Page 1

K

Service Source

LaserWriter 12/640 PS

Page 2

K

Service Source

Overview

LaserWriter 12/640 PS

Page 3

Overview About This Overview - 1

About This Overview

This overview briefly

describes the servicing

issues of the LaserWriter

12/640 PS, especially

those that distinguish it

from previous Apple laser

printers.

Page 4

Overview General - 2

General

The LaserWriter 12/640

PS is a 600 dpi, 12 ppm

monochrome laser printer

that is positioned as the

workgroup laser printing

solution for Mac OS and

Windows users.

It features excellent print

quality, cross platform

support, and state-of-theart paper handling options.

LaserWriter driver 8.4

releases concurrently with

this printer.

Page 5

Overview Options - 3

Options

There are three options that are available for the Laser-

LW 12/640 PS Options

Writer 12/640 PS:

• Duplexer unit

• Face-up catch tray

• 500-sheet feeder (accommodates either standard or

envelope cassette)

Each of the options can be added independently of one another

so there are several configurations that you might

encounter. The animation “LW12/640 PS Options” shows

how the options go together.

Page 6

Overview Paper Path - 4

Paper Path

The printer has a basic S-shaped paper path and multi-

LW12/640 PS Paper Path

purpose tray arrangement generally similar to the LaserWriter 16/600 PS.

On the exit side of the fuser assembly, however, there is a

brand new function: the paper deflector guide. This

solenoid-actuated guide switches paper between one of two

paths. The inside path is the face-down delivery path that

continues straight up to the delivery rollers and output tray.

The outside path serves three purposes.

• Paper feed into the optional duplexer.

• Paper delivery to the optional face-up tray.

• If no options are attached, the outside path will feed

paper directly out the rear of the printer.

Note

: The “LW 12/640 PS Paper Path” animation shows

the sequence of a duplex print job.

Page 7

Overview Duplexer - 5

Duplexer

The most unique mechanical feature you will encounter is

the optional duplexer unit. The term “duplex” denotes twosided printing.

The duplexer is an L-shaped feeder that cradles the

underside and rear of the printer. When duplex printing is

selected through software, the paper deflector guide is

actuated and the sheet of paper diverts into the duplexer.

There the paper is flipped and circulated back to the cassette

feed roller in preparation for its second imaging cycle.

The drive train in the horizontal leg of the duplexer receives

drive directly through an idler gear in the pickup drive

assembly in the printer. The feed roller at the entrance to

the duplexer also receives drive from the printer, but the

other feed rollers in the vertical leg of the duplexer are

driven by the duplexer motor.

Page 8

Overview Sheet Feeder - 6

Sheet Feeder

An optional 500-sheet feeder is available. As with the

LaserWriter 16/600 PS design, the sheet feeder fits

squarely beneath the printer (or the duplexer, if present)

to form a dual front-loading cassette arrangement. An

envelope cassette is available for the sheet feeder only.

The feeder has a receptacle connector that mates with the

printer and has its own circuit board. However, the feeder

does not have its own motor. Instead it derives mechanical

drive directly from the gear train above, either the pickup

drive assembly in the printer or the intermediate gear train

in the duplexer. There is a pickup roller and pickup

solenoid in the sheet feeder.

Page 9

Overview Face-Up Tray - 7

Face-Up Tray

The face-up tray is an option that attaches to the rear of the

printer (or to the rear of the duplexer, if present).

This tray performs similarly to previous printers, except

that output to this tray is selected through software, not by

the setting of a lever. The presence of this tray is not sensed

by the controller.

Optional

Face-Up Tray

Page 10

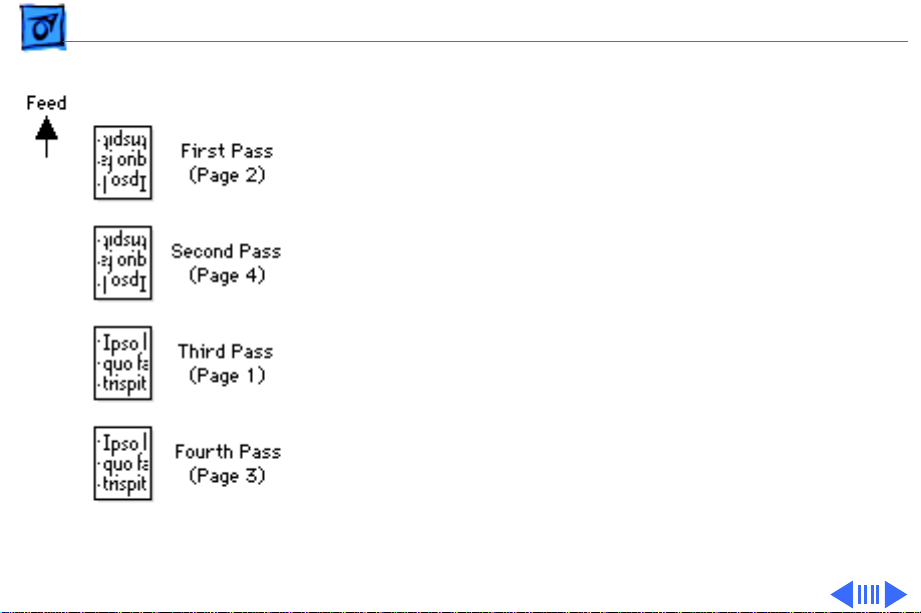

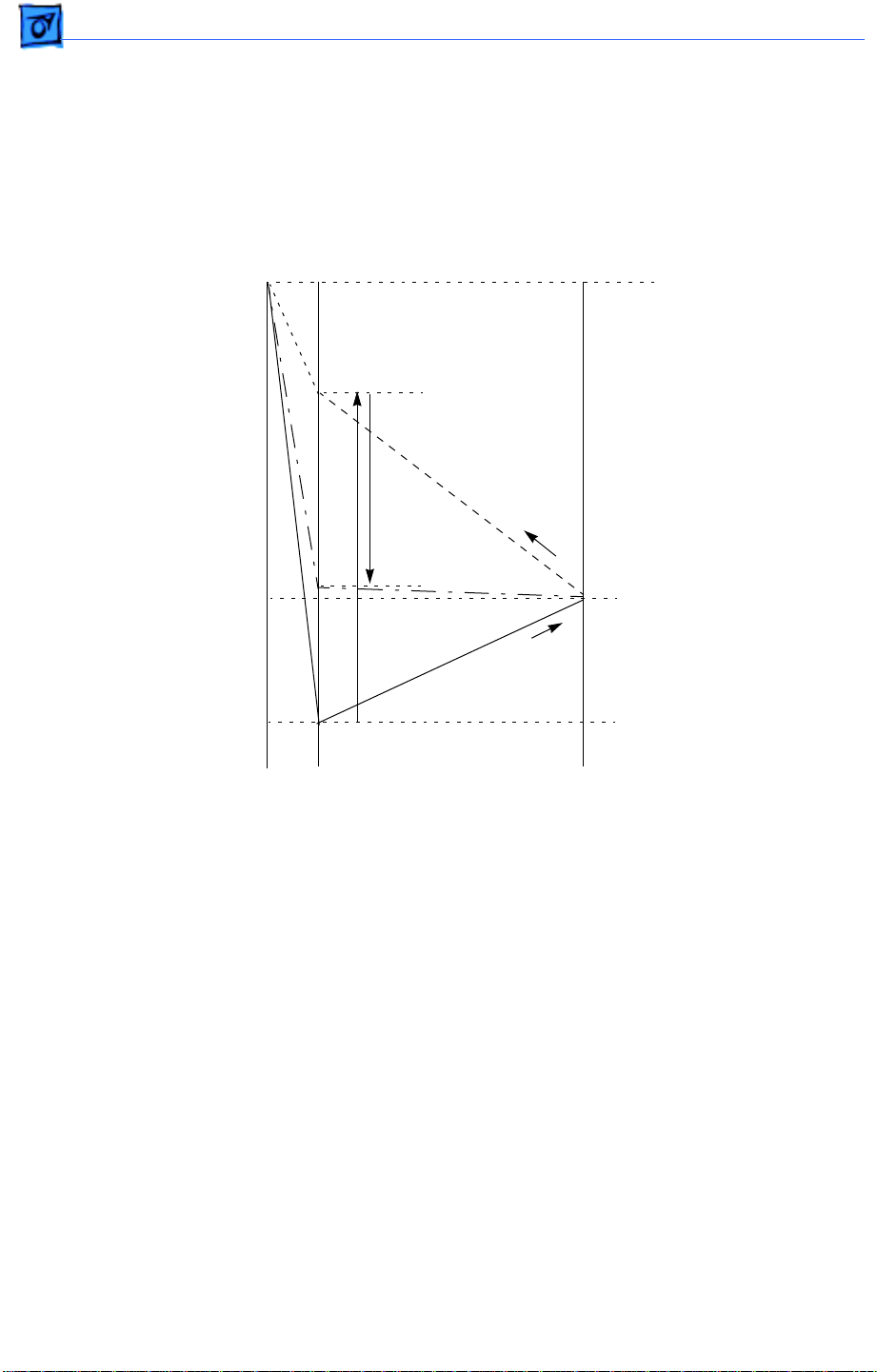

Overview Duplex Scan Anomalies - 8

Duplex Scan Anomalies

After side one prints during a duplex job, the paper parks

itself onto a horizontal shelf beneath the cassette. The

duplexer motor then reverses direction. The trailing edge of

the paper becomes the leading edge, and the paper exits the

shelf and continues the path toward side-two printing.

Order of Scanning

Duplex documents stack in the face-down delivery tray in

correct book order (with odd-numbered pages facing down).

To achieve this, page two is imaged during the first pass and

page one during the second pass.

Long Edge Binding

The reversing action of the duplexer flips the paper over

Long Edge Binding

Scan/Feed Directions

along its short axis. If you have chosen long edge binding in

Page 11

Overview Duplex Scan Anomalies - 9

the software, the I/O controller flips the imaging data

accordingly to counteract the reversal of the paper. The net

effect is even-numbered pages scanned in reverse.

For example, page 2 of a portrait oriented job images right

to left from the bottom up. (This anomaly does not occur

with short edge binding). For this reason, be aware that

some skew or image cutoff symptoms may appear to be 180

degrees off from normally scanned pages.

Double-Page Batching

If there is enough buffer memory space available, the

controller will image a print job four pages (two sheets) at

a time. For example, the imaging order of an eight-page

document would be pages 2, 4, 1, and 3 (with sheets one and

two then being delivered), followed by pages 6, 8, 5, and 7

(with sheets three and four delivered). This batching

Sequence of

Double-Page Batching

feature maximizes throughput speed.

Page 12

Overview Miscellaneous - 1 0

Miscellaneous

Fuser Pressure Roller

The fuser pressure roller provides an opposing surface to

the fuser heater roller, the same function as in previous

laser printers. However in the LaserWriter 12/640 PS,

this pressure roller is seated in the chassis and is not a part

of the fuser assembly itself.

Power Supply Assembly

The power supply assembly is a large multifunctional

circuit board located in the lower section of the engine. In

addition to the DC power supply functions that are common

in previous engines, this assembly also houses some sensors

and switches, as well as the high-voltage power supply and

various other functions.

Page 13

Overview Miscellaneous - 1 1

Beam Detection

Laser beam detection occurs outside of the laser/scanner

assembly, in the start-of-scan (SOS) sensor located in the

mirror assembly.

Two Shutters

There are two laser shutters, one inside the laser/scanner

assembly and one covering the mirror assembly. Both are

actuated with the closure of the top cover.

Two "Exit" Sensors

Unlike previous printers, there are two paper sensors

downstream of the fuser assembly. The first is the fuser

exit sensor that monitors the exiting of paper from the fuser

assembly. The second is the delivery sensor that monitors

Page 14

Overview Miscellaneous - 1 2

paper after it passes the deflection guide in route to facedown delivery on top of the printer.

One Fan

There is only one fan in this printer.

Support for Heavy Paper

The LaserWriter 12/640 PS supports throughput of 50 lb.

paper for simplex (single-sided) print jobs. You must

print from the multipurpose tray and choose face-up

delivery when using 50 lb paper.

RAM Upgrade

The LaserWriter 12/640 PS comes with 4 MB of RAM in the

righthand of two SIMM slots. This amount does not allow for

Page 15

Overview Miscellaneous - 1 3

duplex printing nor does it enable PhotoGrade. Upgrades are

required if you want either of these additional features.

No SCSI

There is no SCSI support in the LaserWriter 12/640 PS.

Startup Page

The startup page is a single-sided page with a layout similar

to previous PostScript LaserWriter printers. The startup

page does report the presence of a duplexer or sheet feeder

but will not recognize the optional face-up tray.

Page 16

Overview Miscellaneous - 1 4

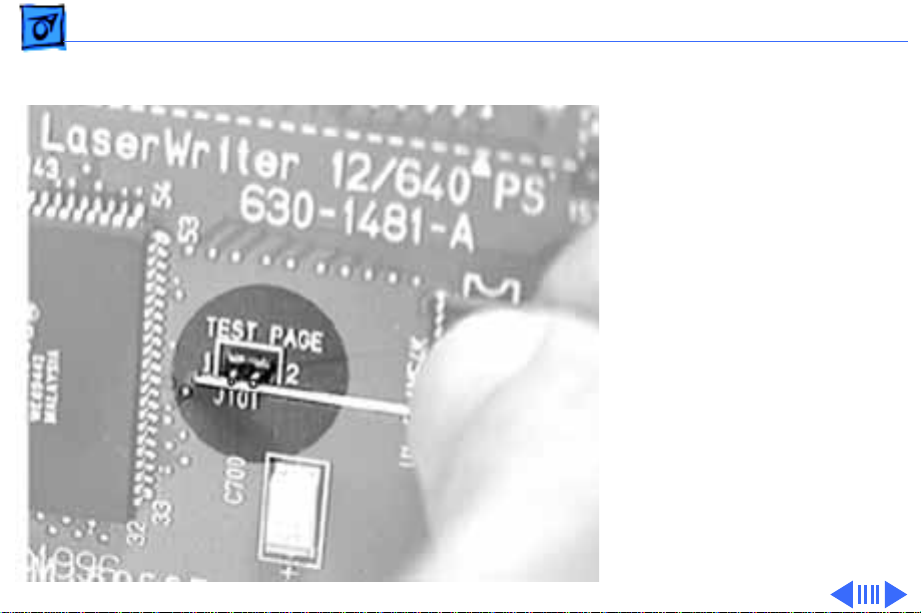

Service Test Page

You may print a service test

page by jumpering

connector J101 on the I/O

controller board. Consequently, unlike previous

printers, the I/O controller

board must be installed to

run a service test page.

Page 17

Overview Miscellaneous - 1 5

Top Cover Closure

The closing of the top cover initiates several more events

than in previous printers. They are listed below and are

described in detail in the “Principles of Operation” chapter.

• Actuation of cover interlock

• Opening of the laser shutter

• Opening of the mirror assembly shutter

• Latching of the top cover

• Pressing of the jam release plate

• Actuation of the toner cartridge latching mechanism

• Actuation of the fuser idler gear

Page 18

K

Service Source

Principles of Operation

LaserWriter 12/640 PS

Page 19

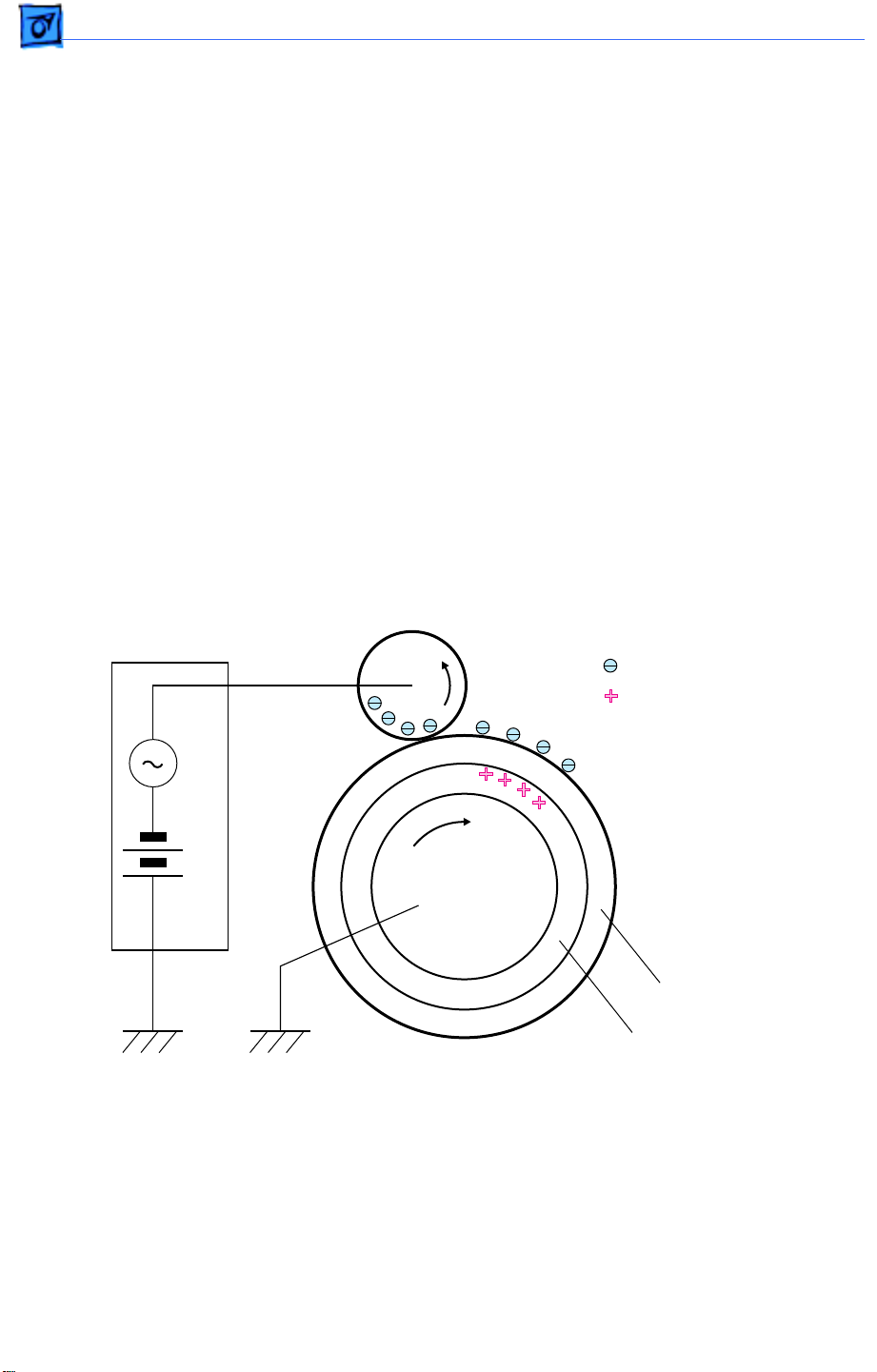

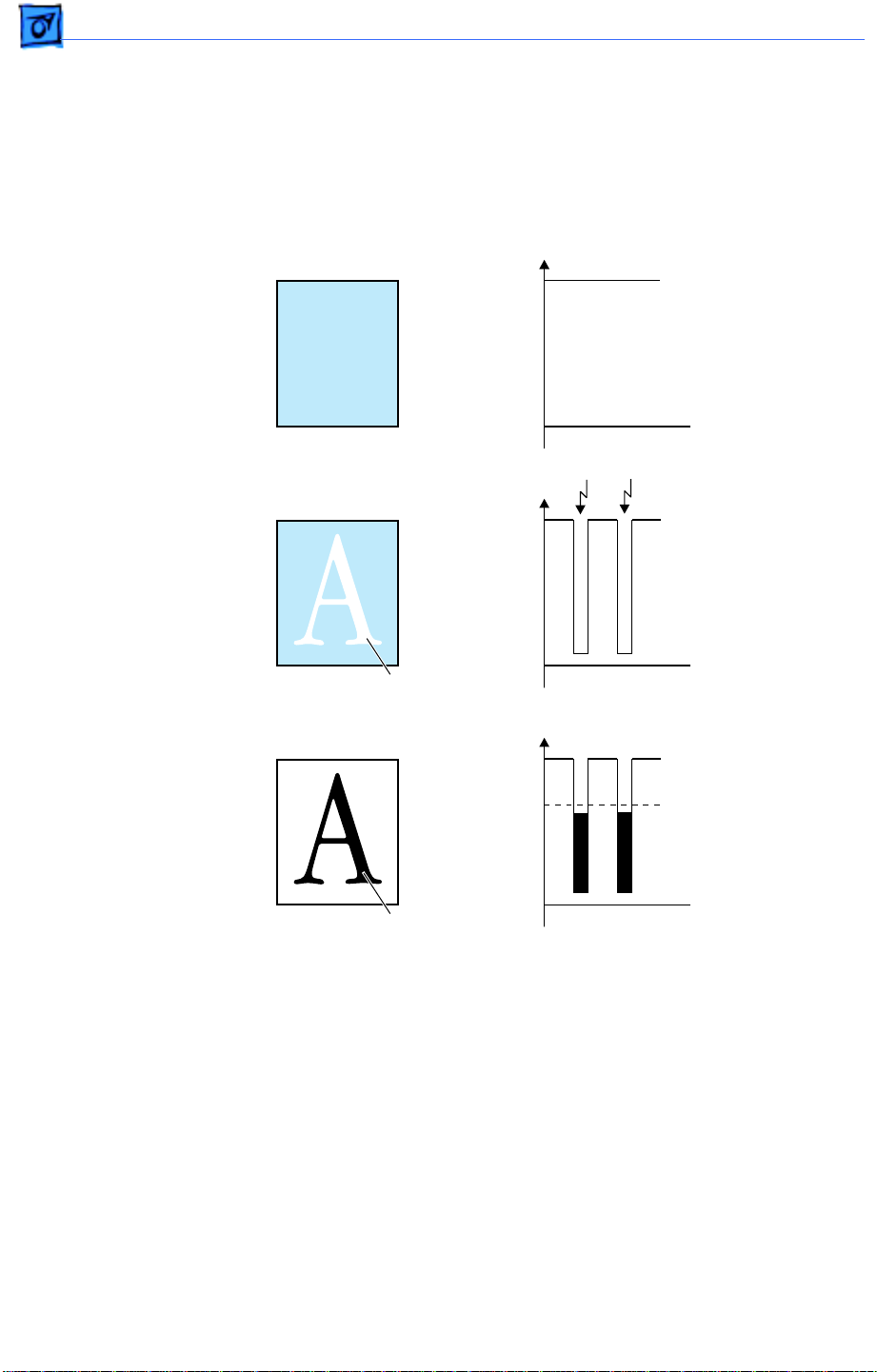

Principles of Operation Print Process - 1

Print Process

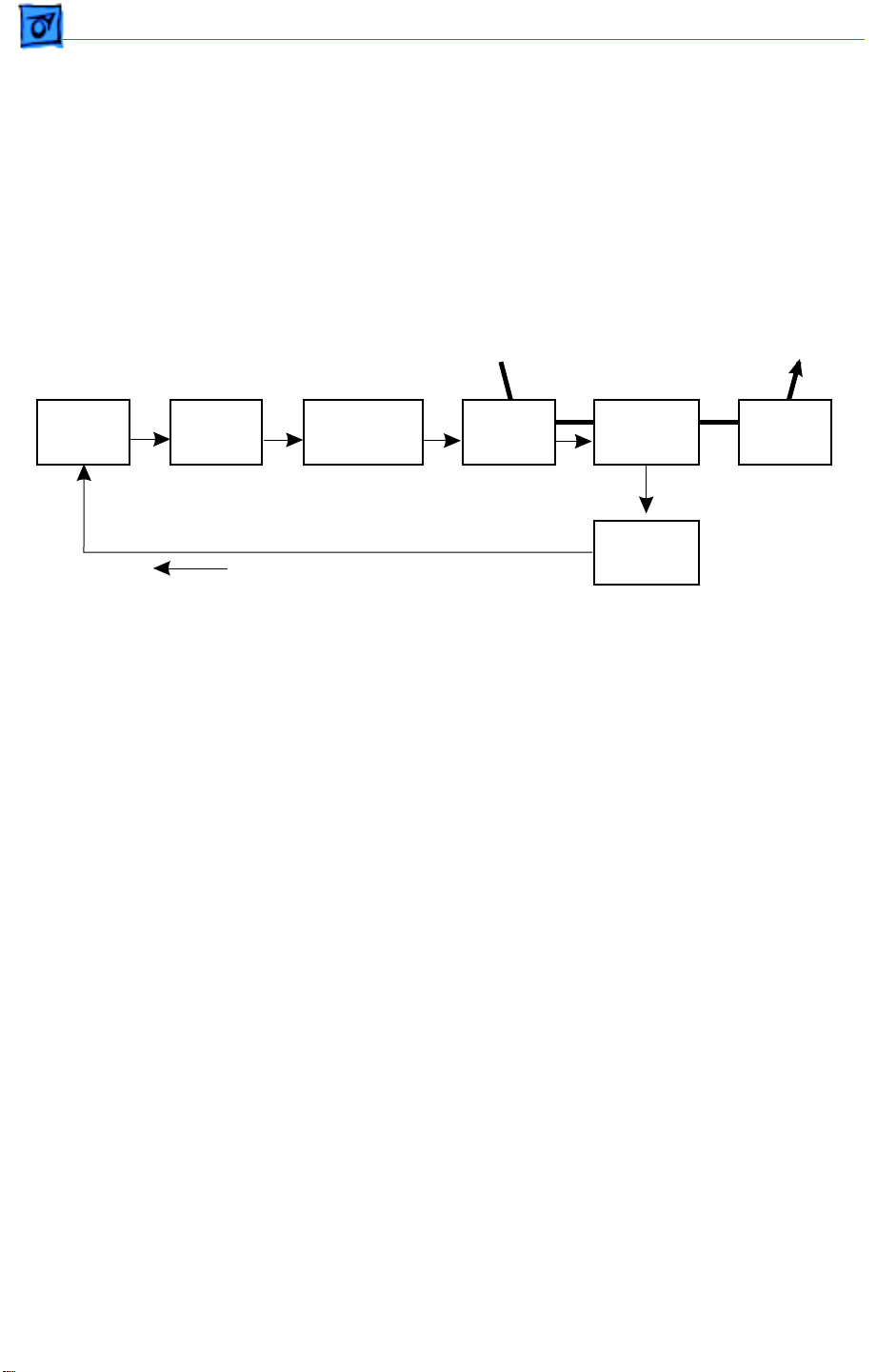

Print Process Overview

The print process consists of the stages shown below, during which a toner image forms on

the drum surface, transfers and then bonds to the paper. Each sheet of paper passes through

steps 4 to 6. During printing,the drum surface repeatedly cycles through steps 1 to 5, as

well as cleaning stage 7.

1

Charging

2

Exposure

Xerographic Cycle

Cycle repeats for the next print

3

Development

Paper Enters

4

Transfer

5

Discharge

7

Cleaning

Paper Exits

6

Fusing

1 Charging

Places a uniform density of negative electric charge onto the drum surface.

2 Exposure

Scans the drum surface with a thin beam of laser light that switches on and off according to

the video signal from the printer controller. This exposure forms an invisible electrostatic

latent image on the drum surface.

3 Development

Attracts toner onto the electrostatic latent image on the drum surface, thus forming a

visible toner image.

4 Transfer

Transfers the toner image from the drum surface to the paper.

5 Discharge

Enables the paper to come off the drum surface.

6 Fusing

Fixes the toner image to the paper.

7 Cleaning

Cleans the drum surface of any residual toner.

Page 20

Principles of Operation Print Process - 2

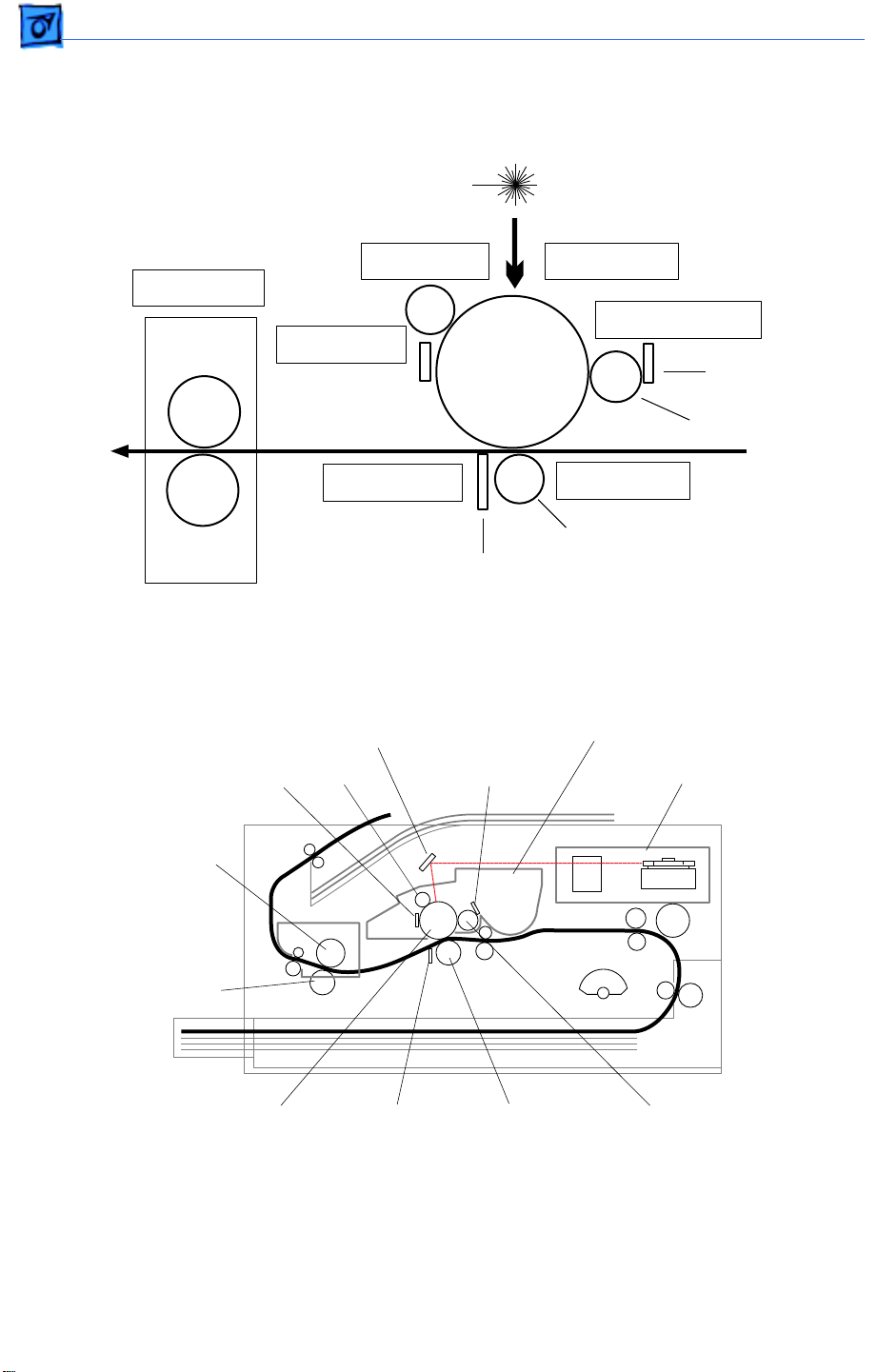

Print Process Diagram and Paper Path

Laser Beam

1 Charging 2 Exposure

6 Fusing

Fuser

Roller

BCR

7 Cleaning

Drum

Cleaning

Blade

3 Development

CM Blade

Attraction Roller

Paper

4 Transfer5 Discharge

Pressure

Roller

Cleaning Blade

Fuser Roller

Pressure Roller

Detack Saw

Mirror Assembly

Transfer Roller

Toner Cartridge

CM BladeBCR

Laser/Scanner Assy

Drum Detack Saw

Transfer Roller Attraction Roller

Page 21

Principles of Operation Print Process - 3

Print Process Description

1 Charging

During this stage, the drum surface receives a uniform negative charge.

Note

: The drum surface is made of a photoconductive material and the inner part of the

drum is made of a conductive material. This negative charge is actually placed onto the

outside surface of the photoconductor layer.

The charge is imparted by the bias charge roller (BCR) within the toner cartridge. The

BCR is a conductive roller in contact with the drum surface and is supplied with a discharge

voltage by the high-voltage power supply (HVPS). The discharge occurs through the small

gaps between the BCR and the drum. The discharge voltage is an AC voltage with a negative

DC voltage superposed. The negative DC voltage is about -330 V. The AC voltage varies

within the range of about 1.6 to 2.0 kVp-p with the discharge current since the AC current

is regulated to be constant.

Note

: Before this stage, the drum surface will have been given a uniform negative

charge relative to the inner conductor of the drum (see “Cleaning”).

High-Voltage

Power Supply

(HVPS)

AC

DC

CR

Bias Charge Roller (BCR)

Negative Charge

Positive Charge

Drum

Photoconductor Layer

Conductor Layer

Page 22

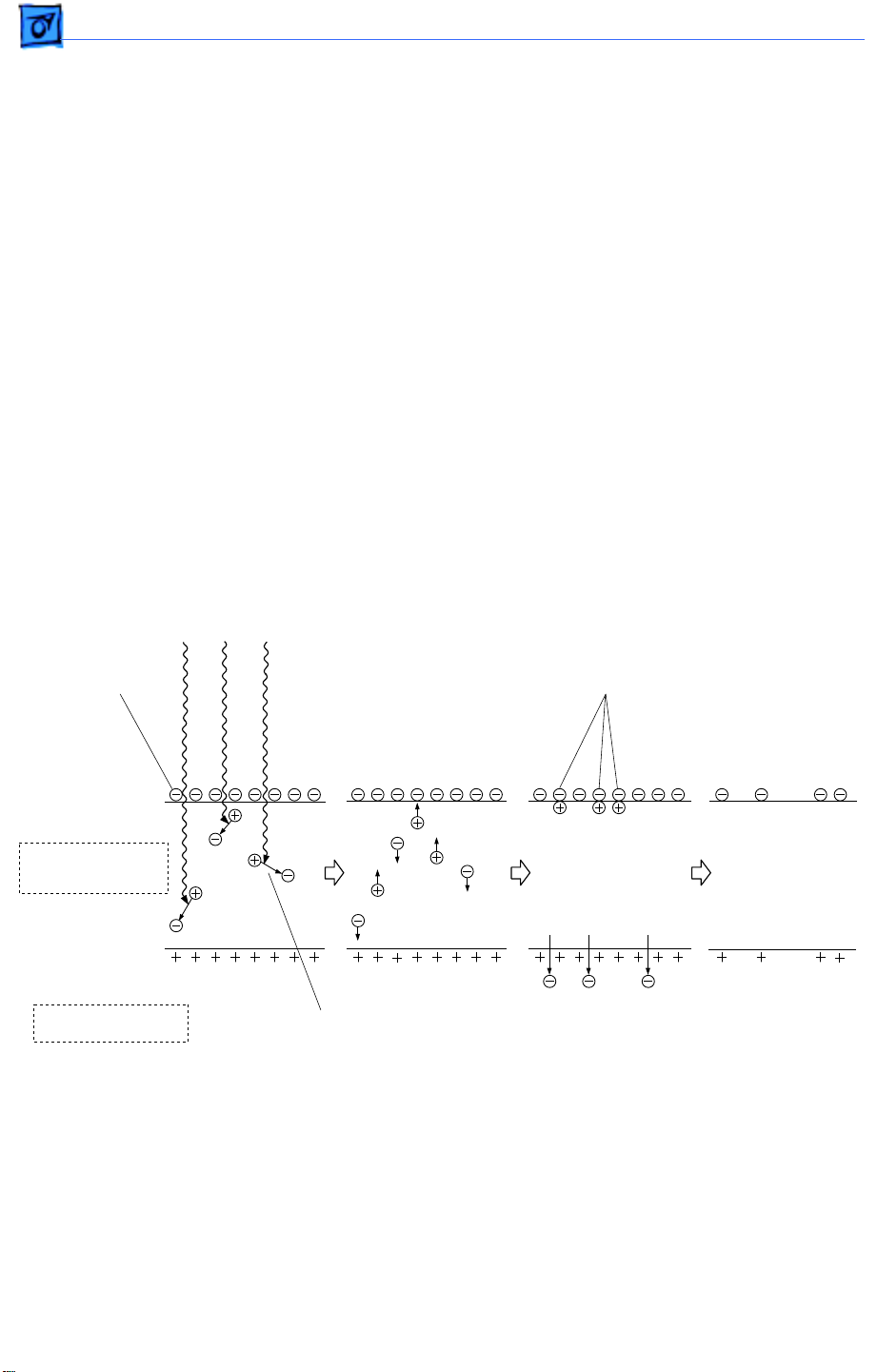

Principles of Operation Print Process - 4

2 Exposure

During this stage, the laser beam scans across the negatively charged drum surface.

The laser beam is emitted from the laser diode in the laser/scanner assembly. This diode is

stationary. Its beam reflects off the face of a rapidly rotating scanning mirror, through a

correction lens, and outward off a stationary mirror which directs the beam onto the

surface of the drum.

The laser beam is modulated according to the video signal from the printer controller,

switched on when the video signal denotes a black pixel and off when it denotes a white pixel.

The laser beam that strikes the drum surface generates electron-hole pairs in the

photoconductor layer, exciting electrons to the conduction band and thereby creating holes

in the valence band. The electrons are attracted by the electric field and move toward the

inner conductor of the drum to flow into it. The holes move toward the outside surface of the

photoconductor layer and recombine with the negatively charged electrons at the surface to

decrease the negative charge at the surface. The resultant less-negatively charged parts

(parts whose potential has risen relative to the inner conductor) in the drum surface form

an invisible electrostatic latent image.

Electron

Photoconductor

Layer

Conductor Layer

Laser Light

Electron-hole pair

Recombination

Decrease of

Negative Charge

Page 23

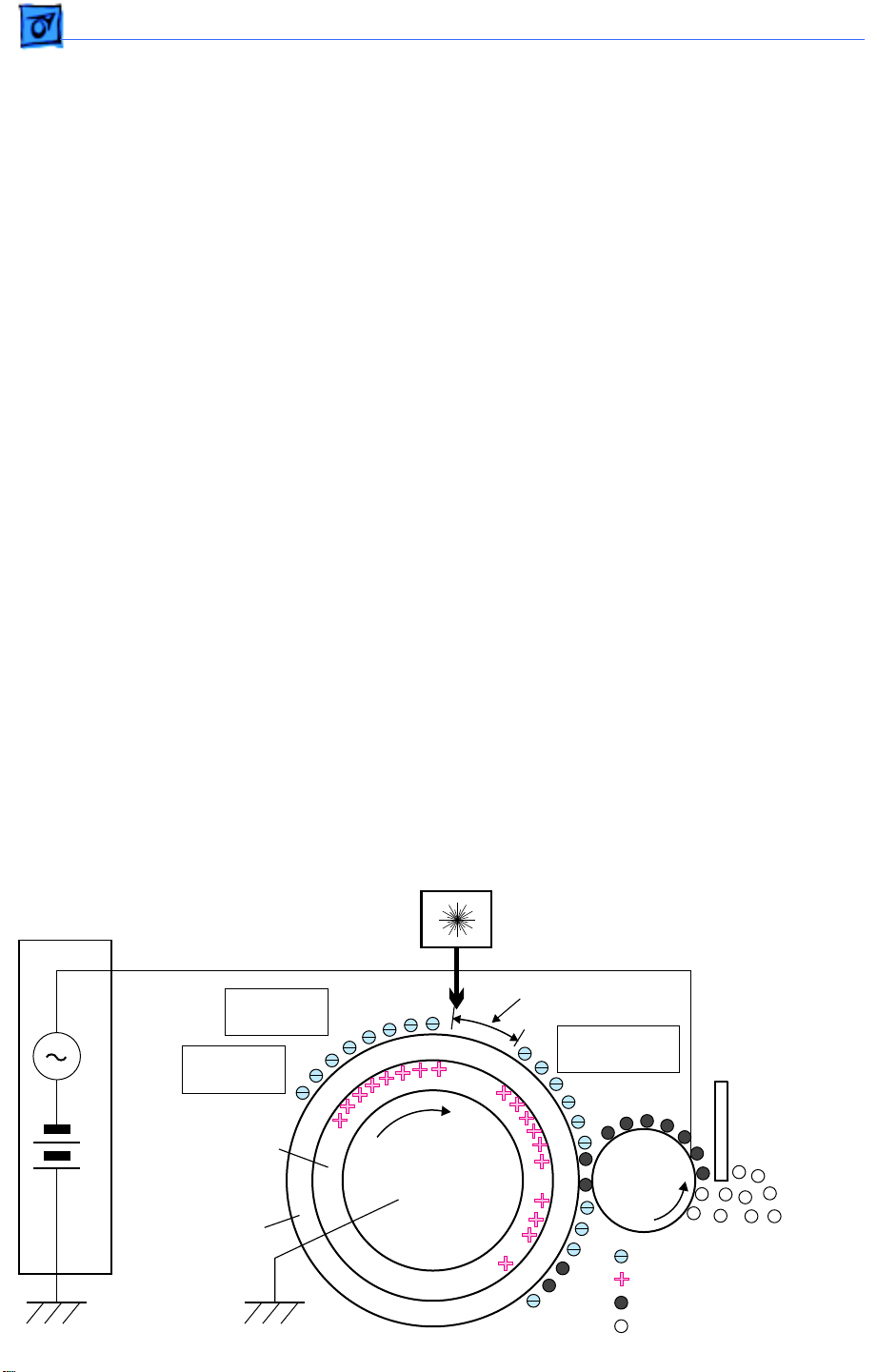

Principles of Operation Print Process - 5

3 Development

During this stage, the electrostatic latent image on the drum surface attracts toner and

forms a visible toner image.

The LaserWriter 12/640 PS uses nonconducting magnetic toner that readily transfers to

plain paper. The toner is supplied from the toner compartment to the attraction roller

positioned close to the drum within the toner cartridge. Because of its slight magnetism, the

toner is attracted to the surface of the attraction roller and is spread evenly into a very thin

layer by the charging and metering blade (CMB). This blade is made of silicone rubber. As

it comes into contact with the toner, the resulting friction imparts a negative charge onto

the toner particles.

The attraction roller is covered with a thin conductive sleeve. A development bias (DB)

voltage is applied to the conductive sleeve from the HVPS. The DB voltage is a negative DC

voltage with an AC voltage superposed. The DC voltage is about -250 V and the AC voltage is

about 1.7 kVp.

Since the attraction roller is kept at a potential of about -250 V DC relative to the

conductor layer of the drum, the parts of the drum surface with the full negative charge

have a lower electric potential than the attraction roller, and the parts with decreased

negative charge have a higher electrical potential.

Therefore, the negatively charged toner on the attraction roller is pulled only to those areas

of the drum with the decreased negative charge (since the attracting force of the positive

charge on the conductor layer of the drum is greater than the repelling force of the negative

charge on the drum surface, the toner is attracted in spite of the repelling force of the

negative charge). As the toner adheres, the negative charge of those parts increases because

of the negative charge of the toner, lowering the electric potential and increasing the

repelling force of those parts to decrease the resultant attracting force.

The AC voltage agitates the toner particles on the attraction roller surface and facilitates

toner release. The invisible electrostatic latent image on the drum surface is thus developed

into a visible toner image.

HVPS

AC

DC

Development Bias

2

Exposure

1

Charging

Conductor

Layer

Drum

Scanner

Irradiated Part of

the Drum Surface

3

Development

CM Blade

Attraction

Roller

Photoconductor

Layer

Negative Charge

Positive Charge

Negatively Charge Toner

Non-Charged Toner

Page 24

Principles of Operation Print Process - 6

3 Development (cont.)

The change of the electric potential of the drum surface while the drum

surface passes through the charging to the development steps

0 V

¡

Development Bias

About -250 V

Bias Charge

About -330 V

Conductor Layer

of the Drum

The electric potential of the parts of the drum surface struck

a:

by the laser beam (the areas with decreased negative charge)

rises above the electric potential of the attraction roller.

The electric potential of the parts with decreased negative charge

b:

lowers as the toner is attracted.

c:

The degree of inclination of the line indicates the strength

of the force and the direction of inclination indicates the

direction of the force exerted on the toner particles.

b

a

¬

¿

Drum Surface

Attracting

c

c

Repelling

Attraction Roller

¿ Charged

¡ Exposed

¬ Developed

Page 25

Principles of Operation Print Process - 7

3 Development (cont.)

The diagram below illustrates the change of the potential as the drum surface passes from

the charging through the development stages:.

Drum Surface Voltage

1 Charging

2 Exposure

3 Development

Electrostatic Latent

Image (Invisible)

-V

-V

-V

About -233V

Bias Charge

0

0

About -250V

Development Bias

Toner Image

(Visible)

0

Page 26

Principles of Operation Print Process - 8

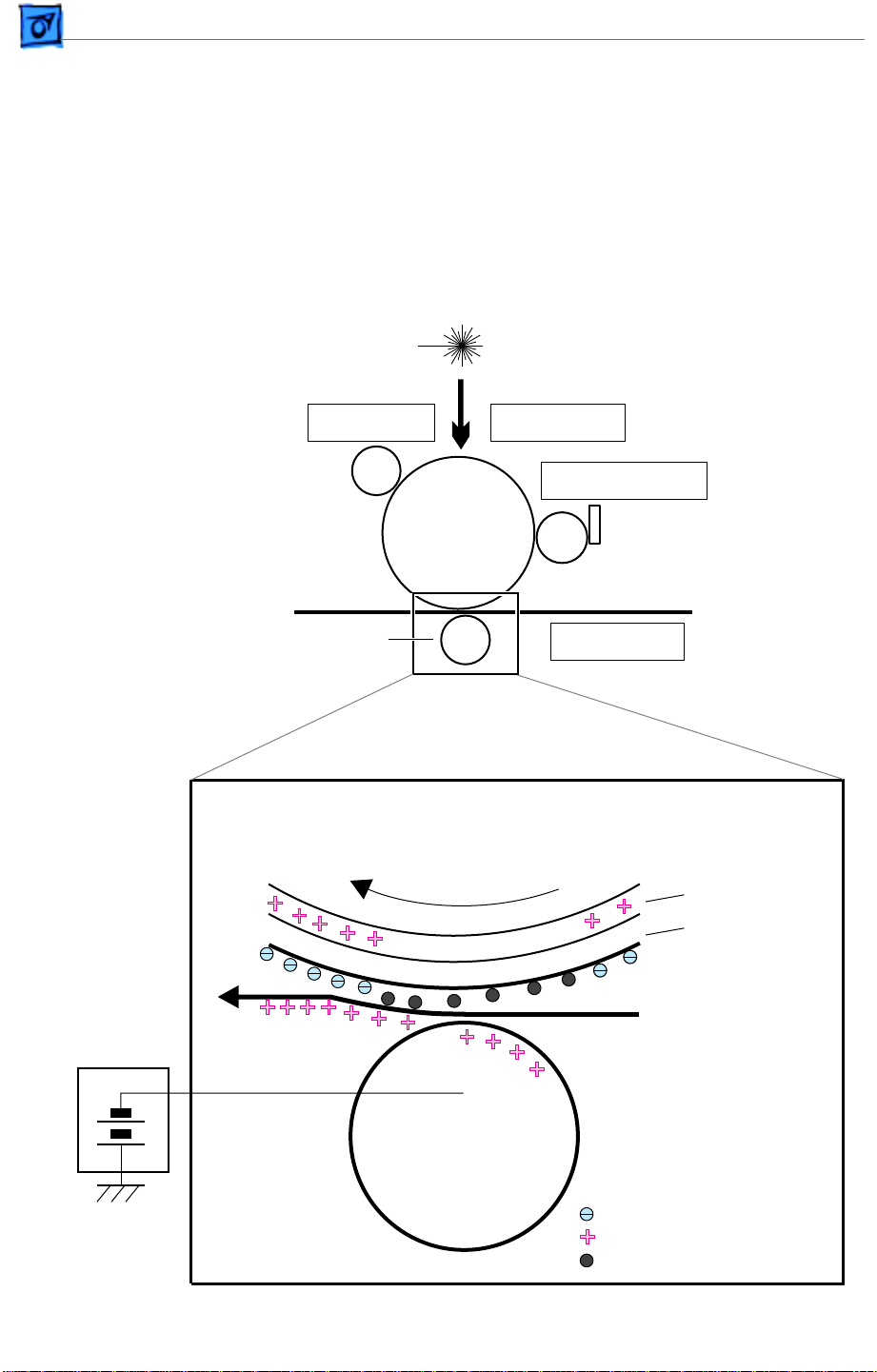

4 Transfer

During this stage, the toner transfers from the drum to the paper.

The bias transfer roller (BTR), referred to herein simply as the transfer roller, applies a

positive charge to the back side of the paper as it feeds between the roller and the drum. The

toner image transfers from the drum surface to the front side of the paper due to this

positive charge on the back side of the paper.

The paper is attracted by the negative charge induced in the inner conductor layer of the

drum by the positive charge of the paper and sticks to the drum surface.

Laser Beam

1 Charging 2 Exposure

3 Development

Drum

HVPS

Transfer Roller

TR

4 Transfer

Drum

Conductor Layer

Photoconductor

Layer

Paper

Transfer Roller

Negative Charge

Positive Charge

Negatively Charged Toner

Page 27

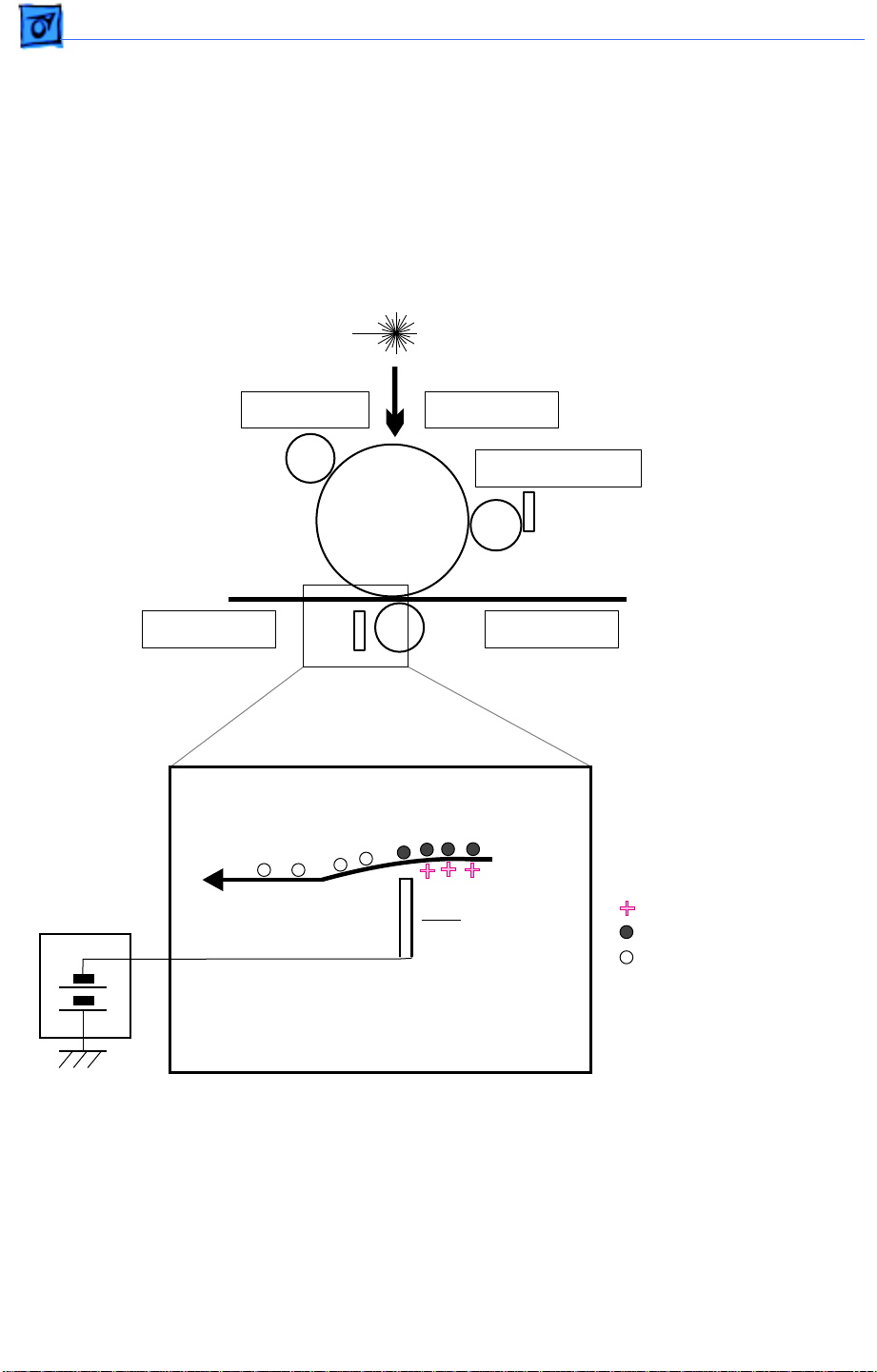

Principles of Operation Print Process - 9

5 Discharge

During this stage, the paper comes off the drum surface.

The detack saw applies a negative charge to the back side of the paper to neutralize the

positive charge previously applied by the transfer roller. The force which attracts the

paper to the drum surface disappears, and the paper releases naturally from the drum due

to gravity.

Laser Beam

1 Charging 2 Exposure

3 Development

Drum

HVPS

5 Discharge

DS

4 Transfer

Paper

Detack Saw

Positive Charge

Negatively Charged Toner

Non-Charged Toner

Page 28

Principles of Operation Print Process - 10

6 Fusing

During this stage, heat and pressure fix toner to the paper.

The toner image transferred from the drum surface to the paper is easily dislodged. To fix

the image to the paper, the paper is passed between the fuser assembly and a pressure

roller. The fuser roller applies the heat necessary to bond toner to paper and also supplies

rotational force to help pull the paper evenly through. The pressure roller, though neither

heated or mechancially driven, provides the surface against which the pressure and heat can

be evenly applied.

Page 29

K

Service Source

Specifications

LaserWriter 12/640 PS

Page 30

Specifications Introduction - 1

Introduction

Specifications information for this product can be found in this chapter and also in the Spec

Database, which you can access in one of three ways:

Ñ Launch it directly by double-clicking the Apple Spec Database runtime alias at the

top level of the Main Service Source CD.

Ñ Select "Apple Spec Database" from the Service Source drop-down main menu.

Ñ Click the Acrobat toolbar icon for the database, which is near the right end of the

toolbar with the letters "SP."

Page 31

Specifications Engine - 2

Engine

Marking Engine

Laser

Speed

Life Expectancy (Printer)

Fuji Xerox P893 laser-xerographic

Type: Semiconductor laser GaAlAs

Wavelength: 780 nm

Output power: 5 mW

SimplexÑ12 pages per minute maximum using A4-size paper.

Actual speed depends on the images printed.

DuplexÑ8 pages per minute maximum using U.S. letter-size

paper. Actual speed depends on the images printed.

Average number of prints between failure is 180,000 pages.

Page 32

Specifications Engine - 3

Life Expectancy (Toner Cartridge)

Printing Materials

Life expectancy is 6,000 pages when printing text documents with

average page coverage (5% black). An example of a 5% black

page coverage is a page consisting of double-spaced 14-point

courier type. Printing images and other graphics may impact

toner cartridge life expectancy.

16- to 28-pound laser-quality bond (60 to 90 g/m 2 ); up to

50-pound (190 g/m 2 ) stock when fed manually through the

multipurpose tray and delivered through the face-up output

tray. Accepts most textured and colored stock. Accepts mediumweight photocopier transparencies and labels. Envelopes can be

printed from the multipurpose tray or from the optional

envelope cassette (sheet feeder only).

The paper used should not scorch, melt, transfer material, or

release hazardous emissions when heated to 200¡ C (393¡ F)

for 0.1 seconds.

Page 33

Specifications Engine - 4

Paper Sizes and Capacity

Supports U.S. letter, A4, B5, executive, and legal in the standard

paper cassette. The paper cassette holds 250 sheets of 20pound (75 g/m 2 ) paper. The multipurpose tray can hold up to

80 sheets of standard U.S. letter paper, and other paper sizes

from postcard up to U.S. legal. An optional 500-sheet cassette

is available that supports letter, A4, and U.S. legal-paper

sizes. An envelope cassette that can automatically feed up to 50

envelopes is also available. The envelope cassette is compatible

only with the 500-sheet feeder.

Page 34

Specifications Engine - 5

Dimensions

Printer only

Height 9.5 in. 24.2 cm)

Width 15.9 in. (40.5 cm)

Depth 16.7 in. (42.4 cm)

Printer with optional duplex printing unit

Height 11.89 in. (30.2 cm)

Width 15.9 in. (40.5 cm)

Depth 20.47 in. (52.0 cm)

Printer with optional 500-sheet cassette and feeder

Height 14.0 in. (35.6 cm)

Width 15.9 in. (40.5 cm)

Depth 16.7 in. (42.4 cm)

Printer with optional duplex printing unit and 500-sheet

cassette feeder

Height 16.2 in. (41.1cm)

Width 15.9 in. (40.5 cm)

Depth 20.4 in. (52.0 cm)

Page 35

Specifications Engine - 6

Weight

Voltage Requirements

Approximately 30 lb. (14 kg)

U.S.

103.5 to 126.5 VAC, 58 to 62 Hz

Europe/Australia

198 to 264 VAC, 48 to 52 Hz

Note

: The LaserWriter 12/640 PS printer does not contain a

universal power supply or fuser assembly.

Page 36

Specifications Engine - 7

Power Consumption

Energy-saving mode

26 W

Standby average

100/120 V, approximately 125 W

220/240 V, approximately 120 W

Operating average

110/120 V, approximately 390 W

220/240 V, approximately 370 W

Maximum power consumption

110/120 V, approximately 790 W, 6.8 A

220/240 V, approximately 770 W, 3.5 A

Page 37

Specifications I/O Controller - 8

I/O Controller

Microprocessor

ROM

RAM

AMD Am29040 30-MHz RISC microprocessor

4 MB (including 35 Type 1 fonts)

4 MB (expandable to 64 MB)

72-pin, 70 ns or less SIMMs are required. See ÒUpgradesÓ for

full information about possible configurations.

Page 38

Specifications I/O Controller - 9

Ports

Resolution

LocalTalk

Parallel

AAUI Ethernet port with three protocols:

EtherTalk

Novell NetWare IPX (PSERVER or RPRINTER)

TCP/IP (BSD lpd)

External Ethernet transceivers available for:

Thin Coax (10BASE-2)

Twisted Pair (10BASE-T)

Thick Coax (10BASE-5)

(All ports/protocols simultaneously active)

Two-position communication switch

600 dpi

Page 39

Specifications I/O Controller - 10

Grayscale Imaging

Languages

Standard

85 lines/inch dithered halftone, 101 gray levels

106 lines/inch dithered halftone, 129 gray levels

141 lines/inch dithered halftone, 73 gray levels

PhotoGrade (12 MB of RAM required)

85 lines/inch halftone, 201 gray levels

106 lines/inch halftone, 257 gray levels

141 lines/inch halftone, 145 gray levels

PostScript Level 2 (2015)

PCL5 (LaserJet IIID emulation)

Page 40

Specifications I/O Controller - 11

Fonts on Disk

Sixty-four fonts are provided with the LaserWriter 12/640 PS,

including such fonts as ITC Avant Garde ¨ , ITC Bookman ¨ ,

Chicago, Courier, Delphian, Garamond Condensed, Geneva,

Helvetica ¨ , Helvetica Black, Helvetica Compressed, Helvetica

Narrow, Lubalin Graph, Lucida Bright, Machine, Monaco,

Nadianne, New Century Schoolbook, New York, Old English

Text, Onyx, Oxford, Palatino ¨ , Swing, Symbol, Times ¨ , ITC

Zapf Chancery ¨ , ITC Zapf Dingbats ¨ , and Zeal.

Page 41

Specifications I/O Controller - 12

Fonts in ROM

PostScript

The following fonts are resident in the printer ROM:

AvantGarde Book, AvantGarde BookOblique, AvantGarde Demi,

AvantGarde DemiOblique

Bookman Demi, Bookman DemiItalic, Bookman Light, Bookman

LightItalic

Courier, Courier Bold, Courier BoldOblique, Courier Oblique

Helvetica, Helvetica Bold, Helvetica Bold Oblique, Helvetica

Narrow, Helvetica Narrow Bold, Helvetica Narrow

BoldOblique, Helvetica Narrow Oblique, Helvetica Oblique

NewCentury Schoolbook Bold, NewCentury Schoolbook BoldItalic,

NewCentury Schoolbook Italic, NewCentury Schoolbook Roman

Palatino Bold, Palatino BoldItalic, Palatino Italic, Palatino Roman

Symbol

Times Bold, Times Bold Italic, Times Italic, Times Roman

Zapf Chancery MediumItalic

Zapf Dingbats

Page 42

Specifications I/O Controller - 13

PCL

The following PCL fonts are resident in the printer ROM:

Times Roman, Time Bold, Time Italic, Times Bold Italic

Univers Medium, Univers Medium Bold, Univers Medium Italic,

Univers Medium Bold Italic

Courier 12 pitch, 10 point Medium; Courier 12 pitch, 10 point

Bold; Courier 12 pitch, 10 point Italic; Courier 10 pitch, 12

point Medium; Courier 10 pitch, 12 point Bold; Courier 10

pitch, 12 point Italic

Line Printer Font 16.67 pitch, 8.5 point, Medium

Page 43

Specifications Environmental Information - 14

Environmental Information

Operating Temperature

Operating Humidity

Storage (Toner Cartridge)

Storage (Printer)

50¡ to 90¡ F (10¡ to 32¡ C)

15 to 80 percent RH non-condensing

Temperature 32¡ to 95¡ F (0¡ to 35¡ C)

Humidity 15 to 85 percent RH non-condensing

Temperature 32¡ to 122¡ F (0¡ to 40¡ C)

Humidity 35 to 85 percent RH non-condensing

Page 44

Specifications Finished Goods Accessories - 15

Finished Goods Accessories

Ethernet

Toner Cartridge

Printer Options

Apple Ethernet Thin Coax Transceiver M0329Z/B

Apple Ethernet Twisted Pair Transceiver M0437Z/B

Apple Ethernet AUI Adapter M0432LL/A

LaserWriter 12/640 PS Toner Cartridge M4683G/A

LaserWriter 12/640 PS 500-Sheet Feeder M4682G/A (includes

standard 500-sheet cassette). Envelope cassette M4680G/A is

also available for the sheet feeder.

LaserWriter 12/640 PS Face-Up Output Tray M4698G/A

LaserWriter 12/640 PS Duplex Printing Unit M4697G/A

Page 45

Principles of Operation Print Process - 11

7 Cleaning

During this stage, any residual toner on the drum is cleaned off to prepare for the next

print cycle.

The residual toner is collected in a special compartment separate from the fresh toner

compartment. The transfer rate is more than 90%, but varies according to the percentage

of printed pixels and the environmental conditions such as temperature and humidity.

Residual toner cannot be re-used.

BCR

Cleaning Blade

Toner Cartridge

Used Toner Drum

CM Blade

Attraction

Roller

Silicone Rubber

Page 46

Principles of Operation Paper Transportation - 12

Paper Transportation

Paper Path Flowchart

The chart below shows the parts that feed paper through the LaserWriter 12/640 PS

engine. Parts are shown in the order in which they occur during a print cycle.

Pickup Roller

(Optional Sheet Feeder)

Cassette Feed Roller

Duplexer

Cassette Feed

Pickup Roller

Preregistration Feed and Pinch Rollers

Registration Feed and Pinch Rollers

Drum and Transfer Roller

Fuser Roller and Pressure Roller

Fuser Exit and Pinch Rollers

Manual Feed

Pickup Roller

Paper Deflector Guide

Duplexer and/or

Face-Up Delivery Tray

Delivery Rollers

and Pinch Rollers

Output Tray

Page 47

Principles of Operation Paper Transportation - 13

Paper Path Diagram

The cross-sectional diagram below illustrates the elements indicated in the previous chart.

The roller diameters are listed below the diagram.

Delivery Roller Registration Pinch Roller

Delivery

Pinch Roller

Fuser Roller

Fuser Pinch Roller

Fuser Exit Roller

Pressure Roller

Drum

Transfer

Roller

Roller Diameter (inches/mm)

Delivery Roller

Drum

Registration Pinch Roller

Delivery Pinch Roller

Fuser Roller

Fuser Pinch Roller

Fuser Exit Roller

Pressure Roller

Transfer Roller

Registration Feed Roller

Cassette Pickup Roller

Cassette Feed Roller

Cassete Feed Pinch Roller

Preregistration Feed Roller

Manual Feed Pickup Roller

Preregistration Pinch Roller

Registration

Feed Roller

.34

1.18

.39

.39-.43

.89

.31

.53

.90

.63

.56

.79

.55

.79

.55

.55

.63

Cassette

Pickup Roller

in. 8.8

30.0

10.0

10.0-10.8

22.6

8.0

13.6

23.0

15.9

14.3

20.0

14.0

20.0

14.0

14.0

16.0

Preregistration

Pinch Roller

Manual Feed

Pickup Roller

Preregistration

Feed Roller

Cassette Feed

Pinch Roller

Cassette Feed

Roller

mm

Page 48

Principles of Operation Print Image Creation - 14

Print Image Creation

Print Image Generation

The image data signal (VIDEO) is sent from the I/O controller board to the laser/scanner

assembly via the DC controller board. The video signal is passed through the DC controller

board as received from the I/O controller without buffering or additional processing. The

signal is converted into laser light, which is scanned onto the surface of the photosensitve

drum as described below. As a result, an electrostatic latent image is produced on the drum

surface.

Mirror Assembly

Laser/Scanner

Assembly

Host Computer

Interface Cable

I/O Controller

Drum

J26

DC Controller Board

Page 49

Principles of Operation Print Image Creation - 15

Laser/Scanner Assembly Structure and Operation

The laser light source used for the LaserWriter 12/600 PS is a semiconductor laser diode

(LD) with a rated maximum output power of 5 mW.

The laser diode is switched on and off according to the video signal. The power of the laser

light is monitored and controlled by the monitor circuit so that it remains constant.

The laser light from the diode is aimed directly at a hexagonal mirror that is being rotated

at a very high speed by the scanner motor. The six facets of the mirror reflect the laser

beam in turn as the mirror rotates.

The beam reflected by the hexagonal mirror passes through a correction lens and outward

from the laser/scanner assembly. The beam reflects downward off a stationary mirror and

through a slit in the toner cartridge, striking the surface of the photosensitive drum.

At the beginning of each scan, the laser beam strikes the start-of-scan (SOS) sensor. The

on and off switch of the laser light is determined by the signal from the SOS sensor.

Start-of-Scan (SOS) Sensor

Laser Diode Board

Hexagonal Mirror

Stationary Mirror

Drum

Correction Lens

Page 50

Principles of Operation Print Image Creation - 16

Note

: One horizontal line of an image is drawn by scanning the pulsating laser beam

across the drum. The timing and location of the pulse is a function of the VIDEO signal

originating from the I/O controller board. By rotating the drum and scanning

additional lines, a two-dimensional image is built. The resolution of a laser printer is

determined by the number of pixels per inch (in the horizontal direction) and the

number of scans per inch (in the vertical direction). The LaserWriter 12/640 PS

has a resolution of 600 x 600.

Direction of Paper

600 scans/inch

600 dots/inch

Page 51

Principles of Operation Mechanical Drive - 17

Mechanical Drive

The generation and transmission of mechanical drive in the LaserWriter 12/640 PS is

shown in the diagram below.

Pickup Motor

Main Motor

Gear cluster in the

pickup drive assembly

transmits the drive

force to the rollers

shown to the right.

Gear cluster in the

main drive assembly

transmits the drive

force to the rollers

shown to the right.

Cassette

Pickup Roller

Cassette

Feed Roller

Preregistration

Feed Roller

Manual Feed

Pickup Roller

Registration

Feed Roller

Photosensitive

Drum

Drive Transfer

Assembly

Transfer Roller

Fuser Roller

Delivery Rollers

Page 52

Principles of Operation Mechanical Drive - 18

1 Pickup Motor Mechanical Drive (Part 1 of 2)

The drive force generated by the pickup motor is transmitted to the cassette and

preregistration feed rollers and to the cassette feed clutch gear via the pickup drive

assembly. The rotation of the cassette pickup roller is controlled by the cassette feed clutch

gear and the cassette feed solenoid.

Pickup Drive Assembly

Pickup Motor

Preregistation

Feed Roller

Cassette Feed

Clutch Gear

Cassette Feed Solenoid

Cassette Pickup Roller

Cassette Feed Roller20T Idler Gear

Page 53

Principles of Operation Mechanical Drive - 19

2 Pickup Motor Mechanical Drive (Part 2 of 2)

The drive force generated by the pickup motor is also transmitted to the manual feed clutch

gear via the pickup drive assembly. The rotation of the manual feed pickup roller is

controlled by the manual feed clutch gear and the manual feed solenoid.

Manual Feed Solenoid Pickup Motor

Pickup Drive Assembly

Manual Feed Pickup Roller

Manual Feed Clutch Gear

Page 54

Principles of Operation Mechanical Drive - 20

3 Main Motor Mechanical Drive (Part 1 of 3)

The drive force from the main motor is transmitted to the registration feed roller via the

main drive assembly.

Registration Pinch Roller

Registration Feed Roller

Main Drive Assembly

Main Motor

Page 55

Principles of Operation Mechanical Drive - 21

4 Main Motor Mechanical Drive (Part 2 of 3)

The drive force from the main motor is also transmitted throught the main drive assembly

to the photosensitive drum, and from the drum to the transfer roller.

Photosensitive Drum

Main Drive Assembly

Transfer Roller

Main Motor

Page 56

Principles of Operation Mechanical Drive - 22

5 Main Motor Mechanical Drive (Part 3 of 3)

The drive force from the main motor is also transmitted to the fuser roller drive gear and

the delivery assembly drive gear via the drive transfer assembly. When the toner cartridge

is removed, the idler gear opens the path of drive force transmission, thus cutting off

mechanical drive to the fuser assembly.

Toner Cartridge

Delivery Roller Shaft

Delivery Assembly

Drive Gear

Drive Transfer Assembly

Main Drive Assembly

Idler Gear

Fuser Roller

Drive Gear

Fuser Roller

Fuser Assembly

Main Motor

Page 57

Principles of Operation Function of Major Components - 23

Function of Major Components

The function of the major components of the LaserWriter 12/640 PS is briefly described

below. The components are divided into the following seven blocks, which correspond to the

exploded views that appear in the exploded view chapter.

Cassette (Deck 1)

Paper Transport

Fusing and Paper Exit

Drive & Xerographic

Electrical

Frame

Cassette (Deck 1)

Paper Cassette

The cassette holds cut sheets of plain paper. Envelopes must be fed from the multipurpose

tray or the optional envelope cassette, and post cards must be fed from the multipurpose

tray.

The cassette has an adjustable paper guide at the left rear. By adjusting this rear paper

guide to the size of the paper used, individual actuator tabs on the left side of the cassette are

engaged, thereby actuating the corresponding microswitch on the cassette sizing assembly

board.

The cassette has a slot that allows passage of paper from the optional lower deck.

Cassette Sizing Assembly

Three paper size microswitches and the leaf spring actuator are mounted onto the cassette

size assembly printed circuit board.

Each microswitch is on when it is being pressed by the spring actuator. The size of paper

(or a no-cassette-present state) is detected by the combination of on and off switches.

Page 58

Principles of Operation Function of Major Components - 24

Cassette (Deck 1)

Paper Cassette

Cassette Sizing Assembly

Microswitches

Leaf Spring Actuator

Page 59

Principles of Operation Function of Major Components - 25

Paper Transport (1 of 2)

Pickup Drive Assembly

The pickup drive assembly is responsible for mechanical drive to the cassette and manual

feed pickup rollers and to the cassette and preregistration feed rollers. It is powered by the

pickup motor. Contained within the assembly itself are the two feed rollers and the cassette

feed solenoid.

Main Drive Assembly

The main drive assembly is responsible for all mechanical drive from the registration

roller through paper delivery. It is powered by the main motor.

Drive Transfer Assembly

The drive transfer assembly is the gear train that transfers mechanical drive from the

main motor to the fuser assembly, delivery roller shaft, and photosensitive drum. An idler

gear is located along the path of the drive force transmission to the fuser. The idler gear

closes the path when the toner cartridge is installed

Registration Feed Roller

The registration feed roller, which is driven by the operation of the main drive assembly,

feeds paper in concert with the registration pinch roller. The pinch roller is spring-loaded

but passive. It receives no mechanical drive.

Registration Sensor/Actuator

The registration sensor is mounted to the power supply assembly. The registration actuator

is mounted to the frame. The sensor detects when paper reaches the registration position.

The signal of the registration sensor is used to position paper in synch with the toner image

on the drum.

Preregistration Sensor/Actuator

The preregistration sensor is mounted to the power supply assembly. The actuator is

mounted to the chute registration assembly. The preregistration sensor detects when paper

reaches the preregistration position.

Paper Deflector Solenoid

Switches the direction of the paper deflector guide.

Paper Deflector Guide

This guide is on the delivery side of the fuser. It controls whether paper passes into the

duplexer/face-up tray or outward onto the output tray.

Page 60

Principles of Operation Function of Major Components - 26

Paper Transport (1 of 2)

Registration Pinch Roller

Main Drive Assembly

Registration Feed Roller

Paper Deflector Solenoid

Main Motor

Pickup Motor

Preregistration Feed Roller

Cassette Feed Roller

Pickup Drive Assembly

Cassette Feed Solenoid

Preregistration

Actuator A

Preregistration

Actuator B

Cassette Pickup Roller

Registration

Feed Roller

Paper Deflector Guide

Registration Actuator

Registration Sensor

Registration

Pressure Roller

Preregistration Pinch Roller

Preregistration Feed Roller

Cassette Pinch Roller

Cassette Feed Roller

Cassette Pickup Roller

Page 61

Principles of Operation Function of Major Components - 27

Paper Transport (2 of 2)

Multipurpose Frame Assembly

The multipurpose frame assembly includes the manual feed solenoid, manual feed clutch

gear, manual feed pickup roller, separation pad, and the manual feed paper-present sensor

and actuator.

Page 62

Principles of Operation Function of Major Components - 28

Paper Transport (2 of 2)

Manual Feed Solenoid

Manual Feed

Clutch Gear

Manual Feed Paper-Present

Actuator

Manual Feed Paper-Present

Sensor

Multipurpose Frame

Assembly

Manual Feed Pickup Roller

Separation Pad

Page 63

Principles of Operation Function of Major Components - 29

Fusing and Paper Exit

Fuser Assembly

The major parts contained within the fuser assembly include the fuser heater bulb, fuser

roller, thermostat, fuse, and temperature sensor assembly.

The fuser heater bulb is located inside the fuser roller. Power to the bulb is switched on

and off so that the temperature of the fuser roller surface is kept constant. When the

temperature of the fuser rises to the predetermined upper limit temperature, the power

supply is switched off. This safeguard is known as first-stage overheat protection.

The fuser roller applies the heat for melting and fusing the toner to paper. It is connected to

the frame ground through a diode so that negative charge flows, thereby preventing the

toner image from being disturbed during the fusing process.

The thermostat is a part of the fuser bulb circuit and provides the second-stage overheat

protection. If the first-stage overheat protection fails to prevent overheat and the

thermostat reaches the predetermined temperature, the contacts of the thermostat open to

break the circuit between the fuser bulb and the power supply.

The fuse is also a part of the fuser bulb circuit and provides the third-stage overheat

protection. If the first and second stage protection both fail to prevent overheat and the fuse

reaches the predetermined temperature, the fuse melts to open the circuit between the

fuser and the power supply.

The temperature sensor is a resistor whose resistance varies rapidly with temperature. It

is positioned in contact with the surface of the fuser roller. Power to the fuser bulb is

switched on and off so that the temperature of the surface of the fuser roller is kept

constant.

Fuser Pressure Roller

The fuser pressure roller is a sponge roller covered with a tube. It is located beneath the

fuser assembly and is spring-loaded to apply pressure against the fuser roller as paper

passes. The fuser pressure roller is not mechanically driven.

Fuser Exit Sensor/Actuator

The fuser exit sensor is actuated as paper exits the fuser assembly but before paper reaches

the paper deflector guide.

Delivery Sensor/Actuators

The delivery sensor is actuated as paper reaches the delivery rollers.

Delivery Roller Shaft

The delivery roller shaft holds three fixed delivery rollers that feed paper through to the

output tray on the top of the printer.

Page 64

Principles of Operation Function of Major Components - 30

Fusing and Paper Exit

Fuser Exit Actuator

Delivery Rollers

Fuser Assembly

Fuser Exit Sensor

Temperature

Sensor Assembly

Fuser Roller

Pressure Roller

Fuser Roller

Thermostat

Fuse

Heater Bulb

Fuser Exit

Pinch Roller

Pressure Roller

Fuser Exit Roller

Page 65

Principles of Operation Function of Major Components - 31

Drive and Xerographic

For full description of the components in this section, see the “Print Image Creation” topic.

Laser/Scanner Assembly

The laser/scanner assembly includes the laser diode, scanner, lenses, and mirrors.

Note

: The laser/scanner assembly is a precision optical system. Never open the

cover. Touching the parts may result in permanent damage to the components.

Mirror Assembly

The mirror assembly includes the start-of-scan sensor (SOS) and the stationary mirror

that reflects the beam from the scanner mirror onto the photosensitive drum.

Toner Cartridge

The toner cartridge consists of a photosensitive drum and a toner container integrated into

one unit. It includes the following major components.

Photosensitive Drum

Bias Charge Roller (BCR)

Attraction Roller

Charging and Metering Blade (CMB)

Cleaning Blade

Laser Shutter

Transfer Roller

Page 66

Principles of Operation Function of Major Components - 32

Drive and Xerographic (1 of 2).

Mirror Assembly

Toner Cartridge

Latch Shaft

Laser/Scanner Assembly

Spring

Lever Latch

Transfer Roller

Drum Shaft

Toner Cartridge

Flange

Toner Cartridge Latching Mechanism

Page 67

Principles of Operation Function of Major Components - 33

Drive and Xerographic (2 of 2)

Start-of-Scan Sensor (SOS)

Laser Diode

Cylinder Lens

Hexagonal Mirror

Scanner Assembly

Collimator Lens

CM Blade

Lens L1

Bias Charge Roller

Mirror M1

Mirror Assembly

Laser/Scanner Assembly

Toner Cartridge

Shutter

Cleaning Blade

Attraction Roller

Photosensitive

Drum

Page 68

Principles of Operation Function of Major Components - 34

Electrical

Power Supply Assembly

The power supply assembly is a large multifunctional circuit board located in the lower

section of the engine. Listed below are its major components.

Low-voltage power supply (LVPS): The LVPS generates stabilized DC voltages of 5 V,

12 V, and 24 V and supplies these voltages to the electrical components of the printer.

High-voltage power supply (HVPS): The HVPS generates AC and DC high voltages for

charge, development, transfer, and discharge in the print process. Those voltages are

supplied to the bias charge roller, attraction roller, transfer roller, and detack saw.

Interlock switch: This switch opens the supply circuits of 24 VDC and 5 VDC (+B) for

driving the laser diode.

Cassette paper-present sensor: This sensor is actuated by the cassette paper-present

actuator and detects when the cassette runs out of paper.

Power inlet: The power inlet is hard-wired directly to the circuit board.

DC Controller Board

The DC controller board controls the whole operation of the printer. Listed below are its

major functions:

Communication with the I/O board

Collection of the information from the sensors and switches.

Control of the laser/scanner assembly, fuser assembly, drive assemblies, and

solenoids.

Control of the print sequence.

Distribution of the low DC voltages to electrical components from the power supply

assembly.

Fan

The fan forces the air out of the printer to prevent overheating. There is only one fan in the

LaserWriter 12/640 PS.

Page 69

Principles of Operation Function of Major Components - 35

Electrical

Registration

Sensor

Cassette Paper-

Present Sensor

I/O Controller Board

DC Controller Board

Power

Inlet

Power Supply

Assembly

Fan

Preregistration

Sensor

Interlock Switch

Page 70

Principles of Operation Function of Major Components - 36

Frame

When the top cover closes, the seven events described below take place.

Cover Interlock Actuator

Top cover closure actuates the interlock switch on the power supply assembly. There are

three components that work together to actuate this switch.

Top cover actuator: The thin plastic post built into the top cover.

Spring-loaded actuator: The vertical assembly that transfers actuation downward.

Actuator arm: The arm that contacts the interlock switch on the power supply

assembly.

Laser Shutter

A plastic post built into the top cover extends through a cutout in the top of the laser/

scanner assembly. The laser shutter facing the mirror assembly opens, thus allowing the

laser beam to leave the laser/scanner assembly.

Mirror Assembly Shutter

A plastic post built into the top cover presses open the shutter that covers the mirror

assembly. Unless this shutter and the one above are in an open position, the laser can not

reach the photosensitive drum.

Cover Latch

Two latches on the chassis hook onto the underside of the cover to assure tight closure of the

cover. The right cover latch has an integral spring-loaded plate that is actuated by the top

cover release lever.

Jam Release Plate

The top cover presses against the surface of the jam release plate to the left of the laser/

scanner assembly. In a cover-closed position, this plate presses against the

preregistration pinch roller assembly, resulting in a tight gripping surface for paper feed.

In a cover-open condition, the pinch roller does not grip the paper, thus facilitating

removal of paper jams.

Toner Cartridge Latching Mechanism

Top cover closure actuates a cam mechanism that presses and stabilizes the toner cartridge.

See the “Drive and Xerographic (1 of 2)” illustration.

Fuser Idler Gear Actuation

There is a spring-loaded lever on the drive transfer assembly that controls the position of

the fuser idler gear. When the top cover is closed, this lever is pressed, thus completing

the drive train to the fuser assembly.

Page 71

Principles of Operation Function of Major Components - 37

Frame

Fuser Idler

Gear Actuation

Jam Release Plate Laser

Shutter

Mirror Assembly

Shutter

Toner Cartridge

Latching Mechanism

Cover Interlock

Actuator

Cover

Latch

Interlock Switch

(on Power Supply Assy.)

Actuator Arm

Top Cover Actuator

(Spring-Loaded)

Page 72

Principles of Operation Function of Major Components - 38

General Wiring Diagram

Fuser Assembly

14

J242

-2

P242

J242

To Duplexer or Sheet Feeder

P/J

232

-1

2

P/J

234-1

J2341

Cassette

Feed

Solenoid

Delivery

Sensor

P/J

285

33

Cassette Size

Sensing Assembly

Cassette Size

Microswitch

P/J234 P/J236

2

P/J

234-2

J2342

Manual

Feed

Solenoid

236-1

J236-2

236-3

Manual Feed

Paper-Present

Sensor

3

P/J

P/J

Fuser Exit

Sensor

P/J

281

P231

P/J

28

7

P/J

15

23

DC Controller

Thermistor

STS2 STS1

22

J292

P/J291

P/J29

P/J

26

21

Board

P/J

26

Fuser Heater

2

P/J11

Main

Switch

Cover

Interlock

Switch

Preregistration

Sensor

Registration

Sensor

Cassette Paper-

Present Sensor

Power Supply

Assembly

Laser/Scanner

Assembly

7

4

P/J

262

P/J

261

Laser

Diode

Scanner

Motor

N

L

Inlet

FG

P/J

222

P/J

221

Fan

Toner

Cartridge

(not used)

M

Pickup Motor

M

Main Motor

6

P/J

24

6

P/J

25

26

P/J

30

P/J

22

3

P/J

Start-of-Scan

301

3

Sensor

Paper Deflector

Solenoid

P/J 31

I/O Board

Page 73

Principles of Operation Function of Major Components - 39

Ports

LocalTalk

Port

Ethernet Port

Communication Switch

Parallel Port

Page 74

K

Service Source

Troubleshooting

LaserWriter 12/640 PS

Page 75

Troubleshooting About the Status Panel - 1

About the Status Panel

The LaserWriter 12/640 PS has a status panel that consists of

three LEDs. The status reported through the LEDs is generated by

the I/O controller board based upon signals that the board receives

Ready

Paper

Out

Paper

Jam

from the printer sensing system and other engine monitoring

mechanisms. There are two types of reporting.

• End-user reporting consists of LED arrays that can be

observed by end users without need of special tools. This type of

reporting can be broken down into POST and PostScript

reporting (see following topics).

• Service technician reporting consists of LED arrays that can

only be observed through the use of a special tool. This

reporting is also referred to as EPOST (see topic later in this

chapter). Whereas end-user reporting can help you in

troubleshooting over the phone, EPOST requires that you be at

the printer location.

Page 76

Troubleshooting POST (Power-On Self Test) - 2

POST (Power-On Self Test)

When you switch on power, all the status panel LEDs illuminate

briefly. This confirms that power is getting to the status panel and

that all LEDs are operational. All LEDs then extinguish and come

back on. This marks the start of POST.

POST is a set of diagnostic procedures that are written into

firmware on the I/O controller board. POST executes in the first

10 seconds of startup and checks the following three areas of the

printer in order:

• Stage 1 I/O controller (ROM & SIMMs)

• Stage 2 I/O controller (miscellaneous circuitry)

• Stage 3 D/C controller board

Page 77

Troubleshooting POST (Power-On Self Test)/Stage Failure/POST - 3

Stage Failure/POST

POST extinguishes the LEDs from top to bottom as each test stage

passes. (The Ready LED is considered here to be the top LED). In a

POST Example

functional printer, the testing process takes about 40 seconds,

after which control passes to PostScript code in ROM and the

normal warm-up continues (see “PostScript Reporting” in this

chapter).

However, if POST detects a fault during any stage, the status panel

enters an error state and flashes the bottom two LEDs forever.

Making note of the stage from which this error array first

appears can help you choose the modules to bring on a service call.

For example, suppose failure occurs during stage two (only the

top LED had extinguished before the error array appears). This

indicates an I/O board failure, so a replacement board should

definitely accompany you on site.

Page 78

Troubleshooting PostScript Reporting - 4

PostScript Reporting

PostScript reporting starts as soon as POST is completed. Most of

the time, PostScript will report according to the literal

designation of the LED. (For example, the paper-out LED

illuminates when the paper cassette is empty). However, there

are some instances where closer observation is critical in

interpreting the status panel.

• Solid ready light: In some cases, the ready light will illuminate

for as long as 15 seconds before a PostScript fault is reported.

Make sure to wait this extra time for PostScript to execute

before shutting down to perform further troubleshooting.

• Behavior before PostScript error: As with stage-reporting

during POST, it is sometimes necessary to note what occurs

before

following page notes where this is important.

the error array first appears. The chart on the

Page 79

Troubleshooting PostScript Reporting/End-User Error Codes - 5

End-User Error Codes

Array

Description Explanation

Ready LED on

Ready LED flashes Printer is warming up or processing a job 1.

Paper-Out and

Paper-Jam LEDs

flash

All LEDs off

Paper-Out LED

illuminates

Paper-Jam LED

illuminates

Paper-Jam LED

flashes

Printer is ready

An error has been detected in POST. Observation

of LED behavior prior to this array can isolate the

fault to one of three general area (see "POST") 2.

The top cover is open.

No paper or cassette is not installed 3.

Paper is jammed in printer or toner cartridge

is missing 4.

Laser/scanner assembly error.

1

If the ready LED flashes forever, turn off the printer, disconnect it from the

network, and restart the printer. If the flashing does not recur, the problem

is most likely with networking or host computer software. If the flashing occurs

with a stand-alone printer, a faulty fan may be the problem.

2

If this array is preceded by the following behavior, the problem is likely with

the fuser assembly: ready LED comes on; ready LED flashes; fan comes on; and

paper for startup page is picked up but jams in the printer.

3

In some cases, this array can result from a faulty scanner motor or main motor.

4

For some residual paper jams (for example, where a jam exists in the delivery

area at time of startup), the printer may exhibit a ready state to the point where

the fan will come on and the paper for the startup page is picked up.

Page 80

Troubleshooting EPOST (Extended Power-On Self Test) - 6

EPOST (Extended Power-On Self Test)

EPOST behaves exactly like POST in that it checks the same three

areas in the same order and displays an error array if a fault is

detected. However, EPOST has more extensive testing and its error

arrays are completely different. When a fault is detected during

EPOST, all LEDs extinguish and the status panel will loop through

the following sequence until you switch off power:

•

All LEDs On

•

All LEDs Off

•

EPOST Error Code

•

All LEDs Off

If no error is detected by EPOST, an EPOST test page will print

before control is passed on to the PostScript interpreter (if a

duplex unit is attached, two double-sided pages will print).

for approximately one second

for approximately one second

for approximately one second

for approximately two seconds, then repeat loop

Page 81

Troubleshooting EPOST (Extended Power-On Self Test) - 7

Initiating EPOST

To initiate EPOST, you must have the printer rollback test plug

(P/N 922-1489). This test plug is colored bright green to

differentiate it from the older version black plug. Do not use the

black plug on the LaserWriter 12/640 PS. It won’t harm

anything; it just won’t work.

Switch off the printer and install the test plug into the LocalTalk

port on the back of the I/O controller board. Switch the printer

back on.

Page 82

Troubleshooting EPOST (Extended Power-On Self Test) - 8

Stage Failure/EPOST

An EPOST error code can either illuminate solidly (for I/O

controller failures) or flash (for engine failures). The chart on

the next page shows the possible error arrays. The “EPOST

EPOST Example 1

EPOST Example 2

Example” animations demonstrate two of the combinations.

The “Example 1” animation simulates an I/O board error. Notice

how the EPOST announcement sequence (all LEDs on for a second

then all LEDs off for a second) is followed by a paper jam LED that

illuminates solidly for about a second.

The “Example 2” animation simulates a DC controller board

error. Notice how the EPOST announcement sequence is followed

by a paper jam LED that flashes for about a second.

Page 83

Troubleshooting EPOST (Extended Power-On Self Test)/EPOST Error Codes - 9

EPOST Error Codes

All LEDs on for a second, then off for a second, followed by a

one-second display of...

...Solid Jam LED

= I/O Controller Board Error

...Solid Jam & Out LEDs

= ROM (I/O Controller) Error

...Solid Ready LED

= General SIMM Error

...Solid Ready & Jam LEDs

= SIMM (A/B) Error

...Solid Ready & Out LEDs

= SIMM (C/D) Error

FLASH

FLASH

FLASH

FLASH

FLASH

FLASH

FLASH

FLASH

FLASH

...Flashing Jam LED

= DC Controller Board Error

...Flashing Out LED

= Fuser Assembly Error

...Flashing Jam & Out LEDs

= Laser/Scanner Error

...Flashing Ready LED

= Fan Error

...Flashing Ready & Jam LEDs

= Miscellaneous Engine Error*

...Flashing Ready & Out LEDs

= Duplexer Error

FLASH

FLASH

FLASH

*

Miscellaneous engine error includes paper jams, top lid open, missing paper

cassette, no paper, or duplexer open.

...All Three LEDs Flashing

= Toner Cartridge Missing

Note: Always check for paper jams when a miscellaneous engine error occurs.

Many times paper is picked up to do a test print and an error occurs. When

you restart, the test will detect the paper jam first if the jam has not been

removed.

Page 84

Troubleshooting Cleaning the Mirror - 10

Cleaning the Mirror

There is a small peach-colored square cleaner built into the

mirror assembly. Slide this square back and forth to remove

particles from the mirror.

Mirror

Cleaner

Page 85

Troubleshooting Duplexer Jams - 11

Duplexer Jams

The paper guide provided with the duplexer

during setup. (Refer users to page 137 of the user manual). If you

must

be installed

Paper Guide

Page 86

Troubleshooting Duplexer Jams - 12

fail to install this guide properly, jamming will frequently occur

as paper enters the duplexer from the printer. Be sure that the

two locking connectors are also fully snapped into place.

Locking Connectors

Page 87

Troubleshooting Duplexer Jams - 13

If accordion-style jamming still occurs in the duplexer after

proper installation of the paper guide, replace the vertical

duplexer assembly (P/N 922-2001)

Page 88

Troubleshooting Printing with 8.3 Driver/EPOST Error Codes - 14

Printing with 8.3 Driver

For purposes of troubleshooting paper feed, you can print with the

LaserWriter 8.3 driver from Mac OS computers. Simply copy the

PPD for the LaserWriter 12/640 PS into the Printer

Descriptions folder in the System Folder, select the printer

through the Chooser, and click on Setup.

You can print duplex jobs by clicking on the Options button in the

print dialog and making the appropriate selection. However, you

cannot print to the face-up tray with the 8.3 driver.

Note

: The LaserWriter 12/640 PS PPD is available on the June

1996 Service Source CD (path: Service Source:Service

Manuals:Clips).

Page 89

Troubleshooting Out of Paper in Multipurpose Tray - 15

Out of Paper in Multipurpose Tray

If you are trying to print from the standard cassette and get an

error message saying that there is no paper in the multipurpose

tray, the problem may be in cassette setup.

There is a paper-length guide at the end of the cassette that must

be adjusted for letter size paper (the position as shipped is for A4

paper). When the AutoSelect feature built into PostScript

searches for letter size paper, the cassette will be passed over and

the controller assumes that the paper should be in the

multipurpose tray.

To rectify this situation, make sure that the length guide is

adjusted for letter size paper, see the next page for the graphic.

Page 90

Troubleshooting Out of Paper in Multipurpose Tray/EPOST Error Codes - 16

.

Length Guide

in Letter Position

Page 91

Troubleshooting Multipurpose Tray Paper Jams - 1 7

Multipurpose Tray Paper Jams

There have been a number of reported problems with the

multipurpose tray and its associated components. In the process of

resolving these problems, service providers may inadvertently

dislocate the solenoid flapper or actuator that is responsible for

releasing the multipurpose tray paper pickup roller so that it can

complete its paper pickup cycle. When this occurs the paper

pickup roller rotates constantly resulting in paper jams (if paper

is present) and annoying noises whenever the printer is being

used. Correcting the problem requires a service call.

Refer to the Multipurpose Tray Paper Jams pdf.

repair procedure.

file for the

Page 92

Troubleshooting Testing the Print Engine without the I/O Board - 18

Testing the Print Engine without the I/O Board

Remove the I/O board. The DC Controller interface connects to the

back of the I/O board. Just below this interface board is a metal

plate which has a grid etched into it. This grid is the key to the

pins located on the interface just above it.

On the DC controller interface, locate the pin marked TP (test

print). Jumper the pin “TP” to one of the pins marked “G”

(ground). Be careful to jumper the correct pins since some pins

carry DC voltage.

You can also try forcing a test print without removing the I/O by

starting with the test print pins (on the I/O board) jumpered, and

then applying power. If you start with the pins jumpered before

turning the printer on, this should bypass the power-on self test.

Page 93

Troubleshooting False Paper Jam Error with Startup Page - 19

False Paper Jam Error with Startup Page

Symptom:

LaserWriter 12/640 tries to print the startup page. No paper is

picked up. EPOST reports a DC Controller error. When the DC

controller board is replaced, the problem remains. Upon

initiating a service test print, the motor will spin for about a

second and then will stop with no test page output.

Discussion

in the shield that covers the pickup drive assembly, and initiate a

service test print. You should see the pickup motor spin, and about

a second later see the solenoid trigger. If it does not, you either

have a bad solenoid, bad cassette size sensor board, or a bad cable

that runs between the solenoid and the sensor board. In the case of

the bad cassette size sensor board, it can cause EPOST to display a

DC controller error.

A false paper jam error occurs when the

: Observe the pickup solenoid through the small hole

Page 94

Troubleshooting Print Quality Problems - 1

Image Quality Problems

It can be easily determined whether an image quality problem is being caused by the print engine or by the

I/O controller board by producing a service test page. The service test page can be generated by jumpering the two pins of connector J101 on the I/O controller board.

If the test page is normal, but the regular prints have an image quality problem, the problem is probably

with the I/O controller board. If the test print has also the image quality problem, the problem is probably

in the print engine.

When troubleshooting an image problem, produce a test print using letter size or A4 paper, exactly identify the symptom, and isolate the problem by referencing the accompanying troubleshooting tables.

If the tables do not lead you to a solution to the problem, examine each part listed in the initial analysis of

the table corresponding to the problem. The fault is probably among those parts. Replace the part or parts

that in your judgment will most likely resolve the problem.

Roller Diameters

For a listing of the diameters of the rollers in the LaserWriter 12/640 PS, see page 13 in the Principles of

Operation chapter. Knowing these diameters can assist in troubleshooting repetitive horizontal print

defects.

List of Troubleshooting Tables

The troubleshooting tables cover the following typical fourteen image quality problems:

Table P-1 Light Prints

Table P-2 Blank Prints

Table P-3 Black Prints

Table P-4 Vertical Band Deletions

Table P-5 Horizontal Band Deletions

Table P-6 Vertical Streaks

Table P-7 Horizontal Streaks

Table P-8 Spot Deletions

Table P-9 Spots

Table P-10 Residual Image

Table P-11 Background

Table P-12 Skewed Image

Table P-13 Damaged Prints

Table P-14 Unfused Image

Table P-15 No PhotoGrade

Table P-16 No Duplex Printing

Table P-17 Duplex Page Upside-Down

Table P-18 No Multipurpose Tray Printing

Note : Vertical refers to the direction of paper travel. Horizontal refers to the direction perpendicular to

the direction of paper travel.

Page 95

1

2

3

4

5

6

7

8

Troubleshooting Print Quality Problems - 2

P-1 Light Prints

Problem

The overall image density is lighter than normal.

Initial Analysis

Inspect the following components. Are they compatible with your printer version, correctly installed, not damaged, deformed or contaminated, or free of

foreign objects sticking?

• Toner Cartridge • Power Supply Assy • Transfer Roller Assy

• Mirror Assembly • Laser/Scanner Assy • DC Controller Board

• Fuser Assembly • Fuser Pressure Roller • Static Eliminator

• Top Cover

Step Actions and Questions

Paper conditions (moisture, warp, etc.)

Is the problem solved if you use new sheets of paper?

Toner cartridge

Is the problem solved by replacing the toner cartridge with a

new one?

Dirty reflecting mirror

Is the problem solved if you use the peach-colored slider

(built into the mirror assembly) to wipe the mirror clean?

Drum ground

Is the toner cartridge drum grounded securely?

* Check the drum ground path: drum > drum shaft pin >

Laser beam path

Are there obstructions or contamination on the laser beam

path from the laser/scanner assembly to the Drum?

Transfer roller assembly

Are there foreign objects or contamination on the roller

portion of the transfer roller assembly?

Charging and development

Is the toner image on the drum normally developed?

* Switch off the printer power while the development is in

progress, and visually check the toner image on the drum (the

area upstream of the transfer step).

Action

(When There Is Problem)

Replace the paper. Advise

the customer to stock paper

in a dry place.

Replace the toner cartridge.

Clean the mirror.

Restore the continuity of the

drum ground path.

Remove the obstructions or

contamination.

Replace the transfer roller

assembly.

Go to FIP-2.18 Power

Supply Assy (HV part)

failure.

Transfer

Is the toner image on the drum transferred normally on the

paper?

* Switch off the printer power while the transfer is in

progress, and visually check the toner image on the drum.

Go to FIP-2.18 Power

Supply Assy (HV part)

failure.

Page 96

1

2

3

4

5

6

Troubleshooting Print Quality Problems - 3

P-2 Blank Prints

Problem

The entire print is blank.

Initial Analysis

Inspect the following components. Are they compatible with your printer version,

correctly installed, not damaged, deformed or contaminated, or free of foreign

objects sticking?

• Toner Cartridge • Power Supply Assy • Transfer Roller Assy

• Mirror Assembly • Laser/Scanner Assy • DC Controller Board

• Fuser Assembly • Fuser Pressure Roller • Static Eliminator

• Top Cover

Step Actions and Questions

Toner cartridge

Is the problem solved by replacing the toner cartridge with a

new one?

Drum ground

Is the toner cartridge drum grounded securely?

* Check the drum ground path: drum > drum shaft pin >

Laser beam path

Are there obstructions or contamination on the laser beam

path from the laser/scanner assembly to the Drum?

Transfer roller assembly

Are there foreign objects or contamination on the roller

portion of the transfer roller assembly?

Charging and development

Is the toner image on the drum normally developed?

* Switch off the printer power while the development is in

progress, and visually check the toner image on the drum (the

area upstream of the transfer step).

Transfer

Is the toner image on the drum transferred normally on the

paper?

* Switch off the printer power while the transfer is in

progress, and visually check the toner image on the drum.

Action

(When There Is Problem)

Replace the toner cartridge.

Restore the continuity of the

drum ground path.

Remove the obstructions or

contamination.

Replace the transfer roller

assembly.

Go to FIP-2.18 HV failure.

Go to FIP-2.18 Power

Supply Assy (HV part)

failure.

Page 97

1

2

3

Troubleshooting Print Quality Problems - 4

P-3 Black Prints

Problem

The entire print is black.

Initial Analysis