Page 1

K

Service Source

LaserWriter 10/600 A3+

This printer is an Asia-only product.

Page 2

Table of Contents

Section 1 Introduction

Section 2 Specifications

Section 3 Parts Lists

Section 4 Removal and Replacement Procedures (RRP)

Section 5 Principle of Operation

Section 6 General Procedures and Information

Section 7 Fault Isolation Procedures

Section 8 Installation and Removal

Page 3

LaserWriter 10/600 A3+

Section 1

Introduction

Section Contents

1. About This Manual

1.1 How This Manual Is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Revision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Notational Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.4 OEM-Specific Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.5 Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

2. Associated Documents

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

3. Safety Information

3.1 Safety Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3.2 Laser Beam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

3.3 Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3.4 Driving Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3.5 High Temperature Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3.6 Warning / Caution Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3.6.1 Laser Warning Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3.6.2 High Temperature Caution Label. . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3.6.3 High Voltage Caution Label . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Page 4

Introduction — LaserWriter 10/600 A3+ 1 – 1

1. ABOUT THIS MANU AL

This document serves as a standard service manual of Fuji Xerox Co., Ltd, which contains the

knowledge and information for the maintenance of this printer.

This document was prepared for OEM customers of Fuji Xerox either as a service manual or as

material for preparing their own service manuals of this printer. Other uses of this document are

prohibited.

No portion of this document may be reproduced or used for other purposes without prior consent of

Fuji Xerox.

1.1 How This Manual Is Organized

This manual has eight sections. The contents of the sections are briefly explained below;

Section 1 Introduction

of this manual, related documents, and safety information.

Section 2 Specifications

replacement parts, and the optional devices.

Section 3 Parts List

Section 4 Removal and Replacement Procedures (RRP)

removal and replacement of parts.

Section 5 Principles of Operation

process and the functions of the major components of the printer.

Section 6 General Procedures and Information

in locating the cause of trouble and the operations for using them, and also provides useful

information for troubleshooting such as the location of the connector (plug/jack) and electrical

wiring.

Section 7 Fault Isolation Procedures

it and the maintenance information.

describes general information on this manual such as the organization

describes the specifications of this printer, consumable, periodic

shows the exploded drawings of the printer with lists of the part names.

explains the procedures for the

describes the basic information of this printer such as print

describes the functions for giving assistance

explains the procedures for analysis of trouble to resolve

Section 8 Installation and Removal

explains the installation and removal of the printer.

Page 5

Introduction — LaserWriter 10/600 A3+ 1 – 2

1.2 Revision

The revision of this manual is made in the following manner, and the revised manual is sent when

revisions are made.

(Method of Revision)

s When the entire manual is subject to be revised, the issue number printed on the cover is

increased as Issue 1, Issue 2, Issue 3 and so on.

s Partial revision is made by pages.

s Revised new pages replace old pages or are added to the manual. The modified, added or

deleted parts on the revised pages are clearly indicated with a black bar called "change bar".

| :

This mark is put at the left of the modified, added or deleted parts in the text.

s When a previously revised page is revised again, the change bars of the previous revision are

deleted, and the parts altered by the latest revision are indicated with new change bars.

1.3 Notational Conventions

The following terms are used to indicate the notes during maintenance or added information for the

text.

Warning : Indicates an operating or maintenance procedure, if not strictly observed, it

could result in injury or loss of life.

Caution : Appears before a procedure or work which, if not observed, could result in personal

injury or destruction of equipment.

Note : Emphasizes specific procedure, work, rule, and so on.

Memo : Contains additional information set off from the text.

1.4 OEM-Specific Specification

The OEM customer specific specifications are described on separate pages added after the this

manual.

Page 6

Introduction — LaserWriter 10/600 A3+ 1 – 3

1.5 Abbreviations

This manual contains general and other abbreviations specific for this manual as follows;

ASSY = Assembly

BCR = Bias Charge Roll

CM Blade = Charging & Metering Blade

CRU = Customer Replaceable Unit

DB = Development Bias

DTS = Detack Saw

EP = Electrophotography

H/R = Heat Roll

I/F = Interface

LVPS = Low Voltage Power Supply

MSI = Multi Sheet Inserter

N/P = No Paper

P/H = Paper Handling

PPM = Prints Per Minute

REGI. = Registration

SOS = Start Of Scan

TR = Transfer Roll

2. Associated Documents

AUX = Auxiliary

BTR = Bias Transfer Roll

CR = Charge Roll

CST = Cassette

dpi = Dots per inch

ELEC. = Electric

ESS = Electronic Subsystem

HVPS = High Voltage Power Supply

LD = Laser Diode

MCU = Machine Control Unit

N/F = Normal Force

OPC = Organic Photo Conductor

P/R = Pressure Roll

PWB = Printed Wiring Board

ROS = Raster Output Scanner

TEMP. = Temperature

TRANS. = Transport

There are documents associated with this manual as follows;

s

Operator Manual (Standard Manual)

Describes the operation and handling of this printer.

s

Performance Specifications

Contains the detailed specifications of this printer.

(If some contents of this manual do not agree with the Performance Specifications, follow the

Performance Specifications.)

s

Video Interface Specifications

Describes the video interface specifications of this printer.

s

Spare Parts List

Provides the information on the spare parts of this printer.

Page 7

Introduction — LaserWriter 10/600 A3+ 1 – 4

3. Safety Information

To prevent an accident while working on the printer, strictly observe

described in this manual.

Never conduct dangerous operations or operations not in this manual.

There may be several dangerous things other than those described below, always work with extreme

caution for safety reasons.

warnings

and

cautions

3.1 Safety Components

This printer has safety components to protect from accidents to occur (fuse, thermostat, interlock

switches and so on) and safety component for user operation (cover , panel and so on). They must be

kept in their operational state.

Never modify the printer (especially of the safety components).

3.2 Laser Beam

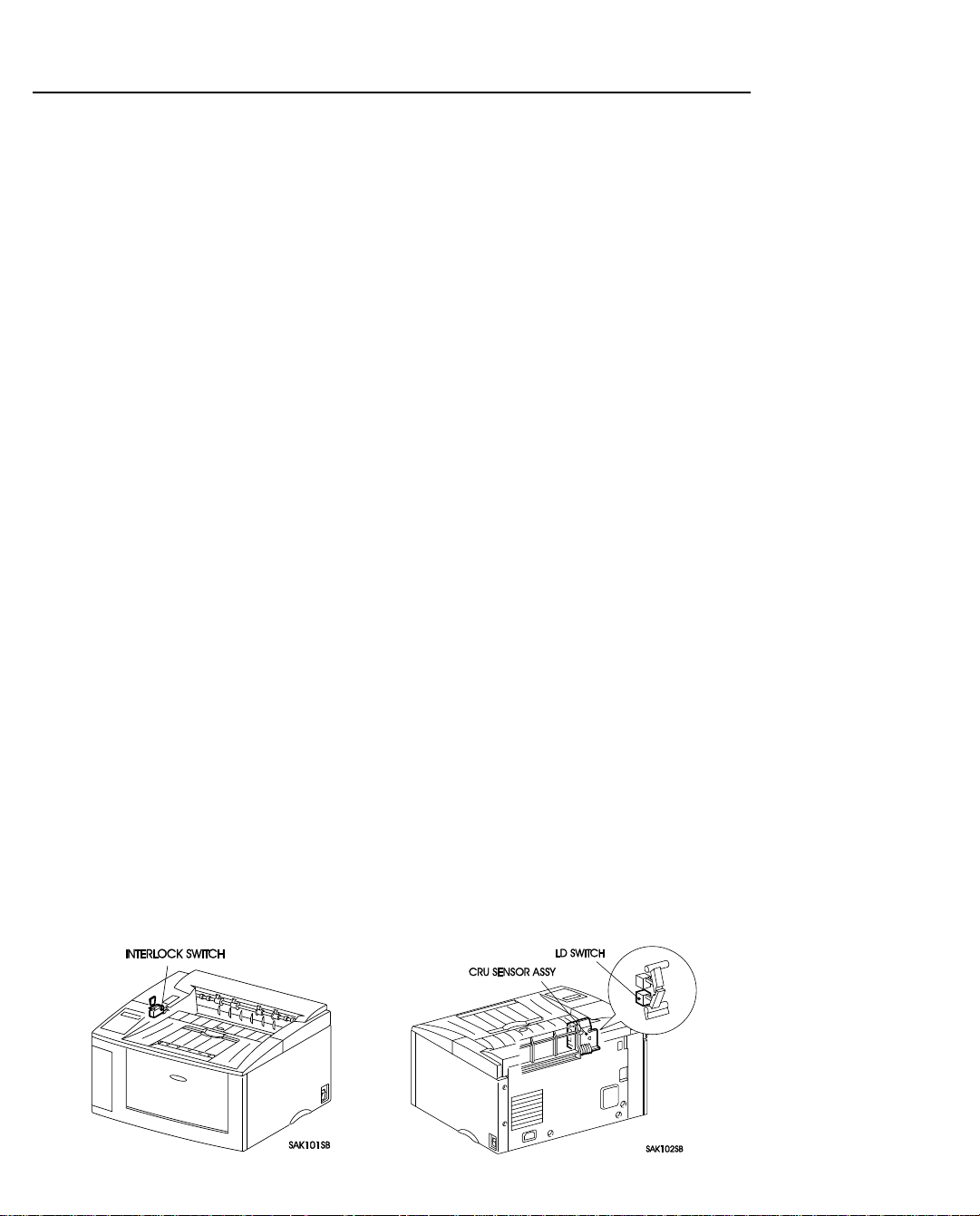

To avoid exposure to the laser beam, this printer is equipped with the two safety switches; Interlock

Switch and CRU Switch in the CR U Sensor Assembly. The Interlock Switch turns OFF when opening covers and stops supply of the power. The CRU Switch cuts the circuit when the EP Cartridge is

removed and stops power supply to the circuit of the output of the laser beam.

Caution : 1. Direct eye exposure to the laser beam may cause eye injury or blindness.

2. Never open the covers in which a warning label on the laser beam is sealed.

3. Switch OFF the printer power when you perform removal and reinstallation of the

printer.

4. Be sure to follow the procedure described in this manual when you work on the

printer during its operation.

5. Remove the EP Cartridge before you press the Interlock Switch by hand or tools during maintenance operation. (Do not turn on the Interlock Switch and CRU Switch at

the same time.)

6. Recognize the character of the laser beam and the dangers that are involved that can

inflict harm to the human body, and take precaution when handling the laser beam in

order to avoid injury to you and those around you.

Note : The laser beam is characterized by a very small range of wave lengths and the similar

phase of waves, in contrast with other light (the light of the sun and that of an electric lamp,

for example). Therefore, the laser beam is monochromatic and has a high focusability, and

can reach long distance in a thin beam. The thin laser beam has a very high energy density

and high temperature and can inflict injury to the human body.

Memo : The laser beam used for this printer is invisible and you cannot see it.

Page 8

Introduction — LaserWriter 10/600 A3+ 1 – 5

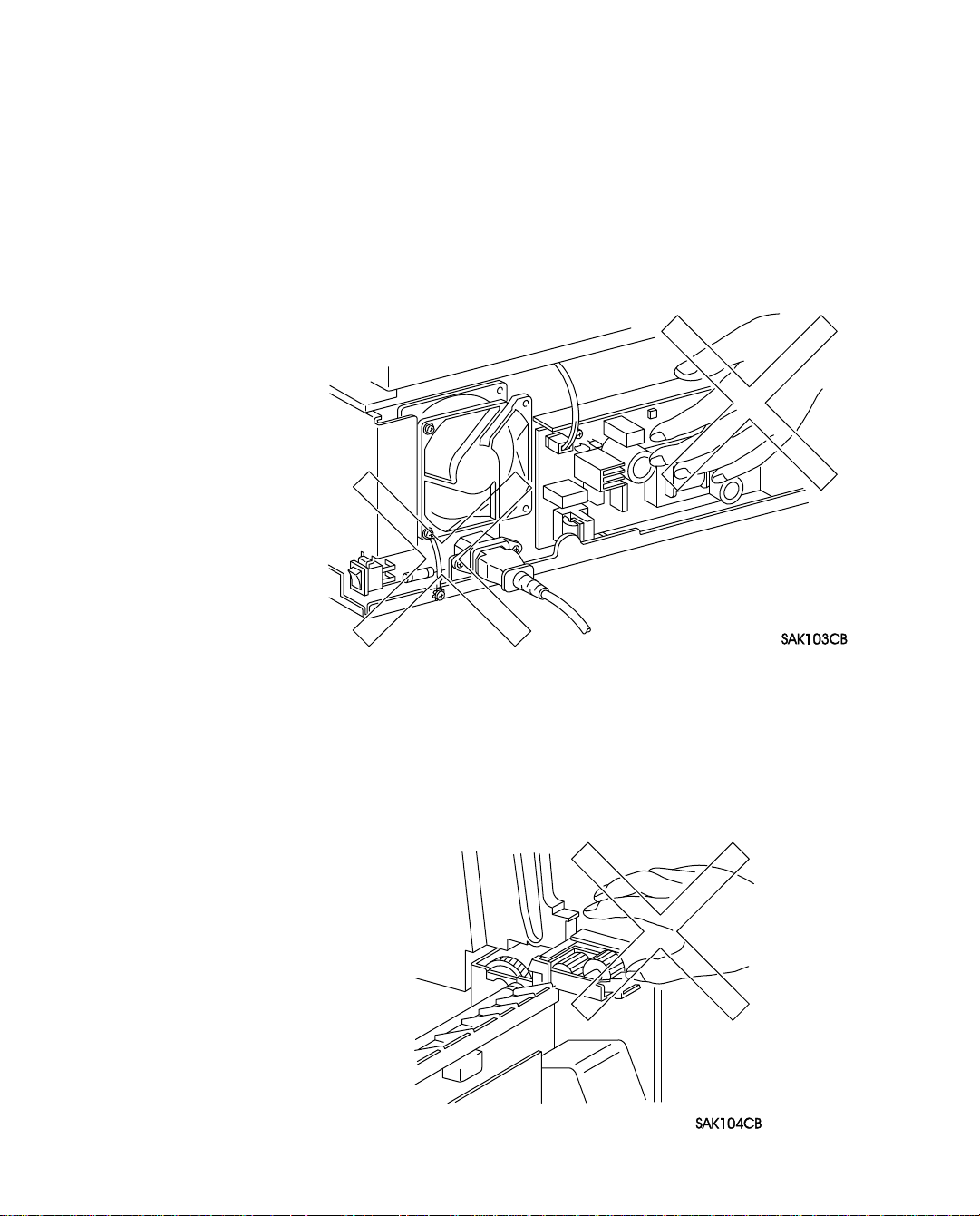

3.3 Power

When working on the printer, be sure to switch off the printer power and unplug the power cord to

avoid electric shock, burn or injury.

When it is necessary to work with the power on such as when measuring the voltage, conduct the

work with great care to avoid an electric shock and follow the procedures described in this manual.

Warning : Do not touch live parts other than those necessary to do so when working on the

printer when power on.

The power switch/inlet section (LVPS Assembly) is supplied with power even if

the power is switched OFF, therefore never touch the live parts.

3.4 Driving Sections

When working on the driving sections such as gears, to avoid injury, make sure to switch the power

OFF, disconnect the power cord, and rotate gears by hand (hand crank).

Warning : Never touch the gears while the printer is in operation.

Page 9

Introduction — LaserWriter 10/600 A3+ 1 – 6

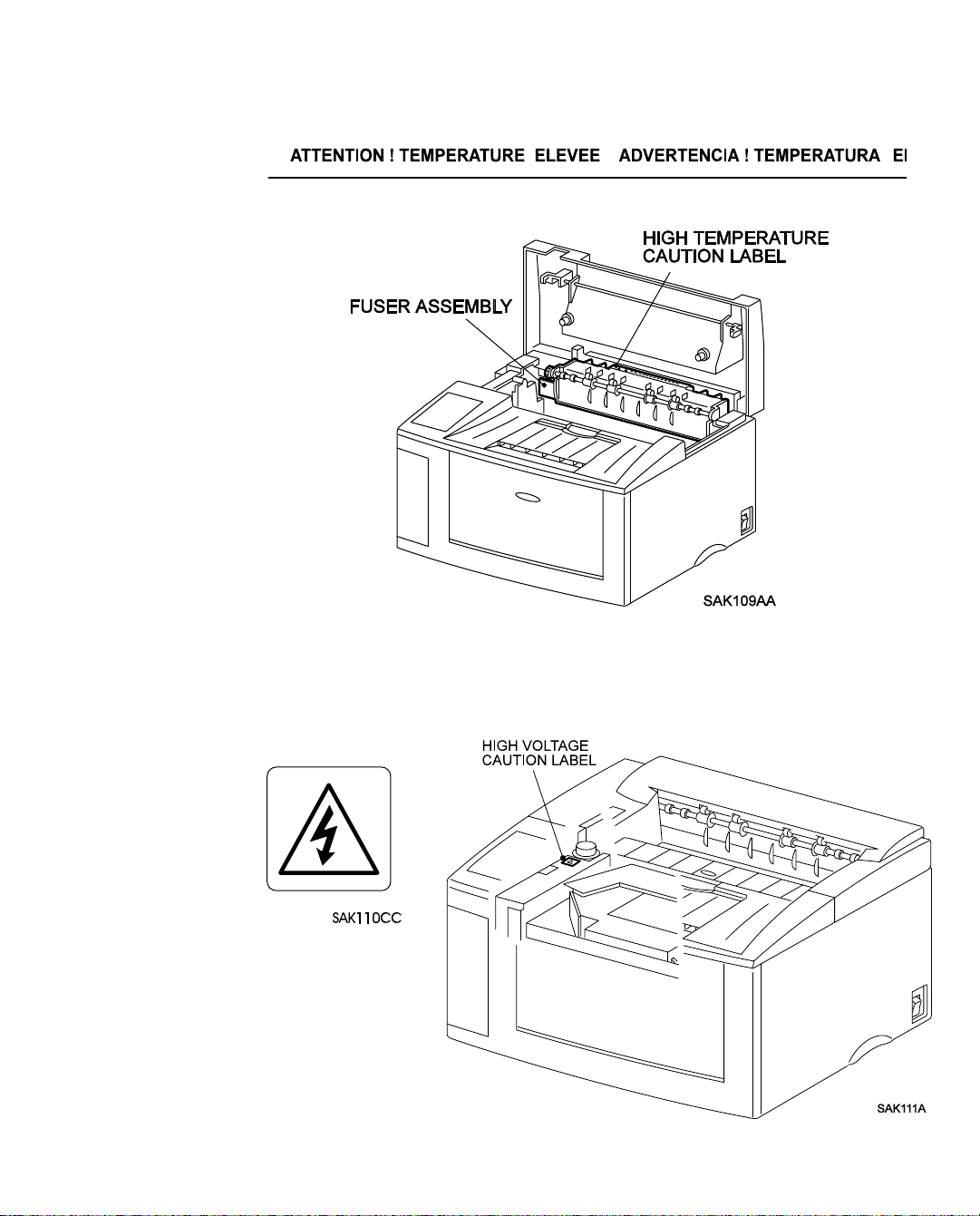

3.5 High Temperature Sections

When working on the high temperature sections such as fuser component, to avoid burn or injury,

make sure to switch the power OFF, disconnect the power cord, and begin to work after the temperature of the component has gone down significantly.

Caution : The temperature is high just after the printer operates, therefore begin to work after let-

ting the component cool down.

3.6 Warning / Caution Labels

Warning and caution labels are sealed on dangerous parts in the printer to warn and prevent accident.

Check whether these labels are firmly sealed in place and are not soiled when performing maintenance or repair.

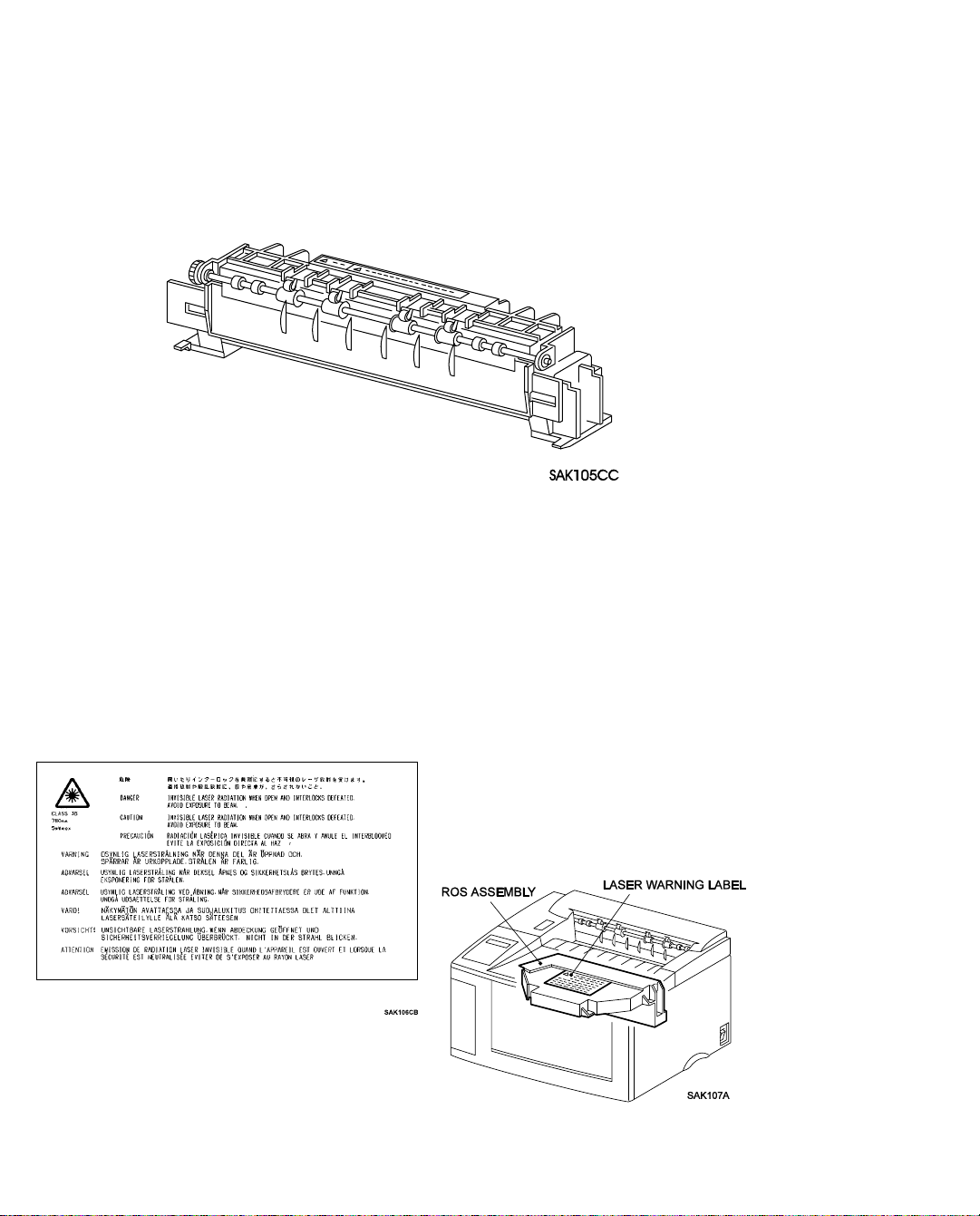

3.6.1 Laser Warning Label

To avoid direct exposure of the laser beam to the engineer, a laser warning label is sealed on top of

the laser output unit (ROS Assembly).

Page 10

Introduction — LaserWriter 10/600 A3+ 1 – 7

3.6.2 High Temperature Caution Label

To avoid burn of customers, caution labels are sealed on top of the fuser unit (Fuser Assembly).

3.6.3 High Voltage Caution Label

To reduce the risk of electric shocks to the engineer, caution labels are sealed on top of the frame

(Main Frame Assembly) which is on top of the high voltage power supply (HVPS)

.

Page 11

LaserWriter 10/600 A3+

Section 2

Specifications

Section Contents

1. Specifications

1.1 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

1.1.1 Basic Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

1.1.2 Functional Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

1.2 Functional Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

1.2.1 Method of Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

1.2.2 Method of Exposing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

1.2.3 Method of Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

1.2.4 Continuous Printing Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

1.2.5 Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

1.2.6 Warm-up Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

1.2.7 Maximum Paper Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

1.2.8 Maximum Printing Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

1.2.9 Maximum Paper held in Output Tray. . . . . . . . . . . . . . . . . . . . . . .2-3

1.2.10 Means for Feeding Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

1.2.11 Maximum Sheets of Feeding Paper . . . . . . . . . . . . . . . . . . . . . . .2-3

1.2.12 Paper Weight Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

1.2.13 Types of Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

1.2.14 Standard Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

1.2.15 Paper Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

1.3 Electric Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

1.3.1 Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

1.3.2 Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

1.4 Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

1.4.1 Dimensions and Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

1.4.2 Space Requirements (Minimum Installation Space) . . . . . . . . . . . . . . .2-6

1.5 Operating Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

1.5.1 Temperature & Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

1.5.2 Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

1.5.3 Horizontal Bias . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

1.5.4 Noise(when the front tray is closed) . . . . . . . . . . . . . . . . . . . . . . .2-7

1.6 Printing Accuracy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Page 12

LaserWriter 10/600 A3+

Section 2

Specifications

2. Consumable

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

3. Parts which require Periodical Replacement

. . . . . . . . . . . . . . 2-8

Page 13

Specifications — LaserWriter 10/600 A3+ 2 – 1

1. Specifications

1.1 Configuration

1.1.1 Basic Configuration

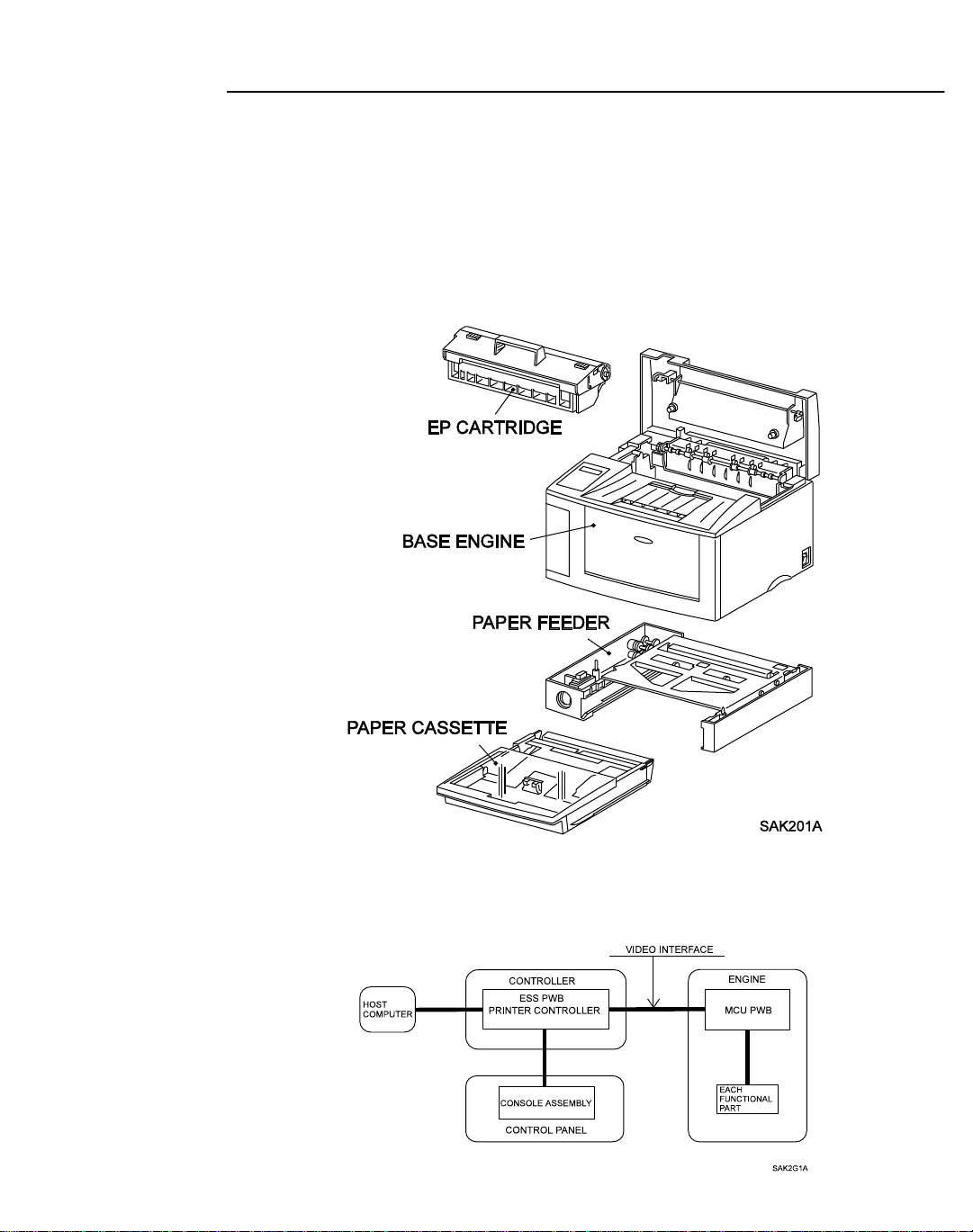

The LaserWriter 10/600 A3+ laser printer has two types of configurations;

• Basic configuration 1 = Base engine + EP cartridge

• Basic configuration 2 = Base engine + EP cartridge + Paper feeder + Paper cassette

Note: The basic configuration 2 includes options.

1.1.2 Functional Configuration

Functional configuration of this printer consists of the engine, controller, and control panel.

Page 14

Specifications — LaserWriter 10/600 A3+ 2 – 2

1.2 Functional Specifications

1.2.1 Method of Printing

Electrophotographic printing

1.2.2 Method of Exposing

Scanning done by light beam of a semiconductor laser

1.2.3 Method of Fusing

Fusing by heat and pressure

1.2.4 Continuous Printing Speed

The speed of printing varies depending on the size of paper.

• LETTER(LEF), A4(LEF), EXECUTIVE(LEF), B5(LEF), A5(LEF),

STATEMENT(LEF), Postcard(SEF), MONARCH(SEF) .......................................10.3PPM

• A4(SEF), LETTER(SEF), B5(SEF), C5(SEF), COM-10(SEF), DL(SEF)...............8.1PPM

• B4(SEF), LEGAL14"(SEF), LEGAL13"(SEF)........................................................6.8PPM

• LEDGER(SEF), A3(SEF)..........................................................................................5.9PPM

• Nonstandard size

The speed of printing determined by the specification of the nonstandard size paper is as follows :

Nonstandard size 1 : 5.2PPM

Nonstandard size 2 : 3.0PPM

Note : 1. The specification for nonstandard size is determined by the OEM contract with Fuji

Xerox.

The nonstandard size 1 is standard specification, and the nonstandard size 2 is a special optional specification which is usually not available.

2. SEF is the abbreviation for Short Edge Feed which means feeding of paper with the

short edge (side) facing the front, and LEF for Long Edge Feed which means feeding of

paper with the long edge (side) facing the front.

When neither SEF nor LEF is indicated, the orientation of paper is SEF.

Memo : PPM stands for Prints Per Minute, that is, the number of paper sheets the printer can

print per minute.

1.2.5 Resolution

• 600 dpi (23.62 dot/mm)

Memo : "dpi" is the abbreviation of dots per inch, that is, the number of dots per inch.

Page 15

Specifications — LaserWriter 10/600 A3+ 2 – 3

1.2.6 Warm-up T ime

The warm-up time consists of the time from when the printer power is turned on to when the printer

is ready to print.

Within 65 seconds when the nominal voltage is applied.

Memo : The Main Motor will start to rotate when the warm-up begins and will stop when the

warm-up is completed.

1.2.7 Maximum Paper Size

• For standard paper, maximum printable paper size is either LEDGER or A3.

• For nonstandard size paper, maximum printable paper size is selected by the specification as

follows (provided that only printing operation is possible);

Nonstandard size 1 : Max. 297.0mm x 508.0 mm

Nonstandard size 2 : Max 297.0mm x 900.00mm

Note : The specification for nonstandard size is determined by the OEM contract with Fuji

Xerox. The nonstandard size 1 is standard specification, and the nonstandard size 2 is

special optional specification which is usually not available.

1.2.8 Maximum Printing Area

4.0 millimeters in from all four sides of the standard paper.

1.2.9 Maximum Paper held in Output Tray

250 sheets of A4 Fuji Xerox standard paper type L at the ambient temperature of 22 oC and humidity of 55%RH.

1.2.10 Means for Feeding Paper

This printer has two types of paper feeds :

• Front tray feeding

Multi-sheet manual feeding from the front tray at the front of the printer.

• Cassette feed (optional)

Feeding from paper cassette installed on the paper feeder.

Note : Maximum of two cassettes can be installed on the paper feeder. Feeding is available with

maximum of three cassettes or trays.

1.2.11 Maximum Sheets of Feeding Paper

• Front tray feeding

Standard paper = 150 sheets, Postcard=75 sheets, Specified envelope=20 sheets

Specified label = 75 sheets, Specified OHP film(transparencies)=75 sheets

• Cassette feeding

Page 16

Specifications — LaserWriter 10/600 A3+ 2 – 4

- Universal Cassette

Standard paper = 250 sheets,Specified label = 20 sheets,

Specified OHP film (transparencies)=20 sheets

1.2.12 Paper Weight Limitations

• Front tray feeding

Normal paper60~135g/m

Postcards190g/m

2

2

• Cassette feeding

Normal paper60~90g/m

2

1.2.13 Types of Paper

Standard paper (cut sheets), postcards, specified envelopes, specified labels and specified OHP

films(transparencies)

1.2.14 Standard Paper

Fuji Xerox L paper (size A4 and A3), XEROX 4024DP (Letter)

1.2.15 Paper Size

Available paper size is selected by the specification of standard paper and the nonstandard paper.

Specifications for standard size :

For front tray feeding, all specified paper sizes are available. Cassette feed can be used for up

to eight types of paper.

• Front tray feeding (19 types of standard size + nonstandard size)

LEDGER(SEF), A3(SEF), B4(SEF), LEGAL14"(SEF), LEGAL13"(SEF), A4(SEF),

LETTER(SEF), LETTER(LEF), A4(LEF), B5(SEF), EXECUTIVE(LEF), B5(LEF),

A5(LEF), STATEMENT(LEF)

Postcard (SEF), C5(SEF), COM-10(SEF), DL(SEF), MONARCH(SEF)

Nonstandard size(See the "Specification for nonstandard size")

• Cassette feeding

- Universal Cassette (8 types)

A3(SEF), B4(SEF), LEGAL14"(SEF), A4(SEF), LETTER(LEF), A4(LEF),

B5(LEF), A5(LEF)

Memo : The dimensions for each paper type are shown below ; (unit : mm)

Standard paper : LEDGER [279.4 x 431.8], A3[297.0 x 420.0],

B4 [257.0 x 364.0],LEGAL14"[215.9 x 355.6],

LEGAL13"[215.9 x 330.2]

A4[210.0 x 297.0], LETTER[215.9 x 279.4]

EXECUTIVE [184.2 x 266.7], B5 [182.0 x 257.0]

A5[149.0 x 210.0], STATEMENT[139.7 x 215.9]

Page 17

Specifications — LaserWriter 10/600 A3+ 2 – 5

Postcard : Postal card [100.0 x 148.0]

Specifications for nonstandard size :

There are two specifications according to the combination of the nonstandard size 1 and 2, that

is, "only nonstandard size 1" and "nonstandard size 1 and 2". The paper size for nonstandard is

determined by the specifications.

• Nonstandard size 1 : Laser beam scanning direction : 86mm~305mm,

Paper feed direction : 90mm~508mm

• Nonstandard size 2 : Laser beam scanning direction : 86mm~305mm,

Paper feed direction : 90mm~900mm

Note : 1. The specification for nonstandard size is determined by the OEM contract with Fuji

Xerox. The nonstandar d size 1 is standard specification, and the nonstandard size 2 is a

special optional specification which is usually not available.

2. This printer can print on nonstandard size paper, while the print quality and the reliability of feeding are out of the scope of the specification.

Page 18

Specifications — LaserWriter 10/600 A3+ 2 – 6

1.3 Electric Specifications

1.3.1 Power Source

Power supply specifications are listed below:

• 220V mode

Voltage : 220/240VAC (198~264VAC), Frequency : 50/60 Hz (47~63Hz)

1.3.2 Power Consumption

The maximum power consumption of the LaserWriter 10/600 A3+ laser printer (not including the

Printer Controller and associated components) during printing and during the Sleep Mode (stops

the power supply to the fuser) are as follows;

• Operating voltage 100VAC : Printing................... 550 watts or less

Sleep mode.............15watts or less

• Operating voltage 120VAC: Printing...................650 watts or less

Sleep mode.............5 watts or less

• Operating voltage 240VAC: Printing...................TBD watts or less

Sleep mode.............TBD watts or less

1.4 Mechanical Specifications

1.4.1 Dimensions and Weight

EP cartridge, Printer Controller, and their attached parts are not included.

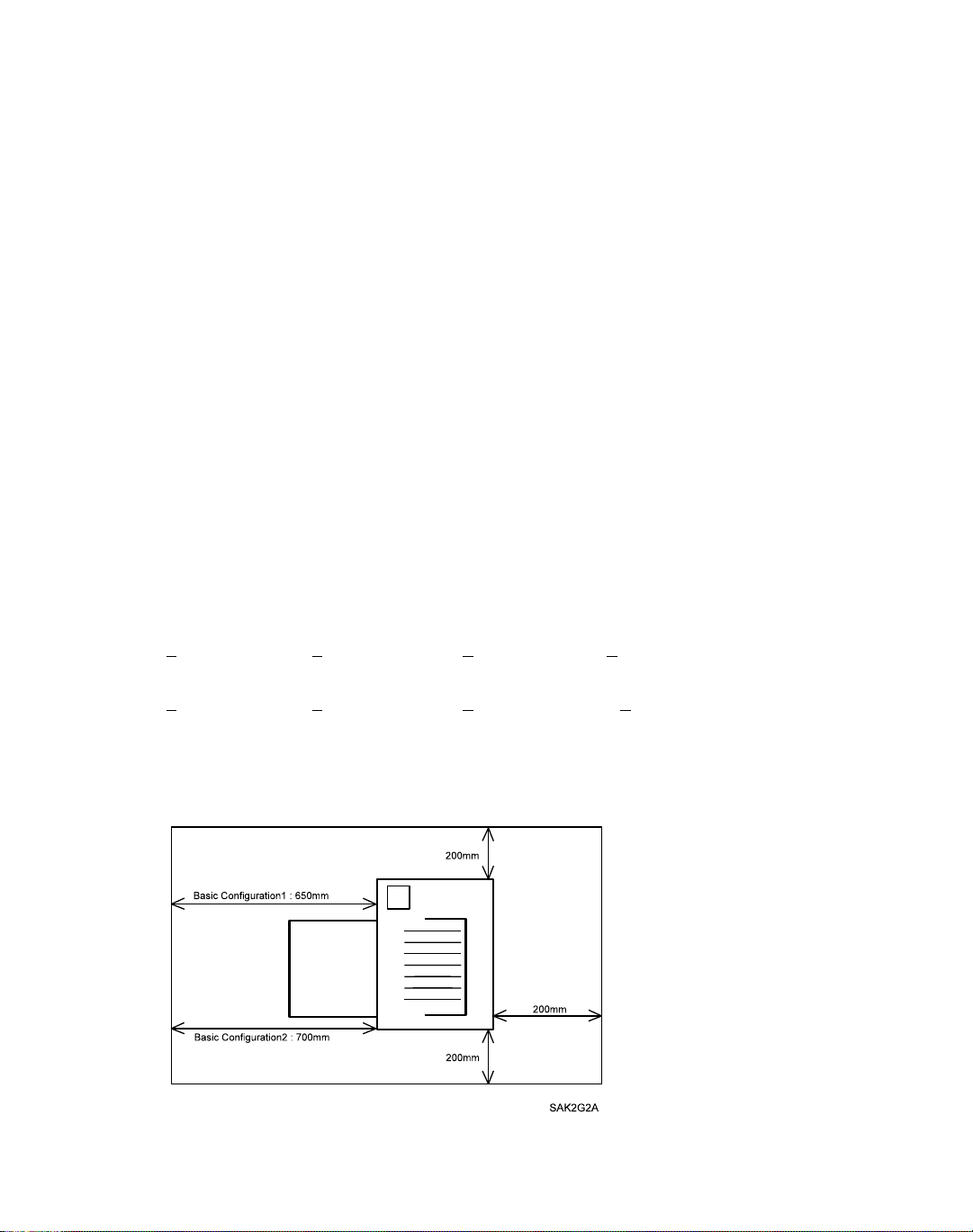

• For Basic configuration 1(Only front tray feeding)

Width : 466 +

• For Basic configuration 2 (with the 1st cassette feeding)

Width : 466 + 5mm,Depth : 497 + 5mm,Height : 324 + 5mm,Weight : 18.5 + 1Kg

1.4.2 Space Requirements (Minimum Installation Space)

400mm minimum overhead clearance

.

5mm,Depth : 386 + 5mm,Height : 257 + 5mm,Weight : 14 + 1Kg

Page 19

Specifications — LaserWriter 10/600 A3+ 2 – 7

1.5 Operating Environment

1.5.1 Temperature & Humidity

5 ~ 35oC / 15 ~ 85%RH (with no dew condensation)

1.5.2 Altitude

0 ~ 2500m

1.5.3 Horizontal Bias

Less than 5oC off level

1.5.4 Noise (when the front tray is closed)

• Machine running : 49.8 dB

• Machine in standby : 32.0 dB

1.6 Printing Accuracy

Memo : For more information, read "How to read Printing Accuracy" in Section 6 of this man-

ual.

• Lead Edge Registration : +

• Side Edge Registration : + 2.5mm or less

•Skew :+ 2.0mm or less (at a width of 245mm)

• Vertical Accuracy : + 1.3mm or less (at a width of 210mm)

• Horizontal Accuracy : + 2.0mm or less

• Linearity in the direction

of paper trave : + 1.0mm or less (at a width of 390mm)

• Magnification accuracy in

the direction of paper trave : 100 + 0.8% or less (at a width of 390mm)

2.0mm or less

(at a width of 245mm and a height of height of 390mm)

Page 20

Specifications — LaserWriter 10/600 A3+ 2 – 8

2. Consumable

Usually customers can replace consumable.

When a consumable causes a trouble, or when trouble is resolved by the replacement of a consum-

able, customer engineer may replace it.

• Paper

See paper specification mentioned in this section.

• EP cartridge

EP cartridge is an integrated unit which includes photoreceptor, black toner, charger, developer, and cleaner.

Note : EP cartridge has an average life of 6000 prints (A4 size (LEF) with 5% image coverage).

The life varies depending on the sensitivity of the photoreceptor and the contents of the

image.

3.Parts which require Periodical Replacement

To avoid trouble, the following units are recommended to be replaced when the printer reaches a

specified number of prints.

• Fuser Assembly : Life=100000 prints

• Pick Up Roll : Life=100000 prints

• Retard Pad Assembly : Life=100000 prints

Note : The life is the number of the prints on standard paper of A4(LEF). Life may decrease by

half when printing on nonstandard size paper or A3 paper.

Memo : The following rollers and parts are considered to wear off with paper;

BTR Assembly, Trans. Chute Assembly, Feed Roll, Turn Roll Assembly

( Standard paper of A4(LEF)

( Standard paper of A4(LEF)

( Standard paper of A4(LEF)

)

)

)

Page 21

LaserWriter 10/600 A3+

Section Contents

1. Parts Lists

Section 3

Parts Lists

1.1 Notes on using Parts Lists

PL1 Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

PL2 Fuser & Paper Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

PL3 Paper Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

PL4 Multi Sheet Inserter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

PL5 Drive & Xerographic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

PL6 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

PL7 250 Feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

PL9 250 Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

2. Parts Reference

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Page 22

LaserWriter 10/600 A3+ 3 – 1

1. Parts Lists

This printer is divided into 10 plates(PL) as shown below according to the specification.

This section provides illustrations for assembly and corresponding part names.

• PL1 Cover • PL6 Electrical

• PL2 Fuser & Paper Exit • PL7 250 Feeder

• PL3 Paper Transportation

• PL4 Multi Sheet Inserter • PL9 250 Cassette

• PL5 Drive & Xerographics

1.1 Notes on using Parts Lists

1. The numbers in illustration correspond to item numbers in the list to find the names of parts.

2. "PLX.Y" indicates that the part is shown as item Y in plate X.

3. The alphabet characters in the illustration represents types of screws or clips ,etc. as follows:

E=Ering, S=Screw ,N=Hexagonal nutt,K=KL clip.

4. The mark t represents the items of assembly parts in the illustration.

5. A circled alphabet character with a line in the illustration indicates the cut of the line at that

point. It is connected to the point of the same alphabet character.

6. "With(2-5)",which is labeled on the assembly part in illustration or list, indicates it includes

item 2,3,4,and 5 of the specific plate. "With(2-5),PL6.7"means it includes item 2,3,4,and 5

of the specific plate and item 7 of the plate 6.

7. Items with $ are recommended parts(recommended spare parts)which principally can be

supplied.(Other items need to be discussed to supply.)

8. Parts with * in the list have "note" or "memo" for reference described on the same page.

9. "

(J1-J2,P3)

ness or wire is the J1 of the connector and another terminal is jack 2 and plug 3 of the connector.

(For the location of connector (P/J),see"Section6.4.Connector Locations.")

10. "High Assembly" in the list indicates upper assembly parts which include the specific parts.

"which is labeled on the harness or wire, etc., indicates one terminal of the har-

Note : 1. For information on spare parts, see "Spare parts lists" issued separately.

2. According to the specification of OEM, configuration may differ and some parts may not

exist.(Especially for "PL5 Electrical", major difference may exist according to the specification.)

Page 23

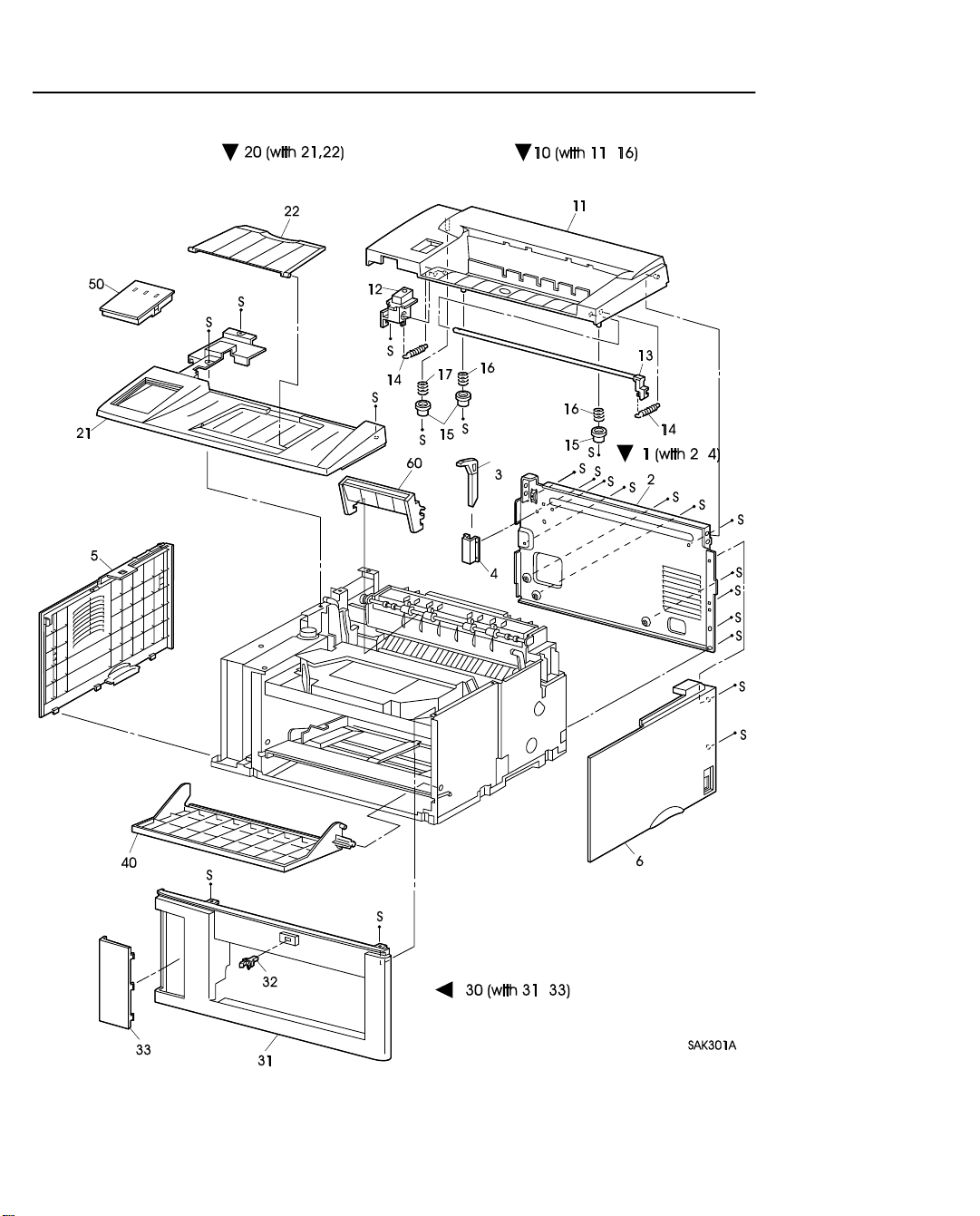

Parts Lists — LaserWriter 10/600 A3+ 3 – 2

PL1 Covers

Page 24

Parts Lists — LaserWriter 10/600 A3+ 3 – 3

PL1 Covers

Item Parts Name High Assembly

1 REAR FRAME ASSEMBLY (with2-4) ..........................................----

2 REAR FRAME................................................................................. PL1.1

3 PUSH LEVER..................................................................................PL1.1

4 LEVER HOLDER............................................................................PL1.1

5 LEFT COVER..................................................................................----

6 RIGHT COVER ...............................................................................----

10 POP UP ASSEMBLY (with11-17) ..................................................----

11 POP UP COVER.............................................................................. PL1.10

12 LATCH BUTTON............................................................................PL1.10

13 LATCH ASSEMBLY.......................................................................PL1.10

14 LATCH SPRING..............................................................................PL1.10

15 CRU STOPPER................................................................................PL1.10

16 STOPPER SPRING..........................................................................PL1.10

17 POP UP SPRING..............................................................................PL1.10

20 TOP COVER ASSEMBLY (with21,22) .........................................----

21 TOP COVER....................................................................................PL1.20

22 TOP TRAY....................................................................................... PL1.20

30 FRONT COVER ASSEMBLY (with31-33)....................................----

31 FRONT COVER...............................................................................PL1.30

32 TRAY LATCH.................................................................................PL1.30

33 GUIDE COVER............................................................................... PL1.30

40 FRONT TRAY ................................................................................ ----

$

50 CONSOLE ASSEMBLY .................................................................----

Page 25

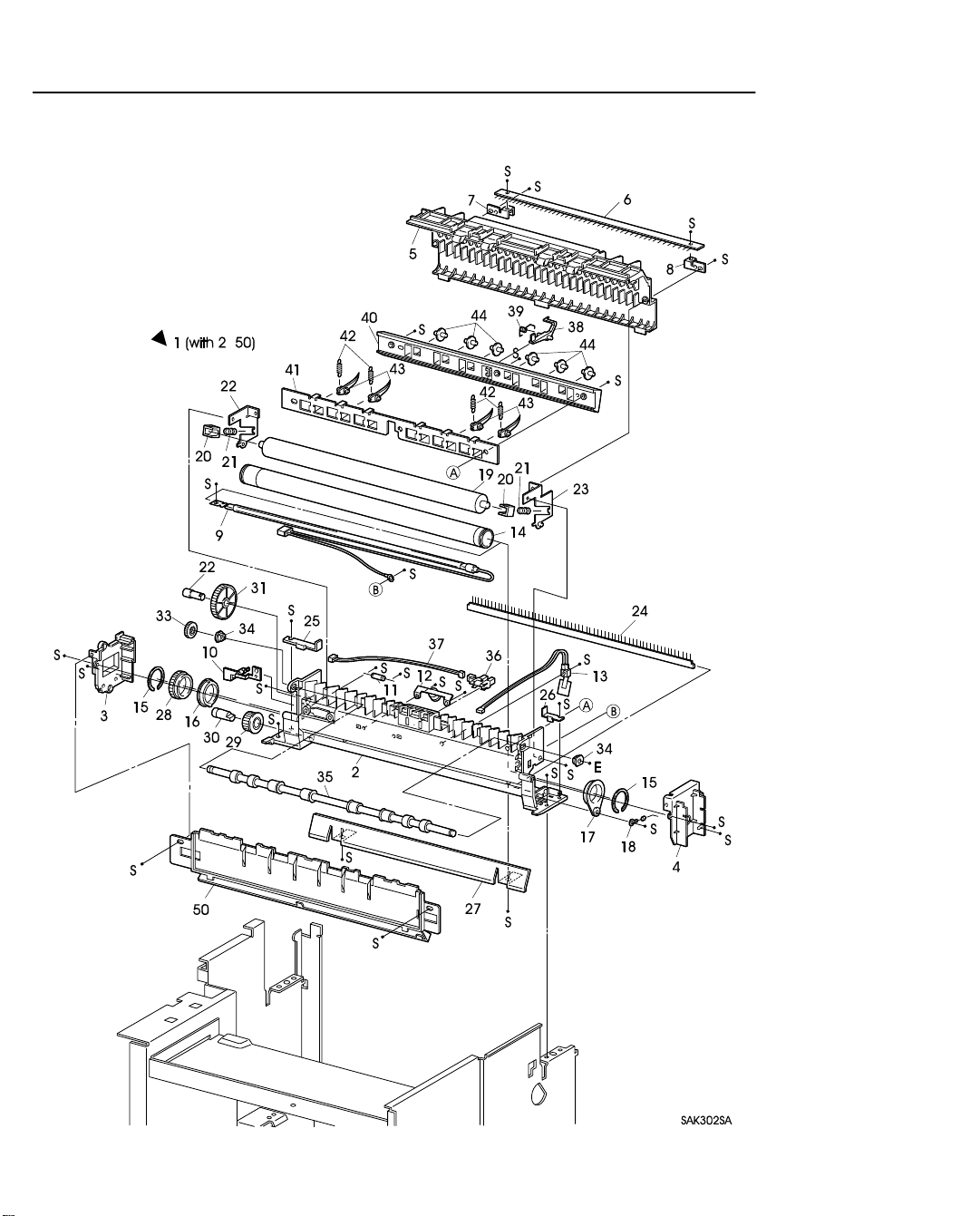

Parts Lists — LaserWriter 10/600 A3+ 3 – 4

PL2 Fuser & Paper Exit

Page 26

Parts Lists — LaserWriter 10/600 A3+ 3 – 5

PL2 Fuser & Paper Exit

Item Parts Name High Assembly

1 FUSER ASSEMBLY (with2-50)*1.................................................----

2 FUSER FRAME ASSEMBLY.........................................................PL2.1

3 FUSER COVER L............................................................................ PL2.1

4 FUSER COVER R............................................................................PL2.1

5 FUSER TOP COVER ASSEMBLY ................................................PL2.1

6 EXIT ELIMINATOR....................................................................... PL2.1

7 ELIMINATOR BRACKET L.......................................................... PL2.1

8 ELIMINATOR BRACKET R..........................................................PL2.1

9 HEATER ROD.................................................................................PL2.1

10 LAMP GUIDE..................................................................................PL2.1

11 THERMAL FUSE............................................................................PL2.1

12 THERMOSTAT ...............................................................................PL2.1

13 TEMPERATURE SENSOR ASSEMBLY ......................................PL2.1

14 HEAT ROLL....................................................................................PL2.1

15 H/R RING......................................................................................... PL2.1

16 H/R BEARING L .............................................................................PL2.1

17 H/R BEARING R.............................................................................PL2.1

18 H/R DIODE......................................................................................PL2.1

19 PRESSURE ROLL...........................................................................PL2.1

20 P/R BEARING .................................................................................PL2.1

21 NIP SPRING.....................................................................................PL2.1

22 NIP LEVER L ..................................................................................PL2.1

23 NIP LEVER R.................................................................................. PL2.1

24 P/R ELIMINATOR ..........................................................................PL2.1

25 P/R EARTH PLATE L.....................................................................PL2.1

26 P/R EARTH PLATE R..................................................................... PL2.1

27 FUSER INLET CHUTE...................................................................PL2.1

28 H/R GEAR........................................................................................PL2.1

29 H/R IDLER GEAR...........................................................................PL2.1

30 H/R IDLER SHAFT.........................................................................PL2.1

31 EXIT IDLER GEAR ........................................................................PL2.1

32 EXIT IDLER SHAHT......................................................................PL2.1

33 EXIT GEAR..................................................................................... PL2.1

34 EXIT BEARING ..............................................................................PL2.1

35 EXIT ROLL ASSEMBLY ...............................................................PL2.1

36 EXIT SENSOR................................................................................. PL2.1

37 EXIT HARNESS (J152-J153).......................................................... PL2.1

38 EXIT ACTUATOR ..........................................................................PL2.1

39 EXIT TORSION SPRING................................................................PL2.1

40 EXIT CHUTE................................................................................... PL2.1

41 FINGER BRACKET........................................................................PL2.1

42 FINGER SPRING.............................................................................PL2.1

43 H/R FINGER....................................................................................PL2.1

44 EXIT CHUTE ROLL .......................................................................PL2.1

50 EXIT COVER...................................................................................PL2.1

*1

: Periodic Replacement Parts

Page 27

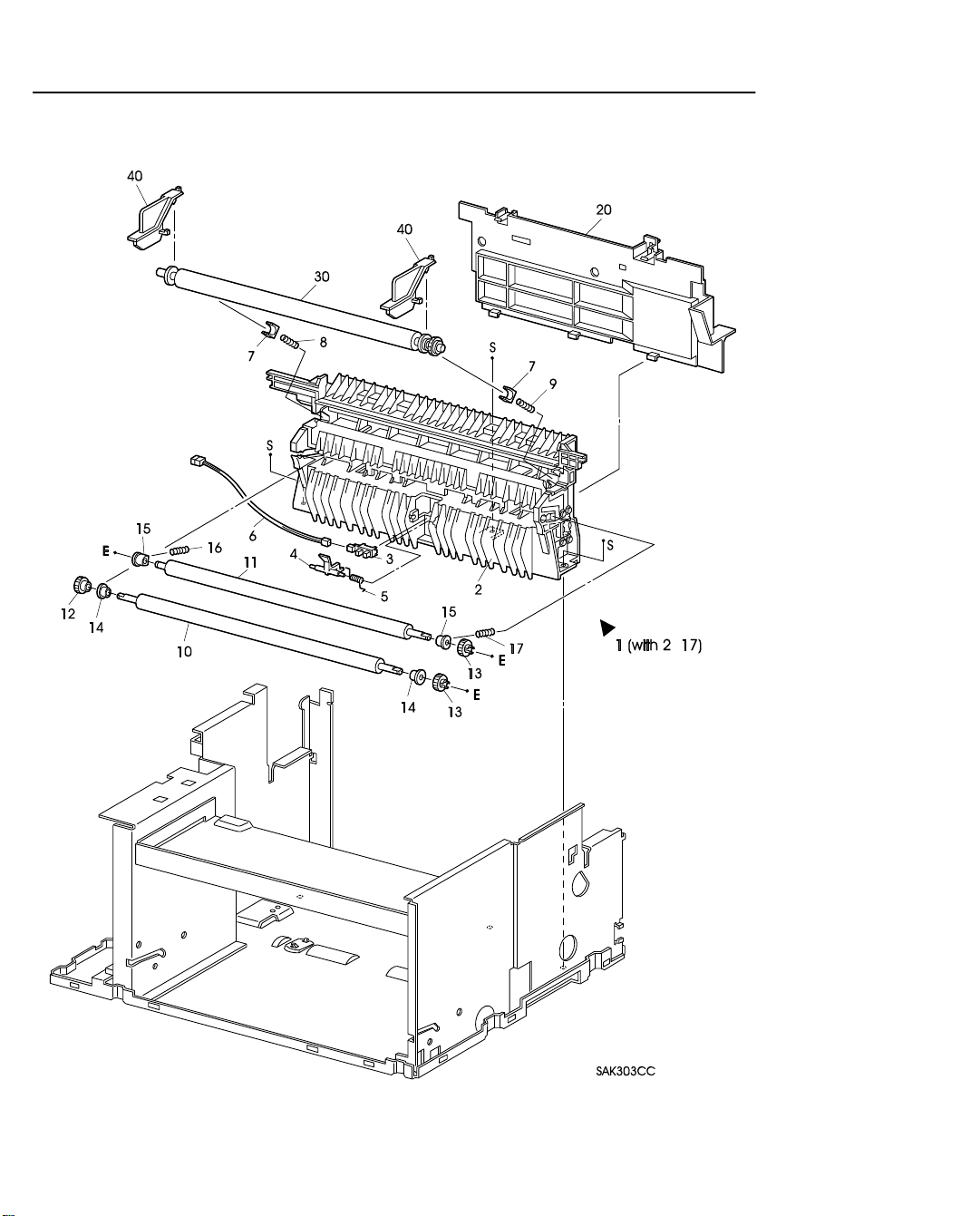

Parts Lists — LaserWriter 10/600 A3+ 3 – 6

PL3 Paper Transportation

Page 28

Parts Lists — LaserWriter 10/600 A3+ 3 – 7

PL3 Paper Transportation

Item Parts Name High Assembly

$

1 TRANSPORT CHUTE ASSEMBLY (with2-17)............................----

2 TRANSPORT SUB ASSEMBLY.................................................... PL3.1

3 REGISTRATION SENSOR............................................................. PL3.1

4 REGISTRATION ACTUATOR ......................................................PL3.1

5 REGISTRATION SPRING..............................................................PL3.1

6 REGISTRATION SENSOR HARNESS (P122-J123)..................... PL3.1

7 BTR BEARING................................................................................PL3.1

8 BTR SPRING L................................................................................ PL3.1

9 BTR SPRING R................................................................................PL3.1

10 RUBBER REGISTRATION ROLL.................................................PL3.1

11 METAL REGISTRATION ROLL...................................................PL3.1

12 REGISTRATION IN GEAR............................................................PL3.1

13 REGISTRATION OUT GEAR........................................................PL3.1

14 REGISTRATION FRONT BEARING............................................ PL3.1

15 REGISTRATION BACK BEARING.............................................. PL3.1

16 REGISTRATION ROLL SPRING L...............................................PL3.1

17 REGISTRATION ROLL SPRING R............................................... PL3.1

20 CHUTE PLATE ...............................................................................----

$

30 BTR ASSEMBLY ...........................................................................----

40 BTR STOPPER *1 .......................................................................... ----

*1

: This keeps the BTR ASSEMBLY attached with the Transport Sub Assembly during transporta-

tion. Remove it during installation.

Page 29

Parts Lists — LaserWriter 10/600 A3+ 3 – 8

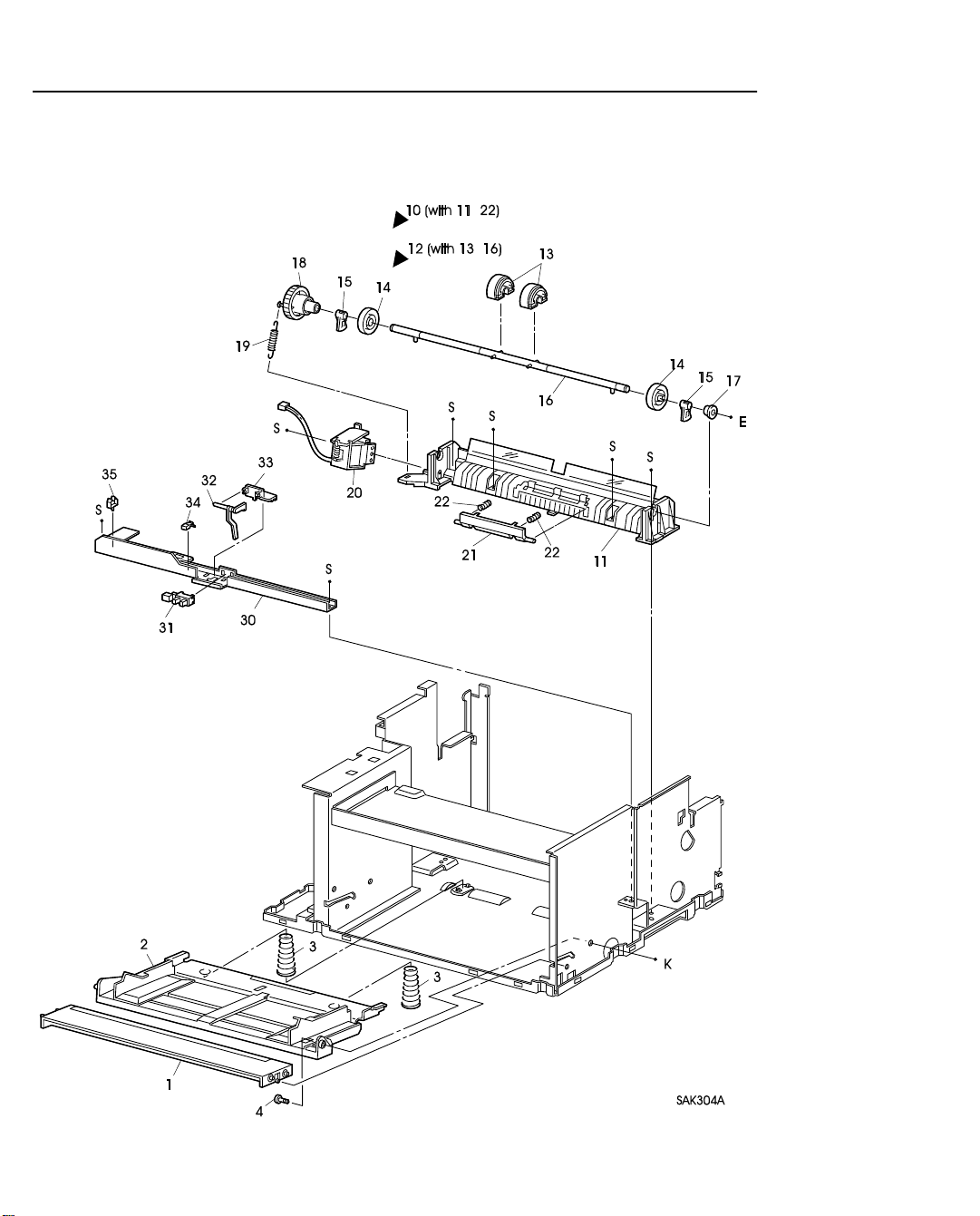

PL4 Multi Sheet Inserter

Page 30

Parts Lists — LaserWriter 10/600 A3+ 3 – 9

PL4 Multi Sheet Inserter

Item Parts Name High Assembly

1 FRONT IN TRAY............................................................................----

2 FRONT BOTTOM TRAY ...............................................................----

3 MSI N/F SPRING.............................................................................----

4 BOTTOM TRAY STUD..................................................................----

$

10 MSI CHUTE ASSEMBLY (with11-22) ..........................................----

11 MSI CHUTE..................................................................................... PL4.10

12 PICK UP ROLL ASSEMBLY (with13-16).....................................PL4.10

$

13 PICK UP ROLL *1...........................................................................PL4.12

14 CORE ROLL....................................................................................PL4.12

15 PICK UP CAM.................................................................................PL4.12

16 PICK UP SHAFT .............................................................................PL4.12

17 TRANSPORT BEARING................................................................PL4.10

18 PICK UP GEAR...............................................................................PL4.10

19 PICK UP SPRING............................................................................ PL4.10

20 PICK UP SOLENOID......................................................................PL4.10

$

21 RETARD PAD ASSEMBLY *1......................................................PL4.10

22 RETARD SPRING...........................................................................PL4.10

30 SENSOR BRACKET....................................................................... ----

$

31 MSI NO PAPER SENSOR...............................................................----

32 MSI N/P ACTUATOR.....................................................................----

33 CLAMP S......................................................................................... ----

35 CLAMP M........................................................................................----

*1

: Periodic Replacement Parts

Page 31

Parts Lists — LaserWriter 10/600 A3+ 3 – 10

PL5 Drive & Xerographics

Page 32

Parts Lists — LaserWriter 10/600 A3+ 3 – 11

PL5 Drive & Xerographics

Item Parts Name High Assembly

1 MAIN FRAME ASSEMBLY ..........................................................----

2 CLAMP P......................................................................................... ----

3 FRAME BRACKET......................................................................... ----

$

10 ROS ASSEMBLY (with11-13)........................................................----

11 ROS SUB ASSEMBLY ...................................................................PL5.10

12 SCANNER ASSEMBLY................................................................. PL5.10

13 SOS HARNESS (J111-J113)............................................................PL5.10

$

20 DRIVE ASSEMBLY........................................................................----

$

21 REGISTRATION CLUTCH ASSEMBLY...................................... ----

22 REGISTRATION DRIVE GEAR....................................................----

23 DRIVE BEARING L........................................................................ ----

24 DRIVE BEARING R........................................................................----

$

30 CRU SENSOR ASSEMBLY ...........................................................----

31 CRU GUIDE ASSEMBLY L........................................................... ----

32 CRU GUIDE ASSEMBLY R...........................................................----

40 BASE PLATE *1..............................................................................----

41 EP CARTRIDGE *2.........................................................................----

*1

: This is only for basic configuration 1. This part is removed when Feeder 250 is installed for

use.

*2

: Consumable

Page 33

Parts Lists — LaserWriter 10/600 A3+ 3 – 12

PL6 Electrical

Page 34

Parts Lists — LaserWriter 10/600 A3+ 3 – 13

PL6 Electrical

Item Parts Name High Assembly

$

1 LVPS ASSEMBLY..........................................................................----

$

2 HVPS................................................................................................----

3 KNOB VOLUME............................................................................. ----

$

4 MCU PWB .......................................................................................----

$

5 FAN.................................................................................................. ----

$

6 INTERLOCK SWITCH................................................................... ----

10 LVPS HARNESS (J10-J101)...........................................................----

11 HVPS HARNESS (J13-J131)...........................................................----

12 ROS HARNESS (J11-J112,J114).....................................................----

13 FUSER HARNESS (J15-J151,J154)................................................----

14 P/H HARNESS (J12-J121,J122,J124,P125) ....................................----

15 CRU HARNESS (J16-J161).............................................................----

16 TRAY HARNESS (J17-J171)..........................................................----

17 HARNESS ASSEMBLY LED (J127-J128)..................................... ----

20 BUSH................................................................................................----

21 EDGE SADDLE............................................................................... ----

22 CLAMP L.........................................................................................----

23 CONNECTOR 2PW......................................................................... ----

24 CONNECTOR 3PB..........................................................................----

30 HARNESS SHIELD......................................................................... ----

31 ELECTRIC SHIELD........................................................................----

32 REAR PANEL..................................................................................----

33 SHIELD ASSEMBLY (with34,35)..................................................----

34 CONTROLLER SHIELD.................................................................PL6.33

35 OPTION SHIELD ............................................................................PL6.33

36 ESS HARNESS (J106-J142)............................................................----

37 ESS PWB..........................................................................................----

Page 35

Parts Lists — LaserWriter 10/600 A3+ 3 – 14

PL7 250 Feeder

Page 36

Parts Lists — LaserWriter 10/600 A3+ 3 – 15

PL7 250 Feeder

Item Parts Name High Assembly

1 FEEDER ASSEMBLY 250 (with2-34)............................................----

2 FEEDER FRAME 250 .....................................................................PL7.1

3 FEED ROLL ASSEMBLY (with4,5)...............................................PL7.1

4 FEED SHAFT ASSEMBLY............................................................ PL7.3

$

5 FEED ROLL..................................................................................... PL7.3

$

6 TURN ROLL ASSEMBLY..............................................................PL7.1

7 FEED BEARING .............................................................................PL7.1

8 TRANSPORT BEARING................................................................PL7.1

9 FEED SPRING.................................................................................PL7.1

$

10 FEED SOLENOID........................................................................... PL7.1

11 FEED GEAR ....................................................................................PL7.1

12 FEED IDLER GEAR........................................................................PL7.1

$

13 ELECTRIC CLUTCH .....................................................................PL7.1

15 TURNTURN IDLER GEAR............................................................ PL7.1

16 IN GEAR..........................................................................................PL7.1

17 OUT GEAR......................................................................................PL7.1

18 SIZE GEAR......................................................................................PL7.1

$

19 FEEDER PWB .................................................................................PL7.1

20 PWB BRACKET..............................................................................PL7.1

$

21 CASSETTE SENSOR......................................................................PL7.1

$

22 CST NO PAPER SENSOR ..............................................................PL7.1

23 HARNESS GUIDE...........................................................................PL7.1

24 CASSETTE HARNESS (J175-J271,J272,J273)..............................PL7.1

25 TRAY UPPER HARNESS (P171-J173)..........................................PL7.1

26 TRAY LOWER HARNESS (J174-J171)......................................... PL7.1

27 CONNECTOR BRACKET..............................................................PL7.1

$

28 OUTER CHUTE ASSEMBLY........................................................ PL7.1

29 FEED HOUSING L.......................................................................... PL7.1

30 FEED HOUSING R..........................................................................PL7.1

31 FEEDER EARTH PLATE ...............................................................PL7.1

32 FEEDER TIE PLATE ......................................................................PL7.1

33 HOUSING CAP ...............................................................................PL7.1

34 FEEDER EARTH WIRE..................................................................PL7.1

50 FEEDER JOINT...............................................................................----

Page 37

Parts Lists — LaserWriter 10/600 A3+ 3 – 16

PL9 250 Cassette

Page 38

Parts Lists — LaserWriter 10/600 A3+ 3 – 17

PL9 250 Cassette

Item Parts Name High Assembly

1 UNIVERSAL CASSETTE (with10-21)...........................................PL9.1

10 CASSETTE HOUSING ...................................................................PL9.1

11 BOTTOM PLATE ASSEMBLY......................................................PL9.1

12 CST N/F SPRING ............................................................................PL9.1

13 CST LATCH L.................................................................................PL9.1

14 CST LATCH R.................................................................................PL9.1

15 CST LATCH SPRING .....................................................................PL9.1

16 INNER CHUTE................................................................................PL9.1

17 INNER SPRING............................................................................... PL9.1

18 EXTENSION HOUSING................................................................. PL9.1

19 END GUIDE.....................................................................................PL9.1

20 END GUIDE LOWER .....................................................................PL9.1

21 CASSETTE COVER........................................................................PL9.1

Page 39

Parts Lists — LaserWriter 10/600 A3+ 1 – 18

2. Parts Reference

[A]

ACTUATOR HOLDER.......................PL 4.33

[B]

BASE PLATE............................... ......PL5.40

BOTTOM PLATE ASSEMBLY..........PL 9.11

BOTTOM TRAY STUD .....................PL 4. 4

BTR ASSEMBL Y ...............................PL 3.30

BTR BEARING ..................................PL 3. 7

BTR SPRING L ..................................PL 3. 8

BTR SPRING R ..................................PL 3. 9

BTR STOPPER...................................PL 3.40

BUSH ..................................................PL 6.20

[C]

CASSETTE COVER...........................PL 9.21

CASSETTE HARNESS......................PL 7.24

CASSETTE HOUSING......................PL 9.10

CASSETTE SENSOR.........................PL 7.21

CHUTE PLATE...................................PL 3.20

CLAMP L............................................PL 6.22

CLAMP M...........................................PL 4.35

CLAMP P............................................PL 5. 2

CLAMP S............................................PL 4.34

CONNECTOR 2PW............................PL 6.23

CONNECTOR 3PB.............................PL 6.24

CONNECTOR BRACKET.................PL 7.27

CONSOLE ASSEMBL Y.....................PL 1.50

CONTROLLER SHIELD ...................PL 6.34

CORE ROLL.......................................PL 4.14

CRU GUIDE ASSEMBLY L ..............PL 5.31

CRU GUIDE ASSEMBLY R..............PL 5.32

CRU HARNESS..................................PL 6.15

CRU SENSOR ASSEMBLY...............PL 5.35

CRU STOPPER...................................PL 1.15

CST LATCH L ....................................PL 9.13

CST LATCH R ....................................PL 9.14

CST LATCH SPRING ........................PL 9.15

CST N/F SPRING...............................PL 9.12

CST NO PAPER SENSOR.................PL7.22

[D]

DRIVE ASSEMBL Y...........................PL 5.20

DRIVE BEARING L ..........................PL 5.23

DRIVE BEARING R ..........................PL 5.24

[

E]

EDGE SADDLE .................................PL 6.21

ELECTRIC CLUTCH.........................PL 7.13

ELECTRIC SHIELD...........................PL 6.31

ELIMINATOR BRACKET L..............PL 2. 7

ELIMINATOR BRACKET R..............PL 2. 8

END GUIDE.......................................PL 9.19

END GUIDE LOWER........................ PL 9.20

EP CARTRIDGE................................PL 5.50

ESS HARNESS...................................PL 6.36

ESS PWB............................................PL 6.37

EXIT ACTUATOR.............................. PL 2.38

EXIT BEARING................................. PL 2.34

EXIT CHUTE .....................................PL 2.40

EXIT CHUTE ROLL.......................... PL 2.44

EXIT COVER.....................................PL 2.50

EXIT ELIMINATOR ..........................PL 2. 6

EXIT GEAR........................................PL 2.33

EXIT HARNESS ................................ PL 2.37

EXIT IDLER GEAR...........................PL 2.31

EXIT IDLER SHAFT.........................PL 2.32

EXIT ROLL ASSEMBLY...................PL 2.35

EXIT SENSOR ...................................PL 2.36

EXIT TORSION SPRING..................PL 2.39

EXTENSION HOUSING ...................PL 9.18

[F]

FAN.....................................................PL 6. 5

FEED BEARING................................PL 7. 7

FEED GEAR....................................... PL 7.11

FEED HOUSING L ............................PL 7.29

FEED HOUSING R............................PL 7.30

FEED IDLER GEAR..........................PL 7.12

FEED ROLL .......................................PL 7. 5

FEED ROLL ASSEMBLY..................PL 7. 3

FEED SHAFT ASSEMBLY ............... PL 7. 4

FEED SOLENOID..............................PL 7.10

FEED SPRING....................................PL 7. 9

FEEDER ASSEMBLY 250.................PL 7. 1

FEEDER EARTH PLATE...................PL 7.31

FEEDER EARTH WIRE....................PL 7.34

FEEDER FRAME 250........................ PL 7. 2

FEEDER JOINT..................................PL 7.50

FEEDER PWB....................................PL 7.19

FEEDER TIE PLATE..........................PL 7.32

FINGER BRACKET...........................PL 2.41

FINGER SPRING...............................PL 2.42

FRAME BRACKET ..........................PL 5. 3

FRONT BOTTOM TRAY...................PL 4. 2

FRONT COVER.................................PL 1.31

FRONT COVER ASSEMBLY............PL 1.30

FRONT IN TRAY ...............................PL 4. 1

FRONT TRAY ....................................PL 1.40

FUSER ASSEMBLY...........................PL 2. 1

FUSER COVER L...............................PL 2. 3

FUSER COVER R..............................PL 2. 4

FUSER FRAME ASSEMBLY............ PL 2. 2

FUSER HARNESS.............................PL 6.13

FUSER INLET CHUTE ..................... PL 2.27

FUSER TOP COVER

[G]

GUIDE COVER..................................PL 1.33

[

H]

H/R BEARING L................................ PL 2.16

H/R BEARING R ............................... PL 2.17

H/R DIODE ........................................ PL 2.18

H/R FINGER ...................................... PL 2.43

H/R GEAR..........................................PL 2.28

H/R IDLER GEAR ............................. PL 2.29

H/R IDLER SHAFT ........................... PL 2.30

H/R RING...........................................PL 2.15

HARNESS ASSEMBLY LED............PL 6.17

HARNESS GUIDE.............................PL 7.25

HARNESS SHIELD...........................PL 6.30

HEAT ROLL .......................................PL 2.14

HEATER ROD....................................PL 2. 9

HOUSING CAP.................................. PL 7.33

HVPS .................................................. PL 6. 2

HVPS HARNESS...............................PL 6.11

[I]

IN GEAR ............................................ PL 7.16

INNER CHUTE..................................PL 9.16

INNER SPRING.................................PL 9.17

INTERLOCK SWITCH......................PL 6. 6

[K]

KNOB VOLUME................................PL 6. 3

[L]

LAMP GUIDE....................................PL 2.10

LA TCH ASSEMBLY..........................PL 1.13

LATCH BUTTON............................... PL 1.12

LATCH SPRING ................................ PL 1.14

LEFT COVER.....................................PL 1. 5

LEVER HOLDER .............................. PL 1. 4

LVPS ASSEMBLY.............................PL 6. 1

LVPS HARNESS ................................ PL 6.10

[M]

MAIN FRAME ASSEMBLY .............PL 5. 1

MCU PWB.......................................... PL 6. 4

METAL REGISTRATION ROLL......PL 3.11

MSI CHUTE.......................................PL 4.11

MSI CHUTE ASSEMBLY .................PL 4.10

ASSEMBLY ..... PL 2. 5

Page 40

Parts Lists

MSI N/F SPRING................................PL 4. 3

MSI N/P ACTUATOR........................PL 4.32

MSI NO PAPER SENSOR..................PL 4.31

[N]

NIP LEVER L .....................................PL 2.22

NIP LEVER R.....................................PL 2.23

NIP LEVER SPRING..........................PL 2.21

[O]

OPTION SHIELD ...............................PL 6.35

OUT GEAR.........................................PL 7.17

OUTER CHUTE ASSEMBLY............PL 7.28

[P]

P/H HARNESS....................................PL 6.14

P/R BEARING ....................................PL 2.20

P/R EARTH PLATE L.........................PL 2.25

P/R EARTH PLATE R ........................PL 2.26

P/R ELIMINATOR..............................PL 2.24

PICK UP CAM....................................PL 4.15

PICK UP GEAR..................................PL 4.18

PICK UP ROLL...................................PL 4.13

PICK UP ROLL ASSEMBLY.............PL 4.12

PICK UP SHAFT ................................PL 4.16

PICK UP SOLENOID.........................PL 4.20

PICK UP SPRING...............................PL 4.19

POP UP ASSEMBLY..........................PL 1.10

POP UP COVER.................................PL 1.11

POP UP SPRING.................................PL 1.17

PRESSURE ROLL..............................PL 2.19

PUSH LEVER.....................................PL 1. 3

PWB BRACKET.................................PL 7.20

[R]

REAR FRAME....................................PL 1. 2

REAR FRAME ASSEMBLY..............PL 1. 1

REAR PANEL.....................................PL 6.32

REGISTRATION ACTUATOR...........PL 3. 4

REGISTRATION BACK

BEARING......PL 3.15

REGISTRATION

CLUTCH ASSEMBL Y......PL 5.21

REGISTRATION DRIVE GEAR .......PL 5.22

REGISTRATION

FRONT BEARING......PL 3.14

REGISTRATION IN GEAR ...............PL 3.12

REGISTRATION OUTGEAR ............PL 3.13

REGISTRATION

ROLL SPRING L......PL 3.16

REGISTRATION ROLL

SPRING R......PL 3.17

REGISTRATION SENSOR ................PL 3. 3

REGISTRATION SENSOR

HARNESS......PL 3. 6

REGISTRATION SPRING .................PL 3. 5

RETARD PAD ASSEMBLY...............PL 4.21

RETARD SPRING..............................PL 4.22

RIGHT COVER ..................................PL 1. 6

ROS ASSEMBL Y................................PL 5.10

ROS HARNESS..................................PL 6.12

ROS SUB ASSEMBLY.......................PL 5.11

RUBBER REGISTRATION

ROLL......PL 3.10

[S]

SCANNER ASSEMBL Y ....................PL 5.12

SENSOR BRACKET..........................PL 4.30

SHIELD ASSEMBL Y.........................PL 6.33

SIZE HANDLE...................................PL 7.18

SOS HARNESS ..................................PL 5.13

STOPPER SPRING.............................PL 1.16

[T]

TEMPERATURE

SENSOR ASSEMBL Y.....PL 2.13

THERMAL FUSE...............................PL 2.11

THERMOSTAT...................................PL 2.12

TOP COVER.......................................PL 1.21

TOP COVER ASSEMBLY.................PL 1.20

TOP TRAY ..........................................PL 1.22

TRANSPORT BEARING...................PL 4.17

TRANSPORT BEARING...................PL 7. 8

TRANSPORT CHUTE

ASSEMBLY .....PL 3. 1

TRANSPORT SUB ASSEMBLY.......PL 3. 2

TRAY HARNESS ...............................PL 6.16

TRAY LATCH.....................................PL 1.32

TRAY LOWER HARNESS ................PL 7.26

TURN IDLER GEAR .........................PL 7.15

TURN ROLL ASSEMBLY.................PL 7. 6

[U]

UNIVERSAL CASSETTE .................PL 9. 1

Page 41

LaserWriter 10/600 A3+ 4 – i

Section 4

Removal and Replacement Procedures

Section Contents

1. Introduction

1.1 Before you start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.2 Notations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

RRP1 Covers

RRP1.1 Left Cover (PL1.4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

RRP1.2 Top Cover Assembly (PL1.20) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

RRP1.3 Front Cover Assembly (PL1.30) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

RRP1.4 Right Cover (PL1.6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

RRP1.5 Pop Up Assembly (PL1.10). . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

RRP1.6 Rear Frame Assembly (PL1.1) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

RRP1.7 Front Tray (PL1.40). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

RRP1.8 Console Assembly (PL1.50) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

RRP2 Fuser & Paper Exit

RRP2.1 Fuser Assembly (PL2.1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

RRP2.2 Fuser Cover L (PL1.3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

RRP2.3 Fuser Cover R (PL1.4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

RRP2.4 Fuser Top Cover Assembly (PL2.5). . . . . . . . . . . . . . . . . . . . . . . . 4-26

RRP2.5 Exit Chute (PL2.40). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

RRP2.6 Exit Sensor (PL2.36) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

RRP2.7 Exit Actuator (PL2.38) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

RRP2.8 H/R Finger (PL2.43) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-34

RRP2.9 Heater ROD (PL2.9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

RRP2.10 Thermostat (PL2.12). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

RRP2.11 Temperature Sensor Assembly (PL2.13) . . . . . . . . . . . . . . . . . . . . 4-40

RRP2.12 Pressure Roll (PL2.19). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-42

RRP2.13 Heat Roll (PL2.14). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-44

RRP2.14 Exit Roll Assembly (PL2.35) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-46

RRP3 Paper Transportation

RRP3.1 BTR Assembly (PL3.30) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-48

RRP3.2 Transport Chute Assembly (PL3.1) . . . . . . . . . . . . . . . . . . . . . . . . 4-50

RRP3.3 Registration Actuator (PL3.4). . . . . . . . . . . . . . . . . . . . . . . . . . . 4-52

RRP3.4 Registration Sensor (PL3.3). . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-54

Page 42

LaserWriter 10/600 A3+ 4 – ii

Section 4

Removal and Replacement Procedures

RRP4 Multi Sheet Inserter

RRP4.1 MSI N/P Actuator (PL4.32). . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56

RRP4.2 MSI No Paper Sensor (PL4.31). . . . . . . . . . . . . . . . . . . . . . . . . . 4-58

RRP4.3 Toner Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-60

RRP4.4 MSI Chute Assembly (PL4.10) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-62

RRP4.5 Pick Up Roll (PL4.13) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-64

RRP4.6 Pick Up Solenoid (PL4.20) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-66

RRP4.7 Retard Pad Assembly (PL4.21) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-68

RRP4.8 Front IN Tray (PL4.1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-70

RRP4.9 Front Bottom Tray(PL4.2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-72

RRP5 Drive & Xerographic

RRP5.1 CRU Sensor Assembly (PL5.30) . . . . . . . . . . . . . . . . . . . . . . . . . 4-74

RRP5.2 ROS Assembly (PL5.10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-76

RRP5.3 Scanner Assembly (PL5.12). . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-78

RRP5.4 CRU Guide Assembly L (PL5.31) . . . . . . . . . . . . . . . . . . . . . . . . 4-80

RRP5.5 CRU Guide Assembly R (PL5.32) . . . . . . . . . . . . . . . . . . . . . . . . 4-82

RRP5.6 Drive Assembly (PL5.20), Registration Clutch Assembly (PL5.21) . . . . . . . 4-84

RRP6 Electrical

RRP6.1 Rear Panel (PL6.32). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-86

RRP6.2 Fan (PL6.5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-88

RRP6.3 LVPS Assembly (PL6.1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-90

RRP6.4 Shield Assembly (PL6.33) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-92

RRP6.5 ESS PWB (PL6.37) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-94

RRP6.6 Electric Shield (PL6.31). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-96

RRP6.7 MCU PWB (PL6.4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-98

RRP6.8 HVPS (PL6.2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-100

RRP6.9 Interlock Switch (PL6.6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-102

RRP7 Feeder

RRP7.1 Feeder Assembly 250 (PL7.1). . . . . . . . . . . . . . . . . . . . . . . . . . 4-104

RRP7.2 Feed Roll Assembly (PL7.3) . . . . . . . . . . . . . . . . . . . . . . . . . . 4-106

RRP7.3 Feed Roll (PL7.5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-108

RRP7.4 Turn Roll Assembly (PL7.6), Electric Clutch (PL7.13). . . . . . . . . . . . . 4-110

Page 43

LaserWriter 10/600 A3+ 4 – iii

Section 4

Removal and Replacement Procedures

RRP7.5 Feed Solenoid (PL7.10). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-112

RRP7.6 Feeder PWB (PL7.19). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-114

RRP7.7 Cassette Sensor (PL7.21) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-116

RRP7.8 CST No Paper Sensor (PL7.22). . . . . . . . . . . . . . . . . . . . . . . . . 4-118

RRP7.9 Feed Housing L (PL7.29) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-120

RRP7.10 Feed Housing R (PL7.30) . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-122

Page 44

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 1

1. Introduction

This section explains the removal and replacement procedures of the major parts of the printer,

grouping the parts in the same order as the Parts List.

• RRP1-Covers • RRP5-Drive & Xerographics

• RRP2-Fuser and Paper Exit • RRP6-Electrical

• RRP3-Paper Transportation • RRP7-Feeder

• RRP4-Multi Sheet Inserter

Note : 1. Observe how parts are secured in place when removing the parts which are listed as

spare parts by the removal procedures but are not explained in this section before you

begin.

2. The procedure of the optional feeding unit (Feeder Assembly 500) is omitted because it

follows the same procedures as "RRP7 Feeder". See "RRP7 Feeder" if necessary.

3. Though the optional units are assumed to have been removed beforehand as a rule, you

may opt to have optional pars left installed if it is not necessary to remove them.

1.1 Before you start

• Switch off the printer power and disconnect the power cord from the wall outlet.

• Remove the EP Cartridge from the printer. Place the EP Cartridge away from exposure to

direct sunlight.

• Do not use force to remove or install printer components.

• Use only the screw size and type designated in the text. A wrong screw could easily damage

tapped hole.

• Wear a wrist strap to dissipate static electricity.

1.2 Notations

• The notation "RRP X.Y ZZZZ"in a RRP step indicates the name "ZZZZZ" as a part to

remove or replace.

• The notation "(PL X.Y)" after a part name indicates that the part is shown as Item Y in PL X

in "Section 3 Parts Lists". The position of a part to replace or the types of screws can be

known by referring the part list and drawing.

• The direction with respect to the printer are defined as follows;

Front : When you are facing the front side of

the printer, the direction nearest you.

Rear : When you are facing the front side of

the printer, the direction furthest away

from you.

Left : When you are facing the front side of

the printer, the direction to the left.

Right : When you are facing the front side of

the printer, the direction to the right.

• The notation "screw(shape, color, and length of thread)" identifies individual screws.

• The notation "RRP X.Y" indicates that the removal procedure is explained in RRP X.Y.

Page 45

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 2

• The notation "Figure X.Y" indicates that the figure X.Y is referred to for more information.

• A number followed by a bracket "Z)" in the illustration corresponds to a step "Z)" in the

RRP text.

• Use a Phillips screwdriver for the screws shown in the illustrations unless otherwise indicated.

• Black arrows in the illustrations show the direction in the part may be moved. Follow the

numerical order if the arrows are numbered. A white arrow(FRONT) indicates the front

direction of the printer.

• For the location of connectors (P/J), see Section 6 4. Connector Location.

Page 46

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 3

This page is intentionally left blank.

Page 47

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 4

RRP1. Covers

RRP1.1 Left Cover(PL1.4)

Page 48

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 5

RRP1.1 Left Cover(PL1.4)

Warning : Turn power off, remove the EP Cartridge and disconnect the power cord before

performing the following procedure.

Removal

1. Press the Latch Button to open the Pop Up Cover.

2. Press the Top Cover button which latches it with the Left Cover, pull the upper side of the

Left Cover to the left, then lift it up to remove the Left Cover.

Replacement

Reverse the removal procedures for reinstallation.

Note : Be sure to latch the hooks at the bottom of the Left Cover with the frame of the

printer.

Page 49

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 6

RRP1.2 Top Cover Assembly (PL1.20)

Page 50

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 7

RRP1.2 Top Cover Assembly (PL1.20)

Warning : Turn power off, remove the EP Cartridge and disconnect the power cord before

performing the following procedure.

Removal

1. Remove the Left Cover. (RRP1.1)

2. Remove the three screws(silver, with brim, 8mm) securing the Top Cover Assembly to the

base frame.

Note : In the next step, the Top Cover Assembly is still connected with the base frame by

the harness. Be careful not to place the Top Cover Assembly too far from the

printer.

3. Lift the rear part of the Top Cover, slide off the overall Top Cover Assembly to the front,

then separate it from the printer.

4. Remove the connector(P/J127), and remove the Top Cover Assembly with the Console

Assembly.

5. Remove the Console Assembly securing by hooks from the Top Cover Assembly.

(RRP1.8).

Replacement

Reverse the removal procedures for reinstallation.

Caution : Be sure to latch the hooks at the front of the Top Cover with the Front Cover.

Page 51

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 8

RRP1.3 Front Cover Assembly (PL1.30)

Page 52

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 9

RRP1.3 Front Cover Assembly (PL1.30)

Warning : Turn power off, remove the EP Cartridge and disconnect the power cord before

performing the following procedure.

Removal

1. Remove the Left Cover. (RRP1.1)

2. Remove the Top Cover Assembly. (RRP1.2)

3. Open the Front Tray.

4. Remove the two screws(silver, with brim, 8mm) securing the Front Cover Assembly.

5. While lifting and holding the Front Tray , open the upper part of the Front Co v er, then lift it

up to remove the Front Cover Assembly.

Replacement

Reverse the removal procedures for reinstallation.

Caution : Be sure to latch the hooks under the Front Cover with the frame.

Note : Be careful for the superposition of the Front Cover and the Right Cover.

Page 53

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 10

RRP1.4 Right Cover (PL1.6)

Page 54

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 11

RRP1.4 Right Cover (PL1.5)

Warning : Turn power off, remove the EP Cartridge and disconnect the power cord before

performing the following procedure.

Removal

1. Remove the Left Cover. (RRP1.1)

2. Remove the Top Cover Assembly. (RRP1.2)

3. Remove the two screws(silver, with brim, 8mm) securing the Right Cover.

4. Open the upper side of the Right Cover to the right and lift it up to remove the Right Cover.

Replacement

Reverse the removal procedures for reinstallation.

Caution : Be sure to latch the hooks under the Right Cover with the frame.

Page 55

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 12

RRP1.5 Pop Up Assembly (PL1.10)

Page 56

Removal and Replacement Procedures — LaserWriter 10/600 A3+ 4 – 13

RRP1.5 Pop Up Assembly (PL1.10)

Warning : Turn power off, remove the EP Cartridge and disconnect the power cord before

performing the following procedure.

Removal

1. Remove the Left Cover. (RRP1.1)

2. Remove the Top Cover Assembly. (RRP1.2)

3. Remove the Right Cover. (RRP1.4)

4. Remove the Rear Panel. (RRP6.1)

5. Disengage the boss of the Pop Up Cover from the hole of the Rear Frame, then remove the

Pop Up Assembly.