Page 1

1

3

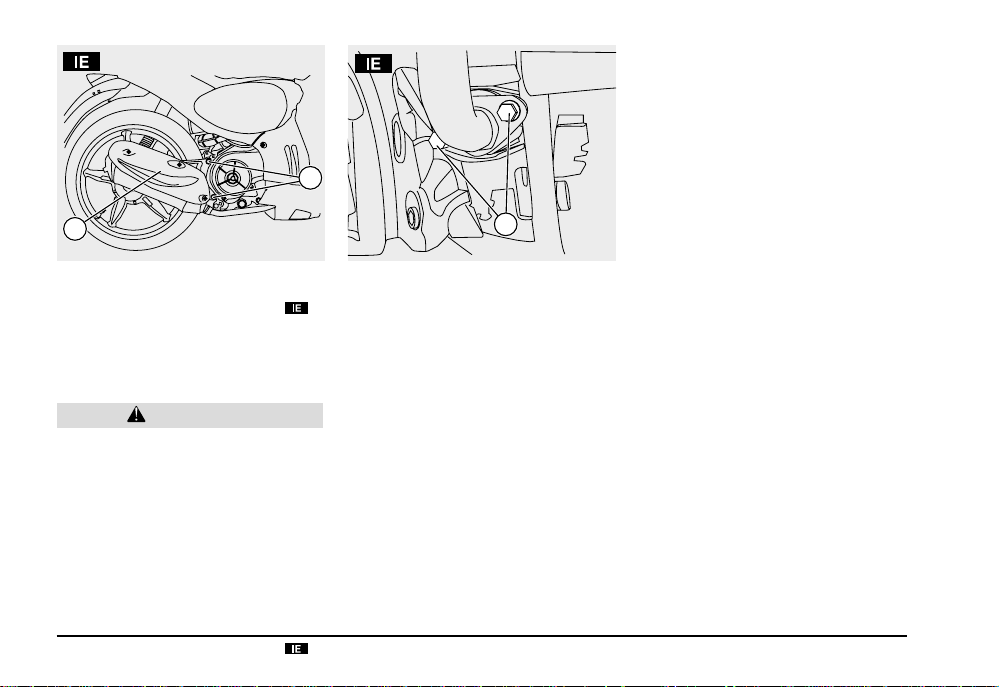

REMOVING

THE EXHAUST SILENCER

Carefully read page 47 (MAINTENANCE).

♦ Position the vehicle on the centre stand,

on a solid and level surface.

WARNING

Before you go on with the following operations, allow the engine and the silencer

to cool down to the ambient temperature

to avoid burns.

use and maintenance

66

Scarabeo 50 - Scarabeo 100 4T

2

♦ Unloose and remove the two fixing screws

(1) from the engine silencer.

Screws (1) driving torque:

25 Nm (2.5 kgm).

♦ Unloose and remove screws (2).

Screws (2) driving torque:

12 Nm (1.2 kgm).

♦ Remove the exhaust silencer (3).

NOTE On reassembly, replace the seal

between the exhaust manifold and the silencer with a new one.

Page 2

100

3

100

1

2

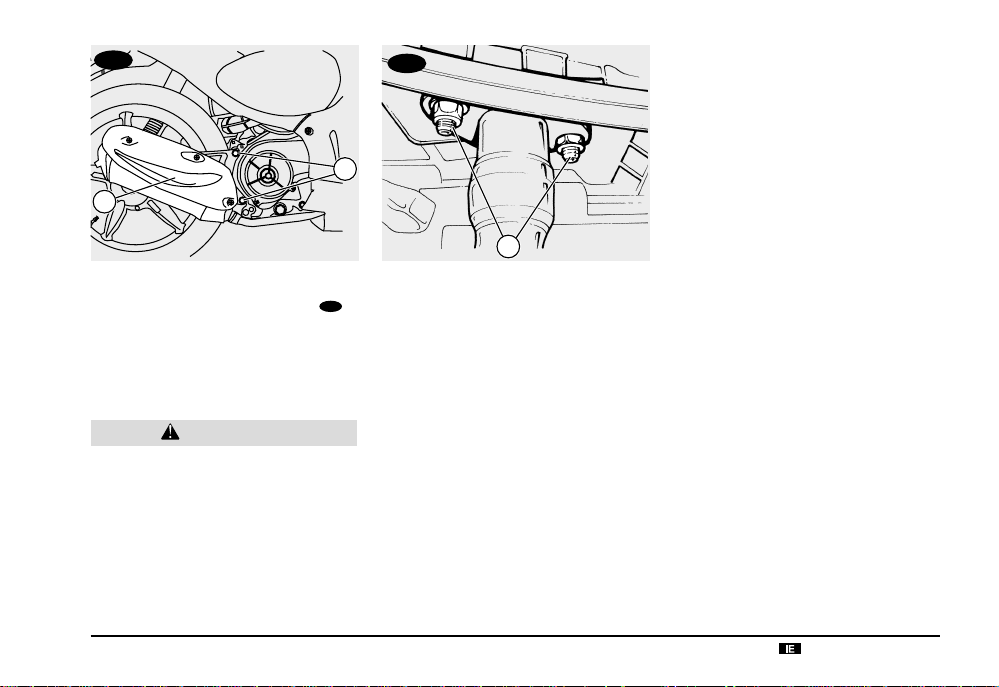

REMOVING

THE EXHAUST SILENCER

Carefully read page 47 (MAINTENANCE).

♦ Position the vehicle on the centre stand,

on a solid and level surface.

100

WARNING

Before you go on with the following operations, allow the engine and the silencer

to cool down to the ambient temperature

to avoid burns.

♦ Remove the inspection cover, see page 65

(REMOVING THE INSPECTION COVER).

♦ Unloose and remove the two fixing screws

(1) from the engine silencer.

Screws (1) driving torque:

25 Nm (2.5 kgm).

♦ Unloose and remove the two nuts (2).

Nuts (2) driving torque:

12 Nm (1.2 kgm).

♦ Remove the exhaust silencer (3).

use and maintenance

NOTE On reassembly, replace the seal

between the exhaust manifold and the silencer with a new one.

Scarabeo 50 - Scarabeo 100 4T

67

Page 3

3

100

2

1

2

1

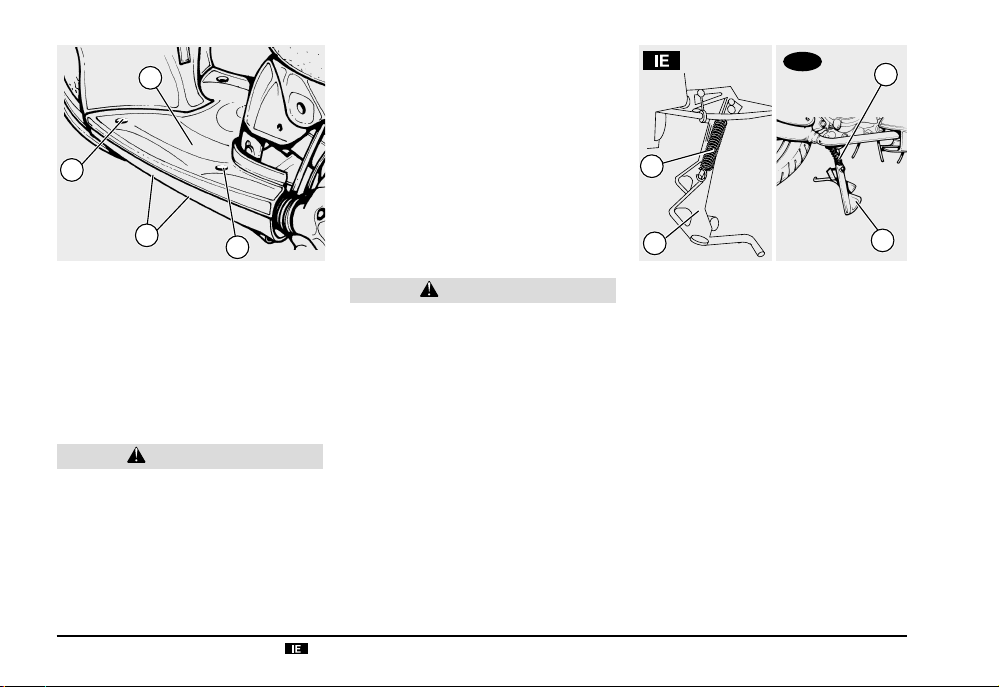

REMOVING THE FOOTBOARD

Carefully read page 47 (MAINTENANCE).

♦ Remove the inspection cover, see page 65

(REMOVING THE INSPECTION COVER).

♦ ★ Unloose and remove the two screws (1).

♦ ★ Unloose and remove the three screws

(2) located under the footboard.

CAUTION

Proceed with care to avoid damaging the

tangs and/or relevant seats.

♦ Slightly lift the rear part of the footboard

(3) and withdraw it from the base of the

inner shield.

use and maintenance

68

Scarabeo 50 - Scarabeo 100 4T

CAUTION

Do not force the lower shield as it is fixed

to the frame with only two front screws.

NOTE On reassembly, first insert the two

central tangs and then the side tangs. Before you insert the three screws (2), visually

check that the footrest - screw holes are

aligned.

2

1

1

CHECKING THE STAND

Carefully read page 47 (MAINTENANCE).

Make sure the stand (1) rotates freely.

Perform the following checks:

♦ The springs (2) must not be damaged,

worn, rusty or weak.

♦ The stand must rotate freely. If necessary,

grease the articulated joint, see page 90

(LUBRICANT CHART).

Page 4

100

3

4

CHECKING THE SWITCHES

Carefully read page 47 (MAINTENANCE).

The vehicle is provided with two switches:

– stoplight switch on the rear brake control

lever (3);

– stoplight switch on the front brake control

lever (4).

To reach the switches:

♦ Remove the lower handlebar cover, see

page 65 (REMOVING THE LOWER HANDLEBAR COVER).

Periodically carry out the following checks:

♦ Make sure that there are no dirt or mud

deposits on the switch; the pin must be able

to move without interferences, returning automatically to its initial position.

♦ Make sure that the cables are connected

correctly.

IDLING ADJUSTMENT

Carefully read page 47 (MAINTENANCE).

Adjust the idling after the first 500 km (312

mi) and every time it is irregular.

To carry out this operation, proceed as follows:

♦ Drive for a few miles until the engine

reaches the normal running temperature,

then stop the engine.

100

♦

Remove the inspection cover, see

page 65 (REMOVING THE INSPECTION

COVER).

♦ Connect an electronic revolution counter

to the spark plug cable.

use and maintenance

WARNING

Before proceeding, make sure that the

room in which you are working is properly ventilated.

♦ Start the engine.

The minimum speed of the engine (idling)

must be about 1500 ± 100 rpm; in this case

the engine does not make the rear wheel

rotate.

The minimum speed of the engine (idling)

must be about 1800 ± 100 rpm; in this case

the engine does not make the rear wheel

rotate.

Scarabeo 50 - Scarabeo 100 4T

100

69

Page 5

100

1

If necessary:

♦ Act on the adjusting screw (1) positioned

on the carburettor.

By SCREWING IT (clockwise), you increase

the engine rpm.

By UNSCREWING IT (anticlockwise), you

decrease the engine rpm.

♦ Twist the throttle grip, accelerating and de-

celerating a few times to make sure that it

functions correctly and to check if the idling

speed is constant.

NOTE Do not act on the air adjusting screw,

to avoid variations of the carburation setting.

CAUTION

If necessary, contact your aprilia Official

Dealer.

use and maintenance

70

Scarabeo 50 - Scarabeo 100 4T

2

3

4

ADJUSTING

THE ACCELERATOR CONTROL

Carefully read page 47 (MAINTENANCE).

The ideal slack of the accelerator control

should be about 2-3 mm, that can be measured on the throttle grip.

To adjust the slack, proceed as follows:

♦ Position the vehicle on the centre stand,

on a solid and level surface.

♦ Remove the protection element (2).

♦ Loosen the nut (3).

♦ Act on the adjuster (4), positioned at the

beginning of the accelerator control cable.

After the adjustment:

♦ Tighten the nut (3), thus locking the adjuster

(4) and put back the protection element (2).

WARNING

After the adjustment, make sure that the

rotation of the handlebar does not modify

the engine idling rpm and that the throttle grip returns smoothly and automatically to its original position after being

released.

Page 6

100

1

1

SPARK PLUG

Carefully read page 47 (MAINTENANCE).

Check the spark plug after the first 500 km

(312 mi), and

mi).

Check or change the spark plug every 8000

km (5000 mi).

Periodically remove the spark plug and clean

it carefully, removing carbon deposits;

change it if necessary.

To gain access to the spark plug:

♦ Remove the inspection cover, see page 65

(REMOVING THE INSPECTION COVER).

To remove and clean the spark plug:

♦ Remove the spark plug cap (1).

♦

Remove all the dirt from the base of the

spark plug, then unscrew it with the spanner you will find in the tool kit and extract it

change

every 4000 km (2500

100

from its seat, taking care that neither dust

nor other substances enter the cylinder.

♦ Make sure that there are neither carbon

deposits, nor corrosion marks on the electrode and on the central porcelain part; if

necessary, clean them with the special

cleaners for spark plugs, with an iron wire

and/ or a metal brush.

♦ Energetically blow some air, in order to pre-

vent the removed residues from getting into

the engine. If the spark plug has crackings

on the insulating material, corroded electrodes or excessive deposits, it must be

changed.

♦ Check the spark plug gap with a thickness

gauge. The gap must be 0.5 - 0.6 mm; if

necessary adjust it, carefully bending the

earth electrode.

♦ Make sure that the washer is in good con-

ditions. With the washer on, screw the

spark plug by hand in order not to damage

the thread.

use and maintenance

♦ Tighten the spark plug by means of the

spanner you will find in the tool kit, giving it

half a turn to compress the washer.

Spark plug driving torque:

20 Nm (2.0 kgm)

CAUTION

The spark plug must be well tightened,

otherwise the engine may overheat and

be seriously damaged.

Use the recommended type of spark plug

only, see page 86 (TECHNICAL DAT A), in

order not to compromise the life and performance of the engine.

♦ Connect the spark plug pipe (1).

♦

Keep the pipe in the same position as

before its disassembly.

♦ Refit the inspection cover, page 65 (RE-

MOVING THE INSPECTION COVER).

Scarabeo 50 - Scarabeo 100 4T

71

Page 7

BATTERY

Carefully read page 47 (MAINTENANCE).

WARNING

Risk of fire.

Keep fuel and other flammable substances away from the electrical components.

CAUTION

Never invert the connection of the battery

cables.

Connect and disconnect the battery with

the ignition switch in position “

erwise some components may be damaged.

Connect first the positive cable (+) and

then the negative cable (–).

Disconnect following the reverse order.

”, oth-

Check the electrolyte level and the terminals

tightening after the first 500 km (312 mi) and

then every 4000 km (2500 mi) or 12 months.

100

Check the electrolyte level and the terminals

tightening after the first 1000 km (625 mi)

and then every 4000 km (2500 mi) or 12

months.

WARNING

The electrolyte in the battery is toxic and

caustic and if it gets in contact with the

skin it can cause burns, since it contains

sulphuric acid. Wear protection clothes,

a face mask and/or goggles during maintenance operations.

In case of contact with the skin, rinse with

plenty of water.

In case of contact with the eyes, rinse with

plenty of water for fifteen minutes, then

consult an oculist without delay.

If the electrolyte is accidentally swallowed, drink a lot of water or milk, then

continue drinking milk of magnesia or

vegetable oil and consult a doctor without delay.

The battery gives off explosive gases;

keep it away from flames, sparks, cigarettes and any other source of heat.

During the recharging or the use, make

sure that the room is properly ventilated

and avoid inhaling the gases released

during the recharging.

KEEP AWAY FROM CHILDREN.

Do not incline the vehicle too much, in

order to avoid dangerous leaks of the

battery fluid.

The electrolyte is corrosive.

Do not pour or spill it, especially on the

plastic parts.

NOTE If servicing or technical advice is

required, contact an aprilia Official Dealer

that will certainly give you accurate and fast

assistance.

use and maintenance

72

Scarabeo 50 - Scarabeo 100 4T

Loading...

Loading...