Page 1

Site Master

S113C, S114C,

S331C, S332C,

Antenna, Cable and

Spectrum Analyzer

User's Guide

Hand-Held Tester for Transmission Lines

and other RF Components

Page 2

WARRANTY

The Anritsu product(s) listed on the title page is (are) warranted against defects in

materials and workmanship for one year from the date of shipment.

Anritsu's obligation covers repairing or replacing products which prove to be defec

tive during the warranty period. Buyers shall prepay transportation charges for

equipment returned to Anritsu for warranty repairs. Obligation is limited to the origi

nal purchaser. Anritsu is not liable for consequential damages.

-

-

LIMITATION OF WARRANTY

The foregoing warranty does not apply to Anritsu connectors that have failed due to

normal wear. Also, the warranty does not apply to defects resulting from improper or

inadequate maintenance by the Buyer, unauthorized modification or misuse, or op

eration outside the environmental specifications of the product. No other warranty is

expressed or implied, and the remedies provided herein are the Buyer's sole and

exclusive remedies.

-

TRADEMARK ACKNOWLEDGMENTS

MS-DOS, Windows, Windows 95, Windows NT, Windows 98, Windows 2000 and

Windows ME are registered trademarks of the Microsoft Corporation.

Anritsu and Site Master are trademarks of Anritsu Company.

NOTICE

Anritsu Company has prepared this manual for use by Anritsu Company personnel

and customers as a guide for the proper installation, operation and maintenance of

Anritsu Company equipment and computer programs. The drawings, specifications,

and information contained herein are the property of Anritsu Company, and any unauthorized use or disclosure of these drawings, specifications, and information is

prohibited; they shall not be reproduced, copied, or used in whole or in part as the

basis for manufacture or sale of the equipment or software programs without the

prior written consent of Anritsu Company.

October 2001 10580-00060

Copyright ã 2001 Anritsu Co. Revision: A

Page 3

Page 4

Table of Contents

Chapter 1 - General Information

Introduction..................................1-1

Description ..................................1-1

Standard Accessories .............................1-1

Options ....................................1-2

Optional Accessories .............................1-2

Performance Specifications .........................1-3

Preventive Maintenance ...........................1-6

Calibration ..................................1-6

InstaCal Module ...............................1-7

Annual Verification..............................1-7

Chapter 2 - Functions and Operations

Introduction..................................2-1

Test Connector Panel.............................2-1

Front Panel Overview ............................2-2

Function Hard Keys .............................2-3

Keypad Hard Keys ..............................2-4

Soft Keys ...................................2-6

Power Monitor Menu ............................2-15

Symbols ...................................2-19

Self Test ...................................2-19

Error Codes .................................2-19

Self Test Errors ..................................2-19

Range Errors ...................................2-21

InstaCal Error Messages .............................2-22

Battery Information.............................2-24

Charging a New Battery ..........................2-24

Charging the Battery in the Site Master.....................2-24

Charging the Battery in the Optional Charger .................2-24

Battery Charge Indicator.............................2-25

Battery Life ....................................2-25

Important Battery Information .........................2-26

Chapter 3 - Getting Started

Introduction..................................3-1

Power On Procedure .............................3-1

Select the Frequency or Distance ......................3-2

Calibration ..................................3-2

Calibration Verification ..............................3-3

Manual Calibration Procedure ..........................3-4

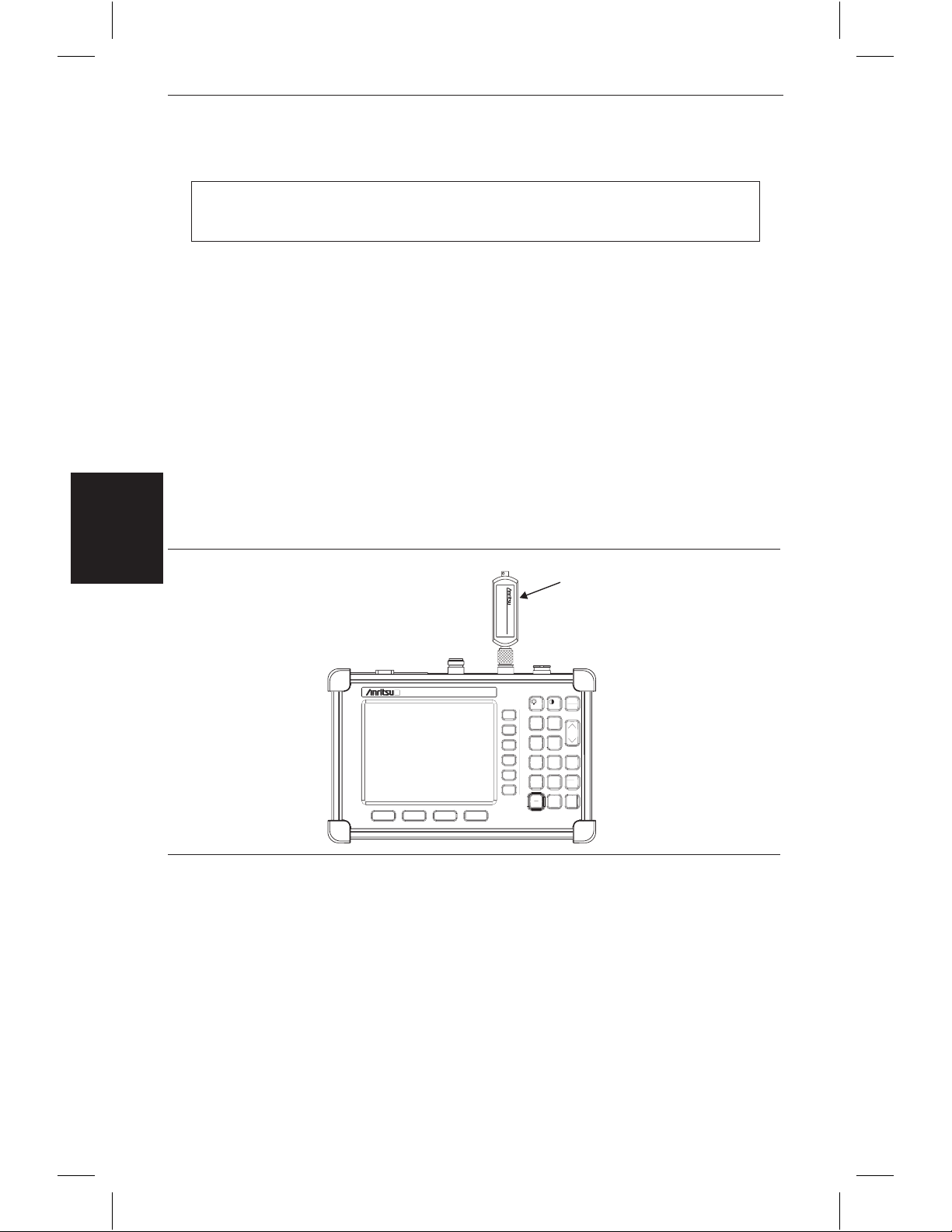

InstaCal Module Verification ...........................3-5

InstaCal Module Calibration Procedure .....................3-6

Calibration with the Test Port Extension Cable .................3-6

i

Page 5

Setting the Scale................................3-7

Auto Scale ......................................3-7

Amplitude Scale...................................3-7

Save and Recall a Setup ...........................3-7

Saving a Setup ...................................3-7

Recalling a Setup ..................................3-8

Save and Recall a Display ..........................3-8

Saving a Display ..................................3-8

Recalling a Display .................................3-8

Set the Distance and Cable Type .........................3-9

Changing the Units .................................3-9

Changing the Display Language..........................3-9

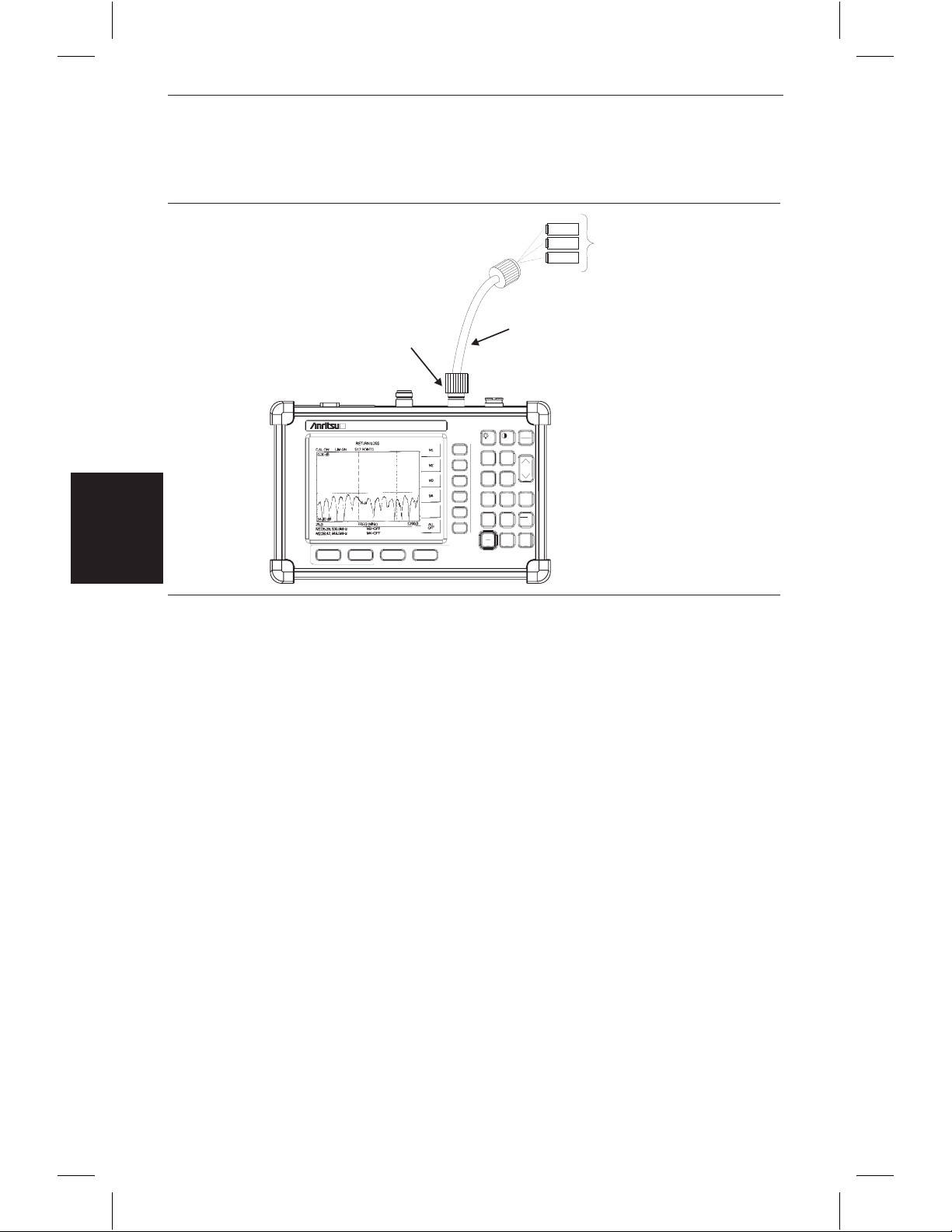

Printing....................................3-10

Printing a Screen .................................3-10

Printer Switch Settings ..............................3-11

Using the Soft Carrying Case........................3-12

Chapter 4 - Cable & Antenna Measurements

Introduction..................................4-1

Line Sweep Fundamentals ..........................4-1

Information Required for a Line Sweep ..................4-2

Typical Line Sweep Test Procedures ....................4-3

System Return Loss Measurement ........................4-3

Insertion Loss Measurement............................4-4

Distance-To-Fault (DTF) Transmission Line Test ................4-8

Antenna Subsystem Return Loss Test ......................4-10

Chapter 5 - Spectrum Analyzer Measurements

Introduction..................................5-1

Occupied Bandwidth .............................5-1

Channel Power Measurement ........................5-2

Channel Power Measurement with the Site Master ...............5-2

Adjacent Channel Power Measurement ..................5-4

Out-of-Band Spurious Emission Measurements ..............5-6

In-Band/Out-of-Channel Measurements ..................5-7

Field Strength Measurement.........................5-8

Antenna Calculations.............................5-9

Chapter 6 - Power Measurement

Introduction..................................6-1

Power Measurement .............................6-1

ii

Page 6

Chapter 7 - Site Master Software Tools

Introduction..................................7-1

Features ....................................7-1

System Requirements.............................7-1

Installation ..................................7-2

Communication Port Setting............................7-2

Interface Cable Installation ............................7-3

Using Software Tools .............................7-3

Downloading Traces from the Site Master .................7-3

Plot Capture..................................7-4

Plot Properties ................................7-4

Trace Overlay or Plot Overlay...........................7-5

Saving Traces ....................................7-5

Custom Cable List .................................7-6

Entering Antenna Factors .............................7-7

Uploading Antenna Factors ............................7-8

Creating a Database ................................7-8

Printing Formats ..................................7-8

Appendix A - Reference Data

Coaxial Cable Technical Data........................A-1

Appendix B - Windowing

Introduction .................................B-1

Examples ...................................B-1

iii/iv

Page 7

Page 8

Chapter 1

General Information

Introduction

This chapter provides a description, performance specifications, optional accessories, pre

ventive maintenance, and calibration requirements for the Site Master models S113C,

S114C, S331C, and S332C. Throughout this manual, the term Site Master will refer to the

models S113C, S114C, S331C, and S332C.

Model

S113C

S114C

S331C

S332C

Frequency Range

2 to 1600 MHz

2 to 1600 MHz, 100 kHz to 1600 MHz Spectrum Analysis

25 to 4000 MHz

25 to 4000 MHz, 100 kHz to 3000 MHz Spectrum Analysis

Description

The Site Master is a hand held SWR/RL (standing wave ratio/return loss), and Distance-ToFault (DTF) measurement instrument that includes a built-in synthesized signal source. All

models include a keypad to enter data and a liquid crystal display (LCD) to provide graphic

indications of SWR or RL over the selected frequency range and selected distance. The Site

Master is capable of up to 2.5 hours of continuous operation from a fully charged

field-replaceable battery and can be operated from a 12.5 dc source. Built-in energy conservation features can be used to extend battery life over an eight-hour work day.

The Site Master is designed for measuring SWR, return loss, or cable insertion loss and locating faulty RF components in antenna systems. Power monitoring is available as an option. Site Master models S114C and S332C include spectrum analysis capability. The

displayed trace can be scaled or enhanced with frequency markers or limit lines. A menu

option provides for an audible “beep” when the limit value is exceeded. To permit use in

low-light environments, the LCD can be back lit using a front panel key.

-

1

Standard Accessories

The Software Tools PC-based software program provides a database record for storing

measurement data. Site Master Software Tools can also convert the Site Master display to a

Microsoft Windowsä 95/98/NT4/2000/ME workstation graphic. Measurements stored in

the Site Master internal memory can be downloaded to the PC using the included null-mo

dem serial cable. Once stored, the graphic trace can be displayed, scaled, or enhanced with

markers and limit lines. Historical graphs can be overlaid with current data, and underlying

data can be extracted and used in spreadsheets or for other analytical tasks.

The Site Master Software Tools program can display all of the measurements made with the

Site Master (SWR, return loss, cable loss, distance-to-fault) as well as providing other func

tions, such as converting display modes and Smith charts. Refer to Chapter 7, Software

Tools, for more information.

-

-

1-1

Page 9

Chapter 1 General Information

The following items are supplied with the basic hardware.

Soft Carrying Case

·

AC-DC Adapter

·

Automotive Cigarette Lighter 12 Volt DC Adapter,

·

CDROM disk containing the Software Tools program. This program contains Fault Lo

·

cation (DTF) and Smith Chart functions

Serial Interface Cable (null modem type)

·

InstaCal Module

·

One year Warranty (includes battery, firmware, and software)

·

User's Guide

·

Options

Option 5 — Add Power Monitor

·

Optional Accessories

Anritsu Precision N (m) Open/Short/Load, 42 dB, Part No. OSLN50LF

·

Anritsu Precision N (f) Open/Short/Load, 42 dB, Part No. OSLNF50LF

·

Anritsu Precision N (m) Short/Open, Part No. 22N50

·

Anritsu Precision N (f) Short/Open, Part No. 22NF50

·

·

Site Master Precision N (m) Load, 42 dB, Part No. SM/PL

·

Site Master Precision N (f) Load, 42 dB, Part No. SM/PLNF

·

7/16 (m) Precision Open/Short/Load, Part No. 2000-767

·

7/16 (f) Precision Open/Short/Load, Part No. 2000-768

·

Adapter, Precision N (m) to N (m), Part No. 34NN50A

·

Adapter, Precision N (f) to N (f), Part No. 34NFNF50

·

Adapter, 7/16 (f) to N (m), Part No. 510-90

·

Adapter, 7/16 (f) to N (f), Part No. 510-91

·

Adapter, 7/16 (m) to N (m), Part No. 510-92

·

Adapter, 7/16 (m) to N (f), Part No. 510-93

·

Adapter, 7/16 DIN (m) to 7/16 DIN (m), Part No. 510-96

·

Adapter, 7/16 DIN (f) to 7/16 DIN (f), Part No. 510-97

·

Armored Test Port Extension Cable, 1.5 meter, N (m) to

N (f), Part No. 15NNF50-1.5C

·

Armored Test Port Extension Cable, 3.0 meter, N (m) to

N (f), Part No. 15NNF50-3.0C

·

Armored Test Port Extension Cable, 5.0 meter, N (m) to

N (f), Part No. 15NNF50-5.0C

·

Armored Test Port Extension Cable, 1.5 meter, N (m) to

N (m), Part No. 15NN50-1.5C

-

1-2

Page 10

Chapter 1 General Information

Armored Test Port Extension Cable, 3.0 meter, N (m) to

·

N (m), Part No. 15NN50-3.0C

Armored Test Port Extension Cable, 5.0 meter, N (m) to

·

N (m), Part No. 15NN50-5.0C

Armored Test Port Extension Cable, 1.5 meter, N (m) to

·

7/16 DIN (f), Part No. 15NDF50-1.5C

Armored Test Port Extension Cable, 1.5 meter, N (m) to

·

7/16 DIN (m), Part No. 15ND50-1.5C

RF Detector, 1 to 3000 MHz, N(m) input connector, 50 Ohms, Part No. 5400-71N50

·

RF Detector, 0.01 to 20 GHz, N(m) input connector, 50 Ohms, Part No. 560-7N50B

·

Transit Case for Site Master, Part No. 760-215A

·

Antenna SMA (f), 50 W, 1.71 to 1.88 GHz, Part No. 2000-1030

·

Antenna SMA (f), 50 W, 1.85 to 1.99 GHz, Part No. 2000-1031

·

Antenna SMA (f), 50 W, 2.4 to 2.5 GHz, Part No. 2000-1032

·

Antenna SMA (f), 50 W, 806 to 869 MHz, Part No. 2000-1034

·

Antenna SMA (f), 50 W, 896 to 941 MHz, Part No. 2000-1035

·

HP Deskjet 350 Printer, Part No. 2000-766

·

Serial-to-Parallel Converter Cable (use with the HP 350 Printer), Part No. 2000-753

·

Seiko DPU-414 Thermal Printer, Part No. 2000-754 (U.S.) or

·

2000-761 (Europe)

· US Adapter (use with the DPU-414 Printer),

Part No. 2000-1002

·

Europe Adapter (use with the DPU-414 Printer)

Part No. 2000-1003

·

Japan Adapter (use with the DPU-414 Printer)

Part No. 2000-1194

·

Battery Pack (use with the DPU-414 Printer)

Part No. 2000-1004

·

Serial Interface Cable (use with the DPU-414 Printer),

Part No. 2000-1012

·

Thermal Paper (use with the DPU-411/DPU-414 Printer),

Part No. 2000-755

·

Rechargeable Battery, NiMH

Part No. 633-27

·

Battery Charger with universal power supply, NiMH only

Part No. 2000-1029

Performance Specifications

Performance specifications are provided in Table 1-1, on the following page.

1-3

Page 11

Chapter 1 General Information

Table 1-1. Performance Specifications (1 of 2)

Specifications are valid when the unit is calibrated at ambient temperature after a 5 minute

warmup. Typical values are provided for reference only and are not guaranteed.

Description

Site Master: Frequency Range:

S113C, S114C

S331C, S332C

Frequency Accuracy (RF Source Mode) £75 parts per million @ 25°C*

Frequency Resolution: S113C, S114C

S331C, S332C

SWR: Range

Resolution

Return Loss: Range

Resolution

**Distance-To-Fault (DTF):

Vertical Range Return Loss:

SWR:

Horizontal Range

Horizontal Resolution for Coax

(rectangular windowing)

2 to 1600 MHz

25 to 4000 MHz

10 kHz

100 kHz

1.00 to 65.00

0.01

0.00 to 54.00 dB

0.01 dB

0.00 to 54.00 dB

1.00 to 65.00

0 to ((# of data points –1) ´ resolution) a maximum

of 1000m (3281 ft.) with a maximum of 517 points

resolution, # of data pts. = 130, 259, 517

(. )( )15 108´ Vp

FD

Where V

the cable; dp is the number of data points

(130, 259, 517); DF is the stop frequency minus the

start frequency (Hz)

is the relative propagation velocity of

p

Value

Horizontal Resolution for Waveguide

RF Power Monitor:

Display Range

Detector Range

Offset Range

Resolution

Test Port Connector Type N, 50W, female

***Immunity to Interfering signals

up to the level of: S113C, S114C

S331C, S332C

Maximum Input without Damage:

Test Port, Type N (f)

RF Power Detector

Measurement Accuracy:

Measurement accuracy depends on calibration components. Precision calibration components

have a directivity of 42 dB.

Cable Insertion Loss: Range

Resolution

Transmission Line Loss (one-port)

Range

Resolution

8

15 10 1

.((/))´-FF

F

D

Where F

is the start frequency (Hz); DF is the stop fre-

F

1

quency minus the start frequency (Hz)

–80.0 to +80 dBm or

10.0 pW to 100.0 kW

–50 dBm to +20 dBm, or 10 mW to 100 mW

0 to +60.0 dB

0.1 dB or 0.1 W

on-channel on-frequency

+17 dBm +10 dBm

+17 dBm –6 dBm

+20 dBm, 50W, +50 VDC

+20 dBm, 50W, +50 VDC

0.00 to 54.00 dB

0.01 dB

0.00 to 20.00 dB

0.01 dB

is the waveguide cutoff frequency (Hz);

C

2

1

c

1-4

Page 12

Chapter 1 General Information

Table 1-2. Performance Specifications (2 of 2)

Spectrum Analyzer:

Frequency Range S114C

S332C

Frequency Reference Aging

Accuracy

Frequency Span S114C

S332C

Sweep Time ³650 ms (full span)

Resolution Bandwidth

Accuracy

Video Bandwidth 100 Hz to 300 kHz in 1-3 sequence

SSB Phase Noise (1 GHz) @ 30 kHz offset £ –75 dBc/Hz

Spurious Responses, Input Related £ –45 dBc

Spurious Residual Responses £ –95 dBm

Note: 10 kHz resolution bandwidth, input terminated, no attenuation

Amplitude

Measurement Range –97 dBm to +20 dBm typical

Dynamic Range ³ 65 dB typical

Maximum Safe Input Level +20 dBm, maximum measurable safe input

Displayed Average Noise Level: £ –80 dBm (100 kHz to 300 kHz) typical

Display Range, Log Scale 2 to 15 dB/div. in 1 dB steps; 10 divisions displayed.

Frequency Response

RF Input VSWR 2.0:1

Resolution (Ref. Level) 1.0 dB

Total Level Accuracy ±2 dB ³ 300 kHz typical

General

Internal Memory:

Trace Memory

Instrument configuration

RS-232

Electromagnetic Compatibility Complies with European community requirements

Power Supply:

External DC Input +12.5 to +15 Vdc, 1100 mA max.

Temperature: Storage

Operating

Weight: 2.15 kg (4.76 pounds)

Dimensions: 25.4 x 17.8 x 6.1 cm

100 kHz to 1.6 GHz

100 kHz to 3.0 GHz

±1 ppm/yr

±2 ppm

0 Hz (zero span) 100 kHz to 1.6 GHz

0 Hz (zero span) 100 kHz to 3.0 GHz

500 ms (zero span)

10 kHz, 30 kHz, 100 kHz, 1 MHz

± 20% typical

+27 dBm, maximum input (damage)

+27 dBm, peak pulse power

+50 Vdc

£ –97 dBm (>300 kHz) typical

±3 dB <300 kHz typical

200 maximum

10 setup locations

9 pin D-sub, three wire serial

for CE marking

–20° C to 75° C

0° C to 50° C

(10x7x2.4inches)

* ±2 ppm/D°C from 25°C

** Fault location is accomplished by inverse Fourier Transformation of data taken with the Site Master. Resolution and

maximum range depend on the number of frequency data points, frequency sweep range and relative propagation velocity

of the cable being tested.

*** Immunity measurement is made in CW mode with incoming interfering signal exactly at the same frequency (worst

case situation). Typical immunity is better when swept frequency is used.

1-5

Page 13

Chapter 1 General Information

Preventive Maintenance

Site Master preventive maintenance consists of cleaning the unit and inspecting and clean

ing the RF connectors on the instrument and all accessories.

Clean the Site Master with a soft, lint-free cloth dampened with water or water and a mild

cleaning solution.

CAUTION: To avoid damaging the display or case, do not use solvents or abra

sive cleaners.

Clean the RF connectors and center pins with a cotton swab dampened with denatured alco

hol. Visually inspect the connectors. The fingers of the N (f) connectors and the pins of the

N (m) connectors should be unbroken and uniform in appearance. If you are unsure whether

the connectors are good, gauge the connectors to confirm that the dimensions are correct.

Visually inspect the test port cable(s). The test port cable should be uniform in appearance,

not stretched, kinked, dented, or broken.

Calibration

The Site Master is a field portable unit operating in the rigors of the test environment. An

Open-Short-Load (OSL) calibration should be performed prior to making a measurement in

the field (see Calibration, page 3-2). A built-in temperature sensor in the Site Master advises the user, via an icon located on the right side of the LCD screen, that the internal temperature has exceeded a safety window, and the user is advised to perform another OSL

calibration in order to maintain the integrity of the measurement.

-

-

-

NOTES:

For best calibration results—compensation for all measurement uncertain

ties—ensure that the Open/ Short/Load is at the end of the test port or optional

extension cable; that is, at the same point that you will connect the antenna or

device to be tested.

For best results, use a phase stable Test Port Extension Cable (see Optional

Accessories). If you use a typical laboratory cable to extend the Site Master test

port to the device under test, cable bending subsequent to the OSL calibration

will cause uncompensated phase reflections inside the cable. Thus, cables

which are NOT phase stable may cause measurement errors that are more pro

nounced as the test frequency increases.

For optimum calibration, Anritsu recommends using precision calibration com

ponents.

1-6

-

-

-

Page 14

Chapter 1 General Information

InstaCal Module

The Anritsu InstaCal module can be used in place of discrete components to calibrate the

Site Master. The InstaCal module can be used to perform an Open, Short and Load (OSL)

calibration procedure. Calibration of the Site Master with the InstaCal takes approximately

45 seconds (see Calibration, page 3-2). Unlike a discrete calibration component, the

InstaCal module can not be used at the top of the tower to conduct load or insertion loss

measurements. The module operates from 2 MHz to 4 GHz and weighs eight ounces.

Anritsu recommends annual re-characterization of the InstaCal module to verify perfor

mance with precision instrument data. The re-characterization can be performed at a local

service center or at the factory.

Annual Verification

Anritsu recommends an annual calibration and performance verification of the Site Master

and the OSL calibration components and InstaCal module by local Anritsu service centers.

Anritsu service centers are listed in Table 1-2 on the following page.

The Site Master itself is self-calibrating, meaning that there are no field-adjustable compo

nents. However, the OSL calibration components are crucial to the integrity of the calibra

tion and therefore, must be verified periodically to ensure performance conformity. This is

especially important if the OSL calibration components have been accidentally dropped or

over-torqued.

-

-

-

1-7

Page 15

Chapter 1 General Information

Table 1-2. Anritsu Service Centers

UNITED STATES

ANRITSU COMPANY

685 Jarvis Drive

Morgan Hill, CA 95037-2809

Telephone: (408) 776-8300,

1-800-ANRITSU

FAX: 408-776-1744

ANRITSU COMPANY

10 New Maple Ave., Unit 305

Pine Brook, NJ 07058

Telephone: (201) 227-8999,

1-800-ANRITSU

FAX: 201-575-0092

ANRITSU COMPANY

1155E. Collins Blvd

Richardson, TX 75081

Telephone: 1-800-ANRITSU

FAX: 972-671-1877

AUSTRALIA

ANRITSU PTY. LTD.

Unit 3, 170 Foster Road

Mt. Waverley, VIC 3149

Australia

Telephone: 03-9558-8177

Fax: 03-9558-8255

BRAZIL

ANRITSU ELECTRONICALTDA.

Praia de Botafogo 440, Sala 2401

CEP 22250-040,Rio de Janeiro,RJ,

Brasil

Telephone: 021-28-69-141

Fax: 021-53-71-456

CANADA

ANRITSU INSTRUMENTS LTD.

215 Stafford Road, Unit 102

Nepean, Ontario K2H 9C1

Telephone: (613) 828-4090

FAX: (613) 828-5400

CHINA

ANRITSU (SHANGHAI) ACSH

2F, Rm. B, 52 Section Factory Building

No. 516 Fu Te Road (N)

Waigaoqiao Free Trade Zone

Pudong, Shanghai 200131

Telephone: 021-5868-0226

FAX: 021-5868-0588

FRANCE

ANRITSU S.A

9 Avenue du Quebec

Zone de Courtaboeuf

91951 Les Ulis Cedex

Telephone: 016-44-66-546

FAX: 016-44-61-065

GERMANY

ANRITSU GmbH

Grafenberger Allee 54-56

D-40237 Dusseldorf, Germany

Telephone: 0211-96 85 50

FAX: 0211-96 85 555

INDIA

MEERA AGENCIES (P) LTD

A-23 Hauz Khas

New Delhi 110 016

Telephone: 011-685-3959

FAX: 011-686-6720

ISRAEL

TECH-CENT, LTD

Haarad St. No. 7, Ramat Haahayal

Tel-Aviv 69701

Telephone: (03) 64-78-563

FAX: (03) 64-78-334

ITALY

ANRITSU Sp.A

Rome Office

Via E. Vittorini, 129

00144 Roma EUR

Telephone: (06) 50-22-666

FAX: (06) 50-22-4252

JAPAN

ANRITSU CORPORATION

1800 Onna Atsugi-shi

Kanagawa-Prf. 243 Japan

Telephone: 0462-23-1111

FAX: 0462-25-8379

KOREA

ANRITSU CORPORATION LTD.

#901 Daeo Bldg. 26-5

YeoidoDong, Youngdeungpo

Seoul Korea 150 010

Telephone: 02-782-7156

FAX: 02-782-4590

SINGAPORE

ANRITSU (SINGAPORE) PTE LTD

10, Hoe Chiang Road

#07-01/02

Keppel Towers

Singapore 089315

Telephone: 65-2822400

FAX: 65-2822533

SOUTH AFRICA

ETESCSA

12 Surrey Square Office Park

330 Surrey Avenue

Ferndale, Randburt, 2194

South Africa

Telephone:01-11-787-7200

Fax: 01-11-787-0446

SWEDEN

ANRITSU AB

Botvid Center

S-1585

Stockholm, Sweden

Telephone: (08) 534-717-00

FAX: (08) 534-717-30

TAIWAN

ANRITSU CO., LTD.

8F, No. 96, Section 3

Chien Kuo N. Road

Taipei, Taiwan,R.O.C.

Telephone: (02) 515-6050

FAX: (02) 509-5519

UNITED KINGDOM

ANRITSU LTD.

200 Capability Green

Luton, Bedfordshire

LU1 3LU, England

Telephone: 015-82-41-88-53

FAX: 015-82-31-303

1-8

Page 16

Chapter 2

Functions and Operations

Introduction

This chapter provides a brief overview of the Site Master functions and operations, provid

ing the user with a starting point for making basic measurements. For more detailed infor

mation, refer to Chapter 4, Measurements and Chapter 7, Software Tools.

The Site Master is designed specifically for field environments and applications requiring

mobility. As such, it is a lightweight, handheld, battery operated unit which can be easily

carried to any location, and is capable of up to 2.5 hours of continuous operation from a

fully charged battery. Built-in energy conservation features allow battery life to be extended

over an eight-hour workday. The Site Master can also be powered by a 12.5 Vdc external

source. The external source can be either the Anritsu AC-DC Adapter (P/N 40-115) or 12.5

Vdc Automotive Cigarette Lighter Adapter (P/N 806-62). Both items are standard accesso

ries.

Test Connector Panel

The connectors and indicators located on the test panel are listed and described below.

12.5-15VDC

(1100 mA)

When using the AC-DC Adapter, always use a three-wire power cable connected

to a three-wire power line outlet. If power is supplied without grounding the equip

ment in this manner, there is a risk of receiving a severe or fatal electric shock.

12.5 to 15 Vdc @ 1100 mA input to power the unit or for battery charging.

WARNING

-

-

2

-

-

Battery

Charging

External

Power

Serial

Interface

RF Out RF output, 50 W impedance, for reflection measurements.

RF In RF input, 50 W impedance, for spectrum analysis measurements.

RF Detector RF detector input for the Power Monitor.

Illuminates when the battery is being charged. The indicator automatically shuts

off when the battery is fully charged.

Illuminates when the Site Master is being powered by the external charging unit.

RS232 DB9 interface to a COM port on a personal computer (for use with the

Anritsu Software Tools program) or to a supported printer.

2-1

Page 17

Chapter 2 Functions and Operations

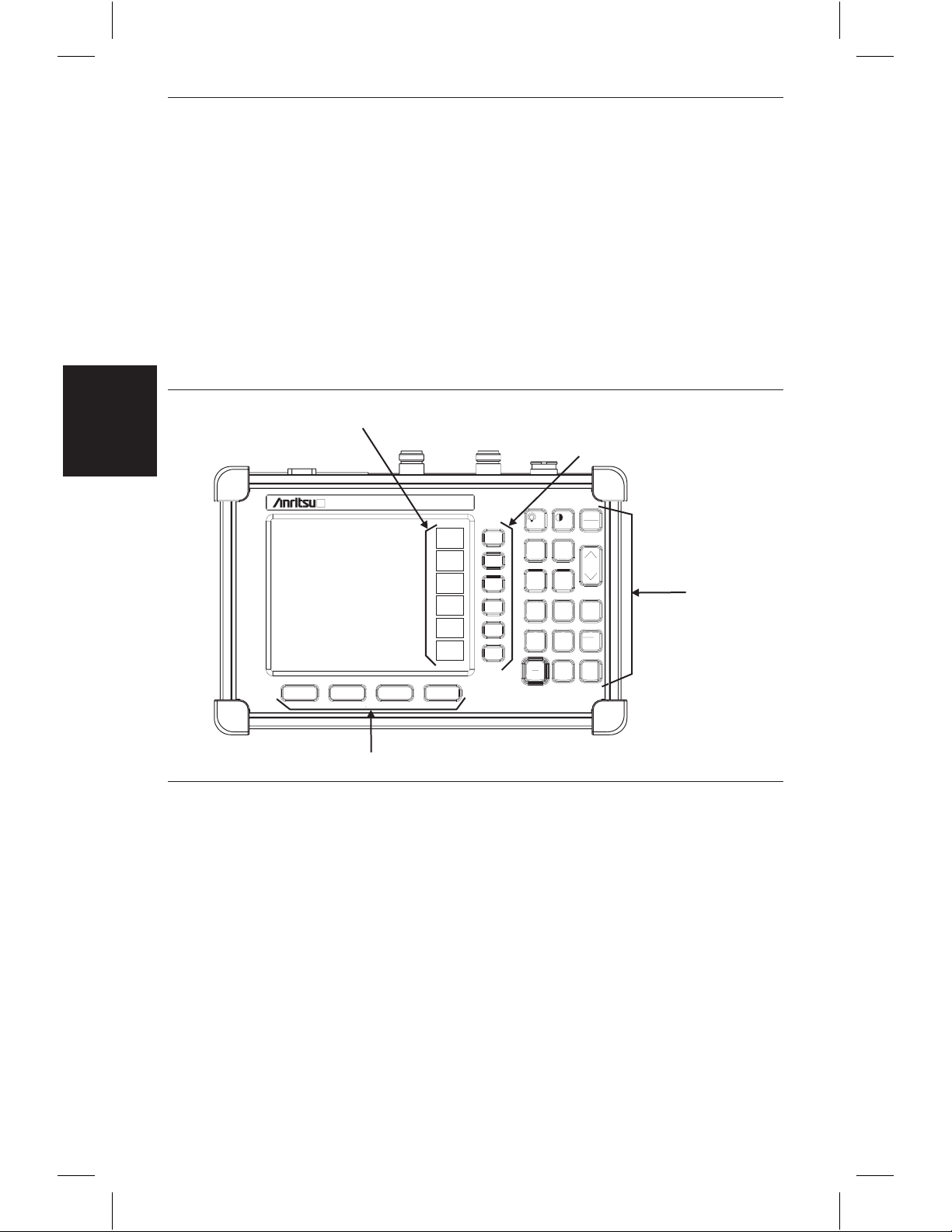

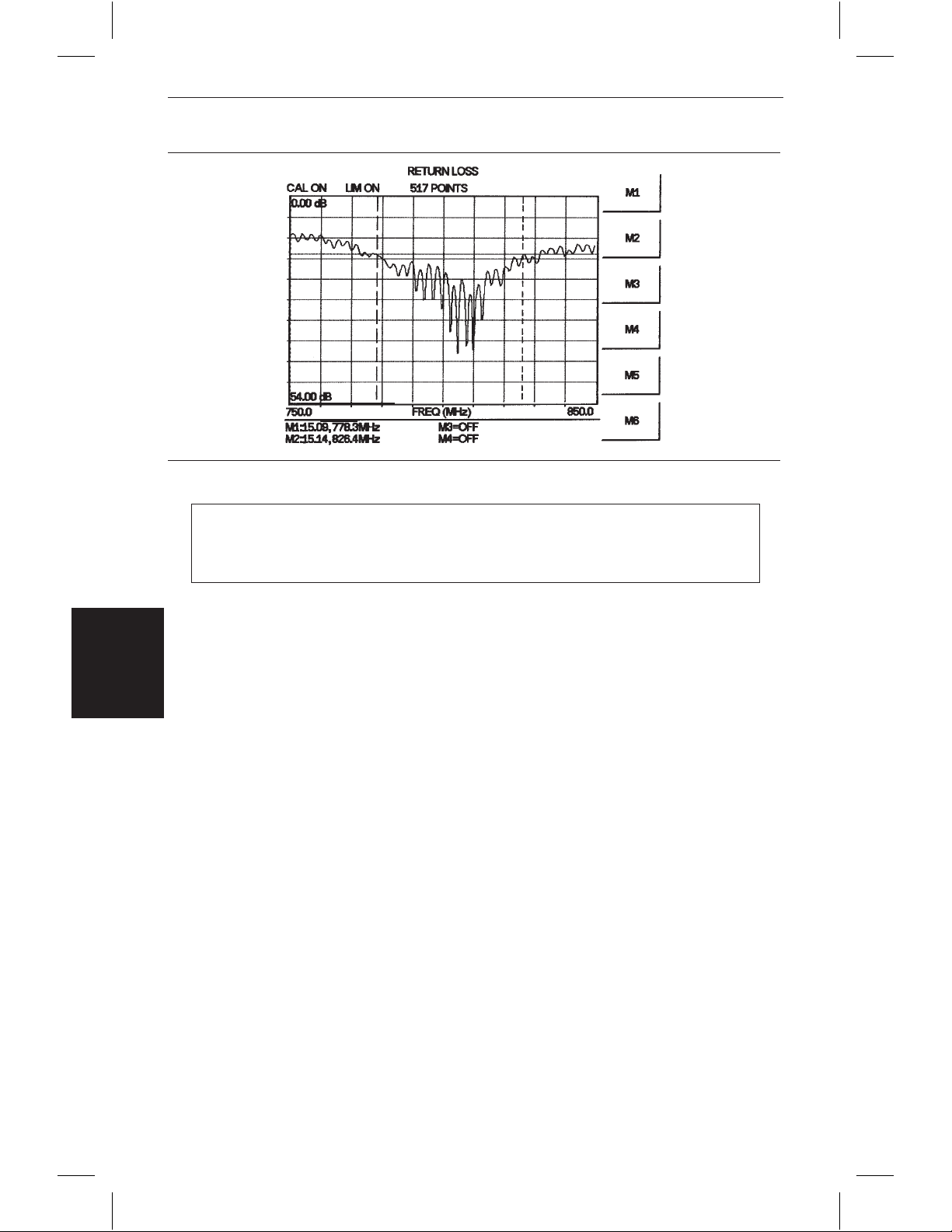

Front Panel Overview

The Site Master menu-driven user interface is easy to use and requires little training. Hard

keys on the front panel are used to initiate function-specific menus. There are four function

hard keys located below the display, Mode, Frequency/Distance, Amplitude and Sweep.

There are seventeen keypad hard keys located to the right of the display. Twelve of the key

pad hard keys perform more than one function, depending on the current mode of operation.

The dual purpose keys are labeled with one function in black, the other in blue.

There are also six soft keys that change function depending upon the current mode selec

tion. The current soft key function is indicated in the active function block to the right of

the display. The locations of the different keys are illustrated in Figure 2-1.

Active

Function

MODE

Block

FREQ/DIST

Site Master S332C

AMPLITUDE

SWEEP

START

CAL

SAVE

SETUP

LIMIT

SAVE

DISPLAY

ON

OFF

1

3

5

7

9

Soft Keys

2

AUTO

SCALE

4

RECALL

SETUP

6

MARKER

8

RECALL

DISPLAY

0

PRINT

.

ESCAPE

CLEAR

ENTER

RUN

HOLD

SYS

Keypad

Hard

Keys

+

-

/

-

Function Hard Keys

Figure 2-1. Site Master Soft Keys

The following sections describe the various key functions.

2-2

Page 18

Chapter 2 Functions and Operations

Function Hard Keys

MODE Opens the mode selection box (below). Use the Up/Down arrow key to select a

mode. Press the

MEASUREMENT MODE

FREQ - SWR

DTF - SWR

POWER MONITOR

SPECTRUM ANALYZER

Figure 2-2. Mode Selection Box

FREQ/DIST Displays the Frequency or Distance to Fault softkey menus depending on the

measurement mode.

ENTER key to implement.

RETURN LOSS

CABLE LOSS - ONE PORT

RETURN LOSS

AMPLITUDE Displays the amplitude softkey menu for the current operating mode.

SWEEP Displays the Sweep function softkey menu for the current operating mode.

2-3

Page 19

Chapter 2 Functions and Operations

Keypad Hard Keys

This section contains an alphabetical listing of the Site Master front panel keypad controls

along with a brief description of each. More detailed descriptions of the major function

keys follow.

The following keypad hard key functions are printed in black on the keypad keys.

0-9 These keys are used to enter numerical data as required to setup or per

form measurements.

+/–

·

ESCAPE

CLEAR

UP/DOWN

ARROWS

NOTE: At turn on, before any other keys are pressed, the Up/Down arrow key

may be used to adjust the display contrast. Press

eration.

ENTER Implements the current action or parameter selection.

The plus/minus key is used to enter positive or negative values as required

to setup or perform measurements.

The decimal point is used to enter decimal values as required to setup or

perform measurements.

Exits the present operation or clears the display. If a parameter is being

edited, pressing this key will clear the value currently being entered and

restore the last valid entry. Pressing this key again will close the parame

ter. During normal sweeping, pressing this key will move up one menu

level.

Increments or decrements a parameter value. The specific parameter value

affected typically appears in the message area of the LCD.

ENTER to return to normal op-

-

-

ON

OFF

SYS Allows selection of display language and system setup parameters.

Turns the Anritsu Site Master on or off. When turned on, the system state

at the last turn-off is restored. If the ESCAPE/CLEAR key is held down

while the ON/OFF key is pressed, the factory preset state will be restored.

Choices are OPTIONS, CLOCK, SELF TEST, STATUS and

LANGUAGE.

2-4

Page 20

Chapter 2 Functions and Operations

The following keypad hard key functions are printed in blue on the keypad keys.

Turns the liquid crystal display (LCD) back-lighting ON or OFF.

(Leaving back lighting off conserves battery power.)

LCD Contrast adjust. Use the Up/Down arrow key and

ENTER to adjust

the display contrast.

AUTO

Automatically scales the display for optimum resolution.

SCALE

LIMIT Displays the limit line menu for the current operating mode.

MARKER Displays the marker menu of the current operating mode.

PRINT Prints the current display to the selected printer via the RS232 serial port.

RECALL

DISPLAY

Recalls a previously saved trace from memory. When the key is pressed, a

Recall Trace selection box appears on the display. Select a trace using the

Up/Down arrow key and press the

To erase a saved trace, highlight the trace and select the

ENTER key to implement.

DELETE TRACE

softkey. To erase all saved traces, select the DELETE ALL TRACES

softkey.

RECALL

SETUP

Recalls a previously saved setup from memory location 1 through 10.

When the key is pressed, a

RECALL SETUP selection box appears on the

display. Select a setup using the Up/Down arrow key and press the

ENTER key to implement. Setup 0 recalls the factory preset state.

RUN

HOLD

SAVE

DISPLAY

SAVE

SETUP

START

CAL

When in the Hold mode, this key starts the Site Master sweeping and provides a Single Sweep Mode trigger; when in the Run mode, it pauses the

sweep. When in the Hold mode, the hold symbol (page 2-19) appears on

the display. Hold mode conserves battery power.

Saves up to 200 displayed traces to non-volatile memory. When the key is

pressed,

TRACE NAME: appears in the lower left of the display. Save the

display with up to 16 alphanumeric characters for that trace name and

press the

ENTER key to implement.

Saves the current system setup to 1 of 10 internal non-volatile memory lo

cations. When the key is pressed, a

SAVE SETUP selection box appears

on the display. Use the Up/Down arrow key to select a setup and press the

ENTER key to implement.

Starts the calibration in SWR, Return Loss, Cable Loss, or DTF measure

ment modes (not available in Spectrum Analyzer mode).

-

-

2-5

Page 21

Chapter 2 Functions and Operations

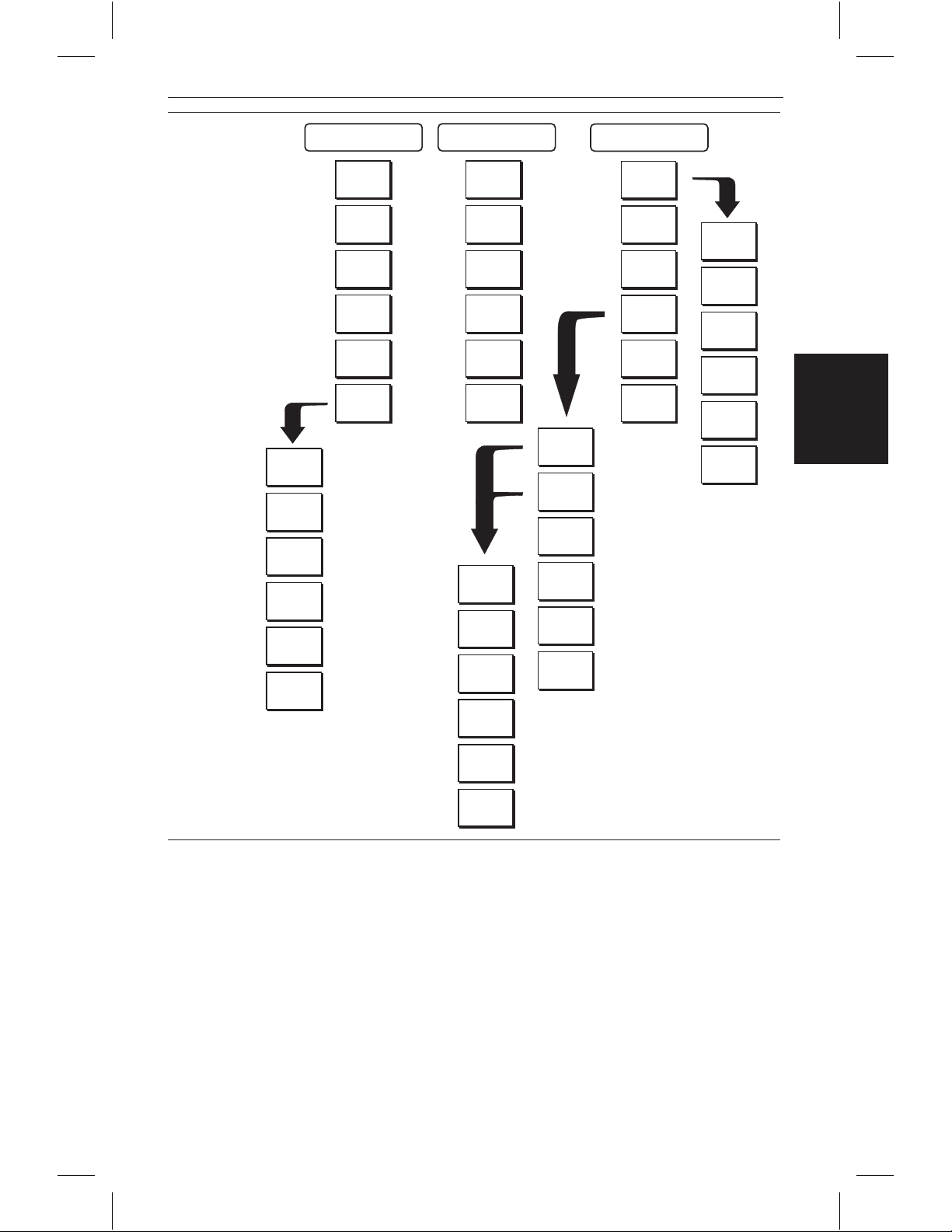

Soft Keys

Each keypad key opens a set of soft key selections. Each of the soft keys has a correspond

ing soft key label area on the display. The label identifies the function of the soft key for the

current Mode selection.

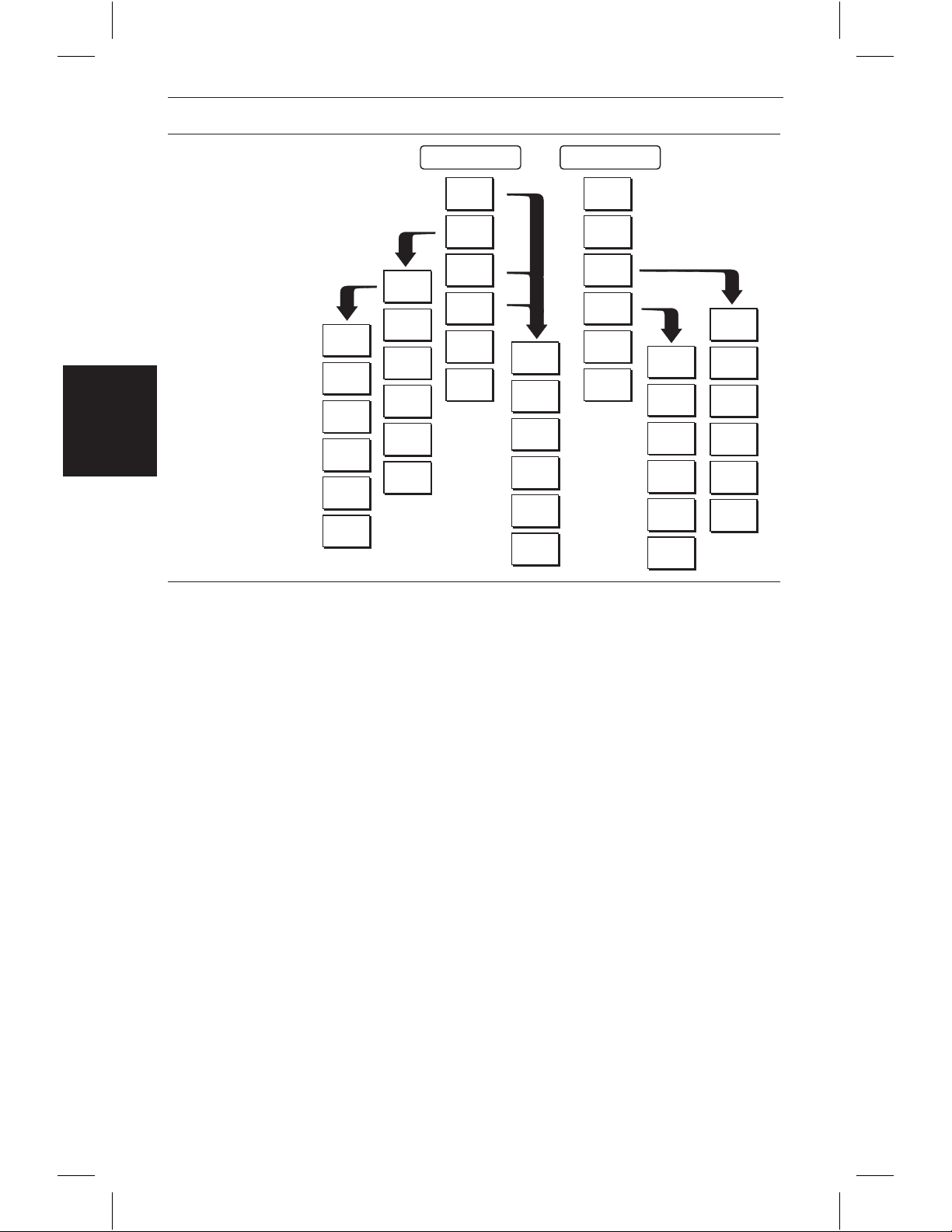

Figures 2-3 through 2-7 show the soft key labels for each Mode selection.

MODE=FREQ:

SOFTKEYS:

FREQ/DIST

F1

F2

AMPLITUDE

TOP

BOTTOM

ON/OFF

SELECT

TRACE

SWEEP

RESOLUTION

SINGLE

SWEEP

TRACE

MATH

TRACE

OVERLAY

130

259

517

-

Figure 2-3. Frequency Mode Soft Key Labels

TOP

OF

LIST

PAG E UP

PAGE

DOWN

BOTTOM

OF

LIST

DELETE

TRACE

DELETE

ALL

TRACE

BACK

2-6

Page 22

Chapter 2 Functions and Operations

MODE=DTF:

SOFTKEYS:

CABLE

WINDOW

LOSS

PROP

VEL

FREQ/DIST

D1

D2

DTF AID

MORE

AMPLITUDE

TOP

BOTTOM

TOP

OF

LIST

ON/OFF

SELECT

TRACE

SWEEP

RESOLUTION

SINGLE

SWEEP

TRACE

MATH

TRACE

OVERLAY

130

259

517

PAG E UP

BACK

BOTTOM

DELETE

Figure 2-4. Distance to Fault Mode Soft Key Labels

PAGE

DOWN

OF

LIST

TRACE

DELETE

ALL

TRACE

BACK

2-7

Page 23

Chapter 2 Functions and Operations

EDIT

FULL

ZERO

SPAN

UP

1-2-5

SPAN

DOWN

1-2-5

BACK

FREQ/DIST

CENTER

SPAN

START

STOP

MODE=SPECTRUM ANALYZER:

SOFTKEYS:

GHz

MHz

kHz

Hz

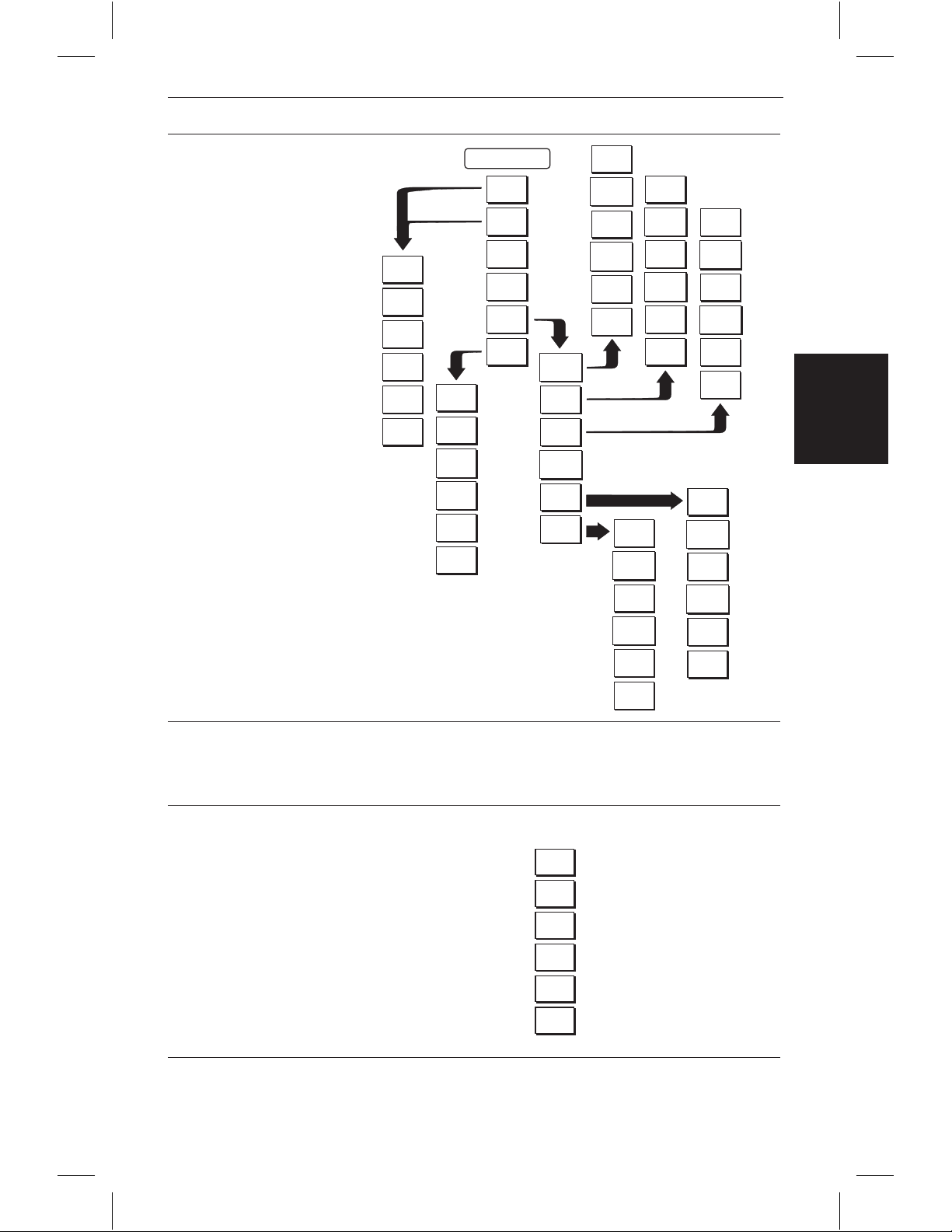

Figure 2-5. Spectrum Analyzer Mode Soft Key Labels

GHz

MHz

kHz

Hz

AMPLITUDE

REF

LEVEL

SCALE

ATTEN

UNITS

dBm

dBV

dBmV

dBuV

BACK

AUTO

MANUAL

EDIT

BACK

2-8

Page 24

Chapter 2 Functions and Operations

MODE=SPECTRUM ANALYZER:

SOFTKEYS:

AUTO

MANUAL

EDIT

BACK

RESET

A

AB®

ABA-

®

A+B

®

A

TRACE

B

BACK

SWEEP

RBW

VBW

MAX

HOLD

CONT/

SINGLE

MEASURE

TRACE

FIELD

STRNGTH

OBW

DETEC-

TION

AVERAGE

(1-25)

CHANNEL

POWER

ACP

ON/OFF

SELECT

ANTENNA

BACK

CENTER

CHANNEL

CHANNEL

CHANNEL

SPACING

FREQ

MAIN

BW

ADJ

BW

METHOD

%

dBc

MEASURE

BACK

POSITIVE

PEAK

AVERAGE

NEGATIVE

PEAK

BACK

CENTER

FREQ

INT

BW

CHANNEL

SPAN

MEASURE

Figure 2-7. Spectrum Analyzer Mode Soft Key Labels (continued)

MODE=POWER MONITOR:

SOFTKEYS:

OFFSET

Figure 2-6. Power Monitor Mode Soft Key Labels

UNITS

REL

ZERO

MEASURE

BACK

BACK

2-9

Page 25

Chapter 2 Functions and Operations

FREQ/DIST Displays the frequency and distance menu depending on the measurement mode.

Frequency

Menu

Distance

Menu

Provides for setting sweep frequency end points when

FREQ mode is selected.

Selected frequency values may be changed using the keypad or Up/Down arrow

key.

F1 — Opens the F1 parameter for data entry. This is the start value for the

q

frequency sweep. Press

F2 — Opens the F2 parameter for data entry. This is the stop value for the

q

frequency sweep. Press

ENTER when data entry is complete.

ENTER when data entry is complete.

Provides for setting Distance to Fault parameters when a DTF mode is selected.

Choosing

DIST causes the soft keys, below, to be displayed and the correspond

ing values to be shown in the message area. Selected distance values may be

changed using the keypad or Up/Down arrow key.

D1 — Opens the start distance (D1) parameter for data entry. This is the start

q

value for the distance range (D1 default = 0). Press

ENTER when data entry

is complete.

D2 — Opens the end distance (D2) parameter for data entry. This is the end

q

value for the distance range. Press

DTF AID — Provides interactive help to optimize DTF set up parameters.

q

Use the Up/Down arrow key to select a parameter to edit. Press

ENTER when data entry is complete.

ENTER when

data entry is complete.

MORE — Selects the Distance Sub-Menu, detailed below.

q

-

Distance

Sub-Menu

Provides for setting the cable loss and relative propagation velocity of the coaxial cable. Selected values may be changed using the Up/Down arrow key or keypad.

q

LOSS — Opens the Cable Loss parameter for data entry. Enter the loss per

foot (or meter) for the type of transmission line being tested. Press

ENTER

when data entry is complete. (Range is 0.5 to 5.000 dB/m, 1.524 dB/ft)

q

PROP VEL (relative propagation velocity) — Opens the Propagation Veloc

ity parameter for data entry. Enter the propagation velocity for the type of

transmission line being tested. Press

ENTER when data entry is complete.

(Range is 0.010 to 1.000)

q

CABLE — Opens a list of cable folders for selection of a common coaxial ca

ble folder or custom coaxial cable folder. Select either folder and use the

Up/Down arrow key and

ENTER to make a selection. This feature provides a

rapid means of setting both cable loss and propagation velocity. (Refer to Ap

pendix A for a listing of common coaxial cables showing values for Relative

Propagation Velocity and Nominal Attenuation in dB/m or dB/ft @

1000 MHz, 2000 MHz and 2500 MHz.) The custom cable folder can consist

of up to 24 user-defined cable parameters downloaded via the Site Master

Software Tools program.

q

WINDOW — Opens a menu of FFT windowing types for the DTF calcula

tion. Scroll the menu using the Up/Down arrow key and make a selection

with the

ENTER key.

-

-

2-10

q

BACK — Returns to the Distance Menu.

Page 26

Chapter 2 Functions and Operations

Choosing FREQ/DIST in Spectrum Analyzer mode causes the soft keys, below, to be dis

played and the corresponding values to be shown in the message area.

CENTER ¾ Sets the center frequency of the Spectrum Analyzer display . En

q

ter a value using the Up/Down arrow key or keypad, press

ESCAPE to restore previous value.

SPAN ¾ Sets the user-defined frequency span. Use the Up/Down arrow key

q

or keypad to enter a value in MHz. Also brings up

EDIT allows editing of the frequency span. Enter a value using the num

q

FULL and ZERO softkeys.

ENTER to accept,

ber keys.

FULL span sets the Spectrum Analyzer to its maximum frequency span.

q

ZERO span sets the span to 0 Hz. This displays the input signal in an am

q

plitude versus time mode, which is useful for viewing modulation.

SPAN UP 1-2-5 activates the span function so that the span may be in

q

creased quickly in a 1-2-5 sequence.

SPAN DOWN 1-2-5 activates the span function so that the span may be

q

reduced quickly in a 1-2-5 sequence.

BACK returns to the previous menu level.

q

START ¾ Sets the Spectrum Analyzer in the START-STOP mode. Enter a

q

start frequency value (in kHz, MHz, or GHz) using the Up/Down arrow key

or keypad, press

ENTER to accept, ESCAPE to restore.

-

-

-

-

-

q STOP ¾ Sets the Spectrum Analyzer in the START-STOP mode. Enter a

stop frequency value (in kHz, MHz, or GHz) using the Up/Down arrow key

or keypad, press

ENTER to accept, ESCAPE to restore.

2-11

Page 27

Chapter 2 Functions and Operations

AMPLITUDE Displays the amplitude or scale menu depending on the measurement mode.

Amplitude

Menu

Provides for changing the display scale. Selected values may be changed using

the Up/Down arrow key or keypad.

Choosing

AMPLITUDE in FREQ or DTF measurement modes causes the soft

keys, below, to be displayed and the corresponding values to be shown in the

message area.

TOP — Opens the top parameter for data entry and provides for setting the

q

top scale value. Press

BOTTOM — Opens the bottom parameter for data entry and provides for set

q

ting the bottom scale value. Press

Choosing

AMPLITUDE in SPECTRUM ANALYZER mode causes the soft keys,

ENTER when data entry is complete.

ENTER when data entry is complete.

below, to be displayed and the corresponding values to be shown in the message

area.

REF LEVEL — Activates the amplitude reference level function.

q

SCALE — Activates the scale function in a 2 through 15 dB logarithmic am

q

plitude scale.

ATTEN — Sets the Anritsu input attenuator so that it is either coupled auto

q

matically to the reference level (

UNITS — Choose from the menu of amplitude related units. Selection of

q

AUTO) or manually adjustable (MANUAL).

-

dBm sets absolute decibels relative to 1 mW as the amplitude unit. Selection

of dBV, dBmV or dBmV sets absolute decibels relative to 1 volt, 1 millivolt,

or 1 microvolt respectively as the amplitude unit.

-

-

2-12

Page 28

Chapter 2 Functions and Operations

SWEEP Displays the Sweep function soft key menu for the current operating mode.

Sweep Menu Provides for changing the display resolution, single or continuous sweep, and

access to the Trace Math functions.

Choosing

SWEEP in FREQ or DTF measurement modes causes the soft keys

below to be displayed.

RESOLUTION — Opens the display to change the resolution. Choose 130,

q

259, or 517 data points. (In DTF mode, resolution can be adjusted through

the DTF-AID table.)

SINGLE SWEEP — Toggles the sweep between single sweep and continu

q

ous sweep. In single sweep mode, each sweep must be activated by the

RUN/HOLD button.

TRACE MATH — Opens up the Trace Math functions (trace-memory or

q

trace+memory) for comparison of the real time trace in the display with any

of the traces from memory. (Not available in DTF mode.)

TRACE OVERLAY — Opens up the Trace Overlay functions menu to allow

q

the current trace to be displayed with a trace in memory overlaid on it.

Choose ON or OFF and SELECT TRACE to select the trace from memory to

be overlaid.

Choosing

SWEEP in SPECTRUM ANALYZER mode causes the soft keys below

to be displayed.

RBW — Sets the resolution bandwidth so that it is either coupled automati-

q

cally to the span (

q

VBW — Sets the video bandwidth so that it is either coupled automatically to

the span (

AUTO) or manually adjustable (MANUAL).

AUTO) or manually adjustable (MANUAL).

-

q

MAX HOLD — Displays and holds the maximum responses of the input sig-

nal.

q

CONT/SINGLE — Toggles between continuous and single sweep.

q

MEASURE — Activates a menu of measurement related functions. Use the

corresponding softkey to select the measurement function.

q

FIELD STRENGTH — Accesses a menu of field strength measurement

options.

ON/OFF - Turns field strength measurements on or off.

SELECT ANTENNA - Selects an antenna profile to be used for field

strength measurements.

BACK - Returns to the previous menu.

q

OBW — Activates the occupied bandwidth menu. Select either

METHOD, % or dBc method of occupied bandwidth measurement.

METHOD allows selection of either % of power or dB Down.

Selecting % allows entry of the desired % of occupied bandwidth to be

measured.

Selecting dBc allows entry of the desired power level (dBc) to be mea

sured.

q

DETECTION — Accesses a menu of detector modes including POSI

TIVE PEAK detection, AVERAGE detection and NEGATIVE PEAK

detection.

-

-

2-13

Page 29

Chapter 2 Functions and Operations

AVERAGE (1-25) — The display will be an average of the number of

q

sweeps specified here. For example, if the number four is entered here,

the data displayed will be an average of the four most recent sweeps.

CHANNEL POWER — Activates Channel Power measurement. Chan

q

nel power is measured in dBm. Channel Power density is measured in

dBm/Hz.

ACP — Accesses a menu of Adjacent Channel Power ratio measurement

q

options:

CENTER FREQ - Activates the center frequency function and sets the

Anritsu Site Master to the center frequency. A specific center frequency

can be entered using the keypad or Up/Down arrow key. Select the GHz,

MHz, kHz,orHz softkey to accept the center frequency input.

MAIN CHANNEL BW - Sets the bandwidth of the main channel.

ADJACENT CHANNEL BW - Sets the bandwidth of the adjacent chan

nel.

CHANNEL SPACING - Sets the channel spacing.

MEASURE - Begins the ACP measurement.

BACK - Returns to the previous menu.

BACK - Returns to the previous menu.

q

TRACE — Activates a menu of trace related functions. Use the correspond-

q

ing softkey to select the desired trace function.

NOTE: For this function, Trace A is always the runtime trace, and Trace B is always a saved trace. Refer to page for information on saving and recalling

traces.

-

-

q

RESET A — Clears the current runtime trace.

q

A ® B — Stores the current runtime trace into the Trace B buffer.

q

A–B® A — Performs a subtraction trace math operation.

q

A+B®A — Performs an addition trace math operation.

q

TRACE B — Accesses a menu of saved trace options.

VIEW B - Provides a trace overlay of the saved trace with the current

runtime trace.

CLEAR B - Turns off trace overlay.

RECALL TRACE ® B - Recalls the saved trace B buffer.

q

BACK — Returns to the previous menu level.

2-14

Page 30

Chapter 2 Functions and Operations

Power Monitor Menu

Selecting POWER MONITOR from the Mode menu causes the soft keys, described below,

to be displayed and the corresponding values shown in the message area.

UNITS — Toggles between dBm and Watts.

q

REL — Turns relative mode OFF, if currently ON. If relative mode is cur

q

rently OFF, turns it ON and causes the power level to be measured and saved

as the base level. Subsequent measurements are then displayed relative to this

saved value. With units of dBm, relative mode displays dBr; with units of

Watts, relative mode displays % (percent).

OFFSET — Turns Offset OFF, if currently ON. If Offset is currently OFF,

q

turns it ON and opens the Offset parameter for data entry. Press

when data entry is complete.

Offset is the attenuation (in dB) inserted in the line between the DUT and the

RF detector. The attenuation is added to the measured input level prior to dis

play.

ZERO — Turns Zero OFF, if currently ON. If Zero is currently OFF, this

q

softkey turns it ON and initiates collection of a series of power level samples,

which are averaged and saved. This saved value is then subtracted from subsequent measurements prior to display.

-

ENTER

-

2-15

Page 31

Chapter 2 Functions and Operations

MARKER Choosing MARKER causes the soft keys, below, to be displayed and the corre

sponding values to be shown in the message area. Selected frequency marker or

distance marker values may be changed using the keypad or Up/Down arrow

key.

M1 — Selects the M1 marker parameter and opens the M1 marker second

q

level menu.

ON/OFF — Turns the selected marker on or off.

q

EDIT — Opens the selected marker parameter for data entry. Press

q

ENTER when data entry is complete or ESCAPE to restore the previous

value.

MARKER TO PEAK — Places the selected marker at the frequency or

q

distance with the maximum amplitude value.

MARKER TO VALLEY — Places the selected marker at the frequency or

q

distance with the minimum amplitude value.

BACK — Returns to the Main Markers Menu.

q

M2 through M4 — Selects the marker parameter and opens the marker second

q

level menu.

ON/OFF — Turns the selected marker on or off.

q

EDIT — Opens the selected marker parameter for data entry. Press

q

ENTER when data entry is complete or ESCAPE to restore the previous

value.

-

q DELTA (Mx-M1) — Displays delta amplitude value as well as delta fre-

quency or distance for the selected marker with respect to the M1 marker.

q

MARKER TO PEAK — Places the selected marker at the frequency or

distance with the maximum amplitude value.

q

MARKER TO VALLEY — Places the selected marker at the frequency or

distance with the minimum amplitude value.

q

BACK — Returns to the Main Markers Menu.

q

M5 — Selects the M5 marker parameter and opens the M5 second level

menu.

q

ON/OFF — Turns the selected marker on or off.

q

EDIT — Opens the selected marker parameter for data entry. Press

ENTER when data entry is complete or ESCAPE to restore the previous

value.

q

PEAK BETWEEN M1 & M2 — Places the selected marker at the fre

quency or distance with the maximum amplitude value between marker

M1 and marker M2.

q

VALLEY BETWEEN M1 & M2 — Places the selected marker at the fre

quency or distance with the minimum amplitude value between marker

M1 and marker M2.

q

BACK — Returns to the Main Markers Menu.

-

-

2-16

q

M6 — Selects the M6 marker parameter and opens the M6 second level

menu.

Page 32

Chapter 2 Functions and Operations

ON/OFF — Turns the selected marker on or off.

q

EDIT — Opens the selected marker parameter for data entry. Press

q

ENTER when data entry is complete or ESCAPE to restore the previous

value.

LIMIT

PEAK BETWEEN M3 & M4 — Places the selected marker at the peak be

q

tween marker M3 and marker M4.

VALLEY BETWEEN M3 & M4 — Places the selected marker at the valley

q

between marker M3 and marker M4.

BACK — Returns to the Main Markers Menu.

q

Pressing LIMIT on the data keypad activates a menu of limit related functions.

Use the corresponding softkey to select the desired limit function. Then use the

Up/Down arrow key to change its value, which is displayed in the message area

at the bottom of the display.

Choosing

LIMIT in FREQ or DTF measurement modes causes the soft keys be

low to be displayed.

SINGLE LIMIT — Sets a single limit value in dBm. Menu choices are:

q

ON/OFF

EDIT

BACK

MULTIPLE LIMITS — Sets multiple user defined limits, and can be used to

q

create a limit mask for quick pass/fail measurements. Menu choices are:

SEGMENT 1

SEGMENT 2

SEGMENT 3

SEGMENT 4

SEGMENT 5

BACK

-

-

q

LIMIT BEEP — Turns the audible limit beep indicator on or off.

Choosing

LIMIT in SPECTRUM ANALYZER measurement mode causes the soft

keys below to be displayed.

q

SINGLE LIMIT — Sets a single limit value in dBm. Menu choices are:

ON/OFF

EDIT

BACK

q

MULTIPLE UPPER LIMITS — Sets multiple user defined upper limits, and

can be used to create an upper limit mask for quick pass/fail measurements.

Menu choices are:

SEGMENT 1

SEGMENT 2

SEGMENT 3

SEGMENT 4

SEGMENT 5

BACK

q

MULTIPLE LOWER LIMITS — Set multiple user defined lower limits, and

can be used to create a lower limit mask for quick pass/fail measurements.

Menu choices are:

2-17

Page 33

Chapter 2 Functions and Operations

SEGMENT 1

SEGMENT 2

SEGMENT 3

SEGMENT 4

SEGMENT 5

BACK

LIMIT BEEP — Turns the audible limit beep indicator on or off.

q

SYS Displays the System menu softkey selections.

OPTIONS — Displays a second level of functions:

q

UNITS — Select the unit of measurement (English or metric).

q

PRINTER — Displays a menu of supported printers. Use the Up/Down

q

arrow key and

FIXED CW — Toggles the fixed CW function ON or OFF. When OFF, a

q

ENTER key to make the selection.

narrow band of frequencies centered on the selected frequency is gener

ated. When CW is ON, only the center frequency is generated. Output

power is pulsed in all modes.

CHANGE DATE FORMAT — Toggles the date format between

q

MM/DD/YY, DD/MM/YY, and YY/MM/DD.

-

BACK — Returns to the top-level SYS Menu.

q

CLOCK — Displays a second level of functions:

q

q HOUR — Enter the hour (0-23) using the Up/Down arrow key or the key-

pad. Press

ENTER when data entry is complete or ESCAPE to restore the

previous value.

q

MINUTE — Enter the minute (0-59) using the Up/Down arrow key or the

keypad. Press

ENTER when data entry is complete or ESCAPE to restore

the previous value.

q

MONTH — Enter the month (1-12) using the Up/Down arrow key or the

keypad. Press

ENTER when data entry is complete or ESCAPE to restore

the previous value.

q

DAY — Enter the day using the Up/Down arrow key or the keypad. Press

ENTER when data entry is complete or ESCAPE to restore the previous

value.

q

YEAR — Enter the year (1997-2036) using the Up/Down arrow key or

the keypad. Press

ENTER when data entry is complete or ESCAPE to re

store the previous value.

q

BACK — Returns to the top-level SYS menu.

q

SELF TEST — Start an instrument self test.

q

STATUS — Displays the current instrument status, including calibration sta

tus, temperature, and battery charge state. Press ESCAPE to return to opera

tion.

-

-

-

2-18

q

Language — Pressing this soft key immediately changes the language used

to display messages on the Site Master display. Choices are English, French,

German, Spanish, Chinese, and Japanese. The default language is English.

Page 34

Chapter 2 Functions and Operations

Symbols

Table 2-1 provides a listing of the symbols used as condition indicators on the LCD display.

Table 2-1. LCD Icon Symbols

Icon Symbol

Site Master is in Hold for power conservation. To resume sweeping, press

HOLD

the

RUN/HOLD key. After 10 minutes without a key press, the Site Master

will automatically activate the power conservation mode.

ò

dx

T

6

CAL ON

CAL ON!

CALL OFF

Integrator Failure. Intermittent integrator failure may be caused by inter

ference from another antenna. Persistent integrator failure indicates a need

to return the Site Master to the nearest Anritsu service center for repair.

Lock fail indication. Check battery. (If the Site Master fails to lock with a

fully charged battery, call your Anritsu Service Center.)

When calibration is performed, the Site Master stores the ambient temper

ature. If the temperature drifts outside the specified range, this indicator

will flash. A recalibration at the current temperature is recommended.

Indicates the remaining charge on the battery. The inner white rectangle

grows longer as the battery charge depletes.

Indicates internal data processing.

The Site Master has been calibrated.

The Site Master has been calibrated with the InstaCal Module.

The Site Master has not been calibrated.

-

-

Self Test

At turn-on, the Site Master runs through a series of quick checks to ensure the system is

functioning properly. Note that the battery voltage and temperature are displayed in the

lower left corner below the self test message. If the battery is low, or if the ambient temper

ature is not within the specified operational range, Self Test will fail. If Self Test fails and

the battery is fully charged and the Site Master is within the specified operating range, call

your Anritsu Service Center.

Error Codes

Self Test Errors

A listing of Self Test Error messages is given in Table 2-2.

-

2-19

Page 35

Chapter 2 Functions and Operations

Table 2-2. Self Test Error Messages

Error Message

BATTERY LOW

EXTERNAL

POWER LOW

PLL FAILED

INTEGRATOR

FAILED

EEPROM R/W

FAILED

OUT OF TEMP.

RANGE

RTC BATTERY

LOW

LO LOCK FAIL The local oscillator in the spectrum analyzer has phase lock loop er-

Battery voltage is less than 9.5 volts. Charge battery. If condition per

sists, call your Anritsu Service Center.

External supply voltage is less than 12.5 volts. Call your Anritsu Ser

vice Center

Phase-locked loops failed to lock. Charge battery. If condition persists

with a fully charged battery, call your Anritsu Service Center

Integration circuit could not charge to a valid level. Charge battery. If

condition persists with a fully charged battery, call your Anritsu Ser

vice Center.

Non-volatile memory system has failed. Call your Anritsu Service

Center.

Ambient temperature is not within the specified operating range. If the

temperature is within the specified operating range and the condition

persists, call your Anritsu Service Center.

The internal real-time clock battery is low. A low or drained clock battery will affect the date stamp on saved traces. Contact your nearest

Anritsu Service Center.

rors. If condition persists with a fully charged battery, call your Anritsu

Service Center.

Description

-

-

-

POWER MONITOR

FAIL

BATTERY CAL

LOST

MEMORY FAIL

The time and date

Have not been set

on this Site Master.

To set it, after exit

ing here press

the <SYS>

[CLOCK] keys.

Press ENTER or

ESC to continue

Note: A listing of Anritsu Service Centers is provided in Table 1-2 , page 1-8.

Failure of the power monitor system board voltages. If condition persists, call your Anritsu Service Center.

Battery communication failed. The indicated battery charge status may

be invalid. If condition persists, call your Anritsu Service Center.

The EEPROM test on the Site Master main board has failed. If condi

tion persists, call your Anritsu Service Center.

The time and date are not properly set in the Site Master. If condition

persists, call your Anritsu Service Center.

-

-

2-20

Page 36

Range Errors

A listing of Range Error messages is given in Table 2-3.

Table 2-3. Range Error Messages (1 of 2)

Error Message

RANGE

ERROR:F1 > F2

RANGE

ERROR:D1 > D2

RANGE

ERROR:D2 >

DMax=xx.x ft (m)

The start (F1) frequency is greater than the stop (F2) frequency.

The start (D1) distance is greater than the stop (D2) distance.

The stop distance (D2) exceeds the maximum unaliased range. This

range is determined by the frequency span, number of points,

and relative propagation velocity:

MaximumUnaliased Range

Where: dp is the number of data points (130, 259, or 517)

V

is the relative propagation velocity

f

F2 is the stop frequency in Hz

F1 is the start frequency in Hz

Maximum Unaliased Range is in meters

Chapter 2 Functions and Operations

Description

8

´-

( . )( )( )15 10

=

dp V

1

FF

-

21

f

RANGE ERROR:

TOP<=BOTTOM

RANGE ERROR:

TOP>=BOTTOM

CAL

INCOMPLETE

DIST REQUIRES

F1<F2

DIST REQUIRES

CAL

NO STORED

SWEEP AT THIS

LOCATION

USE OPTIONS

MENU TO

SELECT A

PRINTER

DISTANCE AND

CABLE

INSERTION LOSS

MODE ARE

INCOMPATIBLE

The SWR scale parameter top value is less than or equal to its bottom

value.

The RL scale parameter top value is greater than or equal to its bottom

value.

A complete open, short, and load calibration must be performed before calibration can be turned on.

Valid distance to fault plots require a non-zero frequency span.

Distance-to-fault measurements cannot be performed with CAL OFF.

Attempting to recall a display from a location that has not been previ

ously written to. That is, the location does not contain stored sweep.

Attempting to print a display with no printer selected. Select a printer,

then retry.

DTF measurements only display RL or SWR versus distance.

-

2-21

Page 37

Chapter 2 Functions and Operations

Table 2-3. Range Error Messages (2 of 2)

Error Message

CANNOT ZERO

NO DETECTOR

INSTALLED

CANNOT ZERO

INPUT SIGNAL

TOO HIGH

POWER MONITOR

OPTION NOT

INSTALLED

Attempting to perform a Power Monitor zero adjust function with no

RF detector connected to the Site Master.

Attempting to perform a Power Monitor zero adjust function with an

input of greater than –20 dBm.

Attempting to enter Power Monitor mode with no Option 5 installed.

Description

InstaCal Error Messages

If an InstaCal module that has not been characterized in more than one year is connected to

the Site Master, the follow message will be displayed:

The InstaCal Module Connected, S/N XXXXX

Was Characterized more than 1 year ago.

Characterization date

Current SiteMaster Date

You are advised to return this InstaCal module

to the factory for re-characterization.

Press ENTER to continue, see manual for details.

Return the InstaCal module to the factory for re-characterization in order to ensure contin

ued accurate measurements.

If the serial number of the connected InstaCal module does not match the serial number

stored in the Site Master, the following message is displayed:

The InstaCal characterization data stored in the SiteMaster

is for a module different than the one currently connected.

SiteMaster contains data for InstaCal module S/N:

Currently connected InstaCal Module S/N:

Would you like to overwrite the previously

loaded InstaCal characterization?

Press the YES soft key to update the stored InstaCal characterization to use the currently

connected module.

Press the

NO soft key to keep the stored InstaCal characterization.

2-22

-

Page 38

A listing of InstaCal error messages is given in Table 2-4.

Table 2-4. InstaCal Error Messages

Chapter 2 Functions and Operations

Error Message

FAILED TO READ

SERIAL NUMBER

OF INSTACAL

MODULE

FAILED TO SUC

CESSFULLY

TRANSFER

INSTACAL MOD

ULE DATA TO

SITE MASTER

FAILED TO SET

BAUD WITH

INSTACAL

MODULE

Description

The Site Master was unable to read the InstaCal module serial number.

The Site Master was unable to transfer all necessary data between the

-

InstaCal module and the Site Master.

-

The Site Master was unable to establish communication with the

InstaCal module.

2-23

Page 39

Chapter 2 Functions and Operations

Battery Information

Charging a New Battery

The NiMH battery supplied with the Site Master has already completed three charge and

discharge cycles at the factory and full battery performance should be realized after your

first charge.

NOTE: The battery will not charge if the battery temperature is above 45° Cor

below 0° C.

Charging the Battery in the Site Master

The battery can be charged while installed in the Site Master.

Step 1. Turn the Site Master off.

Step 2. Connect the AC-DC adapter (Anritsu part number: 40-115) to the Site Master

charging port.

Step 3. Connect the AC adapter to a 120 VAC or 240 VAC power source as appropriate

for your application.

The green external power indicator on the Site Master will illuminate, indicating

the presence of external DC power and the battery will begin charging. The indicator will remain lit as long as the battery is charging. Once the battery is fully

charged, the battery indicator will turn off. If the battery fails to charge, contact

your nearest Anritsu service center.

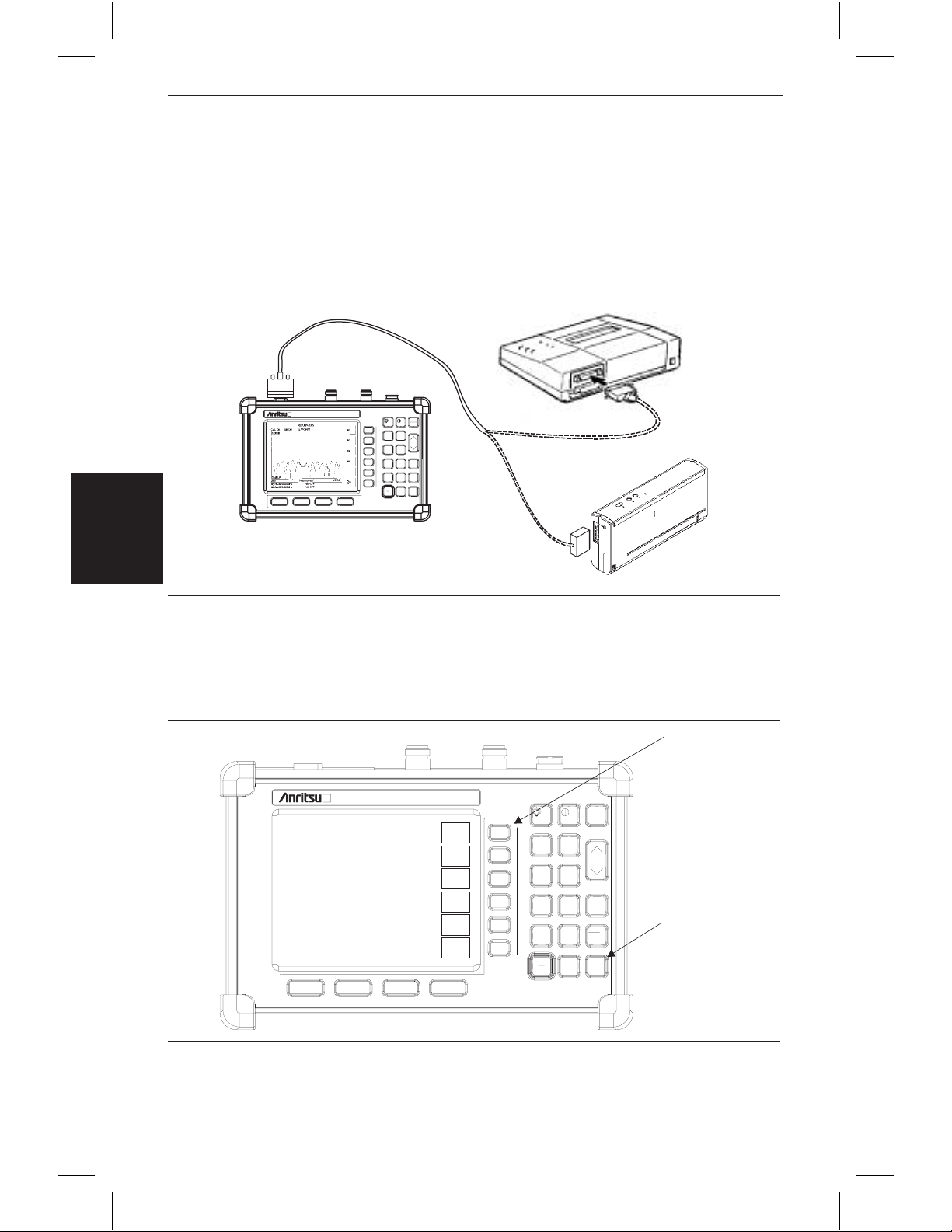

Charging the Battery in the Optional Charger

Up to two batteries can be charged simultaneously in the optional battery charger.

Step 1. Remove the NiMH battery from your Site Master and place it in the optional

charger (Anritsu part number 2000-1029).

Step 2. Connect the lead from the AC-DC adapter to the charger.

Step 3. Connect the AC-DC adapter to a 120 VAC or 240 VAC power source as appro

priate for your application.

Each battery holder in the optional charger has an LED charging status indicator. The LED

color changes as the battery is charged:

Red indicates the battery is charging

Green indicates the battery is fully charged

Yellow indicates the battery is in a waiting state (see below).

A yellow light may occur because the battery became too warm during the charge cycle.

The charger will allow the battery to cool off before continuing the charge. A yellow light

may also indicate that the charger is alternating charge to each of the two batteries.

-

A blinking red light indicates less than 13 VDC is being supplied to the charger stand.

Check that the correct AC charger adapter is connected to the charger stand. If the battery

fails to charge, contact your nearest Anritsu Service Center.

2-24

Page 40

Chapter 2 Functions and Operations

The NiMH battery will last longer and perform better if allowed to completely discharge

before recharging. For maximum battery life, it is recommended that the NiMH battery be

completely discharged and recharged once every three months.

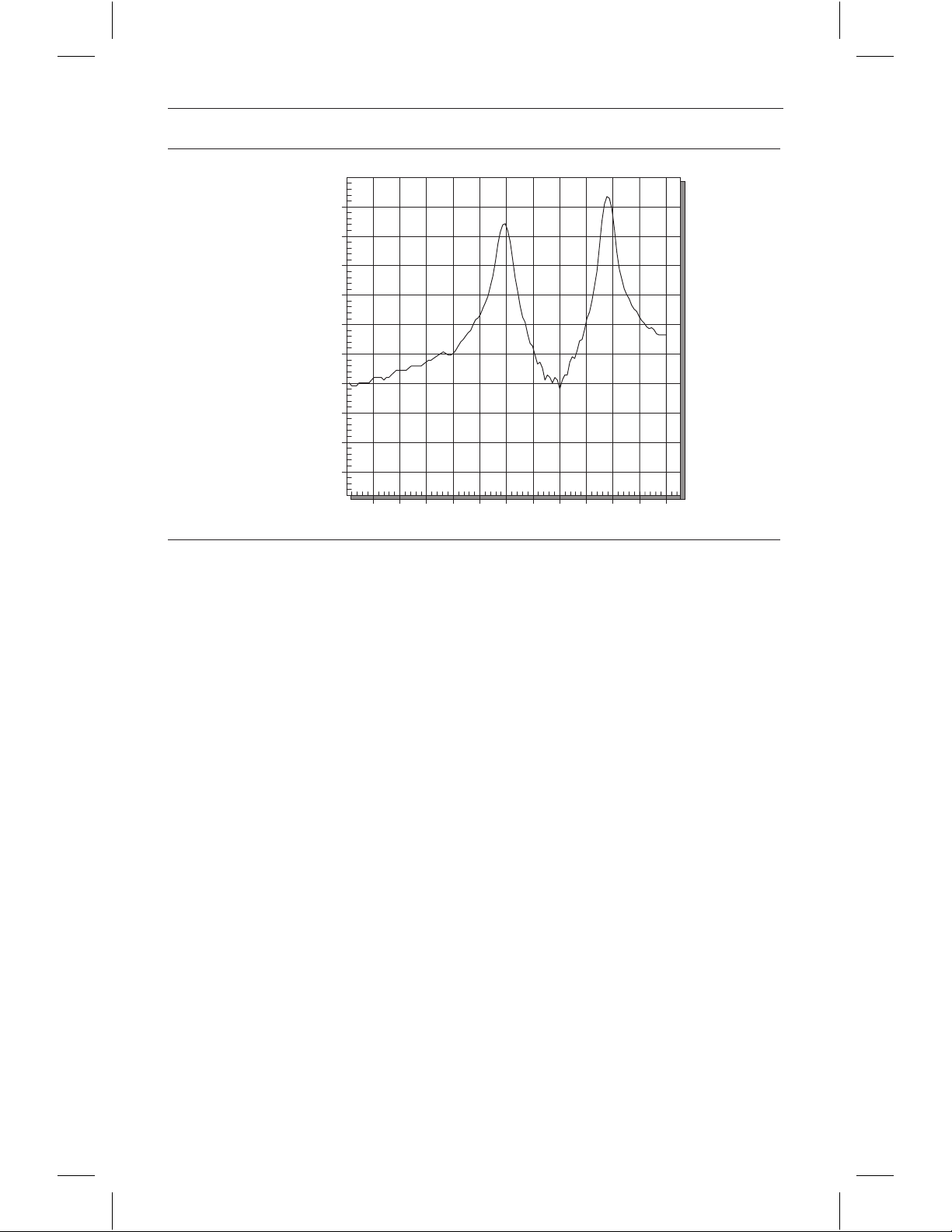

Battery Charge Indicator

When the AC-DC adapter is unplugged from the Site Master, the battery indicator symbol

will be continuously displayed at the top left corner of the Site Master display (Figure 2-8).

BATTERY INDICATOR

Figure 2-8. Site Master Battery Indicator

A totally black bar indicates a fully charged battery. When LOW BATT replaces the battery

indicator bar at the top left corner, a couple of minutes of measurement time remains. If a

flashing LOW BATT is accompanied by an audio beep at the end of each trace, the battery

has approximately one minute of useable time remaining.

Once all the power has drained from the battery, the Site Master display will fade. At this

point, your Site Master will switch itself off and the battery will need to be recharged.

Battery Life

It is normal for NiMH batteries to self-discharge during storage, and to degrade to 80% of

original capacity after 12 months of continuous use.

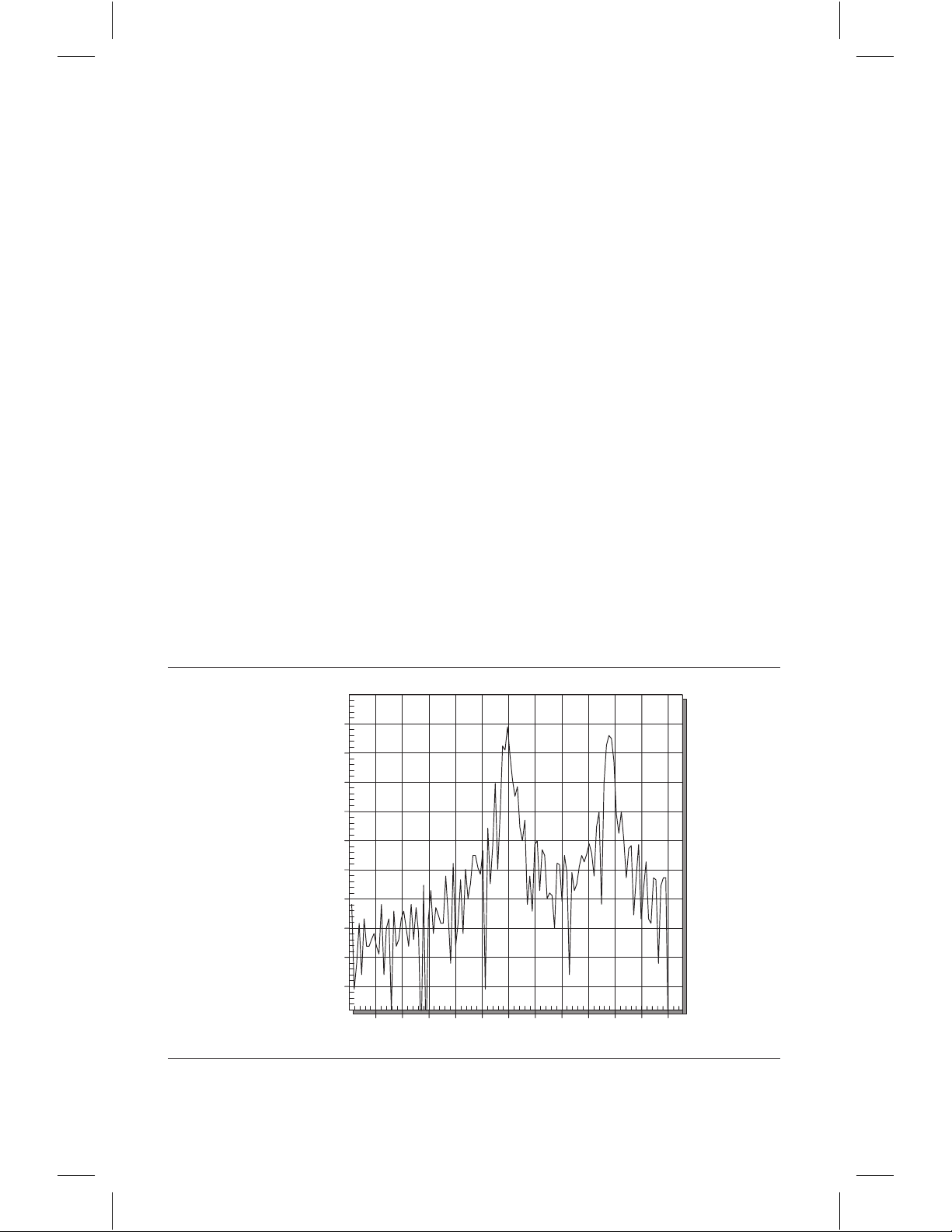

Figure 2-9. NiMH Battery Storage Characteristics

2-25

Page 41

Chapter 2 Functions and Operations

The battery can be charged and discharged 300 to 500 times, but it will eventually wear out.

The battery may need to be replaced when the operating time between charging is notice

ably shorter than normal.

Important Battery Information

With a new NiMH battery, full performance is achieved after three to five complete

·

charge and discharge cycles. The NiMH battery supplied with the Site Master has already

completed three charge and discharge cycles at the factory.

Recharge the battery only in the Site Master or in an Anritsu approved charger.

·

When the Site Master or the charger is not in use, disconnect it from the power source.

·

Do not charge batteries for longer than 24 hours; overcharging may shorten battery life.

·

If left unused a fully charged battery will discharge itself over time. Storing the battery in

·

extreme hot or cold places will reduce the capacity and lifetime of the battery. The bat

tery will discharge faster at higher ambient temperatures.

Discharge an NiMH battery from time to time to improve battery performance and bat

·

tery life.

The battery can be charged and discharged hundreds of times, but it will eventually wear

·

out.

The battery may need to be replaced when the operating time between charging is notice-

·

ably shorter than normal.

-

-

-

Do not short-circuit the battery terminals.

·

Do not drop, mutilate or attempt to disassemble the battery.

·

·

Never use a damaged or worn out charger or battery.

·

Always use the battery for its intended purpose only.

·

Temperature extremes will affect the ability of the battery to charge: allow the battery to

cool down or warm up as necessary before use or charging.

·

Batteries must be recycled or disposed of properly. Do not place batteries in garbage.

·

Do not dispose of batteries in a fire!

2-26

Page 42

Chapter 3

Getting Started

Introduction

This chapter provides a brief overview of the Anritsu Site Master. The intent of this chapter

is to provide the user with a starting point for making basic measurements.

Power On Procedure

The Anritsu Site Master is capable of up to 2.5 hours of continuous operation from a fully

charged, field-replaceable battery. Built-in energy conservation features allow battery life to

be extended over an eight-hour workday.

The Site Master can also be operated from a 12.5 Vdc source (which will also simulta

neously charge the battery). This can be achieved with either the Anritsu AC-DC Adapter

(P/N 40-115) or 12.5 Vdc Automotive Cigarette Lighter Adapter (P/N 806-62). Both items

are included as standard accessories (see Chapter 1).

To power on the Site Master:

Step 1.

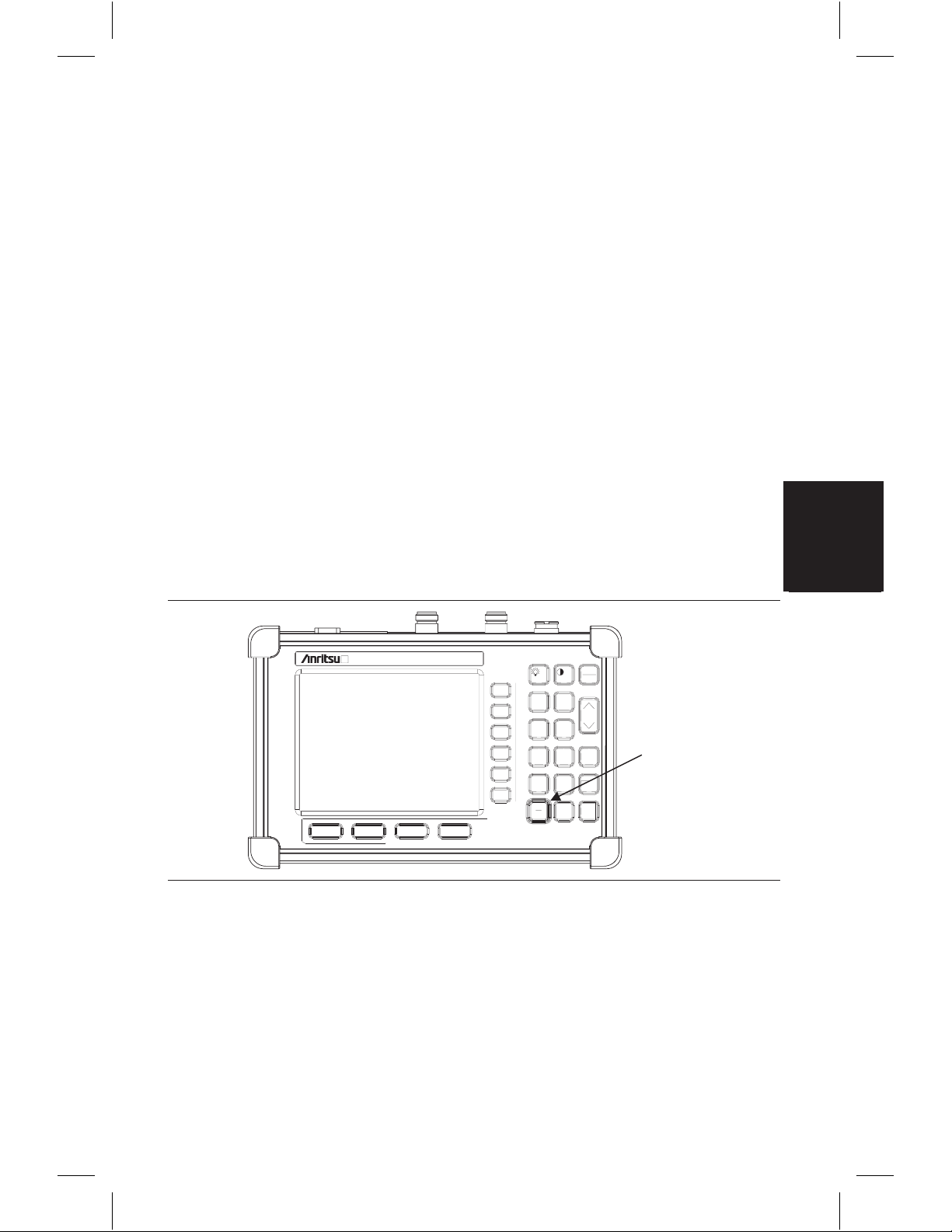

Figure 3-1. Site Master On/Off Key

Press the ON/OFF front panel key (Figure 3-1).

Site Master S332C

2

1

START

AUTO

CAL

SCALE

3

4

SAVE

RECALL

SETUP

SETUP

6

5

LIMIT

MARKER

8

7

RECALL

SAVE

DISPLAY

DISPLAY

9

0

PRINT

ON

OFF

MODE

FREQ/DIST

AMPLITUDE

SWEEP

.

ESCAPE

CLEAR

ENTER

RUN

HOLD

SYS

ON/OFF

KEY

+

-

/

-

3

Step 2.

The Site Master takes about five seconds to perform a series of self-diagnostic

and adjustment routines. At completion, the screen displays the Anritsu logo, the

model number, and the firmware version. The Site Master will continue after a

10 second timeout, or:

Press ENTER to continue.

The Site Master is now ready for operation.

3-1

Page 43

Chapter 3 Getting Started

Select the Frequency or Distance

Regardless of the calibration method used, the frequency range for the desired measure

ments must be set before calibrating the Site Master. The following procedure selects the

frequency range for the calibration.

Step 1. Press the

Step 2. Press the

Step 3. Enter the desired start frequency using the key pad or the Up/Down arrow key.

Step 4. Press

Step 5. Press the

Step 6. Enter the desired stop frequency using the keypad or the Up/Down arrow key.

Step 7. Press