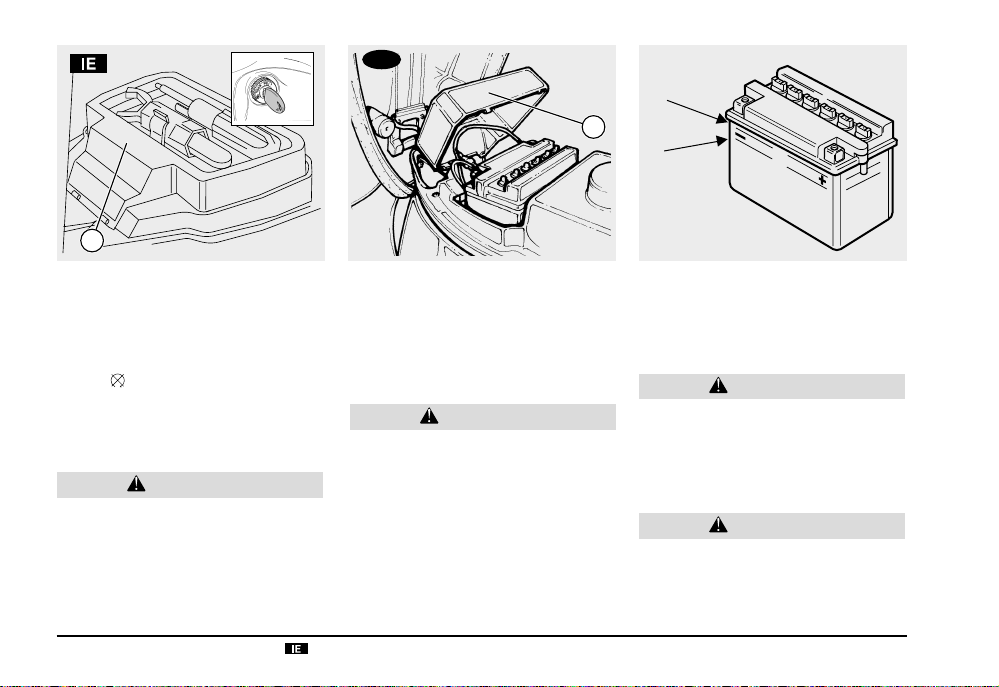

CHECKING AND CLEANING

THE TERMINALS

Carefully read page 72 (BATTERY).

♦ Gain access to the battery, see page 74

(ACCESS TO BATTERY).

♦ Make sure that the cable terminals (1) and

the battery terminals (2) are:

– in good conditions (and not corroded or

covered with deposits);

– covered with special grease or Vaseline.

If necessary:

♦

Make sure that the ignition switch is in position

“ ”.

♦ Disconnect first the negative (–) and then

the positive cable (red) (+).

♦ Brush with a wire brush to eliminate any

sign of corrosion.

♦ Reconnect first the positive (red) (+) and

then the negative cable (–).

♦ Cover the terminals with special grease or

Vaseline.

♦ Refit the battery, see page 75 (INSTALL-

ING THE BATTERY).

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

73

Page 2

100

MAX

1

MIN

1

REMOVING THE BATTERY

Carefully read page 72 (BATTERY).

ACCESS TO BATTERY

♦ Make sure that the ignition switch is in po-

sition “

♦ Lift the saddle, see page 24 (UNLOCKING

♦ Remove the battery cover (1).

”.

/ LOCKING THE SADDLE).

CAUTION

The battery is connected to the electrical

wires. Do not force the wires while removing the battery.

use and maintenance

74

Scarabeo 50 - Scarabeo 100 4T

COMPLETE REMOVAL

♦ Disconnect first the negative (-) and then

the positive cable (red) (+).

♦ Detach the breather pipe.

♦ Remove the battery from its compartment

and put it on a flat surface, in a cool and

dry place.

WARNING

Once it has been removed, the battery

must be stored in a safe place and kept

away from children.

CHECKING

THE ELECTROLYTE LEVEL

Carefully read page 72 (BATTERY).

♦ Remove the battery (see REMOVING THE

BATTERY).

♦ Make sure that the fluid level is included

between the two “MIN” and “MAX” notches

stamped on the battery side.

Otherwise:

♦ Unscrew and remove the element plugs.

CAUTION

Top up with distilled water only.

Do not exceed the “MAX” mark, since the

electrolyte level increases during the recharge.

♦ Top up by adding distilled water.

CAUTION

After topping up, put back the element

plugs in the correct position.

♦ Put back the element plugs.

Page 3

RECHARGING THE BATTERY

Carefully read page 72 (BATTERY).

♦ Remove the battery, see page 74 (REMOV -

ING THE BATTERY).

♦ Take a suitable battery charger.

♦ Unscrew and remove the element plugs.

♦

Check the electrolyte level, see page 74

(CHECKING THE ELECTROLYTE LEVEL).

♦ Connect the battery with a battery charger.

NOTE A recharge with an amperage equal

to 1/10 th of the battery capacity is recommended.

♦ Switch on the battery charger.

♦ After the recharging operation, check the

electrolyte level again and if necessary top

up with distilled water.

♦ Tighten the element plugs.

CAUTION

Reassemble the battery only 5-10 minutes

after disconnecting the recharger, since

the battery continues to produce gas for

a short lapse of time.

INSTALLING THE BATTERY

Carefully read page 72 (BATTERY).

♦ Make sure that the ignition switch is in po-

sition “

”.

♦ Put the battery in its container.

♦ Connect the breather pipe.

CAUTION

Always connect the battery breather pipe,

to prevent the sulphuric acid vapours

from corroding the electric system,

painted parts, rubber elements or gaskets

when they exit the breather pipe itself.

The breather pipe must be connected in

such a way as not to be squashed, otherwise it may cause a pressure increase

inside the battery, with the risk of damaging it.

100

♦ Connect, in order, the positive (red) (+) and

negative (

♦ Cover the terminals with special grease or

-) cable.

Vaseline.

CAUTION

Upon reassembly, put the electrical cables in the correct position taking care

not to squash them.

The negative cable (

upon the positive cable (+). Take care to

position it on the side, between the battery and the box.

♦ Push the battery into the battery holder

♦ Close the battery cover (1).

♦ Lower the saddle, see page 24 (UNLOCK-

ING / LOCKING THE SADDLE).

-) must not be placed

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

75

Page 4

3

1

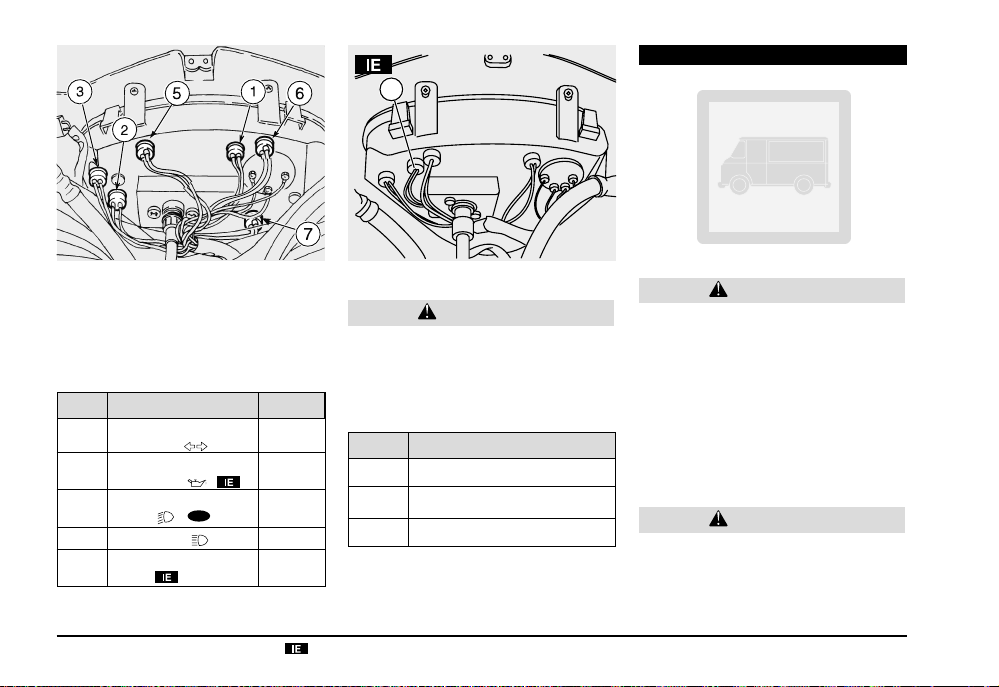

CHANGING THE FUSES

Carefully read page 47 (MAINTENANCE).

CAUTION

Do not repair faulty fuses.

Never use fuses different from the recommended ones.

The use of unsuitable fuses may damage

the electric system or, in case of short

circuit, may even cause a fire.

NOTE If a fuse blows frequently, there prob-

ably is a short circuit or an overload in the

electric system.

In this case it is advisable to consult an

aprilia Official Dealer.

use and maintenance

76

Scarabeo 50 - Scarabeo 100 4T

If an electric component does not work or

works irregularly, or if the engine fails to start,

it is necessary to check the fuses (1).

To carry out the checking:

♦ Turn the ignition switch to position “ ”, to

avoid any accidental short circuit.

♦ Gain access to the battery in order to work

on the fuses, see page 74 (ACCESS TO

BATTERY).

♦ Extract the fuses (1) one by one and check

if the filament (2) is broken.

♦ Before replacing a fuse, try to find out the

cause of the trouble, if possible.

♦ Then replace the damaged fuse with a new

one having the same amperage.

NOTE If you use one of the spare fuses

(3), put a new fuse in the appropriate seat.

♦ Reposition the inspection cover, see page

65 (REMOVING THE INSPECTION

COVER).

LOCATION OF FUSES

7.5 A fuse (1) - From key switch to:

all electrical loads, other than the lights circuit that is powered with alternate current.

Page 5

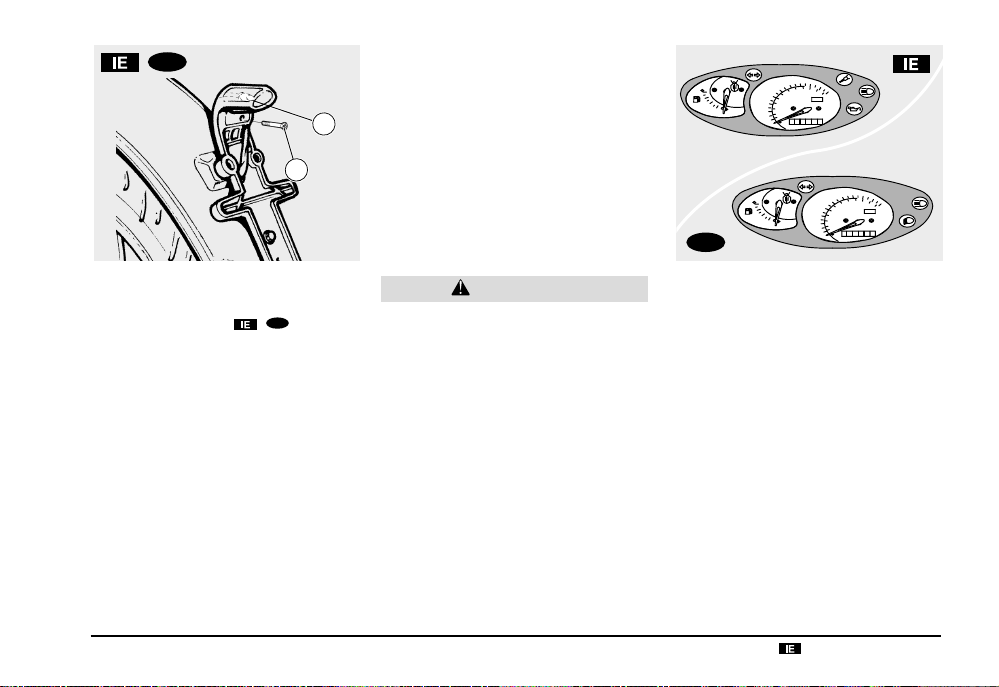

ADJUSTING THE VERTICAL

HEADLIGHT BEAM

NOTE To check the direction of the head-

light beam, specific procedures must be

adopted, in accordance with the regulations

in force in the country where the vehicle is

used.

To rapidly check the correct direction of the

beam, place the vehicle on flat ground, 10 m

away from a wall.

♦ Turn on the low beam, sit on the vehicle

and make sure that the beam projected on

the wall is slightly under the horizontal line

of the headlight (about 9/10th of the total

height).

1

To adjust the headlight beam:

♦ Position the vehicle on the centre stand,

on a solid and level surface.

♦ Act on the suitable screw (1) by means of

a screwdriver.

By TURNING IT CLOCKWISE, you set the

beam upwards.

By TURNING IT ANTICLOCKWISE, you

set the beam downwards.

BULBS

Carefully read pages 48-53 (REGULAR

SERVICE INTERVALS CHART).

WARNING

Risk of fire.

Keep fuel and other flammable substances away from the electrical components.

CAUTION

Before changing a bulb, position the vehicle on the centre stand, move the igni-

tion switch to position “

few minutes, so that the bulb cools down.

Change the bulb wearing clean gloves or

using a clean and dry cloth.

Do not leave fingerprints on the bulb,

since these may cause its overheating

and consequent breakage.

If you touch the bulb with bare hands,

remove any fingerprint with alcohol, in

order to avoid any damage.

DO NOT FORCE THE ELECTRIC CABLES.

” and wait a

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

77

Page 6

1

2

CHANGING

THE HEADLIGHT BULBS

Carefully read page 77 (BULBS).

The headlight houses:

– one low / high beam bulb (1);

– one parking light bulb (2).

To change them:

♦ Remove the front handlebar cover, see

page 65 (REMOVING THE FRONT HANDLEBAR COVER).

use and maintenance

78

Scarabeo 50 - Scarabeo 100 4T

LOW / HIGH BEAM BULB

♦ Turn the bulb socket anticlockwise (3) and

remove it from its seat.

♦ Gently press and turn anticlockwise the

low/high beam bulb (1), remove it and replace it with one of the same type.

PARKING LIGHT BULB

CAUTION

Do not pull the electrical wires when removing the bulb socket.

♦ Get hold of the parking light bulb socket

(4), pull it and remove it from its seat.

♦ Withdraw the bulb (2) and replace it with

one of the same type.

Page 7

5

3

1

4

2

CHANGING THE FRONT

DIRECTION INDICATOR

BULBS

Carefully read page 77 (BULBS).

♦ Position the vehicle on the stand.

♦ Unscrew and remove the screw (1).

NOTE While removing the protection

screen, proceed carefully in order not to

break the cog.

♦ Remove the protection screen (2).

♦ Remove the amber yellow glass (3).

NOTE Upon reassembly, correctly position

the protection screen in its seat.

Tighten the screw (1) moderately and carefully, to avoid damaging the protection

screen.

6

♦ Press the bulb (4) slightly and rotate it an-

ticlockwise.

♦ Extract the bulb (4) from its seat.

7

6

NOTE Insert the bulb in the bulb socket,

making the two bulb pins coincide with the

relevant guides on the socket.

♦ Correctly install a new bulb of the same

type.

NOTE If the bulb socket (5) goes out of its

seat, insert it correctly, making the bulb socket

opening coincide with the screw seat.

CHANGING

THE REAR LIGHT BULB

Carefully read page 77 (BULBS).

♦ Position the vehicle on the stand.

♦ Unscrew and remove the two screws (6).

NOTE While removing the protection

screen, proceed carefully in order not to

break the cog.

♦ Remove the protection screen (7).

♦ Press the bulb slightly and rotate it anti-

clockwise.

♦ Remove the bulb from its seat.

NOTE Insert the bulb in the socket, mak-

ing the two bulb pins coincide with the relevant guides on the socket.

♦ Correctly install a new bulb of the same

type.

NOTE Upon reassembly, correctly position

the protection screen in its seat.

Tighten the screws (6) moderately and carefully, to avoid damaging the protection

screen.

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

79

Page 8

6

1

1

2

CHANGING THE REAR

DIRECTION INDICATOR

BULBS

Carefully read page 77 (BULBS).

♦ Position the vehicle on the stand.

♦ Unscrew and remove the two screws (1).

NOTE While removing the protection

screen, proceed carefully in order not to

break the cog.

♦ Remove the protection screen (2).

NOTE Upon reassembly, correctly position

the protection screen in its seat.

♦ Remove the protection screen (3), by pull-

ing it to the vehicle external side.

use and maintenance

80

Scarabeo 50 - Scarabeo 100 4T

5

♦ Gently press on the amber yellow glass (4),

turn it anticlockwise and remove it.

4

3

NOTE While removing the protection

screen, proceed carefully in order not to break

the cog.

♦ Press the bulb (5) slightly and rotate it an-

ticlockwise.

♦ Extract the bulb (5) from its seat.

NOTE Insert the bulb in the bulb socket,

making the two bulb pins coincide with the

relevant guides on the socket.

♦ Correctly install a new bulb of the same

type.

NOTE If the bulb socket (6) goes out of its

seat, insert it correctly, making the bulb

socket opening coincide with the screw seat.

Page 9

100

70

80

60

90

50

40

4/4

1/2

R

1

50

30

40

aprilia

mph km/h

30

20

20

10

0 00 01000

0

Km

2

CHANGING THE NUMBER

PLATE BULB (in the countries

where required)

Carefully read page 77 (BULBS).

To change the bulb:

♦ Unscrew and remove the screw (1).

♦ Withdraw the rubber bulb socket (2).

♦ Remove the bulb from its seat.

♦ Correctly fit a new bulb following the same

operations in the reverse order.

100

CAUTION

To extract the bulb socket, do not pull the

electric wires.

NOTE Upon reassembly, make sure the

bulb socket is properly inserted in its seat.

use and maintenance

70

80

60

90

50

40

50

30

40

aprilia

mph km/h

30

20

20

10

0 00 01000

0

Km

100

4/4

1/2

R

CHANGING

THE DASHBOARD BULBS

Carefully read page 77 (BULBS).

The dashboard contains:

– the warning light bulbs;

– the dashboard lighting bulbs.

To change the bulbs:

♦ Remove the front handlebar cover, see

page 65 (REMOVING THE FRONT HANDLEBAR COVER).

Scarabeo 50 - Scarabeo 100 4T

81

Page 10

TRANSPORT

4

WARNING LIGHT BULBS

NOTE Extract the bulb sockets one by one,

in such a way as to avoid positioning them

incorrectly during the reassembly.

♦ Extract the relative bulb socket:

Pos. Warning light Colour

Direction

1

indicators (

2 stroke

2

oil reserve (

Low

2

beam (

High beam (

3

Injection

4

check

♦ Extract the bulb and replace it with one of

the same type.

use and maintenance

82

)

)

100

)

)

Scarabeo 50 - Scarabeo 100 4T

green

red

green

blue

red

DASHBOARD LIGHTING BULBS

CAUTION

Extract the bulb sockets one by one, in

such a way as to avoid positioning them

incorrectly during the reassembly.

♦ Extract the bulb socket of the dashboard

part in which there has been a light decrease:

Pos. Lit part

5 Upper right part

6 Upper left part (*)

7 Lower right part

(*) This bulb may not be installed on some

versions.

♦ Extract the bulb and replace it with one of

the same type.

WARNING

Before transporting the vehicle, it is necessary to empty the fuel tank and the carburettor completely, see page 83 (DRAINING THE FUEL TANK) making sure that

both are completely dry.

During transport the vehicle must be kept

in vertical position and be firmly anchored, in order to avoid any leakage of

fuel, oil or coolant.

WARNING

In case of failure, do not tow the vehicle,

but ask for assistance.

Page 11

DRAINING THE FUEL TANK

Carefully read page 27 (FUEL).

WARNING

Risk of fire.

Wait until the engine and the exhaust silencer have completely cooled down.

Fuel vapours are noxious for your health.

Before proceeding, make sure that the

room in which you are working is properly ventilated.

Do not inhale fuel vapours.

Do not smoke, nor use free flames.

DO NOT DISPOSE OF FUEL IN THE ENVIRONMENT.

♦ Position the vehicle on the centre stand,

on a solid and level surface.

♦ Stop the engine and wait until it has cooled

down.

♦ Prepare a container with capacity exceed-

ing the fuel quantity present in the tank

and put it on the ground on the left side of

the vehicle.

♦ Remove the fillercap.

♦ Empty the fuel tank by means of a manual

pump or a similar system.

WARNING

After draining the tank, put back the filler

cap in the correct position.

♦

Put back the filler cap.

4

1

T o drain the carburettor completely , proceed

as follows:

♦ Remove the hose clamp (4) from the right-

hand side of the vehicle.

♦ Position the tube free end (1) inside a con-

tainer.

100

♦ Open the passenger left-hand footrest (2).

♦ Insert a screwdriver between the footrest

and engine operating on the left-hand side

of the vehicle.

NOTE On reassembly, always replace the

clamp with a new one.

use and maintenance

♦ Open the carburettor outlet by loosening

the drain screw (3) positioned under the

float chamber.

When all the fuel has flowed out of the carburettor:

♦ Tighten the drain screw (3) completely.

WARNING

Tighten the drain screw (3) with care, to

avoid fuel leakages from the carburettor

during the refuelling.

If necessary, contact an aprilia Official

Dealer.

Scarabeo 50 - Scarabeo 100 4T

83

Page 12

CLEANING

Clean the vehicle frequently if it used in particular areas or conditions, such as:

♦ Polluted areas (cities and industrial areas).

♦ Areas characterized by an high percent-

age of salinity and humidity (sea areas, hot

and humid climates).

♦ Particular conditions (use of salt and anti-

ice chemical products on the roads during

the winter).

♦ Avoid leaving deposits of industrial and

polluting powders, tar spots, dead insects,

bird droppings, etc. on the body.

♦ Avoid parking the vehicle under trees, since

in some seasons residues, resins, fruits or

leaves fall down, which contain substances

that may damage the paint.

WARNING

After the vehicle has been washed, its

braking functions could be temporarily

impaired because of the presence of water on the grip surfaces. Calculate long

braking distances to avoid accidents.

Brake repeatedly to restore normal conditions.

Carry out the preliminary checking operations, see page 37 (PRELIMINARY

CHECKING OPERATIONS).

use and maintenance

84

Scarabeo 50 - Scarabeo 100 4T

To remove dirt and mud from the painted

surfaces use a low- pressure water jet, carefully wet the dirty parts, remove mud and filth

with a soft car sponge impregnated with a

lot of water and shampoo (2 – 4% parts of

shampoo in water).

Then rinse with plenty of water and dry with

chamois leather.

To clean the outer parts of the engine use a

degreaser, brushes and wipers.

CAUTION

To clean the lights, use a sponge soaked

with water and a neutral detergent, rubbing the surfaces delicately and rinsing

frequently with plenty of water.

Polish with silicone wax only after having carefully washed the vehicle. Do not

wash the vehicle under the sun, especially

during the summer, when the body is still

warm, since if the shampoo dries before

being rinsed away, it can damage the

paint.

Do not use liquids at a temperature exceeding 40°C to clean the plastic components of the vehicle.

CAUTION

Do not direct high-pressure water or air

jets or steam jets on to the following components: wheel hubs, controls on the

right and left side of the handlebar, bearings, brake pumps, instruments and indicators, exhaust pipes, glove/tool kit

compartment, ignition switch/steering

lock, radiator wings, fuel cap, lights and

electric connections.

Do not use alcohol or solvents to clean

the rubber and plastic parts and the saddle: use water and mild soap.

WARNING

Do not apply protection waxes onto the

saddle, in order not to make it too slippery.

Page 13

LONG PERIODS OF INACTIVITY

Precautions are needed to avoid the adverse

effects of prolonged inactivity.

Further, it is important to carry out the necessary repairs and a general check up before the period of inactivity, since you could

forget to carry them out later.

Proceed as follows:

♦

Completely drain the tank and carburettor,

see page 83 (DRAINING THE FUEL

TANK).

♦

R

emove the spark plug, see page 71

(SPARK PLUG) and pour one teaspoon (5-

3

) of oil for two-stroke engines in the

10 cm

cylinder.

NOTE Put a clean cloth on the cylinder,

next to the spark plug seat, as a protection

against oil splashes.

♦ Turn the ignition switch to “ ” and press

the engine start button “

onds to distribute the oil evenly on the cyl-

inder surfaces.

♦ Remove the cloth.

♦ Refit the spark plug.

♦ Remove the battery, see page 74 (REMOV -

ING THE BATTERY).

♦ Wash and dry the vehicle, see page 84

(CLEANING).

♦

Polish the painted surfaces with wax.

” for a few sec-

♦ Inflate the tyres, see page 34 (TYRES).

♦ By means of a suitable support, position

the vehicle so that both tyres are raised

from the ground.

♦ Place the vehicle in an unheated, not-hu-

mid room, away from sunlight, with minimum temperature variations.

♦ Position and tie a plastic bag on the final

pipe of the exhaust silencer, in order to prevent moisture from getting into it.

♦ Cover the vehicle avoiding the use of plas-

tic or waterproof materials.

AFTER A PERIOD OF INACTIVITY

♦ Uncover and clean the vehicle, see page

84 (CLEANING).

♦ Check the charge of the battery, see page

75 (RECHARGING THE BATTERY) and

install it, see page 75 (INSTALLING THE

BATTERY).

♦ Check that the carburettor drain screw is

fully tightened (drainage closing index), see

page 83 (DRAINING THE FUEL TANK).

♦ Refuel, see page 27 (FUEL).

♦ Carry out the preliminary checking opera-

tions, see page 37 (PRELIMINARY

CHECKING OPERATIONS).

WARNING

Have a test ride at moderate speed in a

low-traffic area.

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

85

Page 14

TECHNICAL DATA

100

100

100

DIMENSIONS Max. length ........................................................

ENGINE Model .................................................................

Max. width (brake levers)...................................

Max. height (rearview mirrors) ...........................

Seat height.........................................................

Wheel base ........................................................

Minimum free height from ground ......................

Empty weight (in running order).........................

Type ...................................................................

Number of cylinders ........................................... Horizontal single-cylinder

Total displacement .............................................

Bore / stroke ...................................................... 41.0 mm / 37,4 mm -

Compression ratio..............................................

Starting ..............................................................

Clutch................................................................. centrifugal

Change gear ...................................................... automatic continuous variator

Change gear ...................................................... ventilated automatic continuous variator

Cooling............................................................... forced air

TRANSMISSION Variator .............................................................. automatic continuous

Primary .............................................................. V belt

Ratios................................................................. minimum for continuous change:

maximum for continuous change:

Secondary.......................................................... with gears

CAPACITY Fuel (reserve included) ...................................... 8

use and maintenance

86

Fuel reserve ....................................................... 1

Transmission oil .................................................

Engine oil ...........................................................

Mixer oil (reserve included)................................

Mixer oil reserve ................................................

Seats.................................................................. n° 1 (2 in the countries where this is allowed)

Seats.................................................................. n° 2

Vehicle max. load (driver + luggage) ................. 110 kg

Vehicle max. load (driver + passenger + luggage)

Scarabeo 50 - Scarabeo 100 4T

100

185 kg (in the countries where this is allowed)

1905 mm 705 mm 1270 mm 780 mm 1250 mm 145 mm 86 kg -

100

2T -

4T

ABAI -

49.38 cm3 -

10.5:1 electric -

120 cm3 -

0.8 l

1.5

0.6

100

100

1905 mm

100

705 mm

100

1270 mm

100

780 mm

100

1245 mm

100

140 mm

94 kg

4T2V

100

96.21 cm

100

100

100

10.5:1

100

electric + kick starter

3

100 cm

3

50 mm / 49 mm

2.90 -

0.75 -

100

2.63

0.76

Page 15

CARBURETTOR Model:

– standard ..........................................................

Choke tube ........................................................

FUEL SUPPLY Fuel

100

..................................................... premium petrol DIN 51 600 (4 Stars), minimum octane number 98

100

KEIHIN CVK 20 - DELLORTO PHVD 22

throttle body BING Ø 18 mm -

100

Ø 20 mm / Ø 22 mm

(N.O.R.M.) and 88 (N.O.M.M.)

FRAME Type ................................................................... split single tube with double cradle

SUSPENSIONS Front................................................................... hydraulically operated telescopic fork

Stroke ................................................................ 80 mm

Rear ................................................................... hydraulic single-shock absorber

Stroke ................................................................

78 mm -

100

82 mm

BRAKES Front................................................................... disc brake, Ø220 mm with hydraulic transmission

Rear ............................................................ disc brake, Ø190 mm with hydraulic transmission

100

Rear

............................................................ Ø 140 mm

WHEEL Rims................................................................... alloy

Front................................................................... 1.60 x 16"

Rear ................................................................... 1.85 x 16"

TYRES Front...................................................................

Rear ...................................................................

2.50 x16” 42J SAVA MC 26 CAPRI 46M

REINF

2.75 x 16” 46J SAVA MC 26 CAPRI 52 M

REINF

100

80 / 80 x 16”

100

90 / 80 - 16”

STANDARD INFLATION PRESSURE

Front................................................................... 190 kPa (1.9 bar)

Rear ................................................................... 220 kPa (2.2 bar)

INFLATION PRESSURE WITH PASSENGER (in the countries where this is allowed)

Front................................................................... 190 kPa (1.9 bar)

Rear ................................................................... 230 kPa (2.3 bar)

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

87

Page 16

IGNITION Type ................................................................... T.C.I. -

100

Spark advance

Spark advance

Standard spark plug...........................................

............................................ variable con 20° at 4000 rpm

100

............................................ 17° at 7500 rpm

NGK CPR 8E -

Spark plug gap................................................... 0.6 ± 0.05 mm

rpm at slow running ........................................... 1900+o-50

C.D.I.

100

NGK BR8 HS

ELECTRIC

SYSTEM Battery ............................................................... 12 V - 4 Ah (sealed

Fuse ................................................................... 7.5 A

Generator (with permanent magnet)..................

Low / high beam bulbs ....................................... 12 V - 35 / 35 W

Parking light bulb ............................................... 12 V - 5 W (W 2.1 x 9.5 d)

Direction indicators bulbs................................... 12 V - 10 W

Stop/tail light bulb .............................................. 12 V - 5/21 W

Number plate bulb ............................................. 12 V - 5 W

Dashboard lighting bulb ..................................... 12 V - 1.2 W

High beam warning lights .................................. 12 V - 1.2 W

Direction indicators warning lights ..................... 12 V - 3 W

Mixer oil reserve warning light ........................... 12 V - 1.2 W

Injection check warning light .............................. 12 V - 2 W

use and maintenance

88

Scarabeo 50 - Scarabeo 100 4T

12 V - 140 W /

) - 12 V - 9 Ah

100

13 V - 120 W

100

Page 17

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

89

Page 18

LUBRICANT CHART

Engine oil (recommended): SUPERBIKE 4, SAE 5W - 40.

As an alternative to the recommended oil, it is possible to use high-quality oils with characteristics in compliance with or superior to CCMC G4, A.P.I. SG. specifications.

WARNING

In case of severe driving conditions or use of the vehicle in warm climates, it is recommended to use synthetic oil of the 5W50/

Transmission oil (recommended):

As an alternative to the recommended oil, it is possible to use high-quality oils with characteristics in compliance with or superior to the A.P.I.

GL-4 specifications.

Mixer oil (recommended):

As an alternative to the recommended oil, use high-quality oils with characteristics in compliance with or superior to the ISO-L-ETC++, A.P .I.

TC++ specifications.

Fork oil (recommended):

If you need an oil with intermediate characteristics in comparison with the F.A. 5W and F.A. 20W or FORK 5W and FORK

20W, these can be mixed as indicated below:

SAE 10W =

SAE 15W = F.A. 5W 33% of the volume + F.A. 20W 67% of the volume, or

Bearings and other lubrication points (recommended):

As an alternative to the recommended product, use high-quality grease for rolling bearings, working temperature range -30°C.... +140°C,

dripping point 150°C... 230°C, high protection against corrosion, good resistance to water and oxidation.

Protection of the battery poles: neutral grease or vaseline.

F.A. 5W 67% of the volume + F.A. 20W 33% of the volume, or

FORK 5W 67% of the volume + FORK 20W 33% of the volume;

FORK 5W 33% of the volume + FORK 20W 67% of the volume.

F.C., SAE 75W - 90 or GEAR SYNTH, SAE 75W - 90.

GREEN HIT 2 or CITY 2T.

F.A. 5W or F.A. 20W fork oil;

an alternative FORK 5W or FORK 20W fork oil.

10W50 type.

AUTOGREASE MP or GREASE 30.

WARNING

Brake fluid (recommended):

F.F., DOT 5 (DOT 4 compatible) or BRAKE 5.1, DOT 5 (DOT 4 compatible).

Use new brake fluid only.

WARNING

Engine coolant (recommended):

use and maintenance

90

Use only antifreeze and anticorrosive without nitrite, ensuring protection at -35°C at least.

ECOBLU - 40°C or COOL.

Scarabeo 50 - Scarabeo 100 4T

Page 19

NOTE

ASK FOR GENUINE SPARE PARTS ONLY

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

91

Page 20

Importers

use and maintenance

92

Scarabeo 50 - Scarabeo 100 4T

Page 21

Importers

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

93

Page 22

WIRING DIAGRAM - Scarabeo

1

41

N

BBB

N

42

Bi

B

1

N

43

use and maintenance

94

40

38

37

GBBBiAz

B

ViGBBiR

G

Vi

B

B

1

M

2

G/R

3

N

4

5

6

G

7

8

V/R

9

Bi

10

11

12

Bi/R

13

V

14

R/M

15

Ro

16

R/N

17

M/G

18

Bi/G

19

B/G

20

Ar/N

21

22

35

36

-C

+

V/R

B

R

Gr/V

V/R

Gr/V

AzAz

1

Gr/VBiR

V/R

Ar/N

B

V/R

39

Vi

1

Az

B

B

R

2

3

33

34

32

Gr/V

B

1

R/N

N

V/R

Gr/V

B

31

29

ON

OFF

LOCK

N

1

NBiG

Gr

BRB/N

Gr

30

G

B/NRBiBGr

Az

Az

B/N

V/R

Ar

1

L

B

V/R

Ar

R/N

28

26

27

G/RG/RVG

V/RV/G

M

1

1

Ro

G

V

1

G/R

Vi

V/R

Vi

23

Az

Az

V/G

V/G

G

G

B

R

V/G

R/N

V/G

R/N

21

22

R/M

11

Bi/ViBi/Vi

Bi/G

B/G

GBiRo

M/G

1

Bi

B

5

R/N

M

V/R

Ro

6 87 9104

R/M

R/M

Bi/R

G/R

12

B

G/R

15

Ar

R/N

V/R

1 2

R

3

5

Ar

R/N

V/R

R/N

V

13

P

R

15 A

1

7.5 A

R

R

R

N

M

16

14

N

ArBR/M

R/N

17

ARANCIO BIANCO

Ar/Bi

VISTO DAL LATO CHE

SI CONNETTE AL REGOLATORE

Ar/Bi

VBAr

11

Ar

G V

18

BLU

VERDEARANCIO

19

24

B

R

1

25

Ro Ro

20

Scarabeo 50 - Scarabeo 100 4T

Page 23

WIRING DIAGRAM KEY - Scarabeo

1) Multiple connectors

2) Electronic control unit (ECU)

3) Serial connection

4) Throttle sensor

5) Pick-up

6) Temperature sensor

7) Oil pump

8) Fuel injector

9) Air injector

10) Fuel pump

11) H.T. coil

12) Spark plug

13) Fuse

14) Battery

15) Start relay

16) Starter

17) Injection relay

18) Voltage regulator

19) Generator

20) Resistor

21) Front stoplight switch

22) Rear stoplight switch

23) Rear left direction indicator

24) Rear stoplight

25) Rear right direction indicator

26) Oil level switch

27) Control diode

28) RH switch

29) Key switch

30) Flashers

31) LH switch

32) Horn

33) Fuel level sensor

34) Injection check warning light

35) Fuel level instrument

36) Direction indicator warning light

37) High beam warning light

38) Dashboard light

39) Oil reserve warning light

40) Dashboard

41) Front left direction indicator

42) Low/high beam bulb (35/35W)

43) Front right direction indicator

CABLE COLOURS

Ar orange

Az light blue

B blue

Bi white

G yellow

Gr grey

M brown

N black

R red

V green

Vi violet

Ro pink

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

95

Page 24

WIRING DIAGRAM - Scarabeo

30 27

252629

23

N

B

RAzBiBB

G

Bi

Az

R

BGV/R

NN

Bi

Az

G

R

38

N

Az

B

32

34

33

31

B

Bi

Bi

N

N

B

B

G

G

38

B

B

N

R

35

B

M

G/Bi

Gr

V/R

38

N

M

36

1

100

C-

+

V/R

B

Gr/V

Gr/V

38

Gr/V

V/R

G/Bi

Bi/R

B

M

4312

2

3

19

ON

OFF

LOCK

V/R

ArBBi/R

38

V/R

BArBi/R

Bi/R

Gr/V

Bi

N

Az

G

B

R

V/R

Gr

G/Bi

B

V

V/R

V

B

B/N

G/Bi

38

5

3

4

38

12

V

G

5

40 6

GrGr

N

G/N

B

BiRB/NB/N

NBiG/N

Az Az

R

B

B

G/R

8

R

Ar

37

7.5 A

N

R

R

V/G

V/R

R

9

V/G

V/R

R

10

M

7

3838

V

G/N G/N

V

GG

B

Gr/V

38

B

Gr/V

13

17

M

G/R G/R

V/G V/R

16

Az

Az

V/G

V/G

G

G

B

R

38

G

B

38

G

B

15

B

R

14

12

use and maintenance

96

Scarabeo 50 - Scarabeo 100 4T

Page 25

WIRING DIAGRAM KEY - Scarabeo

100

1) Generator

2) Transducer

3) Spark plug

5) Voltage regulator

6) Battery

7) Starter

8) Start relay

9) Front stoplight switch

10) Rear stoplight switch

12) Number plate bulb

13) Fuel level sensor

14) Rear right direction indicator

15) Rear stoplight

16) Rear left direction indicator

17) RH switch

18) LH switch

19) Key switch

23) Dashboard

25) Low beam warning light

26) Dashboard light

27) Fuel level instrument

29) High beam warning light

30) Direction indicator warning light

31) Front right direction indicator

32) Front left direction indicator

33) Parking lights bulb

34) Low / high beam bulb (35/35W)

35) Horn

36) Pick up

37) Fuse

38) Multiple connectors

40) Automatic starter

CABLE COLOURS

Ar orange

Az light blue

B blue

Bi white

G yellow

Gr grey

M brown

N black

R red

V green

Vi violet

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

97

Page 26

NOTE

ASK FOR GENUINE SPARE PARTS ONLY

use and maintenance

98

Scarabeo 50 - Scarabeo 100 4T

Page 27

NOTE

ASK FOR GENUINE SPARE PARTS ONLY

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

99

Page 28

NOTE

ASK FOR GENUINE SPARE PARTS ONLY

use and maintenance

100

Scarabeo 50 - Scarabeo 100 4T

Page 29

NOTE

ASK FOR GENUINE SPARE PARTS ONLY

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

101

Page 30

NOTE

ASK FOR GENUINE SPARE PARTS ONLY

use and maintenance

102

Scarabeo 50 - Scarabeo 100 4T

Page 31

NOTE

ASK FOR GENUINE SPARE PARTS ONLY

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

103

Page 32

aprilia s.p.a. wishes to thank its customers for the purchase of this vehicle.

- Do not dispose of oil, fuel, polluting substances and components in the

environment.

- Do not keep the engine running if it isn’t necessary.

- Avoid disturbing noises.

- Respect nature.

use and maintenance

104

Scarabeo 50 - Scarabeo 100 4T

Loading...

Loading...