Page 1

100

5

100

2

3

100

6

4

1

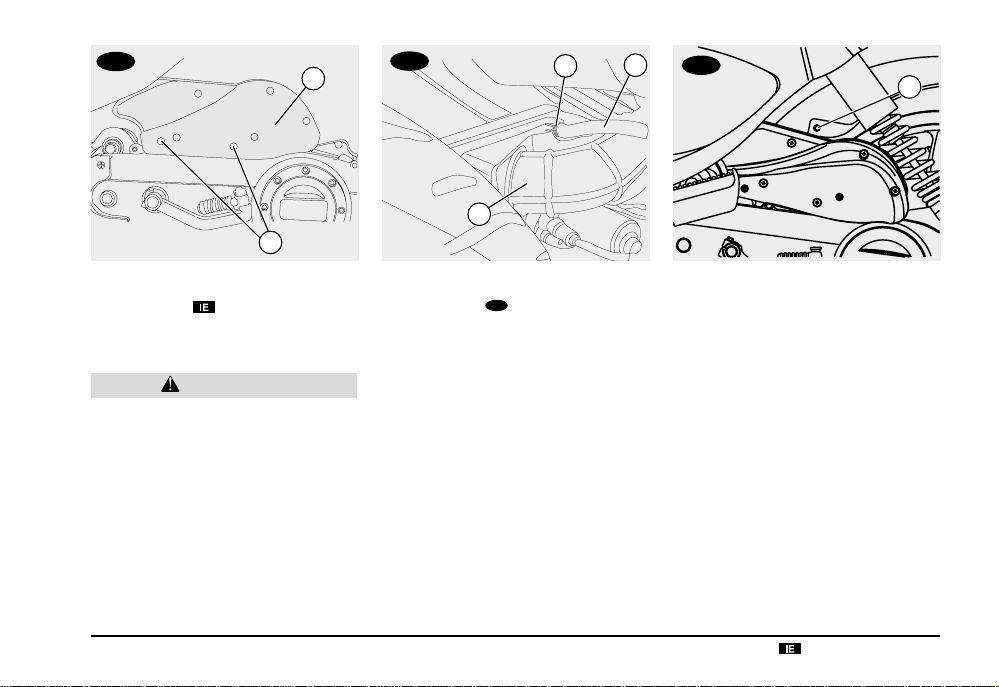

REMOVING AIR CLEANER BOX

ASSEMBLY

Carefully read page 47 (MAINTENANCE).

CAUTION

The disassembly and reassembly operations of the air cleaner box assembly are

difficult and complicated. Contact an

aprilia Official Dealer.

REMOVING AIR CLEANER BOX

ASSEMBLY

Carefully read page 47 (MAINTENANCE).

♦

Position the vehicle on the centre stand,

on a solid and level surface, see page 46

(POSITIONING THE VEHICLE ON THE

CENTRE STAND).

♦

Unscrew and remove the two screws (1)

keeping the relative stop nuts.

♦

Unloose the splash guard fixing screw with

filter box (6).

♦

Withdraw clamp (2) from the air tube (3)

using a suitable tool (3).

♦

Unloose the fixing clamp and remove the

air cleaner-carburettor tube (4) from the

air cleaner (5).

♦

Remove the air cleaner box assembly (5).

100

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

57

Page 2

100

6

4

1

1

aprilia

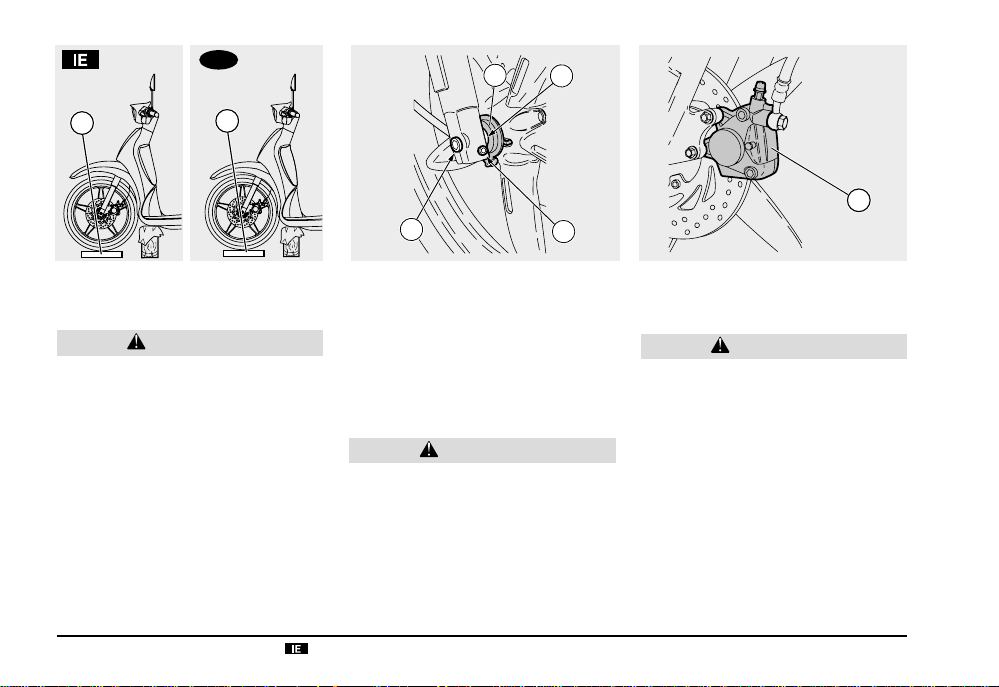

FRONT WHEEL

DISASSEMBLY

CAUTION

The disassembly and reassembly operations of the front wheel may result difficult and complicated for an unskilled

operator.

Contact an aprilia Official Dealer if necessary.

If you wish to perform this operation personally, follow the steps below.

Carefully read page 47 (MAINTENANCE).

Upon disassembly and reassembly of the

wheel, be careful not to damage the pipeline, discs and brake pads.

use and maintenance

58

Scarabeo 50 - Scarabeo 100 4T

3

♦ Position the vehicle on the centre stand,

2

on a solid and level surface.

NOTE Arrange for a support with a base

of 200x200mm and suitable height.

♦ Place the support under the vehicle and a

spongy cloth between them, so that the

front wheel can move freely and the vehicle cannot fall down.

CAUTION

Make sure that the vehicle is stable.

♦ Put a suitable support (1) under the tyre to

hold the wheel in the right position, after

releasing it.

♦ Unloose screw (2) of the wheel pin clamp.

♦ Completely unscrew the wheel pin (3).

Wheel pin-nut driving torque:

50 Nm (5.0 kgm).

5

♦ Hold the front wheel and manually remove

the wheel pin (3).

♦ Keep the washer (4).

CAUTION

Do not actuate the front brake lever after

removing the wheel to prevent the caliper

pistons from falling out of their seats,

causing the brake fluid to leak out.

In this case, contact an aprilia Official

Dealer that will carry out the required

maintenance operations.

♦ Move the front wheel forward until the disc

can be removed from the brake caliper (5).

♦ Remove the front wheel.

♦ Disable the odometer transmission (6).

Page 3

REASSEMBLY

Carefully read page 47 (MAINTENANCE).

CAUTION

While reassembling the wheel, be careful

not to damage the brake pipe, the disc

and the pads.

To reassemble the front wheel, proceed as

follows:

♦ Smear a thin layer of grease on the whole

length of the wheel pin (3), see page 90

(LUBRICANT CHART).

♦ Position the wheel between the fork rods,

onto the support (1).

♦ Insert the tang (8) of the odometer trans-

mission (7) in the seat on the wheel hub.

WARNING

Risk of personal injury. Do not use your

fingers to align the holes.

♦ Move the wheel to align the central hole

with the holes on the fork.

7

4

2

3

♦ Insert the wheel between the rods. Insert

with care the disc in the brake caliper.

♦ Insert the washer (4) between the

odometer transmission (7) and the fork

right-hand rod.

♦ Fully insert the wheel pin (3) and tighten it

manually.

♦ Tighten the wheel pin (3).

Wheel pin nut driving torque:

50 Nm (5.0 kgm).

♦ Pull the front brake lever and repeatedly

push down the handlebar to allow the fork

to sink.

This allows the fork rods to bed properly.

♦ Tighten the screw (2) of the wheel pin

clamp.

Driving torque of the wheel pin clamp

screws: 12 Nm (1.2 kgm).

8

♦ Make sure that the following components

are not dirty:

– tyre;

– wheel;

– brake discs.

CAUTION

After reassembly, pull the front brake lever repeatedly and check the correct functioning of the braking system.

Check the wheel centering.

Have the driving torques, centering and

balancing of the wheel checked by your

aprilia Official Dealer, in order to avoid

accidents that may be harmful for you

and/or other people.

use and maintenance

Scarabeo 50 - Scarabeo 100 4T

59

Page 4

REAR WHEEL

DISASSEMBLY

CAUTION

The disassembly and reassembly operations of the rear wheel may result difficult and complicated for an unskilled operator. Contact an aprilia Official Dealer

if necessary.

If you wish to perform this operation personally, follow the steps below.

Carefully read page 47 (MAINTENANCE).

Before performing the following opera-

tions, allow the engine and silencer to

cool down to the ambient temperature in

order to avoid burns.

On disassembly and reassembly of

the wheel, be careful not to damage the

pipeline, disc and brake pads.

♦ Position the vehicle on the centre stand,

on a solid and level surface.

♦ Remove the silencer, see page 66 (RE-

MOVING THE EXHAUST SILENCER).

♦ Remove the cover (1).

100

2

2

1

1

NOTE T o be able to unloose the wheel nut

(2) it is necessary to block the wheel.

♦

Completely pull the rear brake lever (3),

interposing a card (4), and keep it pulled

by means of a plastic clamp (5).

♦ Unscrew and remove the wheel nut (2) and

the washer.

NOTE Upon reassembly, change the wheel

nut (special type).

Wheel nut (2) driving torque:

110 Nm (11 kgm).

♦ Release the rear brake lever.

100

♦

Unloose the splash guard, see page

57.

100

♦

Withdraw the wheel.

♦ Remove the rear brake caliper, see

page 64 (REMOVING THE REAR BRAKE

CALIPERS

).

4

3

5

♦ Withdraw the wheel.

NOTE Use aprilia Genuine Spare Parts

only.

♦ After reassembly, make sure that the fol-

lowing components are not dirty:

– tyre;

– wheel;

brake discs.

–

CAUTION

After reassembly, pull the rear brake lever repeatedly and check the correct functioning of the braking system. Check the

wheel centering.

Have the driving torques, centering and

balancing of the wheel checked by your

aprilia Official Dealer, in order to avoid

accidents that may be harmful for you and/

or other people.

use and maintenance

60

Scarabeo 50 - Scarabeo 100 4T

Page 5

1

CHECKING THE BRAKE PAD

WEAR

Carefully read page 31 (BRAKE FLUID recommendations), page 32 (DISC

BRAKES), page 47 (MAINTENANCE).

Check the brake pad wear after the first 500

km (312 mi) and successively every 2000

km (1250 mi).

The wear of the brake pads depends on the

use, on the kind of drive and on the road.

The wear will be greater when the vehicle is

driven on dirty or wet roads.

WARNING

Check the wear of the brake pads especially before every trip.

To carry out a rapid checking of the wear of

the front pads, proceed as follows:

♦ Position the vehicle on the centre stand,

on a solid and level surface.

♦ Remove the brake caliper cover (1).

♦ Carry out a visual check between brake

disc and pads.

WARNING

The excessive wear of the friction material would cause the contact of the pad

metal support with the disc, with consequent metallic noise and production of

sparks from the caliper; braking efficiency, safety and soundness of the disc

would thus be negatively affected.

use and maintenance

♦ If the thickness of the friction material (even

of one pad only) has reduced to about 1.5

mm, replace both pads.

WARNING

Have the pads changed by your aprilia

Official Dealer.

Scarabeo 50 - Scarabeo 100 4T

61

Page 6

100

1

CHECKING THE BRAKE SHOES

WEAR

Carefully read the instructions on page

33 (REAR DRUM BRAKE

page 47 (MAINTENANCE).

Check the rear brake shoes wear after the

first 1000 km (625 mi) and then every 4000

km (2500 mi).

62

100

use and maintenance

100

) and

Scarabeo 50 - Scarabeo 100 4T

To check the rear brake shoes wear follow

the steps below:

100

♦ Remove the rear wheel, see page 60

(REAR WHEEL).

♦ Now check the thickness of the friction ma-

terial, that should never be lower than 1mm.

If the thickness of the friction material has

reached the limit value, if you notice irregularities in the operation or if the parts are

damaged, contact an aprilia Official

Dealer that will see to their replacement.

INSPECTING THE FRONT AND

REAR SUSPENSIONS

Carefully read page 47 (MAINTENANCE).

Check the tightening of all the parts and the

functioning of the front and rear suspension

articulated joints after the first 1000 km (625

mi), and then every 4000 km (2500 mi).

CAUTION

If you notice irregularities in the operation or if the help of a qualified technician is necessary, contact your aprilia

Official Dealer.

Page 7

100

aprilia

CHECKING THE STEERING

Carefully read page 47 (MAINTENANCE).

Check the steering play every now and then.

To check the steering it is necessary to:

♦ Position the vehicle on the centre stand,

on a solid and level surface.

NOTE Arrange for a support with base of

200x200mm and of a suitable height.

CAUTION

Make sure that the vehicle is stable.

♦ Place the support under the vehicle and a

spongy cloth between them, so that the

front wheel can move freely and the vehicle cannot fall down.

♦ Shake the fork in the direction of travel.

NOTE Do not shake the fork excesively,

otherwise you may take in consideration the

movement of the stand, thus observing an

incorrect slack.

Repeat the previous operation more than

once.

♦ If you find that there is a considerable slack,

contact your aprilia Official Dealer to restore the optimal steering conditions.

use and maintenance

CHECKING

THE ENGINE FULCRUM AXIS

Carefully read page 47 (MAINTENANCE).

Periodically check the slack existing between

the engine pin bushes and the engine pin.

To carry out this operation, proceed as follows:

♦ Position the vehicle on the centre stand,

on a solid and level surface.

♦ Shake the wheel transversally with respect

to the riding direction.

♦ If you find that there is a considerable slack,

contact your aprilia Official Dealer, to restore the optimal operating conditions.

Scarabeo 50 - Scarabeo 100 4T

63

Page 8

2

3

4

6

5

1

REMOVING THE

REAR BRAKE CALIPER

Carefully read page 47 (MAINTENANCE).

CAUTION

When disassembling the brake caliper, be

careful not to damage the pipeline, disc

and brake pads.

♦ Position the vehicle on the centre stand on

a solid and level surface.

♦ Unloose and remove the two screws (1).

Tightening torque of brake caliper screws

(1): 27 Nm (2.7 kgm).

WARNING

On reassembly of the brake caliper, replace the caliper fixing screws (1) with two

new screws of the same type.

use and maintenance

64

Scarabeo 50 - Scarabeo 100 4T

CAUTION

Do not actuate the rear brake lever after

removing the brake caliper to prevent the

pistons from falling out of their seats,

causing the brake fluid to leak out.

In this case, contact an aprilia Official

Dealer that will carry out the required

maintenance operations.

♦ Carefully withdraw the brake caliper (2)

from the brake disc.

WARNING

After reassembling, repeatedly actuate

the rear brake lever and check the braking system functioning.

REMOVING

THE REAR-VIEW MIRRORS

Carefully read page 47 (MAINTENANCE).

♦ Position the vehicle on the centre stand,

on a solid and level surface.

♦ Lift the protective case (3).

CAUTION

Hold the rear-view mirror (4), to prevent

it from accidentally falling down.

♦ Hold the screw (5) and unloose the nut (6)

completely.

♦ Remove the rear-view mirror (4).

Page 9

2

5

7

1

1

REMOVING THE LOWER

HANDLEBAR COVER

Carefully read page 47 (MAINTENANCE).

♦ Position the vehicle on the centre stand,

on a solid and level surface.

♦ Unscrew and remove the two screws (1)

shown by the arrows.

♦ Unscrew and remove the two screws (2).

CAUTION

Proceed with care to avoid damaging the

tang (4) seat (3).

♦ ★ Using a small screwdriver, lift the tang

(4) found inside the front handlebar cover

(5).

♦ ★ Repeat the above operation also on the

lower part of the handlebar cover.

4

3

CAUTION

Handle the plastic or painted components

with care and avoid scraping or damaging them.

♦ Remove the front handlebar cover (5) tak-

ing care not to break the tangs.

NOTE On reassembly, check that the tangs

are fitted properly.

use and maintenance

6

REMOVING

THE INSPECTION COVER

Carefully read page 47 (MAINTENANCE).

CAUTION

Handle the painted components with care

and avoid scraping or damaging them.

♦ Position the vehicle on the centre stand,

on a solid and level surface.

♦ ★ Unscrew and remove the screw (6).

♦ Remove the inspection cover (7).

Scarabeo 50 - Scarabeo 100 4T

65

Loading...

Loading...