Page 1

MP1900A

this

Signal Quality Analyzer-R

Operation Manual

Ninth Edition

For safety and warning information, please read

manual before attempting to use the equipment.

Keep this manual with the equipment.

ANRITSU CORPORATION

Document No.: M-W3911AE-9.0

Page 2

Safety Symbols

DANGER

WARNING

CAUTION

To prevent the risk of personal injury or loss related to equipment malfunction, Anritsu Corporation uses the

following safety symbols to indicate safety-related information. Ensure that you clearly understand the meanings of

the symbols BEFORE using the equipment. Some or all of the following symbols may be used on all Anritsu

equipment. In addition, there may be other labels attached to products that are not shown in the diagrams in this

manual.

Symbols used in manual

This indicates a very dangerous procedure that could result in serious injury or

death if not performed properly.

This indicates a hazardous procedure that could result in serious injury or death if

not performed properly.

This indicates a hazardous procedure or danger that could result in light-to-severe

injury, or loss related to equipment malfunction, if proper precautions are not taken.

Safety Symbols Used on Equipment and in Manual

The following safety symbols are used inside or on the equipment near operation locations to provide information

about safety items and operation precautions. Ensure that you clearly understand the meanings of the symbols and

take the necessary precautions BEFORE using the equipment.

This indicates an obligatory safety precaution. The obligatory operation is

This indicates a warning or caution. The contents are indicated symbolically in or

This indicates a note. The contents are described in the box.

These indicate that the marked part should be recycled.

This indicates a prohibited operation. The prohibited operation is indicated

symbolically in or near the barred circle.

indicated symbolically in or near the circle.

near the triangle.

MP1900A

Signal Quality Analyzer-R

Operation Manual

19 June 2017 (First Edition)

12 February 2021 (Ninth Edition)

Copyright © 2017-2021, ANRITSU CORPORATION.

All rights reserved. No part of this manual may be reproduced without the prior written permission of the

publisher.

The operational instructions of this manual may be changed without prior notice.

Printed in Japan

ii

Page 3

For Safety

Electric Shock

Repair

Calibration

WARNING

● ALWAYS refer to the operation manual when working near locations

at which the alert mark shown on the left is attached. If the advice in

the operation manual is not followed, there is a risk of personal injury

or reduced equipment performance. The alert mark shown on the left

may also be used with other marks and descriptions to indicate other

dangers.

● Overvoltage Category

This equipment complies with overvoltage category II defined in IEC

61010. DO NOT connect this equipment to the power supply of

overvoltage category III or IV.

● To ensure that the equipment is grounded, always use the supplied

3-pin power cord, and insert the plug into an outlet with a ground

terminal. If power is supplied without grounding the equipment, there

is a risk of receiving a severe or fatal electric shock or causing

damage to the internal components.

● Only qualified service personnel with a knowledge of electrical fire and

shock hazards should service this equipment. This equipment cannot

be repaired by the operator. DO NOT attempt to remove the

equipment covers or unit covers or to disassemble internal

components. There are high-voltage parts in this equipment

presenting a risk of severe injury or fatal electric shock to untrained

personnel. In addition, there is a risk of damage to precision

components.

● The performance-guarantee seal verifies the integrity of the equipment.

To ensure the continued integrity of the equipment, only Anritsu

service personnel, or service personnel of an Anritsu sales

representative, should break this seal to repair or calibrate the

equipment. Be careful not to break the seal by opening the

equipment or unit covers. If the performance-guarantee seal is

broken by you or a third party, the performance of the equipment

cannot be guaranteed.

iii

Page 4

For Safety

LCD

Falling Over

WARNING

● This equipment should always be positioned in the correct manner. If

the cabinet is turned on its side, etc., it will be unstable and may be

damaged if it falls over as a result of receiving a slight mechanical

shock.

Always set up the equipment in a position where the power switch

can be reached without difficulty.

● This equipment uses a Liquid Crystal Display (LCD). DO NOT subject

the equipment to excessive force or drop it. If the LCD is subjected to

strong mechanical shock, it may break and liquid may leak.

This liquid is very caustic and poisonous.

DO NOT touch it, ingest it, or get in your eyes. If it is ingested

accidentally, spit it out immediately, rinse your mouth with water and

seek medical help. If it enters your eyes accidentally, do not rub your

eyes, rinse them with clean running water and seek medical help. If

the liquid gets on your skin or clothes, wash it off carefully and

thoroughly with soap and water.

iv

Page 5

For Safety

Check Terminal

CAUTION

Cleaning

Static Sensitive

● Always remove the main power cable from the power outlet before

cleaning dust around the power supply and fan.

- Clean the power inlet regularly. If dust accumulates around the

power pins, there is a risk of fire.

- Keep the cooling fan clean so that the ventilation holes are not

obstructed. If the ventilation is obstructed, the cabinet may

overheat and catch fire.

● Never input a signal of more than the indicated value between the

measured terminal and ground. Input of an excessive signal may

damage the equipment.

● Always take the following anti-static measures to prevent the internal

circuit from being damaged when using a connector indicated by the

symbol shown on the left.

- Wear a wrist strap connected to the ground terminal of this

equipment.

- Connect the ground wires of this equipment, external measuring

instruments and DUT before connecting a coaxial cable.

- Eliminate static electricity charged between the cores and outer

conductors of an external device and the coaxial cable, before

connecting this equipment and the external device.

● This is a heavy object. When lifting and moving this equipment,

always work in a group of two or more, or use a trolley. There is a

risk of back injury, if this equipment is lifted or moved by one person.

v

Page 6

For Safety

External

Storage Media

SSD

CAUTION

The MP1900A saves data and programs to an external storage media

which has USB interface.

If this media is mishandled or becomes faulty, important data may be

lost. It is recommended to periodically back up all important data and

programs to protect them from being lost accidentally.

Anritsu will not be held responsible for lost data.

Pay careful attention to the following points.

● Never remove the memory card from the equipment while it is being

accessed.

● The memory card may be damaged by static electric charges.

● Anritsu has thoroughly tested all external storage media shipped with

this equipment. Users should note that external storage media not

shipped with this equipment may not have been tested by Anritsu, thus

Anritsu cannot guarantee the performance or suitability of such media.

The equipment is equipped with a SSD (Solid State Drive) from which,

as with any hard disk, data may be lost under certain conditions. It is

recommended to periodically back up all important data and programs

to protect them from being lost accidentally.

Anritsu will not be held responsible for lost data.

To reduce the possibility of data loss, particular attention should be

given to the following points.

● The equipment should only be used within the recommend

temperature range, and should not be used in locations where the

temperature may fluctuate suddenly.

● Always follow the guidelines to ensure that the equipment is set up in

the specified manner.

● Always ensure that the fans at the rear and side of the equipment

are not blocked or obstructed in any way.

● Exercise care not to bang or shake the equipment whilst the power is

on.

● Never disconnect the mains power at the plug or cut the power at the

breaker with the equipment turned on.

vi

Page 7

For Safety

Lifetime of Parts

Use in a

E

Use in

Atmospheres

CAUTION

Residential

nvironment

Corrosive

The life span of certain parts used in this equipment is determined by the

operating time or the power-on time. Due consideration should be given

to the life spans of these parts when performing continuous operation

over an extended period. The safety of the equipment cannot be

guaranteed if component parts are used beyond their life spans. These

parts must be replaced at the customer's expense even if within the

guaranteed period described in Warranty at the beginning of this manual.

For details on life-span, refer to the corresponding section in this

manual.

Parts with operating time-dependent life span: LCD backlight

(40,000 hours)

This equipment is designed for an industrial environment.

In a residential environment, this equipment may cause radio

interference in which case the user may be required to take adequate

measures.

Exposure to corrosive gases such as hydrogen sulfide, sulfurous acid,

and hydrogen chloride will cause faults and failures.

Note that some organic solvents release corrosive gases.

vii

Page 8

Equipment Certificate

Anritsu Corporation certifies that this equipment was tested before shipment

using calibrated measuring instruments with direct traceability to public

testing organizations recognized by national research laboratories, including

the National Institute of Advanced Industrial Science and Technology, and

the National Institute of Information and Communications Technology, and

was found to meet the published specifications.

Anritsu Warranty

Anritsu Corporation will repair this equipment free-of-charge if a malfunction

occurs within one year after shipment due to a manufacturing fault, and

software bug fixes will be performed in accordance with the separate

Software End-User License Agreement, provide, however, that Anritsu

Corporation will deem this warranty void when:

● The fault is outside the scope of the warranty conditions separately

described in the operation manual.

● The fault is due to mishandling, misuse, or unauthorized modification or

repair of the equipment by the customer.

● The fault is due to severe usage clearly exceeding normal usage.

● The fault is due to improper or insufficient maintenance by the customer.

● The fault is due to natural disaster, including fire, wind or flood,

earthquake, lightning strike, or volcanic ash, etc.

● The fault is due to damage caused by acts of destruction, including civil

disturbance, riot, or war, etc.

● The fault is due to explosion, accident, or breakdown of any other

machinery, facility, or plant, etc.

● The fault is due to use of non-specified peripheral or applied equipment

or parts, or consumables, etc.

● The fault is due to use of a non-specified power supply or in a

non-specified installation location.

● The fault is due to use in unusual environments

● The fault is due to activities or ingress of living organisms, such as

insects, spiders, fungus, pollen, or seeds.

In addition, this warranty is valid only for the original equipment purchaser. It

is not transferable if the equipment is resold.

Anritsu Corporation shall assume no liability for damage or financial loss of

the customer due to the use of or a failure to use this equipment, unless the

damage or loss is caused due to Anritsu Corporation’s intentional or gross

(Note)

.

viii

Page 9

negligence.

Note:

For the purpose of this Warranty, "unusual environments" means use:

● In places of direct sunlight

● In dusty places

● Outdoors

● In liquids, such as water, oil, or organic solvents, and medical fluids, or

places where these liquids may adhere

● In salty air or in place chemically active gases (sulfur dioxide, hydrogen

sulfide, chlorine, ammonia, nitrogen dioxide, or hydrogen chloride etc.)

are present

● In places where high-intensity static electric charges or electromagnetic

fields are present

● In places where abnormal power voltages (high or low) or instantaneous

power failures occur

● In places where condensation occurs

● In the presence of lubricating oil mists

● In places at an altitude of more than 2,000 m

● In the presence of frequent vibration or mechanical shock, such as in

cars, ships, or airplanes

Anritsu Corporation Contact

In the event of this equipment malfunctions, please contact an Anritsu

Service and Sales office. Contact information can be found on the last page

of the printed version of this manual, and is available in a separate file on the

PDF version.

ix

Page 10

This product and its manuals may require an Export License/Approval by

the Government of the product's country of origin for re-export from your

country.

Before re-exporting the product or manuals, please contact us to confirm

whether they are export

W

controlled items, the products/manuals need

to be broken/shredded so as not to be unlawfully used for military purpose.

This product contains a

Perchlorate Material

www.dtsc.ca.gov/hazardouswaste/perchlorate

Notes On Export Management

-controlled items or not.

hen you dispose of export-

FOR CALIFORNIA USA ONLY

CR Coin Lithium Battery which contains

– special handling may apply; See

x

Page 11

Crossed-out Wheeled Bin Symbol

Equipment marked with the Crossed-out Wheeled Bin Symbol complies with

council directive 2012/19/EU (the “WEEE Directive”) in European Union.

For Products placed on the EU market after August 13, 2005, please contact

your local Anritsu representative at the end of the product's useful life to

arrange disposal in accordance with your initial contract and the local law.

xi

Page 12

Software End-User License Agreement (EULA)

Please carefully read and accept this Software End-User License Agreement (hereafter this EULA)

before using (includes executing, copying, installing, registering, etc.) this Software (includes programs,

databases, scenarios, etc., used to operate, set, etc., Anritsu electronic equipment, etc.). By using this

Software, you shall be deemed to have agreed to be bound by the terms of this EULA, and Anritsu

Corporation (hereafter Anritsu) hereby grants you the right to use this Software with the Anritsu

specified equipment (hereafter Equipment) for the purposes set out in this EULA.

Article 1. Grant of License and Limitations

1. You may not to sell, transfer, rent, lease,

lend, disclose, sublicense, or otherwise

distribute this Software to third parties,

whether or not paid therefor.

2. You may make one copy of this Software for

backup purposes only.

3. You are not permitted to reverse engineer,

disassemble, decompile, modify or create

derivative works of this Software.

4. This EULA allows you to install one copy of

this Software on one piece of Equipment.

Article 2. Disclaimers

To the extent not prohibited by law, in no

event shall Anritsu be liable for direct, or

any incidental, special, indirect or

consequential damages whatsoever,

including, without limitation, damages for

loss of profits, loss of data, business

interruption or any other commercial

damages or losses, and damages claimed by

third parties, arising out of or related to your

use or inability to use this Software, unless

the damages are caused due to Anritsu’s

intentional or gross negligence.

Article 3. Limitation of Liability

1. If a fault (bug) is discovered in this Software,

failing this Software to operate as described

in the operation manual or specifications

even though you have used this Software as

described in the manual, Anritsu shall at its

own discretion, fix the bug, or replace the

software, or suggest a workaround,

free-of-charge, provided, however, that the

faults caused by the following items and any

of your lost or damaged data whatsoever

shall be excluded from repair and the

warranty.

i) If this Software is deemed to be used

for purposes not described in the

operation manual or specifications.

ii) If this Software has been used in

conjunction with other

non-Anritsu-approved software.

iii) If this Software or the Equipment has

been modified, repaired, or otherwise

altered without Anritsu's prior

approval.

iv) For any other reasons out of Anritsu's

direct control and responsibility, such

as but not limited to, natural disasters,

software virus infections, or any

devices other than this Equipment, etc.

2. Expenses incurred for transport, hotel, daily

allowance, etc., for on-site repairs or

replacement by Anritsu engineers

necessitated by the above faults shall be

borne by you.

3. The warranty period for faults listed in

Section 1 of this Article shall be either 6

months from the date of purchase of this

Software or 30 days after the date of repair

or replacement, whichever is longer.

xii

Page 13

Article 4. Export Restrictions

You shall not use or otherwise export or

re-export directly or indirectly this Software

except as authorized by the laws and

regulations of Japan and the United States,

etc. In particular, this Software shall not be

exported or re-exported (a) into any Japan or

US embargoed countries or (b) to anyone

restricted by the Japanese export control

regulations, or the US Treasury

Department's list of Specially Designated

Nationals or the US Department of

Commerce Denied Persons List or Entity

List. In using this Software, you warrant

that you are not located in any such

embargoed countries or on any such lists.

You also agree that you will not use or

otherwise export or re-export this Software

for any purposes prohibited by the Japanese

and US laws and regulations, including,

without limitation, the development, design

and manufacture or production of missiles or

nuclear, chemical or biological weapons of

mass destruction, and conventional

weapons.

Article 5. Change of Terms

Anritsu may change without your approval

the terms of this EULA if the changes are for

the benefit of general customers, or are

reasonable in light of the purpose of this

EULA and circumstances of the changes. At

the time of change, Anritsu will inform you

of those changes and its effective date, as a

general rule 45

website, or in writing or by e-mail.

days, in advance on its

Article 6. Termination

1. Anritsu may terminate this EULA

immediately if you violate any conditions

described herein. This EULA shall also be

terminated immediately by Anritsu if there

is any good reason that it is deemed difficult

to continue this EULA, such as your

violation of Anritsu copyrights, patents, etc.

or any laws and ordinances, or if it turns out

that you belong to an antisocial organization

or has a socially inappropriate relationship

with members of such organization.

2. You and Anritsu may terminate this EULA

by a written notice to the other party 30

days in advance.

Article 7. Damages

If Anritsu suffers any damages or loss,

financial or otherwise, due to your violation

of the terms of this EULA, Anritsu shall

have the right to seek proportional damages

from you.

Article 8. Responsibility after Termination

Upon termination of this EULA in

accordance with Article 6, you shall cease all

uses of this Software immediately and shall

as directed by Anritsu either destroy or

return this Software and any backup copies,

full or partial, to Anritsu.

Article 9. Negotiation for Dispute

Resolution

If matters of interpretational dispute or

items not covered under this EULA arise,

they shall be resolved by negotiations in

good faith between you and Anritsu.

Article 10. Governing Law and Court of

Jurisdiction

This EULA shall be governed by and

interpreted in accordance with the laws of

Japan without regard to the principles of the

conflict of laws thereof, and any disputes

arising from or in relation to this EULA that

cannot be resolved by negotiation described

in Article 9 shall be subject to and be settled

by the exclusive agreed jurisdiction of the

Tokyo District Court of Japan.

Revision History:

February 29th, 2020

xiii

Page 14

●

Use antivirus software.

Cautions Against Computer Virus Infection

Copying files and data

Only files that have been provided directly from Anritsu or generated

using Anritsu equipment should be copied to the instrument.

All other required files should be transferred by means of USB flash

drive or CompactFlash media after undergoing a thorough virus

check.

● Adding software

Do not download or install software that has not been specifically

recommended or licensed by Anritsu.

● Network connections

Ensure that the network has sufficient anti-virus security protection in

place.

Protection against malware (malicious software such as viruses).

●

This equipment runs on Windows Operating System.

● To connect This equipment to network, the following is advised.

- Activate Firewall.

- Install important updates of Windows.

-

xiv

Page 15

CE Conformity Marking

Anritsu affixes the CE conformity marking on the following product(s) in

accordance with the Decision 768/2008/EC to indicate that they conform to

the EMC, LVD, and RoHS directive of the European Union (EU).

CE marking

1. Product Model

Model: MP1900A Signal Quality Analyzer-R

2. Applied Directive

EMC: Directive 2014/30/EU

LVD: Directive 2014/35/EU

RoHS: Directive 2011/65/EU, (EU) 2015/863

3. Applied Standards

EMC: Emission: EN 61326-1: 2013 (Class A)

•

Immunity: EN 61326-1: 2013 (Table 2)

IEC 61000-4-2 (ESD) B

IEC 61000-4-3 (EMF) A

IEC 61000-4-4 (Burst) B

IEC 61000-4-5 (Surge) B

IEC 61000-4-6 (CRF) A

IEC 61000-4-8 (RPFMF) A

IEC 61000-4-11 (V dip/short) B, C

*: Performance Criteria

A: The equipment shall continue to operate as intended during and

after the test. No degradation of performance or loss of function

is allowed below a performance level specified by the

manufacturer, when the equipment is used as intended.

The performance level may be replaced by a permissible loss of

performance. If the minimum performance level or the

permissible performance loss is not specified by the

manufacturer, either of these may be derived from the product

description and documentation and what the user may

reasonably expect from the equipment if used as intended.

Performance Criteria*

xv

Page 16

Serial number

If the third digit of the serial number is "7", the product

complies with Directive 2011/65/EU as amended by (EU)

2015/863.

(Pb,Cd,Cr6+,Hg,PBB,PBDE,DEHP,BBP,DBP,DIBP)

If the third digit of the serial number is "6", the product

complies with Directive 2011

(Pb,Cd,Cr6+,Hg,PBB,PBDE)

Third digit

B: The equipment shall continue to operate as intended after the

test. No degradation of performance or loss of function is

allowed below a performance level specified by the

manufacturer, when the equipment is used as intended.

The performance level may be replaced by a permissible loss of

performance. During the test, degradation of performance is

however allowed. No change of actual operating state or stored

data is allowed. If the minimum performance level or the

permissible performance loss is not specified by the

manufacturer, either of these may be derived from the product

description and documentation and what the user may

reasonably expect from the equipment if used as intended.

C: Temporary loss of function is allowed, provided the function is

self-recoverable or can be restored by the operation of the

controls.

Harmonic current emissions:

EN 61000-3-2: 2014 (Class A equipment)

No limits apply to this equipment with an active input

power under 75 W.

LVD: EN 61010-1: 2010 (Pollution Degree 2)

•

RoHS: EN IEC 63000: 2018 (Category 9)

•

xvi

/65/EU.

Page 17

4. Contact

Name: Anritsu GmbH

Address, city: Nemetschek Haus, Konrad-Zuse-Platz 1

81829 München,

Country: Germany

Name: ANRITSU EMEA Ltd.

Address, city: 200 Capability Green, Luton

Bedfordshire, LU1 3LU

Country: United Kingdom

xvii

Page 18

RCM Conformity Marking

Anritsu affixes the RCM mark on the following product(s) in accordance with

the regulation to indicate that they conform to the EMC framework of

Australia/New Zealand.

RCM marking

1. Product Model

Model: MP1900A Signal Quality Analyzer-R

2. Applied Standards

EMC: Emission: EN 61326-1: 2013 (Class A equipment)

xviii

Page 19

About Eco label

The label shown on the left is attached to Anritsu products meeting our

environmental standards.

Details about this label and the environmental standards are available

on the Anritsu website at https://www.anritsu.com

xix

Page 20

xx

Page 21

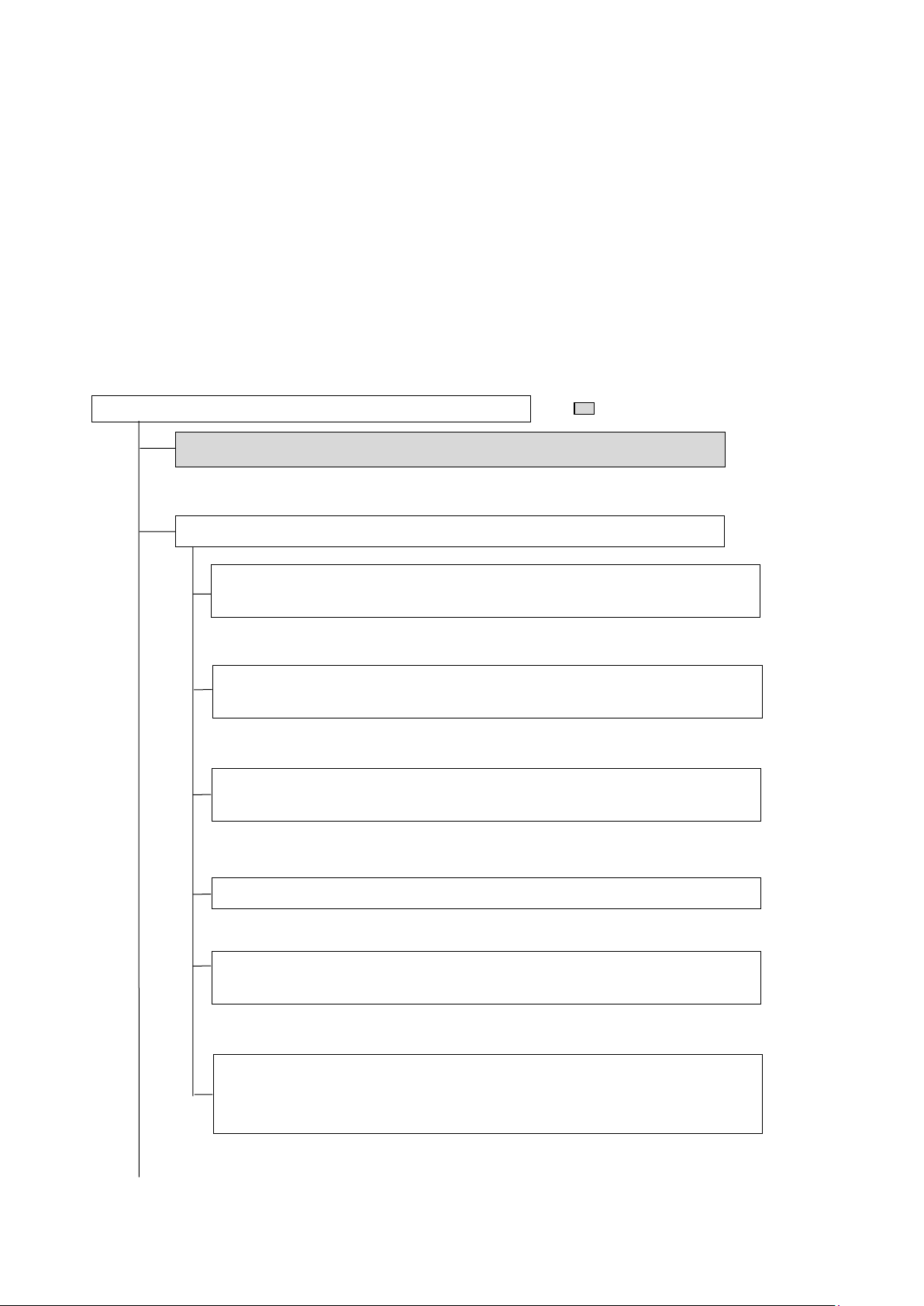

About This Manual

Configuration of Signal Quality Analyzer-R Series Operation

Describes the basic operations, panel details, and maintenance of the MP1900A, as

well as the steps from module installation to the start of use.

indicates this document.

Describes the panel details, how to operate, performance test, maintenance, and

troubleshooting of the

Module Operation Manual

Operation Manual

Describes the panel details, how to operate, performance test, maintenance, and

troubleshooting of the MU181000A

Describes the panel details, how to operate, performance test and maintenance of the

MU181500B.

Describes the panel details, how to operate, performance test, maintenance, and

Operation Manual

Describes the panel details, performance test, maintenance, and troubleshooting of

Describes the panel details, performance test, maintenance, and troubleshooting of

the

A testing system combining an MP1900A Signal Quality Analyzer-R,

module(s), and control software is called the Signal Quality Analyzer-R

Series. The operation manuals of the Signal Quality Analyzer-R Series

consist of separate documents for MP1900A, module(s), and control

software, as shown below.

MP1900A Signal Quality Analyzer-R Operation Manual

MU195020A 21G/32G bit/s SI PPG MU195040A 21G/32G bit/s SI ED

MU195050A Noise Generator Operation Manual

module to be installed on the MP1900A.

MU196020A PAM4 PPG MU196040A PAM4 ED MU196040B PAM4 ED

Operation Manual

MU196020A, MU196040A, and MU196040B.

MU181000A 12.5GHz Synthesizer MU181000B 12.5GHz 4 port Synthesizer

and MU181000B.

MU181500B Jitter Modulation Source Operation Manual

MU183020A 28G/32G bit/s PPG MU183021A 28G/32G bit/s 4ch PPG

the MU183020A and MU183021A.

MU183040A 28G/32G bit/s ED MU183041A 28G/32G bit/s 4ch ED

MU183040B 28G/32G bit/s High Sensitivity ED

MU183041B 28G/32G bit/s 4ch High Sensitivity ED Operation Manual

troubleshooting of the MU183040A, MU183041A, MU183040B, and MU183041B.

I

Page 22

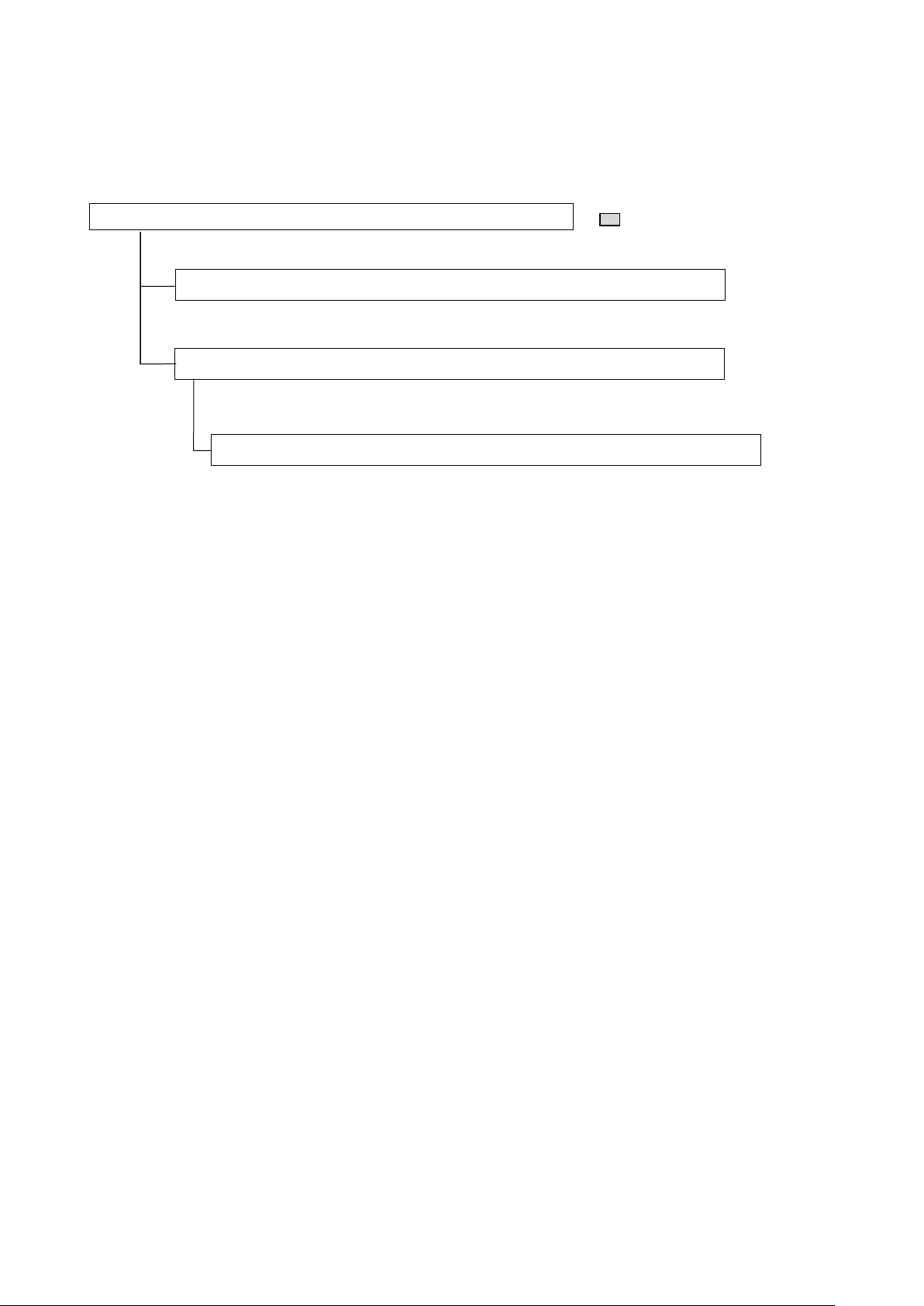

Extended Application Operation Manual

MX183000A High-Speed Serial Data Test Software Operation Manual

Describes the setup and operating procedure of MX183000A.

Describes the operation of the extended application for the Signal Quality Analyzer-R

Series.

Configuration of Signal Quality Analyzer-R Series Operation (Cont’d)

indicates this document.

MX190000A Signal Quality Analyzer-R Control Software Operation Manual

Describes the operation of the software that controls the Signal Quality Analyzer-R

Series.

II

Page 23

5 4 3 2 1

Table of Contents

For Safety ............................................................ iii

About This Manual ................................................. I

Chapter 1 Overview ............................................ 1-1

1.1 Product Overview........................................................ 1-2

1.2 Product Configuration ................................................. 1-3

1.3 Specifications.............................................................. 1-6

Chapter 2 Panels and Connections .................. 2-1

2.1 Front Panel ................................................................. 2-2

2.2 Rear Panel .................................................................. 2-3

2.3 Side Panel .................................................................. 2-4

Chapter 3

3.1 Environmental Conditions of Installation Site ............... 3-2

3.2 Distance from Fan ....................................................... 3-3

3.3 Installing and Removing Modules ................................ 3-4

3.4 Power Connection ....................................................... 3-9

3.5 Measures Against EOS and ESD .............................. 3-11

3.6 Connecting with Peripheral Devices .......................... 3-12

3.7 Connecting Network .................................................. 3-14

3.8 Windows Security Measures ..................................... 3-15

Preparation Before Use.................... 3-1

6

7

8

Chapter 4 Start/Stop Procedures...................... 4-1

4.1 Start Procedure ........................................................... 4-2

4.2 Stop Procedure ........................................................... 4-3

III

Page 24

Chapter 5 Remote Control ................................. 5-1

5.1 Remote Interface Settings ........................................... 5-2

5.2 Using Ethernet ............................................................ 5-5

5.3 Using GPIB ................................................................. 5-8

Chapter 6 Installing MX190000A ....................... 6-1

6.1 Installing MX190000A ................................................. 6-2

Chapter 7 Troubleshooting ............................... 7-1

7.1 Problems upon Power-on ............................................ 7-2

7.2 Problem upon Module Replacement............................ 7-3

7.3 Software Problems ...................................................... 7-4

Chapter 8 Maintenance ...................................... 8-1

8.1 Daily Maintenance ...................................................... 8-2

8.2 Touch Panel Calibration .............................................. 8-3

8.3 System Recovery Function ......................................... 8-7

8.4 Caution on Storage ................................................... 8-27

8.5 Transportation........................................................... 8-28

8.6 Calibration ................................................................ 8-29

8.7 Disposal .................................................................... 8-30

IV.

Page 25

Overview

Chapter 1 Overview

This chapter provides an overview and the specifications of the MP1900A

Signal Quality Analyzer-R (hereinafter, referred to as “MP1900A”).

1.1

Product Overview........................................................ 1-2

1.2 Product Configuration ................................................. 1-3

1.2.1 Standard Configuration ................................... 1-3

1.2.2 Optional Accessories....................................... 1-5

1.3 Specifications.............................................................. 1-6

1

1-1

Page 26

Chapter 1 Overview

1.1 Product Overview

By installing various plug-in modules (hereinafter, referred to as

“module”), the MP1900A can support research, development and

production of module devices for the optical communication market or

high-speed bus interface such as PCI Express. The MP1900A is also

useful for research and development for the next-generation

communication market, including optical packet transmission.

Up to 8 modules can be installed into the MP1900A. The MP1900A is

equipped with touchpanel LCDs, keys and a rotary encoder for easy

operation. Remote control can also be performed by adding the GPIB or

LAN.

The latest information on modules that can be installed to the MP1900A

is available on the Anritsu website at https://www.anritsu.com.

1-2

Page 27

Overview

1.2 Product Configuration

Main unit

MP1900A

Signal Quality Analyzer-R

1

Accessories

G0342A

ESD Discharger

1

Power Cord, 3M

1

J1627A

GND connection cable

1

P0031A

USB Memory

1

Stores the latest set of the

MX183000A Software.

Z0306A

Wrist strap

1

MP1900A-110/210

Windows 10 Upgrade Retrofit

1

Hardware option

Enterprise 2019 LTS.

1.2.1 Standard Configuration

The MP1900A can operate alone, without an external control PC.

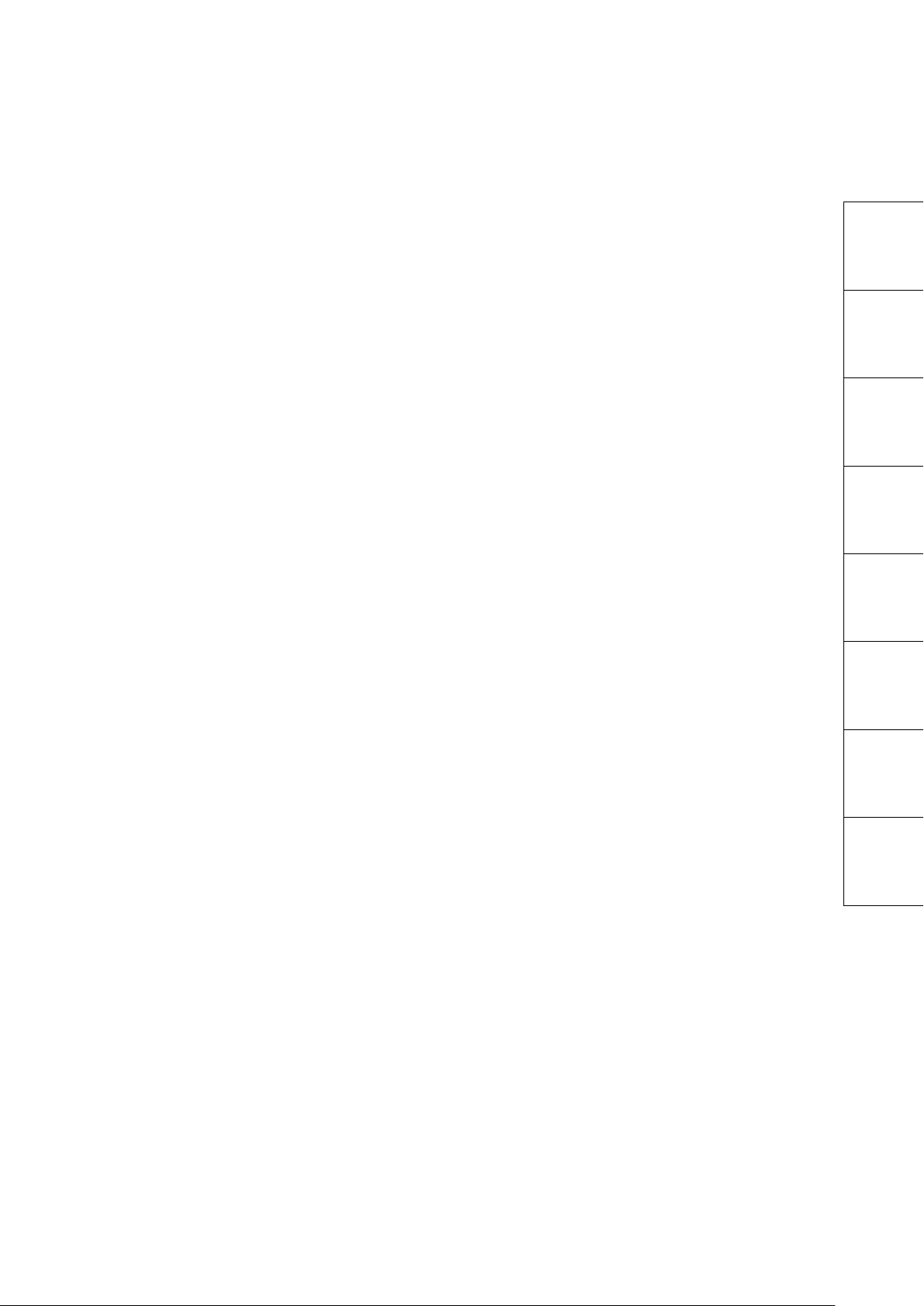

Figure 1.2.1-1 MP1900A appearance

1.2 Product Configuration

1

Table 1.2.1-1 shows the standard configuration of the MP1900A. The

latest information is available on the Anritsu website.

https://www.anritsu.com/en-us/test-measurement/products/mp1900a

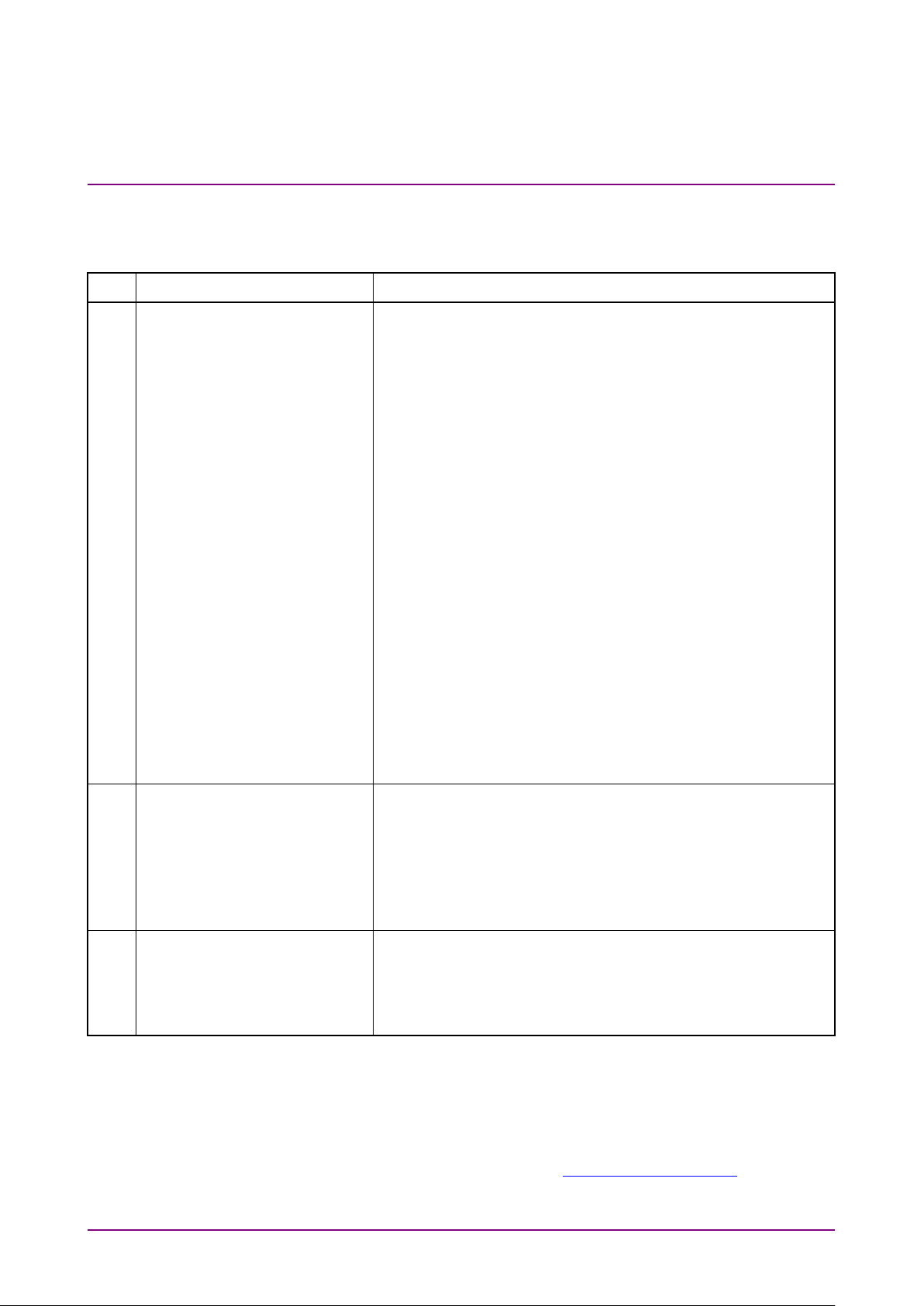

Table 1.2.1-1 Standard Configuration

Item Model Product Name Q’ty Remarks

operation manuals, the

MX190000A Software and

Table 1.2.1-2 Option

Model Product Name Q’ty Remarks

Upgrade from Windows Embedded

Standard 7 to Windows 10 IoT

1-3

Page 28

MU195020A*

21G/32G bit/s SI PPG

MU195040A*

21G/32G bit/s SI ED

MU195050A*

Noise Generator

MU196020A*

PAM4 PPG

MU196040A*

PAM4 ED

MU196040B*

PAM4 ED

MU181000A

12.5GHz Synthesizer

MU181000B

12.5GHz 4port Synthesizer

MU181500B

Jitter Modulation Source

MU183020A*

28G/32G bit/s PPG

MU183021A*

28G/32G bit/s 4ch PPG

MU183040B*

28G/32G bit/s High Sensitivity ED

MU183041B*

28G/32G bit/s 4ch High Sensitivity ED

Chapter 1 Overview

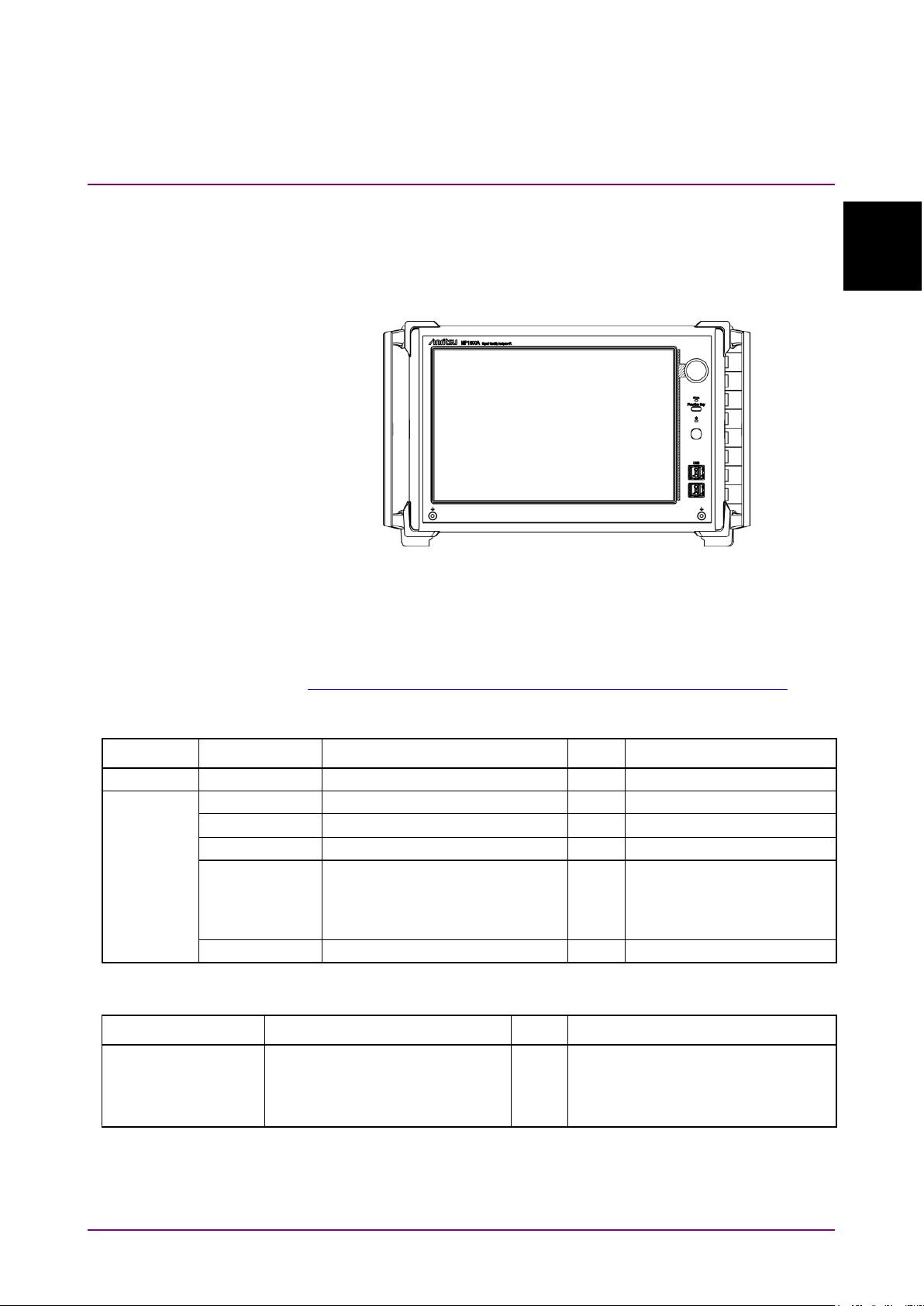

■ Module insertion slots

The MP1900A is equipped with slots for installing up to 8 modules into

the side panel.

Figure 1.2.1-2 MP1900A Side Panel

The following modules are installable to the MP1900A.

Table 1.2.1-3 Installable Modules

Model Product Name

*: The module has restrictions on installation positions and a number

to install.

For the latest information of the modules that are installable to the

MP1900A, refer to the Anritsu web site (https://www.anritsu.com).

1-4

Page 29

Overview

1.2.2 Optional Accessories

B0736A

Front Cover (For MP1900A)

Necessary to put the

case.

B0737A

Carrying Case (For MP1900A)

B0738A

Rack Mount Kit (For MP1900A)

J0008

GPIB CABLE, 2.0 m

2 m

W3813AE

MX183000A Operation Manual

Printed version

W3911AE

MP1900A Operation Manual

Printed version

W3915AE

MU195020A/40A/50A Operation Manual

Printed version

W3976AE

MU196020A/40A/40B Operation Manual

Printed version

W3913AE

MX190000A Operation Manual

Printed version

Z0541A

USB Mouse

Z0917A

Shielded LAN Cable, 5m

Shielded LAN cable, 5 m

Z1746A

Stylus

Z1953A

Gigabit Ethernet Switch (5Port)

5 ports

B0576A

Blank Panel

Z1964A

Torque Wrench (Right Angle)

1.2 Product Configuration

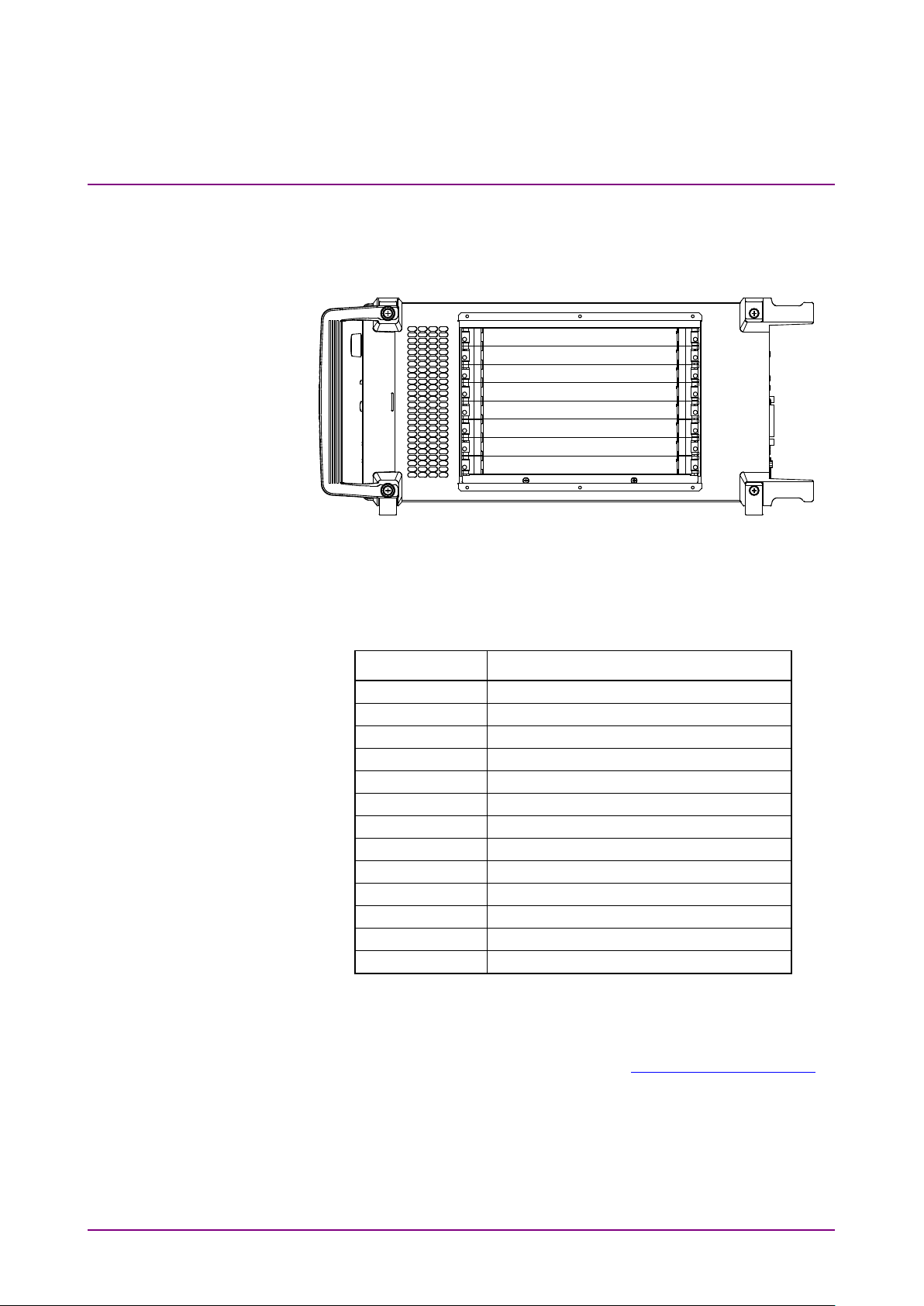

Table 1.2.2-1 shows the options for the MP1900A. All options are sold

separately.

Table 1.2.2-1 Optional Accessories

Model Product Name Remarks

MP1900A into the carrying

1

1-5

Page 30

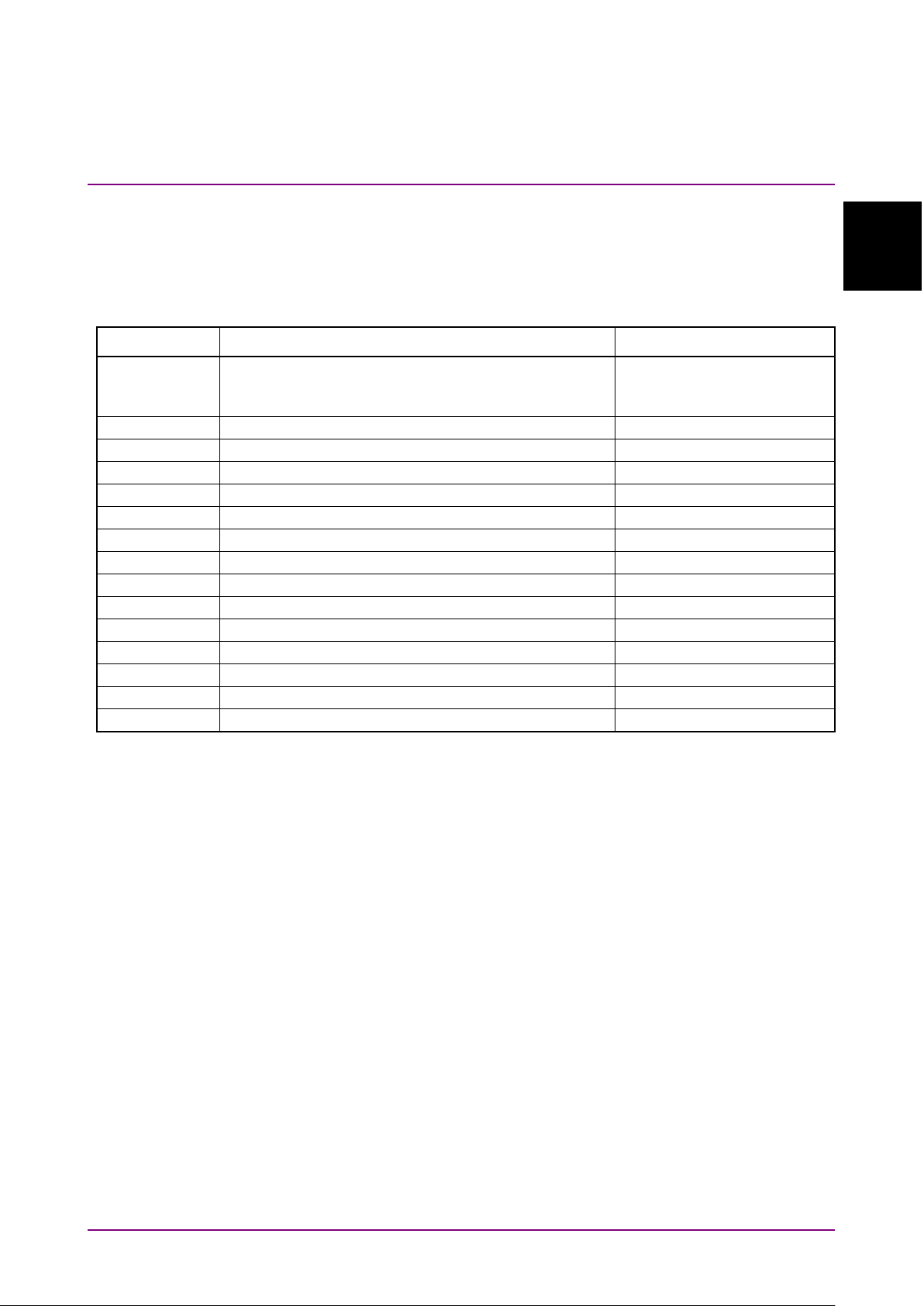

1

Functions

1.1

Input device, button

Resistance film touch panel, Rotary encoder, Function button,

Power button

1.2

LED

Power, Power Standby, Disk Access

1.3

LCD

12.1 inch WXGA (1280 × 800)

1.4

Ethernet

Rear panel 10/100/1000 Base-T RJ45 1 port

Reserved for future use )

1.5

External Display

VGA/HDMI

Rear panel D-Sub 15pin 1 port

Rear panel HDMI Type A 1 port

1.6

USB

Front panel USB Type A 4 ports

Rear panel USB Type A 2 ports

1.7

GPIB

Rear panel 1 port (For remote control)

1.8

Module slot

8 Slots (Slot1 to Slot8)

1.9

Functional earth terminal

Front panel 2 jacks

Rear panel 1 terminal

1.10

OS

Windows 10 IoT Enterprise 2019 LTSC

1.11

Internal storage device

SATA 2.5-inch SSD 1 Unit (tray loading)*1

1.12

Function

System and measurement sound output

Software-defined functions button

1.13

Remote interface

GPIB, Ethernet External (automatic switchover)

1.14

Internal reference clock

10 MHz ± 1 ppm (Accuracy at initial shipment)

2

Environmental performance

Power supply*2

AC 100 to 120 V, 200 to 240 V (automatic switching between

Power consumption

1350 VA

Operating temperature range

+5 to +40°C (without condensation)

Storage temperature range

–20 to +60°C (Recommended storage temperature range: +5 to

3

Mechanical measurements

Dimensions

222.5 mm (H) × 340 mm (W) × 451 mm (D) (Protrusions

excluded)

Mass

20 kg (excluding modules, blank panels, protective cover,

power cord)

Chapter 1 Overview

1.3 Specifications

Table 1.3-1 MP1900A Specifications

No. Item Specifications

(External: For remote control)

Rear panel 10/100/1000 Base-T RJ45 1 port (Internal:

100 and 200 V systems), 50 to 60 Hz

+30°C)

≤

Removing and replacing the

*1:

warranty coverage.

*2: Operating voltage is –10 to +10% of rated voltage

The information on options and application parts for the MP1900A is

available on the Anritsu website at https://www.anritsu.com.

1-6.

by Customer is outside the scope of

SSD

Page 31

Panels and Connections

Chapter 2 Panels and Connections

This section describes panels and connections of the MP1900A

2.1

Front Panel ................................................................. 2-2

2.2 Rear Panel .................................................................. 2-3

2.3 Side Panel .................................................................. 2-4

2

2-1

Page 32

1

GND terminal

Connects to the wrist strap during operation, as a countermeasure

the MP1900A.

2

3

USB ports

Four USB ports are provided. Turn the connected peripherals off

before turning off the MP1900A.

4

Power switch

Turns the power to the MP1900A on/off. When this switch is turned

unplug the power cord to turn off the Standby LED entirely.

5

Function Key

Software-defined functionkey.

Signal Quality Analyzer-R Control Software Operation Manual

.

6

Storage device access

LED

Flashes when the storage device is being accessed.

7

Rotary encoder

Rotate to increase/decrease the numeric value.

Chapter 2 Panels and Connections

2.1 Front Panel

7

6

5

4

3

2 1

Figure 2.1-1 Front panel

Table 2.1-1 Front panel

No. Name Function

against static electricity. Be sure to use the wrist strap when using

off while the power cord is connected, the Standby LED above the

switch lights.

When the power is automatically turned off because of the

temperature abnormality, the Standby LED flashes. In this case,

For details, refer to Chapter 3 “Basic Operations” in the

MX190000A

2-2

Page 33

Panels and Connections

2.2 Rear Panel

1

GPIB connector

The GPIB connector. Connect a cable to the GPIB connector on the

it on may cause failure.

2

SSD

Slot to install a storage device. Open the cover when replacing the

storage device.

3

USB port

Two USB ports are provided. Turn off the connected peripherals

before turning off the MP1900A.

4

Ethernet connector

RJ45 for Internal, RJ45 for External

Refer to 5.2 “Using Ethernet” for detail

5

Inlet

Connect to a 100 to 120 Vac or to a 200 to 240 Vac power supply via

the 3-pin power cord.

6

VGA

VGA connector to display the screen to an external display device.

7

HDMI

HDMI connector to display the screen to an external display device.

8

Functional GND

GND terminal for ESD (Electrostatic Discharge)

Connect to Device under test with cables for common grounding.

2.2 Rear Panel

2

1

Figure 2.2-1 Rear panel

Table 2.2-1 Rear panel

No. Name Function

4 3

2

5 6 7 8

terminal

rear panel before turning on the MP1900A. Connection after turning

10/100/1000BASE are supported.

Internal: Reserved for future use.

External: Connectable to network

This is an interface for remote control.

2-3

Page 34

Chapter 2 Panels and Connections

2.3 Side Panel

Eight slots for installing modules are provided on the left side. See 3.3

“Installing and Removing Modules” for how to install/remove the module

to/from the slots.

Figure 2.3-1 Side panel

2-4.

Page 35

Chapter 3

This chapter describes preparations required before starting

measurements.

3.1

Environmental Conditions of Installation Site ............... 3-2

3.2 Distance from Fan ........................................................ 3-3

3.3 Installing and Removing Modules ................................. 3-4

3.3.1 Installing modules ............................................. 3-4

3.3.2 Removing modules ........................................... 3-7

3.4 Power Connection ........................................................ 3-9

3.4.1 Power Requirements ........................................ 3-9

3.4.2 Connecting the Power Cord ............................. 3-9

3.5 Measures Against EOS and ESD ............................... 3-11

3.5.1 How to use the GND connection cable .......... 3-11

3.5.2 How to use the ESD Discharger ..................... 3-11

3.6 Connecting with Peripheral Devices ........................... 3-12

3.7 Connecting Network ................................................... 3-14

3.8 Windows Security Measures ...................................... 3-15

3.8.1 Activating Firewall ........................................... 3-16

3.8.2 Installing Windows Important Update

3.8.3 Using Antivirus Software ................................ 3-22

Preparation Before Use

Programs (Windows Update) ......................... 3-19

3

Preparation Before Use

3-1

Page 36

Chapter 3 Preparation Before Use

3.1 Environmental Conditions of Installation Site

The MP1900A operates in the temperature range from 5 to 40C. Avoid

using it under any of the following environment conditions which may

cause failure.

● Strong vibrations

● High humidity or dust

● Direct sunlight

● Chemically active gases

● Substantial temperature changes

Note:

Dew may form inside of the MP1900A if it is moved to a warm

location after operating for a long time in a cool location. In such a

case, be sure to wait until the MP1900A becomes completely dry

before turning on the power switch. Doing so with condensation

present may cause a short circuit and damage the MP1900A.

Install the MP1900A horizontally as shown in Figure 3.1-1.

Figure 3.1-1 Installation Orientation

CAUTION

If the MP1900A is not installed in a “good” direction as

above, a small shock may turn it over and harm the user.

3-2

Page 37

3.2 Distance from Fan

A cooling fan is provided at the rear of the MP1900A. Install the

MP1900A at least 10 cm away from walls, peripheral devices, or the like

to prevent blockage of ventilation. Insufficient ventilation may cause the

internal temperature to rise, resulting in failure.

3.2 Distance from Fan

Min 10 cm away

Min 10 cm away

Figure 3.2-1 Distance from fan

Min 10 cm away

3

Preparation Before Use

3-3

Page 38

Chapter 3 Preparation Before Use

3.3 Installing and Removing Modules

Slots from the module are Slot1, Slot2, Slot3, Slot4, Slot5, Slot6, Slot7,

Slot8 from the top.

3.3.1 Installing modules

1. Disconnect the power cord.

2. Fully insert a module, sliding along the grooves.

3. Check that the module ejectors are set facing out. Fit the hooks into

Figure 3.3-1 MP1900A modules

holes on the chassis.

Hooks

Ejector

Figure 3.3.1-1 Module hooks

3-4

4. Upon insertion, use a Phillips screwdriver to tighten the screws on

both the left and right sides of the module.

Page 39

3.3 Installing and Removing Modules

Screws

Figure 3.3.1-2 Module screws

CAUTION

● Be sure to check that the power cord of the MP1900A is

disconnected before installing the modules. Installing

modules with the power cord connected may result in

failure.

3

Preparation Before Use

● Take countermeasures against static electricity (ESD)

when installing modules. Failure to do so may result in

failure.

● Make sure to insert the module completely horizontally

into the groove (see the figure below). Failure to do so

may deform the metal spring on top of the modules.

Insertion direction

Groove

Correct: plug-in module horizontal to grooves

Incorrect: plug-in module not horizontal to grooves

Figure 3.3.1-3 Module insertion

● Do not touch any electric component mounting surface.

Doing so may damage the components.

3-5

Page 40

Chapter 3 Preparation Before Use

CAUTION

● Be careful not to catch your fingers when manipulating

the ejector. Doing so may cause injury.

● Tighten the left and right screws after inserting a

module. Failure to do so may cause malfunction or

failure of the module, or allow it to drop out when

transported.

● Attach a blank panel to every slot where no module is

installed. Not attaching blank panels may result in

failure due to air currents or internal temperature rise.

3-6

Page 41

3.3.2 Removing modules

1. Disconnect the power cord.

2. Loosen the left and right screws on the module to be removed.

3. Press the red ejector lock buttons on both sides of the module to

unlock the ejector.

3.3 Installing and Removing Modules

Screws

3

Preparation Before Use

Figure 3.3.2-1 Modules screws

4. Set the ejectors to the outside.

5. Hold the ejectors and gently pull out the module.

Figure 3.3.2-2 Modules ejectors

3-7

Page 42

Chapter 3 Preparation Before Use

CAUTION

● Be sure to check that the power cord of the MP1900A is

disconnected before pulling out the modules. Pulling

out modules with the power cord connected may result

in failure.

● Take countermeasures against static electricity (ESD)

when pulling out modules. Failure to do so may result in

failure.

● Make sure to pull out the module completely

horizontally from the grooves (see the figure below).

Failure to do so may deform the metal spring on top of

the modules.

Pullout direction

Grooves

Correct: plug-in module horizontal to grooves

Incorrect: plug-in module not horizontal to grooves

Figure 3.3.2-3 Module pullout

● Do not touch any electric component mounting surface.

Doing so may damage the components.

● Be careful not to catch your fingers when manipulating

the ejector. Doing so may cause injury.

● Be sure to loosen the left and right screws on the

module and to release the ejector lock before setting

the ejector outside. Failure to do so may damage the

ejector.

3-8

Page 43

3.4 Power Connection

This section describes the procedures for supplying power.

3.4.1 Power Requirements

For normal operation of the MP1900A, observe the power voltage range

described below.

3.4 Power Connection

Power source Voltage range Frequency

100 Vac system 100 to 120 V 50 to 60 Hz

200 Vac system 200 to 240 V 50 to 60 Hz

Changeover between 100 and 200 V systems is made automatically.

Supplying power exceeding the above range may result in

electrical shock, fire, failure, or malfunction.

3.4.2 Connecting the Power Cord

Insert the power plug into an outlet, and connect the other end to the

power inlet on the rear panel. To ensure that the MP1900A is grounded,

always use the supplied 3-pin power cord, and insert the plug into an

outlet with an GND terminal. When the power cord is connected, the

Standby LED is lit and the MP1900A enters the standby status.

3

Preparation Before Use

CAUTION

3-9

Page 44

Chapter 3 Preparation Before Use

WARNING

If the MP1900A is connected to an ungrounded outlet, there

is a risk of receiving a fatal electric shock. In addition, the

peripheral devices connected to the instrument may be

damaged.

Always connect the MP1900A to a properly grounded

outlet. Do not use the instrument with an extension cord or

transformer that does not have a ground wire.

Unless otherwise specified, the signal-connector ground

terminal, like an external conductor of the coaxial

connector, of the instrument is properly grounded when

connecting the power cord to a grounded outlet. Connect

the ground terminal of DUT to a ground having the same

potential before connecting with the instrument. Failure to

do so may result in an electric shock, fire, failure, or

malfunction.

CAUTION

If an emergency arises causing the MP1900A to fail or

malfunction, disconnect the MP1900A from the power

supply by disconnecting either end of the power cord.

When installing the MP1900A, arrange the power inlet and

outlet so that an operator may easily connect or

disconnect the power cord. Moreover, DO NOT fix the

power cord around the plug and the power inlet with a

holding clamp or similar device.

If the MP1900A is mounted in a rack, a power switch for the

rack or a circuit breaker may be used for power

disconnection.

It should be noted that, the power switch on the front panel

of the MP1900A is a standby switch, and cannot be used to

cut the main power.

The MP1900A has a storage device. Do not remove the

power cord during startup of the MP1900A, except for an

emergency.

3-10

Page 45

3.5 Measures Against EOS and ESD

3.5 Measures Against EOS and ESD

This section describes how to prevent MP1900A from being damaged by

electrical over-stress (EOS) or electrostatic discharge (ESD).

3.5.1 How to use the GND connection cable

There is a risk of damaging MP1900A due to EOS if MP1900A and other

peripheral equipment (including experimental circuits) are not connected

to the common ground.

When connecting MP1900A and other peripheral (including experimental

circuits), connect other peripheral equipment to the ground terminal of

MP1900A’s chassis with the GND connection cable before connecting the

I/O connectors.

MP1900A

3

Preparation Before Use

Figure 3.5.1-1 How to Use the GND Connection Cable

3.5.2 How to use the ESD Discharger

There is a risk of damaging MP1900A if the coaxial cable you connect to

MP1900A is charged electrostatically.

To prevent MP1900A from being damaged by ESD, remove electrostatic

charges from the cable by using the ESD Discharger before cabling the

connectors.

The ESD Discharger can be used with one of SMA connector (and its

compatible connector) and V connector (and its compatible connector).

Other

Peripheral

Equipment

Figure 3.5.2-1 How to Use the ESD Discharger

3-11

Page 46

Chapter 3 Preparation Before Use

3.6 Connecting with Peripheral Devices

1. USB mouse, keyboard and other USB devices

Connect a cable with a Type A connector to the USB port on the front

or rear panel. Turn off the connected devices before turning off the

MP1900A.

2 ports 4 ports

Figure 3.6-1 USB interface

2. The MP1900A has four USB ports on the front panel and two USB

ports on the rear panel as standard. Use the USB ports to connect

the USB mouse or a keyboard.

3. Ethernet

Connect the RJ modular plug of a 10 BASE-T, 100 BASE-TX or

1000BASE-TX cable to the RJ45 connector on the rear panel. Refer to

5.2 “Using Ethernet” for details.

4. External display

Before turning on the MP1900A, connect the display cable to the

HDMI or VGA connector on the rear panel. The external display can

be used when the MP1900A is turned on. Connecting after the

MP1900A has been turned on may cause failure. Turn off the display

before turning off the MP1900A.

3-12

Page 47

3.6 Connecting with Peripheral Devices

3

Preparation Before Use

VGA HDMI

Figure 3.6-2 Display interface

5. A D-SUB 15 pins connector and a HDMI Type A connector are

provided on MP1900A’s rear panel as a standard feature. When the

resolution is set to 1280 × 800 pixels, simultaneous display on the

external display and the built-in LCD of the MP1900A can be

performed.

6. GPIB

Connect a cable to the GPIB connector on the rear of the MP1900A

before turning on the MP1900A. Connecting after the MP1900A has

been turned on may cause failure. Refer to 5.3 “Using GPIB” for

details.

3-13

Page 48

Chapter 3 Preparation Before Use

3.7 Connecting Network

When connecting the MP1900A to a network, be sure to set the IP address

using Network Connections on Windows, so as not to conflict with the IP

address of any other device on the network. Consult your network

administrator for available IP address. Refer to 5.2 “Using Ethernet” for

the IP address setting procedure. Do not connect the MP1900A to a

network which has possibly been invaded by a virus.

3-14

Page 49

3.8 Windows Security Measures

MP1900A uses Windows Embedded Standard 7 (WES7) 64-bit version or

Windows 10 IoT Enterprise (Win10) 64-bit version. When connecting

MP1900A to a network, in addition to connecting to secure and

virus-protected networks, the following procedures are recommended in

order to add protection against malware (malicious software) and viruses.

● Activating firewall

● Installing Windows important update programs

● Using antivirus software

The security measure settings condition of this product can be confirmed

from the Control Panel of Windows.

When the OS is WES7

1. Click Start → Control Panel from the Windows menu bar hidden in

the lower part of the screen.

3.8 Windows Security Measures

3

Preparation Before Use

2. Click System and Security → Action Center.

3. Click Security, and confirm security measures settings condition.

When the OS is Win10

1. Click Start → Windows System → Control Panel from the Windows

menu bar hidden in the lower part of the screen.

2. With View by: Category, click System and Security → Security and

Maintenance.

3. Click Security, and confirm security measures settings condition.

Note:

Security warnings are not displayed by factory default.

CAUTION

When connecting MP1900A to the Internet or to an external

network, there is a possibility an unpredictable problem or

damage may occur. Anritsu Corporation does not

recompense for any damage caused by connecting

MP1900A to a network.

3-15

Page 50

Chapter 3 Preparation Before Use

3.8.1 Activating Firewall

It is recommended to turn On the Windows firewall on MP1900A.

When the OS is WES7

1. Click Start → Control Panel from the Windows menu bar hidden in

2. With View by: Category, click System and Security → Windows

Note:

3. Click Turn Windows Firewall on or off found in left side of Windows

the lower part of the screen.

Firewall to show Windows Firewall window.

Windows Firewall is On when MP1900A is shipped from factory.

The settings to allow external communications are already done so

that MP1900A is operated properly by remote-control, etc. Thus,

additional settings are unnecessary.

Firewall window.

3-16

Figure 3.8.1-1 Windows Firewall Window

Page 51

3.8 Windows Security Measures

4. Customize Settings window will be shown where Windows firewall

On/Off settings can be changed.

Use MP1900A with the following checkboxes Off (unchecked).

● Block all incoming connections, including those in the list of

allowed programs

● Notify me when Windows Firewall blocks a new program

3

Preparation Before Use

Figure 3.8.1-2 Customize Settings Window

When the OS is Win10

1. Click the Start icon to open the Start menu, and then click

Windows System → Control Panel in the W column of the application

list displayed.

2. With View by: Category, click System and Security → Windows

Defender Firewall to show Windows Defender Firewall window.

Note:

Windows firewall is On when MP1900A is shipped from factory.

3. Click Turn Windows Defender Firewall on or off found in the left side

of Windows Defender Firewall window.

Figure 3.8.1-3 Windows Defender Firewall Window

3-17

Page 52

Chapter 3 Preparation Before Use

4. Customize Settings window will be shown where Windows firewall

On/Off settings can be changed.

Use the MP1900A with the following checkboxes Off (unchecked).

● Block all incoming connections, including those in the list of

allowed programs

● Notify me when Windows Firewall blocks a new program

Figure 3.8.1-4 Customize Settings Window

3-18

Page 53

3.8 Windows Security Measures

3.8.2 Installing Windows Important Update Programs (Windows Update)

It is necessary to regularly check for important Windows update

programs and keep them up-to-date. However, since executing update

program downloads and installations will decrease the performance of

MP1900A, deactivate automatic updates for Windows Update. Instead, it

is recommended to check for new updates, execute downloads and

installations periodically when MP1900A is not in use for measurement.

When the OS is WES7

1. Click Start → Control Panel from the Windows menu bar hidden in

the lower part of the screen.

2. With View by: Category, click System and Security → Windows

Update to show Windows Update window.

3. To deactivate automatic updates, click Change settings found in left

side of Windows Update window.

3

Preparation Before Use

Figure 3.8.2-1 Windows Update Window

3-19

Page 54

Chapter 3 Preparation Before Use

4. Select Never check for updates (not recommended) in Important

updates, then click OK.

Figure 3.8.2-2 Change settings Window

5. To check for newly available update programs (manual update), click

Check for updates in Windows Update window.

Figure 3.8.2-3 Windows Update Window (manual update)

6. When a new update program is found, download and install following

the displayed instructions.

3-20

Page 55

3.8 Windows Security Measures

When the OS is Win10

1. Click the Start icon to open the Start menu, and then click

Settings icon.

2. Click Update & Security to show Windows Update window.

3. To turn off automatic updates, select Windows Update found in left

side of Windows Update window, and then click Advanced options.

3

Preparation Before Use

Figure 3.8.2-4 Windows Update Window

4. Advanced options window will be shown.

Confirm if Automatically download updates even over metered data

connections (charges may apply) is set to Off.

Figure 3.8.2-5 Advanced options Window

3-21

Page 56

Chapter 3 Preparation Before Use

5. To check for newly available update programs (manual update), click

Check for updates in Windows Update window.

Figure 3.8.2-6 Windows Update Window (manual update)

6. When a new update program is found, download and install following

the displayed instructions.

3.8.3 Using Antivirus Software

It is recommended to install antivirus software on MP1900A. However,

since the automatic updates for virus data library and the full scans run

in the background by the antivirus software will decrease the

performance of MP1900A, do not execute them. Instead, it is

recommended to run them periodically when MP1900A is not in use for

measurement.

The antivirus software that checked operation in MP1900A is shown

below.

● Trend Micro OfficeScan XG

● Norton Security Deluxe (confirmed by version 22.11.0.41)

Note:

Refer to the antivirus software operation manual for its installation

and operation procedures. Although it is confirmed that no negative

effects in the general usage of MP1900A are caused by using the

software mentioned above, there is no guarantee for different

software even if containing similar functions.

3-22.

Page 57

Start/Stop Procedures

Chapter 4 Start/Stop Procedures

This chapter describes the start and stop procedures of the application

software for using the MP1900A.

4.1

Start Procedure ........................................................... 4-2

4.2 Stop Procedure ........................................................... 4-3

4

4-1

Page 58

Standby LED

Inlet

Chapter 4 Start/Stop Procedures

4.1 Start Procedure

At non-standby status (when Standby LED is off)

(1) When the power cord is connected, the Standby LED is lit and the

MP1900A enters the standby status.

Figure 4.1-1 Front and rear panels

At standby status (when Standby LED is on)

(1) Turn on the power switch of the MP1900A.

The power lamp is lit and Windows starts.

(2) After starting Windows, the Application Selector screen is displayed.

Touch the icon of the application to be started. For details of the

Application Selector screen, refer to the

Analyzer-R Control Software Operation Manual

MX190000A Signal Quality

.

4-2

Figure 4.1-2 Application Selector screen

Page 59

Start/Stop Procedures

4.2 Stop Procedure

(1) Press and hold the power switch on the front panel. The Power lamp

goes off, and then the Standby LED lights up (enters standby

status).

The MP1900A has a storage device. Do not remove the

power cord during startup of the MP1900A, except for an

emergency

4.2 Stop Procedure

CAUTION

4

4-3

Page 60

Chapter 4 Start/Stop Procedures

4-4.

Page 61

Remote Control

Chapter 5 Remote Control

Remote control of the MP1900A can be performed via Ethernet or GPIB

interface. This chapter describes the remote control procedure.

5.1

Remote Interface Settings ............................................ 5-2

5.2 Using Ethernet .............................................................. 5-5

5.3 Using GPIB ................................................................... 5-8

5

5-1

Page 62

Chapter 5 Remote Control

5.1 Remote Interface Settings

To remote-control the MP1900A by using the remote interface, set the

remote interface from

MP1900A has started, and select

window.

Refer to

Operation Manual

MX190000A Signal Quality Analyzer-R Control Software

Remote Control. Start the application after the

for details of System Toolbar.

Remote Control on the General Settings

5-2

Figure 5.1-1 System Toolbar

Tap the Navigation Tab on the upper right corner of the screen to display

the System Toolbar. Then Touch

.

Page 63

5.1 Remote Interface Settings

Remote Control

[1]

[3]

[2]

[5]

[4]

Figure 5.1-2 General Settings Window

Next, touch Remote Control to display a dialog box for setting remote

control. Set TCP port number and GPIB address for the MP1900A.

Figure 5.1-3 Remote Control Dialog Box

5

5-3

Page 64

[1]

SCPI control TCP port

Set the TCP/IP socket port number to remote-control

Software functions as the TCP server.

[2]

GPIB Address

Set the GPIB address of the MP1900A used when GPIB

is selected for the active interface.

[3]

Defaults

Resets the settings to default. The default values are

GPIB Address: 1

[4]

Cancel

Close this dialog box.

[5]

OK

Save the setting and close this dialog box.

Chapter 5 Remote Control

No. Type Function/operation

Table 5.1-1 Remote Control setting

MP1900A via Ethernet interface.

Perform the settings according to the Control PC or

other external controller.

MX190000A Signal Quality Analyzer-R Control

shown below.

SCPI control TCP port: 5 001

Refer to

MX190000A Signal Quality Analyzer-R Control Software

Operation Manual

for details of remote control.

5-4

Page 65

Remote Control

5.2 Using Ethernet

Specify IP Address, Subnet Mask, and Gateway for the MP1900A.

Connect the controller to the IP Address displayed on the Remote Control

tab.

(1) Click the Show Desktop icon at the right bottom of the screen.

Windows desktop is displayed.

5.2 Using Ethernet

Figure 5.2-1 Show Desktop Icon

(2) Click the Settings icon (

(3) Click Network and Internet to change the IP address, subnet mask,

and gateway address. Click

Network Connection window.

Figure 5.2-2 Network Connection Window

(4) Right-click the Ethernet icon, and then click Properties.

(5) Click Internal Protocol Version 4 (TCP IPv4), and then click

Properties.

) on the Windows Start menu.

Change adapter options to display the

5

5-5

Page 66

IP address

192.168.1.101

Subnet mask

255.255.255.0

Default gateway

Blank (not set)

Chapter 5 Remote Control

(6) Set the items in the Internal Protocol Version 4 (TCP/IPv4)

Properties dialog box.

Figure 5.2-3 Internal Protocol Version 4

(TCP/IPv4) Properties dialog box

Notes:

● For the IP address of the remote interface, set the address other

than “192.168.1.xxx”. The “192.168.1.xxx” address is used for

the module address. If this address is set, the module may not

operate properly.

● Do not change settings of Ethernet 2 (Do Not Change). When

the settings are changed, the application is not started normally.

Set the following values if the settings are changed.

Table 5.2-1 Ethernet 2 (Do Not Change) Default Values

Item Setting

5-6

Page 67

5.2 Using Ethernet

Remote Control

Twisted pair cable

HUB

Refer to

Operation Manual

External connector installed on the rear panel to connect the 10

BASE-T/100 BASE-TX/1000 BASE-TX cable.

MX190000A Signal Quality Analyzer-R Control Software

for details such as setup restrictions. Use the

5

Figure 5.2-4 Ethernet Cable Connection

5-7

Page 68

GPIB cable

Chapter 5 Remote Control

5.3 Using GPIB

The GPIB is available using the set GPIB address (refer to 5.1, “Remote

Interface Settings”).

GPIB connector is located on the rear panel. Be sure to connect the GPIB

cable before turning on the MP1900A. Up to 15 devices, including the

controller, can be connected in one GPIB system. Note that the cable

length is limited, as shown below.

● Total cable length: ≤20 m

● Cable length between devices: ≤4 m

Figure 5.3-1 GPIB Cable Connection

5-8

Page 69

Remote Control

(a) Daisy Chain

(b) Star

(c) Loop

Connect cables without forming loops.

5.3 Using GPIB

Figure 5.3-2 GPIB Cable Connection Methods

5

5-9

Page 70

Chapter 5 Remote Control

5-10.

Page 71

Installing MX190000A

Chapter 6 Installing MX190000A

This chapter describes how to install the MX190000A Signal Quality

Analyzer-R Control Software (hereinafter, referred to as “MX190000A”),

when reinstalling or upgrading MX190000A is required.

6.1

Installing MX190000A ................................................. 6-2

6

6-1

Page 72

Chapter 6 Installing MX190000A

6.1 Installing MX190000A

The MP1900A comes with MX190000A. When reinstalling or upgrading

MX190000A is required, follow the installation procedure described

below.

To re -install the MX190000A, use the USB flash drive supplied with the

MP1900A. If the MX190000A is updated, the firmware of the MP1900A

and each module should also be updated.

(1) Insert the USB flash drive into the MP1900A to copy the files to the

storage device. Files to be copied are stored in the following folder as

follows:

\Installer\MX190000A_VER_x_xx_xx.exe

x_xx_xx above indicates the software version.

(2) Execute “MX190000A_VER_x_xx_xx.exe” to start installation.

When overwriting a version of MX190000A that has already been

installed in the MP1900A (e.g., when upgrading the version), a

message dialog box “Reinstall all program features installed by the

previous setup.” is displayed. Touc h

In this event, Steps 4 (this step) to 8 are omitted. Proceed with Step

9.

(3) The installer starts. Touch

Next.

Yes to continue the installation.

6-2

Page 73

6.1 Installing MX190000A

Installing MX190000A

(4) Enter a user name, a company name, and the serial number into the

respective textbox, and then touch Next.

For the serial number, enter the 10-digit serial number of the

MP1900A that is to be controlled by MX190000A.

(5) The error message shown below will be displayed if an incorrect

serial number is entered and

error message, and then enter the correct serial number.

Next is touched. Touch OK to close the

6

6-3

Page 74

Chapter 6 Installing MX190000A

(6) Select MP1900A in the Setup Type and touch Next. When installing

the application to a PC, select External PC. Refer to

MX190000A

Signal Quality Analyzer-R Control Software Operation Manual

details.

for

(7) When installation is ready (the following window is displayed), touch

Install to start installation.

6-4

Page 75

6.1 Installing MX190000A

Installing MX190000A

(8) The following window is displayed when the installation completes

normally. Touch Finish to end the installation procedure.

(9) Be sure to check the software version of the MP1900A after

installing MX190000A. If the firmware version is not the latest,

necessary files must be downloaded. Refer to

Quality Analyzer-R Control Software Operation Manual

on how to check the version and how to upgrade the software.

MX190000A Signal

for details

6

6-5

Page 76

Chapter 6 Installing MX190000A

6-6.

Page 77

Troubleshooting

Chapter 7 Troubleshooting

This chapter describes the procedures to check if a failure has occurred

during abnormal operation of the MP1900A.

7.1

Problems upon Power-on ............................................ 7-2

7.2 Problem upon Module Replacement............................ 7-3

7.3 Software Problems ...................................................... 7-4

7

7-1

Page 78

The MP1900A

Is the power cord loose?

Fully connect the cable.

Is the Standby LED is

If the power cord is removed and inserted during

turned on by pressing the power switch on the front

Check if the power is being supplied to the power

version.

Is the MP1900A powered

abnormality?

When the power is automatically turned off because

off the Standby LED entirely.

Chapter 7 Troubleshooting

7.1 Problems upon Power-on

Table 7.1-1 Remedies for problems upon power-on

Symptom Location to Check Remedy

cannot be turned

on.

turned on?

startup of the MP1900A, the MP1900A may not be

panel. In this event, take either of these actions:

1. Remove the power cord, leave the Standby LED

turned off for at least 5 seconds, and then

reconnect the power cord.

2. Press and hold the power switch for at least 5

seconds, release the power switch, and then

press the power switch again.

cord. If the MP1900A cannot be turned on even

when the power is being supplied, the MP1900A

may have failed. Contact an Anritsu Service and

Sales office. Contact information can be found on

the last page of the printed version of this manual,

and is available in a separate file on the PDF

on after shutting it down

because of the temperature

of the temperature abnormality, the Standby LED

flashes. In this case, unplug the power cord to turn

7-2

Page 79

7.2 Problem upon Module Replacement

Troubleshooting

A module is not

Is the module installed

properly?

Install the module again by referring to 3.3

“Installing and Removing Modules”.

Are the appropriate

Confirm the MP1900A software version and the

version.

7.2 Problem upon Module Replacement