Anritsu MG3696A, MG3695A, MG3694A, MG3693A, MG3692A Service Manual

...

SERIES

MG369XA

SYNTHESIZED SIGNAL GENERATORS

MAINTENANCE MANUAL

490 JARVIS DRIVE

MORGAN HILL, CA 95037-2809

P/N: 10370-10355

REVISION: D

PRINTED: FEBRUARY 2005

COPYRIGHT 2005 ANRITSU CO.

WARRANTY

The Anritsu product(s) listed on the title page is (are) warranted against defects in materials and

workmanship for three years from the date of shipment.

Anritsu's obligation covers repairing or replacing products which prove to be defective during the

warranty period. Buyers shall prepay transportation charges for equipment returned to Anritsu for

warranty repairs.Obligation is limited to the original purchaser.Anritsuis not liable for consequen

tial damages.

LIMITATION OF WARRANTY

The foregoing warranty does not apply to Anritsu connectors that have failed due to normal wear.

Also,the warranty does not apply to defects resulting from improper or inadequate maintenance by

the Buyer,unauthorized modification or misuse, or operation outside of the environmental specifications of the product. No other warranty is expressed or implied, and the remedies provided herein

are the Buyer's sole and exclusive remedies.

TRADEMARK ACKNOWLEDGMENTS

Adobe Acrobat is a registered trademark of Adobe Systems Incorporated.

MS-DOS and Windows are registered trademarks of Microsoft Corporation.

-

NOTICE

Anritsu Company has prepared this manual for use by Anritsu Company personnel and customers

as a guide for the proper installation, operation, and maintenance of Anritsu Company equipment

and computer programs. The drawings, specifications, and information contained herein are the

property of Anritsu Company, and any unauthorized use or disclosure of these drawings, specifica

tions,and information is prohibited; they shall not be reproduced, copied, or used in whole or in part

-

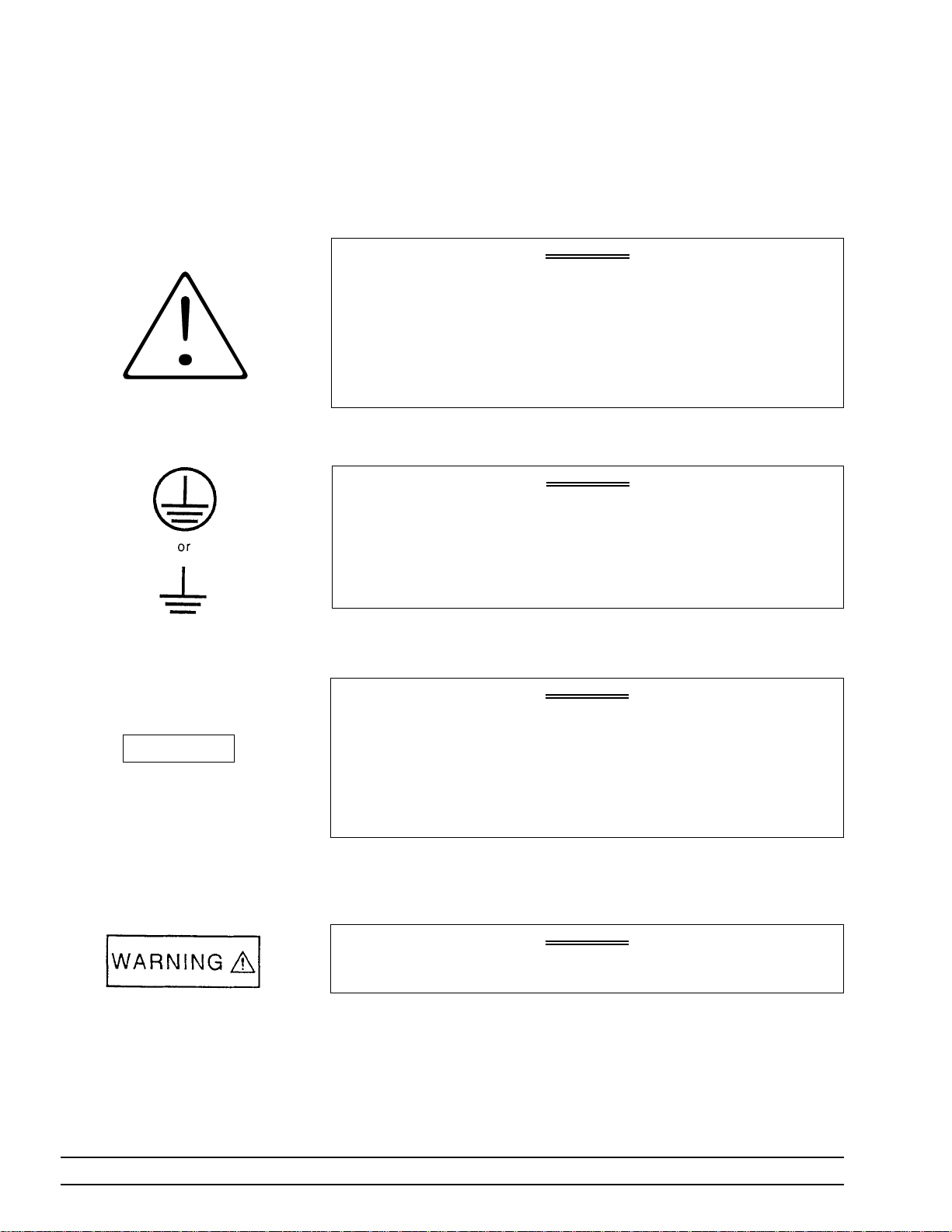

Safety Symbols

To prevent the risk of personal injury or loss related to equipment malfunction, ANRITSU Company uses the

following symbols to indicate safety-related information.For your own safety,please read this information

carefully BEFORE operating the equipment.

Symbols used in manuals

DANGER

Indicates a very dangerous procedure that could result in serious in

jury or death if not performed properly.

WARNING Indicates a hazardous procedure that could result in serious injury or

death if not performed properly.

CAUTION Indicates a hazardous procedure or danger that could result in light-

to-severe injury,or loss related to equipment malfunction, if proper

precautions are not taken.

Safety Symbols Used on Equipment and in Manuals

(Some or all of the following five symbols may or may not be used on all ANRITSU equipment. In addition,

there may be other labels attached to products that are not shown in the diagrams in this manual.)

The following safety symbols are used inside or on the equipment near operation locations to provide information about safety items and operation precautions. Ensure that you clearly understand the meanings of

the symbols and take the necessary precautions BEFORE operating the equipment.

This symbol indicates a prohibited operation.The prohibited operation

is indicated symbolically in or near the barred circle.

-

This symbol indicates a compulsory safety precaution. The required

operation is indicated symbolically in or near the circle.

This symbol indicates warning or caution. The contents are indicated

symbolically in or near the triangle.

This symbol indicates a note. The contents are described in the box.

These symbols indicate that the marked part should be recycled.

MG369XA MM Safety-1

For Safety

WARNING

Always refer to the operation manual when working near locations

where the alert mark, shown on the left, is attached. If theoperation,

etc.,is performed without heeding the advice in the operation manual,

there is a risk of personal injury. In addition, the equipment perfor

mance may be reduced.

-

Repair

Moreover,this alert mark is sometimes used with other marks and de

scriptions indicating other dangers.

WARNING

When supplying AC power to this equipment, connect the accessory

3-pin power cord to a 3-pin grounded power outlet.If a grounded 3-pin

outlet is not available, use a conversion adapter and ground the green

wire,orconnect theframegroundon therearpanel of theequipmentto

ground.Ifpoweris suppliedwithoutgroundingthe equipment,there is

a risk of receiving a severe or fatal electric shock.

WARNING

Thisequipment cannot berepairedbythe operator.DONOTattempt to

remove the equipment covers or to disassemble internal components.

Only qualified service technicians with a knowledge of electrical fire

andshock hazards should service this equipment.Thereare high-volt

age parts in this equipment presenting a risk of severe injury or fatal

electric shock to untrained personnel. In addition, there is a risk of

damage to precision components.

-

-

WARNING

If this equipment is used in a manner not specified by the manufac

turer, the protection provided by the equipment may be impaired.

Safety-2 MG369XA MM

-

Table of Contents

Chapter 1 General Information

1-1 Scope of Manual ............................1-3

1-2 Introduction ..............................1-3

1-3 Description ...............................1-3

1-4 Identification Number .........................1-5

1-5 Online Manual .............................1-5

1-6 Related Manuals ............................1-5

Operation Manual ······················1-5

GPIB Programming Manual ·················1-5

1-7 Options .................................1-5

1-8 Level of Maintenance .........................1-6

Troubleshooting ·······················1-6

Repair ····························1-6

Calibration··························1-6

Preventive Maintenance ···················1-6

1-9 Component Handling .........................1-6

1-10 Preventive Maintenance........................1-8

1-11 Startup Configurations ........................1-9

1-12 Recommended Test Equipment ...................1-10

MG369XA MM i

Table of Contents (Continued)

Chapter 2 Functional Description

2-1 Introduction ..............................2-3

2-2 Major Subsystems ...........................2-3

Digital Control ························2-3

Front Panel Assembly ····················2-4

Frequency Synthesis ·····················2-4

A9 YIG Assembly·······················2-5

ALC/AM/Pulse Modulator···················2-5

RFDeck···························2-5

Power Supply ························2-5

Inputs/ Outputs ·······················2-6

Motherboard/ Interconnections ················2-6

2-3 Frequency Synthesis ..........................2-9

Phase Lock Loops ······················2-9

Overall Operation ······················2-10

RF Outputs 0.01 MHz to 65 GHz ··············2-14

Frequency Modulation····················2-15

Phase Modulation ······················2-15

Analog Sweep Mode ·····················2-16

Step Sweep Mode ······················2-16

2-4 ALC/AM/Pulse Modulation......................2-17

ALC Loop Operation ····················2-17

Pulse Generator Operation ·················2-19

2-5 RF Deck Assemblies .........................2-20

RF Deck Configurations ···················2-20

YIG-tuned Oscillator ····················2-21

RF Signal Filtering ·····················2-22

0.01 to 2 GHz Down Converter (Option 5) ··········2-23

0.01 to 2.2 GHz Digital Down Converter (Option 4) ·····2-23

Switched Doubler Module ··················2-24

Source Quadrupler Module ·················2-25

Step Attenuators ······················2-26

ii MG369XA MM

Table of Contents (Continued)

Chapter 3 Performance Verification

3-1 Introduction ..............................3-3

3-2 Test Records ..............................3-3

3-3 Connector and Key Notation......................3-4

3-4 Recommended Test Equipment ....................3-4

3-5 Measurement Uncertainty.......................3-4

3-6 Internal Time Base Aging Rate Test .................3-6

3-7 Spurious Signals Test .........................3-9

3-8 Single Sideband Phase Noise Test ..................3-11

3-9 Power Level Accuracy and Flatness Tests ..............3-19

Power Level Log Conformity·················3-20

Power Level Accuracy (³ –60 dBm) ·············3-22

Power Level Accuracy (< –60 dBm) ·············3-23

Power Level Flatness ····················3-26

Maximum Leveled Power ··················3-27

3-10 Residual FM Tests ..........................3-28

Locked FM Mode Off ····················3-29

Locked FM Mode On ····················3-30

Unlocked Narrow FM Mode On ···············3-30

Unlocked Wide FM Mode On ················3-31

3-11 Frequency Modulation Tests .....................3-32

FM Attenuator ·······················3-33

Locked FM Accuracy ····················3-41

FM Accuracy ························3-50

Unlocked Narrow FM Accuracy ···············3-59

FM/FM Flatness ······················3-61

FM/FM Bandwidth ·····················3-68

Alternate FM and FM Accuracy Tests ············3-75

MG369XA MM iii

Table of Contents (Continued)

3-12 Amplitude Modulation Tests .....................3-83

External AM Accuracy ···················3-84

Internal AM Accuracy ····················3-86

AM Roll Off ·························3-88

AM Flatness ························3-90

3-13 Pulse Modulation Tests........................3-92

Rise Time, Fall Time and Overshoot ·············3-94

Pulse Power Accuracy ····················3-97

Pulse On/Off Ratio ·····················3-100

Chapter 4 Calibration

4-1 Introduction ..............................4-3

4-2 Recommended Test Equipment ....................4-3

4-3 Test Records ..............................4-3

4-4 Subassembly Replacement.......................4-4

4-5 Connector and Key Notation......................4-4

4-6 Initial Setup ..............................4-6

Interconnection························4-6

PC Setup···························4-7

4-7 Preliminary Calibration .......................4-10

Equipment Setup ······················4-10

Calibration Steps ······················4-11

Alternate 10 MHz

Reference Oscillator Calibration ··············4-14

4-8 Frequency Synthesis Tests ......................4-16

Coarse Loop/ YIG Loop ···················4-16

Fine Loop ··························4-17

4-9 Switched F ilter Shaper ........................4-18

Equipment Setup ······················4-18

Log Amplifier Zero Calibration ···············4-19

Limiter DAC Adjustment ··················4-19

Shaper DAC Adjustment ··················4-21

iv MG369XA MM

Table of Contents (Continued)

4-10 RF Level Calibration .........................4-22

4-11 ALC Bandwidth Calibration .....................4-25

Equipment Setup ······················4-25

Bandwidth Calibration ···················4-26

4-12 ALC Slope Calibration ........................4-27

Equipment Setup ······················4-27

ALC Slope DAC Adjustment·················4-28

4-13 AM Calibration ............................4-31

Equipment Setup ······················4-31

AM Calibration Procedure··················4-32

4-14 FM Calibration ............................4-34

Equipment Setup ······················4-34

FM Calibration Procedure ··················4-35

Chapter 5 Troubleshooting

5-1 Introduction ..............................5-3

5-2 Recommended Test Equipment ....................5-3

5-3 Error Messages.............................5-3

Self-Test Error Messages ···················5-3

Normal Operation Error and Warning/Status Messages ····5-7

5-4 No Error Message...........................5-10

5-5 Troubleshooting Tables........................5-10

Chapter 6 Removal and Replacement Procedures

6-1 Introduction ..............................6-3

6-2 Exchange Assembly Program .....................6-3

6-3 Chassis Covers ............................6-10

6-4 Front Panel Assembly ........................6-12

6-5 A2 Microprocessor PCB Board ....................6-13

6-6 A3 Reference/Fine Loop PCB.....................6-14

6-7 A4 Coarse Loop PCB .........................6-15

MG369XA MM v

Table of Contents (Continued)

6-8 A5—A9 PCB Removal ........................6-17

Card Cage Cover ······················6-17

A5 Auxiliary PCB ·····················6-18

A6ALCPCB························6-18

A7YIGLockPCB······················6-19

A8DDSPCB························6-19

A9 YIG Assembly ······················6-19

6-9 Power Supply Assembly .......................6-20

Power Supply Top Assembly·················6-20

12 Volt Power Supply PCB ·················6-21

Power Supply Regulator PCB ················6-22

6-10 Anritsu Customer Service Centers..................6-24

Appendix A Test Records

A-1 Introduction ..............................A-1

A-2 Uncertainty Specifications ......................A-1

A-3 Test Records ..............................A-1

Appendix B Performance Specifications

B-1 MG369XA Technical Data Sheet ...................B-1

vi MG369XA MM

Table of Contents

1-1 Scope of Manual ............................1-3

1-2 Introduction ..............................1-3

1-3 Description ...............................1-3

1-4 Identification Number .........................1-5

1-5 Online Manual .............................1-5

1-6 Related Manuals ............................1-5

Operation Manual ······················1-5

GPIB Programming Manual ·················1-5

1-7 Options .................................1-5

Chapter 1

General Information

1-8 Level of Maintenance .........................1-6

Troubleshooting ·······················1-6

Repair ····························1-6

Calibration··························1-6

Preventive Maintenance ···················1-6

1-9 Component Handling .........................1-6

1-10 Preventive Maintenance........................1-8

1-11 Startup Configurations ........................1-9

1-12 Recommended Test Equipment ...................1-10

Figure 1-1.

Typical Series MG369XA Synthesized Signal Generator (Model MG3692A Shown)

1-2 MG369XA MM

Chapter 1 General Information

1-1 Scope of Manual This manual provides service information for the Model MG369XA

Signal Generators. The service information includes replaceable parts

information, troubleshooting, performance verification tests, calibra

tion procedures, functional circuit descriptions and block diagrams,

and assembly/subassembly removal and replacement. Throughout this

manual, the terms MG369XA or synthesizer are used to refer to the in

strument. Manual organization is shown in the table of contents.

-

-

1-2 Introduction This chapter provides a general description of the MG369XA identifi

cation numbers, related manuals, and options. Information is included

concerning level of maintenance, replaceable subassemblies and RF

components, exchange assembly program, and preventive maintenance. Static-sensitive component handling precautions and lists of

exchangeable subassemblies and recommended test equipment are

also provided.

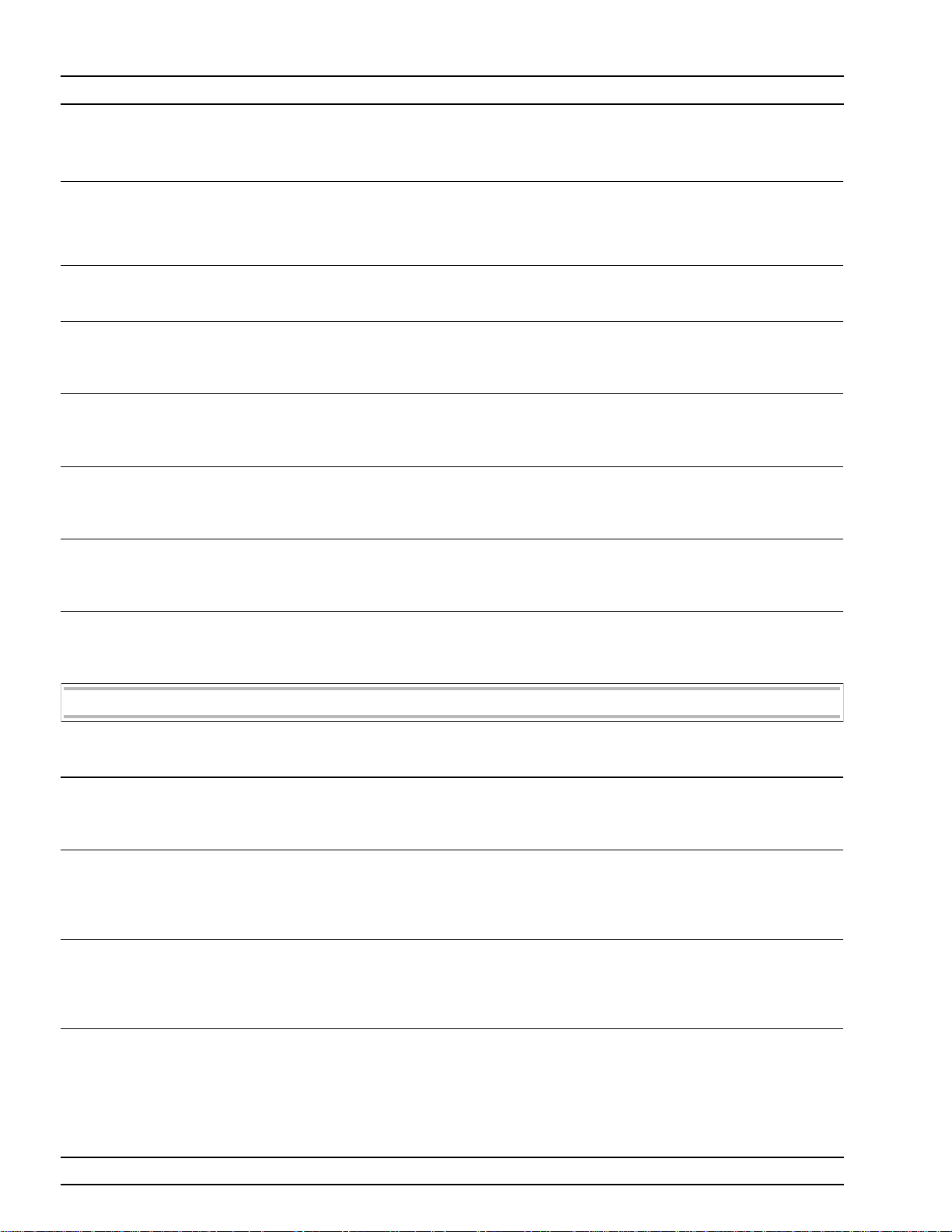

1-3 Description The series MG369XA is a microprocessor-based, synthesized signal

source with high resolution phase-lock capability. It generates both

discrete CW frequencies and broad (full range) and narrow band step

sweeps across the frequency range of 2 GHz to 65 GHz. Options are

available to extend the low end of the frequency range to 0.1 Hz. All

functions of the CW generator are fully controllable locally from the

front panel or remotely (except for power on/standby) via the

IEEE-488 General Purpose Interface Bus (GPIB).Table 1-1 on

page 1-4 lists models, frequency ranges, and maximum leveled output

power.

-

MG369XA MM 1-3

Description General Information

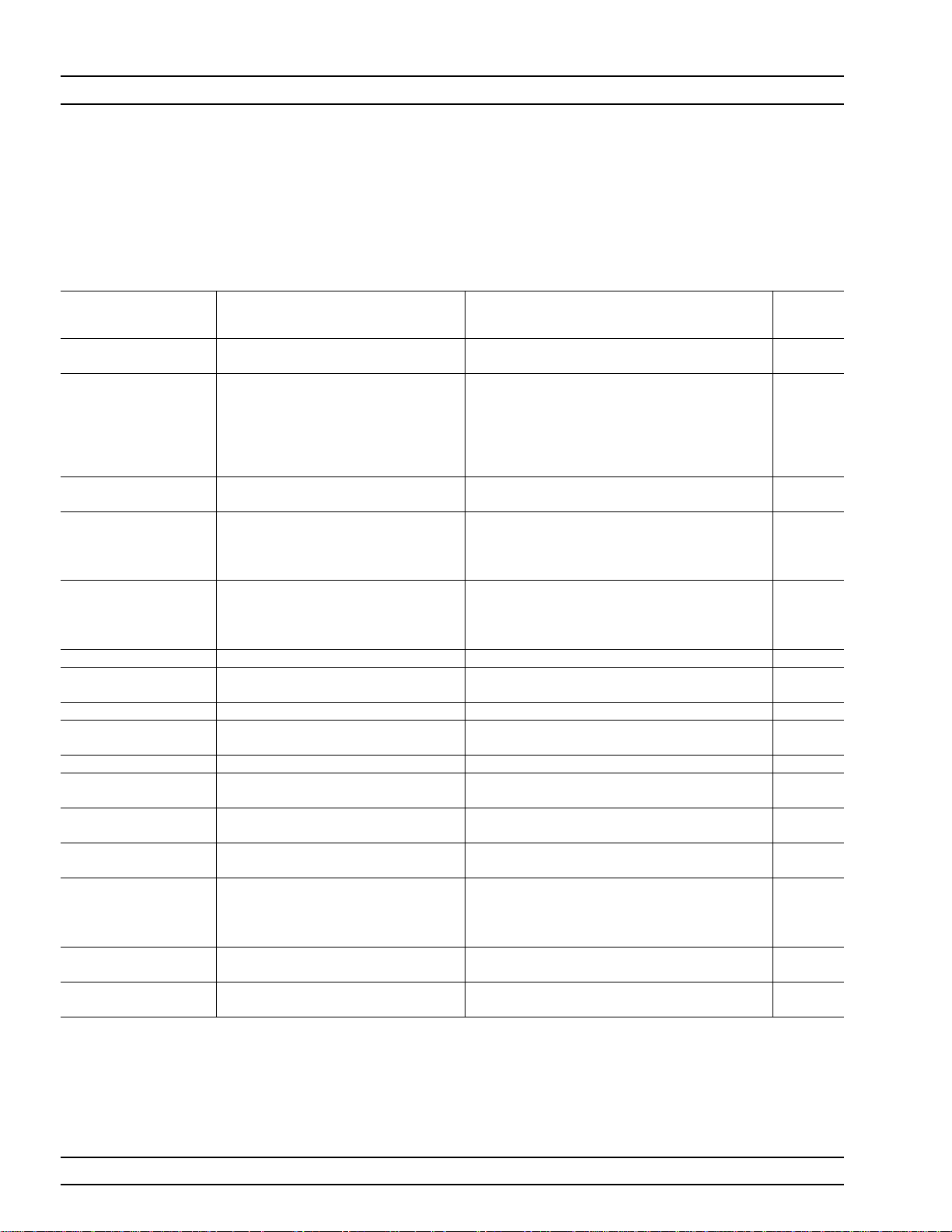

Table 1-1. Series MG369XA Models

Max Leveled

Model

Number Configuration

Frequency

Range

Max Leveled

Output Power

Max Leveled

Output Power

w/Step Attenuator

Output Power

w/Electronic

Step Attenuator

MG3691A

MG3692A

MG3693A

MG3694A

MG3695A

MG3696A

w/opt 4

w/opt 5

Standard

w/opt 4

w/opt 5

Standard

Standard

w/opt 4

w/opt 5

Standard

Standard

w/opt 4

w/opt 5

Standard

Standard

w/opt 4

w/opt 5

Standard

Standard

w/opt 4

w/opt 5

Standard

Standard

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £8.4 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £8.4 GHz

>8.4 – £20.0 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £20.0 GHz

>20.0 – £30.0 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £20.0 GHz

>20.0 – £40.0 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £20.0 GHz

>20.0 – £50.0 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £20.0 GHz

>20.0 – £65.0 GHz

With Option 15 (High Power) Installed

+17.0 dBm

+17.0 dBm

+13.0 dBm

+17.0 dBm

+17.0 dBm

+13.0 dBm

+13.0 dBm

+13.0 dBm

+13.0 dBm

+9.0 dBm

+6.0 dBm

+13.0 dBm

+13.0 dBm

+9.0 dBm

+6.0 dBm

+12.0 dBm

+12.0 dBm

+10.0 dBm

+3.0 dBm

+12.0 dBm

+12.0 dBm

+10.0 dBm

+3.0 dBm

+15.0 dBm

+15.0 dBm

+11.0dBm

+15.0 dBm

+15.0 dBm

+11.0dBm

+11.0dBm

+11.0dBm

+11.0dBm

+7.0 dBm

+3.0 dBm

+11.0dBm

+11.0dBm

+7.0 dBm

+3.0 dBm

+10.0 dBm

+10.0 dBm

+8.0 dBm

+0.0 dBm

+10.0 dBm

+10.0 dBm

+8.0 dBm

+0.0 dBm

+13.0 dBm

+13.0 dBm

+9.0 dBm

+13.0 dBm

+13.0 dBm

+9.0 dBm

+3.0 dBm

Not Available

Not Available

Not Available

Not Available

*

w/opt 4

MG3691A

MG3692A

MG3693A

MG3694A

Note: In models with Option 22, rated output power is reduced by 2 dB.

* Typical 60 - 65 GHz.

w/opt 5

Standard

w/opt 4

w/opt 5

Standard

Standard

w/opt 4

w/opt 5

Standard

Standard

Standard

Option 4

Option 5

Standard

Standard

Standard

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £8.4 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £10.0 GHz

>10.0 – £20.0 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £10.0 GHz

>10.0 – £20.0 GHz

>20.0 – £30.0 GHz

³0.01 – £2.2 GHz

³0.01 – £2.0 GHz

³2.0 – £10.0 GHz

>10.0 – £20.0 GHz

>20.0 – £40.0 GHz

+19.0 dBm

+19.0 dBm

+19.0 dBm

+19.0 dBm

+19.0 dBm

+19.0 dBm

+17.0 dBm

+15.0 dBm

+15.0 dBm

+15.0 dBm

+12.0 dBm

+14.0 dBm

+15.0 dBm

+15.0 dBm

+15.0 dBm

+12.0 dBm

+14.0 dBm

+18.0 dBm

+18.0 dBm

+18.0 dBm

+18.0 dBm

+18.0 dBm

+18.0 dBm

+15.0 dBm

+14.0 dBm

+14.0 dBm

+14.0 dBm

+10.0 dBm

+12.0 dBm

+14.0 dBm

+14.0 dBm

+14.0 dBm

+10.0 dBm

+12.0 dBm

+15.0 dBm

+15.0 dBm

+13.0 dBm

+15.0 dBm

+15.0 dBm

+13.0 dBm

+7.0 dBm

Not Available

Not Available

1-4 MG369XA MM

General Information Identification Number

1-4 Identification Number All Anritsu instruments are assigned a unique six-digit ID number,

such as “875012.” The ID number is imprinted on a decal that is af

fixed to the rear panel of the unit. Special-order instrument configura

tions also have an additional special number tag attached to the rear

panel of the unit, such as SM1234.

When ordering parts or corresponding with Anritsu customer service,

please use the correct serial number with reference to the specific in

strument's model number (i.e., Model MG3692A CW Signal Generator,

Serial No. 875012, and the special's number, if appropriate).

-

-

1-5 Online Manual This manual is available on CD ROM as an Adobe Acrobat Portable

Document Format (*.pdf) file. The file can be viewed using Acrobat

Reader, a free program that is also included on the CD ROM. The file

is “linked” such that the viewer can choose a topic to view from the dis

played “bookmark” list and “jump” to the manual page on which the

topic resides. The text can also be word-searched. Contact Anritsu customer service for price and availability.

-

-

1-6 Related Manuals This is one of a three manual set that consists of an operation manual,

a GPIB programming manual, and a maintenance manual.

Operation

Manual

GPIB

Programming

Manual

1-7 Options The options available for the Anritsu MG369XA series signal genera

tors are described in the product data sheet (p/n 11410-00327). A copy

of this data sheet is located in Appendix B.

The operation manual provides instructions for operating the MG369XA using the front panel controls.

It also includes general information, performance

specifications, installation instructions, and operation verification procedures. The Anritsu part num

ber for the Model MG369XA Operation Manual is

10370-10353.

The GPIB programming manual provides informa

tion for remotely operating the MG369XA using

product specific commands sent from an external

controller via the IEEE 488 General Purpose Inter

face Bus (GPIB). It contains a complete listing and

description of all MG369XA GPIB product specific

commands and several programming examples. The

Anritsu part number for the Model MG369XA GPIB

Programming Manual is 10370-10354.

-

-

-

-

MG369XA MM 1-5

Level of Maintenance General Information

1-8 Level of Maintenance Maintenance of the MG369XA consists of:

Troubleshooting the instrument to a replaceable subassembly or

q

RF component

Repair by replacing the failed subassembly or RF component.

q

Calibration

q

Preventive maintenance

q

Trouble

shooting

Repair Most instrument failures are field repairable by re-

Calibration The MG369XA may require calibration after repair.

Preventive

Maintenance

-

The MG369XA firmware includes internal diagnos

tics that self-test most of the internal assemblies.

When the MG369XA fails self-test, one or more error

messages appear to aid in troubleshooting the fail

ure to a replaceable subassembly or RF component.

Chapter 5—Troubleshooting lists and describes the

self-test error messages and provides procedures for

isolating MG369XA failures to a replaceable subas

sembly or RF component.

placing the failed subassembly or RF component.

Detailed instructions for removing and replacing

failed subassemblies and components are provided

in Chapter 6—Removal and Replacement Procedures.

Refer to Chapter 4—Calibration for a listing of requirements and procedures.

Preventive maintenance on the MG369XA consists

of cleaning the fan honeycomb filter, described in

Section 1-10.

-

-

-

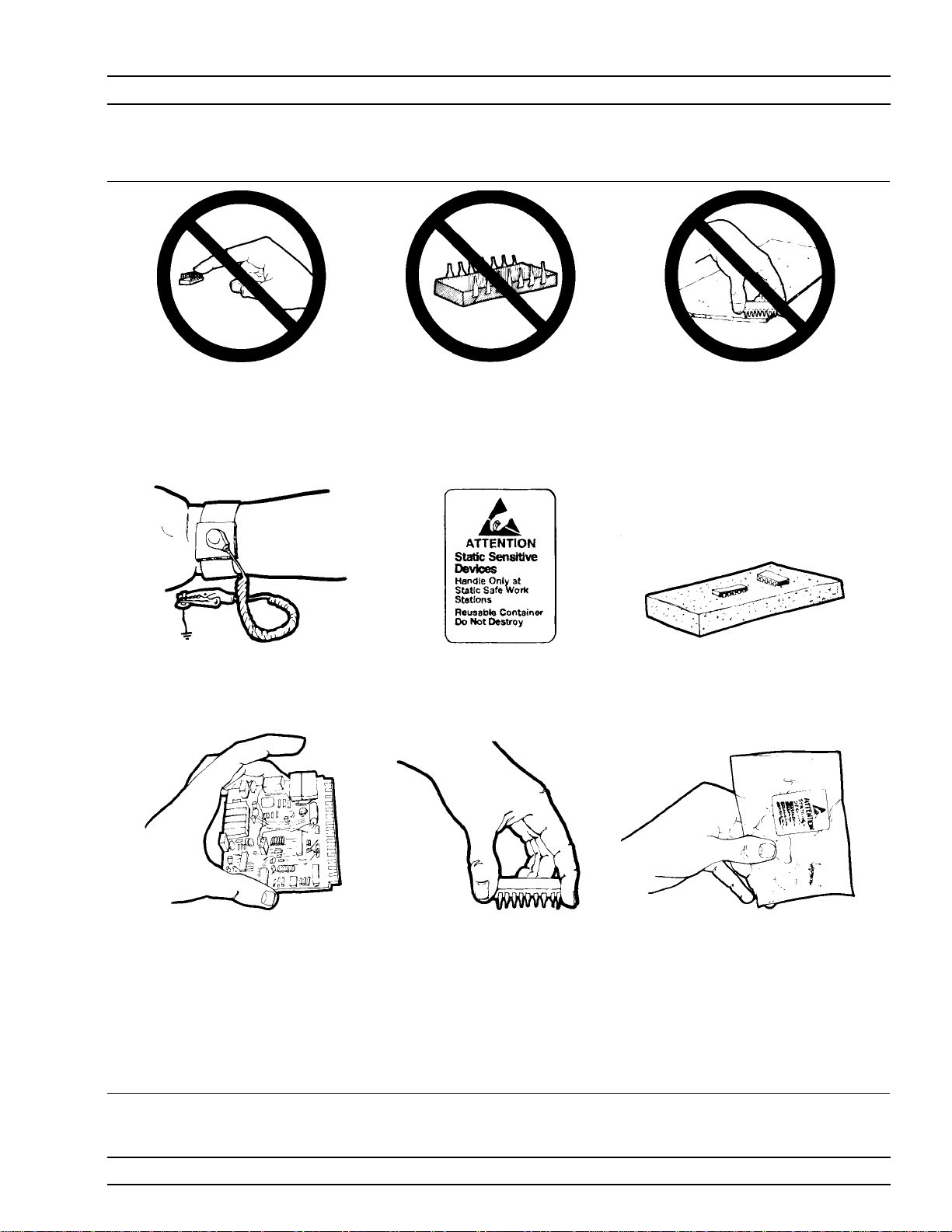

1-9 Component Handling The MG369XA contains components that can be damaged by static

electricity.Figure 1-2 illustrates the precautions that should be fol

lowed when handling static-sensitive subassemblies and components.

If followed, these precautions will minimize the possibilities of

static-shock damage to these items.

NOTE

Use of an grounded wrist strap when handling subassem

blies or components is strongly recommended.

1-6 MG369XA MM

-

-

General Information Component Handling

1. Do not touch exposed contacts

on any static sensitive

component.

4. Wear a static-discharge

wristband when working with

static sensitive components.

2. Do not slide static sensitive

component across any surface.

5. Label all static sensitive

devices.

3. Do not handle static sensitive

components in areas where the

floor or work surface covering

is capable of generating a

static charge.

6. Keep component leads shorted

together whenever possible.

7. Handle PCBs only by their

edges. Do not handle by the

edge connectors.

10. Additional Precautions:

Keep work spaces clean and free of any objects capable of holding or storing a static charge.

Connect soldering tools to an earth ground.

Use only special anti-static suction or wick-type desoldering tools.

Figure 1-2. Static-Sensitive Component Handling Precautions

8. Lift & handle solid state de

vices by their bodies – never

by their leads.

-

9. Transport and store PCBs and

other static sensitive devices

in static-shielded containers.

MG369XA MM 1-7

Preventive Maintenance General Information

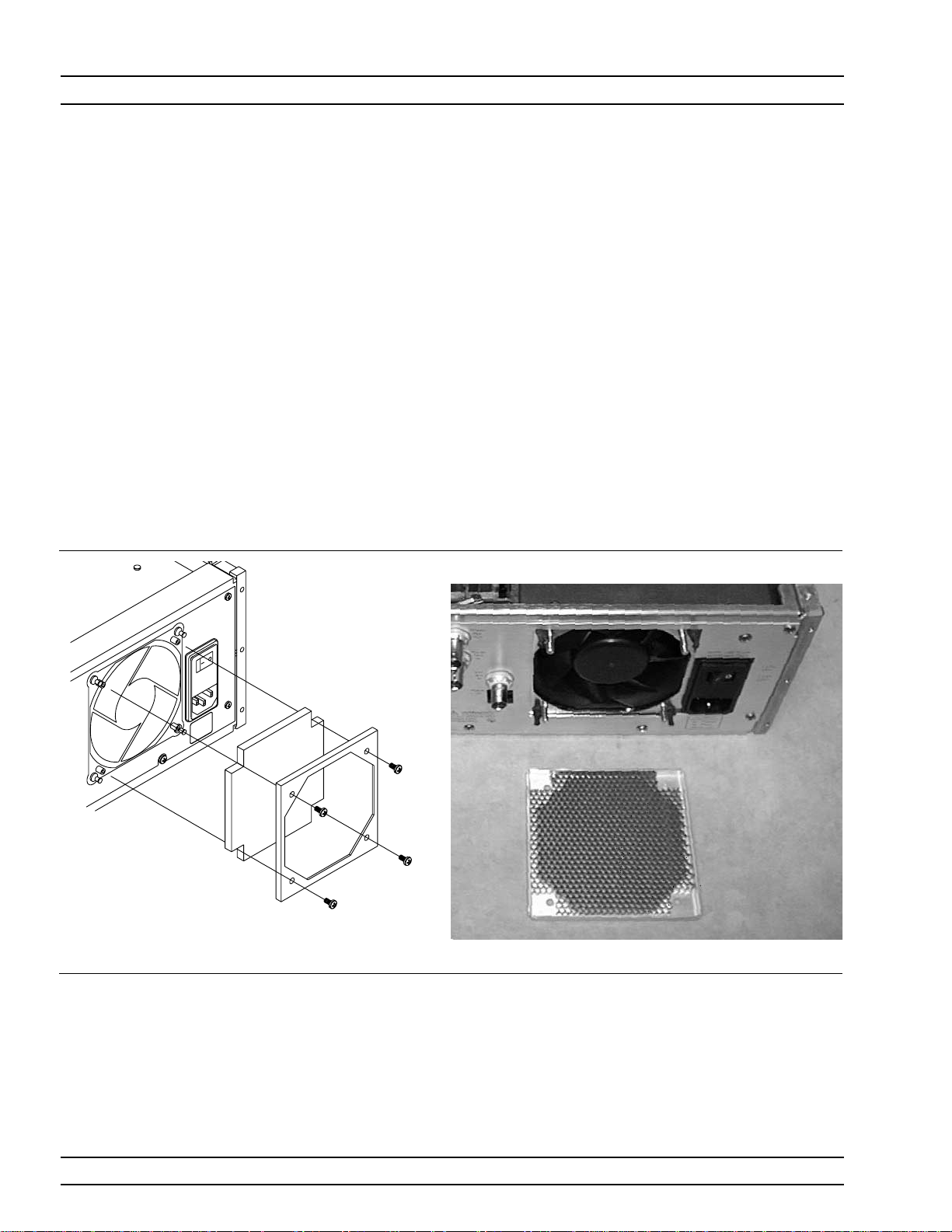

1-10 Preventive

Maintenance

The MG369XA must always receive adequate ventilation.A blocked

fan filter can cause the instrument to overheat and shut down. Check

and clean the rear panel fan honeycomb filter periodically.Clean the

fan honeycomb filter more frequently in dusty environments. Clean

the filter as follows.

Step 1. Use a #3 screwdriver to remove the four screws that

fasten the filter guard to the rear panel (see

Figure 1-3). Retain the screws for reassembly.

Step 2. Vacuum the honeycomb filter to clean it.

Step 3. Reinstall the filter guard.

Step 4. Fasten the filter guard to the rear panel using the

four screws that were removed in Step 1.

Figure 1-3. Removing/Replacing the Fan Filter Guard

1-8 MG369XA MM

General Information Startup Configurations

1-11 Startup

Configurations

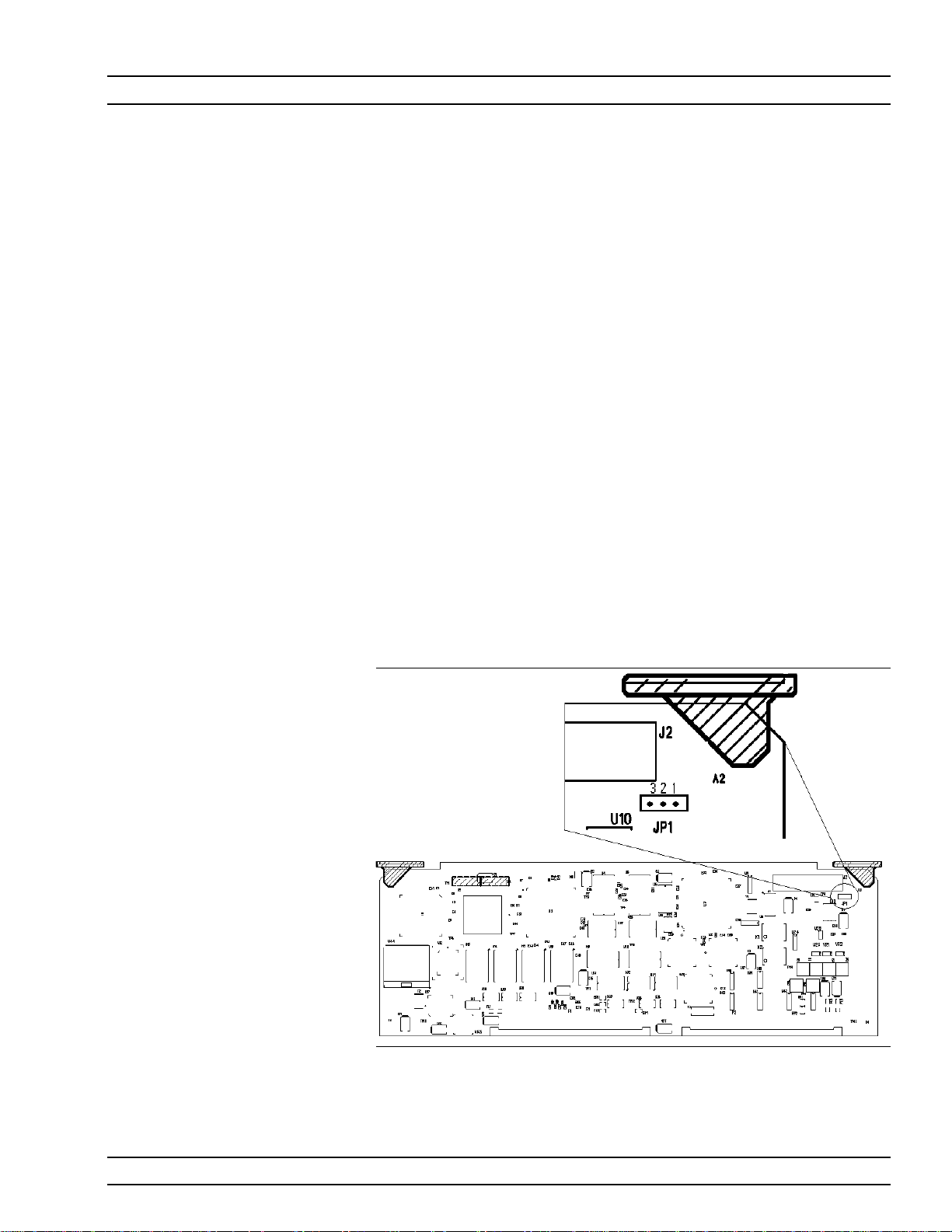

The MG369XA comes from the factory with a jumper across pins 2 and

3 of the A2 microprocessor PCB connector JP1 (Figure 1-4). In this

configuration, connecting the instrument to line power automatically

places it in operate mode (front panel OPERATE LED on).

The startup configuration can be changed so that the signal generator

comes up in standby mode (front panel STANDBY LED on) when it is

connected to line power.Change the startup configuration as follows:

Step 1. Disconnect the instrument from line power.

Step 2. Remove the top cover from the MG369XA and A2

PCB.Refer to Section 6-5 for instructions.

Step 3. Locate the connector JP1 and remove the jumper

from across pins 2 and 3.Refer to Figure 1-4 below.

Step 4. Install the jumper across pins 1 and 2 of the connec-

tor JP1.

Step 5. Install the top covers and connect the signal genera-

tor to line power.The instrument should come up in

standby mode.

Figure 1-4. Startup Configuration of A2 Connector JP1

MG369XA MM 1-9

Recommended Test Equipment General Information

1-12 Recommended Test

Equipment

Table 1-2 provides a list of recommended test equipment needed for

the performance verification, calibration, and troubleshooting proce

dures presented in this manual.

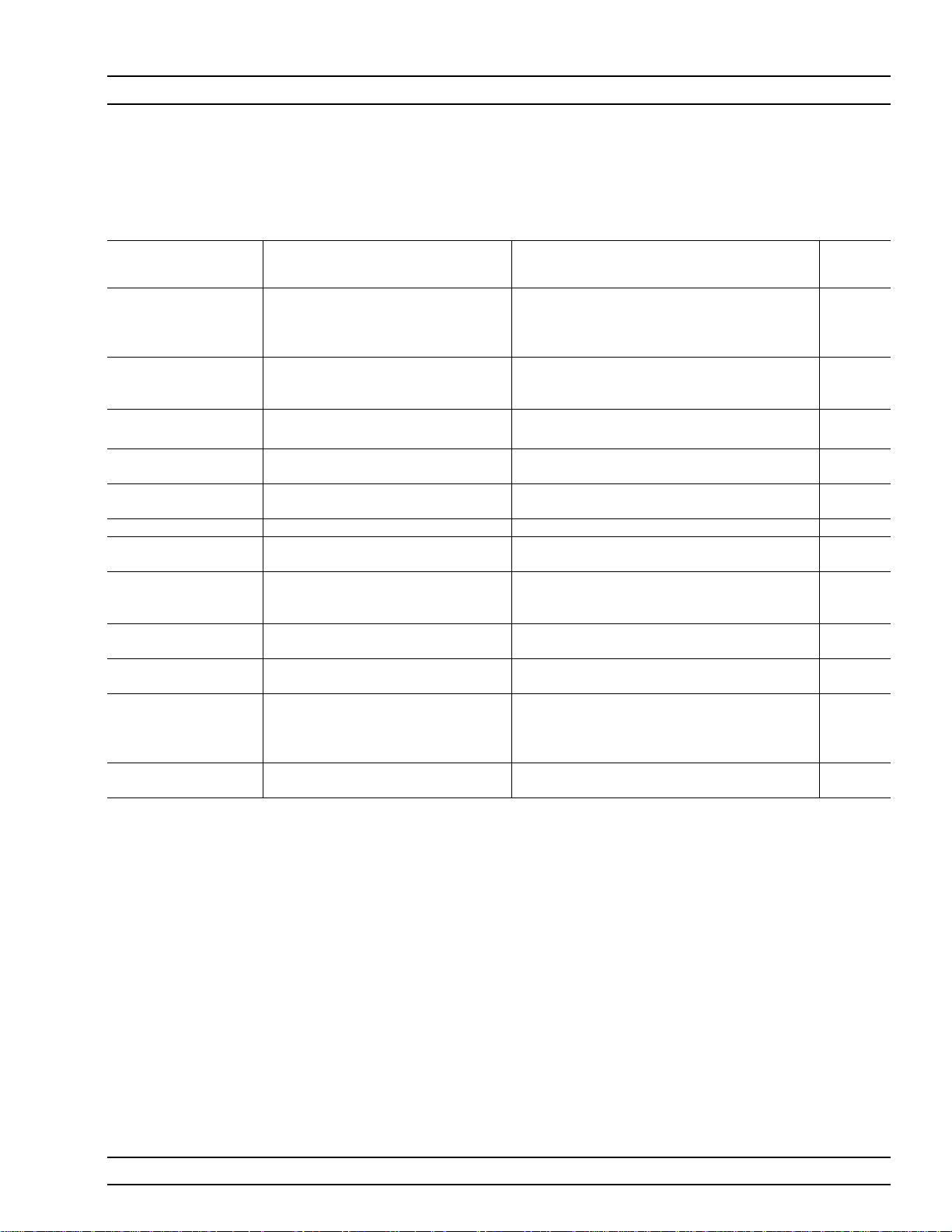

Table 1-2. Recommended Test Equipment

INSTRUMENT

Spectrum Analyzer

Phase Noise Measure

ment System

Modulation Analyzer

Frequency Counter

Power Meter with

Power Sensor

Power Supply Output: +1V DC Agilent E3631A P

Digital Multimeter

Function Generator DDS, 0.01 to 10 MHz Agilent 33120A C, P

Digital Sampling

Oscilloscope

Measuring Receiver Noise Floor: <–140 dBm @ 500 MHz Anritsu Model ML2530A C, P

Frequency Reference

Local Oscillator Frequency: 0.01 to 40 GHz

Local Oscillator

(Level Calibration)

Scalar

Network Analyzer with

RF Detector

Diplex Switch Assembly

Mixer

* P = Performance Verification Tests; C = Calibration; T = Troubleshooting

Frequency: 0.01 to 50 GHz

Resolution Bandwidth: 10 Hz

Frequency Range: 5 MHz to 26.5 GHz

See Table 3-2 on page 3-11

AM and FM Measurement Capability to

>500 MHz and –20 dBm

Frequency Range: 0.01 to 40 GHz

Input Impedance: 50W

Resolution: 1 Hz

Other: External Time Base Input

Frequency: 0.01 to 65 GHz

Power Range: –70 to +20 dBm

Minimum 1% RMS ACV Accuracy at

100 kHz

Frequency: 50 GHz

Frequency: 10 MHz

Accuracy:5x10

Frequency: 0.01 to 40 GHz

Frequency: 0.01 to 60 GHz

Frequency Range: 0.1 Hz to 10 MHz

Frequency Range: 0.01 to 40 GHz

Frequency Range: 500 MHz to 40 GHz

Conversion Loss: 10 dB (typical)

CRITICAL

SPECIFICATION

–12

(1 of 2)

parts/day

RECOMMENDED

MANUFACTURER/MODEL

HP8565E C, P

Aeroflex/Comstron PN9000 with:

PN9060-00 Status Module

PN9470-00 Noise Output Module

PN9450-00 Lock Control Module

PN9342-00 Phase Detector Module

PN9530-00 Crystal Oscillator Module

HP8901A P

Anritsu Model MF2414B C, P

Anritsu Model ML2437A/38A with Power Sensor:

MA2421A (100 kHz to 18 GHz)

MA2474A (0.01 to 40 GHz)

SC6230 (0.01 to 65 GHz)

Fluke 8840A C, P

Agilent 86100A with:

83484A 50 GHz Module

Absolute Time Corp., Model 300 C, P

Anritsu Model MG3694A with:

Options 3, 4 and 15

Anritsu Model 69067B with:

Option 14 and SM5709

Anritsu Model 56100A with RF Detector:

560-7K50 (0.01 to 40 GHz)

560-7VA50(0.01 to 50 GHz)

SC5198 (0.01 to 60 GHz)

Anritsu P/N: 46504

Anritsu P/N: 29850

Anritsu P/N: 60-114 C, P

USAGE*

C, P

C, T

-

P

P

P

C

C

1-10 MG369XA MM

General Information Recommended Test Equipment

Table 1-2.

INSTRUMENT

Attenuator

Attenuator

Adapter

2.4 mm (m) to K (f)

Adapter

3.5 mm (m) to BNC (f)

Feed Through

Termination

Tee Connectors: 50W BNC Any common source P

Cables

AUX I/O Interface Cable

Special AUX I/O

Cable Assembly

Serial Interface

Assembly

Personal Computer

Level Calibration

Software

* P = Performance Verification Tests; C = Calibration; T = Troubleshooting

Recommended Test Equipment (2 of 2)

CRITICAL

SPECIFICATION

Frequency Range: DC to 40 GHz

Max Input Power: >+20 dBm

Attenuation: 3, 6, 10, and 20 dB

Frequency Range: DC to 60 GHz

Max Input Power: >+20 dBm

Attenuation: 10 dB

Frequency Range: 0.01 to 40 GHz

50W Any common source P

50W BNC Any common source P

Connectors: 50W BNC

RF Connections: K-Cables

Provides interface between the

MG369XA and the

56100A Scalar Network Analyzer

Provides interface between the

MG369XA and the Power Meter

Provides serial interface between the

PC and the MG369XA

IBM AT or compatible with

GPIB interface

Provides automated power level cali

bration of the MG369XA

RECOMMENDED

MANUFACTURER/MODEL

Anritsu, Model 41KC-3

Anritsu, Model 41KC-6

Anritsu, Model 41KC-10

Anritsu, Model 41KC-20

Anritsu, Model 41V-10 C

Any common source

(Agilent P/N: 11904-60003)

Any common source C, P

Anritsu P/N:806-7 C

Anritsu P/N: 806-97 P

Anritsu P/N: T1678 C

PC: Any common source

GPIB Interface: National Instruments P/N:

PCI-GPIB (Desktop)

PCMCIA-GPIB (Notebook)

Anritsu P/N: 2300-497 C

USAGE*

C, P

P

C

MG369XA MM 1-11/1-12

Table of Contents

2-1 Introduction ..............................2-3

2-2 Major Subsystems ...........................2-3

Digital Control ························2-3

Front Panel Assembly ····················2-4

Frequency Synthesis ·····················2-4

A9 YIG Assembly·······················2-5

ALC/AM/Pulse Modulator···················2-5

RFDeck···························2-5

Power Supply ························2-5

Inputs/ Outputs ·······················2-6

Chapter 2

Functional Description

Motherboard/ Interconnections ················2-6

2-3 Frequency Synthesis ..........................2-9

Phase Lock Loops ······················2-9

Overall Operation ······················2-10

RF Outputs 0.01 MHz to 65 GHz ··············2-14

Frequency Modulation····················2-15

Phase Modulation ······················2-15

Analog Sweep Mode ·····················2-16

Step Sweep Mode ······················2-16

2-4 ALC/AM/Pulse Modulation......................2-17

ALC Loop Operation ····················2-17

Pulse Generator Operation ·················2-19

Table of Contents (Continued)

2-5 RF Deck Assemblies .........................2-20

RF Deck Configurations ···················2-20

YIG-tuned Oscillator ····················2-21

RF Signal Filtering ·····················2-22

0.01 to 2 GHz Down Converter (Option 5) ··········2-23

0.01 to 2.2 GHz Digital Down Converter (Option 4) ·····2-23

Switched Doubler Module ··················2-24

Source Quadrupler Module ·················2-25

Step Attenuators ······················2-26

2-2 MG369XA MM

Chapter 2 Functional Description

2-1 Introduction This chapter provides brief functional descriptions of the major sub

systems that are contained in each model of the MG369XA.In addi

tion, the operation of the frequency synthesis, automatic level control

(ALC), and RF deck subsystems is described so that the reader may

better understand the overall operation of the instrument. Block dia

grams are included to supplement the written descriptions.

2-2 Major Subsystems The MG369XA circuitry consists of various distinct subsystems that

are contained on one or more printed circuit board (PCB) assemblies

or in microwave components located on the RF deck. The following

paragraphs identify the subsystems that make up the instrument and

provide a brief description of each.Figure 2-1 (page 2-7) is an overall

block diagram of a typical MG369XA.

Digital

Control

This circuit subsystem consists of the A2 Microprocessor PCB. The central processor unit (CPU) located on this PCB is the main controller for the

MG369XA. This controller directly or indirectly controls all functions of the instrument.The CPU contains memory that stores the main operating system

components and instrument firmware, instrument

calibration data, and front panel setup data during

the power-off condition. It has a GPIB interface that

allows it to communicate with external devices over

the GPIB and a serial interface to a serial terminal

port on the rear panel. The CPU is directly linked

via a dedicated data and address bus to the front

panel assembly,the A5 Auxiliary/Analog Instruction

PCB,the A6 ALC PCB, the A7 Yig-lock PCB, the

A9 YIG assembly, the optional A8 DDS PCB of the

CW Generator or Function Generator of the Signal

Generator, and the A13 Pulse Generator PCB.

-

-

-

Interface circuits on the A2 PCB indirectly link the

CPU to the A3 reference/fine loop PCB, and the A4

coarse loop PCB. The A2 PCB contains circuits that

perform parallel-to-serial and serial-to-parallel data

conversion. The A2 also contains circuitry for many

of the rear panel signals and a 13-bit resolution digi

tal volt meter (DVM).

MG369XA MM 2-3

-

Major Subsystems Functional Description

Front Panel

Assembly

Frequency

Synthesis

This circuit subsystem consists of the front panel,

the front panel rotary data knob,the front panel

control PCB, and the liquid crystal display (LCD).

The subsystem interfaces the front panel LCD, light

emitting diodes (LEDs), and keys to the CPU via the

dedicated data and address bus. The front panel ro

tary data knob is also linked to the CPU via the data

and address bus.

The front panel PCB contains the keyboard matrix

conductive rubber switches. It has circuits to control

the LCD dot-matrix display, turn the front panel

LEDs on and off, and convert keyboard switch ma

trix signals to parallel key code.It also contains the

standby/operate line switch and the optical encoder

for the rotary data knob.

The frequency synthesis subsystem consists of the

A3 reference/fine loop PCB, the A4 coarse loop PCB,

the A7 YIG lock PCB, and the A9 YIG assembly. It

provides the reference frequencies and phase lock

circuits for precise control of the YIG-tuned oscillator frequencies, as follows:

q

The reference loop circuitry located on the A3

PCB supplies the stable 10 MHz and 500 MHz

reference frequency signals for the rest of the

frequency synthesis system

q

The A4 coarse loop PCB generates coarse tun

ing frequencies of 219.5 to 245 MHz for use by

the YIG lock PCB

q

The fine loop circuitry located on the A3 PCB

provides fine tuning frequencies of 21.5 to

40 MHz for use by the YIG lock PCB

q

The A7 YIG lock PCB performs phase detec

tion of the YIG-tuned oscillator's output fre

-

quency and provides a YIG loop error voltage

signal. This error signal is further conditioned,

producing a correction signal that is used to

fine tune and phase lock the YIG-tuned

oscillator

The CPU sends control data to the A3 reference/ fine

loop PCB and the A4 coarse loop PCB as serial data

words. Refer to Section 2-3 for a functional overview

of the frequency synthesis subsystem.

2-4 MG369XA MM

Functional Description Major Subsystems

A9 YIG

Assembly

ALC/AM/Pulse

Modulator

The A9 YIG assembly contains the YIG-tuned oscil

lator and associated PCB assembly.The PCB assem

bly contains the driver circuitry that provides the

tuning current and bias voltages for the YIG-tuned

oscillator. The CPU controls the A9 YIG assembly

via the dedicated data and address bus.

This ALC circuit subsystem consists of the A6 ALC

PCB,the A6A1 AM module, and part of the A9 YIG

PCB assembly.It provides the following:

Level control of the RF output power

q

Current drive signals to the PIN switches lo

q

cated in the A10 switched filter assembly

(SWF), the A12 switched doubler module

(SDM), and the source quadrupler module

(SQM)

Drive signals for the step attenuator (Option 2)

q

and the diplexers (used with Option 22)

The CPU controls the A6 ALC PCB (and the A6A1

AM module via the A6 PCB) and the A9 YIG PCB

assembly via the dedicated data and address bus. It

sends control data to the A13 Pulse Generator PCB

via the A1 Motherboard as serial data words. Refer

to Section 2-4 for a functional overview of the ALC

subsystem.

-

-

RF Deck This subsystem contains those elements related to

the generation, modulation, and control of the

sweep- and CW-frequency RF signals. These ele

ments include the A9 YIG-tuned oscillator/PCB as

sembly,the 0.01 to 2 GHz down converter assembly

(A11), the A10 switched filter assembly, the A12

switched doubler module, the source quadrupler

module, the directional coupler/level detector, and

the optional step attenuator.Refer to Section 2-5 for

a functional overview of the RF deck subsystem.

Power Supply The power supply subsystem consists of the power

input connector/filter module, the regulator PCB, the

power supply PCB, the standby power supply PCB,

and the power module fan unit.It supplies all the

regulated DC voltages used by the MG369XA cir

cuits. The voltages are routed throughout the instru

ment via the motherboard PCB.

-

-

MG369XA MM 2-5

Major Subsystems Functional Description

Inputs/

Outputs

The A21 rear panel PCB and the A2 microprocessor

PCB contain the interface circuits for the majority of

the rear panel input and output connectors, includ

ing the AUX I/O connector.

The A5 Auxiliary PCB (or the optional A5 Analog In

struction PCB) provides a 0V to +10V ramp signal to

the rear panel HORIZ OUT connector,a V/GHz signal

to the rear panel AUX I/O connector,and a SLOPE

signal to the A6 ALC PCB for slope-vs-frequency cor

rection of the RF output power.

The rear panel EXT ALC IN, AM IN, and AM OUTare

routed through the A21 rear panel PCB, and then

through the motherboard PCB to the A6 ALC PCB.

The rear panel connectors, 10 MHz REF OUT and

10 MHz REF IN, are routed through the A21 PCB

and coupled to the A3 Reference/Fine Loop PCB via

coaxial cables.

The rear panel FM/FMINandFM/FM OUT connec-

tors are routed through the A21 rear panel PCB and

then through the Motherboard PCB to the A7

YIG-lock PCB. The rear panel PULSE TRIG IN connector is routed through the A21 rear panel PCB

and then to the A6 ALC PCB (or optional A13 Pulse

Generator PCB for units with Option 24 installed).

The rear panel PULSE SYNC OUT and PULSE

VIDEO OUT connectors are routed through the A21

rear panel PCB, and then to the optional A13 Pulse

Generator PCB via coaxial cables. The rear panel

EFC IN connector is routed to the A3 Reference/Fine

Loop PCB via coaxial cables.

-

-

-

-

Motherboard/

Interconnections

The rear panel IEEE-488 GPIB and SERIAL I/O con

nectors are routed through the A21 rear panel PCB

and then through the motherboard to the A2 micro

processor PCB.

The motherboard PCB and associated cables provide

the interconnections for the flow of data, signals, and

DC voltages between all internal components and

assemblies throughout the MG369XA.

2-6 MG369XA MM

-

Loading...

Loading...